Rosemount Manual: World Class 3000 O2 Analyzer DR Direct Replacement Probe-Rev 3.3 | Rosemount Manuals & Guides

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

Oxygen Analyzer Direct

Replacement Probe for

use with Existing Signal

Conditioning Electronics

http://www.processanalytic.com

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical repre-

sentative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and mainte-

nance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate In-

struction Manual and per applicable local and national codes. Connect all products to the

proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is subject to change without notice.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

HIGHLIGHTS OF CHANGES

Effective June, 1996 Rev. 3

Page Summary

--- General. Updated text and illustrations to reflect probe design

changes.

Page 1-15 Added “Extended temperature by-pass arrangements” to Figure 1-15,

sheet 3 of 3.

Effective December, 1996 Rev. 3.1

Page Summary

Page P-2 Added "Safety instructions for the wiring and installation of this

apparatus".

Page 1-4 Corrected Figure 1-3 item listing.

Page 2-1 Added one WARNING to read new safety instructions and another

WARNING regarding protective covers and grounds.

Page 3-1 Added WARNING regarding protective covers and grounds.

Page 4-1 Added WARNING regarding protective covers and grounds.

Page 4-6 Added title block to Figure 4-6.

Page 5-1 Added WARNING regarding protective covers and grounds.

Page 7-1 Corrected cell replacement kit part numbers in Table 7-1.

Page 7-2 Corrected cell replacement kit part number in Table 7-1.

Effective May, 1997 Rev. 3.2

Page Summary

Page P-2 Added safety sheet.

Effective February, 1998 Rev. 3.3

Page Summary

Page 2-2 Figure 2-1. Changed calibration gas tube dimensions.

World Class 3000

PREFACE.........................................................................................................................P1

Definitions ......................................................................................................................... P1

Safety Instructions ........................................................................................................... P2

1-0 DESCRIPTION AND SPECIFICATIONS........................................................................ 1-1

1-1 Component Checklist ..................................................................................................... 1-1

1-2 System Overview............................................................................................................ 1-1

1-3 Physical Description ....................................................................................................... 1-3

1-4 Probe Exterior................................................................................................................. 1-5

1-5 Probe Interior .................................................................................................................. 1-7

1-6 Junction Box .................................................................................................................... 1-8

1-7 Cable Assembly...............................................................................................................1-9

1-8 Probe Options................................................................................................................. 1-9

2-0 INSTALLATION .............................................................................................................. 2-1

2-1 Locating The Oxygen Analyzer Probe.......................................................................... 2-1

2-2 Service Required .............................................................................................................2-1

2-3 Mechanical Installation ................................................................................................... 2-6

2-4 Electrical Installation ........................................................................................................ 2-7

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

TABLE OF CONTENTS

3-0 STARTUP........................................................................................................................ 3-1

3-1 Overview.......................................................................................................................... 3-1

3-2 Models 218, 225, And 132 (Analog) Electronics Setup............................................. 3-1

3-3 Model 218A Electronics Setup ..................................................................................... 3-2

3-4 Model TC200 Veritrim Electronics Setup ..................................................................... 3-3

3-5 Model 132 Digital Electronics Setup............................................................................ 3-4

3-6 The Yokogawa ZA8C And AV8C Converter Electronics Setup ................................ 3-4

4-0 MAINTENANCE AND SERVICE .................................................................................. 4-1

4-1 Overview.......................................................................................................................... 4-1

4-2 Probe Calibration ............................................................................................................. 4-1

4-3 Cell Replacement ........................................................................................................... 4-1

4-4 Optional Ceramic Diffusion Element Replacement ..................................................... 4-3

4-5 Replacement Of Contact And Thermocouple Assembly ............................................. 4-5

4-6 Replacement Of Heater, V-Strut And Backplate Assembly ..................................... 4-7

4-7 Calibration And Reference Gas Lines For High Temperature -

Corrosive Environment Operation ................................................................................... 4-9

5-0 TROUBLESHOOTING .................................................................................................... 5-1

5-1 Overview.......................................................................................................................... 5-1

5-2 Probe Troubleshooting ................................................................................................... 5-1

6-0 RETURN OF MATERIAL .............................................................................................. 6-1

7-0 REPLACEMENT PARTS ................................................................................................ 7-1

8-0 INDEX.............................................................................................................................. 8-1

Rosemount Analytical Inc. A Division of Emerson Process Management i

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

Figure 1-1. Typical System Package ....................................................................................... 1-1

Figure 1-2. Typical System Installation .................................................................................... 1-3

