Rosemount NGA 2000 TFID Hydrocarbon Analyzer Module SW 3.7 Supplement to SW 3.4 Software-1st Ed. Manuals & Guides

Instruction Manual

HAS55E03IM11S

11/2003

Software Version 3.7.x

Supplement to Software Manual 3.4.x

NGA 2000 Software Manual for

TFID Analyzer and Analyzer Module (combined with

NGA 2000 Platform, MLT, CAT 200 or TFID Analyzer)

www.EmersonProcess.de

TFID Software 3.7.x Instruction Manual

HAS55E03IM11S

11/2003

ESSENTIAL INSTRUCTIONS

READ THIS P AGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and test s

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products

to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson Process Management (Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR W ARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical

shock and personal injury.

The information contained in this document is subject to change without notice. Misprints

reserved.

1st Edition 1 1/2003 (Addendum to TFID Software 3.4.x)

© 2006 by Emerson Process Management

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Software 3.7.x – Supplement to Software 3.4.x and 3.6.x

Table of Contents

A Addendum from Software 3.4.x to 3.6.x

1 Display Controls Menus ………………………………………………………………A-1

2 Analyzer Basic Controls (calibration) & Setup Menu………………………………A-3

3 Tolerances Menus……………………………………………………………………..A-4

B Addendum from Software 3.6.x to 3.7.x

4 Calculator on Control Module Level ………………………….…………….Page 1 -14

5 Programmable Logic Control (PLC) on Control Module Level……….….Page 1 - 28

6 System Calibration - Software Version 3.7.x………………………Supplement 1 - 34

7 Additional AK Protocol Commands - Software Version 3.7.x …..…….……Page 1-3

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] 11/03 Content I

Software 3.7.x – Supplement to Software 3.4.x and 3.6.x

II Content HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] 11/03

Addendum for Software Revision 3.6.x to 3.4.x

This chapter describes some important features / changes

implemented in software revision 3.6.x, shipped with the newest

versions of Fisher-Rosemount NGA gas analyzers and has to be

used in combination with the software 3.4.x manual.

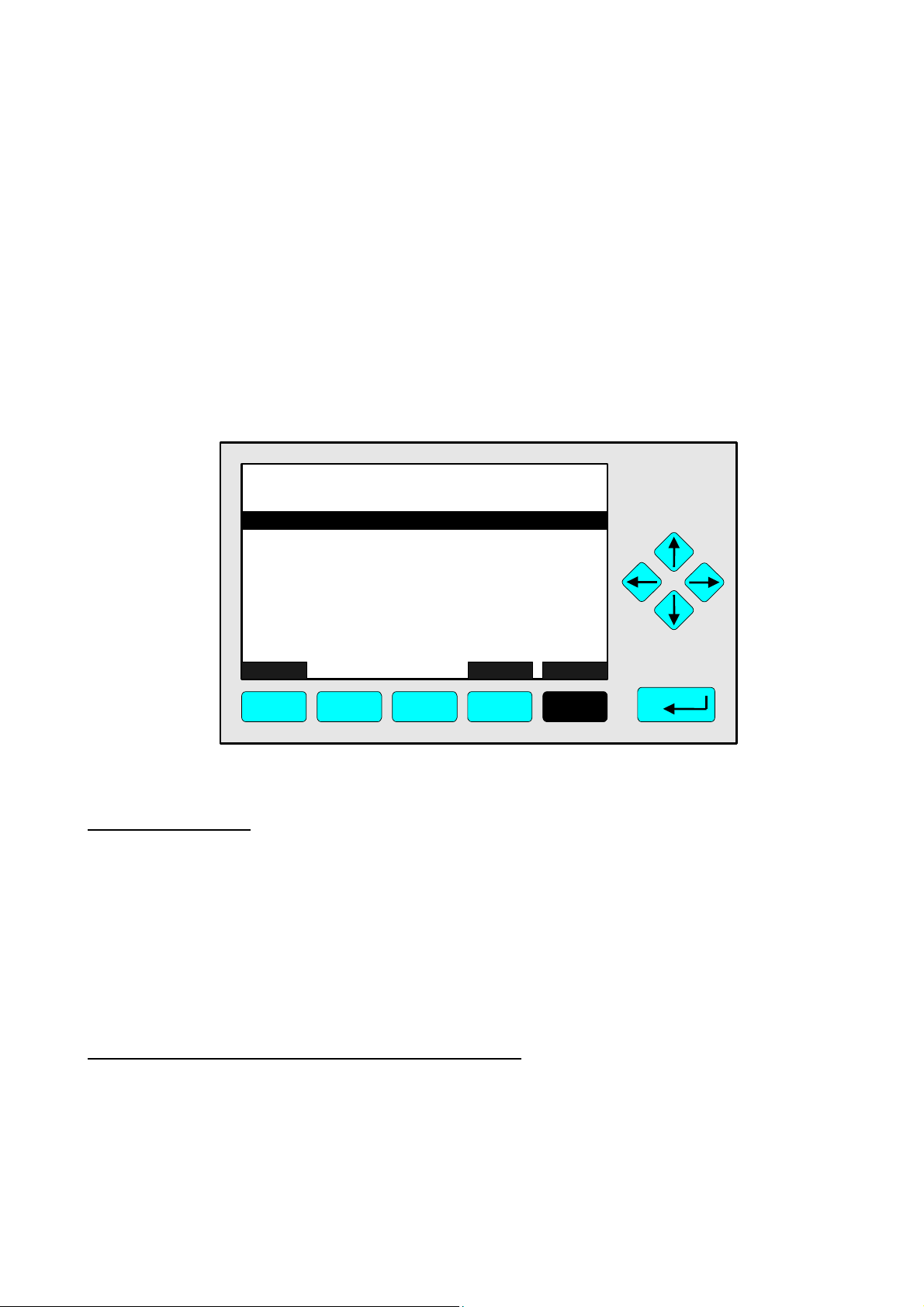

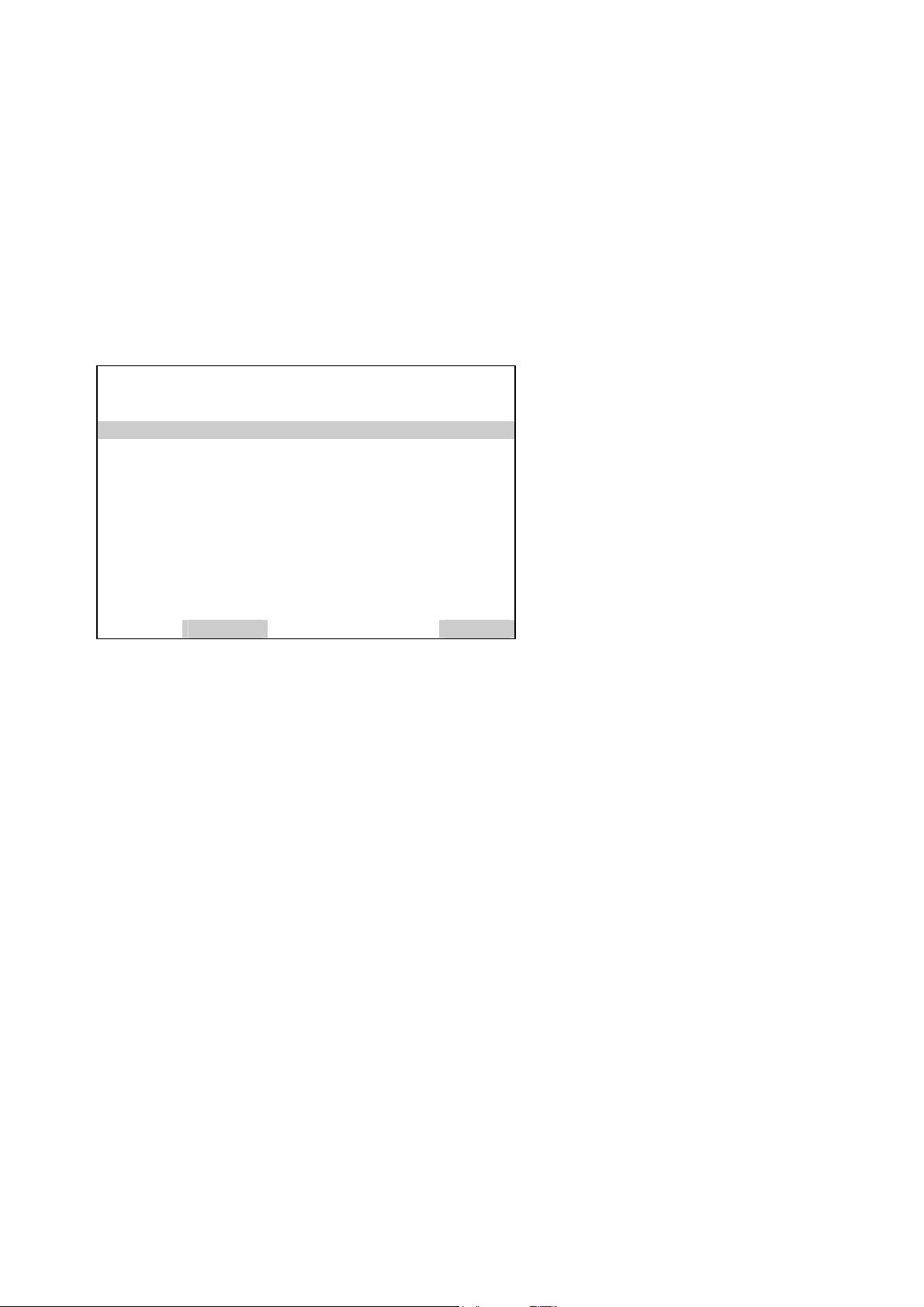

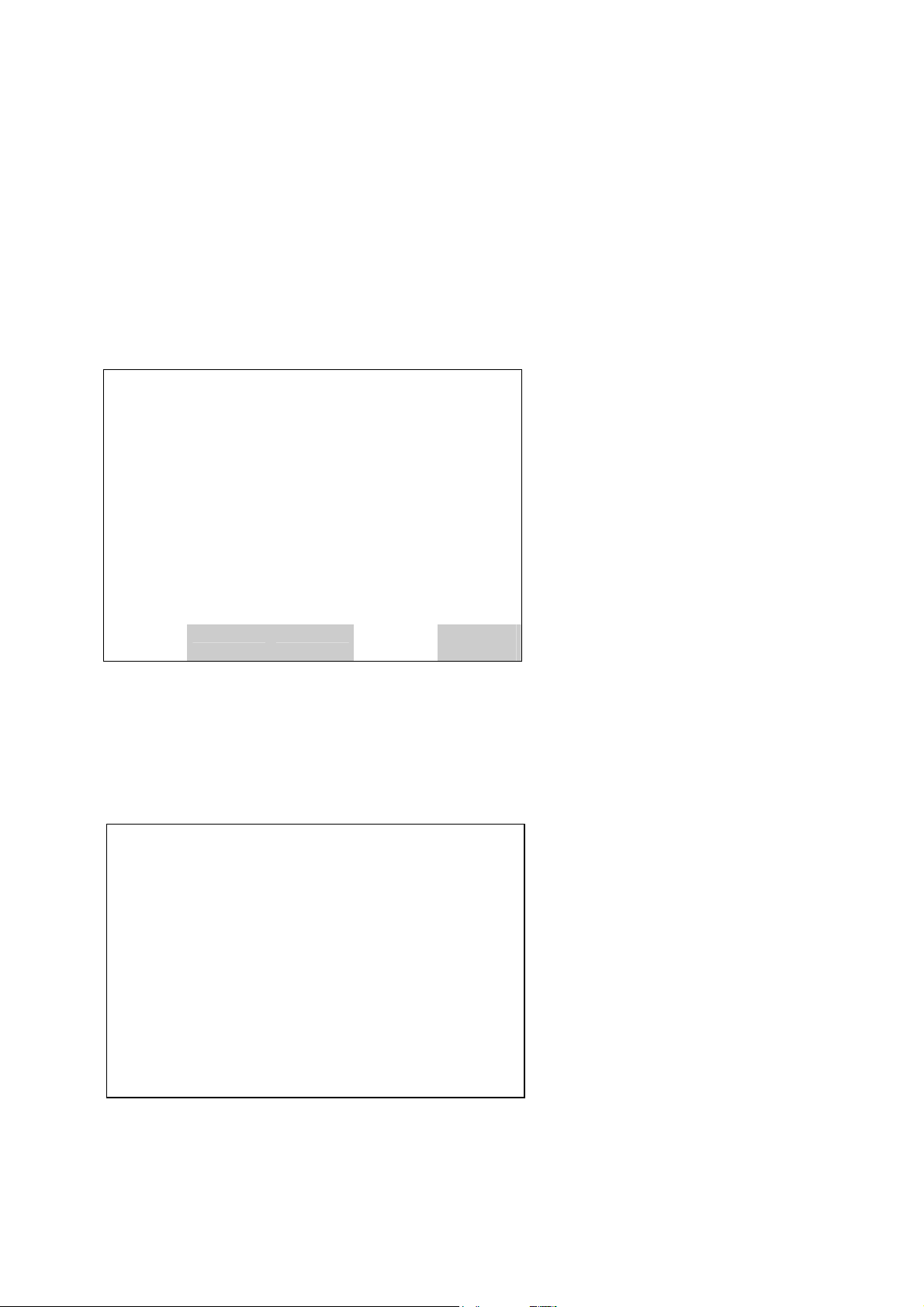

1. Display Controls Menu

The Display Controls menu (see chapter 7) now has additional menu lines:

Setting parameters:

TAG

-- Display Controls --

Brightness:

Contrast:

Display measurement menu after: 10 Min

Default measurement menu:

Switch off backlight after:

Measure

F1

Single component

F2

F3 F4 F5

Back... More...

37.50 ppm

74 %

23 %

10 Min

♦ Select any line of variables using the ↓ -key or the ↑ -key.

♦ Select the variable using the ↵ -key or the → -key.

♦ Change the whole value using the ↑ -key or the ↓ -key

or select single digits using the ← -key or the → -key and enter a new value using

the ↑ -key or the ↓ -key.

♦ Confirm the new value using the ↵ -key or

cancel and return to the previous value using the F2 -key.

Line of variables "Display measurement menu after:"

The value entered in this line defines the time to expire without operator input before the display

automatically returns to the measurement display.

Options: 10 s, 30 s, 1 min, 5 min, 10 min, 30 min, Never.

HAS55E03IM11S [NGA-e (TFID Software 3.4.X addendum)] 11/03

NGA 2000

A - 1

Line of variables "Default measurement menu:"

Use this line to select the display the analyzer returns to when the time entered in line “display

measurement menu after:” has expired.

Options: Single Component (Display) or Multi Component (Display)

Line of variables "Switch off backlight after:"

The value entered in this line defines the time to expire without operator input before the

backlight is switched off automatically. Using this function saves energy and expands the

backlight’s lifetime.

Options: 10 s, 30 s, 1 min, 5 min, 10 min, 30 min, Never.

