00809-0100-5800 , Rev BB

Rosemount™ CT5800 Continuous Gas

Analyzer

Reference Manual

August 2020

Preface

Published by Emerson.

All possible care has been taken in the preparation of this publication, but Emerson and its agents and distributors accept no

liability for any inaccuracies that may be found. This manual reflects the state of the product at the issue date below, but further

enhancements while in service may mean that the manual does not reflect your particular system.

Emerson reserves the right to make changes without notice both to this publication and the products which it describes.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic,

mechanical, photocopying, recording, or otherwise without the express prior written permission of the copyright holder.

If you require additional technical assistance, request help from cascade.support@emerson.com or Emerson distribution partners.

Send general inquiries to cascade.support@emerson.com.

2

Important information

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section must not be changed, amended, or removed.

Important

Users must read, understand, and comply with the following information before proceeding.

All users, installers, operators, and maintainers must be familiar with operating the analyzer. To install, start up, operate, maintain,

and service the analyzer in a safe manner, it is MANDATORY to read all additional instruction manuals shipped with the analyzer.

The following instruction manual(s) are available and/or referenced within this manual:

Rosemount CT5800 Quick Start Guide: 00825-0100-5800

User information

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section must not be changed, amended, or removed.

Important

All users must read this page before proceeding!

Emerson (Rosemount) designs, manufactures, and tests its products to meet many national and international standards. The

Rosemount CT5800 is a sophisticated technical product, and to ensure it continues to operate as designed and within normal

specifications, it MUST be installed, used, and maintained correctly. The following instructions MUST be adhered to and

integrated into your safety program when installing, using, and maintaining Emerson (Rosemount) products.

• Failure to follow the proper instructions may cause:

— Loss of life

— Personal injury

— Damage to property

— Damage to this instrument

— Warranty invalidation

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson (Rosemount) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the installation instructions of the appropriate manual and in accordance with applicable

local and national codes.

• Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by Emerson (Rosemount).

• Unauthorized parts and procedures can affect the product’s performance, place the safe operation of your process at risk, and

VOID YOUR WARRANTY. Look-alike substitutions may result in fire, electrical hazards, or improper operation.

• To prevent electrical shock and personal injury, all equipment doors must be closed and protective covers in place, except

when maintenance is being performed by qualified personnel.

• The information contained in this document is subject to change without notice.

3

General safety notice/residual risk

Installation, operation, and maintenance of the analyzer must be in accordance with these instructions.

When operated as intended and all applicable safety instructions are observed, an element of risk will remain, including, but not

limited to, the following:

• Explosion protection measures may become ineffective on the occurrence of one failure (for Category 3 instruments).

• The emission of gases hazardous to health may be possible when all gas connections have been correctly made.

To avoid exposure to the dangers of residual risks, take particular care when installing, operating, maintaining, and servicing the

analyzer.

Authorized personnel

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section must not be changed, amended, or removed.

In-depth specialist knowledge is an absolute requirement for working with and on the analyzer. Personnel installing, operating,

servicing, and maintaining the analyzer must be instructed, trained, qualified, and authorized for hazardous areas with the

operating company and the manufacturer. It is the operating company's responsibility to:

• Train staff

• Observe safety regulations

• Follow the safety instructions and procedures in the product manual

Operators must:

• Be trained

• Read and understand all relevant sections of the product manual before commencing work

• Know the safety mechanisms and regulations

WARNING

To avoid explosions, loss of life, personal injury, and damage to this equipment and on-site property, do not install, operate,

maintain, or service this instrument before reading and understanding this instruction manual and receiving appropriate training.

4

Regulations and standards

Regulations / Standards Description

2014/35/EU The Low Voltage Directive

94/9/EC (until April 19, 2016)

2014/34/EU (from April 20, 2016)

(1)

(2)

The ATEX Directive

2014/30/EU The Electromagnetic Compatibility Directive

2012/19/EU Waste Electrical and Electronic Equipment (WEEE) Directive

USA 21 CFR 1040.1 Laser products

NEC 505 National Electrical Code (issued by ANSI: American National

Standards Institute and NFPA 70: National Fire Protection

Association)

EN 6223: 2008 EMC Safety Standard

IEC 60079-10: 2002-06 Electrical apparatus for explosive gas atmospheres. Part 10:

Classification of hazardous areas

IEC 60529:1992 + A2 2013 Ingress protection

BS EN 60825-1:2007 Safety of laser products. Equipment classification and requirements

(identical to IEC 608250-1 2007).

BS EN 61010-1 2010 IEC 61010-1 2010 Safety requirements for electrical equipment for measurements,

control, and laboratory use. General requirements.

IEC 61241-10: 2004-06 Electrical apparatus for use in the presence of combustible dust.

Part 10: Classification of areas where combustible dusts are or may

be present.

BS EN 61326-1: 2013 Electrical equipment for measurement, control, and laboratory use.

EMC requirements. General requirements.

BS EN60079-0: 2012 Explosive atmospheres - Part 0: Equipment - General requirements

BES EN 60079-1: 2014 Explosive atmospheres. Equipment protection by flameproof

enclosures d

IEC 60079-0:2011 Ed 6 Explosive atmospheres - Part 0: Equipment - General requirements

IEC 60079-1:2014 Ed 7 Explosive atmospheres, Part 1: Equipment protection by flameproof

enclosures d

(1) May affect equipment tested prior to April 20, 2016, but shipped at a later date.

(2) All equipment tested from April 20, 2016 will be subject to the directive.

Associated publications

Quick Start Guide

Compliance approvals

This product complies with USA 21 CFR 1040.10.

This product is designed and manufactured under an approved quality management

system to ISO 9001: 2015.

Emerson and the Rosemount CT5800 have satisfied the requirements for applying

the CE marking to the Rosemount CT5800 Gas Analyzer.

This equipment meets all requirements of the EMC and Low Voltage directives.

5

Explosive / hazardous area protection This article is in accordance with IEC 60079-0: 2011 Clause 30.

This article must not be changed, amended, or removed.

Emerson has satisfied the requirements of and complies with IEC, ATEX, and North

American regulators for operation of electrical/electronic equipment in hazardous

locations .

Waste disposal

Do not dispose of measuring tools into household waste.

Only for EC countries:

In accordance with European Directive 2012/19/EU for Waste Electrical and

Electronic Equipment and its implementation into national right, measuring tools

that are no longer usable must be collected separately and disposed of in an

environmentally correct manner.

6

Safety and information notices

This article is in accordance with IEC 60079-0: 2011 Clause 30. This article must not be changed amended or removed. All

authorized users, installation, operation and maintenance personnel, must observe the following safety precautions and

warnings.

DANGER

WILL CAUSE DEATH

Failure to follow this warning will result in death or serious injury to personnel.

WARNING

DANGER TO PERSONNEL

Failure to follow this warning may result in death or serious injury to personnel.

CAUTION

MAY CAUSE DAMAGE TO EQUIPMENT

Failure to follow this warning may result in damage to the equipment.

NOTICE

Important or tip messages will appear in this format.

7

Safety information

All authorized users, including installation, operation, and maintenance personnel, must observe the following safety precautions

and warnings.

This article is in accordance with IEC 60079-0: 2011 Clause 30.

This article must not be changed, amended, or removed.

DANGER

FLAMMABLE SUBSTANCES

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Internal parts of the analyzer may reach temperatures of 140 °F (60 °C) and may present an ignition source. Failure to observe this

warning will cause death, personal injury, and/or damage to persons and/or property.

Exercise care when using oil, paint, cleaning rags, and other flammable substances near the analyzer. A fire may result if this

precaution is not observed. Always assume that the interior of an analyzer is hot unless it has been switched off and allowed to

cool down.

DANGER

ELECTRIC SHOCK

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this precaution will cause death, personal injury, and/or damage to persons and/or property.

This analyzer operates using mains voltage that is dangerous to life.

Make sure the circuit breakers are set to OFF and tagged off before opening the front cover.

DANGER

FAILURE TO LOCK-OUT GAS HANDLING SYSTEM WILL CAUSE DEATH.

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Unauthorized operation of the gas handling system when maintenance is being performed on the analyzer or its associated pipes/

hoses may result in highly flammable gas being released, causing fire or explosion.

Always lock out the gas handling system when shutting down the analyzer.

DANGER

FAILURE TO VENT SAMPLE GAS WILL CAUSE DEATH.

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The sample gas in the system must be vented to prevent fire or explosion during maintenance and to prevent damage to the

analyzer during startup.

The sample gas in the pipes leading to the analyzer must be purged to prevent hazards to personnel during maintenance.

Purging the sample gas must be done in accordance with the safe working procedures for the site.

Allow the analyzer and system for returning the sample gas to run for five minutes to allow any sample gas in the system to be

returned to the exhaust.

WARNING

EXPLOSION HAZARD

The unit described in this manual may not be used in explosive atmospheres without additional safety measures.

8

WARNING

ELECTRICAL SHOCK

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Installation requires access to live parts which can cause death or serious injury.

Do not operate without covers secure.

Do not open while energized.

For safety and proper performance, this instrument must be connected to a properly grounded three-wire source of power.

WARNING

TOXIC GASES

The analyzer's exhaust may contain toxic gases, such as (but not limited to) sulfur dioxide. These gases can cause serious injuries.

Avoid inhaling exhaust gases.

Connect the exhaust pipe to a suitable flue and inspect the pipes regularly for leaks.

Make sure all connections are airtight to avoid leaks.

WARNING

GASES HAZARDOUS TO HEALTH

Follow the safety precautions for all gases (sample and span gases) and gas cylinders.

Before opening the gas lines, purge them with air or neutral gas (N2) to avoid danger from escaping toxic, flammable,

explosive, or hazardous gases.

WARNING

FLAMMABLE OR EXPLOSIVE GASES

When supplying explosive gases or flammable gases with concentrations of more than 25% of the lower explosion limit, Emerson

recommends implementing one or more additional safety measures:

Purging the unit with inert gas

Stainless steel internal pipes

Flame arrestors on gas inlets and outlets

Infallible measuring cells

WARNING

CONNECTING UNITS FOR PERMANENT INSTALLATION

Failure to complay may cause the risk of injury or death and invalidate the analyzer's warranty. Working on units equipped with

screw-type terminals for electrical components may result in the exposure of energized components.

Only qualified personnel familiar with possible risks should install the analyzer.

Wall-mounted units have no power switch and are operational when connected to a power supply. The operating company is

therefore required to have a power switch or circuit breaker (as per IEC 60947-1/-3) available on the premises. This switch

must be installed near the unit, easily accessible to operators, and labeled as a power cut-off for the analyzer.

WARNING

EXPLOSION HAZARD

Exhaust gases may contain hydrocarbons and other toxic gases, such as carbon monoxide. Carbon monoxide is toxic. Faulty gas

connections may lead to explosion and death.

Ensure that all gas connections are connected as labeled and airtight.

9

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011, Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially hazardous situation, which

if not avoided, could result in death or serious injury.

Read all instruction manuals (including versions for auxiliary equipment) before installing this instrument.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially hazardous situation which,

if not avoided, could result in death or serious injury.

When installing and wiring this equipment, comply with all relevant national legislative requirements and regulations.

Consider all safety instructions within this manual and all associated analyzer manuals.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially hazardous situation which,

if not avoided, could result in death or serious injury.

When the analyzer is out of order, shut off all inputs and outputs connected to external equipment.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially hazardous situation which,

if not avoided, could result in death or serious injury.

Only properly trained personnel who understand the content of all applicable manuals and related instructions must conduct the

startup procedure.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially hazardous situation which,

if not avoided, could result in death or serious injury.

Do not open in an explosive atmosphere.

WARNING

Do not open when energized.

10

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to comply will void certification and may cause explosions. Failure to observe this warning and/or follow safety instructions

could cause an explosion or potentially hazardous situation which, if not avoided, could result in death or serious injury.

Use only replacement parts and components authorized by Emerson. All replacement parts and components must be suitable Excertified components for use in hazardous areas.

WARNING

EXPLOSION HAZARD BY BATTERY

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially hazardous situation which,

if not avoided, could result in death or serious injury.

The Rosemount CT5800 contains a low voltage battery for data backup purposes on the CPU.

Under normal operating conditions, there is no need to replace the battery during the analyzer lifetime. However, if you do

replace it, make sure to only use the same type and model.

WARNING

OPTICAL RADIATION EXPOSURE HAZARD

The analyzer contains lasers. Opening the analyzer and attempting to perform adjustments or procedures other than those

specified in this manual may result in hazardous optical radiation exposure.

Failure to follow the correct procedures may cause damage to the eye.

The Rosemount CT5800 is Class 1. The beams are fully enclosed, and there is no access to the laser beams while the product is in

operation or during maintenance. Do not look at the lasers with any kind of magnifier or optical measuring device.

The use of control or adjustments or performance of procedures other than those specified herein may result in hazardous

radiation exposure.

In accordance with USA 21 CFR 1040, the Rosemount CT5800 has warning labels at appropriate positions.

The locations of the safety labels in the analyzer are specified in Safety and system labels and annotation.

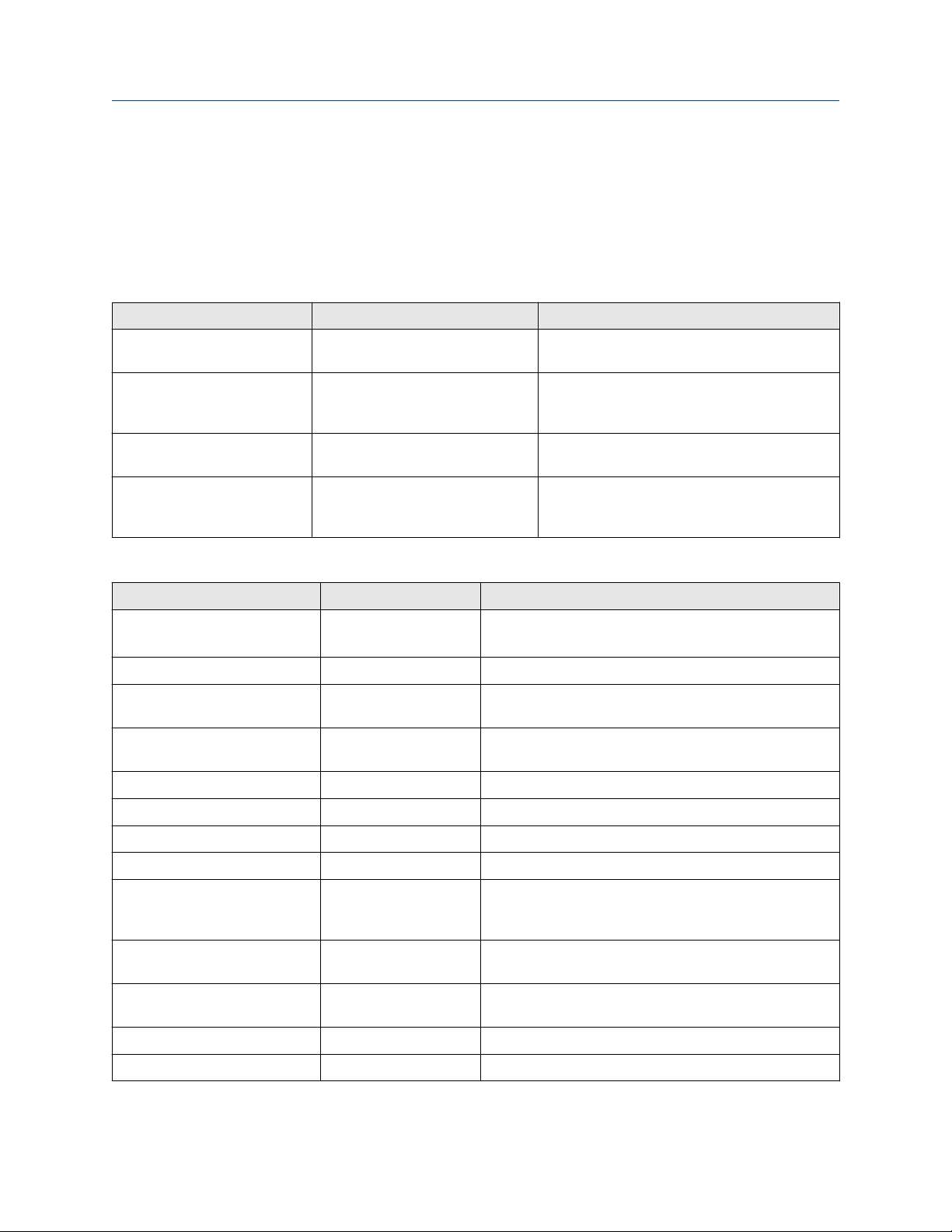

Classification

There are three types of lasers that may be included in the Rosemount CT5800: Quantum Cascade Lasers (QCLs), Interband

Cascade Lasers (ICLs), and Tunable Diode Lasers (TDLs). The characteristics of the lasers contained within are given in the table

below.

Parameter

Operation mode Pulsed Pulsed Pulsed

Lasers per system 1 - 6 1 - 6 1 - 6 Maximum of 6 lasers

Wavelength 4 -10 µm 2 - 5 µm 760 nm

Power < 5 mW < 5 mW < 5 mW

Pulse duration < 1 µs 1 µs < 5 µs

QCL ICL TDL Comments

per system

11

Parameter QCL ICL TDL Comments

Pulse repetition

frequency

Duty cycle < 5% < 5% < 5%

< 100 kHz < 100 kHz < 100 kHz

WARNING

HAZARDOUS SUBSTANCES

Gas handling components within the analyzer will contain particulate matter residue from the sample gases. Over the life of the

analyzer, the concentration of the particulate matter will become enriched within the gas handling components.

When performing repairs or maintenance on the analyzer:

— Handle used gas handling components with extreme caution.

— Avoid direct skin contact with used gas handling components.

— Do not smoke, drink, or eat in the work area.

— Wear goggles or eye shields.

— Wear a suitable face mask to protect against inhalation of particulate matter.

— Do not wet fingers, eyes, or any exposed skin.

— Pack used gas handling components for disposal in sealed packaging and label them Contaminated.

— Dispose of contaminated items as hazardous material according to the applicable local, national, or international health and

safety regulations and pollution regulations.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Unauthorized operation of the gas handling system when maintenance is being performed on the analyzer or its associated pipes/

hoses may release highly flammable gas, causing fire or explosion.

Always lock-out tag-out the gas handling system when shutting down the analyzer.

WARNING

HEAVY ITEM

Handle the analyzer with caution during unpacking, installing, maintaining, and transporting to prevent crushing of hands,

feet, or other body parts.

The analyzer weighs 176.4 lb. (80 kg). Always use suitable lifting/moving equipment when moving the analyzer.

Wear suitable protective gloves and protective footwear.

When preparing the analyzer for transport by air, road, or rail, safeguard the analyzer against movement or break-away during

transport by securely strapping it in place.

12

WARNING

HEAVY INSTRUMENT

Failure to observe this warning and/or follow safety instructions could result in death or serious injury.

The analyzer weighs 176.4 lb. (80 kg) and must be wall or frame mounted.

Emerson recommends that a minimum of two people move and lift the analyzer using suitable lifting and transportation

equipment.

Use suitable fasteners for weight of the analyzer.

Make sure the wall or stand the analyzer is mounted on is solid, stable, and of suitable material to hold the analyzer.

Do not mount the analyzer on stud or partition walls.

WARNING

HAZARDOUS GAS

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The product stream that the analyzer is examining may be hazardous even at low concentrations.

Therefore, take special care to ensure that the sample gas return port either returns the sample gas to the product stream or

discharges the sample gas to a location that will not cause a hazard.

WARNING

ELECTROSTATIC CHARGING HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The keypad is non-conducting and may generate an ignition capable level of electrostatic charges under certain extreme

conditions.

Ensure that the equipment is not installed in a location where it may be subjected to external conditions (such as high pressure

steam) which might cause a build-up of electrostatic charges on non-conducting surfaces. Only clean equipment with a damp

cloth.

WARNING

HIGH PRESSURE GAS AND AIR

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The calibration gas supply and compressed air supply operate at a pressure that can cause injury, e.g., damage to eyes and skin

punctures from debris blown by the high pressure gas or compressed air.

Always lock off or tag off the calibration gas supply and compressed air supply when shutting down the analyzer.

WARNING

BURNS

Some parts of the analyzer may be heated to 140 °F (60 °C). Failure to allow sufficient cooling may cause serious burn injury to

personnel.

Do not touch any part of the analyzer.

Assume all parts of the analyzer are hot unless it has been switched off and allowed to cool down.

Always wear proper protective equipment when handling the analyzer.

Switch off the analyzer and allow it to cool for at least two hours before fitting, removing, or performing any maintenance.

The analysis cell is insulated against heat loss. Allow the analyzer to cool for at least 12 hours before performing any

maintenance on, or in the vicinity of, the analysis cell.

13

WARNING

CRUSHING HAZARD

Take care not to crush hands when closing the frront door of analyzer field housings.

Keep out of the closing area between the enclosure cover and base.

WARNING

EXPLOSION

Danger of explosion if battery is incorrectly replaced.

Replace with only the same or equivalent type of battery.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end users’ equipment. This could

be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your system. Restrict physical access

by unauthorized personnel to protect end users’ assets. This is true for all systems used within the facility.

CAUTION

EQUIPMENT DAMAGE

Failure to follow the startup procedure may result in damage to the analyzer.

Always follow the startup procedure.

CAUTION

EQUIPMENT DAMAGE

Failure to follow the shutdown procedure may result in damage to the analyzer.

Always follow the shutdown procedure.

CAUTION

UNSERVICEABLE EQUIPMENT

If the pressure and temperature measurements are out of tolerance, refer to Troubleshooting and diagnostics for guidance.

CAUTION

EMC

This is a Class A product. In a domestic environment, this product may cause radio interference, in which case you may be required

to take adequate measures.

14

CAUTION

EQUIPMENT DAMAGE

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

CAUTION

EQUIPMENT DAMAGE

Ensure that the local power voltage where the unit is to be installed corresponds to the unit’s nominal voltage as given on the

name plate label.

CAUTION

EQUIPMENT DAMAGE

Do not power up or try to operate the analyzer unless it is physically secure and all electrical and pneumatic connections to the

analyzer are in place.

Before commencing the start-up process, it is important to ensure that electrical power, sample gas handling facilities, and

any calibration gases that are required are available to the analyzer.

CAUTION

EQUIPMENT DAMAGE

Additional notes for units with screw-type terminals:

Cables for external data processing must be double-insulated against mains power.

If this is not possible, cables must be laid in such a way as to guarantee a clearance of at least 0.2 in. (5 mm) from power

cables. This clearance must be permanently secured (e.g., with cable ties).

15

Safety and system labels and annotation

The labels and annotation applied to the analyzer are specified in the table below.

Label type Example Location

Identification label (including serial

number, model number, and USA FDA

compliance label

Laser radiation CAUTION label Interior on analysis cell

Made in the UK

Manufactured XXXX 2017

Rosemount CT5800 Continuous Gas

Analyzer

Serial number: CT5800-XXXX

Model number: CT5800

Glendevon House

Castle Business Park

Stirling, FK9 4TZ

United Kingdom

Tel. +44 (0)1786 447 721

Fax: +44 (0) 1786 475 822

Emerson.com/RosemountGasAnalysis

Bottom right

Laser module identification label On each laser module housing

Earth identification label Back plate

WARNING statement Interior adjacent to electric power

AC power supply voltage label Interior adjacent to electric power

AC power supply Danger label External on base adjacent to mains power

connections

connections

input conduit

16

Reference Manual Contents

00809-0100-5800 August 2020

Contents

Chapter 1 Plan......................................................................................................................... 19

1.1 Description................................................................................................................................19

1.2 Equipment purpose and role......................................................................................................20

1.3 System overview........................................................................................................................21

1.4 Customer information............................................................................................................... 23

1.5 Safety precautions and conditions for safe use...........................................................................24

1.6 Qualified personnel....................................................................................................................25

1.7 Software version........................................................................................................................25

1.8 Gas detection............................................................................................................................ 25

1.9 Detailed system specifications...................................................................................................26

1.10 Unpacking the analyzer........................................................................................................... 30

Chapter 2 Install.......................................................................................................................33

2.1 Site requirements...................................................................................................................... 33

2.2 Mounting...................................................................................................................................35

2.3 Connecting the system..............................................................................................................37

2.4 Test connections....................................................................................................................... 49

2.5 Closing the housing................................................................................................................... 53

2.6 Commissioning..........................................................................................................................54

Chapter 3 Start-up procedure...................................................................................................55

3.1 Introduction.............................................................................................................................. 55

3.2 Preparation for use.................................................................................................................... 55

3.3 Start-up procedure.................................................................................................................... 56

Chapter 4 Operating the analyzer.............................................................................................59

4.1 Introduction.............................................................................................................................. 59

4.2 Normal operation...................................................................................................................... 59

4.3 Front panel controls and indicators............................................................................................60

4.4 Display controller.......................................................................................................................62

4.5 Gas Sensor Main Screen............................................................................................................. 63

4.6 Pressure and Temperature screen..............................................................................................64

4.7 Help system...............................................................................................................................65

4.8 Main menu................................................................................................................................ 66

4.9 BACK button..............................................................................................................................66

Chapter 5 Verifying gas concentrations....................................................................................67

5.1 Verification................................................................................................................................67

Chapter 6 Gas calibration......................................................................................................... 77

6.1 Required tools........................................................................................................................... 77

Rosemount CT5800 17

Contents Reference Manual

August 2020 00809-0100-5800

6.2 Gas service menu definitions..................................................................................................... 77

6.3 Calibration.................................................................................................................................78

Chapter 7 Troubleshooting and diagnostics............................................................................. 87

7.1 Troubleshooting, repairs, and failure diagnostics.......................................................................87

7.2 Using the Built-in Self-Test (BIST) fault diagnostics.....................................................................91

7.3 Faults menu...............................................................................................................................95

7.4 Diagnostics menu......................................................................................................................97

7.5 Visual examination.................................................................................................................... 98

7.6 Failure diagnostics..................................................................................................................... 99

7.7 Repairable items......................................................................................................................103

7.8 Tools required for troubleshooting.......................................................................................... 104

7.9 Opening the enclosure............................................................................................................ 105

7.10 Replacing the display and control buttons............................................................................. 107

7.11 Replacing the fuses................................................................................................................111

7.12 Replacing the terminal electric cooler (TEC) board.................................................................115

7.13 Replacing the peripheral board..............................................................................................118

7.14 Replacing the motherboard...................................................................................................121

7.15 Replacing the DIN rail components........................................................................................125

7.16 Optical and pneumatic repairs............................................................................................... 143

7.17 Closing the enclosure............................................................................................................ 152

Chapter 8 Shutdown procedure............................................................................................. 155

8.1 Safety precautions .................................................................................................................. 155

8.2 Shutdown procedure...............................................................................................................156

Chapter 9 Preventative maintenance..................................................................................... 161

9.1 Maintaining the analyzer..........................................................................................................161

9.2 Scheduled maintenance.......................................................................................................... 161

Appendix A CSA / IECEx Certificates...........................................................................................163

A.1 CSA Certification..................................................................................................................... 164

A.2 IECEx Certification................................................................................................................... 168

Appendix B Theory of operation................................................................................................173

B.1 Overview................................................................................................................................. 173

B.2 Laser measurement principle...................................................................................................173

B.3 Gas concentration measurements........................................................................................... 173

Appendix C Spare parts list....................................................................................................... 175

Appendix D Engineering drawings............................................................................................ 177

D.1 List of engineering drawings....................................................................................................177

Appendix E Glossary and abbreviations.................................................................................... 183

18 Emerson.com/Rosemount

Reference Manual Plan

00809-0100-5800 August 2020

1 Plan

1.1 Description

The Rosemount™ CT5800 Continuous Gas Analyzer, referred to hereafter as Rosemount

CT5800 or analyzer, is an electronic sensor that uses laser spectroscopy to perform

analysis of process gas streams.

The function of the analyzer is to detect and measure up to twelve different types of gas at

concentrations ranging from parts per million (ppm) to percentage levels in the process

gas stream.

Built within a flameproof enclosure, the analyzer is designed for operation in potentially

explosive environments to measure industrial process applications requiring Ex hazardous

area certification.

The analyzer is designed to be wall mounted. However, take care to make sure that the

analyzer is not exposed to vibration and/or excess low frequency.

1.1.1

WARNING

HEAVY ITEM

In accordance with IEC 60079-0: 2011 Clause 30.

Failure to properly handle the analyzer may cause injury to personnel.

Make sure the wall the unit is mounted on is solid, stable, and of a suitable material to

hold the weight of the analzyer.

Handle the analyzer with caution during unpacking, installing, maintenance, and

transporting to prevent crushing of hands, feet, or other body parts.

The analyzer weighs 176.4 lb. (80 kg).

Emerson recommends that a minimum of two people move and lift the analyzer.

Wear suitable protective gloves and protective footwear.

Note

This manual is intended for the personnel who install, operate, and maintain the

equipment.

Intended use

The Rosemount CT5800 is intended to be used as an analyzer for industrial purposes. Do

not use the analyzer in medical, diagnostic, or life support applications or as a safety

device.

WARNING

An interruption of the protective earth line (e.g. in an extension cable) may result in risk to

operators.

Rosemount CT5800 19

Plan

August 2020 00809-0100-5800

Reference Manual

WARNING

Live parts are accessible when operating the analyzer with doors open or covers removed.

WARNING

The emission of gases hazardous to health may be possible even when all gas connections

have been correctly made.

1.1.2 Notes on batteries

This analyzer contains an Li battery (button cell) of type CR 2032. The battery is soldered

into position and usually does not need to be replaced during the analyzer's lifetime.

At the end of lifetime, dispose of the analyzer in compliance with the waste regulations.

WARNING

EXPLOSION

Batteries may leak, overheat, or explode if not handled propery.

Do not open or try to charge a battery.

Do not expose batteries to heat or fire.

Replace batteries only with the same or equivalent type of battery.

1.1.3 Installing and connecting the unit

The following notices should be followed to ensure compliance with the low voltage

directive (Europe) and other applicable regulations.

• Suitably ground all connectors provided for this purpose.

• Properly reinstate all safety covers and grounding connections after maintenance work

or troubleshooting.

• Provide a fuse at the installation site which will completely disconnect the analyzer in

case of failure. Installing an isolating switch may also be beneficial. In either case, these

components must be constructed to conform to recognized norms.

1.2 Equipment purpose and role

The analyzer is a gas sensor system that can be configured to measure the concentrations

of multiple small molecules in a gas sample that is provided to the analyzer via a sample

line.

20 Emerson.com/Rosemount

Reference Manual Plan

00809-0100-5800 August 2020

The types of molecules that are measured depend on the system configuration.

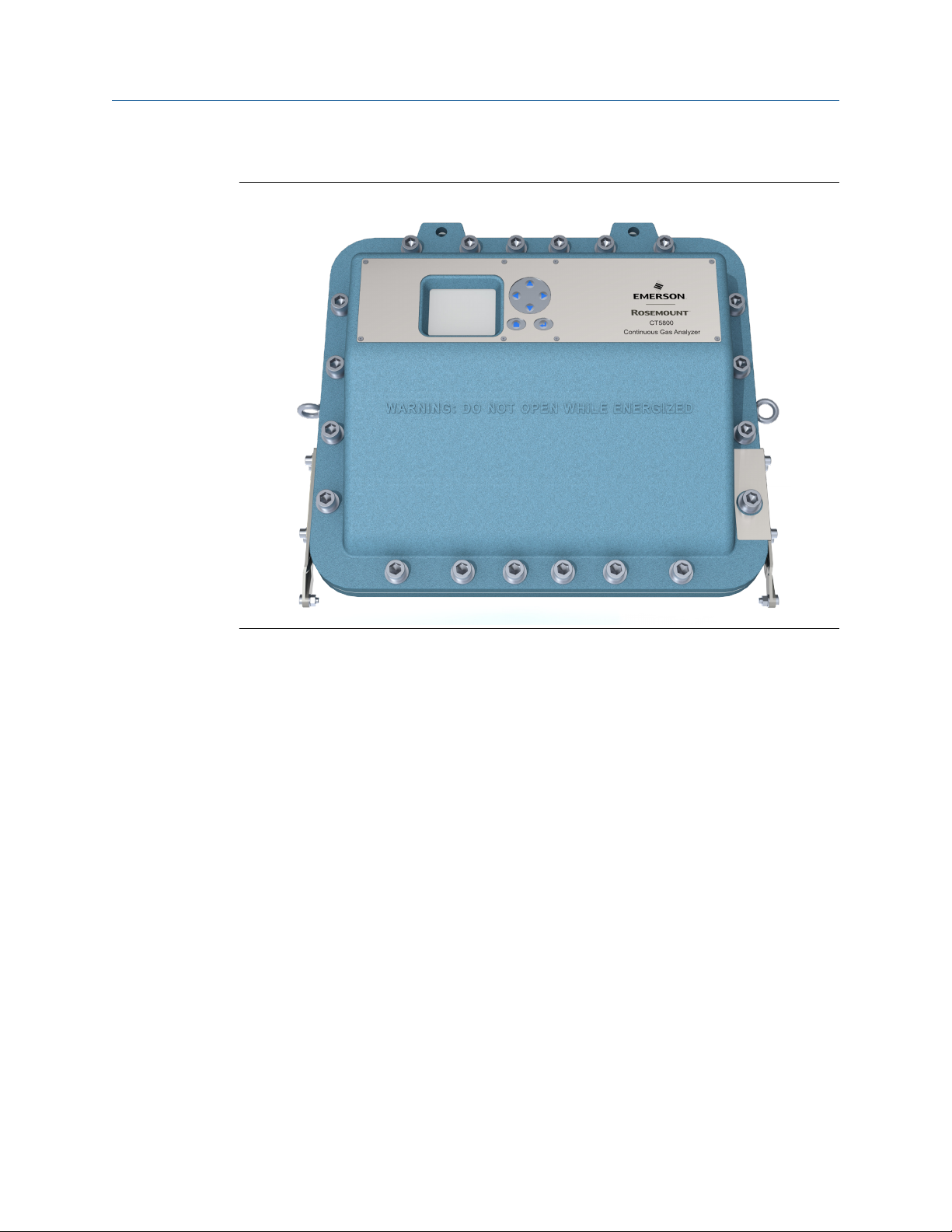

Figure 1-1: Rosemount CT5800

The analyzer can be configured to detect and measure up to twelve different gases,

depending on the combination of laser modules fitted.

1.3 System overview

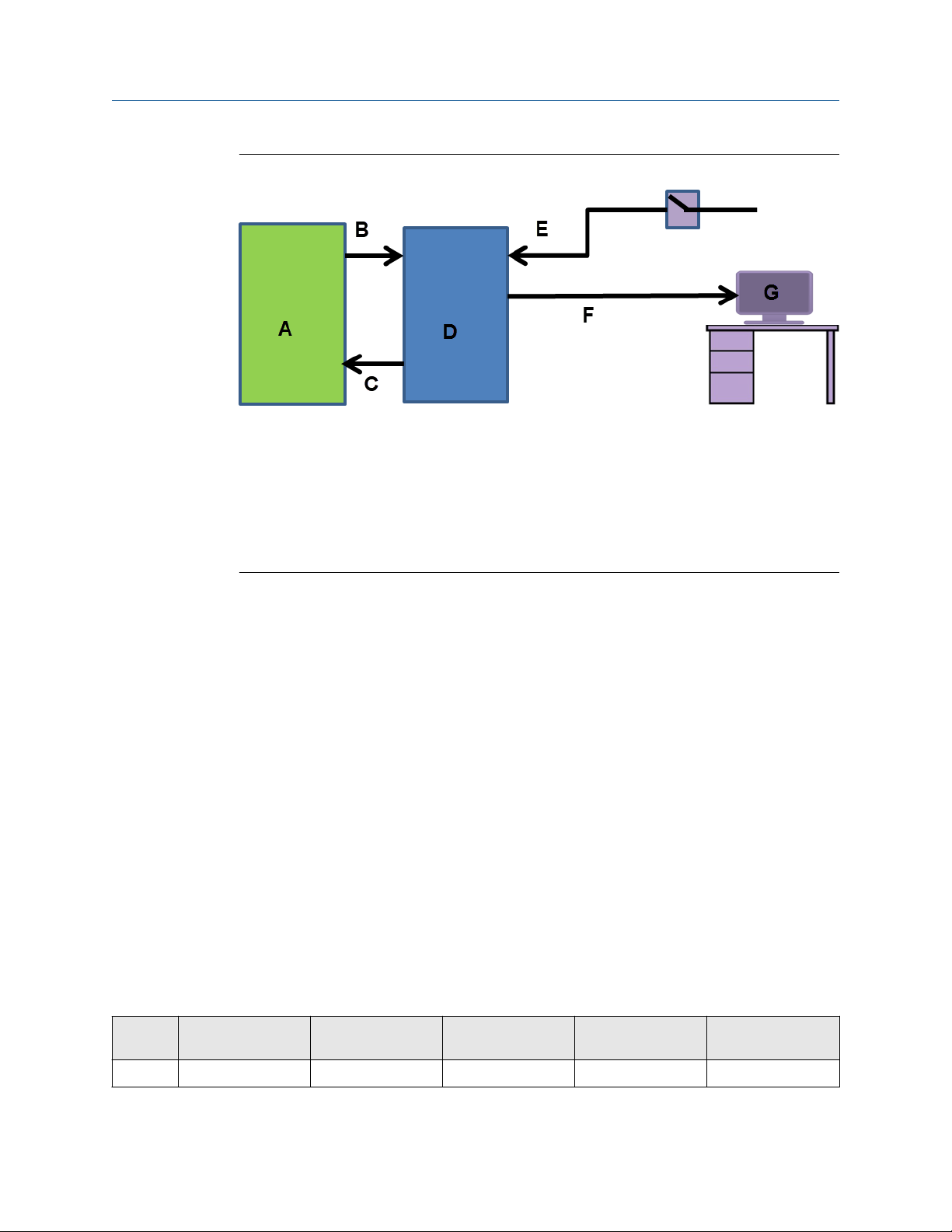

A complete Rosemount™ CT5800 system consists of a gas handling system, the analyzer,

and the associated interconnecting wiring and gas piping.

Measurement data from the analyzer can be displayed in the process control center.

The Rosemount CT5800 is supplied by Emerson. The gas handling system may be

provided by either you or Emerson, depending upon the specific installation. The circuit

breakers used to control the application of electrical power to the analyzer, the

interconnecting wires, and gas piping are provided by you. In Figure 1-2, the items

supplied by Emerson are colored blue, customer-supplied items are colored purple, and

items that can be supplied by either Emerson or you are green. Table 1-1 lists the main

items of the system.

Rosemount CT5800 21

Plan Reference Manual

August 2020 00809-0100-5800

Figure 1-2: Complete Rosemount CT5800 Gas Analysis System

A. Gas handling system

B. Sample supply line

C. Sample ENTER (exhaust) line

D. Rosemount CT5800 gas analyzer

E. Electrical power

F. Measurement data

G. Control center

Emerson has designed the analyzer for industrial process applications requiring ATEX Zone

1 hazardous area certification; the analyzer has an Ex d flameproof enclosure. It contains

an optical system with multiple lasers and a series of optical components that provide an

optical path, a heated multi-pass analysis cell, and sample inlet and outlet ports that can

be connected to a gas handling system and control and analysis electronics. The number

of lasers installed depends upon customer requirements. The complete system operates

Vac from a 110/240 Vac 50/60 Hz supply.

The analyzer uses mid-infrared optical absorption spectroscopy to measure gas

concentrations. The light sources are lasers, which are operated to produce wavelength

sweeps that cover the absorption lines of the gases. The light from each laser is routed

through an optical path to the analysis cell, which provides measurement of low

concentrations of the subject gases. An external sample handling system conditions the

sample gas and draws it through the analysis cell. The light exits the multi-pass analysis

cell and is directed to a receiver in the analyzer. The variation in the intensity of light in the

vicinity of the absorption lines is measured, and the concentration is determined using a

comprehensive spectral fitting routine.

There is no sample conditioning provided within the analyzer; the sampled gas must be

brought within the parameters shown in Detailed system specifications before entering

the analyzer. Detailed characteristics of the analyzer are also given in Detailed system

specifications.

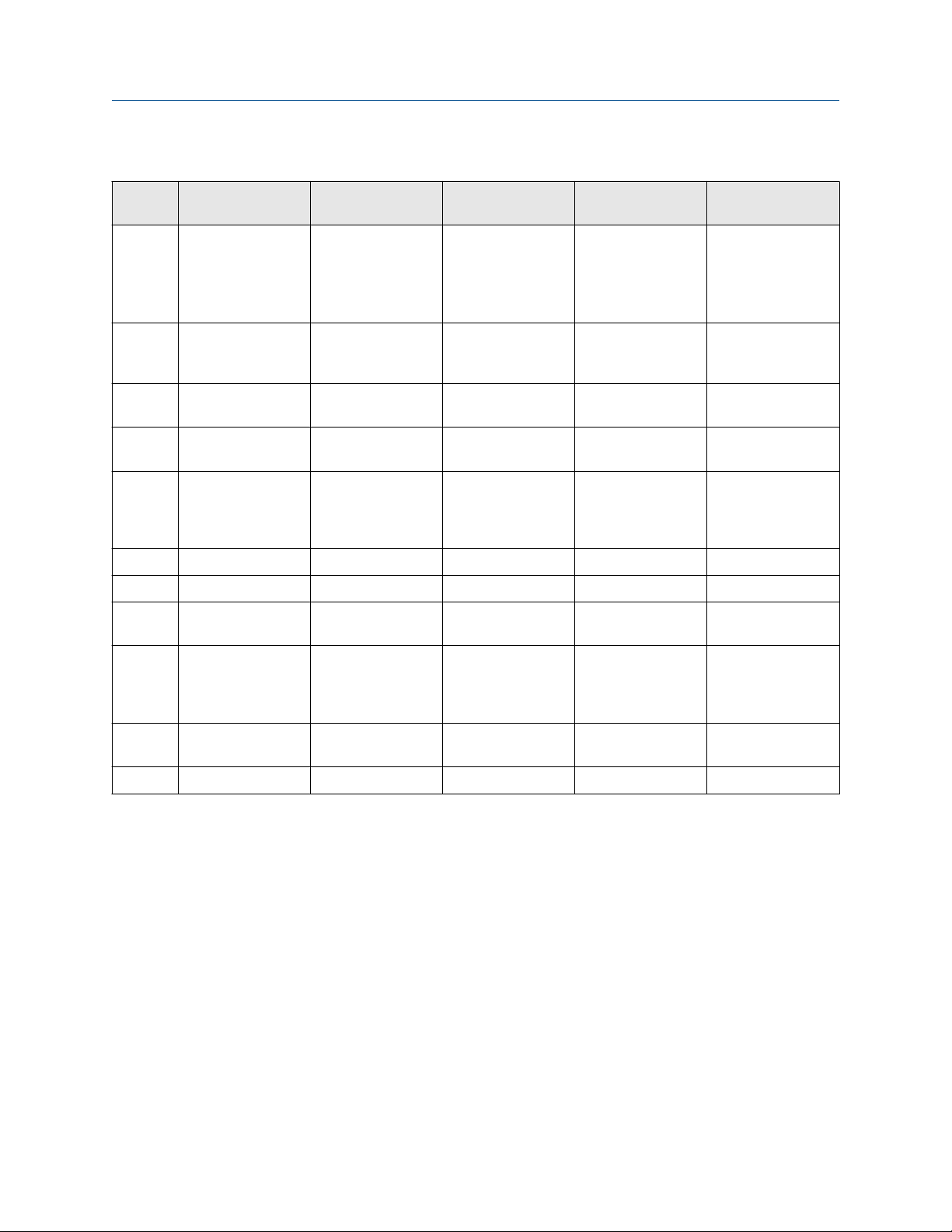

Table 1-1: Main Items of the Rosemount CT5800 System

Item Name or

description

Supplied by Part number Quantity Notes

1 Rosemount CT5800 Emerson 1 N/A

22 Emerson.com/Rosemount

Reference Manual

Plan

00809-0100-5800 August 2020

Table 1-1: Main Items of the Rosemount CT5800 System (continued)

Item Name or

description

2 Rosemount CT5800

software package,

version 5.x.x

3 Gas handling

system

4 Heated gas sample

line hose

5 Exhaust line hose

(for sample gas)

6 Reference gas

cylinders

(instrument gas) for

calibration purposes

7 Pressure regulator Customer Customer choice 1 per gas cylinder N/A

8 Pneumatic T-piece Customer Customer choice 1 N/A

9 Excess flow line Customer Customer choice 1 Required for

Supplied by Part number Quantity Notes

Emerson N/A 1 Software is

embedded in PC

board.

Version described in

manual

Customer

(optionally by

Emerson)

Customer/Emerson Customer choice 1 Optional supply by

Customer /Emerson Customer choice 1 Optional supply by

Customer Customer choice Dependent upon

Customer choice or

Emerson

1 Optional supply by

Emerson

Emerson

Emerson

N/A

number of gases

being measured

calibration

10 240 Vac power

cable

11 Cable from analyzer

to control center

12 Main circuit breaker Customer Customer choice 1 N/A

Customer Customer choice 1 Connect

Rosemount CT5800

to mains power

supply

Customer Customer choice 1 N/A

1.4 Customer information

This manual contains all the important information that must be followed to ensure the

correct operation and safety of personnel when operating the analyzer.

All personnel must read this manual carefully before commencing any work on the

analyzer.

For information regarding installation, consult Install and the Quick Start Guide.

Emerson is committed to continuously improving its products and documentation. Every

effort will be made to include in the documentation any modifications by the

manufacturer. However, this document reflects the supplied sensor at the revision date on

the front cover.

Should you require further information, or should particular problems arise that are not

covered in this manual, you can request additional help from Cascade Technical Support

Rosemount CT5800 23

Plan

August 2020 00809-0100-5800

(cascade.support@emerson.com) or Emerson distribution partners. Further contact

details for Emerson can be found on the back page of this manual.

Reference Manual

1.5 Safety precautions and conditions for safe use

WARNING

SAFE USE PRECAUTIONS

Before installing or performing any maintenance on the analyzer, read and understand the

safety information given in the preliminary information of this manual.

The analyzer described in this document has been quality control tested and left the

manufacturer in pristine condition. To achieve the correct and safe operation of this

product, it must be transported, installed, operated, and maintained as described by the

manufacturer.

All lasers used within the analyzer are Class 1. The emitted laser light is invisible (midinfrared) and the pulse duration so short that the unprotected eye will not be damaged.

The nature of the laser beam path and beam width further ensures that it should be

impossible to cause any eye damage. The analyzer has warning labels at appropriate

positions in accordance with USA 21 CFR 1040.10.

IECEx - Specific Condition of Use

• This equipment has flamepaths which differ from those in IEC 60079-1. Cascade

Technologies Ltd (cascade.support@emerson.com)shall be contacted for guidance

when maintaining the flamepaths.

• The fasteners which secure the cover are non-standard and shall therefore only be

replaced by fasteners supplied by the manufacturer for this purpose. The fasteners

must always be fitted with the washer supplied by the manufacturer.

• The equipment has non-conductive surfaces which are a potential electrostatic

charging hazard – see the instructions for guidance.

• The user shall ensure that the flow of process gas is limited to a maximum flow rate of 6

litres per minute.

• The equipment shallonly be used with process gases which are classified for equipment

group IIB + H2 and must not contain oxygen or any other oxidizer in concentrations

greater than that found in normal air.

CSA Certificate North American - Conditions of Acceptability

• The equipment has flameproof joints with dimensions which are other than those

specified in Table 2 of ANSI/UL 60079-1: 6th Edition and Table 3 of CSA C22.2

60079-1:16. These flameproof joints are not intended to be repaired but where

necessary the original manufacturer (cascade.support@emerson.com) shall be

contacted for guidance and information on the dimensions of the flameproof joints.

• The fasteners which secure the cover are non-standard and shall therefore only be

replaced by fasteners supplied by the manufacturer for this purpose. The fasteners

must always be fitted with the washer supplied by the manufacturer.

24 Emerson.com/Rosemount

Reference Manual Plan

00809-0100-5800 August 2020

• The equipment has non-conductive surfaces which are a potential electrostatic

charging hazard – see the instructions for guidance.

• The user shall ensure that the flow of process gas is limited to a maximum flow rate of 6

litres per minute.

• The equipment shall only be used with process gases which are in gas groups B, C or D

(Divisions) or IIB + H2 (Zones) and must not contain oxygen or any other oxidizer in

concentrations greater than that found in normal air.

• This assessment does not cover reliable function, performance, or other properties of

the equipment not related to safety.

• The equipment is to be installed using wire no larger than 1mm2 (18 AWG).

• The equipment is only to be installed by manufacturer trained personnel.

• If at any time there is a conflict between the system safety provisions and any relevant

local (national or regional) requirements, the local requirements always take

precedence.

• The equipment is not to be used with flammable liquids.

1.6 Qualified personnel

This manual provides installation, operation, and maintenance personnel with the level of

knowledge required to safely start, operate, and switch off the analyzer.

Only technically qualified personnel in the field of analysis and control who are familiar

with this manual and have been specially trained on the analyzer should install, operate,

switch off, and service the analyzer. Only qualified and trained persons have the required

specific knowledge to correctly interpret the general safety information, warnings, and

procedures given in this manual and apply them to this particular application. Emerson or

its distribution partners can provide this training on request.

Knowledge of the safety information within this manual and its technically correct

implementation are prerequisites for danger-free installation, operation, and maintenance

of the analyzer.

1.7 Software version

The analyzer includes software that is used to control the operation of the analyzer. This

document describes the software version as: 5.12.7 minimum.

1.8 Gas detection

The analyzer is highly configurable in the gases that can be detected and their range of

concentrations.

Rosemount CT5800 25

Plan Reference Manual

August 2020 00809-0100-5800

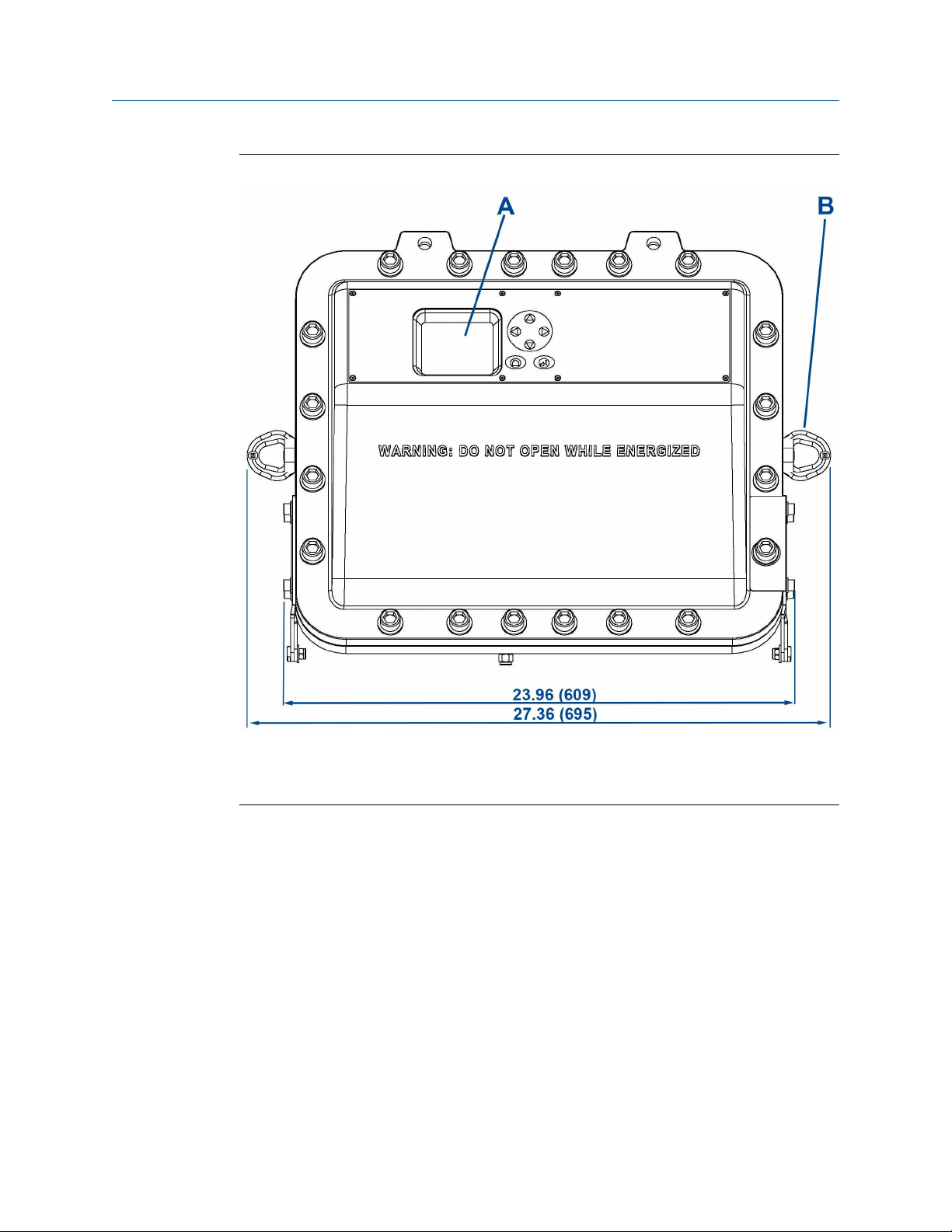

1.9 Detailed system specifications

Table 1-2 gives the physical characteristics of the analyzer. Figure 1-3 shows schematic

diagrams of the sensor and mounting points. Table 1-3 gives the general characteristics of

the analyzer.

Table 1-2: Physical Characteristics

Rosemount CT5800 Value Comment

External dimensions (closed) 694.5 x 292 x 515 mm

27.34 x 11.5 x 20.28 in.

External dimensions (open) 27.34 x 11.5 x 41.24 in.

694.5 x 292 x 1047.5 mm

Front panel swept radius 21.46 in.

545 mm

Weight 80 kg

176.37 lb.

Length x width x height

Nominal dimensions

Nominal dimensions, front panel at lowest point

To open the enclosure, the minimum height

required is 1030 mm (40.55 in.)

Allow sufficient space for the front panel to

swing through an arc of 180 ° (see Figure 1-5).

Approximate weight

The analyzer must be wall mounted. Do not

mount it on stud or partitioned walls.

Table 1-3: General Characteristics

Rosemount CT5800 Value Comment

Voltage 220/240 ± 10% Vac

110/120 ± 10% Vac

Peak power consumption 1100 W Max consumption per gas analyzer

Continuous steady-state power

consumption

Electrical compartment

enclosure

Optical compartment enclosure N/A Aluminum

800 W N/A

N/A Aluminum

50 Hz ± 5% (factory set)

60 Hz ± 5% (factory set)

Measurement technique N/A Mid IR absorption spectroscopy

Mid IR source N/A Quantum Cascade™ Laser

Near IR source N/A Interband Cascade Laser Tunable diode laser

Laser classification Class 1 BS EN 60825-1: 2007 safety of laser products. Equipment

classification and requirements (identical to IEC 60825-1

2007)

Inlet gas port connector ¼ in.

6 mm

Outlet (exhaust) gas port

connector

Measurement result signals 4 to 20 mA 4 or 8 channel outputs, specify on order

Warm-up time 90 minutes N/A

26 Emerson.com/Rosemount

¼ in.

6 mm

Swagelok® type, factory-configured, specify on order

Swagelok type, factory-configured, specify on order

Reference Manual Plan

00809-0100-5800 August 2020

Figure 1-3: Rosemount CT5800 Dimensions: Front View

Dimensions are in inches (mm).

A. User interface

B. 2 off lifting eyelets

Rosemount CT5800 27

Plan Reference Manual

August 2020 00809-0100-5800

Figure 1-4: Rosemount CT5800 Dimensions: Side View

Dimensions are in inches (mm).

A. Rating plate

B. External earth point

28 Emerson.com/Rosemount

Reference Manual Plan

00809-0100-5800 August 2020

Figure 1-5: Rosemount CT5800 Radius for Opening

Dimensions are in inches (mm).

A. Opening arc

Table 1-4: Environmental Characteristics

Environmental characteristic Value Comment

Operating temperature range -4 to 131 °F (-20 to 55 °C) Ambient temperature

Sample gas temperature range 39 to 140 °F (4 to 60 °C)

Sample gas moisture content 8% Maximum (dependent on analyser

configuration)

Sample gas particulate density 5 mg/m

Sample gas particulate size 10 µm Maximum

IP code 66 IP to IEC 60529

Ambient humidity range 10 to 95% Relative humidity (non-condensing) at

3

Maximum

113 °F (45 °C)

Rosemount CT5800 29

Plan Reference Manual

August 2020 00809-0100-5800

1.9.1 Optical description

The laser modules are located in the core of the analyzer. Each laser module produces a

separate light beam, and these beams are combined linearly as the modules are aligned in

the system. The combined beams are closely coupled, parallel, and coaxial about a virtual

line. The laser light beams pass through an optical steering assembly, which directs the

laser beam through the sample cell.

The sample cell contains a set of mirrors to create a path through the sample gas that is

between 0.7 ft. (0.2 m) and 49.2 ft. (15 m) through multiple reflections along the length of

the cell. The laser beams exit the cell at the opposite end from where they entered and are

directed using a second optical block to a receiver.

By measuring and analyzing the light detected by the receiver unit, it is possible to

accurately determine the concentrations of the target molecules within the gas sample

cell.

1.10 Unpacking the analyzer

WARNING

HEAVY ITEM

In accordance with IEC 60079-0: 2011 Clause 30.

Failure to propery handle the analyzer may cause injury to personnel.

Make sure the wall the analyzer is mounted on is solid, stable, and of suitable material to

hold the weight of the analyzer.

Handle the analyzer with caution during unpacking, installing, maintaining, and

transporting to prevent crushing of hands, feet, or other body parts.

The analyzer weighs 176.4 lb. (80 kg).

Emerson recommends that a minimum of two people move and lift the analyzer.

Wear suitable protective gloves and protective footwear.

WARNING

TRANSPORTATION HAZARD

Failure to use proper lifting procedures may cause injury to personnel or damage the

analyzer.

Use safety-approved lifting equipment.

Follow safe lifting procedures for the weight and mass of the analyzer.

30 Emerson.com/Rosemount

Loading...

Loading...