Page 1

Instruction Manual

760002-A

July 2002

Model NGA2000 FID2

Flame Ionization Detector Module

http://www.processanalytic.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical representative

for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of

the product.

• Install your equipment as specified in the Installation Instructions of the appropriate Instruc-

tion Manual and per applicable local and national codes. Connect all products to the proper elec-

trical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and

maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by

Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe

operation of your process at risk, and VOID YOUR WARRANTY. Look-alike substitutions may result

in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons, to prevent electrical shock and personal

injury.

The information contained in this document is subject to change without notice.

Teflon® is a registered trademark of E.I. duPont de Nemours and Co., Inc.

Kynar® is a registered trademark of Pennwalt, Inc.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

Page 3

Model NGA2000 FID2

TABLE OF CONTENTS

PREFACE...........................................................................................................................................P-1

Definitions ...........................................................................................................................................P-1

Safety Summary .................................................................................................................................P-2

General Precautions For Handling And Storing High Pressure Gas Cylinders .................................P-5

Documentation....................................................................................................................................P-6

Compliances .......................................................................................................................................P-6

Glossary of Terms ............................................................................................................................P-7

1-0 DESCRIPTION AND SPECIFICATIONS..............................................................................1-1

1-1 Overview................................................................................................................................1-1

1-2 Typical Applications...............................................................................................................1-1

1-3 Theory of Technology............................................................................................................1-2

1-4 Gas Safety Features..............................................................................................................1-5

1-5 Fuel Gas Option ....................................................................................................................1-5

1-6 Specifications ........................................................................................................................1-7

a. General ...........................................................................................................................1-7

b. Physical...........................................................................................................................1-7

c. Gas Requirements ..........................................................................................................1-8

d. Gas Connections.............................................................................................................1-8

Instruction Manual

760002-A

July 2002

2-0 INSTALLATION ....................................................................................................................2-1

2-1 Unpacking..............................................................................................................................2-1

2-2 Assembly ...............................................................................................................................2-1

2-3 Location .................................................................................................................................2-1

2-4 Gases ....................................................................................................................................2-1

a. Overview .........................................................................................................................2-1

b. Connections ....................................................................................................................2-2

c. Gas Specifications ..........................................................................................................2-2

2-5 Electrical Connections ...........................................................................................................2-5

2-6 Analytical Leak Check ...........................................................................................................2-6

a. Flow Indicator Method.....................................................................................................2-6

b. Manometer Method.........................................................................................................2-6

c. Troubleshooting Leaks....................................................................................................2-6

2-7 Installation Guidelines ...........................................................................................................2-7

3-0 OPERATION .........................................................................................................................3-1

3-1 Overview................................................................................................................................3-1

3-2 Displays & Operating Keys....................................................................................................3-1

a. Menu Lines & Softkey Functionality................................................................................3-1

b. Common Function Keys..................................................................................................3-2

c. Entering & Changing Variables.......................................................................................3-3

d. Starting a Function..........................................................................................................3-3

e. Measure Mode Display ...................................................................................................3-4

f. Main Menu ......................................................................................................................3-4

Rosemount Analytical Inc. A Division of Emerson Process Management Contents i

Page 4

Instruction Manual

760002-A

July 2002

3-3 Startup & Initialization............................................................................................................3-7

a. Flame Ignition..................................................................................................................3-9

b. Internal Pressure Settings...............................................................................................3-10

c. Binding ............................................................................................................................3-12

d. Optimization ....................................................................................................................3-12

e. Shut Down Procedure .....................................................................................................3-12

f. Safety System .................................................................................................................3-13

3-4 Routine Operation .................................................................................................................3-14

3-5 Basic Controls, Setup and Status..........................................................................................3-15

a. Analyzer Channel Status ................................................................................................3-15

b. Single Component Display..............................................................................................3-15

c. Multi Component Display ................................................................................................3-16

3-6 Basic Controls .......................................................................................................................3-17

3-7 Display Controls ....................................................................................................................3-18

3-8 Analyzer And I/O, Expert Controls And Setup.......................................................................3-19

a. Range Settings................................................................................................................3-21

b. Physical Measurements..................................................................................................3-21

c. Concentration Alarms .....................................................................................................3-22

d. Linearization Parameters ................................................................................................3-23

e. Linearization Functions ...................................................................................................3-24

f. Response Time ...............................................................................................................3-26

g. Automatic Range Change...............................................................................................3-27

h. Display Units ...................................................................................................................3-28

i. Physical Measurements & Pressure Limits ....................................................................3-29

j. Single Component Display Parameters ..........................................................................3-30

k. Configuration Storage .....................................................................................................3-31

3-9 Calibration Methods...............................................................................................................3-32

a. Overview .........................................................................................................................3-32

b. Basic Controls Calibration...............................................................................................3-32

c. Expert Controls Calibration .............................................................................................3-32

d. System Calibration And Setup ........................................................................................3-32

3-10 Calibration Setup ...................................................................................................................3-33

a. Gas List ...........................................................................................................................3-33

b. Response Factor.............................................................................................................3-33

c. Calibration Parameters ...................................................................................................3-34

3-11 Basic Controls Calibration .....................................................................................................3-35

3-12 Expert Controls Calibration....................................................................................................3-36

a. Calibration Results..........................................................................................................3-37

b. Calibration Factors..........................................................................................................3-38

c. Calibration Details ...........................................................................................................3-39

3-13 System & Network I/O Module Controls (Setup) – System SIO............................................3-40

a. System SIO .....................................................................................................................3-40

b. Analog Output Setup.......................................................................................................3-41

c. Serial Interface Setup .....................................................................................................3-44

d. Relay Outputs Setup.......................................................................................................3-45

3-14 System & Network I/O Module Controls (Setup) – System DIO ...........................................3-47

3-15 System Configuration and Diagnostics .................................................................................3-48

a. Diagnostic Menus............................................................................................................3-49

b. Analyzer Module Diagnostics..........................................................................................3-50

c. Load/Save Module Configuration....................................................................................3-55

d. Date and Time.................................................................................................................3-56

e. Security Codes................................................................................................................3-57

f. System Reset..................................................................................................................3-58

g. System Tag .....................................................................................................................3-58

Model NGA2000 FID2

ii Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 5

Model NGA2000 FID2

4-0 MAINTENANCE AND SERVICE ..........................................................................................4-1

4-1 Overview................................................................................................................................4-1

4-2 Disassembly ..........................................................................................................................4-2

4-3 Fuses .....................................................................................................................................4-2

4-4 Burner Block Removal And Installation .................................................................................4-4

4-5 Burner Startup And Troubleshooting.....................................................................................4-4

4-6 Maintenance Schedule ..........................................................................................................4-8

5-0 REPLACEMENT PARTS ......................................................................................................5-1

5-1 Matrix .....................................................................................................................................5-1

5-2 Replacement Parts ................................................................................................................5-2

6-0 RETURN OF MATERIAL ......................................................................................................6-1

6-1 Return Of Material .................................................................................................................6-1

6-2 Customer Service ..................................................................................................................6-1

6-3 Training..................................................................................................................................6-1

Instruction Manual

760002-A

July 2002

Rosemount Analytical Inc. A Division of Emerson Process Management Contents iii

Page 6

Instruction Manual

760002-A

July 2002

Figure 1-1. Flame Ionization Detection Technology.................................................................. 1-1

Figure 1-2. FID2 Analyzer Flow Diagram .................................................................................. 1-3

Figure 1-3. FID2 Wiring Diagram............................................................................................... 1-4

Figure 2-1. FID2 Outline and Mounting Dimensions ................................................................. 2-3

Figure 2-2. FID2 Rear Panel ..................................................................................................... 2-4

Figure 2-3. FID2 Front Panel.................................................................................................... 2-5

Figure 2-4. Leak Test - Flow Indicator Method.......................................................................... 2-6

Figure 2-5. Leak Test - Manometer Method.............................................................................. 2-6

Figure 3-1. Measure Mode Display ........................................................................................... 3-1

Figure 3-2. The Display Screen................................................................................................. 3-3

Figure 3-3. Changing Variables................................................................................................. 3-3

Figure 3-4. Function Confirmation Display ................................................................................ 3-3

