NGA 2000

N

ON

-D

ISPERSIVE INFRARED

A

NALYZER

Rosemount Analytical

M

ODULE

N

OTICE

T

HE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE

Pyrex® is a registered trademark of Corning Glass Works

®

Irtran

is a registered trademark of Eastman Kodak Co.

®

Teflon

Ty-Rap

and Viton® is a registered trademark of E.I. duPont de Nemours and Co., Inc.

®

is a registered trademark of Thomas & Betts Corp.

.

Manual Part Number 748332-D

June 1997

Printed in U.S.A.

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

C

P

REFACE

PURPOSE/SAFETY SUMMARY........................................................................P-1

GLOSSARY ......................................................................................................P-4

SPECIFICATIONS..............................................................................................P-6

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE ....P-8

RETURNING PARTS TO THE FACTORY .........................................................P-8

TRAINING ......................................................................................................P-8

DOCUMENTATION............................................................................................P-8

COMPLIANCES..................................................................................................P-9

ONTENTS

S

ECTION

1.1 OVERVIEW ...............................................................................................1-1

1.2 TYPICAL APPLICATIONS.........................................................................1-1

1.3 THEORY OF TECHNOLOGY....................................................................1-2

1.4 SAMPLE REQUIREMENTS ......................................................................1-4

1-5 PURGE KITS.............................................................................................1-5

1.6 FEATURES................................................................................................1-5

S

ECTION

2.1 UNPACKING..............................................................................................2-1

2.2 ASSEMBLY................................................................................................2-1

2.3 LOCATION ................................................................................................2-2

2.4 GASES ......................................................................................................2-2

2.5 ELECTRICAL CONNECTIONS .................................................................2-5

1. I

2. I

2.4.1 Specifications...............................................................................2-2

2.4.2 Connections.................................................................................2-3

NTRODUCTION

NSTALLATION

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

i

C

ONTENTS

S

ECTION

3.1 OVERVIEW............................................................................................... 3-1

3.2 DISPLAY SCREENS.................................................................................3-1

3.2.1 RUN MODE DISPLAY............................................................................3-1

3.3 STARTUP PROCEDURE..........................................................................3-2

3.4 BINDING ...................................................................................................3-5

3.5 CALIBRATION ..........................................................................................3-5

3.6 LINEARIZATION.......................................................................................3-8

3.7 ROUTINE OPERATION............................................................................3-9

S

ECTION

4.1 OVERVIEW............................................................................................... 4-1

4.2 PCB REPLACEMENT...............................................................................4-2

4.3 POWER FUSE REPLACEMENT ..............................................................4-2

3. S

3.2.2 Menu Displays.............................................................................3-1

3.2.3 Help Displays...............................................................................3-2

4. M

TARTUP AND OPERATION

AINTENANCE AND TROUBLESHOOTING

4.4 MODULE FAN REPLACEMENT...............................................................4-2

4.5 CHOPPER MOTOR REPLACEMENT ......................................................4-3

4.6 SOURCE REPLACEMENT.......................................................................4-3

4.7 DETECTOR REMOVAL............................................................................4-3

4.8 FLOW SENSOR REPLACEMENT............................................................4-3

4.9 CASE TEMPERATURE SENSOR REPLACEMENT ................................4-4

4.10 THERMAL FUSE REPLACEMENT...........................................................4-4

4.11 OSCILLATOR TUNE/SOURCE BALANCE SHUTTER ADJUSTMENT....4-4

4-12 CLEANING CELLS ...................................................................................4-8

4-13 CELL DESICCANT ...................................................................................4-10

4.14 MODULATION CHECK.............................................................................4-10

S

ECTION

5.1 REPLACEMENT PARTS ..........................................................................5-1

5.

REPLACEMENT PARTS

A

PPENDIX

ii

A. I

DENTIFICATION MATRIX

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

NFRARED ANALYZER DATA SHEET

I

ENERAL PRECAUTIONS FOR HANDLING

G

ARRANTY

W

IELD SERVICE AND REPAIR FACILITIES

F

F

IGURES

1-1 NGA 2000 NDIR Analyzer Module (Typical - Actual configuration May

Vary)..............................................................................................1-3

1-2 NDIR Technology ......................................................................................1-4

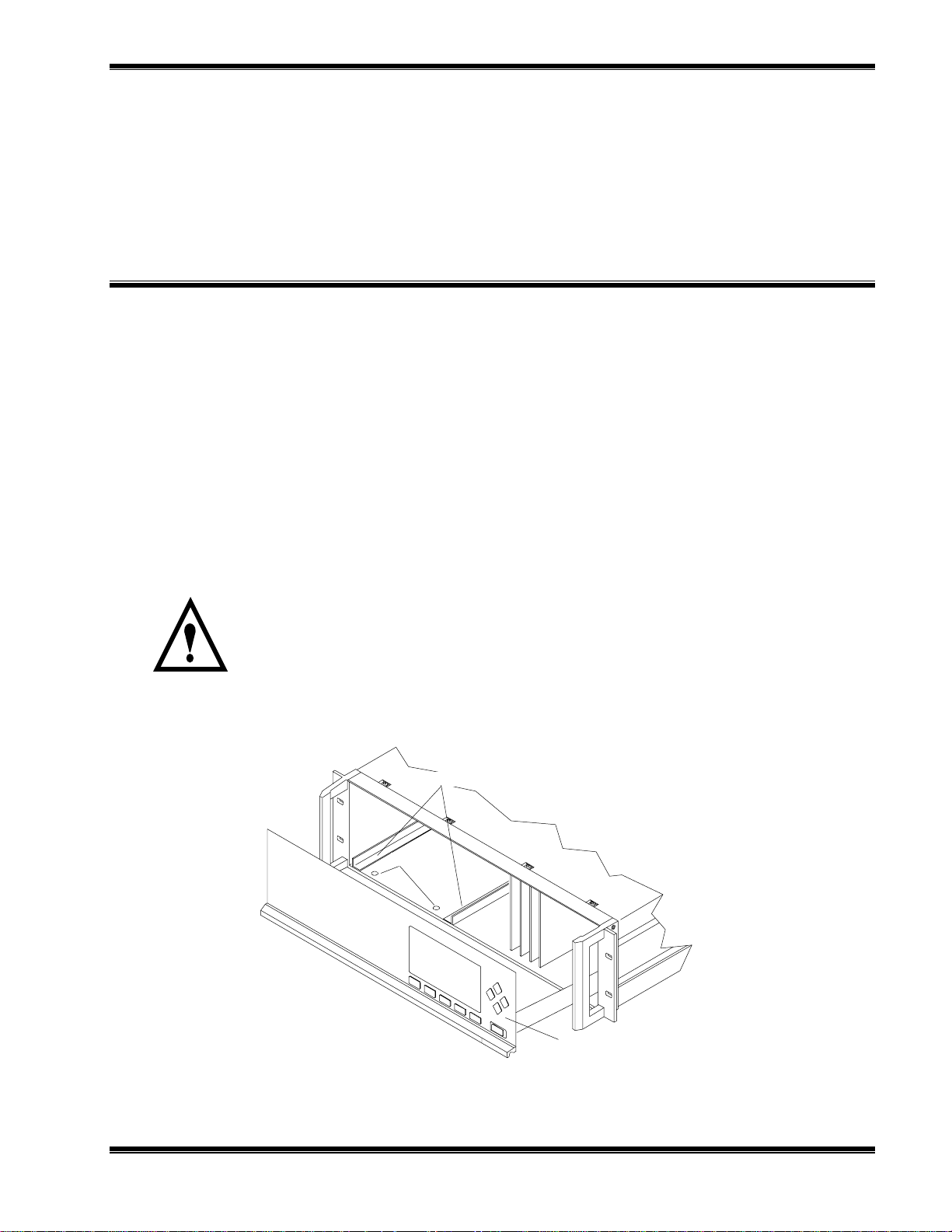

2-1 Analyzer Module Installation Into Instrument Platform...............................2-1

2-2 Outline and Mounting Dimensions.............................................................2-4

2-3 NDIR Back Panel.......................................................................................2-5

2-4 NDIR Front Panel Electrical Connections..................................................2-5

2-5 NDIR Wiring Diagram................................................................................2-6

3-1 Run Mode Display.....................................................................................3-3

3-2 Main Menu Display....................................................................................3-3

3-3 Basic Controls Menu..................................................................................3-3

3-4 Expert Controls and Setup Menu...............................................................3-4

3-5 Technical Level Configuration Menu .........................................................3-4

3-6 Typical Help Screen...................................................................................3-4

3-7 Typical Linearization Curve, Linearizer OFF..............................................3-7

3-8 Operator-Determined Linearization Curve (Normalized)............................3-7

3-9 Display Screens (1 of 5)............................................................................3-10

3-10 Display Screens (2 of 5)............................................................................3-11

3-11 Display Screens (3 of 5)............................................................................3-12

3-12 Display Screens (4 of 5)............................................................................3-13

3-13 Display Screens (5 of 5)............................................................................3-14

4-1 Printed Circuit Board Fold-Out Panel Views..............................................4-2

4-2 Module Fan Assembly...............................................................................4-3

4-3 Motor/Source Assembly.............................................................................4-4

4-4 Cell, PCB Assembly (Exploded View)........................................................4-6

4-5 Oscillator Tune, Source Balance Shutter Adjustments..............................4-7

4-6 Detector Block (Exploded View) ................................................................4-7

4-7 Cell Disassembly.......................................................................................4-9

TORING HIGH PRESSURE CYLINDERS

& S

C

ONTENTS

T

ABLES

2-1. Cell Purging Times at Atmospheric Sample Pressure...............................2-2

3-1 NDIR Analyzer Module Alarms..................................................................3-6

4-1 Cell Desiccant............................................................................................4-10

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

iii

C

ONTENTS

N

OTES

iv

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

P

REFACE

P

URPOSE/SAFETY SUMMARY

The purpose of this manual is to provide information concerning the components,

functions, installation and maintenance of this particular NGA 2000 module.

Some sections may describe equipment not used in your configuration. The user

should become thoroughly familiar with the operation of this module before operating

it. Read this instruction manual completely.

To avoid explosion, loss of life, personal injury and damage to this equipment

and on-site property, all personnel authorized to install, operate and service this

equipment should be thoroughly familiar with and strictly follow the instructions

in this manual. SAVE THESE INSTRUCTIONS.

If this equipment is used in a manner not specified in these instructions,

protective systems may be impaired.

DANGER

personal injury, death, or substantial property damage if the warning is ignored.

WARNING

personal injury, death, or substantial property damage if the warning is ignored.

CAUTION

personal injury or property damage if the warning is ignored.

NOTE

important but not hazard-related.

is used to indicate the presence of a hazard which

is used to indicate the presence of a hazard which

is used to indicate the presence of a hazard which

is used to indicate installation, operation or maintenance information which is

will

cause

can

cause

will or can

cause

severe

severe

minor

WARNING: ELECTRICAL SHOCK HAZARD

Operate this equipment only when covers are secured. Servicing requires

access to live parts which can cause death or serious injury. Refer servicing to

qualified personnel.

For safety and proper performance, this module must be connected to a

properly grounded three-wire source of electrical power.

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-1

P

REFACE

WARNING: POSSIBLE EXPLOSION HAZARD

This equipment is not designed for and should not be used in the analysis of

flammable samples. Use of this equipment in this way could result in explosion

and death.

WARNING: POSSIBLE EXPLOSION HAZARD

Ensure that all gas connectors are made as labeled and are leak free. Improper

gas connections could result in explosion or death.

CAUTION: PRESSURIZED GAS

This module requires periodic calibration with a known standard gas. See

General Precautions for Handling and Storing High Pressure Gas Cylinders at

the rear of this manual.

