Rosemount NGA 2000 TFID Hydrocarbon Analyzer Module SW 3.4 Software-1st Ed. Manuals & Guides

Instruction Manual

ETC00612

02/2001

Instruction Manual

Software Manual 3.4.x

Thermo Flame Ionization Detector

TFID Analyzer or Analyzer Module (combined with NGA 2000

Platform, MLT or CAT 200)

st

Edition 02/2001

1

www.EmersonProcess.com

TFID Software 3.4.x Instruction Manual

ETC00612

02/2001

ESSENTIAL INSTRUCTIONS

READ THIS P AGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and test s

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products

to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson Process Management (Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR W ARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical

shock and personal injury.

The information contained in this document is subject to change without notice. Misprints

reserved.

1st Edition 02/2001

© 2001 by Emerson Process Management

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Contents

1 Introduction 1 - 1

2 Menu Structure 2 - 1

3 Startup and Operation, General Notes and Main Menu 3 - 1

3.1 Starting and Initializing...................................................................................3 - 1

3.2 Display and Function......................................................................................3 - 2

3.3 "TAG" and Operating Keys ............................................................................ 3 - 2

3.4 Lines and Softkey Functionality ..................................................................... 3 - 3

3.5 Important Function Softkeys .......................................................................... 3 - 4

3.6 Entering/Changing of Variables ..................................................................... 3 - 5

3.7 Executing a Function......................................................................................3 - 6

3.8 Main Menu ..................................................................................................... 3 - 7

4 Analyzer Basic Controls (Calibration) and Setup 4 - 1

4.1 Analyzer Channel Status................................................................................4 - 3

4.1.1 Status Details

– e.g. Failures........................................................................ 4 - 5

– e.g. Acknowledge and Clear Failures.................................4 - 9

4.1.2 Current Operation Parameters (Analyzer Operation Settings)....................... 4 - 13

4.2 Single Component Display - Change of Channel........................................... 4 - 15

4.3 Multi Component Display - Change of Channel............................................. 4 - 17

4.4 Calibration Procedure Status.........................................................................4 - 19

4.5 Zero Calibration..............................................................................................4 - 21

4.6 Span Calibration/ Basic Parameters..............................................................4 - 25

4.7 Active Zero Gas, Span Gas, Sample Gas or Test Gas - Close all Valves ..... 4 - 29

4.8 Flow measurement.........................................................................................4 - 31

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 06/01

NGA 2000 I

5 Analyzer and I/O, Expert Controls & Setup 5 - 1

5.1 Analyzer Module Setup (or Controls)..............................................................5 - 3

5.1.1 Calibration Parameters...................................................................................5 - 5

– Span gases.........................................................................................5 - 6

– Tolerances ..........................................................................................5 - 8

– Calibration procedure setup................................................................5 - 10

– Time controlled calibration..................................................................5 - 13

– Calibration...........................................................................................5 - 15

– Advanced calibration methods............................................................5 - 18

– Zero Gases.........................................................................................5 - 20

5.1.2 Alarm Parameters...........................................................................................5 - 21

5.1.3 Range parameters..........................................................................................5 - 25

– Begin and end of ranges.....................................................................5 - 27

– Response times (t90) ...........................................................................5 - 28

– Autoranging control.............................................................................5 - 29

5.1.4 Cross Interference Compensation..................................................................5 - 31

5.1.5 Linearization...................................................................................................5 - 33

5.1.6 Programmable Logic Control (PLC)................................................................ 5 - 37

5.1.7 Programmable Calculator...............................................................................5 - 45

5.1.8 Measurement Display Configuration...............................................................5 - 49

5.1.9 Acknowledgement of Status Reports .............................................................5 - 53

5.1.10 Concentration Measurement Parameters.......................................................5 - 55

5.1.11 Concentration Peak Measurement.................................................................5 - 57

5.1.12 Differential Measurement ...............................................................................5 - 59

5.1.13 Gasflow Setup................................................................................................5 - 61

5.1.14 Pressure Compensation.................................................................................5 - 62

5.1.15 Flow Measurement.........................................................................................5 - 64

5.1.16 Temperature Measurement............................................................................5 - 65

5.1.17 Load/Save Analyzer Module Configuration ....................................................5 - 66

5.1.18 Inputs and Outputs (Local SIO/DIO)...............................................................5 - 69

– Local SIO .............................................................................5 - 70

– Local DIO .............................................................................5 - 76

– Signal codes .............................................................................5 - 77

5.1.19 Delay and Average.........................................................................................5 - 81

5.1.20 Special Functions...........................................................................................5 - 83

5.1.21 AK-Protocol Communication ..........................................................................5 - 84

II NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 06/01

5.2 I/O Module Controls (System or CM SIO/DIO).............................................5 - 85

5.2.1 SIO Module..................................................................................................5 - 86

– Analog output setup.................................................................5 - 87

– Serial interface setup ...............................................................5 - 91

– Configuration of Relay Outputs................................................5 - 92

5.2.2 DIO Module(s).............................................................................................. 5 - 95

– Configuration of the 8 DIO module inputs................................ 5 - 96

– Configuration of the 24 DIO module outputs............................5 - 98

5.3 I/O Module Setup (Network I/O Modules)....................................................5 - 101

6 System Configuration and Diagnostics 6 - 1

6.1 Diagnostic Menus...........................................................................................6 - 3

6.1.1 Control Module Diagnostics................................................................. 6 - 4

6.1.2 Analyzer Module Diagnostics..............................................................6 - 5

6.2 Load/Save Module Configuration................................................................... 6 - 6

6.3 Date and Time ...............................................................................................6 - 7

6.4 Security Codes............................................................................................... 6 - 8

6.5 Network Module Binding................................................................................6 - 10

6.6 System Reset................................................................................................. 6 - 12

7 Display Controls 7 - 1

Supplement:

System Calibration

Tables:

Response factors

Conversion factors ppm ↔↔↔↔ mg/Nm³

Index

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 06/01

NGA 2000 III

1 Introduction

This software manual describes step by step how to operate successfully with the

NGA 2000 Series 19" TFID (Thermo-FID) analyzer modules and analyzers.

Chapter 2 shows the TFID software menu structure. Chapter 3 describes the analyzers

display and keyboard as well as the main menu and submenus. Chapter 4 describes the

basic controls incl. calibration with detaile d illustra tions. So you ca n easily comp are the

actual analyzer (module) display with the illustrations of this manual.

Chapter 5 describes the expert configurations of the analyzer module and of the I

utput Modules (I/O modules). Chapter 6 describes the system configuration and

O

nput/

diagnostics. The layout of both chapters is not as detailed as of chapter four. By default,

the way through the menus is described giving the menu lines you have to enter

sequentially to reach a specific menu within the TFID software . At the end of this

description you will find an illustration of the final submenu screen followed by set up

instructions and explanations of functions and variables of each expert or system

configuration menu. Chapter 7 will give you some information about the display controls.

Not all sections of Chapter 5 (expert configurations) are important for each operator.

Which section is of interest depends on the NGA 2000 configuration with reference to the

following components:

♦

Control Module CM

♦

Analyzer Module AM

♦

Input/Output Modules I/O's (SIO = Standard I/O, DIO = Digital I/O)

♦

Network I/O Modules Analog Output with 3 Alarms I/O, Auto Calibration I/O,

System Auto Calibration I/O

You can distinguish the following system units and SIO/DIO configurations:

System Unit SIO/DIO-Configuration

Section

Page

TFID analyzer module (AM):

•

without front panel,

i.e. without control unit

•

can be combined with a platform, a

MLT analyzer, a TFID analyzer or a

customer developed control unit

Platform (CM S oftware):

•

Control unit with front panel

•

Without measurement channels

TFID analyzer (CM plus TFID AM

software = TCA software):

•

Analyzer with front panel

•

CM and AM software in the same

analyzer, i.e. all functions of the

control unit and of the AM are

combined in one controller board

⇒

1 local SIO and 1 local DIO (or 2

local DIO’s) can be installed in the

TFID/MLT analyzer module

⇒

SIO and DIO can be configured

for the MLT AM channels or the

TFID analyzer module only

⇒

1 SIO and up to 4 DIO's can be

installed in the platform (CM I/O)

⇒

SIO and DIO can be configured

for all MLT channels % AM’s

combined with the platform

⇒

1 SIO and 1 DIO (or 2 DIO’s) can

be installed in the TFID/MLT

analyzer (CM I/O)

⇒

SIO and DIO can be configured

for all MLT channels and AM’s

combined with the TFID/MLT

analyzer

∗ 5.1.18

p. 5-69

∗ 5.2

p. 5-85

∗ 5.2

p. 5-85

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

1 - 1

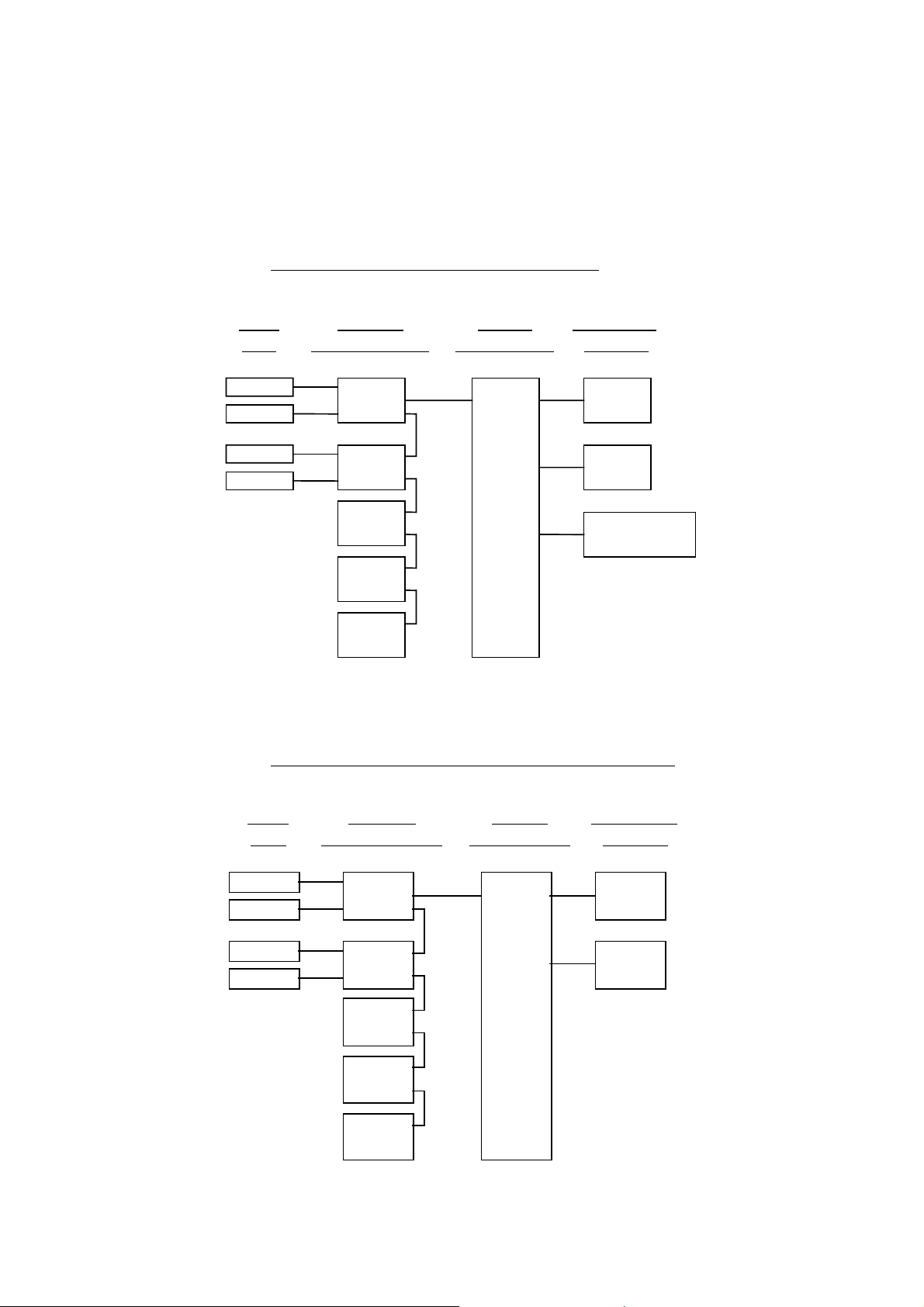

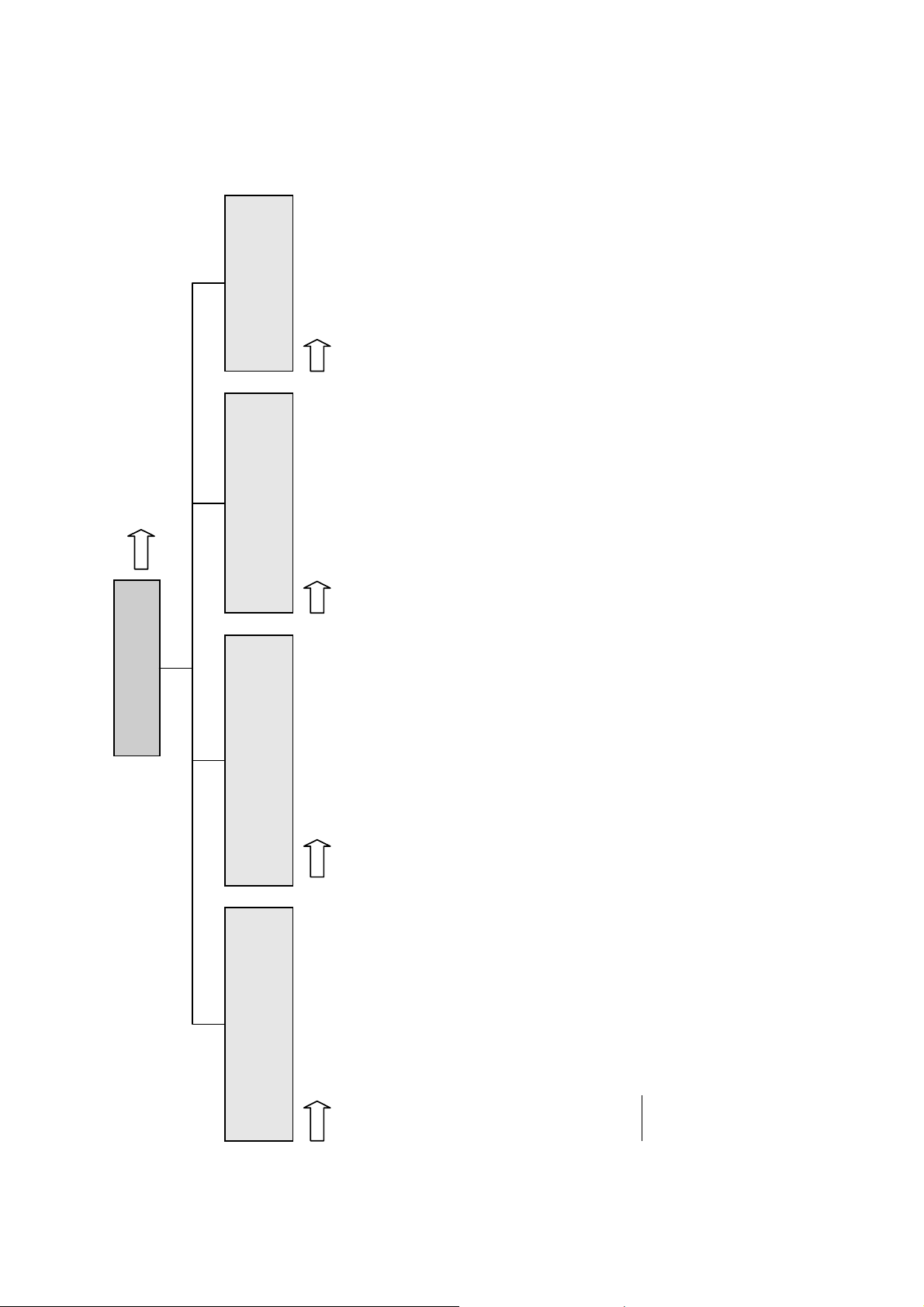

The following illustrations explain the relationship between the hardware configuration and

A

the software setup of the modules:

NGA 2000 System containing a Platform

(see 5.1.18)

(see 5.1.18)

Local

I/O's

SIO

nalyzer

Modules (AM's)

Control

Module (CM)

System I/O

TFID

DIO

SIO

MLT

DIO

(additional

manuals)

(additional

manuals)

(additional

manuals)

CLD

Platform

PMD

FID

NG A 2000 Sy stem containing an TFID Analyzer

Modules

1 SIO

4 DIO's

max.