Figure 3-5. Main Menu .............................................................................................................. 3-4

Figure 3-6. Main Menu Sub Menus ........................................................................................... 3-5

Figure 3-7. Module Manufacturing Data Displays ..................................................................... 3-6

Figure 3-8. Startup Display........................................................................................................ 3-7

Figure 3-9. Analyzer Diagnostics Menu .................................................................................... 3-8

Figure 3-10. Self Test Results Menu........................................................................................... 3-8

Figure 3-11. Light Flame Menu ................................................................................................... 3-9

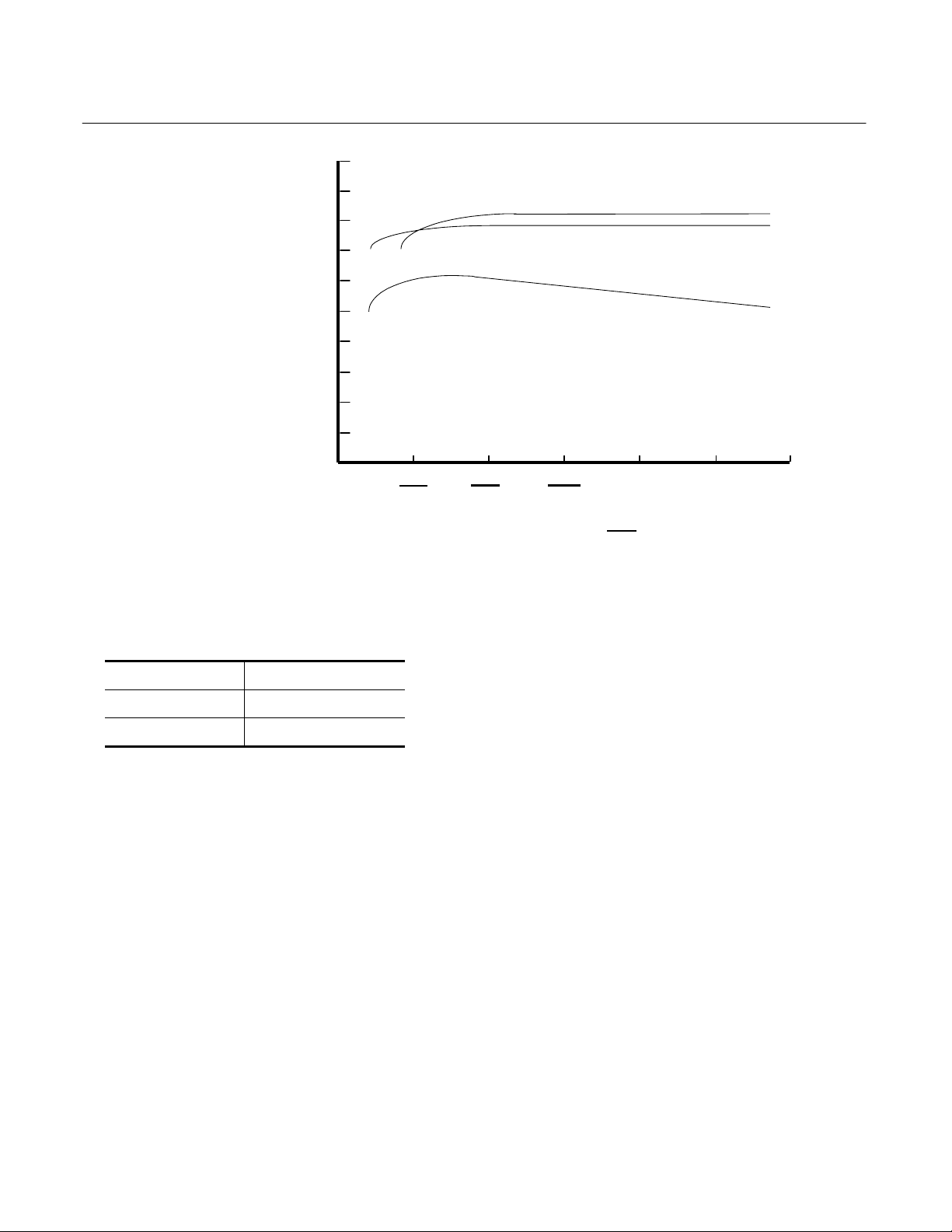

Figure 3-12. Typical Module Response vs. Sample Pressure Setting ....................................... 3-10

Figure 3-13. Typical Module Response vs. Fuel Pressure Setting ............................................ 3-10

Figure 3-14. Typical Module Response vs. Burner Air Pressure Setting ................................... 3-11

Figure 3-15. Current Measurement Parameters Menu ............................................................. 3-15

Figure 3-16. Single Component Display.................................................................................... 3-15

Figure 3-17. Multi Component Display ...................................................................................... 3-16

Figure 3-18. Basic Controls Menu ............................................................................................. 3-17

Figure 3-19. Display Controls Menu .......................................................................................... 3-18

Figure 3-20. Analyzer and I/O Expert Controls and Setup Menu.............................................. 3-19

Figure 3-21. Analyzer and I/O Expert Controls and Setup Menu - Sub Menus ........................ 3-19

Figure 3-22. Expert Controls Menu ........................................................................................... 3-20

Figure 3-23. Range Settings Menu ........................................................................................... 3-21

Figure 3-24. Physical Measurements........................................................................................ 3-21

Figure 3-25. Concentration Alarm Setup Menu......................................................................... 3-22

Figure 3-26. Gas Measurement Parameters Menu................................................................... 3-23

Figure 3-27. Linearization Parameters Menu ............................................................................ 3-23

Figure 3-28. Linearity Coefficients Menu................................................................................... 3-23

Figure 3-29. Linearization Functions Menu ............................................................................... 3-24

Figure 3-30. Polynomial Setup Menu ........................................................................................ 3-24

Figure 3-31. Gas Concentrations Menu .................................................................................... 3-24

Figure 3-32. Midpoint Correction Setup Menu .......................................................................... 3-25

Figure 3-33. Response time/delay Parameters......................................................................... 3-26

Figure 3-34. Automatic Range Control Menu............................................................................ 3-27

Figure 3-35. Actual Switch Levels Menu ...................................................................................... 3-27

Figure 3-36. Display Units Menu ............................................................................................... 3-28

Figure 3-37. Physical Measurements Menu.............................................................................. 3-29

Figure 3-38. Pressure Limits Menu ........................................................................................... 3-29

Figure 3-39. Temperature Limits Menu ..................................................................................... 3-29

Figure 3-40. Physical Measurement Parameters (Temperature Limits) Menu ......................... 3-29

Figure 3-41. Displayed Parameters Menu................................................................................. 3-30

Figure 3-42. Store/Restore User Settings Menu ....................................................................... 3-31

Model NGA2000 FID2

LIST OF ILLUSTRATIONS

iv Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 7

Model NGA2000 FID2

Figure 3-43. Analyzer Manufacturing Data Menu...................................................................... 3-31

Figure 3-44. Store Historical Data Menu ................................................................................... 3-31

Figure 3-45. Calibration Gas List Menu..................................................................................... 3-33

Figure 3-46. Calibration Parameters Menu ............................................................................... 3-34

Figure 3-47. Analyzer Zero Menu.............................................................................................. 3-35

Figure 3-48. Expert Controls Menu ........................................................................................... 3-36

Figure 3-49. Zero/Span Calibration Menu ................................................................................. 3-36

Figure 3-50. Analyzer Zero Menu.............................................................................................. 3-36

Figure 3-51. Zero/Span Calibration Menu ................................................................................. 3-37

Figure 3-52. Zero/Span Diagnostic Data Menu......................................................................... 3-37

Figure 3-53. Calibration Factors Menu...................................................................................... 3-38

Figure 3-54. Range Factors Menu ............................................................................................ 3-38

Figure 3-55. Range Factors Manufacturer Settings Display ..................................................... 3-38

Figure 3-56. System & Network I/O Module Controls Menu ..................................................... 3-40

Figure 3-57. System SIO Module Menu .................................................................................... 3-40

Figure 3-58. Analog Output Setup Menu................................................................................... 3-41