CAUTION: HAND INJURY HAZARD

Dropping the front panel of the Platform while hand or fingers are inside either

case handle can cause serious injury.

P-2

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

P

REFACE

CAUTION: PARTS INTEGRITY

Tampering with or unauthorized substitution of components may adversely

affect safety of this product. Use only factory approved components for repair.

CAUTION: OVERBALANCE HAZARD

This Analyzer Module may tip instrument over if it is pulled out too far and the

Platform is not properly supported.

WARNING: OVER-VOLTAGE SPIKING

If this Analyzer Module is used with a non-Rosemount Analytical power supply,

adding Rosemount Analytical PN 903341 Current Protector in series with the

24V positive power line will prevent over-voltage spiking and resultant fuse

blowing when powering up the instrument.

Note

Apply leak test liquid to cell or detectors only as a last resort.

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-3

P

REFACE

G

LOSSARY

NALYZER MODULE

A

The module that contains all sensor/detector components for development of a

Primary Variable signal; includes all signal conditioning and temperature control

circuitry.

ACKPLANE

B

The interconnect circuit board which the Controller Board, Power Supply, Analyzer

Module power and network cables, I/O Modules and Expansion Modules plug into.

ONTROL MODULE

C

The Operator Interface plus the Controller Board.

ONTROLLER BOARD

C

The computer board that serves as the Network Manager and operates the Display

and Keypad.

ISTRIBUTION ASSEMBLY

D

The Backplane and the card cages that hold I/O and Expansion Modules.

XPANSION MODULE

E

A circuit board that plugs into the Backplane from the front of the Platform and

performs special features not related to I/O functions.

I/O M

A circuit board that plugs into the Backplane from the rear of the Platform. Has a

connector terminal for communication with external data acquisition devices and

provides an input/output function.

ODULE

P-4

PERATOR INTERFACE

O

The Display and Keyboard.

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

P

REFACE

LATFORM

P

Any workable collection of the following: Controller Board, Power Supply, Distribution

Assembly, Enclosure and Operator Interface.

OWER SUPPLY

P

Any of a variety of components that provides conditioned power to other NGA 2000

components, from the Power Supply Board that plugs into the front of the Backplane

in a stand-alone instrument to several larger ones that can power larger collections of

modules and components.

RIMARY VARIABLE

P

The measured species concentration value from an Analyzer Module.

ECONDARY VARIABLE

S

Data placed on the network by a module regarding current status, e.g., sample flow,

source voltage and other diagnostic information.

OFTKEYS

S

The five function keys located below the front panel display; they assume the function

displayed directly above each on the display, a function dictated by software.

YSTEM

S

Any collection of Analyzer M odule(s), Platform(s) , I/O Module(s) and Expansion Modul e(s).

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-5

P

REFACE

S

PECIFICATIONS

M

EASUREMENT SPECIES

R

ANGES

R

EPEATABILITY

M

INIMUM DETECTABLE

L

EVEL

N

OISE

L

INEARITY

R

ESPONSE TIME

D

RIFT (ZERO AND SPAN

E

FFECT OF

T

EMPERATURE

E

NVIRONMENT

A

MBIENT TEMPERATURE

E

FFECT OF FLOW

P

OWER REQUIREMENTS

:

:

:

:

:

:

:

:

- G

ENERAL

Heteroatomic gases such as ammonia (NH3), carbon dioxide

:

(CO2), carbon monoxide (CO), carbon monoxide + carbon

dioxide ethylene (C2H4), hexane (C6H14), methane (CH4), nitric

oxide (NO) and sulfur dioxide (SO2)

10 ppm fullscale to 100% fullscale (application-dependent); 4

fullscale selections, including suppressed zero ranges

1% of fullscale (at constant temperature)

±

0.1% CO2 (at 1 atm. sample pressure; application dependent)

<1% of fullscale, peak-to-peak

1% of fullscale with 4th order polynomial

±

.05 to 30 seconds (selectable) for 0 to 90% of fullscale

<±1% of fullscale/24 hours at constant temperature

):

(application dependent);

<±2% of fullscale/week at constant temperature (application

dependent)

<±1% of fullscale over any 10°C interval for rate of change no

greater than 10°C per hour (application dependent)

Location - Class B controlled, indoor, non-hazardous

0 to 45°C (32 to 113°F)

:

:

<1% of range when sample flow rate is changed by ≤250

ml/min. (No effect if flow rate is between 0 and 500 ml/min.)

24 VDC ±5%, 100 W max.; ripple and noise: <100 mV peak-to-

:

peak; line and load regulations: <±1%

S

PECIFICATIONS

T

EMPERATURE

F

LOW RATE

P

RESSURE

P

ARTICULATES

D

EWPOINT

M

ATERIALS IN CONTACT

WITH SAMPLE

:

:

:

:

:

P-6

- S

AMPLE

Non-flammable;: 0°C to 55°C (32°F to 138°F)

500 to 1400 ml/min.

Maximum 690 hPa-gauge (10 psig), higher pressure in

pressurized cell applications

:

filtered to <2 microns

<40°C (104°F), no entrained liquid

Gold plated Pyrex, sapphire, quartz, Irtran, FEP Teflon, Viton-

A, 316 stainless steel

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

P

REFACE

S

PECIFICATIONS

C

ASE CLASSIFICATION

D

IMENSIONS

W

EIGHT

M

OUNTING

M

AXIMUM LENGTH OF

LON C

:

:

ABLE

:

:

- P

HYSICAL

General purpose for installation in weather-protected areas

:

See Outline and Mounting Dimensions, Figure 2-3

Standard: 11 kg (24.2 lbs.); extended: 12.5 kg (27.5 lbs.)

Inside a Platform or custom-installed in a panel

1600 m (1 mile) between Analyzer Module and Platform

See the Preface Section of the Platform manual for specifications regarding Platform

related components.

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-7

P

REFACE

C

USTOMER SERVICE

For order administration, replacement Parts, application assistance, on-site or factory

repair, service or maintenance contract information, contact:

R

ETURNING PARTS TO THE FACTORY

Before returning parts, contact the Customer Service Center and request a Returned

Materials Authorization (RMA) number. Please have the following information when

you call:

Number.

Prior authorization by the factory must be obtained before returned materials will be

accepted. Unauthorized returns will be returned to the sender, freight collect.

When returning any product or component that has been exposed to a toxic, corrosive

or other hazardous material or used in such a hazardous environment, the user must

attach an appropriate Material Safety Data Sheet (M.S.D.S.) or a written certification

that the material has been decontaminated, disinfected and/or detoxified.

Model Number, Serial Number, and Purchase Order Number or Sales Order

, T

ECHNICAL ASSIST ANCE AND FIELD SERVICE

Rosemount Analytical Inc.

Process Analytical Division

Customer Service Center

1-800-433-6076

Return to:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

T

RAINING

A comprehensive Factory Training Program of operator and service classes is

available. For a copy of the

the Technical Services Department at:

D

OCUMENTATION

The following NGA 2000 Non-Dispersive Infrared Analyzer instruction materials are

available. Contact Customer Service or the local representative to order.

748332 Instruction Manual (this document)

Current Operator and Service Training Schedule

Rosemount Analytical Inc.

Phone: 1-714-986-7600

FAX: 1-714-577-8006

contact

P-8

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

C

9

6

OMPLIANCES

This product may carry approvals from several certifying agencies, including Factory

Mutual and the Canadian Standards Association (which is also an OSHA accredited,

Nationally Recognized Testing Laboratory), for use in non-hazardous, indoor locations

P

REFACE

FM

APPROVED

Rosemount Analytical Inc. has satisfied all obligations from the European

Legislation to harmonize the product requirements in Europe.

This product complies with the standard level of NAMUR EMC.

Recommendation (May 1993).

This product satisfies all obligations of all relevant standards of the EMC framework in

Australia and New Zealand.

®

97-C219

NAMUR

N

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-9

P

REFACE

N

OTES

P-10

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

I

NTRODUCTION

1

1.1 OVERVIEW

This manual describes the Non-Dispersive Infrared (NDIR) Analyzer Module of

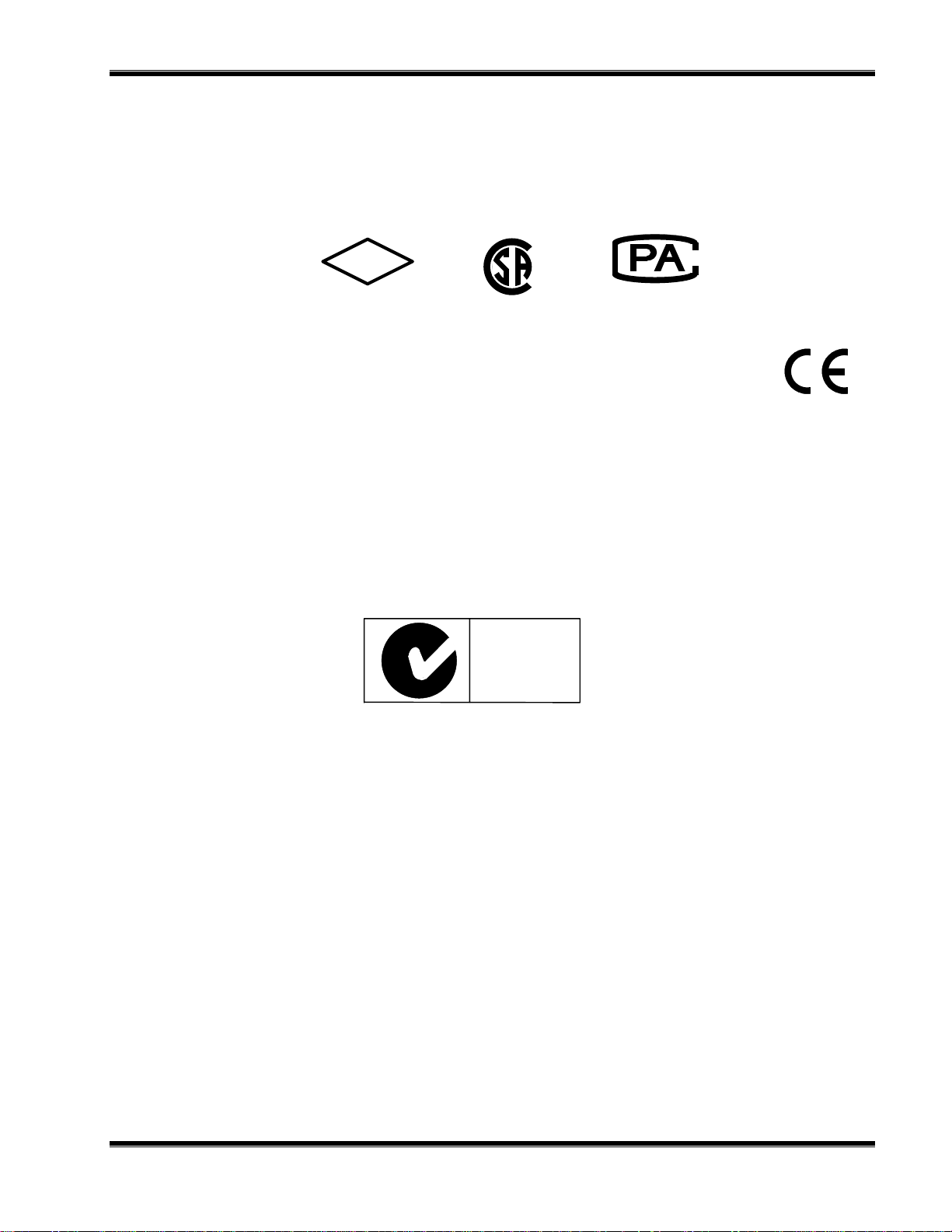

Rosemount Analytical's NGA 200 Series of gas analysis components. See Figure 1-1.

