Rosemount NGA 2000 FID Hydrocarbon Analyzer Module SW 3.9 Software-1st Ed. Manuals & Guides

Page 1

Instruction Manual

HAS62E-IM-SW39

04/2006

Software Version 3.9.x

NGA 2000 Software Manual for

FID Analyzer Module (combined with

NGA 2000 Plat form, MLT, CAT 200 or TFID Analyzer)

www.EmersonProcess.com

Page 2

FID Software 3.9.x Instruction Manual

HAS62E-IM-SW39

04/2006

ESSENTIAL INSTRUCTIONS

READ THIS P AGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and test s

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products

to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson Process Management (Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR W ARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical

shock and personal injury.

The information contained in this document is subject to change without notice. Misprints

reserved.

1st Edition 04/2006

© 2006 by Emerson Process Management

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

Contents: 1

2 Menu structure.......................................................................................................................................2- 1

3 Display and keyboard ...........................................................................................................................3- 1

3.1 Starting and initializing.............................................................................................................................3- 1

3.2 Display and operation..............................................................................................................................3- 2

3.3 The keyboard...........................................................................................................................................3- 2

3.4 Menu items..............................................................................................................................................3- 3

3.5 Common F-key functions.........................................................................................................................3- 4

3.6 Entering and editing parameters .............................................................................................................3- 5

3.7 Current measurement parameters ..........................................................................................................3- 5

3.8 The main menu........................................................................................................................................3- 6

3.8.1 Control module manufacturing data ........................................................................................................3- 7

3.8.2 Analyzer module manufacturing data......................................................................................................3- 8

4 Basic controls........................................................................................................................................4- 1

4.1 Measurement...........................................................................................................................................4- 3

4.1.1 Changing channels..................................................................................................................................4- 5

4.1.2 Changing the order of the multi-component display................................................................................4- 7

4.1.3 Changing the measurement range..........................................................................................................4- 9

4.1.4 Automatic range change..........................................................................................................................4- 13

4.1.5 Lighting the flame ....................................................................................................................................4- 17

4.2 Calibration................................................................................................................................................4- 21

4.2.1 Zeroing.....................................................................................................................................................4- 23

4.2.2 Spanning..................................................................................................................................................4- 27

5 Analyzer and I/O, expert controls & setup..........................................................................................5- 1

5.1 Analyzer module setup............................................................................................................................5- 3

5.1.1 Calibration gas list ...................................................................................................................................5- 5

5.1.2 Calibration parameters............................................................................................................................5- 13

5.1.3 Concentration alarm setup ......................................................................................................................5- 15

5.1.4 Gas measurement parameters................................................................................................................5- 17

5.1.4.1 Linearization parameters.........................................................................................................................5- 19

5.1.4.2 Response time/delay parameters............................................................................................................5- 23

5.1.4.3 Range setting..........................................................................................................

5.1.4.4 Automatic range change control..............................................................................................................5- 27

5.1.4.5 Units.........................................................................................................................................................5- 29

5.1.4.6 Linearization functions.............................................................................................................................5- 31

5.1.5 Analyzer parameter list............................................................................................................................5- 33

5.1.6 Displayed parameters..............................................................................................................................5- 35

5.2 System & network I/O module controls & setup......................................................................................5- 37

5.2.1 System SIO module.................................................................................................................................5- 39

5.2.1.1 Analog output setup.................................................................................................................................5- 41

5.2.1.2 Serial interface setup...............................................................................................................................5- 47

5.2.1.3 Relay outputs setup.................................................................................................................................5- 49

5.2.2 System DIO module ................................................................................................................................5- 51

5.3 Analyzer module controls........................................................................................................................5- 55

5.3.1 Physical measurements ..........................................................................................................................5- 57

.................................5- 25

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

1 - 1

Page 4

6 System configuration and diagnostics................................................................................................6- 1

6.1 Diagnostic menus ....................................................................................................................................6- 3

6.1.1 Control module diagnostics .....................................................................................................................6- 5

6.1.2 Analyzer module diagnostics...................................................................................................................6- 7

6.1.2.1 Power supply voltages.............................................................................................................................6- 9

6.1.2.2 Primary variable parameters....................................................................................................................6- 11

6.1.2.3 Physical measurement parameters.........................................................................................................6- 13

6.1.2.4 Temperature control parameters.............................................................................................................6- 15

6.1.2.5 Miscellaneous control parameters...........................................................................................................6- 17

6.1.2.6 Auto ignition parameters..........................................................................................................................6- 19

6.1.2.7 Self test results ........................................................................................................................................6- 21

6.1.2.8 Software diagnostics................................................................................................................................6- 23

6.1.2.9 Analyzer start up......................................................................................................................................6- 25

6.2 Load/Save configuration (CM/MCA)........................................................................................................6- 27

6.3 Date and time...........................................................................................................................................6- 29

6.4 Security codes .........................................................................................................................................6- 31

6.5 Network module management.................................................................................................................6- 33

6.6 Measurement display setup.....................................................................................................................6- 37

6.7 Miscellaneous..........................................................................................................................................6- 39

7 Display controls.....................................................................................................................................7- 1

Supplement:

Calculator on Control Module Level (CM Calculator) ........................................................................ Page 1 - 14

Programmable Logic Control on Control Module Level (CM PLC)................................................... Page 1 - 28

System Calibration .............................................................................................. Page 1 - 34

1- 2

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 04/06

Page 5

Introduction: 1

This software handbook describes the individual steps for successfully operating the FID

analyzer module and FID analyzer (analyzer module in a platform) from the Emerson Process

Management NGA 2000 series.

⇒ Chapter 2 contains an overview of the FID software menu structure.

⇒ Chapter 3 introduces the user interface (display and keys) and the main menu with its

submenus.

⇒ Chapter 4 describes the basic functions (measurement and calibration) in detail and step

by step.

⇒ Chapter 5 describes the expert level for the configuration of the module and any I/O

modules.

⇒ Chapter 6 describes the system configuration and diagnostics.

⇒ Chapter 7 contains information about the display controls.

Not all the contents of chapter 5 are relevant to all users. Which sub-chapters are relevant

depends on the configuration of the NGA 2000 system with regard to the following components:

Control module CM

Analyzer module AM

Input/Output-Modules I/O (SIO = Standard Input/Output;

DIO = Digital Input/Output)

Network I/O-Modules Analogue output with 3 alarms I/O;

Auto-Calibration I/O (“Autocal”);

System Auto-Calibration I/O (“Syscal”)

The following table gives the possible SIO/DIO configurations:

System unit SIO/DIO Configuration Chapter

FID analyzer module (AM)

No front panel, i.e. no control unit.

Can be combined with a platform, an MLT

analyzer, a TFID analyzer or a customerspecific control unit.

Platform (CM Software)

Control unit with front panel.

No measurement channels.

1 local SIO and 1 local DIO (or 2 local DIOs)

can be built into an MLT AM or a TFID AM

only.

SIO and DIO in the AM can only be

configured for the MLT/TFID channel.

No local FID I/Os

1 SIO and up to 4 DIOs can be built into the

platform.

SIO and DIO can be configured for all AMs

connected to the platform, e.g. for the FID.

System I/Os

see MLT/TFIDmanual.

5.2

FID analyzer (CM and FID analyzer module

software)

FID analyzer: FID AM in a Platform with front

panel

FID analyser module in a single MLT/TFIDAnalysator, i.e. all control unit and FID analyzer

module functions are displayed.

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

1 SIO and 1 DIO (or 2 DIOs) can be built in to

the MLT/TFID analyzer (CM I/Os).

