Page 1

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Oxymitter 5000 Hazardous Area

Oxygen Transmitter

http://www.raihome.com

Page 2

Page 3

HIGHLIGHTS OF CHANGES

Effective September 2006 Rev 2.0

Page Summary

General Reformatted entire manual from a two column layout. Replaced SPS 4000 information

with SPS 4001B information. Removed all references to JIS specifications. Added

information pertaining to the Local Operator Interface (LOI). Added information pertaining

to the remote electronics option.

Page TOC-4 Removed List of Illustrations and List of Tables from the table of contents in Rev 1.4.

Page i Moved from backside of cover in Rev 1.4.

Page 1-2 Updated Figure 1-1, Typical System Package to show SPS 4001B and remote electronics.

Page 1-5 Updated Figure 1-2, Hazardous Area Oxymitter 5000 Autocalibration System Options to

show the SPS 4001B.

Page 1-6 Added Figure 1-3, Membrane Keypad and Figure 1-4, Local Operator Interface (LOI).

Added step 4 under System Features

Page 1-7 Removed step 6 under System Features from Rev 1.6.

Page 1-10 Added Figure 1-7, Typical System Installation – Oxymitter 5000 with Remote Electronics.

Page 1-11 Added Mounting and Operation instructions for the SPS 4001B.

Page 1-14 thru 1-15 Updated the specifications table and added applicable certifications regarding the

Hazardous Area Oxymitter 5000.

Page 1-16 Updated Table 1-1, Product Matrix.

Page 1-18 Removed Table 1-4, Single Probe Autocalibration Sequencer Coding from Rev 1.4.

Page 2-1 Added first Warning.

Page 2-2 Added first Note.

Page 2-4 Added Figure 2-2, Hazardous Area Oxymitter 5000 Remote Electronics Installation.

Page 2-8 Added third Note.

Page 2-10 Added Figure 2-8, Remote Electronics Mounting and corresponding text.

Page 2-11 Added Note and fifth Warning.

Page 2-12 Added Figure 2-10, Electrical Installation - Hazardous Area Oxymitter 5000 with Integral

Electronics.

Page 2-13 thru 2-14 Added information under Electrical Installation with Remote Electronics.

Page 2-15 Added Figure 2-10, Electrical Installation - Hazardous Area Oxymitter 5000 with Remote

Electronics.

Page 2-16 Added information regarding the installation of the interconnecting cable. Removed Figure

2-7, Terminal Block from Rev 1.4.

Page 2-18 Added body text under IMPS 4000 Connections and SPS4001B Connections.

Page 3-2 Added Caution.

Page 4

HIGHLIGHTS OF CHANGES (CONTINUED)

Effective September 2006 Rev 2.0 (Continued)

Page Summary

Page 4-1 thru 4-6 Added Section 4, Configuration of Hazardous Area Oxymitter 5000 with LOI.

Page 5-1 thru 5-4 Pages 3-6 thru 3-8 in Section 3, Startup and Operation of Rev 1.4 was moved to Section 5,

Startup and Operation of Oxymitter 5000 with Membrane Keypad.

Page 6-1 thru 6-10 Added Section 6, Startup and Operation of Hazardous Area Oxymitter 5000 with LOI.

Page 7-1 Added body text under Overview.

Page 7-2 Added Figure 7-1, O2 Sensor mV Reading vs. % O2 at 736°C (Reference Air, 20.9% O2).

Page 7-4 Added Figure 7-2, Diagnostic LEDs.

Page 7-7 thru 7-21 Added the LOI in Figures 7-3 thru 7-17 with descriptive text to accompany each figure.

Page 7-22 and 7-23 Added text and Figure 7-18, Probe Leakage Paths.

Page 8-0 Moved the "Calibration Record for Rosemount Analytical in Situ O2 Probe", from the back

of the section to the front.

Page 8-6 and 8-7 Added information under the Calibration with LOI heading.

Page 8-7 Removed information regarding LED Status Indicators and Table 4-1, Diagnostic/Unit

Alarms from Rev 1.4.

Page 8-8 thru 8-23 Updated procedural steps throughout section.

Page 8-9 Added step 3 under Entire Replacement of Electronics (with Housing). Removed Figure

4-4, Terminal Block from Rev 1.4.

page 8-10 Updated Figure 8-3, Hazardous Area Oxymitter 5000 with Integral Electronics - Exploded

View, to show the LOI module and Window Cover.

Page 8-11 Added Figure 8-4, Hazardous Area Oxymitter 5000 with Remote Electronics - Exploded

View.

Page 8-16 Added third Warning.

Page A-1 thru A-22 Moved Safety Instructions P-3 thru P-12 from the preface in Rev 1.4 to Appendix A in Rev

2.0.

Page B-1 Moved Section 10, Return of Material from Rev 1.4 to Appendix B in Rev 2.0.

Page C-1 thru C-6 Moved Appendix A to Appendix C in Rev 2.0.

Page D-1 thru D-10 Moved Appendix B to Appendix D in Rev 2.0.

Page E-1 Moved Appendix C to Appendix E in Rev 2.0.

Effective January 2007 Rev 2.1

Page Summary

General Revised reference air specifications to read 0.25 l/min (0.5 scfh) throughout the manual.

Page 7-1 thru 7-6 Added section 7.

Page 8-22 Added the paragraph and procedural steps after 'Heater Not Open, but Unable to Reach

736°C Setpoint.'

Page 11-1 Added Model 375 Handheld Communicator information.

Page 5

HIGHLIGHTS OF CHANGES (CONTINUED)

Effective January 2007 Rev 2.1 (Continued)

Page Summary

Page 11-2 Added Asset Management Solutions (AMS) information.

Page A-2 thru A-24 Added note 11 to the safety data section. Added new language translations.

Page B-1 Updated the return of materials address.

Back cover Updated the address blocks.

Effective July 2008 Rev. 2.2

Page Summary

Page 6-4 Added note regarding cleaning the LOI screen before use.

Page 6

Page 7

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

Table of Contents

Essential Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Oxymitter 5000 with Fieldbus Communications. . . . . . . . . . . . . . . . . . . iii

SECTION 1

Description and

Specifications

SECTION 2

Installation

Component Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Foundation Fieldbus Technology . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Handling the Oxymitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

System Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

IMPS 4000 (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

SPS 4001B (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Probe Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Diffusion Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Abrasive Shield Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Selecting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Probe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Remote Electronics Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Electrical Installation with Integral Electronics. . . . . . . . . . . . . . . . . . 2-10

Connect Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Electrical Installation with Remote Electronics . . . . . . . . . . . . . . . . . 2-13

Connect Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Calibration Handshake Logic I/O . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Install Interconnecting Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Pneumatic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Calibration Gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

IMPS 4000 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

SPS 4001B Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

SECTION 3

Configuration of

Hazardous Area

Oxymitter 5000 with

Membrane Keypad

Verify Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Terminal Block Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Hazardous Area Oxymitter 5000 Configuration . . . . . . . . . . . . . . . 3-2

Logic I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Recommended Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

TOC-1

Page 8

Hazardous Area Oxymitter 5000

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

SECTION 4

Configuration of

Hazardous Area

Oxymitter 5000 with LOI

SECTION 5

Startup and Operation of

Hazardous Area

Oxymitter 5000 with

Membrane Keypad

SECTION 6

Startup and Operation of

Hazardous Area

Oxymitter 5000 with LOI

Verify installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Terminal Block Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Hazardous Area Oxymitter 5000 Configuration . . . . . . . . . . . . . . . 4-2

Logic I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Recommended Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Power Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Power Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Start Up Oxymitter 5000 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Navigating the Local Operator Interface . . . . . . . . . . . . . . . . . . . . . . . 6-3

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Lockout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

LOI Key Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

LOI Menu Tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Hazardous Area Oxymitter 5000 Setup at the LOI . . . . . . . . . . . . . . . 6-6

LOI Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Oxymitter 5000 Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

SECTION 7

Model 375 Handheld

Communicator

SECTION 8

Troubleshooting

SECTION 9

Maintenance and Service

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Fieldbus Terminal Block Connections . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Off-Line and On-Line Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Logic I/O Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Fieldbus Menu Tree. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

FOUNDATION Fieldbus O2 CAL Method . . . . . . . . . . . . . . . . . . . . . . 7-5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Alarm Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Alarm Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Identifying And Correcting Alarm Indications. . . . . . . . . . . . . . . . . . . . 8-5

Heater Not Open, but Unable to Reach 736°C Setpoint . . . . . . . . . . 8-22

Calibration Passes but Still Reads Incorrectly. . . . . . . . . . . . . . . . . . 8-22

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Calibration with Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Semi-Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Manual Calibration with Membrane Keypad. . . . . . . . . . . . . . . . . . 9-4

FOUNDATION Fieldbus O2 CAL Method . . . . . . . . . . . . . . . . . . . . . . 9-6

Calibration with LOI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Hazardous Area Oxymitter 5000 Repair . . . . . . . . . . . . . . . . . . . . . . . 9-8

Removal and Replacement of Probe . . . . . . . . . . . . . . . . . . . . . . . 9-8

Replacement of Entire Electronics (with Housing) . . . . . . . . . . . . . 9-9

Electronic Assembly Replacement. . . . . . . . . . . . . . . . . . . . . . . . 9-12

Terminal Block Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

TOC-2

Page 9

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Entire Probe Replacement (Excluding Electronics) . . . . . . . . . . . 9-15

Heater Strut Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Cell Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Ceramic Diffusion Element Replacement. . . . . . . . . . . . . . . . . . . 9-21

Contact and Thermocouple Assembly Replacement . . . . . . . . . . 9-22

SECTION 10

Replacement Parts

SECTION 11

Optional Accessories

APPENDIX A

Safety Data

APPENDIX B

Return of Material

APPENDIX C

Fieldbus Parameter

Description

APPENDIX D

Analog Input (AI)

Function Block

Probe Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Electronics Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Model 375 Handheld Communicator. . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Asset Management Solutions (AMS). . . . . . . . . . . . . . . . . . . . . . . . . 11-2

By-Pass Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

IMPS 4000 Intelligent Multiprobe Test Gas Sequencer. . . . . . . . . . . 11-3

SPS 4001B Single Probe Autocalibration Sequencer . . . . . . . . . . . . 11-4

O2 Calibration Gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Safety Data Sheet for Ceramic Fiber Products . . . . . . . . . . . . . . . . .A-24

Returning Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Fieldbus Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

Signal Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

Direct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

Indirect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

Indirect Square Root. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-6

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-6

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-7

Advanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-8

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-8

Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-8

L_TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-8

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-8

Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-9

Temperature Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-9

Pressure Transmitter used to Measure Level in an Open Tank. .D-10

Differential Pressure Transmitter to Measure Flow . . . . . . . . . . .D-12

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-13

APPENDIX E

PID Function Block

Setpoint Selection and Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-6

Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-6

TOC-3

Page 10

Hazardous Area Oxymitter 5000

Feedforward Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-6

Tracking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-6

Output Selection and Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-7

Bumpless Transfer and Setpoint Tracking. . . . . . . . . . . . . . . . . . . . . .E-7

PID Equation Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-7

Reverse and Direct Action. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-7

Reset Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-8

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-8

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-8

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-9

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-10

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-10

Closed Loop Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-10

Application Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-11

Basic PID Block for Steam Heater Control. . . . . . . . . . . . . . . . . .E-11

Feedforward Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-12

Cascade Control with Master and Slave Loops . . . . . . . . . . . . . .E-13

Cascade Control with Override. . . . . . . . . . . . . . . . . . . . . . . . . . .E-14

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-16

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

TOC-4

Page 11

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

Oxymitter Oxygen Transmitters

READ THIS PAGE BEFORE PROCEEDING!

