Rosemount Manual: SPS 4000 Single Probe Autocalibration Sequencer-Rev 1.1 | Rosemount Manuals & Guides

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

SPS 4000

Single Probe

Autocalibration Sequencer

http://www.processanalytic.com

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical repre-

sentative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and mainte-

nance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate In-

struction Manual and per applicable local and national codes. Connect all products to the

proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is subject to change without notice.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

HIGHLIGHTS OF CHANGES

Effective Feb., 1999 Rev. 1.0

Page Summary

Page 1-1 Added note concerning the Oxymitter 5000.

Page 1-2 Added the Oxymitter 5000 to the product matrix in Table 1-1. Removed

the disposable gas bottles and flow regulators from the product matrix

in Table 1-1 and created Table 1-2 to distinguish these components as

separate order items because the calibration gas bottles cannot be

shipped via airfreight.

Page 7-1 Added Table 7-2 to list the calibration gas bottles and flow regulators

as replacement parts.

Effective April, 2001 Rev. 1.1

Page Summary

Page 7-1 Table 7-1; changed part number of solenoid, items 24 and 30.

SPS 4000

PREFACE........................................................................................................................ P-1

Definitions ........................................................................................................................P-1

Safety Instructions .......................................................................................................... P-2

1-0 DESCRIPTION AND SPECIFICATIONS........................................................................ 1-1

1-1 Component Checklist ..................................................................................................... 1-1

1-2 Overview.......................................................................................................................... 1-1

1-3 Specifications................................................................................................................... 1-4

1-4 Physical Description ....................................................................................................... 1-5

1-5 Theory of Operation....................................................................................................... 1-6

2-0 INSTALLATION .............................................................................................................. 2-1

2-1 Overview.......................................................................................................................... 2-1

2-2 Mechanical Installation ................................................................................................... 2-1

2-3 Gas Connections ............................................................................................................ 2-1

2-4 Electrical Connections .................................................................................................... 2-3

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

TABLE OF CONTENTS

3-0 OPERATION ...................................................................................................................3-1

3-1 Overview.......................................................................................................................... 3-1

3-2 Calibration Requirements ............................................................................................... 3-1

3-3 Calibration Gas Flow Setup .......................................................................................... 3-2

3-4 Automatic Calibration ..................................................................................................... 3-2

3-5 Semi-Automatic Calibration ............................................................................................ 3-2

4-0 MAINTENANCE AND SERVICE .................................................................................. 4-1

4-1 Overview.......................................................................................................................... 4-1

4-2 Fuse Replacement ......................................................................................................... 4-1

4-3 Board Replacement ........................................................................................................ 4-1

4-4 Solenoid Replacement ................................................................................................... 4-3

4-5 Pressure Switch Replacement ...................................................................................... 4-5

4-6 Check Valve Replacement ............................................................................................ 4-6

4-7 Pressure Regulator (Optional) Maintenance ................................................................ 4-6

4-8 Flowmeter Adjustments .................................................................................................. 4-6

4-9 Flowmeter Replacement................................................................................................. 4-6

5-0 TROUBLESHOOTING .................................................................................................... 5-1

5-1 Overview.......................................................................................................................... 5-1

5-2 SPS 4000 Troubleshooting............................................................................................ 5-1

6-0 RETURN OF MATERIAL .............................................................................................. 6-1

7-0 REPLACEMENT PARTS ............................................................................................... 7-1

8-0 INDEX.............................................................................................................................. 8-1

