Reference Manual

00809-0100-4731, Rev FA

April 2003

TM

and Radar Gauges

www.rosemount.com

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™ and APEX Sentry™ Radar Gauge

APEX™ and APEX Sentry™

Radar Gauge

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers.

Customer Central: 1-800-999-9307(7:00 a.m. to 7:00 p.m. CST)

Technical support, quoting, and order-related questions.

North American1-800-654-7768 (24 hours a day – Includes Canada)

Response Center: Equipment service needs.

For equipment service or support needs outside the United States, contact your local

Rosemount representative.

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

Rosemount APEX Radar Gauge may be protected by U.S. Patent Nos. 4,945,360 and 5,546,088 and

other U.S. and foreign patents and patents pending.

Rosemount and the Rosemount logotype are registered trademarks of Rosemount Inc.

PlantWeb is a trademark of the Fisher-Rosemount group of companies.

APEX, APEX Sentry, and the APEX logotypes are trademarks of Rosemount Inc.

HART is a registered trademark of the HART Communication Foundation.

Teflon, VITON, and Kalrez are registered trademarks of E.I. du Pont de Nemours & Co.

Cover Photo: APEX002C

www.rosemount.com

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™ and APEX Sentry™ Radar Gauge

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Components of the APEX and

APEX Sentry Radar Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

System Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

APEX /Hybrid System Overview

(APEX Radar Gauge Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Addressing Concerns about Exposure to

The APEX and APEX Sentry Radar Gauges . . . . . . . . . . . . . . . . . 1-7

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Before You Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Telecommunications Agency Requirements . . . . . . . . . . . . . . . . . 2-4

Operation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Tank Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Unpacking the APEX and APEX Sentry Radar Gauges. . . . . . . . . 2-5

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Process Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Dielectric Constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Foam and Vapors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Changing Density, Temperature, or Pressure. . . . . . . . . . . . . . 2-6

Turbulence or Vortices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Coating, Condensate, or Corrosion. . . . . . . . . . . . . . . . . . . . . . 2-7

Vessel Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

General Vessel Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Heating Coils and Agitators. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Cables, Floats, Baffles, or Trays . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Inlet Pipes or Flows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Specific Tank Shapes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Spherical Vessel Considerations. . . . . . . . . . . . . . . . . . . . . . . 2-10

Horizontal Vessel Mounting Surface . . . . . . . . . . . . . . . . . . . . 2-11

Stilling Well, Bypass Cage, and

Bridle Connection Considerations . . . . . . . . . . . . . . . . . . . . . . 2-12

Nozzle Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Non-horizontal Mounting Surface . . . . . . . . . . . . . . . . . . . . . . 2-13

Tank Nozzle Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Process Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

www.rosemount.com

APEX™ and APEX Sentry™ Radar Gauge

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Flange Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Access Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Wall, Nozzle, or Standoff Clearance . . . . . . . . . . . . . . . . . . . . 2-20

Mounting the Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Electrical Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Check Processor Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Conduit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Grounding the Gauge Housing . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Transient Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

External Power Shut-off Switch. . . . . . . . . . . . . . . . . . . . . . . . 2-24

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Cable Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Power vs. Distance Requirements . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Hazardous Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

DC Main Power Supply with 4–20 mA Loop

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

DC Main Power Supply Fuse Size and Type . . . . . . . . . . . . . 2-26

DC Main Power Supply with No Loop Power Supply . . . . . . . . . . 2-27

AC Main Power Supply with 4–20 mA Loop

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

AC Main Power Supply Fuse Size and Type . . . . . . . . . . . . . 2-29

Wiring Optional Gauge Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Model 751 Field Signal Indicator . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

(APEX Radar Gauge and APEX Sentry Radar Gauge) . . . . . 2-29

APEX/Hybrid System Installation (APEX Radar Gauge Only) . . . 2-31

3- or 4-Wire RTD (APEX Radar Gauge Only) . . . . . . . . . . . . . . . 2-32

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Reference Manual

00809-0100-4731, Rev FA

April 2003

SECTION 3

Configuration

TOC-2

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Basic Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Key Measurement Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Reference Gauge Height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Minimum Clearance to Product Level . . . . . . . . . . . . . . . . . . . . 3-3

Maximum Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Upper Range Value (20 mA Point) . . . . . . . . . . . . . . . . . . . . . . 3-3

Lower Range Value (4 mA Point) . . . . . . . . . . . . . . . . . . . . . . . 3-3

Volume Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Special Cases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Dish-bottom Tanks, Empty Tank Detection . . . . . . . . . . . . . . . . 3-4

Null Zones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Field Configuration Using the Integral

Display Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

(APEX Radar Gauge Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Starting the Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Setting Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™ and APEX Sentry™ Radar Gauge

Configuration Options Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Setting the Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Setting the Output Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Setting the Display Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Setting the Reference Gauge Height . . . . . . . . . . . . . . . . . . . 3-12

Setting the 4 mA Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Setting the 20 mA Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Exiting the Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Model 275 HART Communication Option . . . . . . . . . . . . . . . . . . . . . 3-15

Commissioning on the Bench With HART . . . . . . . . . . . . . . . . . . 3-15

Setting the Loop to Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Bench Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Field Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Connections and Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Using a Model 275 HART Communicator . . . . . . . . . . . . . . . . 3-18

Set Transmitter Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Set Reference Gauge Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Set 4 and 20 mA Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Volume Configuration (APEX Radar Gauge Only) . . . . . . . . . . . . 3-18

Set Volume Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Set Primary Variable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Set Range Values

(4 and 20 mA points) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Choose Tank Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Enter Tank Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Enter Strapping Table Information . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Standard Volume (Apex Radar Gauge Only) . . . . . . . . . . . . . . . . 3-20

Enable RTD Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Enter Volume Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

AMS Configuration Tool Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Strapping Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Transmitter Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Rerange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Radar Configuration Tool (RCT) Option . . . . . . . . . . . . . . . . . . . . . . 3-25

Installing the RCT Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Specifying the COM Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Using the Setup Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Using the Setup Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Setup - Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Setup - Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Setup- Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Setup - Tank Config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Setup - Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Setup - LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Setup - Advanced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Logging Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Saving the log to a disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Using the Advanced Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Tank Plotting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

TOC-3

APEX™ and APEX Sentry™ Radar Gauge

Reference Manual

00809-0100-4731, Rev FA

April 2003

SECTION 4

Hardware and Software

Maintenance and

Troubleshooting

APPENDIX A

Reference Data

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Product Buildup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Splashing and Coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Alarm and Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Local Operator Interface Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

HART Communicator Software Diagnostics . . . . . . . . . . . . . . . . . . . . 4-7

AMS Configuration Software Diagnostics . . . . . . . . . . . . . . . . . . . . . . 4-8

Removing the Gauge Housing From the Flange . . . . . . . . . . . . . . . . 4-10

Antenna Selection Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Telecom Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Process Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Software Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-7

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Materials of Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Configuration Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-16

APPENDIX B

Product Certificates

TOC-4

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . B-1

European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

ATEX Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Flame-Proof enclosure Ex d protection type in

accordance with EN50 018 . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

European Pressure Equipment Directive (PED) (97/23/EC) . . . . . B-1

Electro Magnetic Compatibility (EMC) (89/336/EEC) . . . . . . . . . . . B-2

Low Voltage Directive (93/68/EEC) . . . . . . . . . . . . . . . . . . . . . . . . B-2

Other important guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Hazardous Locations Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

North American Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Approval Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™ and APEX Sentry™ Radar Gauge

Section 1 Introduction

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-3

System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-6

Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 1-8

USING THIS MANUAL NOTE

All information included refers to both the APEX Radar Gauge

and the APEX Sentry Radar Gauge unless otherwise stated.

Section 2: Installation

• Mechanical considerations

• Electrical considerations

• Mounting, wiring, and field configuration instructions

Section 3: Configuration

• Field Configuration Using the Integral Display

• Level Configuration

• Volume Configuration

Section 4: Hardware and Software Maintenance and Troubleshooting

• Preventive maintenance

• Hardware and software diagnostic messages

Appendix A: Reference Data

• Specifications

• Dimensional Drawings

• Ordering Information

Appendix B: Product Certificates

• European ATEX Directive information

• Examples of intrinsic safety labels

• Approval drawings for installation

www.rosemount.com

Reference Manual

00809-0100-4731, Rev FA

APEX™ and APEX Sentry™ Radar Gauge

April 2003

SAFETY MESSAGES Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the safety messages listed at the beginning of each section before performing

an operation preceded by this symbol.