Network I/O

(see 5.2.1)

(see 5.2.2)

(see 5.1.18)

(see 5.1.18)

Local

I/O's

SI O

DIO

SI O

DIO

(additional

manuals)

(additional

manuals)

(additional

manuals)

Analyzer

Modules (AM's)

TFID

MLT

CLD

PMD

FID

Control

Module (CM)

System I/O

Modules

1 SIO

(see 5.2.1)

1 DIO

(see 5.2.2)

TFID Analyzer

1 - 2

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

1 Introduction

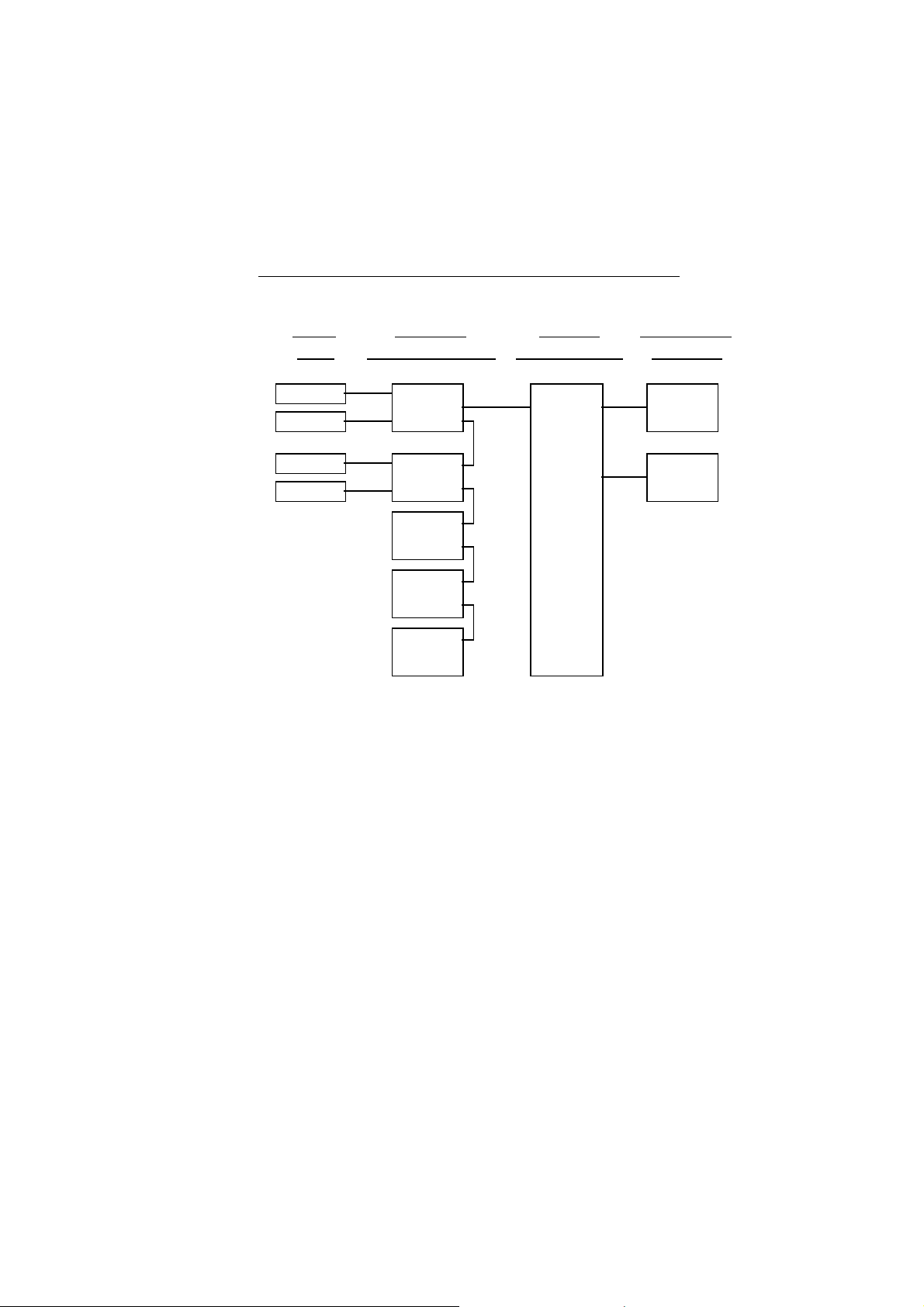

NGA 20 0 0 Sys te m co nt aining an ML T Ana ly zer

Local

I/O's

(see 5.1.18)

(see 5.1.18)

SIO

DIO

SIO

DIO

(additi onal

manuals)

(additi onal

manuals)

(additi onal

manuals)

Note:

This software manual describes the software of all TFID analyzers and TFID analyzer

modules combined with a platform, an FTID analyzer or an MLT analyzer.

It will not describe the software of TFID analyzer modules running at a customer control

unit.

The software of MLT analyzers / MLT analyzer modules is nearly identically to the TFID

software. An separate software manual is available containing the MLT specific functions.

Analyzer

Mod u le s (AM's)

MLT

TFID

CLD

PMD

FID

Control

Mod u le (CM)

MLT Analyzer

System I/O

Modules

1 SIO

1 DIO

( see 5. 2 .1)

( see 5. 2 .2)

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

1 - 3

1 - 4

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

2 Menu Structure

Section 3.8

System configuration

Main Menu

Analyzer and I/O, expert

Display controls...

- Brightness:

- Contrast:

(CM)

to "Measure" after

- Switch automatically

...

and diagnostics...

(AM, CM, network I/O's)

- System calibration...

- Diagnostic menus...

local SIO/DIO)

incl.

(CM/MCA)

- Load/save configuration

controls & setup...

(AM

- Analyzer module controls...

(System I/O's: SIO, DIO)

module controls...

- System & network I/O

(CM)

(Lock any level)

- Security codes (PIN)...

- Date and time...

like

controls)

MLT/TFID

for

analyzer module

(AM:

- Analyzer module setup...

(CM)

(CM)

(AM, CM, I/O's: SIO, DIO etc.)

- Network module managment...

- System reset...

- System tag:

(Network I/O's)

module setup...

- System & network I/O

(calibration) & setup...

Analyzer basic controls

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

Section 4 Section 5 Section 6 Section 7

- Flow zero gas!

- Calibration procedure state...

- Start zero calibration procedure!

- Start span calibration procedure!

- Check calibration deviation:

- Range number:

- Span gas:

- Range upper limit:

NGA 2000

- Flow span gas!

- Valves => F5:

- Flow sample gas!

- Flow test gas!

- Close all valves!

Notes:

the function, lines ending with ":" display module parameters - some can be changed.

* All setups in the menu "Analyzer basic controls (calibration) & setup" are valid for the analyzer or analyzer module (AM).

* Menu lines ending with three points (...) are followed by submenus with further functions and setups, lines ending with "!" allow to start

you can find which functionality will be setup:

AM (A nalyzer Module), CM (C ontrol Module), local, system or network I/O (Input/Output Module).

* At each menu point of the "Analyzer and I/O, expert controls & setup" and "System configuration and diagnostics"

2 - 1

2 - 2

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

3

A

Startup and Operation, General Notes and Main Menu

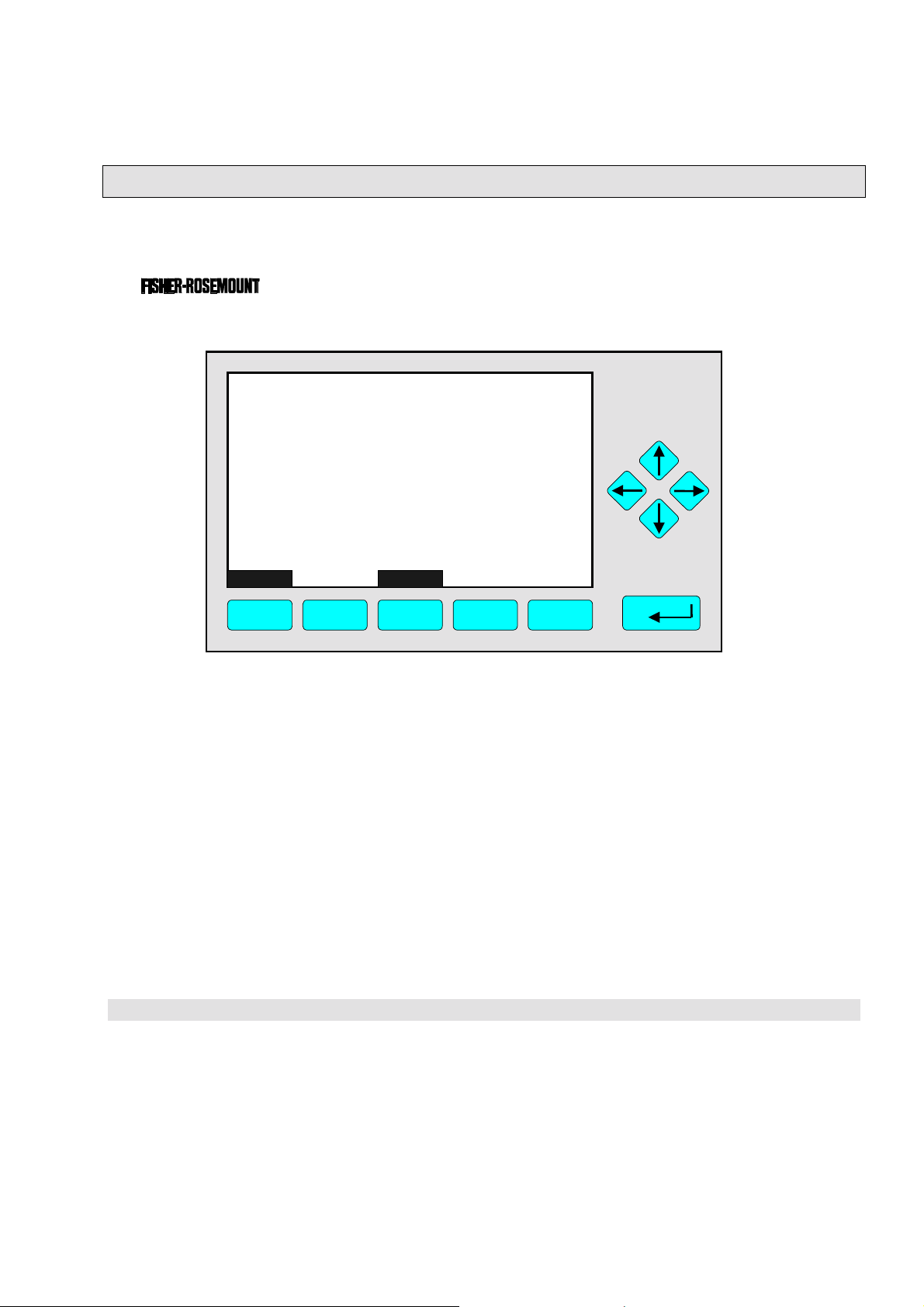

3.1 Starting and Initializing (Refer to the operation manual, too !)

After switching on the TFID analyzer / analyzer module ( as part of a NGA network), the

initialization procedure will be performed. . A self test is started showing a sequence of

several screens with information about the initialization status, software revision notes and

the

tag:

(C) 2000 FISHER-ROSEMOUNT Analytical

NGA-2000 Control-Module Rev. 3.4 /P010

LCDReset

F1 F2 F3 F4 F5

Language:P010/01/00

Initializing Network

Initializing network interface

bort

The network is initialized while the screen shows the messages “Initializing network

interface” , “ Searching for nodes” and “Calculating binds”.

If you press the F1-key during the initializing, you will reset the LCD brightness and

contrast to factory settings (see also section 7). Pressing the F3-key will abort the

network initializing. There will be no connection to any analyzer module. Only the control

module menus (platform or TFID analyzer) will be available.

At the end of the initializing procedure you can see the single component display of

channel one (see illustration on next page). It is the starting point to all the other channel

displays, menus and submenus.

The instructions of the basic controls (chapter four) are all beginning at the single component display. Since this screen is customer configurable the actual analyzer display

might differ from the one shown in this manual (see section 5.1.8 pg. 5-49 and section 7).

