Page 1

NGA 2000

F

LAME IONIZATION

A

NALYZER

D

ETECTION

M

ODULE

Rosemount Analytical

Page 2

N

OTICE

HE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE

T

.

OSEMOUNT ANALYTICAL'S

R

UNDER

Teflon® is a registered trademark of E.I. duPont de Nemours and Co., Inc.

Kynar® is a registered trademark of Pennwalt, Inc.

U.S. P

ATENT

NGA 2000

5.787.015.

SYSTEM OF MODULAR GAS ANALYZERS AND CONTROLLERS ARE PATENTED

,

Manual Part Number 748331-E

November 1998

Printed in U.S.A.

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

Page 3

C

ONTENTS

P

REFACE

PURPOSE/SAFETY SUMMARY........................................................................P-1

GLOSSARY ......................................................................................................P-4

SPECIFICATIONS - GENERAL..........................................................................P-7

SPECIFICATIONS - GAS REQUIREMENTS .....................................................P-8

SPECIFICATIONS - PHYSICAL.........................................................................P-9

SPECIFICATIONS - GAS CONNECTIONS........................................................P-9

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE ....P-10

RETURNING PARTS TO THE FACTORY .........................................................P-10

TRAINING ......................................................................................................P-10

DOCUMENTATION............................................................................................P-10

COMPLIANCES..................................................................................................P-11

S

ECTION

1.1 OVERVIEW ..............................................................................................1-1

1.2 TYPICAL APPLICATIONS........................................................................1-1

1.3 THEORY OF TECHNOLOGY...................................................................1-1

1.4 GAS SAFETY FEATURES.......................................................................1-3

1.5 FUEL GAS OPTION .................................................................................1-3

S

ECTION

2.1 UNPACKING.............................................................................................2-1

2.2 ASSEMBLY...............................................................................................2-1

2.3 LOCATION ...............................................................................................2-2

2.4 GASES .....................................................................................................2-3

1. I

2. I

2.4.1 Overview.....................................................................................2-3

NTRODUCTION

NSTALLATION

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

i

Page 4

C

ONTENTS

2.4.2 Connections................................................................................2-4

2.4.3 Specifications .............................................................................2-5

2.4.4 Leak Test....................................................................................2-7

2.5 ELECTRICAL CONNECTIONS................................................................2-7

S

ECTION

3.1 OVERVIEW..............................................................................................3-1

3.2 DISPLAYS................................................................................................3-1

3.3 RUN MODE DISPLAY..............................................................................3-1

3.4 MENU DISPLAYS....................................................................................3-1

3.5 HELP DISPLAYS .....................................................................................3-2

3.6 STARTUP PROCEDURE.........................................................................3-6

3.7 BINDING ..................................................................................................3-9

3.8 CALIBRATION .........................................................................................3-9

3.9 ROUTINE OPERATION...........................................................................3-10

3.10 SAFETY SYSTEM....................................................................................3-11

S

ECTION

4.1 BURNER DISASSEMBLY AND CLEANING.............................................4-1

4.2 COMPONENT REPLACEMENT...............................................................4-3

3. S

4. M

TARTUP AND OPERATION

AINTENANCE AND TROUBLESHOOTING

4.3 BURNER STARTUP TROUBLESHOOTING ...........................................4-3

S

ECTION

5.1 REPLACEMENT PARTS ..........................................................................5-1

A

PPENDIX

ENERAL PRECAUTIONS FOR HANDLING

G

ARRANTY

W

IELD SERVICE AND REPAIR FACILITIES

F

5. R

5.1.1 Electronics..................................................................................5-1

5.1.2 Electro-Mechanical.....................................................................5-1

5.1.3 O-Rings and Gaskets.................................................................5-1

5.1.4 Burner Assembly and Components............................................5-2

5.1.5 Pneumatics.................................................................................5-2

EPLACEMENT PARTS

A. FID I

DENTIFICATION MATRIX

TORING HIGH PRESSURE CYLINDERS

& S

ii

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 5

F

IGURES

1-1 Flame Ionization Detection Technology....................................................1-1

1-2 NGA 2000 Flame Ionization Detection Module - Top View.......................1-2

2-1 Analyzer Module Installation Into Platform ...............................................2-1

2-2 Back Panel Connections...........................................................................2-2

2-3 FID Module Flow Diagram........................................................................2-4

2-4 Front Panel Connections, Controls and Indicators...................................2-5

2-5 Outline and Mounting Dimensions............................................................2-8

2-6 FID Wiring Diagram..................................................................................2-9

3-1 Run Mode Display....................................................................................3-2

3-2 Main Menu Display...................................................................................3-2

3-3 Basic Controls Menu Display....................................................................3-3

3-4 Expert Controls and Setup Menu Display.................................................3-3

3-5 Technical Configuration Menu Display.....................................................3-3

3-6 Typical Help Screen..................................................................................3-4

3-7 Typical Curves of Module Response vs. Pressure Setting on Sample

Pressure Regulator........................................................................3-5

3-8 Typical Curves of Module Response vs. Pressure Setting on Fuel

Pressure Regulator........................................................................3-5

3-9 Typical Curves of Module Response vs. Pressure Setting on Air

Pressure Regulator........................................................................3-6

3-10 Front Panel Torquing Sequence...............................................................3-12

3-11 Display Screens (1 of 5)...........................................................................3-13

3-12 Display Screens (2 of 5)...........................................................................3-14

3-13 Display Screens (3 of 5)...........................................................................3-15

3-14 Display Screens (4 of 5)...........................................................................3-16

3-15 Display Screens (5 of 5)...........................................................................3-17

4-1 FID Burner Assembly................................................................................4-2

C

ONTENTS

T

ABLES

1-1 Analyzer Characteristics Relative to Fuel Gas...........................................1-5

3-1 FID Analyzer Module Alarms....................................................................3-4

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

iii

Page 6

C

ONTENTS

N

OTES

iv

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 7

P

REFACE

P

URPOSE/SAFETY SUMMARY

The purpose of this manual is to provide information concerning the components,

functions, installation and maintenance of this particular NGA 2000 module.

Some sections may describe equipment not used in your configuration. The user

should become thoroughly familiar with the operation of this module before operating

it. Read this instruction manual completely.

To avoid explosion, loss of life, personal injury and damage to this equipment

and on-site property, all personnel authorized to install, operate and service this

equipment should be thoroughly familiar with and strictly follow the instructions

in this manual. Save these instructions.

If this equipment is used in a manner not specified in these instructions,

protective systems may be impaired.

DANGER

personal injury, death, or substantial property damage if the warning is ignored.

WARNING

personal injury, death, or substantial property damage if the warning is ignored.

CAUTION

personal injury or property damage if the warning is ignored.

NOTE

important but not hazard-related.

is used to indicate the presence of a hazard which

is used to indicate the presence of a hazard which

is used to indicate the presence of a hazard which

is used to indicate installation, operation or maintenance information which is

will

cause

can

cause

will or can

cause

severe

severe

minor

WARNING: ELECTRICAL SHOCK HAZARD

Operate this equipment only when covers are secured. Servicing requires

access to live parts which can cause death or serious injury. Refer servicing to

qualified personnel.

For safety and proper performance, this module must be connected to a

properly grounded three-wire source of electrical power.

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

P-1

Page 8

P

REFACE

WARNING: POSSIBLE EXPLOSION HAZARD

This equipment is used in the analysis of sample gases which may be

flammable, and the burner fuel used in the ionization process is flammable. A

continuous dilution purge system is factory-installed (in accordance with

Standard ANSI/NFPA 496-1993, Chapter 6, and it must be functional at all times

during operation. DO NOT DISABLE THIS PURGE SYSTEM.

WARNING: FLAMMABLE SAMPLES

Consult the factory if flammable samples will be measured.

WARNING: PARTS INTEGRITY

Tampering with or unauthorized substitution of components may adversely

affect safety of this product. Use only factory-approved components for repair.

WARNING: POSSIBLE EXPLOSION HAZARD

Ensure that all gas connections are made as labeled and are leak free. Improper

gas connections could result in explosion and death.

CAUTION: PRESSURIZED GAS

This module requires calibration with a known standard gas. See General

Precautions for Handling and Storing High Pressure Gas Cylinders at the rear of

this manual.

CAUTION: OVERBALANCE HAZARD

This Analyzer Module may tip instrument over if it is pulled out too far and the

Platform is not properly supported.

P-2

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 9

P

REFACE

CAUTION: HAND INJURY HAZARD

Dropping the front panel of the Platform while hand or fingers are inside either

case handle can cause serious injury.