Figure 3-59. Analyzer Modules Menu ....................................................................................... 3-41

Figure 3-60. Signals Menus....................................................................................................... 3-41

Figure 3-61. Output Signal If Assigned Module Fails Menu...................................................... 3-42

Figure 3-62. Special Scaling for Concentration Signal Menu.................................................... 3-43

Figure 3-63. Analog Output Updates Per Second Menu........................................................... 3-43

Figure 3-64. Serial Interface Setup Menu ................................................................................. 3-44

Figure 3-65. AK Protocol Definitions Menu ............................................................................... 3-44

Figure 3-66. Relay Output Setup Menu..................................................................................... 3-45

Figure 3-67. Relay Output Setup - Choose Source Module Menu............................................ 3-45

Figure 3-68. Relay Output Setup - Choose Signal Menu (Screen 1 of 3)................................. 3-46

Figure 3-69. Relay Output Setup - Choose Signal Menu (Screen 2 of 3)................................. 3-46

Figure 3-70. Relay Output Setup - Choose Signal Menu (Screen 3 of 3)................................. 3-46

Figure 3-71. System DIO Module Menu.................................................................................... 3-47

Figure 3-72. System Configuration and Diagnostics Menu - Sub Menus ................................. 3-48

Figure 3-73. Diagnostics Menus................................................................................................ 3-49

Figure 3-74. Diagnostics Menus – Analyzer Diagnostics Menu................................................ 3-50

Figure 3-75. Analyzer Diagnostics – Power Supply Voltages Menu ......................................... 3-50

Figure 3-76. Analyzer Diagnostics – Primary Variable Parameters Menu................................ 3-50

Figure 3-77. Analyzer Diagnostics – Physical Measurement Parameters Menu (Scrn 1 of 2). 3-51

Figure 3-78. Analyzer Diagnostics – Physical Measurement Parameters Menu (Scrn 2 of 2). 3-51

Figure 3-79. Analyzer Diagnostics – Pressure Limits Menu ..................................................... 3-51

Figure 3-80. Analyzer Diagnostics – Temperature Limits Menu ............................................... 3-51

Figure 3-81. Analyzer Diagnostics – Temperature Control Parameters Menu ......................... 3-52

Figure 3-82. Analyzer Diagnostics – Miscellaneous Control Parameters Menu ....................... 3-52

Figure 3-83. Miscellaneous Control Parameters – Pressure Settings Menu ............................ 3-52

Figure 3-84. Analyzer Diagnostics – Trend Display Control Menu ........................................... 3-53

Figure 3-85. Analyzer Diagnostics – Auto Ignition Parameters Menu ...................................... 3-53

Figure 3-86. Analyzer Diagnostics – Self Test Results Menu ................................................... 3-53

Figure 3-87. Analyzer Diagnostics – Software Diagnostics Menu ............................................ 3-54

Figure 3-88. Analyzer Diagnostics – Analyzer Starting Up Menu ............................................. 3-54

Figure 3-89. System Configuration and Diagnostics - Load/Save Configuration Menu............ 3-55

Figure 3-90. System Configuration and Diagnostics - Date and Time Menu............................ 3-56

Figure 3-91. System Configuration and Diagnostics - Security Codes Menu ........................... 3-57

Figure 3-92. System Configuration and Diagnostics - System Reset Menu ............................. 3-58

Figure 4-1. Location of Major Components ............................................................................... 4-1

Figure 4-2. Removal of FID2 Cover .......................................................................................... 4-2

Figure 4-3. Main Power Fuse Location ..................................................................................... 4-3

Figure 4-4. Fuse Locations on Module Board ........................................................................... 4-3

Instruction Manual

760002-A

July 2002

Rosemount Analytical Inc. A Division of Emerson Process Management Contents v

Page 8

Instruction Manual

760002-A

July 2002

Figure 4-5. FID2 – Exploded View ............................................................................................ 4-5

Figure 4-6. Removal of Oven Cover.......................................................................................... 4-6

Figure 4-7. Burner Block -Exploded View ................................................................................. 4-7

Figure 4-8. Burner ..................................................................................................................... 4-8

Table 1-1. Gas Flow Rates ..................................................................................................... 1-5

Table 1-2. Analyzer Characteristics Relative to Fuel Gas ...................................................... 1-6

Table 2-1. Gas Supply Pressures ........................................................................................... 2-4

Table 3-1. Factory Defaults for Internal Pressures ............................................................... 3-11

Table 3-2. Calibration Gas HC Response Factors ............................................................... 3-33

Model NGA2000 FID2

LIST OF TABLES

vi Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 9

Model NGA2000 FID2

The purpose of this manual is to provide information concerning the components,

functions, installation and maintenance of the NGA2000 FID2 and the System Accessories

of the NGA 2000 System.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

The following definitions apply to DANGERS, WARNINGS, CAUTIONS and NOTES found throughout

this publication.

Instruction Manual

760002-A

July 2002

PREFACE

DEFINITIONS

DANGER .

Highlights the presence of a hazard which will cause severe personal injury, death, or substantial

property damage if the warning is ignored.

WARNING .

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

CAUTION.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of effectiveness.

NOTE

Highlights an essential operating procedure,

condition or statement.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-1

Page 10

Instruction Manual

760002-A

July 2002

Model NGA2000 FID2

SAFETY SUMMARY

If this equipment is used in a manner not specified in these instructions, protective systems may be

impaired.

AUTHORIZED PERSONNEL

To avoid explosion, loss of life, personal injury and damage to this equipment and on-site property,

all personnel authorized to install, operate and service the this equipment should be thoroughly

familiar with and strictly follow the instructions in this manual. SAVE THESE INSTRUCTIONS.

DANGER.

ELECTRICAL SHOCK HAZARD

Do not operate without doors and covers secure. Servicing requires access to live parts which can

cause death or serious injury. Refer servicing to qualified personnel. For safety and proper performance this instrument must be connected to a properly grounded three-wire source of power.

WARNING .

POSSIBLE EXPLOSION HAZARD

This equipment is used in the analysis of sample gases which may be flammable, and the burner

fuel used in the ionization process IS flammable. A system of intrinsically safe electronics and an

explosion proof tower are used to prevent any ignition of a flammable gas leak. For this to be effective, the module MUST be placed in a well-ventilated area, with unobstructed air flow around it.

DO NOT place it within another enclosure without assuring this ventilation.

DO NOT obstruct the vent holes on the top and sides of the module.

DO NOT place the FID module within another enclosure unless the latter has a guaranteed air circulation such as to dilute a worst case fuel or sample leak below 25% of the LEL. Doing so will negate the safety features and may result in an explosion, serious injury, property damage and death.

WARNING .

FLAMMABLE SAMPLES

Consult the factory if flammable samples will be measured.

P-2 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Page 11

Model NGA2000 FID2

Tampering or unauthorized substitution of components may adversely affect safety of this product.

Use only factory documented components for repair.

Do not place hands or fingers in the Platform front handles when front panel is open. Dropping the

front panel of the Platform while hand or fingers are inside either handle can cause serious injury.

Ensure that all gas connections are made as labeled and are leak free. Improper gas connections

could result in explosion or death.

Instruction Manual

760002-A

July 2002

WARNING.

PARTS INTEGRITY

WARNING.

HAND INJURY HAZARD

WARNING.

POSSIBLE EXPLOSION HAZARD

WARNING.

POSSIBLE EXPLOSION HAZARD

Protection against explosion depends upon a special fuel flow restrictor in the fuel inlet fitting. DO

NOT REMOVE THE FUEL INLET RESTRICTOR. Use the correct fuel flow restrictor for the fuel being

used. Do not use 100% hydrogen fuel in a 40% H2/60% He configured FID module. Replace with

factory supplied fitting only.

CAUTION .

PRESSURIZED GAS

This module requires periodic use of pressurized gas. See General Precautions for Handling and

Storing High Pressure Gas Cylinders, page P-5.

CAUTION .

OVERBALANCE HAZARD

This analyzer module may tip instrument over if it is pulled out too far and the Platform is not properly supported.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-3

Page 12

Instruction Manual

760002-A

July 2002

CAUTION.