SIO and DIO can be configured for all AMs

connected to the MLT/TFID analyzer, e.g.

FID.

System I/Os

NGA 2000

5.2

1 - 1

Page 6

NGA 2000 system with platform and FID analyzer module

NGA 2000 system with MLT analyzer and FID analyzer module

1- 2

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 7

NGA 2000 system with TFID analyzer and FID analyzer module

Introduction: 1

This manual concerns all FID analyzer modules combined with a platform, an MLT

analyzer or a TFID analyzer. This manual is also relevant for the CAT 200, which

consists of an MLT 1 in an EExd housing which is operated via a touch-screen front

panel or a magnetically operated front panel. There is a separate manual for the

CAT 200 which includes all CAT-related issues.

FID analyzer modules operated via a customer-specific control unit are not described

in this manual.

Network I/O modules have their own manuals which should be consulted for further

detail. In this manual, these I/O modules are only very briefly described.

Further questions should be directed to our Service Support Center.

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

1 - 3

Page 8

1- 4

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 9

Menu structure: 2

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

2 - 1

Page 10

2- 2

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 11

Display and keyboard: 3

3.1. Starting and initializing

On being powered up, the FID analyzer module (whether on a platform or as part of an NGA

network) runs through the initializing phase. This also includes a self-test of the analyzer(s) or

analyzer module(s). The LCD screen displays the company name and software version number

as well as a series of messages which indicate the status of the initialization cycle. Finally the

single component display of the FID is displayed, which serves as a starting point from which

the main menu, the analyzer module status menu and, if appropriate, the multi-channel display

of the analyzer network can be accessed.

(C) 2005 Emerson Process Management

NGA 2000 Control-Module Rev.3.9.4 / P017

Language: P017 / 02 / 00

Initializing Network

Installing network interface

LCDReset Abort

F1

F2

F3 F4

F5

All the instructions for the basic controls (chapter 4) begin at the single component display. The

actual display may vary from the illustrations in this manual, since it can be configured by the

client.

FID_WO1000001

6.28 ppm THC

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

ON

50

47

100000

900000

340 hPa

51.4 C

524401

490

61

Analyzer tag

Can be set to any

value. This is the

factory setting: “WO”

stands for “Work

Order”

F1

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

F2

F3 F4

F5

NGA 2000

3 - 1

Page 12

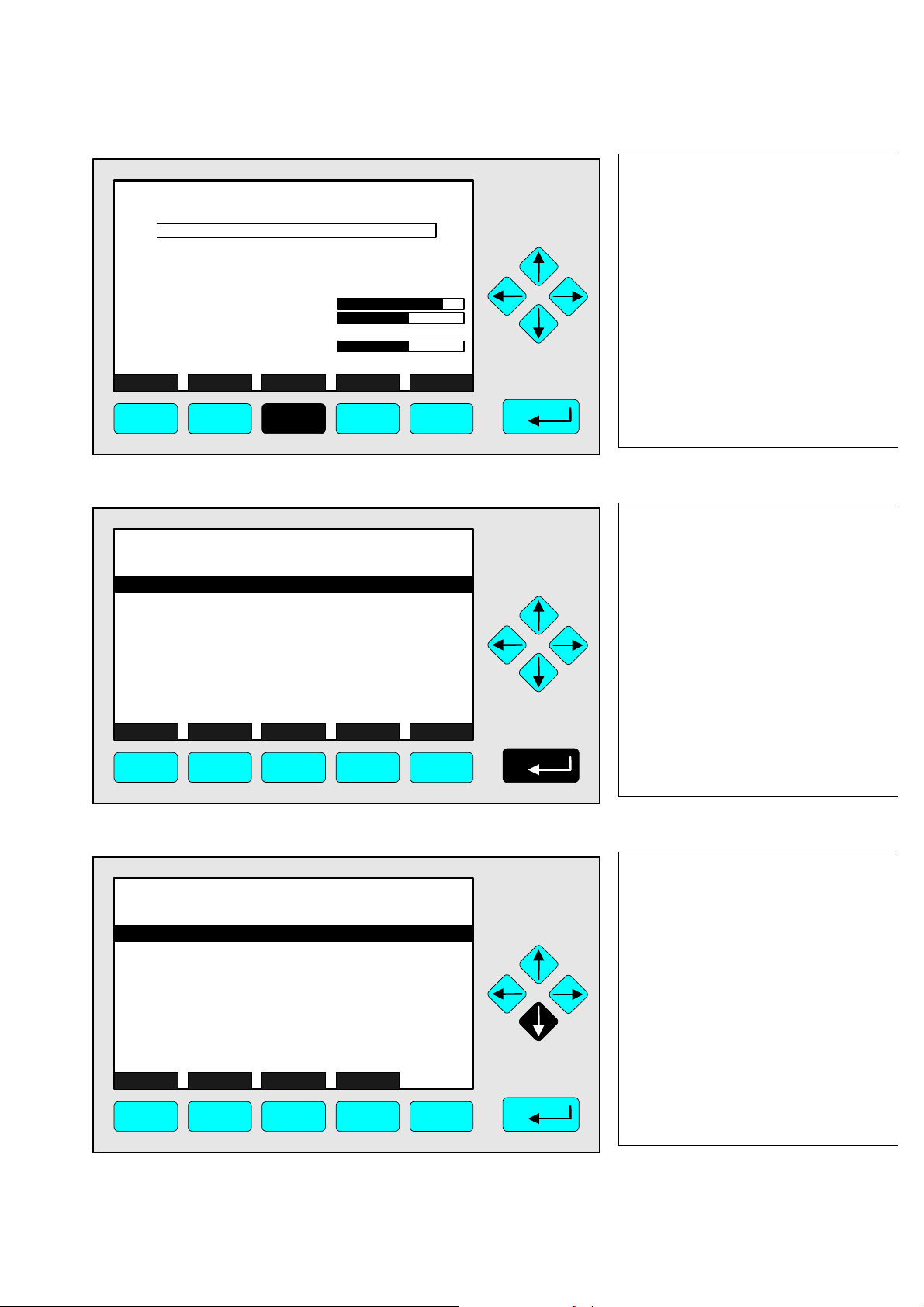

3.2. Display and operation

The measurement display and all operational steps are carried out via the LCD screen. The

keyboard itself comprises 5 function keys, 4 arrow keys and an Enter key. This handbook uses

simplified sketches to represent the user interface:

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer and I/O, expert controls & setup...

System configuration and diagnostics...

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status Channel Lock... MFG Data

F1

F2

-- Main menu --

03:11:05 August 16, 2006

F3 F4

6.28 ppm

Emerson

F5

The functions of the individual keys and the operation of the unit depend on:

the configuration of the analyzer or analyzer module

the optional modules (e.g. I/O modules) installed

the menu currently displayed.

If the power supply is interrupted, all user-specific module parameters are saved in a batteryoperated buffer.

3.3 The keyboard

FID_WO1000001

6.28 ppm THC

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

F1

F2

ON

50

47

100000

340 hPa

51.4 C

524401

F3 F4

490

61

900000

F5

Arrow keys

↑ -key and ↓ -key:

Move up or down within a

menu;

Change or edit a setting.

← -key and → -key:

Change to previous or

next submenu or page;

Select an individual digit

or character.

Enter key

Confirm a selection;

Execute the selected

command;

Change to the selected

Function keys: Function depends on the current menu and

menu.

is displayed on the LCD screen above each key.