Rosemount Analytical Inc. A Division of Emerson Process Management i

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

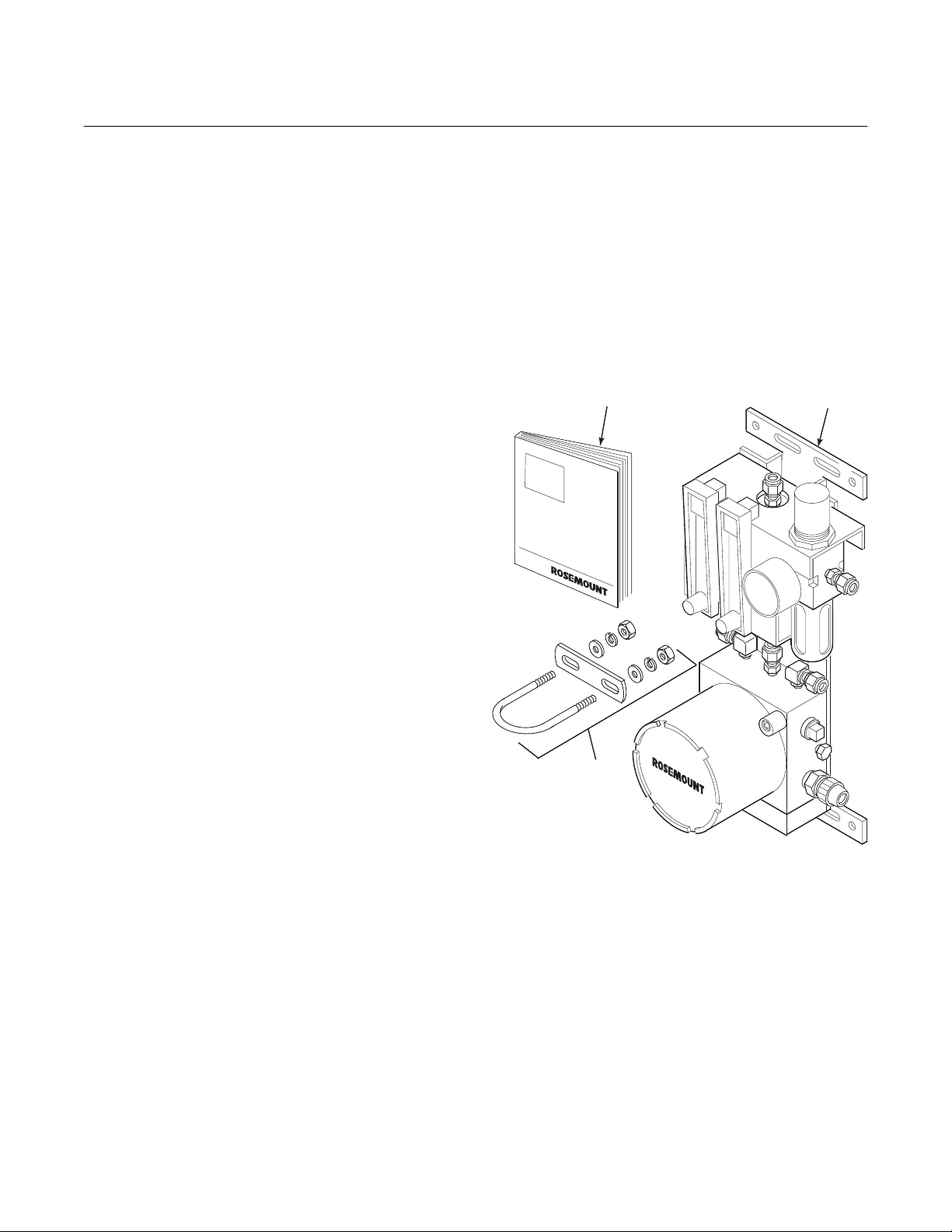

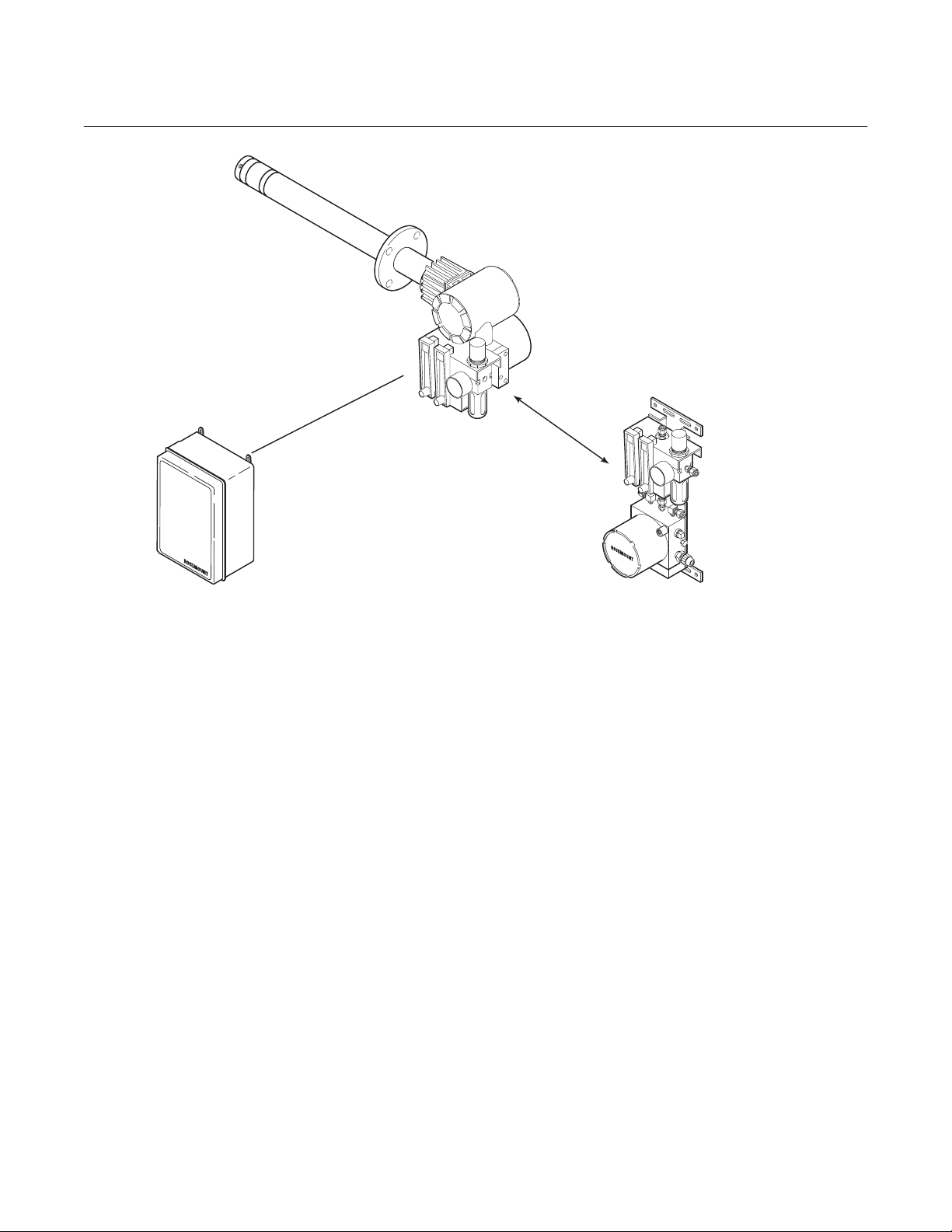

Figure 1-1. Typical SPS 4000 Package ................................................................................... 1-1

Figure 1-2. Autocalibration System Installation Options .......................................................... 1-3

Figure 1-3. SPS 4000 Components ......................................................................................... 1-5

Figure 1-4. SPS 4000 Calibration Setup .................................................................................. 1-7

Figure 2-1. Installation.............................................................................................................. 2-2

Figure 2-2. Electrical Connections ........................................................................................... 2-4

Figure 4-1. SPS 4000, Exploded View ..................................................................................... 4-2

Figure 4-2. Board Connections ................................................................................................ 4-4