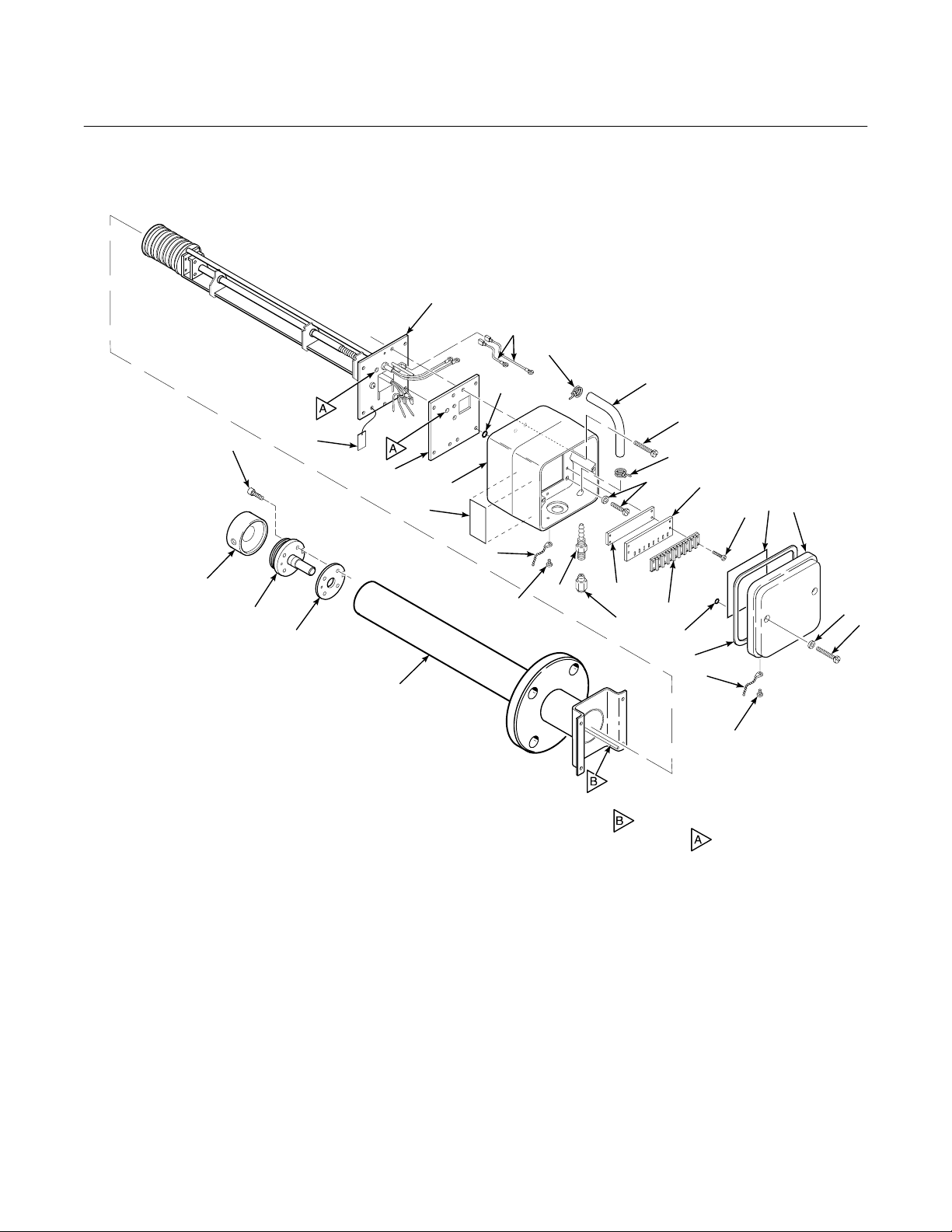

Figure 1-3. Oxygen Analyzer Probe - Exploded View.............................................................. 1-4

Figure 1-4. Main Probe Components ....................................................................................... 1-5

Figure 1-5. Cell and Tube Assemblies ..................................................................................... 1-5

Figure 1-6. Optional Ceramic Diffusor and Vee Deflector Assembly....................................... 1-7

Figure 1-7. Inner Probe Assembly............................................................................................ 1-8

Figure 1-8. Junction Box .......................................................................................................... 1-8

Figure 1-9. Abrasive Shield Assembly ................................................................................... 1-10

Figure 1-10. Ceramic Diffusion/Dust Seal Assembly ............................................................... 1-11

Figure 1-11. Flame Arrestor Diffusion/Dust Seal Assembly..................................................... 1-11

Figure 1-12. Ceramic Diffusion Assembly................................................................................ 1-11

Figure 1-13. Flame Arrestor Diffusion Assembly ..................................................................... 1-11

Figure 1-14. Snubber Diffusion/Dust Seal Assembly............................................................... 1-12

Figure 1-15. Bypass Probe Option (Sheet 1 of 3) .................................................................... 1-13

Figure 2-1. Probe Installation (Sheet 1 of 5) ............................................................................ 2-2

Figure 2-2. Orienting the Optional Vee Deflector ..................................................................... 2-7

Figure 2-3. Wiring the Direct Replacement Probe ................................................................... 2-8

Figure 3-1. Temperature Controller Card Calibration Points ................................................... 3-1

Figure 3-2. Main PCB (Model 218A) EPROM Replacement ................................................... 3-2

Figure 3-3. Main PCB (Model TC200) EPROM Replacement ................................................. 3-3

Figure 3-4. Main PCB (Model 132) EPROM Replacement...................................................... 3-4

Figure 3-5. DR Probe Wired to the ZA8C or A V8C Converter ................................................ 3-5

Figure 4-1. Cell Wiring Connection .......................................................................................... 4-2

Figure 4-2. Removal of Optional Ceramic Diffusor and Vee Deflector .................................... 4-3

Figure 4-3. Cell Replacement Kit ............................................................................................. 4-3

Figure 4-4. Junction Box Mechanical Connections.................................................................. 4-5

Figure 4-5. Inner Probe Replacement (Heater, V-Strut, and Backplate Assembly)................ 4-6

Figure 4-6. Heater, Strut, and Backplate Assembly (Inner Probe Assembly).......................... 4-6

Figure 4-7. Oxygen Analyzer Probe, Cross-Sectional View .................................................... 4-8

Figure 4-8. High Temperature – Corrosive Environment Kit .................................................... 4-9

World Class 3000

LIST OF ILLUSTRATIONS

LIST OF TABLES

Table 1-1. Specifications for Oxygen Analyzing Equipment

Table 5-1. Fault Finding .......................................................................................................... 5-2

Table 7-1. Replacement Parts for Probe ................................................................................ 7-1

ii Rosemount Analytical Inc. A Division of Emerson Process Management

1 2

............................................... 1-6

World Class 3000

The World Class 3000 Direct Replacement Probe can be used with any of the following

model electronics: 218, 225, 218A, ZA8C, and TC200. Read the appropriate setpoint adjustment in this manual to prevent damage to the probe.

The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of this particular probe.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

The following definitions apply to WARNINGS, CAUTIONS, and NOTES found throughout this

publication.

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

CAUTION

!