The NDIR Analyzer Module is designed to continuously determine the concentration

of oxygen in a flowing gaseous mixture. The concentration is expressed in one of

three fashions:

parts-per-million

•

percent of composition

•

percent of fullscale

•

The user can obtain an output that is linear with concentration by initiating a linearizer,

which is based on a fourth-order polynomial. The linearizer is incorporated in the

Analyzer Module's electronic circuitry and is adjustable through interconnection with

the network.

The entire Analyzer Module is designed as a slide-in module (if configured in standalone instrument fashion), removable from the front of the Platform, with gas

connections made from the rear. All electronics relative to sample detection and

conditioning are included in this module.

1.2 TYPICAL APPLICATIONS

The NDIR Analyzer Module is designed to cover a wide range of process, stack and

automotive applications. Typical measurements include:

HEMICAL AND PETROLEUM

C

Carbon dioxide: Manufacture of ethylene oxide, phthalic anhydride and

•

ammonia; nitrogen generation; and producer gas monitoring

Carbon Monoxide: Stack monitoring

•

Methane: Ammonia manufacture

•

Acetylene: Manufacture of acetylene, acrylonitrile, and vinyl chloride

•

Sulfur Dioxide: Sulf uric acid stack gas

•

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infraraed Analyzer

1-1

I

NTRODUCTION

OOD AND AGRICULT URE

F

EROSPACE AND OCEANOGRAPHY

A

ETALS AND CERAMICS

M

Carbon Dioxide and Water Vapor: Blanketing of perishables, fermentation

•

processes, photosynthesis studies, personnel protection

Carbon Dioxide, Carbon Monoxide, and Water Vapor: Diving and space

•

chambers

Carbon Dioxide: Monitoring of producer gas, steel converting, manufacture of

•

cement, soaking pit, heat treating

Carbon Monoxide: Inert gas generation, producer gas monitoring, rotary kiln

•

roasting, tin plate annealing, steel converting, aluminum power processing,

porcelain kilns, tunnels

Water Vapor: Heat treating, hydrogen brazing, nickel and chrome plating

•

Sulfur Dioxide: Flash smelting

•

Ammonia: Ammonia dissociation

•

1.3 THEORY OF TECHNOLOGY

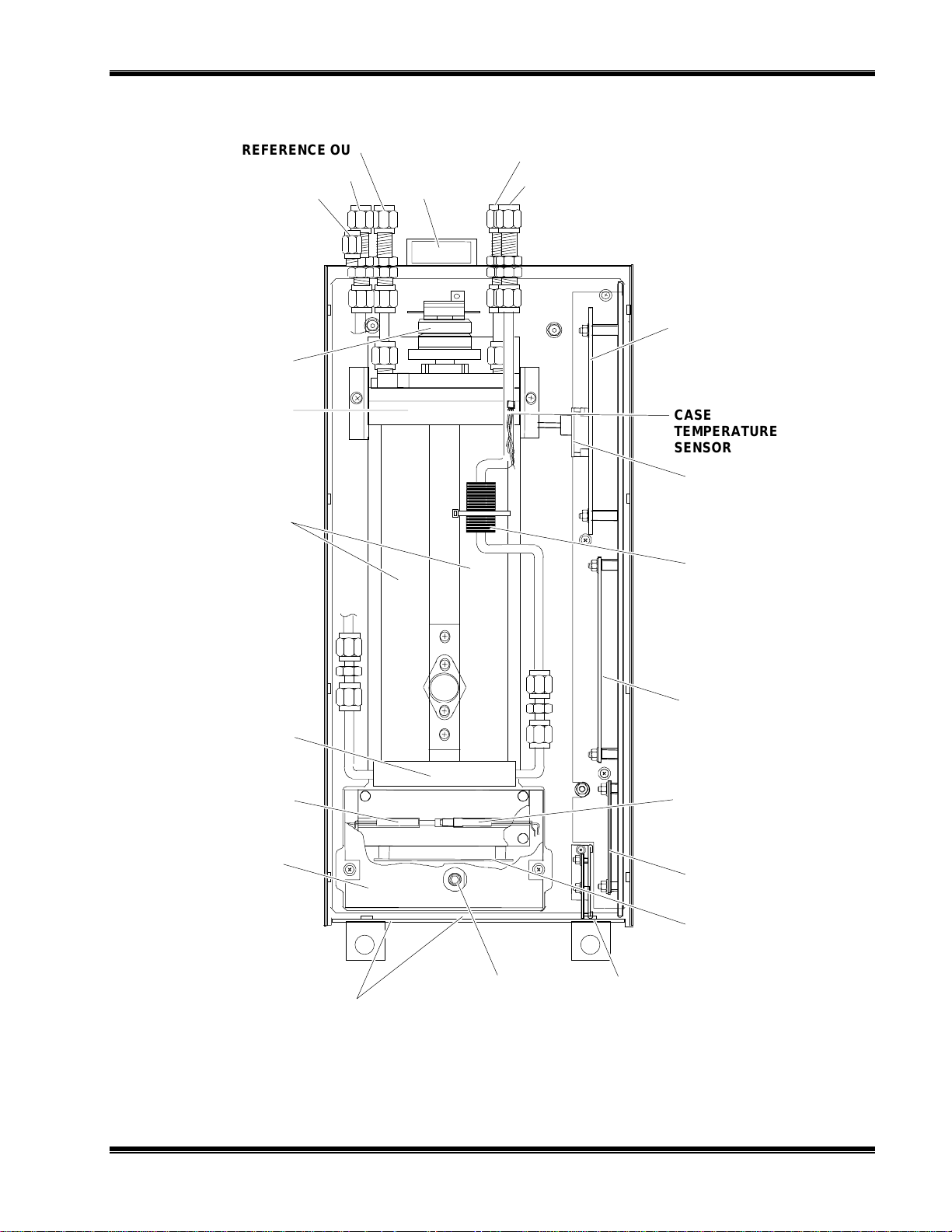

Inside of the Analyzer Module, two equal-energy infrared beams are directed through

two parallel optical cells, a flow-through sample cell and a reference cell. The

reference cell may be sealed or may contain a continuously flowing reference gas.

(See Figure 1-2.)

The infrared radiation is interrupted by a chopper at a frequency of 5 Hz.

During analysis, a portion of the infrared radiation is absorbed by the component of

interest in the sample. The quantity of infrared radiation that is absorbed is

proportional to the component concentration.

1-2

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infraraed Analyzer

REFERENCE OUT

(

)

REFERENCE IN

PURGE GAS IN

CHOPPER MOTOR

FAN

SAMPLE OUT

(BOTTOM)

SAMPLE IN

POWER SUPPLY

BOARD

I

NTRODUCTION

SOURCE

CELLS

DETECTOR

THERMAL FUSE

DETECTOR COVER

CASE

TEMPERATURE

SENSOR

PRESSURE

COMPENSATION

BOARD

FLOW SENSOR

MICRO BOARD

DETECTOR

TEMPERATURE

CONTROL RTD

SIGNAL BOARD

OPTION

IGURE

F

748332-D Rosemount Analytical June 1997

1-1. NGA 2000 NDIR A

SHUTTER ADJUST

ACCESS HOLES

NALYZER MODULE (TYPICAL

ONFIGURATION MAY VARY

C

OSCILLATOR

TUNE ADJUST

)

OSCILLATOR

BOARD

NETWORK INPUT

MODULE

CTUAL

- A

NGA Non-Dispersive Infraraed Analyzer

1-3

I

NTRODUCTION

The detector is a "gas microphone" based on the Luft principle. The detector is

generally filled with the same gas being analyzed. The infrared energy is therefore

absorbed at the same wavelengths in the detector as that in the sample cell, making

the detector specific for the analyzed component. The detector converts the

difference in energy between sample and reference cells to a capacitance change.

This change, which is proportional to component concentration, is processed and

expressed as the primary variable on the network.

Other modules comprising the NGA 2000 unit then use this variable for a variety of

purposes (e.g., expressing the gas concentration on the Front Panel Display or

sending it to external data acquisition devices).

For a general understanding of the electrical interconnections in the NDIR Analyzer

Module, see Figure 2-5.

IGURE

F

INFRARED

SOURCE

REFERENCE

CELL

DETECTOR

STATIONARY

PLATE

1-2. NDIR T

DIAPHRAGM,

DARK STATE

ECHNOLOGY

CHOPPER

SAMPLE IN

SAMPLE

CELL

SAMPLE

DIAPHRAGM,

DISTENDED

COMPONENT OF INTEREST

NON-INTERFERING COMPOUNDS

1.4 SAMPLE REQUIREMENTS

Maximum allowable sample pressure is 690 hPa-gauge (10 psig) for a standard

configuration NDIR that has a flow restrictor which sets the flow at between 0.5 L/min.

to 1 L/min. Special high pressure cells (up to 10,350 hPa-gauge, 150 psig) are

available. Sample temperature range is 0°C to 55°C, and maximum dewpoint is 40°C.

The sample must be filtered to exclude particulates larger than 2 microns in size.

Consult factory for special configurations with specifications outside of those listed

above.

1-4

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infraraed Analyzer

1.5 PURGE KITS

A purge kit for the motor source or motor source/flowing reference cell accompanies

some NDIR modules. The purpose of these kits is to improve performance and

accuracy through the reduction of ambient CO2 interference.

protection from explosion hazard.

The purge gas vents into the case, which has no

They do not provide

outlet fitting for these types of purge gases.

1.6 FEATURES

Among the features available in the NDIR Analyzer Module are:

Pressure compensation for barometric fluctuations (optional)

•

Flow sensing

•

I

NTRODUCTION

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infraraed Analyzer

1-5

I

NTRODUCTION

N

OTES

1-6

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infraraed Analyzer

I

NSTALLATION

2

2.1 UNPACKING

If the NDIR Analyzer Module is received as a separate unit, carefully examine the

shipping carton and contents for signs of damage. Immediately notify the shipping

carrier if the carton or contents is damaged. Retain the carton and packing material

until all components associated with the Analyzer Module are operational.

2.2 ASSEMBLY

If the NDIR Analyzer Module requires assembly with other components (e.g., the

Platform and associated I/O Modules), do so at this time. Following the guides on the

bottom left and bottom center of the Platform, carefully slide the Analyzer Module

halfway into place.

CAUTION: HAND INJURY HAZARD

Do not place hands or fingers in the Platform front handles when front panel is

open. Dropping the front panel of the Platform while hand or fingers are inside

either handle can cause serious injury.