CAUTION: PURGE AIR REQUIREMENT

This Analyzer Module must be used in conjunction with a device (Platform or PC

Interface) that can actively monitor network variables related to pressure or flow

of the continuous dilution purge, or the front panel LEDs of the Analyzer

Module, as installed, must be visible. The purpose of this requirement is to

maintain adherence to ANSI/NFPA 496 standard which assures the continued

viability of the purge system. Under no circumstances should any pressure or

flow indicator be connected to the PURGE AIR OUT outlet of the Analyzer

Module because this may affect the sealing performance of the module.

CAUTION: OVER-VOLTAGE SPIKING

If this Analyzer Module is used with a non-Rosemount Analytical power supply,

adding Rosemount P/N 903341 Current Protector in series with the 24 V positive

power line will prevent over-voltage spiking and resultant fuse blowing when

powering up the instrument.

Note

This Analyzer Module is completely leak-tested at the factory for gas leakage.

The user is responsible for testing for leakage at the inlet and outlet fittings on

the rear panel (with a test procedure chosen by the user). The user is also

responsible for leak-testing periodically and if any internal pneumatic

components are adjusted or replaced. See leak test instructions in section 2.4.4.

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

P-3

Page 10

P

REFACE

G

LOSSARY

NALYZER MODULE

A

The module that contains all sensor/detector components for development of a

Primary Variable signal; includes all signal conditioning and temperature control

circuitry.

ACKPLANE

B

The interconnect circuit board which the Controller Board, Power Supply, Analyzer

Module power and network cables, I/O Modules and Expansion Modules plug into.

ONTROL MODULE

C

The Operator Interface plus the Controller Board.

ONTROLLER BOARD

C

The computer board that serves as the Network Manager and operates the Display

and Keypad.

ISTRIBUTION ASSEMBLY

D

The Backplane and the card cages that hold I/O and Expansion Modules.

XPANSION MODULE

E

A circuit board that plugs into the Backplane from the front of the Platform and

performs special features not related to I/O functions.

I/O M

A circuit board that plugs into the Backplane from the rear of the Platform. Has a

connector terminal for communication with external data acquisition devices and

provides an input/output function.

O

The Display and Keyboard.

P

Any workable collection of the following: Controller Board, Power Supply, Distribution

Assembly, Enclosure and Operator Interface.

P

ODULE

PERATOR INTERFACE

LATFORM

OWER SUPPLY

Any of a variety of components that provides conditioned power to other NGA 2000

components, from the Power Supply Board that plugs into the front of the Backplane

in a stand-alone instrument to several larger ones that can power larger collections of

modules and components.

P-4

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 11

P

REFACE

RIMARY VARIABLE

P

The measured species concentration value from an Analyzer Module.

ECONDARY VARIABLE

S

Data placed on the network by a module regarding current status, e.g., sample flow,

source voltage and other diagnostic information.

OFTKEYS

S

The five function keys located below the front panel display; they assume the function

displayed directly above each on the display, a function dictated by software.

YSTEM

S

Any collection of Analyzer Module(s), Platform(s), I/O Module(s) and Expansion

Module(s).

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

P-5

Page 12

P

REFACE

N

OTES

P-6

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 13

P

REFACE

S

PECIFICATIONS

M

EASUREMENT SPECIES

R

ANGES

H2/H

E FUEL

H2

FUEL OPTION

R

EPEATABILITY

M

INIMUM DETECTABLE LEVEL

N

OISE

L

INEARITY

R

ESPONSE TIME

CEMS

ICEE

Z

ERO DRIFT

S

PAN DRIFT

E

FFECT OF TEMPERATURE

O

PERATING TEMPERATURE

P

OWER REQUIREMENTS

- G

ENERAL

Total hydrocarbons

0 to 100 ppm (output scalable down to 0-2 ppm fullscale)

low range: 0 to 4 ppm CH4, through 0 to 1% CH

high range:: 0 to 50 ppm CH4, through 0 to <5% CH

low range: 0 to 1 ppm CH4, through 0 to 2500 ppm CH

high range:: 0 to 10 ppm CH4, through 0 to 2% CH

1% of fullscale at a constant temperature, sample flow and fuel, burner

≤

4

4

4

4

air and sample pressure

0.04 ppm H2/He fuel

0.01 ppm H2 fuel

1% of fullscale, peak to peak

≤

1% of fullscale for H2/He fuel and He fuel

≤ ±

30 sec. For 10% to 90% of fullscale, with sample bypass flow at 0.5

≤

L/min. (non-flammable sample)

1 sec. For 10% to 90% of fullscale, with sample bypass flow at 0.5

≤

L/min. (non-flammable sample)

1% of fullscale/24 hours at constant temperature, hydrocarbon

≤ ±

concentration of supply gases, sample flow and fuel, burner air and

sample pressure

1% of fullscale/24 hours at constant temperature, hydrocarbon

≤ ±

concentration of supply gases, sample flow and fuel, burner air and

sample pressure

2% of fullscale for any temperature change of 10°C and rate of

≤ ±

change less than 10°C/hour

32°F to 113°F (0°C to 45°C)

+24 VDC ±5%, 120 W max.. direct to analyzer module;

Ripple and Noise: <100 mV peak to peak

Line and Load Regulations: <±1%

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

P-7

Page 14

P

REFACE

S

PECIFICATIONS

B

URNER AIR

F

LOW RATE

THC

S

UPPLY PRESSURE

F

UEL GAS (STANDARD

F

LOW RATE

THC

S

UPPLY PRESSURE

Unless this Analyzer Module is factory- or field-configured specifically for

using 100% hydrogen fuel, DO NOT USE PURE HYDROGEN FUEL. An

explosion resulting in severe personal injury or death could occur. Also,

each Analyzer Module is factory-configured for either mixed or pure

hydrogen fuel, and cannot use the fuel for which it was not configured

unless field reconfiguration is done.

- G

AS REQUIREMENTS

Zero-grade air

350 to 400 ml/min

ppm, CH

≤

4

1725 to 3450 hPa-gauge (25 to 50 psig)

)

Premixed 40% hydrogen and 60% helium

75 to 80 ml/min.

0.5 ppm, CH

≤

4

2415 to 3450 hPa-gauge (35 to 50 psig)

WARNING: POSSIBLE EXPLOSION HAZARD

F

UEL GAS

S

AMPLE

P

URGE AIR

(H

OPTION

2

F

LOW RATE

THC

S

UPPLY PRESSURE

F

LOW RATE

THC

S

UPPLY PRESSURE

T

EMPERATURE

P

ARTICULATES

D

EWPOINT

F

LOW RATE

S

UPPLY PRESSURE

)

Zero-grade hydrogen

35 to 40 ml/min.

0.5 ppm, CH

≤

4

2415 to 3450 hPa-gauge (35 to 50 psig)

Non-flammable (below 100% of LEL)

0.5 to 40 ml/min.

0.5 ppm, CH

≤

4

483 to 1035 hPa-gauge (7 to 15 psig)

32°F to 132°F (0°C to 55°C), <20°C variance/24 hours,

<10°C variance/hour

Filtered to <2 microns

<45°C

Instrument air, nitrogen or other non-flammable gas (refer

to ANSI/NFPA 496 for the requirements for the Protective

Gas System)

16 to 18 L/min.

689 to 1378 hPa-gauge (10 to 20 psig)

P-8

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 15

P

REFACE

S

PECIFICATIONS

M

ATERIALS IN CONTACT

WITH SAMPLE

D

IMENSIONS

W

EIGHT

M

OUNTING

C

ASE CLASSIFICATION

MAX. S

FROM PLATFORM

S

PECIFICATIONS

S

B

F

UEL IN

P

P

B

B

P

V

EPARATION

AMPLE IN

URNER AIR IN

URGE AIR IN

URGE AIR OUT

YPASS OUT

URNER EXHAUST OUT

RESSURE RELIEF

ALVE

- P

HYSICAL

Stainless steel, Teflon, glass-filled Teflon, brass, neoprene,

Kynar

See Figure 2-5, Outline and Mounting Dimensions

10.43 kg (23 lbs.)

Horizontal, inside a Platform or custom installed in a panel

General Purpose for installation in weather protected area

1600 m (1 mile)

- G

AS CONNECTIONS

1/4 inch O.D. tube fitting

1/4 inch O.D. tube fitting

1/4 inch O.D. tube fitting

3/8 inch O.D. tube fitting

3/8 inch O.D. tube fitting

1/4 inch O.D. tube fitting

1/2 inch O.D. tube connection, tygon or equivalent (this

connection shall slope downward 6° minimum from

horizontal)

CAUTION: PRESSURE RELIEF

See the Preface Section of the Platform manual for specifications regarding Platform

related components.