Explosions could result in death or serious injury:

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART-based communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform these procedures.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

As a matter of routine, shut off the APEX Radar Gauge and all other equipment in the tank

before you enter the tank.

1-2

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™ and APEX Sentry™ Radar Gauge

OVERVIEW The APEX and APEX Sentry Radar Gauges use a radar signal to measure

the level of liquid in a vessel. Because the radar gauge is mounted on top of a

vessel and its components do not contact the product, it is a dependable

alternative to a standard insertion device that can become broken or corroded

when inserted into the process. The APEX Radar Gauge also works well in

turbulent, aerated, solids-laden, viscous, or corrosive liquids, and thick pastes

or slurries.

The advanced 24 GHz frequency technology in the gauges significantly

increases the reliability of your level measurement for a wide range of tank

level applications. The gauges use radar technology based on frequency

modulated continuous wave (FMCW) transmission of microwaves. Radar

(microwave) signals are sent from the gauge to the surface of the material

and reflected back to the gauge receiver. The receiver evaluates the

frequency difference between the transmitted and returned signals. The

gauge analyzes the signals to determine the distance to the product surface.

The 24 GHz frequency and advanced electronics allow the radar gauges to

use a small antenna and maintain a narrow beamwidth. The small, lightweight

antenna simplifies installation while the narrow beamwidth allows unwanted

echoes from vessel obstructions such as agitators, heat exchangers, filling

pipes, baffles, thermowells, and intermittent filling streams to be avoided. The

narrow beam also increases mounting flexibility because the gauge can be

mounted on existing flanges located close to tank walls.

1-3

Reference Manual

00809-0100-4731, Rev FA

April 2003

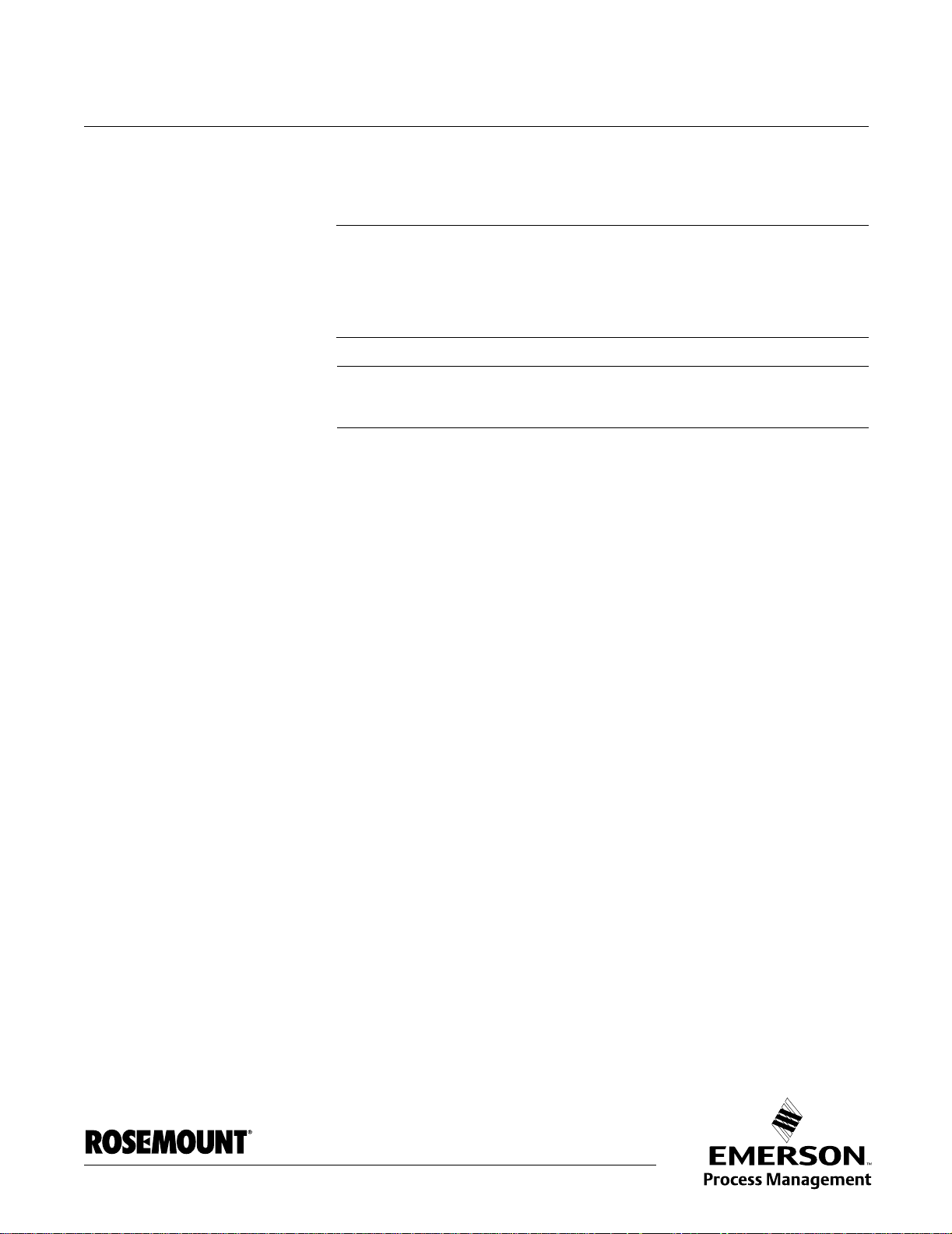

Which Radar Gauge is Best for Your Level Measurement Application?

APEX™ and APEX Sentry™ Radar Gauge

Step 1. Dielectric vs. Distance

Choose the appropriate

shaded region for the application.

Dielectric

Constant, ε

(1)

1.5 - 4.0

4.0 - 10.0 Organic or concentrated acids,

> 10.0 Water-based fluids, alcohols,

(1) Consult Factory when dielectric less than 4

Liquid Examples

r

Hydrocarbons, petrochemicals,

freons, vegetable oils, toluene,

...

organic solvents, ...

dilute acids, acetone, glycols, ...

Step 2. Liquid Surface Quality

Dielectric vs.

(from Step 1.)

Distance Region

Match surface

quality with

shaded region

from Step 1.

Region A

Region B

Region C

Dielectric

Constant

0 m

5 m (16.4 ft)

7,5 m (24.6 ft)

10 m (32.8 ft)

15 m (49.2 ft)

20 m (65.6 ft)

Maximum Distance

30 m (98.4 ft)

CALM

No waves,

storage

Possible

SENTRY-

go to Step 3.

Possible

SENTRY-

go to step 3.

APEX APEX APEX

1.5 to 4.0

Region

Region

Region

Surface Quality

MOVING

Mild rolling,

no splashing,

surface

unbroken

Possible

SENTRY-

go to step 3.

APEX APEX

A

B

C

Dielectric

Constant

4.0 to 10.0

Region

Region

Region

Dielectric

Constant

> 10.0

APEX

Region

Region

Region

(1)

A

B

C

TURBULENT

Heavy

agitation,

vapors, filling,

splashing, or

reactions

A

B

C

Step 3. Tank Geometry

YES APEX Sentry

NO APEX only

NOTE: To meet most telecommunications requirements, the APEX and APEX

Sentry Radar Gauges must be installed on enclosed or vented metal tanks.

However, other tank types may be approved in country of final destination. Refer to

product manual (document number 00809-0100-4731) for detailed information.

Is flange height

(A) 0,5 m (19.6 in)?

— AND —

Is the radar beam free

of any obstructions, such as fill

tubes, baffles, or

exposed agitators?