PREFACE

DEFINITIONS

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in injury, death, or long-term

health hazards of personnel.

NOTE

Highlights an essential operating procedure,

condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETIN

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in damage to or destruction of

equipment, or loss of effectiveness.

NOTE TO USERS

The number in the lower right corner of each illustration in this publication is a manual illustration number. It is not a part number, and is not related to the illustration in any technical

manner.

Rosemount Analytical Inc. A Division of Emerson Process Management P-1

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

FOR THE WIRING AND INSTALLATION

The following safety instructions apply specifically to all EU member states. They should

be strictly adhered to in order to assure compliance with the Low Voltage Directive. NonEU states should also comply with the following unless superseded by local or National

Standards.

1. Adequate earth connections should be made to all earthing points, internal and external,

where provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced.

The integrity of all earth terminals must be maintained at all times.

3. Mains supply cords should comply with the requirements of IEC227 or IEC245.

World Class 3000

IMPORTANT

SAFETY INSTRUCTIONS

OF THIS APPARATUS

4. All wiring shall be suitable for use in an ambient temperature of greater than 75°C.

5. All cable glands used should be of such internal dimensions as to provide adequate cable

anchorage.

6. To ensure safe operation of this equipment, connection to the mains supply should only be

made through a circuit breaker which will disconnect all circuits carrying conductors during a

fault situation. The circuit breaker may also include a mechanically operated isolating switch.

If not, then another means of disconnecting the equipment from the supply must be provided

and clearly marked as such. Circuit breakers or switches must comply with a recognized

standard such as IEC947. All wiring must conform with any local standards.

7. Where equipment or covers are marked with the symbol to the right, hazardous voltages are likely to be present beneath. These covers should only be

removed when power is removed from the equipment — and then only by

trained service personnel.

8. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain surfaces may remain hot to the touch.

9. Where equipment or covers are marked with the symbol to the right, refer to

the Operator Manual for instructions.

10. All graphical symbols used in this product are from one or more of the following standards: EN61010-1, IEC417, and ISO3864.

P-2 Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

DESCRIPTION AND SPECIFICATIONS

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

SECTION 1

1-1 COMPONENT CHECKLIST

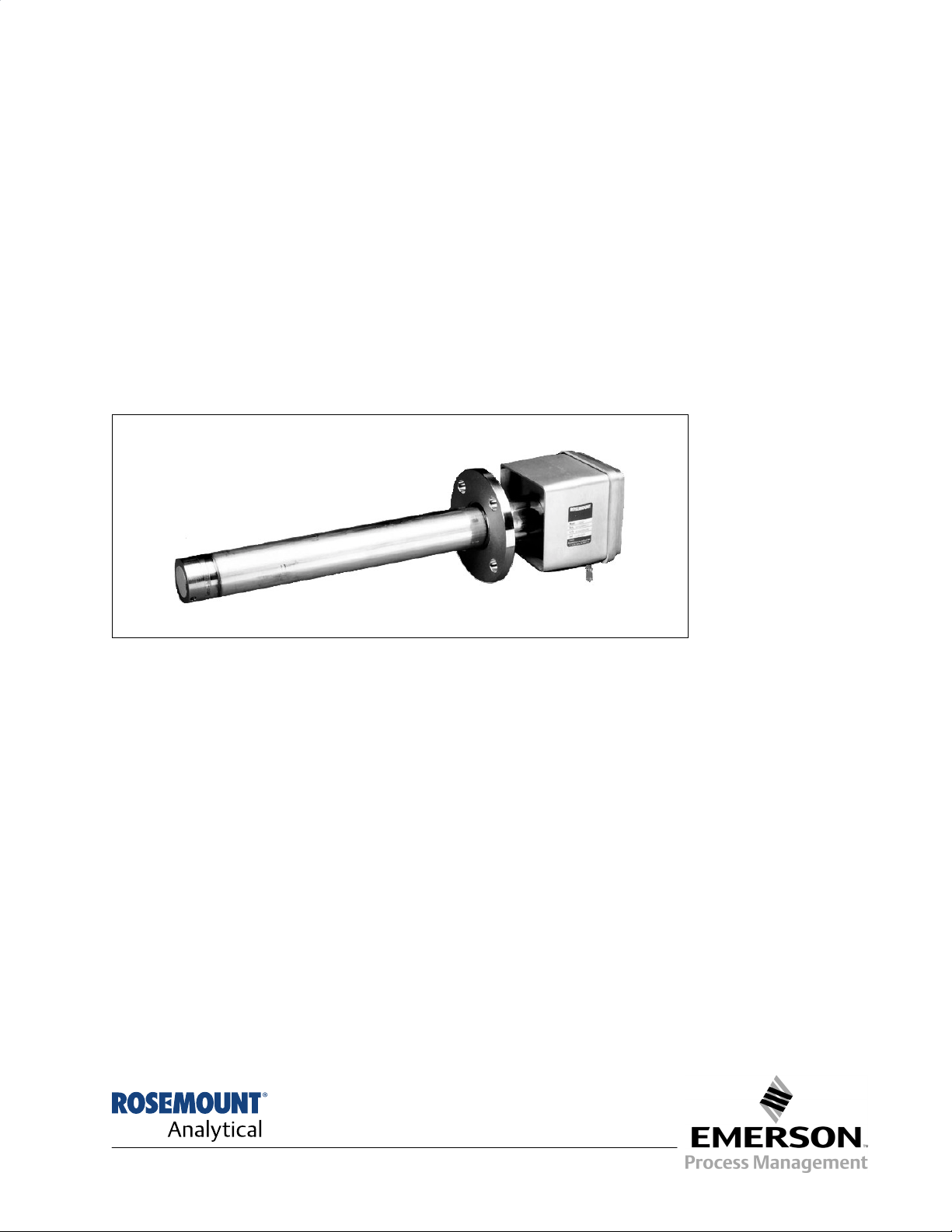

The Direct Replacement (DR) Probe package of

the World Class 3000 Oxygen Analyzer typically

includes the probe, the instruction bulletin, and

the mounting hardware. These three items are

shown in Figure 1-1. Record the Part Number,

Serial Number, and Order Number of your

system on the first page of this manual.

