Instruction Manual

90002496

04/2008

Instruction Manual

Platform

for NGA 2000 CLD, FID, HFID, MLT

and WCLD Analyzer Modules

1/1 19“, 3 HU Housing

rd

3

Edition 04/2008

www.EmersonProcess.com

Platform for CLD, FID, HFID, ML T AND WCLD Instruction Manual

90002496

04/2008

ESSENTIAL INSTRUCTIONS

READ THIS P AGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and test s

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products

to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson Process Management (Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR W ARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical

shock and personal injury.

The information contained in this document is subject to change without notice. Misprints

reserved.

1st Edition 06/1995 2

nd

Edition 03/1999

3rd Edition 04/2008

© 2008 by Emerson Process Management

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Rosemount Analytical

SAFETY SUMMARY S - 1

General S - 2

Gases and Gas Conditioning (Sample Handling of analyzer modules) S - 3

Supply Voltage S - 4

Instrument specific notes for the user S - 5

Additional notes for service / maintenance S - 6

Electrostatic Discharge S - 7

CONTENTS

Table of Contents

INTRODUCTION E - 1

Platform E - 1

EMC-Housing E - 1

DESCRIPTION

1. Technical Description 1 - 1

1.1 Front Panel 1 - 3

1.2 Rear Panel 1 - 4

1.3 Internal Layout 1 - 5

1.3.1 Interconnection Board ICB 01 1 - 7

1.3.2 Power Supply Unit 1 - 9

1.3.3 Line - Fan - Module (LFM 01) 1- 10

Ventilation 1 - 11

1.3.4 Controller Board ACU 02 1 - 12

1.3.5 Network Module LEM 01 1 - 13

2.

- (open)

4.

90002496(2) [NGA-Platform e] 30.03.99

i

CONTENTS

OPERATION

5. Preparation 5 - 1

5.1 Installation Site 5 - 1

5.2 External Modules 5 - 2

5.3 Installation of an Analyzer Module into the Platform 5 - 3

5.4 Installation of PCBs / Rear Mounting Modules 5 - 4

5.4.1 Rear Mounting Modules 5 - 4

5.4.2 Internal Slots (with 5 A power supply only) 5 - 4

6. Switching On 6 - 1

6.1 24 Vdc - Operation 6 - 2

Rosemount Analytical

6.2 230 / 115 Vac - Operation 6 - 2

7. Switching Off 7 - 1

8.

- (open)

10.

11. TROUBLESHOOTING 11 - 1

11.1 Instrument has no Function (LCD display is dark) 11 - 1

11.2 No Measurement Screen 11 - 2

11.3 Line - Fan - Module (LFM 01) 11 - 3

11.4 Power Supply Unit 11 - 3

11.5 Fuses 11 - 4

11.5.1 AC - Fuses 11 - 4

11.5.2 DC - Fuses 11 - 4

12.

- (open)

14.

ii

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

MAINTENANCE

15. Opening the Housing 15 - 1

15.1 Front Panel 15 - 1

15.2 Housing Cover 15 - 2

16. (open)

17. Removal / Replacement of Components 17 - 1

17.1 Removal of Analyzer Module 17 - 1

17.2 Removal / Replacement of PCBs / Rear Mounting Modules 17 - 2

17.2.1 Rear Mounting Modules 17 - 2

CONTENTS

17.2.2 Internal Slots 17 - 2

17.3 Removal / Replacement of Front Panel 17 - 3

17.4 Replacement of EPROM / Buffer Battery on the ACU 02 17 - 4

17.4.1 Removal of ACU 02 17 - 4

17.4.2 Replacement of EPROM 17 - 5

17.4.3 Replacement of Buffer Battery 17 - 6

17.4.4 Installation of ACU 02 17 - 6

18. (open)

19. Cleaning of Housing Outside 19 - 1

90002496(2) [NGA-Platform e] 30.03.99

iii

CONTENTS

20. TECHNICAL DATA 20 - 1

20.1 Platform 20 - 1

20.1.1 Housing 20 - 1

20.1.2 Environments 20 - 1

20.2 Line - Fan - Module (LFM 01) 20 - 4

20.2.1 Electrical Safety 20 - 4

20.3 Internal Power Supply Unit 20 - 5

20.3.1 5 A Power Supply 20 - 5

20.3.2 10 A Power Supply 20 - 5

Rosemount Analytical

SUPPLEMENT

21. Pin Assignments 21 - 1

21.1 24 Vdc Input (LFM 01) 21 - 1

21.2 230/115 Vac Input (LFM 01) 21 - 1

21.3 24 Vdc Output to analyzer module (internal) 21 - 1

INDEX R - 1

List of Figures R - 5

iv

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

SAFETY SUMMARY

Safety Summary

Outside and/or inside platform or at operation manual resp. different symbols gives you a hint to

special sources of danger.

Source of danger !

See Operation Manual!

GENERAL

Electrostatic Discharge (ESD) !

Explosives !

Hot components !

T oxic !

Risk to health !

Platform specific notes for the user !

In operation manual we will give partly additional informations to these symbols.

Strictly follow these instructions please !

90002496(2) [NGA-Platform e] 30.03.99

S - 1

SAFETY SUMMARY

GENERAL

Rosemount Analytical

1. General

◆ The following gener al safety precautions must be observed during all phases of operation,

service and repair of this instrument !

Failure to comply with these precautions or with specific w arnings elsewhere in this manual

violates safety standards of design, manufacture and intended use of this instrument !

Failure to comply with these precautions may lead to personal injury and damage to this

instrument !

◆ Fisher-Rosemount GmbH & Co. does not take responsibility (liability) for the customer´s

failure to comply with these requirements !

◆ Do not attempt internal service or adjustment unless other person, capable of rendering first

aid and resuscitation, is present !

◆ Because of the danger of introducing additional hazards, do not perform any unauthorized

modification to the instrument !

Return the instrument to a Fisher-Rosemount Sales and Service office for service or repair

to ensure that safety features are maintained !

◆ Instruments which appear damaged or defective should be made inoperativ e and secured

against unintended operation until they can be repaired by qualified service personnel.

S - 2

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

SAFETY SUMMARY

GENERAL / GASES AND GAS CONDITIONING (SAMPLE HANDLING)

Operating personnel must not remove instrument covers !

Component replacement and internal adjustments must be made by qualified

service personnel only !

Read all operation manuals before attempting to operate with the instrument !

Be sure to observe the additional notes, safety precautions and warnings given

in the individual operation manuals (e. g. platform, analyzer modules and

I/O-modules) !

Do not operate the instrument in the presence of flammable gases or explosive

atmosphere without supplementary protective measures !

At photometer or heated components there could be exist hot components !

2. Gases and Gas Conditioning (Sample Handling of analyzer modules)

Be sure to observe the safety regulations for the respective gases

(sample gas and test gases / span gases) and the gas bottles !

Inflammable or explosiv e gas mixtures must not be purged into the instrument

without supplementary protective measures !

To avoid a danger to the operators by e xplosive, toxic or unhealthy gas

components, first purge the gas lines with ambient air or nitrogen (N2) before

cleaning or exchange parts of the gas paths.

90002496(2) [NGA-Platform e] 30.03.99

S - 3

SAFETY SUMMARY

SUPPLY VOLTAGE

3. Supply Voltage

The socket outlet shall be installed near the equipment and shall be easily

accessible to disconnect the device from the socket outlet.

Verify whether the line voltage stated on the instrument (LFM 01) or power supply

agrees with that of your mains line!

Be sure to observe the safety precautions and warnings given by

manufacturer of pow er supply !

Rosemount Analytical

◆ NGA 2000 platform is a Safety Class 1 instrument

The platform is provided with a protective earth terminal.

T o prevent shoc k hazard, the instrument chassis and cabinet must be connected

to an electrical ground. The instrument must be connected to the AC pow er

supply mains through a three-conductor power cable, with the third wire firmly

connected to an electrical ground (safety ground) at the power outlet.

If the instrument is to be energized via an external power supply , that goes for the

power supply too .

Any interruption of the protective (grounding) conductor or disconnection of the

protective earth terminal will cause a potential shock hazard that could result in

personal injury. Deliberate disconnection is inadmissible / prohibited !

Verify that the position of input voltage switch of the 10 A power supply agrees

with that of your mains line (Fig. 20-3 and 1-4) !

Verify correct polarity for 24 V dc - operation !

S - 4

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

4. Instrument specific notes for the user

The installation site for the instrument has to be dry and remain above freezing

point at all times.

The instrument must be exposed neither to direct sunlight nor to strong sources

of heat. Be sure to observe the permissible ambient temperature !

For outdoor sites, we recommend to install the instrument in a protective cabinet.

At least, the instrument has to be protected against rain (e.g., shelter).

Free flo w of air into and out of the platform (ventilation slits) must not be hindered

by nearby objects or w alls !

SAFETY SUMMARY

INSTRUMENT SPECIFIC NOTES FOR USER

Use only from our factory optional delivered cables or equiv alent shielded cables

to be in agreement with the CE - conformity.

The customer has to guarantee, that the shield is be connected bothsided.

Shield and connectors housing have to be connected conductiv e.

Sub.-min.-D-plugs/soc kets have to be scre w ed to the analyzer.

By using of optional delivering terminal strip adapters the analyzer is not be in

agreement with the CE - conformity . In this case CE - conf ormity is to be declared

by customer as “manufacturer of system”.

90002496(2) [NGA-Platform e] 30.03.99

S - 5

SAFETY SUMMARY

ADDITIONAL NOTES FOR SERVICE / MAINTENANCE

5. Additional notes for service / maintenance

Operating personnel must not remove instrument covers !

Component replacement and internal adjustments must be made by qualified

service personnel only !

Always disconnect power, discharge circuits and remove external voltage

sources before troub leshooting, repair or replacement of any component !

Any work inside the instrument without switching off the power must be

performed by a specialist, who is familiar with the related danger, only !

Rosemount Analytical

In case of exchanging fuses the customer has to be certain that fuses of specified

type and rated current are used. It is prohibited to use repaired fuses or def ective

fuse holders or to short-circuit fuse carriers (fire hazard).

At component replacement or installation the RF shielding contacts must not be

bended !

S - 6

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

ELECTROSTATIC DISCHARGE

SAFETY SUMMARY

5.1 Electrostatic Discharge

The electronic parts of the analyzer can be irreparably damaged if exposed to electrostatic

discharge (ESD).

The instrument is ESD protected when the covers have been secured and safety precautions

observed. When the housing is open, the internal components are not ESD protected anymore.

Although the electronic parts are reasonable safe to handle, you should be a ware of the following

considerations:

Best ESD example is when you w alked across a carpet and then touched an electrical grounded

metal doorknob. The tiny spark which has jumped is the result of electrostatic discharge (ESD).

You prevent ESD by doing the following:

Remove the charge from your body before opening the housing and maintain during work with

opened housing, that no electrostatic charge can be built up.

Ideally you are opening the housing and working at an ESD - protecting workstation.

Here you can wear a wrist trap.

However, if you do not have such a workstation, be sure to do the following procedure exactly:

Discharge the electric charge from your body. Do this by touching a device that is grounded

electrically (any device that has a three - prong plug is grounded electrically when it is plugged into

a power receptacle).

This should be done several times during the operation with opened housing (especially after

leaving the service site because the movement on a low conducting floors or in the air might cause

additional ESDs).

90002496(2) [NGA-Platform e] 30.03.99

S - 7

SAFETY SUMMARY

Rosemount Analytical

S - 8

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

INTRODUCTION

Introduction

This operation manual informs you about the platform, which is used for accommodating

analyzers or analysis modules of the NGA 2000 series (19", 3 HU, IP 20-housing).

Platform

This housing, together with the operator interface and the built-in controller board ACU 02,

represents the platform for analyzers of the NGA 2000 series.

EMC-Housing

Should the housing be used as an EMC-assembly carrier for non-EMC analysis modules, please

be aware that the installation differs from the description given in this manual. The following

changes must be taken into consideration:

1. The 19" operator interf ace (chapter 1.1) will be substituted by two 1/2 19" blind front panels .

Each blind front panel can be dismounted separately by remo ving the respective screws

(6 for each panel).

2. The controller board ACU 02 (chapter 1.3.4) will be replaced by a bulkhead plate.

3. Only rear-panel modules using network can be built-in in this housing.

Modules which need the ICB-bus can not be connected, because the A CU 02 board is not

installed.

4. The operation of built-in analyzer module and any additional rear-panel modules must be

carried out via a "true-type" platform or a superior analyzer.

90002496(2) [NGA-Platform e] xx.03.99

E - 1

INTRODUCTION

Rosemount Analytical

E - 2

90002496(2) [NGA-Platform e] xx.03.99

Rosemount Analytical

TECHNICAL DESCRIPTION

1. Technical Description

The basis for analyzers of the NGA 2000 series is a 19", 3 HU housing of IP 20 protection class.

The instrument can be delivered as table top or rac k mountable unit.

The platform contains all components necessary for operating the analyzer and can be used as

a "stand alone" analysis instrument when combined with an analyzer module and an Input/Output

(I/O) module, or it can be configured as a system when equipped with sev eral analyzer and I/O

modules.

The conceptional design is depicted in the block diagram below (Fig. 1-1).

90002496(2) [NGA-Platform e] 30.03.99

Fig. 1-1: Block diagram platform design (external)

1 - 1

TECHNICAL DESCRIPTION

Rosemount Analytical

NGA standard housing contains:

◆ the front panel (84 DU, see chapter 1.1)

◆ the interconnection board ICB 01 (see chapter 1.3.1)

◆ the line-fan module LFM 01 (12 DU, see chapter 1.3.3), the power supply (see chapter 1.3.2)

and the controller board ACU 02 (see chapter 1.3.4)

◆ the network module LEM 01 for connecting the platform with external analyzer modules

(see chapter 1.3.5)

◆ 5 free slots (PCBs, 5 DU) on the rear panel, which can be assigned optionally with

“Input / Output Modules” (I/O's)

e.g. programmable I/O's: one SIO and up to 4 DIO boards

◆ 4 internal free slots (Euro cards) which can be assigned optionally (for 5 A power supply only)

AC DC

Platform

Analyzer Module

Analyzer Module

Analyzer Module

1 - 2

Network Cable

Fig. 1-1a: Analyzer system via platform (schematic diagram)

Network Cable

24VDC Cable

Power supply

24VDC Cable

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

TECHNICAL DESCRIPTION

FRONT PANEL

1.1 Front Panel

The 1/1-19" front panel (84 DU) accommodates the LCD display , accompanying front panel circuit

board AFP 01 and the keys necessary for operating the instrument (see Fig. 1-2).