ANALYZER MODULE GUIDES

PIN SEATS

DISENGAGED FRONT PANEL

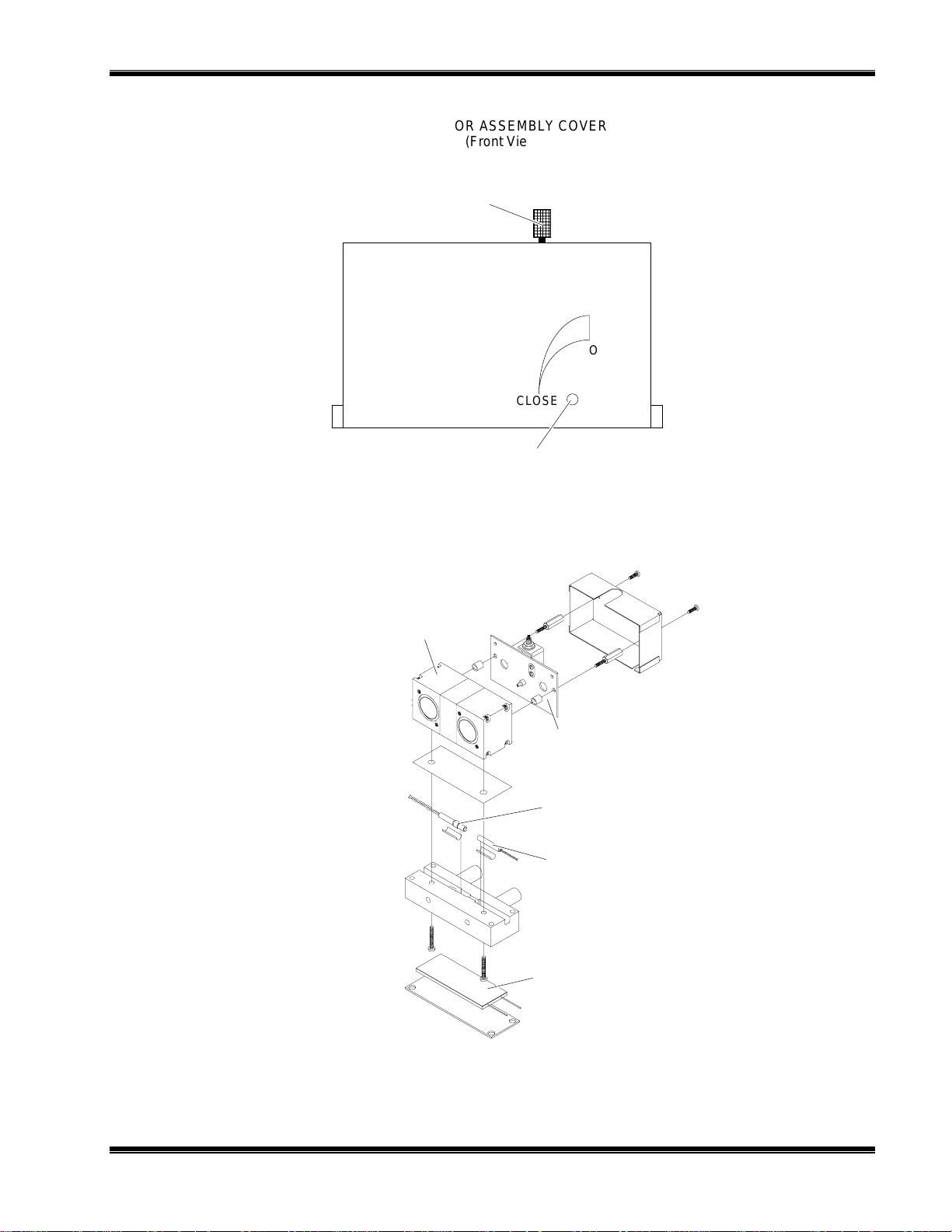

IGURE

F

2-1. A

NALYZER MODULE INSTALLATION INTO INSTRUMENT PLATFORM

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

2-1

I

NSTALLATION

Lift the spring-loaded pins on the front of the Analyzer Module, and carefully slide it

the rest of the distance. Secure the module in position by releasing the pins, which

seat in the available holes in the bottom of the case (see Figure 2-1). If the module

and Platform are difficult to assemble, remove the module, ensure the top cover of the

module is firmly seated on the hold-down screws, and repeat the assembly procedure.

Install I/O Module(s) according to guidelines in the I/O manual. After startup and

calibration have been performed, secure the front panel with the six screws provided.

2.3 LOCATION

Install the NDIR Analyzer Module in a clean, non-hazardous, weather protected,

vibration free location free from extreme temperature variations. For best results,

install the instrument near the sample stream to minimize sample transport time.

Operating ambient temperature is 0oC to 45oC (32oF to 113oF). Sample dewpoint is

40°C or less.

Note

Unrestricted air flow in the rear of the Analyzer Module is critical to its

performance and reliability.

CELL LENGTH CELL VOLUME

mm inch without inlet tube cell with inlet tube at 750 mm Hg

3 0.118 0.85 12 2 sec.

4 0.157 1.14 12 2 sec.

8 0.315 2.28 13 2 sec.

16 0.630 3.56 16 2 sec.

32 1.25 9.12 20 2 sec.

64 2.52 18.24 25 3 sec.

128 4.03 35.48 44 3 sec.

232 9.13 65.12 73 6 sec.

343 13.50 97.76 105 13 sec.

381 15.00 108.60 116 14 sec.

ABLE

T

2-1. C

2.4 GASES

2.4.1 S

PECIFICATIONS

TOTAL VOLUME INCCTIME FOR 2 VOLUMES AT

IN CC

ELL PURGING TIMES AT ATMOSPHERIC SAMPLE PRESSURE

2 SCFH (1L/MIN)

2-2

ALIBRATION GASES

C

All applications require a zero standard gas to set the zero point on the display and

external data acquisition devices. if the factory provided Calibration and Data Sheet

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

I

NSTALLATION

(in the rear of the manual) specifies a background gas, use this as a zero gas. If a

background gas is not specified, use dry nitrogen.

Span gas should be between 75% and 100% of fullscale span. Flowing reference (if

used) should be dry nitrogen.

LOW RATE

F

Recommended sample flow rate is 1 to 2 SCFH (500 TO 1000 cc/min). A lower flow

rate will not affect readings but may result in an undesirable time lag. Excessive flow

can produce increases cell pressurization and reading error.

At higher cell pressures, the nonlinearity of the calibration curve increases. Therefore,

the calibration curve should be redrawn for higher flow rates. Also, the effect of

increased cell pressurization can be negated if the same flow rate is used for sample,

zero and span gases. But, if flow is high enough to cause elevated pressure, careful

control (tighter tolerance) of flow rate is required to avoid errors.

If low is kept at or below 2 SCFH (1 L/min), sample and instrument temperatures

reach equilibrium regardless of strea m temperature (within sp ecifications; 0 to 55°C).

At extremely high flow rates, this may not be true, although no such effect has been

noted up to 18 SCFH (9 L/min).

See Table 2-1 for cell purging times at atmospheric sample pressure.

AMPLE PRESSURE/FILTRATION

S

Sample should be introduced to the Analyzer Module at a maximum 690 hPa-gauge

(10 psig). Pressurized applications are available, which require pressurized cells and

careful control of flow rates, consult factory for these applications. Sample should be

filtered for particulates down to two microns.

EAK TEST

L

The Analyzer Module is completely tested at the factory for gas leakage. The user is

responsible for testing for leakage only at the inlet and outlet fittings on the rear panel.

The user is also responsible for internal leak testing periodically and if any internal

pneumatic components are adjusted or replaced (with a test procedure chosen by the

user).

2.4.2 C

ONNECTIONS

(See Figure 2-3) Connect inlet and outlet lines for sample/zero/span and flowing

reference (if applicable) to appropriately labeled fittings on the rear panel. All four

connections are 1/4 inch ferrule-type compression fittings.

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

2-3

I

[

]

[28]

NSTALLATION

4.3

[109]

8.4

[213]

6.2

[157]

8.2

[208]

[15]

.6

2.8

[71]

[13]

.5

.6

[15]

1.1

1.1

[27]

1.1

[28]

20.0

[508.0]

STANDARD

24.8

[628.7]

EXTENDED

6.0

[152]

STANDARD

8.4

213

17.41

[142.2]

22.41

[569.2]

EXTENDED

1.6

[40]

G. POWER CABLE TO NETWORK.

F. NETWORK CABLE CONNECTIONS TO PLATFORM.

E. PURGE GAS IN: 1/4" O.D. TUBE FITTING.

D. REFERENCE IN: 1/4" O.D. TUBE FITTING.

C. REFERENCE OUT: 1/4" O.D. TUBE FITTING.

B. SAMPLE OUT: 1/4" O.D. TUBE FITTING.

A. SAMPLE IN: 1/4" O.D. TUBE FITTING.

5.6

[143]

1.0

[25]

DIMENSIONS

5. MODULE TO BE IN STALLED WITHIN ±15° OF HORIZONTAL.

4. POWER REQUIREMENTS: 24 VDC 3.5 A.

3. ELECTRICAL INSTALLATION MUST BE IN COMPLIANCE WITH NATIONAL ELECTRICAL

CODE (ANSI/NFPA 70) AND/O R ANY APPLICABLE NATIONAL OR LOCAL CODES.

2. MODULE IS NOT WEATHERPROOF.

1. APPROXIMATE WEIGHT: 24.2 LB (11.0 kg).

IGURE

F

2-2 O

2-4

UTLINE AND MOUNTING DIMENSIONS

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

INCH

[mm]

2.5 ELECTRICAL CONNECTIONS

Note

Electrical connections must be in compliance with National Electrical Code

(ANSI/NFPA 70) and/or any applicable national or electrical codes.

Two electrical connections are required on the Analyzer Module; POWER and

NETWORK. See Figure 2-4. On the Analyzer Module, two NETWORK connections

are available, either of which is appropriate for : 1) interconnection with Backplane of

the Platform (see Platform instruction manual) or 2) "daisy chaining" with other NGA

2000 components.

Connect Analyzer Module POWER 24 VDC power source, either the Platform or

external power source.

FAN

I

NSTALLATION

IGURE

F

OUT

SAMPLE

IN

10 PSI M AX

(69 kPa MAX)

Note: Reference and purge gas connections are applicable only to certain applications.

2-3. NDIR B

ACK PANEL

OUT

REFERENCE

IN

10 PSI M AX

(69 kPa MAX)

PURGE IN

15 PSI (103 kP a) MAX

NETWORK 1

NETWORK 2

POWER

IGURE

F

748332-D Rosemount Analytical June 1997

2-4. NDIR F

RONT PANEL ELECTRICAL CONNECTIONS

FUSE

NGA Non-Dispersive Infrared Analyzer

2-5

I

NSTALLATION

SAMPLE J2-1

SOURCE J2-2

REFERENCE J2- 3

SOURCE J2-4

FLOW SENSOR

FAN ASSEMBLY

MODULATION CHECK

HEATSINK/SOURCE

MOTOR ASSEMBLY

REF S O URCE

SAMPLE SOURCE

J2

J1

J15

J14

RESISTOR

DRIVER

SOURCE ASSY

J4

POWER

SUPPLY

BOARD

J6 J10

J9

PRESSURE

COMPEN SATION

BOARD

J7

1 2 3 4

J5

1 2

CHASSIS

GROUND

J3

J11

J8

FUSE, THERMAL

CUTOFF

RTD, TEMP CTRL

J4 J5 J6

J1

COMPUTER BOARD

J2

J3

CASE TEMPERATURE

SENSOR

HEATER

SENSOR °C

DETECTOR BASE

RECORDER

J5

J7

SIGNAL

J4

BOARD

BOARD

J6

J3 J1

J2

J7

°°°°

C

OSCILLATOR

J1

OUTPUT

J5

LON/POWER

BOARD

IGURE

F

2-5. NDIR W

IRING DIAGRAM

2-6

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

S

TARTUP AND OPERATION

3

3.1 OVERVIEW

Prior to initial startup, the user should leak test the module as outlined in Section 2.

For the remainder of this section, Analyzer Module interconnection with a Platform or

some interfacing component will be assumed. Display and Keypad information shall

refer to that which the user can expect to see and do with regard to the Front Panel of

the Platform.

(For a complete description of Platform Front Panel controls and indicators, see

Section 1 of the Platform Components instruction manual.)