A - 2

NGA 2000

HAS55E03IM11S [NGA-e (TFID Software 3.4.X addendum)] 11/03

Addendum for Software Revision 3.6.x to 3.4.x

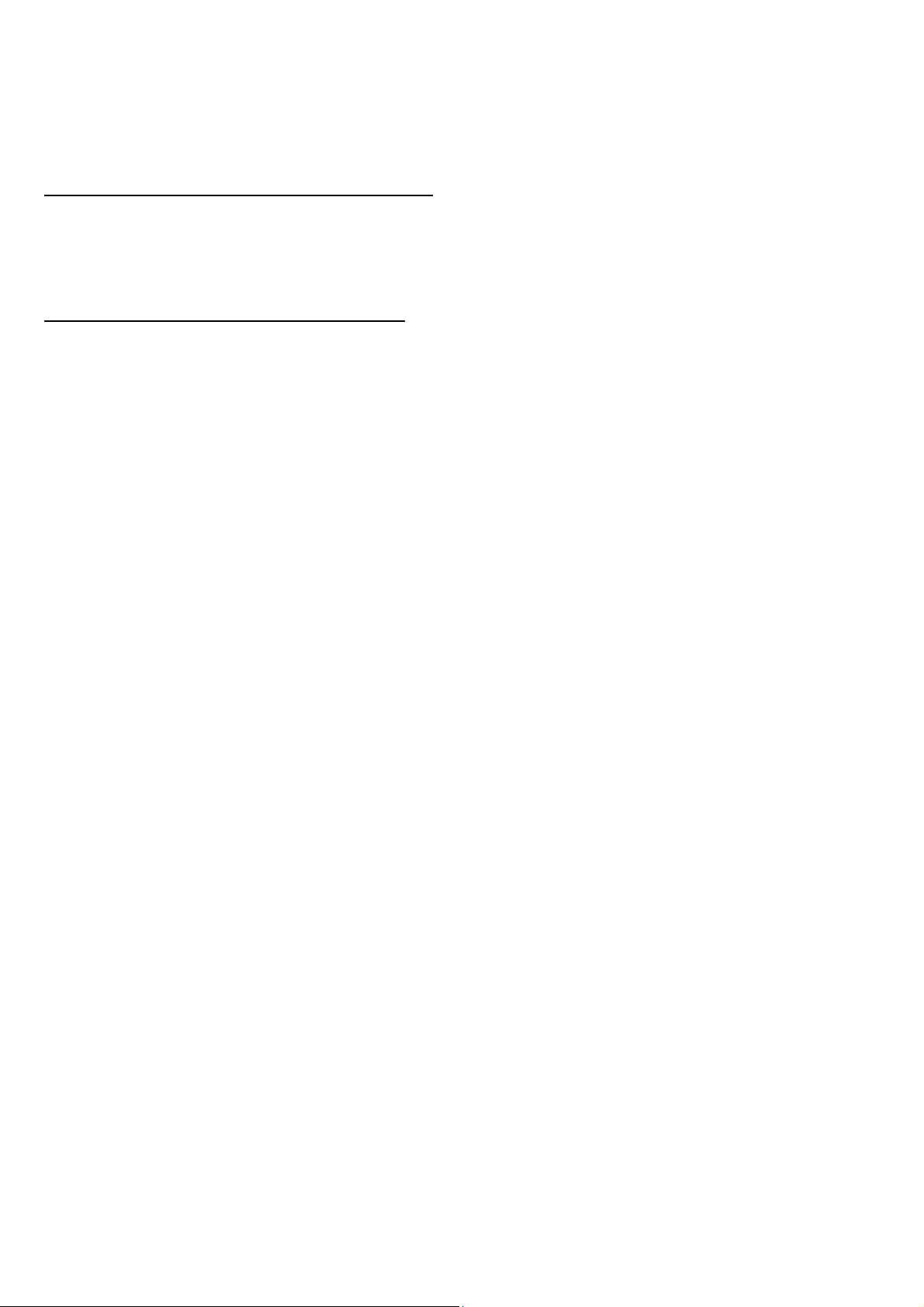

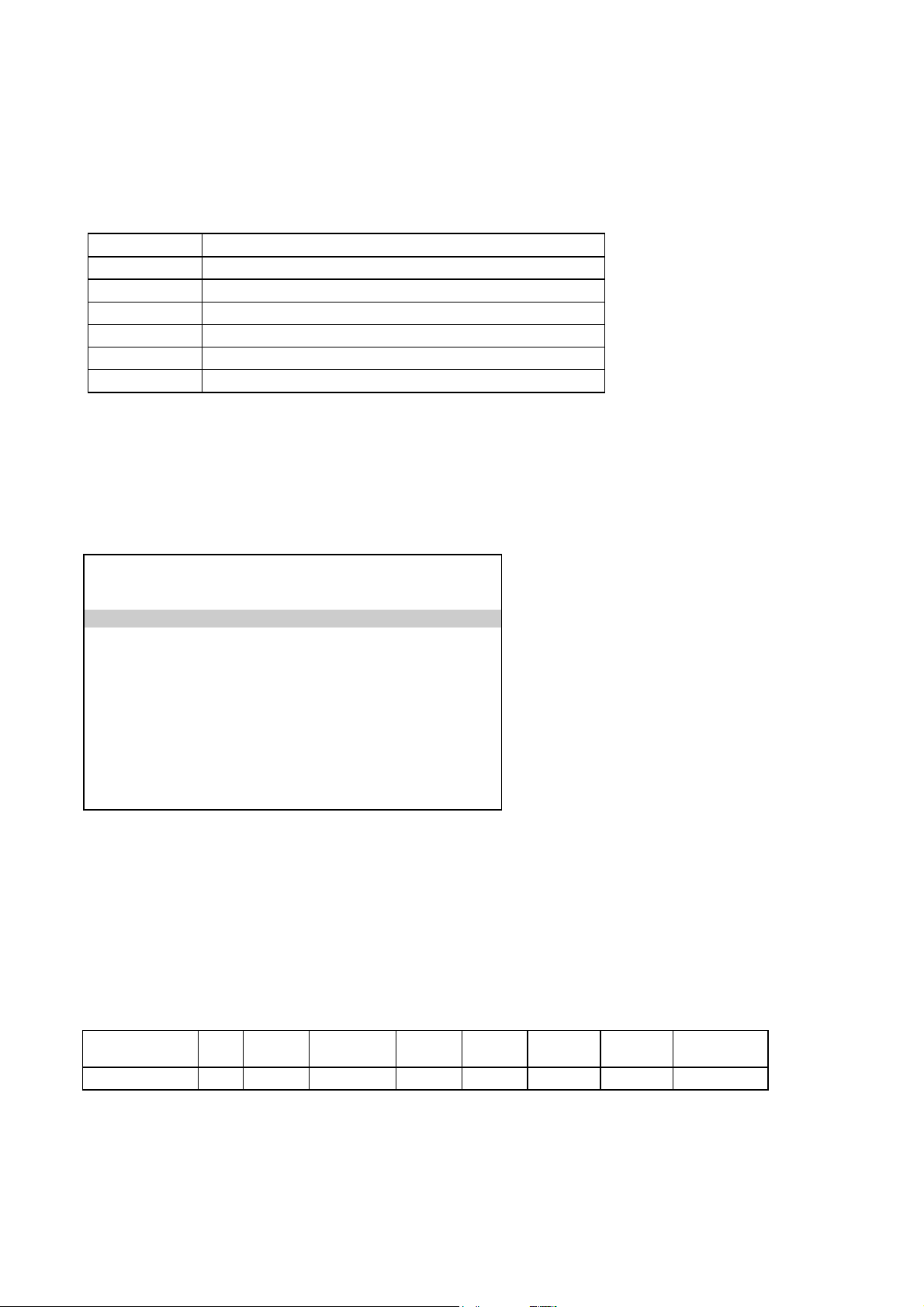

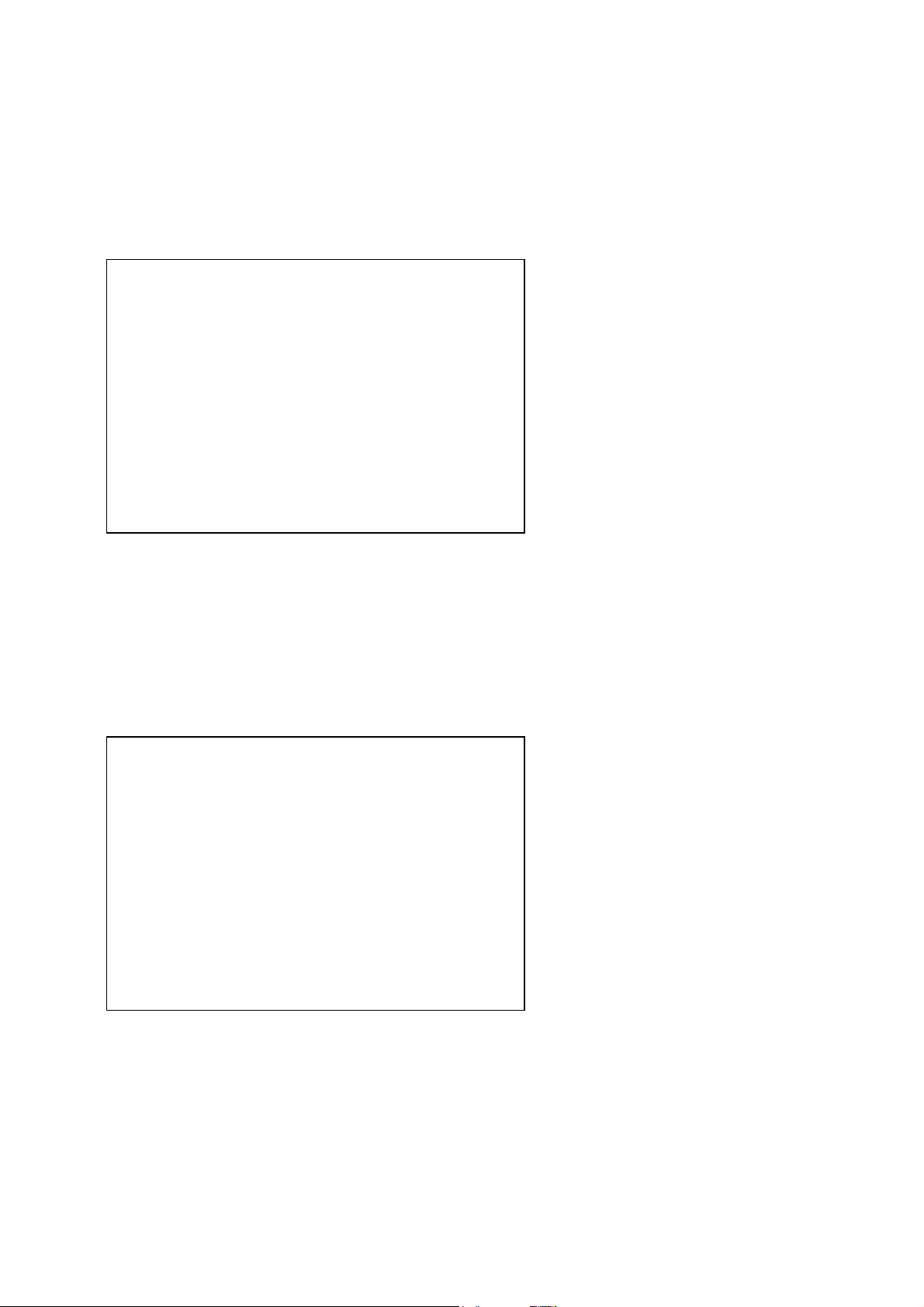

2. Analyzer Basic Controls (calibration) & Setup Menu

One line was added to this menu (see chapter 4.4, p. 4-19):

Function Line "Undo last zero & span calibration !"

TAG

-- Analyzer Basic Controls (calibration) & Setup --

Calibration procedure state..

Start zero calibration procedure !

Start span calibration procedure !

Check calibration deviation:

Undo last zero & span calibration !

Range number:

Span gas:

Range upper limit:

Operation status:

Measure Status... Channel Back...

F1 F2 F3 F4 F5

37.50 ppm

Disabled

1

46.00 ppm

50.00 ppm

Ready

Valves...

Use this function to reset an analyzer’s calibration values to default factory settings if the last

calibration procedure has been completed with a poor result due to wrong settings and the

calibration is in an undefined status.

Depend on the “Measurement Display Configuration” settings a screen may appear asking for

confirmation prior to executing the function (see chapter 3.7, p. 3-6 and chapter 5.1.8,

p. 5-49).

HAS55E03IM11S [NGA-e (TFID Software 3.4.X addendum)] 11/03

NGA 2000

A - 3

3. Tolerances Menu

The stability tolerance range 1 … 4 lines of the menu Tolerances (see chapter 5.1, p. 5-8) have

been moved into a new menu within the service level:

The stability tolerance function is still enabled but not longer operator definable.

Factory setting for all 4 values (ranges 1 … 4) is 10 %.

TAG

-- Tolerances --

Max. zero calibration deviation: 20.00 %

Max. span calibration deviation: 20.00 %

Check calibration deviation:

Last zero calibration:

Last span calibration:

Measure Channel Back...

F1 F2 F3 F4 F5

95.00 ppm

Disabled

Success

Success

A - 4

NGA 2000

HAS55E03IM11S [NGA-e (TFID Software 3.4.X addendum)] 11/03

Calculator on Control Module Level

Calculator on Control Module Level

(Platform, TFID, MLT or CAT 200 Analyzer)

1 SYSTEM CALCULATOR (ON CONTROL MODULE LEVEL)........................................................................2

1.1 P

1.2 L

1.3 CONSTANT VALUES......................................................................................................................................5

1.4 M

1.5 MENU TREE FOR THE SYSTEM CALCULATOR ..................................................................................................6

2 DISPLAY CALCULATOR RESULTS ON MINI-BARGRAPH.......................................................................11

2.1 D

2.2 A

3 ASSIGNMENT TO SIO ANALOG OUTPUTS ...............................................................................................14

RINCIPLE OF PROGRAM SET-UP ..................................................................................................................2

IVE VALUES (REAL MEASURING VALUES) ......................................................................................................4

EMORY VALUES.........................................................................................................................................5

1.5.1 Submenu 'Signals' .................................................................................................................................7

1.5.2 Submenu 'Programming' .......................................................................................................................9

ISPLAY MODE ..........................................................................................................................................11

SSIGN SIGNALS AND CONVENIENT NAMES ..................................................................................................12

PICTURE 1-1: SYSTEM CALCULATOR MENU.................................................................................................................6

P

ICTURE 1-2 : SIGNAL ASSIGNMENT OF SYSTEM CALCULATOR ....................................................................................7

PICTURE 1-4: CONSTANT VALUES ASSIGNMENT ..........................................................................................................9

PICTURE 1-5: PROGRAMMING THE SYSTEM CALCULATOR ..........................................................................................10

P

ICTURE 2-1: MEASUREMENT DISPLAY SET-UP.........................................................................................................11

PICTURE 2-2: PLATFORM SELECTED SIGNAL ASSIGNMENT .........................................................................................12

PICTURE 2-3: LISTING OF ASSIGNED SIGNALS............................................................................................................13

TABLE 1-1: THE OPERATORS OF THE SYSTEM CALCULATOR ........................................................................................3

TABLE 1-2: LIVE VALUES POOL...................................................................................................................................4

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 1

Calculator on Control Module Level

1 System Calculator (on Control Module Level)

1.1 Principle of program set-up

As it would be a too high effort to realize a comfortable mathematical formula system we created a syntax which

is easy to input and easy to realize.

As we assume that customers or service people have to set-up the program only one times for an installed

system it should be acceptable to realize a form which is only done by inputting numbers.

Therefore we have mainly to differ between positive and negative numbers.

The program operations are assigned with negative numbers.

The operands which are used by these input operations are positive numbers. These positive numbers

symbolize signals which are part of a signal pool.

Also we have to know that there are used different classes of operands. That means we have different

classes of signal pools.

Those are:

• Live values (real measuring values)

• Constant values

• Memory values.

In each of these classes exists an own numbering and we determine by the operator itself which class of these

operands is meant.

Remark:

Opposite to former versions allowing calculator function within ONE TFID/MLT/CAT 200 analyzer module (AM)

or for ONE TFID/MLT analyzer (or CAT 200 analyzer resp.) ONLY now the system calculator is based on the

C

ontrol Module level (CM).

This allows to include ALL analyzer modules resp. MLT channels of a NGA 2000 analyzer system into the

calculation.

The results of the system calculator can be put onto the 2-8 analog outputs of the programmable Input/Output

Module SIO.

The SIO as a Control Module I/O is then located in a platform or in a TFID, MLT or CAT 200 Analyzer.

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 2

Calculator on Control Module Level

In the following table we find all the currently available operators (negative numbers) and their meaning. Hereby

is used the acronym "IR" for the actually calculated intermediate result of the program.