ETC00612(1) [NGA-e (TFID Software 3.4.X)] 06/01

NGA 2000

3 - 1

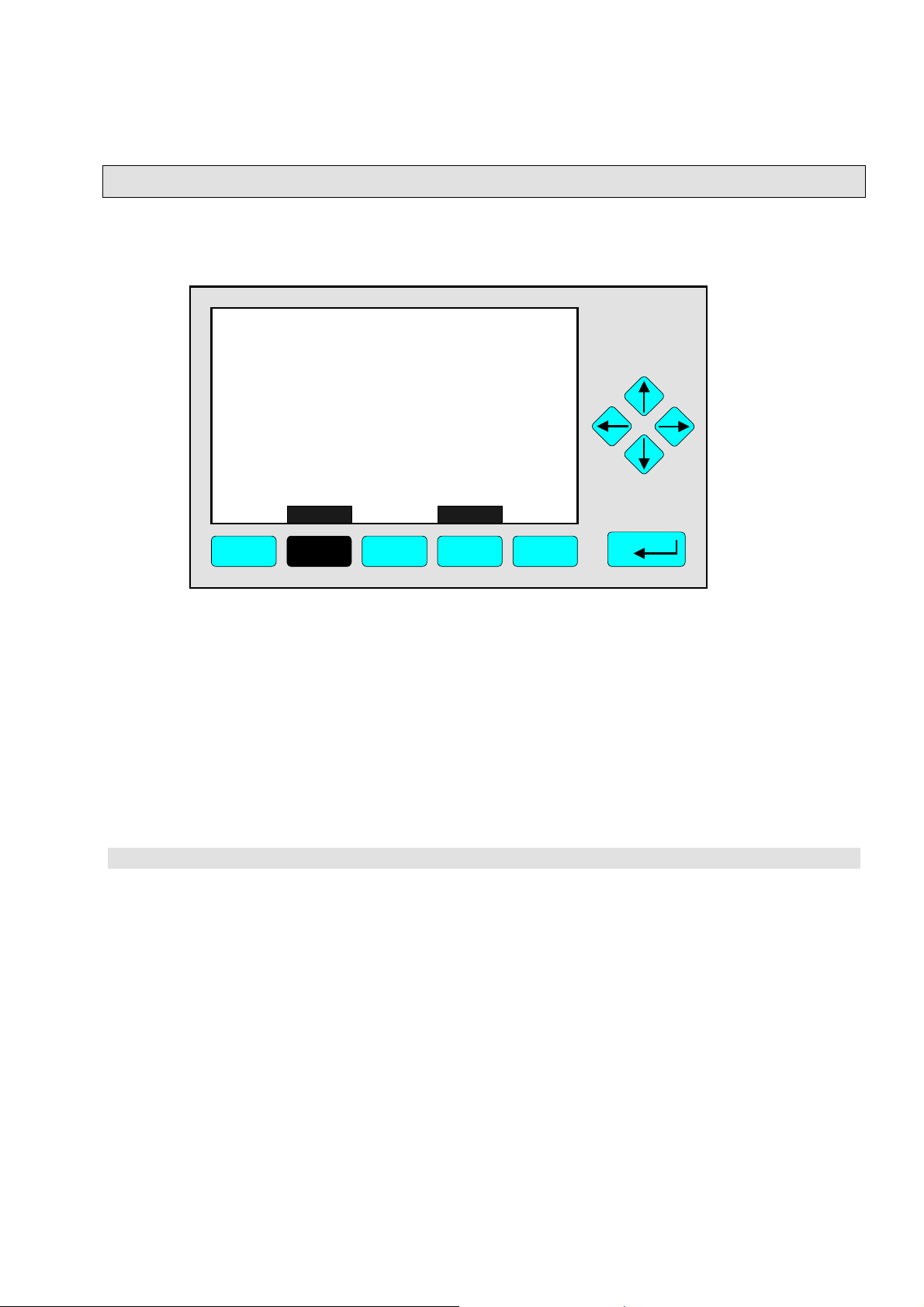

3.2 Display and Function

The LCD screen shows all analyzer measurement values and all customer instructions.

You can operate with five function keys, four arrow keys (cursors) and the enter key. The

function of each key depends on:

♦

the type of analyzer/analyzer module used

♦

the optional auxiliary modules (e.g. I/O boards) used

♦

the individual menu displayed

In case of power failure all customer specific module parameters are saved in a battery-

powered buffer.

3.3 "TAG" and Operating Keys

At the top left of each menu page you will find the tag of the current channel.

Typical tags:

♦ TFID/R1: T

♦

MLT/CH1/R1: MLT Analyzer or Analyzer Module / CHannel 1 / Range 1

By default screen dumps in this manual will show "TAG". Specific TFID menu pages will use

"TFID" instead to show this property.

hermo FID Analyzer or Analyzer Module / Range 1

TAG

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel

F1 F2 F3 F4 F5

Range: 1

0.0 100.0

BasicCal

Function Keys:

♦

Keys without defined function

♦

The current function depends on

the menu selected

♦

The softkey legend is shown on

the display right above the key

Cursor keys:

↑↑↑↑ -key / ↓↓↓↓ -key:

♦

Line up / line down

within the same menu

♦

Alteration of numbers,

variables or digits

←←←← -key / →→→→ -key:

♦

Moving back/forth

between the pages of

a menu

♦

Selection of digits

♦

Start a selected

function

Enter Key:

♦

To confirm a previously entered value

(variable)

♦

To start a selected function

(alternative

♦

To enter a menu (via menu line)

: →→→→ -key)

3 - 2

NGA 2000

ETC00612(1) [NGA-e (TFID Software 3.4.X)] 06/01

3

p

w

Startup and Operation, General Notes and Main Menu

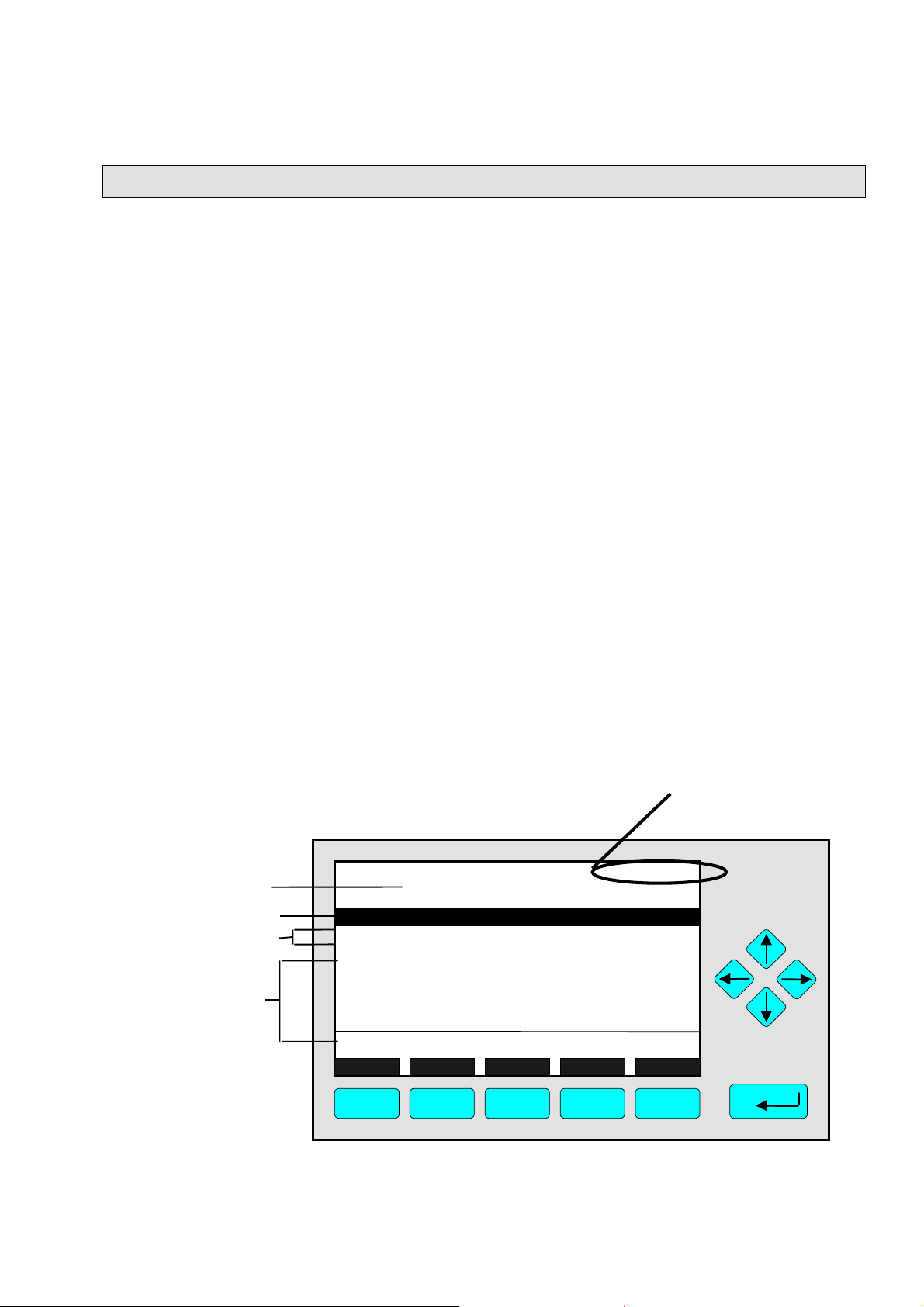

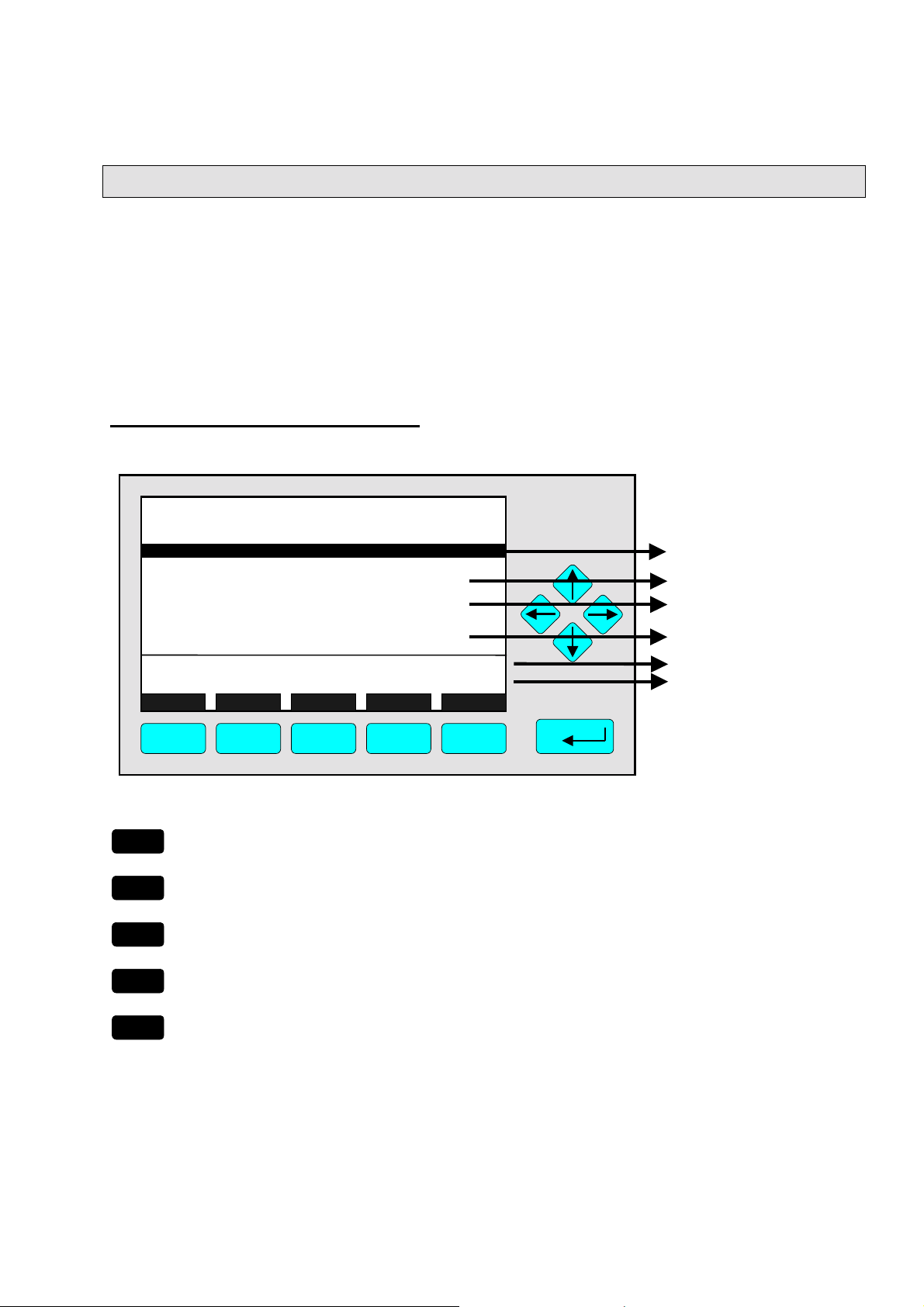

3.4 Lines and Softkey Functionality

Lines can be selected by using the ↓↓↓↓ -key or the ↑↑↑↑ -key. The selected line is displayed

white on black (highlighted). There are four different types of lines in the menus:

Menu line... / Menu Softkey...

♦

Line/Softkey description ending with three dots.

♦

You will enter a submenu/next menu by pressing the softkey resp. by pressing the

↵↵↵↵

-key or the →→→→ -key while the menu line is highlighted.

Function line / Function Softkey !

♦

Line/Softkey description ending with an exclamation-mark.

♦

You will start a function (e.g. calibration) by pressing the softkey resp. by pressing the

↵↵↵↵

-key or the →→→→ -key while function line is highlighted.

Line of variables:

♦

Line ending with a colon.

♦

View module parameters (variables).

♦

Some parameters can be changed (e.g. begin of range). Other parameters showing a

status (e.g. temperature) are for information only and cannot be changed. They are

displayed below a separation line within the menu.

Text line

♦

Line without any punctuation marks.

♦

Giving additional information only (such as headlines a.s.o.).

The following illustrations explain the function of lines and softkeys as described above:

Current channel measurement signal (see TAG).

It is always shown on the single component display.

Menu Headline

Menu Line

Function Lines

Lines of Variables

(The last one can not

be changed – belo

the separation line)

TAG

-- Basic Controls and Setup --

Calibration procedure status...

Start zero calibration procedure!

Start s

Check calibration deviation:

Range number:

Span gas: 100 ppm

Range upper limit: 100 ppm

Operation status: Ready

an calibration procedure!

Measure Status... Channel Back...

37.50 ppm

Enabled

1

Valves...

F1 F2 F3 F4 F5

ETC00612(1) [NGA-e (TFID Software 3.4.X)] 06/01

NGA 2000

3 - 3

TAG

Text Line

-- Calibr ation Pr oc edure State --

Proc edure state:

Maximum rema in ing procedure time :

Valve position:

Concent ration in span gas units:

Last zero calibration:

Last span calibrati on:

Last zero calibration was:

Last spa n cal ibra t ion was:

Succ essful zero+span ca libr ated ranges:

Measure Cancel !

F1 F2 F3 F4 F5

Function Softkey

3.5 Important Function Softkeys

Channel

37.50 ppm

Ready

Samplegas

37.50 ppm

Success

Success

1+2+3+4

More...

Fr i 05-29-1998 13:32:0 6

Fr i 05-29-1998 13:37:2 3

Back...

Menu Softkeys

0 s

Display

♦

Switch from the single component display to the multi component display.

♦

F1 in the single component display.

Measure

♦

Switch from any menu or submenu to the single component display of the selected

channel.

♦

F1 in any screen except the single component display.

Status (see section 4.1 page 4-3!)

♦

Switch to the menu "Analyzer Channel Status":

Shows the most important parameters and information about the status of the current

channel or module.

♦

If available: F2.

Main (see section 3.8 page 3-7!)

♦

Switch from the single component display to the main menu.

♦

F3 in the single component display.

Channel

♦

Scroll through the channels in the current menu. In the main menu and the single

component display you may scroll through all channels of the connected analyzer /

analyzer modules. In submenus this key is without function although it is displayed (only

activated in MLT software). TFID is a single channel analyzer or AM only!