1-2 SYSTEM OVERVIEW

a. Scope

This Instruction Bulletin has been designed

to supply details needed to install, start up,

and troubleshoot the Rosemount World

Class 3000 Oxygen Analyzer. The Direct

Replacement Probe can be interfaced to a

number of different and earlier model

electronics packages. These electronic

packages are not covered in this manual.

For specific information concerning calibration and operation of the system, refer to

the Instruction Bulletin applicable to your

electronics package.

b. System Function

The Rosemount Oxygen Analyzer (Probe) is

designed to measure the net concentration

of oxygen in an industrial process; i.e., the

oxygen remaining after all fuels have been

oxidized. The probe is permanently positioned within an exhaust duct or stack. The

sampling system is in situ rather than

extractive.

2

1. Oxygen Analyzer Probe

2. Mounting Adapter Plate with

Mounting Hardware and

Gasket

3. Instruction Bulletin

3

1

19290001

Figure 1-1. Typical System Package

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

The equipment measures oxygen percentage by reading the voltage developed

across a heated electrochemical cell, which

consists of a small yttria-stabilized, zirconia

disc. Both sides of the disc are coated with

porous metal electrodes. When operated at

the proper temperature, the millivolt output

voltage of the sensor cell is given by the

following Nernst equation:

EMF = KT log

10(P1/P2

) + C

Where:

1. P

is the partial pressure of the oxygen

2

in the measured gas on one side of the

cell,

2. P

is the partial pressure of the oxygen

1

in the reference gas on the other side,

3. T is the absolute temperature,

4. C is the cell constant,

5. K is an arithmetic constant.

NOTE

For best results, use clean, dry,

instrument air (20.95% oxygen) as a

reference gas.

vapor. Therefore, it may be considered an

analysis on a "wet" basis. In comparison

with older methods, such as the Orsat

apparatus, which provides an analysis on a

"dry" gas basis, the "wet" analysis will, in

general, indicate a lower percentage of

oxygen. The difference will be proportional

to the water content of the sampled gas

stream.

c. System Configuration

The DR probe is similar to the Exchange

Probe (NE model) except that the DR uses

a 115 V heater like most older systems. The

DR does not require a separate power supply as does the NE. The DR probe (like the

NE) is available in five lengths. The length

of stack penetration depends on the size of

the stack or duct. The length options are

18 in., 3 ft, 6 ft, 9 ft, and 12 ft (457 mm, 0.9

m, 1.8 m, 2.7 m, and 3.7 m).

d. Features

1. Output voltage and sensitivity increase

as the oxygen concentration

decreases.

When the cell is at operating temperature,

oxygen ions will travel through the cell from

high to low oxygen partial pressures. The

resulting output voltage is about 50 mV per

decade. The voltage varies with the ratio of

oxygen partial pressures of the reference

gas over the sample gas. Thus, the output

signal increases as the sample oxygen level

decreases. This property gives the analyzer

high sensitivity at low oxygen levels.

Oxygen analyzer equipment measures net

oxygen concentration in the presence of all

the products of combustion, including water

2. In situ, non-sampling analyzer.

3. Field replaceable cell.

4. Analyzer constructed of rugged

316 LSS for all wetted parts.

5. Suitable for use in temperatures up to

1300°F (700°C).

6. The DR probe uses a 115 V heater

and does not require a separate heater

power supply.

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

e. Handling the Oxygen Analyzer

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

GASES

It is important that printed circuit

boards and integrated circuits are

handled only when adequate antistatic

precautions have been taken to prevent possible equipment damage.

The oxygen analyzer is designed for

industrial application. Treat each

component of the system with care to

avoid physical damage. The probe

contains components made from ceramics, which are susceptible to

shock when mishandled.

NOTE

Retain packaging in which the oxygen

analyzer arrived from the factory in

case any components are to be

shipped to another site. This packaging has been designed to protect the

product.

f. System Considerations

Prior to installation of your Rosemount

World Class 3000 Oxygen Analyzer, make

sure you have all of the components

necessary to make the system installation.

Ensure all components are properly

integrated to make the system functional.

STACK

CALIBRATION

INSTRUMENT

AIR SUPPLY

(REF. GAS)

GAS

PRESSURE

REGULATOR

FLOWMETER

EXISTING

ELECTRONICS

Figure 1-2. Typical System Installation

connecting test gas tanks to the oxygen

analyzer when the probe is to be calibrated.

NOTE

Ambient air is not recommended for

use as high test gas. An 8% O

balance in nitrogen is recommended

for high test gas.

DUCT

ADAPTER

OXYGEN

ANALYZER

(PROBE)

2

PLATE

VOLTAGE

19290002

LINE

Once you have verified you have all the

components, select mounting locations and

determine how each component will be

placed in terms of available power supply,

ambient temperatures, environmental considerations, convenience, and serviceability.

A typical installation is illustrated in Figure

1-2.

If test gas bottles will be hooked up permanently, an optional check valve is recommended next to the calibration fittings on

the probe head. This is to prevent breathing

of calibration gas line and subsequent flue

gas condensation and corrosion. The check

valve is in addition to the stop valve in the

test gas kit or the solenoid valve in the

multiprobe test gas sequencer units.

After selecting the probe mounting location,

provision should be made for a platform

1-3 PHYSICAL DESCRIPTION

where the probe can be easily serviced.