3- 2

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 13

Display and keyboard: 3

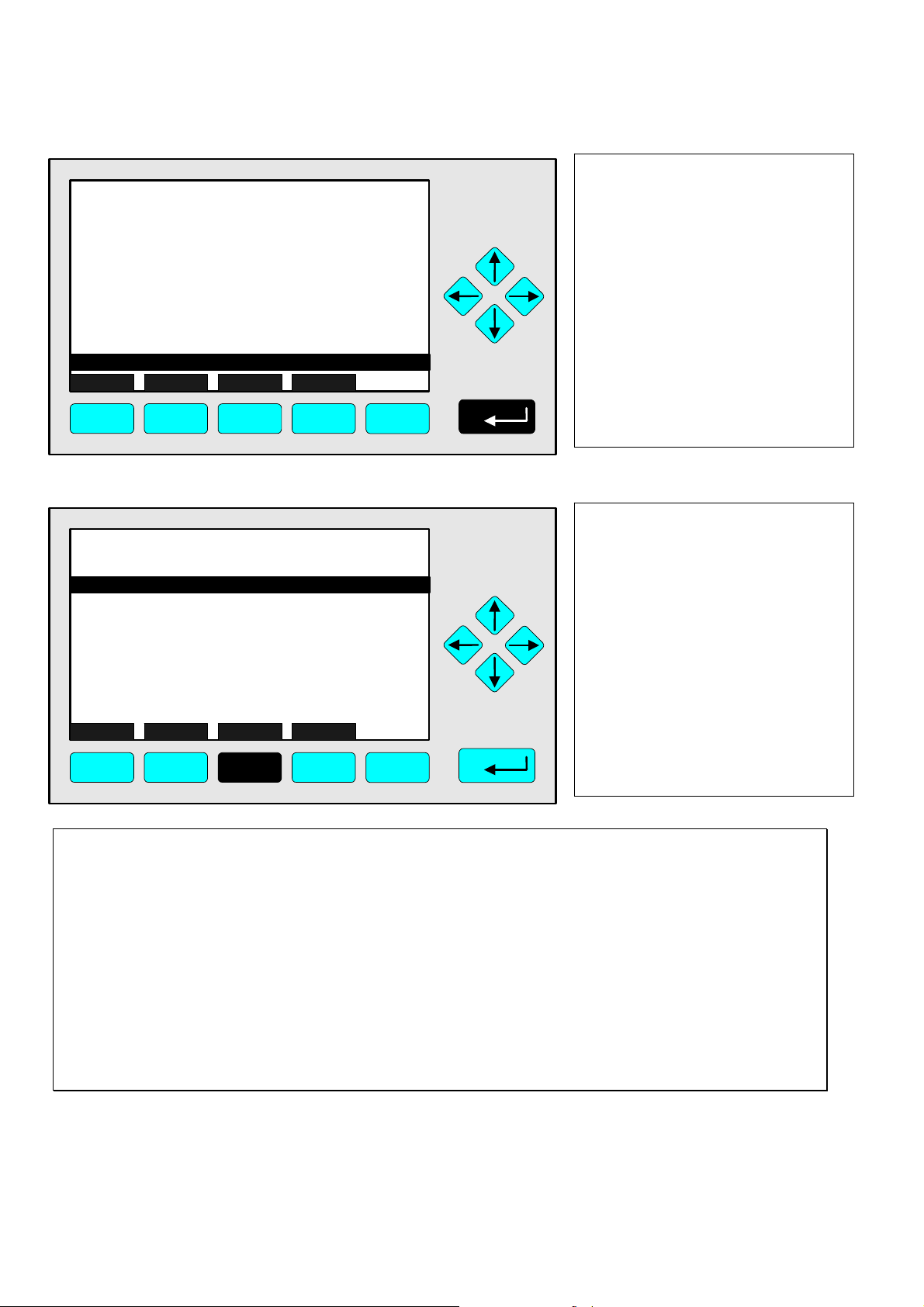

3.4 Menu items

A menu item can be selected with the ↑ -key or the ↓ -key. A selected item is shown in inverted

colours (white text against a black background). There are four different types of menu item:

Submenu...

An item ending in three dots.

Pressing the ↵ -key or the → -key accesses a submenu.

Command line !

An item ending in an exclamation point.

Pressing the ↵ -key or the → -key executes the selected function.

Parameter:

An item ending in a colon.

Displays a parameter. Some parameters can be changed, others are read-only.

If the parameter is editable, pressing the ↵ -key or the → -key puts the parameter into edit mode.

Text line

An item not ending in any of the above punctuation marks.

For information only; cannot be edited.

Text line

Parameter

Submenu

Function key labels

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

F1

F2

Basic Controls

F3 F4

6.28 ppm

1

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

F5

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

3 - 3

Page 14

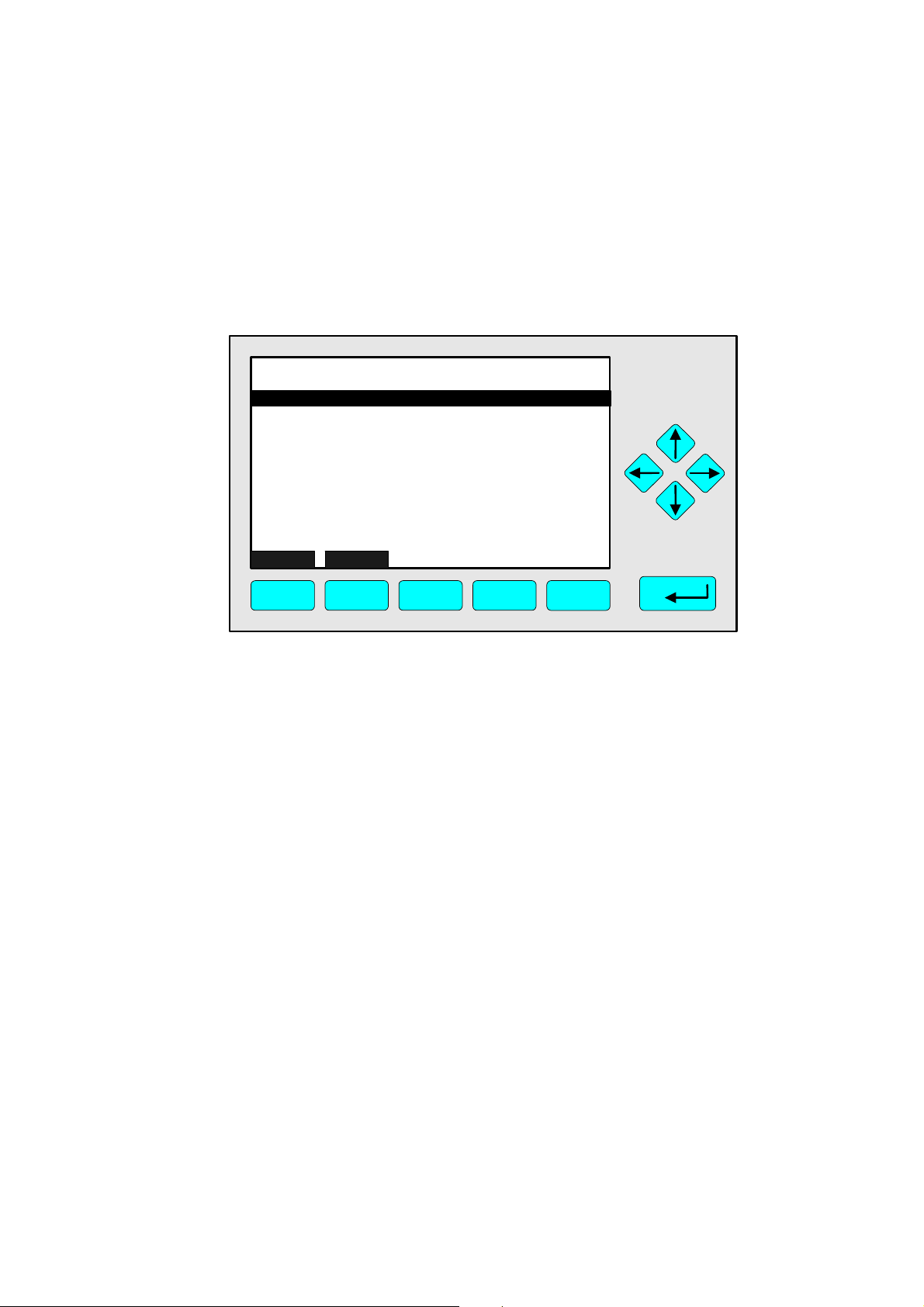

FID_WO1000001

Command line

-- System Reset --

System res et !