For assembling and disassembling the analyz er module and for maintenance and repair, the front

panel can be swivelled out after releasing the six fastening screws, while the instrument may

remain in operation.

Footing

(table-top housing only)

Fastening screws

front panel

LCD display

F 3F 1 F 2 F 4 F 5

Softkeys

(Function depends on menu)

Cursor keys

NGA 2000

ENTER key

Mounting

(with rack mount-

able housing only)

90002496(2) [NGA-Platform e] 30.03.99

Fig. 1-2: Housing, Front View

(Front panel)

1 - 3

TECHNICAL DESCRIPTION

REAR PANEL

Rosemount Analytical

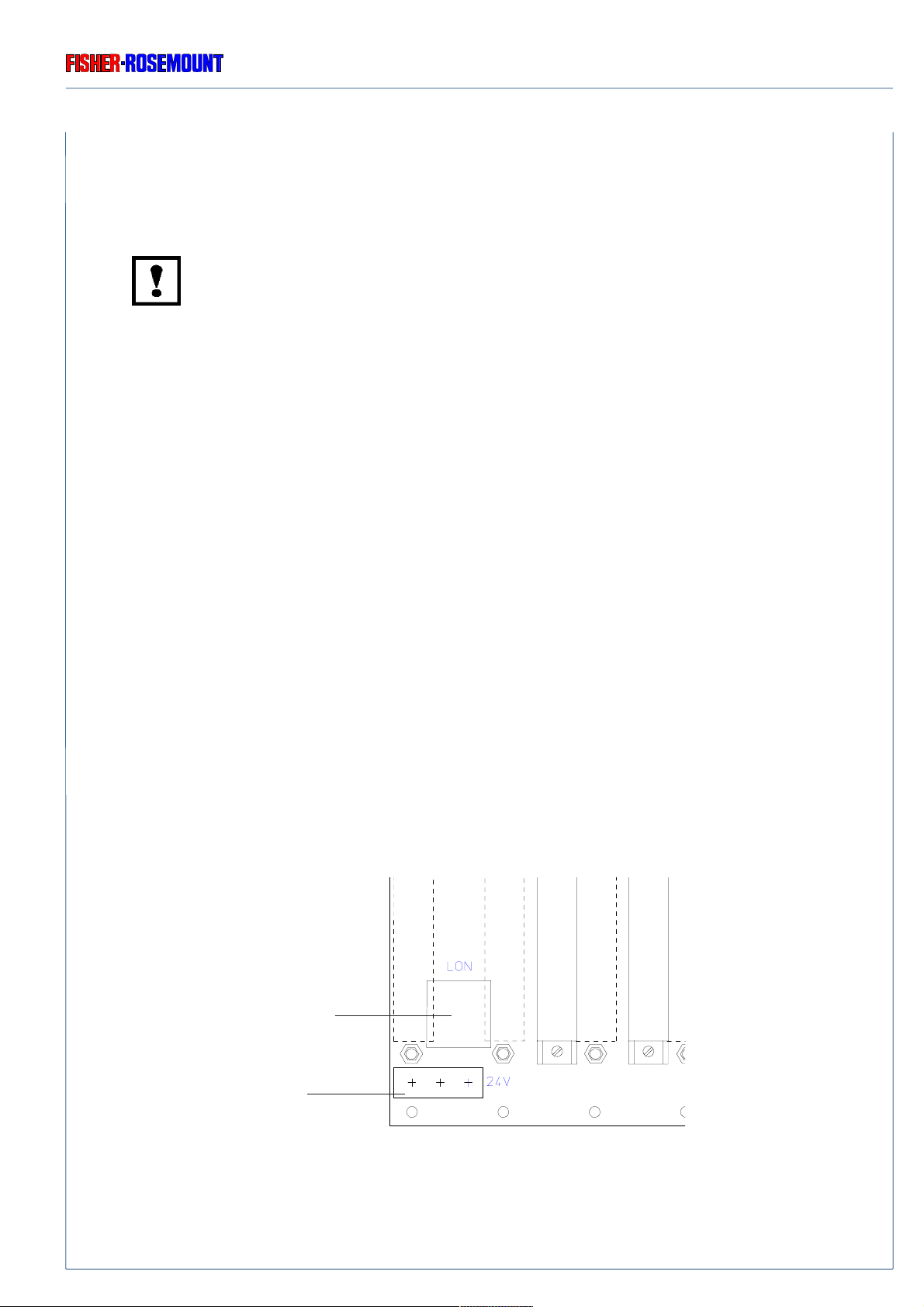

1.2 Rear Panel

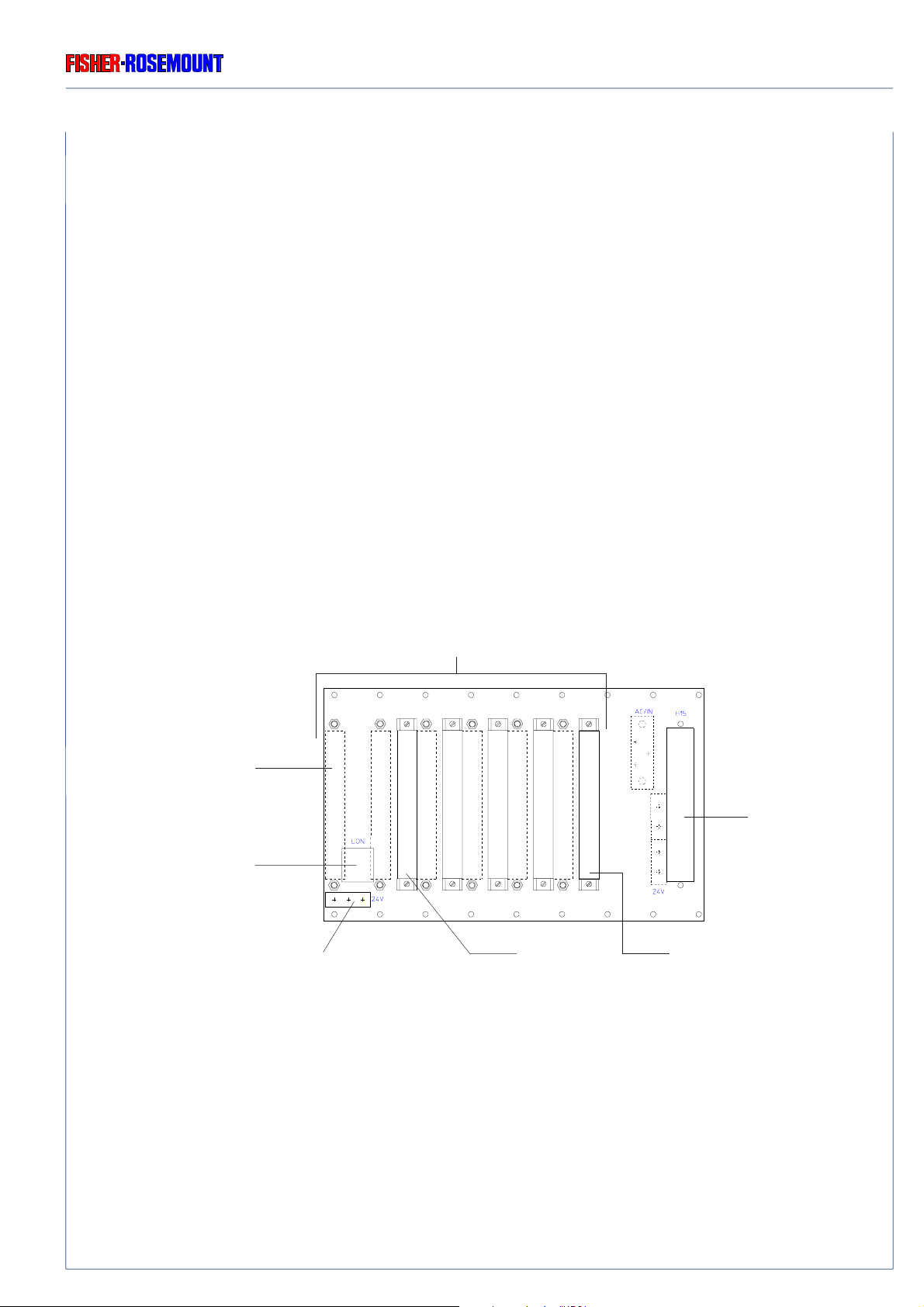

The rear panel (84 DU) accommodates (see Fig. 1-3):

◆ the line-fan module LFM 01 (12 DU, see chapter 1.3.3)

◆ the network module LEM 01 for connecting the platform with external analyzer modules

(see chapter 1.3.5)

◆ 5 free slots (PCBs, 5 DU) on the rear panel, which can be assigned optionally with

“Input / Output Modules” (I/O's)

e.g. programmable I/O's: one SIO and up to 4 DIO boards

◆ the gas fittings and optional electrical connections of analyzer modules (see separately

operation manual)

Analyzer module

(optionally built-in)

Footing

Line - Fan - Module

LFM 01 (12 DU)

5 free slots for optional

rear-panel modules

(PCB's, 5 DU)

Network Module

LEM 01 (5 DU)

(table-top housing only)

Mounting (at the front)

(with rack mountable

housing only)

1 - 4

Fig. 1-3: Housing, Rear View

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

TECHNICAL DESCRIPTION

INTERNAL LAYOUT

1.3 Internal Layout

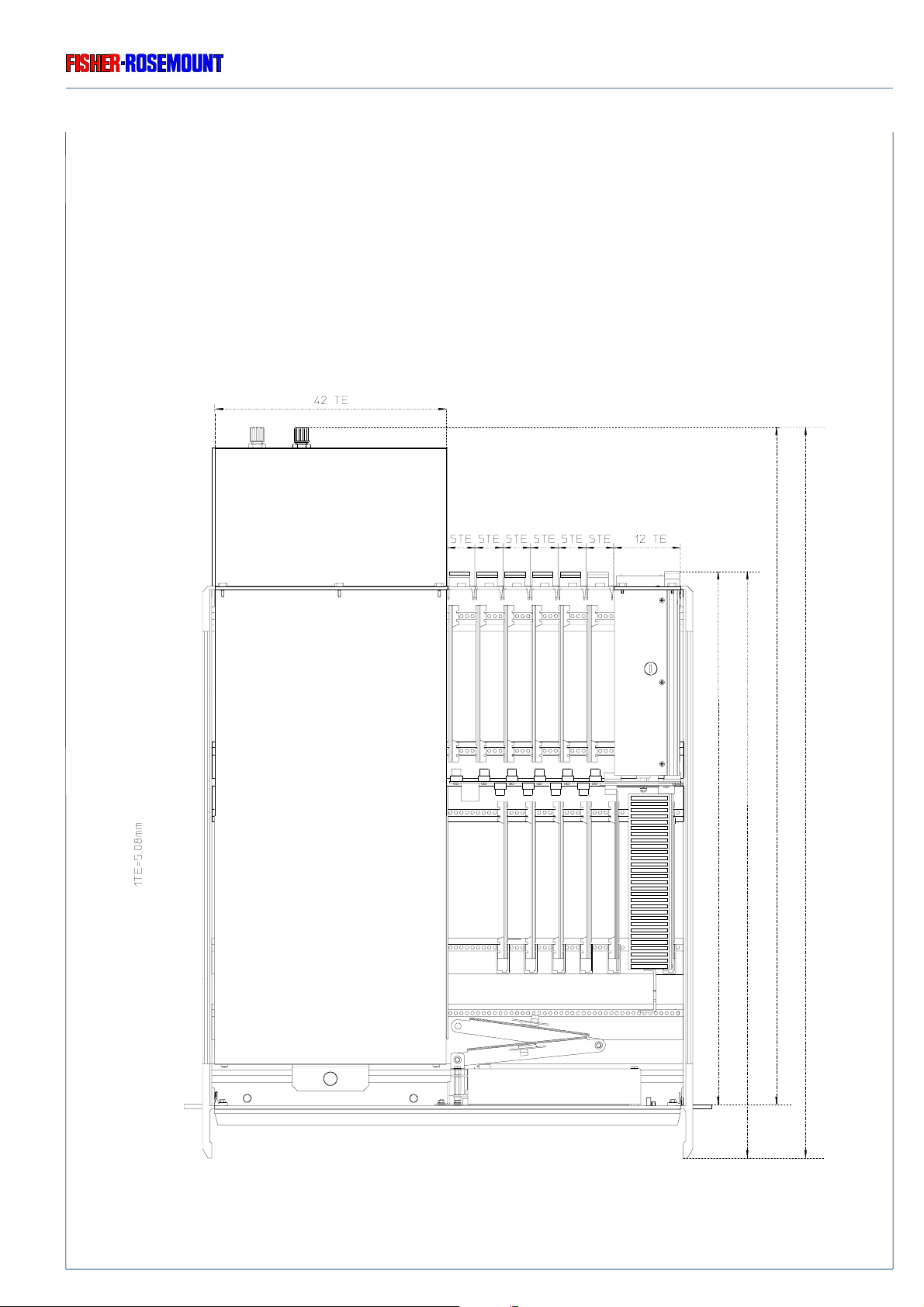

The interior of the housing is divided into two 42 DU wide halves.

When looking from the front side, on the right there is the electronics with interconnection board

and printed circuit board (PCB of Euro standard format).

On the left side, there is spare room for locating an analyzer module.