748331-E Rosemount Analytical November 1998

VALVE RESTRICTION

No connection shall be made to this fitting. If this

caution is ignored, damage to the case seals may occur,

and the instrument will not operate properly.

NGA 2000 Flame Ionization Detection Module

P-9

Page 16

P

REFACE

C

USTOMER SERVICE

For order administration, replacement Parts, application assistance, on-site or factory

repair, service or maintenance contract information, contact:

R

ETURNING PARTS TO THE FACTORY

Before returning parts, contact the Customer Service Center and request a Returned

Materials Authorization (RMA) number. Please have the following information when

you call:

Number.

Prior authorization by the factory must be obtained before returned materials will be

accepted. Unauthorized returns will be returned to the sender, freight collect.

When returning any product or component that has been exposed to a toxic, corrosive

or other hazardous material or used in such a hazardous environment, the user must

attach an appropriate Material Safety Data Sheet (M.S.D.S.) or a written certification

that the material has been decontaminated, disinfected and/or detoxified.

Model Number, Serial Number, and Purchase Order Number or Sales Order

, T

ECHNICAL ASSIST ANCE AND FIELD SERVICE

Rosemount Analytical Inc.

Process Analytical Division

Customer Service Center

1-800-433-6076

Return to:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

T

RAINING

A comprehensive Factory Training Program of operator and service classes is

available. For a copy of the

the Technical Services Department at:

D

OCUMENTATION

The following NGA 2000 Flame Ionization Detection Module instruction materials are

available. Contact Customer Service or the local representative to order.

748331 Instruction Manual (this document)

Current Operator and Service Training Schedule

Rosemount Analytical Inc.

Phone: 1-714-986-7600

FAX: 1-714-577-8006

contact

P-10

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 17

C

9

6

OMPLIANCES

This product may carry approvals from several certifying agencies, including Factory

Mutual and the Canadian Standards Association (which is also an OSHA accredited,

Nationally Recognized Testing Laboratory), for use in non-hazardous, indoor locations

P

REFACE

FM

APPROVED

Rosemount Analytical Inc. has satisfied all obligations from the European

Legislation to harmonize the product requirements in Europe.

This product complies with the standard level of NAMUR EMC.

Recommendation (May 1993).

This product satisfies all obligations of all relevant standards of the EMC framework in

Australia and New Zealand.

®

97-C219

NAMUR

N

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

P-11

Page 18

P

REFACE

N

OTES

P-12

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 19

I

NTRODUCTION

1

1.1 OVERVIEW

This manual describes the Flame Ionization Detector (FID) Analyzer Module of

Rosemount Analytical's NGA 2000 Series of gas analysis components. See Figures

1-1 and 1-2.

The FID Analyzer Module is designed to continuously determine the concentration of

hydrocarbons in a flowing gaseous mixture. The concentration is expressed in

parts-per-million or percent of volume.

The entire FID Analyzer Module is designed as a slide-in module (if configured in

stand-alone instrument fashion), removable from the front of the Platform, with gas

connections made from the rear. All electronics relative to sample detection and

conditioning are included in this module.

1.2 TYPICAL APPLICATIONS

The monitoring of atmospheric air for low-level hydrocarbon contaminants and

determining the hydrocarbon content of exhaust emissions from internal combustion

engines are examples of typical applications for the FID Analyzer Module.

1.3 THEORY OF TECHNOLOGY

This Analyzer Module uses the flame

ionization method of detection. The sensor is

a burner in which a regulated flow of sample

gas passes through a flame sustained by

regulated flows of a fuel gas (hydrogen or a

hydrogen/diluent mixture) and air.

Within the flame, the hydrocarbon

components of the sample stream undergo a

complex ionization that produces electrons

and positive ions. Polarized electrodes

collect these ions, causing current to flow

through an electronic measuring circuit.

Negative Ion

Collection

Ring

+90V

Sample

F

IGURE

1-1. F

D

LAME IONIZATION

ETECTION

Signal

Conditioning

Positive

Carbon

Ions

Air

Fuel

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

1-1

Page 20

NTRODUCTION

I

The ionization current is proportional to the rate at which carbon atoms enter the

burner, and is therefore a measure of the concentration of hydrocarbons in the

sample. This measure of concentration is placed on the network, where it is can be

shown on the Platform Display or on other data acquisition devices.

Gas Lines

(See Figure 2-2)

Purge Air

Fuel Shutoff

Solenoid Valve

Pressure Regulator

Capillary

Case Heater Silicon

Pad (On Base)

Purge Air Flow Switc h

Fuel Pressure Sensor

Air Pressure Sensor

Ignite/Operate Mode

Burner-Air Flow

Solenoid Valve

Air Circulation Fan

Purge Air

Heater Cartridge

Sample Press u re

Sensor

Purge Air Outlet

Pressure Switch

Preamp Board

(In Shield)

Detector (Burner)

Computer Board

Sample Bypass

Flow Sensor

DC-DC Converter

Safety Board

Burner Air

and Fuel

Regulators

(Stacked Vertically)

Sample Back Pressure Regulators

F

IGURE

1-2. NGA 2000 F

1-2

Manual Ignite Switch

LAME IONIZATION DETECTION MODULE

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Power Supply Board

Network & Power Module

- T

OP VIEW

Page 21

1.4 GAS SAFETY FEATURES

The FID Analyzer Module is designed with a factory installed continuous dilution purge

system in accordance with standard ANSI/NFPA 496 - 1993, Chapter 6. Front-panel

LEDs indicate that the burner flame is lit and that the purge system is enabled. In

addition, fuel gas is automatically shut off when a flame-out condition occurs or the

safety system is disabled.

The purge system is enabled only if there is proper purge gas flow in, purge gas

pressure, and internal case pressure, and after five times the case volume has been

exchanged.

All tubing ahead of the burner is rigid metallic tubing assembled with ferrule/nut type

compression fittings. However, should an internal fuel leak occur, a worst-case leak

would be dissipated below 25% of the LEL of hydrogen through the combination of an

inlet fuel flow restrictor and purge gas flow.

NTRODUCTION

I

This module is designed to use 100% hydrogen fuel or 40% H

2

/60% He fuel at a

maximum inlet pressure of 3446 hPa-gauge (50 psig). A different flow restrictor is

used for each fuel type.

A standard FID Analyzer Module is only equipped to analyze a non-flammable

sample, below 100% of the LEL.

WARNING: POSSIBLE EXPLOSION HAZARD

Protection against explosion depends upon a special fuel flow restrictor in the

fuel inlet fitting. Do not remove fuel inlet restrictor. Use the correct fuel flow

restrictor for the fuel being used. Do not use 100% hydrogen fuel in a 40%

H2/60% He configured Analyzer Module. Replace only with factory supplied

fitting.

1.5 FUEL GAS OPTION

The standard FID Analyzer Module requires 40% hydrogen/60% helium burner fuel

gas. As an option, the analyzer module can be equipped to use 100% hydrogen fuel.

The particular application and characteristics of the sample gas to be measured will

dictate the preferred type of fuel. The following guidelines can be used f or determining

fuel gas type:

1. For measuring low-level hydrocarbons in ambient air or in other sample gas with

relatively constant oxygen content, 100% hydrogen is preferable. It provides the

highest obtainable sensitivity and maximum stability. Zero drift caused by ambient

temperature variations of the fuel cylinder is somewhat lower for 100% hydrogen

than for mixed fuel. (With either fuel, it is desirable to maintain a constant cylinder

temperature.)

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

1-3

Page 22

NTRODUCTION

I

2. For monitoring internal combustion exhaust emissions or other sample gas with

varying oxygen content, mixed fuel is preferable. In fact, a hydrogen/helium mixture

is more desirable than a hydrogen/nitrogen mixture. With this type of sample, the

use of mixed fuel gas minimizes the error introduced by oxygen synergism.

An effective way to reduce the effect of internal oxygen is to dilute it with an inert gas.

This can be accomplished with a constant dilution of sample and calibration gases

upstream from the burner. But it is simpler and more accurate to provide that diluent in

the form of premixed fuel. Both nitrogen and helium have been used as a diluent, but

helium has proven to be most effective in improving the quality of response to the

various species of hydrocarbons.

As indicated earlier the flame output signal is optimum when the ratio of hydrogen flow

to inert flow is about 40/60. Therefore, this is the chosen composition for

hydrogen/helium premixed fuel.

The sample flow is kept low to maximize the dilution effect while still providing

adequate sensitivity. The burner air flow is normally about four times the fuel flow, and

changes have little effect on signal strength. For a given flow, the signal can be

optimized by adjusting the fuel flow rate.