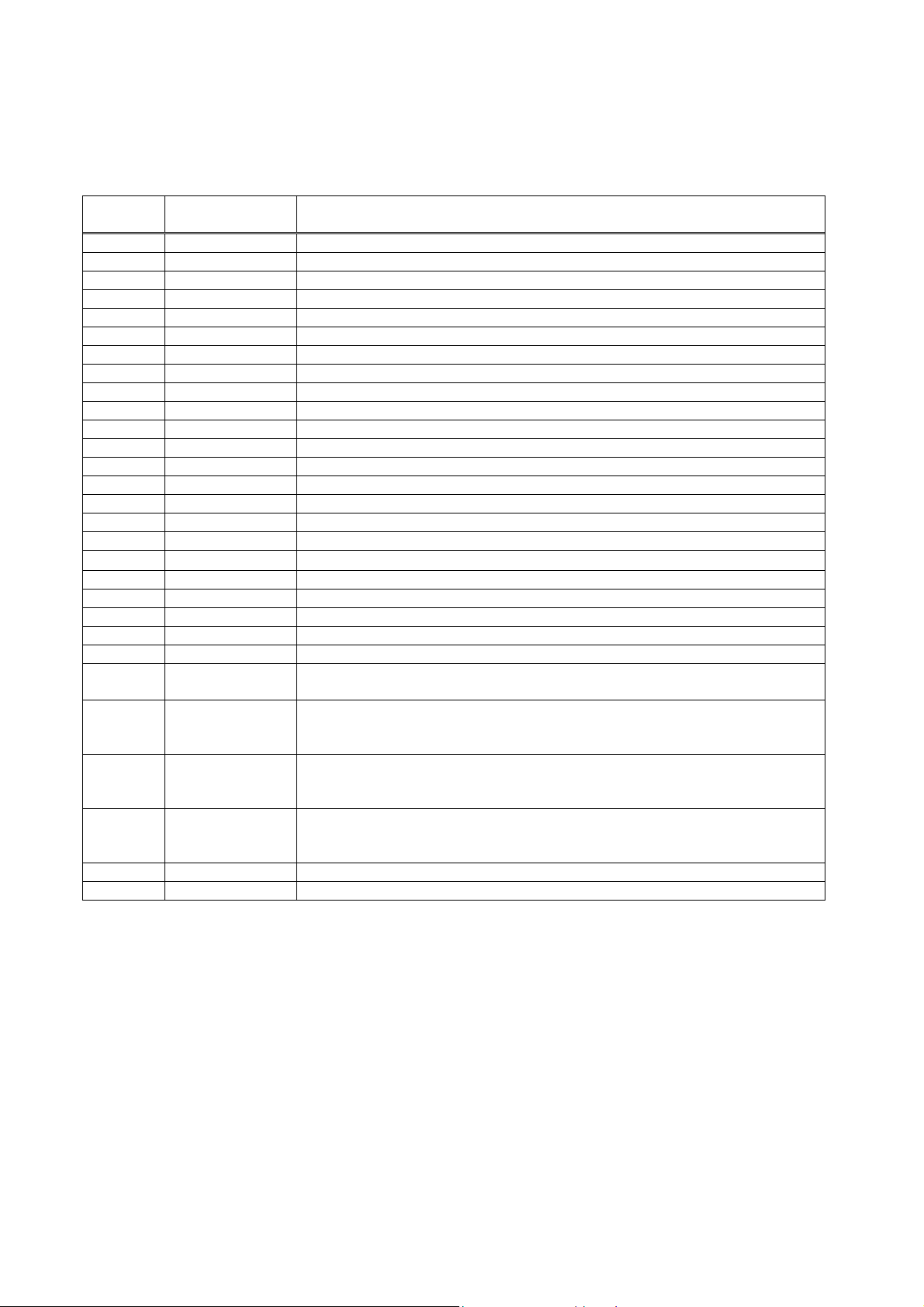

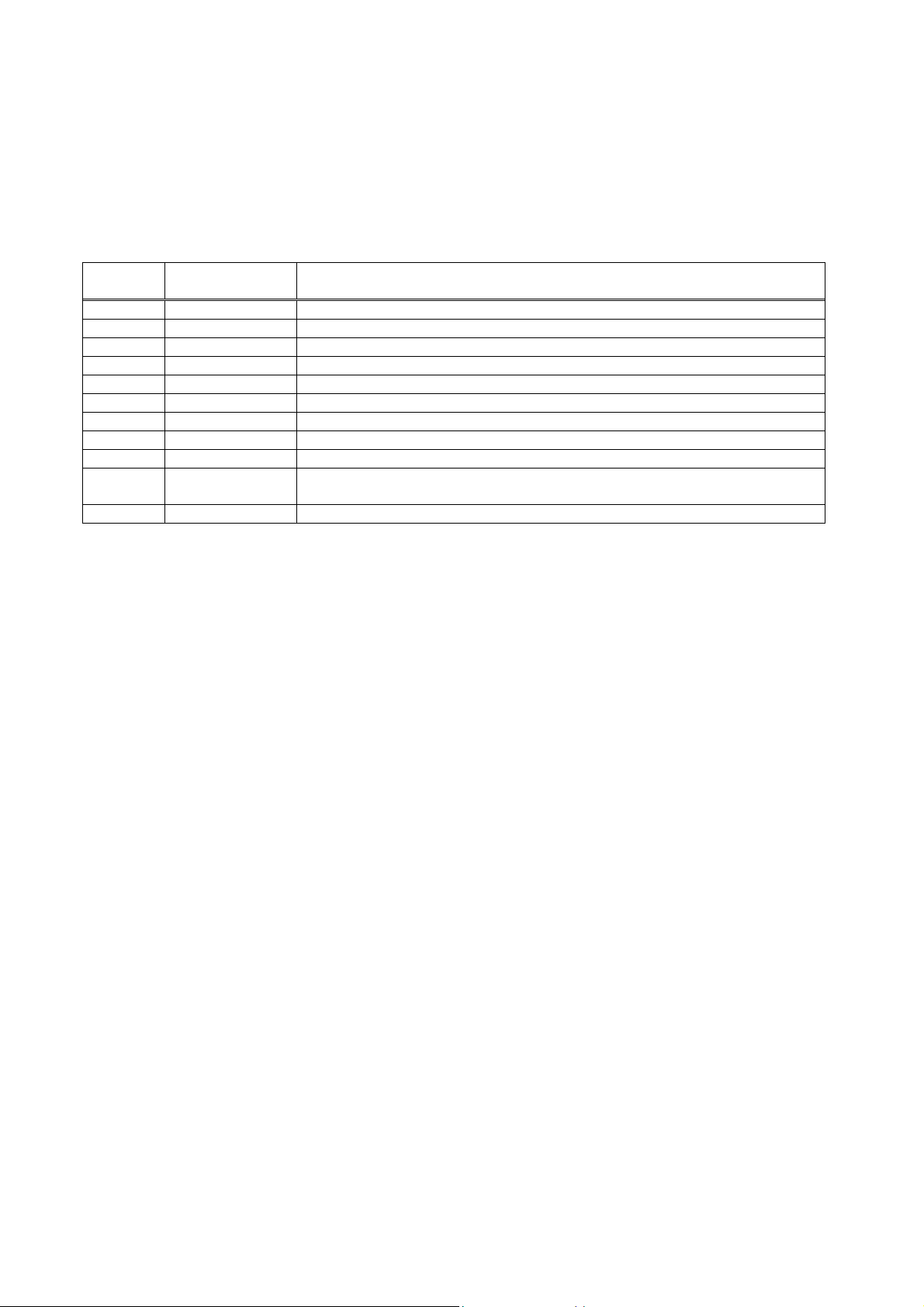

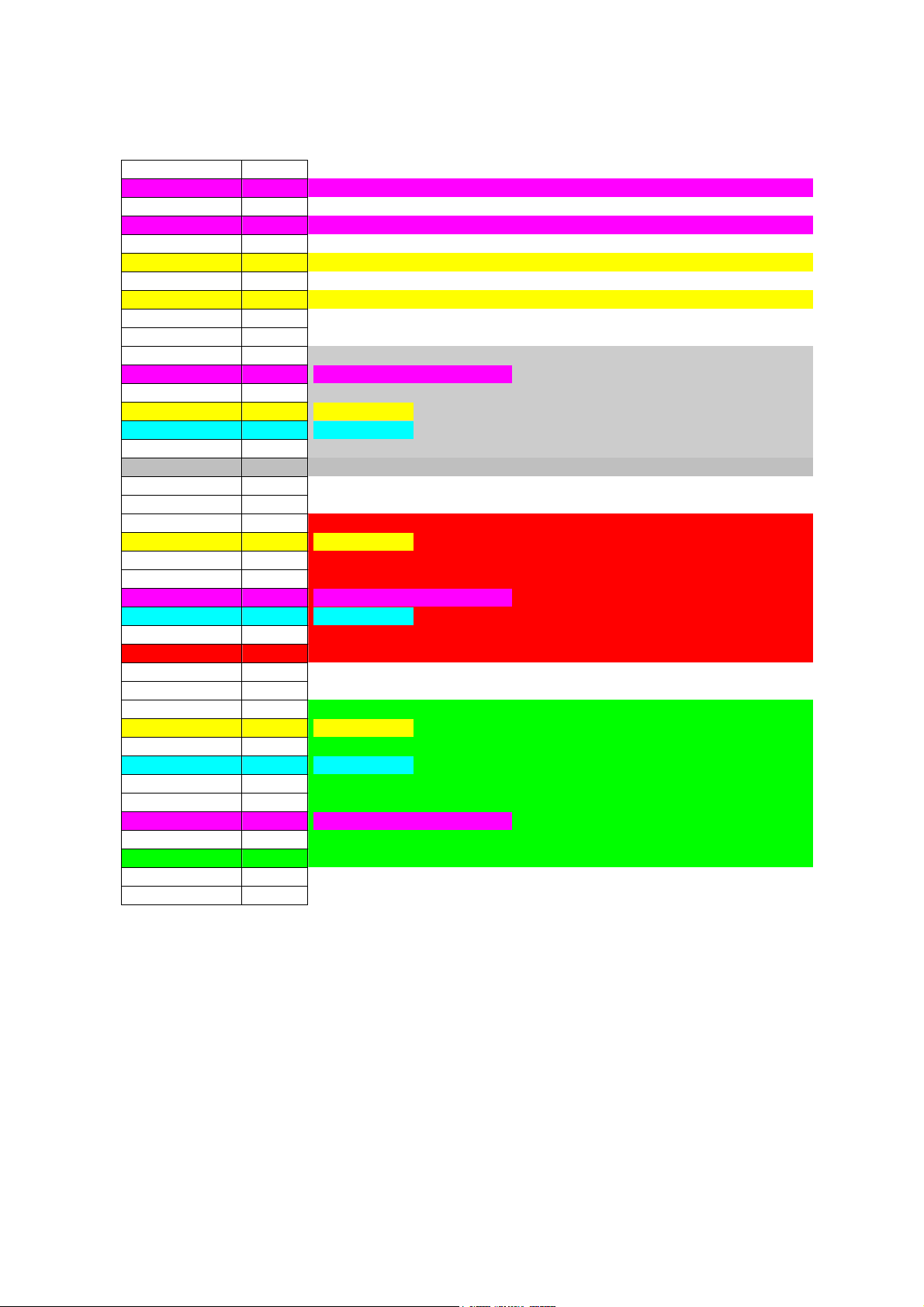

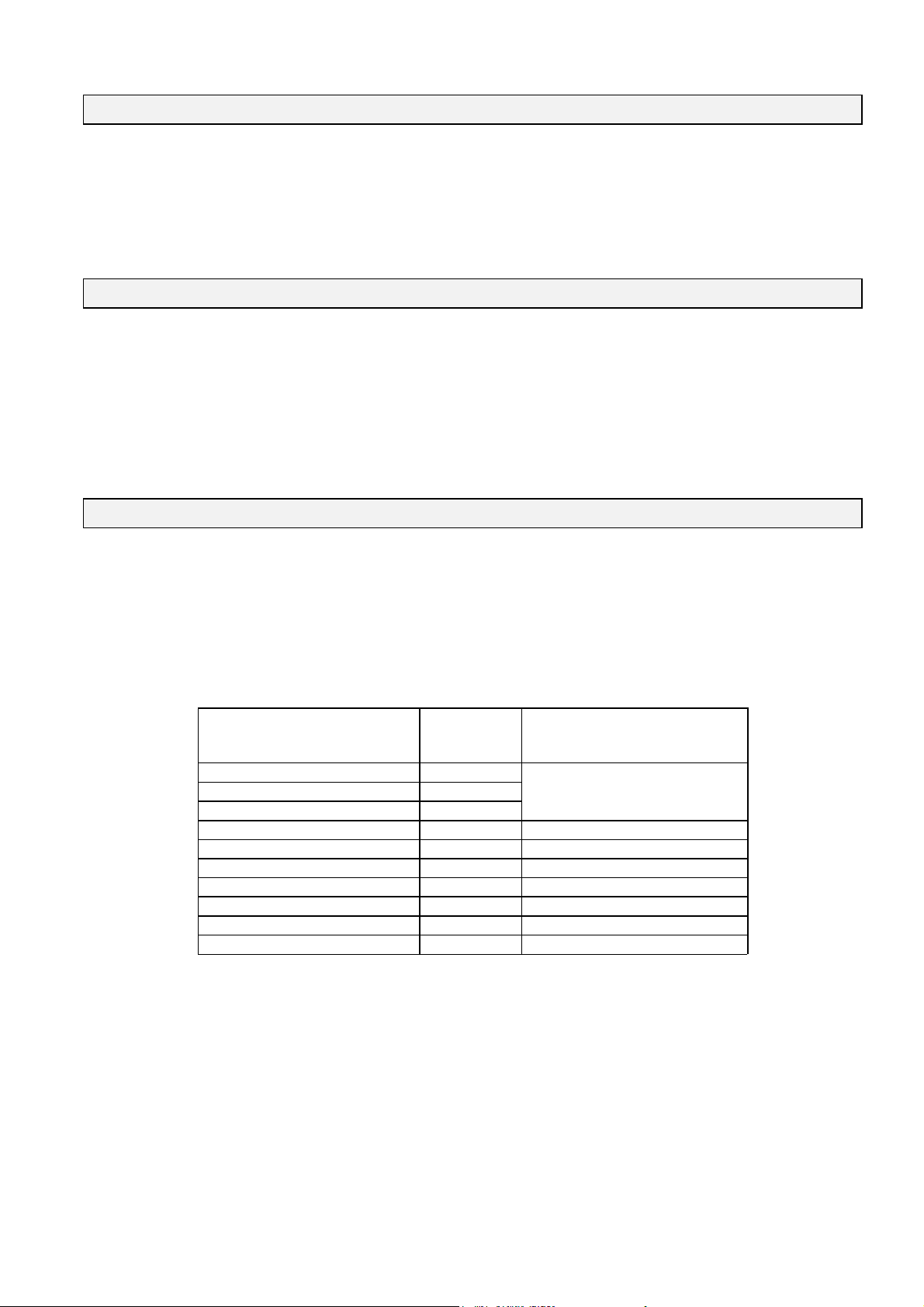

Table 1-1: The Operators of the System Calculator

Operator

number

-10 SUBM m subtract following memory value operand from IR (IR = IR – m)

-11 DIVM m divide IR by following memory value operand (IR = IR / m)

-12 MULM m multiply IR with following memory value operand (IR = IR * m)

-13 STOM m store IR at following memory value and set IR = 0.0 (m = IR; IR = 0)

-14 STOR r store IR to following result and set IR = 0.0 ( r = IR; IR = 0)

-15 NOP no operation (placeholder)

-16 ABS convert IR into absolute value (IR = |IR|)

-17 EOP end of program

-18 SQRT

-19 NEG negate IR (IR = -IR)

-20 INC increment IR (IR = IR + 1)

-21 DEC decrement IR (IR = IR – 1)

-22 INV invert IR (IR = 1 / IR)

-23 EXP exponential function (IR = eIR)

-24 POWM IR raised to the power of the following memory value operand

-25 IF> m1 m2 m3 if IR > 1st following memory value

-26 IF< m1 m2 m3 if IR < 1st following memory value

-27 IF= m1 m2 m3 if IR = 1st following memory value

-28 LN natural logarithm (IR = ln(IR))

-29 LOG base 10 logarithm (IR = log(IR))

Acronym Description

-1 ADD l add following live value operand to the IR (IR = IR + l)

-2 SUB l subtract following live value operand from IR (IR = IR – l)

-3 DIV l divide IR by following live value operand (IR = IR / l)

-4 MUL l multiply IR with following live value operand (IR = IR * l)

-5 ADDC c add following constant value operand to the IR (IR = IR + c)

-6 SUBC c subtract following constant value operand from IR (IR = IR – c)

-7 DIVC c divide IR by following constant value operand (IR = IR / c)

-8 MULC c multiply IR with following constant value operand (IR = IR * c)

-9 ADDM m add following memory value operand to the IR (IR = IR + m)

build square root of IR (IR = √IR)

(IR = IR

then IR = 2

else IR = 3

then IR = 2

else IR = 3

then IR = 2

else IR = 3

m

)

nd

following memory value

rd

following memory value

nd

following memory value

rd

following memory value

nd

following memory value

rd

following memory value

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 3

Calculator on Control Module Level

1.2 Live values (real measuring values)

In the platform calculator we have a signal pool of momentary up to 25 possible live signals.

The first 10 signals in this pool are fix assigned the rest of the signals are free assignable.

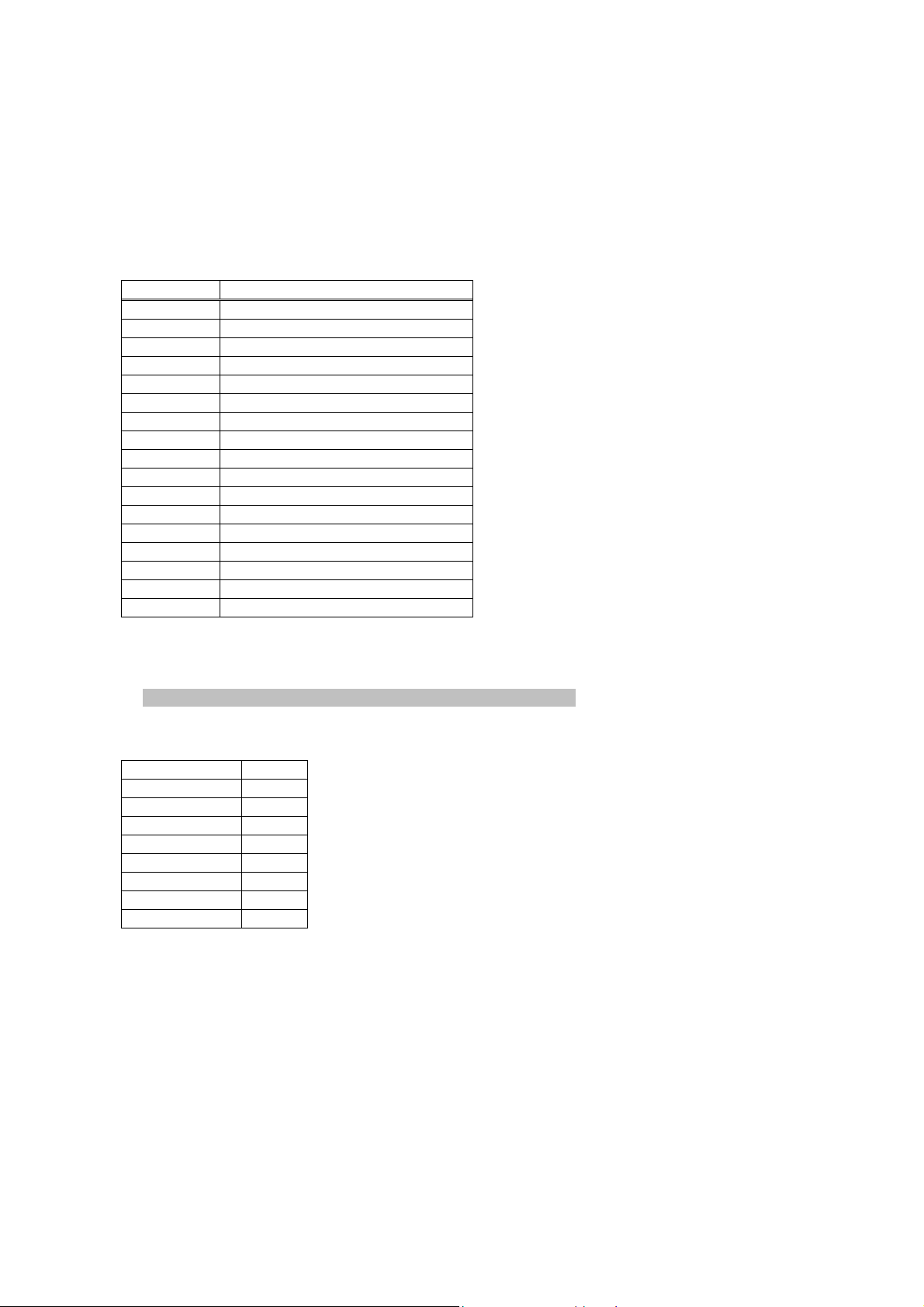

Table 1-2: Live Values Pool

Number Assignment assignment type

Signal 1 Result 1 fixed

Signal 2 Result 2 fixed

Signal 3 Result 3 fixed

Signal 4 Result 4 fixed

Signal 5 reserved fixed

Signal 6 reserved fixed

Signal 7 reserved fixed

Signal 8 reserved fixed

Signal 9 reserved fixed

Signal 10 reserved fixed

Signal 11 MLT 1/CH1 Concentration programmable

Signal 12 TFID Concentration programmable

Signal 13 MLT 2/CH3 Temperature programmable

Signal 14 TFID Temperature programmable

Signal 15 not assigned programmable

.... ........... programmable

Signal 25 not assigned programmable

By using these numbers of the signal pool we determine the live value operands in the calculator's program.

