Page 1

NGA 2000

LAME IONIZATION

F

NALYZER

A

ETECTOR

D

ODULE

M

Rosemount Analytical

2

Page 2

N

OTICE

T

HE INFORMATION CONTAINE D IN THIS DOCUMENT IS SUBJ E CT T O CHANGE WITHOUT NOTICE

.

Rosemount Analytical's NGA 2000 system of Modular G as Analyzers and Controllers are patented,

under U.S. Patent 5.787.015.

Manual Part Number 748364-D

November 1998

Printed in U.S.A.

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

Page 3

ONTENTS

C

PREFACE

PURPOSE/SAFETY SUMMARY........................................................................P-1

GLOSSARY ......................................................................................................P-4

SPECIFICATIONS - GENERAL .........................................................................P-7

SPECIFICATIONS – GAS REQUIREMENTS .................................................... P-8

SPECIFICATIONS - PHYSICAL.........................................................................P-9

SPECIFICATIONS - GAS CONNECTIONS .......................................................P-9

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE....P-10

RETURNING PARTS TO THE FACTORY.........................................................P-10

TRAINING ......................................................................................................P-10

DOCUMENTATION............................................................................................P-10

COMPLIANCES .................................................................................................P-11

QUICK STARTUP PROCEDURE.......................................................................P-13

SECTION 1. INTRODUCTION

1.1 OVERVIEW..............................................................................................1-1

1.2 TYPICAL APPLICATIONS .......................................................................1-2

1.3 THEORY OF TECHNOLOGY...................................................................1-2

1.4 GAS SAFETY FEATURES.......................................................................1-3

1.5 FUEL GAS OPTION.................................................................................1-4

S

ECTION

2.1 UNPACKING............................................................................................2-1

2.2 ASSEMBLY..............................................................................................2-1

2.3 LOCATION...............................................................................................2-1

2.4 GASES.....................................................................................................2-2

2. I

2.4.1 Connections................................................................................2-3

NSTALLATION

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

i

Page 4

C

ONTENTS

SECTION 2. (CONTINUED)

2.4.2 Gas Specifications...................................................................... 2-3

2.5 ELECTRICAL CONNECTIONS ............................................................... 2-5

2.6 INSTALLATION GUIDELINES................................................................. 2-7

SECTION 3. STARTUP AND OPERATION

3.1 OVERVIEW ............................................................................................. 3-1

3.2 DISPLAYS ............................................................................................... 3-1

3.2.1 Run Mode Display...................................................................... 3-1

3.2.2 Menu Displays............................................................................ 3-2

3.2.3 Help Displays ............................................................................. 3-4

3.3 STARTUP PROCEDURE ........................................................................ 3-4

3.4 OPTIMIZATION PROCEDURE................................................................ 3-9

3.5 BINDING.................................................................................................. 3-9

3.6 CALIBRATION......................................................................................... 3-10

3.7 CALIBRATION DETAILS......................................................................... 3-12

3.8 ROUTINE OPERATION........................................................................... 3-13

3.9 SHUT DOWN PROCEDURE..................................................................... 3-14

3.10 SAFETY SYSTEM................................................................................... 3-14

3.11 ALARM INDICATIONS............................................................................. 3-14

3.12 CONFIGURATION STORAGE ................................................................ 3-15

SECTION 4. MAINTENANCE AND TROUBLESHOOTING

4.1 GENERAL................................................................................................ 4-1

4.2 FUSES..................................................................................................... 4-2

4.3 BURNER BLOCK REMOVAL AND INSTALLATION............................... 4-3

4.4 BURNER STARTUP TROUBLESHOOTING........................................... 4-4

4.5 MAINTENANCE SCHEDULE .................................................................. 4-7

S

ECTION

5.

REPLACEMENT PARTS

5.1 REPLACEMENT PARTS......................................................................... 5-1

ii

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 5

APPENDIX A. GAS SAFETY FEATURES

A.1 GAS SAFETY FEATURES.......................................................................A-1

A.2 FUEL GAS OPTION.................................................................................A-1

C

ONTENTS

A

PPENDIX

B.1 ANALYZER SETUP CHECKLIST............................................................B-1

B.2 AUXILIARY MODULE SETUP.................................................................B-3

B.3 COMPUTER INTERFACE SETUP ..........................................................B-3

B. A

B.1.1 System Setup.............................................................................B-1

B.1.2 Analyzer Module Setup..............................................................B-1

NALYZER SETUP CHECKLIST

APPENDIX C. USER INTERFACE HELP

C.1 INSTRUCTIONS......................................................................................C-1

C.2 MENU ITEMS ..........................................................................................C-1

APPENDIX D. FID 2 MENU STRUCTURE

D.1 BASIC CONTROLS MENUS ...................................................................D-1

D.2 EXPERT CONTROLS MENUS................................................................D-3

D.3 ANALYZER SETUP MENUS...................................................................D-6

D.4 ANALYZER TECHNICAL CONFIGURATION MENUS............................D-15

D.5 DIAGNOSTIC MENUS.............................................................................D-19

APPENDIX E. FID 2 IDENTIFICATION MATRIX

ENERAL PRECAUTIONS FOR HANDLING AND STORING HIGH PRESSURE CYLINDERS

G

ARRANTY

W

IELD SERVICE AND REPAIR FACILITIES

F

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

iii

Page 6

C

ONTENTS

FIGURES

P-1 FID 2 Front Panel.................................................................................... P-13

1-1 FID 2 Analyzer Module............................................................................ 1-1

1-2 Flame Ionization Detection Technology................................................... 1-2

1-3 FID 2 Analyzer Flow Diagram.................................................................. 1-3

2-1 FID 2 Outline and Mounting Dimensions................................................. 2-3

2-2 FID 2 Rear Panel..................................................................................... 2-4

2-3 FID 2 Front Panel .................................................................................... 2-6

3-1 Run Mode Display....................................................................................3-1

3-2 Main Menu............................................................................................... 3-2

3-3 Basic Controls Menu................................................................................ 3-3

3-4 Expert Controls Menu.............................................................................. 3-3

3-5 Analyzer Module Setup Menu.................................................................. 3-4

3-6 Typical Help Menu................................................................................... 3-4

3-7 Analyzer Diagnostics Menu ..................................................................... 3-5

3-8 Self Test Results Menu............................................................................ 3-5

3-9 Light Flame Menu.................................................................................... 3-6

3-10 Typical Curves of Module Response vs. Pressure Setting on

Sample Pressure Regulator.......................................................... 3-7

3-11 Typical Curves of Module Response vs. Pressure Setting on

Fuel Pressure Regulator............................................................... 3-8

3-12 Typical Curves of Module Response vs. Pressure Setting on

Air Pressure Regulator................................................................. 3-8

3-13 Typical Calibration Gas List Menu........................................................... 3-10

3-14 Zero and Span Calibration Menu............................................................. 3-10

3-15 Calibration Parameters Menu.................................................................. 3-10

3-16 Zero/Span Diagnostic Data (Span).......................................................... 3-11

3-17 Analyzer Manufacturing Data Menu......................................................... 3-13

3-18 Store/Restore User Settings Menu.......................................................... 3-16

3-19 Store Historical Data Menu...................................................................... 3-16

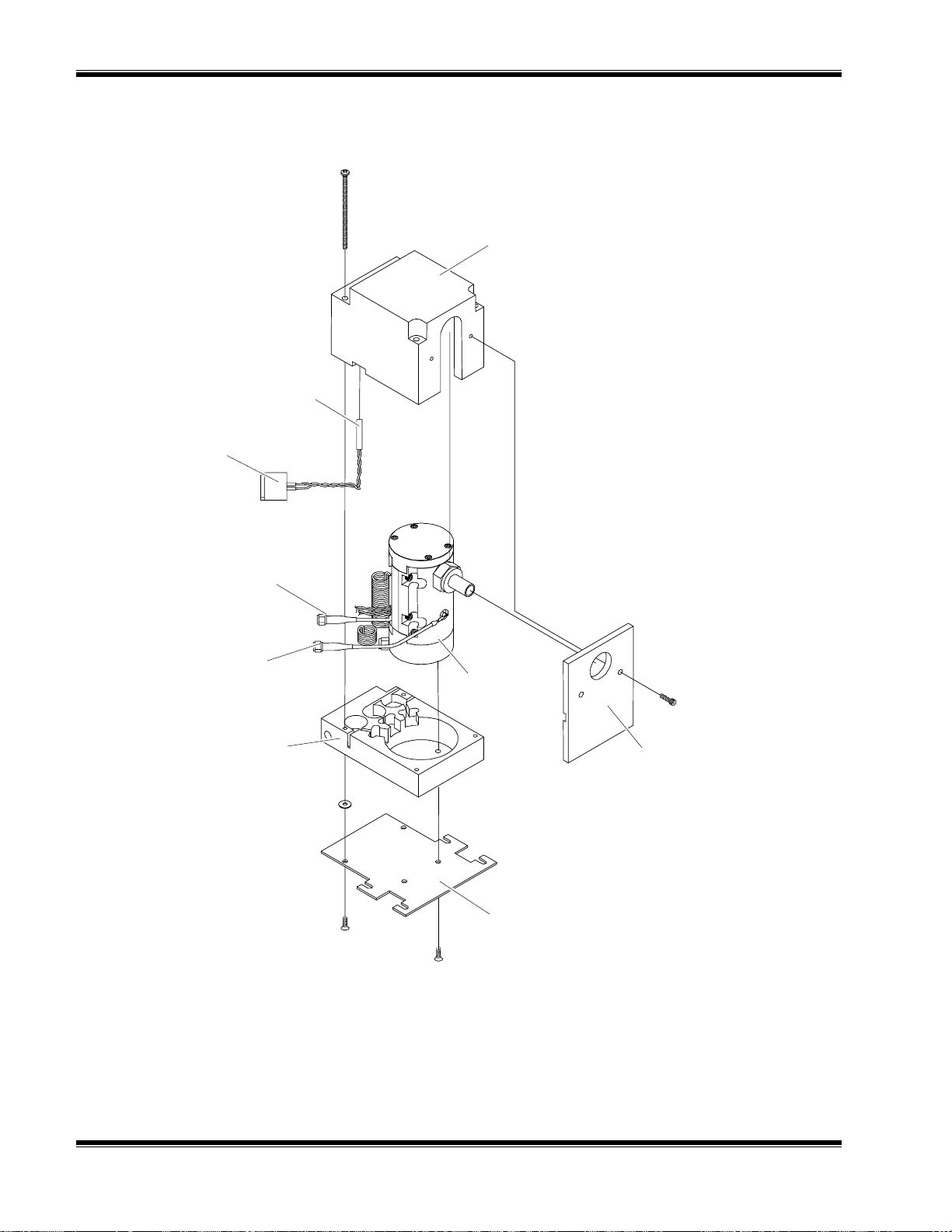

4-1 Locations of Major Components of the FID 2.......................................... 4-1