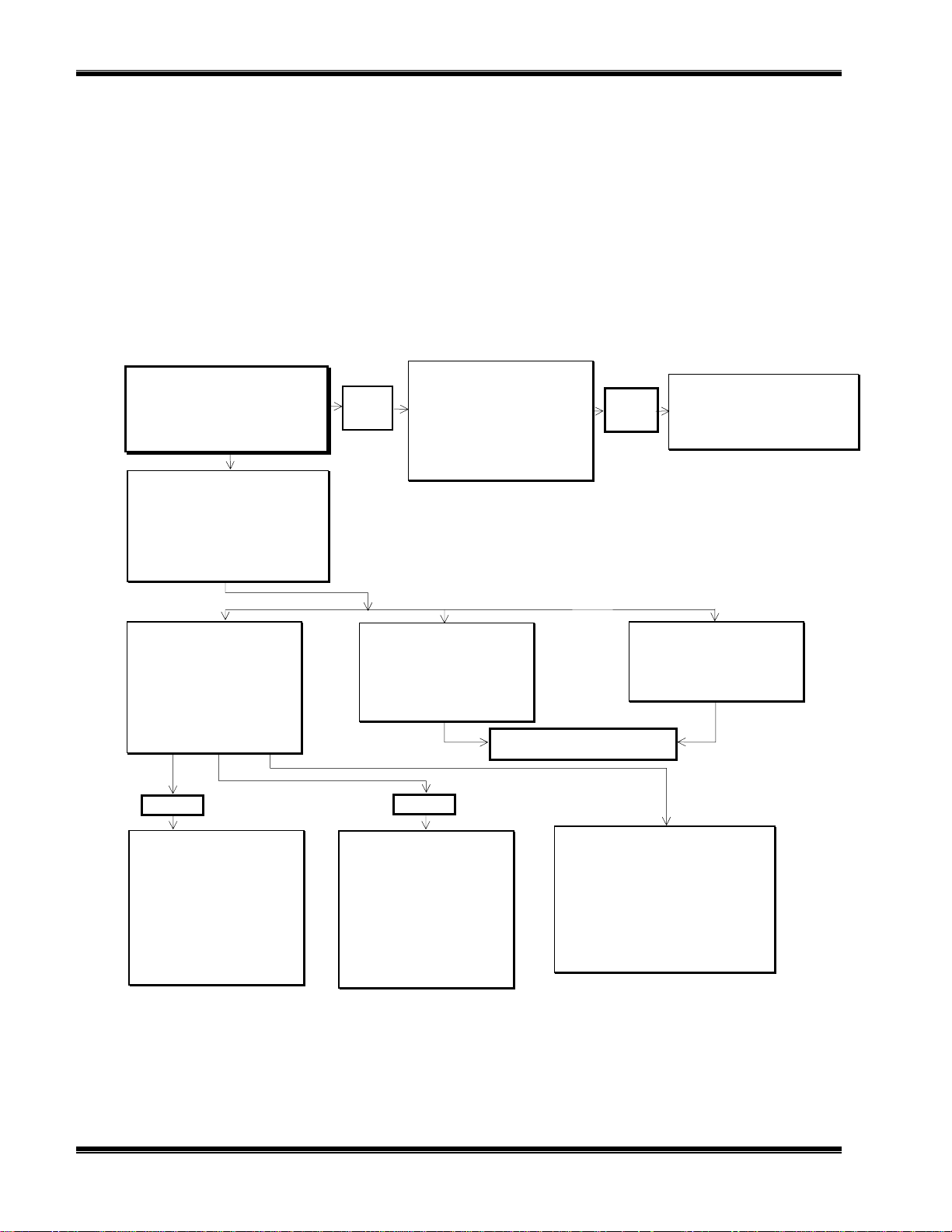

3.2 DISPLAYS SCREENS

Three kinds of Display Screens are available to the user (see Figures 3-1 through

3-6.):

Run Mode

•

Menu

•

Help

•

3.2.1 R

3.2.2 M

UN MODE DISPLAY

The Run Mode is the normal mode of operation. In this mode, the Display will show

current gas measurement, the component of interest, the current operations of the

softkeys, a graphic bar representing the displayed concentration as a percent of

fullscale, and up to 4 user-selectable secondary variables and associated bargraphs.

If more than one Analyzer Module is connected to the system, the Run Mode display

will show as many as four gas measurements on a single screen. Alarm messages

may also appear on the display (See Table 3-1).

ENU DISPLAYS

The Menu structure enables the user to access data and functions, and put

information onto the network.

The Main Menu (see Figure 3-2) is subdivided into three levels of control based

748332-D Rosemount Analytical June 1997

NGA 2000 Non-Dispersive Infrared Analyzer

3-1

S

TARTUP AND OPERATION

generally on which personnel is likely to use it: Basic Controls, Expert Controls and

Setup, and Technical Controls. (See Figures 3-3 through 3-5.) Many layers of the

menu structure are described at appropriate places throughout this manual.

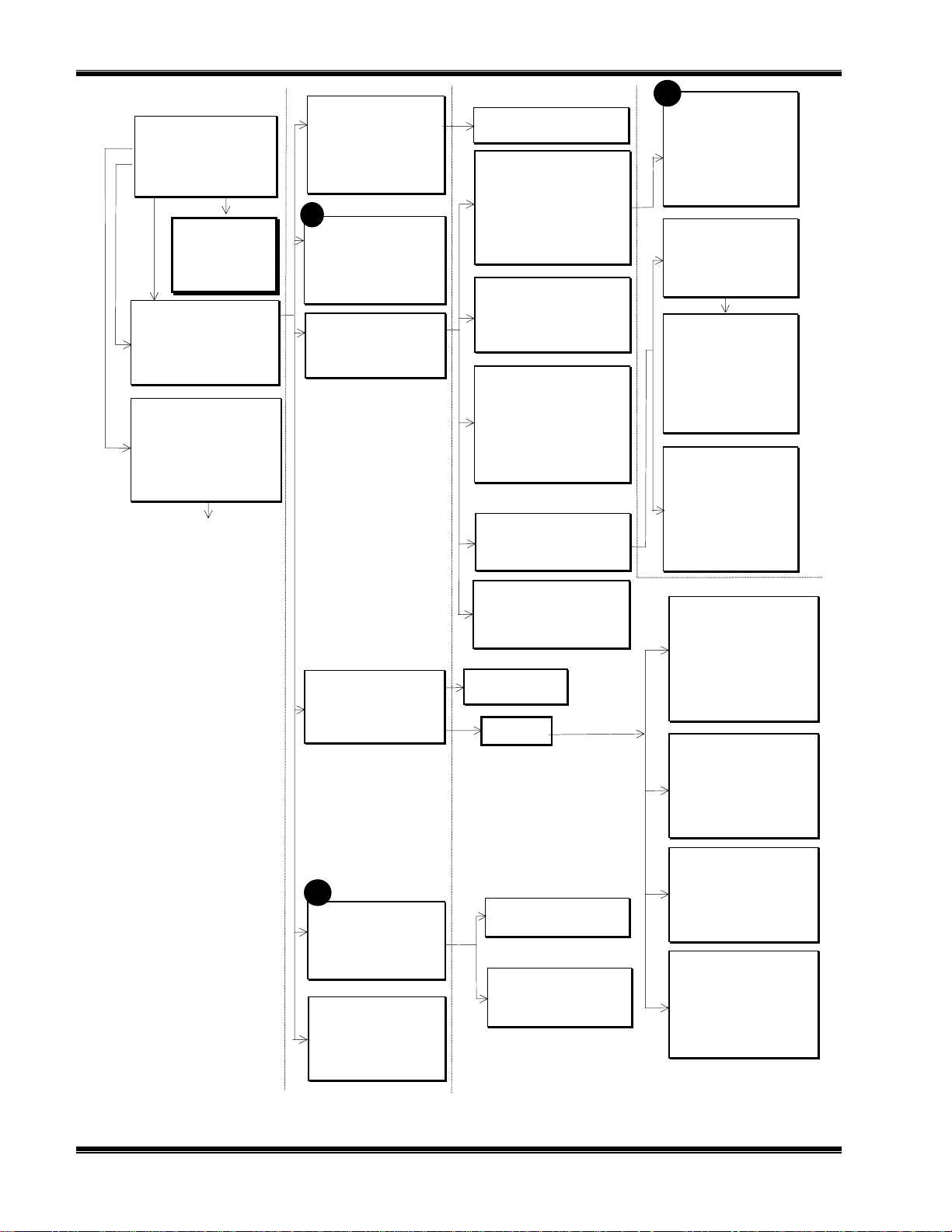

See Figures 3-9 through 3-13 for flow charts depicting Menu screens related to this

Analyzer Module.

From the Run Mode display, press the MENUS softkey to gain access to the Main

Menu. (See Figure 3-2.)

3.2.3 H

ELP DISPLAYS

The Help structure is on-line "tutorial," context-sensitive and topic-interconnected, so

that the user can practically operate NGA 2000 without need of an instruction manual.

3.3 STARTUP PROCEDURE

Introduce zero gas into SAMPLE INLET and reference and source purge gas, if

applicable, into their respective inlets. Ensure that gas pressures are set to

requirements listed on the Specifications page of the Preface section of this manual.

Apply power to the NDIR Analyzer Module. If it is associated with a Platform, do this

by plugging in the Platform to a power source. The Platform has no ON/OFF power

switch. Once power has been supplied to the Platform, the NDIR Analyzer Module will

be energized.

If the user's system contains only one Analyzer Module, all system components, the

Controller Board and the network "self-install" (bind together) during initial startup. If

the system contains more than one Analyzer Module, the startup procedure will

interrogate the network to locate and identify all components on the network. The

user will have to bind appropriate combinations of components after the startup

sequence.

3-2

After the warm-up period (about one hour for the NDIR Analyzer Module), all modules

are completely functional.

Check the tune and detector signal values against the factory settings listed in the

Diagnostic Service menus. If both settings are within ±5% tolerance of factory setting,

go to section 3.4 for binding and 3.5 for calibration. If not, refer first to section 4.11 for

instructions about oscillator tune/source balance shutter adjustments

June 1997 Rosemount Analytical 748332-DNGA 2000 Non-Dispersive Infrared Analyzer

Analyzer PQ 322-14

y

y

y

y

23.2 % CO

S

TARTUP AND OPERATION

IGURE

F

3-1. R

0 ppm

Secondar

Secondar

Secondar

Secondar

Variable: XXXX

Variable: XXX

Variable: XXXX

Variable: XXXX

Display Parms. Menu Dual Info

F1 F2 F3 F4 F5

UN MODE DISPLAY

23.2 % CO Analyzer XXXXXXXX

Basic Controls

Expert controls and setup ...

(Operational configuration)

Technical level configuration ...

(Diagnostic and manufacturing/service)

Delete alarm message!

Display Parms. Info

50

Main Menu

IGURE

F

IGURE

F

3-2. M

3-3. B

F1

F2 F3 F4 F5

AIN MENU DISPLAY

23.2 % CO Analyzer XXXXXXXX

Measurement range Numbers:

Range upper limit: 25%

Range and functional control: Local

Calibration…

Status: Ready

Home Escape Zero Span Info

F1

F2 F3 F4 F5

ASIC CONTROLS MENU

Basic Controls

748332-D Rosemount Analytical June 1997

NGA 2000 Non-Dispersive Infrared Analyzer

3-3

S

g

p

p

p

TARTUP AND OPERATION

23.2 % CO Analyzer XXXXXXXX

ert controls and setu

Ex

Expert analyzer controls ...

Auxiliary module controls ...

System set up ...

Analyzer module set up ...

Auxiliary module set up ...

Home Escape Info

IGURE

F

IGURE

F

3-4. E

3-5. T

F1

F2 F3 F4 F5

XPERT CONTROLS AND SETUP MENU

23.2 % CO Analyzer XXXXXXXX

Technical confi

System set up ...

Service menus...

Diagnostic menus...

Other module diagnostic menus...

listing of all modules...

Status: normal

uration menu

Home Info

F1

F2 F3 F4 F5

ECHNICAL LEVEL CONFIGURATION MENU

IGURE

F

3-4

3-6. T

23.2 % CO Analyzer XXXXXXXX

Main Menu Hel

The Main Menu for the analyzer system.

Note that this menu refers to the particular

analyzer selected from t he run screen, when

used in a system. The s oftkey marked “HOME”

will always return you to this screen.