Example of a calculator program with upper signal assignment:

Result 1 = (MLT 1/CH1 Concentration) + (TFID Concentration)

Step (o+1) -1 ADD (at beginning the intermediate result IR = 0)

Step (o+2) 11 Signal 11 (here: MLT1/CH1 Concentration)

Step (o+3) -1 ADD

Step (o+4) 12 Signal 12 (here: TFID Concentration)

Step (o+5) -14 Store IR to result

Step (o+6) 1 Result 1

Step (o+7) -17 End of program

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 4

Calculator on Control Module Level

1.3 Constant values

The same principle is used for the constant values. We have a pool of free assignable constant values.

Example of a constant signal pool:

Number Assignment

Constant-1 1.000000

Constant-2 10.00000

Constant-3 100.0000

Constant-4 1000.000

Constant-5 10000.00

.... ...........

Constant-21 500.0000

By using the numbers of the signal pool we determine again the constant operands in the calculator's program.

Example of a calculator program with upper live signal and constant assignment:

Result1 = (MLT 1/CH1-Concentration) + 100

Step (o+1) -1 ADD (addition by using the live operand's class)

Step (o+2) 11 Live value number 11 (here: MLT1/CH1-Concentration)

Step (o+3) -5 ADDC (addition by using the constant operand's class)

Step (o+4) 3 Constant number 3 (here: 100.0)

Step (o+5) -14 Store IR to result

Step (o+6) 1 Result 1

Step (o+7) -17 End of program

1.4 Memory values

The same principle as in constant values is used again for the memory values. We have a pool of usable

memory places where intermediate calculation results can be stored to.

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 5

Calculator on Control Module Level

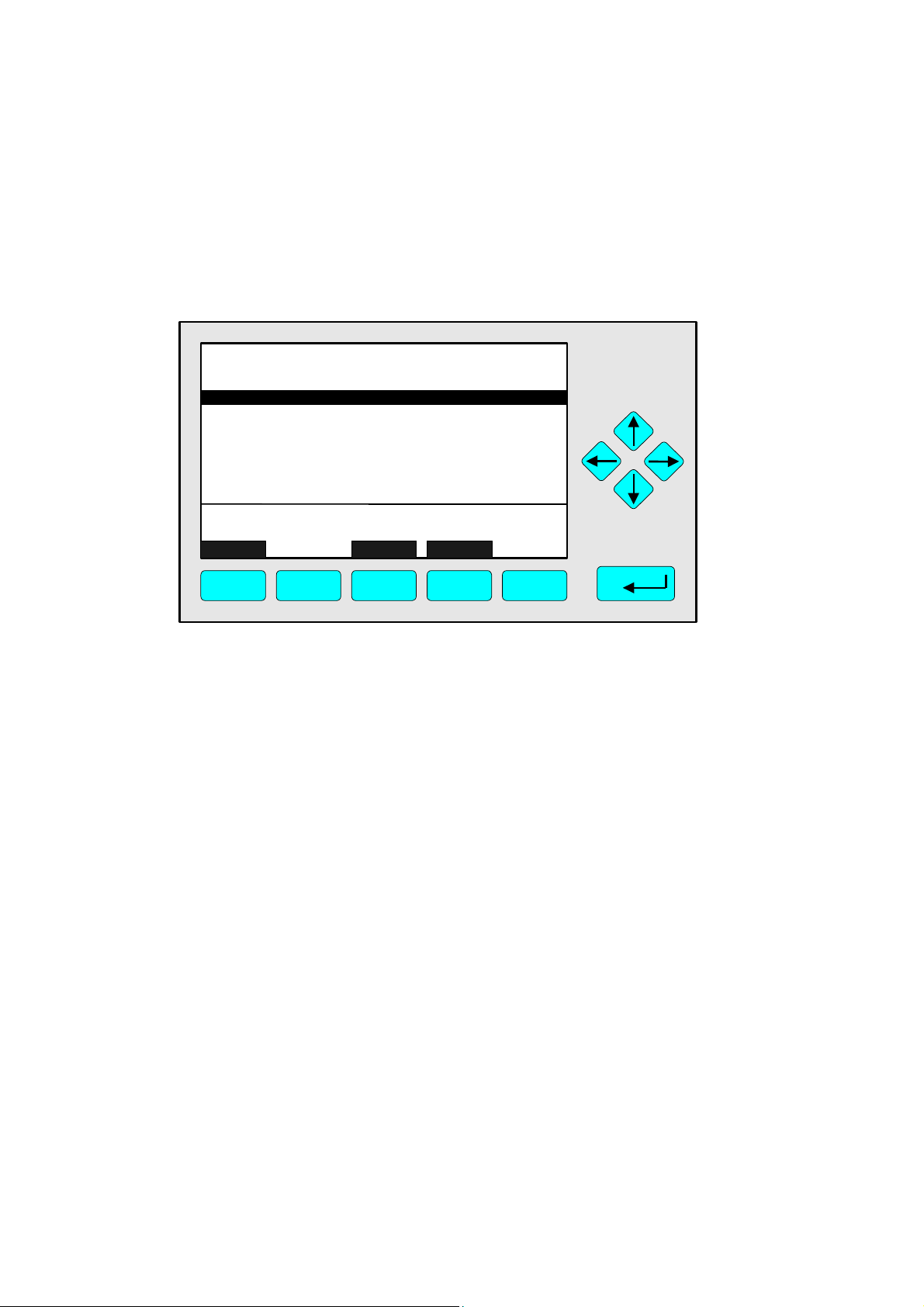

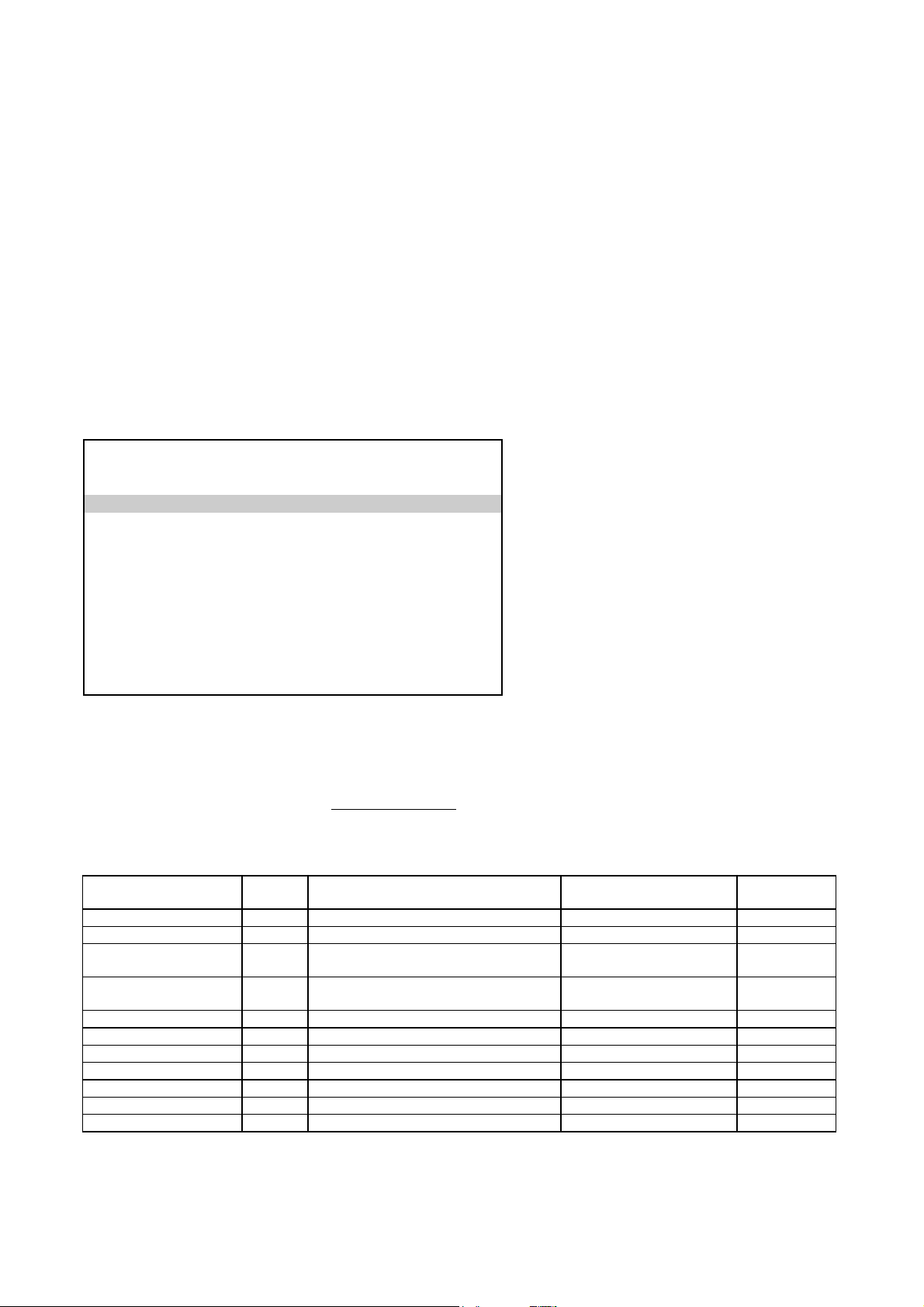

1.5 Menu tree for the system calculator

The following pictures show the menu tree and the LON variables which are assigned to the single menu lines.

System configuration and diagnostics...

↓

System calculator...

↓

- System calculator-

Programming...

Signals...

Units...

Scaling...

Calculator is: Enabled

Program error in step: 0

Result Calculator 1: 0.1234

Result Calculator 2: 1234.5

Result Calculator 3: 123.45

Result Calculator 4: 98.765

Picture 1-1: System Calculator Menu

With the 'Calculator is' parameter we show whether the system calculator functionality is

• Disabled

• Enabled

• has a Program Error (after trying to enable)

In the case of a program error by the 'Program error in step:' parameter is displayed in what step of the program

this error happened. If there is no error this parameter equals '0'.

CALCSTATUS

CLCERRLINE

CALC1RESULT

CALC2RESULT

CALC3RESULT

CALC4RESULT

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 6

Calculator on Control Module Level

1.5.1 Submenu 'Signals'

The live values' signal assignment is done in the submenu 'Signals...".

System configuration and diagnostics...

↓

System calculator...

↓

Signals...

↓

- Signals -

Signal number: 11

Choose signal source module...

Choose signal...

Signal name: Concentration

Signal comes from: MLT/CH1

Current signal value: 123.45 ppm

View...

Picture 1-2 : Signal Assignment of System Calculator

CALCSIGNUMC

CALCSRCSEL_

CALCSIGSEL_

CALCSIGC

CALCSRCC

CALCVALC

fct3: CASIGLST_

The single signals of the pool (selected by 'Signal number') are assigned by first selecting the source analyzer

module (AM) resp. analyzer channel of the requested signal and then the signal name itself.

Please, note that is only possible to modify the programmable type of signal numbers.

To realize the signal name's selection there is used an already implemented feature of the AMs. It has being

used for the small bar graphs display and for the analog outputs of the SIO module. It is the SVCONT/SVNAME

variable mechanism. This mechanism provides the possibility to have a link to the LON variables of an AM

which are listed in the SVCONT enum. In the SVNAME variable are listed the related human readable strings.

If we want to assign the signals not via the menu but via LON variable access we have to do the following steps:

1. Enter signal number by setting CALCSIGNUMC.

2. Enter the source of the signal by setting CALCSRCC to the TAG-variable's string of the requested channel.

3. Set CALC_ENTRYSIG (instead of using CALCSIGC) to the enum value that the signal has in the SVCONT-

variable.

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 7

Calculator on Control Module Level

It is possible to show a listing of the whole signal pool with the entered programmable as well as the fixed

assignments.

-- Signal List --

List offset: 10

Signal (o+1): Concentration: MLT/CH1

Signal (o+2): Concentration: MLT/CH2

Signal (o+3): Concentration: MLT/CH3

Signal (o+4): Concentration: TFID

Signal (o+5): Temperature: MLT/CH1

Signal (o+6): Temperature: MLT/CH2

Signal (o+7): Pressure: MLT/CH1

Signal (o+8): Flow: MLT/CH3

Signal (o+9): ????: ????

Signal (o+10): ????: ????

<< Back... >>

Picture 1-3: Listing of Signal Assignment

LISTOFFSET

MENU1LINE

MENU2LINE

MENU3LINE

MENU4LINE

MENU5LINE

MENU6LINE

MENU7LINE

MENU8LINE

MENU9LINE

MENU10LINE

fct3: BACKVARS

fct4: ESCAPE

fct5: LOADVARS

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 8

Calculator on Control Module Level

1.5.2 Submenu 'Programming'

The constant values are configured in the submenu 'Programming...".

System configuration and diagnostics...

↓

System calculator...

↓

Programming...

↓

- Constants (1/3) -

Constant -1: 1.000000

Constant –2: 10.00000

Constant –3: 100.0000

Constant –4: 1000.000

Constant –5: 10000.00

Constant –6: 100000.0

Constant –6: 1000000

Programming...

More...

Picture 1-4: Constant Values Assignment

CALCAC1

CALCAC2

CALCAC3

CALCAC4

CALCAC5

CALCAC6

CALCAC7

CALCPRG_

fct5: CALCCONS2

System configuration and diagnostics...

↓

System calculator...

↓

Programming...

↓

More...

↓

- Constants (2/3) -

Constant –8: 0.100000

Constant –9: 0.010000

Constant –10: 0.001000

Constant –11: 0.000100

Constant –12: 0.000010

Constant –13: 0.000001

Constant –14: 0.200000

More...

CALCBC1

CALCBC2

CALCBC3

CALCBC4

CALCBC5

CALCBC6

CALCBC7

fct5: CALCCONS3

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 9

Calculator on Control Module Level

After having done the set-up of the signals we can do the programming of Calculator algorithm itself. It is done

in the submenu 'Programming...".

System configuration and diagnostics...

↓

System calculator...

↓

Programming...

↓

Programming...

↓

-- Programming --

Program offset (o): 0

Step (o+1): -2

Step (o+2): 67

Step (o+3): -4

Step (o+4): -3

Step (o+5): 37

Step (o+6): -8

Step (o+7): 1

Step (o+8): -7

Step (o+9): 0

Step (o+10): 0

<< Back... >>

Picture 1-5: Programming the System Calculator

If we want to assign the signals not via the menu but via LON variable access we have to be aware of following:

1. The PLC-programming as well as the programming for the system calculator happens indirectly via the edit

variable-array ED_INTx.

To differ what the programming is for there exists the LON variable PROGTYP.

Setting PROGTYP = 0 means we want to program the system calculator.

Setting PROGTYP = 1 means we want to program the system PLC.

2. By using the variable LISTOFFSET we determine what part of the whole programming list we want to

program.

For example, setting LISTOFFSET = 60, means by usage of ED_INT1...ED_INT10 we are able to modify

the program steps 61...70.

LISTOFFSET

ED_INT1

ED_INT2

ED_INT3

ED_INT4

ED_INT5

ED_INT6

ED_INT7

ED_INT8

ED_INT9

ED_INT0

fct3: BACKVARS

fct4: ESCAPE

fct5: LOADVARS

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 10

Calculator on Control Module Level

2 Display Calculator Results on Mini-bargraph

In order to show the calculator results on the mini-bargraphs of the single component display we overworked the

architecture of the bargraph displays.

All the signals which are shown on this display in the versions up to now belonged always to the selected

component, that means they belonged all to the same AM-channel or to an I/O module which is bound to it.

To show a calculator result which belongs to the CM we have to assign signals of a different node/subnode

to the single component display's bargraphs. Therefore we have chosen a way which enables us to do a

complete free signal assignment.

Also we are able to set-up the calculator result's unit and its range limits.

And finally we are able to assign an own signal name to the bar graphs. Up to now there have been shown the

name that is noticed in the SVNAME variable. For most of signals this is sufficient. But especially for signals

which have no unique function (like calculator results) we want to show configurable and therefore more intuitive

signal names.

By inventing this new bargraphs display structure we also looked to have a behavior which can fulfill the current

functionalities.

Therefore we created the possibility to assign signals of I/O modules and their implemented SVCONT/SVNAME

signals as well as the ANALOGOUTPUT/ANOPUNITS variable of older I/O module versions.

2.1 Display mode

For each selectable component we can compose bar graph displays. This composition can show signals of a

prepared pool from any attached network node.

To have the possibility of being compatible to current software versions we create also a mode which displays

the signals as they are selected by the analyzers itself.

System configuration and diagnostics...

↓

Measurement display set-up...

↓

-- Measurement display set-up (1/2)--

Choose component module...

Selected component module: MLT/CH1

Display mode for line 1: Disabled

Display mode for line 2: AnalyzerSelected

Display mode for line 3: PlatformSelected

Display mode for line 4: PlatformSelected

Signal number for line 1: 1

Signal number for line 2: 1

Signal number for line 3: 2

Signal number for line 4: 4

Signals

Picture 2-1: Measurement Display Set-up

LINSRCSEL_

LINESRCMODC

LINEDISPC1

LINEDISPC2

LINEDISPC3

LINEDISPC4

LINESIGNC1

LINESIGNC2

LINESIGNC3

LINESIGNC4

In upper menu we first select the component we want to do the assignment for ("Choose component

module...").