4-2 Removal of FID 2 Cover .......................................................................... 4-2

4-3 Main Power Fuse..................................................................................... 4-2

4-4 Fuse Locations on Module Board............................................................ 4-3

4-5 Physical Measurement Parameters Menu............................................... 4-4

4-6 FID 2 – Exploded View............................................................................ 4-5

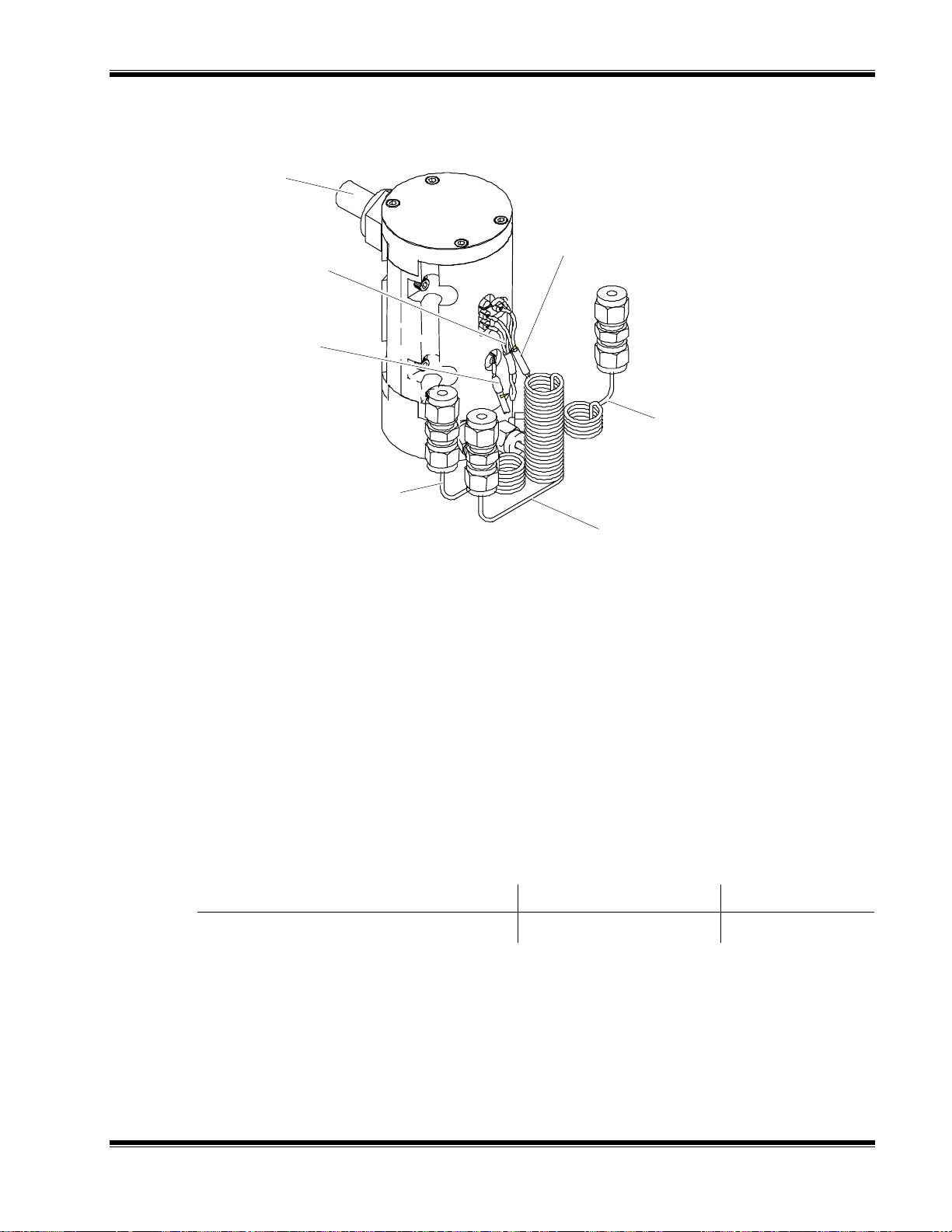

4-7 Burner Block – Exploded View.................................................................4-6

4-8 Burner...................................................................................................... 4-7

iv

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 7

FIGURES (CONTINUED)

D-1 Main Menu...............................................................................................D-1

D-2 Basic Control Menu..................................................................................D-1

D-3 Zero “Are you sure?” Menu......................................................................D-2

D-4 Light Flame Menu....................................................................................D-2

D-5 Main Menu...............................................................................................D-3

D-6 Expert Controls and Setup Menu.............................................................D-3

D-7 Expert Controls Menu..............................................................................D-4

D-8 Range Settings Menu..............................................................................D-4

D-9 Zero/span Calibration Menu - Zero..........................................................D-5

D-10 Analyzer Zero Menu.................................................................................D-5

D-11 Zero/Span Diagnostic Data Menu............................................................D-6

D-12 Analyzer Module Set Up Menu ................................................................D-6

D-13 Calibration Gas List Menu........................................................................D-7

D-14 Calibration Parameters Menu..................................................................D-7

D-15 Gas Measurement Parameters Menu......................................................D-8

D-16 Linearization Parameters.........................................................................D-9

D-17 Linearity Coefficients Menu......................................................................D-9

D-18 Response Time/Delay Parameters Menu................................................D-10

D-19 Units Menu...............................................................................................D-11

D-20 Midpoint Correction Set Up Menu............................................................D-12

D-21 Physical Measurements Parameters Menu.............................................D-12

D-22 Physical Measurements Parameters (More) Menu .................................D-13

D-23 Pressure Limits Menu..............................................................................D-13

D-24 Temperature Limits Menu........................................................................D-14

D-25 Displayed Parameters Menu....................................................................D-14

D-26 Store/Restore User Settings Menu..........................................................D-15

D-27 Main Menu..............................................................................................D-15

D-28 Technical Configuration Menu.................................................................D-16

D-29 Control Module Service Menu..................................................................D-16

D-30 Control Module Manufacturing Data Selection Menu ..............................D-16

D-31 Analyzer Manufacturing Data ..................................................................D-17

D-32 Control Module Service History Selection Menu......................................D-17

D-33 Analyzer Service History Menu...............................................................D-18

D-34 Analyzer Module Service Notes...............................................................D-18

D-35 Control Module Diagnostic Selection Menu.............................................D-19

D-36 Analyzer Diagnostics Menu .....................................................................D-19

D-37 Power Supply Voltages Menu..................................................................D-20

D-38 Primary Variable Parameters Menu.........................................................D-20

D-39 Calibration Factors Selection Menu.........................................................D-21

C

ONTENTS

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

v

Page 8

C

ONTENTS

FIGURES (CONTINUED)

D-40 Range 1 Factors Menu............................................................................ D-21

D-41 Range 1 Factors History Menu................................................................ D-22

D-42 Physical Measurements Parameters Menu............................................. D-22

D-43 Temperature Control Parameters Menu.................................................. D-23

D-44 Miscellaneous Control Parameters Menu ............................................... D-23

D-45 Miscellaneous Control parameters (more) Menu .................................... D-24

D-46 Pressure Settings Menu.......................................................................... D-24

D-47 Trend Storage Control............................................................................. D-25

D-48 Auto Ignition Parameters Menu............................................................... D-25

D-49 Self Test Results..................................................................................... D-26

D-50 Software Diagnostics............................................................................... D-26

D-51 Analyzer Starting Up Menu .................................................................... D-27

D-52 Re-Initialize Menu................................................................................... D-27

TABLES

1-1 Gas Flow Rates....................................................................................... 1-5

1-2 Analyzer Characteristics Relative to Fuel Gas......................................... 1-5

2-1 Gas Supply Pressures............................................................................. 2-5

3-1 FID 2 Analyzer Module Alarms ................................................................ 3-15

4-1 Maintenance Schedule............................................................................ 4-7

A-1 Typical Flow Rates with Premixed Fuel................................................... A-2

A-2 Analyzer Characteristics for Different Fuels............................................ A-3

vi

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 9

P

REFACE

PURPOSE/SAFETY SUMMARY

The purpose of this manual is to provide information concerning the components,

functions, installation and maintenance of this particular NGA 2000 module.

Some sections may describe equipment not used in your configuration. The user

should become thoroughly familiar with the operation of this module before operating

it. Read this instruction manual completely.

To avoid explosion, loss of life, personal injury and damage to this equipment

and on-site property, all personnel authorized to install, operate and service this

equipment should be thoroughly familiar with and strictly follow the instructions

in this manual. Save these instructions.

If this equipment is used in a manner not specified in these instructions,

protective systems may be impaired.

DANGER is used to indicate the presence of a hazard which will cause severe

personal injury, death, or substantial property damage if the warning is ignored.

WARNING is used to indicate the presence of a hazard which can cause severe

personal injury, death, or substantial property damage if the warning is ignored.

CAUTION is used to indicate the presence of a hazard which will or can cause minor

personal injury or property damage if the warning is ignored.

NOTE is used to indicate installation, operation or maintenance information which is

important but not hazard-related.

WARNING: ELECTRICAL SHOCK HAZARD

Operate this equipment only when covers are secured. Servicing requires

access to live parts which can cause death or serious injury. Refer servicing to

qualified personnel.