ESSENTIAL INSTRUCTIONS

Emerson Process Management designs, manufactures and tests its products

to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly

install, use, and maintain them to ensure they continue to operate within

their normal specifications. The following instructions MUST be adhered to

and integrated into your safety program when installing, using, and

maintaining Rosemount Analytical products. Failure to follow the proper

instructions may cause any one of the following situations to occur: Loss of

life; personal injury; property damage; damage to this instrument; and

warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the

product.

• If you do not understand any of the instructions, contact your

Emerson Process Management representative for clarification.

• Follow all warnings, cautions, and instructions marked on and

supplied with the product.

• Inform and educate your personnel in the proper installation,

operation, and maintenance of the product.

• Install your equipment as specified in the Installation Instructions

of the appropriate Instruction Manual and per applicable local and

national codes. Connect all products to the proper electrical and

pressure sources.

• To ensure proper performance, use qualified personnel to install,

operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Emerson Process Management.

Unauthorized parts and procedures can affect the product's

performance, place the safe operation of your process at risk, and

VOID YOUR WARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers

are in place, except when maintenance is being performed by

qualified persons, to prevent electrical shock and personal injury.

http://www.raihome.com

The information contained in this document is subject to change without

notice.

Page 12

Hazardous Area Oxymitter 5000

RISKOFELECTRICAL SHOCK

WARNING:REFER TOINSTRUCTIONMANUAL

PROTECTIVECONDUCT OR TERMINAL

EARTH(GROUND) TERMINAL

:

:

:

:

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

PREFACE

DEFINITIONS

The purpose of this manual is to provide information concerning the

components, functions, installation and maintenance of the Oxymitter 5000

Hazardous Area Oxygen Transmitter.

Some sections may describe equipment not used in your configuration. The

user should become thoroughly familiar with the operation of this module

before operating it. Read this instruction manual completely.

The following definitions apply to WARNINGS, CAUTIONS, and NOTES

found throughout this publication.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of

effectiveness.

SYMBOLS

NOTE

Highlights an essential operating procedure, condition, or statement.

NOTE TO USERS

The number in the lower right corner of each illustration in this publication is a

manual illustration number. It is not a part number, and is not related to the

illustration in any technical manner.

ii

Page 13

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

OXYMITTER 5000 WITH FIELDBUS COMMUNICATIONS

NOTE

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, make sure you thoroughly

understand the contents before installing, using, or maintaining this product.

The products described in this manual are NOT designed for nuclear-qualified applications.

Using non-nuclear-qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Fisher-Rosemount nuclear-qualified products, contact your local

Fisher-Rosemount Sales Representative.

Rosemount Analytical is a registered trademark of Rosemount Analytical Inc.

Delta V, the Delta V logotype, PlantWeb, and PlantWeb logotype are

trademarks of Fisher-Rosemount.

FOUNDATION is a trademark of the Fieldbus Foundation.

Emerson Process Management satisfies all obligations coming from legislation

to harmonize the product requirements in the European Union.

iii

Page 14

Hazardous Area Oxymitter 5000

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

iv

Page 15

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

Section 1 Description and Specifications

Component Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 1-1

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

IMPS 4000 (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-11

SPS 4001B (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-11

Probe Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-11

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-14

COMPONENT CHECKLIST

SYSTEM OVERVIEW

Scope

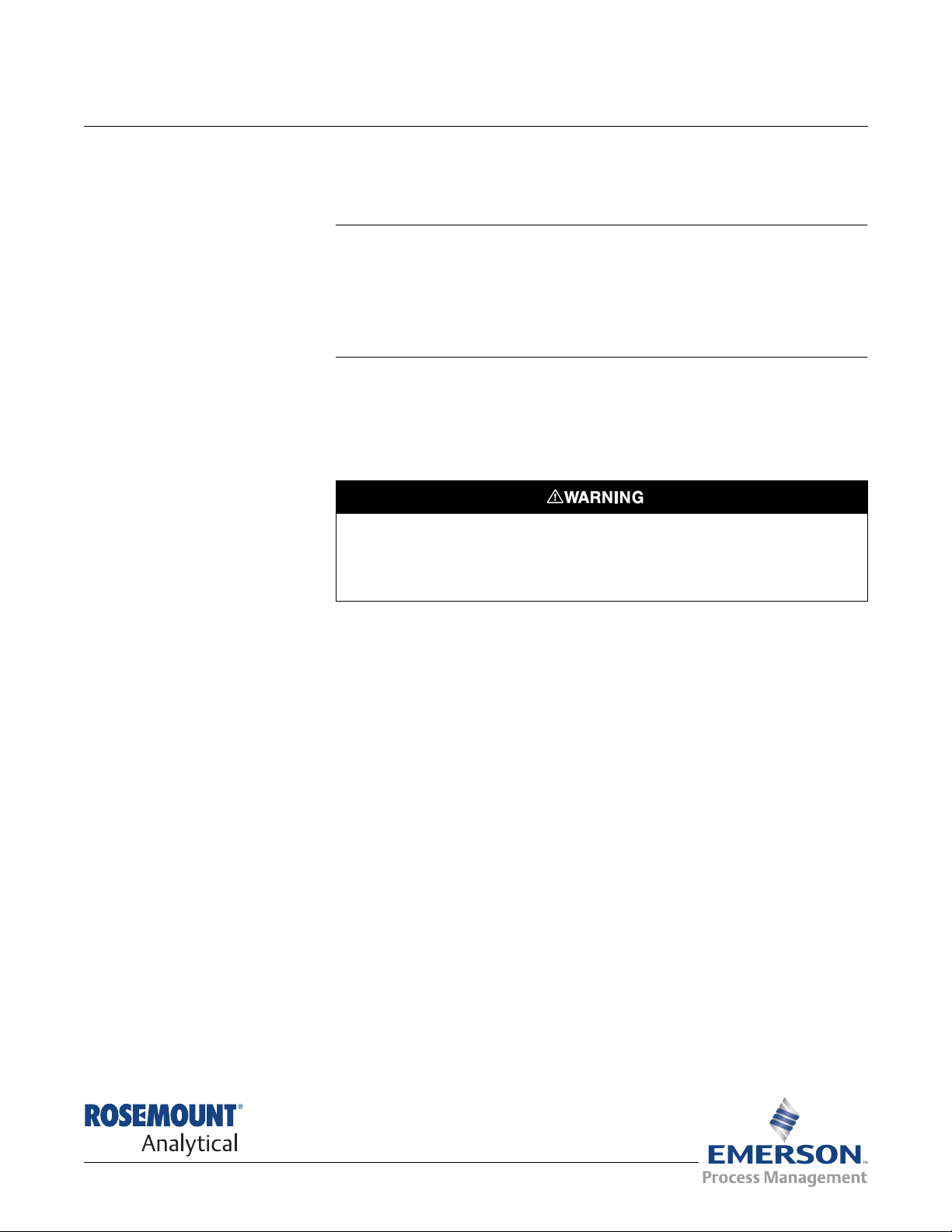

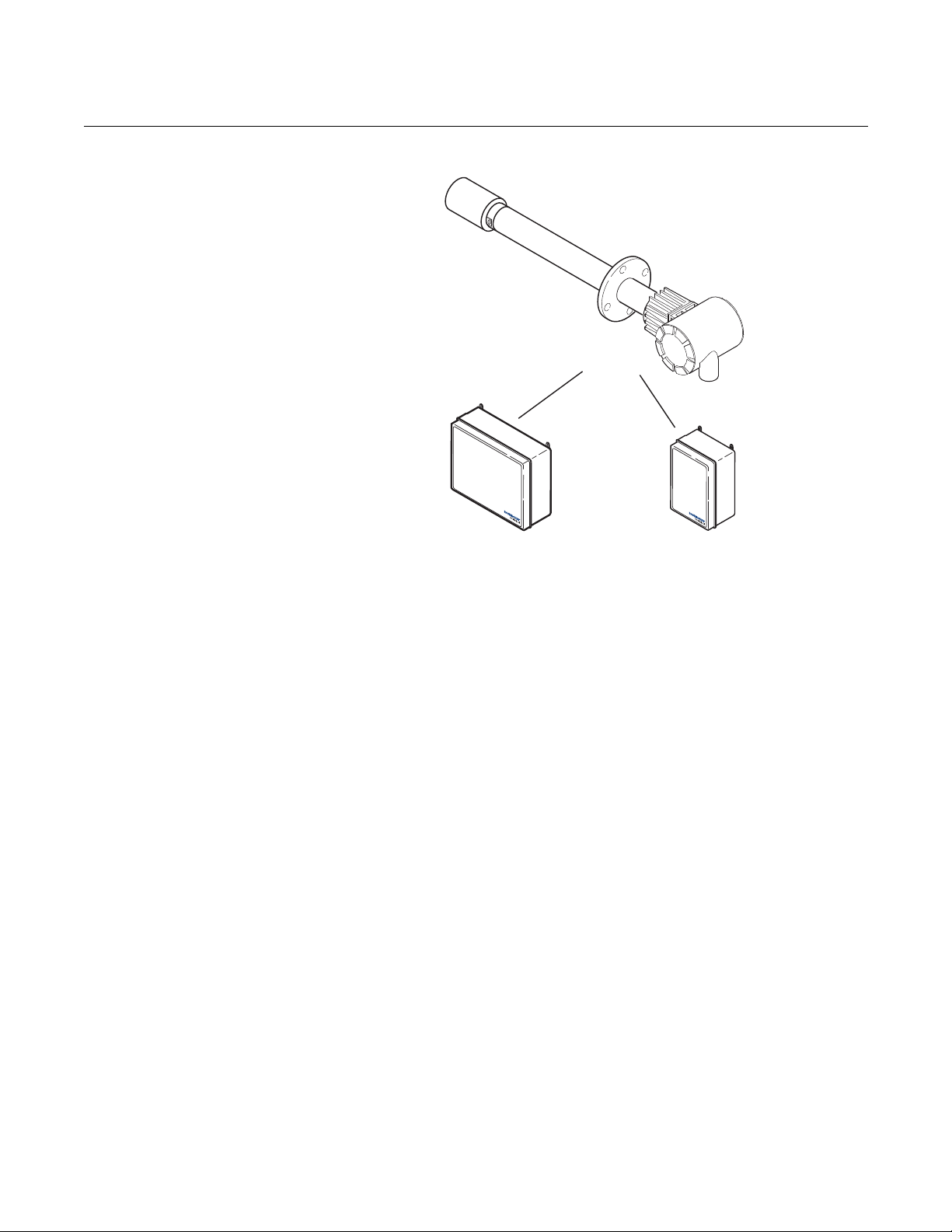

A typical Rosemount Analytical Hazardous Area Oxymitter 5000 Oxygen

Transmitter should contain the items shown in Figure 1-1. Record the part

number, serial number, and order number for each component of your system

in the table located on the first page of this manual.

The Oxymitter 5000 is offered in both hazardous area and general purpose configurations.

The hazardous area version has special markings on the approval label. The general

purpose does not. If you received the general purpose version, ensure you do not install it in

a potentially explosive atmosphere.

Also, use the product matrix in Table 1-1 at the end of this section to compare

your order number against your unit. The first part of the matrix defines the

model. The last part defines the various options and features of the

Hazardous Area Oxymitter 5000. Ensure the features and options specified

by your order number are on or included with the unit.