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 11

Calculator on Control Module Level

By use of the four "Display mode for line x"-parameters we select the handling of the 4 bar graphs.

Disabled: The bar graph is switched off.

AnalyzerSelected: The bar graph receives the signal from the SVNAMEx-variable of the selected component

module (AM). This is the already implemented and mainly used mode.

PlatformSelected: The bar graph receives its signal from a signal pool that is installed in the Control Module

itself.

2.2 Assign signals and convenient names

If we use the 'PlatformSelected' signal mode we have to determine what signal number of the pool has to be

displayed. The selection of this number is performed in the appropriate menu line "Signal number for line x".

Now we have to determine only what kind of signal is behind each signal number of the pool.

This is done in the following menu display.

System configuration and diagnostics...

↓

Measurement display set-up...

↓

Signals...

↓

- Assign mini-bargraph signals -

Signal number: 4

Choose signal source module...

Choose signal...

Signal description: NOx-Calculation

Signal comes from: Control Module

Signal name: Sys.-calculator 1

View...

Picture 2-2: Platform selected Signal Assignment

SGNSNUMC

AUXSRCSEL_

AUXSIGSEL_

SGNDESCRC

SGNSRCMODC

SGNSRCSIGC

fct3: AUXLIST_

We are able to assign signals which come from all installed nodes/subnodes and have the SVCONT/SVNAME

variable. Further more we present I/O modules which have the ANALOGOUTPUT / ANOPUNITS variable.

The procedure is the following:

First we select the signal number we want to assign the signal for.

Then we choose the source (node/subnode) the signal shall come from.

After this we choose the signal itself of the selected source.

With the "Signal description" parameter, which is an editable string variable, we create the ability to give a

convenient signal name to each of the assigned signals.

If we want to assign this not via the menu but via LON variable access we have to do the following steps:

1. Enter signal number by setting SGNSNUMC.

2. Enter the source of the signal by setting SGNSRCMODC to the TAG variable's string of the requested

channel.

3. Set SGN_ENTRYSIG (instead of using SGNSRCSIGC) to the enum value that the signal has in the

SVCONT variable.

4. Enter the signal description by setting SGNDESCRC.

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 12

Calculator on Control Module Level

A complete overview of the signals in the pool can be obtained then in the following menu.

System configuration and diagnostics...

↓

Measurement display set-up...

↓

Signals...

↓

View...

↓

- Signal List Signal offset (o): 0

Signal 1+o: Sys.-calculator 1: Control Module

Description: Sum of CO and CO2

Signal 2+o: Sys.-calculator 2: Control Module

Description: SysCalc2

Signal 3+o: Sys.-calculator 3: Control Module

Description: SysCalc3

Signal 4+o: Sys.-calculator 4: Control Module

Description: SysCalc4

Signal 5+o: ????: ????

Description: ????

<< Back... >>

Picture 2-3: Listing of assigned Signals

LISTOFFSET

MENU1LINE

MENU2LINE

MENU3LINE

MENU4LINE

MENU5LINE

MENU6LINE

MENU7LINE

MENU8LINE

MENU9LINE

MENU10LINE

fct3: BACKVARS

fct4: ESCAPE

fct5: LOADVARS

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 13

Calculator on Control Module Level

3 Assignment to SIO Analog Outputs

The assignment of the system calculator results to an analog output of the SIO board is realized by extending

the selectable module types. Now it is also possible to select the platform itself with its own signals (calculator

results).

That means we have added the SVCONT/SVNAME variable for node/subnode 0 (platform).

Here we assigned then the new CALCxRESULT variables of the system calculator.

HAS55E03IM11S(1) [NGA-e (TFID software 3.7.x)] CM Calculator Page 14

Programmable Logic Control (PLC) on Control Module Level

Programmable Logic Control (PLC)

on Control Module Level

(Platform, TFID, MLT or CAT 200 Analyzer)

Contents

1 FUNCTION SURVEY .......................................................................................................................................3

2 PRINCIPLE OF PROGRAM SETUP ...............................................................................................................4

3 OPERATORS...................................................................................................................................................5

4 INPUT SIGNALS..............................................................................................................................................6

5 OUTPUT SIGNALS..........................................................................................................................................7

6 ACTIONS .........................................................................................................................................................9

7 TIME CONTROLED LOGIC...........................................................................................................................10

7.1 O

7.2 O

7.3 REPEATED PULSE MODE ...........................................................................................................................11

7.4 SINGLE PULSE MODE ................................................................................................................................12

7.5 R

7.6 INHIBITED SINGLE PULSE MODE .................................................................................................................13

7.7 CLOCK TRIGGERED PULSE MODE...............................................................................................................13

7.8 C

8 MENU TREE FOR THE SYSTEM PLC .........................................................................................................15

8.1 S

8.2 S

8.3 S

8.4 S

8.5 SUBMENU 'RESULTS' .................................................................................................................................24

9 APPLICATIONS.............................................................................................................................................25

9.1 S

9.2 REMOTE VALVE SWITCHING WITH AN ACTIVE SYSTEM CALIBRATION ............................................................27

FF-DELAY MODE.....................................................................................................................................10

N-DELAY MODE ......................................................................................................................................11

ETRIGGERING SINGLE PULSE MODE .........................................................................................................12

OUNTER MODE........................................................................................................................................14

UBMENU 'SIGNALS' ..................................................................................................................................16

8.1.1 Input Signals Listing ............................................................................................................................17

8.1.2 Output Signals Listing..........................................................................................................................18

UBMENU 'ACTIONS'..................................................................................................................................19

8.2.1 Actions Listing .....................................................................................................................................20

UBMENU 'TIMERS' ....................................................................................................................................21

UBMENU 'PROGRAMMING' ........................................................................................................................23

TREAM CONTROL WITH AN ACTIVE SYSTEM CALIBRATION ..........................................................................25

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 1

Programmable Logic Control (PLC) on Control Module Level

Listing of used Pictures

PICTURE 1-1: BLOCK DIAGRAM OF THE SYSTEM PLC...................................................................................................3

PICTURE 7-1: THE TIMER FUNCTION BLOCK ..............................................................................................................10

P

ICTURE 7-2: OFF-DELAY TIMER MODE DIAGRAM .....................................................................................................10

PICTURE 7-3: ON-DELAY TIMER MODE DIAGRAM .......................................................................................................11

PICTURE 7-4: REPEATED-PULSE TIMER MODE DIAGRAM ...........................................................................................11

P

ICTURE 7-5: SINGLE PULSE TIMER MODE DIAGRAM.................................................................................................12

PICTURE 7-6: RETRIGGERING SINGLE PULSE TIMER MODE DIAGRAM .........................................................................12

P

ICTURE 7-7: INHIBITED SINGLE PULSE TIMER MODE DIAGRAM .................................................................................13

PICTURE 7-8: CLOCK TRIGGERED PULSE TIMER MODE DIAGRAM...............................................................................13

PICTURE 7-9: COUNTER MODE DIAGRAM ..................................................................................................................14

P

ICTURE 8-1: SYSTEM PLC MENU ...........................................................................................................................15

PICTURE 8-2 : INPUT SIGNAL ASSIGNMENT OF SYSTEM PLC......................................................................................16

PICTURE 8-5 : ACTIONS ASSIGNMENT OF SYSTEM PLC .............................................................................................19

P

ICTURE 8-6: LISTING OF ACTIONS ASSIGNMENT.......................................................................................................20

PICTURE 8-7: TIMERS SETUP OF SYSTEM PLC .........................................................................................................21

PICTURE 8-8: LISTING OF TIMERS' CONFIGURATION ..................................................................................................22

P

ICTURE 8-9: DISPLAY OF TIMERS' STATES ..............................................................................................................22

PICTURE 8-10: PROGRAMMING THE SYSTEM PLC .....................................................................................................23

PICTURE 8-11: DISPLAY OF THE SYSTEM PLC RESULTS............................................................................................24

Listing of used Tables

TABLE 3-1: THE OPERATORS OF THE SYSTEM PLC .....................................................................................................5

TABLE 4-1: EXAMPLE OF AN INPUT SIGNALS POOL.......................................................................................................6

T

ABLE 5-1: OUTPUT SIGNALS POOL............................................................................................................................7

TABLE 5-2: EXAMPLE OF A PLC PROGRAM USING INPUT AND OUTPUT SIGNALS .............................................................8

T

ABLE 5-3: EXAMPLE OF A SR-FLIP-FLOP AS PLC PROGRAM .....................................................................................8

TABLE 6-1: EXAMPLE OF AN ACTIONS POOL ................................................................................................................9

TABLE 6-2: EXAMPLE OF A PLC PROGRAM USING ACTIONS ..........................................................................................9

T

ABLE 8-1: DIFFERENT TIMER MODES AND THE RELATED MEANING OF THE OTHER PARAMETERS ...............................21

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 2

y

ato

s

STINAME/

AM_INPUT

actions

of all LON

subnodes

Actions

stem Calculator

PLC Computing

r

r

usable

editable

Program

System Clock

PLC-

Timer

Timer

Outputs

Output Signals

Timer Inputs

PLC Memories

usage for

- DIO Outputs

- SIO Relays

PLC

usage

Results

for external

PLC Results

- Bargraphs

- S

Input

STCONT/

STNAME

Signals

of all LON

Programmable Logic Control (PLC) on Control Module Level

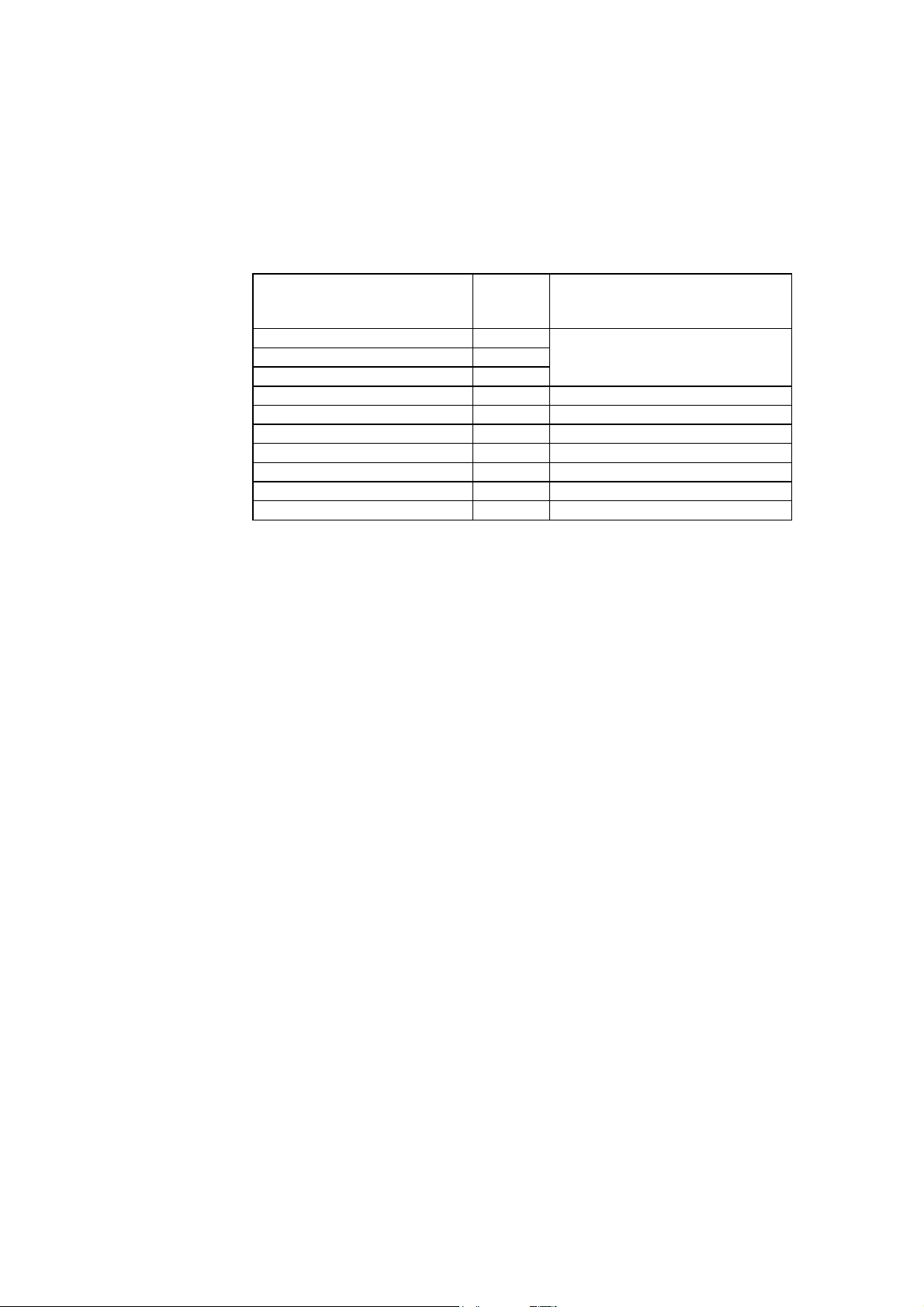

1 Function Survey

Picture 1-1: Block diagram of the System PLC

subnodes

System

Signals

Pumps

DIO Inputs

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 3

Programmable Logic Control (PLC) on Control Module Level

2 Principle of Program Setup

As it would be a too high effort to realize a comfortable mathematical formula system we created a syntax which

is easy to input and easy to realize.

As we assume that customers or service people have to setup the program only one times for an installed

system it should be acceptable to realize a form which is only done by inputting numbers.

Therefore we have mainly to differ between positive and negative numbers.

The program operations are assigned with negative numbers.

The operands which are used by these input operations are positive numbers. These positive numbers

symbolize signals which are part of a signal pool.

Also we have to know that there are used different classes of operands. That means we have different

classes of signal pools.

Those are:

• Input signals

• Output signals

• Actions.

In each of these classes exists an own numbering and we determine by the operator itself which class of these

operands is meant.

Remark:

Opposite to former versions allowing PLC function within ONE TFID/MLT/CAT 200 analyzer module (AM) or for

ONE TFID/MLT analyzer (or CAT 200analyzer resp.) ONLY now the system PLC is based on the C

M

odule level (CM).

This allows to include ALL analyzer modules resp. MLT channels of a NGA 2000 analyzer system into the PLC

system.

The results of the system PLC can be put onto the programmable Input/Output Modules SIO or DIO.

The SIO or DIO’s can work as Control Module I/O’s being then located in a platform or in a MLT, CAT 200 or

TFID Analyzer but also as local I/O’s in (remote) TFID, MLT or CAT 200 analyzer module.

ontrol

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 4

Programmable Logic Control (PLC) on Control Module Level

3 Operators

In the following table we find all the currently available operators (negative numbers) and their meaning. Hereby

is used the acronym "IR" for the actually calculated intermediate result of the PLC program.

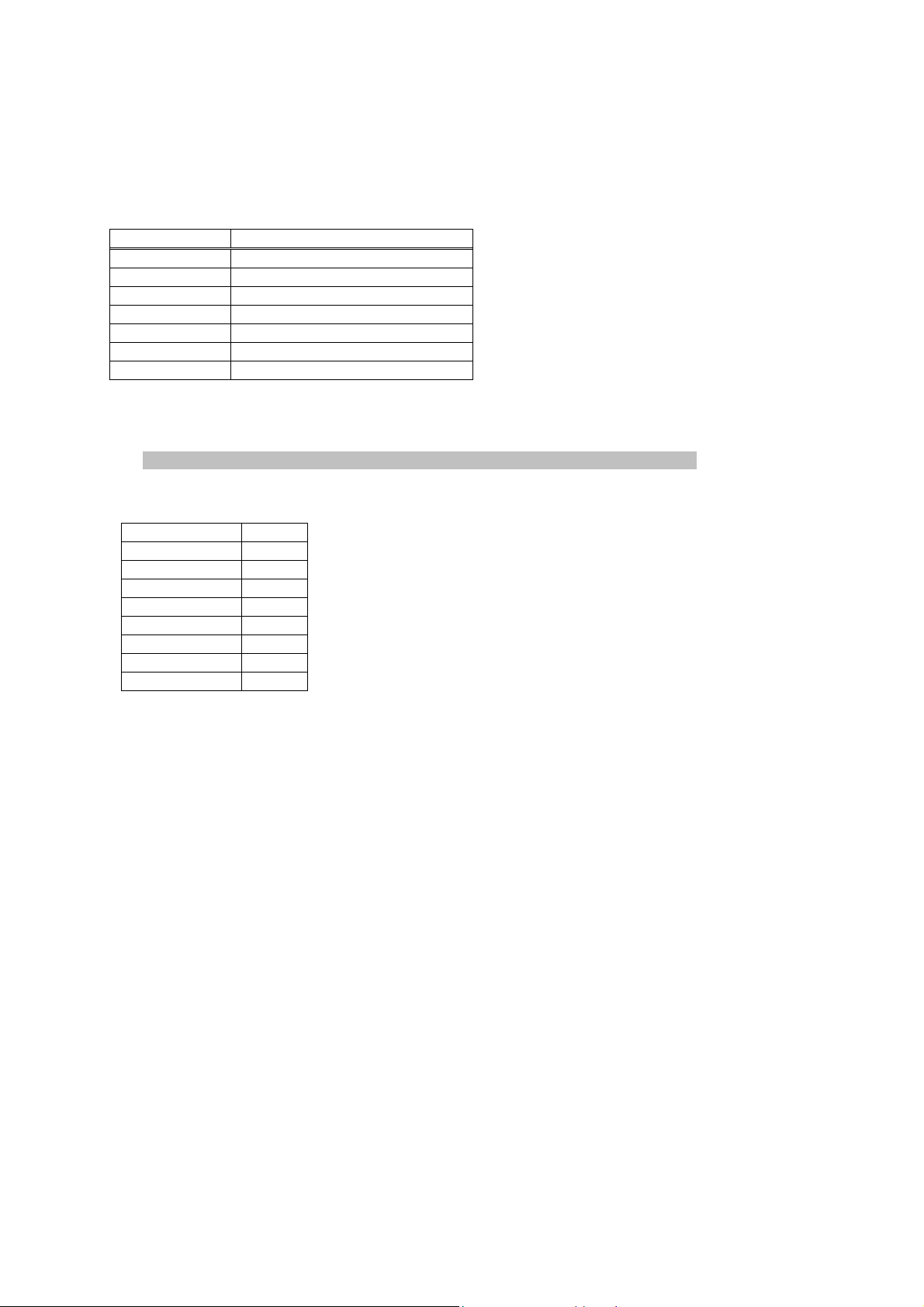

Table 3-1: The Operators of the System PLC

Operator

number

-10 IF i1 i2 if IR = True then IR = input signal with 1st following ID

-11 CALL actions call according IR by using following ID of actions pool

Acronym Description

-1 NOP no operation (placeholder)

-2 OR OR combine the input signals with following ID; store to IR

-3 AND AND combine the input signals with following ID; store to IR

-4 INVERT invert the IR

-5 STORE set/clear the output signal with the following ID according IR

-6 CLEAR clear the IR

-7 END end of program

-8 SET set the IR

-9 LOAD load IR according input signal with following ID;

else IR = input signal with 2

nd

following ID

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 5

Programmable Logic Control (PLC) on Control Module Level

4 Input Signals

In the platform PLC we have a signal pool for the input signals.