Help menu system...

Help on help...

Keyboard controls...

Editing controls.. .

Home Escape Map

F1 F2 F3 F4 F5

YPICAL HELP SCREEN

June 1997 Rosemount Analytical 748332-DNGA 2000 Non-Dispersive Infrared Analyzer

S

TARTUP AND OPERATION

3.4 BINDING

To achieve full coordination between Analyzer Modules and associated I/O Modules,

the user must bind those components together in the System Set Up portion of the

Technical Configuration Menu

in software. (See Figure 3-12 of this manual and

Section 1.5 of the I/O Modules manual for binding instructions.)

3.5 CALIBRATION

Calibration can be executed from the

be entered only through

the Expert Controls and Setup

3-11 for display screen paths.

To calibrate the Analyzer Module, introduce zero gas into the SAMPLE INLET, and do

the following:

1. If the multi-Analyzer Module, split Run Mode display is shown, press the DISPLAY

softkey until the desired Analyzer's Run Mode display is acquired.

Basic Controls

menu. Calibration gas data can

menu. See Figures 3-9 and

2. Press the MENUS softkey to enter the

selections from the

Main Menu

: Expert Controls and Setup, Analyzer Module

Main Menu

and make the following

Setup, Calibration Gases.

3. Input appropriate data in the

4. Press the HOME softkey to return to the

Calibration Gas List

Main Menu.

menu.

5. Use the ↓ arrow key to select Basic Controls.

6. Press the ZERO softkey to enter the

Analyzer Zero

menu, press ZERO again and

wait.

7. Introduce span gas into the SAMPLE INLET, press SPAN softkey to enter the

Analyzer Span

8. Press HOME to re-enter the

menu, press SPAN again and wait.

Main Menu.

9. Press DISPLAY softkey for the Run Mode display.

If the user is unable to calibrate the Analyzer Module (i.e., when ZERO or SPAN is

initiated, nothing happens), a possible solution relates to the use of an incorrect gas

for zeroing or spanning (e.g., using a high concentration gas to zero or a zero gas to

span the Analyzer Module). Simply recalibrating with the appropriate gas(es) will not

correct the problem because the ZERO OFFSET or SPAN FACTOR has been set to

an extreme value in the process.

To remedy the problem, do the following:

1. Select the following from the

Module Set Up, and Calibration Parameters.

748332-D Rosemount Analytical June 1997

Main Menu

: Expert Controls and Setup, Analyzer

NGA 2000 Non-Dispersive Infrared Analyzer

3-5

S

TARTUP AND OPERATION

2. Using the ↓ arrow, select Zero Ranges, press ENTER and, using the up/down

arrows, toggle to SEPARATE. Do the same for the Calibrate Ranges selection. Do

not press ESCAPE at any time unless retention of prior settings is desired.

3. Return to the

Main Menu

and make the following selections: Expert Controls and

Setup, Expert Controls, CAL DATA softkey, FACTORS softkey, and Range 1 (2, 3,

4) Factors (do Steps 4 and 5 for each range).

4. Select Zero Offset, press ENTER, adjust the value to 500000 with the ↑ and

arrow keys, and press ENTER. Do not press ESCAPE at any time unless retention

of prior settings is desired.

5. Refer to the Data Sheet in the rear of this manual for Span Factors as originally set

at the factory. Select Span Factor, press ENTER, adjust the value to match the

values on the Data Sheet with the ↑ and ↓ arrow keys, and press ENTER. If Data

Sheet is not available, enter 0.000015 with the ↑ and ↓ arrow keys, and press

ENTER. Do not press ESCAPE unless retention of prior settings is desired.

6. Attempt to recalibrate the Analyzer Module according to the procedure outlined at

the beginning of Section 3.4. If recalibration fails, return to the

Range Factors

menu, readjust factors and try calibrating again.

Another cause of failure to calibrate is the following: The value for "Maximum range"

is lower than the upper limit value for the range in use. See the

Range Settings

menu for this information (See Figure 3-11).

DISPLAY MESSAGE DESCRIPTION TYPE

BAROMETER System Barometer WARNING

CASE TEMP Case Temperature WARNING

CHOP SPEED Chopper Speed WARNING

CRUDE NOISE Calculated Noise WARNING

DET SIG Detector Signal WARNING

DET TEMP Detector Temperature WARNING

LIN ERROR Linearizer Error WARNING

N15 VOLTS Power Supply, -15V WARNING

P12 VOLTS Power Supply, +12V WARNING

P15 VOLTS Power Supply, +15V WARNING

P24 VOLTS Power Supply, +24V WARNING

P5 VOLTS Power Supply, +5V WARNING

PERCENT MOD Percent Modulation WARNING

RAW SIGNAL Raw Signal WARNING

SVFLOW Sample Bypass Flow WARNING

SW ERROR Software Error FAILURE

↓

ABLE

T

3-6

3-1. NDIR A

NALYZER MODULE ALARMS

June 1997 Rosemount Analytical 748332-DNGA 2000 Non-Dispersive Infrared Analyzer

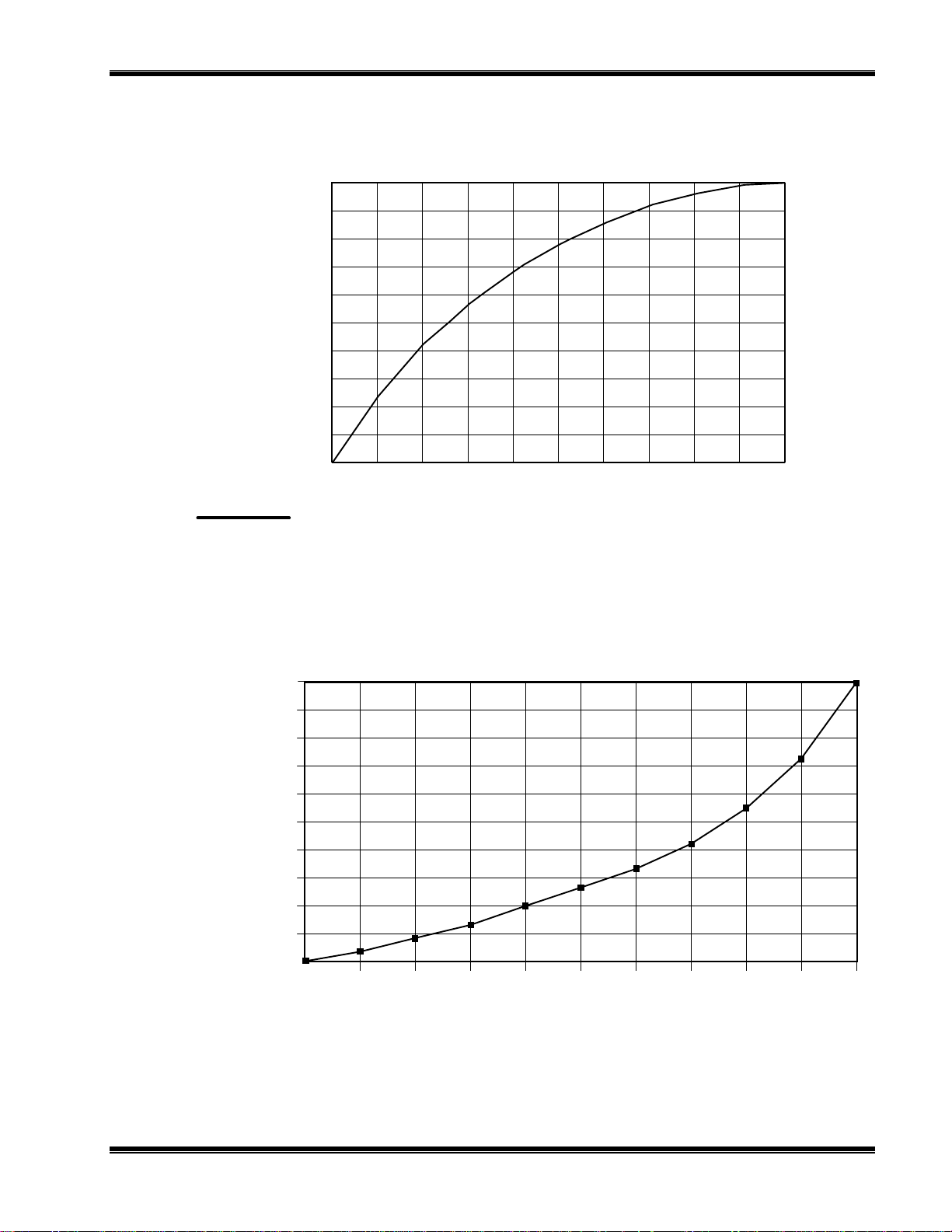

READING

% FULLSCALE

S

100 %

50 %

0 %

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

TARTUP AND OPERATION

IGURE

F

3-7. T

CONCENTRATION

NORMALIZED

YPICAL LINEARIZATION CURVE

Display ppm

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

CONCENTRATION

ppm

INEARIZER

, L

OFF

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

IGURE

F

748332-D Rosemount Analytical June 1997

3-8. O

PERATOR-DETERMINED LINEARIZATION CURVE (NORMALIZED

READINGS, NORMALIZED

(Axis Reversed)

NGA 2000 Non-Dispersive Infrared Analyzer

)

3-7

S

TARTUP AND OPERATION

3.6 LINEARIZATION

The NDIR Analyzer Module can be operated in linear and non-linear mode.

Linearization can be toggled ON/OFF in

In the OFF position, linearization is disabled for all ranges, and the component of

interest is measured in percent of fullscale. In the ON position, measurement is in

engineering units: Either ppm or percent of concentration.

The NDIR Analyzer Module is linearized with the following fourth-order polynomial:

the Expert Controls

menu (see Figure 3-10).

Y = AO + A1X + A2X

2

+ A3X3 + A4X

4

Where:

X = the normalized non-linear input

AO, A1, A2, A3, A4 = linearization coefficients

Y = the normalized linear output

Linearization coefficients can be developed and stored for each range through the

Expert Controls

menu. The operating range is selected by entering RANGE = 1, 2, 3

or 4 in the Range Mode section that that menu.

Coefficients for each selected range are automatically used when the module is in

Linearization Mode. The user instructs the Analyzer Module as to which set of

coefficients are to be used for each range. Maximum dynamic range is 3:1.

When ordered, special linearization coefficients for non-standard fullscale ranges are

entered in the appropriate range(s) at the factory. If a range is not specified, the set of

coefficients will be for Range 4.

3-8

The operator may want the module to output measurement in engineering units (ppm).

This response is linear over the operating range. The following coefficients will make

no correction to the non-linear response, but will cause the NDIR Analyzer Module to

output gas measurement in engineering units:

A0 = 0.00000

A1 = 1.00000

A2 = 0.00000

A3 = 0.00000

A4 = 0.00000

To calculate linearization coefficients other than those installed at the factory, take a

June 1997 Rosemount Analytical 748332-DNGA 2000 Non-Dispersive Infrared Analyzer

S

TARTUP AND OPERATION

minimum of 11 data points. (A more accurate curve can be obtained as the user

approaches 21 data points. If urgent, a curve can be created with as few as four

points, but this is only a temporary fix. A more accurate curve should be created as

soon as possible.)

These data points can be obtained with an accurate gas divider or other flow mixing

device. Before calculating coefficients, the data must be normalized to ranges of 0 to

1 units for both percent and concentration readings. Then, the axis must be reversed

as illustrated in Figures 3-7 and 3-8. A multiple linear regression is then used to

calculate coefficients. (For example: If the range is 0 to 5000 ppm and readings are 0

to 100%, then divide all of the concentrations by 5000 and the readings by 100. Put

the normalized concentrations on the Y-axis and the normalized readings on the Xaxis.)

