Page 1

MILLENNIUM

2-Channel

Rack Mount

User

Controller

Manual

Model:

RM2-ARD

covering

FIRE (F)/TOXIC (T)/COMBUSTIBLE (C)

co

mbinations

Part number: MAN-

0096 Rev 0

May 2008

Page 2

Net Safety Monitoring Inc

TABLE OF CONTENTS

Important Information

Warranty

Contact Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Fire Head

ST Series Sensors

Combustible Sensors and Transmitters / Controllers.....

Step 1 — Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpack

.............................................................................................................

Locate

Figure 1: Dimensional Drawings

Mount

Step 2 — Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Field Installation

Configuration

Settings

.............................................................................................................

Using Jumpers

Relay Outputs

Current Outputs

Digital Outputs.

Figure 2: Analog/Relay/Digital RM2 System

Figure 3: ST Series Toxic

Figure 4:

Figure 5: Remote Reset—Wiring

Step 3 — Operate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Start Up

Front Panel

............................................................................................................

Normal Operation

Table 1: Normal Operation Indicators

Operational Test

Figure 6: RM2 Front Panel Functionality

LEDs

.......................... ...................... .......................... ............................... ............. 5

Channel LEDs

Common System LEDs

Display

Cal/Reset Button

RS-232 PC COMM port

Using the Front Panel

.........................................................................................................

............................................................................................

.................................

.................................................................................................................... 2

............................................................................. 2

.................................................................................................................... 2

..............................................................................................

........................................................................................................ 2

....................................................................................................... 2

..................................................................................................

...............................................................................................

...............................................................................................

Board—Wiring................................. 3

SENSOR—Wiring

FIRE HEAD and CONTROLLER/TRANSMITTER—Wiring

............................................................................. 4

.................................................................................................. 5

..............................................................................................

.......................................................... 4

................. 4

..................................................................... 5

.......................................................................................................

................................................................ 5

.................................................................................................

...................................................................................

.................................................................................................................. 6

................................................................................................... 6

........................................................................................ 6

......................................................................................

2

2

2

5

5

Communication

RS-232 Communications Port

Terminal Software

Figure 7: Terminal Software—Setup Prope rties

Using Terminal Software

1

1

1

2

2

2

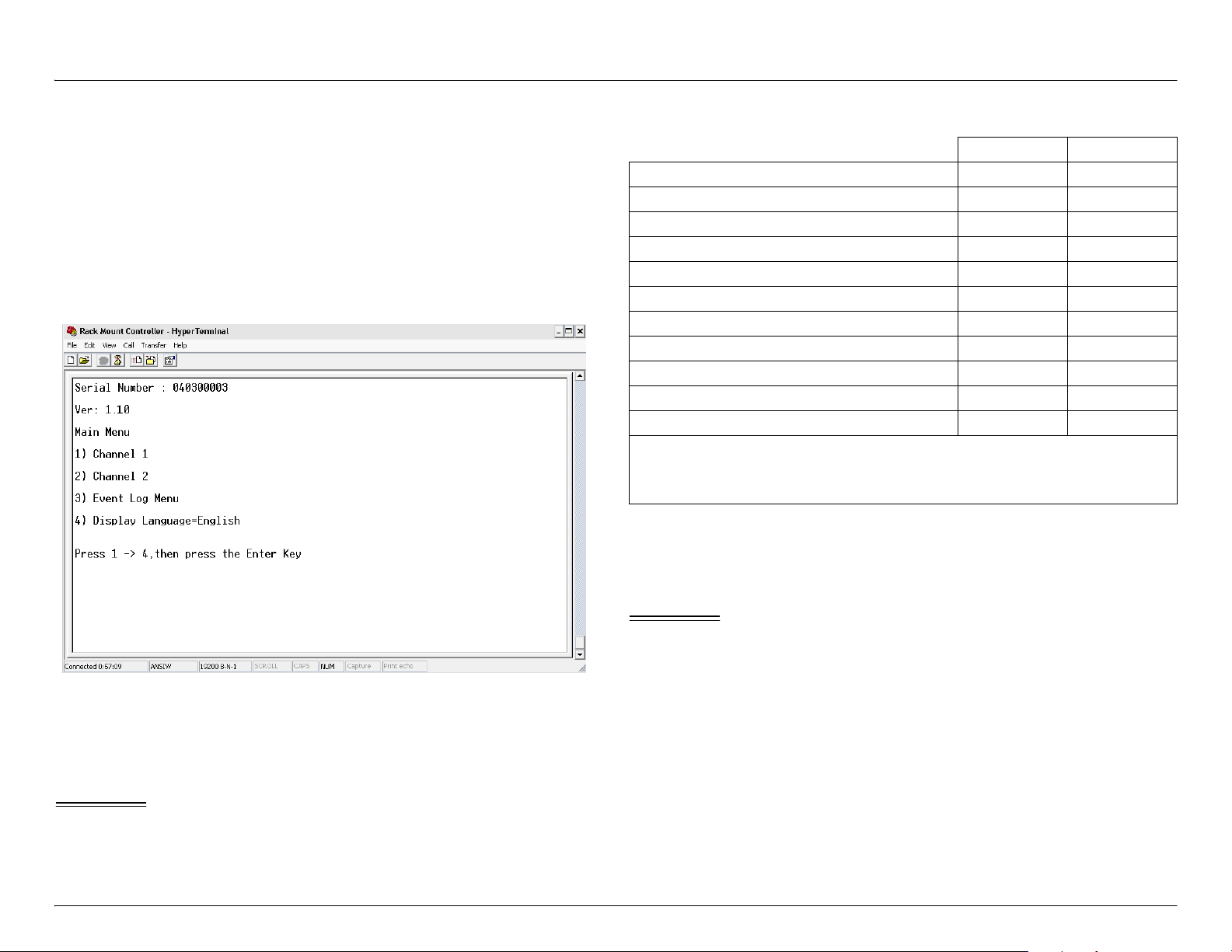

Figure 8: Terminal Software—Main Menu

Setting Options

Front Panel / Terminal Functionality

Power Down Mode

BYPASS Mode—

Permanent OFF

Relay Options

Review Relay Settings

Figure 9: Terminal Software—Relay Settings

Setting Relays—Terminal Software

Setting Relays—Front Pa nel

FIRE

ST S

Select Display Language

Calibration

Calibration Procedure—ST Series SENSORS

Figure 10: Calibration Procedure

Abort Calibration

Calibration Failure/Interruption

Reset

...............................................................................................................

Manual Reset

Remote Reset

................................................................................................

............................................................................... 6

................................................................................................. 6

...................................................... 6

....................................................................................... 7

.............................................................. 7

.................................................................................................

................................................................................................ 7

FIRE only

................................................................................................

................................................................................. 8

...................................................................................................

........................................................................................... 8

........................................................ 8

...................................................................... 9

................................................................................. 9

......................................................................................................

ERIES SENSORS/CONTROLLE RS

..................................................

................................................................................

......................................................................................................

................................................ 10

........................................................................... 11

...........................................................................................

.....................................................................

....................................................................................................... 11

....................................................................................................... 11

6

7

8

8

9

9

10

10

11

11

11

Step 4 — Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Event Logging

5

Fire

6

6

ST Series Sensors

6

Setting Time and Date

Figure 11: Event Logging Menu

Figure 12: Event Logging Display Menu

..................................................................................................................

Table 2: FIRE—Current Output, LEDs and Display Messages

FIRE ONLY—Manual Visual Integrity (VI) Testing

Table 3: Manual Visual Integrity Testing—

FIRE ONLY—Force Alarm Output Test

Table 4: ST SERIES SENSORS—Curre nt Output, LEDs and Display Messages 15

................................................................................................

...................................................................................

............................................................................ 12

............................................................... 12

........................... 13

.......................................... 14

FIRE only

............................................................. 14

........................................ 14

...........................................................................................

12

12

13

15

Page 3

Net Safety Monitoring Inc

Controllers/Transmitters

Table 5:

Messages

C

ONTROLLERS/TRANSMITTERS

................................................................................................................ 16

................................................................................ 16

—Current

Output, LEDs and

Display

Digital output form Modbus Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hardware Setup............................. ............

Figure 13: User interface for Modbus

Software Setup............................ ...............

................................................................... 17

setup............................................................. 17

................................................................... 18

Modbus Register definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 6: Status bit assignment for sensor ty pe(Combustible, Toxic and

Fire).......... 18

GAS: Modbus Register and Status bit assignment . . . . . . . . . . . . . . 19

Table 7: Status bit assi gnment for Combustible sensor output

Table 8: Status bit assi gnment for Toxic sensor (ST series) output

conditions................ 19

conditions.......... 19

FIRE: Modbus Register and Status bit assignment . . . . . . . . . . . . . 2 0

Table 9: Status bit assi gnment for Fire head outp ut

Table 9(cont’d): Status bit assignment for Fire head output

conditions.................................. 20

conditions..................... 20

Step 5 — Maintain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SENSORS—Periodic Response Test

Troubleshoot

..................................................................................................

................................................................... 21

How to Return Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2

Spare Parts/Accessories

Table 10: Part Numbering

.................................................................................

......................................................................................

Appendix A: Electrostatic Sensitive Device (ESD) ........................ 2 3

Appendix B: Resistance Table (Ohms) ........................................... 24

Appendix C: RM2 Specifications .................................................... 25

22

21

22

Page 4

Net Safety Monitoring Inc

I

MPOR TANT

INFORMATION

This manual is for informational purposes only. Although every effort has been

made to ensure the correctness of the information, technical inaccuracies m ay

occur and periodic changes may be made without notice. Net Safety Monitoring

Inc., assumes no responsibility for any err ors contained within this manual.

If the products or procedures are used for purposes other than as described in the

manual, without receiving prior confirmation of validity or suitability , Net

Safety Monitoring Inc., does not guarantee the results and assumes

obligation

or liability.

No part of this manual may be copied, disseminated or distributed without the

express written consent of Net Safety Monitoring Inc.

Net Safety

Monitoring

Inc., products are

carefully

designed and

high quality components and can be expected to provide many years of trouble free

service. Each product is thoroughly tested, inspected and calibrated prior to

shipment. Failures can occur which are beyond the control of the manufacturer.

Failures can be minimized by adhering to the operating and maintenance

instructions herein. Where the absolute greatest of reliability is

redundancy

should be designed into the system.

required,

no

manufactured

from

Warranty

Net Safety Monitoring Inc., warrants its electronic assemblies for 36 months

from date of purchase.

No other warranties or liability, expressed or implied, will be honoured by Net

Safety Monitoring Inc.

Contact Net Safety Monitoring Inc., or an authorized representative for details.

We welcome your input at Net Safety Moni toring. If you have any comments

please contact us at the phone/address below or visit our web site and complete

our on-line customer survey: www.net-safety.com.

Contact Information

Net Safety Monitoring Inc.

2721 Hopewell Place NE

Calgary, AB

Canada

T1Y 7J7

T elephone: (403) 219-0688

Fax: (403) 2 19-069 4

www.net-safety.com

E-mail: netsafe@net-safety.com

Copyright © 2005

Net Safety Monitoring Inc.

Printed in Canada

Page 5

Net Safety Monitoring Inc

I

NTRODUCTION

S

RM2

The RM2-ARD is a 2-channel, 4-20 mA input

of Net Safety’s monitoring devices. Channel #1

independently and can be used for any c ombination of

detectors, toxic gas

available outputs from this device are: 4-20 mA analog signal, relay and

digital for Modbus applications. For Modbus setup see pages 17-20.

Note: All three (3) outputs can be utilized at the same time.

Y S T E M

monitor for use with a variety

and Channel #2 function

Net Safety’s fire

se

nsors or combustible sensor with transmitters. The

Fire Head

Net Safety’s UV/IRS, UVS, IRS, UVU-120-H2 and Phoenix IR3S fire detector

heads can be used in conjunction with the RM2.

ST Series Sensors

A variety of Net Safety’s ST Series 4-20 mA Toxic gas sensors can be

connected to the RM2.

Combustible

Net Safety’s Uni-Tr an and Millennium Combustible Gas Controllers or

Transmitters can be used in conjunction with the RM2. Com bustible sensors

should always be connected to transmitter or controller . The 4-20 output from

this combination then connected to the RM2.

Manual

The manual has been designed to m ake installation of the RM2 System easy . To

ensure proper installation and usage follow the simple steps outlined in the

following pages. Consult the manual provided with the detector device(s) being

connected to the RM2 for specific information.

If you encounter any problems, consult th e troubleshooting section or contact

your sales representative.

Sensors and Tr a nsmitters / C o n trollers

Step 1 — INSTALL

Step 2 — WIRE

Step 3 —

O

PERATE

Step 4 — MONITOR

Step 5 —

RM2-ARD 1

M

AINTAIN

Page 6

Net Safety Monitoring Inc.

STEP 1 — I

NSTALL

U

N P A C K

Carefully remove all components from the packaging. Check components

against the enclosed packing list and inspect all components for obvious

damage such as broken or loose parts. If you find any components missing or

damaged, notify your representative or Net Safety Monitoring immediately .

Locate

Locate Fire Heads, Sensors, Controllers or Transmitters as per the manual

provided with the specific product.

Figure 1: Dimensional Drawings

Mount

The RM2 can be fitted into a cage and located in a Class 1, Division 2 location.

0.690"

8.566"

0.576"

0.059"

0.540"

0.970"

STEP 2 — W

F

I E L

D IN S T A L L A T I O N

IRE

WARNING: Wiring codes and regulations may vary . W iring must comply

with applicable regulations relating to the installation of electrical equi pment

and is the responsibility of the installer. If in doubt, consult a qualified official

before wiring the system.

The following figures illustrate the basic connections f or a Fire Head, Sensor,

Controller or Transmitter as well as information for external equipment.

Consult the manual for the specific Fire Head, Controller or Transmitter

regarding further wiring information.

Configuration

T wo Analog Input chan nels wi th Current Loop an d Relay a nd Dig ita l Output.

Refer to Figure 2, "Analog/Relay/Digital RM2 System Board—W iring",

on page 3 for illustration.

S

E T T I N G S

Once field wiring is complete, the Relay Contacts and the Isolated/Non-isolated

analog outputs should be configured.

Usi ng J um p er s

Place Jumper(s) over appropriate pins in order to set

Relays Contacts as Open or Closed, and set Isolated or

Non-isolated analog output. See Figure 2 on page 3.

Relay Outputs

The relay outputs have SPDT, form C, normally open/normally closed contacts

rated for 5 Amps @ 30 V dc or 250 V ac. Each channel has two dedicated alarm

relays and a fifth relay is a Common Fault relay.

Current Outputs

A 4-20 mA dc analog current output (isolated/non-isolated) transmits

information to other devices.

Digital Outputs

For digital output, connections to PLC (RTU) are made via terminals

19 and 20 (A and B)for Modbus communications. See page 3 and pages 17-20.

RS 485 Bus Terminator Jumpers (JP9 and JP11) should be placed over jumper pins

for Modbus communication. The user should wire the system according to RS 485

convention and local Electrical codes.

RM2-ARD 2

Page 7

Net Safety Monitoring Inc.

Figure 2: Analog/Relay/ Digital RM2 System Board—

Wiring

Note: The Common System Fault Relay is fixed as Energized/Non-latching.

Refer to T able 2 on page 13, T a ble 4 on page 15 and Table 5 on page 16 for status indicators.

COMMON FAILURE FAULT

CHANNEL#1 FAULT LOW

R1

CHANNEL#1 FIRE HIGH

CHANNEL#2 FAULT LOW

CHANNE #2 FIRE HIGH

+24 V Supply

4-20 mA Signal

Manual Visual Integrity (Fire O

Manual Visual Integrity (Fire ONL

FIREHEADS/SENSORS

Digital output to PLC (RTU)

Digital output to PLC (RTU)

TRANSMITTERS/CONTROLLERS

Supply Common

4-20 mA Signal

Supply Common

Isolated Power +24V

NLY)

+24 V Supply

Y)

R2

R3

R4

A

B

4-20 mA Output CH#1

4-20 mA Output CH#2

RM2 Remote Reset

Main Power (+24V)

Supply Common

Relay contacts are jumper selectable as

Normally OPEN or Normally CLOSED

Position 1 & 2 = CLOSED

Position 2 & 3 = OPEN

(default Closed - 1 & 2)

RS 485 Bus

Termination jumpers

(JP 9 & JP 11)

Analog Output - Channel #1

Analog Output - Channel #2

Analog Outputs are jumper selectable as

Position 1 & 2 = Non -i solat ed (default)

Position 2 & 3 = Isol ated dc

(default Closed - 1 & 2)

Earth Ground

Note: Connect Shield to Supply Common (COM). Refer to "Remote Reset—W iring" on page 4 for instructions on wiring a Remote Reset button.

Note: For FIRE HEAD and

C

ONTROLLER/TRANSMITTER

wiring, consult the manual provided with the fire or gas product for specific wiring instructions.

RM2-ARD 3

Page 8

Net Safety Monitoring Inc.

Figure 3: ST Series Toxic

S

ENSOR

—

Wiring

RM2

ST Series

ST1200/01

ST1300/01

ST1500

ST1600

ST1800

ST1250

Note: Refer to MAN-0081 for terminal designations if the Net Saftey

multi-purpose junction box is being used.

Note: For ST Series Toxic sensors, use shielded copper instrument wire

(minimum 18 AWG) for separations up to 500 feet; use 16 A WG for

separations of 500 to 2000 feet. Consult t he factory if greater distance

Note: To compensate for distance when remotely calibrating(sensor wired for

required.

separation), decrease the tubing diameter or increase the calibration gas

flow rate. Always confirm calibration at the sensor.

Sensors

Figure 4: F

IRE HEAD and CONTROLLER/TRANSMITTER

+24V / +24Vdc

4-20 / 4-20 O/P

COM / COMMON

RM2

White

Black wire

Red

Blue

wire

wire

wire

RM2

Note: Refer to the F

more detailed wiring instructions.

Figure 5: Remote Reset

Note: Clears latched alarms for both RM2 channels.

IRE HEAD or CONTROLLER/TRANSMITTER

—Wiring

—

Wiring

manual for

RM2-ARD 4

Page 9

Net Safety Monitoring Inc

STEP 3 —

O

PERATE

Figure 6: RM2 Front Panel Functionali ty

S

T A R

T UP

Once all terminal wiring and Jumper settings are complete, the RM2 may be

powered up.

The time it takes the RM2 to power up is dependent on whether it is connected

to a Fire head , a transmitter/controller with sensor or directly to ST series sensor.

For

C

ONTROLLERS

after the system has been powered up;

current output is 3.0 mA.

with sensor and

FIRE Heads , a 90 seconds routine will begin

the System Status LED blips green and

The unit will power up immediately when a

ST series

sensor is directly connected to it.

Note:

Channel types are defined at purchase and factory set.

Normal Operation

Once the warm-up routine has ended, normal operation begins as indicated in

T able 1.

Table 1: Normal Operation Indicators

Type

Fire Head

ST Series Sensors

Controllers/

Transmitters

System

Status LED

Green Blip

Channel 1 or 2

Display Message

N O R M

0 0

Current

Output

4.0 mA

Operational Test

Once normal operation has been established, consult the manual provided with

the Fire Head, Sensor, Controller or Transmitter for instructions on operational

testing.

Ensure that all safety precautions and regulatory requirements for the

application are met.

F

RO N

T PA N E L

The RM2 Front Panel contains convenient LEDs and displays to provide

information regarding the RM2 status; the push button facilitates various

settings/activities; and the RS-232 port supports communication with a PC.

Channel Type Identifier

(YELLOW) Functions as

(1 per channel)

Fault LED for Fire;

Low Alarm for Gas

%LEL

CHANNEL

1

R1 R2

Cal/Reset

FIR

E

CHANNEL

Scrolling Display

(1 per channel)

(RED) Functions as

Alarm LED for Fire;

High Alarm f or Gas

2

Calibration/Reset

Button

(1 per

channel)

System Fault LED

R3 R4

Cal/Reset

Fault Status

RS-232

PC COMM

Model#: RM2

System Status LED

(also active during

calibration)

Serial Port

PC Communication

Interface RJ-11

LEDs

There are two LEDs dedicated to each channel and two additional System

LEDs. The LEDs will turn solid or flash depending upon the status of the RM2.

Refer to the section titled "Monitor" on page 12 and review the tables listing the

various devices, LEDs and states.

RM2-ARD 5

Page 10

Net Safety Monitoring Inc.

Channel LEDs

T wo LEDs are dedicated to each channel and, dependi ng on the type of detector

connected (fire or gas), the LED indicates which relay has been tripped.

LED MARKED GAS CONNECTED FIRE CONNECTED LED

R1 or R3 LOW alarm FAULT alarm yellow

R2 or R4 HIGH alarm FIRE alarm red

C

OLOUR

Common System LEDs

A Fault and Status LED are provided and are common to both channels. The

Status LED is also active during calibration.

Display

Each channel has a separate, 4-character scrolling display visible in most

lighting conditions.

Cal/Reset Button

Each channel has a push button for calibration (ST SENSORS only), setting relay

options, clearing latched alarms, turning channels on or off and bypassing

channels.

RS-232 PC COMM port

The COMM port is an RJ-11 compatible, RS-232 suitable PC communications

port for interfacing with the RM2 at the Front Panel (refer to

"Communication" on page 6 for details).

Using the Front Panel

1. Ensure that the RM2 has been turned on and no fault is present.

2. Press and hold the Cal/Reset button until the message

S w i t c h O n

displays and the countdown 10 to 1 finishes.

3. An option will scroll across the display followed by the prompt

Y E S ?

4. To select an option, momentarily press the Cal/Reset button at the Y E S

prompt.

5. If you do not wish to select that option wait until the next option appears

and then select

Y E S ?

6. A selection is acknowledged with a flashing Y E S .

7. If no option is selected, the RM2 returns to normal operation.

C

O M M U N I C A T I O N

RS-232 Communications Port

The RS-232 is compatible with standard terminal software which m ust be used

to communicate with the RM2. The terminal software can be used to modify

various options, set parametres and view the Event L og.

A RJ-11 compatible cable and DB9 connector are required to connect the RM2

serial port (refer to "Part Numbering" on page 18) to an interface device such as

PDA or computer loaded with standard Terminal software.

WARNING: The Alarm System connected to the RM2 must be in

Bypass.

Terminal Software

RS-232 compatible terminal software must be installed on the device

communicating with the RM2 (i.e., computer , PDA, etc.). When creating a new

connection definition, the appropriate COM port must be defined for proper

communication to be established. The Properties for that port must be set as

shown in Figure 7, "Terminal Software—Setup Properties", on page 6.

Figure 7: Terminal Software

?

—Setup Properties

RM2-ARD 6

Page 11

T

Net Safety Monitoring Inc

Using Terminal Software

1. Open terminal software and establish a connection.

2. Once connected, press Enter for Main Menu.

3. The Main Menu will display an entry for each channel plus Event Logging

and Display Language as well as a serial and version number.

4. Enter a number 1, 2, 3, etc., and press Enter to m ake a selection from any

menu.

5. Press Enter twice to return to the Main Menu.

Figure 8: Terminal Software—Main Menu

S

E T T I N

G OP T I O N S

Options can be set from the Front Panel, the RS-232 T erminal interface or, in some

cases, both.

WARNING: DO NOT interrupt setup from Front Panel by using Terminal

software.

Front Panel / Terminal Functionality

Calibrate

S

ENSOR

*

Set and Review Relay settings

Set Sensor Range

Set Display Language

Reset Channel

Power Down mode per channel

Momentary BYP ASS** m ode per channel

Channel Permanent OFF

Define Channel T ype

Event Logging - setup and review

Current Firmware version

Front Panel

*

* *

*

*

*

erminal

*

*

*

*

*

*

* ST Series Sensors only; otherwise calibrate from Uni-Tran/Millennium

controller/transmitter.

** BYPASS mode is only available when both channel types are FIRE.

Power Down Mode

Each channel can be individually turned of f from the Front Panel for

maintenance.

WARNING: When in power down mode, the RM2 channel will neither

alarm nor transmit current output.

1. Press and hold the Cal/Reset button on the Front Panel. Wait for the

S w i t c h O n message and countdown (10-0) to complete.

2. When

P o w e r D o w n C h a n n e l Y E S ? displays press the Cal/Reset

Button.

3. The message

A r e y o u s u r e ? Y E S ? displays. At the Y E S ? prompt,

press the Cal/Reset button to select. The RM2 channel is now powered

down.

4. The message

O f f will continue to scroll on the display while the channel is

in power down mode.

5. To return to normal channel operation, press the Cal/Reset button. Channels

defined as

FIRE have a 90 second start delay prior to returning to normal

operation.

RM2-ARD 7

Page 12

Net Safety Monitoring Inc

BYPASS Mode—FIRE only

When both Channels are defined as FIRE, each channel can be individually

placed into Bypass mode from the Front Panel for testing and detector

replacement. When in Bypass mode, the channel relays will not trip nor will an

output signal be transmitted.

Bypass mode is momentary; pressing the Cal/Reset Button will return the

Channel to normal operation.

1. Press and hold the Cal/Reset button on the Front Panel. Wait for the

S w i t c h O n message and countdown (10-0) to complete.

2. When

C h a n n e l B y p a s s Y E S ? displays press the Cal/Reset Button.

3. The message A r e y o u s u r e ? displays. At the Y E S ? prompt, press the

Cal/Reset button to select.

4. The message

B y p a s s C h a n n e l will continue to scroll and the Yellow

System Fault LED will turn Solid. Press the Cal/Reset Button at any time to

return channel to

N O R M .

Permanent OFF

If a channel is not required, it can be permanently turned OFF using the

T erminal Software.

1. Open terminal software and establish a connection.

2. Once connected, press Enter for Main Menu.

3. Select the Channel number to be turned off.

4. Enter 1 (sensor type) until =

Off is displayed.

Note: The Terminal Software must also be used to turn the Channel ON.

R

E L A

Y OP T I O N S

Review Relay Settings

The current relay settings can be viewed using either the Terminal Software or

the Front Panel. Use Cal/Reset button for either channel and select

R e l a y S e t t i n g s when using Front Panel; enter a channel number and

R e v i e w

review displayed settings using T erm inal Software.

Figure 9: Terminal Software

—Relay Settings

Current

1) Sensor type=Fire

2) Coil Status=De-Energized

3) Latch Status=Non Latching

Press 1->3, then press the Enter key

Current

1) Sensor type=ST Series

2) Coil Status=De-Energized

3) Latch Status=Non Latching

4) High Alarm Level=40

5) Coil Status=De-Energized

6) Latch Status=Non Latching

7) Low Alarm Level=20

8) Sensor Range=100

Press 1->8, then press the Enter key

Note: When switching Sensor Type, establish a new connection and reset all

WARNING: Do not attempt to setup the RM2 using the Terminal

Software if setup has already begun at Front Panel.

Setting for Channel #1

Fault Relay=Energized, Non Latching

High Alarm

Setting for Channel #2

Fault Relay: Energized, Non Latching

High Alarm

Low Alarm

options.

default settings (fixed)

Refer to "F

IRE" on page 9 for de-

tails regarding these relay settings.

or Unitran/Millennium

default settings (fixed)

Refer to "ST SERIES SENSORS/

C

ONTROLLERS" on page 9 for

details regarding these

relay settings.

Selectable 10, 20, 25, 50,

100, 200, 250, 500, 1000

RM2-ARD 8

Page 13

Net Safety Monitoring Inc

Setting Relays—Terminal Software

Set the Low and High Alarm relays for Gas as well as Sensor range. Set the

High Alarm for Fire. The Fault Relay is fixed as Energized/Non-latching and

cannot be changed.

WARNING: The scale (PPM) of the sensor connected, with or without a

controller, must match the scale entered in the field Sensor Range.

1. Open terminal software and establish a connection.

2. Once connected, press Enter twice for Main Menu.

3. Enter a number 1 or 2 for the required Channel.

4. Enter the number for a setting. In most cases, entering a number will toggle

between setting options; for alarm levels and range, a prompt will appear at

the bottom of the screen

. Enter level/range and press Enter again to confirm

entry.

5. Press Enter twice to return to the Main Menu.

Setting Relays—Front Panel

F

IRE

The High Alarm (Fire relay) can be set to Energized or De-Energized and

Latching or Non-latching. The Fault Relay is fixed as Energized/Non-latching.

Step 1: Press and hold the Cal/Reset button on the Front Panel. Wait for the

S w i t c h O n message and countdown (10-0) to complete.

Step 2: When S e t R e l a y O p t i o n s Y E S ? displays press the Cal/

Reset Button.

Step 3: The message

display then shows

E n e r g i z e d Y E S ?

setting when it displays. The flashing

H i g h A l a r m – – – C o i l S t a t u s displays. The

E n e r g i z e d Y E S ? and then D e -

. Press the Cal/Reset Button to select the

Y E S confirms the selection.

If no selection is made, the next option displayed.

Step 4: The message

L a t c h i n g Y E S ? and then N o n L a t c h i n g Y E S ? . Press the

L a t c h S t a t u s displays. The display then shows

Cal/Reset Button to select the setting when it displays. The flashing

Y E S confirms the selection.

Step 5: Once set, the RM2 will return to

N O R M .

ERIES SENSORS/CONTROLLERS

ST S

There are two settings for the Alarm Relays: Low and High. The Coil Status,

Latch Status and Alarm Level for the Low alarm are set first, followed by the

High. The Fault Relay is fixed as Energized/Non-latching and cannot be

changed.

Step 1: Press the Cal/Reset button, wait for countdown to finish and when

S e t R e l a y O p t i o n s Y E S ? displays press the Cal/Reset

Button again to select. The flashing

Step 2: The message

display then shows

E n e r g i z e d Y E S ?

setting when it displays. The flashing

Step 3: The message

L a t c h i n g Y E S ? and then N o n L a t c h i n g Y E S ? . Press the

Cal/Reset Button to select. The flashing

L o w A l a r m – – – C o i l S t a t u s displays. The

E n e r g i z e d Y E S ? and then D e -

. Press the Cal/Reset Button to select the

L a t c h S t a t u s displays. The display then shows

Y E S confirms the selection.

Y E S confirms the selection.

Y E S confirms the

selection.

Step 4: The message

S e t L o w displays. Low alarm set-points are then

displayed in varying increments (increment dependant upon

defined sensor range). When the required level displays, press the

Cal/Reset Button to select. The level chosen will flash to confirm

the selection.

Step 5: The message

display then shows

E n e r g i z e d Y E S ? . Press the Cal/Reset Button to select. The

flashing

Step 6: The message

L a t c h i n g Y E S ? and then N o n L a t c h i n g Y E S ? . Press the

Cal/Reset Button to select. The flashing

H i g h A l a r m – – – C o i l S t a t u s displays. The

E n e r g i z e d Y E S ? and then D e -

Y E S confirms the selection.

L a t c h S t a t u s displays. The display then shows

Y E S confirms the

selection.

Step 7: The message

S e t H i g h displays. High alarm set-points are then

displayed in varying increments (increment dependant upon

defined sensor range). The high alarm set-point is always higher

than the low alarm level. When the required level displays, press

the Cal/Reset Button to select. The level chosen will flash to

confirm the selection.

Step 8: Once set, the RM2 will return to

0 0 .

RM2-ARD 9

Page 14

Net Safety Monitoring Inc

S

E L E C

T DI S P L A

Y LA N G U A G E

The display language can onl y be set using the Terminal interface.

1. Open terminal software and establish a connection.

2. Once connected, press Enter twice for Main Menu.

3. The Main Menu will display.

4. Enter the number 4 to select

4) Display Language.

5. The language will change to Espanol then Francais and back to English

each time 4 is entered.

6. Press Enter twice for Main Menu.

Note: The factory default is English.

C

A L I B R A T I O N

WARNING: When using a combustible sensor with the RM2 , the

sensor has to be connected to a transmitter or controller. The 4-20 output

from this configuration is then connected to the RM2 as signal. Calibration

must be performed transmitter or controller NOT the RM2. Refer to the

Uni-Tran or

Use the

messages will appear at RM2.

Calibration Procedure—ST Series

WARNING: The calibration procedure requires approximately

5 minutes to complete. If gas is not applied at the appropriate time, a calibration

failure may occur (refer to "Calibration Failure/Interruption" on page 11 for

specific information).

For accurate performance, calibrate sensors using 50% span of the specific gas

of concern. The concentration of gas, c orresponding to 100% of full scale, is

converted to a linear 4 to 2 0 mA output signal which can be powered from the

primary dc supply of the instrument. Power up the unit for at least 4 hours

BEFORE first calibration.

The following calibration procedure should be followed to ensure an accurate

correlation between the 4 to 20 mA output signal and the gas concentration.

Millennium transmitter manuals for calibration instructions.

ONTROLLERS /TRANSMITTERS to monitor display messages. Not all

C

S

ENSORS

Note: The ST Series S

1. Confirm successful power up of RM2

ENSORS must be calibrated from the RM2 Front Panel.

—Status LED Green Blip; no fault

indicated.

2. Press and Hold Cal/Reset Button until

S w i t c h O N and countdown

completes.

3. When

4. When

5. Wait for

C a l i b r a t e S e n s o r Y E S ? displays, press the Cal/Reset Button

to select

Y E S ? Selection will be confirmed by a flashing Y E S .

A p p l y C l e a n A i r displays apply clean air.

A p p l y 5 0 % S p a n G a s to display and apply specific gas at a

rate of 0.5 litres per minute.

6. The display will show the actual gas value at last calibration.

7. Re move span gas when the message

8. The message

9. Apply zero gas (clean air) again to purge system.

C a l C o m p l e t e will display when calibration is complete.

R e m o v e G a s displays.

Note: Always apply test gas after calibration to verify operation.

RM2-ARD 10

Page 15

Net Safety Monitoring Inc

Figure 10: Calibration Procedure Abort Calibration

The Calibration procedure may be aborted. When the display shows

Display

Shows

C a l i b r a t e

S e n s o r

Y E S

A p p l y C l e a n

A i

A p p l y 5 0

S p a n G a s

C a l i b r a t i n

G a s V a l u e @

l a s t c a l i b r a t i o

R e m o v e G a s

Action

Select Y E S

?

Apply clean (zero air)

r

%

g

Apply specific gas

n

Remove gas

Wait

?

Status LED and

Current Output

Status LED Solid

Green / 3.0 mA

Status LED Fast

Flash Red / 3.3 mA

Status LED Fast

Flash Red / 3.3 mA

Status LED Solid

Green / 3.6 mA

5 0 % S p a n G a s , press and hold the Cal/Reset button until the abort

calibration countdown 10-0 com pletes and the displa y retur ns to

Calibration Failure/In terru ptio n

If the calibration procedure fails, the Status LED alternates between Green and

Red and the analog output changes back and forth from 3. 0 to 3.3 mA. The

message

message

F a i l Z e r o is displayed if span gas is not applied or recognized; the

F a i l S p a n will display if the calibration process is interrupted.

The unit remains in a failed state until manually reset. After the Manual Reset,

the unit will return to normal operation based on previous calibration values.

See "Manual Reset" on page 1 1 for instructions.

R

E S E T

Manual Reset

A Manual Reset is required to clear a latched relay alarm for individual

channels. Simply press the specific Channel’s Cal/Reset Button, on the Front

Panel of the RM2, to clear a latched alarm.

C a l

C o m p l e t e

0 0

Apply clean air

purge

system

Normal

Operation

to

Status LED Solid

Green / 3.6 mA

Status LED Blip /

Green 4.0 mA

Remote Reset

The RM2 can be wired to an external device (refer to illustration"Remote

Reset—Wiring" on page 4) so latched alarms for both channels may be

remotely cleared.

A p p l

0 0 .

y

RM2-ARD 11

Page 16

Net Safety Monitoring Inc

STEP 4 —

M

ONITOR

E

V E N

T LO G G I N G

The Event Logging feature securely stores in protected RAM up to 1000 events.

The time and date of each occurrence is recorded along with the channel,

detector type and the associated alarm, fault or calibration event. A maximum of

1000 events are stored although as few as 10 events may be viewed at a time.

When the 1000th event is reached, the first event stored will be removed.

In order to accurately track events, the time and date must first be set.

Setting Time and Date

Step 1: Open terminal software and establish a connection.

Step 2: Press Enter for Main Menu.

Step 3: T ype 3 and press Enter to select 3) Event

Step 4: T ype 1 and press Enter to select

Step 5: Enter the hour (24 hours) and then minutes.

Step 6: T ype 2 and press enter to select 2) Date.

Step 7: Enter the day/month/year using 2-di gits for each and separate with

Step 8: Press Enter to confirm entry.

Use 2-digits for hour/minutes and separate with a space.

a space.

Log

Menu.

1) Time.

Figure 1 1: Event Logging Menu

Event Logging Menu

1) Time (HH:MM)=14/04

2) Date (DD/MM/YY)=03/12/03

3) Display last 10 Events

4) Display All Events

Enter 1->4, then press the Enter key

Once the time and date have been set the RM2 will automatically and accurately

track the alarm and fault conditions as well as other events such as sensor

calibration.

Figure 12: Event Logging Display Menu

Time(HH:MM):14.12 - Date (DD/MM/YY):03/12/03 - Ch:02 Event: vi fault

Time(HH:MM):14.12 - Date (DD/MM/YY):03/12/03 - Ch:02 Event: Warning!!

Time(HH:MM):14.12 - Date (DD/MM/YY):03/12/03 - Ch:01 Event: high alarm

Time(HH:MM):03.11 - Date (DD/MM/YY):03/17/03 - Ch:02 Event: fire

Time(HH:MM):19.12 - Date (DD/MM/YY):05/02/03 - Ch:02 Event: fault

Time(HH:MM):22.09 - Date (DD/MM/YY):06/22/03 - Ch:01 Event: high alarm

Time(HH:MM):06.01 - Date (DD/MM/YY):08/11/03 - Ch:01 Event: calibrate

Press Enter Key to exit

Note: Press Enter at any time to stop the scroll through all events.

RM2-ARD 12

Page 17

Net Safety Monitoring Inc.

F

I RE

Table 2: FIRE—Current Output, LEDs and Display Messages

Status

Power Down Mode 0 mA

Current O/P

Channel 1 and

LEDs

R1 &

R3

Fault

(yellow)

off

R2 &

Fire

(red)

off

2

R4

(yellow

System LEDs

Fault

off

Status

(red)

(green)

-

Blip

Scrolled

Display

Messages

O f f

RM2 System failure 0 mA

Fire Head Electronic failure 0-0.5 mA Solid

Internal Power Fault or system power out of

range

1.0 mA Solid

Automatic VI Test Failure 2.0 mA Solid

Start Delay (90 seconds) 3.0 mA

Normal Operation 4.0 mA

Bypass mode 4.0 mA

Background radiation source UV 6.0 mA

Background radiation source IR 8.0 mA

Early W arni ng - Intermittent radiation

detected

16.0 mA

Fire confirmed 20.0 mA

off

off

off

off

off

off

off

Solid

* The last message displayed prior to the failure will remain on the display .

-

Solid -

off

off

off

off

off

off

Solid - Blip

off

off

off

off

off

off

off

off

off

off

off

off

-

Blip

-

Blip

-

Blip

-

Blip

-

Blip

-

Blip

-

Blip

-

Blip

-

Blip

-

l a s t m e s s a g e *

S e n s o r F a u l t

S e n s o r F a u l t

V I F a u l t

S t a r t D e l a y M i l l e n n i u m

N O R M

C h a n n e l B y p a s s

U V P r e s e n t

I R P r e s e n t

W a r n i n g ! !

F I R E ( f l a s h e s )

RM2-ARD 13

Page 18

Net Safety Monitoring Inc

FIRE ONLY—Manual Visual Integrity (VI) Testing

The RM2 can be wired (using Terminal 13 for Channel 1 and T erminal 17 for

Channel 2) so F

IRE HEAD Visual Integrity test results can be displayed and

monitored by the RM2.

WARNING: Both Channels must be set to F

IRE for VI Testing and the

connected alarm system placed in bypass. The Phoenix IR3S cannot be wired

for VI testing.

Step 1: Press and hold Channel #1 or #2 Cal/Reset button on the Front

Panel. W ait for the

complete.

S w i t c h O n message and countdown (10-0) to

Step 2: When M a n u a l V I T e s t Y E S ? displays press the Cal/Reset

Button.

Step 3: After 5 seconds, the test lamp turns on for 30 seconds and analog

output drops to 3 mA.

Step 4: Refer to T able 3 below for the list of possible status messages for

the Visual Integrity Test.

Step 5: The VI T est message is displayed for 30 seconds or press and hold

the Cal/Reset Button until the VI display message flashes

(approximately 10 seconds) to return to

30 seconds.

N O R M before the

Table 3: Manual Visual Integrity Testing—FIRE only

Status Display Message

F

IRE ONLY—Force Al a rm O u tp ut Test

The Force Alarm Output tests Relay contacts by switching relays for 2 seconds

and stepping Analog output through the primary alarm levels. Test s are initiated

from the RM2.

WARNING: The connected alarm system must be placed in bypass

during the Force Alarm Output test.

Step 1: Press and hold Channel #1 or #2 Cal/Reset button on the Front

Panel. W ait for the

S w i t c h O n message and countdown (10-0) to

complete.

Step 2: When

F o r c e A l a r m O u t p u t Y E S ? displays press the Cal/

Reset Button.

Step 3: When I s i t S a f e t o A c t i v a t e A l a r m s ? Y E S ? displays,

press the Cal/Reset Button.

Note: If you do not press

Y E S ? as this prompt, the RM2 will return to

normal operation.

Step 4: When

R e l a y s Y E S ? displays, press the Cal/Reset Button. The

flashing

times during the Relay test and then return to

If

Y E S confirms the selection. The message O n will flash 4

N O R M .

Y E S ? is not selected, the next option is displayed.

Step 5: When A n a l o g O P ? Y E S ? displays, press the Cal/Reset

Button. The RM2 will then test primary analog output responses

and then return to

N O R M .

VI Fault

Optical surfaces require cleaning

Optical surfaces clean

Optical surfaces perfectly clean

RM2-ARD 14

F A I L

P A S S

G O O D

B E S T

Page 19

R

Net Safety Monitoring Inc.

ST

S

E R I E

S SE N S O R S

When calibrating a sensor, status is reflected by the System LEDs.

Table 4: ST SERIES SENSORS—Current Output, LEDs and Display Messages

Status

Current O/P

Start Delay (few seconds) 3.0 mA

Normal operation 4.0 mA

Power Down Mode 0 mA

RM2 System failure 0 mA

Sensor Fault <2.5 mA

Excess drift (>10%) 2.5 mA

Calibrate Sensor 3.0 mA

Apply clean air 3.0 mA

Apply calibration gas - 50% span

3.3 mA

Span is set, remove gas 3.6 mA

Return to normal operation 3.6 mA

Calibration procedure failed/interrupted 3.0 / 3.3 mA

Gas present

>4.0-20.0 mA

* The last message displayed prior to the failure will remain on the display .

Channel 1 and

LEDs

1&R3

Low

(yellow)

(when

off

off

off

off

off

off

off

off

off

off

off

ON

set

point

reached)

2

R2 &

R4

High

(red)

off

off

off

-

Solid off

off

off

off

off

off

off

off

ON

(when

(yellow)

Solid - Blip

Solid - Blip

set

point

reached)

System LEDs

Fault

off

off

off

off

off

off

off

off

off

Alternate

off

Status

(red)

(green)

-

Blip

-

Blip

-

Blip

-

Solid

Fast

Flash

-

Solid

-

Solid

-

S t a r t D e l a y M i l l e n n i u m

-

l a s t m e s s a g e *

C a l i b r a t e S e n s o r

Solid

-

Blip

A p p l y C l e a n A i r

A p p l y 5 0 % S p a n G a s

1 t o 1 0 0 % f u l l S c a l e

Scrolled

Display

S e n s o r F a u l t

( g a s v a l u e

R e m o v e g a s

C a l . c o m p l e t e

( g a s v a l u e

Messages

0 0

O f f

N e g D r i f t

F a i l Z e r o

F a i l S p a

)

n

)

RM2-ARD 15

Page 20

R

Net Safety Monitoring Inc.

C

O N T RO L L E R S

/TR A N S M I T T E R S

The RM2 receives and interprets the 4-20 current output sent by the Un i-Tran or the Millennium. Not all visuals

Table 5: CONTROLLERS/TRAN SMITTERS—Current Output, LEDs and Display Messages

Status

Start Delay (90 seconds)

Message will also appear

when calibrating

the

C

ONTROLLER

RANSMITTER

T

from

/

Normal operation

Message will also appear

when calibrating

the

C

ONTROLLER

RANSMITTER

T

from

/

Current O/P

3.0 mA

4.0 mA

Power Down Mode 0 mA

Channel 1 and 2 LEDs System LEDs

1&R3

Low

(yellow)

off

off

off

R2 &

High

(red)

off

off

off

R4

Fault

(yellow)

off

off

off

Status

(red)

off

off

off

(green)

Blip

Blip

Blip

aler

ts will appear at the RM2.

Scrolled

S t a r t D e l a y M i l l e n n i u m

Display

Messages

0 0

O f f

RM2 System failure 0 mA

Sensor Fault 2.5 mA

Gas present

>4.0-20.0 mA

off

off

ON

(when set

reached)

point

off

off

ON

(when set

reached)

Solid

Solid

off

off

point

off

off

off

l a s t m e s s a g e *

Blip

Blip

S e n s o r F a u l t

1 t o 1 0 0 % f u l l S c a l e

* The last message displayed prior to the failure will remain on the display .

RM2-ARD 16

Page 21

Digital output from Modbus Set-up:

The RM2-ARD also allows digital output to be monitored by the user. Ensure that the proper connections are made when connecting the RM2ARD output terminals 19 and 20 (marked ‘A’ and ‘B’) to PLC (RTU). For output bit assignments for Combustible and Toxic sensor see table 7

and table 8. For output bit assignment for Fire head see table 9.

Hardware Setup

Figure 13: User interface for Modbus setup

For Hyper Terminal connection: An RJ11 cable with DB9 (female) connector is

used for RS-232 serial connection. Use the RJ 11 and DB9 (female) connector

with a RS-232(male) to USB converter, if the computer doesn’t ha ve a RS-232

serial connection.

RM2‐ARD

RJ11 connection

Output terminal A

Output terminal B

Front of unit Rear of unit

Modbus RTU Slave Modbus RTU Master

Note: For Modbus communication, the user should w ire the system according RS 485 conventions and adhere to local electrical codes.

User input interface for hyper terminal

Computer

USB or RS232 serial input

PLC

A

B

RM2‐ARD

17

Page 22

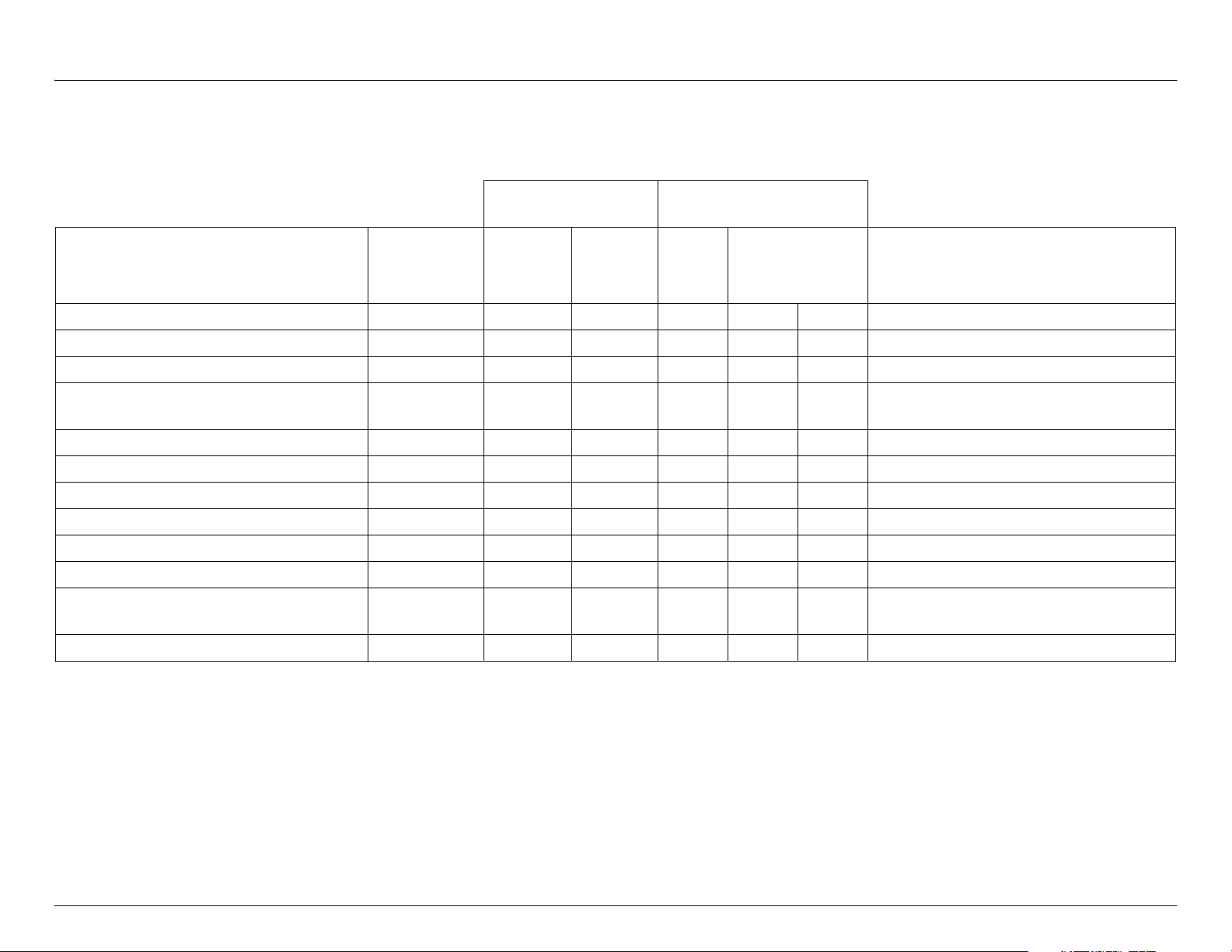

Software Setup

Connect the Modbus output using baud rates of 4800, 9600, 14.4 K, 19.2K, 28.8 K, 38.4K or 57.6 K bps. Parity is none and stop bit is 1.

Addresses are assigned by the user.

Modbus Register definitions

Four Modbus registers are utilized when setting up for digital output. They are as follows:

40001 Scaled sensor output channel 1 40003 Status Bits channel 1(binary)

40002 Scaled sensor output channel 2 40004 Status Bits channel 2(binary)

Binary values of Registers 40003 and 40004 are used indicate the type of sensor /detector being used. With 16 bits( 2 byte) assigned to each

register , only bits # ‘s 0, 1, 2 and 3 are utilized at this time. Table 1 below shows the bits assigned for combustible sensor setup, toxic sensor and

Flame detector.

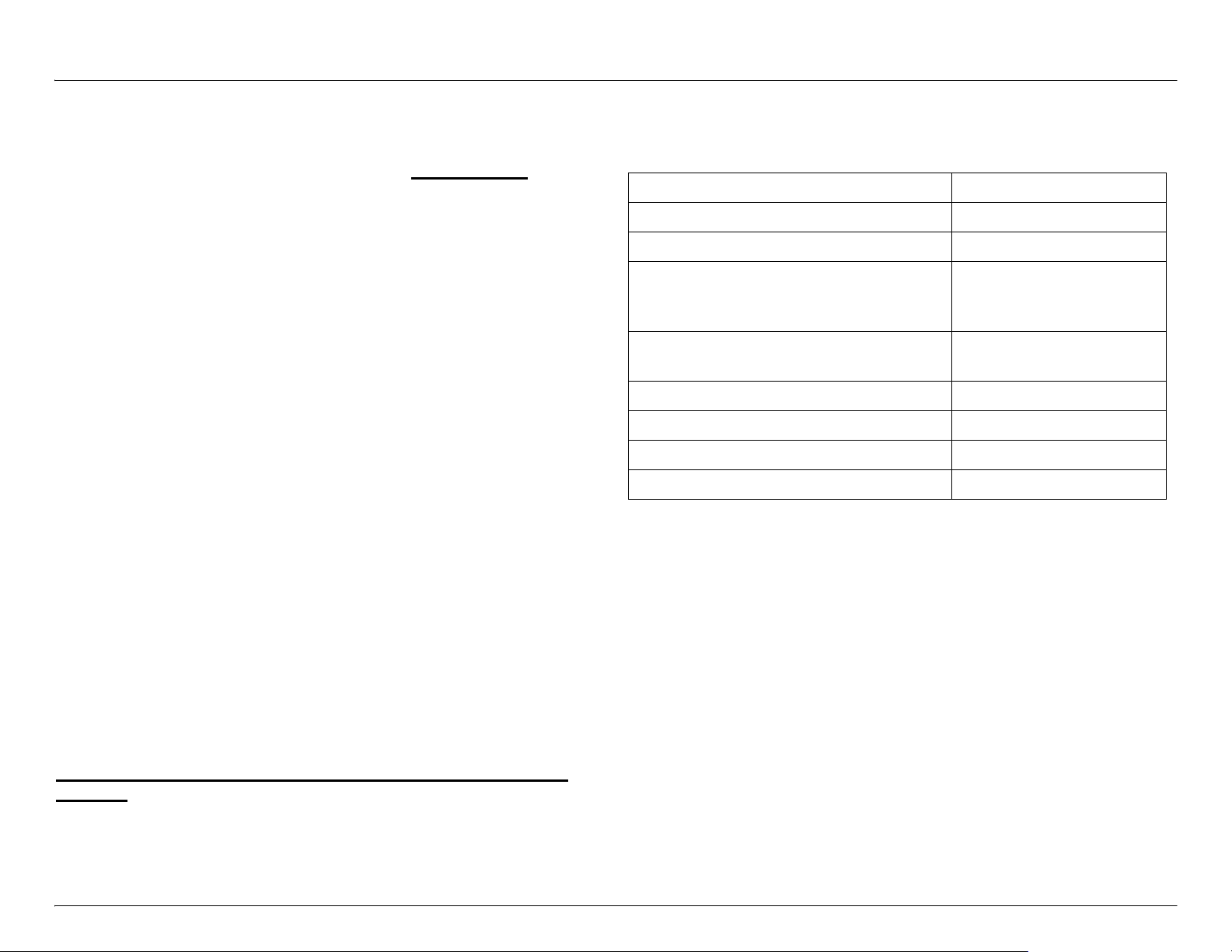

Table 6: Status bit assignment for sensor type (Combustible, Toxic and Fire)

Assigned Registers

& Channel #

Channel is

inactive(turned off)

Status bits for

Combustible set-up

Status bits for Toxic

sensor(ST series)

Status bits for

Fire heads

Register 40003

(Channel 1)

Register 40004

(Channel 2)

RM2‐ARD

xxxx xxxx 0000 0000 xxxx xxxx 0000 0001 xxxx xxxx 0000 0010 xxxx xxxx 0000 0011

xxxx xxxx 0000 0000 xxxx xxxx 0000 0001 xxxx xxxx 0000 0010 xxxx xxxx 0000 0011

18

Page 23

Note: The Status bits for Oxygen (to be released soon) will be xxxx xxxx 0000 0100

GAS: Modbus Registers and Status bit assignment

Combustible gas detection: The table below shows the status registers and bit assignments for various outputs when Combustible gas

sensor (with transmitter) is connected to the RM2-ARD unit.

Table 7: Status bit assignment for Combustible (signal from LEL sensor and transmitter) output conditions

Assigned Registers

& Channel #

Combustible

Power up

Combustible

Sensor fault

Combustible

Low Alarm activated

Combustible High

Alarm activated

Register 40003

(Channel 1)

Register 4004

(Channel 2)

xxxx xxxx 0001 0001 xxxx xxxx 0010 0001 xxxx xxxx 0100 0001 xxxx xxxx 1000 0001

xxxx xxxx 0001 0001 xxxx xxxx 0010 0001 xxxx xxxx 0100 0001 xxxx xxxx 1000 0001

Toxic gas detection: The table below shows the status register and bit assignments for various outputs when a Toxic (ST series) gas

sensor is connected to the RM2-ARD unit.

Table 8: Status bit assignment for Toxic sensor (ST series) output conditions

Assigned Registers

& Channel #

Register 40003

(Channel 1)

Register 4004

(Channel 2)

Toxic

Power up

xxxx xxxx 0001 0010 xxxx xxxx 0010 0010 xxxx xxxx 0100 0010 xxxx xxxx 1000 0010

xxxx xxxx 0001 0010 xxxx xxxx 0010 0010 xxxx xxxx 0100 0010 xxxx xxxx 1000 0010

Toxic (ST series)

Sensor fault

Toxic

Low Alarm activated

Toxic High

Alarm activated

RM2‐ARD

19

Page 24

k

g

k

g

FIRE: Modbus Registers and Status bit assignment

Fire detection: The table below shows the status registers and bit assignments for various outputs when a Fire head is connected to

the RM2-ARD unit. Outputs are indicated by address of 40001 and 40002 registers.

Table 9: Status bit assignment for Fire head output conditions

Assigned Registers

& Channel #

Fire head

Power up

Normal operation Fire head

fault

Bac

round IR

Energy(8.0 mA)

Bac

round UV

Energy(6.0 mA)

Register 40001

xxxx 0000 0000 0001 xxxx 0000 0000 0100 xxxx 0000 0000 1000 xxxx 0000 0001 0000 xxxx 0000 0010 0000

(Channel 1)

Register 40002

xxxx 0000 0000 0001 xxxx 0000 0000 0100 xxxx 0000 0000 1000 xxxx 0000 0001 0000 xxxx 0000 0010 0000

(Channel 2)

Note: Status bits for output due to Self- test failure (not yet used) will be xxxx xxxx 0000 0010

Table 9 (cont’d): Status bit assignment for Fire head output conditions

Assigned Registers

& Channel #

Instant fire warning Fire present Channel bypassed,

(available only if

both channel are set

for fire)

Register 40001

xxxx 0000 0100 0000 xxxx 0000 1000 0000 xxxx 0001 0000 0000 xxxx 0010 0000 0000

(Channel 1)

Register 40002

xxxx 0000 0100 0000 xxxx 0000 1000 0000 xxxx 0001 0000 0000 xxxx 0010 0000 0000

(Channel 2)

Note: Channel bypass is only available if both channels are set for fire.

Sensor power OFF

(loss of power from

Fire head)

RM2‐ARD

20

Page 25

Net Safety Monitoring Inc

STEP 5 —

SENSORS—Periodic Response Test

M

AINTAIN

We recommend the sensors be verified or calibrated every 3 months. A typical

response check involves the application of calibration gas to the sensor, then t he

observation of the response LEDs, analog output, display and external

monitoring equipment. Be sure to prevent unwanted response of external

monitoring devices and equipment during this procedure. If the response to

calibration gas is within its specified accuracy then it is not necessary

perform

a calibration. For example, when 50% of full scale is applied, the

to

response is expected to be between 11.5 mA (47% of full scale) and 12.5 mA

(53% of full scale). An additional consideration is the accuracy tolerance of the

calibration gas which may be + or - a few percent. If t he calibration gas is + or 10% of full scale then the reading may be from 10.7 mA (42% of full scale) to

13.3 mA (58% of full scale).

T

RO U B L E SH O OT

- Response to the input should be checked and, if necessary, calibration should

be performed whenever any of the following occur. Refer to "Calibration" on

page 10 for calibration instructions.

•Excess negative drift is indicated by 2.5 mA current output

•Sensor or controller/transmitter is connected or disconnected

•Long term or high concentration exposure to gas

- The RM2 is not designed to be repaired in the field. If a problem should

develop, first calibrate the device and carefully check for faulty wiring. If it is

determined that the problem is caused by an electronic failure, the device must

be returned to the factory for repair. Refer "How to Return Equipment" on

page 18 for detailed instructions.

- Apparent sensor failure (see "Calibration Failure/Interruption" on page 11)

may occur if calibration process has begun but span gas is not applied when

prompted or if span gas is removed during calibration process. Perform a

manual reset (refer to "Manual Reset" on page 11) and re-calibrate sensor.

- If Front Panel buttons appear non-responsive

—recycle power. (Can occur

when set up at Front Panel is interrupted by an attempt to also set up using

T erminal) . DOES NOT af fect detection functionalit y.

- Consult the manual supplied with the Fire Head, Millennium or Uni-Tran for

further troubleshooting information.

RM2-ARD 21

Page 26

Net Safety Monitoring Inc.

HOW TO RETURN

E

QUIPMENT

A Material Return Authorization number is required in order to return

equipment. Please contact Net Safety Monitoring at (403) 219-0688 before

returning equipment or consult our Service Department to possibly avoid

returning equipment.

If you are required to return equipment, include the following i nformation:

1. A Material Return Authorization number (provided over the phone to you

by Net Safety).

2. A detailed description of the problem. The more specific you are regarding

the problem, the quicker our Service department can determine and correct

the problem.

3. A company name, contact name and telephone number.

4. A Purchase Order, from your company , authorizing repairs or request for

quote.

5. Ship all equipment, prepaid to:

Net Safety Monitoring Inc

2721 Hopewell Place NE

Calgary, Alberta, Canada

T1Y 7J7

6. Mark all packages: RETURN for REP AIR

W a ybills, for shipments from outside Canada, m ust state:

Equipment being returned for repair

All charges to be billed to the sender

Also, please ensure a duplicate copy of the packing slip is enclosed inside the

box indicating item 1-4 along with the courier and account number for returning

the goods.

All Equipment must be Shipp ed prepaid. Collect shipments will not be

accepted.

Pack items to protect them from damage and use anti-static bags or aluminumbacked cardboard as protection from electrostatic discharge.

S

P A

RE PA R T S

/AC C E S S O R I E S

Table 10: Part Numbering

Description Net Safety Part Number

Communications Kit RM2-COM-KIT

W all m ount Controller Box WM2-HSG-ASSY

Solar Shield, 2-channel Analog/Relay

Output for Toxic and Combustible sensors or

SS2-AR

Fire Detectors

Solar Shield, 2-channel Controller/Terminal

Box

SS2-HSG-ASSY -12V or

24V

Solar Shield 2-Battery Enclosure SS-2BAT-ASSY

Solar Shield Pole Installation Assembly SS-POLE-ASSY

Solar Shield 50 Ft Power Cable Extension CAB-0035

Solar Shield Battery Box Interconnect cable CAB-0041

RM2-ARD 22

Page 27

Net Safety Monitoring Inc

Appendix A:

E

LECTROSTATIC SENSITIVE DEVICE (ESD)

Electrostatic discharge (ESD) is the transfer, between bodies, of an electrostatic

charge caused by direct contact or induced by an electrostatic field.

The most common cause of ESD is physical contact. Touching an object can

cause a discharge of electrostatic energy

occurs near electronic components, it can damage or destroy those components.

In some cases, damage is instantaneous and an immediate malfunction occurs.

However, symptoms are not always

or seemingly normal for an indefinite period of time, followed by a sudden

failure.

T o eliminate potential ESD damage, review the following guidelines:

• Handle boards by metal shields—taking care not to touch electronic

components

• Wear grounded wrist or foot straps, or ESD shoes or heel grounders to

dissipate unwanted static energy

• Prior to handling boards, dispel an y charge in your body or equi pment

• Ensure components are transported and stored in static safe packaging

• When returning boards, carefully package in the original carton and static

protective wrapping

• Ensure ALL personnel are educated and trained in ESD Control Procedures

In general, exercise accepted and proven precautions normally observed when

handling electrostatic sensitive devices.

A warning label is placed on the packaging, identifying product using

electrostatic sensitive semiconductor devices.

—ESD! If the charge is sufficient and

immediate—performance

may be marginal

RM2-ARD 23

Page 28

A

A

A

A

A

A

A

Net Safety Monitoring Inc.

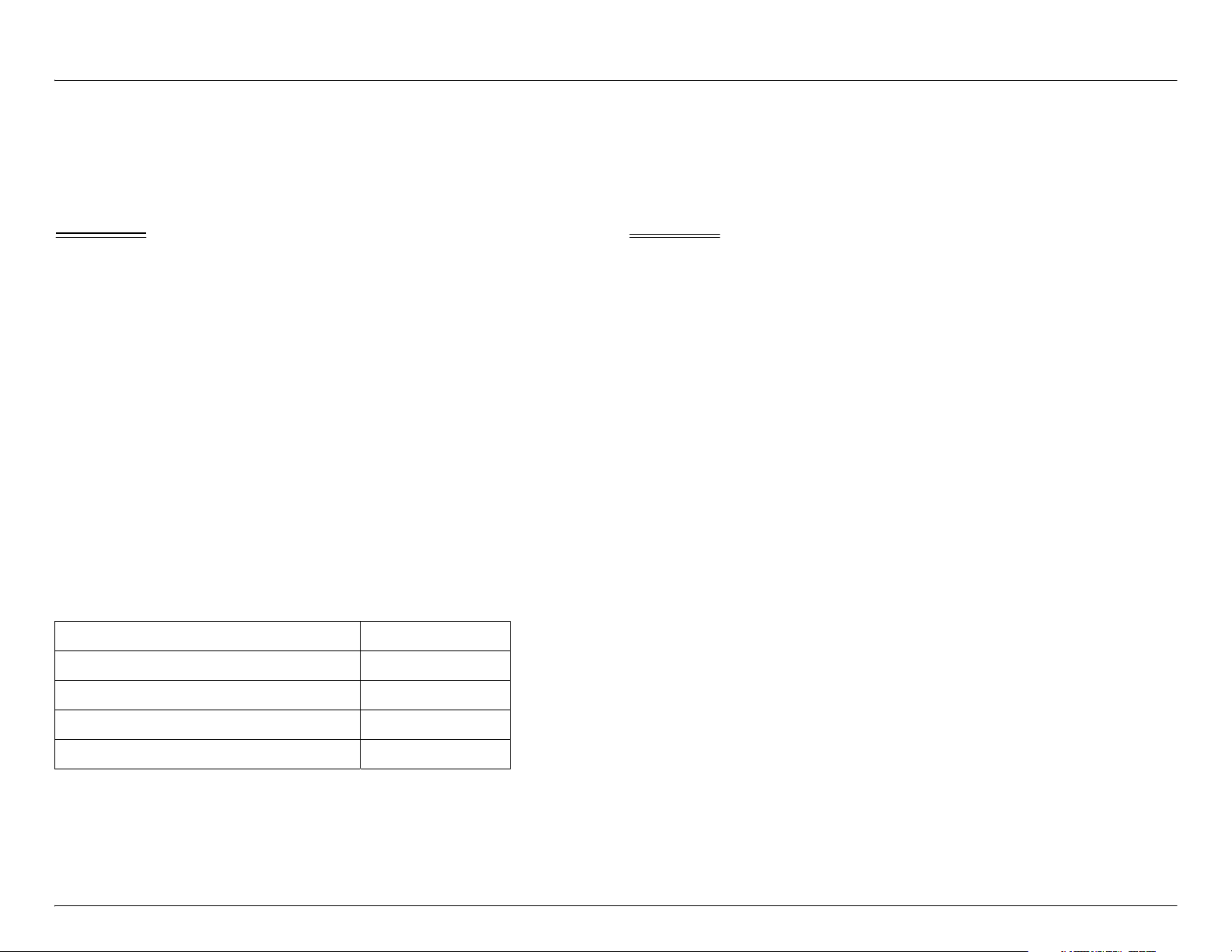

Appendix B: RESISTANCE TABLE (Ohms)

Distance (Feet)

100 1.02 0.64 0.40 0.25 0.16 0.10 0.06

200 2.03 1.28 0.80 0.51 0.32 0.20 0.13

300 3.05 1.92 1.20 0.76 0.48 0.30 0.19

400 4.06 2.55 1.61 1.01 0.64 0.40 0.25

500 5.08 3.20 2.01 1.26 0.79 0.50 0.31

600 6.09 3.83 2.41 1.52 0.95 0.60 0.38

700 7.11 4.47 2.81 1.77 1.11 0.70 0.44

800 8.12 5.11 3.21 2.02 1.27 0.80 0.50

900 9.14 5.75 3.61 2.27 1.43 0.90 0.57

1000 10.20 6.39 4.02 2.53 1.59 1.09 0.63

1250 12.70 7.99 5.03 3.16 1.99 1.25 0.79

1500 15.20 9.58 6.02 3.79 2.38 1.50 0.94

1750 17.80 11.20 7.03 4.42 2.78 1.75 1.10

2000 20.30 12.80 8.03 5.05 3.18 2.00 1.26

2250 22.80 14.40 9.03 5.68 3.57 2.25 1.41

2500 25.40 16.00 10.00 6.31 3.97 2.50 1.57

3000 30.50 19.20 12.00 7.58 4.76 3.00 1.88

3500 35.50 22.40 14.10 8.84 5.56 3.50 2.21

4000 40.60 25.50 16.10 10.00 6.35 4.00 2.51

4500 45.70 28.70 18.10 11.40 7.15 4.50 2.82

5000 50.10 32.00 20.10 12.60 7.94 5.00 3.14

5500 55.80 35.10 22.10 13.91 8.73 5.50 3.46

6000 61.00 38.30 24.10 15.20 9.53 6.00 3.77

6500 66.00 41.50 26.10 16.40 10.30 6.50 4.08

7000 71.10 44.70 28.10 17.70 11.10 7.00 4.40

7500 76.10 47.90 30.10 19.00 12.00 7.49 4.71

8000 81.20 51.10 23.10 20.20 12.70 7.99 5.03

9000 91.40 57.50 36.10 22.70 14.30 8.99 5.65

10 000 102.00 63.90 40.20 25.30 15.90 9.99 6.28

Note: Resistance shown is one way . This figure should be doubled when determining closed loop resistance.

WG #20

WG #18

WG #16

WG #14

WG #12

WG #10

WG #8

RM2-ARD 24

Page 29

Net Safety Monitoring Inc

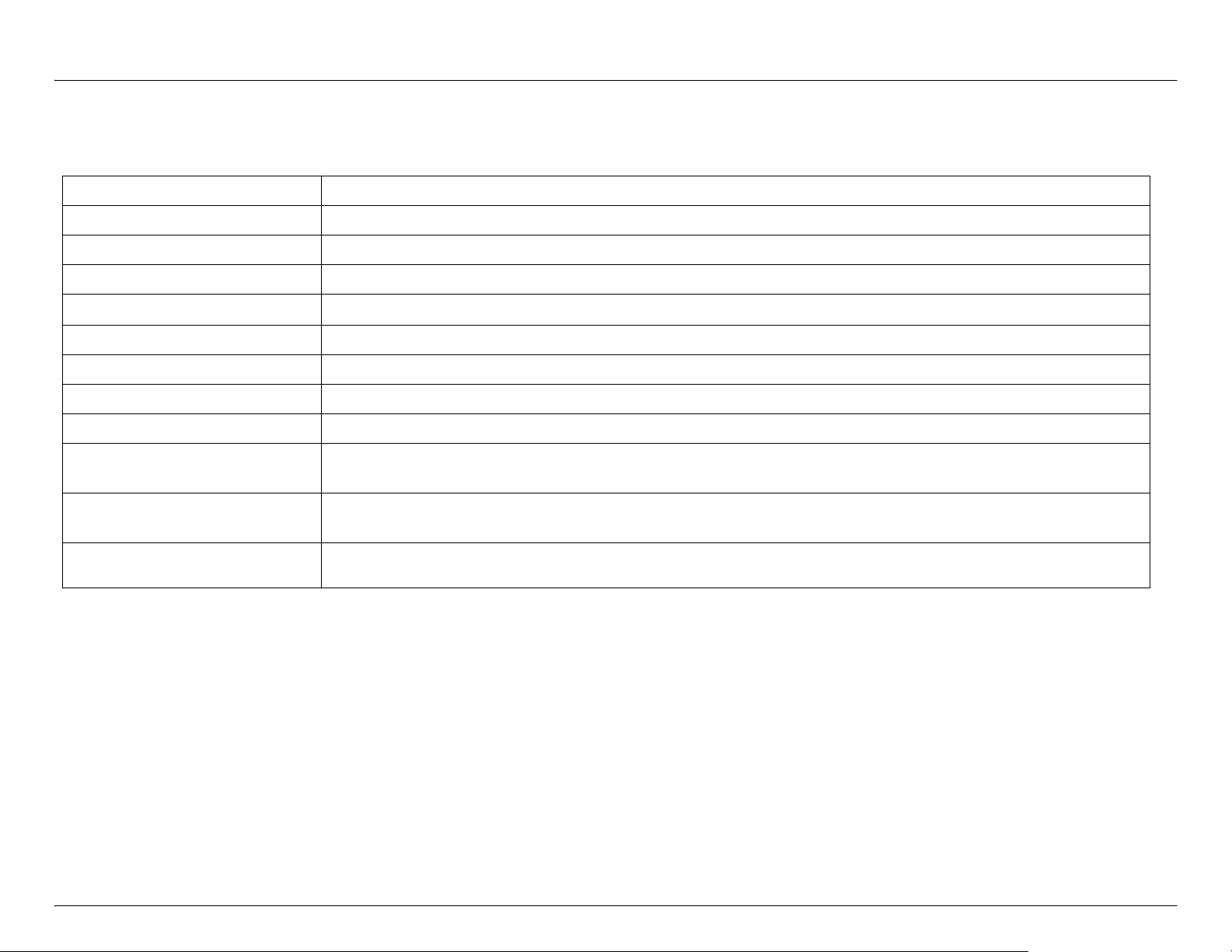

Appendix C: RM2 S

PECIFICATIONS

MILLENNIUM RM2-ARD (ANALOG / RELAY / DIGITAL)

Operating V oltage

Power Consumption 12 V dc

Power Consumption 24 V dc

Operating T emperature

Humidity Range

Chassis Material

Weight

Certifications

Current Outputs-2 channel

Relay Output-5 relays

Digital Output

10.5 V dc to 32 V dc

nominal 150 mA/250 mA (1.8 W/3.0 W) de-energized/energized m aximum 290 mA/3.48 W

nominal 80 mA/130 mA (1.92 W/3.12 W) de-energized/energized maximum 160 mA/3.84 W

-40

°C to +80°C (-40F to +176F)

0-100% relative humidity , non-condensing

16 gauge steel / powder coated or chromatic

2 lbs (0.9 kilograms)

CSA and NRTL/C for hazardous locations. Class 1, Division 2, Groups A, B, C and D

4 to 20 mA - Into a maximum loop im pedance of 800 Ohms at 32 V dc or 150 Ohms at 10.5 V dc. Isolated or non-

isolated loop supply.

Form C contacts rated 5 Am ps at 30 V dc / 250 V ac. Sel ectable ener gized/de-energized, latching/non-latching Fire

Relay . Fault relay is factory set as energized, non-latching and cannot be modified.

Digital output available via terminals 19 and 20 (A and B) for Modbus communication.

RM2-ARD 25

Page 30

Y

NET SAFET

MONITORING

Net Safety Monitoring

2721

Hopewell Place NE

C

algary,

Alberta, Canada Tl Y 7J7

Telephone: (403) 219-0688 Fax: (403)

netsafe@net-safety.com

E-mail:

N\'/W.netsafety.com

Inc.,

INC.

219-0694

Loading...

Loading...