The first part in this pool are fix assigned the rest of the signals are free assignable.

Table 4-1: Example of an Input Signals Pool

Signal

Assignment assignment type

ID

1 PLC Result 1 fixed

2 PLC Result 2 fixed

3 PLC Result 3 fixed

.. .. fixed

15 PLC Result 15 fixed

16 PLC Memory 1 fixed

17 PLC Memory 2 fixed

.. .. fixed

30 PLC Memory 15 fixed

31 PLC Timer1 Out fixed

32 PLC Timer2 Out fixed

33 PLC Timer3 Out fixed

34 PLC Timer4 Out fixed

35 PLC Timer5 Out fixed

36 PLC Timer6 Out fixed

37 PLC Timer7 Out fixed

38 PLC Timer8 Out fixed

39 reserved fixed

40 reserved fixed

41 System-DIO-Board 1 Input 1 fixed

42 System-DIO-Board 1 Input 2 fixed

.. .. fixed

47 System-DIO-Board 1 Input 7 fixed

48 System-DIO-Board 1 Input 8 fixed

49 System-DIO-Board 2 Input 1 fixed

50 System-DIO-Board 2 Input 2 fixed

.. .. fixed

55 System-DIO-Board 2 Input 7 fixed

56 System-DIO-Board 2 Input 8 fixed

57 System-Pump 1 fixed

58 System-Pump 2 fixed

.. .. fixed

62 reserved fixed

63 On-Signal fixed

64 Off-Signal fixed

65 MLT1/CH1-Failure programmable

66 MLT1/CH1-Conc.Low-Low programmable

67 MLT1/CH3-Flow Low programmable

68 TFID-Cal. in progress programmable

69 CLD-Maintenance request programmable

70 Control Module-SYS:Valve1 programmable

71 Control Module-SYS:Valve2 programmable

72 Control Module-SYS:Valve3 programmable

.. .. programmable

127 not assigned programmable

128 not assigned programmable

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 6

Programmable Logic Control (PLC) on Control Module Level

5 Output Signals

The same principle as for input signals is used for the output signals. We have a pool of usable buffer places

where intermediate calculation results can be stored to.

The content of these buffers may be used for further processing.

Table 5-1: Output Signals Pool

Signal

Assignment Tip

ID

1 Result 1 full usable LON variable (PLCRESULT1)

2 Result 2 full usable LON variable (PLCRESULT2)

3 Result 3 full usable LON variable (PLCRESULT3)

.. .. full usable LON variable

.. .. full usable LON variable

14 Result 14 full usable LON variable (PLCRESULT14)

15 Result 15 full usable LON variable (PLCRESULT15)

16 Memory 1 intermediate storage

17 Memory 2 intermediate storage

.. .. intermediate storage

.. .. intermediate storage

29 Memory 14 intermediate storage

30 Memory 15 intermediate storage

31 Timer 1 Input1 usage depends on timer mode

32 Timer 2 Input1 usage depends on timer mode

33 Timer 3 Input1 usage depends on timer mode

34 Timer 4 Input1 usage depends on timer mode

35 Timer 5 Input1 usage depends on timer mode

36 Timer 6 Input1 usage depends on timer mode

37 Timer 7 Input1 usage depends on timer mode

38 Timer 8 Input1 usage depends on timer mode

39 reserved

40 reserved

41 Timer 1 Input2 usage depends on timer mode

42 Timer 2 Input2 usage depends on timer mode

43 Timer 3 Input2 usage depends on timer mode

44 Timer 4 Input2 usage depends on timer mode

45 Timer 5 Input2 usage depends on timer mode

46 Timer 6 Input2 usage depends on timer mode

47 Timer 7 Input2 usage depends on timer mode

48 Timer 8 Input2 usage depends on timer mode

49 reserved

50 reserved

.. ..

56 reserved

57 System-Pump 1 full usable LON variable (SYSPUMP1)

58 System-Pump 2 full usable LON variable (SYSPUMP2)

59 reserved

.. ..

69 reserved

70 reserved

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 7

Programmable Logic Control (PLC) on Control Module Level

In the output signal pool the Results1..15 are assigned as full usable LON variable-array.

They are also implemented in the STCONT/STNAME-feature. So the PLC Results can be linked to digital

outputs of DIO or to the relays of SIO.

They are also implemented in the SVCONT/SVNAME-feature. So we are able to link them to analog outputs of

SIO, the bargraphs display and to the system calculator signals.

By using the signal IDs of the signal pools we determine the input resp. the output signal operands in the PLC's

program.

Following are examples that use the signal assignment of "Table 4-1: Example of an Input Signals Pool".

Result1 = (MLT1/CH1-Failure) OR (MLT/CH1-Conc.Low-Low) OR (DIO1-Input5)

Table 5-2: Example of a PLC program using input and output signals

Step (o+1) -2 OR (at beginning the intermediate result IR = 0)

Step (o+2) 65 Input-Signal 65 (here: MLT1/CH1-Failure)

Step (o+3) 66 Input-Signal 66 (here: MLT/CH1-Conc.Low-Low)

Step (o+4) 45 Input-Signal 45 (System-DIO-Board 1 Input 5)

Step (o+5) -5 Store IR to output buffer

Step (o+6) 1 Output-Signal 1 (PLC Result 1)

Step (o+7) -7 End of program

SR-Flip-Flop

Set

(DIO1-Input5)

Reset

(DIO1-Input6)

Out

(Result5)

0 0 last Out

0 1 0

1 0 1

1 1 1

Table 5-3: Example of a SR-Flip-Flop as PLC program

Step (o+1) -9 LOAD

Step (o+2) 46 IR = 'Reset' ->Input-Signal 46 (System-DIO-Board 1 Input 6)

Step (o+3) -10 IF (Reset = 1)

Step (o+4) 64 then IR = 0

Step (o+5) 5 else IR = last Out (PLC Result 5)

Step (o+6) -5 STORE

Step (o+7) 30 to Memory15

Step (o+8) -9 LOAD

Step (o+9) 45 IR = 'Set' ->Input-Signal 45 (System-DIO-Board 1 Input 5)

Step (o+10) -10 IF (Set = 1)

Step (o+11) 63 then IR = 1

Step (o+12) 30 else Memory15

Step (o+13) -5 STORE

Step (o+14) 5 to Out (PLC Result 5)

Step (o+15) -7 End of program

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 8

Programmable Logic Control (PLC) on Control Module Level

6 Actions

The same principle as for input and output signals is used again for the actions We have a pool where available actions of the different modules can be assigned to. By using the action IDs of this pool the single actions can be called according to the intermediate result which is calculated in the PLC program.

Table 6-1: Example of an Actions Pool

Action

ID

1 MLT1/CH1-AM:Zero-Cal programmable

2 MLT1/CH1-HoldAnalogOutput programmable

3 MLT1/CH3-ExtStatus1 programmable

4 MLT1/CH2-External failure programmable

5 Control Module-SYS:Zero-Cal programmable

6 Control Module-SYS:Cancel-Cal programmable

7 not assigned programmable

8 not assigned programmable

19 not assigned programmable

20 not assigned programmable

Following is an example that uses the signal assignment of "Table 4-1: Example of an Input Signals Pool" and

of "Table 6-1: Example of an Actions Pool"

This means: Start zero calibration of MLT1/CH1 if flow of MLT1/CH3 is not too low and digital input 5 of DIO-

Table 6-2: Example of a PLC program using actions

Assignment assignment type

.. programmable

.. programmable

MLT1/CH1-AM:Zero-Cal = /(MLT1/CH3-Flow Low) AND (DIO1-Input5)

Board 1 goes high.

Step (o+1) -2 OR (at beginning the intermediate result IR = 0)

Step (o+2) 67 Input-Signal 67 (here: MLT1/CH3-Flow Low)

Step (o+3) -4 invert the IR (build "/(MLT1/CH3-Flow Low)" )

Step (o+4) -3 AND (current IR with following input signals)

Step (o+5) 37 Input-Signal 37 (System-DIO-Board 1 Input 5)

Step (o+5) -8 perform action

Step (o+6) 1 Action-ID 1 (here: MLT1/CH1-AM:Zero-Cal)

Step (o+7) -7 End of program

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 9

Programmable Logic Control (PLC) on Control Module Level

7 Time controlled Logic

In order to do time dependent logic controls it is necessary to use timers.

These timers enable us to have:

• switch-off delays

• switch-on delays

• configurable pulse width square waves

• date and time controlled start of timer functions

To achieve all these variety of features the timers are implemented in different running modes. To control the

timers by other PLC signals the timers are provided with 2 digital inputs. The function of the digital inputs

depends on the elected timer mode.

The output of the timer function block is used by the PLC again for further processing.

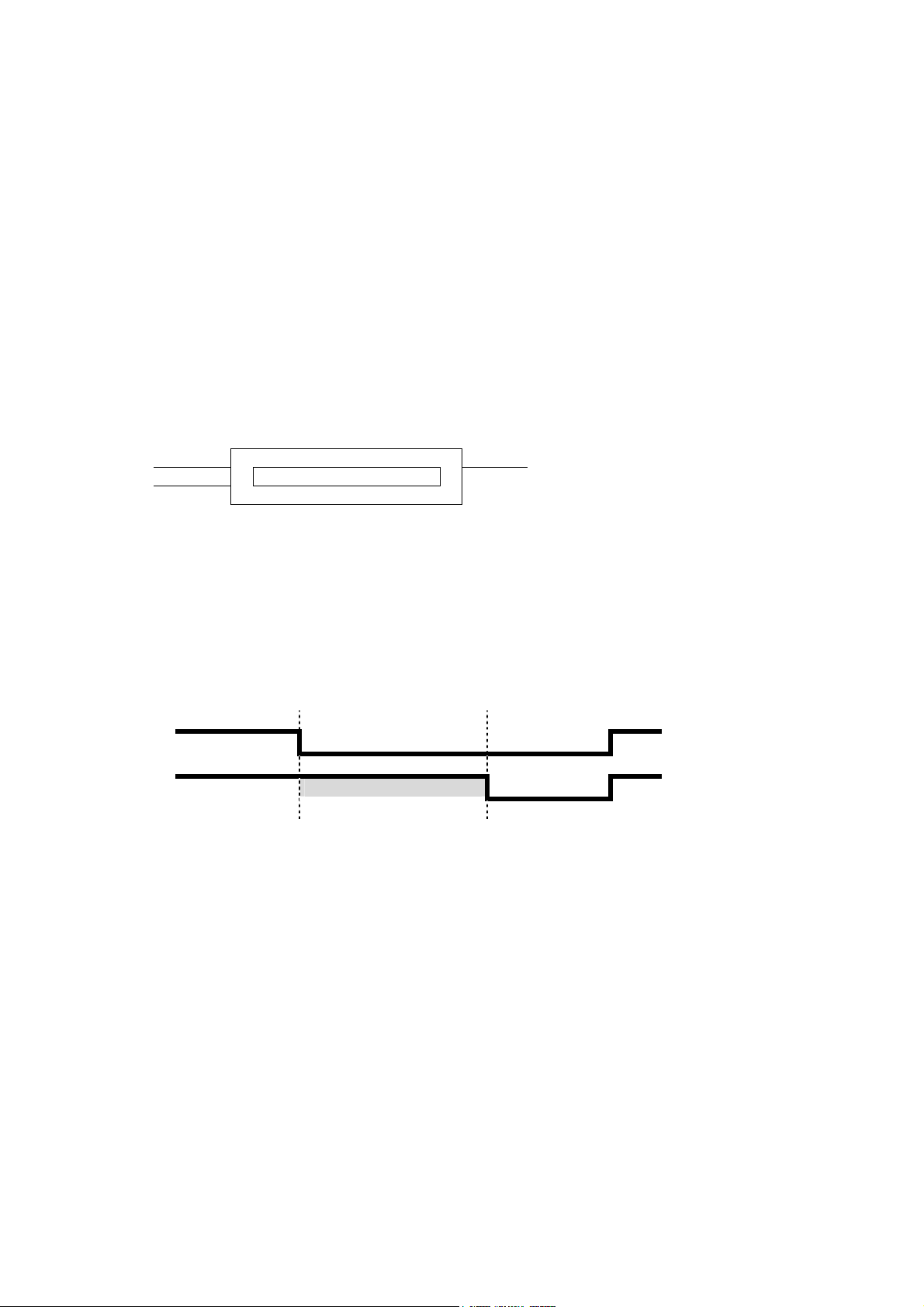

Picture 7-1: The Timer Function Block

Input 1

internal timer parameters Output

Input 2

7.1 Off-Delay Mode

The following picture shows the timed response of the 'Off-delay' timer mode.

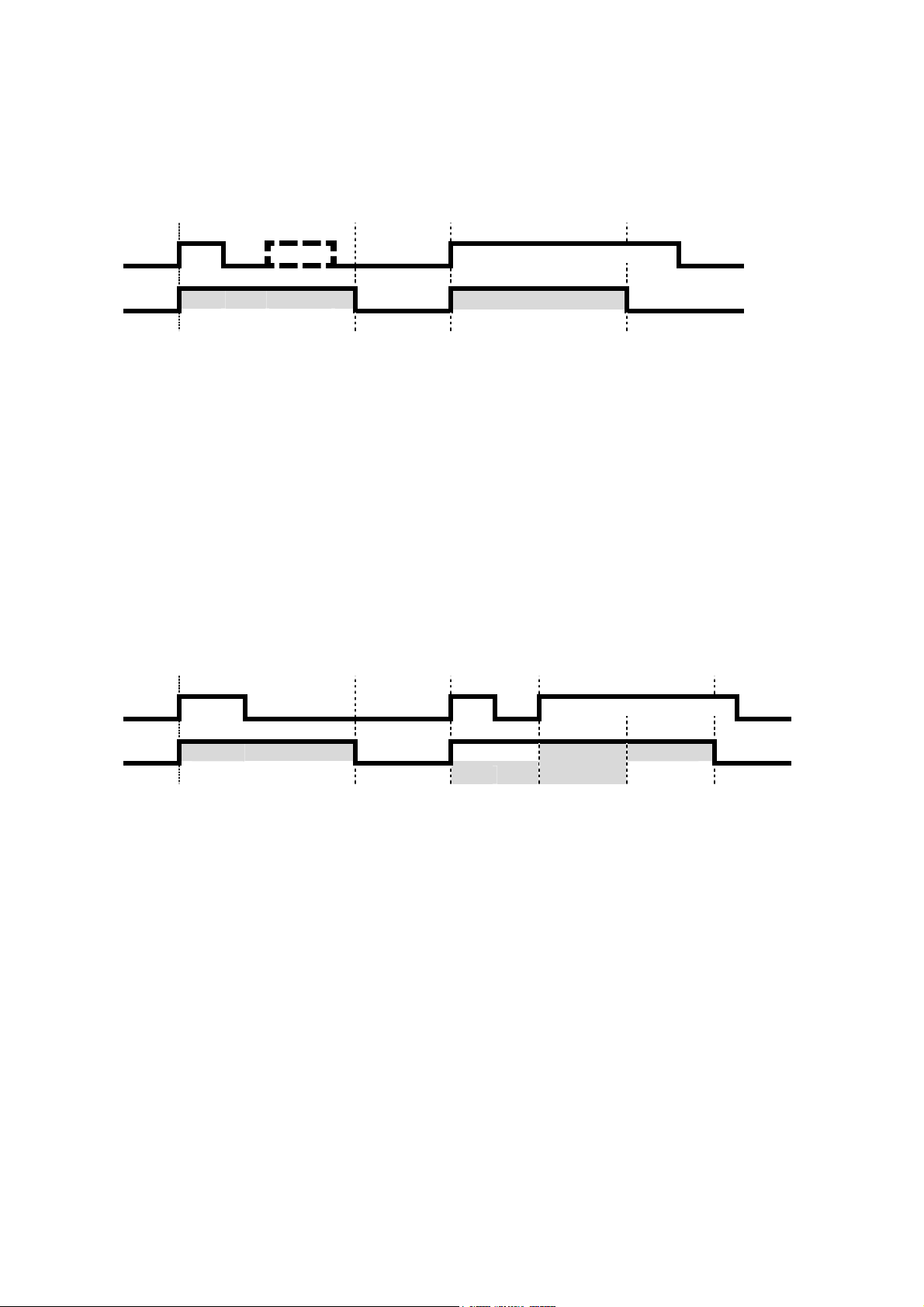

Picture 7-2: Off-delay Timer Mode Diagram

Input1

Output time duration

When 'Input1' of the timer is True, 'Output' is set True and the elapsed time counter is set to zero.