For safety and proper performance, this module must be connected to a

properly grounded three-wire source of electrical power.

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

P-1

Page 10

REFACE

P

WARNING: POSSIBLE EXPLOSION HAZARD

This equipment is used in the analysis of sample gases which may be

flammable, and the burner fuel used in the ionization process IS flammable. A

system of intrinsically safe electronics and an explosion proof tower are used to

prevent any ignition of a flammable gas leak. For this to be effective, the

module MUST be placed in a well-ventilated area, with unobstructed air flow

around it.

DO NOT place it within another enclosure without assuring this ventilation.

DO NOT obstruct the vent holes on the top and sides of the module.

DO NOT place the FID module within another enclosure unless the latter has a

guaranteed air circulation such as to dilute a worst case fuel or sample leak

below 25% of the LEL. Doing so will negate the safety features and may result

in an explosion, serious injury, property damage and death.

WARNING: FLAMMABLE SAMPLES

Consult the factory if flammable samples will be measured.

WARNING: PARTS INTEGRITY

Tampering with or unauthorized substitution of components may adversely

affect safety of this product. Use only factory-approved components for repair.

WARNING: POSSIBLE EXPLOSION HAZARD

Ensure that all gas connections are made as labeled and are leak free. Improper

gas connections could result in explosion and death.

P-2

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 11

REFACE

P

WARNING: STATIC ELECTRICITY

Circuit boards in this instrument are static-sensitive. Take all static precautions

when handling the circuit boards.

WARNING: POSSIBLE EXPLOSION HAZARD

Protection against explosion depends upon a special fuel flow restrictor in the

fuel inlet fitting. DO NOT REMOVE THE FUEL INLET RESTRICTOR. Use the

correct fuel flow restrictor for the fuel being used. Do not use 100% hydrogen

fuel in a 40% H2/60% He configured FID module. Replace with factory supplied

fitting only.

CAUTION: PRESSURIZED GAS

This module requires calibration with a known standard gas. See General

Precautions for Handling and Storing High Pressure Gas Cylinders at the rear of

this manual.

CAUTION: CONTRO LLE D ENV I RO NMENT

This equipment is for use in a controlled environment. Refer to the

specifications (page P-7 ) in this manual for environmental conditions.

CAUTION: HOT OVEN COMPONENTS

The oven and sample manifold are controlled to 80

cool down before touching any of these components.

Note

°°°°

C. Allow the analyzer to

This Analyzer Module is completely leak-tested at the factory for gas leakage.

The user is responsible for testing for leakage at the inlet and outlet fittings on

the rear panel (with a test procedure chosen by the user). The user is also

responsible for leak-testing periodically and if any internal pneumatic

components are adjusted or replaced. See leak test instructions on page 2-5.

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

P-3

Page 12

REFACE

P

GLOSSARY

NALYZER MODULE

A

The module that contains all sensor/detector components for development of a

Primary Variable signal; includes all signal conditioning and temperature control

circuitry.

ACKPLANE

B

The interconnect circuit board which the Controller Board, Power Supply, Analyzer

Module power and network cables, I/O Modules and Expansion Modules plug into.

ONTROL MODULE

C

The Operator Interface plus the Controller Board.

ONTROLLER BOARD

C

The computer board that serves as the Network Manager and operates the Display

and Keypad.

ILUENT

D

The material used to dilute another material. In air, nitrogen is the diluent for the

oxygen we need to breathe.

ISTRIBUTION ASSEMBLY

D

The Backplane and the card cages that hold I/O and Expansion Modules.

XPANSION MODULE

E

A circuit board that plugs into the Backplane from the front of the Platform and

performs special features not related to I/O functions.

LAME IONIZATION

F

A technique for measuring hydrocarbon gases. A flame is used to ionize the carbon

atoms, and the charge thus generated is measured.

AS CHROMATOGRAPHY

G

A technique of separating gas stream components using absorption media, allowing

the detector to measure individual species within the stream.

YDROCARBON

H

P-4

A chemical containing only hydrogen and carbon atoms. Methane, propane and

octane are hydrocarbons.

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 13

REFACE

P

YDROCARBONS

H

Organic molecules containing just carbon and hydrogen. Methane, propane and oils

are example of hydrocarbons.

I/O M

ODULE

A circuit board that plugs into the Backplane from the rear of the Platform. Has a

connector terminal for communication with external data acquisition devices and

provides an input/output function.

ONIZATION

I

Generation of electrically charged particles from a neutral material. In the FID, the

flame causes hydrocarbon molecules to split into such charged ions.

LED

Light Emitting Diode – a solid state indicator light.

PERATOR INTERFACE

O

The Display and Keyboard.

LATFORM

P

Any workable collection of the following: Controller Board, Power Supply, Distribution

Assembly, Enclosure and Operator Interface.

OWER SUPPLY

P

Any of a variety of components that provides conditioned power to other NGA 2000

components, from the Power Supply Board that plugs into the front of the Backplane

in a stand-alone instrument to several larger ones that can power larger collections of

modules and components.

RIMARY VARIABLE

P

The measured species concentration value from an Analyzer Module.

URGE

P

A safety system that uses an air flow to keep any fuel gas leak under the lower

explosive limit (LEL).

AMPLE CONDITIONING

S

The process of altering the state of the sample gas so as to make it suitable for an

analyzer. This includes removing condensable water, changing the pressure, and

filtering.

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

P-5

Page 14

REFACE

P

ECONDARY VARIABLE

S

Data placed on the network by a module regarding current status, e.g., sample flow,

source voltage and other diagnostic information.

OFTKEYS

S

The five function keys located below the front panel display; they assume the function

displayed directly above each on the display, a function dictated by software.

PECIES

S

A particular gas within a mixture. Oxygen is a species in air.

UBNODE

S

A subsection of the analyzer devoted to measuring one of the species for which it is

set up. Analyzers with multiple subnodes can measure multiple gases.

YSTEM

S

Any collection of Analyzer Module(s), Platform(s), I/O Module(s) and Expansion

Module(s).

P-6

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 15

SPECIFICATIONS - GENERAL

REFACE

P

MEASUREMENT SPECIES

H2/HE

R

FUEL

EPEATABILITY

MINIMUM DETECTABLE LEVEL

N

OISE

L

INEARITY

R

ESPONSE TIME

Z

ERO DRIFT

S

PAN DRIFT

E

FFECT OF TEMPERATURE

Total hydrocarbons

low range: 0 to 4 ppm CH4, through 0 to 1% CH

high range:: 0 to 50 ppm CH4, through 0 to <5% CH

4

4

≤1% of fullscale at a constant temperature, sample flow

and fuel, burner air and sample pressure

0.04 ppm H2/He fuel

0.01 ppm H2 fuel – methane equivalent

≤1% of fullscale, peak to peak

≤ ±1% of fullscale for H2/He fuel and H2 fuel

<1 second for bypass flow rate of 500 cc/min (for a

sample change at the rear panel connector of the

instrument)

≤ ±1% of fullscale/24 hours at constant temperature,

hydrocarbon concentration of supply gases, sample flow

and fuel, burner air and sample pressure

≤ ±1% of fullscale/24 hours at constant temperature,

hydrocarbon concentration of supply gases, sample flow

and fuel, burner air and sample pressure

≤ ±2% of fullscale for any temperature change of 10°C

and rate of change less than 10°C/hour

O

PERATING TEMPERATURE

O

PERATING HUMIDITY

P

OWER REQUIREMENTS

41°F to 104°F (5°C to 40°C)

<95% relative humidity, non-condensing

+24 VDC ±5%, 120 W max.. direct to analyzer module;

Ripple and Noise: <100 mV peak to peak

Line and Load Regulations: <±1%

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

P-7

Page 16

REFACE

P

SPECIFICATIONS - GAS REQUIREMENTS

BURNER AIR

F

LOW RATE

THC

S

UPPLY PRESSURE

FUEL GAS (STANDARD)

F

LOW RATE

THC

S

UPPLY PRESSURE

Hydrocarbon free grade air

350 to 400 ml/min

≤0.1 ppm CH

4

1725 to 3450 hPa-gauge (25 to 50 psig)

Premixed 40% hydrogen and 60% helium

110 to 110 ml/min.

≤0.5 ppm CH

4

3101 to 3450 hPa-gauge (45 to 50 psig)

WARNING: POSSIBLE EXPLOSION HAZARD

Unless this Analyzer Module is factory- or field-configured specifically

for using 100% hydrogen fuel, DO NOT USE PURE HYDROGEN FUEL.

An explosion resulting in severe personal injury or death could occur.

Also, each Analyzer Module is factory-configured for either mixed or

pure hydrogen fuel, and cannot use the fuel for which it was not

configured unless field reconfiguration is done.

S

AMPLE

F

LOW RATE

S

UPPLY PRESSURE

T

EMPERATURE

P

ARTICULATES

D

EWPOINT

Non-flammable (below 100% of LEL)

0.5 to 2.0 L/min.

483 to 1035 hPa-gauge (7 to 15 psig)

32°F to 248°F (0°C to 120°C), <20°C variance/24 hours,

<10°C variance/hour

Filtered to <2 microns

<45°C

P-8

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 17

SPECIFICATIONS - PHYSICAL

REFACE

P

MATERIALS IN CONTACT WITH

SAMPLE

D

IMENSIONS

W

EIGHT

MOUNTING

CASE CLASSIFICATION

MAX. S

P

EPARATION FROM

LATFORM

Stainless steel, Teflon, glass-filled Teflon, Viton

See Figure 2-5, Outline and Mounting Dimensions

10.43 kg (23 lbs.)

Horizontal

General Purpose for installation in weather

protected area

1600 m (1 mile)

SPECIFICATIONS - GAS CONNECTIONS

S

AMPLE IN

B

URNER AIR IN

F

UEL IN

B

YPASS OUT

1/4 inch O.D. tube fitting

1/4 inch O.D. tube fitting

1/4 inch O.D. tube fitting

1/4 inch O.D. tube fitting

B

URNER EXHAUST

O

UT

T

HE BURNER EXHAUST AND BYPASS OUT SHALL BE VENTED TO ATMOSPHERIC PRESSURE

AND TO A NON

-

CLASSIFIED LOCATION

3/8 inch O.D. tube slip-fit connection, tygon or equivalent

(this connection shall slope downward 6° minimum from

horizontal)

.