CONTROLLED ENVIRONMENT

This equipment is for use in a controlled environment. Refer to Section 1-6 Specifications (page 1-

7) in this manual for environmental conditions.

CAUTION.

HOT OVEN COMPONENTS

The oven and sample manifold are controlled to 80°C. Allow the analyzer to cool down before

touching any of these components.

CAUTION.

OVER-VOLTAGE SPIKING

If this analyzer module is used with a non-Rosemount Analytical power supply, adding Rosemount

Analytical PN 903341 Current Protector in series with the 24V positive power line will prevent overvoltage spiking and resultant fuse blowing when powering up the instrument.

Model NGA2000 FID2

CAUTION .

STATIC ELECTRICITY

Circuit boards in this instrument are static-sensitive. Take all static precautions when handling the

circuit boards

NOTE

This Analyzer Module is completely leak-tested at the factory for gas leakage. The user is responsible for testing for leakage at the inlet and outlet fittings on the rear panel (with a test procedure

chosen by the user). The user is also responsible for leak-testing periodically and if any internal

pneumatic components are adjusted or replaced. See leak test instructions in Section 2-6 on page

2-6.

P-4 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Page 13

Instruction Manual

760002-A

Model NGA2000 FID2

July 2002

GENERAL PRECAUTIONS FOR HANDLING AND STORING HIGH

PRESSURE GAS CYLINDERS

Edited from selected paragraphs of the Compressed Gas Association's "Handbook of Compressed

Gases" published in 1981

Compressed Gas Association

1235 Jefferson Davis Highway

Arlington, Virginia 22202

Used by Permission

1. Never drop cylinders or permit them to strike each other violently.

2. Cylinders may be stored in the open, but in such cases, should be protected against extremes of weather

and, to prevent rusting, from the dampness of the ground. Cylinders should be stored in the shade when located in areas where extreme temperatures are prevalent.

3. The valve protection cap should be left on each cylinder until it has been secured against a wall or bench, or

placed in a cylinder stand, and is ready to be used.

4. Avoid dragging, rolling, or sliding cylinders, even for a short distance; they should be moved by using a suitable hand-truck.

5. Never tamper with safety devices in valves or cylinders.

6. Do not store full and empty cylinders together. Serious suckback can occur when an empty cylinder is attached to a pressurized system.

7. No part of cylinder should be subjected to a temperature higher than 125

permitted to come in contact with any part of a compressed gas cylinder.

8. Do not place cylinders where they may become part of an electric circuit. When electric arc welding, precautions must be taken to prevent striking an arc against the cylinder.

°

F (52°C). A flame should never be

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-5

Page 14

Instruction Manual

9

6

760002-A

July 2002

Model NGA2000 FID2

DOCUMENTATION

The following NGA2000 FID2 instruction materials are available. Contact Customer Service Center or the

local representative to order.

760002 Instruction Manual (this document)

COMPLIANCES

This product may carry approvals from several certifying agencies, like The Canadian Standards

Association (CSA), which is also an OSHA accredited Nationally Recognized Testing Laboratory (NRTL),

and LCIE - a French Notified Body.

The certification marks appear on the product name-rating plate.

®

NRTL /C

Rosemount Analytical Inc. has satisfied all obligations from the European Legislation to harmonize the

product requirements in Europe.

This product complies with the standard level of NAMUR EMC. Recommendation (May 1993).

LCIE 98 ATEX 6004 X

EEx d ib IIB (+H

0°C Ta +40°C

Date of Manufacture:

0081

) T6

2

II 2 G

NAMUR

This product satisfies all obligations of all relevant standards of the EMC framework in Australia and New

Zealand.

N

P-6 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Page 15

Model NGA2000 FID2

GLOSSARY OF TERMS

Analyzer Module

The module that contains all sensor/detector components for development of a Primary Variable signal;

includes all signal conditioning and temperature control circuitry.

Backplane

The interconnect circuit board which the Controller Board, Power Supply, Analyzer Module power and

network cables, I/O Modules and Expansion Modules plug into.

Control Module

The Operator Interface plus the Controller Board.

Controller Board

The computer board that serves as the Network Manager and operates the Display and Keypad.

Distribution Assembly

Instruction Manual

760002-A

July 2002

The Backplane and the card cages that hold I/O and Expansion Modules.

Expansion Module

A circuit board that plugs into the Backplane from the front of the Platform and performs special features

not related to I/O functions.

I/O Module

A circuit board that plugs into the Backplane from the rear of the Platform. Has a connector terminal for

communication with external data acquisition devices and provides an input/output function.

Operator Interface

The Display and Keyboard.

Platform

Any workable collection of the following: Controller Board, Power Supply, Distribution Assembly, Enclosure

and Operator Interface.

Power Supply

Any of a variety of components that provides conditioned power to other NGA 2000 components, from the

Power Supply Board that plugs into the front of the Backplane in a stand-alone instrument to several larger

ones that can power larger collections of modules and components.

Primary Variable

The measured species concentration value from an Analyzer Module.

Secondary Variable

Data placed on the network by a module regarding current status, e.g., sample flow, source voltage and

other diagnostic information.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-7

Page 16

Instruction Manual

760002-A

July 2002

Softkeys

The five function keys located below the front panel display; they assume the function displayed directly

above each on the display, a function dictated by software.

System

Any collection of Analyzer Module(s), Platform(s), I/O Module(s) and Expansion Module(s).

Model NGA2000 FID2

P-8 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Page 17

Model NGA2000 FID2

+

+++

+

DESCRIPTION AND SPECIFICATIONS

1-1 OVERVIEW

Instruction Manual

760002-A

July 2002

SECTION 1

This manual describes the Flame Ionization

Detector (FID2) Analyzer Module of

Rosemount Analytical's NGA 2000 Series of

gas analysis components.

The FID2 Analyzer Module is designed to use

a flame ionization technique to measure the

total concentration of hydrocarbon (including

certain oxygenated hydrocarbons)

components within the sample stream.

The entire FID2 Analyzer Module is designed

as a module with electrical connections at its

front, and gas connections made from the

rear. All electronics relative to sample control

and signal conditioning are included in this

module.

Igniter

Positive

Electrode

1-2 TYPICAL APPLICATIONS

Typical applications for the FID2 Analyzer

Module include:

• The monitoring of atmospheric air for low-

level total hydrocarbon contaminants

• Determining the total hydrocarbon content of

exhaust emissions from internal combustion

engines

• Carbon bed monitoring

Determining the total hydrocarbons content of

process and product gases from air

separation plants.

Exhaust

-

-

Ions

-

-

-

Negative

Electrode

Flame

Air

Fuel + Sample

Figure 1-1. Flame Ionization Detection Technology

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Page 18

Instruction Manual

760002-A

July 2002

Model NGA2000 FID2

1-3 THEORY OF TECHNOLOGY

This Analyzer Module uses the flame

ionization method of detection. The sensor is

a burner in which a regulated flow of gas

sample passes through a flame sustained by

regulated flows of a fuel gas (a

hydrogen/diluent mixture) and air.

Within the flame, the hydrocarbon

components of the sample stream undergo a

complex ionization that produces electrons

and positive ions. Polarized electrodes collect

these ions, causing current to flow through an

electronic measuring circuit.

The ionization current is proportional to the

rate at which carbon atoms enter the burner,

and is therefore a measure of the

concentration of hydrocarbons in the sample.

The gas pressures are continuously

monitored and controlled through electronic

pressure transducers.

The measurement of concentration is placed

on the network, where it can be shown on the

Platform Display or on other data acquisition

devices.