Typical flow rates with premixed fuel:

Fuel 100 cc/min

Sample 7 cc/min

Air 400 cc/min

Note that with a 40/60 premixed fuel, the above flow rates amount to 40 cc (8%)

hydrogen, 67 cc (13%) inert plus sample and 400 cc (79%) air, which compare closely

to the 30 cc (8%) hydrogen, 45 cc (12%) inert/sample and 300 cc (80%) air noted

earlier for straight hydrogen fuel.

Since sample flow in the case of mixed fuel operation is only about 1/6 of that with

straight hydrogen fuel, higher sensitivity is obtained with the latter. However, in any

application where the sample contains more than one species of hydrogen and/or a

varying concentration of oxygen, mixed fuel is preferred.

The mixed fuel is recommended, not only for sample containing variable

concentrations of oxygen, but also for a specific pure gas application. If straight

oxygen samples are used with straight hydrogen fuel, the mixture entering the burner

is essentially 40% H2/60% O2, which tends to produce an unstable signal. The mixed

fuel works better. Note that the choice of fuel determines certain analyzer

characteristics, as shown in Table 1-1.

1-4

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 23

ANALYZER FUEL GAS

CHARACTERISTICS 100% H

FULLSCALE SENSITIVITY

FUEL CONSUMPTION

O

PERATING RANGE

1 ppm, CH4 to 2%, CH

35 to 40 cc/min 75 to 80 cc/min

276 to 345 hPa-gauge

2

(4 to 5 psig)

NTRODUCTION

I

40% H2/60% HE

4

4 ppm, CH4 to <5%, CH

4

207 to 345 hPa-gauge

(3 to 5 psig)

T

ABLE

1-1. A

NALYZER CHARACTERISTICS RELATIVE TO FUEL GAS

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

1-5

Page 24

NTRODUCTION

I

N

OTES

1-6

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 25

I

NSTALLATION

2

2.1 UNPACKING

If the FID Analyzer Module is received as a separate unit, carefully examine the

shipping carton and contents for signs of damage. Immediately notify the shipping

carrier if the carton or contents is damaged. Retain the carton and packing material

until all components associated with the Analyzer Module are operational.

2.2 ASSEMBLY

If the Analyzer Module requires assembly with other components (e.g., the Platform

and associated I/O Modules), do so at this time. Following the guides on the bottom

left and bottom center of the Platform, carefully slide the Analyzer Module halfway into

place.

CAUTION: HAND INJURY HAZARD

Do not place hands or fingers in Platform front handles when the front panel is

open. Dropping front panel while hand or fingers are inside either handle can

cause serious injury.

ANALYZER MODULE GUI DES

PIN SEATS

DISENGAGED FRONT PANEL

F

IGURE

2-1. A

NALYZER MODULE INSTALLATION INTO PLATFORM

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

2-1

Page 26

NSTALLATION

I

Lift the spring loaded pins on the front of the module, and carefully slide it the rest of

the distance. Secure the module in position by releasing the pins, which seat in the

available holes in the bottom of the case (see Figure 2-1). If the module and Platform

are difficult to assemble, remove the module, ensure the top cover of the module is

firmly seated on the hold down screws, and repeat the assembly procedure.

Connect the network cable to either the NETW ORK 1 or NETWORK 2 connection on

the Analyzer Module (see Figure 2-4), and the NETWORK connection on the

Backplane (see Platform manual). Connect the power cable to both the Analyzer

Module front panel and to the Backplane.

Install I/O Module(s) according to guidelines in the I/O manual. After startup and

calibration have been performed, secure the Front Panel with the six screws provided.

2.3 LOCATION

Install the Analyzer Module in a clean, weather-proofed, non-hazardous, vibration free

location free from extreme temperature variations. For best results, install the Analyzer

Module near the sample stream to minimize sample transport time.

MIXED

FUEL

IN

F

IGURE

2-2. B

PURGE

AIR OUT

SAMPLE

PRESSURE

RELIEF

VALVE

PURGE

AIR IN

ACK PANEL CONNECTIONS

BURNER

AIR IN

IN

BYPASS

OUT

VENT TO SAFE AREA

SLOPE DOWNWARD

6° MINIMUM

MAXIMUM INPUT PRESSURE

FUEL: 50 PSIG (3450 hPa)

BURNER AIR: 50 PSIG (3450 hPa)

SAMPLE: 15 PSIG (1035 hPa)

PURGE AIR: 20 PSIG (1378 hPa)

BURNER

EXHAUST

OUT

WARNING: INSTALLATION RESTRICTIONS

For safety, the Analyzer Module should be installed in a non-confined, ventilated

space. Do not block any of the rear panel outlets as they are part of the safety

system.

Operating ambient temperature is 0°C to 45°C, limited to temperature changes of less

than 10°C/hr. Acceptable dew point range is less than 95% relative humidity, but not in

excess of 45°C wet bulb temperature.

2-2

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 27

The cylinders of fuel, air, and calibration gas(es) and the source of purge air should be

located in an area of relatively constant ambient temperature.

2.4 GASES

NSTALLATION

I

2.4.1 O

VERVIEW

During normal operation, the Analyzer Module requires fuel and air to maintain the

burner flame as well as suitable standard gases for calibration and instrument air for

purge requirements. Criteria for selection of these gases follow in section 2.4.3.

After initial startup or after startup following a prolonged shutdown, the analyzer may

display baseline drift for a considerable period of time, particularly on the most

sensitive range. Commonly, the drift is caused by small amounts of hydrocarbons in

the inner walls of the tubing in both the internal flow system and the external gas

supply system. Drift results from any factor influencing the equilibrium of these

absorbed hydrocarbons, such as temperature or pressure.

Note that this type of drift occurs only when the flame is burning. If drift occurs when

the flame is extinguished, the electronic circuitry is at fault. To minimize drift, use clean

fuel and air, keep the analyzer clean, and locate the gas cylinders in an area of

relatively constant ambient temperature.

The cylinders supplying all gases each should be equipped with a clean, hydrocarbon

free, two stage regulator and a shutoff valve.

All new external gas tubing (except for PURGE IN/OUT and SAMPLE BYPASS) is strongly

recommended, preferably pre-cleaned, stain-less steel, gas chromatograph grade tubing.

Thoroughly clean before use. if a hydrocarbon based cleaning solvent such as acetone is

used, purge tubing with dry nitrogen or helium for several minutes before using.

Gas line connections are compression fittings. Do not use pipe thread tape.

Since the oxidation of hydrogen is accompanied by the formation of water vapor, the

Exhaust tubing always should be slanted downward at least 6 degrees from horizontal.

Otherwise, water may accumulate in the line, causing back pressure and noisy

readings, or may back up in the line and flood the burner.

If the sample is toxic or noxious, or is to be reclaimed, connect the Bypass outlet to a

suitable disposal system. Do not use any device that may cause back pressure in the

line.

Purge air and burner air should be supplied from separate sources.

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

2-3

Page 28

NSTALLATION

I

2.4.2 C

BURNER

EXHAUST

OUT

REGULATOR

Restrictor

ONNECTIONS

Reference Figure 2-2. Connect inlet and outlet lines for sample, burner fuel and air,

exhaust, bypass, and purge to appropriately labeled fittings on the rear panel. All

connections are 1/4 inch ferrule type compression fittings except the PURGE AIR IN

and OUT connections, which are 3/8 inch compression fittings. The BURNER

EXHAUST OUT is a 1/2 inch connection. Burner exhaust, bypass and purge air out

must be vented at atmospheric pressure to a non-classified location in accordance

with ANSI/NFPA-496.