Measure Back...

F1

Are you sure ???

F2

F3 F4

3.5 Common F-key functions

Display

Change from the single component display to the multi-component display.

Measure

Change from the main menu to the single component display.

6.28 ppm

F5

Status

Change to the “Current measurement parameters” display for the most important parameters and status

information of the FID module or the current channel.

Always F2, when this function is available.

) ch. 3.7, page 3-5.

Main

Change from the single-component display to the main menu.

HOME

Change from a submenu to the main menu.

ESCAPE or Back

Change to the previous menu.

Revert a changed, but not yet confirmed, parameter to its previous value.

Lock

Locks all levels for which security has been activated.

F4 in the main menu.

Channel

Changes to a different channel within the same menu, if more than one channel is available. Each channel is

cycled through in turn.

In the main menu the channels of all analyzers are available, in submenus only the channels of the currently

selected analyzer module.

3- 4

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 15

Display and keyboard: 3

3.6 Entering and editing parameters

The Enter key

Pressing the Enter key when an editable parameter is selected will put that parameter into

edit mode: only the value itself will be displayed white on black. Pressing the Enter key again

will save the new value.

The ↑ -key and the ↓ -key:

Depending on the value being edited, these keys will:

change the numerical value

scroll through a list of options

change a letter or other character

Numbers with more than one digit will generally be incremented or decremented. Letters are

changed one at a time.

The

←

-key and the → -key:

Select an individual digit or character. Certain numerical parameters can be edited one digit

at a time.

3.7 Current measurement parameters

Pressing F2 (“Status”) in the single component display accesses the “Current measurement

parameters” menu:

FID_WO1000001

Current measurement parameters

Status details...

Measurement range number:

Range change control:

Flame condition:

Linearization mode:

Analyzer operational state:

Analyzer alarm condition:

Alarm level reported:

Current total variable updates per second:

HOME ESCAPE MORE

F1

F2

F3 F4

6.28 ppm

1

Local

ON

DISABLED

NORMAL

NORMAL

FAILURE

25

F5

Press F3 (“More”) for

information on:

Response time

Bypass sample flow

Sample pressure

Preamp temperature

Purge control status

In this menu the status of the FID analyzer module can be checked. Pressing F3 (“MORE”)

accesses a second page; press F2 (“ESCAPE”), F4 (“MORE”) or the ← -key to return to the first

page. Pressing the Enter key with the “Status details” line selected accesses further submenus

listing error messages and many other details.

These menus are informative only. None of the settings here can be changed; this can only be

done via the “Basic controls”, “Analyzer module setup” and “Analyzer module controls” menus

(chapters 4, 5.1 and 5.2 respectively).

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

3 - 5

Page 16

3.8 The main menu

Pressing F3 or the → -key in the single component display accesses the main menu. From this

menu all levels of the FID analyzer or analyzer module can be accessed allowing measurement,

calibration and data transfer parameters to be set.

F2

-- Main Menu --

16:35:32 June 15 2005

F3 F4

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer & I/O, expert controls and setup...

System configuration and diagnostics...

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

6.28 ppm

Emerson

F5

See chapter 4

See chapter 5

See chapter 6

Siehe Kapitel 4

See chapter 7

To set: ch. 6.3, page 6-29

Factory setting

F1: Change to the single component display of the current channel

F2: Change to the “Current measurement parameters” menu ) ch. 3.7, page 3-5

F3: Change to a different channel ) ch. 3.5, page 3-4

F4: Lock level(s) using security codes ) ch. 6.4, page 6-31

F5: Change to the “Manufacturing data” menu ) below

Pressing F5 accesses submenus in which important information about the control module and

the analyzer module can be found:

FID_WO1000001

Control module manufacturing data...

Analyzer module manufacturing data...

Measure <<< Back... >>>

F1

-- Manufacturing Data --

F2

F3 F4

6.28 ppm

F5

3- 6

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 17

3.8.1 Control module manufacturing data

FID_WO1000001

Control module manufacturing data...

Analyzer module manufacturing data...

-- Manufacturing Data --

6.28 ppm

FID_WO1000001

Display and keyboard: 3

-- Control Module Manufacturing Data --

Emerson Process Management

FAX. (+49) 6055 884 - 209

Copyright (c) 2005

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Tel (+49) 6055 884 - 0

6.28 ppm

Measure <<< Back... >>>

F1

F2

F3 F4

F5

Measure Back... More

F1

FID_WO1000001

-- Control Module Version Information --

Serial number:

Manufacturing date:

Hardware revision:

Software revision:

Revision date:

Revision time:

Phrase dictionary version:

Language:

Measure Back...

F1

F3 F4

F2

ACV02 R:3.9.0 D:Jul 17 2003

F3 F4

F2

F5

6.28 ppm

CM1

20.05.2004

3.9.4 / P017

Nov 11 2005

12:01:04

P017 / 01 / 00

English

F5

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

3 - 7

Page 18

3.8.2 Analyzer module manufacturing data

FID_WO1000001

Control module manufacturing data...

Analyzer module manufacturing data...

Measure <<< Back... >>>

F1

-- Manufacturing Data --

F3 F4

F2

FID_WO1000001

-- Analyzer Module Manufacturing Data --

Emerson Process Management

FAX. (+49) 6055 884 - 209

Copyright (c) 2005

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Tel. (+49) 6055 884 - 0

6.28 ppm

F5

6.28 ppm

FID_WO1000001

More...

Minimum range:

Maximum range:

Measured gas:

Capillary:

Flow sensor:

HOME ESCAPE

F1

FID_WO1000001

Serial number:

Manufacturing date:

Hardware revision:

Software revision:

Revision date:

Revision time:

Analyzer manufacturing data

F2

-- Analyzer Module Version Information --

13.5 ml/min @ 5psig

F3 F4

02:28:10 February 01, 2005

3.9.4 / P017

Nov 11 2005

6.28 ppm

4.0 ppm

10000 ppm

THC

Present

F5

6.28 ppm

FID1

0.5

12:33:56

Measure Back... More...

F1

F2

F3 F4

F5

Measure Back...

F1

F3 F4

F2

F5

3- 8

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 19

Basic controls: 4

Introduction

Chapter 4 describes the most important basic functions which are needed to configure a FID

analyzer module with an NGA front panel.

The following basic functions are available:

Measurement ) Chapter 4.1, page 4-3ff

Calibration ) Chapter 4.2, page 4-21ff

The basic settings are fully explained and illustrated step by step. The two-column layout shows

the user interface of the NGA front panel on the left. This enables the user to follow each step

and compare the illustrations with the analyzer display screen. On the right, each step is briefly

described. Each sub-chapter begins and ends with a single component display. The keys to be

pressed for each step are highlighted in black.