The Oxygen Analyzer Probe, Figure 1-3 conA source of instrument air is required at the

probe for reference gas use. Since the

sists of three component groups: probe exterior,

inner probe, and junction box, Figure 1-4.

probe is equipped with an in place calibration feature, provision should be made for

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

NOTE: NOT ALL PARTS SHOWN ARE AVAILABLE FOR

PURCHASE SEPARATELY. FOR LIST OF

AVAILABLE PARTS, SEE TABLE 7-1.

World Class 3000

1

26

20

18

23

21

19

16

14

20

12

29

10

17

11

13

15

9

28

3

2

4

30

27

25

24

11

22

10

5

6

NOTE: ITEM , CALIBRATION GAS TUBE,

FITS INTO HOLES WHEN PROBE IS

ASSEMBLED.

1. Heater, Strut, and Backplate 11. Probe Junction Box Cover 22. Gas Connection

Assembly 12. Cover Gasket 23. Seal Cap

2. Diffusion Assembly 13. Insulating Sheet 24. Label

3. Retainer Screw 14. O-Ring 25. Probe Junction Box

4. Cell and Flange 15. Terminal Block Screw 26. Ground Wires

5. Corrugated Seal 16. Terminal Block 27. Insulating Gasket

6. Probe Tube Assembly 17. Terminal Block Marker 28. Washer

7. Cover Screw 18. Terminal Block Mounting Plate 29. Screw

8. Washer 19. Probe Junction Box Screws 30. Tag

9. Cover Chain Screw 20. Hose Clamp

10. Cover Chain 21. Hose

35900002

8

7

Figure 1-3. Oxygen Analyzer Probe - Exploded View

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

PROBE

EXTERIOR

(SENSING CELL INSTALLED)

PROBE

INTERIOR

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

PROBE

JUNCTION

BOX

Figure 1-4. Main Probe Components

1-4 PROBE EXTERIOR

Primary probe exterior components include a

flange-mounted zirconium oxide cell, mounted

on a tube assembly and protected by a snubber

diffusion assembly.

a. Cell and Flange Assembly

The primary component in the cell and

flange assembly, Figure 1-5, is a

yttria-stabilized zirconium oxide cell. The

cell creates an electrical signal when the

oxygen level on one side is out of balance

with the oxygen level on the other side. This

signal is proportional to the difference in

oxygen levels.

b. Probe Tube Assembly

21240006

The tube assembly includes a flange which

mates with a stack-mounted flange (shown

attached to the probe flange in Figure 1-4).

Studs on the stack flange make installation

easy. There is also a tube to carry calibration gas from the junction box to the

process side of the cell during calibration.

PROBE TUBE

CORRUGATED

SEAL

CELL AND

FLANGE

ASSEMBLY

Four screws secure the cell and flange assembly, Figure 1-5, to the probe tube assembly. When in place, the cell is inside the

tube.

21240007

Figure 1-5. Cell and Tube Assemblies

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

Table 1-1. Specifications for Oxygen Analyzing Equipment

1 2

Probe lengths, nominal ...................................................................... 18 in. (457 mm), 3 ft (0.91 m),

6 ft (1.83 m), 9 ft (2.74 m), or 12 ft (3.66 m),

depending on duct dimensions

Temperature limits in process

measurement area ....................................................................... 50° to 1300°F (10° to 704°C)

Standard/current output ................................................................ 4-20 mA dc signal (factory set)

O

indication (Digital display

2

and analog output)........................................................................ 0.1% O

or ±3% of reading, whichever is greater

2

using Rosemount test gases

System speed of response ................................................................ less than 3 seconds (amplifier output)

Resolution sensitivity ......................................................................... 0.01% O

transmitted signal

2

Probe reference air flow .................................................................... 2 scfh (56.6 L/hr) clean, dry, instrument

quality air (20.95% O

), regulated to

2

5 psi (34 kPa)

Calibration gas mixtures .................................................................... Rosemount Hagan Test Gas Kit Part No.

6296A27G01 contains 0.4% O

and 8% O

Nominal

2N2

Nominal

2N2

Calibration gas flow ........................................................................... 5 scfh (141.6 L/hr)

Power supply ..................................................................................... 115 ±10% Vac at 50/60 Hz

Power requirement ............................................................................ 200 VA

Ambient operating temperature (Junction Box)................................. 300°F (149°C) [160°F (71°C) max for YEW

replacement]

Approximate shipping weights:

18 in. (457 mm) package ....................................................... 55 lbs (24.97 kg)

3 ft (0.91 m) package ............................................................. 60 lbs (27.24 kg)

6 ft (1.83 m) package ............................................................. 65 lbs (29.51 kg)

9 ft (2.74 m) package ............................................................. 72 lbs (32.66 kg)

12 ft (3.66 m) package ........................................................... 78 lbs (35.38 kg)

1

All static performance characteristics are with operating variables constant.

2

Equipment ordered utilizing this document as reference will be supplied to the USA standard design.

Customers requiring the EEC standard design should request the EEC documentation and utilize its ordering

data. Temperatures over 1000°F (537°C) may affect the ease of field cell replaceability.