See the Preface Section of the Platform manual for specifications regarding Platform

related components.

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

P-9

Page 18

REFACE

P

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE

For order administration, replacement Parts, application assistance, on-site or factory

repair, service or maintenance contract information, contact:

Rosemount Analytical Inc.

Process Analytical Division

Customer Service Center

1-800-433-6076

RETURNING PARTS TO THE FACTORY

Before returning parts, contact the Customer Service Center and request a Returned

Materials Authorization (RMA) number. Please have the following information when

you call: Model Number, Serial Number, and Purchase Order Number or Sales Order

Number.

Prior authorization by the factory must be obtained before returned materials will be

accepted. Unauthorized returns will be returned to the sender, freight collect.

When returning any product or component that has been exposed to a toxic, corrosive

or other hazardous material or used in such a hazardous environment, the user must

attach an appropriate Material Safety Data Sheet (M.S.D.S.) or a written certification

that the material has been decontaminated, disinfected and/or detoxified.

Return to:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

TRAINING

A comprehensive Factory Training Program of operator and service classes is

available. For a copy of the Current Operator and Service Training Schedule contact

the Technical Services Department at:

Rosemount Analytical Inc.

Phone: 1-714-986-7600

FAX: 1-714-577-8006

D

OCUMENTATION

The following NGA 2000 Flame Ionization Detection Module instruction materials are

available. Contact Customer Service or the local representative to order.

748364 Instruction Manual (this document)

P-10

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 19

COMPLIANCES

This product may carry approvals from several certifying agencies, like The Canadian

Standards Association (CSA), which is also an OSHA accredited Nationally

Recognized Testing Laboratory (NRTL), and LCIE - a French Notified Body.

The certification marks appear on the product name-rating plate.

REFACE

P

NRTL /C

®

LCIE 98 ATEX 6004 X

EEx d ib IIB (+H

0°C Ta +40°C

Date of Manufacture:

0081

) T6

2

II 2 G

Rosemount Analytical has satisfied all obligations from the European Legislation to

harmonize the product requirement in Europe.

This product complies with the standard level of NAMUR EMC

NAMUR

Recommendations (1993).

This product satisfies all obligations of all relevant standards of the EMC framework in

Australia and New Zealand.

N96

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

P-11

Page 20

REFACE

P

NOTES

P-12

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 21

REFACE

P

Q

UICK STARTUP PROCEDURE

The purpose of this reference guide is to provide a easy to follow, step by step

procedure through initial start up and ignition of the FID2 Analyzer Module. This

procedure assumes that the customer has already made all necessary electrical and

gas connections and established the proper network connections.

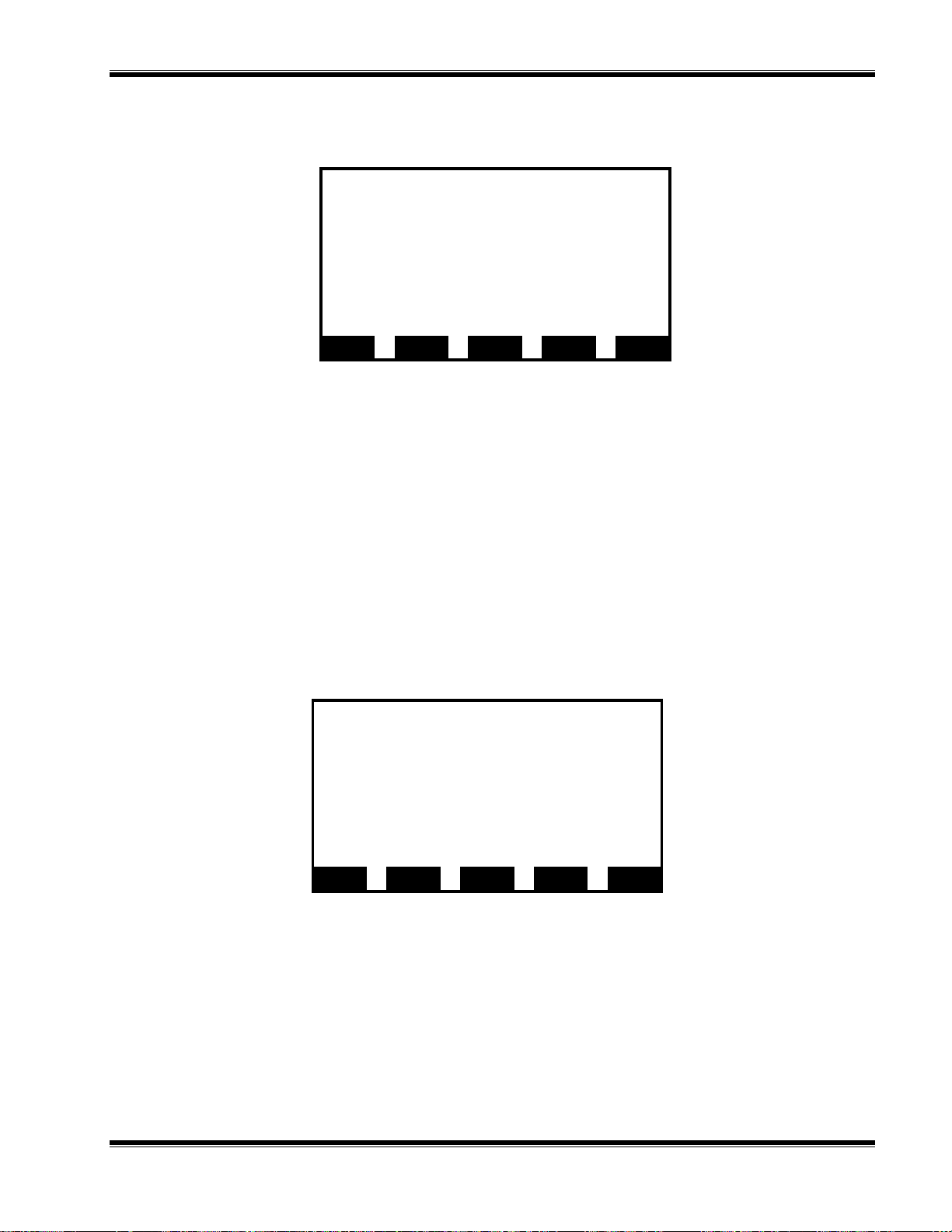

1. Turn on power to the instrument. The #1 LED (POWER) will illuminate. The #3

LED (BLOCK) will begin flas hing.

2. If sample gas has been connected and the sample pressure to the analyzer is

sufficient to provide an accurate reading, the #4 LED (SAMPLE) will be

illumninated.

3. Allow the analyzer module to warm up and the burner block temperature to reach

the proper minimum ignition temperature (50°C). When the burner block

temperature reaches the minimum ignition temperature, the #5 LED (IGNITE OK)

will come on.

FID 2

FUEL OVERRIDE

IGNITE

POWER FLAME BLOCK SAMPLE IGNITE FUEL/AIR

OK

IGURE

F

748364-D Rosemount Analytical November 1998

P-1. FID2 F

RONT PANEL

3 2 1 LON2 LON1

T 6A

24V

250 V

NGA 2000 FID 2 Analyzer Module

P-13

Page 22

REFACE

P

4. The instrument is now ready to be lit. Lighting the burner can be conducted in one

of two methods: a) manual ignition from the front panel of the Analyzer Module or

b) autoignite from the Platform.

a) To light the instrument from the Analyzer Module, hold the "FUEL

OVERRIDE/IGNITE" switch (located to the left of the indicator lights) in the up

(FUEL OVERRIDE) position for 30 seconds. Immediately move the switch to

the down (IGNITE) position. The "IGNITE" mode is automatically set to stay on

for a preset time period and does not require the switch to be held down. If the

lighting procedure was successful, the #2 LED (FLAME) will begin flashing as

the flame temperature rises to the correct operating temperature. Once this

LED becomes solidly lit, the flame has reached operating temperature.

b) To light the instrument from the Platform using the autoignite mode, simply

press the "light" softkey shown in the "Light Flame" menu of the Platform. The

Analyzer Module will begin to go through an automated sequence of

enrichment and ignition similar to the manual mode described in step 5. If the

burner fails to light on the first try, the Analyzer Module will perform 2 more

tries before terminating the autoignite sequence. If the Analyzer Module fails to

light after 3 attem pts, an erro r me ssage will be displa yed sho wing th e cau se o f

the fault.

5. If the burner fails to light, check all gas connections for proper gas composition and

pressure, block temperature, and outlets for obstructions. Repeat step 4.

6. If the flame is lit, the #2 LED will begin f lashing. Once the flame temperature has

reached the correct operating temperature, the LED will remain on solid.

7. If the fuel and air pressures and ratios are within proper operating parameters to

support a continuous flame operation, the #6 LED (FUEL/AIR) will illuminate. This

light will not be on before or during fla me ignition.

8. Once the burner block temperature reaches the control temperature of 80°C, the

#3 LED will stay on solid.

9. If the instrument has been successfully lit, the temperatures are up to proper

operating levels, and the fuel, air, and sample gases are properly adjusted to

support the flame and achieve reliable results, all 6 indicator lights will be lit solid.

The unit is now ready for calibration or burner optimization.

P-14

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 23

I

NTRODUCTION

1

1.1 OVERVIEW

This manual describes the Flame Ionization Detector (FID 2) Analyzer Module of

Rosemount Analytical's NGA 2000 Series of gas analysis components. See Figure 1-

1.

The FID 2 Analyzer Module is designed to use a flame ionization technique to

measure the total concentration of hydrocarbon (including certain oxygenated

hydrocarbons) components within the sample stream.

The entire FID 2 Analyzer Module is designed as a module with electrical connections

at its front, and gas connections made from the rear. All electronics relative to sample

control and signal conditioning are included in this module.