Bulkhead

3/8T

Brass

PURGE AIR

Plug

1/4MPT

Brass

Run Tee

1/4T - 1/8MPT

Brass

Tubing, Teflon

1/4” OD

PURGE

FLOW

SWITCH

Tubing, Copper

1/4” OD

Union

1/4T

Brass

Diffuser

Tubing, SS

3/8” OD

PURGE

AIR

HEATER

PURGE AIR

IN

Elbow

3/8T - 1/4MPT

Brass

Tubing, Viton

1/4” OD

PURGE

PRESS

SENSOR

Elbow

1/4T - 1/4MPT

Kynar

SAMPLE

PRESS

SENSOR

Elbow

1/8T - 1/4MPT

SS

SAMPLE

IN

CAPILLARY

Branch Tee

1/8T - 1/8FPT

SS

SAMPLE

BACK PRESS

REGULATOR

SAMPLE

Elbow

1/8T - 1/8MPT

Kynar

Connector

1/8T - 1/8MPT

Kynar

BYPASS

OUT

Bulkhead Reducer

1/4T - 1/8T

Brass

FLOW

SENSOR

Tubing,

Teflon

1/8” OD

Elbow

1/8T - 1/4MPT

SS

BURNER

AIR IN

Tubing,

Teflon

1/8” OD

BURNER

AIR PRESSURE

REGULATOR

Connector

1/8T - 3/8MPT

SS

Filter

Bulkhead Reducer

1/4T - 1/8T

SS

GA

IN OUT

BURNER

AIR

PRESS

SENSOR

Bulkhead

3/8T - 1/4MPT

Brass

COM

3-WAY

VALVE

NO

Air

Measurement

Restrictor

1/8T - 1/8MPT

SS

PURGE AIR

Run Tee

1/4T - 1/4FPT

Brass

Connector

1/8T - 1/8MPT

SS

Air Ignite

Restrictor

1/8T - 1/8MPT

SS

NC

Run Tee

1/8T - 1/8MPT

SS

Bulkhead Connector

OUT

1/4T - 1/8NPT

SS

Purge Exit

Restrictor

BURNER

Fuel Restrictor

Tubing,

Viton

1/4” OD

PRESS

SW

Connector

1/16T - 1/8MPT

SS

Fuel Restrictor

MIXED FUEL

IN

SOLENOID

VALVE

Connector

1/8T - 1/8MPT

SS

GA

IN OUT

FUEL

PRESS

SENSOR

FUEL

PRESSURE

REGULATOR

Connector

1/8T - 3/8MPT

SS

F

IGURE

2-3. FID M

ODULE FLOW DIAGRAM

2-4

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 29

NSTALLATION

A

A

I

F

IGURE

2-4. F

BURNER

AIR

FUEL

WARNING

!

TTENTIO

!

SAMPLE

FUEL OVERRIDE

RONT PANEL CONNECTIONS

POWER

HEAT

FLAME

, C

LON

1

LON

ON

PURGE

1 +

AIR

2 -

3 GND

T 6A

260V

2

IGNITE

ONTROLS AND INDICATORS

FID

WARNING

!

TTENTION

!

NETWORK 1

NETWORK 2

POWER

FUSE

It is recommended that no connection be made to the PURGE AIR OUT port. If,

however, the analyzer's location requires interconnection with a venting system, the

3/8" O.D. line should be kept as short as possible, and no longer than four feet.

CAUTION: POSSIBLE INSTRUMENT DAMA GE

No connection should be made to the PRESSURE RELIEF VALVE fitting. Doing

so may cause damage to the instrument.

2.4.3 S

PECIFICATIONS

UEL GAS

F

Standard analysis usually requires mixed fuel, i.e., 40% (±2%) hydrogen and 60%

helium. H2/He mixed fuel is recommended over H2/N2 fuel because of better linearity

in concentration output. Such blends are supplied by many gas vendors specifically for

this use, with a guaranteed maximum total hydrocarbon content of 0.5 ppm, measured

as methane. This specification should be used when obtaining these mixtures.

Note

The fuel restrictor is marked with a red dot, and the sample capillary is marked with a

red or green dot for mixed fuel applications.

Some applications require the use of 100% hydrogen fuel. When using this option,

always ensure that sample pressure (4 to 5 psig) is present when fuel flow is present.

Otherwise, the detector tip may be damaged.

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

2-5

Page 30

NSTALLATION

I

Note

The fuel restrictor and sample capillary are marked with a white dot for 100%

hydrogen fuel applications.

URNER AIR

B

In order to ensure a low background signal, burner air should contain less than 1 ppm

maximum total hydrocarbon content. An alternate source for burner air and zero gas

(see CALIBRATION GASES below) is a combination diaphragm pump and heated

palladium catalyst. This process continuously removes moderate amounts of

hydrocarbons and carbon monoxide from ambient air.

URGE AIR

P

Instrument quality air, nitrogen, or other nonflammable gas is required for the saf ety

purge system.

ALIBRATION GASES

C

Calibration method and gases depends on the type of fuel gas used, the operating

range, and the desired measurement accuracy. In all methods, zero and span gases

are used, and are introduced through the sample inlet at the rear of the module.

ERO GAS

Z

- Analysis is affected by the background gas of the sample. Therefore, it is

recommended to use zero gas with as close to the background composition of the

sample as possible. Normally less than 0.5 THC as CH4 is sufficient.

If the burner fuel is 100% hydrogen, the zero gas, background gas of the sample or

background gas of the span gas cannot be hydrogen or oxygen. These gases

combined with pure hydrogen fuel would generate excessive heat in the burner,

causing deterioration of the internal components of the burner.

PAN GAS

S

- Span gas consists of a specified concentration of methane or other

hydrocarbon in a background gas such as nitrogen. Analysis is affected by the

background gas of the sample. Therefore, span gas containing the same background

gas as the sample is recommended. Then, the background effect is canceled out.

AMPLE GAS

S

- Sample gas should be nonflammable (below 100% of the sample's

LEL). For high sensitivity applications requiring background gas compensation,

contact the factory.

LOW RATE

F

- The sample flow rate must be between 0.5 L/min. and 2 L/min. Flow rate

for purge air should be 16 to 18 L/min.

RESSURIZATION/FILTRATION

P

the range of 483 to 1035 hPa-gauge (7 to 15 psig), and internally, should be 345

2-6

- Sample pressure at the SAMPLE inlet should be within

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 31

NSTALLATION

I

hPa-gauge (5 psig) nominally. Burner fuel pressures should be: 1725 to 3450

hPa-gauge (25 to 50 psig) for cylinder regulator, 1518 to 1723 hPa-gauge (22 to

25 psig) internal. Burner air pressures should be: 1725 to 3450 hPa-gauge (25 to 50

psig) for cylinder regulator, 965 to 1103 hPa-gauge (14 to 16 psig) internal. Purge air

(external supply) pressure should be between 689 and 1378 hPa-gauge (10 and

20 psig), 689 to 827 hPa-gauge (10 to 12 psig) nominal. The internal purge air

regulator pressure is factory preset at a nominal setting of 551 hPa-gauge (8 psig)

with a supply pressure of 689 hPa-gauge (10 psig). Noncompliance with these

specifications, particularly those concerning purge air, could cause over-pressure

damage to the module. The nominal internal case pressure is about 0.5 to 1.0 inch of

water, and the pressure relief valve is set at 1/3 psig (nominal).

At the very least, the module's safety system, which requires a certain volume of

purge air flowing through the case before allowing burner ignition, will not allow the

instrument to operate.

All internal pressure settings are preset at the factory, but the operator should check

for accuracy. Sample should be filtered for particulates down to two microns.

2.4.4 LEAK TEST

The Analyzer Module is completely tested at the factory for gas leakage. The user is

responsible for testing for leakage at the inlet and outlet fittings on the rear panel. The

user is also responsible for internal leak testing periodically and if any internal

pneumatic components are adjusted or replaced (with a test procedure chosen by the

user).

2.5 ELECTRICAL CONNECTIONS

Two electrical connections are required on the Analyzer Module: POWER and

NETWORK. See Figure 2-4. On the Analyzer Module, two NETWORK connectors are

available, either of which is appropriate for: 1) interconnection with the Backplane of

the Platform or 2) "daisy-chaining" with other NGA 2000 components. Connect

Analyzer Module POWER to Backplane POWER or external 24 VDC power source.

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

2-7

Page 32

NSTALLATION

[

]

[

]

[

]

[

]

[

]

[

]

I

8.2

[208.2]

FID

4.3

[109.7]

.25

[6.3]

Dimensions:

1.9

[49.4]

1.1

27.9

.9

[22.5]

[152.4]

17.75

[450.9]

20.0

[510.0]

6.0

5.7

143.6

4.3

109.1

2.9

73.6

1.4

35.6

.8

[20.9]

1.8

[46.3]

1.7

43.4

3.1

[78.0]

INCHES

[MM]

F

IGURE

2-5. O

UTLINE AND MOUNTING DIMENSIONS

2-8

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 33

C

A

CABLE

ASSEMBLY,

FLAT 24COND

CARTRIDGE

HEATER

P6

J6

J1

P1

POWER

SUPPLY

BOARD

J4

P4

J5

P5

CABLE ASSEMBLY,

FLAT 3 COND

P9

J9

OVEN HEATER

FUEL SOL.