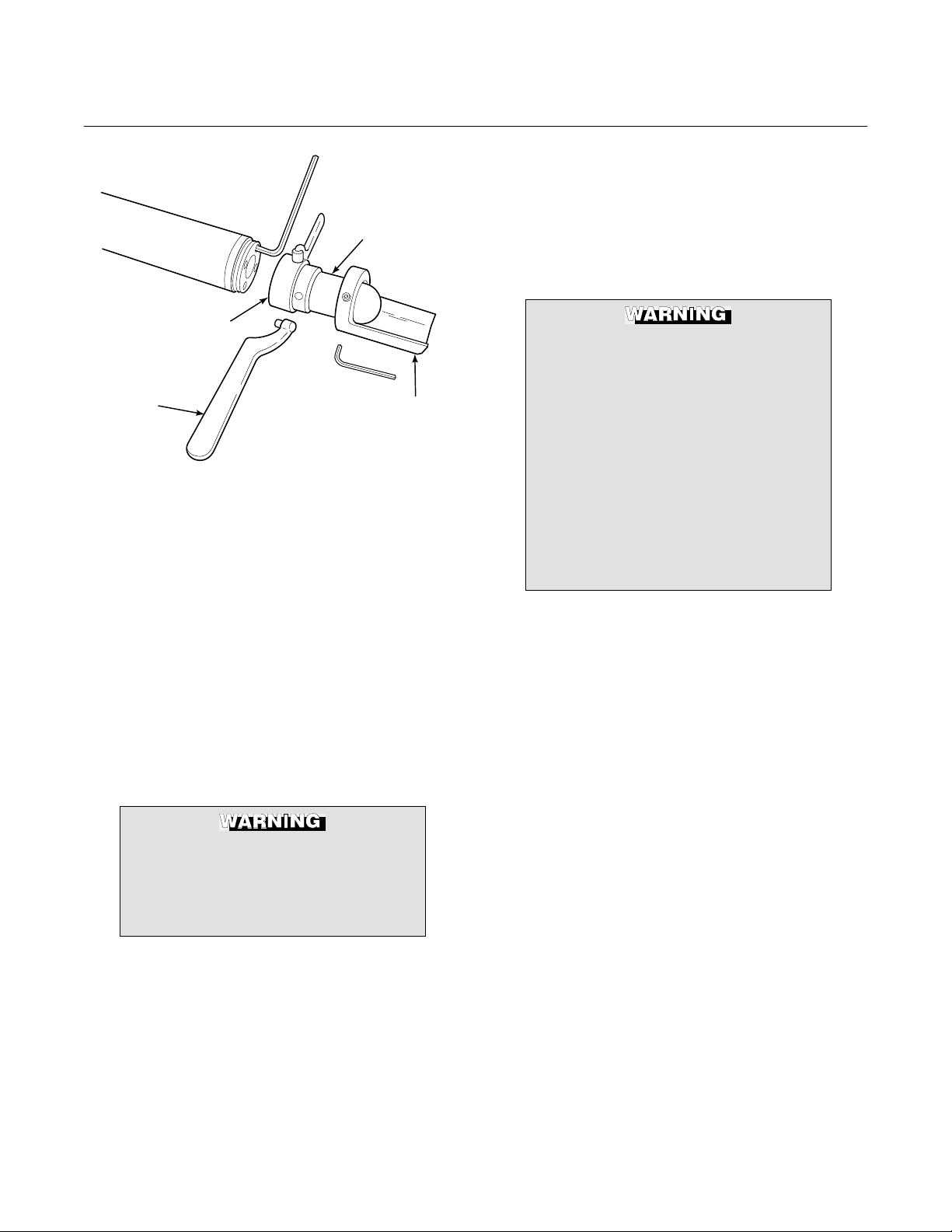

c. Snubber Diffusion Assembly

The snubber diffusion assembly protects

the cell from heavy particles and isolates

the cell from changes in temperature. The

snubber assembly threads onto the cell and

flange assembly. Pin spanner wrenches

An optional ceramic diffusor element and

vee deflector shown in Figure 1-6, is available. The ceramic diffusor assembly is also

available in a flame arresting version to

keep heat from the cell from igniting flue

gases.

(probe disassembly kit 3535B42G01) are

applied to holes in the diffusion element hub

to remove or install the snubber assembly.

1-6 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

is noted in the calibration data sheet supplied with each probe.

DIFFUSION

ELEMENT

HUB

PIN

WRENCH

VEE

DEFLECTOR

21240024

Figure 1-6. Optional Ceramic Diffusor and Vee

Deflector Assembly

Systems that use an abrasive shield require

a special diffusor assembly with a hub that

is grooved to accept two dust seal gaskets.

This special diffusor is available in both

snubber and ceramic versions. See Probe

Options, paragraph 1-8.

d. Cell – General

The components which make up the cell are

machined to close tolerances and assembled with care to provide accurate oxygen

measurements. Any replacement requires

attention to detail and care in assembly to

provide good results.

Every probe should be calibrated and

checked after repair or replacement of cell,

pad and wire, heater, and thermocouple, or

after disassembly of the probe.

There are two styles of the heater/strut

inner probe assembly. P/Ns

3D39441G06 through G10 identify the

44 V heater design. P/Ns 3D39441G01

through G05 and G11 through G15

identify the 115 V heater design. Both

styles look the same. When replacing

a strut, be sure the replacement has

the same part number as the original.

A stainless steel tag is attached to the

inner probe assembly to identify the

115V design. Operating a probe on the

wrong heater voltage can cause injury

or severe damage to equipment.

1-5 PROBE INTERIOR

The inner probe assembly, Figure 1-7, consists

of six main parts:

a. Ceramic support rod with four holes running

through the length. The holes serve as insulated paths for the cell signal wire and

thermocouple wires.

b. A heater that is helically wrapped on a

quartz support cylinder and insulated.

Failure to follow the instructions in

this manual could cause danger to

personnel and equipment. Read and

follow instructions in this manual

c. A chromel-alumel thermocouple which acts

as the sensing element for the temperature

controller. (Not visible in Figure 1-7; located

within ceramic support rod.)

carefully.

d. A platinum screen pad which forms electri-

The oxygen probe includes an inner electrode for the cell assembly. It consists of a

platinum pad and a platinum/inconel composite wire which produces the cell constant

offset voltage described in the Nernst equation.

With this pad and wire, the constant will be

between -10 and +15 mV. The cell constant

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-7

cal contact with the inner electrode of the

electrochemical cell. (Not visible in Figure

1-7; located at end of ceramic support rod.)

The pad is attached to an inconel/stainless

steel wire which carries the signal to the

terminal strip.

e. A V-strut assembly to give support to the

inner probe assembly.