See the example on the next page.

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

4 - 1

Page 20

Example: Changing from the single component display to the main menu

⇒ The first illustration shows the initial situation

⇒ Pressing key F3 changes the display to that in the second illustration

1. Change to the main menu

FID_WO1000001

6.28 ppm THC

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

340 hPa

51.4 C

ON

524401

50

47

100000

490

61

900000

Press F3 or the → -key.

F1

F2

F3 F4

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer & I/O, expert controls and setup...

System configuration and diagnostics...

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

F2

-- Main Menu --

16:35:32 June 15 2005

F3 F4

F5

6.28 ppm

Emerson

F5

2. Any further instructions

follow, e.g.:

Change to the basic controls

Press the ↵ -key or the → -key.

4- 2

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 21

This subchapter describes the following functions:

Changing channels

) Chapter 4.1.1, page 4-5

Changing the order of the multi-component display

) Chapter 4.1.2, page 4-7

Changing the measurement range

) Chapter 4.1.3, page 4-9

Automatic range change

) Chapter 4.1.4, page 4-13

Lighting the flame

) Chapter 4.1.5, page 4-17

Basic controls: 4.1

Measurement

Chapters 4.1.1 and 4.1.2 are only relevant to systems with more than one

measurement channel.

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

4 - 3

Page 22

4- 4

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 23

FID_WO1000001

6.28 ppm THC

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

ON

50

47

100000

340 hPa

51.4 C

524401

490

61

900000

Basic controls: 4.1.1

Changing channels

1. Change to the multicomponent display

Press F1.

Note: The multi-component

display can be reached from

any single component display

by this method.

F1

F2

F3 F4

6.28

45.00

333.0

150.0

20.00

Select Status... Tags Off

F1 F2 F3 F4 F5

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

FID

ppm THC

ppm CO

ppm SO2

ppm NO

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

F5

10

10

10

10

10

LCDReset

2. Activate select function

Press F1 or the ↓ -key.

Note: If there are no other

channels connected to the

FID, only the bargraph of the

FID itself will be displayed. A

change of channels will then

not be possible.

6.28

>

45.00

333.0

150.0

20.00

Select Status... Tags Off

F1

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

F2 F3 F4 F5

FID

ppm THC

ppm CO

ppm SO2

ppm NO

%O2

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

10

10

10

10

10

LCDReset

NGA 2000

2. Select a channel

Press the ↑ or ↓ -key until the

> symbol appears in the line

you wish to select.

4 - 5

Page 24

3. Return to the single

6.28

45.00

>

333.0

150.0

20.00

FID

ppm THC

MLT25/CH1/R2

ppm CO

MLT25/CH2/R2

ppm SO2

MLT25/CH3/R2

ppm NO

MLT25/CH4/R2

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

10

10

10

10

10

component display

Press F1.

Select Status... Tags Off

F1

F2 F3 F4 F5

FID_WO1000001

45.28 ppm CO

0 Range: 2 250

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

F1

F2

ON

50

47

100000

340 hPa

51.4 C

524401

F3 F4

LCDReset

4. The single component

display after selecting a new

channel.

490

61

900000

F5

4- 6

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 25

Changing the order of the multi-component display

FID_WO1000001

6.28 ppm THC

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

ON

50

47

100000

340 hPa

51.4 C

524401

Basic controls: 4.1.2

1. Change to the multicomponent display

Press F1.

490

61

900000

F1

F2

6.28

45.00

333.0

150.0

20.00

Select Status... Tags Off

F1

ppm THC

MLT25/CH1/R2

ppm CO

MLT25/CH2/R2

ppm SO2

MLT25/CH3/R2

ppm NO

MLT25/CH4/R2

F2 F3 F4 F5

F3 F4

FID

0

0

0

0

0

%O2

[1]

[2]

[3]

[4]

[5]

F5

10

10

10

10

10

LCDReset

2. Activate select function

Press F1 or the ↓ -key.

Note: If no other channels are

connected to the FID, only the

bargraph of the FID itself will

be displayed, and steps to

change the order are

superfluous.

6.28

>

45.00

333.0

150.0

20.00

Select Status... Tags Off

F1

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

F2 F3 F4 F5

FID

ppm THC

ppm CO

ppm SO2

ppm NO

%O2

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

10

10

10

10

10

LCDReset

NGA 2000

2. Select a channel to appear

in the first line

Press the ↑ or ↓ -key until the

> symbol is next to the

appropriate bargraph.

Example: MLT channel 2

) is to be displayed in the

(SO

2

first line.

4 - 7

Page 26

3. Set the selected bargraph

6.28

45.00

333.0

>

150.0

20.00

FID

ppm THC

MLT25/CH1/R2

ppm CO

MLT25/CH2/R2

ppm SO2

MLT25/CH3/R2

ppm NO

MLT25/CH4/R2

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

10

10

10

10

10

to the first line

Press the ↵ -key.

Select... Display Tags Off

F1

F2 F3 F4 F5

333.0

6.28

45.00

150.0

20.00

Select Status... Tags Off

F1

MLT25/CH2/R2

ppm SO2

ppm THC

MLT25/CH1/R2

MLT25/CH3/R2

MLT25/CH4/R2

F2 F3 F4 F5

FID

ppm CO

ppm NO

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

LCDReset

10

10

10

10

10

LCDReset

4. The multi-component

display after setting the

order of bargraphs

It is now possible to select any single component display. See chapter 4.1.1 for

further instructions.

4- 8

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 27

FID_WO1000001

6.28 ppm THC

51.4 C

ON

50

47

100000

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

340 hPa

524401

Basic controls: 4.1.3

Changing the measurement range

1. Change to the main menu

Press F3 or the → -key.

490

61

900000

F1

F2

F3 F4

F2

-- Main Menu --

16:35:32 June 15 2005

F3 F4

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer & I/O, expert controls and setup...

System configuration and di ag nost ic s. ..

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

Basic Controls

F5

6.28 ppm

Emerson

F5

6.28 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

2. Change to the basic

controls

Press the ↵ -key or the

→ -key.

3. Select “Measurement

range number”

1

Press the ↵ -key or the

→ -key.

F1

F2

F3 F4

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

F5

NGA 2000

4 - 9

Page 28

FID_WO1000001

Basic Controls

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

Back...

6.28 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

4. Set the new range number

1

Press the ↑-key or the ↓ -key

until the required range

number appears.

Example: Changing from

range 1 to range 2.

F1

F2

F3 F4

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

F1

F2

Basic Controls

Back...

F3 F4

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

Basic Controls

F5

6.28 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

F5

6.28 ppm

25.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

5. Confirm range number

2

Press the ↵ -key.

Note: To cancel the change

and return to the previous

value, press F2.

6 Change to the main menu

2

Press the ← -key or F1.

Note: The range upper limit

(2nd line) automatically

changes to the value

previously set for the selected

range.

F1

F2

F3 F4

F5

4- 10

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 29

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer & I/O, expert controls and setup...

System configuration and di ag nost ic s. ..

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

-- Main Menu --

16:35:44 June 15 2005

6.28 ppm

Emerson

Basic controls: 4.1.3

Changing the measurement range

7. Change to the single

component display

Press F1.