F

IGURE

FRONT

Intrinsic Safety Board

1-1. FID 2 A

Module Board

Computer Board

Regulator

Burner

Oven

(Cover removed)

REAR

Flow Control Manifold

NALYZER MODULE

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

1-1

Page 24

NTRODUCTION

+++++

I

1.2 TYPICAL APPLICATIONS

Typical applications for the FID 2 Analyzer Module include:

• The monitoring of atmospheric air for low-level total hydrocarbon contaminants

• Determining the total hydrocarbon content of exhaust emissions from internal

combustion engines

• Carbon bed monitoring

• Determining the total hydrocarbons content of process and product gases from

air separation plants

1.3 THEORY OF TECHNOLOGY

This Analyzer Module uses the flame ionization method of detection. The sensor is a

burner in which a regulated flow of gas sample passes through a flame sustained by

regulated flows of a fuel gas (hydrogen or a hydrogen/diluent mixture) and air.

Within the flame, the hydrocarbon components of the sample stream undergo a

complex ionization that produces electrons and positive ions. Polarized electrodes

collect these ions, causing current to flow through an electronic measuring circuit.

Igniter

Exhaust

-

Ions

Negative

Electrode

Flame

Fuel + Sample

F

IGURE

1-2. F

-

Positive

Electrode

-

-

-

Air

LAME IONIZA TION DETECTION TECHNOLOGY

The ionization current is proportional to the rate at which carbon atoms enter the

burner, and is therefore a measure of the concentration of hydrocarbons in the

sample.

1-2

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 25

The gas pressures are continuously monitored and controlled through electronic

pressure transducers.

The measurement of concentration is placed on the network, where it can be shown

on the Platform Display or on other data acquisition devices.

FID

EXHAUST

FUEL IN

Bulkhead

1/4T

w/Restrictor

AIR I N

Bulkhead

1/4T

w/Filter

FUEL FLOW

CONTROL

ELEMENT

FUEL FLOW

CONTROL

AIR FLOW

CONTROL

ELEMENT

FUEL PRESSURE

SENSOR 0-30 PSIG

SENSOR,AIR

PRESSURE

0 - 30 PSIG

Elbow 1/16T - 1/8 NPT

Cres

Elbow 1/16T - 1/8 NPT

Cres

Elbow

1/16T - 1/8 NPT

Cres

SENSOR,SAMPLE

PRESSURE

0 - 15 PSIG

NTRODUCTION

I

OVEN

Bulkhead 1/4T

External

Filter/Restrictor

Required

SAMPLE IN

SAMPLE

BYPASS

Bulkhead

1/4T

FOR STANDARD MIXED FUEL APPLICATION USE 658146 FUEL CAPILLARY AND 659031 SAMPLE CAPILLARY.

1

FOR 100% FUEL APPLICATION USE 658145 FUEL CAPILLARY AND 659033 SAMPLE CAPILLARY.

F

IGURE

1-3. FID 2 A

NALYZER FLOW DIAGRAM

Union

1/16T

Cres

Elbow

1/4T- 1/4MPT

Cres

Union

1/16T

Cres

Union

1/16T

Cres

Union

1/16T

Cres

FUEL

CAPILLARY

1

AIR CAPILLARY

SAMPLE

CAPILLARY

1

FLAME

IONIZATION

DETECTOR

(FID)

1.4 GAS SAFETY FEATURES

The FID 2 module is divided into two parts - a pneumatic section and an electronic

section. The two sections are separated by a pair of solid partitions to prevent any

leak of gas in the pneumatic section from reaching the electronics. The electrical

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

1-3

Page 26

NTRODUCTION

I

connections into the pneumatic section are made intrinsically safe by a series of overvoltage protection devices and current limiting resistors. The burner itself is an

explosion-proof assembly. The combination of these two techniques allows the

analyzer to meet international safety standards without the use of an expensive

continuous-dilution purge - but ONLY when it is installed in a general purpose area

with good air circulation.

WARNING: POSSIBLE EXPLOSION HAZARD

Hydrocarbon concentration(s) in the sample gas must be below the Lower

Explosion Limit (LEL).

All tubing ahead of the burner is rigid m etallic tubing assembled with ferrule/nut type

compression fittings. However, should an internal fuel leak occur, a worst-case leak

would be dissipated below 25% of the LEL of hydrogen by natural dilution outside of

the pneumatic section before it could be ignited by any external ignition source, and

there is nothing within the pneumatic section to ignite it.

The FID 2 is designed to use 100% hydrogen fuel or 40% H2/60% He fuel at a

maximum inlet pressure of 3446 hPa-gauge (50 psig). A different flow restrictor is

used for each fuel type1.

WARNING: POSSIBLE EXPLOSION HAZARD

Protection against explosion depends upon a special fuel flow restrictor1 at the

fuel inlet. DO NOT REMOVE THE FUEL INLET RESTRICTOR.

1.5 FUEL GAS OPTION

The standard FID 2 Analyzer Module requires 40% hydrogen/60% helium burner fuel

gas. As an option, the analyzer module can be equipped to use 100% hydrogen fuel.

The particular application and characteristics of the sample gas to be measured will

dictate the preferred type of fuel. The following guidelines can be used for determining

fuel gas type:

For measuring low-level hydrocarbons in ambient air or in other sample gas with

relatively constant oxygen content, 100% hydrogen is preferable. It provides the

highest obtainable sensitivity and maximum stability.

1

The fuel restrictor is part of the Flow Control Manifold Assembly, which is specific to an application.

1-4

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 27

NTRODUCTION

I

For monitoring internal combustion exhaust emissions or other sample gas with

varying oxygen content, mixed fuel is preferable. In fact, a hydrogen/helium mixture is

more desirable than a hydrogen/nitrogen mixture. With this type of sample, the use of

mixed fuel gas minimizes the error introduced by oxygen synergism.

Changes in the burner air flow rate have little effect on signal strength. For a given

flow, the signal can be optimized by adjusting the fuel flow rate.

Typical flow rates to the burner:

2

MIXED FUEL

T

ABLE

F

UEL

S

AMPLE

A

IR

1-1. G

GAS FLOW PURE H

30 cc/min 100 cc/min

55 cc/min 13 cc/min

300 cc/min 400 cc/min

AS FLOW RATES

Note that with a 40/60 premixed fuel, the above flow rates amount to 40 cc (8%)

hydrogen, 73 cc (14%) inert plus sample and 400 cc (78%) air, which compare closely

to the 30 cc (8%) hydrogen, 55 cc (14%) inert/sample and 300 cc (78%) air noted

earlier for straight hydrogen fuel.

ANALYZER

CHARACTERISTICS

F

ULL SCALE SENSITIVITY

F

UEL CONSUMPTION

O

PERATING SETTING FOR

S

AMPLE PRESSURE

R

EGULATOR

1 ppm, CH4 to <2500 ppm CH

50 to 60 cc/min 100 to 110 cc/min

345 hPa-gauge (5 psig) 345 hPa-gauge (5 psig)

100% H

2

4

40% H2/60% He

4 ppm, CH4 to <1%,

CH

4

T

ABLE

748364-D Rosemount Analytical November 1998

1-2. A

NALYZER CHARACTERISTICS RELATIVE TO FUEL GAS

NGA 2000 FID 2 Analyzer Module

1-5

Page 28

NTRODUCTION

I

N

OTES

1-6

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 29

I

NSTALLATION

2

2.1 UNPACKING

When the FID 2 Analyzer Module is received, carefully examine the shipping carton

and contents for signs of damage. Immediately notify the shipping carrier if the carton

or contents is damaged. Retain the carton and packing material until all components

associated with the Analyzer Module are operational.

2.2 ASSEMBLY

The FID 2 analyzer module MUST NOT be placed within a conventional NGA platform,

single module enclosure or dual module enclosure since the latter would not allow free

flow of air around the module, thus violating its safety certification. The enclosure is

designed so that this would be very hard to do anyway.

There is a special platform specifically designed to accept this module; consult the

factory for details.

Install the Platform and I/O Module(s) according to guidelines in the Platform manual.

2.3 LOCATION

WARNING: POSSIBLE EXPLOSION HAZARD

Do not place the FID 2 module within another enclosure unless the latter has a

guaranteed air circulation such as to dilute a worst case fuel or sample leak

below 25% of the LEL. Failure to will negate the safety features and may result

in explosion, serious injury, material damage and death. Also, do not cover the

vent holes on the top and sides of the module.

Install the Analyzer Module in a clean, weather-proofed, non-hazardous, vibration-free

location free from extreme temperature variations. For best results, install the Analyzer

Module near the sample stream to minimize sample transport time.

Operating ambient temperature is 5 °C to 40 °C, limited to temperature changes of

less than 10 °C/hr. Acceptable dew point range is less than 95% relative humidity,

but not in excess of 40°C wet bulb temperature.

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

2-1

Page 30

NSTALLATION

I

The cylinders of fuel, air, and calibration gases should be located in an area of

relatively constant ambient temperature.

2.4 GASES

During normal operation, the Analyzer Module requires fuel and air to maintain the

burner flame as well as suitable standard gases for. Refer to the criteria for selection

of these gases in Section 2.4.2.

After initial startup or after startup following a prolonged shutdown, the analyzer may

display baseline drift for a considerable period of time, particularly on the most

sensitive range.

Commonly, the drift is caused by small amounts of organics (such as hydrocarbons) in

the inner walls of the tubing in both the internal flow system and the external gas

supply system. Drift results from any factor influencing the equilibrium of these

adsorbed hydrocarbons, such as temperature or pressure. Hydrocarbons adsorbed

within the analyzer in the gas passageways (or in th e fuel or air lines) will elevate the

overall baseline.

Note that this type of drift occurs only when the flame is burning. If drift occurs when

the flame is extinguished, the electronic circuitry is at fault or the burner or cabling is

contaminated with a conductive film. To minimize drift, use clean fuel and air, keep the

analyzer clean, and locate the gas cylinders in an area of relatively constant ambient

temperature.

The cylinders supplying all gases each should be equipped with a clean, hydrocarbonfree, two-stage regulator and a shutoff valve.