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

HEATER

INSULATING

GASKET

V-STRUT

CERAMIC

SUPPORT

ROD

Figure 1-7. Inner Probe Assembly

f. A tube to carry reference gas to the cell.

Refer to Section 4, Maintenance and Service,

for repair procedures for probe components.

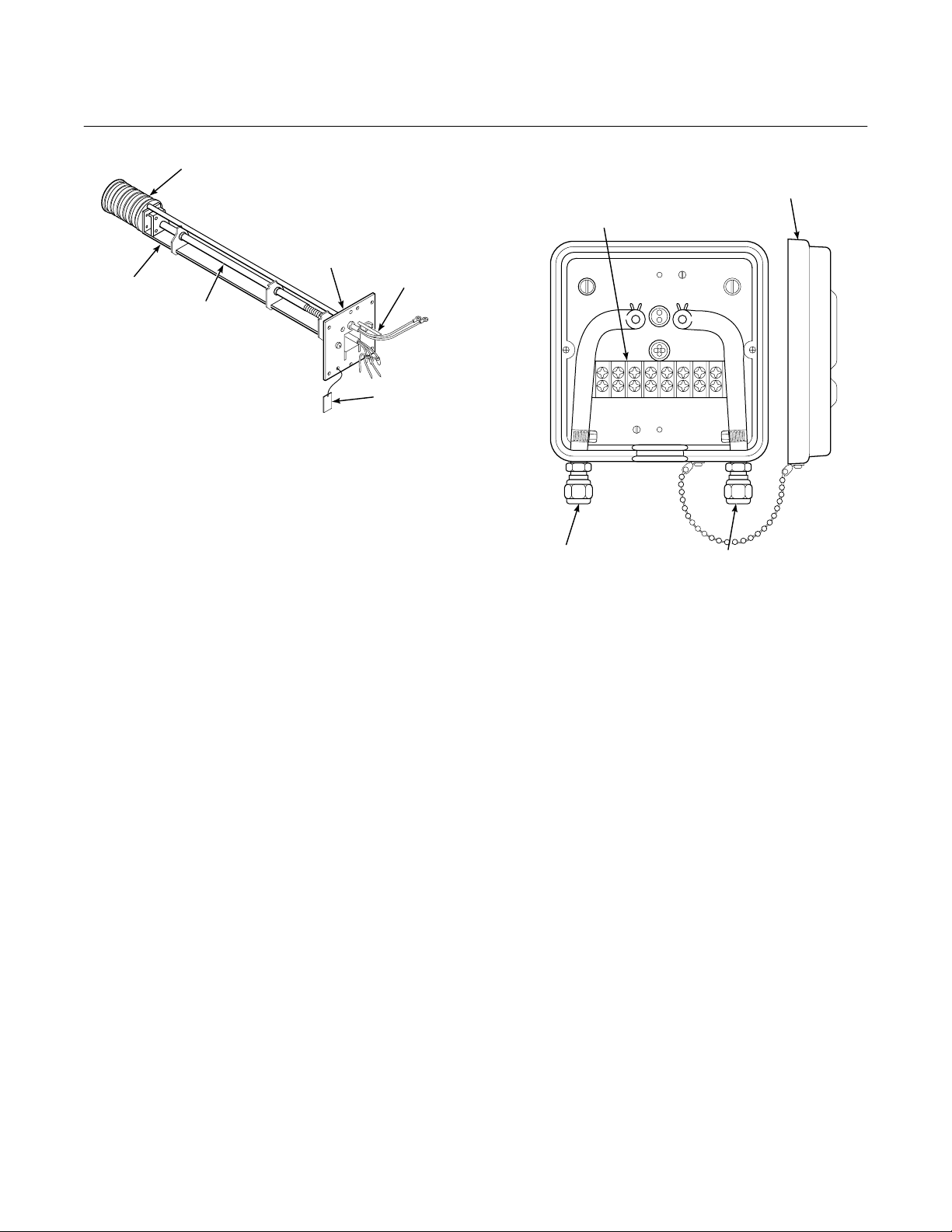

1-6 JUNCTION BOX

The junction box, Figure 1-8, is positioned at the

external end of the probe and contains a terminal strip for electrical connections and fittings for

reference and calibration gases. Fittings are for

0.250 inch stainless steel tubing on American

units, and 6 mm tubing on European units. The

calibration fitting has a seal cap which must remain in place except during calibration. A tubing

fitting is also supplied to be used with the

calibration gas supply during calibration.

If the calibration gas bottles will be permanently

hooked up to the probe, a manual block valve is

required at the probe (between the calibration

fitting and the gas line) to prevent condensation

of flue gas down the calibration gas line.

During operation and calibration, reference gas

is supplied through the reference gas fitting to

the reference side of the cell. This gives the

REFERENCE

GAS TUBE

TAG

21220004

PROBE

JUNCTION BOX

COVER

TERMINAL

STRIP

CALIBRATION

GAS FITTING

REFERENCE

GAS FITTING

21240029

Figure 1-8. Junction Box

system a known quantity of oxygen with which

to compare the oxygen level in the process gas.

Though ambient air can be used for this purpose, accuracy can only be assured if a

reference gas air set is used.

During calibration, two gases of different known

oxygen concentrations are injected one at a

time through the calibration gas fitting. Stainless steel tubing delivers this gas to the process

side of the cell. In a healthy cell, the difference

in oxygen pressure from the process side to the

reference side of the cell will cause a millivolt

output proportional to the difference in oxygen

levels. The electronics unit can use the two millivolt outputs caused by the two calibration

gases for either automatic or semi-automatic

calibration.

1-8 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

World Class 3000

1

Do not attempt to remove a process

gas sample through either gas fitting.

Hot gases from the process would

damage gas hoses in the junction box.