F1

F2

F3 F4

F2

ON

50

47

100000

340 hPa

51.4 C

524401

F3 F4

FID_WO1000001

6.28 ppm THC

0 Range: 2 25

Sample pressure:

Case temperature:

Flame:

Raw signal:

Display Status... Main... Channel BasicCal

F1

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

F5

900000

F5

490

61

NGA 2000

8. The single component

display showing the new

measurement range

4 - 11

Page 30

4- 12

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 31

FID_WO1000001

6.28 ppm THC

51.4 C

ON

50

47

100000

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

340 hPa

524401

Basic controls: 4.1.4

Automatic range change

1. Change to the main menu

Press F3 or the → -key.

490

61

900000

F1

F2

F3 F4

F2

-- Main Menu --

16:35:32 June 15 2005

F3 F4

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer & I/O, expert controls and setup...

System configuration and di ag nost ic s. ..

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

Basic Controls

F5

6.28 ppm

Emerson

F5

6.28 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

2. Change to the basic

controls

Press the ↵ -key or the

→ -key.

3. Select menu item

“Automatic range change

control”

1

Press the ↑-key or the ↓ -key

until the line “Automatic range

change control” is displayed

against a black background.

F1

F2

F3 F4

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

F5

NGA 2000

4 - 13

Page 32

FID_WO1000001

Basic Controls

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

6.28 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

4. Select the item

1

Press the ↵ -key or the

→ -key.

F1

F2

F3 F4

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass-Durchfluss:

Messbereiche mit gültiger Kalibrierung:

Kalibrierart:

Flammenzustand:

Flamme zünden...

F1

F2

Basic Controls

Back...

F3 F4

F5

6.28 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

F5

5. Set the required value

1

Press the ↑-key or the ↓ -key

until the required value is

displayed.

The following settings are available:

Disabled Automatic range change control is switched off.

Enabled:SLC On The new switch level is automatically calculated (see

ch. 5.1.4.4, page 5-27).

Enabled: SLC Off The new switch level is not automatically calculated.

4- 14

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 33

FID_WO1000001

Basic Controls

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid cali bration:

Calibration status:

Flamen condition:

Light flame...

Back...

6.28 ppm

10.0 ppm

10.0 ppm

Enabled:SLC Off

0.0 ml/min

1&2&3&4

READY

ON

Basic controls: 4.1.4

Automatic range change

6. Confirm new setting

1

Press the ↵ -key.

Note: To cancel the change

and return to the previous

value, press F2.

F1

F2

F3 F4

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

F1

F2

Basic Controls

F3 F4

F5

6.28 ppm

10.0 ppm

10.0 ppm

Enabled:SLC Off

0.0 ml/min

1&2&3&4

READY

ON

F5

7. Change to the main menu

1

Press the ← -key or F1.

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer and I/O, expert controls & setup...

System configuration and di ag nost ic s. ..

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

F2

-- Main Menu --

16:36:05 June 15, 2005

F3 F4

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

6.28 ppm

Emerson

F5

NGA 2000

8. Change to the single

component display

Press F1.

4 - 15

Page 34

FID_WO1000001

6.28 ppm THC

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

340 hPa

51.4 C

ON

524401

50

47

100000

9. The single component

display after completion of

the preceding steps

490

61

900000

F1

F2

F3 F4

F5

4- 16

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 35

FID_WO1000001

-4.76 ppm THC

51.4 C

OFF

50

47

100000

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

F1

F2

340 hPa

524401

F3 F4

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer and I/O, expert controls & setup...

System configuration and di ag nost ic s. ..

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

-- Main Menu --

16:02:09 June 15, 2005

490

61

900000

F5

-4.76 ppm

Emerson

Basic controls: 4.1.5

Lighting the flame

1. Change to the main menu

Press F3 or the → -key.

Note: When the flame is unlit,

the FID will show an obviously

nonsensical measurement.

The line “Flame status” shows

the value “OFF”. In order to

use the FID, the flame must be

lit.

2. Change to the basic

controls

Press the ↵ -key or the

→ -key.

F1

F2

F3 F4

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

F1

F2

Basic Controls

F3 F4

F5

-4.76 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

Bereit

OFF

F5

3. Select menu item “Light

flame”

1

Press the ↑-key or the ↓ -key

until the line “Light flame” is

displayed against a black

background.

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

4 - 17

Page 36

FID_WO1000001

Basic Controls

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

-4.76 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

OFF

4. Select the item

1

Press the ↵ -key or the

→ -key.

F1

F2

F3 F4

F5

FID_WO1000001

Flame condition:

Auto-ignition:

Ignition system enable:

Number of ignition attempts so far:

Time on this cycle - secs:

Fuel supply pressure:

Burner air pressure:

Sample pressure:

Purge gas pressure:

Flame temperature:

Status:

HOME ABORT LIGHT ENRICH

F1

F2

Light Flame

AIR PRESSURE TOO LOW

F3 F4

-4.76 ppm

OFF

ENABLED

ON

0

0

1602 hPa

1042 hPa

341 hPa

691 hPa

51.0 C

F5

5. Check values and light

flame

If the values shown are within

certain limits, the flame can be

lit.

Press F3.

The flame can only be lit when the system has been successfully purged. The

following conditions must be met for the purge cycle to commence:

Purge gas pressure no less than 680 hPa

Purge gas flow between approx. 16 and 18 l/min

Small difference in pressure outside and inside the case

Before the flame can be ignited, the system must have been successfully purged. In

addition, the following conditions must be met:

Burner air pressure approx. 1040 hPa

Sample gas pressure approx. 340 or 140 hPa, depending on the type of capilliaries

4- 18

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 37

FID_WO1000001

Light Flame

Flame condition:

Auto-ignition:

Ignition system enable:

Number of ignition attempts so far:

Time on this cycle - secs:

Fuel supply pressure:

Burner air pressure:

Sample pressure:

Purge gas pressure:

Flame temperature:

Status:

ABORT

-4.76 ppm

OFF

ENABLED

ON

15

1602 hPa

1042 hPa

341 hPa

691 hPa

51.0 C

AIR PRESSURE TOO LOW

Basic controls: 4.1.5

Lighting the flame

6. Burner air is enriched

The line “Time on this cycle”

0

starts counting the seconds.

Note: To abort the procedure,

press F2.

F1

F2

FID_WO1000001

Flame condition:

Auto-ignition:

Ignition system enable:

Number of ignition attempts so far:

Time on this cycle - secs:

Fuel supply pressure:

Burner air pressure:

Sample pressure:

Purge gas pressure:

Flame temperature:

Status:

ABORT

F1

F2

Light Flame

F3 F4

PARAMETERS NORMAL

F3 F4

F5

-4.76 ppm

OFF

ENABLED

ON

72

1602 hPa

1042 hPa

341 hPa

691 hPa

176 C

F5

7. Flame is ignited

The flame temperature rises. If

0

it remains steady at more than

115°C, the flame has been

successfully lit.

The FID can be configured to start a new cycle automatically after a failed ignition

attempt. The maximum number of attempts can be set in the “Auto ignition

parameters” menu (see chapter 6.1.2.6, page 6-19).

By default the FID makes up to 3 attempts.

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

4 - 19

Page 38

FID_WO1000001

Light Flame

Flame condition:

Auto-ignition:

Ignition system enable:

Number of ignition attempts so far:

Time on this cycle - secs:

Fuel supply pressure:

Burner air pressure:

Sample pressure:

Purge gas pressure:

Flame temperature:

Status:

HOME ABORT LIGHT ENRICH

6.28 ppm

ON

ENABLED

ON

81

1602 hPa

1042 hPa

341 hPa

691 hPa

176 C

PARAMETERS NORMAL

8. Change to the main menu

Press the ← -key or F1.

0

F1

F2

F3 F4

F2

-- Main Menu --

16:03:45 June 15, 2005

F3 F4

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer and I/O, expert controls & setup...