*

* See “Antenna Selection

Guidelines” on page A-1

LEVEL-APEX_07A, APEX_08A, APEX_011A

1-4

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™ and APEX Sentry™ Radar Gauge

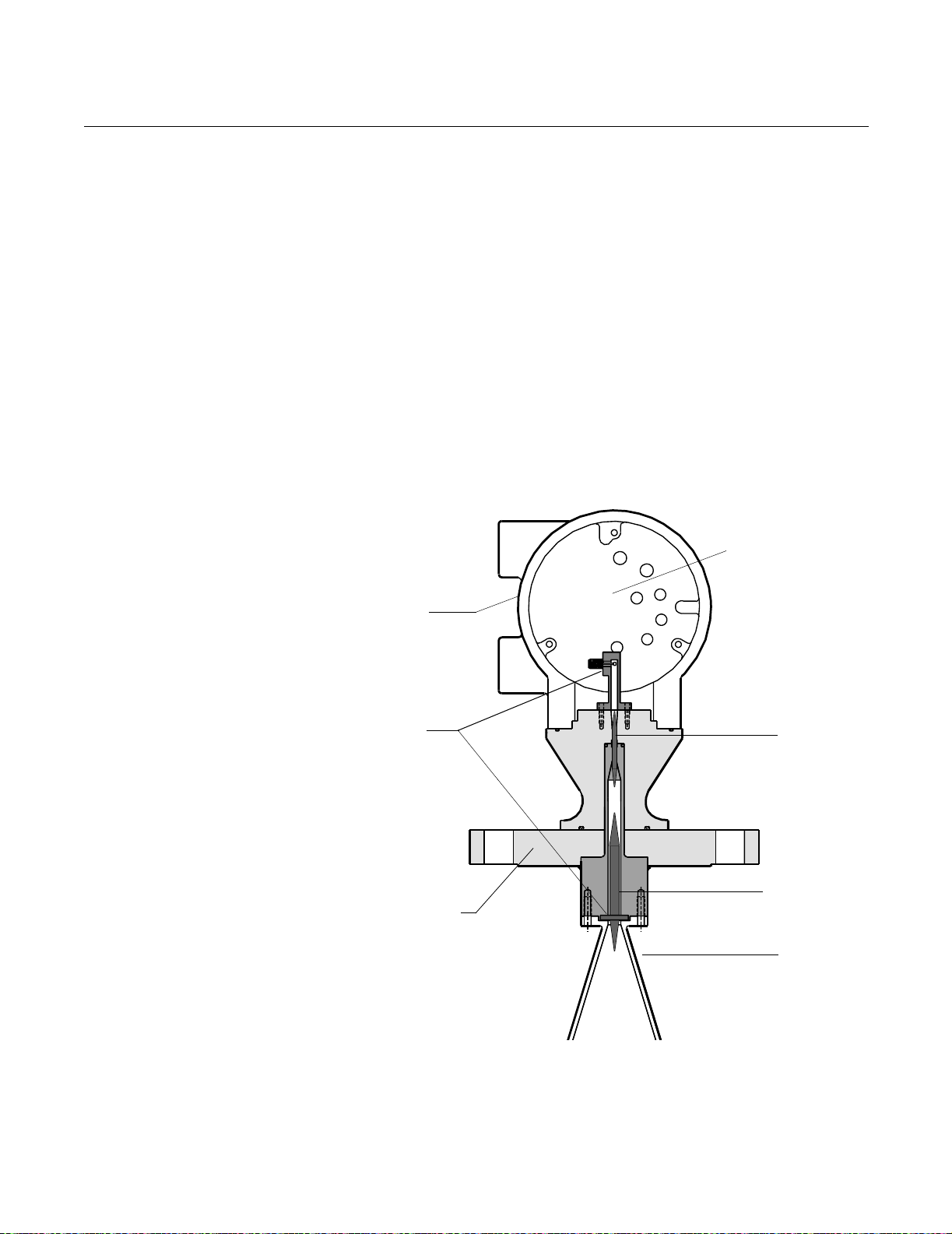

Components of the

APEX and

APEX Sentry Radar

Gauges

Figure 1-1. Cross-sectional View

of the APEX Radar Gauge

The top of the APEX and APEX Sentry Radar Gauges is an aluminum gauge

housing (see Figure 1-1). The gauge housing includes advanced radar

electronics for signal processing.

The radar electronics is the heart of the gauge. It produces an

electromagnetic wave by using an oscillator that converts direct current (dc)

power into a radar signal. It also receives the return signal.

The radar signal passes from the electronics through a waveguide containing

an alumina ceramic process barrier. The waveguide is the entire path from

the electronics to the antenna.

The antenna is a cone-shaped device made of stainless steel. The antenna

controls the signal beamwidth by helping to keep the radar signal focused on

its target (the product in the tank) so it does not spread out over the entire

vessel and give false echoes. A larger antenna provides a more focused,

narrow beam. (Refer to Appendix A: Reference Data for further information

regarding beamwidth.)

Radar

Electronics

Aluminum

Gauge

Housing

Waveguide

Flange

Alumina

Ceramic

Tef lon

Vapor Seal

Antenna

1-5

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™ and APEX Sentry™ Radar Gauge

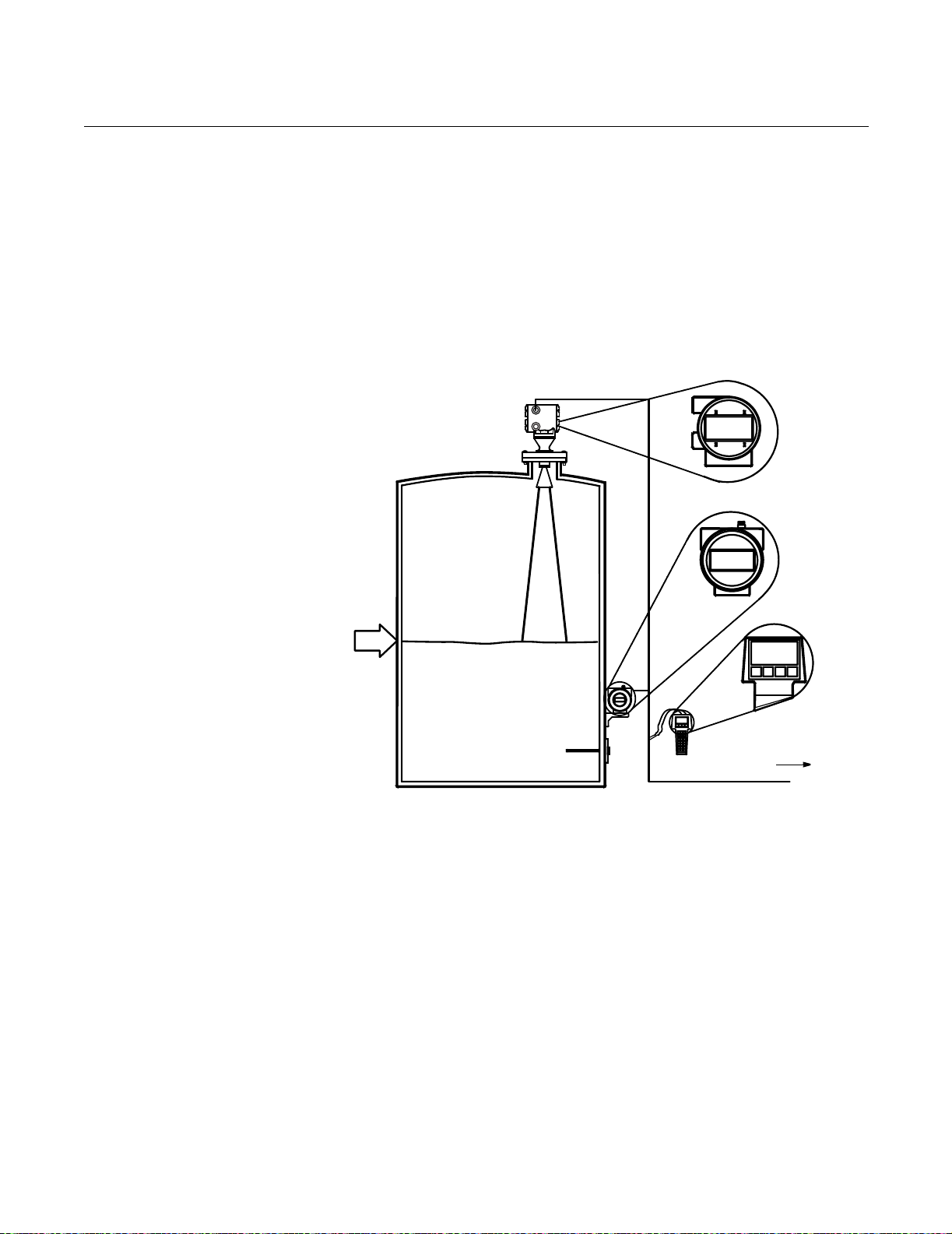

SYSTEM ARCHITECTURE

Figure 1-2. APEX System

Architecture and Display

Options

The output of the APEX and APEX Sentry Radar Gauges is a 4–20 mA

analog signal superimposed with a digital HART signal. As a result, the

primary variable (4–20 mA output) can be configured to represent either level

(APEX and APEX Sentry Radar Gauges) or calculated volume (APEX Radar

Gauge only), with up to three additional variables available through the HART

signal.