This Instruction Manual provides the information needed to install, start up,

operate, and maintain the Hazardous Area Oxymitter 5000. Signal

conditioning electronics outputs a digital FOUNDATION fieldbus signal

representing an O2 value and provides a membrane keypad or full function

Local Operator Interface (LOI) for setup, calibration, and diagnostics. This

same information, plus additional details, can be accessed via fieldbus digital

communications.

http://www.raihome.com

Page 16

Hazardous Area Oxymitter 5000

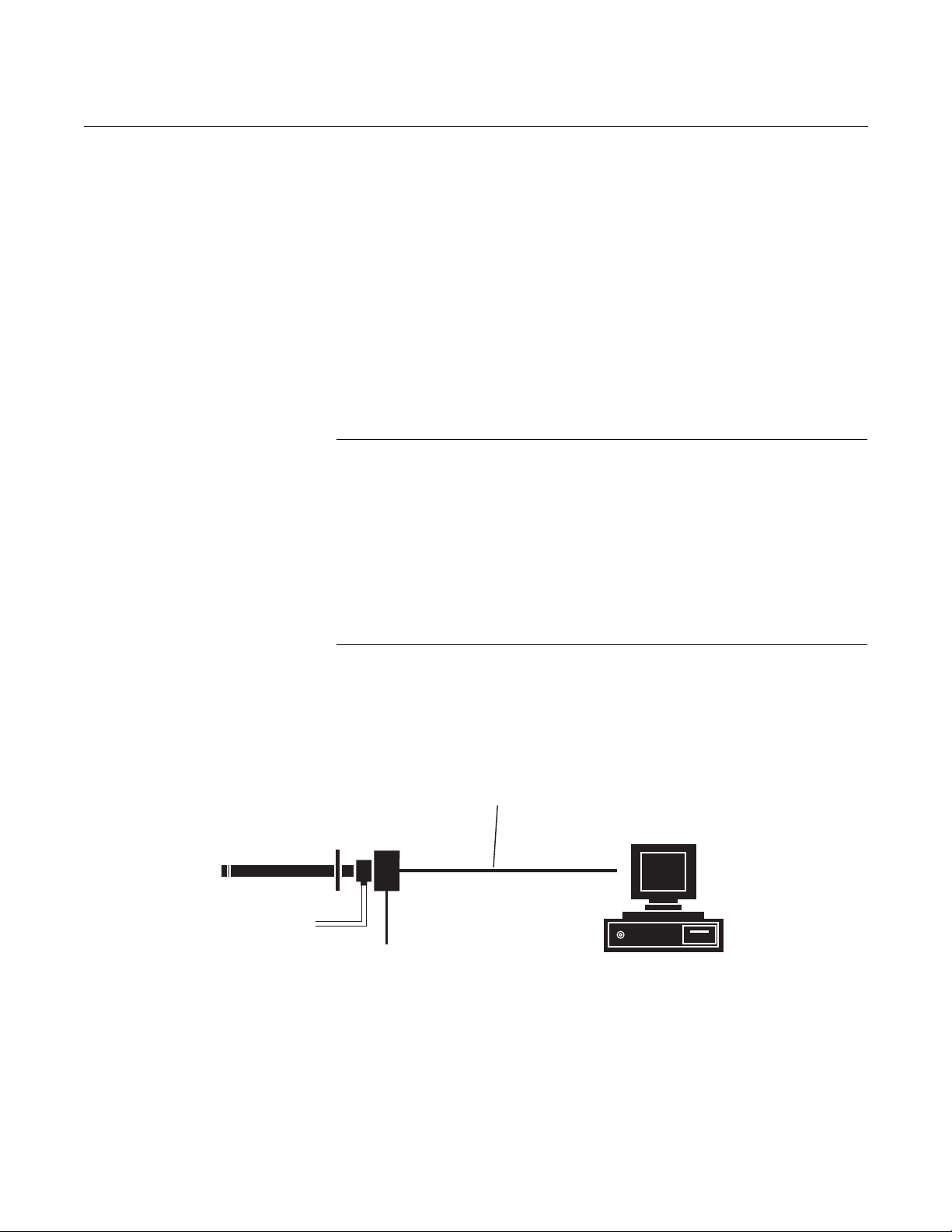

Figure 1-1. Typical System

Package

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

1. Instruction Manual

2. IMPS 4000 Intelligent Multiprobe Test Gas Sequencer (Optional)

3. Hazardous Area Oxymitter 5000 with Integral Electronics

4. SPS 4001B Single Probe Autocalibration Sequencer (Optional) (Safe area only)

5. Mounting Plate with Mounting Hardware and Gasket

6. Hazardous Area Oxymitter 5000 with Remote Electronics (Optional)

7. Reference Air Set (used if SPS 4001B without reference air option or IMPS 4000 not supplied)

1-2

Page 17

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

Foundation Fieldbus Technology

System Description

Foundation fieldbus is an all digital, serial, two-way communication system

that interconnects field equipment such as sensors, actuators, and

controllers. Fieldbus is a Local Area Network (LAN) for instruments used in

both process and manufacturing automation with built-in capacity to distribute

the control application across the network. The fieldbus environment is the

base level group of digital networks in the hierarchy of planet networks.

The fieldbus retains the desirable features of the 4-20 mA analog system,

including a standardized physical interface to the wire, bus powered devices

on a single wire, and intrinsic safety options, and enables additional

capabilities, such as:

• Increased capabilities due to full digital communications

• Reduced wiring and wire terminations due to multiple devices on one

set of wires

• Increased selection of suppliers due to interoperability

• Reduced loading on control room equipment with the distribution of

some control and input/output functions to field devices

• Speed options for process control and manufacturing applications

The Hazardous Area Oxymitter 5000 is designed to measure the net

concentration of oxygen in an industrial process; i.e., the oxygen remaining

after all fuels have been oxidized. The probe is permanently positioned within

an exhaust duct or stack and performs its task without the use of a sampling

system.

The equipment measures oxygen percentage by reading the voltage

developed across a heated electrochemical cell, which consists of a small

yttria-stabilized, zirconia disc. Both sides of the disc are coated with porous

metal electrodes. When operated at the proper temperature, the millivolt

output voltage of the cell is given by the following Nernst equation:

EMF = KT log10(P1/P2) + C

Where:

• P2 is the partial pressure of the oxygen in the measured gas on one

side of the cell.

• P1 is the partial pressure of the oxygen in the reference air on the

opposite side of the cell.

• T is the absolute temperature.

• C is the cell constant.

• K is an arithmetic constant.

NOTE

For best results, use clean, dry, instrument air (20.95% oxygen) as the

reference air.

1-3

Page 18

Hazardous Area Oxymitter 5000

When the cell is at operating temperature and there are unequal oxygen

concentrations across the cell, oxygen ions will travel from the high oxygen

partial pressure side to the low oxygen partial pressure side of the cell. The

resulting logarithmic output voltage is approximately 50 mV per decade. The

output is proportional to the inverse logarithm of the oxygen concentration.

Therefore, the output signal increases as the oxygen concentration of the

sample gas decreases. This characteristic enables the Hazardous Area

Oxymitter 5000 to provide exceptional sensitivity at low oxygen

concentrations.

The Hazardous Area Oxymitter 5000 measures net oxygen concentration in

the presence of all the products of combustion, including water vapor.

Therefore, it may be considered an analysis on a "wet" basis. In comparison

with older methods, such as the portable apparatus, which provides an

analysis on a "dry" gas basis, the "wet" analysis will, in general, indicate a

lower percentage of oxygen. The difference will be proportional to the water

content of the sampled gas stream.

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

System Configuration

Hazardous Area Oxymitter 5000 units are available in three length options,

giving the user the flexibility to use an in situ penetration appropriate to the

size of the stack or duct. The options on length are 457 mm (18 in.), 0.91 m (3

ft), and 1.83 m (6 ft).

The electronics control probe temperature and provide an output, that

represents the measured oxygen concentration. The power supply can accept

voltages of 90-250 VAC and 48/62 Hz; therefore, no setup procedures are

required. The oxygen sensing cell is maintained at a constant temperature by

modulating the duty cycle of the probe heater portion of the electronics. The

electronics accepts millivolt signals generated by the sensing cell and

produces the outputs to be used by remotely connected devices. The output

is a FOUNDATION fieldbus digital communication signal.