System configuration and diagnostics...

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

FID_WO1000001

6.28 ppm THC

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

ON

50

47

100000

340 hPa

51.4 C

524401

F5

6.28 ppm

Emerson

F5

490

61

900000

9. Change to the single

component display

Press F1.

10. The single component

display after lighting the

flame

F1

F2

F3 F4

F5

4- 20

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 39

Basic controls: 4.2

Calibration

This subchapter describes the following functions:

Zeroing

) Chapter 4.2.1, page 4-23

Spanning

) Chapter 4.2.2, page 4-27

Before the FID can be used, each measurement range must be successfully zeroed

and spanned. Zeroing should be performed first.

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

4 - 21

Page 40

4- 22

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 41

FID_WO1000001

6.28 ppm THC

51.4 C

ON

50

47

100000

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

340 hPa

524401

Basic controls: 4.2.1

Zeroing

1. Change to the main menu

Press F3 or the → -key.

490

61

900000

F1

F2

F3 F4

F2

-- Main Menu --

16:35:32 June 15 2005

F3 F4

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer & I/O, expert controls and setup...

System configuration and di ag nost ic s. ..

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

Basic Controls

F5

6.28 ppm

Emerson

F5

6.28 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

2. Change to the basic

controls

Press the ↵ -key or the

→ -key.

3. Change to the “Analyzer

zero” menu

1

Press F3.

F1

F2

F3 F4

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

F5

NGA 2000

4 - 23

Page 42

FID_WO1000001

Analyzer zero

Are you sure?

You must have zero gas flowing through the analyzer.

Calibration time:

Measurement range number:

Calibration status:

Error message for last zero:

HOME ESCAPE ZERO Prüf-Kal

6.28 ppm

0 s

READY

CAL OK

4. Commence zeroing.

Press F3.

Note: Pressing F2 will take you

1

back to the “Basic Controls”

menu.

F1

F2

F3 F4

F5

Before calibration can begin, the following conditions must be met:

Zero gas must flow through the analyzer for a sufficient period of time.

The measured value must be stable.

Each range can be zeroed separately, or all together. This preference can be set in

the “Calibration parameters” menu (see chapter 5.1.2, page 5-13).

FID_WO1000001

Are you sure?

You must have zero gas flowing through the analyzer.

Calibration time:

Measurement range number:

Calibration status:

Error message for last zero:

Analyzer zero

ZEROING - WAIT

3.02 ppm

CAL OK

10 s

1

5. Zeroing in progress

Note: To abort the procedure,

press F2.

Abort Prüf-Kal

F1

F2

F3 F4

F5

4- 24

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 43

FID_WO1000001

Are you sure?

You must have zero gas flowing through the analyzer.

Calibration time:

Measurement range number:

Calibration status:

Error message for last zero:

HOME ESCAPE ZERO Prüf-Kal

F1

F2

Analyzer zero

F3 F4

0.05 ppm

17 s

READY

CAL OK

F5

Basic controls: 4.2.1

Zeroing

6. Change to the main menu

Press F1.

Note: To span the analyzer

1

directly after zeroing, press F2

to return to the “Basic

Controls” menu and follow the

instructions in chapter 4.2.2

from step 3 onwards.

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer and I/O, expert controls & setup...

System configuration and di ag nost ic s. ..

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

F2

-- Main Menu --

16:40:38 June 15, 2005

F3 F4

FID_WO1000001

0.02 ppm THC

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

ON

50

47

100000

340 hPa

51.4 C

524401

0.02 ppm

Emerson

F5

490

61

900000

7. Change to the single

component display

Press F1.

8. The single component

display after zeroing

F1

F2

F3 F4

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

F5

NGA 2000

4 - 25

Page 44

4- 26

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 45

FID_WO1000001

6.28 ppm THC

51.4 C

ON

50

47

100000

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

340 hPa

524401

Basic controls: 4.2.2

Spanning

1. Change to the main menu

Press F3 or the → -key.

490

61

900000

F1

F2

F3 F4

F2

-- Main Menu --

16:35:32 June 15 2005

F3 F4

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer & I/O, expert controls and setup...

System configuration and di ag nost ic s. ..

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

FID_WO1000001

Measurement range number:

Range upper limit:

Span gas concentration:

Automatic range change control:

Bypass sample flow:

Ranges with valid calibration:

Calibration status:

Flame condition:

Light flame...

HOME ESCAPE ZERO SPAN

Basic Controls

F5

6.28 ppm

Emerson

F5

6.28 ppm

10.0 ppm

10.0 ppm

Disabled

0.0 ml/min

1&2&3&4

READY

ON

2. Change to the basic

controls

Press the ↵ -key or the

→ -key.

3. Change to the “Analyzer

span” menu

1

Press F4.

F1

F2

F3 F4

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

F5

NGA 2000

4 - 27

Page 46

FID_WO1000001

Analyzer span

Are you sure?

You must have span gas flowing through the analyzer.

Calibration time:

Measurement range number:

Calibration status:

Error message for last span:

HOME ESCAPE SPAN

6.28 ppm

0 s

READY

CAL OK

4. Commence spanning

Press F4.

Note: Pressing F2 will take you

1

back to the “Basic Controls”

menu.

F1

F2

F3 F4

F5

Before calibration can begin, the following conditions must be met:

Span gas must flow through the analyzer for a sufficient period of time.

The measured value must be stable.

Each range can be spanned separately, or all together. This preference can be set in

the “Calibration parameters” menu (see chapter 5.1.2, page 5-13).

If it is not possible to calibrate all ranges with the same span gas, the ranges must be

calibrated separately.

The span gas concentration must be between 10% and 110% of the upper limit of the

current range. See chapter 5.1.1, page 5-5.

FID_WO1000001

Are you sure?

You must have span gas flowing through the analyzer.

Calibration time:

Measurement range number:

Calibration status:

Error message for last span:

Analyzer span

SPANNING - WAIT

8.14 ppm

10 s

CAL OK

1

5. Spanning in progress

Note: To abort the procedure,

press F2.

Abort

F1

F2

F3 F4

F5

4- 28

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 47

FID_WO1000001

Are you sure?

You must have span gas flowing through the analyzer.

Calibration time:

Measurement range number:

Calibration status:

Error message for last span:

HOME ESCAPE SPAN

Analyzer span

9.76 ppm

18 s

READY

CAL OK

Basic controls: 4.2.2

Spanning

6. Change to the main menu

Press F1.

1

F1

F2

F3 F4

FID_WO1000001

Analyzer basic controls (calibration) & setup...

Analyzer and I/O, expert controls & setup...

System configuration and di ag nost ic s. ..

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

F2

-- Main Menu --

16:42:38 June 15, 2005

F3 F4

F5

9.76 ppm

Emerson

F5

7. Change to the single

component display

Press F1.

FID_WO1000001

9.76 ppm THC

51.4 C

ON

50

47

100000

0 Range: 1 10

Sample pressure:

Case temperature:

Flame status:

Raw signal:

Display Status... Main... Channel BasicCal

F1

F2

340 hPa

524401

F3 F4

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

900000

F5

490

61

NGA 2000

8. The single component

display after spanning

4 - 29

Page 48

4- 30

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 49

Analyzer and I/O, expert controls & setup: 5

Introduction

Main menu

↓

Analyzer and I/O, expert controls & setup

↓

FID_WO1000001

-- Analyzer and I/O, Expert Controls & Setup --

Analyzer module controls...

System & network I/O module controls...

Analyzer module setup...

System & network I/O module setup...

(Note: Controls & setup are identical for MLT/TFID)

Measure Channel Back...