In addition to using the HART Communicator, you can view level and volume

variables using an optional Integral Display on the gauge or a Model 751 Field

Signal Indicator as a remote display (see Figure 1-2).

Optional

Integral Display

Level: 5.10 m

4

–

2

0

Level=

5.10 m

m

A

/

H

A

R

T

S

i

g

n

a

l

Level: 5.10 m

Model 751 Field

Signal Indicator

HART

Communicator

Control System

Level: 5.10 m

LEVEL-0006B

1-6

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™ and APEX Sentry™ Radar Gauge

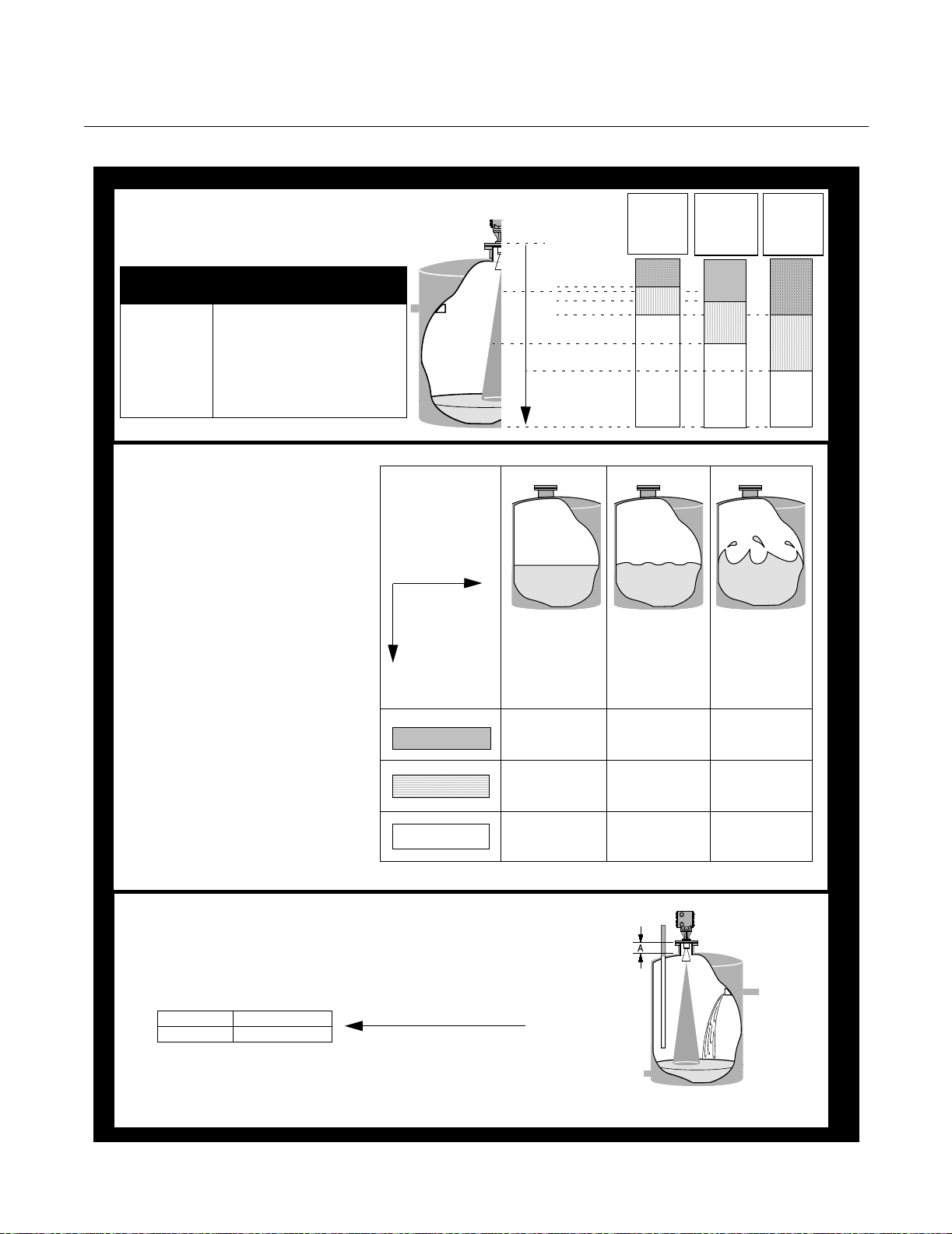

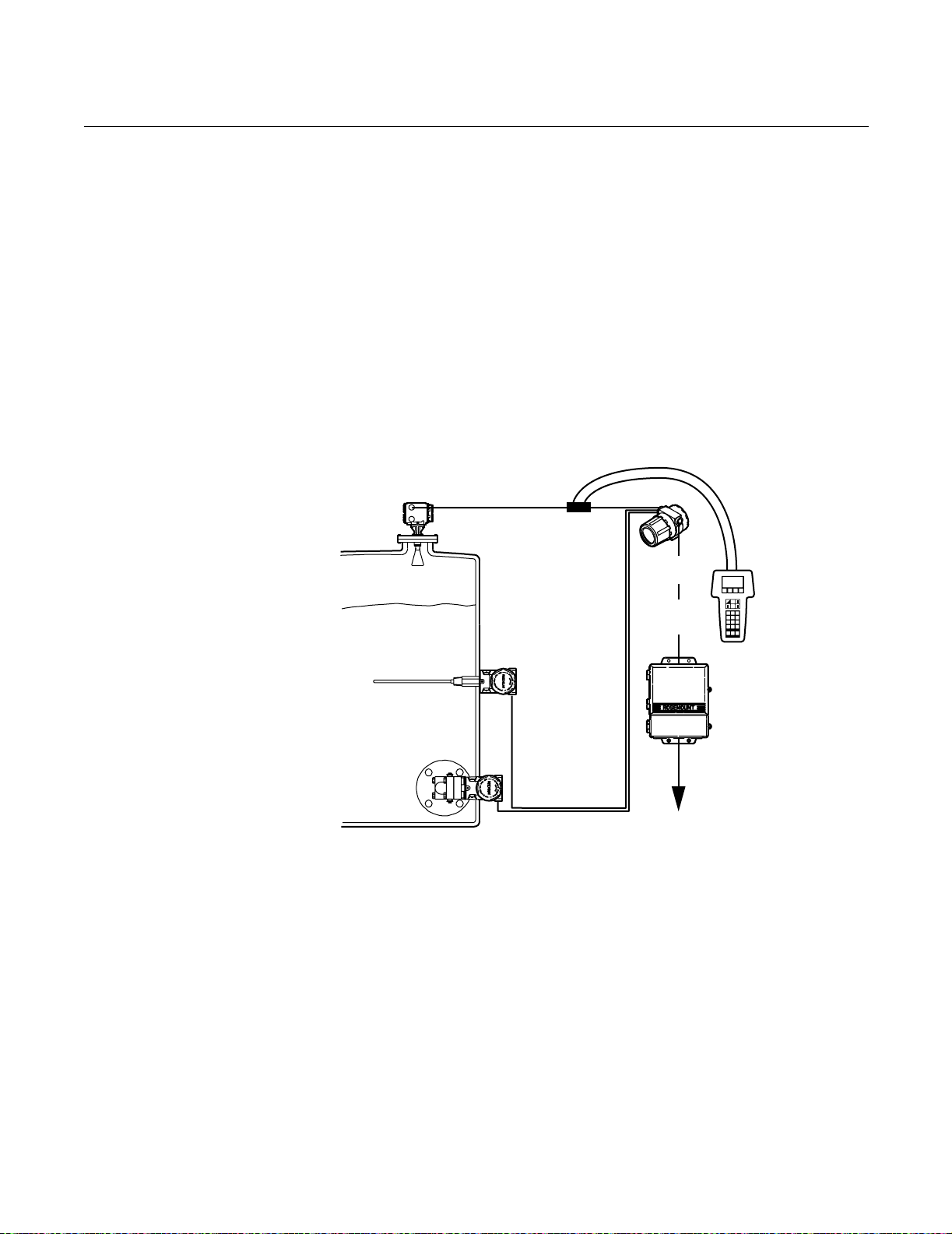

APEX /Hybrid

System Overview

(APEX Radar

Gauge Only)

Figure 1-3. Hybrid System

Option

To maximize the number of available on-line inventory measurements, you

can install and combine an APEX Radar Gauge with a Rosemount

industry-leading pressure transmitter to create a hybrid system (see Figure

1-3). A hybrid system offers the best advantages from both level-based and

pressure-based tank gauging systems:

• Offers all the advantages of the APEX and HTG technologies

• Provides level, volume, mass, and true average

density measurements

• Enhances plant safety since no manual operations are necessary

• Handles traditional problems such as density stratification

For further installation details, please see page 2-1, and refer to the certified

wiring diagrams provided.

APEX

Radar Gauge

Model 3201

HIU

MCAP

Output

HART

Communicator

Addressing Concerns

about Exposure to

The APEX and APEX

Sentry Radar Gauges

Optional

RTD

Optional Pressure Transmitter

RS 485

RS 232

Output

Model 3402 AIM

The Federal Communications Commission has issued a bulletin called

Questions and Answers About Biological Effects and Potential Hazards of

Radio frequency Radiation (OET Bulletin No. 56, Third Edition, January

1989). This document states a recommended power density limit of 5

mW/cm

2

in the frequency range of 1.5–100 GHz. This limit is based on a 1982

ANSI guideline for a time-averaged exposure for humans.

The maximum power density emitted from APEX and APEX Sentry Radar

Gauges is approximately 1.1 mW/cm

When the gauge is mounted in a metal vessel, the emissions external to the

vessel are much lower than the 1.1 mW/cm

2

, which is below the ANSI guideline.

2

measured at the antenna.

For additional information about the safety of radar signals, see Appendix A:

Reference Data.

LEVEL- 2510_04A

1-7

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™ and APEX Sentry™ Radar Gauge

SERVICE SUPPORT If you have reason to believe that your APEX or APEX Sentry Radar Gauge

may need to be returned for service, please contact a Level Applications

Support Specialist at Rosemount Customer Central (1-800-999-9307). They

will help you determine the best course of action, and may transfer you to