Figure 5-1. SPS 4000 Troubleshooting Flowchart (Sheet 1 of 2) ............................................ 5-3

Table 1-1. Product Matrix........................................................................................................ 1-2

Table 1-2. Calibration Components ........................................................................................ 1-2

Table 5-1. SPS 4000 Fault Finding ......................................................................................... 5-2

Table 7-1. SPS 4000 Replacement Parts ............................................................................... 7-1

Table 7-2. Calibration Replacement Parts .............................................................................. 7-1

SPS 4000

LIST OF ILLUSTRATIONS

LIST OF TABLES

ii Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of the SPS 4000 Single Probe Autocalibration

Sequencer.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

The following definitions apply to WARNINGS, CAUTIONS, and NOTES found throughout this

publication.

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

PREFACE

DEFINITIONS

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in injury, death, or long-term

health hazards of personnel.

Highlights an essential operating procedure,

condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETIN

NOTE TO USERS

Highlights an operation or maintenance

procedure, practice, condition, statement, etc. If not strictly observed, could

result in damage to or destruction of

equipment, or loss of effectiveness.

NOTE

The number in the lower right corner of each illustration in this publication is a manual illustration number. It is not a part number, and is not related to the illustration in any technical

manner.

Rosemount Analytical Inc. A Division of Emerson Process Management P-1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

FOR THE WIRING AND INSTALLATION

The following safety instructions apply specifically to all EU member states. They should

be strictly adhered to in order to assure compliance with the Low Voltage Directive. NonEU states should also comply with the following unless superseded by local or National

Standards.

1. Adequate earth connections should be made to all earthing points, internal and external,

where provided.

2. After installation or troubleshooting, all safety covers and safety grounds must be replaced.

The integrity of all earth terminals must be maintained at all times.

3. Mains supply cords should comply with the requirements of IEC227 or IEC245.

SPS 4000

IMPORTANT

SAFETY INSTRUCTIONS

OF THIS APPARATUS

4. All wiring shall be suitable for use in an ambient temperature of greater than 75°C.

5. All cable glands used should be of such internal dimensions as to provide adequate cable

anchorage.

6. To ensure safe operation of this equipment, connection to the mains supply should only be

made through a circuit breaker which will disconnect all circuits carrying conductors during a

fault situation. The circuit breaker may also include a mechanically operated isolating switch.

If not, then another means of disconnecting the equipment from the supply must be provided

and clearly marked as such. Circuit breakers or switches must comply with a recognized

standard such as IEC947. All wiring must conform with any local standards.

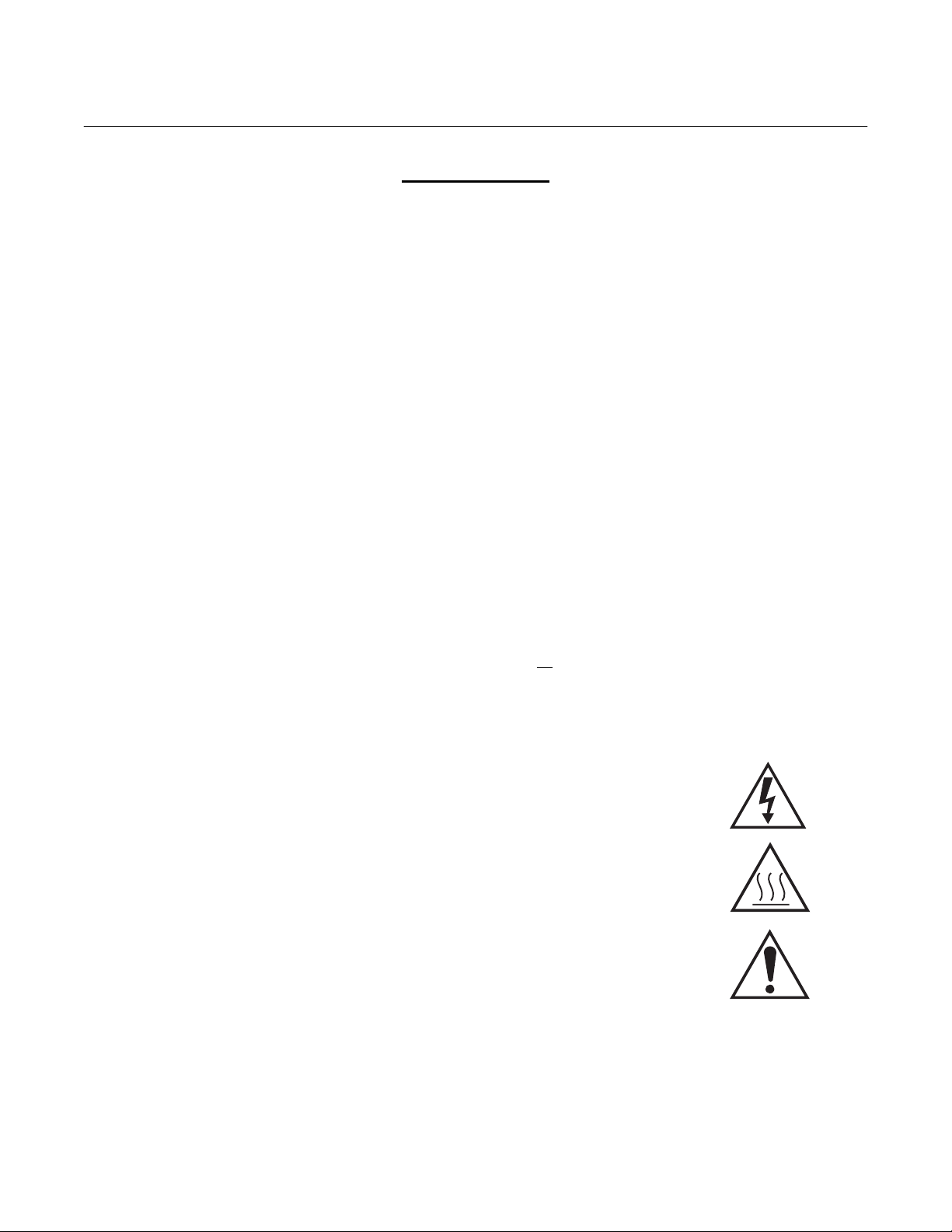

7. Where equipment or covers are marked with the symbol to the right, hazard-

ous voltages are likely to be present beneath. These covers should only be

removed when power is removed from the equipment — and then only by

trained service personnel.

8. Where equipment or covers are marked with the symbol to the right, there is a

danger from hot surfaces beneath. These covers should only be removed by

trained service personnel when power is removed from the equipment. Certain surfaces may remain hot to the touch.

9. Where equipment or covers are marked with the symbol to the right, refer to

the Operator Manual for instructions.

10. All graphical symbols used in this product are from one or more of the follow-

ing standards: EN61010-1, IEC417, and ISO3864.

P-2 Rosemount Analytical Inc. A Division of Emerson Process Management

Instruction Manual

1

IB-106-340AC Rev. 1.1

SPS 4000

SECTION 1

DESCRIPTION AND SPECIFICATIONS

NOTE

The SPS 4000 Single Probe Autocalibration Sequencer operates exactly the same with either

the Oxymitter 4000 Oxygen Transmitter or the Oxymitter 5000 Oxygen Transmitter with

OUNDATION

F

instruction bulletin also include the Oxymitter 5000. When referred to an instruction bulletin

for more information, reference IB-106-340 for the Oxymitter 4000 and IB-106-340-FB for the

Oxymitter 5000.

fieldbus Communications. Any references to the Oxymitter 4000 throughout this

April 2001

1-1 COMPONENT CHECKLIST

A typical SPS 4000 Single Probe Autocalibration Sequencer should contain the items shown

in Figure 1-1. Record the part number, serial

number, and order number for the SPS 4000 on

the first page of this manual.

Also, use the product matrix in Table 1-1 to

compare your order number against your unit.

The first part of the matrix defines the model.

The last part defines the various options and

features of the sequencer. Ensure the features

and options specified by your order number are

on or included with the unit.

1-2 OVERVIEW

The SPS 4000 provides the capability of performing automatic, timed or on demand, calibrations of a single Oxymitter 4000 without sending

a technician to the probe site.

The SPS 4000 can be mounted either directly to

an In situ Oxymitter 4000 or at a remote location

if space is limited. See Figure 1-2. However, this

instruction bulletin only covers remote mounted

sequencers. For information regarding integrally

mounted sequencers, refer to the Oxymitter

4000 Oxygen Transmitter Instruction Bulletin.

For information on equipping your existing

Oxymitter 4000 with an integrally mounted SPS

4000, contact Rosemount.

1

3

1. Instruction Bulletin

2. SPS 4000 (shown with optional reference air components)

3. Optional Mounting Hardware (for pipe mounting)

Figure 1-1. Typical SPS 4000 Package

2

26010001

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

Table 1-1. Product Matrix

SPS 4000 B Autocalibration System for Oxymitter 4000 or Oxymitter 5000. Mounted separate from the probe.

SPS 4000 Autocalibration System - Instruction Bulletin

Code Oxygen Analyzer System

20 Used with Oxymitter 4000 or Oxymitter 5000 system (remote mounted only)

SPS 4000

Code Reference Air

1 No reference air required

2 Reference air provided

Code Fittings and Tubing

1 Brass Fittings, Teflon Tubing

2 Stainless Steel Fittings and Tubing

Code Electrical Classification

10 NEMA 4X

20 Hazardous Area Classifications - Cenelec EExd IIB + H2

30 Hazardous Area Classifications (Class I, Div. I, Group B,C,D) - PENDING

SPS 4000 B 20 1 1 10 Example

Notes:

(1)

Reference air is recommended with 9 ft (2.74 m) and 12 ft (3.66 m) long probes. Reference air is also recommended when ambient air may

not contain the normal 20.95% O

unit nearby with leaks.

2)

Customer to pipe from remote SPS 4000 to probe.

3)

Hazardous area classifications require stainless steel fittings and tubing.

, such as when the probe is mounted into a positive pressure duct with leaks or where there is a process

2

(1)

(2)

(3)

(3)

Table 1-2. Calibration Components

Part Number Description

1A99119G01 Two disposable calibration gas bottles—0.4% and 8%

O

, balance nitrogen—550 liters each, includes bottle

2

rack*

1A99119G02 Two flow regulators for calibration gas bottles

*Calibration gas bottles cannot be shipped via airfreight.

When the bottles are used with “CALIBRATION RECOMMENDED” features,

the bottles should provide 2 to 3 years of calibrations in normal service.

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

OXYMITTER 4000

INTEGRAL OR

REMOTE

INTEGRALLY

MOUNTED SPS 4000

SINGLE PROBE

AUTOCALIBRATION

SEQUENCER

(1 PROBE)

REFER TO IB-106-340

INTELLIGENT MULTIPROBE

IMPS 4000

TEST GAS SEQUENCER

FOR USE WITH OXYMITTER 4000

(1 TO 4 PROBES)

Figure 1-2. Autocalibration System Installation Options

In addition to the SPS 4000, multiprobe sequencers are also available as shown in Figure

1-2. Rosemount has offered multiprobe autocalibration sequencer systems for many years.

These autocalibration systems are most cost

REMOTE MOUNTED SPS 4000

SINGLE PROBE

AUTOCALIBRATION SEQUENCER

FOR USE WITH OXYMITTER 4000

(EXPLO VERSIONS MUST BE REMOTE MOUNTED)

(1 PROBE)

26010003

effective for boilers and other combustion processes that utilize many probes. Users with only

one probe per combustion process can now

take advantage of Rosemount’s autocalibration

capability by utilizing the SPS 4000.