When 'Input1' is False for longer than the 'time duration', 'Output' is set False.

That means it is specified the time duration that must elapse before the False output value is applied.

'Input2' of the timer is not used in this mode.

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 10

Programmable Logic Control (PLC) on Control Module Level

7.2 On-Delay Mode

The following picture shows the timed response of the 'On-delay' timer mode.

Picture 7-3: On-delay Timer Mode Diagram

Input1

Output time duration

When 'Input1' of the timer is False, 'Output' is set False and the elapsed time counter is set to zero. When

'Input1' is True for longer than the 'time duration', 'Output' is set True.

That means it is specified the time duration that must elapse before the True output value is applied.

'Input2' of the timer is not used in this mode.

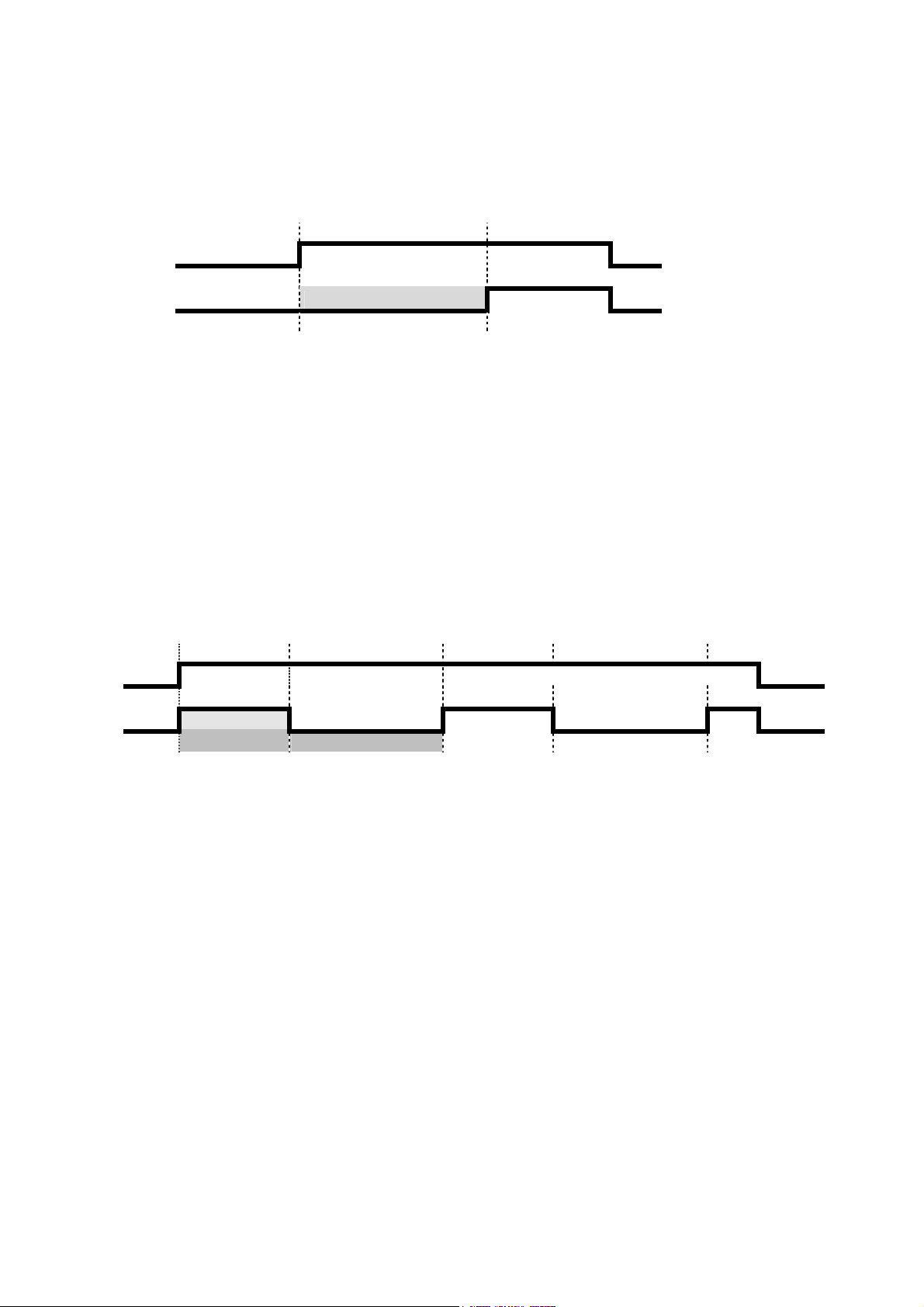

7.3 Repeated Pulse Mode

The following picture shows the timed behavior of the 'Repeated-Pulse' timer mode.

Picture 7-4: Repeated-Pulse Timer Mode Diagram

Input1

Output high duration

period time

When 'Input1' of the timer is False, 'Output' is set False.

When 'Input1' is True, the 'Output' is set according a square wave. On the rising edge of 'Input1' it begins with

setting the 'Output' True until the high duration time is elapsed. Then 'Output' is set False and remains False for

the rest of the period time. Then 'Output' is set True again for the high duration time, and so forth. This

procedure goes on endless until Input1 is set False.

'Input2' of the timer is not used in this mode.

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 11

Programmable Logic Control (PLC) on Control Module Level

7.4 Single Pulse Mode

The following picture shows the timed behavior of the 'Single Pulse' timer mode.

Picture 7-5: Single Pulse Timer Mode Diagram

Input1

Output time duration time duration

When 'Input1' of the timer changes from False to True (rising edge trigger) during 'Output' is False, 'Output' is

set True until time duration is elapsed. Then 'Output' is set False.

'Input2' of the timer is not used in this mode.

Tips: The pulse width on Input1 is not relevant, the duration of the pulse on 'Output' is always the same. The level changes on Input1

are scanned on a configurable rate. Therefore the time between edges (rising and falling) has to be at minimum of this set update

rate.

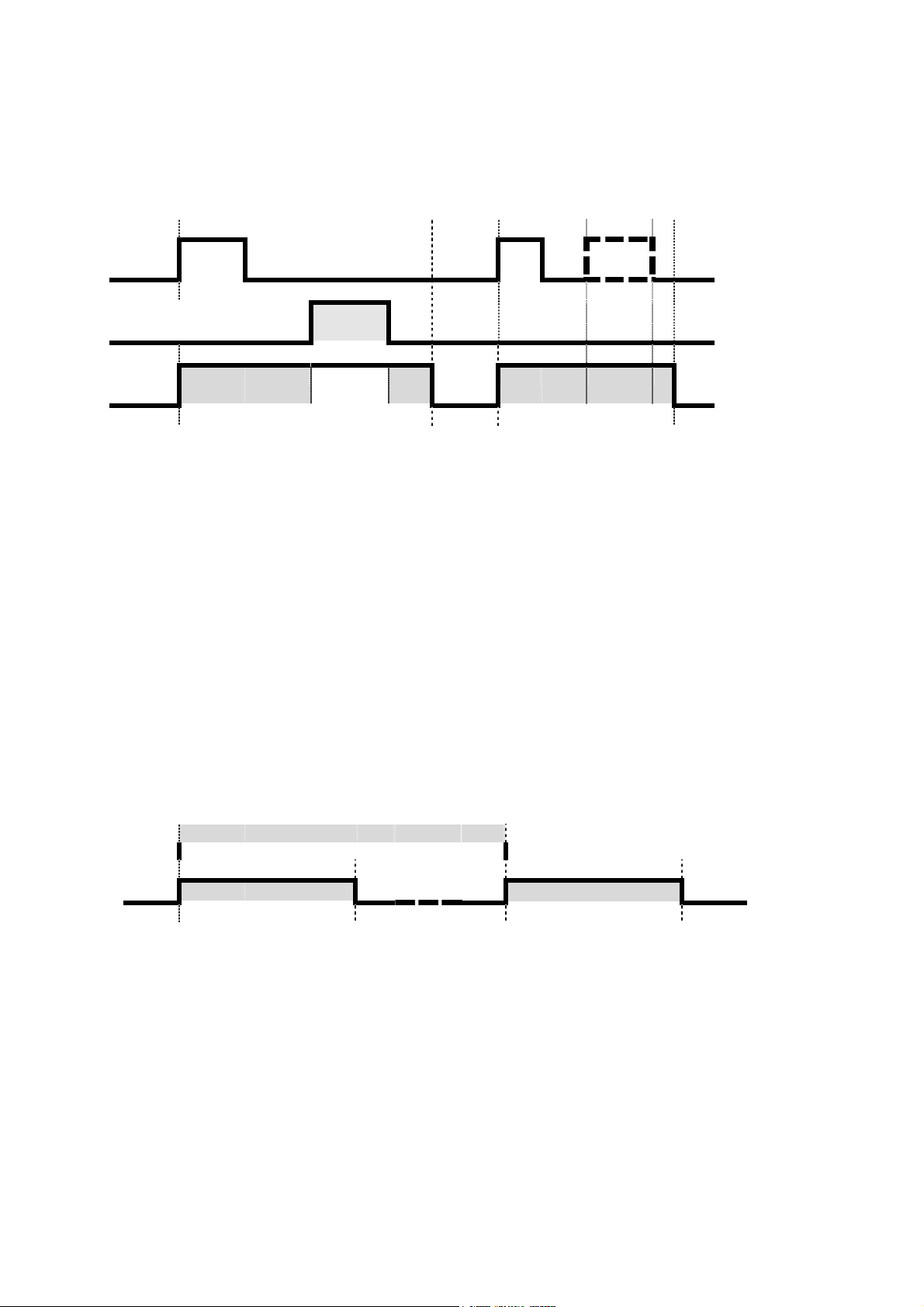

7.5 Retriggering Single Pulse Mode

The following picture shows the timed behavior of the 'Retriggering Single Pulse' timer mode.

Picture 7-6: Retriggering Single Pulse Timer Mode Diagram

retrigger

Input1

Output time duration time duration 2

time duration 1

When 'Input1' of the timer changes from False to True (rising edge trigger), 'Output' is set True until time

duration is elapsed. Then 'Output' is set False.

When 'Input1' changes from False to True again during Output is still set True the elapsing of the duration starts

new.

'Input2' of the timer is not used in this mode.

Tips: The pulse width on Input1 is not relevant, the duration of the pulse on 'Output' is only stretched if there is a rising edge on Input1

again.

The level changes on Input1 are scanned on a configurable rate. Therefore the time between edges (rising and falling) has to be

at minimum of this set update rate.

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 12

Programmable Logic Control (PLC) on Control Module Level

7.6 Inhibited Single Pulse Mode

The following picture shows the timed behavior of the 'Inhibited Single Pulse' timer mode.

Picture 7-7: Inhibited Single Pulse Timer Mode Diagram

Input1

(Trigger)

Input2

(Inhibit)

Output

When 'Input1' (logical trigger) of the timer transitions from False to True (rising edge trigger), 'Output' is set True

until time duration is elapsed. Then 'Output' is set False.

'When 'Input2' (logical inhibit) of the timer is set during 'Output' is True (elapsing duration) the time stops and

retains its value until Input2 transitions to False again. I.e., the duration time is increased by the inhibit pulses

duration.

Tips: The duration of the pulse on 'Output' does not depend on the pulse width of Input1.

Inhibit

pulse

time duration time duration

The level changes on Input1 are scanned on a configurable rate. Therefore the time between edges (rising and falling) has to be

at minimum of this set update rate.

7.7 Clock Triggered Pulse Mode

In the clock triggered pulse mode the behavior of the output is similar as in 'single pulse mode'. But the pulse is

not triggered by Input1 but at a certain date/time.

Picture 7-8: Clock Triggered Pulse Timer Mode Diagram

interval time

Date Time Date Time

Output time duration time duration

When the real time clock of the device reaches a set date/time (time trigger), 'Output' is set True until time

duration is elapsed. Then 'Output' is set False.

This procedure recurs after a set interval time.

'Input1' and 'Input2' of the timer are not used in this mode.

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 13

Programmable Logic Control (PLC) on Control Module Level

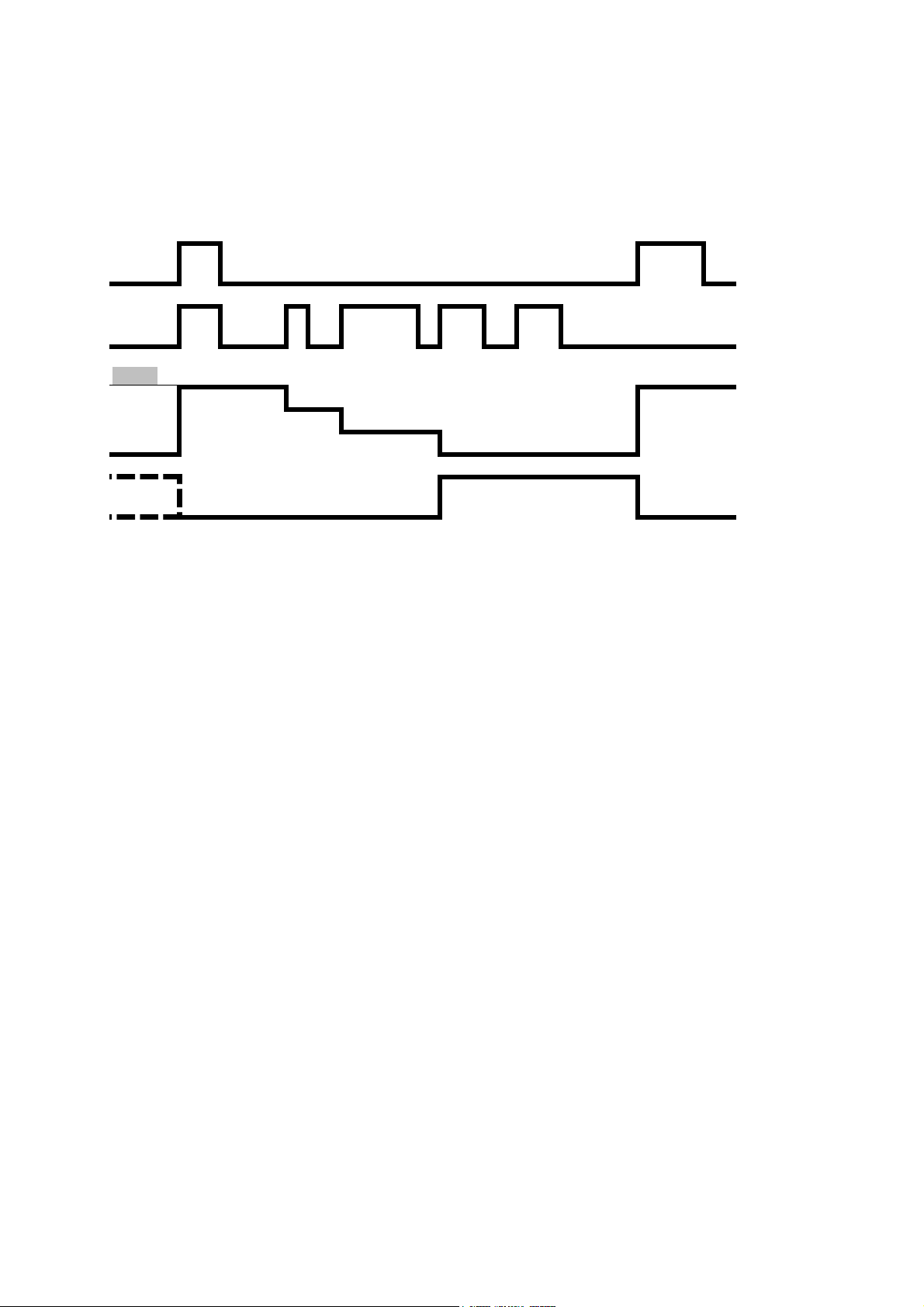

7.8 Counter Mode

The following picture shows the timed behavior of the 'Counter' mode.

Picture 7-9: Counter Mode Diagram

Input2

(Reset)

Input1

(Trigger)

Preset (here : 3)

2

internal 1

count 0

Output

When 'Input2' (logical 'Reset') of the timer is set to True, 'Output' is set False and the internal decrement counter

is set to its preset value.

After Input2 is set False the rising edges on Input1 (logical 'Trigger') decrement the counter. When the counter

is less than or equal to zero, 'Output' is set True and the counter holds its value.

Tips: The level changes on Input1 are scanned on a configurable rate. Therefore the time between edges (rising and falling) has to be

at minimum of this set update rate.