either an Order Administrator or to the Rosemount North American Response

Center (NARC) to arrange the return of your gauge for service or repair.

NOTE

Most radar problems encountered in the field are applications-related, and

can best be dealt with while the gauge is installed.

The representative arranging the return will ask for product model and serial

numbers, and will provide a Return Material Authorization (RMA) number.

The center will also ask for the name of the process material to which the

product was last exposed. If the material to which the product was last

exposed is a hazardous substance as defined by OSHA, a copy of the

required Material Safety Data Sheet (MSDS) for each hazardous substance

identified must be included with the returned products.

The representative arranging your return will detail the additional information

and procedures necessary to return products exposed to hazardous

substances.

1-8

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™and APEX Sentry™ Radar Gauge

Section 2 Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Before You Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-3

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Vessel Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-7

Process Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-16

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-20

Mounting the Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-21

Electrical Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-22

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-24

Wiring Optional Gauge Devices . . . . . . . . . . . . . . . . . . . . page 2-29

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-33

NOTE

All information included refers to both the APEX Radar Gauge

and the APEX Sentry Radar Gauge unless otherwise stated.

This section contains instructions for installing the APEX and APEX Sentry

Radar Gauges, including gauge mounting, wiring, and field configuration

using the APEX integral display or a HART Communicator.

www.rosemount.com

Reference Manual

00809-0100-4731, Rev FA

APEX™and APEX Sentry™ Radar Gauge

April 2003

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury:

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART-based communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit

is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock:

Avoid contact with leads and terminals.

Make sure the main power to the APEX Radar Gauge is off and the lines to any other

external power source are disconnected or not powered while wiring

the gauge.

2-2

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™and APEX Sentry™ Radar Gauge

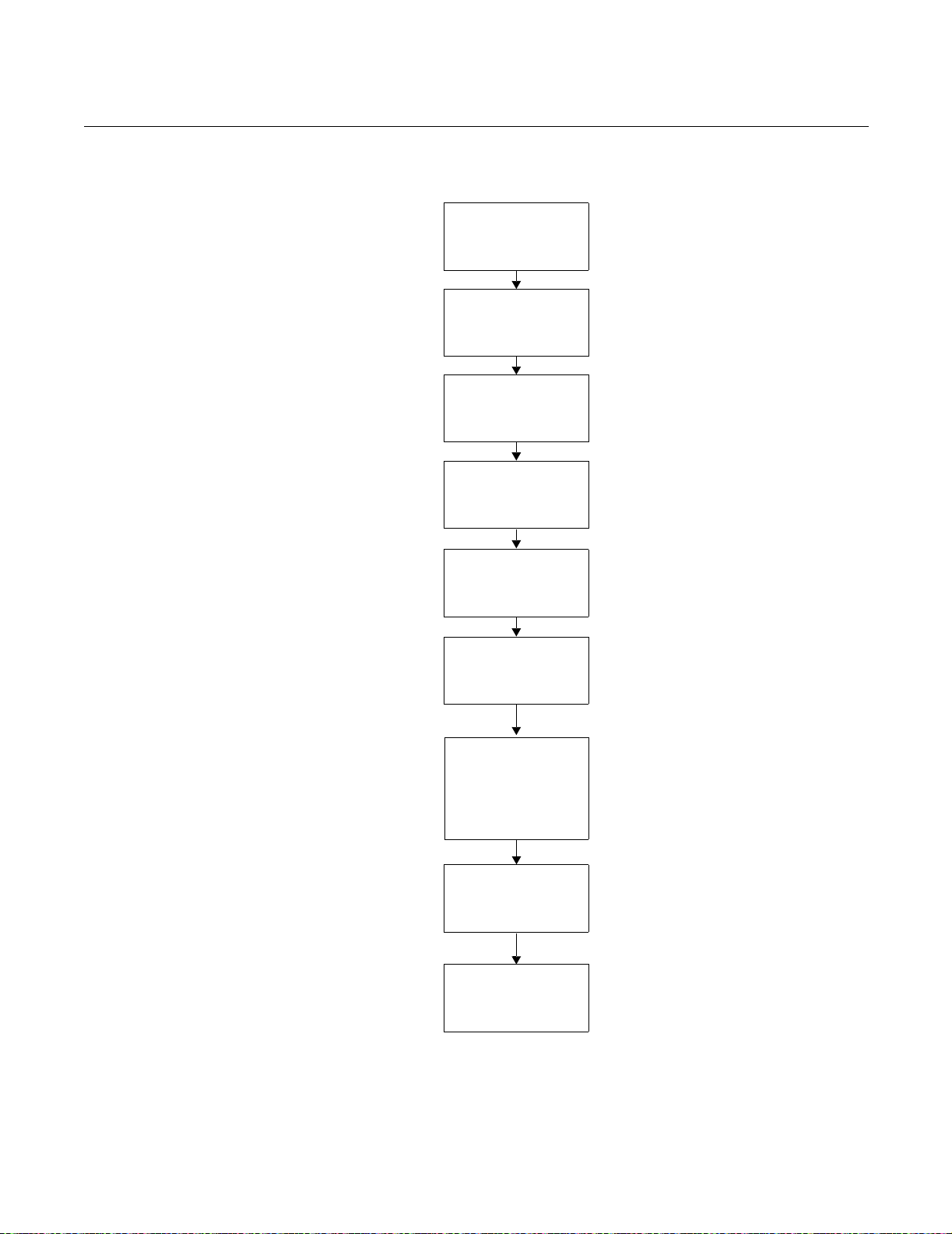

BEFORE YOU INSTALL Follow these steps for proper installation:

Review Installation

Considerations

(see page 2-4)

Check Processor

Switches

(See page 2-22)

Review Electrical

Considerations

(See page 2-24)

Mount Gauge

(See page 2-21)

Wire Gauge

(See page 2-22)

Wire Optional Devices

(See page 2-29)

Make sure covers and

conduit connections

are tight; plug unused

conduit entry

Power Up Gauge

(See page 2-33)

Configure Gauge

(See page 3-1)

2-3

Reference Manual

00809-0100-4731, Rev FA

APEX™and APEX Sentry™ Radar Gauge

April 2003

CONSIDERATIONS This section includes information you should consider before installing the

APEX and APEX Sentry Radar Gauges in the field. It includes information on

the following:

• Telecommunications agency requirements

• Unpacking the gauge

• Mounting requirements

• Vessel and process characteristics to consider

For information about configuring the radar gauge using a HART

Communicator, refer to Section 3: Configuration.

Telecommunications

Agency Requirements

Rosemount APEX and APEX Sentry Radar Gauges have been approved for

installation in closed metal tanks, including those that are vented to the

atmosphere. (See "Tank Requirements" below.) Tanks must be closed (or

vented) to contain radar emissions which can otherwise interfere with

aeronautical aviation. Installation shall be done by trained installers. The

radar gauges must be securely bolted to a standard tank flange in strict

compliance with the manufacturer’s instructions.

Failure to properly install the device could constitute an impermissible

modification of the device. In such an event, the responsibility is placed on the

modifying party to ensure compliance with telecommunications regulations,

and Rosemount shall have no liability whatsoever resulting from unauthorized

installation of the device.

Operation Requirements

The use of this device is on a “no-protection, no-interference” basis. That is,

the user shall accept government operations of high-powered radar in the

same frequency band which may interfere with or

damage this device. On the other hand, devices found to interfere

with Government operations will be required to be removed at the user’s

expense.

APEX and APEX Sentry Radar Gauges installed in the United Kingdom

operate between 24.15-26.05 GHz. All other APEX and APEX Sentry Radar

Gauges operate between 24.05 GHz and 26.05 GHz.

In certain countries, the radar gauge must be switched off when opening the

access door to the tank. Any usage in tanks made of non-metallic materials is

prohibited.

2-4

Underground tanks with all exposed surfaces metallized are sufficient to

contain radar emissions.

Tank Requirements

In the United States only, APEX and APEX Sentry Radar Gauges may also

be installed on enclosed or vented concrete tanks with a minimum wall

thickness of 2.5 inches.

In purchasing an APEX or APEX Sentry Radar Gauge, you agree to install the

device in accordance with these conditions.

At the time of this printing, Rosemount Inc. has received the appropriate

telecommunications approval for sale in the countries shown on page A-13.

If you have any questions about what constitutes proper installation, please

contact Rosemount Customer Central at 1-800-999-9307.

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™and APEX Sentry™ Radar Gauge

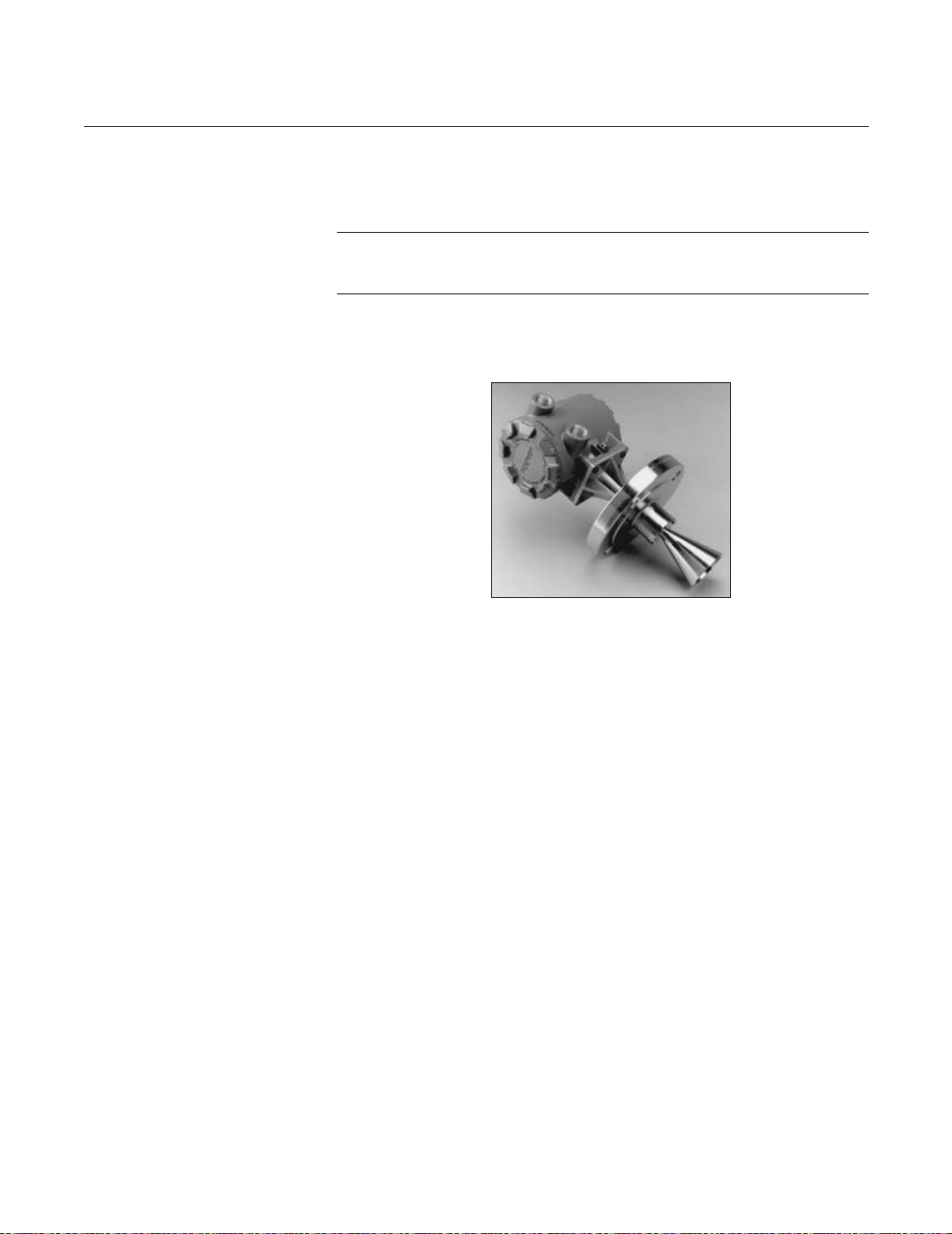

Unpacking the APEX and

APEX Sentry Radar

Gauges

Figure 2-1. APEX Radar Gauge

1. Remove the gauge from the shipping container, taking care not to

damage the contents.

2. Place the gauge on its side on a flat surface as in Figure 2-1.

NOTE

Do not stand the radar gauge upright on its antenna. Be careful not to

damage any part of the antenna during bench inspection or installation.