All new external gas tubing (except for SAMPLE BYPASS) is strongly recommended,

preferably pre-cleaned, stainless steel, gas chromatograph-grade tubing. Thoroughly

clean before use (if a hydrocarbon-based cleaning solvent such as acetone is used,

purge tubing with dry nitrogen or helium for several minutes before using.)

Gas line connections are compression fittings. Do not use pipe thread tape on such

fittings.

Since the oxidation of hydrogen is accompanied by the formation of water vapor, the

exhaust tubing always should be slanted downward at least 6 degrees from horizontal.

Otherwise, water may accumulate in the line, causing back pressure and noisy

readings, or may back up in the line and flood the burner.

If the sample is toxic or noxious, or is to be reclaimed, connect the Bypass outlet to a

suitable disposal system. Do not use any device that may cause back pressure in the

line.

2-2

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 31

4.3

[110]

8.2

[208]

22.6

[573]

2.9

[73]

[19]

NSTALLATION

I

.6

[16]

.8

[17]

.7

1.2

[31]

F

IGURE

2.4.1 C

1.0

[25]

2.2

[55]

2-1. FID 2 O

ONNECTIONS

.9

[23]

UTLINE AND MOUNTING DIMENSIONS

3.1

[78]

[23]

2.8

.8

[71]

[20]

.9

Refer to Figure 2-2. Connect inlet and outlet lines for sample, burner fuel and air,

exhaust, and bypass to appropriately labeled fittings on the rear panel. All connections

are 1/4-inch ferrule-type compression fittings. Burner exhaust and bypass must be

vented at atmospheric pressure to a non-classified location in accordance with

ANSI/NFPA-496.

2.4.2 G

AS SPECIFICATIONS

Fuel Gas — Standard analysis usually requires mixed fuel, i.e., 40% (±2 %) hydrogen

and 60% helium. H2/He mixed fuel is recommended over H2/N2 fuel because of better

linearity in concentration output. Such blends are supplied by many gas vendors

specifically for this use, with a guaranteed maximum total hydrocarbon content of 0.5

ppm, measured as methane. This specification should be used when obtaining these

mixtures.

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

2-3

Page 32

NSTALLATION

I

F

IGURE

FUEL IN

AIR

IN

2-2. FID 2 R

SAMPLE

SAMPLE IN

EAR PANEL

BURNER

EXHAUST

Note:

The Analyzer fuel inlet restrictor fitting and Detector fuel gas capillary inlet are

marked with white dots for pure hydrogen fuel applications and with green dots

for mixed fuel applications.

Note:

Some applications require the use of 100% hydrogen fuel. When using this

option, always ensure that sample gas pressure (4 to 5 psig) is present when

fuel flow is present. Otherwise, the flame tip may be damaged.

Burner Air — In order to ensure a low background signal, hydrocarbon free grade air

with less than 1 ppm maximum total hydrocarbon content is highly recommended. An

alternative source for burner air and zero gas (see CALIBRATION GASES below) is a

combination diaphragm pump and heated palladium catalyst. This process

continuously removes moderate amounts of hydrocarbons and carbon monoxide from

ambient air.

Calibration Gases — Calibration method and gases depends on the type of fuel gas

used, the operating range, and the desired measurement accuracy. In all methods,

zero and span gases are used, and are introduced through the sample inlet at the rear

of the module.

Zero Gas It is recommended that the gas should have a composition as close to

the background composition of the sample as possible.

Span Gas

Span gas consists of a specified concentration of methane and other

hydrocarbons in a background gas such as nitrogen.

2-4

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 33

NSTALLATION

I

Sample Gas — Sample gas must be nonflammable (below 100% of the sample's

LEL).

Flow Rate — The sample flow rate must be between 0.5 L/min. and 2 L/min.

Pressure/Filtration — See Table 2-1 for input pressure specifications.

Noncompliance with these specifications could cause over-pressure damage to the

module.

GAS SUPPLY EXTERNAL PRESSURE INTERNAL PRESSURE

T

ABLE

FUEL

B

S

2-1. G

URNER AIR

AMPLE

AS SUPPLY PRESSURES

50 – 55 psig

1035 - 2070 hPa

30 - 40 psig

1380 - 4140 hPa

5 - 10 psig

345 - 690 hPa

5 psig

345 hPa

15 psig

1035 hPa

5 psig

345 hPa

All internal pressure settings are preset at the factory, but the operator should check

for accuracy. It is essential that the sample be filtered for particulates down to 0.1

microns. A suitable filter is the Balston type 95S6 with 0.1 micron filter element. It

should normally be replaced on a two week schedule, depending on the sample.

Leak Test — The Analyzer Module is completely tested at the factory for gas leakage.

The user is responsible for testing for leakage at the inlet and outlet fittings on the rear

panel. The user is also responsible for internal leak testing periodically and if any

internal pneumatic components are adjusted or replaced (with a test procedure chosen

by the user).

2.5 ELECTRICAL CONNECTIONS

Note

Electrical installation must be in compliance with National Electrical Code

(NEC/NFPA 70) and/or any state or local codes.

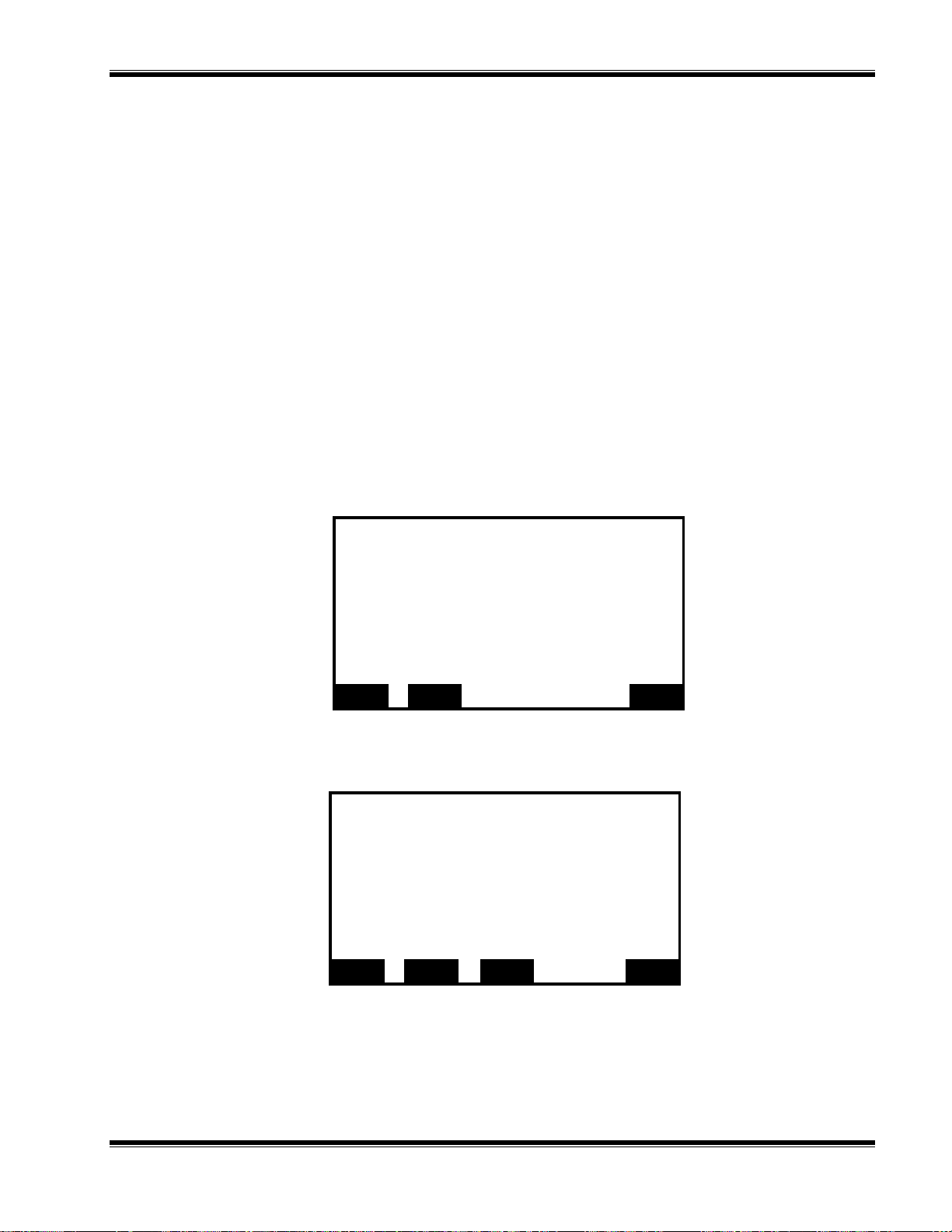

Two electrical connections are required on the Analyzer Module: POWER and

NETWORK. See Figure 2-3. On the Analyzer Module, two NETWORK connectors

are available, either of which is appropriate for: 1) interconnection with the Back plane

of the Platform or 2) "daisy-chaining" with other NGA 2000 components, or 3)

connection to a PC via a suitable LONTALK adapter and software such as the NGA

DDE server and client. Connect Analyzer Module POWER to Back plane POWER or

external 24 VDC power source.

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

2-5

Page 34

NSTALLATION

I

Connect the network cable to either the NETWORK 1 or NETWORK 2 connection on

the Analyzer Module front panel, and the NETWORK connection on the LON I/O

module if used with a Platform, or directly to a computer using appropriate LONTALK

adapter hardware and software such as the NGA DDE server. Connect the power

cable to both the Analyzer Module front panel and to a 24V 5A minimum power supply.

FID 2

FUEL OVERRIDE

F

IGURE

IGNITE

2-3. FID 2 F

POWER FLAME BLOCK SAMPLE IGNITE FUEL/AIR

OK

RONT PANEL

FUSE

3 2 1 LON2 LON1

T 6A

24V

250 V

24V POWER

NETWORK

2-6

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 35

2.6 INSTALLATION GUIDELINES

• Is the Analyzer’s Location clean, weather-proofed, non-hazardous, vibration-free,

and with a stable ambient temperature?

• Are gas supply cylinders equipped with a clean, hydrocarbon free two stage

regulator and shut off valve?