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 19

Model NGA2000 FID2

FID EXHAUST

FLOW CONTROL

MANIFO LD ASSEMBLY

659043

FTG, BULKHEAD

W/RESTRICTOR

1/4T-1/8MP T

FTG, MALE CONN

1/4T-1/8MP T

008435

W/FILTER 017154

REAR PANEL5

SAMPLE IN

FTG, BULKHEAD

SAMPLE OUT

FTG, MALE CONN

1/4T-1/8MP T

008435

FUEL IN

AIR IN

FUEL FLOW

CONTROL

FLUISTER

VALVE

659541

2

AIR FLOW

CONTROL

FLUISTER

VALVE

659541

3

Instruction Manual

760002-A

July 2002

4

4

MANIFO LD

SENSOR, AIR

PRESSURE

0-30 PSIG

659498

SENSOR, FUEL

PRESSURE

0-30 PSIG

659498

BACK PRESSURE

REGULATOR

659063

FTG, ELBOW

1/16T-1/8M PT

904582

(3)

659072

SENSOR, SAMPLE

PRESSURE

0-15 PSIG

659497

659037

FTG, UNION

1/16T

818270

FTG ASSEMBLY

659173

FTG, FLBOW

1/4T-1/4MP T

902147

659038

FTG, UNION

1/16T

818270

FTG, UNION

1/16T

818270

FTG, UNION

1/16T

818270

FUEL

CAPILLAR Y

AIR

CAPILLAR Y

SAMPLE

CAPILLAR Y11

FLAME

IONIZATI ON

DETECTOR

(FID)

5 REAR PANEL IS INCLUDED IN FLOW CONTROL MANIFOLD ASSEMBLY 659043.

4 MANIFO LD ASSEMBLY 659043 MUST BE RETURNED TO FACTORY WHEN REP LACMENT OF AIR AN D/OR FUEL FLOW FLU ISTER VALVES IS R EQUIRED.

3 15 PSI 2 L/MIN.: 659178

2 PSI 1 L/MIN.: 65907 3

NO RES TRICTOR: 008435

2 STD MIXED FUEL: 659514

1 STD MIXED FUEL: 658146 FUE L CAPILLARY, 65 9031 SAMPLE CA PILLARY

Figure 1-2. FID2 Analyzer Flow Diagram

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

Page 20

Instruction Manual

760002-A

July 2002

Model NGA2000 FID2

REAR SECTION OF ANAL YZER FRONT SECTION OF ANALYZER

FUEL

FLOW CONTROL

FLUISTOR

AIR

659070

FLAME

THERMISTOR

BURNER

BLOCK HEATER

2

J1

FUEL

PRESSURE

SENSOR

0-30 PSIG

J12 J13J3 J11 J4

SAMPLE

RESSURE

SENSOR

0-15 PSIG

J6

POLARIZED

COLLECTOR

1

CABLE

CONTINUITY

FLOW CONTROL

NCNC

J7J2

J9

J16

J8 J5

IGNITER

BURNER BLOCK

2

AIR

FLUISTOR

PRESSURE

SENSOR

0-30 PSIG

INTRINSICALL Y SAFE BOARD

POLARIZED

COLLECTOR

1

RTD

BURNER BLOCK ASSEMBLY

1

CONNECTORS J5 AND J6 ON INTRINSICALLY SAFE BOARD ARE INTERCHANGEABLE.

FACTORY REPLACEMENT.

2

MIDDLE

SECTION OF

ANALYZER

THIS SECTION OF INTRINSICALLY

SAFE BOARD CONTAINS CURRENT-

LIMITING RESISTORS

J15

J8J11

NCNC

THIS SECTION OF

INTRINSICALLY SAFE BOARD

CONTAINS ±15 SUPPLIES,

+90V SUPPLY AND LOW-

LEVEL ANALOG CIRCUITS

J15

J15 J14 J25

MODULE BO ARD 65 9060

J6 J5

COMPUTER BOARD

658350

J7

J14 J17

J1J4

J2

J3

J22

J24

J22

LON1

LON2

24V POWER

Figure 1-3. FID2 Wiring Diagram

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 21

Model NGA2000 FID2

Instruction Manual

760002-A

July 2002

1-4 GAS SAFETY FEATURES

The FID2 module is divided into two parts - a

pneumatic section and an electronic section.

The two sections are separated by a pair of

solid partitions to prevent any leak of gas in

the pneumatic section from reaching the

electronics. The electrical connections into

the pneumatic section are made intrinsically

safe by a series of over-voltage protection

devices and current limiting resistors. The

burner itself is an explosion-proof assembly.

The combination of these two techniques

allows the analyzer to meet international

safety standards without the use of an

expensive continuous-dilution purge - but

ONLY when it is installed in a general purpose

area with good air circulation.

WARNING

POSSIBLE EXPLOSION HAZARD

Hydrocarbon concentration(s) in the sample gas must be below the Lower Explosion Limit (LEL).

The FID2 is designed to use 40% H

fuel at a maximum inlet pressure of 3446 hPagauge (50 psig).

1

WARNING

POSSIBLE EXPLOSION HAZARD

Protection against explosion depends

upon a special fuel flow restrictor at the

fuel inlet. DO NOT REMOVE THE FUEL INLET RESTRICTOR.

1-5 FUEL GAS OPTION

The standard FID2 Analyzer Module requires

40% hydrogen/60% helium burner fuel gas.

For monitoring internal combustion exhaust

emissions or other sample gas with varying

oxygen content, mixed fuel is preferable. In

fact, a hydrogen/helium mixture is more

desirable than a hydrogen/nitrogen mixture.

With this type of sample, the use of mixed fuel

gas minimizes the error introduced by oxygen

synergism.

/60% He

2

All tubing ahead of the burner is rigid metallic

tubing assembled with ferrule/nut type

compression fittings. However, should an

internal fuel leak occur, a worst-case leak

would be dissipated below 25% of the LEL of

hydrogen by natural dilution outside of the

pneumatic section before it could be ignited

by any external ignition source, and there is

nothing within the pneumatic section to ignite

it.

Changes in the burner air flow rate have little

effect on signal strength. For a given flow, the

signal can be optimized by adjusting the fuel

flow rate.

Refer to Table 1-1. Gas Flow Rates below.

GAS FLOW MIXED FUEL

UEL

F

AMPLE

S

IR

A

100 cc/min

10 cc/min

400 cc/min

Table 1-1. Gas Flow Rates

1

The fuel restrictor is part of the Flow Control Manifold

Assembly, which is specific to an application.

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Page 22

Instruction Manual

760002-A

July 2002

Model NGA2000 FID2

ANALYZER CHARACTERISTICS

Full Scale Sensitivity

Fuel Consumption

Operating Setting For Sample Pressure Regulator

Table 1-2. Analyzer Characteristics Relative to Fuel Gas

40% H

4 ppm, CH

/60% He

2

to <1%, CH

4

100 to 110 cc/min

345 hPa-gauge (5 psig)

4

1-6 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 23

Model NGA2000 FID2

1-6 SPECIFICATIONS

a. General

Measurement Species .................. Total hydrocarbons

Range H

Repeatability.................................. ≤1% of fullscale at a constant temperature, sample flow and fuel,

Min. Detectable Level ................... 0.04 ppm H

Noise ............................................ <1% of fullscale, peak to peak

Linearity ........................................ ≤ ±1% of fullscale

Response Time ............................ ≤1 sec. for bypass flow rate of 500 cc/min (for a sample change at

Zero Drift ....................................... ≤ ±1% of fullscale/24 hours at constant temperature, hydrocarbon

Span Drift ...................................... ≤ ±1% of fullscale/24 hours at constant temperature, hydrocarbon

Effect of Temperature ................... ≤ ±2% of fullscale for any temperature change of 10°C and rate of

Operating Temperature ................ 41°F to 104°F (5°C to 40°C)

Operating Humidity........................ <95% relative humidity, non-condensing

Power Requirements .................... +24 VDC ±5%, 120 W max.. direct to analyzer module;

/He fuel

2

Low range.............................. 0 to 4 ppm CH

High range ............................. 0 to 50 ppm CH4, through 0 to <5% CH

Ripple and Noise ................... <100 mV peak to peak

Line and Load Regulations.... <±1%

Instruction Manual

760002-A

July 2002

, through 0 to 1% CH

4

burner air and sample pressure

/He fuel – methane equivalent

2

the rear panel connector of the instrument)

concentration of supply gases, sample flow and fuel, burner air and

sample pressure

concentration of supply gases, sample flow and fuel, burner air and

sample pressure

change less than 10°C/hour

4

4

b. Physical

Case Classification........................ General purpose for installation in weather-protected area

Dimensions ................................... See Outline and Mounting Dimensions, Figure 2-1, on page 2-3

Weight .......................................... 10.43 kg (23 lbs.)