3. Inspect the unit and report any shipping damage to the carrier.

RADAR-003AB

Installation

Considerations

Before you install an APEX or APEX Sentry Radar Gauge, be sure to

consider your specific mounting requirements, vessel characteristics, and

process characteristics. Review the following information to ensure a

trouble-free, safe, and accurate installation.

The gauge has an Installation Category II (Overvoltage Category) with

pollution degree 2 classification.

Process Characteristics Dielectric Constant

Dielectric constant is a measure of a material’s ability to reflect a radar signal.

Materials with dielectric constants below 3.0 reflect only a small fraction of the

radar signal. Therefore, special care must be taken when measuring low

dielectric fluids.

The gauge can measure fluids with a dielectric constant as low as 1.8 if

vessel conditions are favorable. For example, water-based compounds tend

to have high dielectrics (water has a dielectric of approximately 80), while

hydrocarbons are low. In cases with low dielectrics, it is important to verify

that the dielectric is high enough for radar to measure. For information on

dielectric constants when using an APEX Radar Gauge, refer to Table 2-1 on

page 2-6. If you are unable to determine the dielectric constant for your

process, or if you are measuring a process with a dielectric constant lower

than 3.0, contact Rosemount Customer Central at 1-800-999-9307 for

assistance.

2-5

Reference Manual

00809-0100-4731, Rev FA

APEX™and APEX Sentry™ Radar Gauge

Table 2-1. Sample list of dielectric constants

Dielectric Constant Ranges for Chemicals Listed

Less Than 1.8 1.8 to 4.0 4.0 to 10.0 10.0 to 15.0 15.0 to 20.0 More than 20.0

carbon dioxide acetylene acetic acid benzyl alcohol ammonia acetone

cyclopentane asphalt bromobutane butyl nitrate butanol ethanol

ethylene benzene butyl alcohol carveol cyclohexanol ethylene glycol

methane butane chlorobenzene creosol diacetone alcohol glycerine

jp4 (military fuel) carbon tetrachloride chloroform dimethyl oxalate dichloro ethane glycol

propane cocaine chlorotoluene ethylene chloride isopropyl alcohol hydrazine

freons cresol hexanol lactic acid hydrogen peroxide

kerosene dibutyl phtalate iodine methylamine hydrogen cyanide

napthalene dichlorobutane methylamine methyl ethyl ketone latex

octane ethylamine phenol nitroglycerin methanol

oleic acid nicotine pyridine sulfur dioxide molasses

petroleum oils phosphorus tripropyl phosphate propanol

stearic acid phosgene vinyl isocyanate sorbitol

styrene sulfur water

sulfur toluene diisocyanate

toluene

vegetable oils

April 2003

Foam and Vapors

Foam may affect the gauge performance because it can reduce the radar

signal being reflected. The effect is highly dependent on the particular

characteristics of the foam. In general, the APEX Radar Gauge reads the top

of the foam if it is sufficiently reflective. The APEX Sentry Radar Gauge is not

for use in applications with foam.

Changing Density, Temperature, or Pressure

The level accuracy is not affected by changes in the density, temperature, or

pressure of the product.

Turbulence or Vortices

The gauge uses advanced signal processing, reducing the effects of

turbulence and vortices. However, the greater the turbulence or vortex the

larger the effect because they disturb the product surface where the signal is

being reflected. With vortices caused by agitators, you need to be aware of

the “swell” effect. That is, the product surface will rise in the vessel when

sufficiently agitated and the radar output will measure this rise. The APEX

Sentry Radar Gauge is not for use in turbulent applications. Refer to Figure

2-18 on page 2-22 for further information.

2-6

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™and APEX Sentry™ Radar Gauge

Coating, Condensate, or Corrosion

The functionality of the gauge may be affected by coating, condensate, or

corrosion, depending on the type of process in the vessel. When conditions

produce heavy condensation or coating, or when the process is corrosive to

316 SST or alumina ceramic, Rosemount suggests using a process “window”

with the gauge to protect the antenna and waveguide.

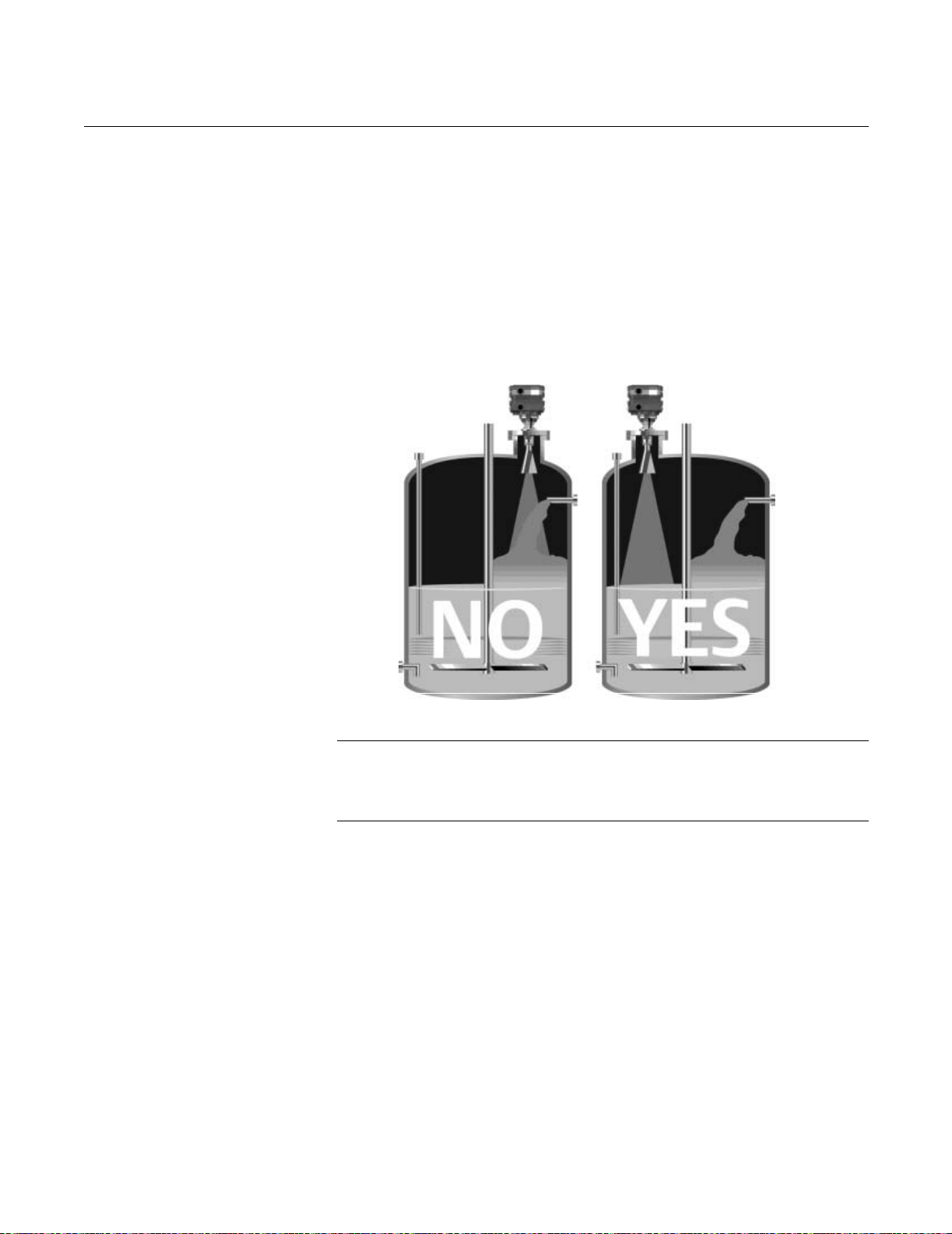

VESSEL CHARACTERISTICS

Figure 2-2. Vessel

Characteristics That May Affect

the Level Reading

Mount the gauge where it will have a clear view of the tank surface, but not in

the top center of the vessel (Figure 2-10).

LEVEL-SEETHEPROCESS.TIF

POOR PLACEMENT PREFERRED PLACEMENT

NOTE

When using an APEX Sentry Radar Gauge, it is necessary for 100% of the

beam cone to contact the liquid surface.