♦

If available: F3 (F4 in the single component display).

3 - 4

NGA 2000

ETC00612(1) [NGA-e (TFID Software 3.4.X)] 06/01

3

Startup and Operation, General Notes and Main Menu

Lock

♦

Lock all three operation levels at the main menu if a security code is activated in the

system configuration and diagnostic menu (see section 6.4 pg. 6-8).

♦

F4 in the main menu.

BasicCal (see section 4.4 pg. 4-19 and 5.1.1 pg. 5-15!)

♦

Switch from the single component display to the menu "Analyzer module calibration".

♦

F5 in the single component display.

MFG Data (see section 3.8 pg. 3-7/8!)

♦

Switch from the main menu to the menu "Module Manufacturing Data":

Additional submenus are available with information about the control module and

analyzer module data, such as manufacturer address , modules serial numbers or

software and hardware revisions.

♦

F5 in the main menu.

Back

♦

Return to the previous menu page (alternative: ←←←← -key)

♦

reset a changed but not confirmed parameter to the previous value.

♦

If available: F4 for returning back, F2 for reset.

More

♦

Entering the next page of the current menu.

♦

If available: F5.

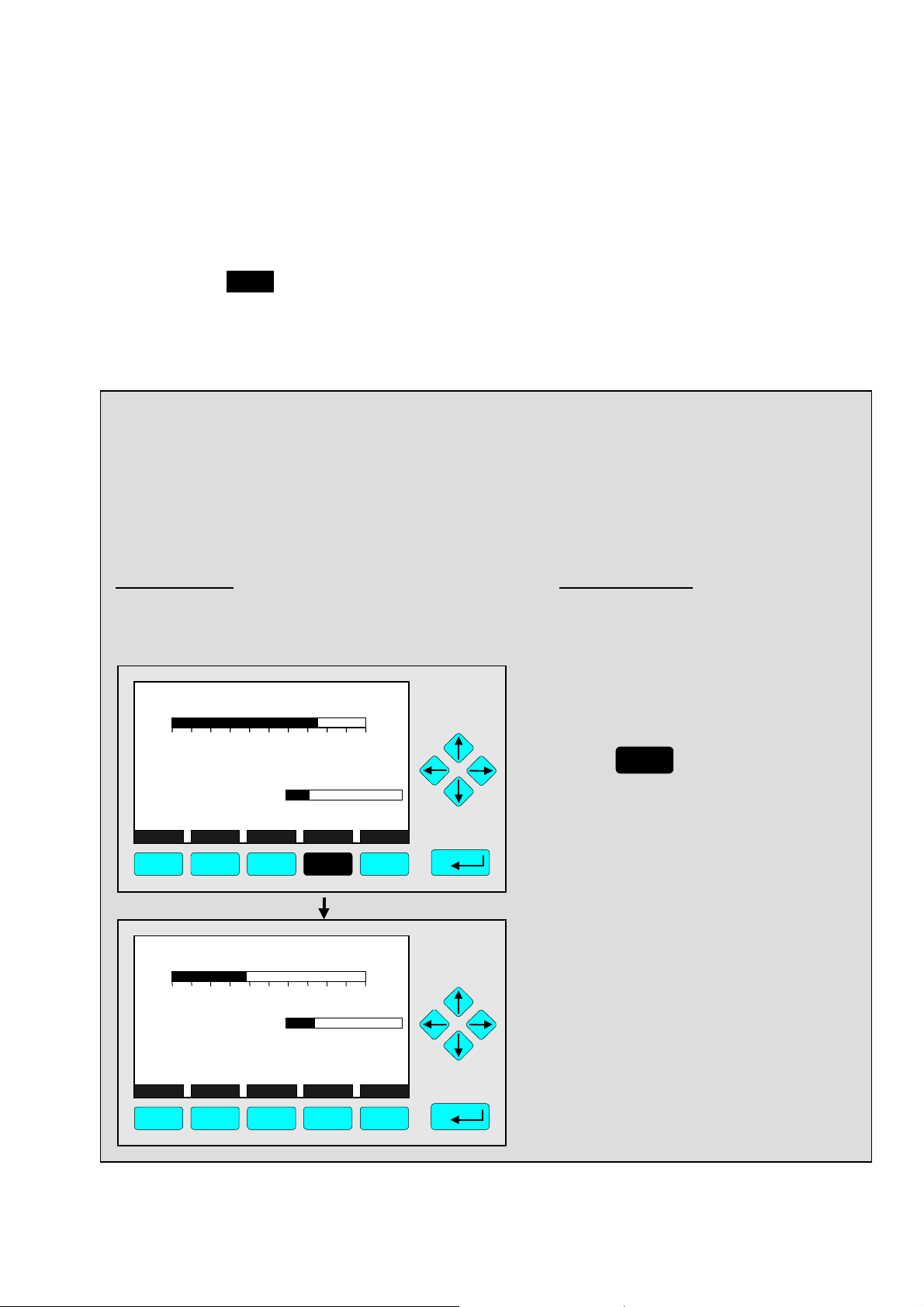

3.6 Entering/Changing Variables

↵↵↵↵

-key

♦

If you have already selected a line of variables (highlighted) and press the

↵↵↵↵

-key, the

parameter will be selected and may be edited.

↵↵↵↵

If you press the

-key again, the new value will be confirmed.

↑↑↑↑ -key / ↓↓↓↓ -key

♦

Function depends on the variable selected: - Changing the parameter values

- Scrolling among variables selecte d

- Changing single digits or characters

- Increasing or decreasing numbers.

←←←← -key / →→→→ -key

♦

Selects single digits within a number.

♦

The number of digits or characters of some variables may be changed.

ETC00612(1) [NGA-e (TFID Software 3.4.X)] 06/01

NGA 2000

3 - 5

3.7 Executing a Function

If you press the

↵↵↵↵

-key or the →→→→ - key while a functio n line is highligh ted the software will

ask for a confirmation:

TAG

-- Confirmation Required --

Do you really want to do this ??

Press "Yes" or "Back..."

Yes Back...

F1 F2 F3 F4 F5

37.50 ppm

♦

If you press the F2 -key the function will start imm e diately.

♦

Pressing the F4 -key will return to the previous menu page.

Note:

Confirmation of function line entries may be disabled:

♦

Select “Measurement Display Configuration” from the Analyzer and I/O, expert controls

& setup menu (see section 5.1.8, page 5-49).

♦

Change “Display confirmation menus” to “No”.

Now the selected function will start immediately after entering. No confirmation is

required.

3 - 6

NGA 2000

ETC00612(1) [NGA-e (TFID Software 3.4.X)] 06/01

3

Startup and Operation, General Notes and Main Menu

3.8 Main Menu

If you press the F3-key (Main...) or the →→→→-key in any single component display, you will

switch to the "Main Menu". From there you can switch to all operating levels of your

TFID/MLT analyzer / analyzer module to set up and control the parameters of

measurement, calibration and data transfer!

Via the F5-key (MFG Data) you may enter several submenus where you will find a lot of

important data about the control module (TFID/MLT analyzer / platform) and the analyzer

module, such as service address or serial number!

Ramifications from the Main Menu:

TAG

-- Main Menu --

Analyzer basic controls (calibration) & setup...

Analyzer and I/O, expert controls & setup...

System configuration and diagnostics...

Display controls...

Time & Date: 14:01:45 25 May 1999

System tag: Fisher-Rosemount

Measure Status... Channel Lock... MFG Data

F1 F2 F3 F4 F5

F1

F2

F3

Enter the current channel’s single component

display

Enter the current channel’s "Analyzer Channel

Status" menu.

Scroll through all channels of connected

analyzers / analyzer modules

95.00 ppm

☞

☞

☞

See chapter 4 !

See chapter 5 !

See chapter 6 !

See chapter 7 !

Setup: see 6.3 pg. 6-7

Factory setting

Section 3.1, pg. 3-1/2 !

Section 4.1, pg. 4-3 !

See channel tag !

F4

F5

Lock any operating level by security code

Enter the menu "Manufacturing Data"

ETC00612(1) [NGA-e (TFID Software 3.4.X)] 06/01

NGA 2000

☞

☞

Section 6.4, pg. 6-8 !

See next pages !

3 - 7

Ramifications from the menu "Manufacturing Data":

1. Control module data:

TAG

-- Manufacturing Da ta --

Control modul e manufac turing data...

Analyzer module manufacturing data.. .

Meas u re

F1

F2

<<<

F3

F4

Back...

95.00 ppm

TAG

(C) Copyright Fisher-Rosemount Analytical Inc., 2001

Manufactured by:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, CA 92807-1802 /USA

Tel: (714) 986-7600

FAX: (714) 577-8739

Measure Back...

F1 F2 F3 F4 F5

95.00 ppm

2. Analyzer module data:

>>>

F5

TAG

(C) Copyright Fisher-Rosemount GmbH & Co, 2001

Manufactured by:

Fisher-Rosemount GmbH & Co

Industriestrasse 1

D-63594 Hasselroth / Germany

Tel. (+49) 6055 884-0

FAX. (+49) 6055 884-209

Measure Or... Back... More...

F1 F2 F4 F5

F3

95.00 ppm

TAG

-- Control Module Version Information --

Serial number: CM 4711

Manufacturing date: 14.02.2001

Hardware revision: ACU02 R: 3.2.4, Final D:Jan 1

Software revision: 3.4/P010

Revision date: Nov 2 2000

Revision time: 16:09:49

Phrase dictionary version:

Language: English

Measure Back...

F1 F2 F3 F4 F5

95.00 ppm

P010/01/00

TAG

Control module data...

Analyzer module data...

Measure

F1 F2 F3 F4 F5

-- Module Manufacturing Data --

<<<

Back...

95.00 ppm

>>>

TAG

-- Analyzer Module Version Information --

Serial number: AM 4712

Manufacturing date: 14.02.2001

Hardware revision: ACU02 R: 3.2.4, Final D:Jan 1

Software revision: 3.4.1 / P010/Ch1

Revision date: Nov 2 2000

Revision time: 16:25:28

Measure Back...

F1 F2 F3 F4 F5

95.00 ppm

More...

TAG

(C) Copyright Fisher-Rosemount GmbH & Co, 2001

Manufactured by:

Fisher-Rosemount GmbH & Co

Industriestrasse 1

D-63594 Hasselroth / Germany

Tel. (+49) 6055 884-0

FAX. (+49) 6055 884-209

Measure Back... More...

F1 F2 F3 F4 F5

TAG

Measurement system: PSV-System

RAM-memory: 763296 Bytes

Local SIO module installed: Enabled

Serial interface adapter: RS-232

Heater installed: No

Local DIO module installed: 2

Sensor system revision:

Sensor system serial number:

Measure Back...