F1

F2

F3 F4

6.28 ppm

F5

From the main menu, pressing the ↵ -key or the → -key in the line “Analyzer and I/O, expert

controls & setup” accesses this menu, from which several submenus lead to options for setting

measurement and calibration parameters for the analyzer or analyzer modules, as well as for

configuring additional modules. The significance of different submenus may vary depending on

the configuration of the NGA-2000 system.

Menu items:

“Analyzer module controls” submenu

Zero and span calibration

Measurement range settings

Lighting the flame

) Ch. 5.3, page 5-55

“System & network I/O module controls” submenu

Configure SIO or DIO modules connected to the analyzer or platform

) Ch. 5.2, page 5-37

“Analyzer module setup” submenu

Set measurement and calibration parameters

Set linearizer parameters

) Ch. 5.1, page 5-3

“System & network I/O module setup” submenu

Configure network I/O modulesEinstellungen der Netzwerk-E/A-Modulen

) Ch. 5.2, page 5-37

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

5 - 1

Page 50

The submenus “System & network I/O module controls” and “...setup” are identical

for the FID module. Options in these areas are available not just for the FID module

but for any modules connected to the network. In some cases, different options may

be available in each area (“...controls” or “...setup”). For further information please

consult the manual for the module, or contact our customer services.

Changing to a submenu:

⇒ Press the ↑ -key or the ↓ -key until the appropriate menu item is displayed against a

black background.

⇒ Press the ↵ -key or the → -key to change to the submenu.

Structure of chapter 5:

All menus which must be navigated through to reach a specific submenu are listed vertically. At

the end of the “breadcrumb” list, the menu is illustrated, following which explanations and

instructions, which may themselves contain illustrations, are to be found.

Example: The concentrations of zero and span gas for each measurement range are to be

set.

Main menu

↓

Analyzer and I/O, expert controls & setup

↓

Analyzer module setup

↓

Calibration gas list

↓

FID_WO1000001

Zero gas - range 1:

Span gas - range 1:

Zero gas - range 2:

Span gas - range 2:

Zero gas - range 3:

Span gas - range 3:

Zero gas - range 4:

Span gas - range 4:

Calibration gas HC response factor:

Operational sample press ure:

Calibration...

HOME ESCAPE

F1

Calibrat ion Gas List

F2

F3 F4

6.28 ppm

0.00 ppm

10.00 ppm

0.00 ppm

25.00 ppm

0.00 ppm

100.0 ppm

0.00 ppm

250.0 ppm

1.00

344 hPa

F5

In this menu the values for the concentrations of zero gas and span gas for the calibration of all

ranges can be set...

Further instructions follow.

5- 2

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 51

Analyzer and I/O, expert controls & setup: 5.1

Analyzer module setup

Main menu

↓

Analyzer and I/O, expert controls & setup

↓

Analyzer module setup

↓

FID_WO1000001

Calibration gas list...

Calibration parameters...

Concentration alarm setup...

Gas measurement parameters...

Analyzer parameter list...

Physical measurement parameters...

Displayed parameters...

Analyzer tag: FID_WO1000001

HOME ESCAPE

F1

Analyzer module set up

F2

F3 F4

6.28 ppm

F5

From this menu various submenus are available, in which measurement and calibration

parameters of the FID analyzer module and the display parameters of the single component

display can be set.

Menu items:

“Calibration gas list” submenu

Set zero and span calibration gas concentrations

) Ch. 5.1.1, page 5-5.

“Calibration parameters” submenu

Set further paramaters for zero and span calibration

) Ch. 5.1.2, page 5-13.

“Concentration alarm setup” submenu

Configure concentration alarms

) Ch. 5.1.3, page 5-15.

“Gas measurement parameters” submenu

Configure settings for measurement ranges, units and linearization

) Ch. 5.1.4, page 5-17.

“Analyzer parameter list” submenu

A summary of various parameters: displayed parameters, concentration parameters,

linearization parameters etc.

) Ch. 5.1.5, page 5-33

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

NGA 2000

5 - 3

Page 52

“Physical measurement parameters” submenu

Information about various measurement parameters

) Ch. 6.1.2.3, page 6-13

“Displayed parameters” submenu

Configure settings for the four additional parameters displayed in the single component

display

) Ch. 5.1.6, page 5-35

“Analyzer tag” parameter

The analyzer tag can be set to any value with a maximum of 30 characters.

A change in this setting must be borne in mind when configuring the programmable

I/Os, if the FID module is part of an analyzer network.

Changing the analyzer tag

⇒ Press the ↑ -key or the ↓ -key until the “Analyzer tag” item is displayed against a black

background.

⇒ Select the item by pressing the ↵ -key or the → -key.

⇒ Select the character to be edited by pressing the ← -key or the → -key.

⇒ Press the ↑ -key or the ↓ -key until the required character is shown.

⇒ Repeat the previous two steps until the required tag is complete.

⇒ Confirm the new tag with the ↵ -key or cancel the changes and return to the previous

value by pressing F2 (Back).

The following characters are available:

Letters A to Z and a to z

Digits 0 to 9

The following characters: ↑ ↓ → ← ∟ ↔ ▲ ▼ ! " # $ % & ´ ( ) * + , - . / ; < = > ? @ [ \ ]

^ _ ` { ¦ } ~ £ Ç ü é á ä à â ç ê ë è ï î ì Ä Â É ff ô ö ò û ù ÿ Ö Ü ¢ £ ¥ × ƒ đ ñ © ß and

the space character

Changing to a submenu

⇒ Press the ↑ -key or the ↓ -key until the appropriate menu item is displayed against a

black background.

⇒ Press the ↵ -key or the → -key to change to the submenu.

5- 4

NGA 2000

HAS62E-IM-SW39(1) [NGA-e (FID-Software 3.9.x)] 03/06

Page 53

Analyzer and I/O, expert controls & setup: 5.1.1

Calibration gas list

Main menu

↓

Analyzer and I/O, expert controls & setup

↓

Analyzer module setup

↓

Calibration gas list

↓

FID_WO1000001

Zero gas - range 1:

Span gas - range 1:

Zero gas - range 2:

Span gas - range 2:

Zero gas - range 3:

Span gas - range 3:

Zero gas - range 4:

Span gas - range 4:

Calibration gas HC response factor:

Operational sample pressure:

Calibration...

HOME ESCAPE

F1

Calibration Gas List

F2

F3 F4

6.28 ppm

0.00 ppm

10.00 ppm

0.00 ppm

25.00 ppm

0.00 ppm

100.0 ppm

0.00 ppm

250.0 ppm

1.00

344 hPa

F5

In this menu the values for the concentrations of zero gas and span gas for the calibration of all

ranges can be set. In the “Calibration” submenu the zero and span gas calibrations can be

started.

Menu items

“Zero gas - range 1/2/3/4” and “Span gas - range 1/2/3/4” submenus

The desired values for the concentrations of zero gas and span gas can be set in this lines.

Please read the notes below!

“Calibration gas HC response factor” parameter

In this line the response factor for the hydrocarbon calibration can be set. The value depends

on the gas to be measured. Please read the notes below!

“Operational sample pressure” parameter

The desired value for the operational pressure of the sample gas can be set in this line. The

value depends on the type of capilliaries used.

“Calibration” submenu

Accesses the “Zero/span calibration” submenu, in which the zero and span calibration can be

started and, if necessary, calibration factors manually set.

) Page 5-7

Setting concentration values for zeo and span gas concentrations

⇒ Press the ↑ -key or the ↓ -key until the appropriate menu item is displayed against a

black background.