1-7 CABLE ASSEMBLY

The Westinghouse and Rosemount systems

use a 7-conductor cable to connect the probe to

the electronics package. Standard length for this

cable is 20 ft (6 m), but lengths up to 150 ft

(45 m) are available. The seven conductors

include one shielded pair of wires for the cell

millivolt signal, one shielded pair of type K wires

for the thermocouple, and three individual

16-gauge wires for the heater and for ground.

The assembled conductors are wrapped by a

TM

Teflon

jacket and braided stainless steel

Instruction Manual

IB-106-300DR Rev. 3.3

TM

shield. The Teflon

ing is suitable for high temperature use. All

metal shields are isolated at the probe end and

connect by drain wires to ground at the

electronics.

1-8 PROBE OPTIONS

a. Abrasive Shield Assembly

The abrasive shield assembly, Figure 1-9, is

a stainless-steel tube that surrounds the

probe assembly. The shield protects the

probe against particle abrasion and corrosive condensations, provides a guide for

ease of insertion, and acts as a probe position support, especially for longer length

probes. The abrasive shield assembly uses

a modified diffusion and vee deflector assembly fitted with dual dust seal packing.

and stainless steel jacket-

February 2000

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-9

Instruction Manual

IB-106-300DR Rev. 3.3

February 2000

World Class 3000

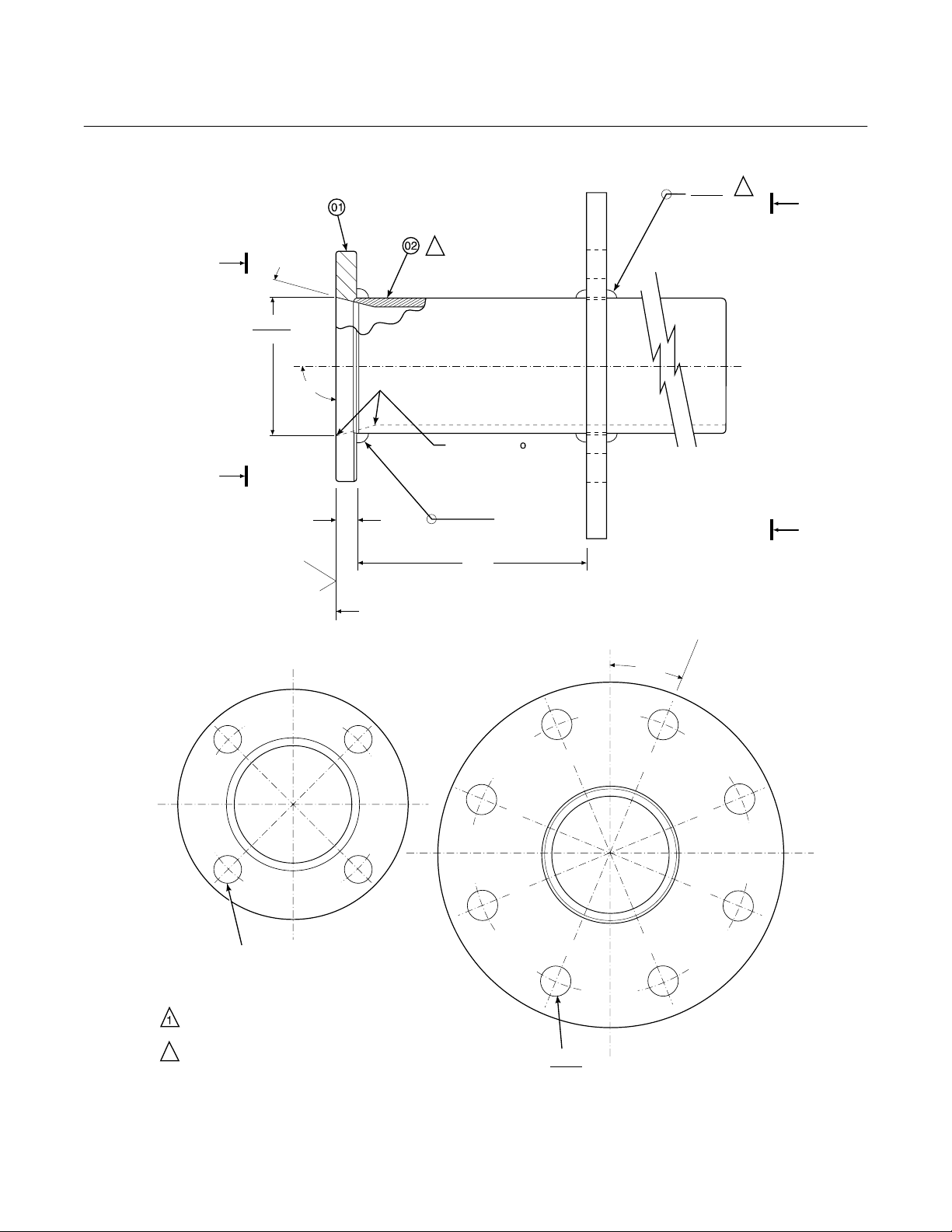

0.187

0.187

2

1

B

A

o

15

03.584

03.554

o

90

ON INSIDE BREAK

FOR SMOOTH

A

0.45 MIN

125

SKIN CUT FACE FOR 90

ROUNDED EDGE ON

BOTH ENDS OF

CHAMFER.

6.00

0.187

o

/

B

NOTES:

VIEW A

o

/

0.75 THRU 4 PLS.

EQ SP ON 4.75 B.C.

WELD ON BOTH SIDES WITH EXPANDING

CHILL BLOCK.

2

BEFORE WELDING, BUTT ITEM 2 WITH

ITEM 1 AS SHOWN.

o

/

Figure 1-9. Abrasive Shield Assembly

VIEW B

o

22.5

0.745

DIA ON A 7.50 DIA B.C. (REF)

0.755

P0009

1-10 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Loading...

Loading...