F1 F2 F3 F4 F5

-- Hardware Configuration --

Channel

95.00 ppm

95.00 ppm

04011999

311976

3 - 8

NGA 2000

ETC00612(1) [NGA-e (TFID Software 3.4.X)] 06/01

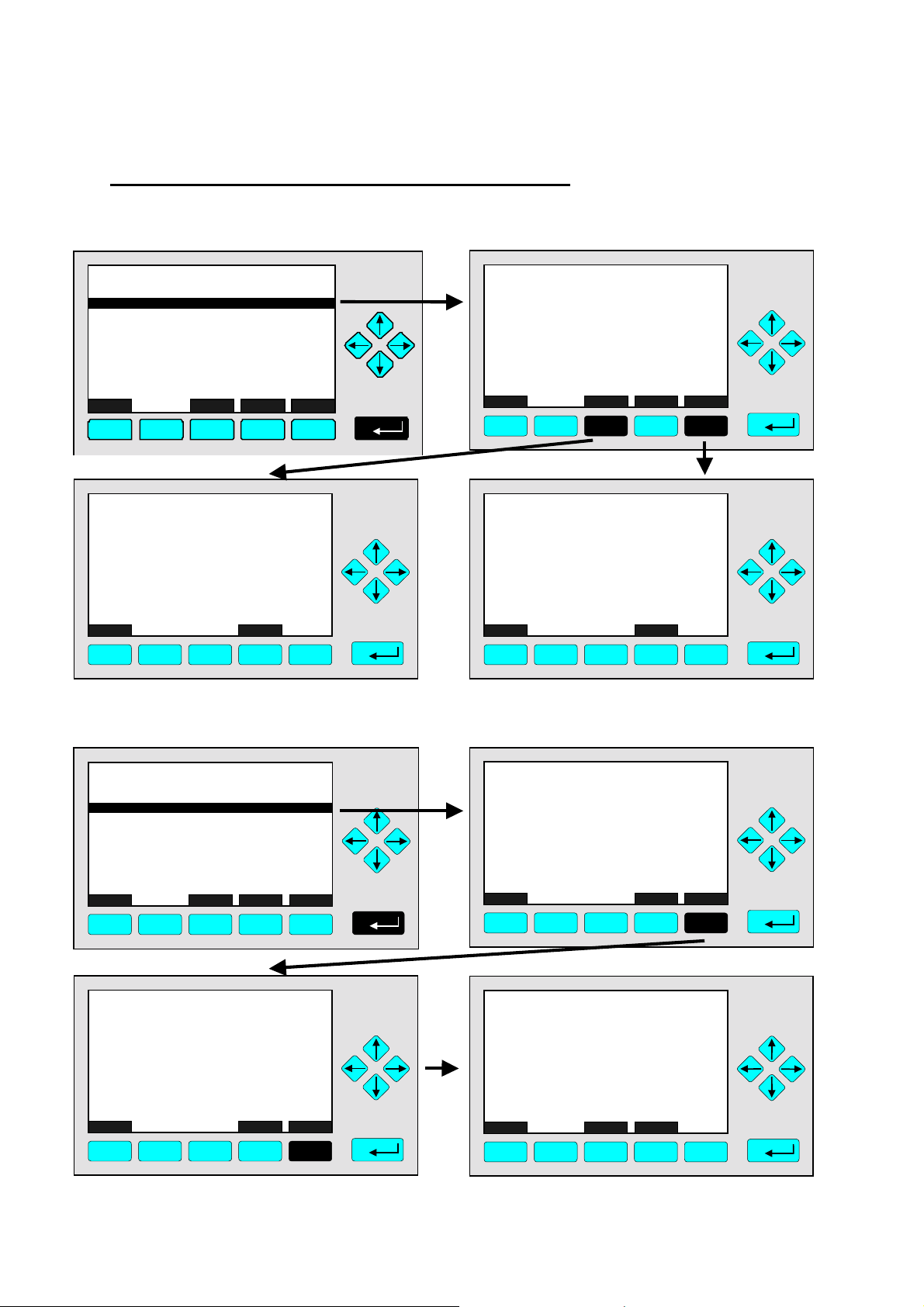

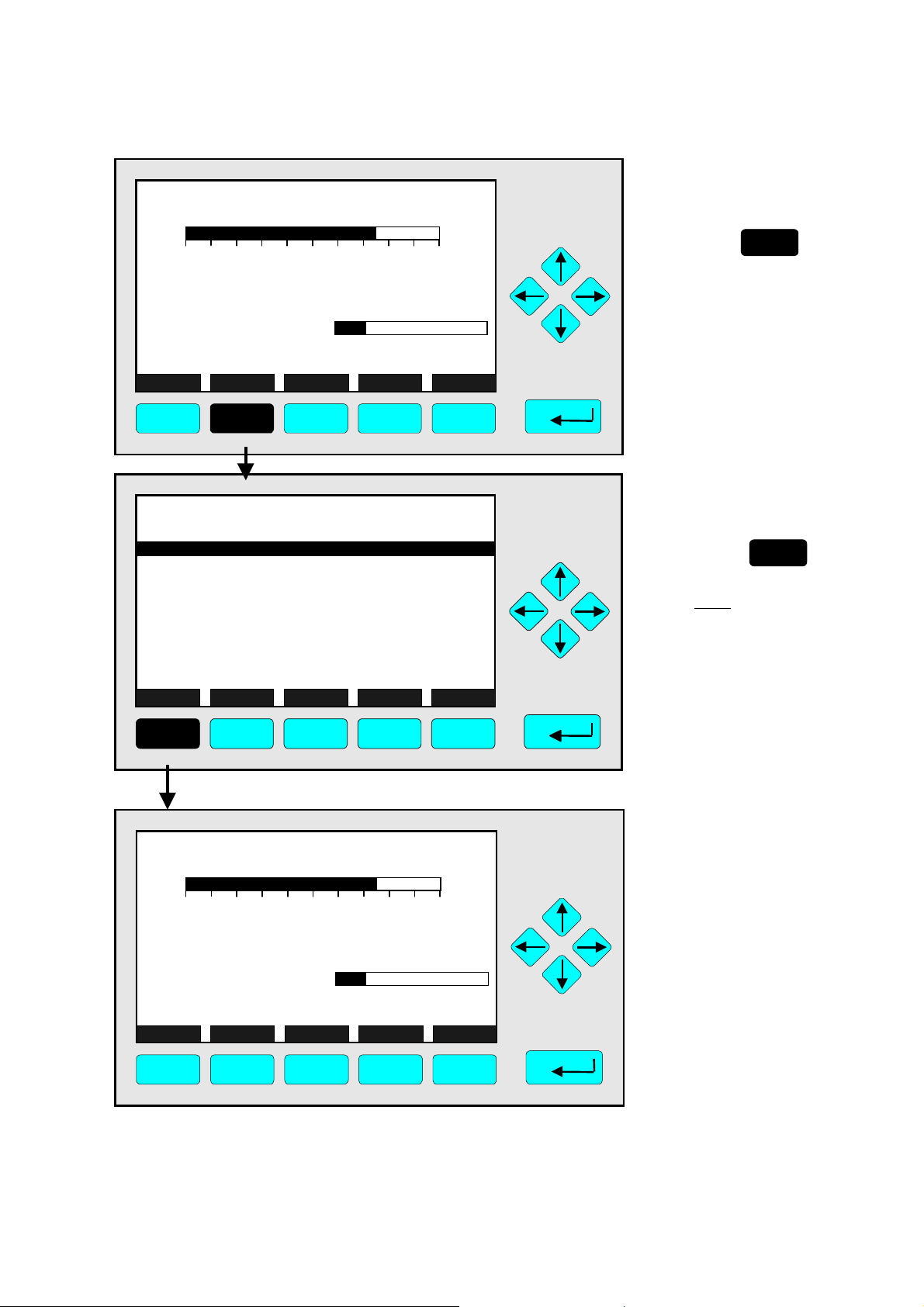

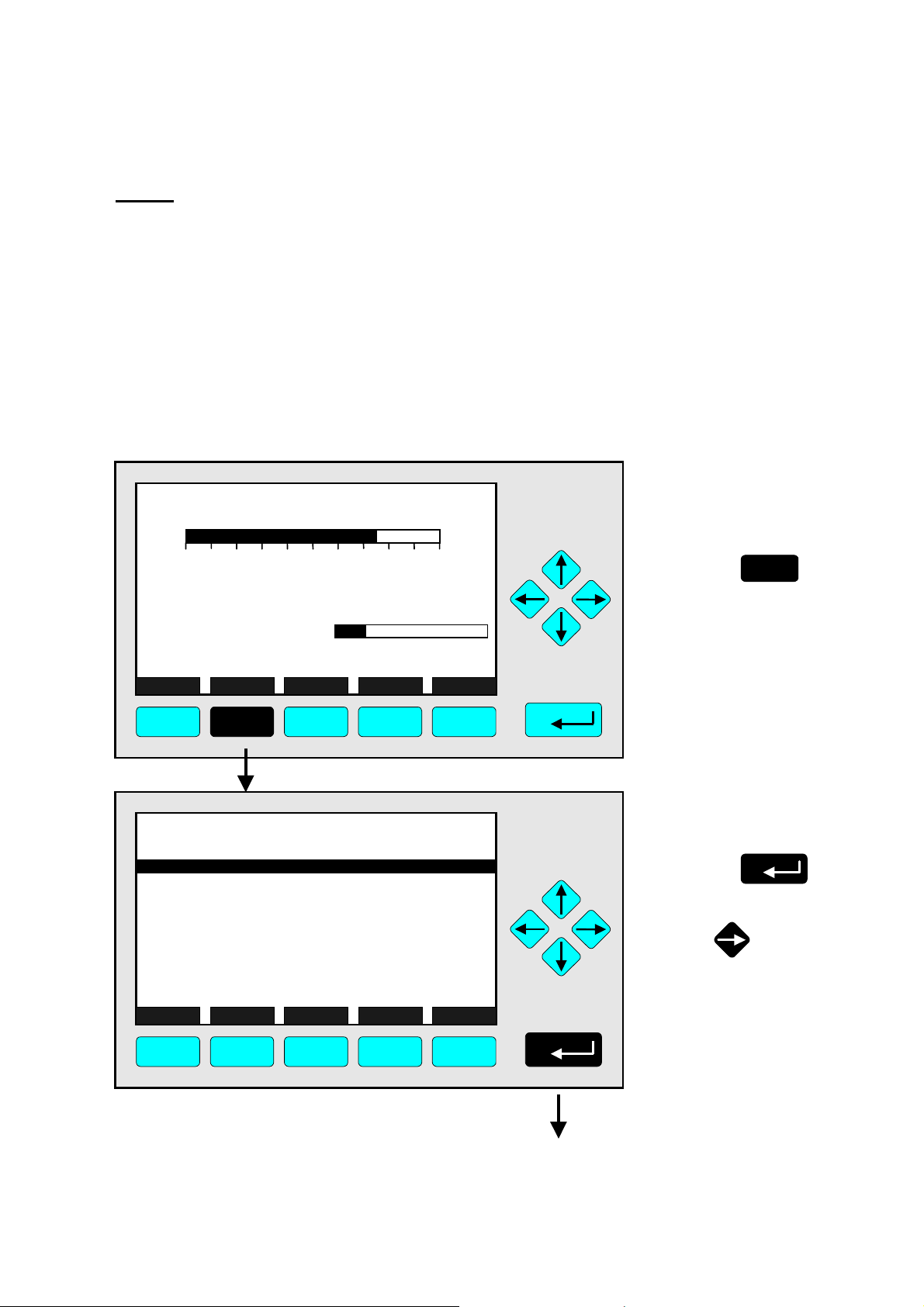

4 Analyzer Basic Controls (

Calibration) & Setup

Chapter 4 "Analyzer basic controls (calibration) & setup" describes the most important

measurement and calibration functions of your TFID/MLT analyzer / analyzer module.

All steps are figured with detailed illustrations and operation instructio ns. In the left column

you can see display and keyboard of the NGA front panel. The keys you have to press are

illustrated in black. In the right column you can read the instructions and notes. All

instructions will begin with any single component display and will end with the corresponding single component display after the setups are done. So you can easily compare the

actual display of the analyzer / analyzer module with the illustrations of this manual.

Example:

You want to change from the single component display of the TFID (propane) to the single

component display of the MLT channel 2 (CO).

• Picture one shows the starting situation: single component display of propane.

• Picture two shows the result you get if you press the F4 -key (Channel):

single component display of CO.

Left column: Right column:

Display and keyboard Instructions and notes

TFID-R1

37.50 ppm Propane

0.00 50.00

Failures: No

Maintenance- No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel BasisCal

F1 F2 F3 F4 F5

MLT25/CH2/R2

95.00 ppm CO

0 250Range: 2

Temperature: 25.0 C

MaintenanceAny_Alarms: No

Operation: Ready

Display Status... Main... Channel BasisCal

F1 F2 F3 F4 F5

Range: 1

0.0 100.0

0.0 100.0

No

⇒ Switch to the single

component display

of another channel

F4

Press

Notice the tag in the

display's upper left corner:

It changed fro m TFID to

MLT2 indicating a different

analyzer / analyzer module.

⇒ Next instruction

or step may be

entered.

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 1

4 - 2

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

TAG

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperat ure: 20.0 C

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

Range: 1

0.0 100.0

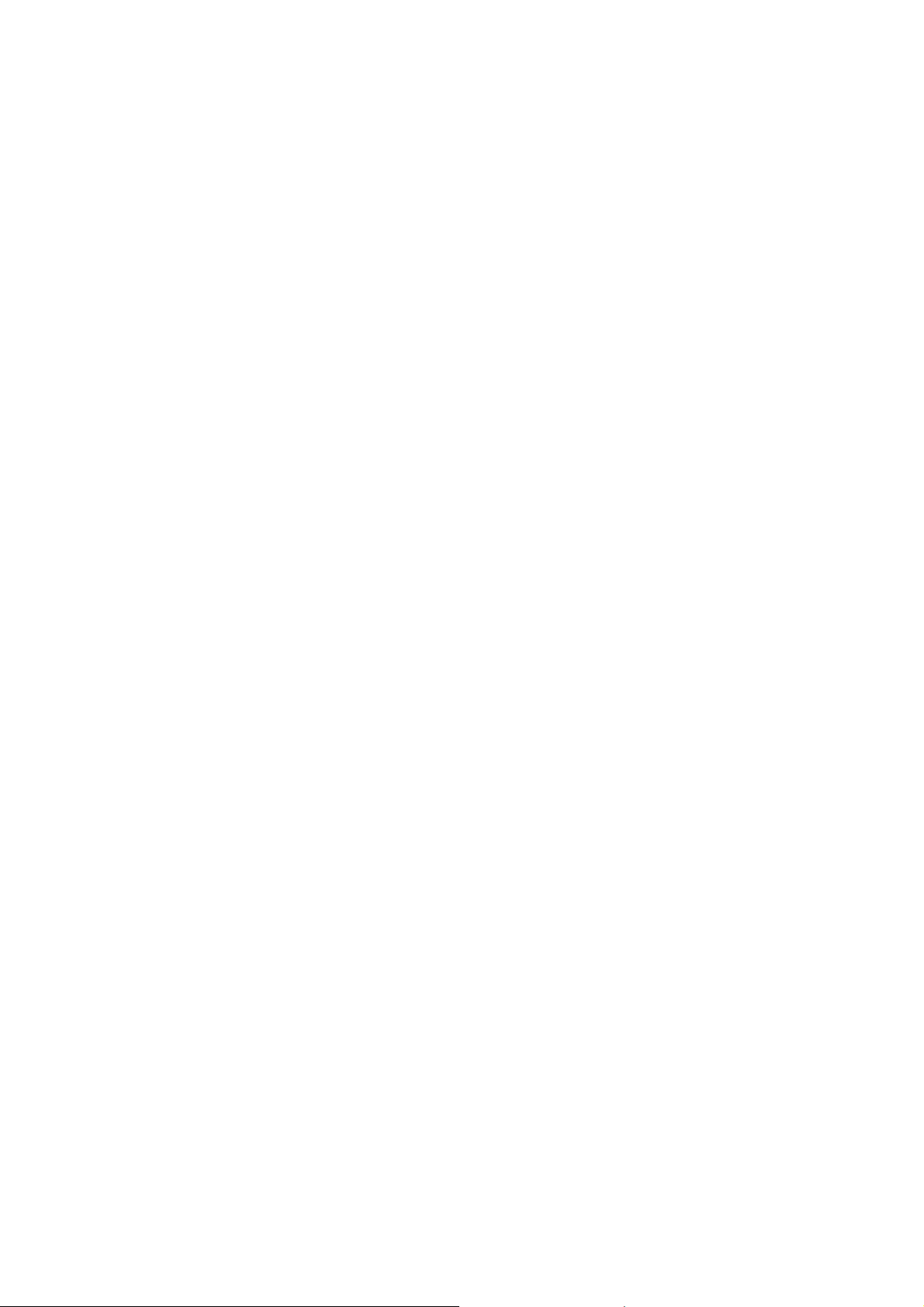

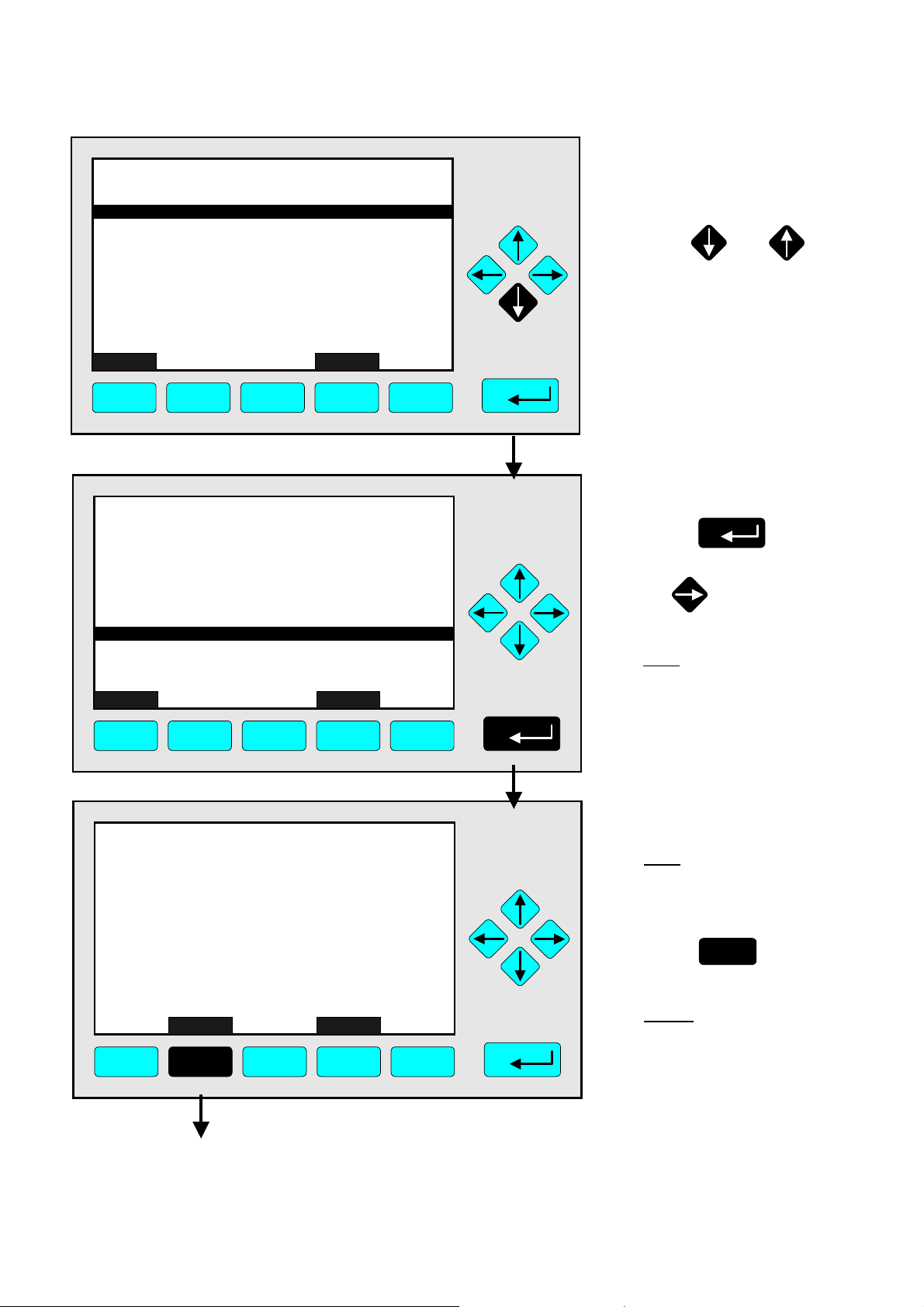

4.1 Analyzer Channel Status

⇒ Open the menu

"Analyzer Channel

Status"

F2

Press

The menu "Analyzer

Channel Status” displays

status information about

the current channel.

Use the menu lines

"Status details..." and

"Current operation

parameters..." to enter

submenus.

(see 4.1.1 pg. 4-5...11 and

4.1.2 pg. 4-13/14)

TAG

-- Analyzer Channel Status --

Status details...

Analyzer operation settings...

General status: Normal

Hours of operation: 164

Operation status: Ready

Events: No

Alarms: No

Failures: No

Maintenance requests: No

Function control/Service: No

Measure Channel Back...

RawMeas More...

37.50 ppm

F1 F2 F3 F4 F5

TAG

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperat ure: 20.0 C

Operation: Ready

Range: 1

0.0 100.0

⇒ Return to the single

component display

F1

Press

Note:

The F2 -key enters the

•

submenu “Primary raw

measurements” and

from there in a second

step using F5 to

”Secondary raw

measurements”.

Via the F5 -key you can

•

switch to submenu "TFID

Pressure & Temperature

Measurements".

⇒ Back in the single

component display

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 3

4 - 4

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

4.1.1 Analyzer Channel Status -

TAG

37.50 ppm C H 4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

TAG

-- Analyzer Channel Status --

Status details...

Analyzer operation settings...

General status: Normal

Hours of operation: 164

Operation status: Ready

Events: No

Alarms: No

Failures: No

Maintenance requests: No

Function control/Service: No

Measure Channel Back...

RawMeas More...

F1 F2 F3 F4 F5

Range: 1

0.0 100.0

37.50 ppm

Status Details

e.g. Failures

⇒ Open the menu

"Analyzer Channel

Status"

F2

Press

⇒ Enter the submenu

"Status Details"

Press

or

Note:

Use the way described

below to enter other submenus of status details:

Maintenance requests

•

Function controls

•

Alarms

•

Events

•

TAG

-- Status Details --

Failures...

Maintenance requests...

Function controls...

Alarms...

Events...

Acknowledge and clear failures !

Acknowledge and clear maintenance requests !

Acknowledge and clear function controls !

Measure Back...

F1 F2 F3 F4 F5

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

37.50 ppm

NGA 2000

⇒ Enter the menu "List of

Possible Failures (1/4)"

↵↵↵↵ -

or

key

4 - 5

Press

Note:

If you want to see other

available status details,

highlight the line you want

using the ↓↓↓↓- or ↑↑↑↑- key and enter

pressing the

TAG

-- List of Possible Failures (1/4) --

One or more f ai lures:

Hydrogen pre s sure too low:

No sourc e voltage:

Invalid inter ference compensat ion:

Sample gas pump #1 fail:

Sample gas pump #2 fail:

Detec tor temper ature too low:

Flame i s off:

Ignition cance le d:

Measure

Back...

37.50 ppm

More...

No

No

No

No

No

No

No

No

No

⇒ Enter the second

menu page

Press

F5

F1

TAG

External Input: No

Probe temperature too low: No

Probe temperature too high: No

Flame temperature sensor fail: No

Sample under pressure too high: N o

Capillary #1: No

Control of sample gas pump #1 fail: No

Sample gas pressure too high: No

Control of sample gas pump #2 fail: No

Measure Back... More...

F1 F2 F3 F4 F5

TAG

Sample gas (Filter/supply/under pressure): No

Capillary #3 or H2 supply: No

Detector signal communication failed: No

Power supply less than 23V: No

Air pressure less than 2.9 bar: No

Igniter broken: N o

Igniter short-circuit: No

Detector temperature sensor fail: No

Sensor temperature sensor fail: No

Ambient temperature too high: No

Measure Back... More...

F2

-- List of Possible Failures (2/4) --

-- List of Possible Failures (3/4) --

F3

F4

37.50 ppm

37.50 ppm

F5

⇒ Enter the

third menu page

F5

Press

⇒ Enter the

last menu page

F5

Press

F1 F2 F3 F4 F5

4 - 6

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

4.1.1 Analyzer Channel Status -

TAG

-- List of Possible Failures (4/4) --

Sample gas throttle closed: No

Burner gas throttle closed: No

Under pressure pump fail: No

Sample gas pump fail: No

Burner gas pump fail: No

Sample gas control valve fail: No

Burner gas control valve fail: No

Measure Back... (1/4)...

F1 F2 F3 F4 F5

37.50 ppm

Status Details

e.g. Failures

⇒ Return to the single

component display

F1

Press

TAG

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperat ure: 20. 0 C

Operation: Ready

Display Status... Main... Channel

F1 F2 F3 F4 F5

Range: 1

0.0 100.0

⇒ Back in the single

component display

of the current

channel

BasicCal

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 7

4 - 8

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

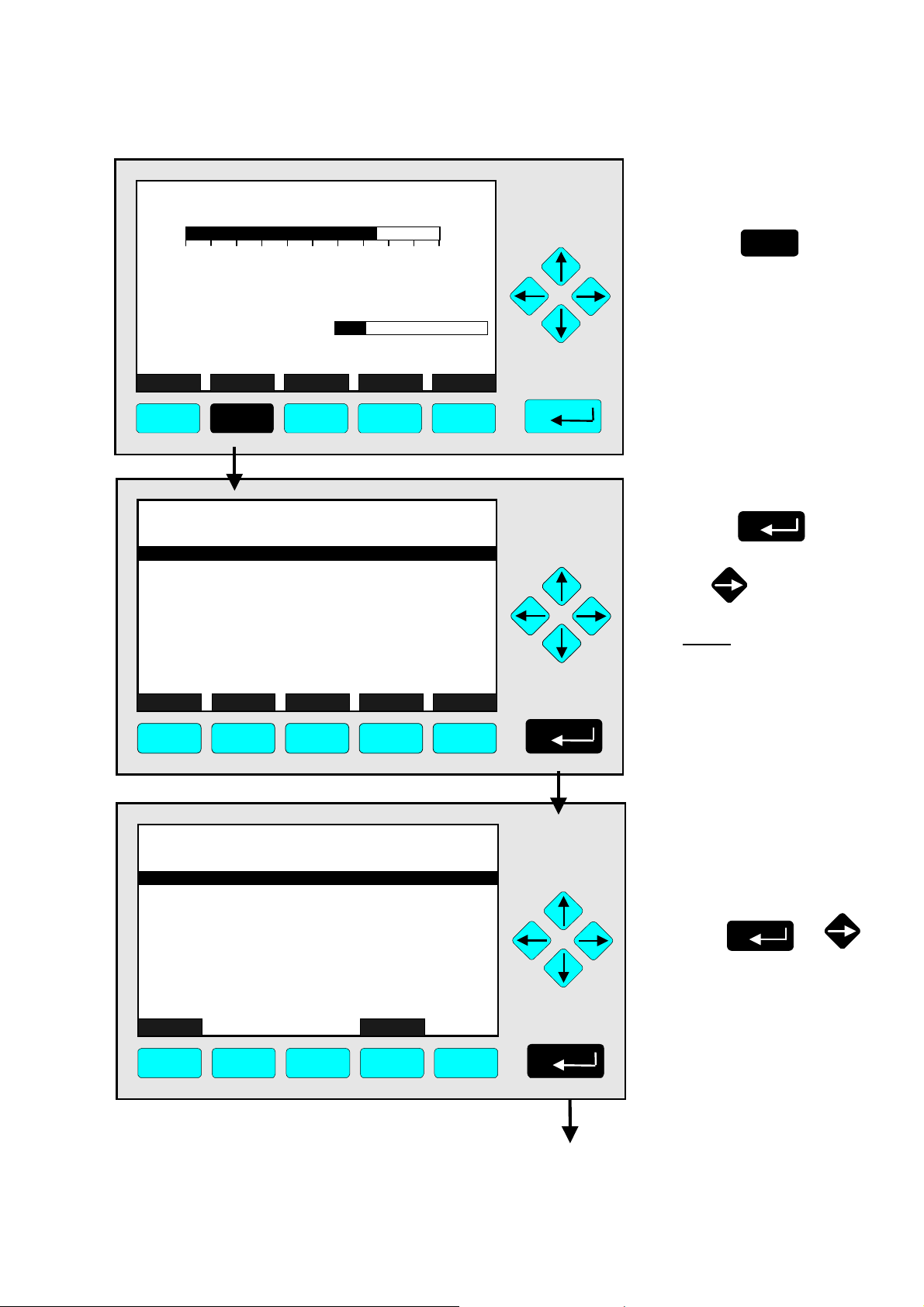

4.1.1 Analyzer Channel Status -

Status Details

e.g. Acknowledge and Clear Failures

Notes:

If you have solved the reasons for the failures reported, you should start this function.

•

The menu "List of Possible Failures" will be ready for new reports!

•

Starting this function is only possible if it is enabled in the menu "Acknowledgement of Status

•

Reports": The line "Acknowledgement allowed in status menu:" has to be set to "Yes"! (see 5.1.9,

pg. 5-53)

Use the same procedure as described below to start the other available functions in the menu

•

"Status Details":

- Acknowledge and clear maintenance requests!

- Acknowledge and clear function controls!

TAG

37.50 ppm CH4

0.00 50.00

Failures: Yes

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

TAG

-- Analyzer Channel Status --

Status details...

Current operation parameters...

General status: Normal

Hours of operation: 164

Operation status: Ready

Events: No

Alarms: No

Failures: No

Maintenance requests: No

Function control/Service: No

Measure Channel Back...

RawMeas More...

Range: 1

0.0 100.0

37.50 ppm

⇒ Switch to the menu

"Analyzer Channel

Status"

F2

Press

⇒ Enter the submenu

"Status Details"

Press

or

F1 F2 F3 F4 F5

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 9

TAG

-- Status Details --

Failures...

Maintenance requests...

Function controls...

Alarms...

Events...

Acknowledge and clear failures !

Acknowledge and clear maintenance requests !

Acknowledge and clear function controls !

Measure Back...

37.50 ppm

F1 F2 F3 F4 F5

TAG

-- Status Details --

Failures...

Maintenance requests...

Function controls...

Alarms...

Events...

Acknowledge and clear failures !

Acknowledge and clear maintenance requests !

Acknowledge and clear function controls !

Measure Back...

37.50 ppm

F1 F2 F3 F4 F5

⇒ Highlight the line

"Acknowledge and

clear failures !"

Press

or

as often as necessary

to get the menu line

"Acknowledge and clear

failures !" displayed

inverse.

⇒ Start the function

Press

or

Note:

Starting this function is only

possible if it is enabled in the

menu "Acknowledgment of

Status Reports"

(see 5.1.9 pg. 5-53) !

TAG

-- Confirmation Required --

Do you really want to do this ??

Press "Yes" or "Back..."

Yes Back...

37.50 ppm

F1 F2 F3 F4 F5

4 - 10

NGA 2000

⇒ Confirm the order

Note: Confirmation is only

requested if it is enabled in

menu the expert configurations (s. 5.1.8, pg. 5-49)

F2

Press

to start

the function immediately.

Option:

Press the F4 -key if you

want to cancel the order

and return to the menu

"Status Details".

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

4.1.1 Analyzer Channel Status -

TAG

- S U C C E S S -

- The selected function has been started/executed (Wait a moment...)

F1 F2 F3 F4 F5

37.50 ppm

Status Details

e.g. Acknowledge and Clear Failures

⇒ Execution message

appears

This message will be displayed when the function

has been started.

The display will return

automatically to the menu

"Status Details".

TAG

-- Status Details --

Failures...

Maintenance requests...

Function controls...

Alarms...

Events...

Acknowledge and clear failures !

Acknowledge and clear maintenance requests !

Acknowledge and clear function controls !

Measure Back...

F1 F2 F3 F4 F5

TAG

37.50 ppm

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Range: 1

0.0 100.0

⇒ Return to the single

component display

of the channel

selected

F1

Press

⇒ Back at the single

component display

of the current

channel after

clearing failures

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 11

4 - 12

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

TAG

Failures: No

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

TAG

Status details...

Analyzer operation setti ngs...

General status: Normal

Hours of operation: 164

Operation status: Ready

Events: No

Alarms: No

Failures: No

Maintenance requests: No

Function co ntrol/Service: No

Measure Channel Back...

F1 F2 F3 F4 F5

TAG

Status details...

Current operation settings...

General Status: Normal

Hours of operations: 164

Operation status: Ready

Events: No

Alarms: No

Failures: No

Maintenance requests: No

Function control/Service: No

Measure Channel Back...

F1 F2 F3 F4 F5

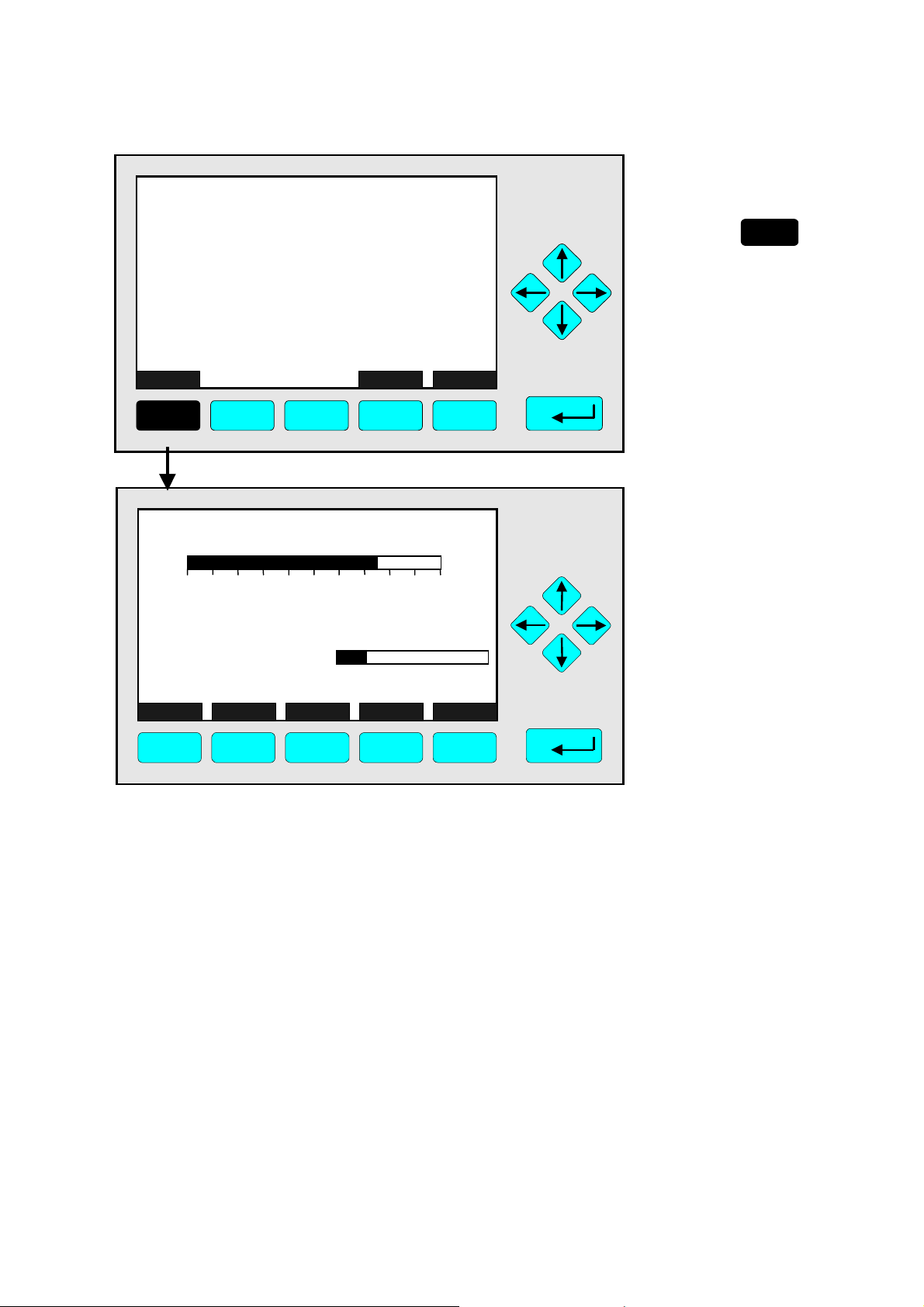

4.1.2 Analyzer Channel Status -Current

37.50 ppm CH4

0.00 50.00

-- Analyzer Channel Status --

RawMeas More...

-- Analyzer Channel Status --

RawMeas

Range: 1

0.0 100.0

37.50 ppm

37.50 ppm

More...

Operation Parameters

⇒ Switch to the menu

"Analyzer Channel

Status"

F2

Press

⇒ Select t he line

"Current operation

parameters..."

Press

once

to have the line "Current

operation parameters..."

highlighted.

⇒ Open the menu

"Analyzer

Operation Settings"

Press

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 13

TAG

-- Analyzer Oper ation Settings --

Remote control via serial port (AK): Enabled

Range and calibration control: Manual

Range: 1

Range upper limit: 50.00 ppm

Span gas concentration: 50.00 ppm

t90-time: 2.00 s

Hours of operation: 164

Last re-start occured: Fri 05-29-1998 15:32:00

Actual zero gas concentration: 0.00 ppm

Auto-start procedures...

Measure Channel Back...

F1 F2 F3 F4 F5

TAG

-- Auto-Start Procedures --

Position in auto-start list:

Channel tag: Procedure type:

Interval mode: Ne v er

Start time: Start date: -

Time & Date: 16:03:25 December 21, 1999

Measure Back...

F1 F2 F3 F4 F5

TAG

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 °C

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

Range: 1

0.0 100.0

37.50 ppm

37.50 ppm

⇒ Enter the submenu

"Auto-start

procedures"

Press

The menu

"Auto-Start Procedures"

enables you to view the

1

-

status of three different

time controlled

calibrations.

(see 5.1.1 pg. 5-13/14)

⇒ Return to the single

component display

⇒ Back at the single

component display

of the current

channel

4 - 14

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

TFID-R1

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 °C

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

MLT25/CH2/R2

95.00 ppm CO

0250

Temperature: 25.0 °C

Maintenance-Requests: No

Any_Alarms: No

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

TFID-R1

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 °C

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

Range: 1

0.0 100.0

Range: 2

0.0 100.0

Range: 1

0.0 100.0

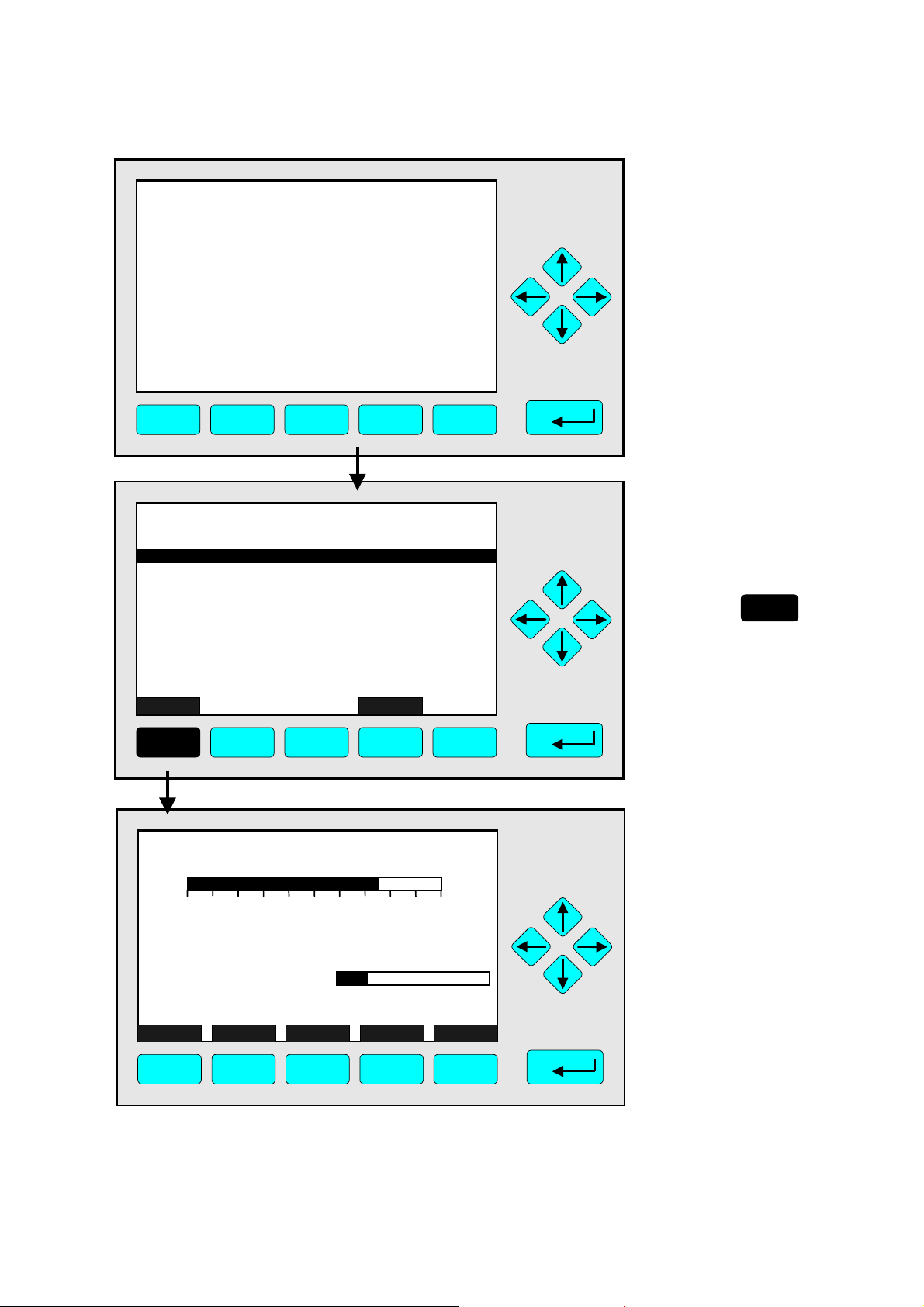

4.2 Single Component Display

Change of Channel

⇒ Switch to the single

component display

of another channel

F4

Press

Example:

Switching from

propane (TFID) to

CO (MLT channel 2)

Note:

Displaying another channel

is enabled only if the TFID

is connected to other

modules / analyzers.

⇒ Return to the single

component display

of the starting

channel

F4

Press

Note:

If there is more than one

channel connected to the

TFID, pressing F4 will

alternately display all

channels and return to the

first channel when the last

has been displayed.

⇒ Single component

display of the

starting channel

appears

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 15

4 - 16

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

TAG

37.50 ppm CH4

0.00 50.00

Range: 1

4.3 Multi Component Display

Change of Channel

⇒ Switch to the

multi component display

F1

Press

Failures: No

Maintenance-Requests: No

Temperature: 20.0 °C

Operation: Ready

Display Status... Main... Channel BasicCal

0.0 100.0

F1 F2 F3 F4 F5

Notes:

•

Displaying multiple

channels is only possible,

if the TFID is connected to

other modules / analyzers.

•

You can open the multi

component display from

any single component

display.

⇒ Enable the "selecting

37.50

95.00

333.0

150.0

20.00

Select Status... Tags Off

F1 F2 F3 F4 F5

TFID

ppm Propane

MLT25/CH1

ppm CO

MLT25/CH2

ppm SO2

MLT25/CH3

ppm NO

MLT25/CH4

%O2

[1]

0.00 250.00

0.00 500.00

0.00 150.00

0.00 100.00

[2]

[2]

[2] F.S.

[2]

LCDReset

50.000.00

symbol":

>

F1

Press

or

Notes:

•

Each bargraph shows the

start and endpoint of range

of the corresponding

channel. (F.S. = f

•

The number in paren-

ull scale)

theses shows the number

of the selected range.

Option:

Using the F3 -key you can

fade out or in the tags.

⇒ Select any channel

37.50

95.00

333.0

150.0

20.00

Select Status... Tags Off

F1 F2 F3 F4 F5

TFID

ppm Propane

MLT25/CH1

ppm CO

MLT25/CH2

ppm SO2

MLT25/CH3

ppm NO

MLT25/CH4

%O2

[1]

0.00 250.00

0.00 500.00

0.00 150.00

0.00 100.00

[2]

[2]

[2] F.S.

[2]

LCDReset

50.000.00

Press

as often as necessary to

place the

line you want to select.

Example:

Change from

CH

4

CO (MLT channel 1)

>

-mark at the

(TFID) to

or

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 17

37.50

95.00

333.0

150.0

20.00

Select Status... Tags Off

F1 F2 F3 F4 F5

TAG

TFID

ppm Propane

MLT25/CH1

ppm CO

MLT25/CH2

ppm SO2

MLT25/CH3

ppm NO

MLT25/CH4

%O2

[1]

0.00 250.00

0.00 500.00

0.00 150.00

0.00 100.00

[2]

[2]

[2] F.S.

[2]

95.00 ppm CO

0250

Temperature: 25.0 °C

Maintenance-Requests: No

Any_Alarms: No

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

Range: 2

0.0 100.0

50.000.00

LCDReset

⇒ Switch to the single

component display of

the selected channel

Press

F1

Note:

Pressing F5 resets the LCDbrightness and contrast to

factory default settings (see

also section 7).

⇒ Single component

display of the

selected channel

4 - 18

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

TAG

37.50 ppm CH4

0.00 50.00

Range: 1

4.4 Calibration Procedure Status

⇒ Open the

menu "Analyzer

Basic Controls

(calibration) &

Setup"

Failures: No

Maintenance-Requests: No

Temperature: 20.0 °C

Operation: Ready

Display Status... Main... Channel BasicCal

0.0 100.0

Press

F5

F1 F2 F3 F4 F5

⇒ Enter the submenu

TAG

-- Analyzer Basic Controls (calibration) and Setup --

Calibration procedure state...

Start zero calibration procedur e !

Start span calibration procedure !

Check calibration deviation: Enabled

Range number: 1

Span gas: 46.00 ppm

Range upper limit: 50.00 ppm

Operation status: Ready

Measure Status... Channel Back...

37.50 ppm

Valves...

F1 F2 F3 F4 F5

TAG

-- Calibration Procedure State --

Procedure state: Ready

Maximum remaining procedure time: 0 s

Valve position: Samplegas

Concentration in span gas units: 37.50 ppm

Last zero calibration: Success

Last span calibration: Success

Last zero calibration was: Fri 05-29-1998 13:32:06

Last span calibration was: Fri 05-29-1998 13:37:23

Successful zero+span calibrated

Measure Cancel ! Back... More...

37.50 ppm

1+2+3+4

F1 F2 F3 F4 F5

"Calibration

Procedure State"

Press

Options:

Softkey F5 opens a

submenu where you can

close all valves or set up

each valve separately for:

•

zero gas

•

span gas

•

sample gas

•

test gas.

(See section 4.7,

pg. 4-29...)

⇒ Open the menu page

"Calibration

Deviations"

Press

F5

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 06/01

NGA 2000

4 - 19

TAG

f

-- Calibration Deviations --

Dev iation from zer o:

Sum of zero deviations:

Dev iation from span:

Sum of s pan deviation s:

Measure

Channel

Back...

-0. 05 ppm

-0. 41 ppm

-0. 14 ppm

-0. 57 ppm

37.50 ppm

Flow ...

F1 F2 F3 F4 F5

TAG

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 °C

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

Range: 1

0.0 100.0

⇒ Return to the single

component display o

the current channel

F1

Press

Options:

•

A basic calibration procedure will reset the deviations to 0.00 (see section

5.1.1, p. 5-18: Advanced

Calibration Methods - Start

basic calibration procedure

!)

•

Using F3 you can change

to other available channels

to check their "Calibration

Deviations".

•

The function key F4

returns back to the menu

"Calibration Procedure

Status".

⇒ Back at the si ngle

component display

4 - 20

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 06/01

TAG

37.50 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 °C

Operation: Ready

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

TAG

-- Analyzer Basic Controls (calibration) & Setup --

Calibration procedure state...

Start zero calibration procedure !

Start span calibration procedure !

Check calibration deviation: Enabled

Range number: 1

Span gas: 46.00 ppm

Range upper limit: 50.00 ppm

Operation status: Ready

Measure Status... Channel Back...

F1 F2 F3 F4 F5

TAG

-- Basic Controls and Setup --

Calibration procedure status...

Start zero calibration procedure !

Start span calibration procedure !

Check calibration deviation: Enabled

Range number: 1

Span gas: 46.00 ppm

Range upper limit: 50.00 ppm

Operation status: Ready

Measure Status... Channel Back...

F1 F2 F3 F4 F5

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

Range: 1

0.0 100.0

37.50 ppm

Valves...

37.50 ppm

Valves...

NGA 2000

4.5 Zero Calibration

⇒ Open the menu

"Analyzer Basic

Controls (calibrations) & Setup"

F5

Press

Caution:

Before starting zero

calibration make sure that

zero gas is available !

(See also section 5.1.1,

pg. 5-5... !)

Note

:

The zeroing of all measurement ranges of the selected

channel is running

simultaneously.

⇒ Highl i ght the

line "Start zero

calibration

procedure !"

Press

get the line "Start zero

calibration procedure !"

highlighted.

⇒ Start the zero

calibration

Press

or

once to

4 - 21

⇒ Confirm to start the

TAG

-- Confirmation Required --

Do you really want to do this ??

Press "Yes" or "Back..."

Yes Back...

F1 F2 F3 F4 F5

37.50 ppm

zero calibration

F2

Press

the zeroing immediately.

Option:

Press the F4 -key if you want

to cancel the procedure.

Notes:

•

The display of this message

depends on the setup in

the expert controls & setup

(see 5.1.8 pg. 5-49).

•

The next 3 illustrations

show the displays you can

see after starting the

zeroing procedure.

to start

TAG

-- Calibration Procedure State --

Procedure state: Purging1-Wait

Maximum remaining procedure time: 8 s

Valve position: Zerogas

Concentration in span gas units: 37.50 ppm

Last zero calibration: Success

Last span calibration: Success

Last zero calibration was: 13:32:06 July 27, 1999

Last span calibration was: 13:38:46 July 28, 1999

Successful zero+span calibrated ranges: 1+2+3+4

Measure Cancel ! Back... More...

F1 F2 F3 F4 F5

Channel

37.50 ppm

⇒ Zeroing:

1. Purging-Wait

Notes:

•

The procedure time depends on the parameters

entered for purge time

(see section 5.1.1 pg. 5-10).

•

The purge time must be long

enough to get a stable signal

before calibration.

•

You can cancel the run-ning

calibration procedure at any

time pressing the

F2 -key.

⇒ Zeroing:

TAG

-- Calibration Procedure State --

Procedure state: Zeroing-Wait

Maximum remaining procedure time: 97 s

Valve position: Zerogas

Concentration in span gas units: 3.13 ppm

Last zero calibration: Success

Last span calibration: Success

Last zero calibration was: 13:32:06 July 27, 1999

Last span calibration was:

Successful zero+span calibrated ranges: 1+2+3+4

Measure Cancel ! Back... More...

Channel

13:38:46 July 28, 1999

3.13 ppm

2. Zeroing-Wait

Note:

The procedure time depends on the parameters

entered for stability time and

averaging time.

(see section 5.1.1 pg. 5-10)

F1 F2 F3 F4 F5

4 - 22

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

TAG

-- Calibration Procedure State --

Procedure state: Ready

Maximum remaining procedure time: 0 s

Valve position: Samplegas

Concentration in span gas units: 0.00 ppm

Last zero calibration: Success

Last span calibration: Success

Last zero calibration was:

Last span calibration was:

Successful zero+span calibrated ranges: 1+2+3+4

Measure

F1 F2 F3 F4 F5

Cancel !

13:32:06 July 27, 1999

13:38:46 July 28, 1999

Channel

Back... More...

TAG

0.00 ppm CH4

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 °C

Operation: Ready

Range: 1

0.0 100.0

0.00 ppm

4.5 Zero Calibration

⇒ Zeroing:

3. Zeroing Done

⇒ Return to the

single component

display of the

current channel

F1

Press

Options:

•

F4 -key: Return to the

menu "Analyzer Module

Calibration".

•

F5 -key: Open menu

"Calibration Deviations".

⇒ Single component

display appears

when zeroing has

finished.

Display Status... Main... Channel BasicCal

F1 F2 F3 F4 F5

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 23

4 - 24

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

4.6 Span Calibration/Basic Parameters

TAG

37.50

Failures:

Maintenance-Requests: No

Temperature:

Operation:

Display Status...

F1 F2 F3 F4 F5

0.00

Range: 1

20.0 °C

Ready

No

0.0 100.0

Main...

ppm CH4

50.00

Channel

BasicCal

Use the menu

"Analyzer Basic Controls (calibration) & Setup" to view

calibration status, start zero / span calibration and set up basic

parameters like "check calibration deviation", "(measuring)

range number", "span gas" and "range upper limit (end of

range)".

Operating this menu is shown on the basis of an example

(Start span calibration procedure). All other procedures are

executed similar.

See additional notes at the end of this chapter too (pg. 4-28)!

TAG

-- Analyzer Basic Controls (calibration) & Setup --

Calibration procedure state...

Start zero calibration procedure !

Start span calibration procedure !

Check calibration deviation: Enabled

Range number: 1

Span gas: 46.00 ppm

Range upper limit: 50.00 ppm

Operation status: Ready

Measu re Status... Channel Back...

F1 F2 F3 F4 F5

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 06/01

37.50 ppm

Valves...

NGA 2000

⇒ Open the

menu "Analyzer

Basic Controls

(calibration) & Setup"

Press

F5

Caution:

Before starting span

calibration, prove that

span gas with correct

concentration is available !

(See also section 5.1.1,

pg.5-6... !)

⇒ Highlight the line

"Start span calibration procedure !"

Press

get the line "Start span

calibration procedure !"

inverse.

Notes:

•

Normally, all

measurement ranges of

the same channel are

calibrated

simultaneously.

•

To calibrate separately

you have to change the

parameters (see 5.1.1

pg. 5-10).

twice to

4 - 25

⇒ Start

TAG

-- Basic Controls and Setup --

Calibration procedure status...

Start zero calibration procedure !

Start span calibration procedure !

Check calibration deviation:

Range number: 1

Span gas: 46.00 ppm

Range upper limit: 50.00 ppm

Operation status: Ready

Measure Status... Channel Back...

F1 F2 F3 F4 F5

37.50 ppm

Enabled

Valves...

span calibration

Press

or

TAG

-- Confirmation Required --

Do you really want to do this ??

Press "Yes" or "Back..."

Yes Back...

F1 F2 F3 F4 F5

37.50 ppm

⇒ Confir m st art i ng

span calibration

Press

the spanning immediately.

Option:

Press the F4 -key if you want

to cancel the procedure.

Notes:

•

The display of this message

depends on the setup in

the expert controls &

setup.

(see 5.1.8 p. 5-49)

•

The 3 following illustrations

show the displays you can

see after starting the

spanning procedure.

F2

to start

TAG

-- Calibration Procedure State --

Procedure state: Purging1-Wait

Maximum remaining procedure time: 8 s

Valve position: Spangas 1

Concentration in span gas units: 37.50 ppm

Last zero calibrati on: Success

Last span calibration: Success

Last zero calibrati on was: 13:32:06 July 27, 1999

Last span calibration was: 13:38:46 July 28, 1999

Successful zero+span calibrated ranges: 1+2+3+4

Measure Cancel ! Back... More...

F1 F2 F3 F4 F5

Channel

37.50 ppm

⇒ Spanning:

Notes:

•

The procedure time depends on the parameters

entered for purge time

(see 5.1.1 p. 5-10).

•

The purge time must be

long enough to get a

stable signal before

starting calibration.

•

You can cancel the

running calibration

procedure at any time with

the F2 -key.

1. Purging-Wait

4 - 26

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 06/01

y

TAG

TAG

Procedure state: Spanning-Wait

Procedur e s t atus: Spanning-Wait

Maximum remaining procedure time: 8 s

Maximum r e maining procedu re time: 108 s

Valve position: Spangas 1

Valve position: Spangas-1

Concentration in span gas units: 37.50 ppm

Concentr ation in span ga s units: 43.57 ppm

Last zero calibration: Success

Last zero calibrat i on: Success

Last span calibration: S uccess

Last span calibration: Success

Last zero calibration was: 13:32:06 July 27, 1999

Last zero calibration was: 09:21:34 July 27, 1999

Last span calibration was: 13:38:46 July 28, 1999

Last span calibration was : 13:37:23 July 27, 1999

Successful zero+span calibrated ranges: 1+2+3+4

Successful zero+span calibrated ranges: 1+2+3+4

Measure Cancel ! Back... More...

Measure Cancel ! Back... More...

-- Calibration Procedure State --

-- Calibration Proce dure Status --

---------------------- Results ----------------------

Channel

4.6 Span Calibration/Basic Parameters

⇒ Spanning:

37.50 ppm

43.57

2. Spanning-Wait

Note:

The procedure time depends on the parameters

entered for stability time

and averaging time.

(see 5.1.1 p.5-10)

F1 F2 F3 F4 F5

F1 F2 F3 F4 F5

TAG

-- Calibration Procedure State --

Procedure state:

Maximum remaining procedure time:

Valve position:

Concentration in span gas units:

Last zero calibration: Success

Last span calibration:

Last zero calibrat i on was: 13:32:06 July 27, 1999

Last span calibr at ion was: 13:38:46 July 28, 1999

Successful zero +span calibrated ranges:

F1 F2

Measure Cancel !

Channel

F3

Back... More...

F4

Samplegas

37.50 ppm

37.50 ppm

Read

8 s

Success

1+2+3+4

F5

⇒ Spanning:

3. Spanning-Ready

⇒ Return to the

single component

display of the

current channel

Press

Options:

•

F4 -key: Return to the

menu "Analyzer Module

Calibration".

•

F5 -key: Enter the menu

"Calibration Deviations".

F1

TAG

50.00 ppm CH4

0.00 50.00

Range: 1 F.S.

⇒ Single component

display appears

when spanning has

finished.

Failures: No

Maintenance-Requests: No

Temperature: 20.0 °C

Operation: Ready

Display Status... Main... Channel BasicCal

0.0 100.0

F1 F2 F3 F4 F5

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 06/01

NGA 2000

4 - 27

Notes

Some notes about how to operate the "Analyzer Basic Controls (calibration) & Setup" menu:

TAG

-- Analyzer Basic Controls (calibrati o n) & Setup --

Calibration procedure state...

Start zero calibration procedure !

Start span calibration procedure !

Check calibration deviation: Enabled

Range number: 1

Span gas: 46.00 ppm

Range upper limit: 50.00 ppm

Operation status: Ready

Measure Status... Channel Back...

F1 F2 F3 F4 F5

37.50 ppm

Valves...

Editing variables

♦

Press ↑↑↑↑ -key or ↓↓↓↓ -key to highlight the appropriate line.

♦

Select the variable to be edited by pressing

↵↵↵↵

-key or →→→→ -key.

If editing is not allowed, check “Application for Basic Controls menu” (5.1.8; pg. 5-52)

to allow editing this variable.

♦

Adjust the variable using the ←←←← -key or →→→→ -key.

Define another range or enable/disable calibration deviation check using the ↑↑↑↑- or ↓↓↓↓ -key.

♦

Enter the parameter using the

↵↵↵↵

-key or return to the previous value pressing F2.

Line of variables „Check calibration deviation“:

Enables or disables the stability and tolerance control during calibration.

Line of variables „Range number“:

Use this variable to select the measuring range (1 to 4).

Line of variables „Span gas“:

Insert the span gas value. Inadmissible high span gas values (outside the linearization) are

not accepted. (Take into account the lowest and highest end of range ! Span gas should be

within 70 to 100 % of the upper limit !).

Line of variables „Range upper limit“:

Enter the end of range (upper limit). Inadmissible high upper limits (outside the linearization)

are not accepted.

4 - 28

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 06/01

4.7 Activate Zero Gas, Span Gas, Sample Gas or Test Gas

Close all Valves

TAG

37.50

Failures:

Maintenance-Requests: No

Temperature:

Operation:

Display Status...

F1 F2 F3 F4 F5

0.00

20.0 °C

Ready

Range: 1

No

Main...

0.0

ppm CH4

50.00

Channel BasicCal

100.0

TAG

-- Analyzer Basic Controls (calibration) & Setup --

Calibration procedure state...

Start zero calibration procedure !

Start span calibration procedure !

Check calibration deviation:

Range number:

Span gas:

Range upper limit:

Operation status:

Measure Status... Channel Back...

F1 F2 F3 F4 F5

37.50 ppm

Enabled

1

46.00 ppm

50.00 ppm

Valves...

Ready

TAG

-- Set Gas Valves --

Flow zero gas !

Flow span gas !

Flow sample gas !

Flow test gas !

Close all valves !

Valve position: Sample gas

Operation state: Ready

Measu re Status... Channel Back...

F1 F2 F3 F4 F5

37.50 ppm

Flow...

⇒ Open the

menu "Analyzer

Basic Controls

(calibration) &

Setup"

Press

F5

Caution:

Before starting zero gas

flow, make sure zero gas is

available !

(See also section 5.1.1,

pg.5-5... !)

⇒ Enter the menu

"Set Gas Valves"

F5

Press

⇒ Start “Flow zero

gas !”

Press

or

Starting this function will

open the zero gas valve as

current gas valve.

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

NGA 2000

4 - 29

⇒ Confir m t o open zero

TAG

37.50 ppm

gas valve

Press

to start the zero

-- Confirmation Required --

Do you really want to do this ??

Press "Yes" or "Back..."

Yes Back...

F1 F2 F3 F4 F5

gas flow immediately.

Option:

Press the F4 -key if you

want to cancel the

procedure and return to the

menu "Set Gas Valves".

Note:

Whether this message

appears or not depends on

the setup in the expert

controls & setup

(see 5.1.8, pg. 5-49).

F2

TAG

37.50 ppm

⇒ Process is start ed

Note:

This message is displayed

- S U C C E S S -

- The selected function has been started/executed (Wait a moment...)

when the function has been

started. After a moment the

display will return

automatically to the menu

"Set Gas Valves".

F1 F2 F3 F4 F5

TAG

-- Set Gas Valves --

Flow zero gas !

Flow span gas !

Flow sample gas !

Flow test gas !

Close all valves !

Valve position: Sample gas

Operation state:

Measure Status... Channel Back...

F1 F2 F3 F4 F5

Ready

37.50 ppm

Flow...

⇒ Additional options

•

Start flow span gas,

sample gas or test gas !

•

Close all valves !

•

F3 -key: Switch to another

available channel to set

gas valves.

•

F4 -key: Return to the

menu "Basic Controls and

Setup " to start zeroing or

spanning.

•

F1 –key: Return to Single

Component Display

4 - 30

NGA 2000

ETC00612(1) [NGA-e (TFID SW 3.4.X)] 02/01

4.8 Flow measurement

TAG

37.50

Failures:

Maintenance-Requests: No

Temperature:

Operation:

Display Status...

0.00

Ready

Range: 1

No

20.0 C

Main...

ppm CH4

0.0

50.00

Channel BasicCal

100.0

⇒ Open the

menu "Analyzer

Basic Controls