Mounting ....................................... Inside a Platform or custom-installed in a panel

Max. Length of LON Cable ........... 1600m (1 mile) between Analyzer Module and Platform

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-7

Page 24

Instruction Manual

760002-A

July 2002

c. Gas Requirements

Sample .......................................... Non-flammable, below 100% LEL

Temperature ......................... 32°F to 248°F (0°C to 120°C), <20°C variance/24 hours, <10°C

Flow Rate............................... 0.5 to 2.0 ml/min.

Supply Pressure .................... 483 to 1035 hPa-gauge (7 to 15 psig)

Particles ................................. Filtered to <2 microns

Dewpoint ............................... <45°C

Materials in contact

with Sample ................ Stainless steel, Teflon, glass-filled Teflon, Viton

Fuel Gas ....................................... Premixed 40% hydrogen and 60% helium

Flow Rate............................... 75 to 110 ml/min.

THC ....................................... ≤0.5 ppm, CH

Supply Pressure .................... 3101 to 3450 hPa-gauge (45 to 50 psig)

Model NGA2000 FID2

variance/hour

4

WARNING.

POSSIBLE EXPLOSION HAZARD

DO NOT USE PURE HYDROGEN FUEL. An explosion resulting in severe personal injury or

death could occur. Also, each Analyzer Module is factory-configured for mixed, and cannot use the fuel for which it was not configured unless field reconfiguration is done.

Burner Air ...................................... Hydrocarbon-free grade air

Flow Rate............................... 350 to 400 ml/min.

THC ....................................... ≤ 0.1 ppm, CH

Supply Pressure .................... 1725 to 3450 hPa-gauge (25 to 50 psig)

d. Gas Connections

Sample In ...................................... 1/4” O.D. tube fitting

Burner Air In .................................. 1/4” O.D. tube fitting

Fuel In............................................ 1/4” O.D. tube fitting

Bypass Out.................................... 1/4” O.D. tube fitting

Burner Exhaust Out....................... 3/8” O.D. tube slip-fit connection, tygon or equivalent (this

connection shall slope downward 6° minimum from horizontal)

4

NOTE

The burner exhaust and bypass out shall be vented to atmospheric pressure and to a nonclassified location. .

See the Preface section of the Platform manual for specifications regarding Platform-related components

(e.g., case dimensions) and the I/O Module manual for specifications regarding I/O (e.g., relay outputs).

1-8 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 25

Model NGA2000 FID2

Instruction Manual

760002-A

July 2002

SECTION 2

INSTALLATION

2-1 UNPACKING

When the FID2 Analyzer Module is received,

carefully examine the shipping carton and

contents for signs of damage. Immediately

notify the shipping carrier if the carton or

contents is damaged. Retain the carton and

packing material until all components

associated with the Analyzer Module are

operational.

2-2 ASSEMBLY

The FID2 analyzer module MUST NOT be

placed within a conventional NGA platform,

single module enclosure or dual module

enclosure since the latter would not allow free

flow of air around the module, thus violating

its safety certification. The enclosure is

designed so that this would be very hard to do

anyway.

There is a special platform specifically

designed to accept this module; consult the

factory for details.

2-3 LOCATION

WARNING.

POSSIBLE EXPLOSION HAZARD

Do not place the FID2 module within another enclosure unless the latter has a

guaranteed air circulation such as to dilute

a worst case fuel or sample leak below

25% of the LEL. Failure to will negate the

safety features and may result in explosion, serious injury, material damage and

death. Also, do not cover the vent holes

on the top and sides of the module.

Install the Analyzer Module in a clean,

weather-proofed, non-hazardous, vibrationfree location free from extreme temperature

variations. For best results, install the

Analyzer Module near the sample stream to

minimize sample transport time.

Operating ambient temperature is 5 °C to

40 °C, limited to temperature changes of less

than 10 °C/hr. Acceptable dew point range is

less than 95% relative humidity, but not in

excess of 40°C wet bulb temperature.

The cylinders of fuel, air, and calibration

gases should be located in an area of

relatively constant ambient temperature.

CAUTION .

PRESSURIZED GAS

See General Precautions for Handling and

Storing High Pressure Gas Cylinders, page

P5.

2-4 GASES

a. Overview

During normal operation, the Analyzer

Module requires fuel and air to maintain

the burner flame as well as suitable

standard gases for. Refer to the criteria

for selection of these gases in Section 24c on page 2-2.

After initial startup or after startup

following a prolonged shutdown, the

analyzer may display baseline drift for a

considerable period of time, particularly

on the most sensitive range.

Commonly, the drift is caused by small

amounts of organics (such as

hydrocarbons) in the inner walls of the

tubing in both the internal flow system and

the external gas supply system. Drift

results from any factor influencing the

equilibrium of these adsorbed

hydrocarbons, such as temperature or

pressure. Hydrocarbons adsorbed within

the analyzer in the gas passageways (or

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-1

Page 26

Instruction Manual

760002-A

July 2002

Model NGA2000 FID2

in the fuel or air lines) will elevate the

overall baseline.

Note that this type of drift occurs only

when the flame is burning. If drift occurs

when the flame is extinguished, the

electronic circuitry is at fault or the burner

or cabling is contaminated with a

conductive film. To minimize drift, use

clean fuel and air, keep the analyzer

clean, and locate the gas cylinders in an

area of relatively constant ambient

temperature.

The cylinders supplying all gases each

should be equipped with a clean,

hydrocarbon-free, two-stage regulator and

a shutoff valve.

All new external gas tubing (except for

SAMPLE BYPASS) is strongly

recommended, preferably pre-cleaned,

stainless steel, gas chromatograph-grade

tubing. Thoroughly clean before use (if a

hydrocarbon-based cleaning solvent such

as acetone is used, purge tubing with dry

nitrogen or helium for several minutes

before using.)

Gas line connections are compression

fittings. Do not use pipe thread tape on

such fittings.

Since the oxidation of hydrogen is

accompanied by the formation of water

vapor, the exhaust tubing always should

be slanted downward at least 6 degrees

from horizontal. Otherwise, water may

accumulate in the line, causing back

pressure and noisy readings, or may back

up in the line and flood the burner.

If the sample is toxic or noxious, or is to

be reclaimed, connect the Bypass outlet

to a suitable disposal system. Do not use

any device that may cause back pressure

in the line.

to appropriately labeled fittings on the rear

panel. All connections are 1/4-inch

ferrule-type compression fittings. Burner

exhaust and bypass must be vented at

atmospheric pressure to a non-classified

location in accordance with ANSI/NFPA-

496.

c. Gas Specifications

Fuel Gas — Standard analysis usually

requires mixed fuel, i.e., 40% (±2 %)

hydrogen and 60% helium. H

fuel is recommended over H

because of better linearity in

concentration output. Such blends are

supplied by many gas vendors specifically

for this use, with a guaranteed maximum

total hydrocarbon content of 0.5 ppm,

measured as methane. This specification

should be used when obtaining these

mixtures.

Burner Air — In order to ensure a low

background signal, hydrocarbon free

grade air with less than 1 ppm maximum

total hydrocarbon content is highly

recommended. An alternative source for

burner air and zero gas (see Calibration

Gases below) is a combination diaphragm

pump and heated palladium catalyst. This

process continuously removes moderate

amounts of hydrocarbons and carbon

monoxide from ambient air.

Calibration Gases — Calibration method

and gases depends on the type of fuel

gas used, the operating range, and the

desired measurement accuracy. In all

methods, zero and span gases are used,

and are introduced through the sample

inlet at the rear of the module.

Zero Gas It is recommended that the

gas should have a composition as close

to the background composition of the

sample as possible.

/He mixed

2

2/N2

fuel

b. Connections

Refer to Figure 2-2 on page 2-4.

Connect inlet and outlet lines for sample,

burner fuel and air, exhaust, and bypass

2-2 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Span Gas Span gas consists of a

specified concentration of methane and

other hydrocarbons in a background gas

such as nitrogen.

Page 27

Model NGA2000 FID2

Instruction Manual

760002-A

July 2002

Sample Gas — Sample gas must be

nonflammable (below 100% of the

sample's LEL).