These data points can be entered into any program capable of computing a fourthorder polynomial curve. This curve will be the mirror image of the curve on the

Calibration and Data Sheet provided in the rear of this manual; however, the

linearization coefficients will be different. Use the coefficients calculated with the

curve in the polynomial shown on the previous page.

After taking the data points, the operator may determine coefficients for user-specific

gas by either using any program capable of calculating a fourth-order curve fit or

calling the factory to have the specific coefficients ca lculated.

When entering the operator-determined coefficients, note that the microprocessor only

recognizes five significant digits to the right of the decimal point (e.g., 0.12345).

3.7 ROUTINE OPERATION

Set the NDIR Analyzer Module for desired operating range. Zero and span the

module, and then supply sample gas to the SAMPLE INLET at the rear of the module.

The NDIR Analyzer Module will now automatically and continuously analyze the

sample stream.

As a check of instrument performance, the operator should keep a log of zero/span

status.

Maximum permissible interval between calibrations depends on the analytical

accuracy required. A frequency of once every 24 hours is recommended initially, and

that practice should be continued unless experience indicates that some other interval

is more appropriate.

Readout accuracy is directly proportional to change in barometric pressure (i.e., a

change in cell pressure of 7.6mm of mercury will result in a readout error of about 1%

of reading). Therefore, if barometric pressure changes significantly, a recheck of

calibration against a span gas is advised. Also, an optional Pressure Compensation

Board is available that electronically compensates.

748332-D Rosemount Analytical June 1997

NGA 2000 Non-Dispersive Infrared Analyzer

3-9

S

TARTUP AND OPERATION

The Analyzer Module will not allow the user to increase the upper limit of a range

beyond the "maximum range" software setting. To change the "maximum range"

value, select the following from the Main Menu: Technical Configuration Menu,

Service Menu, Manufacturing Data, Analyzer Manufacturing Data. Select Maximum

Range, and use the arrow keys to scroll the indicated value. The same applies for

"minimum range" setting.

Basic controls...

Main Menu

Expert controls and setup...

(Operational configuration)

Technical level configuration...

(Diagnostic and manufacturing/service)

Basic level security

(expert, technical)

Enter your security code with softkeys.

Security codes are set in the system setup

menu in the Technical level menus.

Press five characters when Security code

says READY. Press six to return to “READY”.

Security code: 54321

Basic controls

Measurement range number: 1

Range upper limit: 10 ppm

Range and functional control: LOCAL

Zero gas concentration: 0 ppm

Span gas concentration: 9.89 ppm

Ranges with valid calibration: 1&2

Calibration status: Ready

If it won’t calibrate...

Status: Ready

ZERO

Current measurement parameters

Measurement range number: 1

Range change control: Local

PARMS

Expert analyzer controls...

Auxiliary module controls...

System set up...

Analyzer module set up...

Auxiliary module set up...

Local I/O set up...

Measured Gas: CO2

Linearization mode: ON

Gas Measurement Setup: ON

Analyzer operational state: Normal

Analyzer alarm state: Normal

Alarms report: Failure

Expert controls and setup

SPAN

MORE

Technical configuration menu

System set up...

Service menus...

Diagnostic menus...

Other module diagnostic menus...

Listing of all modules...

Expert and Technical menus follow in

succeeding flow charts.

Current measurement parameters

Response time: 2.0 Secs

Sample flow: 1000 ml/min.

Sample pressure: 12.3 kPa

Case Temperature: 55.3°C

IGURE

F

3-10

Are you sure?

You must have zero gas flowing

through the analyzer.

This control does NOT control any

auto-cal. Module bound to this

analyzer!

If you are sure, press ZERO again now.

Press left arrow key when you are

done.

Calibration status: Ready

Error message for last zero: 24-08-94

Analyzer Zero

3-9. D

ISPLAY SCREENS

Are you sure?

You must have zero gas flowing

through the analyzer.

This control does NOT control any

auto-cal. Module bound to this

analyzer!

If you are sure, press SPAN again now.

Press left arrow key when you are

done.

Calibration status: Ready

Error message for last zero: 24-08-94

Analyzer Span

OF

(1

5)

Check that you are flowing the correct gas, and

If it won’t calibrate...

the gas concentration is what it is supposed to be.

Make sure that the reading is stable before

starting. If you have changed the range fullscale

value or any linearizer coefficients, or enabled or

disabled it, or done anything else that would affect

how it measures the gas, you may have made it

hard for the analyzer to calibrate. If so, manually

adjust the coefficients until the readings are close

to correct, and try again.

June 1997 Rosemount Analytical 748332-DNGA 2000 Non-Dispersive Infrared Analyzer

From MAIN MENU

⇒⇒⇒⇒

Expert controls and setup

Expert analyzer controls...

Auxiliary module controls...

System set up...

Analyzer Module set up...

Auxiliary Module set up...

Local I/O set up...

S

TARTUP AND OPERATION

Analyzer module set up...

and Auxiliary module set up... Outlined in the

next flow chart. Local I/O set up information is

included in the I/O Modules manual.

Measurement range number: 1

Range lower limit: 0 ppm

Range upper limit: 10 ppm

Linearizer: ON

Range and functional control: LOCAL

Zero/Span calibration...

Ranges with valid calibration: 1&2

Physical measurements...

CAL DATA

#1

Zero/Span diagnostic data

Date of last zero: 24-0894

Error message for last zero: 24-08-94

Error percentage for last zero: 5%

Raw signal at last zero: 500000

Last zero gas would read: -0.83 ppm

Date of last span: 24-08-94

Error message for last span: Great!

Error percentage for last span 5%

Raw signal at last span: 500000

The last span gas would read: 11.3 ppm

FACTORS

#3

Calibration Factors

Range 1 factors...

Range 2 factors...

Range 3 factors...

Range 4 factors...

Zero compensation factor: 1

Span compensation factor: 1

Expert controls

CAL

Auxiliary module controls

This screen selects any module with a

control screen. This includes any auto

calibration or sample module bound to

this analyzer.

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Dependent on which auxiliary module is present

on the network. See I/O Modules manual.

#2

Zero offset: 500000

Span factor: 0.000015

Fullscale range at calibration: 10 ppm

Measurement range number: 1

Hardware zero offset: 0.0235 V

Raw measurement signal: 0.5250 V

Zero/Span Calibration

Measurement range number: 1

Zero gas concentration: 0 ppm

Span gas concentration: 9.89 ppm

Sample flow: 1000 ml/min.

Raw measurement signal: 0.3256 V

Ranges with valid calibration: 1&2

Status: Ready

Result...

Calibration adjustment limits: Enabled

FACTORS

Range 1 (2,3,4) Factors

System Set Up

Front panel control...

Display resolution...

Auxiliary lines...

See Platform manual for a flow chart

of these displays.

Physical Measurements

Sample flow: 1000 ml/min

Flow lower limit: 150 cc/min.

Flow upper limit: 250 cc/min.

Barometric pressure: 12.3 kPa

Case temperature: 54.3°C

See #1 on this flow chart

Range 1 (2,3,4) Factors

Manufacturer’s settings

HISTORY

Zero offset: 0

Span factor: 1000

Stored settings

Zero offset 500000

Span factor: 500000

IGURE

F

3-10. D

ISPLAY SCREENS

748332-D Rosemount Analytical June 1997

(2

OF

5)

NGA 2000 Non-Dispersive Infrared Analyzer

3-11

S

TARTUP AND OPERATION

From MAIN MENU

⇓

Expert controls and setup

Expert analyzer controls...

Auxiliary module controls...

System set up...

Analyzer Module set up...

Auxiliary Module set up...

Local I/O set up...

For Expert analyzer

controls, Auxiliary module

controls, and System set

up menus, see preceding

flow chard. Local I/O set

up information is included

in the I/O Modules manual.

Analyzer module set up

Calibration gas list...

Calibration param eters...

Gas measurement paramet er s...

Analyzer parameter list...

Physical measurement par ameters...

Displayed physical param eters...

Analyzer tag: IR

Auxiliary module set up

Select an auxiliary module for set up

Local I/O set up...

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Dependent on which auxiliary module is

present on the network.

See I/O Modules manual.

Calibration gas list

Zero gas - range 1: 0 ppm

Span gas - range 1: 9.3 ppm

Zero gas - range 2: 0 ppm

Span gas - range 2: 19.3 ppm

Zero gas - range 3: 0 ppm

Span gas - range 3: 101.1 ppm

Zero gas - range 4: 0 ppm

Span gas - range 4: 247.1 ppm

Calibration...

#4

Calibration Parameters

Calibration adjustment limi ts: enabled

Calibration averaging time: 5 S ec s

Calibration failure alarm: Yes

Cal failure error allowed: 5%

Calibration time out: 60 Secs

Zero ranges: TOGETHER

Span ranges: SEPARATE

Measurement parameters

Linearization parameters...

Response time/delay param eters...

Range setting...

Units...

Linearization functions...

Zero/Span Calibration

See #2 in Figure 3-10

Linearization paramete rs

Range 1 linearizer: Enabled

if enabled, uses curve no.: 1

Range 2 linearizer: Enabled

if enabled, uses curve no.: 2

Range 3 linearizer: Enabled

if enabled, uses curve no.: 3

Range 4 linearizer: Enabled

if enabled, uses curve no.: 4

Case temperature for coefficient s: 45°C

Set coeffi c ients…

Response time/delay parameters

Range 1 t90 time: 10 Secs

Range 2 t90 time: 1 Secs

Range 3 t90 time: 1 Secs

Range 4 t90 time: 1 Secs

LON update rate: 1 per Sec

Output delay time: 0 Secs

Range Settings

Minimum range: 10 ppm

Maximum r ange: 5000 ppm

Range 1 lower limit: 0 ppm

Range 1 upper limit: 10 ppm

Range 2 lower limit: 0 ppm

Range 2 upper limit: 100 ppm

Range 3 lower limit: 0 ppm

Range 3 upper limit: 250 ppm

Range 4 lower limit: 0 ppm

Range 4 upper limit: 1000 ppm

Gas measurement units: ppm

Pressure measurement units: psig

Temperature measurement units: F

Variables are still s e nt as the basic SI unit.

Units

#5

Linearity coefficients

Curve 1 (2,3,4)

AO coeffi c ient: 1.34523E-4

A1 coefficient: 0.983751

A2 coefficient: 0.115751

A3 coefficient: 1.11575E-6

A4 coefficient: 7.3421E-12

Curve upper limit: 10 ppm

Curve over- r ange: 10%

Curve under-range: 5%

Status: Enabled

Polynomial set up

Range to be linearized: 1

Current span gas: 9.69 ppm

Calculated polynom ial order : 4

Gas values shown as: Percent

Gas concentrations...

Analyzer function: Ready

Gas concentrations

Gas value: 0

Raw reading: 0 ppm

Linearized values: 0 ppm

Gas value: 10

Raw reading: 11 ppm

Linearized values: 10 ppm

Point to be measured: Point 1

Analyzer function: Ready

Point 1

Point 2

Midpoint correction set up

Range 1 (2,3,4)

Correction: Disabled

Point being measured: Pt 1

Point 1 gas concentration: 100 ppm

Point 2 gas concentration: 120 ppm

Point 3 gas concentration: 150 ppm

Point 1 reading: 100 ppm

Point 2 reading: 120 ppm

Point 3 reading: 150 ppm

Span gas value: 100 ppm

Analyzer function: Ready

Analyzer Parameter List

Analyzer tag: IR-CO2

First line’s parameter: Flow

Second line’s parameter: Flow

Third line’s parameter: Flow

Fourth line’s parameter: Flow

Linearization parameters...

#6

Physical Measurements

Barometric pressure: 10.13 hPa

Sample flow: 500 cc /min.

Case temperature: 45°C

Detector temperature: 52°C

Pressure limits...