++ +

J10

P10

YEL

GRN

BRN

RED

ORN

NSTALLATION

I

OVEN

HEAT

JP1

J3

FLAME ON

PURGE AIR

P2

J2

POWER MODULE

ASSEMBLY

J4

LED INDICATOR

ASSEMBLY

PWR

MOD

J1

J1

SWITCH ASSEMBLY,

MANUAL IGNITE

J6

J5 +10V REF

CABLE ASSEMBLY,

LON/POWER

MODULE

J5

P5

P3

J2

P2

J3

J8

P8

J11

AIR

BLU

P15

P11

J7

P7

BLK

BLK

RED

RED

J15

AIR

SENSOR,

3-WAY SOLENOID

CASE TEMP

E2 24VOLTE1E3

BLK

RED

J14

P14

RTN

GRN

FLAT 10 COND

HARNESS,

CHASSIS

HEATER

FAN

ASSEMBLY

THERMOSTAT

POWER

J6

J1 J2

P1

RTN

P3

ABLE

SSEMBLY,

FLAT 3

COND

CABLE

ASSEMBLY,

FLAT

16 COND

HARNESS, GLOW PLUG

P4

J4

SAFETY

BOARD

J3

P3

CABLE ASSEMBLY, FLAT

20COND

P6

J6

COMPUTER

ANALYSIS

J5

P5

P4

BOARD

J4

J2P2J3

J1

P1

SENSOR

AIR

J11

P11

PRESS

2-WAY

SOLENOID

J16

P16

FUEL IN

ASSY,

PRESS

SWITCH

PRESSURE

SWITCH

CABLE

P2

J2

1 2 3 4 5 6 7 8

FLO

SW

J1

P1

POWER

RESISTOR

MTG

STUD

P7

J7

P3

GND

STRAP

FLOW

SENSOR

CASE

FLO

SW

FLO

SW

FLO

SEN

HARNESS

POL

VOL

GRY

EI

PUR

E2

PREAMP

J1

SHIELD

BOARD

CHASSIS

GND

CABLE ASSEMBLY,

CATHODE

P1

SHIELD

E3

R37

R38

J13

P13

SENSOR, FLAME-OUT

SENSOR

FUEL

J10

P10

PRESS

SENSOR

SAMPLE

J12

P12

PRESS

BURNERGND

CABLE ASSEMBLY, ANODE

GLOW

PLUG

ASSEMBLY

J1

P1

CATHODE

BURNER

ASSEMBLY

ANODE

F

IGURE

2-6. FID W

IRING DIAGRAM

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

2-9

Page 34

NSTALLATION

I

N

OTES

2-10

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 35

S

TARTUP AND OPERATION

3

3.1 OVERVIEW

Prior to initial startup, the user should leak test the module as outlined in Section 2.

For the remainder of this section, Analyzer Module interconnection with a Platform or

some interfacing component will be assumed. Display and Keypad information shall

refer to that which the user can expect to see and do with regard to the Front Panel of

the Platform.

(For a complete description of Platform Front Panel controls and indicators, see

Section 1 of the Platform instruction manual.)

3.2 DISPLAYS

Three kinds of Display screens are available to the user:

• Run Mode

• Menu

• Help

3.3 RUN MODE DISPLAY

The Run Mode is the normal mode of operation. In this mode, the display (see Figure

3-1) will show current gas measurement, the component of interest, user-selectable

(up to four) secondary variables, the current operations of the softkeys, and a graphic

bar representing the displayed concentration as a percent of fullscale.

If more than one Analyzer Module is connected to the system, another Run Mode

display will show up to four gas measurements at once. Ala rm messages m ay also

appear on the display (See Table 3-1).

3.4 MENU DISPLAYS

The Menu structure enables the user to access data and functions, and put

information onto the network.

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

3-1

Page 36

TARTUP AND OPERATION

S

The Main Menu (see Figure 3-2) is subdivided into three levels of control based

generally on which personnel is likely to use it: Basic Controls, Expert Controls, and

Technical Controls. (See Figures 3-3 through 3-5.) Many layers of the menu structure

are described at appropriate places throughout this manual.

From the Run Mode display, press the MENUS softkey to gain access to the Main

Menu. (See Figure 3-2.)

See Figures 3-11 through 3-15 for flow charts depicting menu screens related to this

Analyzer Module.

3.5 HELP DISPLAYS

The Help structure is intended to be an on-line "tutorial," context-sensitive and

topic-interconnected, so that the user can practically operate NGA 2000 without need

of an instruction manual. (See Figure 3-6.)

F

IGURE

3-1. R

23.2 ppm HC

Display Parms. Menu Dual Info

F1

UN MODE DISPLAY

23.2 ppm HC Analyzer XXXXXXXX

Basic Controls

Expert controls and setup ...

Technical level configuration ...

Analyzer PQ 322-14

F2 F3 F4 F5

Main Menu

Delete alarm message!

Display Parms. Info

F1

F

IGURE

3-2. M

AIN MENU DISPLAY

3-2

F2 F3 F4 F5

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 37

g

p

p

23.2 ppm HC Analyzer XXXXXXXX

Basic Controls

Measurement range numbers:

Range upper limit: 10 ppm

Range and functional control: Local

Bypass sample flow: 1000 ml/min

Ranges with valid calibration 1&2

Calibration status: Ready

If it won’t calibrate…

Flame condition: On

Light flame…

Home Escape Zero Span Info

TARTUP AND OPERATION

S

F

IGURE

F

IGURE

3-3. B

3-4. E

F1

F2 F3 F4 F5

ASIC CONTROLS MENU DISPLAY

23.2 ppm HC Analyzer XXXXXXXX

Ex

ert controls and set u

Expert analyzer controls ...

Auxiliary module controls ...

System set up ...

Analyzer module set up ...

Auxiliary module set up ...

Local I/O set up ...

Home Escape Info

F1 F2 F3 F4 F5

XPERT CONTROLS AND SETUP MENU DISPLAY

23.2 ppm HC Analyzer XXXXXXXX

Home Escape Cal Info

F1 F2 F3 F4 F5

F

IGURE

748331-E Rosemount Analytical November 1998

3-5. T

ECHNICAL CONFIGURATION MENU DISPLAY

Technical confi

System set up .. .

Service menus...

Diagnostic menus...

Other module diagnostic

menus...

listing of all modules...

uration menu

NGA 2000 Flame Ionization Detection Module

3-3

Page 38

TARTUP AND OPERATION

p

S

23.2 ppm HC Analyzer XXXXXXXX

Main Menu Hel

The Main Menu for the analyzer system.

Note that this menu refers to the particular

analyzer selected from t he run screen, when

used in a system. The softkey marked “HOME”

will always return you to this screen.

Help menu system...

Help on help...

Keyboard controls...

Editing controls.. .