Network Module

LEM 01 (5 DU)

Interconnection Board

ICB 01

Analysis module

(optionally built-in)

5 free slots for optional I/O's

(PCBs, 5 DU)

Line- Fan - Module

LFM 01 (12 DU)

5 A

Power Supply

(for MLT, TFID

analyzer modules)

Mounting

rack mountable housing

(option)

90002496(2) [NGA-Platform e] 30.03.99

4 optional internal PCBs

Retention pin of analysis module

(dependent on analysis module version)

Carrying handles

Fig. 1-4a: Internal view of housing (with 5 A power supply)

Controller Board

ACU 02

hinge

front panel

Front panel with LCD display

and AFP 01 - PCB

1 - 5

TECHNICAL DESCRIPTION

INTERNAL LAYOUT

Rosemount Analytical

Network Module

LEM 01 (5 DU)

Interconnection Board

ICB 01

Analyzer module

(optionally built-in)

5 free slots for optional I/O's

(PCBs, 5 DU)

Line- Fan - Module

LFM 01 (12 DU)

10 A

Power Supply

(for CLD, WCLD,

HFID, McFid

analyzer modules)

1 - 6

Controller Board ACU 02

Front panel with LCD display

Carrying handles

Fig. 1-4b: Internal view of housing (with 10 A power supply)

24 Vdc

to

analyzer module

Fan

hinge

front panel

and AFP 01 - PCB

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

INTERCONNECTION BOARD ICB 01

TECHNICAL DESCRIPTION

1.3.1 Interconnection Board ICB 01

The board ICB 01 (see Figs. 1-4 and 1-5) interconnects the line-fan module (LFM 01), the power

supply (PSM) and all inserted PCBs [Euro cards with parallel ICB-bus system] and built-in analysis

module (RJ 45 network interface).

PCBs and the required voltage supply can be connected to the ICB with the so-called ICB-bus

[(a 64-pin plug-in connection DIN 41612 C 64) see Fig. 1-7].

ICB ensures the internal network connection which is necessary for operating the analyzer /

analyzer module.

With 5 A power supply it supplies the analyzer module with 24 Vdc required.

Slots for PCBs

with 64-pin ICB-Bus

(double-sided)

Slot for network module

LEM 01

(Rear side)

internal network - connection

to analyzer module

(RJ 45 socket)

Slot for

24 Vdc to

analyzer module

(with 5 A power supply)

Slot for

Controller board ACU 02

(with 10 A power supply)

Controller board ACU 02

(with 5 A power supply)

Slot for

power supply

90002496(2) [NGA-Platform e] 30.03.99

Fig. 1-5: Printed Circuit Board ICB 01

(viewed from front panel)

1 - 7

TECHNICAL DESCRIPTION

INTERCONNECTION BOARD ICB 01

Rosemount Analytical

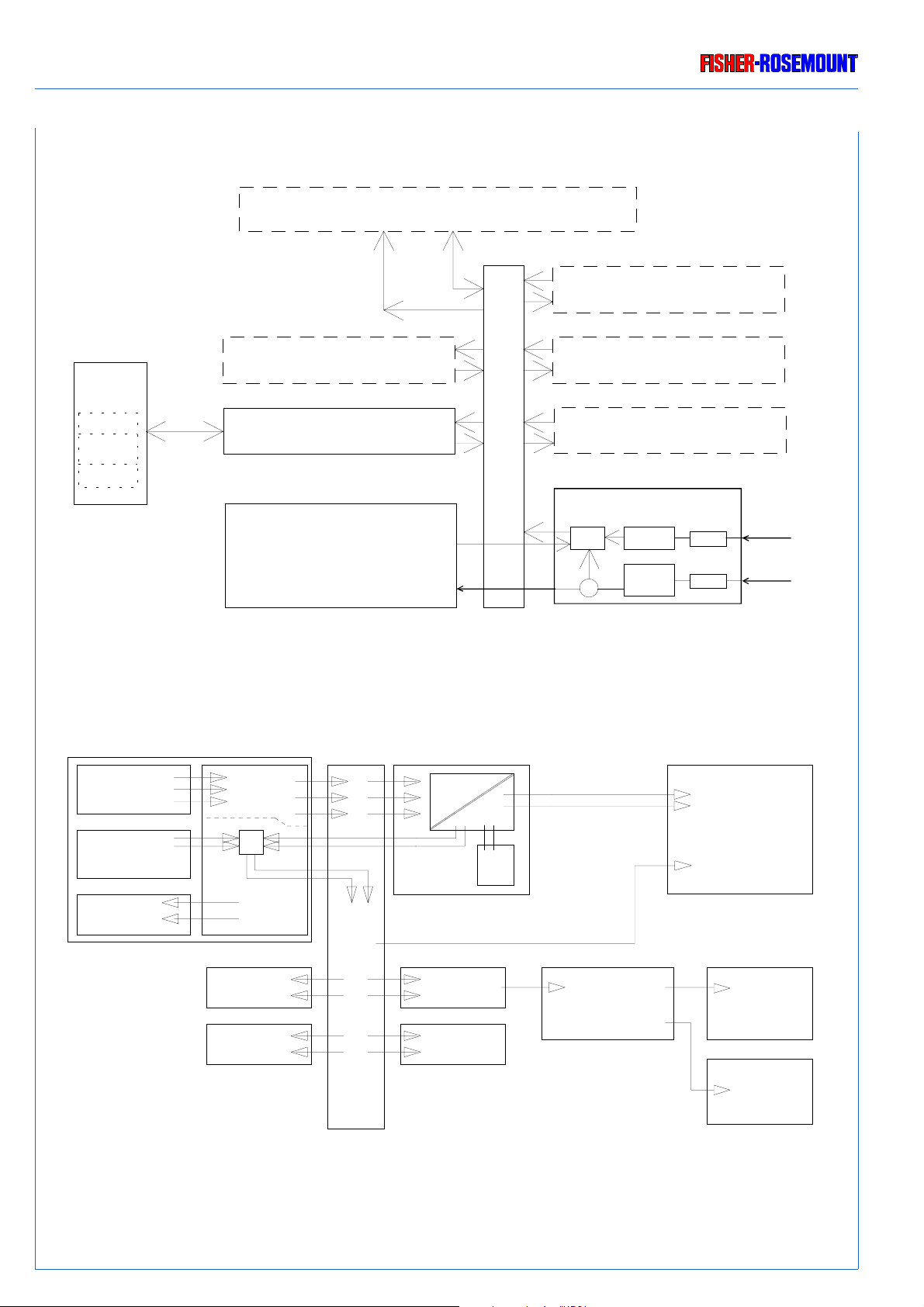

Analyzer Module (AM)

Platform

Front pan el

Keys

AFP - PCB

LCD - Dusplay

Optional PCBs (4 x)

Control Unit ACU 01

(Power Su pply)

24 Vdc / 5 A

24 V dc

24 Vdc

Autorange

230 / 115 Vac

Nertwork

ICB 01

Inter-Connection-Board

Network - Module

Optional Inputs/Outpu ts (4 x)

Standard Inp uts/Outputs

SIO

Line-Fan-Module

LFM 01

Logic

Filter

Main-

filter

Fig. 1-6a: Block diagram internal platform design (with 5 A power supply)

Fuse

Fuse

24 Vdc

Mains

EMI fil te r

LFM 01

ext. 24 Vdc in

Fan

L1, N, PE

or

24 Vdc

L1, N, PE

24 Vdc

230/115 V ac

Power Supply

24 Vdc out

Fan

NEB 01

Network

PCB

PCB

24 Vdc

24 Vdc

ACU AFP

PCB

ICB 01

Fig. 1-6b: Block diagram internal platform design (with 10 A power supply)

24 Vdc

Analyzer Module

Network

LCD

Keyboard

1 - 8

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

TECHNICAL DESCRIPTION

INTERCONNECTION BOARD ICB 01 / POWER SUPLLY UNIT

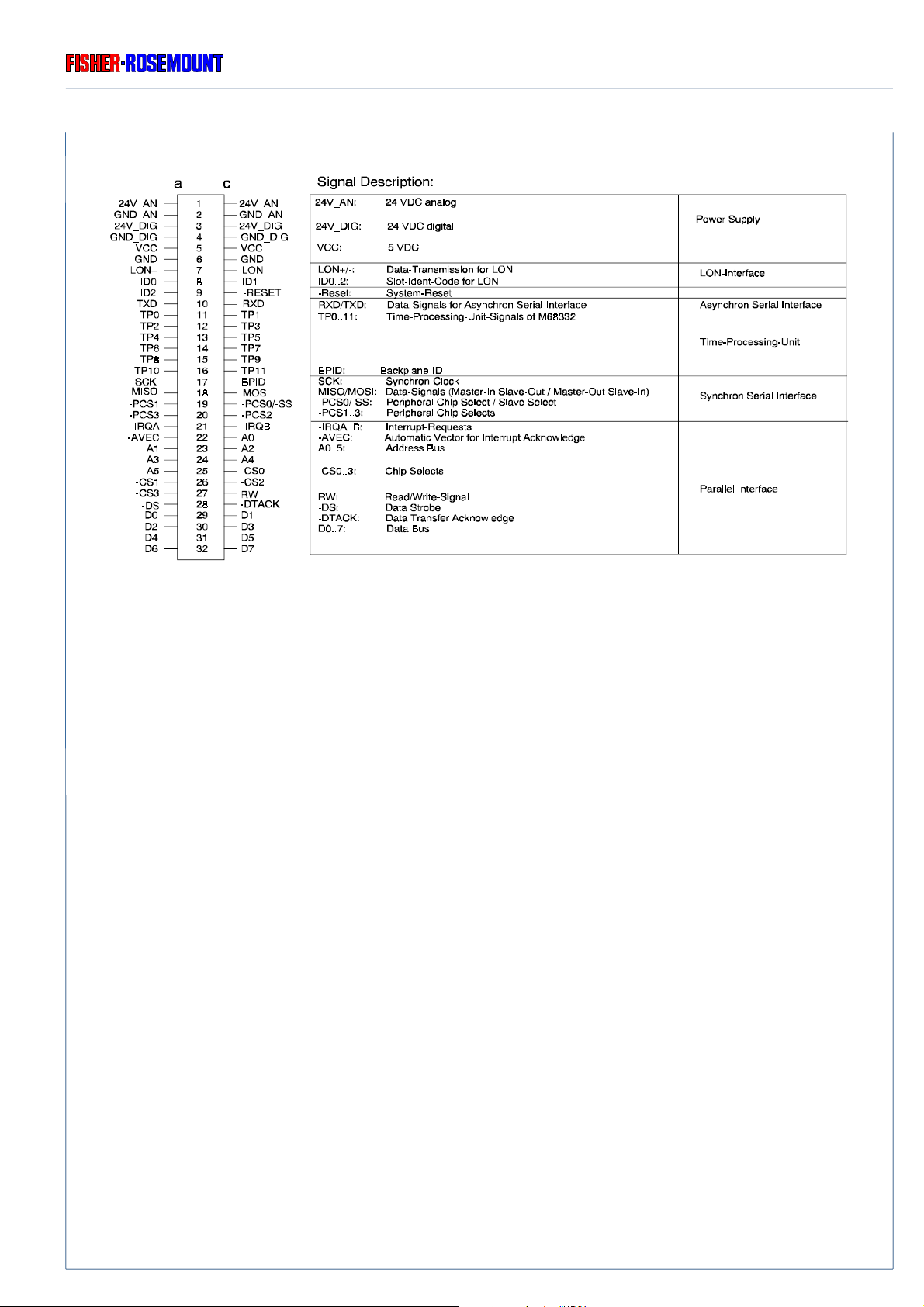

Fig. 1-7: Pin assignment, 64-pin ICB-bus connector

1.3.2 Power Supply Unit

The power supply unit converts the voltage supply from 230 / 115 Vac to 24 Vdc required for

operating the instrument.

Alternatively two different power supplys can be built in (see Fig. 1-4a and 1-4b too):

One power supply can be loaded with up to 5 A and is provided with autoranging between 230

Vac and 115 Vac (rear panel of LFM 01 shows “230/115 VAC”).

The other power supply can be loaded with up to 10 A and is provided with a manual switch

between 230 Vac and 115 V ac (rear panel of LFM 01 sho ws “230 V A C” or “115 V A C”). To prevent

excessively high temper ature inside the housing, a fan is installed inside (see Figs. 1-4b). The air

enters through openings in the front of the side walls.

The necessary connection of line-fan module (see 1.4) is provided by the ICB 01 board via a

matching plug (DIN 41612 / H 15).

The slot is located in front on the outer right side of ICB 01 (when looking from the front panel),

see Figs. 1-5 and 1-4.

To exchange 5 A power supply (standard) to 10 A power supply via retrofit kit, contact service

support center please.

90002496(2) [NGA-Platform e] 30.03.99

1 - 9

TECHNICAL DESCRIPTION

Rosemount Analytical

LINE-FAN MODULE (LFM 01)

1.3.3 Line - Fan - Module (LFM 01)

The NGA basic design has been provided for an operating v oltage of 230 V ac (196 - 264 V ac), 47

- 63 Hz and 115 Vac (93 - 132 Vac) resp., 47 - 63 Hz and / or 24 Vdc ( ± 10 %).

The line-fan-module (LFM 01) connects the NGA unit to the AC mains line or to a 24 Vdc low

voltage supply.

The unit (12 DU) is put in the housing from the rear side (see Figs. 1-8, 1-3 and 1-4).

AC - connector

(230 / 115 Vac;

50 / 60 Hz)

Fuses AC

(F1/F2: T 3,5 A)

POWER

230 V

115 V

50/60 Hz

F1/F2

T3,5A / 230V

~

~

LFM 01

-DC 24 V IN -

Fan

24 Vdc - connector

1

3

2

1 - 10

Fig. 1-8: Rear panel LFM 01 (sectional view of the housing)

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

TECHNICAL DESCRIPTION

LINE-FAN MODULE (LFM 01)

AC - voltage cable is connected via an IEC power lead. Power failure (RF noise) or internal

interference is suppressed by an RF filter with two integrated fuses (5 x 20 mm).

If rear panel of LFM 01 shows “230/115 VAC”, there is built-in the 5 A power supply

with autoranging of input AC voltage.

If rear panel of LFM 01 shows “230 VAC” or “115 VAC”, there is built-in the 10 A

power supply with manual switch of input AC voltage..

Verify beforehand that the line voltage stated on the LFM 01

agrees with that of your power supply line !

Verify that the position of input voltage switch of the 10 A power supply agrees

with that of your power supply line (Fig. 20-3 and 1-4) !