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 14

Programmable Logic Control (PLC) on Control Module Level

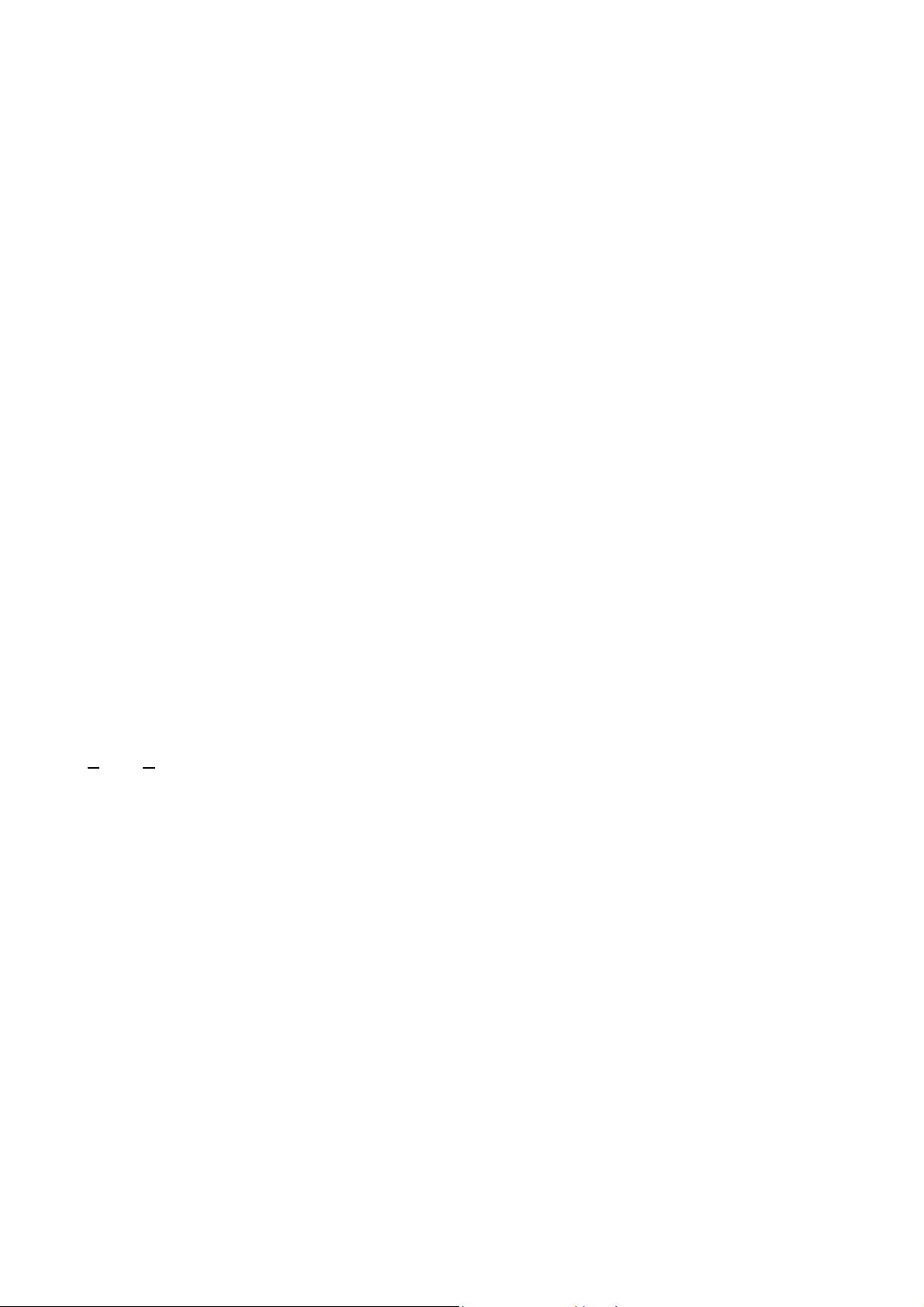

8 Menu Tree for the System PLC

The following pictures show the menu tree and the LON variables which are assigned to the single menu lines.

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

- System programmable logic control (PLC)-

Programming...

Signals...

Timer...

Results...

PLC is: Cycle: 1.0 s

Program error in step: 0

Picture 8-1: System PLC Menu

With the 'PLC is' parameter we disable or enable PLC function. Also, with enabling the PLC there is the choice

with which cyclic rate the programmed algorithm is called.

• Disabled

• has a Program Error (after trying to enable)

• Cycle 0.1 s

• Cycle 0.2 s

• Cycle 0.5 s

• Cycle 1.0 s

In the case of a program error by the 'Program error in step:' parameter is displayed in what step of the program

this error happened. If there is no error this parameter equals '0'.

fct: PLCPROG_

PLCSTATUS

PLCERRLINE

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 15

Programmable Logic Control (PLC) on Control Module Level

8.1 Submenu 'Signals'

All programmable signal assignments are done in the submenu 'Signals...".

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

Signals...

↓

- Signals -

Actions...

- Input signals -

Signal number: 65

Choose signal source module...

Choose signal...

Signal name: Failure

Signal comes from: MLT/CH1

Current signal level: Off

View... Outputs

Picture 8-2 : Input Signal Assignment of System PLC

The single signals of the pool (selected by 'Signal number') are assigned by first selecting the source analyzer

module (AM) resp. analyzer channel of the requested signal and then the signal name itself.

Please, note that it is only possible to modify the programmable type of signal numbers.

For the signal name's selection there is used an already implemented feature of the AMs. It has being used for

the digital outputs of the DIO resp. the SIO module. It is the STCONT/STNAME variable mechanism. This

mechanism provides the possibility to have a link to the LON variables of an AM which are listed in the STCONT

enum. In the STNAME variable are listed the related human readable strings.

If we want to assign the signals not via the menu but via LON variable access we have to do the following steps:

1. Enter signal number by setting PLCSIGNUMC.

2. Enter the source of the signal by setting PLCSRCC to the TAG-variable's string of the requested channel.

3. Set PLC_ENTRYSIG (instead of using PLCSIGC) to the enum value that the signal has in the STCONTvariable.

PLCSIGNUMC [65 .. 128]

PLCSRCSEL_

PLCSIGSEL_

PLCSIGC

PLCSRCC

PLCLEVELC

fct3: PLCSIGLST_

fct5: PLCOUTLST_

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 16

Programmable Logic Control (PLC) on Control Module Level

8.1.1 Input Signals Listing

Via the View function key it is possible to show a listing of the whole input signal pool with the entered

programmable as well as the fixed assignments.

The name of the fix signal assignments can be listed easily by using the enum variable PLC1INAME/

PLC2INAME which contains all the fix assigned signal's name (currently 64 names).

Here is shown a display according "Table 4-1: Example of an Input Signals Pool".

-- Signal List --

List offset: 60

Signal (o+1): ????: fix: Off

Signal (o+2): ????: fix: Off

Signal (o+3): ????: fix: Off

Signal (o+4): ????: fix: Off

Signal (o+5): Failure: MLT/CH1: Off

Signal (o+6): Conc.Low-Low: MLT/CH1: Off

Signal (o+7): Flow Low: MLT/CH3: On

Signal (o+8): Cal. in progress: FID: Off

Signal (o+9): Maintenance request: CLD: Off

Signal (o+10): ????: ????: Off

<< Back... >>

Picture 8-3: Listing of Input Signal Assignment

LISTOFFSET

MENU1LINE (live)

MENU2LINE (live)

MENU3LINE (live)

MENU4LINE (live)

MENU5LINE (live)

MENU6LINE (live)

MENU7LINE (live)

MENU8LINE (live)

MENU9LINE (live)

MENU10LINE (live)

fct3: BACKVARS

fct4: ESCAPE

fct5: LOADVARS

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 17

Programmable Logic Control (PLC) on Control Module Level

8.1.2 Output Signals Listing

Via the Outputs function key it is possible to show a listing of the whole output signal pool.

The name of the this fix output signal assignments can be listed easily by using the enum variable

PLC1ONAME/PLC2ONAME which contains all the fix assigned signal's name.

Here is shown a display with Output Signals

-- Signal List --

List offset: 30

Signal (o+1): PLC Timer-1 In1: Off

Signal (o+2): PLC Timer-2 In1: Off

Signal (o+3): PLC Timer-3 In1: Off

Signal (o+4): PLC Timer-4 In1: Off

Signal (o+5): PLC Timer-5 In1: Off

Signal (o+6): PLC Timer-6 In1: Off

Signal (o+7): PLC Timer-7 In1: Off

Signal (o+8): PLC Timer-8 In1: Off

Signal (o+9): Reserved: Off

Signal (o+10): Reserved: Off

<< Back... >>

Picture 8-4: Listing of Output Signal Assignment

LISTOFFSET

MENU1LINE (live)

MENU2LINE (live)

MENU3LINE (live)

MENU4LINE (live)

MENU5LINE (live)

MENU6LINE (live)

MENU7LINE (live)

MENU8LINE (live)

MENU9LINE (live)

MENU10LINE (live)

fct3: BACKVARS

fct4: ESCAPE

fct5: LOADVARS

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 18

Programmable Logic Control (PLC) on Control Module Level

8.2 Submenu 'Actions'

All programmable action assignments are done in the submenu 'Actions...".

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

Signals...

↓

Actions...

↓

- Actions -

Action number: 1

Choose module...

Choose function...

Function name: AM:Zero-Cal

Action goes to: MLT/CH1

View...

Picture 8-5 : Actions Assignment of System PLC

The single actions of the pool (selected by 'Action number') are assigned by first selecting the source analyzer

module (AM) resp. analyzer channel of the requested action and then the function name itself.

For the function name's selection there is used an already implemented feature. It has being used for the digital

inputs of the DIO module. It is the STINAME and AM_INPUT/DI_MSGE variable mechanism. This mechanism

provides the possibility to have a link to functions of an AM which are listed in the STINAME-enum of the

platform or at the AM_INPUT-enum of the single modules.

If we want to assign the actions not via the menu but via LON variable access we have to do the following steps:

1. Enter action number by setting PLCACTNUMC.

2. Enter the source of the signal by setting PLCACTSRCC to the TAG-variable's string of the requested

channel.

3. Set PLC_ENTRYACT (instead of using PLCACTIONC) to the corresponding enum value. This value is

calculated by usage of STINAME of the platform and AM_INPUT of the selected module.

If you select an action which is listed in STINAME, the enum value is just the value of STINAME.

If you select an action which is listed in AM_INPUT you have to add the enum value of AM_INPUT to the

number of available enum values of STINAME.

PLCACTNUMC [1..20]

PLCASRCSEL_

PLCACTSEL_

PLCACTIONC

PLCACTSRCC

fct3: PLCACTLST_

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 19

Programmable Logic Control (PLC) on Control Module Level

8.2.1 Actions Listing

It is possible to show a listing of the whole actions pool with the entered assignments as well as the

corresponding signal levels.

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

Signals...

↓

Actions...

↓

View...

↓

-- Action List --

List offset: 0

Signal (o+1): AM:Zero-Cal: MLT/CH1: Off

Signal (o+2): HoldAnalogOutput: MLT/CH1: Off

Signal (o+3): ExtStatus1: MLT/CH3: On

Signal (o+4): External failure: MLT1/CH2: Off

Signal (o+5): SYS:Zero-Cal: Control Module: Off

Signal (o+6): SYS:Cancel-Cal: Control Module: Off

Signal (o+7): ????:????:Off

Signal (o+8): ????:????:Off

Signal (o+9): ????:????:Off

Signal (o+10): ????:????:Off

<< Back... >>

Picture 8-6: Listing of Actions Assignment

LISTOFFSET

MENU1LINE (live)

MENU2LINE (live)

MENU3LINE (live)

MENU4LINE (live)

MENU5LINE (live)

MENU6LINE (live)

MENU7LINE (live)

MENU8LINE (live)

MENU9LINE (live)

MENU10LINE (live)

fct3: BACKVARS

fct4: ESCAPE

fct5: LOADVARS

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 20

Programmable Logic Control (PLC) on Control Module Level

8.3 Submenu 'Timers'

The setup of the timers is configured in the submenu 'Timers...".

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

Timers...

↓

- Timers -

Timer number: 1

Timer mode: Off-delay

Duration: 30 sec

Period / Counts: 180 sec

Hours (0..23): 15

Minutes: 10

Month: 3

Day: 21

View... States...

Picture 8-7: Timers Setup of System PLC

PLCTMRNUMC [1..8]

PLCTMRMODC [see Table 8-1]

PLCDURATC [1..3600]

PLCTIMC [1..3600] / PLCUC

PLCHOURC

PLCMINUTC

PLCMONTHC

PLCDAYC

fct3: PLCTMRLST_

fct4: PLCTMRSTAT_

(variable unit)

The single timers are configured by first selecting the timer number itself (currently 1...8).

Further configuration parameters depend on the mode the timer has to run in. Therefore the mode has to be

elected as next.

In following table see the selectable timer modes and the related meaning of the rest of the parameters.

Table 8-1: Different Timer Modes and the Related Meaning of the other Parameters

Timer mode Off-

delay

Duration delay

time

Period/

Counts

Hours

Minutes

Month

Day

For more information on the different timer modes see also chapter "7 Time controlled Logic".

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 21

On-

delay

delay

time

- - period time

- - - - - - date/time of

Repeated-

Pulse

True pulse

width

[seconds]

Single-Pulse Retrig-Single-

Pulse

True pulse

width

- - - Interval time

min. True

pulse width

Inhib-Single-

Pulse

min. True

pulse width

Clock-Trig-

Pulse

True pulse

width

[minutes]

next

triggering

the pulse

Counter

-

Preset

count value

-

Programmable Logic Control (PLC) on Control Module Level

It is possible to show a listing of the timers' configuration.

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

Timers...

↓

View...

↓

- Timer Setup -

Offset (o): 0

Mode / Duration of timer 1+o: On-delay / 20 s

Period / Counts: --- Next Start time: ---Mode / Duration of timer 2+o: Clock-Trig-Pulse / 20 s

Period / Counts: 1440 min

Next start Time & Date: 10:30:00 January 31, 2002

Mode / Duration of timer 3+o: Repeated-Pulse / 2 s

Period / Counts: 6 s

Next Start time: ----

<< Back... >>

Picture 8-8: Listing of Timers' Configuration

It is possible to show the actual states of timers' inputs and outputs as well as the current counting to perform

the different timing functions.

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

Timers...

↓

States...

↓

- Timer States -

Offset (o): 0

Timer 1+o (In1/In2/Out): On/Off/Off

Count: 3

Timer 2+o (In1/In2/Out): Off/On/On

Count: 7

Timer 3+o (In1/In2/Out): Off/Off/ Off

Count: 3

Timer 4+o (In1/In2/Out): On/On/On

Count: 0

Timer 5+o (In1/In2/Out): Off/Off/Off

Count: 0

<< Back... >>

Picture 8-9: Display of Timers' States

LISTOFFSET

MENU1LINE

MENU2LINE

MENU3LINE

MENU4LINE

MENU5LINE

MENU6LINE

MENU7LINE

MENU8LINE

MENU9LINE

MENU10LINE

fct3: BACKVARS

fct4: ESCAPE

fct5: LOADVARS

LISTOFFSET

MENU1LINE

MENU2LINE

MENU3LINE

MENU4LINE

MENU5LINE

MENU6LINE

MENU7LINE

MENU8LINE

MENU9LINE

MENU10LINE

fct3: BACKVARS

fct4: ESCAPE

fct5: LOADVARS

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 22

Programmable Logic Control (PLC) on Control Module Level

8.4 Submenu 'Programming'

After having done the setup of the signals and eventually necessary timers we can do the programming of PLC

algorithm itself. It is done in the submenu 'Programming...".

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

Programming...

↓

-- Programming --

Program offset (o): 0

Step (o+1): -2

Step (o+2): 67

Step (o+3): -4

Step (o+4): -3

Step (o+5): 37

Step (o+6): -8

Step (o+7): 1

Step (o+8): -7

Step (o+9): 0

Step (o+10): 0

<< Back... >>

Picture 8-10: Programming the System PLC

If we want to assign the signals not by means of the menu but via LON variable access we have to be aware of

following:

1. The PLC-programming as well as the programming for the system calculator happens indirectly via the edit

variable-array ED_INTx.

To differ what the programming is for there exists the LON variable PROGTYP.

Setting PROGTYP = 0 means we want to program the system calculator.

Setting PROGTYP = 1 means we want to program the system PLC.

2. By using the variable LISTOFFSET we determine what part of the whole programming list we want to

program.

For example, setting LISTOFFSET = 60, means by usage of ED_INT1...ED_INT10 we are able to modify

the program steps 61...70.

LISTOFFSET

ED_INT1

ED_INT2

ED_INT3

ED_INT4

ED_INT5

ED_INT6

ED_INT7

ED_INT8

ED_INT9

ED_INT0

fct3: BACKVARS

fct4: ESCAPE

fct5: LOADVARS

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 23

Programmable Logic Control (PLC) on Control Module Level

8.5 Submenu 'Results'

The results of the PLC calculations can be observed in the submenu 'Results...".

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

Results...

↓

-- Results (1/2) --

PLC-Output-1: On

PLC-Output-2: Off

PLC-Output-3: Off

PLC-Output-4: Off

PLC-Output-5: Off

PLC-Output-6: Off

PLC-Output-7: Off

PLC-Output-8: On

PLC-Output-9: Off

PLC-Output-10: Off

Back... More...

Picture 8-11: Display of the System PLC Results

System configuration and diagnostics...

↓

System programmable logic control (PLC)...

↓

Results...

↓

More...

↓

-- Results (2/2) --

PLC-Output-11: On

PLC-Output-12: Off

PLC-Output-13: Off

PLC-Output-14: Off

PLC-Output-15: Off

Back... More...

PLCRESULT1

PLCRESULT2

PLCRESULT3

PLCRESULT4

PLCRESULT5

PLCRESULT6

PLCRESULT7

PLCRESULT8

PLCRESULT9

PLCRESULT10

fct4: ESCAPE

fct5: PLCRESULTS2

PLCRESULT11

PLCRESULT12

PLCRESULT13

PLCRESULT14

PLCRESULT15

HAS55E03IM11S(1) [NGA-e (TFID Software 3.7.x)] CM PLC Page 24

Programmable Logic Control (PLC) on Control Module Level

9 Applications

9.1 Stream Control with an active System Calibration

If the system calibration is in the 'sample gas state' we do not want to have only one sample gas stream flowing

but alternating 3 gas streams.

To realize this, we could use 2 timers which give us 3 different signal combinations. These 3 signal

combinations are evaluated in that way that for each combination one of the streams is switched on.

Timer1-Out Timer2-Out Stream 1 Stream 2 Stream 3

On On On Off Off

Off On Off On Off