Temperature limits...

Displayed Parameters

First line’s parameter: Flow

Second line’s parameter: Flow

Third line’s parameter: Flow

Fourth line’s parameter: Flow

May be displayed on the appropriat e

line of the singl e analyzer display

screen.

Linearization functions

Polynomial set up...

Midpoint correction set up...

Use the polynomial set up t o gener ate a

linearizing pol y nomial from up to 20

gases.

Linearity coefficients

See #5 above

NEXT

Pressure Limits

Sample pressure upper limit: 15 kPa

Sample pressure lower limit: 10 kPa

Temperature Limits

Case upper limit: 60 C

Case lower limit: 20 C

Detector upper limit: 69 C

Detector lower limit: 55 C

Analyzer Parameter List

Primary Vari able Parameters

Control mode: LOCAL

Output delay time: 0 Secs

Range 1 upper limit: 10 ppm

Range 2 upper limit: 100 ppm

Range 3 upper limit: 250 ppm

Range 4 upper limit: 1000 ppm

Range 1 lower limit: 0 ppm

Range 2 lower limit: 0 ppm

Range 3 lower limit: 0 ppm

Range 4 lower limit: 0 ppm

Analyzer Parameter List

Primary Vari able Parameters

Range 1 t90 time: 10 Secs

Range 2 t90 time: 1 Secs

Range 3 t90 time: 1 Secs

Range 4 t90 time: 1 Secs

Linearizer on range 1: Enabl ed

Linearizer on range 2: Enabl ed

Linearizer on range 3: Enabl ed

Linearizer on range 4: Enabl ed

Analyzer Parameter List

Calibration Parameters

Calibration averaging time: 5 S ec s

Calibration failure alarm: Yes

Cal failure error allowed: 5%

Calibration time out: 60 Secs

Ranges zeroed: TOGETHER

Calibrate ranges: SEPARATE

Calibration adjustment limi ts: ENABLED

Analyzer Parameter List

Calibration Gases

Zero gas - range 1: 0 ppm

Zero gas - range 2: 0 ppm

Zero gas - range 3: 0 ppm

Zero gas - range 4: 0 ppm

Span gas - range 1: 9.3 ppm

Span gas - range 2: 19.3 ppm

Span gas - range 3: 101.1 ppm

Span gas - range 4: 247.1 ppm

IGURE

F

3-12

3-11. D

ISPLAY SCREENS

(3

OF

5)

June 1997 Rosemount Analytical 748332-DNGA 2000 Non-Dispersive Infrared Analyzer

From MAIN MENU

⇓

Technical configuration menu

System set up...

Service m enus...

Diagnostic menus...

Other module diagnostic menus...

Listing of all modules...

For Diagnostic menus,

Other module diagnostic

menus, and Listing of all

modules, see Figure 3-11.

System Set Up

Main display configuration...

Front panel control...

Date and time...

Module binding...

System Reset...

Security codes...

System tag: Rosemount

Main display configuration, Front

panel control, and Date and time

displays can be found in the Platform

manual.

Module Binding

Analyzer module selec ted: IR-CO2

Select modules...

Proposed bind:

View bindings...

Bind selections!

Unbind everythi ng!

System Reset

Are you sure?

Re-initializing will destroy all the binds!!!

System reset!

Re-initialize network!

Record security codes

Basic level secur ity: Enabled

Expert level security: Enabled

Technical level security: Enabled

Record basic level security code...

Record expert level security code...

Record technical level security code...

Manufacturing data

Control module data. ..

Analyzer module data...

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Select IO modules

Select the modules you wish to bind to the

current analyzer.

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Modules Bound

Analyzer module selec ted: IR-CO2

Auxiliary module: Auto 1023

Auxiliary module: Acal 2322

Auxiliary module: HART 1092

Auxiliary module: None

Auxiliary module None

Auxiliary module: None

Proposed new bind:

#7

Record basic level security codes

(expert, technical)

Press the softkeys in any order to define the

code. The actual code is represented by the

order in which they are pressed, and shown

numerically below. Press the left arrow key

when you are done.

Actual code number: 54321

Control Unit Manufacturing Data

Control unit serial number: 800002356

Manufacturing date code: 12-08-93

Hardware revision number: 1.00

Software revision number: 1.09

Revision notes...

User tag number: PV1c

Analyzer Manufacturing Data

Analyzer module s/n: 900189342

Manufacturing data code: 17-08-93

Bench configurati on c ode: 17

Hardware revision number: 1.13

Software revision number: 1.03

Minimum range: 10 ppm

Maximum r ange: 5000 ppm

Measured gas: CO2

User tag number: IR-CO2

S

TARTUP AND OPERATION

IGURE

F

Service Menus

Manufacturing data. ..

Service history...

In maintenance since: N/A

Record security codes...

3-12. D

ISPLAY SCREENS

Service History

Control module data. ..

Analyzer module data...

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Record security codes

Basic level secur ity: Enabled

Expert level security: Enabled

Technical level security: Enabled

Record basic level security code...

Record expert level security code...

Record technical level security code...

See #7 above

OF

(4

5)

STORE

RESET

Store historical data

Are you sure?

STORE will copy current diagnostic data into

the historical ("was") variables, overwriting

what is currently there.

Reset

Are you sure?

RESET will erase ALL configuration and

manufacturing data, including serial

numbers.

Control Module Service History

Manufacturing date: 12-08-93

In service date: 01-23-94

Last service date: 01-23-94

List notes...

Add service date!

Analyzer module Service History

Manufacturing date: 17-08-93

In service date: 21-06-94

Last zero calibration date: 24-08-94

Last span calibration date: 24- 08- 94

Last service date: 21-06-94

List notes...

Add service date!

This function not applicable.

Slot position: 1

I/O module

748332-D Rosemount Analytical June 1997

NGA 2000 Non-Dispersive Infrared Analyzer

3-13

S

TARTUP AND OPERATION

From MAIN MENU

Technical configuration menu

System set up...

Service m enus...

Diagnostic menus...

Other module diagnostic menus...

Listing of all modules...

Diagnostic menus

Control module diagnostics...

Analyzer module di agnost ics...

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

⇓

For Service set up and

Service m enus, see

preceding flow charts.

Control Unit Diagnostics

See Platform manual.

#8

Analyzer Diagnostics

Power supply voltages...

Primary variable parameters. ..

Physical measurement s...

Temperature control parameters...

Miscellaneous control parameters...

Barometric pressure param eters...

Software diagnostics...

Analyzer diagnostics

Power supply voltages

+15V analog is: 14.98V

+15V analog was: 14.92V

-15V analog is: -14.85V

-15V analog was: -14.92V

+5V digital is: 5.02V

+5V digital was: 4.98V

+24V power is: 2.38V

+24V power was: 2.42V

+12V analog is: 11.88V

+12V analog was: 12.0V

Primary variable parameters

Raw measurement signal: 0.3258

Signal gain setting: 4%

Oscillator tune: 85%

Chopper speed: 5 Hz

Source current: 1.212 A

Modulation check.. .

Percent modulati on: 20%

Calibration time out: 60 Secs

Calibration f ac tors...

Pk-pk noise: 0 ppm

Modulation check

Measurement range number: 1

Detector signal: 7.0

Signal gain setting: 4%

Status Ready

Instructions: Flow zero

Then: Watt

Percent modulati on: 20%

(updated only at the end of this test)

Calibration Factors

See #3 in Figure 3-12

HISTORY

Other module diagnostics

This screen reserved for other modules

if present.

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Listing of all modules

Lists all modules detected on the

network.

Jumps to the module’s diagnostic

screen.

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

Module Tag

For I/O Module diagnostics,

see I/O Modules manual

Analyzer Diagnostics

See #8 above.

Physical measurements

See #6 in Figure 3-12

Temperature control

Fan lower setpoint: 60°C

Fan upper setpoint : 20°C

Minimum fan duty cycle: 30%

Case temperature: 45°C

Detector setpoint: 62°C

Detector P gain: 32.52

Detector I gain: 1.34

Detector bias: 283°C

Detector temperature: 62°C

Miscellaneous control parameters

Fan current: 35 mA

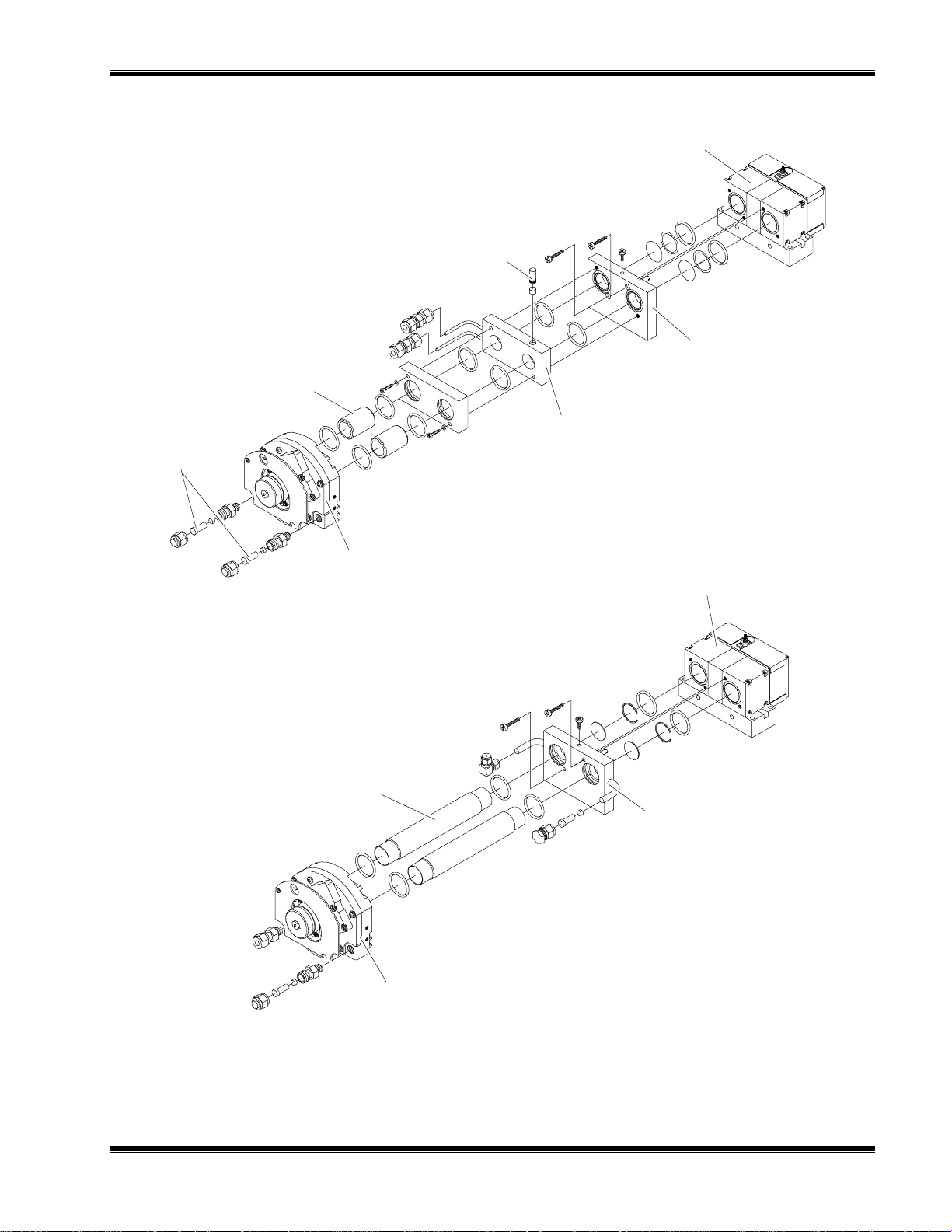

Fan duty cycle: 50%