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

1-3 SPECIFICATIONS

Mounting ............................................................. Integral to Oxymitter 4000

Remote from Oxymitter 4000

Materials of Construction

Manifold/electronics enclosure ................. Aluminum

Mounting brackets .................................... 316 stainless steel (SS)

Pneumatic fittings ..................................... 1/8 in. brass NPT (SS optional)

Pneumatic tubing ...................................... 1/4 in. Teflon (SS optional)

Assembly hardware .................................. Galvanized and stainless steel

Humidity range .................................................... 100% relative humidity

Ambient temperature range ................................ -40° to 149°F (-40° to 65°C)

Electrical classification ........................................ NEMA 4X (IP56)

Explosion-proof option (both pending) ................ CENELEC EExd IIB + H2

(Class 1, Div. 1, Group B, C, D)

SPS 4000

Electrical feedthroughs........................................ 1/2 in. NPT

Input power.......................................................... 90 to 250VAC, 50/60Hz

Power consumption............................................. 5VA maximum

External electrical noise ...................................... EN 50 082-2, includes 4KV electrostatic discharge

Handshake signal to/from

Oxymitter 4000 (self-powered) ................. 5V (5mA maximum)

Cal initiate contact input from control room......... 5 to 30VDC, Form A (SPST)

(one “In-Cal”, one “Cal Failed”)

Cabling distance between SPS 4000 and

Oxymitter 4000 ......................................... Maximum 1000 ft (303 m)

Piping distance between SPS 4000 and

Oxymitter 4000 ......................................... Maximum 300 ft (91 m)

Approximate shipping weight .............................. 10 lbs (4.5 kg)

Fisher-Rosemount has satisfied all obligations coming from the European legislation to harmonize

the product requirements in Europe.

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

SPS 4000

1

Instruction Manual

IB-106-340AC Rev. 1.1

April 2001

1-4 PHYSICAL DESCRIPTION

The main components of the SPS 4000 are described in the following paragraphs and illustrated in Figure 1-3.

a. Manifold

The manifold provides a mounting platform

for the circuit board(s) and terminations and

contains the electrical feedthroughs. Also,

calibration gases are piped into and sequenced through solenoids mounted on the

manifold.

b. Calibration Gas Solenoids

The calibration gas solenoids sequence the

calibration gases. One solenoid controls

calibration gas 1 (high calibration gas), and

the other controls calibration gas 2 (low

calibration gas). The solenoids activate and

deactivate to allow the calibration gases to

flow between the sequencer and Oxymitter

4000.

c. Pressure Switch

The pressure switch detects if the pressure

of a calibration gas is low, which can be

caused by an empty gas bottle, a disconnected gas line, etc. Calibration is prohibited when calibration gas pressure is low.

d. Power Supply Board

This board converts the incoming line voltage from AC to DC for use by the solenoids,

terminations, and the programmable logic

device. The power supply board also has a

5 A, 250 V, slow blow fuse.

REFERENCE AIR

PRESSURE REGULATOR

(OPTIONAL)

NOTE:

CALIBRATION GAS

FLOWMETER

MANIFOLD COVER IS

REMOVED TO SHOW

INTERNAL COMPONENTS.

ALSO, BOARD COMPONENTS

ARE NOT SHOWN FOR CLARITY.

PRESSURE

SWITCH

CALIBRATION GAS 1

(HIGH CAL GAS)

SOLENOID

INTERFACE

BOARD

Figure 1-3. SPS 4000 Components

REFERENCE AIR

FLOWMETER

(OPTIONAL)

MANIFOLD

CALIBRATION GAS 2

(LOW CAL GAS)

SOLENOID

POWER

SUPPLY BOARD

TERMINAL COVER

26010002

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Loading...

Loading...