• Are external tubing, regulators, valves, pumps, fittings etc. clean?

• Is the correct fuel type being used?

• Is the THC content of the supply gases compatible with the analysis range?

• Are the burner exhaust and bypass vented to atmospheric pressure? Is the vent

pressure constant?

• Is the burner exhaust tube slanted down a minimum of 6 degrees from horizontal?

• Have all the external gas connections been leaked checked?

• Has the dead volume for external sample and fuel lines been minimized?

• Has clean stainless steel tubing been used for fuel and sample lines?

NSTALLATION

I

• Is a suitable 0.1 micron filter used in the sample line?

• Is the sample line and filter heated?

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

2-7

Page 36

NSTALLATION

I

N

OTES

2-8

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 37

S

TARTUP AND OPERATION

3

3.1 OVERVIEW

Prior to initial startup, the user should leak test the module as outlined in Section 2.

For the remainder of this section, Analyzer Module interconnection with a Platform or

some interfacing component will be assumed. Display and Keypad information refers

to use of this module with the Platform.

(For a complete description of Platform Front Panel controls and indicators, see the

Platform instruction manual.)

(For detailed information about the software operation of this analyzer, see Appendix E

and F, and the NGA Reference manual.)

3.2 DISPLAYS

Three kinds of Display screens are available to the user:

3.2.1 R

F

IGURE

• Run Mode

• Menu

• Help

UN MODE DISPLAY

3-1. R

UN MODE DISPLAY

FID2

-19.4

0 Range 2

RAW SIGNAL: 556320

PRESSURE: 14.7 psia

CASE TEMPERATURE: 45.3 C

NOISE LEVEL: 0.811 ppm

DISPLAY PARMS. MENU NEXT INFO

ppm THC

50

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

3-1

Page 38

TARTUP AND OPERATION

S

The Run Mode is the normal mode of operation. In this mode, the display will show the

gas measurement of the selected analyzer or subnode(the Control Module may be

connected to many analyzers at once, but only one may be displayed at a time as

shown), the component of interest, user-selectable (up to four) secondary variables,

the current operations of the softkeys, and a graphic bar representing the displayed

concentration as a percent of fullscale.

It is also possible to show up to five analyzers or subnodes on the screen at once,

each analyzer having its own line on the display.

3.2.2 M

ENU DISPLAYS

The following is a brief description of the menus shown on the Platform Control

Module as they apply to the FID 2 analyzer. Much more detail is available in the

Platform manual as well as in the NGA Reference manual.

The first menu shown for any of the subnodes is as follows:

Main Menu

Basic controls . . .

Expert controls and set up . . .

(Operation al configurat i o n)

Technical level configuration . . .

(Diagnosti c and manufacturing/ service)

DISPLAY PARMS. NEXT LOCK INFO

FIGURE

3-2. M

AIN MENU

The Main Menu is subdivided into three levels of control based generally on which

personnel is likely to use it: Basic Controls - Operators, Expert Controls and set up -

System Engineers, and Technical level configuration - Analyzer technicians. Many

layers of the menu structure are described at appropriate places throughout this

manual.

3-2

From the Run Mode display, press the MENUS softkey to gain access to the Main

Menu.

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 39

The Basic controls menu is as follows:

TARTUP AND OPERATION

S

Basic Controls

CRANGE

CURRENTRNGHI

CONTROL

FLOW_IS (1)

CAL_VALIDITY

CALSTAT

DIGDIAG (5)

F

IGURE

3-3. B

Measurem en t range number:

Range upper limit:

Range and functional con t rol:

Bypass sample flow:

Ranges with valid calibr ation:

Calibration status:

If it won’t calibrate . . .

Flame condition:

Light flame . . .

HOME ESCAPE ZERO SPAN INFO

ASIC CONTROLS MENU

This menu allows the user to change the range for all subnodes, to control the

operation of the GC (single shot or continuous operation) and to see its current

operational status, to allow remote control of the range change, and allows links to

other menus to light the flame, zero and span the analyzer.

Note

In the menu figure above, the italicized/capital words are the names of the

network variables whose values are in fact shown on the screen.

The Expert controls menu is as follows:

F

IGURE

3-4. E

Measurem en t range number:

Expert controls

Range upper limit:

Range sett i ngs . .

Linearizer:.

Range and functional con t rol:

Zero/Span calibrati on . . .

Ranges with valid calibr ation:

Physical measurements. . .

Flame condition:

Light flame . . .

HOME ESCAPE CAL CAL DATA INFO

XPERT CONTROLS MENU

CRANGE

CURRENTRNGHI

CURRENTSTAT

CONTROL

CAL_VALIDITY

DIGDIAG

This menu is almost the same as the Basic controls menu but with the addition of a

few extra links.

The analyzer may be configured through the Analyzer set up menu, under Expert

controls and set up.

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

3-3

Page 40

TARTUP AND OPERATION

S

Analyzer module set up

Calibration gas list . . .

Calibration parameters . . .

Gas measurement parameters. . .

Analyzer parame te r l i st. . .

Physical measurement param eters . . .

Displayed para meters. . .

Analyzer tag:

HOME ESCAPE INFOSTORE

TAG

F

IGURE

3-5. A

NALYZER MODULE SETUP MENU

This menu contains links to many other menus used to configure the operation of the

analyzer.

3.2.3 H

ELP DISPLAYS

A typical help menu:

Analyzer module set up

Select the aspect of the analyzer to configure.

Set up the calibration gas values in the calibration gas list.

Set up the other calibration parameters.

Linearizat i on, filte ring and other f unctions ar e set up in men us

under meas urement parameters.

The analyzer pa ra meter lis t simply li sts all the settable pa ra meters

in order.

Physical measurements sho w fl o w, pressure etc. and associated

limits.

Displayed parameters show what is displayed on the four auxiliary

lines on the single co mponent display.

HOME ESCAPE INFO

F

IGURE

3-6. T

YPICAL HELP MENU

3.3 STARTUP PROCEDURE

WARNING: VENTILATION

For safety, the Analyzer Module should be installed in a non-confined, ventilated

space. Do not block any of the ventilation holes as they are part of the safety

system.

3-4

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 41

TARTUP AND OPERATION

S

1. Connect supply gases and outlets to/from module.

2. Connect the LON cable(s) and the +24VDC power cable.

3. Turn power ON.

4. Check the LED’s. The power green LED should be illuminated. The Flame LED

should be OFF. The block LED should be blinking or ON.

5. Allow the network to initialize. Perform any binding of I/O modules required – see

the Platform manual for detail s.

6. Check the general health of the analyzer by reviewing the status of the Self Tests.

All “Pass” conditions should be obtained.

These test results can be found by selecting the following from the Main menu:

Technical level configuration, Diagnostic menus, Analyzer module diagnostics, Self

test results. All tested parameters should indicate "Pass."

F

IGURE

3-7. A

Power supply voltages . . .

Primary variable parameters . . .

Physical measurement param eters. . .

Temperature control parameters . . .

Miscellaneous control parameters . . .

Trend display control . . .

Auto ignition parameters . . .

Self test results . . .

Software diagnostics . . .

Start up analyzer . . .

HOME ESCAPE INFO

Analyzer Diagnostics

NALYZER DIAGNOSTICS MENU

Self test results

RAM test:

Power supply test:

HOME ESCAPE INFO

TEST

SELFTEST (3)

SELFTEST (4)

F

IGURE

3-8. S

ELF TEST RESULTS MENU

Descriptions of the tests performed follow:

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

3-5

Page 42

TARTUP AND OPERATION

S

RAM T

EST

Checks the RAM on the Analysis Computer PCB.

OWER SUPPLY TEST

P

Verifies that all internal DC voltages are within the required tolerances.

The self-test can be repeated at any time by activating the TEST softkey in the

Self Test Results menu.

7. Introduce the remaining supply gases. Perform leak check. (See Specifications

page(s) in the Preface section of this manual)

8. Set and verify the internal gas pressures.

9. Allow the block to warm up to 50°C, approximately 30 minutes.

10. Note the six LED’s on the front panel of the Analyzer Module. They provide

necessary information for proper ignition procedure. The LED’s, when

illuminated, denote the following information:

• Power - unit powered on

• Flame - Flame on. If the module is trying to light the flame, with fuel flowing

but no flame detected, the LED will flash.

• Block - Continuous illumination implies the block temperature is within 5 % of

its operating temperature setpoint ; otherwise the LED will blink. If the oven

temperature is too high the LED blinks at double speed.

F

IGURE

• Sample - Sample pressure is within ±15% capillary requirement.

• Ignite OK - The block temperature is ≥ 50°C allowing proper ignition to occur.

• Fuel/Air - Proper fuel and air conditions exist to support a flame. Fuel

pressure is between 400 and 675 hPa. Air pressure is between 800 and 1200

hPa. The ratio of fuel/air is between 35% and 65%. This light will not come on

until successful ignition.

Light Flame

DIGDIAG (5)

AUTOIGNITE

FUEL_FLOW

TIME_LEFT (2)

TIME_LEFT (1)

PRES_IS (3)

PRES_IS (2)

PRES_IS (1)

TEMP_IS (2)

FID-MSGE

3-9. L

Flame condition:

Auto-ignition:

Ignition system enable:

Number of ignition attempts so far:

Time on this cycle – secs:

Fuel supply pressure:

Burner air pressure:

Sample pr essure:

Flame temperature:

Status:

HOME ABORT LIGHT INFO

IGHT FLAME MENU

3-6

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

Page 43

TARTUP AND OPERATION

S

11. Auto-ignite the flame. The Flame LED should then be continuously illuminated

when the flame is successfully lit.

Auto-ignition provides fuel override and three attempted ignitions (default setting),

if necessary.

Before ignition and operation, Fuel Flow must be set to ON in "Light Flame"

display screen under Basic Controls.

The front panel ignition switch must be manipulated in the following ways:

a. Press up and hold for 30 seconds. This puts the system into the enriched

mode, with lower air flow.

b. Press down to turn on the burner glow plug for up to 10 seconds.

c. Repeat as necessary (if fuel and air sources are farther away than 10 feet,

several more attempts may be necessary).