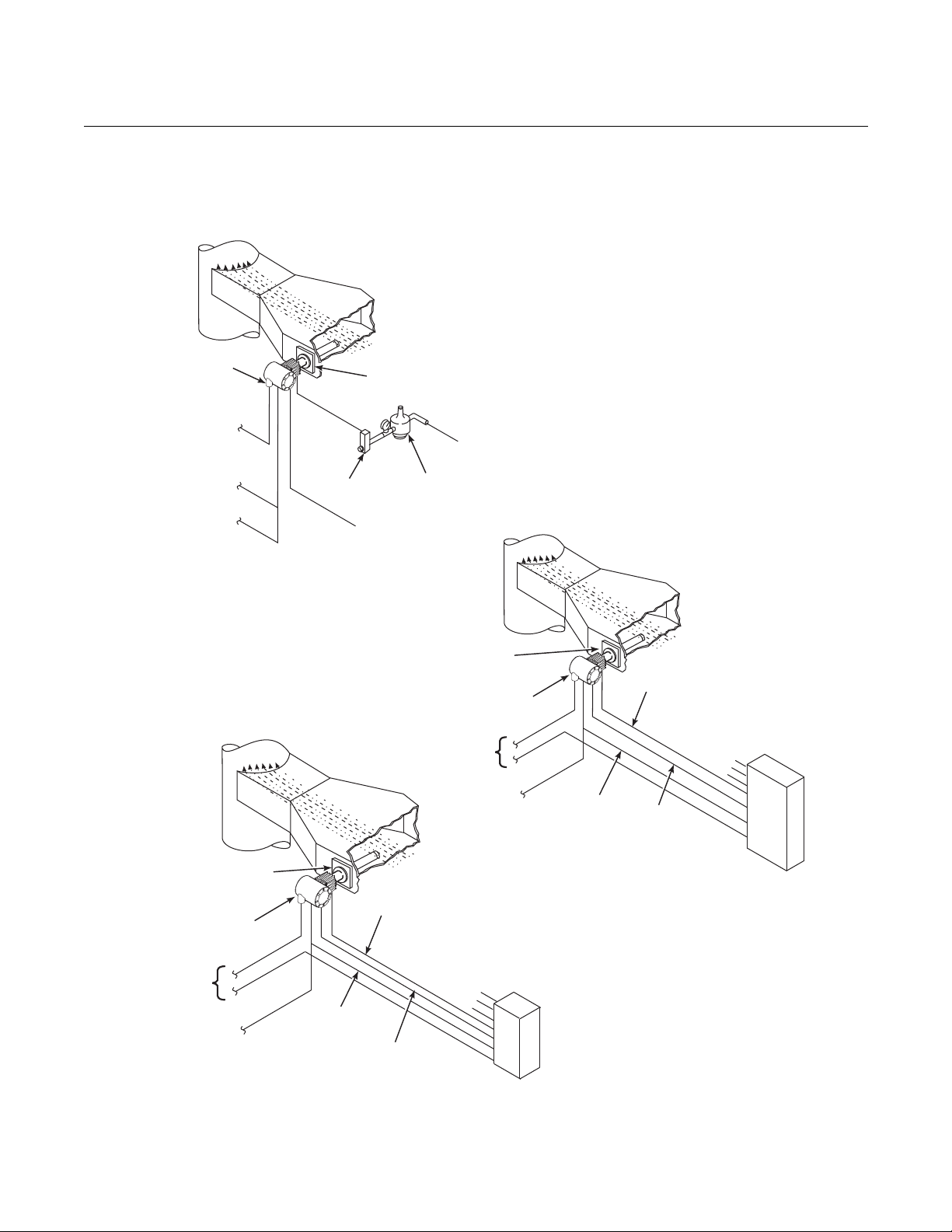

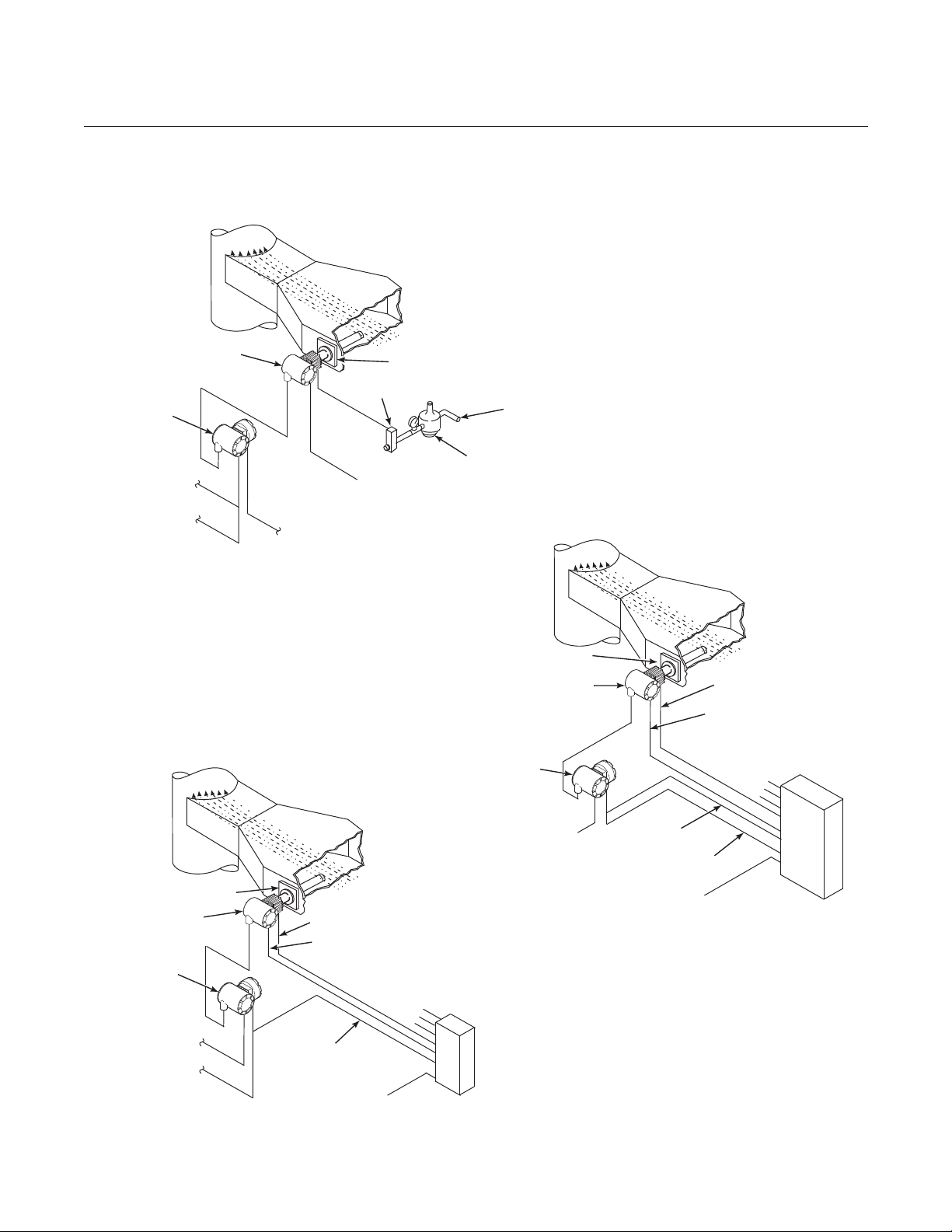

The Oxymitter 5000 transmitter is available with an integral or remote

electronics package. Two calibration gas sequencers are available to the

Hazardous Area Oxymitter 5000, but they must be installed in a

nonhazardous, explosive-free environment: the IMPS 4000 and the SPS

4001B (Figure 1-2).

Systems with multiprobe applications may employ an optional IMPS 4000

Intelligent Multiprobe Test Gas Sequencer. The IMPS 4000 provides

automatic calibration gas sequencing for up to four Hazardous Area Oxymitter

5000 units and accommodates autocalibrations based on the CALIBRATION

RECOMMENDED signal from the Hazardous Area Oxymitter 5000, a timed

interval set up via fieldbus or the IMPS 4000, or whenever a calibration

request is initiated.

1-4

Page 19

Instruction Manual

HAZARDOUS AREA

OXYMITTER5000

IMPS4000

(1to4Probes)

(Mustbeinstalled

inasafearea

orbeX-orZ-purged

bythecustomer)

SPS4001B

(1Probe)

(Mustbeinstalled

inasafearea)

38740068

IM-106-350C, Rev 2.2

July 2008

Figure 1-2. Hazardous Area

Oxymitter 5000 Autocalibration

System Options

Hazardous Area Oxymitter 5000

System Features

For systems with one or two Hazardous Area Oxymitter 5000 units per

combustion process, an optional SPS 4001B Single Probe Autocalibration

Sequencer can be used with each Hazardous Area Oxymitter 5000 to provide

automatic calibration gas sequencing. The sequencer performs

autocalibrations based on the CALIBRATION RECOMMENDED signal from

the Hazardous Area Oxymitter 5000, a timed interval set up in fieldbus, or

whenever a calibration request is initiated.

1. The CALIBRATION RECOMMENDED feature detects when the sensing

cell is likely out of limits. This may eliminate the need to calibrate on a

"time since last cal" basis.

2. The cell output voltage and sensitivity increase as the oxygen

concentration decreases.

1-5

Page 20

Hazardous Area Oxymitter 5000

DIAGNOSTIC

ALARMS

TEST

POINTS

HEATER T/C

HEATER

02 CELL

CALIBRATION

CALIBRATION RECOMMENDED

02 CELL mV +

02 CELL mv HEATER T/C +

HEATER T/C -

INC INC

DEC DEC

HIGH

GAS

LOW

GAS

CAL

TEST GAS +

PROCESS -

% 02

Membrane

Keypad

38740027

38740028

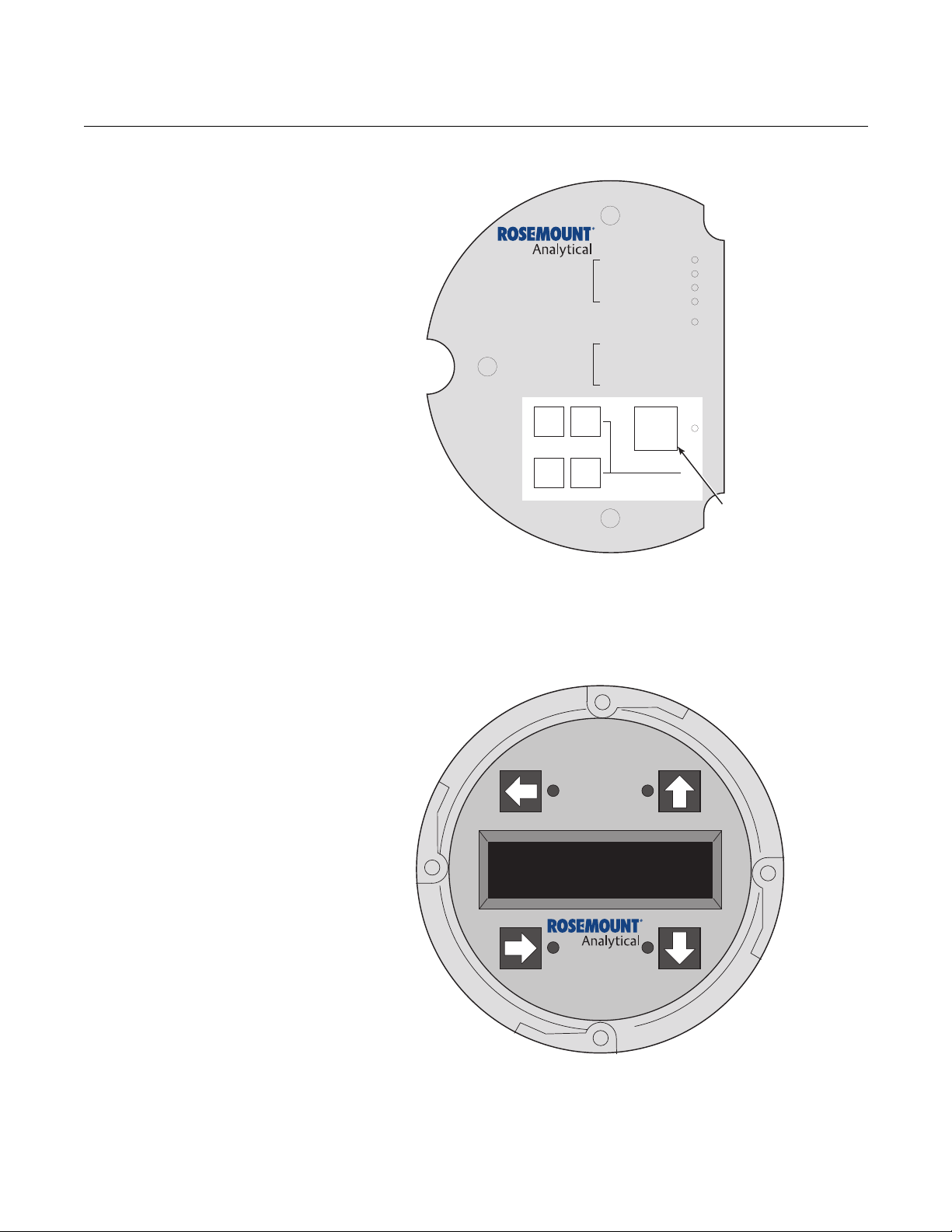

Figure 1-3. Membrane Keypad

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Figure 1-4. Local Operator

Interface (LOI)

1-6

3. Membrane keypad, Figure 1-3, and FOUNDATION fieldbus

communication are standard.

4. An optional Local Operator Interface Figure 1-4 allows continual O2

display and full interface capability.

5. Field replaceable cell, heater, thermocouple, diffuser, and PC boards.

Page 21

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

6. The Hazardous Area Oxymitter 5000 is constructed of rugged 316L

stainless steel for all wetted parts.

7. The electronics are adaptable for line voltages from 90-250 VAC;

therefore, no configuration is necessary.

8. The Hazardous Area Oxymitter 5000 membrane keypad is available in

five languages: English, French, German, Italian, and Spanish.

9. An operator can calibrate and communicate with the Hazardous Area

Oxymitter 5000 in one of four ways:

Accessing the probe keypad requires opening the electronics housing. Opening the

electronics housing will cause the loss of ALL hazardous permits. Opening the electronics

housing in hazardous areas may cause an explosion resulting in loss of property, severe

personal injury, or death. It may be required to get a hot work permit from your company

safety officer before opening the electronic housing.

a. Membrane Keypad. The membrane keypad, housed within the right

side of the electronics housing, provides fault indication by way of

flashing LEDs. Calibration can be performed from the membrane

keypad.

b. Local Operator Interface (LOI). The optional LOI takes the place of

the membrane keypad and allows local communication with the

electronics. Refer to Section 4, Configuration of Hazardous Area

Oxymitter 5000 with LOI for more information.

c. FOUNDATION fieldbus Interface. The Oxymitter 5000's output

carries a signal containing the oxygen level encoded in digital format.