Flow Rate — The sample flow rate must

be between 0.5 L/min. and 2 L/min.

Pressure/Filtration — See Table 2-1 on

page 2-4 for input pressure specifications.

Noncompliance with these specifications

could cause over-pressure damage to the

module.

All internal pressure settings are preset at

the factory, but the operator should check

for accuracy. It is essential that the

4.3

[110]

8.2

[208]

sample be filtered for particulates

down to 0.1 microns. A suitable filter is

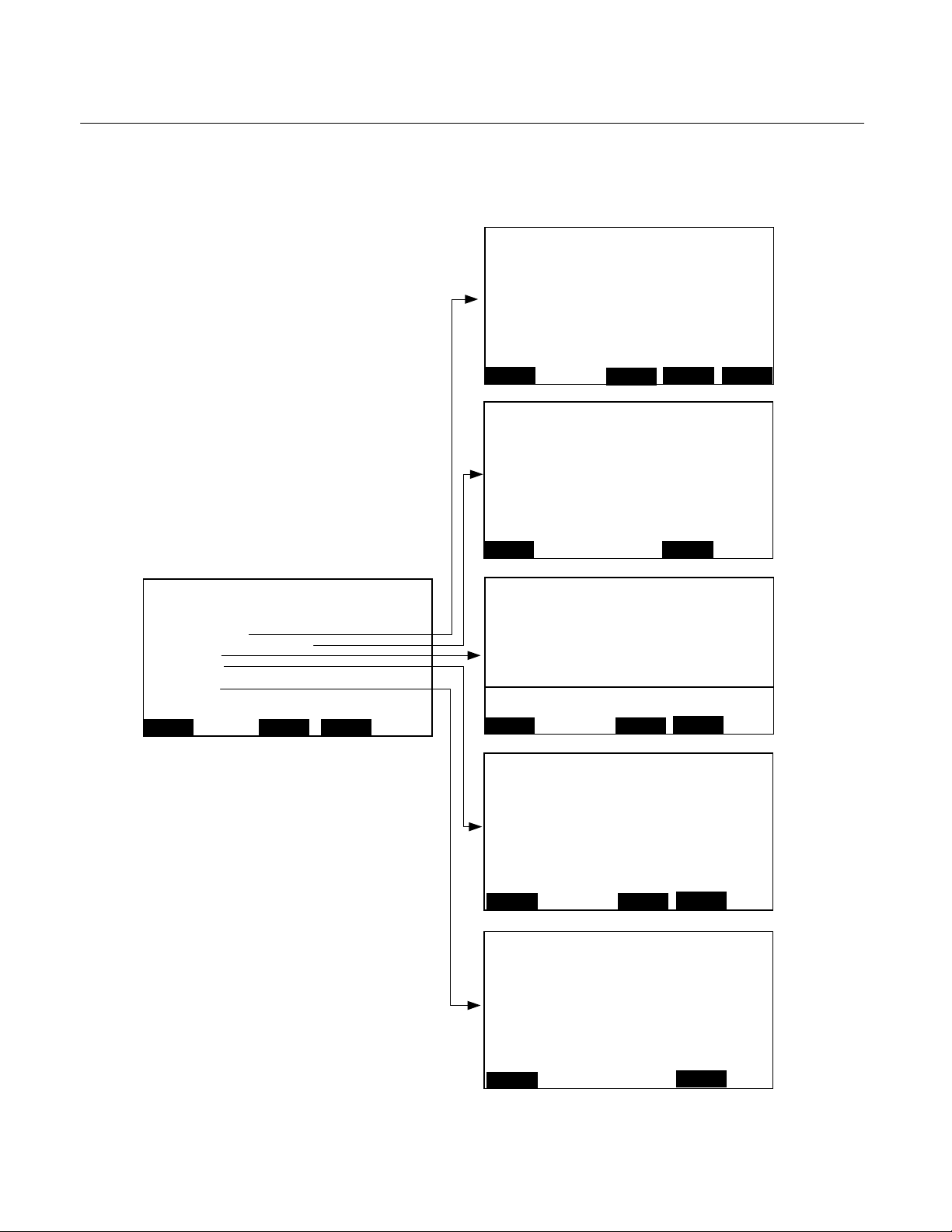

the Balston type 95S6 with 0.1 micron

filter element. It should normally be

replaced on a two week schedule,

depending on the sample.

Leak Test — The Analyzer Module is

completely tested at the factory for gas

leakage. The user is responsible for

testing for leakage at the inlet and outlet

fittings on the rear panel. The user is also

responsible for internal leak testing

periodically and if any internal pneumatic

components are adjusted or replaced

(with a test procedure chosen by the

user).

1.0

[25]

2.2

[55]

[23]

.6

[17]

.7

[20]

[16]

1.2

[31]

2.8

.8

[71]

2.9

[73]

22.6

[573]

.9

3.1

[78]

.8

[19]

[23]