Home Escape Map

F1 F2 F3 F4 F5

F

IGURE

3-6. T

YPICAL HELP SCREEN

DISPLAY MESSAGE DESCRIPTION TYPE

AIR FET FID Air FET current WARNING

AIR PRESS FID Air Pressure WARNING

BAIR FLOW Burner Air Flow WARNING

BAROMETER System Barometer WARNING

BFUEL FLOW Burner Fuel Flow WARNING

BLOCK FET Heater current WARNING

CASE TEMP Case Temperature WARNING

CRUDE NOISE Ca lculated Noise WARNING

CURRENTRNGHI Current, High Range WARNING

CURRENTRNGLO Current, Low Range WARNING

CURRENTSFAC Current Range WARNING

FLAME TEMP Flame Temperature WARNING

FUEL PRES Fuel Pressure WARNING

LIN ERROR Linearizer Error WARNING

N15 VOLTS Power Supply -15V WARNING

P10 VOLTS Power Supply +10V REF WARNING

P15 VOLTS Power Supply +15V WARNING

POL VOLTS Polarizing Volts WARNING

SAMP PRES Sample Pressure WARNING

CALRESULT Calibration Error FA ILURE

PURGE AIR FID Purge Air FAILURE

SW ERROR Software Error FAILURE

T

ABLE

3-1. FID A

NALYZER MODULE ALARMS

3-4

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 39

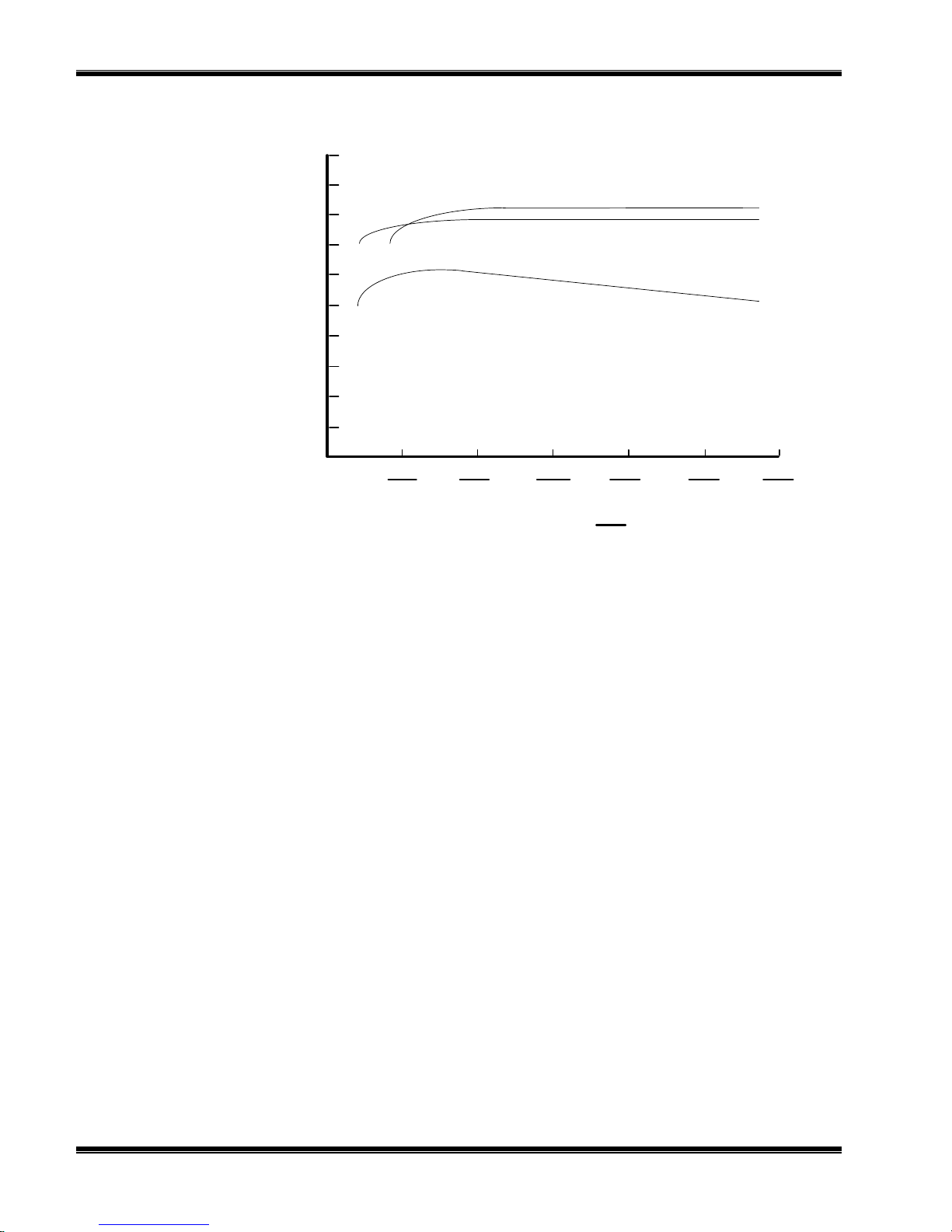

RESPONSE

A

)

A

)

A

)

(100 ppm CH

fullscale )

4

1.0

0.8

0.6

0.4

0.2

TARTUP AND OPERATION

S

SAMPLE: 100 ppm CH4 in N

FUEL: 25 psig (1726 hPa) H

AIR: 25 psig (1726 hPa)

2

2

F

IGURE

3-7. T

RESPONSE

(100 ppm CH

0

0

2

13.76

3

20.64

27.52

SAMPLE PRESSURE

YPICAL CURVES OF MODULE RESPONSE VS

S

AMPLE PRESSURE REGULATOR

1.0

0.8

0.6

fullscale )

4

0.4

0.2

4

5

34.4

6

41.28

psig

hPa

. P

RESSURE SETTING ON

IR: 30 psig (2064 hPa

IR: 20 psig (1376 hPa

IR: 10 psig (688 hPa

SAMPLE: 100 ppm CH4 in N

at 5 psig (344 hPa)

7

48.16

2

F

IGURE

748331-E Rosemount Analytical November 1998

3-8. T

F

YPICAL CURVES OF MODULE RESPONSE VS

UEL PRESSURE REGULATOR

0

0

5

344

10

688

15

1032

20

1376

25

1726

30

2064

psig

FUEL PRESSURE

NGA 2000 Flame Ionization Detection Module

hPa

. P

RESSURE SETTING ON

3-5

Page 40

TARTUP AND OPERATION

psig (

S

1.0

F

IGURE

RESPONSE

(100 ppm CH

3-9. T

A

FUEL: 30

0.8

FUEL: 25 psig (1726 hPa) H

FUEL: 20 psig (1376 hPa) H

SAMPLE: 10 0 ppm CH

10

AIR PRESSURE

15

1032

4

fullscale)

0.6

0.4

0.2

0

0

5

344

688

YPICAL CURVES OF MODULE RESPONSE VS

IR PRESSURE REGULATOR

2064 hPa) H

at 5 psig (344 hPa)

20

1376

psig

hPa

. P

RESSURE SETTING ON

2

2

2

4

25

1726

in N

2

3.6 STARTUP PROCEDURE

Apply power to the FID Analyzer Module. If it is associated with a Platform, do this by

plugging in the Platform to a power source. The Platform has no ON/OFF power

button. Once power has been supplied to the Platform, the FID Analyzer Module will

be energized.

30

2064

If the user's system contains only one Analyzer Module, all system components, the

Controller Board and the network "self-install" (bind together) during initial startup. If

the system contains more than one Analyzer Module, the startup sequence will

interrogate the network to locate and identify all components on the network. The user

will have to bind appropriate combinations of components after the startup sequence

(see section 3.7).

After the warm-up period (about one hour for the FID Analyzer module), all modules

are completely functional.

Before introducing gases to the FID, the user should check the general health of the

analyzer module's electronics by reviewing the results of its self test sequence. These

test results can be found by selecting the following from the Main Menu: Technical

Level Configuration, Diagnostic Menus, Analyzer Module Diagnostics, Self Test. All

tested parameters should indicate "Pass."

3-6

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 41

TARTUP AND OPERATION

S

Descriptions of the tests performed follow:

• EEPROM test - Checks the EEPROM on the Analysis Computer PCB.

• EPROM test - Checks the EPROM on the Analysis Computer PCB.

• RAM test - Checks the RAM on the Analysis Computer PCB.

• Power supply test - Verifies that all internal DC voltages are within the

required tolerances.

• Network test - Checks the internal network interface.

• 20 bit ADC test - Checks the 20-bit ADC on the Analysis Computer PCB by

sending a DC signal through the Preamp PCB and reading the signal back with

the 20-bit ADC.

• 12 bit ADC test - Checks the 12-bit ADC on the Analysis Computer PCB by

sending a DC signal and reading the signal back with the 12-bit ADC.

• Power Supply PCB test - Checks the presence of the Power Supply PCB by

activating the 3-way air solenoid.

• Safety PCB test - Checks the presence of the Safety PCB by sending a

command and reading it back.

• Case temperature test - Compares the temperature read between the Preamp

temperature sensor and the case temperature sensor. They must be within

10°C of each other. This test sometimes fails if the case is opened. The sensor

in the Preamp will take longer to cool off since it is in an enclosure. Re-running

the self-test after thermal equilibrium will produce a positive result if the sensors

are working properly.

The self-test can be repeated at any time by activating the TEST softkey in the Self

Test Results menu.

Set the Range Number (Expert Controls sub-menu) to the desired setting (see Figure

3-12). Introduce all gases at suitable pressures (see Specifications page in the

Preface section of this manual).

Check/set internal pressure regulators according to the following specifications:

INTERNAL PRESSURE

REGULATOR

TYPICAL OPERATING PRESSURES

B

URNER AIR

F

UEL

S

AMPLE

S

AMPLE (MIXED FUEL

748331-E Rosemount Analytical November 1998

(100% H2)

965 to 1103 hPa-gauge (14 to 16 psig)

1516 to 1723 hPa-gauge (22 to 25 psig)

276 to 345 hPa-gauge (4 to 5 psig)

)

207 to 345 hPa-gauge (3 to 5 psig)

NGA 2000 Flame Ionization Detection Module

3-7

Page 42

TARTUP AND OPERATION

S

Purge air of the following specifications must be present:

Flow: 16 to 18 L/min.

Supply Pressure: 689 to 1378 hPa-gauge (10 to 20 psig).

Noncompliance could cause damage to the module. At the very least, the module's

safety system, which requires a certain volume of purge air flowing through the case

before allowing burner ignition, will not allow the instrument to operate. The lowest

purge air flow/pressure setting possible during burner operation is preferable. Thus,

the user should set the external purge air pressure initially at 689 hPa-gauge (10 psig).