The 24 Vdc voltage is connected via a 3-pin socket (XLR), whereby filtered DC voltage has to be

available. The remaining interferences will be prevented by internal filters.

Verify correct polarity for 24 V dc - operation !

The instrument is protected against reversed polarity.

If both 24 Vdc and 230/115 Vac voltage are supplied simultaneously, the AC voltage will be

preferred. The 24 Vdc then is automatically disconnected by a relay. The 24 Vdc will be used only

while cessation of the AC voltage.

Ventilation

To prevent excessively high temperature inside the housing, a ventilator is installed on the rear side

of the LFM 01 (see Figs. 1-8 and 1-3).

The ventilator sucks air from the housing.

The air enters through openings in the front of the side walls.

90002496(2) [NGA-Platform e] 30.03.99

1 - 11

TECHNICAL DESCRIPTION

CONTROLLER BOARD ACU 02

Rosemount Analytical

1.3.4 Controller Board ACU 02

The ACU 02 controller board is the “heart” of the NGA platform. It is a one board CPU card. When

the voltage supply is disconnected, all user data will be safe loaded via a battery buffer.

This board functions as a networks manager, allows the access to each built-in component, and

controls the analyzer modules, the LCD display, and the operation procedures.

The slot for ACU 02 is located on the ICB 01 (when viewed from the front panel) on the right side

of the 64-pin ICB bus with internal5 A power supply and on the left side with internal 10 A power

supply (left from power supplys), see Figs. 1-5 and 1-4.

The board contains the following function blocks:

◆ 32 / 16-bit micro controller

◆ Floating point co-processor

◆ dependent on platform version different RAM / Flash-EEPROM

(Standard: 1 MB RAM extension for up to 15 software channels*); Option: additional 0.5 MB RAM extension

if more than 15 software channels*);contact factory if more than 20 software channels are requested)

◆ Real-time Clock with

Calendar function

Alarm function

◆ Watchdog function

◆ Serial interface RS 232 C

◆ A network interface with ECHELON chip

◆ System bus:

Parallel bus A6 : D8

12 TPU wiring

network bus

Synchron serial bus

◆ Buffered parallel interface for LCD control

◆ Local bus interface (e.g. storage extension)

◆ Switch-mode power supply for 5 V supply (on board)

*) Calculate software channels (SW) as follows: MLT = 1 SW ch. for each measuring channel; all other NGA analyzer modules like

CLD, FID, etc. = 1 SW ch.; SIO/DIO = zero SW ch.; network I/O's = 1/2 SW ch.

1 - 12

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

TECHNICAL DESCRIPTION

NETWORK MODULE LEM 01

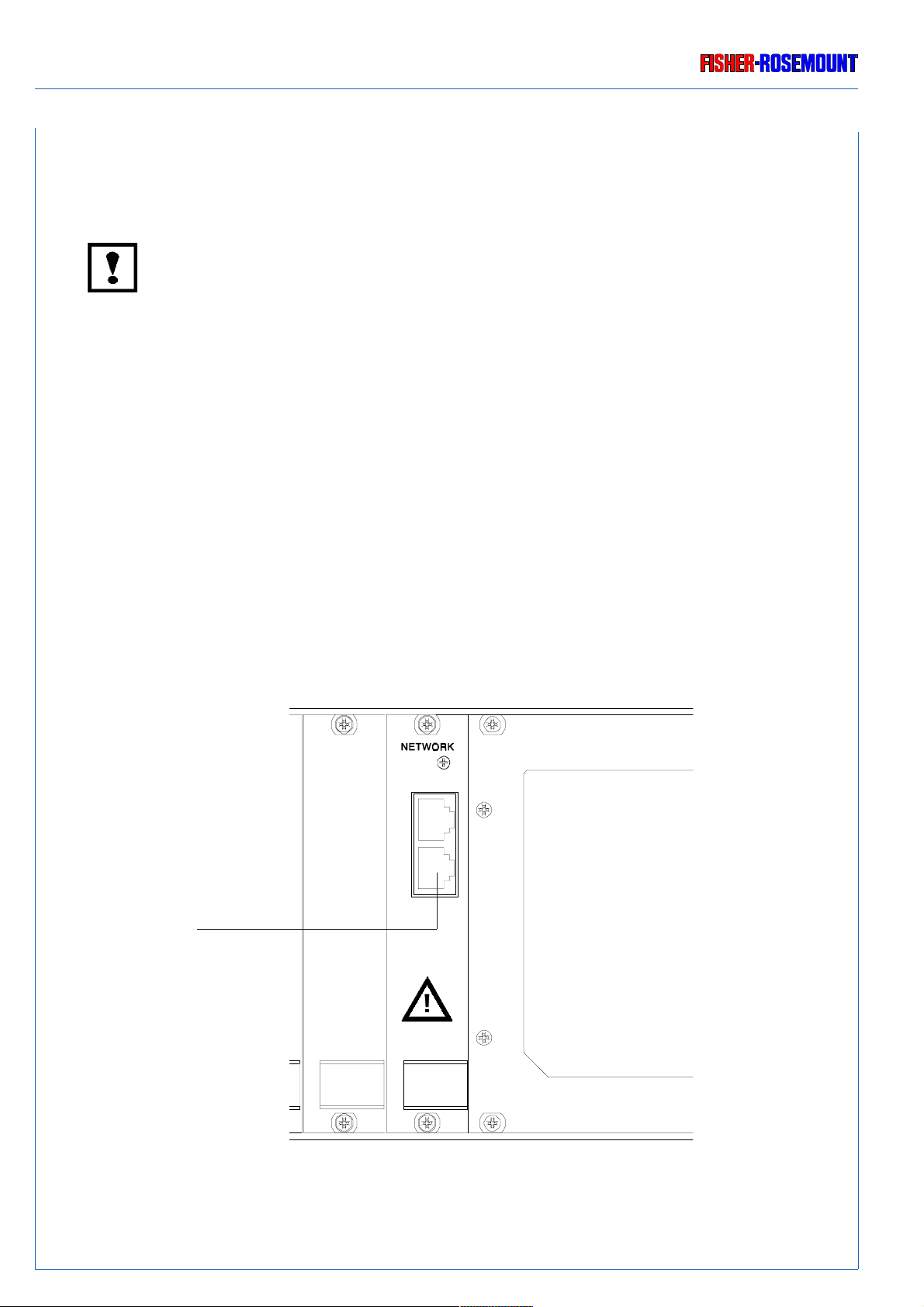

1.3.5 Network Module LEM 01

The network module LEM 01 (see Fig. 1-9) connects the platf orm (controller board) with external

modules via network. The slot on the interconnection board is located on the outer right (vie wed

from the rear side), left from the optionally built-in analyzer module.

Note !

The external modules cannot be supplied with 24 Vdc from the platform and, therefore, hav e to

be externally powered (see Fig. 1-1a, too).

NET

1

NET

2

Network - twin - connector

to external modules

(two RJ 45-sockets)

Analyzer module

(optionally built-in)

Fig. 1-9: Rear panel network module LEM 01 (sectional view of the housing)

RJ 45 sockets are serving for network interconnection.

It is necessary to terminate the ends of a twisted pair bus to minimize reflections (see Fig. 1-11).

Failure to terminate the bus will degrade network performance.

Termination will be done via RJ 45 connectors (see Fig. 1-10).

Fig. 1-10: RJ 45 network termination connector

90002496(2) [NGA-Platform e] 30.03.99

1 - 13

TECHNICAL DESCRIPTION

NETWORK MODULE LEM 01

Rosemount Analytical

Termination

AM AM AM AM

Platform

Termination

AM AM AM AM AM

Termination

AM AM

Termination

AM

Platform

AM

Platform

Termination

AM

Termination

AM AM

Platform

Fig. 1-11: Network termination (examples)

1 - 14

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

PREPARATION

INSTALLATION SITE

5. Preparation

Please check the packing and its contents immediately upon arrival.

If any damage is observed or items are missing, then we request that you notify the forw arder to

undertake a damage surve y and report the loss or damage to us immediately.

5.1 Installation Site

Be sure to observe the additional notes, safety precautions and wa rnings given

in the individual manuals (platform, modules, I/O boards etc.) !

The platform must not operate in explosiv e atmosphere without supplementary

protective measures !

Free flo w of air into and out of the platfrom (ventilation slits) must not be hindered

by nearby objects or w alls !

The installation site for the Platform has to be dry and remain above freezing point

at all times. The platform must be e xposed neither to direct sunlight nor to strong

sources of heat.

Be sure to observe the permissible ambient temperatures (c.f. Item 20: T echnical

Data). For outdoor installation, we recommend to install the platform in a

protective cabinet. At least, the platorm has to be protected against rain (e.g.,

shelter).

90002496(2) [NGA-Platform e] 30.03.99

5 - 1

PREPARATION

EXTERNAL MODULES

Rosemount Analytical

5.2 External Modules

Observe the safety precautions and warnings for the modules !

Consider also the procedure steps with regard to handling, configuration,

and operation if given in the individual manual(s) !

The platform (controller board) can be connected with external analyzer modules via the network

module LEM 01 (see Fig. 5-1). RJ 45 sockets are serving for network interconnection. Be sure

to observe the network termination (see section 1.3.5).

Note !

The external modules cannot be supplied with 24 Vdc from the platform and, therefore, have to

be externally powered (see Fig. 1-1a).

NET

1

NET

2

network - twin - connector

to external modules

(two RJ 45-sockets)

Analyzer module

(optionally built-in)

5 - 2

Fig. 5-1: Rear panel network module LEM 01 (sectional view of the housing)

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

INSTALLATION OF AN ANALYZER MODULE

PREPARATION

5.3 Installation of an Analyzer Module into the Platform

Be shure to observe the safety precautions and warnings !

Installation must be made by qualified service personnel only !

Consider also the procedure steps with regard to handling, configuration,

and operation if given in the individual manual(s) !

For the installation of analyzer module into the platform consider the following steps:

❍ Loosen the six fastening screws for the front panel (Fig. 1-2), hold the handles, and s wing

the front panel to the farest right (see also section 15.1).

❍ Lift the retention pin(s), push the analyzer module in the left half of the housing until the

retension pin(s) lock(s) into the pin seats in the lower analyz er module guides.

❍ Connect the required network wiring between the analyzer module (see the individual

operation manual) and the interconnection board ICB 01 (Fig. 5-2 and 1-5).

❍ Connect the required 24 Vdc wiring between the analyzer module (see the individual

operation manual) and the interconnection board ICB 01 (platform with 5 A power supply,

Fig. 5-2 and 1-5) or the PCB of po wer supply (platform with 10 A power supply, Fig. 1-4b)

resp..

❍ Close the instrument (i.e., re-attach the front panel, see section 15.1).

internal network - connection

to analyzer module

(RJ 45 socket)

24 V DC to

internal analyzer mod-

ule

90002496(2) [NGA-Platform e] 30.03.99

Fig. 5-2: Printed Circuit Board ICB 01

(viewed from front panel)

5 - 3

PREPARATION

INSTALLATION OF PCBS / REAR MOUNTING MODULES

5.4 Installation of PCBs / Rear Mounting Modules

Insert or remove PCBs when the instrument is electrically disconnected only !

Be shure to observe the safety precautions and warnings !

Installation must be made by qualified service personnel only !

Consider also the procedure steps with regard to handling, configuration,

and operation if given in the individual manual(s) !

5.4.1 Rear Mounting Modules

Rosemount Analytical

Follow the procedure steps to insert cards:

❍ Unscrew the shielding blind-plate of the chosen slot and remove it.

❍ Put the backplane module in the chosen slot, and fasten the back panel with screws.

5.4.2 Internal Slots (with 5 A power supply only)

Follow the procedure steps to insert cards:

❍ Loosen the six fastening scre ws of the front panel (Fig. 1-2) and s wing the front panel to the

farest left (see also section 15.1).

❍ Tilt the card ejector upwards and push the card in the chosen slot until the card catch locks

into place.

❍ Close the instrument (i.e., re-attach the front panel, see section 15.1).

5 - 4

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

SWITCHING ON

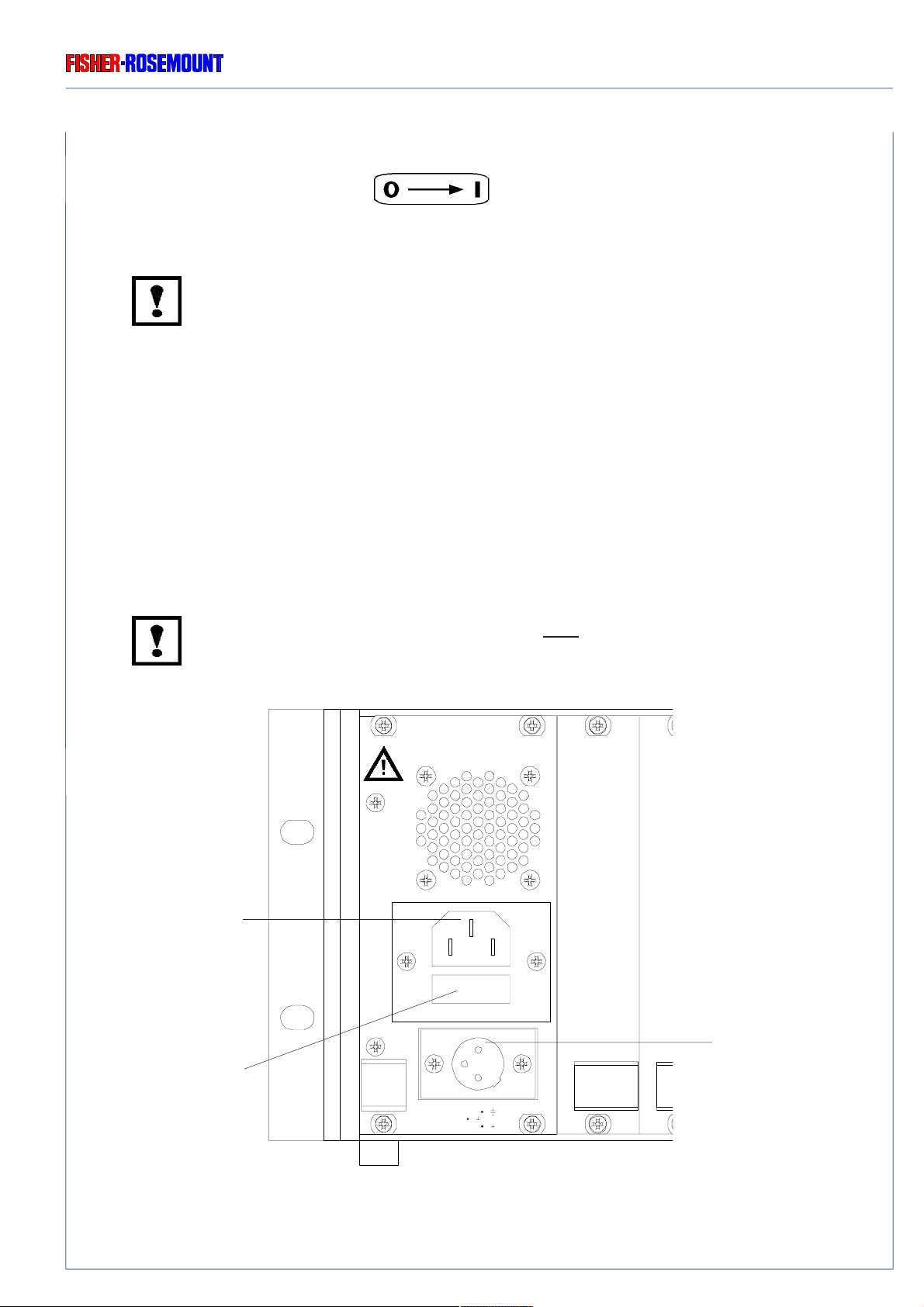

6. Switching On

Be shure to observe the safety precautions and warnings !

Observe the additional notes, safety precautions and warnings given in the

individual manuals (modules, I/O boards) !

Once the instrument has been correctly assembled and installed in accordance with the general

instructions given in section 5., the equipment is ready for operation.

The instrument is switched on by providing the required v oltage.

The instrument is specified for an operating voltage of 230 V A C (196 - 264 V A C), 47 - 63 Hz or

115 V AC (93 - 132 V AC) resp., 47 - 63 Hz and / or 24 V DC (± 10 %).

The platform must be switched on only after s witching on all modules connected

to the network. Be sure to observe the network termination (see section 1.3.5)!

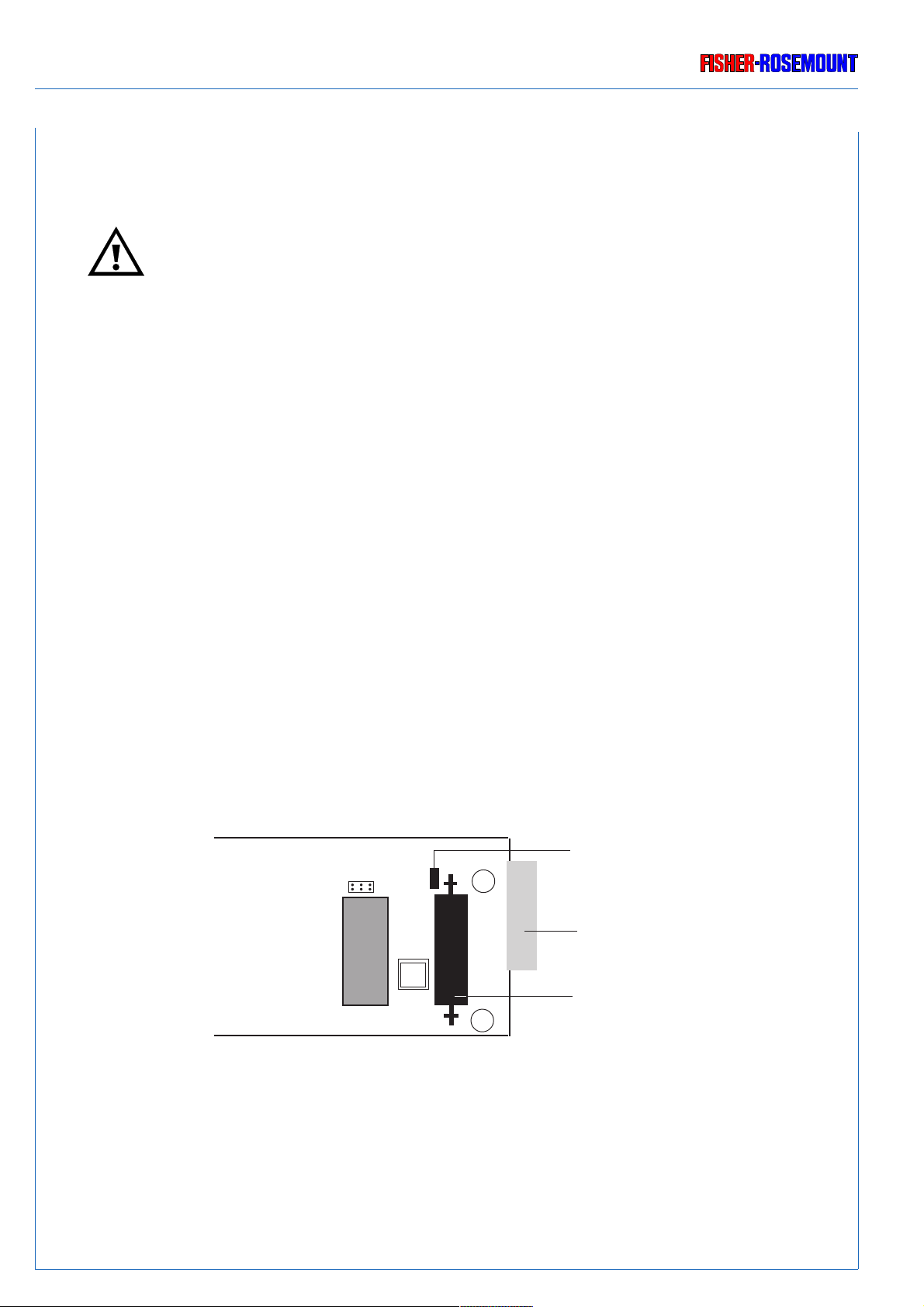

LFM 01

POWER

~

230 V

~

115 V

50/60 Hz

AC - connector

(230 / 115 Vac;

50 / 60 Hz)

AC Fuses

F1/F2: T 3,5 A)

90002496(2) [NGA-Platform e] 30.03.99

F1/F2

T3,5A / 230V

-DC 24 V IN -

1

3

2

Fig. 6-1: Voltage Supply of NGA 2000 - Platform

24 Vdc - connector

6 - 1

SWITCHING ON

Rosemount Analytical

6.1 24 Vdc - Operation

The 24 Vdc v oltage is connected via a 3-pin socket (XLR), whereb y filtered DC voltage has to be

available. The remaining interferences will be prevented by internal filters.

When both 24 Vdc and V ac voltage are supplied simultaneously , the A C voltage will be preferred.

The 24 Vdc then is automatically disconnected by a relay. The 24 Vdc will be used only while

cessation of the AC voltage .

❍ Connect power supply and Line-Fan-Module (LFM 01), (see Fig. 5-1, DC - connector).

V erify whether the line voltage stated on the instrument or power supply agrees

with that of your mains line!

Verify correct polarity for 24 V dc - operation !

Be sure to observe the safety precautions and warnings given by

manufacturer of power supply !

❍ Connect mains line and power supply.

6.2 230 / 115 Vac - Operation

❍ Connect mains line and Line-Fan Module (LFM 01), (see Fig. 5-1, AC - connector).

Verify beforehand that the line voltage stated on the LFM 01

agrees with that of your mains line !

Verify that the position of input voltage switch of the 10 A power supply ag rees

with that of your mains line (Fig. 20-3 and 1-4) !

If rear panel of LFM 01 shows “230/115 VAC”, there is built-in the 5 A power supply

with autoranging of input AC v oltage.

If rear panel of LFM 01 shows “230 VAC” or “115 VAC”, there is built-in the 10 A

power supply with manual switch of input AC voltage..

Upon switching on, the analyzer will perform a self-diagnostic test routine.

After switching on the analyzer , the software intergr ates automatically all the individual modules,

which are incorporated in the analyzer via network and have been previously s witched on, in the

system.

For former inf ormations to the displays while s witching on look at the respective software manual.

6 - 2

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

7. Switching Off

The platform is switched off by disconnecting the voltage supply.

Be shure to observe the safety precautions and warnings !

Consider also the procedure steps with regard to handling, configuration,

and operation if given in the individual manual for analysis module(s)

and additional PCBs !

SWITCHING OFF

90002496(2) [NGA-Platform e] 30.03.99

7 - 1

SWITCHING OFF

Rosemount Analytical

7 - 2

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

11. Troubleshooting

The instrument cover can be removed when necessary (see 15.).

Be sure to observe the safety precautions and warnings !

Trouble-shooting, component replacement and internal adjustments must be

made by qualified service personnel only !

TROUBLESHOOTING

NO FUNCTION (LCD DISPLAY)

11.1 Instrument has no Function (LCD display is dark)

Possible Causes Check / Correct

a) External supply voltage is absent: Check electrical supply

- DC polarity is reversed Check electrical supply

b) Possible error at line-fan module: LFM 01 is not correctly connected,

for further causes see 11.3

c) Possible error at internal power supply: Causes see 11.4

d) Internal connections incorrect or absent: Chec k internal connections:

Check whether ACU 02 is in correct place

Check ACU 02 - AFP 01 connection cable

e) AFP 01 board or LCD display defective Exchange front panel (see 17.3)

g) EPROM / A CU 02 defective: Replace EPROM / ACU 02

(see 17.4 and 17.2)

90002496(2) [NGA-Platform e] 30.03.99

11 - 1

TROUBLESHOOTING

NO MEASUREMENT SCREEN

Rosemount Analytical

11.2 No Measurement Screen

Possible Causes Check / Correct

Internal analyzer module

a) Internal connection incorrect: Check internal connection (24 Vdc/Network)

between ICB and analyzer module, and

replace cable if necessary.

b) Defective analyzer module: See the operating and servicing manual of

the analyzer module.

External modules

a) Switched off module: Switch on the module

b) No external power: Check external power supply

c) Defective network connection: Check network termination (see section 1.3.5).

Check network connection between platform

and external module, or replace the

connection cable or network module (platform)

if necessary.

d) Analyzer module has not been integrated Integrate the analyzer module in the

in the system software (network): system software (see software manual).

e) Defective analyzer module: See the operation manual of the analyzer

module.

11 - 2

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

11.3 Line - Fan - Module (LFM 01)

Possible Causes Check / Correct

a) Fan does not function: For DC operation:

TROUBLESHOOTING

LINE - FAN - MODULE / POWER SUPPLY UNIT

Pull out LFM, check fuse F 3 and replace

if necessary (see section 11.5).

In case the fuse function is properly:

LFM 01 defective, exchange module

For AC oper ation: see section 11.3 b)

b) For AC operation: Fuses defective Check fuses F 1 and F 2 and replace

if necessary (see section 11.5).

In case the fuses function is properly:

LFM 01 defective, exchange module

11.4 Power Supply Unit

Possible Causes Check / Correct

a) External supply voltage is absent: Check electrical supply

b) Green LED does not lighten: Instrument is DC operated

- Possible error at line-fan module: LFM 01 is not correctly connected,

for further causes see 11.3

- Power supply is not correctly connected Open the housing (see section 15.)

- Power supply is defective Exchange the module (see 17.2.2)

90002496(2) [NGA-Platform e] 30.03.99

and check correct fit

11 - 3

TROUBLESHOOTING

FUSES

11.5 Fuses

Be sure to observe the safety precautions and warnings !

Always disconnect power, discharge circuits and remov e external voltage before

checking the fuses !

In case of exchanging fuses the customer has to be certain that fuses of specified

type and rated current are used. It is prohibited to use repaired fuses or def ective

fuse holders or to short-circuit fuse carriers (fire hazard).

After visual checking, check the fuses with an ohmmeter.

Rosemount Analytical

If low impedance has been measured, the fuse is in order .

High impedance means, the fuse is out of order and must be replaced.

11.5.1 AC - Fuses

❍ Hinge down the fuse cov er of the AC socket (see Fig. 11-1).

❍ T ake out and check the fuses . Replace the fuse(s) if necessary [T 3.5 A / 250 V (5 x 20 mm)].

❍ Reclose the cover.

11.5.2 DC - Fuses

❍ Loosen the four f astening screws for the LFM 01 (see Fig. 11-1) and take out the LFM 01.

❍ unscrew the fuse located on the left rear side of the LFM (see Fig. 11-2), and check the fuse.

Replace the fuse if necessary [T 6.25 A / 250 V (5 x 20 mm)].

❍ Reinsert and secure the LFM with the four screws.

11 - 4

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

AC - connector

Fastening Screws

POWER

~

230 V

~

115 V

50/60 Hz

TROUBLESHOOTING

FUSES

LFM 01

AC - Fuses

F1/F2:

T 3,5 A / 230 V

F1/F2

T3,5A / 230V

-DC 24 V IN-

1

3

2

Fig. 11-1: AC - Fuses of LFM 01

fuse cover

24 Vdc - connector

90002496(2) [NGA-Platform e] 30.03.99

DC - Fuse

F3: T 6,25 A / 250 V

Fig. 11-2: DC - Fuse of LFM 01

11 - 5

TROUBLESHOOTING

Rosemount Analytical

11 - 6

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

15. Opening the Housing

Open the housing in case of troubleshooting, repair and service.

Be sure to observe the safety precautions and warnings !

Trouble-shooting, component replacement and internal adjustments must be

made by qualified service personnel only !

OPENING THE HOUSING

15.1 Front Panel

Use the following steps to remo ve the front panel:

❍ Loosen the six fastening screws of the front panel (Fig. 1-2.).

❍ Swing the front panel outwards.

Due to the built-in hinge mechanism, it is possible to swing the front panel at a certain

angle.

Thus, the inserted PCBs or the analysis module are rendered accessible.

The instrument can be operated even with opened front panel which is advantageous

during servicing.

❏ Reassembling is carried out in reverse sequence .

90002496(2) [NGA-Platform e] 30.03.99

15 - 1

OPENING THE HOUSING

15.2 Housing Cover

If required, the cover can be removed.

❍ Loosen the eight lateral recessed head screws on top .

❍ Pull the cover straight up.

❏ Reassembling is carried out in reverse sequence .

Rosemount Analytical

The cellular plastic insulation sticked on the bottom side of the co ver must

always be placed above the power supply unit !

15 - 2

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

17. Removal / Replacement of Components

Exchange components if requested by repair or servicing

Be sure to observe the safety precautions and warnings !

Component replacement and internal adjustments must be made by qualified

service personnel only !

Consider also the procedure steps with regard to handling, configuration,

and operation if given in the individual manual(s) !

REMOVAL / REPLACEMENT OF COMPONENTS

REMOVAL OF ANALYSIS MODULE

17.1 Removal of Analyzer Module

Use the following steps to remove the analyzer module:

❍ Disconnect power.

❍ Loosen the six fastening screws of the front panel (Fig. 1-2) and s wing the front panel to the

farest right (see also section 15.1).

❍ Loosen the gas connections if necessary.

To avoid a danger to the operators by e xplosive, toxic or unhealthy gas

components, first purge the gas lines with ambient air or nitrogen (N2) before

cleaning or exchange parts of the gas paths.

In case it is necessary to open the gas paths, close the analyzers

gas connections with PVC caps immediatly !

❍ Disconnect analyzer module wiring (24 Vdc and network) if necessary (see section 5.).

❍ Unlock the retention pin(s) (Fig. 1-4a) and pull out the analysis module carefully.

❏ For installation see section 5.2.

90002496(2) [NGA-Platform e] 30.03.99

17 - 1

REMOVAL / REPLACEMENT OF COMPONENTS

REMOVAL / REPLACEMENT OF PCBS / REAR MOUNTING MODULES

17.2 Removal / Replacement of PCBs / Rear Mounting Modules

Always disconnect power, discharge circuits and remove external voltage

sources before troub leshooting, repair or replacement of any component !

Be sure to observe the safety precautions and warnings !

Component replacement and internal adjustments must be made by qualified

service personnel only !

17.2.1 Rear Mounting Modules

Rosemount Analytical

❍ Loosen fastening screws of the module of interest, press do wn the le ver to unloc k module

and remove module.

❍ Replace the module und fasten the screws .

17.2.2 Internal Slots

❍ Loosen the six fastening screws of the front panel (Fig. 1-2) and s wing the front panel to the

farest left (see also section 15.1).

PCBs:

❍ Push the card ejector downwards to unlock the card of intereset and remove the card.

❍ Tilt the card ejector of the new card upwards and put in the card until the catch locks

into place.

Power Supply Unit:

❍ Push the catch downwards and remove the power supply unit by pulling at its handel

(Fig. 1-4) .

❍ Put in the new unit until the catch locks into place .

❍ Close the instrument (i.e., re-attach the front panel, see section 15.1).

17 - 2

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

REMOVAL / REPLACEMENT OF COMPONENTS

REMOVAL / REPLACEMENT OF FRONT PANEL

17.3 Removal / Replacement of Front Panel

Front panel plate together with LCD display, circuit board AFP 01, and hinge mechanism

constitutes an unit. Therefore, the front panel has to be disassembled completely when one

component of the unit is out of order.

Be sure to observe the safety precautions and warnings !

Component replacement and internal adjustments must be made by qualified

service personnel only !

❍ Loosen the six fastening screws for the front panel (Fig. 1-2) and swing the front panel

outwards preferably to the right position (see also section 15.1).

❍ Remove the cab le (ACU 02 - AFP 01 connection) from the circuit board ACU 02.

❍ Unscrew both fastening screws (top and bottom screw) by using a short screwdriver

for the hinge mechanism to complete remove the front panel.

❍ Re-insert swivel mechanism and complete front panel in the housing and tighten both

fastening scre ws (top and bottom screws) by using a short screwdriver (see Fig. 17-1).

❍ Re-attach the cable (ACU 02 - AFP 01 connection) to the circuit board ACU 02.

❍ Close the instrument (i.e., re-attach the front panel, see section 15.1).

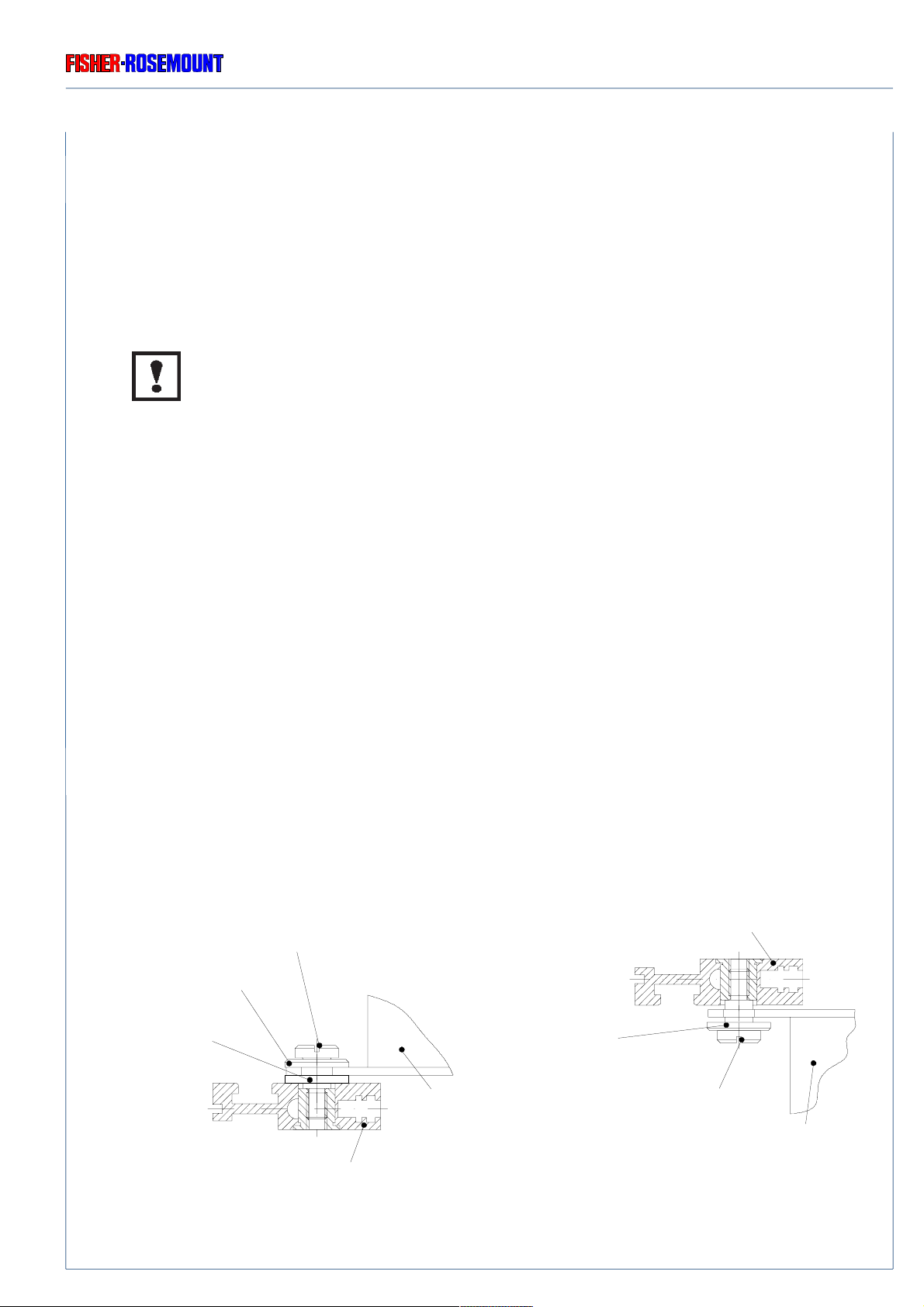

upper housing strut

lower fastening screw

metal washer

NYLON washer

Fig. 17-1: Fastening screws for the hinge mechanism (partial view)

90002496(2) [NGA-Platform e] 30.03.99

lower housing strut

hinge

mechanism

metal washer

upper fastening screw

hinge

mechanism

17 - 3

REMOVAL / REPLACEMENT OF COMPONENTS

REPLACEMENT OF EPROM / BUFFER BATTERY OF ACU 02

Rosemount Analytical

17.4 Replacement of EPROM / Buffer Battery on the ACU 02

Always disconnect power, discharge circuits and remove external voltage

sources before troub leshooting, repair or replacement of any component !

17.4.1 Removal of ACU 02

Use the following steps to remo ve the ACU 02 board:

❍ Loosen the six fastening screws of the front panel (Fig. 1-2) and s wing the front panel to the

farest left (see also section 15.1).

❍ Remove the cab le (ACU 02 - AFP 01 connection) from the circuit board ACU 02.

❍ Push the card ejector for the A CU 02 downwards and remove the board.

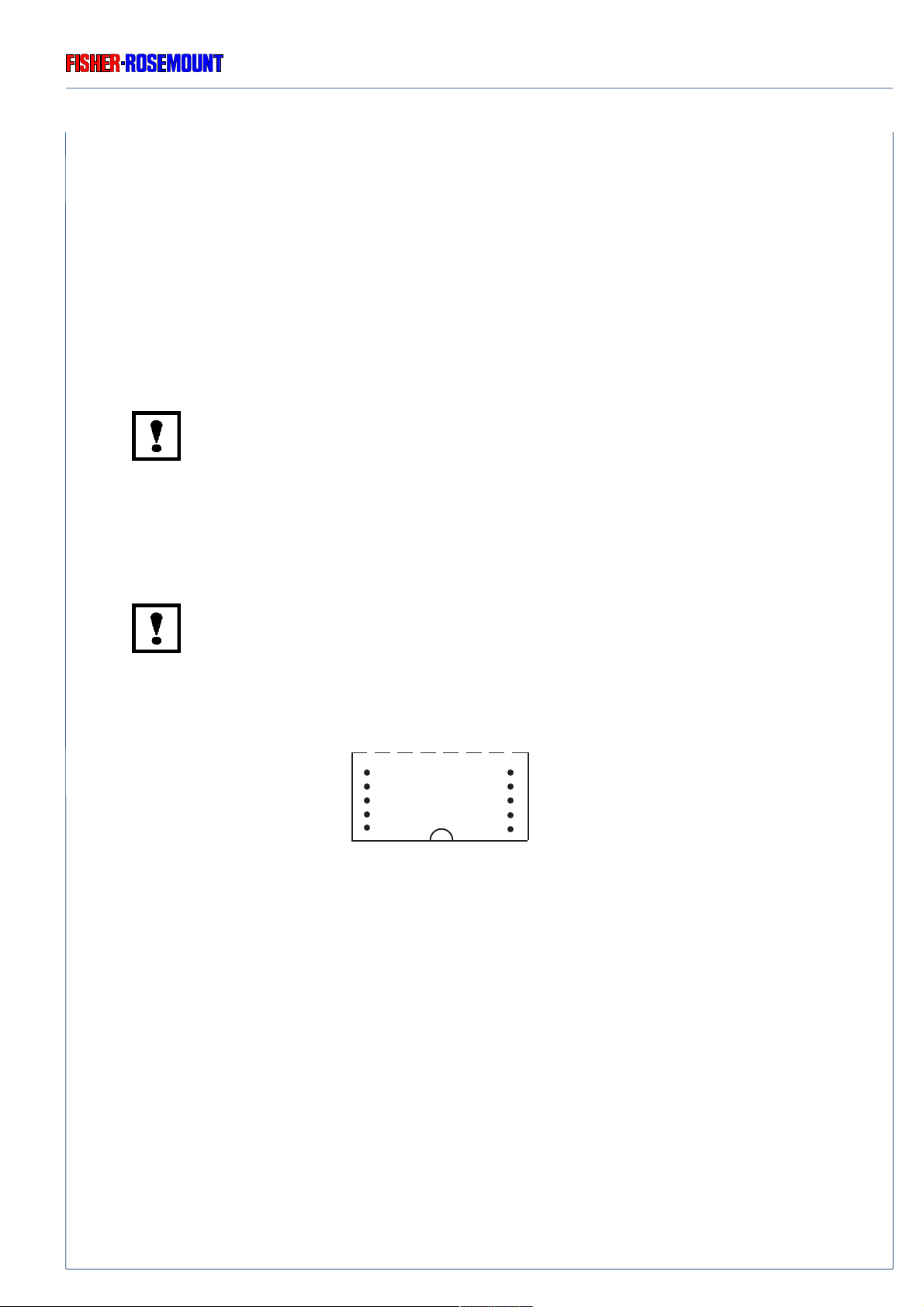

Battery Jumper (P 23)

(P20)

(P23)

+

Connection

to LCD dispaly

17 - 4

D32

EPROM

(P1)

-

Fig. 17-2: Controller Board ACU 02 (partial view, component side)

Buffer battery

on soldering pins

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

REPLACEMENT OF EPROM / BUFFER BATTERY OF ACU 02

REMOVAL / REPLACEMENT OF COMPONENTS

17.4.2 Replacement of EPROM

The EPROM located on the ACU 02 ma y easily be replaced (e.g. in case of a def ective board or

a new program version). Use the following procedure to replace the EPROM:

❍ Remove the ACU 02 (see 17.4.1).

❍ Remove the jumper “P 23” for battery buffer (Fig. 17-2).

All data and compensation values entered by the user will be deleted (RAM-fail) !

❍ Remove the EPR OM from its socket (see Fig. 17-2).

❍ Insert the new EPROM.

Verify polarity when inserting the new EPROM !

A semicircular notch can be found both on the EPR OM and the socket.

○○○○○

○○○○○

For the correct insertion of the EPROM, both notches hav e to be superimposed.

After the replacement:

❍ Re-insert the jumper for battery buffer (Fig. 17-2).

❍ Install the ACU 02 (see 17.4.4).