Flame on is defined as true when the flame temperature is greater than the

block temperature by the amount contained in the variable FLAME_DELTA.

d. If the flame has been lit, but the flame temperature increases slowly, perform

the following steps:

1) After igniting flame, wait for 2 seconds.

2) Press switch down momentarily.

3) Repeat release switch, wait and press down steps as necessary.

12. Check and re-adjust the internal pressures if required. The Fuel/Air light must be

lit for proper operation.

13. The unit is now ready for first binding as described in Section 3.5, and then

optimization as described below.

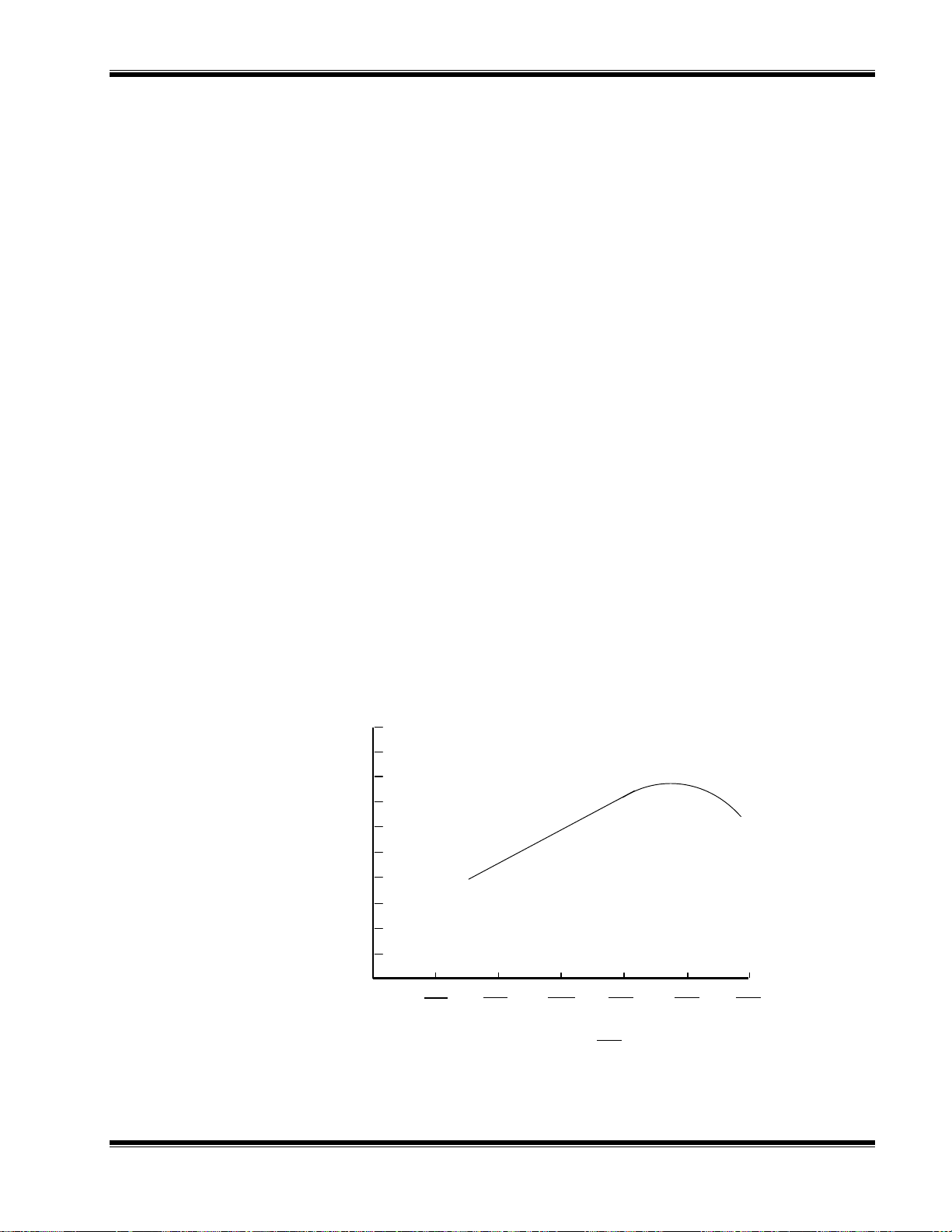

1.0

0.8

RESPONSE

(100 ppm CH

fullscale)

4

0.6

0.4

0.2

SAMPLE: 100 ppm CH4 in N

FUEL: 10 psig (690 hPa) H

AIR: 18 psig (1242 hPa)

0

0

2

13.76

3

20.64

SAMPLE PRESSURE

4

27.52

34.4

psig

hPa

5

6

41.28

2

2

7

48.16

F

IGURE

748364-D Rosemount Analytical November 1998

3-10. T

S

AMPLE PRESSURE REGULATOR

YPICAL CURVES OF MODULE RESPONSE VS

. P

RESSURE SETTING ON

NGA 2000 FID 2 Analyzer Module

3-7

Page 44

TARTUP AND OPERATION

psig (

A

)

A

)

A

)

S

1.0

0.8

F

IGURE

RESPONSE

(100 ppm CH

3-11. T

F

UEL PRESSURE REGULATOR

0.6

fullscale )

4

0.4

SAMPLE: 100 ppm CH4 in N

0.2

0

0

FUEL PRESSURE

YPICAL CURVES OF MODULE RESPONSE VS

1.0

FUEL: 10

0.8

FUEL: 7.5 psig (518 hPa) H

IR: 18 psig (1242 hPa

IR: 14 psig (966 hPa

IR: 10 psig (690 hPa

2

at 5 psig (344 hPa)

5

345

7.5

518

psig

hPa

. P

RESSURE SETTING ON

690 hPa) H

2

2

10

690

F

IGURE

3-8

RESPONSE

(100 ppm CH

3-12. T

A

IR PRESSURE REGULATOR

FUEL: 5 psig (345 hPa) H

SAMPLE: 100 ppm CH4

14

AIR PRESSURE

20

1376

4

fullscale)

0.6

0.4

0.2

0

0

10

690

966

YPICAL CURVES OF MODULE RESPONSE VS

November 1998 Rosemount Analytical 748364-DNGA 2000 FID 2 Analyzer Module

2

2

at 5 psig (344 hPa)

psig

hPa

. P

RESSURE SETTING ON

in N

Page 45

TARTUP AND OPERATION

S

3.4 OPTIMIZATION PROCEDURE

Although the module has been set up for best operation at the factory, settings can

change and your application may be different. The following shows how to optimize

the operation of the FID 2 for your application.

1. Ignite the flame of the FID 2 using the startup procedure as above.

2. Verify that the mixed fuel supply pressure at the Analyzer’s rear panel bulkhead is

between 49 and 50 psig.

3. Allow the Analyzer module response to stabilize. Typically allow 1 to 4 hours.

4. Select the desired range to optimize. For best results use a span gas with a

concentration of 100 ppm CH4 or greater. This will minimize the effects of the

THC contamination in the fuel and burner air supply.

5. Set the internal sample pressure to the desired operating level. The sample

pressure must be kept constant throughout the optimization procedure.

6. Set the internal burner air pressure to between 965 to 1103 hPa-gauge (14 to 16

psig). The burner air pressure must be kept constant throughout the optimization

procedure.

7. Set the internal fuel pressure to 345 hPa-gauge (5 psig). Calibrate the instrument

as stated below.

8. Introduce the span gas and monitor the reading until it is stable. Increase the

internal fuel supply setting in the following sequence: 600 hPa-gauge (8.7 psig),

625 hPa-gauge (9.1 psig), 650 hPa-gauge (9.4 psig), 675 hPa-gauge (9.8 psig),

700 hPa-gauge (10.1 psig), and 725 hPa-gauge (10.5 psig). Monitor the reading

at each fuel pressure setting. Wait at least 2 minutes between fuel setting

changes. Record all the readings.

9. Review the readings for each fuel pressure setting. Select the fuel pressure

setting that produces a reading that is within 1% from the maximum. For this

condition the FID 2 is operating at its optimized plateau.

3.5 BINDING

To achieve full coordination between Analyzer Modules and associated I/O Modules,

the user must bind those components together in the System Set Up portion of the

Technical Configuration Menu in software. (See the Platform manual for binding

instructions.)

Note

If binding is attempted after ignition, the flame may be extinguished. If this

occurs, it must be re-ignited.

748364-D Rosemount Analytical November 1998

NGA 2000 FID 2 Analyzer Module

3-9

Page 46

TARTUP AND OPERATION

S

3.6 CALIBRATION

See Section 2.4.2 for a description of the method for choosing calibration zero and

span gases.

Menus used for calibration include the following:

F

IGURE

3-13. T

Zero gas – range 1:

Calibration gas list

Span gas – range 1:

Zero gas – rang e 2:

Span gas – range 2:

Zero gas – rang e 3:

Span gas – range 3:

Zero gas – rang e 4:

Span gas – range 4:

Calibrati o n gas HC response fact o r:

Calibration. . .

HOME ESCAPE INFO

YPICAL CALIBRATION GAS LIST MENU

Zero/span calib rat io n

Measurem en t range number:

Zero gas concentration:

Span gas co ncentration:

Bypass sample flow:

Flame condition:

Raw measurement signal:

Status:

Result. . .

Calibration adjustment limits:

HOME FACTORS ZERO SPAN INFO

ZEROGAS (1)

SPANGAS (1)

ZEROGAS (2)

SPANGAS (2)

ZEROGAS (3)

SPANGAS (3)

ZEROGAS (4)

SPANGAS (4)

CARBON_ATOMS

CRANGE

CURRENTZERO

CURRENTSPAN

FLOW_IS (1)

DIGDIAG (5)

RAW_SIGNAL

CALSTAT

CALCHKLIMITS

F

IGURE

F

IGURE

3-10

3-14. Z

3-15. C

ERO AND SPAN CALIBRATION MENU

Calibration parame t e rs

Calibration adjustment limits:

Calibration averaging time:

Calibration failure alarm:

Cal failure erro r al lowed: