Page 1

Net Safety™ Millennium

Air Particle Monitor (APM) Oil Mist Detector

Reference Manual

00809-0100-4077, Rev AB

May 2018

Page 2

Important instructions

Because these products are sophisticated technical instruments, it is important that the owner and operation personnel must

strictly adhere both to the information printed on the product nameplate and to all instructions provided in this manual prior to

installation, operation, and maintenance.

WARNING!

Installing, operating, or maintaining this product improperly could lead to serious injury or death from explosion or exposure to

dangerous substances. Comply with all information on the product, in this manual, and in any local and national codes that apply to

the product. Do not allow untrained personnel to work with this product.

The information in this document has been carefully checked and is believed to be entirely reliable with all of the necessary

information included.

WARNING!

All individuals who have or will have responsiblity for using, maintaining, or servicing the product must read this manual carefully.

CAUTION!

EQUIPMENT DAMAGE

The detector is not field repairable due to the meticulous alignment and calibration of the sensors and the respective circuits.

Page 3

Warranty

1. Limited Warranty . Subject to the limitations contained in Section 2 (Limitation of Remedy and Liability) herein, Seller

warrants that (a) the licensed firmware embodied in the Goods will execute the programming instructions provided by

Seller; (b) that the Goods manufactured by Seller will be free from defects in materials or workmanship under normal use

and care; and (c) Services will be performed by trained personnel using proper equipment and instrumentation for the

particular Service provided. The foregoing warranties will apply until the expiration of the applicable warranty period.

Sensors and detectors are warranted against defective parts and workmanship for 24 months from the date of purchase and

other electronic assemblies for 36 months from the date of purchase. Products purchased by Seller from a third party for

resale to Buyer (Resale Products) shall carry only the warranty extended by the original manufacturer. Buyer agrees that

Seller has no liability for Resale Products beyond making a reasonable commercial effort to arrange for procurement and

shipping of the Resale Products. If Buyer discovers any warranty defects and notifies Seller thereof in writing during the

applicable warranty period, Seller shall, at its option, (i) correct any errors that are found by Seller in the firmware or

Services; (ii) repair or replace FOB point of manufacture that portion of the Goods found by Seller to be defective; or (iii)

refund the purchase price of the defective portion of the Goods/Services. All replacements or repairs necessitated by

inadequate maintenance; normal wear and usage; unsuitable power sources or environmental conditions; accident; misuse;

improper installation; modification; repair; use of unauthorized replacement parts; storage or handling; or any other cause

not the fault of Seller are not covered by this limited warranty and shall be replaced or repaired at Buyer's sole expense, and

Seller shall not be obligated to pay any costs or charges incurred by Buyer or any other party except as may be agreed upon

in writing in advance by Seller. All costs of dismantling, reinstallation, freight, and the time and expenses of Seller's

personnel and representatives for site travel and diagnosis under this limited warranty clause shall be borne by Buyer unless

accepted in writing by Seller. Goods repaired and parts replaced by Seller during the warranty period shall be in warranty for

the remainder of the original warranty period or 90 days, whichever is longer. This limited warranty is the only warranty

made by Seller and can be amended only in a writing signed by an authorized representative of Seller. The limited warranty

herein ceases to be effective if Buyer fails to operate and use the Goods sold hereunder in a safe and reasonable manner and

in accordance with any written instructions from the manufacturers. THE WARRANTIES AND REMEDIES SET FORTH ABOVE

ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR WARRANTIES OF ANY KIND, EXPRESSED OR IMPLIED, AS TO

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS

OR SERVICES.

2. Limitation of Remedy and Liability SELLER SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN PERFORMANCE. THE

REMEDIES OF BUYER SET FORTH IN THE AGREEMENT ARE EXCLUSIVE. IN NO EVENT, REGARDLESS OF THE FORM OF THE

CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT, INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER

TORT, OR OTHERWISE), SHALL SELLER'S LIABILITY TO BUYER AND/OR BUYER'S CUSTOMERS EXCEED THE PRICE TO BUYER

OF THE SPECIFIC GOODS MANUFACTURED OR SERVICES PROVIDED BY SELLER GIVING RISE TO THE CLAIM OR CAUSE OF

ACTION. BUYER AGREES THAT IN NO EVENT SHALL SELLER'S LIABILITY TO BUYER AND/OR BUYER'S CUSTOMERS EXTEND TO

INCLUDE INCIDENTAL, CONSEQUENTIAL OR PUNITIVE DAMAGES. THE TERM "CONSEQUENTIAL DAMAGES" SHALL INCLUDE,

BUT NOT BE LIMITED TO, LOSS OF ANTICIPATED PROFITS, REVENUE OR USE AND COSTS INCURRED, INCLUDING WITHOUT

LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF BUYER'S CUSTOMERS.

Page 4

Page 5

Contents

Contents

Chapter 1 Introduction ...................................................................................................................1

1.1 Models covered ............................................................................................................................1

1.2 Service support ............................................................................................................................ 1

1.3 Return of material ........................................................................................................................2

1.4 Product recycling/disposal ...........................................................................................................2

Chapter 2 Installation .....................................................................................................................3

2.1 Unpacking and inspection ............................................................................................................3

2.2 Locate sensor ...............................................................................................................................4

2.3 Dimensions ..................................................................................................................................5

2.4 Mount ..........................................................................................................................................7

2.4.1 Duct mount ...................................................................................................................8

2.5 Wire ...........................................................................................................................................10

2.5.1 Field installation .......................................................................................................... 10

2.5.2 Seals ............................................................................................................................10

2.5.3 Sensor separation ........................................................................................................11

2.5.4 Board assembly ...........................................................................................................11

2.5.5 Installation to transmitter or junction box ................................................................... 12

2.5.6 Faceplate rotation ....................................................................................................... 13

2.5.7 General requirements ................................................................................................. 14

2.5.8 Wiring sensor to transmitter ....................................................................................... 15

2.5.9 Wire sensor to junction box .........................................................................................17

2.5.10 Wiring transmitter to control system ...........................................................................18

2.5.11 External ground ...........................................................................................................18

2.6 Current output ...........................................................................................................................18

2.7 Non-isolated and isolated power configurations ........................................................................ 19

2.8 Installation checklist .................................................................................................................. 21

Chapter 3 Operation .....................................................................................................................23

3.1 Net Safety™ Millennium Transmitter ...........................................................................................23

3.1.1 Display ........................................................................................................................ 24

3.1.2 Status LED ................................................................................................................... 24

3.1.3 On/Off switch ..............................................................................................................24

3.1.4 Setup button ...............................................................................................................24

3.1.5 Magnetic Reed switch ................................................................................................. 24

3.1.6 Current output check .................................................................................................. 24

3.2 Indications and outputs ............................................................................................................. 25

3.3 Alarms ....................................................................................................................................... 25

3.3.1 Net Safety APM fault ....................................................................................................25

3.3.2 Clean window/dirty chamber ...................................................................................... 25

3.3.3 Particulate alarm ......................................................................................................... 26

3.4 Reset ..........................................................................................................................................26

3.4.1 Remote reset ...............................................................................................................26

3.4.2 Manual reset ............................................................................................................... 26

3.5 Normal .......................................................................................................................................26

3.6 Outputs ..................................................................................................................................... 26

Reference Manual i

Page 6

Contents

3.6.1 Relays ..........................................................................................................................26

3.6.2 Current ........................................................................................................................27

3.7 Net Safety APM Sensor ...............................................................................................................27

3.7.1 Sensor power up ......................................................................................................... 27

3.7.2 Sensor communication ............................................................................................... 27

Chapter 4 Programming ...............................................................................................................29

4.1 Main menu .................................................................................................................................29

4.2 Accessing the main menu .......................................................................................................... 29

4.3 Using the main menu .................................................................................................................29

4.3.1 Zero ............................................................................................................................ 31

4.3.2 Sensitivity settings ...................................................................................................... 32

4.3.3 Review relay settings ...................................................................................................33

4.3.4 Set relay options ..........................................................................................................33

4.3.5 Select display language ............................................................................................... 35

Chapter 5 Maintenance ................................................................................................................ 37

5.1 Response check ......................................................................................................................... 37

5.2 Cleaning .................................................................................................................................... 37

5.3 Troubleshooting ........................................................................................................................ 38

5.4 Storage ......................................................................................................................................38

5.5 Spare parts and accessories ........................................................................................................38

Chapter 6 Electrostatic sensitive device ........................................................................................39

Chapter 7 Wire resistance table ....................................................................................................41

Chapter 8 Specifications ...............................................................................................................43

Chapter 9 Certifications ................................................................................................................45

9.1 North American hazardous locations ......................................................................................... 45

9.1.1 Transmitter ................................................................................................................. 45

9.1.2 APM Sensor ................................................................................................................. 45

9.1.3 Junction box (Model JB-MPD) .......................................................................................46

9.2 ATEX (-X model) .........................................................................................................................46

9.2.1 Transmitter ................................................................................................................. 46

9.2.2 APM Sensor ................................................................................................................. 46

9.2.3 Junction box (Model JB-MPD) .......................................................................................47

9.3 IECEx (-X model) ........................................................................................................................ 47

9.3.1 Transmitter (aluminum) ..............................................................................................47

9.3.2 Transmitter (stainless steel) ........................................................................................ 47

9.3.3 APM Sensor ................................................................................................................. 47

9.3.4 Junction box (Model JB-MPD) .......................................................................................48

Chapter 10 Ordering information ...................................................................................................49

ii Millennium Air Particle Monitor

Page 7

1 Introduction

1.1 Models covered

The Net Safety™ Air Particle Monitor (APM) is an infrared optical detector used in hazardous

industrial applications to monitor ambient air for the presence of particulate matter from

products of combustion such as carbon, air particulate matter, or ash.

The Net Safety Millennium Transmitter is an environmentally protected electronic package

contained within an explosion-proof housing. With its scrolling 8-character display and

status LEDs, it provides instructions and status alerts.

The Net Safety APM Sensor is mounted where airborne particles are anticipated to

accumulate, while the Net Safety Millennium Transmitter is located conveniently at eye

level.

The product is available in aluminum and stainless steel (SS).

Models available are:

• MLP-AR-APM-OP: APM, 4-20 mA analog output with alarm and fault relays,

aluminum housing, CSA approved

• MLP-AR-APM-OP-X: APM, 4-20 mA analog output with alarm and fault relays,

aluminum housing, CSA, ATEX, and IECEx approved

• MLP-AR-APM-OP-SS: APM, 4-20 mA analog output with alarm and fault relays,

stainless steel housing, CSA approved

• MLP-AR-APM-OP-SS-X: APM, 4-20 mA analog output with alarm and fault relays,

stainless steel housing, CSA, ATEX, and IECEx approved

Introduction

1.2

Reference Manual 1

Service support

Technical support for this product can be provided by contacting your local Emerson/Net

Safety representative or by contacting the Net Safety Technical Support department at:

Toll Free + 866 347 3427 or Safety.CSC@emerson.com.

Page 8

Introduction

1.3 Return of material

To expedite the repair and return of this product, proper communication between the

customer and the factory is important. Before returning a product for repair, call +1 403

219-0688 or e-mail Safety.CSC@emerson.com for a Material Return Authorization (MRA)

number.

On the return of the equipment, include the following information:

1. MRA number provided to you by Net Safety

2. Company name and contact information

3. Purchase order, from your company, authorizing repairs or request for quote

Procedure

1. Ship all equipment, prepaid to:

Emerson Automation Solutions

158 Edinburgh Ave

Slough, United Kingdom SL 1 4UE

2. Mark all packages with Return for Repair and include MRA number

1.4

Pack items to protect them from damage and use anti-static bags or aluminumbacked cardboard as protection from electrostatic damage.

Important

All equipment must be shipped prepaid. Collect shipments will not be accepted.

Product recycling/disposal

Consider recycling equipment and packaging and dispose of them in accordance with local

and national legislations/regulations.

2 Millennium Air Particle Monitor

Page 9

2 Installation

2.1 Unpacking and inspection

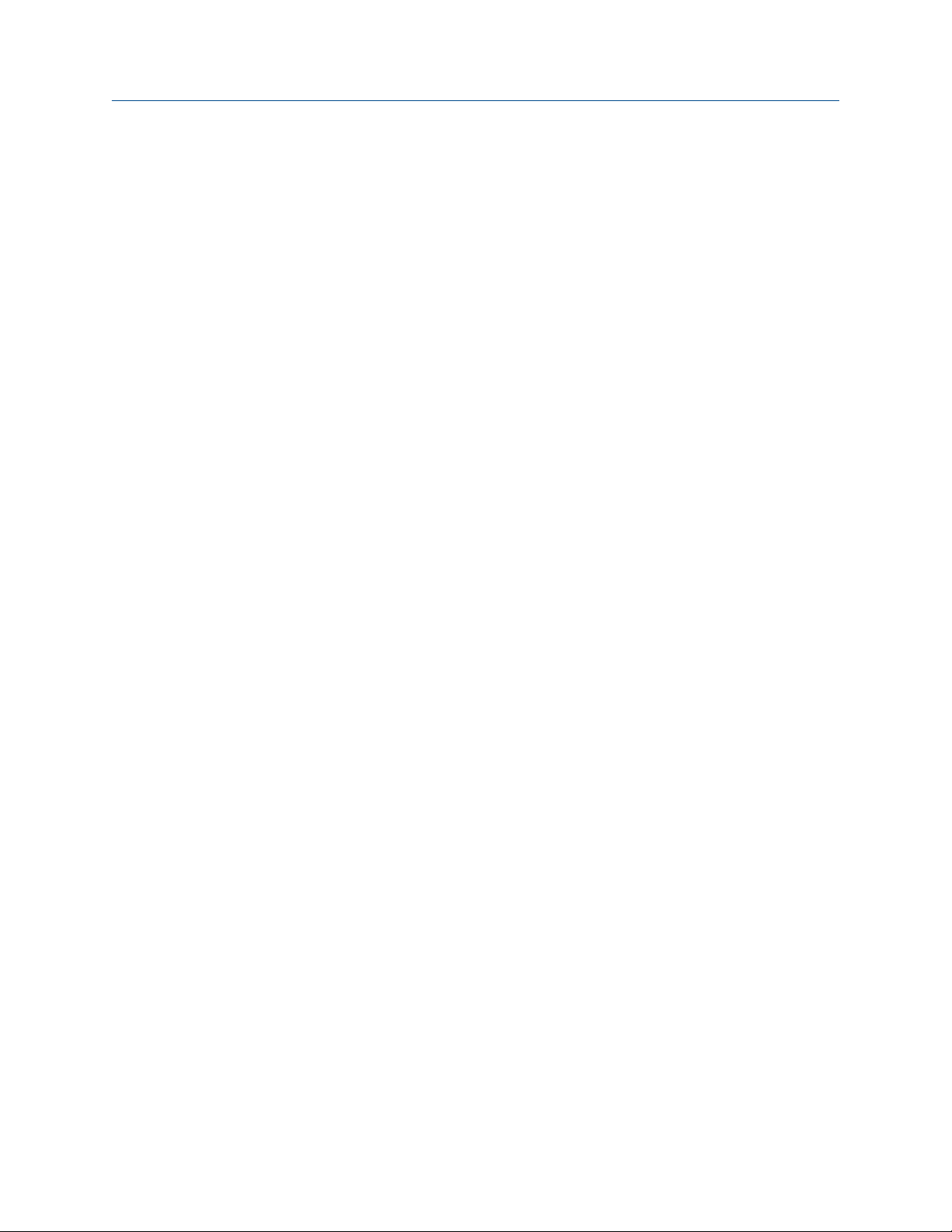

Carefully remove all of the components from the packaging and verify them against the

enclosed packing list. Inspect all components for any obvious damage such as broken or

loose parts. If you find any components missing or damaged, notify your local Emerson

representative or the factory immediately. Figure 2-1 outlines the components supplied

with the Net Safety APM.

Net Safety APM ComponentsFigure 2-1:

Installation

™

A. Housing cover

B. Millennium housing

C. Junction box

D. 3/4 in. NPT

E. 3/4 in. NPT

F. Earth ground screw

G. 3/4 in. NPT

H. Optical path

I. Air particle monitor (APM)

J. Internal window/sensor chamber

K. Optical path protector plate. Uncrew to clean. Refer to Section 5.2 for cleaning instructions.

L. Millennium faceplate

Reference Manual 3

Page 10

Installation

2.2 Locate sensor

Prior to the installation process, develop a location plan for placing the Net Safety APM

Sensor and Transmitter. Proper location of the Net Safety APM Sensor is essential for

providing maximum protection. The most effective placement and number of detectors

varies depending upon conditions. Consider the following points when planning the

installation.

• Carefully locate the Net Safety APM Sensor in an area where particulate may

potentially accumulate.

• Locate the Net Safety APM Sensor where it is safe from potential sources of

contamination, such as oil film, dirt, etc.

• Locate the transmitter where it will be accessible and visible.

• Mount the Net Safety APM Sensor so air currents allow particulate to flow into the

optical path of the sensor.

• If the particulate is expected to be moving horizontally due to air currents, orient the

sensor for maximum detection as shown in Figure 2-1.

• Avoid exposure to excessive heat or vibration whenever possible, because this can

cause premature failure of electronic devices.

• Seek advice from experts and refer to various regulatory publications that discuss

general guidelines for your industry.

• The Net Safety APM works off of the principle of infrared energy being reflected off

of particulate matter passing through the optical path of the Net Safety APM.

Therefore, give careful consideration when installing the Net Safety APM to ensure

that external infrared light does not reach the sensing element.

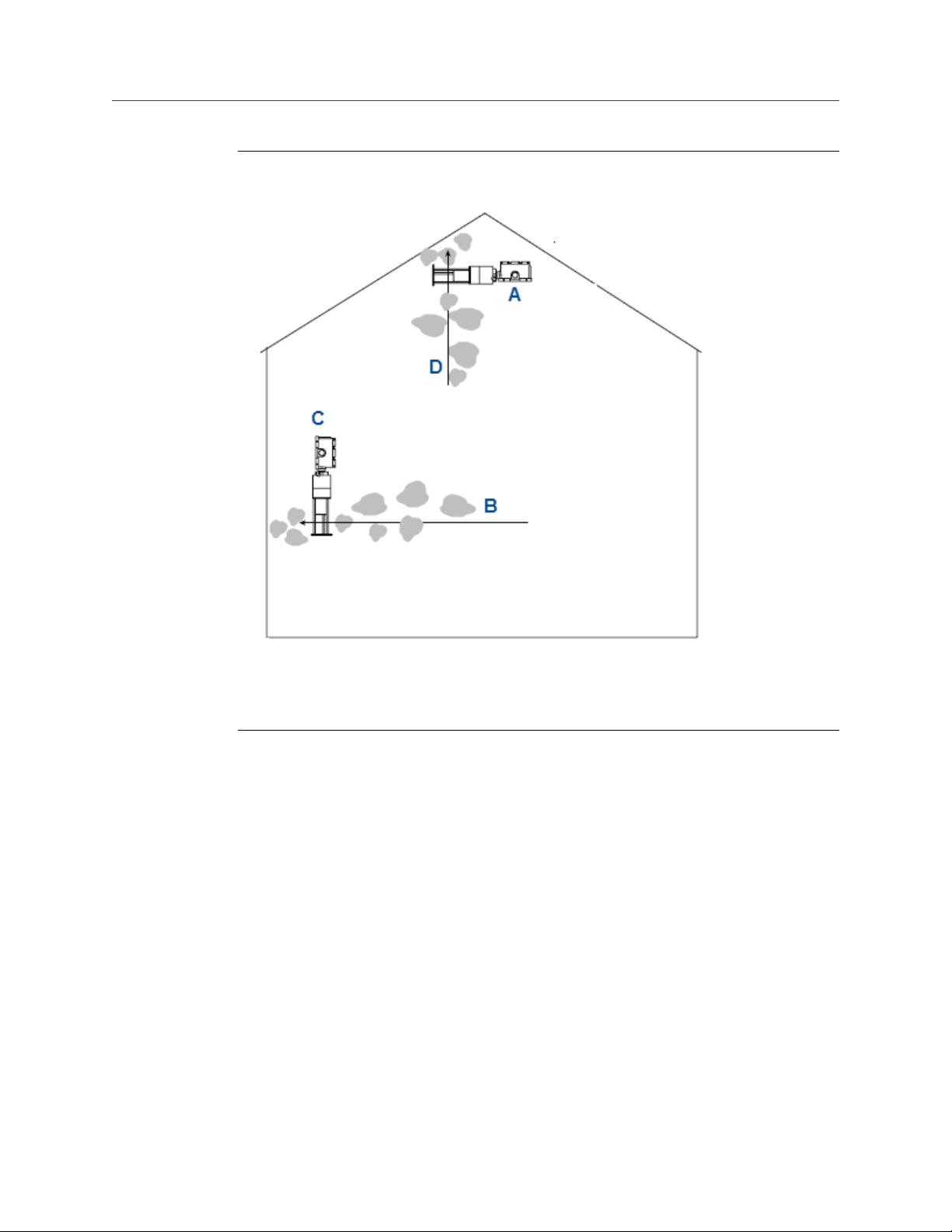

Figure 2-2 illustrates a typical installation of a Net Safety APM Sensor and Transmitter. The

Net Safety APM Sensor is mounted separately from the transmitter using the supplied

junction box. The transmitter is located at eye level, while the sensor is located where

particles are most likely to accumulate. The conduit then connects the two devices.

4 Millennium Air Particle Monitor

Page 11

Installation

Typical InstallationFigure 2-2:

A. Conduit connecting junction box and controller

B. Controller/transmitter mounted at eye level

C. Particulate matter

D. Junction box

E. Net Safety APM Sensor positioned so air current allows particulate matter to flow into sensor

F. Net Safety APM Sensor

2.3

Reference Manual 5

Dimensions

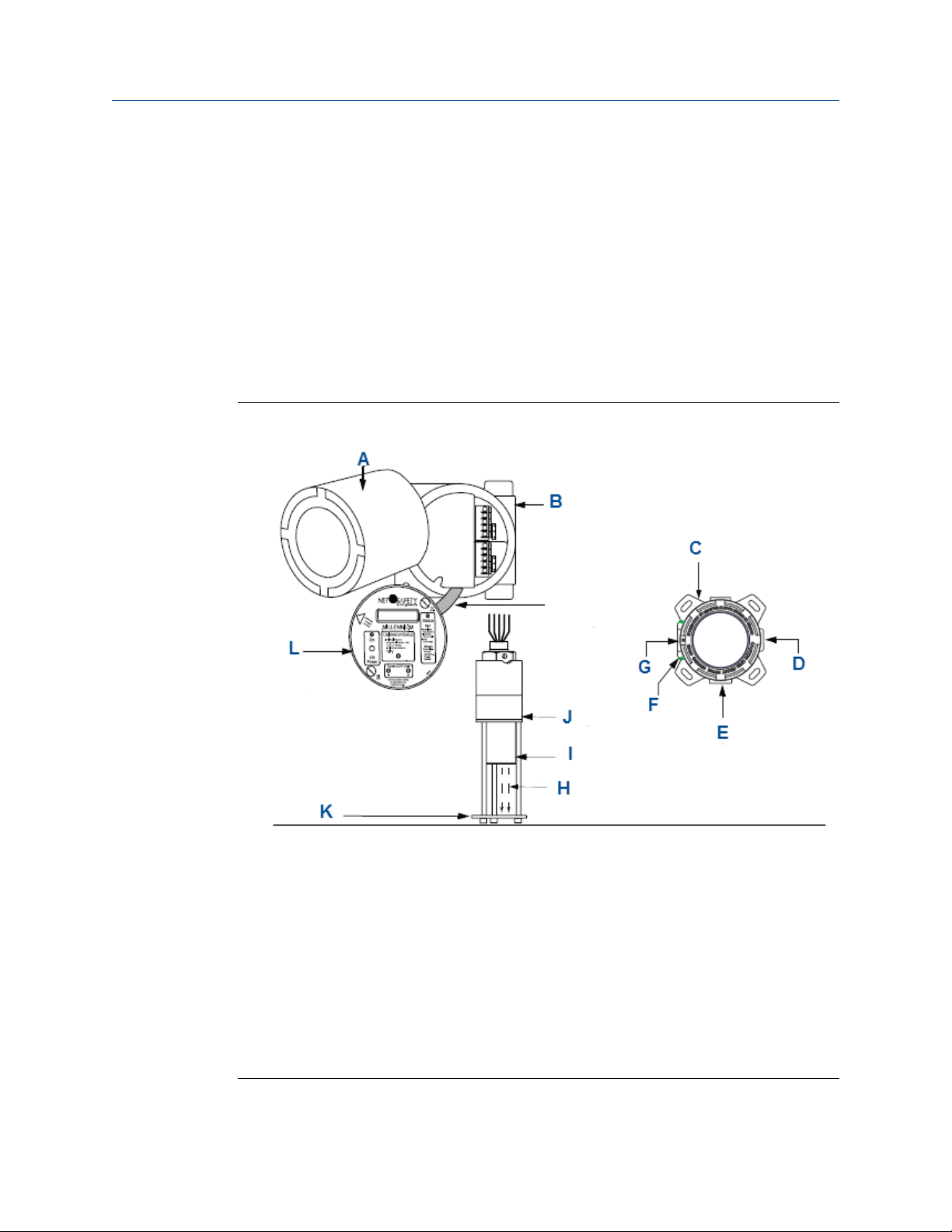

The following figures outline the dimensions of the Net Safety APM connected directly to

the Net Safety Millennium Transmitter (Figure 2-3) or when connected directly to the

multi-purpose junction box (Figure 2-4). There are three (3) ¾ in. NPT conduit entries

available on the Net Safety Millennium Transmitter. Adapters for M20 and ½ in. NPT

threads are also available as spare parts.

Page 12

Installation

Transmitter DimensionsFigure 2-3:

A. ¾ in. FNPT cable entry

B. ¾ in. FNPT cable

Junction Box and Sensor DimensionsFigure 2-4:

6 Millennium Air Particle Monitor

Page 13

2.4 Mount

The sensor must be mounted directly to either a transmitter or to a separate junction box

through a ¾ in. NPT conduit entry. Both the transmitter and junction boxes have mounting

holes to allow mounting to a wall or pole as desired. Mounting kit hardware is required

when mounting the transmitter or junction box to a pole. Contact your local Net Safety

representative for detailed information on the pole mounting kits.

Mount the transmitter at eye-level and make it easily accessible for monitoring and

maintenance purposes. Place the sensor where particles are likely to accumulate and

across the direction of the airflow to allow the particulates to pass through the optical

path. To prevent water damage, seal conduit at all points of entry to the transmitter or

junction box.

Emerson™ recommends mounting the Net Safety APM Sensor such that the air flow will

pass through the optical path of the sensor as shown in Figure 2-5.

Note

The Net Safety APM works off of the principle of infrared energy being reflected off of particulate

matter passing through the optical path of the Net Safety APM. Therefore, give careful consideration

when installing the APM to ensure that external infrared light does not reach the sensing element.

Installation

The Net Safety APM may be affected by sudden bursts of infrared light; therefore, Emerson

recommends putting a time delay (between two [2] and five [5] seconds) into the

monitoring system to prevent nuisance alarms.

Reference Manual 7

Page 14

Installation

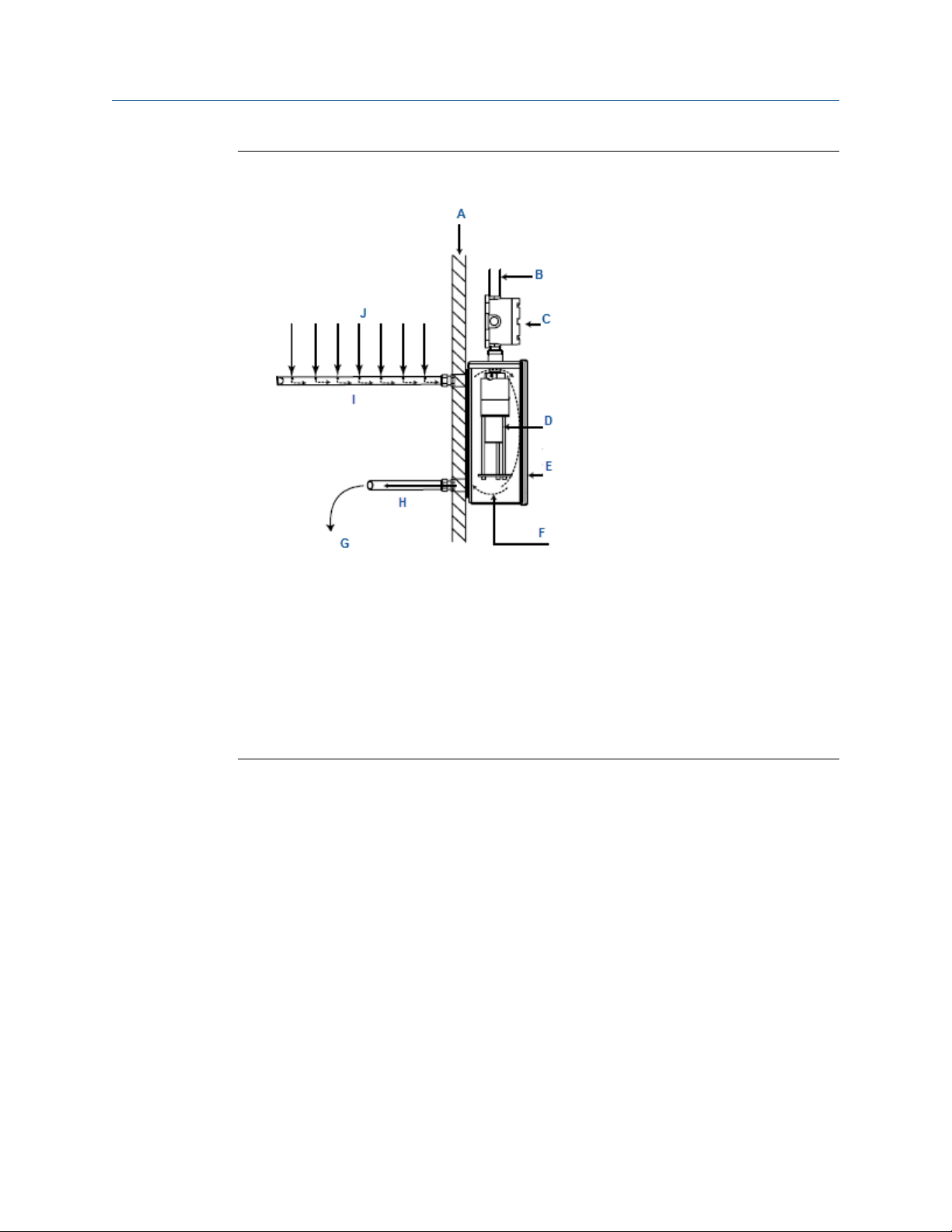

Net Safety APM Mounting LocationsFigure 2-5:

2.4.1

A. APM sensor with junction box

B. Movement of air particulate matter

C. APM sensor with junction box

D. Movement of air particulate matter

Duct mount

Although the Net Safety Monitoring Air Particle Monitor has been proven to detect

particulate matter travelling at speeds of up to 20 meters per second (65.62 feet per

second), the detector is virtually unaffected by the velocity of particulate and air that it is

exposed to. Based on the application and the speed of the particulate matter, you can

perform a zero and adjust the sensitivity settings to suit the application.

Net Safety Monitoring recommends that the Net Safety APM be used with the UDM-001 or

UDM-002 sample draw system to acquire a cross-sectional sample of air and particulate

moving through ducts. The sample is drawn through perforations along the inlet pipe into

a chamber where the Net Safety APM is mounted. Particulate matter from the outlet pipe

is then returned to the duct. Refer to Figure 2-6 and the

UDM-001/UDM-002 reference manual (MAN-0116) for more information.

8 Millennium Air Particle Monitor

Page 15

Installation

Air Flow DrawingFigure 2-6:

A. Duct surface

B. Conduit to controller

C. Junction box

D. APM sensor

E. UDM-001/UDM-002 duct mount

F. Broken lines indicate direction of air flow.

G. Direction of outlet air sample

H. Outlet pipe

I. Perforated sample draw tube (inlet pipe)

J. Direction of air sample flow

Reference Manual 9

Page 16

Installation

2.5 Wire

2.5.1 Field installation

WARNING!

ELECTRIC SHOCK

Failure to follow these installation guidelines could result in death or serious injury. Ensure that

only qualified personnel perform the installation.

Electrical shock could cause death or serious injury. Use extreme caution when making contact

with the leads and terminals.

Do not open the transmitter, sensor, or junction box enclosure when in a classified area or

when an explosive atmosphere may be present unless the power to the transmitter has been

removed.

Avoid touching electronic components as they are susceptible to electrostatic discharge (ESD).

Refer to Chapter 6 for more information.

Avoid contact with the non-metallic enclosure label as contact may create an electrostatic

charging hazard.

2.5.2

NOTICE

Wiring codes and regulations may vary. ATEX requires that supply connections wiring must be

rated at least 5 °C (41 °F) above the maximum ambient temperature of 85 °C (185 °F). Wiring

must comply with all applicable regulations relating to the installation of electrical equipment

in a hazardous area and is the installer's responsibility. If in doubt, consult a qualified official

before wiring the system.

When separating the sensor from the transmitter, Emerson highly recommends the use of

shielded cable to protect against interference caused by extraneous electrical or

electromagnetic noise to meet mandatory CE mark electromagnetic compatibility (EMC)

requirements. In applications where the wiring is installed in conduit, the conduit must not

be used for wiring to other equipment.

Seals

Emerson recommends using seals to further protect the system against any unwanted

water ingression and installing equipment according to applicable local electrical codes.

Emerson especially recommends seals for installations that use high-pressure or steam

cleaning devices in proximity to the transmitter and/or sensor.

• Emerson recommends water-proof and explosion-proof conduit seals to prevent

water accumulation within the enclosure.

• Locate seals as close to the device as possible and not more than 18 inches (46 cm)

away.

• Explosion-proof installations may require an additional seal where conduit enters a

non-hazardous area. Ensure conformity with local wiring codes.

10 Millennium Air Particle Monitor

Page 17

• When pouring a seal, use a fiber dam to assure proper formation of the seal. Never

pour seals at temperatures below freezing.

• Strip back the jacket and shielding of the cable to permit the seal to form around the

individual wires. This will prevent air, particles, and water leakage through the inside

of the shield and into the enclosure.

• Emerson recommends using explosion-proof drains and conduit breathers. In some

applications, alternate changes in temperature and barometric pressure can cause

breathing which allows moist air to enter and circulate inside the conduit. Joints in

the conduit system are seldom tight enough to prevent this breathing.

2.5.3 Sensor separation

Since the Net Safety APM Sensor must be located where it will pick up particulate in an air

flow, and the transmitter where it can be easily reached, it is often necessary to separate

the transmitter and sensor. This is done with the aid of the included sensor separation kit

(SEP). This kit is composed of a junction box and terminal strip. Refer to the

Net Safety Multi-purpose Junction Box manual (MAN-0081) for terminal designation.

The maximum separation distance between the sensor and the transmitter is limited by

the resistance of the connecting wiring, which is a function of the gauge of wire being

used. Net Safety recommends that sensor separation must not exceed 610 m (2,000 ft)

while using 16 AWG (1.31 mm2) wire. Refer to Chapter 7 for wire gauges and resistance

values.

Installation

2.5.4

Note

When the sensor is separated from the transmitter, always ensure that the transmitter is supplying

the required voltage to the sensor terminals inside the junction box. If the 4-20 mA signal is not used,

connect a jumper between the 4-20 terminal and the COM terminal on the transmitter terminal

board.

Board assembly

There are three different fixed boards and a relay board which make up the PCB assembly.

Simply loosen the three locking standoffs, remove one board, insert the other board, and

tighten screws. The boards are susceptible to electrostatic discharge (ESD). Refer to

Chapter 6 for further information on proper handling of this equipment.

Reference Manual 11

Page 18

Installation

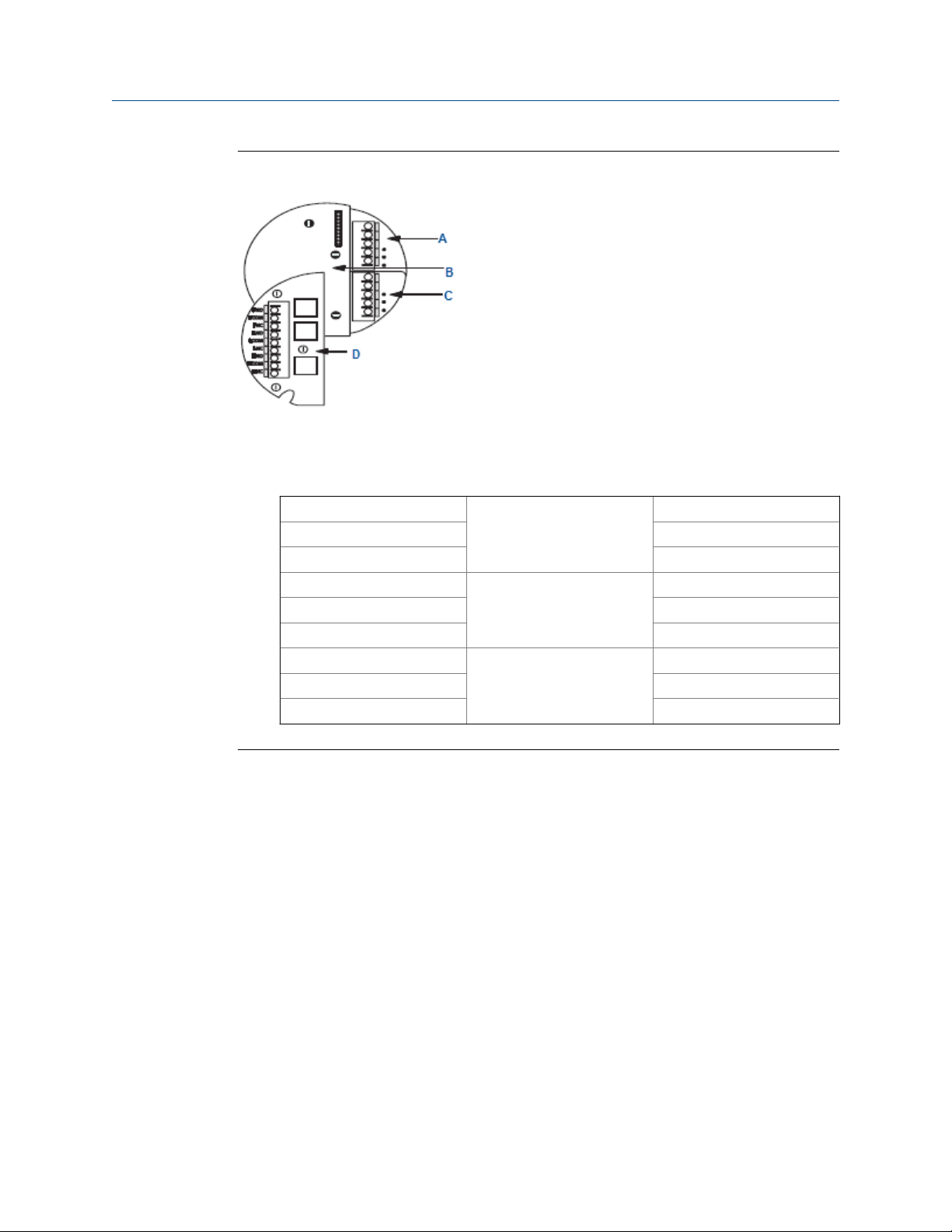

Net Safety Millennium Transmitter Module BoardsFigure 2-7:

A. Terminal board

B. Option board

C. Sensor board

D.

PNO Fault Normally open

PCOM Common

PNC Normally closed

LNO Clean window (low) Normally open

LCOM Common

LNC Normally closed

HNO Alarm Normally open

HCOM Common

HNC Normally closed

Electromechanical Relay BoardTable 2-1:

2.5.5 Installation to transmitter or junction box

The Net Safety APM sensor is supplied with a ¾ in. NPT male conduit connection and is

intended to be mounted directly to an available ¾ in. NPT conduit entry on the Net Safety

Millennium Transmitter or remotely using the supplied junction box.

Tightly thread the sensor to the transmitter or junction box. A minimum of seven (7)

threads need to be engaged to ensure proper water ingress protection and the explosion

proof rating of the devices. Take proper care to ensure that no damage is caused to the

wires on the Net Safety APM Sensor and circuit board inside the transmitter and junction

box.

Emerson recommends using conductive grease on the threads.

The sensor can be mounted in a number of configurations to ensure that air particulate will

pass through the optical path of the sensor. Emerson recommends that the APM be

mounted horizontally to ensure that build-up of dirt, dust, and debris will not affect the

operation of the sensor.

12 Millennium Air Particle Monitor

Page 19

2.5.6 Faceplate rotation

In some applications, it is necessary for the Net Safety Millennium Transmitter to be

mounted in a non-standard orientation. To accommodate such installations and ensure

that the display will appear at the correct angle for viewing, you can rotate the PCB

assembly inside the transmitter’s housing. Figure 2-8 outlines non-standard orientations of

the Net Safety Millennium Transmitter.

Non-standard OrientationFigure 2-8:

WARNING!

Installation

Do not open the transmitter, sensor, or junction box enclosure when in a classified area or

when an explosive atmosphere may be present unless the power to the transmitter has been

removed.

The following section describes the steps required to rotate the Net Safety Millennium

Transmitter faceplate. Refer to Figure 2-9 for the components in the transmitter housing.

The boards may be susceptible to ESD. Refer to Chapter 6 for further information on proper

handling of this equipment.

Procedure

1. Remove the transmitter housing cover.

2. Turn the power to the transmitter off.

3. Unscrew both the knobs marked Pull Here.

4. Lift the transmitter faceplate from the housing and allow to the faceplate to hang

from the ribbon cable.

5. Unscrew the two metal standoffs.

6. Carefully remove the PCB assembly from the housing.

The rotator plate is secured to the bottom of the housing and is accessible after the

PCB assembly has been removed.

7. Rotate the PCB assembly to the desired position and line up the standoffs with the

mounting holes.

8. Insert standoffs in the appropriate horizontal or vertical mounting holes.

9. Tighten standoffs to secure the PCB assembly.

10. Replace faceplate and tighten Pull Here knobs.

11. Return power to the detector and replace the housing cover.

Reference Manual 13

Page 20

Installation

PCB Assembly RotatedFigure 2-9:

2.5.7

A. Horizontal mounting holes

B. Faceplate

C. Ribbon cable

D. Standoffs

E. PCB assembly

F. Vertical mounting holes

General requirements

WARNING!

EXPLOSION

Do not open the transmitter, sensor, or junction box enclosure when in a classified area or

when an explosive atmosphere may be present unless the power to the transmitter has been

removed.

When connecting cable wires, use a small screwdriver to gently press down and hold the

spring connector open. Insert the appropriate wire into the open connector hole, releasing

the screwdriver to secure the wire as shown in Figure 2-10.

The connector accomodates wire sizes between 14 and 20 AWG.

14 Millennium Air Particle Monitor

Page 21

Installation

Terminal ConnectionFigure 2-10:

2.5.8 Wiring sensor to transmitter

Connect the sensor wires to the Net Safety Millennium Transmitter as shown in Figure 2-11.

Table 2-2 outlines the wire colors and their purpose.

Sensor Wire Colors and Terminal DefinitionTable 2-2:

Wire color White Blue Red Black Shield

Marking +24 Vdc Sig A Sig B COM(-) Shld

Function 10.5-32 Vdc connec-

tion

Communication sig-

nal A

Communication sig-

nal B

Common / supply

ground

Earth

ground

Reference Manual 15

Page 22

Installation

Millennium sensor wiringFigure 2-11:

A. Terminal board

B. RST

+24 V

COM

4-20

ISO

C. Wht

Blu

Red

Blk

Shld

D. APM sensor wires

E. APM sensor

F. Sensor board

G. Sensor terminals

H. Power terminals

16 Millennium Air Particle Monitor

Page 23

2.5.9 Wire sensor to junction box

Sensor wiring side refers to wiring between the sensor and junction box. Transmitter

wiring side refers to wiring between the Net Safety Millennium (MLP) Transmitter and

junction box.

Junction Box Wiring (Model JB-MPD)Figure 2-12:

A. Resistor - 120 ohms

B.

Transmitter WiringTable 2-3:

Installation

Terminal Function/marking

1 (GND) Earth ground

2 Vdc (+)

3 COM (-)

4 Sig A

5 Sig B

6 Not used

7 Not used

C.

Terminal Color Function

1 (GND) Green Earth ground

2 White Vdc (+)

3 Black COM (-)

4 Blue A (communication)

5 Red B (communication)

6 N/A Not used

7 N/A Not used

Sensor WiringTable 2-4:

Note

Shield should be terminated at earth ground at panel/PLC/DCS/RTU

Reference Manual 17

Page 24

Installation

2.5.10 Wiring transmitter to control system

Connect the Net Safety Millennium Transmitter to the control system as shown in

Figure 2-11. Table 2-5 outlines the terminal marking and their purpose.

Transmitter ConnectionsTable 2-5:

Marking RST +24V COM 4-20 +VISO

Function Remote reset 10.5-32 Vdc

Connection

Common / supply

ground

Current loop output

(mA)

+24 Vdc isolated

4-20 power

2.5.11 External ground

In order to ensure proper operation of the sensor, an external earth ground is

recommended. Net Safety recommends that the external ground be connected to the

grounding point on the enclosure. Refer to Figure 2-13 for grounding connection location.

External grounding pointFigure 2-13:

A. External grounding

2.6

18 Millennium Air Particle Monitor

Current output

To set the current output, simply move the jumper located on the terminal board near the

power terminals, to the isolated or non-isolated current position. Refer to Figure 2-14.

Page 25

Installation

Note

Unless otherwise specified, all models ship with this jumper in the non-isolated current position (Pin

2 and Pin 3 jumped). Refer to Figure 2-14.

Jumper LocationsFigure 2-14:

2.7

A. Jumper positions to set power source for current output.

Isolated and non-isolated current jumper - place jumper (shorting jack) over Pin 3 and Pin 2

(default position) for non-isolated configuration (source).

B. Place jumper over Pin 1 and Pin 2 for remaining configurations. Refer to Figure 2-1.

Non-isolated and isolated power configurations

For current source using non-isolated configuration, the jumper must remain in the default

position (Pin 2 and Pin 3 jumped). The jumper is placed over Pin 1 and Pin 2 for current sink

using non-isolated configuration.

For isolated configuration using a separate power supply to isolate the current loop, the

jumper must be placed over Pin 1 and Pin 2 for source and sink. Refer to Figure 2-15,

Figure 2-16, Figure 2-17, and Figure 2-16.

Note the jumper position for each configuration.

Reference Manual 19

Page 26

Installation

Detector Non-Isolated Configuration (Source)Figure 2-15:

A. Isolated and non-isolated jumper pins

Detector Non-Isolated Configuration (Sink)Figure 2-16:

A. Isolated and non-isolated jumper pins

20 Millennium Air Particle Monitor

Page 27

Detector Isolated Configuration (Source)Figure 2-17:

A. Isolated and non-isolated jumper pins

Detector Isolated Configuration (Sink)Figure 2-18:

Installation

A. Isolated and non-isolated jumper pins

2.8

Reference Manual 21

Installation checklist

Review the following checklist prior to turning the power on to the transmitter after

installation has been completed:

• Ensure that the transmitter and sensor are properly and firmly mounted.

• Ensure that stopping plugs are securely tightened on any unused conduit entries.

• Ensure that the transmitter and sensor are not obstructed, such that they are

accessible and the particulate matter is not inhibited from reaching the sensors

optical path.

• Ensure adherence to applicable local guidelines and requirements on wiring and

sealing of equipment in hazardous and non-hazardous areas.

Page 28

Installation

• Ensure that proper shielding and grounding practices are adhered to and local codes

are being followed.

• Check system operational voltage and conditions and ensure that they are within

the applicable specifications of the transmitter and sensor.

• Verify wiring at all termination and junction points (transmitter, junction box, and

power supply).

• Ensure that the transmitter housing cover and sensor cap are tightly secured.

22 Millennium Air Particle Monitor

Page 29

3 Operation

3.1 Net Safety™ Millennium Transmitter

WARNING!

EXPLOSION

Do not open the transmitter, sensor, or junction box enclosure when in a classified area or

when an explosive atmosphere may be present unless the power to the transmitter has been

removed.

Figure 3-1 outlines the components on the Net Safety Millennium Transmitter, and the

subsequent sections provide explanations for each component.

Net Safety Millennium Transmitter LayoutFigure 3-1:

Operation

A. Section 3.1.1, Display

B. Section 3.1.2, Status

C. Section 3.1.4, Setup

D. Section 3.1.6, Current output

E. Section 3.1.3, On/off

F. Section 3.1.5, Magnetic Reed switch

Reference Manual 23

Page 30

Operation

3.1.1 Display

A scrolling 8 character display is provided to show various status messages and prompts.

Refer to Table 3-1 for the various display messages.

3.1.2 Status LED

The status LED is used to provide visual indication as to the status of the transmitter and

sensor. Refer to Section 3.2 for specific status conditions of the LED.

3.1.3 On/Off switch

The On/Off switch is used to turn power on and off to the transmitter and sensor. As the

transmitter’s housing must be opened to access the On/Off switch, the area where the

transmitter is located must be de-classified prior to using.

3.1.4 Setup button

The Setup button provides access to the Net Safety Millennium Transmitter’s main menu,

which in turn allows options to be reviewed and set. The Setup button is also used to zero

the sensor. As the transmitter’s housing must be opened to access the button, the area

must be de-classified before using. Refer to Chapter 4 for instructions on programming the

Net Safety Millennium Transmitter.

3.1.5

3.1.6

Magnetic Reed switch

Emerson provides the magnetic Reed switch to avoid opening the housing in an

environment where gas may be present. The magnetic Reed switch functions in the same

manner as the Setup button but in a non-intrusive manner. The magnet comes

permanently attached to the side of the transmitter.

Current output check

Current output check test jacks are provided to facilitate current loop measurements

without breaking external current loop. To take current loop measurements, ensure wiring

is correct and current loop is closed, and then follow steps below

• Set meter on mA scale and insert meter leads into test jacks.

• Put external devices in bypass, if necessary, to avoid unwanted alarm response.

• Perform simulated tests to check output.

• Remove meter leads from test jacks and return external devices to normal.

24 Millennium Air Particle Monitor

Page 31

3.2 Indications and outputs

Transmitter IndicationsTable 3-1:

State Current Output Status LED Display

Main menu entered 3.0 mA Solid green Main menu items

Normal operation 4.0 mA Green blip Clear

Startup delay 3.0 mA Slow red flash Start delay

Dirty optics 3.3 mA Fast red flash Dirty chamber

Particulate present 20 mA Red blip Alarm

Fault condition 2.5 mA Fast red flash Fault

Updating Net Safety APM

Sensor

3.0 mA Slow red flash Busy

3.3 Alarms

Operation

3.3.1 Net Safety APM fault

To ensure proper response, the Net Safety Millennium features self-testing circuitry that

continuously checks for problems. When power is applied, the system automatically

begins a test to ensure proper functionality.

During normal operation, the transmitter continuously monitors the signal from the

internal APM source. If the transmitter determines that the APM program is not running

correctly, it will reset the Net Safety APM Sensor.

3.3.2

Clean window/dirty chamber

Over an extended period, oily film or particulate build-up on the sensor window may

obscure the detector. When dirty, the Clean window alarm trips, the message Dirty

Chamber displays, the Status LED flashes fast red, and the current output is 3.3 mA. Refer

to Section 4.3.2 to define the clean window sensitivity and Section 5.2 on cleaning the Net

Safety APM window.

Reference Manual 25

Page 32

Operation

3.3.3 Particulate alarm

When particulate is present in the Net Safety APM’s chamber, the message Alarm

displays, the Status LED blips red, and the current output is 20.0 mA. If the relay has been

set to non-latching, the unit resets itself; if set to latching, a manual or remote reset is

required to clear the alarm condition. Refer to Section 3.4.

Note

The Net Safety APM may be affected by sudden bursts of infrared light; therefore, Emerson

recommends that a time delay [between two (2) and five (5) seconds] be put into the monitoring

system to prevent nuisance alarms.

3.4 Reset

3.4.1 Remote reset

The Net Safety Millennium is capable of remote reset. A normally open push-button switch

must be connected between the RST terminal and the COM terminal on the terminal

board. If relay is set to Latching, a remote reset is possible.

3.4.2 Manual reset

If a relay is set to Latching, a manual reset is required to clear the alarm condition. Simply

place and hold the magnet against the Reed switch or press and hold Setup for 3-5

seconds. The unit returns to normal operation.

3.5

3.6

Normal

With no particulate present and no fault detected, the display reads Clear, Status LED

blips/blinks green, and the current output is 4.0 mA.

Outputs

3.6.1 Relays

All relay outputs have FORM-C SPDT contacts rated 5 amperes at 30 Vdc/250 Vac. Relays

are dry contacts.

26 Millennium Air Particle Monitor

Page 33

3.6.2 Current

A 4-20 mA dc current output is used to transmit the alarm status and fault conditions to

other devices. This output can be wired for isolated or non-isolated operation. A 4.0 mA

output indicates normal operation; a 20.0 mA output indicates that the alarm threshold

has been exceeded. Current output of 2.5 mA indicates the presence of a system fault.

Current output of 3.3 mA indicates a build-up of particulate in the sensor’s chamber or

dirty window. Refer to Section 3.2 for additional indications and outputs.

3.7 Net Safety APM Sensor

3.7.1 Sensor power up

When the transmitter applies power to the sensor, a warm-up routine begins, and the

sensor is automatically tested to ensure proper functioning. The warm-up time for the Net

Safety APM Sensor is typically one hundred fifty (150) seconds. After the warm-up cycle

has completed, the display reads Clear.

Operation

3.7.2

As part of the self-diagnostic routine of the Net Safety Millennium Transmitter, the analog

output outputs 20 mA on initial power up for a period not greater than 450 milliseconds. If

routine power loss is expected on the system, take appropriate actions to limit false alarm

conditions due to this diagnostic routine.

Sensor communication

The Net Safety APM Sensor uses a proprietary protocol to communicate with the Net

Safety Millennium Transmitter. Never connect the Net Safety APM Sensor to any device

other than a Net Safety Millennium Transmitter. If any problems develop, please refer to

Section 5.3.

Reference Manual 27

Page 34

Operation

28 Millennium Air Particle Monitor

Page 35

4 Programming

4.1 Main menu

The main menu provides access to various functional settings and viewing of current

settings. The following options/settings are available in the main menu.

• Set Zero

• Sensitivity Settings

• Review Relay Settings

• Set Relay Options

• Select Display Language

4.2 Accessing the main menu

Programming

4.3

There are two ways to access the main menu: using the Setup button on the faceplate of

the transmitter or using the magnetic Reed switch.

• Press and hold the Setup button to access the main menu.

• Place and hold the magnet to the transmitter’s housing (10 o’clock position as

shown in Figure 3-1) to access the main menu.

Using the main menu

The following steps outline the actions required to navigate through the menu system.

Refer to Figure 4-1 for the programming flow chart for the Net Safety Millennium

Transmitter.

Reference Manual 29

Page 36

Programming

Programming FlowchartFigure 4-1:

Prerequisites

Ensure that the transmitter is turned on and that no fault is present. If a fault is present, the

menu system isn't accessible.

Procedure

1. Press and hold Setup or hold the magnet next to the triangle on the faceplate as

shown in Figure 3-1 until the message Switch On displays and the countdown (10

to 0) finishes.

30 Millennium Air Particle Monitor

Page 37

2. To set/view an option, press Setup or place the magnet to the Reed switch at the

4.3.1 Zero

If at any time the background particulate levels change, the transmitter may be zeroed to

the new levels. Emerson recommends zeroing every 3 months.

Programming

An option scrolls across the display followed by the prompt YES?

YES? prompt. If you do not wish to select that option, wait five (5) seconds until the

next option appears and then select YES?.

A selection is acknowledged with a flashing YES.

If no option is selected, the transmitter returns to the normal operational mode, and

the display reads Clear.

Important

When the menu system has been entered, the current output changes to 3 mA. Ensure that

external systems are bypassed, as required, prior to entering the menu system.

Important

After initial power-up, allow the unit to warm up for two to four hours before zeroing.

If the sensor has been in operation for a period of time, Emerson recommends that you

clean the window as outlined in Section 5.2.

Be sure the Net Safety APM is energized up and is not indicating a fault; e.g. the display

reads Clear, the status LED is blinking green, and the current output is 4.0 mA.

Prior to beginning the zeroing procedure, ensure that the air surrounding the Net Safety

APM is clean and free of particulate or at the accepted background level for the specific

application.

The following steps outline the procedure to perform a zero of the Net Safety APM Sensor.

Procedure

1. Press and hold Setup or the magnet to the Reed switch to enter the main menu; wait

for the countdown, from 10 to 0, to end.

2. Release Setup or remove the magnet from the Reed switch.

The current output moves to 3.0 mA.

3. When Set Zero and then YES? is displayed, press Setup or use the Reed switch to

select this option.

A flashing YES confirms your selection.

The Net Safety APM has now been zeroed, meaning that the existing level of air

contamination is considered normal.

Reference Manual 31

Page 38

Programming

Tip

If your application has a constant level of particulate present that is required to be ignored by the

APM you can set the zero level with the known particulate present as shown in Figure 4-2.

To further fine tune the Net Safety APM response for your requirements, adjust the

sensitivity settings accordingly. Refer to Section 4.3.2.

Zero Level SettingFigure 4-2:

4.3.2 Sensitivity settings

The Net Safety APM can be set to detect low, medium or high sensitivity levels with high

being the most sensitive. By default the sensitivity is set for high sensitivity from the

factory. Follow the steps below to change the sensitivity.

1. Press and hold Setup or the magnet to the Reed switch to enter the main menu; wait

for the countdown, from 10 to 0, to end.

2. Release Setup or remove the magnet from the Reed switch.

The current output moves to 3.0 mA.

3. When Sensitivity Settings and then YES? is displayed, press Setup or use

the Reed switch to select this option.

A flashing YES confirms your selection.

32 Millennium Air Particle Monitor

Page 39

4. The following three options display: Low Sensitivity YES? , Medium Sensitivity YES? and

High Sensitivity YES?

5. When the required setting is displayed, press Setup button or use the Reed switch to

select.

The selection is acknowledged with a flashing YES.

4.3.3 Review relay settings

This is a read-only mode to provide a summary of the relay settings. Changes to the relay

settings cannot be made in this menu item.

Procedure

1. Press and hold Setup or the magnet to the Reed switch to enter the main menu; wait

for the countdown, from 10 to 0, to end.

2. Release Setup or remove the magnet from the Reed switch.

The current output moves to 3.0 mA.

3. When Review Relay Settings and then YES? is displayed, press Setup or use

the Reed switch to select this option.

Programming

4.3.4

A flashing YES confirms the selection, and the settings are displayed.

Set relay options

This section outlines how to change the normal operation of the Clean Window and Alarm

relays.

Follow the steps below to alter the relay functions or refer to Figure 4-1.

Note

The Fault Alarm relay settings are fixed as normally Energized and Non-Latching and are not adjustable

within the menu system.

Procedure

1. Press and hold Setup or the magnet to the Reed switch to enter the main menu; wait

for the countdown, from 10 to 0, to end.

2. Release Setup or remove the magnet from the Reed switch.

The current output moves to 3.0 mA.

3. When Set Relay Options and then YES? is displayed, press Setup or use the

Reed switch to select.

A flashing YES confirms your selection. The message Set Clean Window Alarm

and then YES? are displayed.

4. Press Setup or use the Reed switch to select this option.

Reference Manual 33

Page 40

Programming

The flashing YES confirms this selection. After the Clean Window Alarm option has

been chosen, the message Coil Status is displayed followed by Energized

YES?.

5. To select that the relay be energized under normal conditions, press Setup or use

the Reed switch to select this option.

To select that the relay be de-energized under normal conditions wait five (5)

seconds for the next selection. If Energized has been selected, a flashing YES

confirms the selection.

6. To select that the relay be de-energized under normal conditions, press Setup or use

the Reed switch to select this option.

If the relay is setup as required, wait five (5) seconds for the next selection.

If De-energized has been selected, a flashing YES confirms the selection.

The display now shows Latch Status, followed by Latching YES?.

7. To select that the relay be latched in its alarm state, press Setup or use the Reed

switch to select this option.

To select that the relay be non-latching, wait five (5) seconds for the next selection.

If latching has been selected, a flashing YES confirms the selection.

8. To select that the relay be non-latching, press Setup or use the Reed switch to select

this option.

If the relay is setup as required, wait five (5) seconds for the next selection. If you

selected Non-latching, a flashing YES confirms the selection.

The message Set Alarm and then YES? are displayed.

9. Press Setup or use the Reed switch to select this option.

A flashing YES confirms this selection. After the Set Alarm option has been chosen,

the message Coil Status is displayed, followed by Energized YES?.

10. To select that the relay be energized under normal conditions, press Setup or use

the Reed switch to select this option.

To select that the relay be de-energized under normal conditions, wait five (5)

seconds for the next selection. If you selected Energized, a flashing YES confirms the

selection.

11. To select that the relay be de-energized under normal conditions, press Setup or use

the Reed switch to select this option.

If the relay is setup as required, wait five (5) seconds for the next selection. If you

selected De-energized, a flashing YES confirms the selection.

The display now shows Latch Status, followed by Latching YES?.

34 Millennium Air Particle Monitor

Page 41

12. To select that the relay be latched in its alarm state, press Setup or use the Reed

switch to select this option.

To select that the relay be non-latching, wait five (5) seconds for the next selection.

If you selected Latching, a flashing YES confirms the selection.

13. To select that the relay be non-latching, press Setup or use the Reed switch to select

this option.

If the relay is setup as required, wait five (5) seconds for the next selection. If you

selected Non-latching, a flashing YES confirms the selection.

4.3.5 Select display language

This section outlines how to change the main display language to English, Spanish, or

French. Follow the steps below to change the display language.

1. Press and hold Setup or the magnet to the Reed switch to enter the main menu; wait

for the countdown, from 10 to 0, to end.

2. Release Setup or remove the magnet from the Reed switch.

The current output moves to 3.0 mA.

3. When Select Display Language and then YES? is displayed, press Setup or

use the Reed switch to select.

Programming

A flashing YES confirms your selection. The messages English and then YES? are

displayed.

4. Press Setup or use the Reed switch to select this option.

The flashing YES confirms this selection.

5. If English is not the desired language, wait five (5) seconds for the next selection.

The message Espanol and then YES? are displayed.

6. Press Setup or use the Reed switch to select this option.

The flashing YES confirms this selection.

7. If Spanish is not the desired language, wait five (5) seconds for the next selection.

The messages Francais and then YES? are displayed.

8. Press Setup or use the Reed switch to select this option.

The flashing YES confirms this selection.

9. If French is not the desired language, wait five (5) seconds for the next selection.

Reference Manual 35

Page 42

Programming

36 Millennium Air Particle Monitor

Page 43

5 Maintenance

5.1 Response check

Emerson™ recommends that you check and test the Net Safety™ APM at least once every

three months.

Spray Smoke Detector Tester (or equivalent product) in the direction of the sensor from a

distance of two feet. Typically, a one to two second burst is adequate to initiate an alarm.

When the alarm activates, the display reads Alarm, the Status LED flashes red, and the

current output is 20.0 mA to indicate detection of particulate matter or canned

contaminant.

After simulation, reset the alarm if latched as outlined in Section 3.4 and zero the Net

Safety APM as per Section 4.3.1 in clear air free of particulates or at the accepted

particulate background level for the specific application.

Maintenance

5.2

CAUTION!

EQUIPMENT DAMAGE

The overuse of artificial particulate detector testers or spraying from too close a range may

impair the operation of the Net Safety APM due to the accumulation of an oily film on the

internal window.

Cleaning

Clean the Net Safety APM sensor routinely. The frequency of cleaning depends on the

application and environment where the Net Safety APM is installed.

When the Dirty Chamber or Clean Window Alarm message is displayed, the lens /

window and chamber require cleaning. Follow the steps below when cleaning.

Procedure

1. Turn off power to the transmitter.

2. Unscrew bolts at the end of circular plate and connecting rods.

3. Using conventional multi-purpose or glass cleaning solution, clean the inner sides of

the sensor chamber and front side of the lens / window.

Use a lint-free towel or sponge to apply the cleaning solution.

4. Ensure that there is no residue left on the lens or window.

5. Put the circular plate back into position, ensuring that the textured surface faces the

Net Safety APM window, and screw in the bolts at the end of the connecting rods.

6. Return power to the Net Safety APM and check for normal operation.

Reference Manual 37

Page 44

Maintenance

7. Complete the Zero procedure (Section 4.3.1) to establish new settings.

If problems develop and persist, contact the Net Safety Service department or refer

to Section 1.3 (Return of material).

5.3 Troubleshooting

The Net Safety Millennium Transmitter and Net Safety APM Sensor are not designed to be

repaired in the field. If a problem should develop, carefully check for faulty wiring. If it is

determined that the problem is caused by an electronic defect, return the device to the

factory for repair (refer to Section 1.2 and Section 1.3 for instructions).

Perform regular checks on the unit around every two to three months to ensure desired

operation. Refer to Section 5.1 for instructions.

5.4 Storage

Store the sensor and its electronic components/parts in locations free from dust and

moisture. Ensure that the storage temperature is well within the limits of the certified

temperatures of the equipment. See Chapter 8 for storage temperatures.

5.5

Spare parts and accessories

Spare Parts and AccessoriesTable 5-1:

Description Part Number

Universal duct mount assembly with 3.3 ft. (1 m) inlet sampling tube UDM-001

Universal duct mount assembly with 4.9 ft. (1.5 m) inlet sampling tube UDM-002

Universal duct mount assembly UDM-003

Magnet assembly HDW-0118

Replacement Millennium transmitter board ML7-TX700

Terminal board for JB-MPD JB-MPD-PCBA

316 stainless steel termination junction box JB-MPD-S

Conduit reducer - ¾ in. (19 mm) to M20 - nickel-plated brass HDW-0148

Conduit reducer - ¾ in. (19 mm) to M20 - stainless steel HDW-0147

38 Millennium Air Particle Monitor

Page 45

6 Electrostatic sensitive device

Electrostatic discharge (ESD) is the transfer, between bodies, of an electrostatic charge

caused by direct contact or induced by an electrostatic field.

The most common cause of ESD is physical contact. Touching an object can cause a

discharge of electrostatic energy. If the charge is sufficient and occurs near electronic

components, it can damage or destroy those components. In some cases, damage is

instantaneous, and an immediate malfunction occurs. However, symptoms are not always

immediate—performance may be marginal or seemingly normal for an indefinite period of

time, followed by a sudden failure.

To eliminate potential ESD damage, review the following guidelines:

• Handle boards by the sides — taking care not to touch electronic components.

• Wear grounded wrist or foot straps, ESD shoes, or heel grounders to dissipate

unwanted static energy.

• Prior to handling boards, dispel any charge in your body or equipment by touching a

grounded metal surface.

• Ensure all components are transported and stored in ESD safe packaging.

• When returning boards, carefully package in the original carton and static protective

wrapping.

• Ensure all personnel are educated and trained in ESD control procedures.

• Clean off the housing with a damp cloth only.

Electrostatic sensitive device

In general, exercise accepted and proven precautions normally observed when handling

electrostatic sensitive devices.

Reference Manual 39

Page 46

Electrostatic sensitive device

40 Millennium Air Particle Monitor

Page 47

7 Wire resistance table

Wire resistance table

Distance

Meters (Feet)

30.5 (100) 1.02 0.64 0.40 0.25

61 (200) 2.03 1.28 0.80 0.51

91.4 (300) 3.05 1.92 1.20 0.76

121.9 (400) 4.06 2.55 1.61 1.01

152.4 (500) 5.08 3.20 2.01 1.26

182.9 (600) 6.09 3.83 2.41 1.52

213.4 (700) 7.11 4.47 2.81 1.77

243.8 (800) 8.12 5.11 3.21 2.02

274.3 (900) 9.14 5.75 3.61 2.27

304.8 (1,000) 10.20 6.39 4.02 2.53

381 (1,250) 12.70 7.99 5.03 3.16

457.2 (1,500) 15.20 9.58 6.02 3.79

533.4 (1,750) 17.80 11.20 7.03 4.42

609.6 (2,000) 20.30 12.80 8.03 5.05

685.8 (2,250) 22.80 14.40 9.03 5.68

762 (2,500) 25.40 16.00 10.00 6.31

914.4 (3,000) 30.50 19.20 12.00 7.58

1066.8 (3,500) 35.50 22.40 14.10 8.84

41292.2 (4,000) 40.60 25.50 16.10 10.00

1371.6 (4,500) 45.70 28.70 18.10 11.40

5,000 (1,524) 50.10 32.00 20.10 12.60

1676.4 (5,500) 55.80 35.10 22.10 13.91

1828.8 (6,000) 61.00 38.30 24.10 15.20

1981.2 (6,500) 66.00 41.50 26.10 16.40

2133.6 (7,000) 71.10 44.70 28.10 17.70

2286 (7,500) 76.10 47.90 30.10 19.00

2438.4 (8,000) 81.20 51.10 23.10 20.20

2743.2 (9,000) 91.40 57.50 36.10 22.70

3048 (10,000) 102.00 63.90 40.20 25.30

AWG #20

0.5 mm

AWG #18

2

0.8 mm

2

AWG #16

1.0 mm

AWG #14

2

2.0 mm

2

Resistance shown is one way. This figure must be doubled when determining closed loop

resistance.

Reference Manual 41

Page 48

Wire resistance table

42 Millennium Air Particle Monitor

Page 49

Specifications

8 Specifications

Electrical SpecificationsTable 8-1:

Specification Value

Operating voltage range 10.5 to 32 Vdc

Power consumption 3.24 W max at 12 Vdc

3.6 W max at 24 Vdc

Current output 4-20 mA into a maximum loop impedance of 800 Ohms at

32 Vdc or 150 Ohms at 10.5 Vdc isolated or non-isolated

loop supply

Environmental SpecificationsTable 8-2:

Specification Transmitter APM sensor Junction box

Storage temperature -40 °C to +85 °C (-40 °F to

+185 °F)

Operating temperature -40 °C to +85 °C (-40 °F to

+185 °F)

Relative humidity 0-100% relative humidity, non-condensing

-40 °C to +75 °C (-40 °F to

+167 °F)

-40 °C to +75 °C (-40 °F to

+167 °F)

-40 °C to +85 °C (-40 °F to

+185 °F)

-40 °C to +85 °C (-40 °F to

+185 °F)

Metallurgy

Aluminum (AL6061 - sensor, A413 - junction box)

Stainless steel (SS316)

Ingress ProtectionTable 8-3:

Product Ingress protection rating

Transmitter • Type 4X

• IP66 IP67 (IECEx stainless steel)

Junction box • Type 4X

• IP67

APM sensor • Type 4X

• IP65

Reference Manual 43

Page 50

Specifications

WeightTable 8-4:

Product Weight

Transmitter Stainless steel: 7.0 lb (3.2 kg)

APM sensor Stainless steel: 4.0 lb (1.8 kg)

Junction box Stainless steel: 3.5 lb (1.6 kg)

Separation

Up to 610 meters (2,000 feet) with 16 AWG (1.31 mm2) wire

Warranty

Electronics: 3 years

Sensors: 2 years

44 Millennium Air Particle Monitor

Page 51

9 Certifications

9.1 North American hazardous locations

9.1.1 Transmitter

Class I, Division 1, Groups B, C, and D T5

Class I, Zone 1 Ex d IIB+H2 T5 AL Version Only

-40 °C ≤ Ta ≤ +75 °C

Type 4X

Certifications

9.1.2 APM Sensor

Class I, Division 1, Groups B, C, and D T5

Class I, Zone 1, AEx db IIB+H2 T5 Gb

Ex db IIB+H2 T5 Gb

IP65, Type 4X

-40 °C ≤ Ta ≤ +75 °C

Reference Manual 45

Page 52

Certifications

9.1.3 Junction box (Model JB-MPD)

Class I, Division 1, Groups B, C, and D Class I Zone 1, AEx d/Ex d IIB+H2 T5

-50 °C ≤ Ta ≤ +85 °C

Type 4X, IP67

9.2 ATEX (-X model)

9.2.1 Transmitter

1180 II 2 G Ex d IIB+H2 T5, IP66

9.2.2

-40 °C ≤ Ta ≤ +85 °C

Presafe 16 ATEX 8594X

APM Sensor

1180 II 2 G Ex db op is IIB+H2 T4 Gb

-40 °C < Ta < +75 °C

IP65

SIRA 17ATEX1242X

EN 60079-0:2012/A11:2013

EN 60079-1:2014

Special conditions for safe use

1. The integral conductors shall be suitably mechanically protected and terminated in

a suitable certified terminal or junction facility.

2. It is the user's responsibility to ensure that the earth continuity of the equipment is

maintained via the mounting arrangement.

3. Flamepath joints are not intended to be repaired.

46 Millennium Air Particle Monitor

Page 53

9.2.3 Junction box (Model JB-MPD)

1180 II 2 G Ex d IIB+H2 T5

-55 °C ≤ Ta ≤ +85 °C IP67

FM07ATEX0044

9.3 IECEx (-X model)

9.3.1 Transmitter (aluminum)

Ex d IIB+H2 T5 Gb

Certifications

9.3.2

9.3.3

-40 °C ≤ Ta ≤ +85 °C

Certificate Number: IECEx DNV 12.0014

IEC 60079-0: 2007-10/IEC 60079-1:2007-04

Transmitter (stainless steel)

Ex d IIB+H2 T5 Gb

-55 °C ≤ Ta ≤ +85 °C

Certificate Number: IECEx FMG 13.0035X

IEC 60079-0:2011/IEC 60079-1:2007/IEC 60529:2001

Consult the manufacturer if dimensional information on the flameproof joints is necessary.

APM Sensor

Ex db op is IIB+H2 T4 Gb

-40 °C ≤ Ta ≤ +75 °C

IP65

Certificate Number: IECEx SIR 17.0061X

IEC 60079-0:2011, 6th Edition

IEC 60079-1:2014, 7th Edition

Reference Manual 47

Page 54

Certifications

IEC 60079-28:2015, 2nd Edition

9.3.4 Junction box (Model JB-MPD)

Ex d IIB+H2 T5 Gb

Certificate Number: IECEx FMG 14.0009X

Consult the manufacturer if dimensional information on the flameproof joints is necessary.

Follow the manufacturer's instructions to reduce the potential of an electrostatic charging

hazard.

48 Millennium Air Particle Monitor

Page 55

10 Ordering information

Model Description

MLP Millennium Transmitter

Output Description

AR 4-20 mA analog and particulate and fault alarm

relays

Sensor Description

APM Air Particle Monitor

Optics Description

OP Optical protection

Separation Description

SEP Sensor separation

Ordering information

Housing Description

SS Stainless steel

Approvals Description

CSA

X ATEX-IECEx

Note

Emerson Automation Solutions

Rosemount

6021 Innovation Blvd.

Shakopee, MN 55379

Toll Free +1 866 347 3427

F +1 952 949 7001

www.Emerson.com/FlameGasDetection

Reference Manual 49

Page 56

Ordering information

50 Millennium Air Particle Monitor

Page 57

Ordering information

Reference Manual 51

Page 58

Ordering information

52 Millennium Air Particle Monitor

Page 59

Ordering information

Reference Manual 53

Page 60

00809-0100-4077

Rev AB

2018

GLOBAL HEADQUARTERS

Emerson Automation Solutions

Rosemount

6021 Innovation Blvd.

Shakopee, MN 55379

Toll Free +1 866 347 3427

+1 952 949 7001

safety.csc@emerson.com

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH-6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

safety.csc@emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

google.com/+RosemountMeasurement

AnalyticExpert.com

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

+971 4 811 8100

+971 4 886 5465

safety.csc@emerson.com

©

2018 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount and

Rosemount logotype are trademarks of Emerson. All other marks are property of their

respective owners.

ASIA-PACIFIC

Emerson Automation Solutions

Asia Pacific Private Limited

1 Pandan Crescent

Singapore 128461

Singapore

+65 777 8211

+65 777 0947

safety.csc@emerson.com

Loading...

Loading...