90002496(2) [NGA-Platform e] 30.03.99

17 - 5

REMOVAL / REPLACEMENT OF COMPONENTS

REPLACEMENT OF EPROM / BUFFER BATTERY OF ACU 02

17.4.3 Replacement of Buffer Battery

Use the following procedure to replace the battery:

❍ Remove the ACU 02 (see 17.4.1).

❍ Remove the jumper “P 23” for battery buffer (Fig. 17-2).

All data and compensation values entered by the user will be deleted (RAM-fail) !

Rosemount Analytical

❍ Unsolder the battery from the soldering pins (see Fig. 17-2).

❍ Solder the new battery (Ordering No. 03 765 180) to the soldering pins (see Fig. 17-2).

Verify polarity when soldering the new battery (Fig. 17-2) !

After the replacement:

❍ Re-insert the jumper for battery buffer (Fig. 17-2).

❍ Install the ACU 02 (see 17.4.4).

17.4.4 Installation of ACU 02

❍ Tilt the card ejector of the ACU 02 upwards and put in the card until the catch loc ks into

place.

❍ Re-attach the cable (A CU 02 - AFP 01 connection) to the circuit board ACU 02.

❍ Close the instrument (i.e., re-attach the front panel, see section 15.1).

❍ Switch on instrument.

Now all the data required by the user can be entered again, e .g. system parameters.

17 - 6

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

CLEANING OF HOUSING OUTSIDE

19. Cleaning of Housing Outside

For cleaning housing outside, you need a soft, fluff free cloth and all purpose detergent.

❍ Disconnect all voltage supplies.

To avoid a danger to the operators by e xplosive, toxic or unhealthy gas

components, first purge the gas lines with ambient air or nitrogen (N2) before

cleaning or exchange parts of the gas paths.

If it is necessary to disconnect the gas connections of analysis modules, the gas

line fittings of the module have to be closed with PVC-caps before cleaning !

❍ Moisten of the soft, fluff free cloth with the cleaning solution

(mixture of 3 parts water, 1 part all purpose detergent max.).

Be sure to use a moisted, but not wet, cloth only !

Be sure, that non liquid can drop into the housing inside !

❍ Cleaning of the platform housing outside with the moisted cloth.

❍ If required, rub off the housing with a dry cloth afterwards.

90002496(2) [NGA-Platform e] 30.03.99

19 - 1

CLEANING OF HOUSING OUTSIDE

Rosemount Analytical

19 - 2

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

20. Technical Data

20.1 Platform

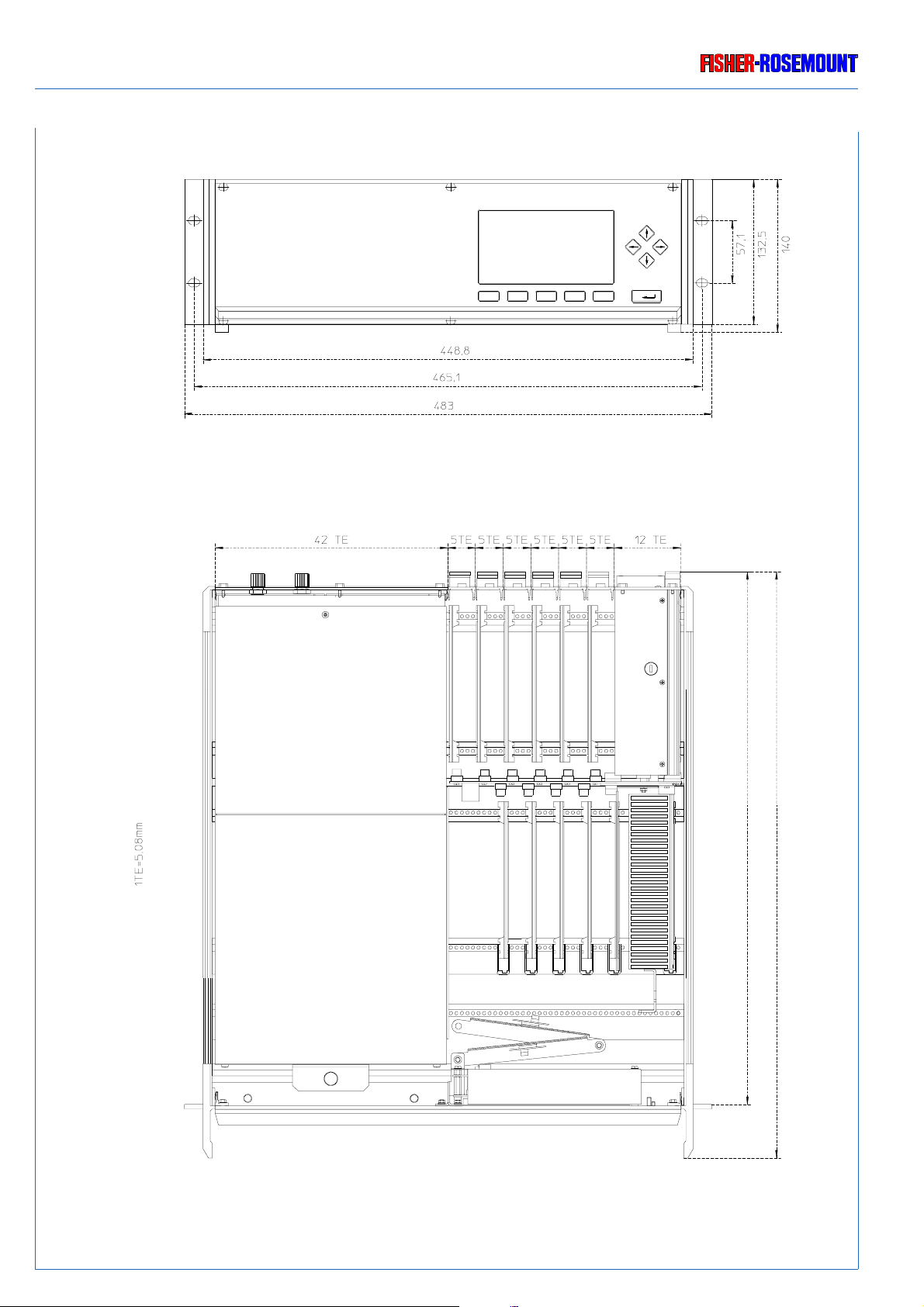

20.1.1 Housing

TECHNICAL DATA

PLATFORM

Certifications

1)

EN 50081-1, EN 50082-2, EN 61010-1

NAMUR, CSA NRTL/C, C-Tick, PAC, IS,

GOSSTANDART

Weight approx. 10 kg (including all standard modules)

Type of housing 19" - 3 HU, rack or table top housing

Materials Aluminum

Protection Class IP 20 (according to DIN standard 40050)

Dimensions see Figs. 20-1 and 20-2

20.1.2 Environments

Permissible ambient temperature + 5 °C to + 45 °C

Solar radiation (sunshine) The housing must not directly be irradiated by

sun light or fluorescence lamps.

Altitude 0 - 1500 m (above sea level)

Humidity (not- condensing) < 90 % rel. humidity at + 20 °C

< 50 % rel. humidity at + 40 °C

Rain / Drop- and splash water The housing must not be exposed to rain or

drop-/splash water.

Explosive atmosphere The housing must not be operated in explosive

atmosphere

1)

partly in preparation

90002496(2) [NGA-Platform e] 30.03.99

20 - 1

TECHNICAL DATA

PLATFORM

Rosemount Analytical

20 - 2

Fig. 20-1: Housing dimensions (in [mm]) (with standard analyzer module)

90002496(2) [NGA-Platform e] 30.03.99

488

537

Rosemount Analytical

TECHNICAL DATA

PLATFORM

Fig. 20-2: Housing dimensions (in [mm]) (with extended analyzer module)

90002496(2) [NGA-Platform e] 30.03.99

488

537

615

664

20 - 3

TECHNICAL DATA

LINE - FAN - MODULE (LFM 01)

Rosemount Analytical

20.2 Line - Fan - Module (LFM 01)

Electrical connections

external IEC connector with 2 fuses and RFI filter.

Audio connector (XLR) / 24 V DC;

pre-connecting shield, 3-pin

internal 230 Vac connector, pre-connecting shield

24 Vdc connector for low voltage

Nominal voltage 230 / 115 Vac, 50 / 60 Hz

Input voltage 93 - 132 Vac, 47 - 63 Hz

or

196 - 264 Vdc, 47 - 63 Hz

and / or

24 V DC ± 10 %

Ripple and noise < 100 mV pp

Fuses AC F1 / F2: T 3,5 A / 230 V (5 x 20 mm)

DC F3: T 6,25 A / 230 V (5 x 20 mm)

Power consumption maxi. 240 VA / 240 W

Outline dimensions 3 HU, 12 DU, 160 mm (length)

Weight 280 g, approx.

Housing material Aluminum, light chromated

20.2.1 Electrical Safety

Over-voltage category II

Pollution degree 2

Safety Class 1

20 - 4

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

20.3 Internal Power Supply Unit

20.3.1 5 A Power Supply

Outline dimensions 8 DU - Euro card slot with handle

Weight 550 g, approx.

Nominal voltage 230 / 115 Vac, 50 / 60 Hz

Input voltages 93 - 132 Vac, 47 - 63 Hz

or

196 - 264 Vac, 47 - 63 Hz

TECHNICAL DATA

POWER SUPPLY UNIT

Output voltages 24 Vdc ± 5 % / 5 A

Electrical connections Connector H 15 / DIN 41612

20.3.2 10 A Power Supply

Input terminal strips

Electrical connections to ICB 01 Connector H 15 / DIN 41612 via PCB PPA 01

Nominal voltage 230 / 115 V ac, 50 / 60 Hz

Input voltage 196–264 V ac or 93–132 V ac, 47-63 Hz

with manual switch

Input power max. 700 VA

Output terminal strips

Electrical connections to analyzer module 24 Vdc connector for low voltage via PCB PPA 01

Output voltage 24 V dc

max. 10.0 A

Output power max. 240 VA

Dimensions 125 x 122 x 103 mm (HxWxD), see Fig. 20-3

90002496(2) [NGA-Platform e] 30.03.99

20 - 5

TECHNICAL DATA

Manual Switch 230 / 115 Vac

Rosemount Analytical

Front View Side View

Fig. 20-3: Dimensional Sketch power Supply SL10 [mm]

20 - 6

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

21. Pin Assignments

Use only from our factory optional delivered cables or equiv alent shielded cables

to be in agreement with the CE - conformity.

The customer has to guarantee, that the shield is be connected bothsided.

Shield and connectors housing have to be connected conductiv e.

Sub.-min.-D-plugs/soc kets have to be scre w ed to the analyzer.

21.1 24 Vdc Input ( LFM 01)

PIN ASSIGNMENTS

VOLTAGE INPUT

1

3

(shield)

2

Supply from front

(see Fig. 6-1, too)

Fig. 21-1: Pin assignments 24 Vdc Input (LFM 01)

21.2 230/115 Vac Input (LFM 01)

Fig. 21-2: Pin assignments 230/115 Vac Input (LFM 01)

PE

Pin 1: ME

Pin 2: + 24 Vdc

Pin 3: 0 V DC (

⊥⊥

⊥)

⊥⊥

shield: housing flange

21.3 24 Vdc Output to analyzer module (internal)

Pin 1: ME

231

Pin 2: + 24 Vdc

Pin 3: 0 V DC (

shield: housing flange

Fig. 21-3: Pin assignments 24 Vdc output to analyzer moduel (internal)

(see Item 5.3, too)

90002496(2) [NGA-Platform e] 30.03.99

⊥⊥

⊥)

⊥⊥

21 - 1

PIN ASSIGNMENTS

Rosemount Analytical

21 - 2

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

INDEX

Index

A

AC - Operation 6 - 2

10 A Power Supply Unit 6 - 2

5 A Power Supply Unit 6 - 2

ACU 02 (Controller Board) 1 - 12

Electrostatic Discharge S - 7

Installation of ACU 02 17 - 6

Removal of ACU 02 17 - 4

Replacement of Buffer Battery 17 - 6

Replacement of EPROM 17 - 5

Safety Measures S - 1

Electrostatic Discharge S - 7

Additional notes for service / maintenance S - 6

Ambient Temperature, permissible 20 - 1

Analyzer Module 1 - 1, 1 - 4, 1 - 5, 1 - 6

Installation of an Analyzer Module 5 - 3

Removal of Analyzer Module 17 - 1

Safety Measures S - 1

Additional notes for service / maintenance S - 6

Gases and Gas Conditioning S - 3

B

Buffer Battery 17 - 4

Replacement 17 - 6

Safety Measures S - 1

C

Cleaning of platform housing outside 19 - 1

Controller Board ACU 02 1 - 12

Electrostatic Discharge S - 7

Installation of ACU 02 17 - 6

Removal of ACU 02 17 - 4

Replacement of Buffer Battery 17 - 6

Replacement of EPROM 17 - 5

Safety Measures S - 1

Electrostatic Discharge S - 7

D

DC - Operation 6 - 2

Dimensions 20 - 1

E

Electrical Safety 20 - 4

Safety Class 20 - 4

Electrostatic Discharge S - 7

Environments 20 - 1

External Modules 5 - 2

F

Front Panel 1 - 3

Removal / Replacement of 17 - 3

Safety Measures S - 1

Fuses 11 - 4.

AC - Fuses 11 - 4

DC - Fuse 11 - 4

Troubleshooting 11 - 4

See

Technical Data

, too

.