This digital output can also be used to communicate with the

Oxymitter and access all of the Oxymitter’s status information.

d. Optional IMPS 4000. The Programmable Logic Controller (PLC) in

the IMPS 4000 provides fault indications using flashing LEDs and

LCD display messages. Refer to the IMPS 4000 Intelligent

Multiprobe Test Gas Sequencer manual for more information.

Handling the Oxymitter

System Considerations

It is important that printed circuit boards and integrated circuits are handled only when

adequate antistatic precautions have been taken to prevent possible equipment damage.

The Hazardous Area Oxymitter 5000 is designed for industrial applications. Treat each

component of the system with care to avoid physical damage. Some probe components are

made from ceramics, which are susceptible to shock when mishandled.

Prior to installing your Hazardous Area Oxymitter 5000, make sure you have

all the components necessary to make the system installation. Ensure all the

components are properly integrated to make the system functional.

After verifying that you have all the components, select mounting locations

and determine how each component will be placed in terms of available line

voltage, ambient temperatures, environmental considerations, convenience,

and serviceability. Figure 1-5 shows a typical system wiring.

1-7

Page 22

Hazardous Area Oxymitter 5000

38740001

FieldbusDigital

Signal

2CalibrationGasLines

byCustomer

[90m(300ft)max]

FieldbusComputer

Terminal

LineVoltage

Hazardous Area

Oxymitter5000

withIntegralElectronics

A typical system installation with integral electronics is illustrated in

Figure 1-6. A typical system installation with remote electronics is illustrated in

Figure 1-7.

A source of instrument air is optional at the Hazardous Area Oxymitter 5000

for reference air use. Since the unit can be equipped with an in-place

calibration feature, provisions can be made to permanently connect

calibration gas bottles to the Hazardous Area Oxymitter 5000.

If the calibration gas bottles will be permanently connected, a check valve is

required next to the calibration fittings on the integral electronics.

This check valve is to prevent breathing of the calibration gas line and

subsequent flue gas condensation and corrosion.

The check valve is in addition to the stop valve in the calibration gas kit and

solenoid valves in the IMPS 4000 or SPS 4001B.

NOTE

The integral electronics is rated NEMA 4X (IP66) and is capable of operation

at temperatures up to 85°C (185°F).

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Figure 1-5. Hazardous Area

Oxymitter 5000 FOUNDATION

Fieldbus Connections

The optional LOI is also rated for operation at temperatures up to 85°C

(185°F). The infrared keypad functionality will deg rade at temperatures above

70°C (158°F).

Retain the original packaging for the Hazardous Area Oxymitter 5000, in case

the components are to be shipped to another site. This packaging is designed

to protect the product.

1-8

Page 23

Instruction Manual

Oxymitter

5000

SPS 4001B

Reference

Air

Logic I/O

Calibration Gas

Adapter Plate

Stack

Duct

Gases

Calibration Gas 1

Calibration Gas 2

Inst. Air Supply

Line Voltage

FieldbusDigital

Signal

38740069

Duct

Stack

Gases

Calibration

Gas

Adapter

Plate

Line

Voltage

Logic I/O

Instrument

Air Supply

(Reference Air)

Pressure

Regulator

Flowmeter

STANDARD

Oxymitter

5000

FieldbusDigital

Signal

*Note: The IMPS 4000 or SPS 4001B must

be installed in a non-hazardous,

explosive-free environment.

Oxymitter

5000

IMPS 4000*

MULTIPROBE

AUTOCALIBRATION

OPTION

IMPS 4000

Reference

Air

Logic I/O

Calibration

Gas

Adapter

Plate

Stack

Duct

Gases

Calibration Gas 1

Calibration Gas 2

Inst. Air Supply

Line

Voltage

Fieldbus

DigitalSignal

SPS 4001B* SINGLE PROBE

AUTOCALIBRATION OPTION

(WITH REFERENCE AIR OPTION)

IM-106-350C, Rev 2.2

July 2008

Figure 1-6. Typical System

Installation – Oxymitter 5000

with Integral Electronics

Hazardous Area Oxymitter 5000

1-9

Page 24

Hazardous Area Oxymitter 5000

Duct

Stack

Gases

Calibration

Gas

Adapter Plate

Line

Voltage

Logic I/O

Instrument

Air Supply

(Reference Air)

Pressure

Regulator

Flowmeter

STANDARD

Oxymitter 5000

Oxymitter 5000

FieldbusDigital

Signal

IMPS 4000

Reference Air

Calibration Gas

Adapter Plate

Stack

Duct

Gases

Calibration Gas 1

Calibration Gas 2

Inst. Air Supply

Line Voltage

FieldbusDigitalSignal

Remote

Electronics

Remote

Electronics

Logic I/O

Line Voltage

*Note: TheIMPS4000orSPS4001Bmust

beinstalledinanon-hazardous,

explosive-freeenvironment.

SPS 4001B* SINGLE PROBE

AUTOCALIBRATION OPTION

(WITH REFERENCE AIR OPTION)

Oxymitter

5000

SPS 4001B

Logic I/O

Calibration Gas

Adapter Plate

Stack

Duct

Gases

Calibration Gas 1

Calibration Gas 2

Inst. Air Supply

Remote

Electronics

Line Voltage

Line Voltage

Reference Air

FieldbusDigital

Signal

38740070

IMPS 4000*

MULTIPROBE

AUTOCALIBRATION

OPTION

Figure 1-7. Typical System

Installation – Oxymitter 5000

with Remote Electronics

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

1-10

Page 25

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

IMPS 4000 (OPTIONAL)

SPS 4001B (OPTIONAL)

Mounting

If using an IMPS 4000 with a Hazardous Area Oxymitter 5000, the IMPS 4000

sequencer must be installed in a non-hazardous, explosive-free environment.

For further IMPS 4000 information, refer to the IMPS 4000 Intelligent

Multiprobe Test Gas Sequencer Instruction Manual.

If using an SPS 4001B with a Hazardous Area Oxymitter 5000, the SPS

4001B sequencer must be installed in a non-hazardous, explosive-free

environment.

The SPS 4001B is fully enclosed in a NEMA cabinet suited for wall-mounting.

This cabinet provides added protection against dust and minor impacts. The

SPS 4001B consists of a manifold and a calibration gas flowmeter. The manifold provides electrical feedthroughs and calibration gas ports to route power

and signal connections and calibration gases to and from the sequencer. In

addition, the manifold houses two calibration gas solenoids that sequence the

gases to the Oxymitter 5000, a pressure switch that detects low calibration

gas pressure, and two PC boards. A terminal strip housed within the terminal

cover provides convenient access for all user connections.

Components optional to the SPS 4001B include a reference air flowmeter and

pressure regulator. The reference air flowmeter indicates the flow rate of

reference air continuously flowing to the Oxymitter 5000. The reference air

pressure regulator ensures the instrument air (reference air) flowing to the

Oxymitter 5000 is at a constant pressure [20 psi (138 kPa)]. The regulator

also has a filter to remove particulates in the reference air and a drain valve to

bleed the moisture that collects in the filter bowl.

Operation

PROBE OPTIONS

Diffusion Elements

Brass fittings and Teflon tubing are standard. Stainless steel fittings and

tubing are optional. Also, disposable calibration gas bottles are available as

an option or can be purchased through a local supplier.

The SPS 4001B works in conjunction with the Oxymitter 5000's CALIBRATION RECOMMENDED feature to perform an autocalibration. This feature

automatically performs a gasless calibration check every hour on the Oxymitter 5000. If a calibration is recommended and its contact output signal is set

for "handshaking" with the sequencer, the Oxymitter 5000 sends a signal to

the sequencer. The sequencer automatically performs a calibration upon

receiving the signal. Thus, no human interface is required for the automatic

calibration to take place.

For further SPS 4001B information, refer to the SPS 4001B Single Probe

Autocalibration Sequencer Instruction Manual.

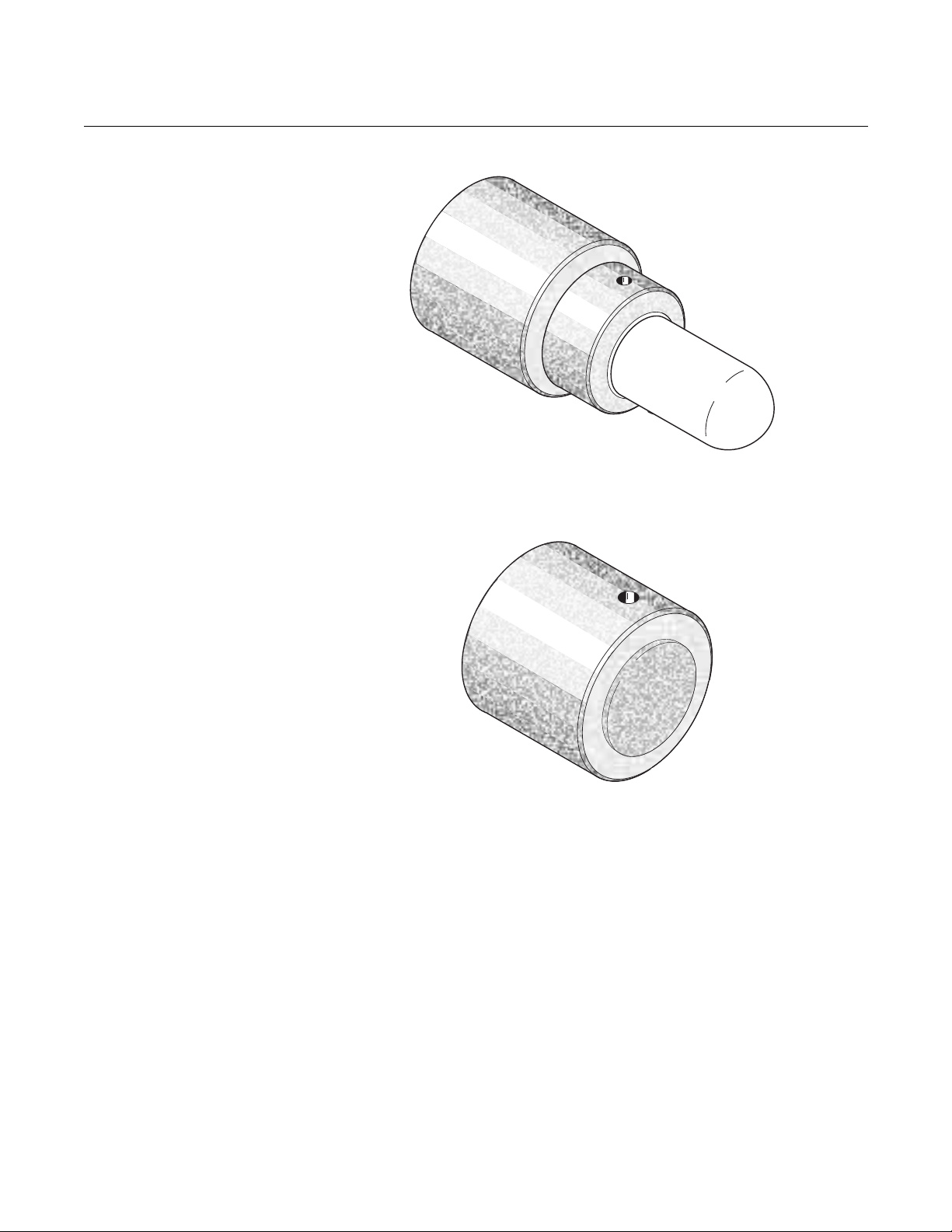

Flame Arrestor Ceramic Diffusion Assembly

The ceramic diffusion assembly, Figure 1-8, includes a set of baffles between

the cell and the stack gases. This keeps 816°C (150 0°F) cell temperatures

from igniting unburned fuel in the stack. The ceramic diffusion assembly is

also available with a dust seal for use with the abrasive shield assembly.