.9

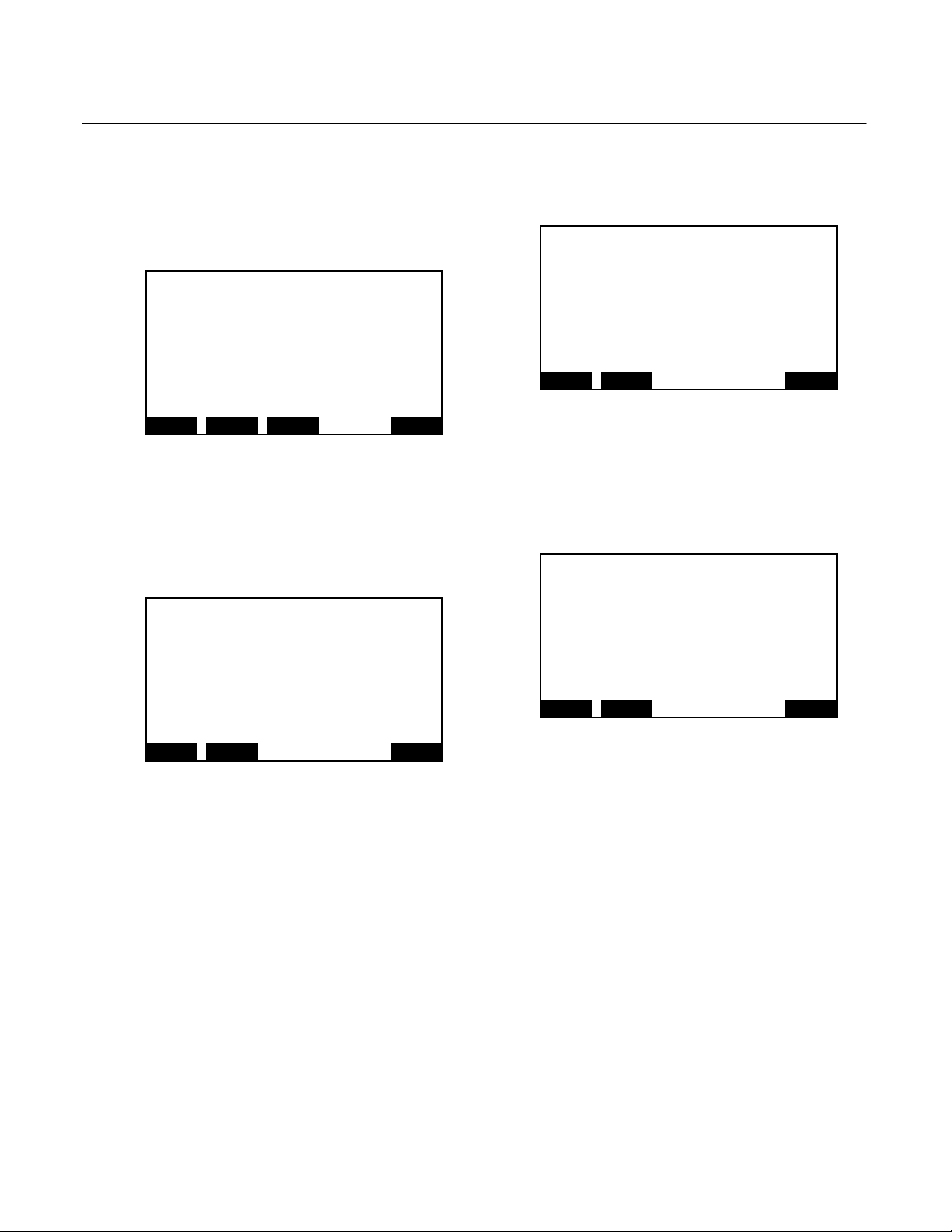

Figure 2-1. FID2 Outline and Mounting Dimensions

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-3

Page 28

Instruction Manual

760002-A

July 2002

MIXED

FUEL IN

AIR IN

Model NGA2000 FID2

BURNER EXHAUST

SAMPLE IN

SAMPLE BYPASS OUT

Figure 2-2. FID2 Rear Panel

Gas supply External Pressure Internal Pressure

Fuel

Burner air

Sample

50 – 55 psig

1035 - 2070 hPa

50 - 55 psig

1380 - 4140 hPa

5 - 10 psig

345 - 690 hPa

5 psig

345 hPa

15 psig

1035 hPa

5 psig

345 hPa

Table 2-1. Gas Supply Pressures

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 29

Model NGA2000 FID2

Instruction Manual

760002-A

July 2002

2-5 ELECTRICAL CONNECTIONS

NOTE

Electrical installation must be in compliance with National Electrical Code

(NEC/NFPA 70) and/or any state or local

codes.

Two electrical connections are required on the

Analyzer Module: POWER and NETWORK.

See Figure 2-3 below. On the Analyzer

Module, two NETWORK connectors are

available, either of which is appropriate for: 1)

interconnection with the Back plane of the

Platform or 2) "daisy-chaining" with other NGA

2000 components, or 3) connection to a PC

via a suitable LONTALK adapter and software

such as the NGA DDE server and client.

Connect Analyzer Module POWER to Back

plane POWER or external 24 VDC power

source.

Connect the network cable to either the

NETWORK 1 or NETWORK 2 connection on

the Analyzer Module front panel, and the

NETWORK connection on the LON I/O

module if used with a Platform, or directly to a

computer using appropriate LONTALK

adapter hardware and software such as the

NGA DDE server. Connect the power cable to

both the Analyzer Module front panel and to a

24V 5A minimum power supply.

FUSE

Figure 2-3. FID2 Front Panel

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-5

24V POWER

NETWORK

Page 30

Instruction Manual

760002-A

July 2002

Model NGA2000 FID2

2-6 ANALYTICAL LEAK CHECK

The FID2 Analyzer Module is completely

tested at the factory for gas leakage. The user

is responsible for testing for leakage only at

the inlet and outlet fittings on the rear panel.

CAUTION

SENSOR PRESSURE

Do not expose the Sensor to pressure in

excess of 1.0 psig as this may cause damage.

a. Flow Indicator Method

Supply air or inert gas such as nitrogen,

at 1 psig (6.8 hPa), to the analyzer

through a flow indicator with a range of 0

to 250 cc/min. Install a shut-off valve at

the sample gas outlet. Set the flow rate to

125 cc/min.

b. Manometer Method

Install a water-filled U-tube manometer at

the sample gas outlet. Install a shut-off

valve at the sample gas inlet. Admit air or

inert gas to the inlet shut-off valve until

the analyzer is pressurized to

approximately 50 hPa. The water column

will be about 500 mm.

FID2 Analyzer Module

Inlet Outlet

Overpressure

approx. 50 hPa

N

2

1 psig

(6.9 kPa)

FID2 Analyzer Module

Inlet Outlet

Flow

Meter

Gas

Outlet

Figure 2-4. Leak Test - Flow Indicator

Method

Close the outlet shut-off valve and notice

that the flow reading drops to zero. If the

flow reading does not drop to zero, the

system is leaking and must be corrected

before the introduction of sample gas or

the application of power.

Water

N

2

Figure 2-5. Leak Test - Manometer Method

Close the inlet shut-off valve and,

following a brief period for pressure

equilibrium, verify that the height of the

water column does not drop over a period

of about 5 minutes. If the water column

height drops, the system is leaking and

must be corrected before the introduction

of any flammable sample gas or

application of power.

c. Troubleshooting Leaks

Liberally cover all fittings, seals, and other

possible sources of leakage with a

suitable leak test liquid such as SNOOP

(part 837801). Bubbling or foaming

indicates leakage. Checking for bubbles

will locate most leaks but could miss

some, as some areas are inaccessible to

the application of SNOOP. For positive

assurance that system is leak free,

perform one of the tests in Section 2-6

above.

2-6 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 31

Model NGA2000 FID2

2-7 INSTALLATION GUIDELINES

• Is the Analyzer’s Location clean,

weather-proofed, non-hazardous, vibration-free, and with a stable ambient temperature?

Instruction Manual

760002-A

July 2002

• Is the burner exhaust tube slanted down

a minimum of 6 degrees from horizontal?

• Have all the external gas connections

been leaked checked?

• Are gas supply cylinders equipped with a

clean, hydrocarbon free two stage regulator and shut off valve?

• Are external tubing, regulators, valves,

pumps, fittings etc. clean?

• Is the correct fuel type being used?

• Is the THC content of the supply gases

compatible with the analysis range?

• Are the burner exhaust and bypass

vented to atmospheric pressure? Is the

vent pressure constant?

• Has the dead volume for external sample

and fuel lines been minimized?

• Has clean stainless steel tubing been

used for fuel and sample lines?

• Is a suitable 0.1 micron filter used in the

sample line?

• Is the sample line and filter heated?

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-7

Page 32

Instruction Manual

760002-A

July 2002

Model NGA2000 FID2

2-8 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Page 33

Model NGA2000 FID2

y

Instruction Manual

760002-A

July 2002

SECTION 3

OPERATION

3-1 OVERVIEW

Once the FID2 has been correctly

assembled and installed in accordance

with the instructions in Section 2, the

analyzer is ready for operation.

Before operating the system, verify that the

Leak Checks have been performed in

accordance with Section 2-6 on page 2-6.

For the remainder of this section, Analyzer

Module interconnection with a Platform or

some interfacing component is assumed.

Display and Keypad information refers to

that which the user can expect to see and

do with regard to the Front Panel of the

Platform.

FID2

77.25

0.00 Range: 1 100.00

Flame temperature: 145 C 100.0 280.0

Block temperature: 67.5 C 40.0 150.0

Sample pressure: 233.06 nPa 100.00 500.00

Raw signal: 495764 100000 900000

Displa

3-2 DISPLAYS & OPERATING KEYS

Status… Main… Channel BasicCal

Figure 3-1. Measure Mode Display

ppm THC

In case of power failure, all user defined

specific module parameters are saved by a

battery powered memory.

The Function Keys, also called softkeys,

are assigned values depending on the

menu or screen being displayed. The

legend is displayed above the keys.

The Enter Key is used to confirm a

previously entered variable value, to start a

selected function or to go to a submenu

selected at a menu line as opposed to the

Function Keys. As an alternate to using the

Enter Key to start a function, the → key

can be used.

The Cursor Keys (↑ or ↓) are used to

move up or down the lines within a menu

or to increment and decrement number

variables.

The Cursor Keys (← or →) are used to

move backwards or forwards between the

pages of a menu or to select numeric digits

for adjustment.

a. Menu Lines & Softkey Functionality

Menu lines can be selected with the ↑

key or the ↓ key. The selected line is

displayed as white lettering on a black

background (highlighted). Menus can

contain four different types of lines:

The LCD screen shows all measurement

values of the analyzer, status values and

all user menu instructions. Operation is

Menu Line – A line ending with three dots (…) indicates that it leads to a submenu.

performed with five function keys, four

arrow (cursor) keys and the enter key. The

function of each key varies depending on

the installed analyzer module, any auxiliary

modules installed, and the individual menu

displayed.

The submenu can be activated by

pressing the ↵ key or the → key when

the line is highlighted.

Function Line – A line ending with an exclamation point (!) indicates that it will start a function. The function can

Rosemount Analytical Inc. A Division of Emerson Process Management Operation 3-1

Page 34

Instruction Manual

760002-A

July 2002

Model NGA2000 FID2

be activated by pressing the ↵ key or