Check the Miscellaneous Control Parameters screen under Technical Diagnostics,

and note whether the Purge Gas (switch) variable is "ON." If it is "OFF," increase

purge air supply by 69 hPa-gauge (1 psig), and recheck the Purge Gas variable until it

reads "ON." DO NOT EXCEED 1378 hPa-GAUGE (20 PSIG). If the maximum setting

is reached, and the Purge Gas variable does not read "ON," contact factory. If the

safety system is initiated successfully (Purge Gas variable is "ON"), continue with the

remainder of the startup procedure.

Note

Do not restrict the PURGE OUT port and the pressure relief valve. They must be

vented to atmospheric pressure.

Two methods of burner ignition are possible: auto-ignition and manual ignition. Note

the four LEDs on the front panel of the Analyzer Module. They provide necessary

information for either ignition procedure. The LEDs, when illuminated, denote the following

information:

Green - unit powered on

Amber - constant illumination indicates case temp. is within 5% of operating

temp. setpoint (i.e., 50°C with burner off, 54°C with burner

on);otherwise, LED will blink

Green - Flame on

Green - purge air system intact (it has filled five volumes of the module

interior)

Auto-ignition provides fuel override and three attempted ignitions (default setting), if

necessary. Manual ignition requires that the Platform front panel, if used, be

disengaged.

CAUTION: HAND INJURY HAZARD

Do not place hands or fingers in Platform front handles when the front panel is

open. Dropping front panel while hand or fingers are inside either handle can

cause serious injury.

3-8

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 43

TARTUP AND OPERATION

S

The manual ignition switch on the Analyzer Module front panel must be manipulated in

the following ways:

• Press up and hold for one minute. This opens burner fuel and air solenoids.

• Press down to ignite burner glow plug for up to 10 seconds.

• Repeat as necessary (if fuel and air sources are farther away than 10 feet,

several more attempts may be necessary).

• Flame on is defined true when the flame temperature exceeds 115°C (239°F).

• If the flame has been lit, but the flame temperature increases slowly, perform

the following steps:

# After igniting flame, release switch for 2 sec.

# Press switch down for 2 sec.

# Repeat release switch and press down steps as necessary.

3.7 BINDING

To achieve full coordination between Analyzer Modules and associated I/O Modules,

the user must bind those components together in the System Set Up portion of the

Technical Configuration Menu in software. (See Figures 3-11 through 3-15 and

section 1.5 of the I/O Modules manual for binding instructions.)

3.8 CALIBRATION

See section 2.3.3 for a description of the method for choosing calibration zero and

span gases.

To calibrate the Analyzer Module, introduce zero gas into the SAMPLE INLET, and do

the following:

1. If more than one Analyzer Module is functional and the split Run Mode display is

shown, press the DISPLAY softkey until the desired Analyzer's Run Mode display

is acquired.

2. Press the MENUS softkey to enter the Main Menu.

3. Verify the fuel type in the Miscellaneous Control Parameters menu (under the

Technical Configuration menu structure, select the following from the Main Menu:

Diagnostic menus, Analyzer Module Diagnostics and then Miscellaneous Control

Parameters).

4. Verify the capillary type in the Analyzer Manufacturing Data menu (under the

Technical Configuration menu structure, select the following from the Main Menu:

Technical Level Configuration, Service Menus, Manufacturing Data, Analyzer

Module Data).

5. In the Calibration Gas List menu (from the Main Menu, select Expert Controls and

748331-E Rosemount Analytical November 1998

NGA 2000 Flame Ionization Detection Module

3-9

Page 44

TARTUP AND OPERATION

S

Setup, Analyzer Module Setup, then Calibration Gas List), enter necessary data,

including the Operational Sample Pressure and the Calibration Gas HC Response

Factor. Common HC factors are: methane (CH4), 1.0, ethane (C2H6), 1.90,

propane (C3H8), 3.00. These factors are not used to compensate the reading, but

are used to select the proper preamp sense resistor.

6. Press HOME to re-enter the Main Menu, enter the Basic Controls menu, introduce

zero gas and allow its response to stabilize, press the ZERO softkey to enter the

Analyzer Zero menu, press ZERO ag ain and w ait.

7. Press the SPAN softkey to enter the Analyzer Span menu, introduce span gas and

allow its response to stabilize, press SPAN again and wait.

8. Press the HOME softkey to re-enter the Main Menu.

9. Press DISPLAY softkey for the Run Mode display.

If the user is unable to calibrate the Analyzer Module (i.e., when ZERO or SPAN is

initiated, nothing happens), several possible solutions present themselves. One

solution relates to the use of an incorrect gas for zeroing or spanning (e.g., using a

high concentration gas to zero or a zero gas to span the Analyzer Module). Simply

recalibrating with the appropriate gas(es) will not correct the problem because the

ZERO OFFSET or SPAN FACTOR has been set to an extreme value in the process.

To remedy the problem, do the following:

1. Verify that correct zero and span calibration gases are being used properly. If so,

attempt to recalibrate according to instructions at the beginning of this section,

ensuring that case temperature and displayed measurement reading are stable

before initiating the calibration routine. If incorrect gases were used in the initial,

failed calibration, skip to Step 2.

2. Make the following selections from the Main Menu: Expert Controls and Setup,

Analyzer Module Setup, then Calibration Parameters. Disable Calibration

Adjustment Limits.

3. Recalibrate the analyzer module according to instructions at the beginning of this

section, ensuring that case temperature and displayed measurement reading are

stable before initiating the calibration routine.

4. Enable Calibration Adjustment Limits in the Calibration Parameters menu.

3.9 ROUTINE OPERATION

After binding and calibration, proceed as follows:

Supply sample gas to SAMPLE INLET. Adjust external flow controller or throttle valve

so that flow discharged from the BYPASS outlet is between 0.5 and 2.0 L/min. The

reading on the SAMPLE BYPASS pressure gauge should be the same as that used

during adjustment of the span control. Adjust, if necessary.

Adjust the Range Number setting. The Analyzer Module will now automatically and

continuously output the measured hydrocarbon content of the sample. Output is in

3-10

November 1998 Rosemount Analytical 748331-ENGA 2000 Flame Ionization Detection Module

Page 45

TARTUP AND OPERATION

S

terms of the particular hydrocarbon present in the span gas. Note that readings

obtained during operation depend on the concentration of total hydrocarbons in the

sample.

If maximum sensitivity is required from the FID Analyzer Module, use an optimum

combination of settings on the SAMPLE, FUEL, and AIR pressure regulators. Settings

must be determined experimentally, but the curves in Figures 3-7, 3-8 and 3-9 may be

used as guides.

The Analyzer Module will not allow the user to increase the upper limit of a range

beyond the "maximum range" software setting. To change the "maximum range"

value, select the following from the Main Menu: Technical Configuration Menu,

Service Menus, Manufacturing Data, and Analyzer Module Data. Select Maximum

Range, and use the arrow keys to scroll the indicated value. The same applies for

Minimum Range settings.

During shutdown, always turn off fuel gas first, then the air and sample gases. The

flame can also be turned off by setting Ignition System Enable to "Off" in the Light

Flame menu (under Basic Controls; see Figure 3-11). Subsequently, remember to set

Ignition System Enable to "On" before attempting to ignite the flame.

After initial startup, or startup following a prolonged shutdown, the Analyzer Module

requires about one day's continuous operation to stabilize. For several days

afterwards, calibrate daily. The frequency of subsequent calibrations can be reduced

as experience dictates, consistent with the accuracy requirements of the particular

application.

3.10 SAFETY SYSTEM

The FID Analyzer Module safety system will not allow ignition or continuous burner

function unless the following conditions are present:

• Internal purge gas pressure is at least 380 hPa-gauge (5.5 psig). (Monitor

display message, Purge Gas Pressure in Physical Measurements menu, for the

proper setting.)

• Internal fuel pressure is less than 2064 hPa-gauge (30 psig). (Monitor display

messages, Fuel Supply Pressure in Physical Measurements menu and Fuel

Pressure Status "ON" in Miscellaneous Control Parameters menu for proper

settings. If the internal fuel pressure has exceeded 2064 hPa-gauge [30 psig],

check that the external pressure is less than 3450 hPa-gauge [50 psig]. The

+24 VDC power to the Analyzer Module must be cycled to continue operation.)

• Flow rate for purge air in is at least 16 L/min. and case pressure is greater than

0.5 inch of water. (Monitor display message, Purge Gas "ON" in Miscellaneous

Control Parameters menu for correct state. Proper sealing hardware must be