1-11

Page 26

Hazardous Area Oxymitter 5000

38740002

38740003

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Figure 1-8. Flame Arrestor

Ceramic Diffusion Assembly

Figure 1-9. Flame Arrestor

Snubber Diffusion Assembly

Abrasive Shield Assembly

1-12

Flame Arrestor Snubber Diffusion Assembly

The snubber diffusion assembly, Figure 1-9, is satisfactory for most

applications. This element is also available with a dust seal for use with an

abrasive shield.

The abrasive shield assembly, Figure 1-10, is a stainless-steel tube that

surrounds the probe assembly. The shield protects against particle abrasion

and condensations, provides a guide for ease of insertion, and acts as a

position support, especially for longer probes. The abrasive shield assembly

uses a modified diffuser and vee deflector assembly, fitted with dual dust seal

packing.

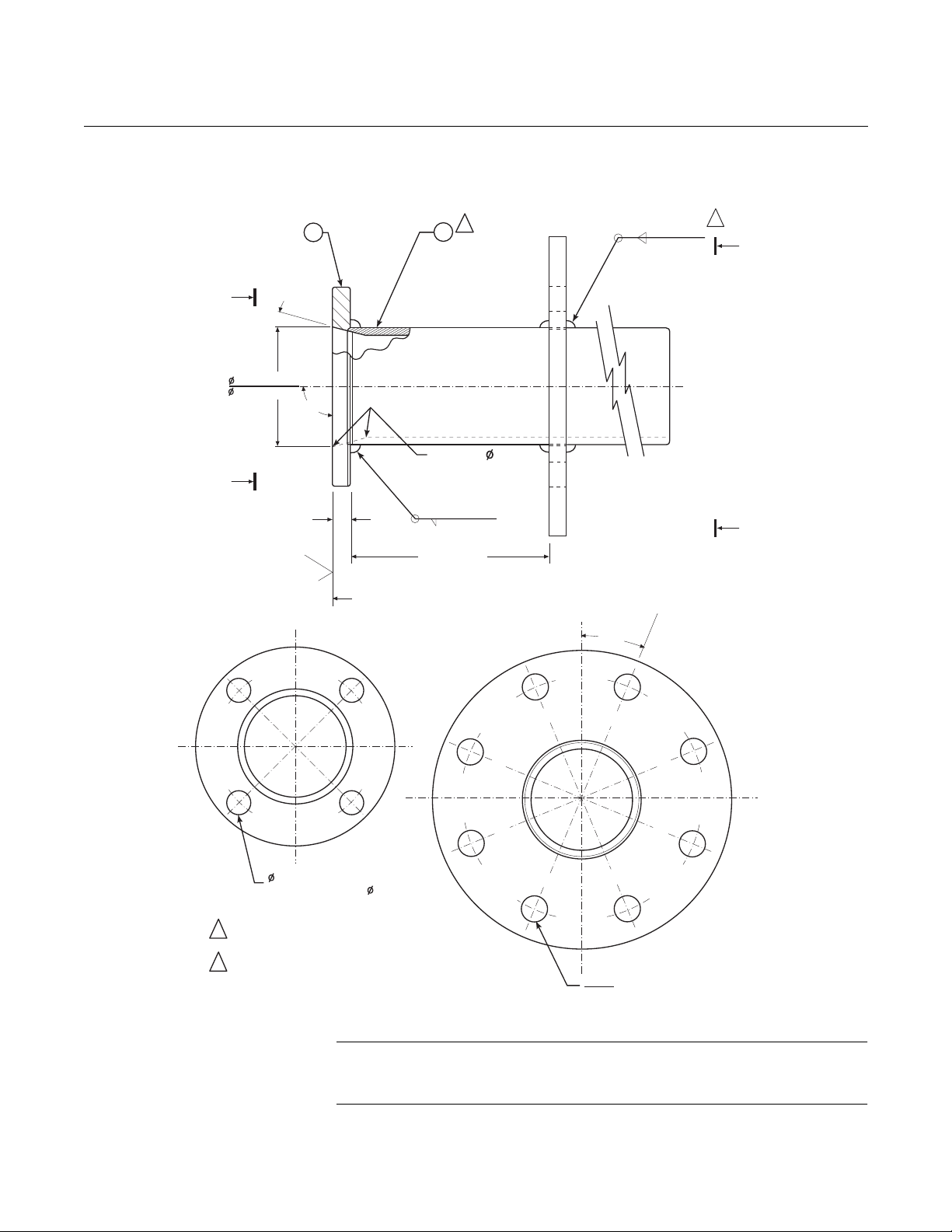

Page 27

Instruction Manual

VIEW A

VIEW B

A

B

A

B

15

o

2

4.7(0.187)

1

Oninsidebreak

forsmooth

roundededgeon

bothendsof

Chamfer.

152.4(6.00)

125

11.4(0.45)MIN

90

o

91.0(3.584)

90.3(3.554)

Skincutfacefor90

o

22.5

o

Diaona190.5(7.50)

DiaB.C.(Ref)

18.9(0.745)

19.2(0.755)

19(0.75)thru4places,

equallyspacedon

120.65(4.75)B.C.

Notes:

1Weldonbothsideswithexpanding

ChillBlock.

2Beforewelding,buttitem2with

item1asshown.

Dimensionsareinmillimeterswith

inchesinparentheses.

38740004

01

02

4.7(0.187)

IM-106-350C, Rev 2.2

July 2008

Figure 1-10. Abrasive Shield

Assembly

Hazardous Area Oxymitter 5000

NOTE

In highly abrasive applications, rotate the shield 90 degrees at normal service

intervals to present a new wear surface to the abrasive flow stream.

1-13

Page 28

Hazardous Area Oxymitter 5000

Fisher-Rosemount has

satisfied all obligations

coming from European

legislation to harmonize

the product requirements

in Europe

SPECIFICATIONS

Hazardous Area Oxymitter Specifications

O2 Range

Standard 0 to 10% O2, 0 to 25% O2, 0 to 40% O2 (via

Accuracy ±0.75% of reading or 0.05% O2, whichever is greater

System Response to Calibration

Gas

Temperature Limits

Process 0° to 704°C (32° to 1300°F) up to 1300°C (2400°F)

Electronics Housing -40° to 70°C (-40° to 158°F) amb ient

Electronics Package -40° to 85°C (-40° to 185°F) [Operating temperature

Local Operator Interface -40° to 70°C (-40° to 158° F), ambient

Probe Lengths 457 mm (18 in.), 0,91 m (3 ft), 1,83 m (6 ft)

Mounting and Mounting Position Vertical or horizontal;

Materials

Probe Wetted or welded parts - 316L stainless steel (SS)

Electronics Enclosure Low-copper aluminum

Calibration Manual, semi-automatic, or automatic

Calibration Gas Mixtures

Recommended

Calibration Gas Flow 2.5 l/min (5 scfh)

Reference Air 0.25 l/min (0.5 scfh), clean, dry, instrument-quality air

Electronics NEMA 4X, IP66 with fitting and pipe on reference

Line Voltage 90-250 VAC, 48/62 Hz; 3/4 in. - 14 NPT conduit port

Pollution Degree 2

Over Voltage Category II

Relative Humidity 5 to 95% (non-condensing)

Foundation fieldbus)

Initial – less than 3 seconds, T90 – less than 8

seconds

with optional accessories

of electronics inside of instrument housing, as

measured by Foundation fieldbus.]

-40° to 85°C (-40° to 185°F), internal [At temperat ures

above 70°C (158°F) inside instrument housing, the

infrared keypad will cease to function, but the

Oxymitter 5000 will continue to operate properly.]

a spool piece, (P/N 3D39761G02), is available to

offset transmitter housing from hot ductwork.

Non-wetted parts - 304 SS, low-copper aluminum

0.4% O2, Balance N

8% O2, Balance N

(20.95% O2), regulated to 34 kPa (5 psi)

exhaust port to clear dry atmosphere

Table continued on next page

2

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

2

1-14

Page 29

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

Hazardous Area Oxymitter Specifications

Signals

Digital Output FOUNDATION fieldbus compatible

Logic I/O Two-terminal logic contact configurable as either an

alarm output or as a bi-directional calibration

handshake signal to IMPS 4000 or SPS 4001B,

self-powered (+5 V) in series with 340 ohms

Conduit ports — 3/4 in.-14 NPT (for Foundation

fieldbus and logic I/O signal lines)

Power Requirements:

Probe Heater 175 W nominal

Electronics 10 W nominal

Maximum 500 W

Hazardous Area Oxymitter Certifications

Hazardous Area Oxymitter 5000 with Integral Electronics

KEMA/ATEX II 2 G EEx d IIB+H2 T6 (Elect Comp) / T2 (Probe)

CSA

FM

Hazardous Area Oxymitter with Remote Electronics

KEMA/ATEX

CSA

FM

Class I, Division 1, Groups B, C, D T2

Class I, Zone 1, Ex d IIB+H2 T2

Class I, Zone 1, AEx d IIB+H2 T2

Class I, Division 1, Groups B, C, D T2

Class I, Zone 1, AEx d IIB+H2 T2

II 2 G EEx d IIB+H2 T2 (Remote Probe)

II 2 G EEx de IIB+H2 T6 (Remote Electronics)

Class I, Zone 1, Ex d IIB+H2 T2 (Remote Probe)

Class I, Zone 1, Ex de IIB+H2 T6 (Remote Electronics)

Class I, Zone 1, AEx d IIB+H2 T2 (Remote Probe)

Class I, Zone 1, AEx de IIB+H2 T6 (Remote

Electronics)

Class I, Zone 1, AEx d IIB+H2 T2 (Remote Probe)

Class I, Zone 1, AEx de IIB+H2 T6 (Remote

Electronics)

1-15

Page 30

Hazardous Area Oxymitter 5000

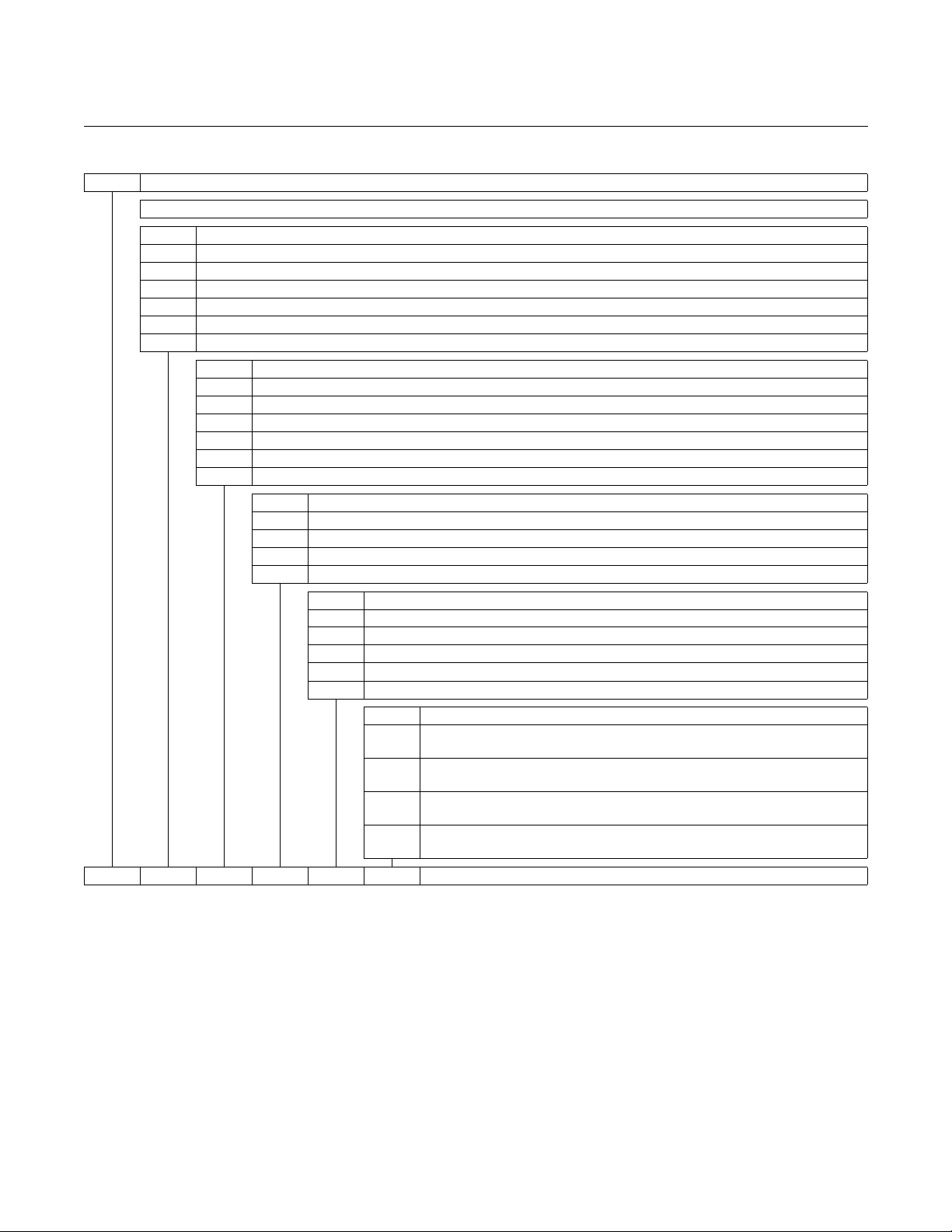

Table 1-1. Product Matrix

OXT5C Oxymitter 5000 Explosion Proof with FOUNDATION fieldbus- In Situ Oxygen Transmitter

Explosion Proof Oxygen Transmitter - Instruction Book

Code Sensing Probe Type with Flame Arrestor

1 Ceramic Diffusion Element Probe (ANSI 3 in. 150 lb bolt cirlce)

2 Snubber Diffusion Element (ANSI 3 in. 150 lb bolt cirlce)

3 Ceramic Diffusion Element Probe (DIN 2527) - 1/4 in. Tube Fittings

4 Snubber Diffusion Element (DIN 2527) - 1/4 in. Tube Fittings

7 Ceramic Diffusion Element Probe (ANSI 3 in. 300 lb bolt cirlce)

8 Ceramic Diffusion Element Probe (ANSI 4 in. 300 lb bolt cirlce)

Code Probe Assembly

0 18 in. (457 mm) Probe

2 18 in. (457 mm) Probe with Abrasive Shield

3 3 ft (0,91 m) Probe

4 3 ft (0,91 m) Probe with Abrasive Shield

5 6 ft (1,83 m) Probe

6 6 ft (1,83 m) Probe with Abrasive Shield

Code Mounting Adaptor- Stack Side

0 No Adaptor Plate ("0" must be chosen under "Mounting Adaptor - Probe Side" below)

1 New Installation - Square weld plate with studs

2 Model 218 Mounting Plate (with Model 218 Shield Removed)

3 Competitor’s Mount

Code Mounting Adaptor-Probe Side

0 No Adaptor Plate

1 Probe Only (ANSI)

2 New Bypass or New Abrasive Shield (ANSI)

4 Probe Only (DIN)

5 New Bypass or New Abrasive Shield (DIN)

Code Electronic Housing - NEMA 4X, IP66

12 FOUNDATION fieldbus electronics, mounted integral to probe, transient

protected termination ATEX EExdllB+H2T2

14 FOUNDATION fieldbus electronics, mounted remotely, transient protected

termination; requires cable ATEX EExdllB+H2T2

22 FOUNDATION fieldbus electronics, mounted integral to probe, transient

protected termination Class I Div. I, Group B,C,D

24 FOUNDATION fieldbus electronics, mounted remotely, transient protected

termination; requires cable Class I Div. I, Group B,C,D

OXT5C 3 3 1 1 14 Example

(1)

(1)

(1)

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

1-16

Page 31

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Cont’d

Code Operator Interface

1 Membrane Keypad - Fieldbus, Blind Cover

2 Membrane Keypad - Fieldbus, Window Cover

3 Gas Florescent LOI, Fieldbus, English only, Window Cover

Code Language

1 English

2 German

3 French

4 Spanish

5 Italian

Code Termination Filtering

Cont’d 1 3 00 01 00 00 00 Example

(3)

00 No Option - Specified as part of Electronic Housing

Code Calibration Accessories

00 No Hardware

01 Cal/Ref Flowmeters and Reference Pressure Regulator

02 Autocalibration Systems - order by seperate part number (for safe areas only)

Code Hazardous Area Approval

00 certification selected elsewhere

Code Control Suite Functionality

Hazardous Area Oxymitter 5000

00 Basic Control Suite

01 Deduct Basic Control Suite

Code Electronics to Probe Cable

00 No Cable, Integral Electronics

10 20 ft (6 m) Cable - Remote Electronics

11 40 ft (12 m) Cable - Remote Electronics

12 60 ft (18 m) Cable - Remote Electronics

13 80 ft (24 m) Cable - Remote Electronics

14 100 ft (30 m) Cable - Remote Electronics

15 150 ft (45 m) Cable - Remote Electronics

16 200 ft (61 m) Cable - Remote Electronics

NOTES:

High Sulfur Service:

High sulfur cell can be selected for any probe; add a line item note to your purchase order requesing the high sulfur ZrO2 cell in place of the standard ZrO2 cell.

(1)

Recommended uses: High velocity particulates in flue stream, installation within 10ft (3,5 m) of soot blowers or heavy salt cake buildup. Applications:

Pulverized coal, recovery boilers, lime kiln.

(2)

Where possible, specify ANSI or DIN designation; otherwise, provide details of the existing mounting plate as follows:

Plate with studs Bolt circle diameter, number, and arrangement of studs; stud thread; and stud height above mounting plate.

Plate without studs Bolt circle diameter, number, and arrangement of holes; thread; and depth of stud mounting plate with accessories.

(3)

Startup, calibration, and operation can be implemented using the standard membrane keypad. Remote access and additional functionality available via

Fieldbus Communications (DeltaV).

1-17

Page 32

Hazardous Area Oxymitter 5000

Table 1-2. Calibration

Components

Table 1-3. Intelligent Multiprobe

Test Gas Sequencer Versions

Part Number Description

1A99119G01 Two disposable calibration gas bottles - 0.4% and 8% O2, balance

1A99119G02 Two pressure regulators for calibration gas bottles

1A99119G03 Bottle rack

Notes:

*Calibration gas bottles cannot be shipped via airfreight.

When the bottles are used with CALIBRATION RECOMMENDED features, the bottles should provide

2 to 3 years of calibrations in normal service.

Part Number Description Number of Oxymitters

3D39695G01 IMPS 1

3D39695G02 IMPS 2

3D39695G03 IMPS 3

3D39695G04 IMPS 4

3D39695G05 IMPS w/115 V Heater 1

3D39695G06 IMPS w/115 V Heater 2

3D39695G07 IMPS w/115 V Heater 3

3D39695G08 IMPS w/115 V Heater 4

3D39695G09 IMPS w/220V Heater 1

3D39695G10 IMPS w/220V Heater 2

3D39695G11 IMPS w/220V Heater 3

3D39695G12 IMPS w/220V Heater 4

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

nitrogen - 550 liters each*

1-18

Page 33

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Hazardous Area Oxymitter 5000

Section 2 Installation

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Electrical Installation with Integral Electronics . . . . . . . .page 2-10

Electrical Installation with Remote Electronics . . . . . . . . page 2-13

Pneumatic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-17

IMPS 4000 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-18

SPS 4001B Connections . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-18

Before installing this equipment, read the "Safety Instructions" for the wiring and installation

of this apparatus in Appendix A of this Instruction Manual. Failure to follow safety

instructions could result in serious injury or death.

The Hazardous Area Oxymitter 5000 and probe abrasive shield are heavy. Use proper

lifting and carrying procedures to avoid personal injury.

Install all protective equipment covers and safety ground leads after installation. Failure to

install covers and ground leads could result in serious injury or death.

http://www.raihome.com

Page 34

Hazardous Area Oxymitter 5000

MECHANICAL INSTALLATION

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Selecting Location

1. The location of the Hazardous Area Oxymitter 5000 in the stack or flue

is most important for maximum accuracy in the oxygen analyzing

process. The Hazardous Area Oxymitter 5000 must be positioned so

the gas it measures is representative of the process. Best results are

normally obtained if the Hazardous Area Oxymitter 5000 is positioned

near the center of the duct (40 to 60% insertion). Longer ducts may

require several Hazardous Area Oxymitter 5000 units since the O2 can

vary due to stratification. A point too near the wall of the duct, or the

inside radius of a bend, may not provide a representative sample

because of the very low flow conditions. The sensing point should be

selected so the process gas temperature falls within a range of 0° to

704°C (32° to 1300°F). Figure 2-1 through Figure 2-5 provide

mechanical installation references.

The ambient temperature of the electronics housing must not exceed

70°C (150°F). For higher ambient temperatures, we r ecommend the

remote mounted electronics option.

NOTE

At temperatures up to 85°C (185°F) inside the housi ng, the infrared keypad

will cease to function, but the transmitter will continue to operate properly.

2. Check the flue or stack for holes and air leakage. The presence of this

condition will substantially affect the accuracy of the oxygen reading.

Therefore, either make the necessary repairs or install the Hazardous

Area Oxymitter 5000 upstream of any leakage.

3. Ensure the area is clear of internal and external obstructions that will

interfere with probe installation and access to the membrane keypad or

LOI. Allow adequate clearance for removal of the Hazardous Area

Oxymitter 5000 (Figure 2-1 or Figure 2-3).

Probe Installation

2-2

Do not allow the temperature of the Hazardous Area Oxymitter 5000 electronics to exceed

85°C (185°F) or damage to the unit may result.

1. Ensure all components are available to install the Hazardous Area

Oxymitter 5000. If equipped with a ceramic diffuser, make sure the

diffuser is not damaged.

2. The Hazardous Area Oxymitter 5000 probe may be installed intact, as it

is received.

NOTE

An abrasive shield is recommended for high velocity particulates in the flu

stream (such as those in coal-fired boilers, kilns, and recovery boilers).

3. Weld or bolt mounting plate (Figure 2-5) onto the duct.

Page 35

Instruction Manual

CoverRemoval& Access

305

305

(12)

(12)

AddtoDIM“A”

forProbewith

CeramicDiffuser

95(3.8)

with

Snubber

Diffuser

DIM"A"

66

(2.6)

76

(3.0)

DIM"B”

RemovalEnvelope

ElecConn

3/4NPT

ANSI ( ) Tube6.35 1/4

DIN

6.35(1/4) Tube

CAL Gas

Ref Air

BottomView

P

S

U

E

I

T

P

I

C

R

H

W

E

N

T

H

G

C

K

E

N

I

-

E

E

R

W

A

V

I

S

O

L

P

-

X

O

M

T

A

G

N

I

N

-

R

I

T

L

A

I

V

E

-

E

E

H

343(13.5)

CAL.

GAS

REF.

GAS

-

-

R

H

G

T

I

N

E

W

H

C

I

T

K

E

P

E

A

I

T

C

U

E

V

L

I

-

M

N

I

N

L

O

A

R

P

N

I

X

E

-

W

G

E

S

I

V

A

T

O

S

E

H

E

R

P

167

(6.58)

(2.89)

73

(1.55)

39

Theseflatfacedflangesare

manufacturedto ANSIandDIN

patterns,andarenotpressurerated.

Alldimensionsareinmillimeters

withinchesinparenthesesunless

otherwisenoted.

Notes:

0.062in.thickGasket

Certification

Approved

Label

External

Earth

External

Earth

Vent

Ref. Air

Internal

Earth

Table1.MountingFlange

(gasketincluded)

(4)Holes

EqSp

onBC

HoleDia

Flange

Dia

DIN

ANSI

152.4

(6.00)

190

(7.5)

19(0.75)

170

(6.69)

18(0.71)

210

(8.25)

Table2.Installation/Removal

DIM"A"

3ft

6ft

Probe

18in.

DIM"B"

2174

(85.6)

1831

(72.1)

917

(36.1)

1448

(57.0)

803

(31.6)

460

(18.1)

38740071

Insulateifexposedto

ambientweatherconditions

Processflowmustbein

thisdirectionwithrespect

toDeflector3534B48G01

500VA

SERIALNO.

TAGNO.

OXYMITTER5000

WATTS:

VOLTS:

FUSE:LINE

OUTPUT:

RosemountAnalyticalInc.

Solon,OH44139

85-264VAC48-62Hz

TM

800-433-6076

4-20 mA

R

5Amps

TM

HART

SMARTFAMILY

IM-106-350C, Rev 2.2

July 2008

Figure 2-1. Hazardous Area

Oxymitter 5000 Probe

Installation

Hazardous Area Oxymitter 5000

2-3

Page 36

Hazardous Area Oxymitter 5000

( )

56.0

2.21

( )

164.6

6.48

246.9 9.72( )

84.6

3.33( )

62.0

(2.44)

DIA.

189.8

7.47( )

140.2

5.52( )

66.5

2.62( )

93.5(3.68)

PipeMount

Configuration

REMOTEELECTRONICS

WITHLOI ANDWINDOWCOVER

REMOTEELECTRONICS

WITHMEMBRANEKEYPAD ANDBLINDCOVER

38740029

WallMount

Configuration

Note: Alldimensionsarein

millimeterswithinchesin

parentheses.

Figure 2-2. Hazardous Area

Oxymitter 5000 Remote

Electronics Installation

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

2-4

Page 37

Instruction Manual

P

S

U

E

I

T

P

I

C

R

H

W

E

N

T

H

G

C

K

E

N

I

-

E

E

R

W

A

V

I

S

O

L

P

-

X

O

M

T

A

G

N

I

N

-

R

I

T

L

A

I

V

E

-

E

E

H

Deflector Assy

3ft

18in.

Probe

Table3. Installation/Removal

6ft

(33.2)

843

(69.4)

1762

387

(15.3)

DIM"A”

1367

(53.8)

2287

(90.0)

912

(35.9)

DIM"B”

Diffuser/Dust

Seal Assy

*AddCheckValveinCAL GasLine

3/4NPT ElectricalConnection

Ref Air

CAL Gas*

ANSI

DIN

1/4in. Tube

1/4in. Tube

GAS

CAL.

Snubber/DustSeal

Assembly

5

(0.2)

91(3.6)Dia

Nominal

99

(3.9)

DIM"A"

Notes:

RemovalEnvelope

DIM"B”

178

(7.00)

343

(13.50)

38740072

(8)Holes

EqSp

OnBC

3D39003

Table4. AbrasiveShield

Hole

Dia

Flange

Dia

229

(9.00)

235

(9.25)

19

(0.75)

24

(0.94)

190

(7.50)

190

(7.48)

Flange

ANSI

DIN

Theseflatfacedflangesaremanufacturedto ANSIandDIN

patterns,andarenotpressurerated.

Alldimensionsareinmillimeterswithinchesinparentheses.

IM-106-350C, Rev 2.2

July 2008

Figure 2-3. Hazardous Area

Oxymitter 5000 Probe with

Abrasive Shield

Hazardous Area Oxymitter 5000

2-5

Page 38

Hazardous Area Oxymitter 5000

22.5

o

B

C

8 Threadedholes

equallyspaced

onDDiaB.C.

AbrasiveShield

FlangeO.D.

A

A

Table5.MountingPlateDimensionsfor

Hazardous AreaOxymitter5000

Dimensions

mm

(in.)

"A"

"B”

StudSize

“C"

DiaB.C.

ANSI

197

(7.75)

0.625-11

152.4

(6.00)

DIN

216

(8.50)

M16x2

170.0

(6.69)

MOUNTINGPLATEFOR

HAZARDOUS AREA OXYMITTER5000

WITH ABRASIVESHIELD

MOUNTINGPLATEFOR

HAZARDOUS AREA OXYMITTER5000

Crosshatchedareain

4cornersmaybeused

toprovideadditional

holesforfieldbolting

ofplatetooutside

wallsurface.

4Studs,

Lockwashersand

Nutsequally

spacedonCDia

B.C.

A

82.6

(3.25)Dia

B

38740073

C

MOUNTINGPLATEOUTLINE

Note:Dimensionsareinmillimeters

withinchesinparentheses.

Table6.MountingPlateDimensionsforHazardous Area

Oxymitter5000with AbrasiveShield

DIN

235

(9.25)

100

(3.94)

190

(7.48)

M20x2.5

ANSI

229

(9.00)

121

(4.75)

191

(7.50)

0.625-11

Dimensions

mm

(in.)

"A"

"B"

Dia

"D"

DiaB.C.

"C"

Thread

Figure 2-4. Hazardous Area

Oxymitter 5000 Mounting Plate

Dimensions

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

2-6

Page 39

Instruction Manual

13(0.50)

95(3.75)

MinimumDia

HoleinWall

StackorDuct

MetalWall

Mountingholes

shownrotated45

o

Weldorboltmountingplatetometalwall

ofstackorduct;Jointmustbeairtight.

13 0.50( )

114(4.50)

O.D.Ref

Pipe4.00in.Sched40Pipe

Sleeve(NotbyEmerson

ProcessManagement)

lengthbyCustomer

Masonry

stackwall

OutsideWall

Surface

JointMust

be Air Tight

MountingHoles

ShownRotated45

of TruePosition

o

FieldWeldPipe

toMountingPlate

BoltMountingPlateto

OutsideWallSurface

82.5(3.25)

MinimumDia

HoleinWall

StackorDuct

MetalWall

Weldorboltmountingplateto

metalwallofstackorduct.

Jointmustbeairtight.

Fieldweldpipe

toMountingPlate

102(4.0)

O.D.Ref

Pipe3.5in.Sched40Pipe

Sleeve(Notby

)

lengthbyCustomer

Emerson

ProcessManagement

Masonry

stackwall

OutsideWall

Surface

JointMust

be Air Tight

BoltMountingPlateto

OutsideWallSurface

38740005

INSTALLATIONFORMASONRY

WALL STACKCONSTRUCTION

INSTALLATIONFORMETAL WALL

STACKORDUCTCONSTRUCTION

Notes:

1.Dimensionsareinmillimeterswith

inchesinparentheses.

ABRASIVESHIELDMOUNTING

PROBEMOUNTING

outoftrueposition

out

2. Allmasonrystackworkandjointsexceptadaptor

platearenotfurnishedbyRosemont Analytical.

IM-106-350C, Rev 2.2

July 2008

Figure 2-5. Hazardous Area

Oxymitter 5000 Mounting Plate

Installation

Hazardous Area Oxymitter 5000

2-7

Page 40

Hazardous Area Oxymitter 5000

4. If using the optional ceramic diffusion element, the vee deflector must

be correctly oriented. Before inserting the Hazardous Area Oxymitter

5000, check the direction of flow of the gas in the duct. Orient the vee

deflector so the apex points upstream toward the flow (Figure 2-6). This

may be done by loosening the setscrews and rotating the vee deflector

to the desired position. Retighten the setscrews.

5. In vertical installations, ensure the system cable drops vertically from

the Hazardous Area Oxymitter 5000 and the conduit is routed below the

level of the electronics housing. This drip loop minimizes the possibility

that moisture will damage the electronics (Figure 2-7).

6. If the system has an abrasive shield, check the dust seal gaskets. The

joints in the two gaskets must be staggered 180 degrees. Make sure the

gaskets are in the hub grooves as the Hazardous Area Oxymitter 5000

slides into the 15 degree forcing cone in the abrasive shield.

NOTE

If process temperatures will exceed 200°C (392°F), use anti-seize compound

on the stud threads to ease future removal of the Hazardous Area Oxymitter

5000.

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

7. Insert probe through the opening in the mounting plate and bolt the unit

to the plate.

NOTE

To maintain CE compliance, ensure a good connection exists between the

mounting plate studs or earthing screws on electronics housing and earth.

8. Ensure the Hazardous Area Oxymitter 5000 is properly earthed by way

of both internal and external points.

Uninsulated stacks or ducts may cause ambient temperatures around the electronics to

exceed 85°C (185°F), which may cause overheating da mage to the electronics

.

9. If duct work insulation is removed for Hazardous Area Oxymitter 5000

probe mounting, make sure the insulation is replaced afterward. See

Figure 2-7.

NOTE

For probe temperatures that will exceed 85°C (185°F ), we recommend the

remote mounted electronics option.

2-8

10. Ensure the probe installation does not obscure the warnings on the

housing covers.

Page 41

Instruction Manual

Vee

Deflector

Vee

Deflector

Ceramic

Diffusion

Element

Setscrew

Filter

GasFlow

Direction

38740006

Apex

P

S

U

E

I

T

P

I

C

R

H

W

E

N

T

H

G

C

K

E

N

I

-

E

E

R

W

A

V

I

S

O

L

P

-

X

O

M

T

A

G

N

I

N

-

R

I

T

L

A

I

V

E

-

E

E

H

GAS

CAL.

LineVotage

FieldbusDigital

Signal

StackorDuct

MetalWall

MountingPlate

ReplaceInsulationafter

InstallingHazardous

AreaOxymitter5000

Insulation

38740007

Drip

Loop

IM-106-350C, Rev 2.2

July 2008

Figure 2-6. Orienting the

Optional Vee Deflector

Hazardous Area Oxymitter 5000

Figure 2-7. Installation with Drip

Loop and Insulation Removal

2-9

Page 42

Hazardous Area Oxymitter 5000

38740008

Instruction Manual

IM-106-350C, Rev 2.2

July 2008

Remote Electronics Installation

Figure 2-8. Remote Electronics

Mounting

ELECTRICAL INSTALLATION WITH INTEGRAL ELECTRONICS

For a Hazardous Area Oxymitter 5000 with the remote electronics option,

install the probe according to the instructions in “Probe Installation” on

page 2-2. Install the remote electronics unit on a wall, stand pipe, or similar

structure (Figure 2-2 and Figure 2-8).

All wiring must conform to local and national codes.

Disconnect and lock out power before connecting the unit to the power supply.

Install all protective equipment covers and safety ground leads after installation. Failure to

install covers and ground leads could result in serious injury or death.

To meet the Safety Requirements of IEC 1010 (EC requirement), and ensure safe operation

of this equipment, connection to the main electrical power supply must be made through a

circuit breaker (min 10 A) which will disconnect all current-carrying conductors during a fault