H

Housing

Controller Board ACU 02 1 - 12

Dimensions 20 - 2, 20 - 3

Front Panel 1 - 3

Inside View 1 - 5, 1 - 6

Line - Fan - Module (LFM 01) 1 - 10

Network Module (LEM 01) 1 - 13

Network Termination 1 - 13, 1 - 14

Power Supply Unit 1 - 9

10 A loading 1 - 6, 1 - 9, 1 - 11, 6 - 2

5 A loading 1 - 5, 1 - 9, 1 - 11, 6 - 2

Printed Circuit Boards (PCB)

Controller Board ACU 02 1 - 12

Interconnection Board ICB 01 1 - 7

Rear Mounting Modules

Line - Fan - Module (LFM 01) 1 - 10

Network - Module (LEM 01) 1 - 13

Rear View 1 - 4

I

Installation of an Analyzer Module 5 - 3

Safety Measures S - 1

Installation of PCBs / Rear Mounting Modules

Internal Slots 5 - 4

Rear Mounting Modules 5 - 4

Safety Measures S - 1

Installation Site 5 - 1

Environments 20 - 1

Permissible Ambient Temperature 20 - 1

Safety Measures S - 1

Instrument specific notes for the user S - 5

Interconnection Board ICB 01 1 - 7

Internal Slots 5 - 4

Installation 5 - 4

Removal / Replacement 17 - 2

Safety Measures S - 1

90002496(2) [NGA-Platform e] 30.03.99

R - 1

INDEX

Rosemount Analytical

L

LEM 01 (Network Module) 1 - 13, 5 - 2

Network Termination 1 - 13, 1 - 14

LFM 01 (Line - Fan - Module) 1 - 10

Technical Data 20 - 4

Line - Fan - Module (LFM 01) 1 - 10

Technical Data 20 - 4

M

Maintenance

Cleaning of platform housing outside 19 - 1

Installation of an Analyzer Module 5 - 3

Internal Slots

Installation 5 - 4

Removal / Replacement 17 - 2

Opening the Housing 15 - 1

Front Panel 15 - 1

Housing Cover 15 - 2

Rear Mounting Modules

Installation 5 - 4

Removal / Replacement 17 - 2

Removal / Replacement of Components 17 - 1

Removal / Replacement of Front Panel 17 - 3

Removal of Analyzer Module 17 - 1

Removal/Replacement of PCBs/Rear Mounting Modules

Internal Slots 17 - 2

Rear Mounting Modules 17 - 2

Replacement of EPROM / Buffer Battery of ACU 02 17 - 4

Installation of ACU 02 17 - 6

Removal of ACU 02 17 - 4

Replacement of Buffer Battery 17 - 6

Replacement of EPROM 17 - 5, 17 - 6

Safety Measures S - 1

Additional notes for service / maintenance S - 6

Electrostatic Discharge S - 7

Gases and Gas Conditioning (Sample Handling) S - 3

General S - 2

Instrument specific notes for the user S - 5

Supply Voltage S - 4

Switching Off 7 - 1

N

Network Module (LEM 01) 1 - 13, 5 - 2

Network Termination 1 - 13, 1 - 14

Network Termination 1 - 13

O

Opening the Housing 15 - 1

Front Panel 15 - 1

Housing Cover 15 - 2

Safety Measures S - 1

Operating Voltage 6 - 1

10 A Power Supply Unit 6 - 2

5 A Power Supply Unit 6 - 2

Operation

Preparation 5 - 1

Installation of an Analyzer Module 5 - 3

Installation Site 5 - 1

Network Termination 1 - 13, 1 - 14

Safety Measures S - 1

Switching Off 7 - 1

Switching On 6 - 1

230 / 115 Vac - Operation 6 - 2

24 Vdc - Operation 6 - 2

Operating Voltage 6 - 1

Safety Measures S - 1

P

Permissible Ambient Temperature 5 - 1, 20 - 1

Pin Assignments 21 - 1

230/115 Vac Input (LFM 01) 21 - 1

24 Vdc Input (LFM 01) 21 - 1

24 Vdc Output to analyzer module (internal) 21 - 1

Power consumption 20 - 4

Power Supply Unit 1 - 9

10 A loading 1 - 6, 1 - 9, 6 - 2

Retrofit kit 1 - 9

Technical Data 20 - 5

5 A loading 1 - 5, 1 - 9

Technical Data 20 - 5

Technical Data 20 - 5

Troubleshooting 11 - 3

Preparation 5 - 1

External Modules 5 - 2

Network Termination 1 - 13, 1 - 14

Installation of an Analyzer Module 5 - 3

Installation of PCBs / Rear Mounting Modules

Internal Slots 5 - 4

Rear Mounting Modules 5 - 4

Installation Site 5 - 1

Ambient Temperature, permissible 20 - 1

Environments 20 - 1

Network Termination 1 - 13, 1 - 14

Safety Measures S - 1

Additional notes for service / maintenance S - 6

Gases and Gas Conditioning (Sample Handling) S - 3

General S - 2

Instrument specific notes for the user S - 5

Supply Voltage S - 4

Printed Circuit Boards (PCB)

Controller Board ACU 02 1 - 12

Interconnection Board ICB 01 1 - 7

Protection Class 20 - 1

R - 2

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

INDEX

R

Rear Mounting Modules 1 - 4

Installation 5 - 4

Line - Fan - Module (LFM 01) 1 - 10

Network Module (LEM 01) 1 - 13

Removal / Replacement 17 - 2

Removal / Replacement of Components 17 - 1

Installation of an Analyzer Module 5 - 3

Removal / Replacement of Front Panel 17 - 3

Removal of Analyzer Module 17 - 1

Removal/Replacement of PCBs/Rear Mounting Modules

Internal Slots 17 - 2

Rear Mounting Modules 17 - 2

Replacement of EPROM / Buffer Battery of ACU 02 17 - 4

Safety Measures S - 1

Removal of Analyzer Module 17 - 1

Safety Measures S - 1

Removal/Replacement of PCBs/Rear Mounting Modules

Internal Slots

Installation 5 - 4

Removal 17 - 2

Rear Mounting Modules

Installation 5 - 4

Removal 17 - 2

Safety Measures S - 1

Replacement of Buffer Battery

Installation of ACU 02 17 - 6

Removal of ACU 02 17 - 4

Replacement 17 - 6

Safety Measures S - 1

Replacement of EPROM

Installation of ACU 02 17 - 6

Removal of ACU 02 17 - 4

Replacement 17 - 5

Safety Measures S - 1

Replacement of EPROM / Buffer Battery of ACU 02 17 - 4

Installation of ACU 02 17 - 6

Removal of ACU 02 17 - 4

Replacement of Buffer Battery 17 - 6

Replacement of EPROM 17 - 5

Safety Measures S - 1

Replacement of Front Panel 17 - 3

Safety Measures S - 1

S

Safety Class 20 - 4

Safety Measures S - 1

Additional notes for service / maintenance S - 6

Electrostatic Discharge S - 7

Gases and Gas Conditioning (Sample Handling) S - 3

General S - 2

Instrument specific notes for the user S - 5

Supply Voltage S - 4

Switching Off 7 - 1

Switching On 6 - 1

230 / 115 Vac - Operation 6 - 2

24 Vdc - Operation 6 - 2

Operating Voltage 6 - 1

10 A Power Supply Unit 6 - 2

5 A Power Supply Unit 6 - 2

Pin Assignments 21 - 1

230/115 Vac Input (LFM 01) 21 - 1

24 Vdc Input (LFM 01) 21 - 1

24 Vdc Output to analyzer module (internal) 21 - 1

Safety Measures S - 1

Additional notes for service / maintenance S - 6

Gases and Gas Conditioning (Sample Handling) S - 3

General S - 2

Instrument specific notes for the user S - 5

Supply Voltage S - 4

T

Technical Data 20 - 1

Ambient Temperature, permissible 20 - 1

Dimensions 20 - 1

Electrical Safety 20 - 4

Safety Class 20 - 4

Environments 20 - 1

Line - Fan - Module (LFM 01) 20 - 4

Operating Voltage 6 - 1

Permissible Ambient Temperature 20 - 1

Power Supply Unit 20 - 5

10 A loading 20 - 5

5 A loading 20 - 5

Protection Class 20 - 1

Weight 20 - 1

Technical Description 1 - 1

Housing

Front Panel 1 - 3

Inside View 1 - 5, 1 - 6

Line - Fan - Modul (LFM 01) 1 - 10

Network Module (LEM 01) 1 - 13

Rear View 1 - 4

Power Supply Unit 1 - 9

10 A loading 1 - 6, 1 - 9

5 A loading 1 - 5, 1 - 9

Printed Circuit Boards (PCB)

Controller Board ACU 02 1 - 12

Interconnection Board ICB 01 1 - 7

Rear Mounting Modules

Line - Fan - Modul (LFM 01) 1 - 10

Network Module (LEM 01) 1 - 13

Termination (Network) 1 - 13, 1 - 14, 11 - 2

90002496(2) [NGA-Platform e] 30.03.99

R - 3

INDEX

Rosemount Analytical

Troubleshooting 11 - 1

Front Panel 11 - 1

Fuses 11 - 4

AC - Fuses 11 - 4

DC - Fuse 11 - 4

Internal Slots

Installation 5 - 4

Power Supply Unit 11 - 3

Removal / Replacement 17 - 2

Safety Measures S - 1

No instrument function (LCD display) 11 - 1

No measurement screen 11 - 2

Network Termination 1 - 13, 1 - 14, 11 - 2

Opening the Housing 15 - 1

Front Panel 15 - 1

Housing Cover 15 - 2

Safety Measures S - 1

Power Supply Unit 11 - 3

Safety Measures S - 1

Rear Mounting Modules

Installation 5 - 4

Removal / Replacement 17 - 2

Safety Measures S - 1

Removal / Replacement of Components 17 - 1

Safety Measures S - 1

Removal / Replacement of Front Panel 17 - 3

Removal of Analyzer Module 17 - 1

Safety Measures S - 1

Removal/Replacement of PCBs/Rear Mounting Modules

Internal Slots 17 - 2

Rear Mounting Modules 17 - 2

Safety Measures S - 1

Replacement of EPROM / Buffer Battery of ACU 02 17 - 4

Installation of ACU 02 17 - 6

Removal of ACU 02 17 - 4

Replacement of Buffer Battery 17 - 6

Replacement of EPROM 17 - 5

Safety Measures S - 1

Additional notes for service / maintenance S - 6

Electrostatic Discharge S - 7

Gases and Gas Conditioning (Sample Handling) S - 3

General S - 2

Instrument specific notes for the user S - 5

Supply Voltage S - 4

Switching Off 7 - 1

V

Voltage Supply

Operating Voltage 6 - 1

10 A Power Supply Unit 6 - 2

5 A Power Supply Unit 6 - 2

Pin Assignments

230/115 Vac Input (LFM 01) 21 - 1

24 Vdc Input (LFM 01) 21 - 1

24 Vdc Output to analyzer module (internal) 21 - 1

W

Weight 20 - 1

R - 4

90002496(2) [NGA-Platform e] 30.03.99

Rosemount Analytical

List of Figures

Fig. Title Page

Fig. 1-1: Block diagram platform design (external) 1 - 1

Fig. 1-1a: Analyzer system via platform (schematic diagram) 1 - 2

Fig. 1-2: Housing, Front View (Front panel) 1 - 3

Fig. 1-3: Housing, Rear View 1 - 4

Fig. 1-4a: Internal view of housing (with 5 A power supply) 1 - 5

Fig. 1-4b: Internal view of housing (with 10 A power supply) 1 - 6

Fig. 1-5: Printed Circuit Board ICB 01(viewed from front panel) 1 - 7

Fig. 1-6a: Block diagram internal platform design (with 5 A power supply) 1 - 8

Fig. 1-6b: Block diagram internal platform design (with 10 A power supply) 1 - 8

Fig. 1-7: Pin assignment, 64-pin ICB-bus connector 1 - 9

Fig. 1-8: Rear panel LFM 01 (sectional view of the housing) 1 - 10

Fig. 1-9: Rear panel network module LEM 01 (sectional view of the housing) 1 - 13

Fig. 1-10: RJ 45 network termination connector 1 - 13

Fig. 1-11: Network termination (examples) 1 - 14

INDEX

LIST OF FIGURES

Fig. 5-1: Rear panel network module LEM 01 (sectional view of the housing) 5 - 2

Fig. 5-2: Printed Circuit Board ICB 01 (viewed from front panel) 5 - 3

Fig. 6-1: Voltage Supply of NGA 2000 - Platform 6 - 1

Fig. 11-1: AC - Fuses of LFM 01 11 - 5

Fig. 11-2: DC - Fuse of LFM 01 11 - 5

Fig. 17-1: Fastening screws for the hinge mechanism (partial view )17 - 3

Fig. 17-2: Controller Board ACU 02 (partial view, component side) 17 - 4

Fig. 20-1: Housing dimensions (in [mm]) (with standard analyzer module) 20 - 2

Fig. 20-2: Housing dimensions (in [mm]) (with extended analyzer module) 20 - 3

Fig. 20-3: Dimensional Sketch power Supply SL10 [mm] 20 - 6

Fig. 21-1: Pin assignments 24 Vdc Input (LFM 01) 21 - 1

Fig. 21-2: Pin assignments 230/115 Vac Input (LFM 01) 21 - 1

Fig. 21-3: Pin assignments 24 Vdc output to analyzer moduel (internal) (see Item 5.3, too) 21 - 1

90002496(2) [NGA-Platform e] 30.03.99

R - 5

NGA 2000 Platform

APPENDIX Declarations of Conformity

A-1 NGA 2000 P

A-2 NGA 2000 PE

Instruction Manual

90002496

04/2008

Instruction Manual

90002496

04/2008

NGA 2000 Platform

Instruction Manual

90002496

04/2008

WORLD HEADQUARTERS

ROSEMOUNT ANAL YTICAL EUROPE

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T 49 6055 884 0

F 49 6055 884209

Emerson Process Management

Rosemount Analytical Inc.

6565 P Davis Industrial Parkway

Solon, OH 44139 USA

T 440.914.1261

Toll Free in US and Canada 800.433.6076

F 440.914.1271

e-mail: gas.csc@EmersonProcess.com

www.raihome.com

GAS CHROMA TOGRAPHY CENTER

AND LATIN AMERICA

Emerson Process Management

Rosemount Analytical Inc.

11100 Brittmoore Park Drive

Houston, TX 77041

T 713 467 6000

F 713 827 3329

NGA 2000 Platform

EUROPE, MIDDLE EAST AND AFRICA

Emerson Process Management

Shared Services Limited

Heath Place

Bognor Regis

West Sussex PO22 9SH

England

T 44 1243 863121

F 44 1243 845354

ASIA-PACIFIC

Emerson Process Management

Asia Pacific Private Limited

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T 65 6 777 8211

F 65 6 777 0947

e-mail: analytical@ap.emersonprocess.com

© Emerson Process Management GmbH & Co. OHG 2007

Loading...

Loading...