Refer to Table 2-2 on page 2-8 for further information.

2-7

APEX™and APEX Sentry™ Radar Gauge

Table 2-2. Beamwidth versus

Distance from flange face

to tank bottom

Distance (D)

from gauge

2-in. Antenna 3-in. Antenna 4-in. Antenna

ft (m) ft (m) ft (m) ft (m)

2 (0.6) 0.4 (0.12) 0.2 (0.07) 0.2 (0.06)

4 (1.2) 0.8 (0.25) 0.5 (0.15) 0.4 (0.11)

6 (1.8) 1.2 (0.37) 0.7 (0.22) 0.6 (0.17)

8 (2.4) 1.6 (0.49) 1.0 (0.29) 0.7 (0.22)

10 (3.0) 2.0 (0.62) 1.2 (0.37) 0.9 (0.28)

15 (4.6) 3.0 (0.93) 1.8 (0.55) 1.4 (0.42)

20 (6.1) 4.1 (1.23) 2.4 (0.73) 1.8 (0.56)

25 (7.6) 5.1 (1.54) 3.0 (0.92) 2.3 (0.70)

30 (9.1) 6.1 (1.85) 3.6 (1.10) 2.8 (0.84)

35 (10.7) 7.1 (2.16) 4.2 (1.28) 3.2 (0.98)

40 (12.2) 8.1 (2.47) 4.8 (1.46) 3.7 (1.12)

45 (13.7) 9.1 (2.78) 5.4 (1.65) 4.1 (1.26)

50 (15.2) 10.1 (3.09) 6.0 (1.83) 4.6 (1.40)

55 (16.8) 11.1 (3.40) 6.6 (2.01) 5.1 (1.54)

60 (18.3) 12.2 (3.70) 7.2 (2.20) 5.5 (1.68)

65 (19.8) 13.2 (4.01) 7.8 (2.38) 6.0 (1.82)

70 (21.3) 14.2 (4.32) 8.4 (2.56) 6.4 (1.96)

75 (22.9) 15.2 (4.63) 9.0 (2.75) 6.9 (2.10)

80 (24.4) 16.2 (4.94) 9.6 (2.93) 7.4 (2.24)

85 (25.9) 17.2 (5.25) 10.2 (3.11) 7.8 (2.38)

90 (27.4) 18.2 (5.56) 10.8 (3.30) 8.3 (2.52)

95 (29.0) 19.2 (5.86) 11.4 (3.48) 8.7 (2.66)

100 (30.5) 20.3 (6.17) 12.0 (3.66) 9.2 (2.80)

Radius (r) from Flange Centerline to

Reference Manual

00809-0100-4731, Rev FA

April 2003

Beamwidth Edge

2-8

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™and APEX Sentry™ Radar Gauge

General Vessel

Considerations

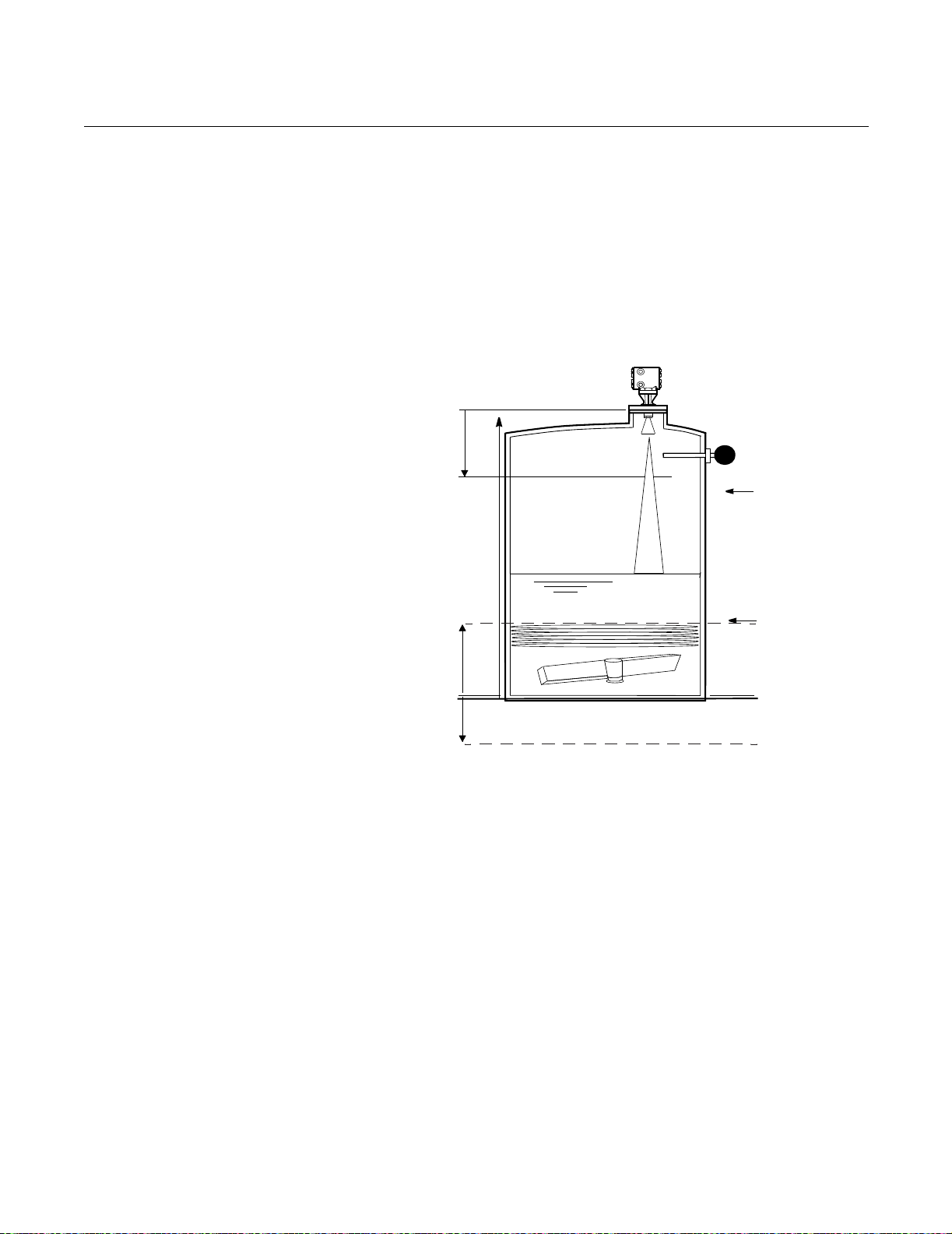

Figure 2-3. User-Programmable

“Null” Zones for

APEX and APEX Sentry Radar

Gauges

Heating Coils and Agitators

If the vessel contains heating coils or agitators (see Figure 2-2), they may

create noise when the radar signal bounces off of them. The noise level is

less if the signal contacts a non-flat surface (for example, round pipe, angled

blade, etc.) that causes the signal to scatter rather than directing it back to the

antenna. To avoid these problems, try to make sure that heating coils or

agitators are below the minimum product level or within the null zones (see

Figure 2-3 on page 2-9 and Figure 2-3 on page 2-9).

Upper

Null

Zone

Radar gauge will not

measure above this line.

Reference

Gauge Height

High Level Switch

URV (20 mA)

LRV (4 mA)

Lower

Null

Zone

-19.6 in.

(-0.5 m)

Radar gauge will not measure below this line.

Reference Line

Cables, Floats, Baffles, or Trays

Cables, floats, baffles, or trays can introduce noise into the radar signal. A

vertical cable or rounded surface causes minimal effect because the radar

signal is scattered rather than directed back to the antenna. To reduce the

amount of noise from cables, floats, baffles, or trays, position the gauge such

that the beam will not contact them.

LEVEL-0579A

2-9

APEX™and APEX Sentry™ Radar Gauge

Inlet Pipes or Flows

The level reading may be affected by the process flowing into the vessel. To

lessen the effects, mount the radar gauge so the beam signal does not

contact the inlet pipe or flow (Figure 2-2).

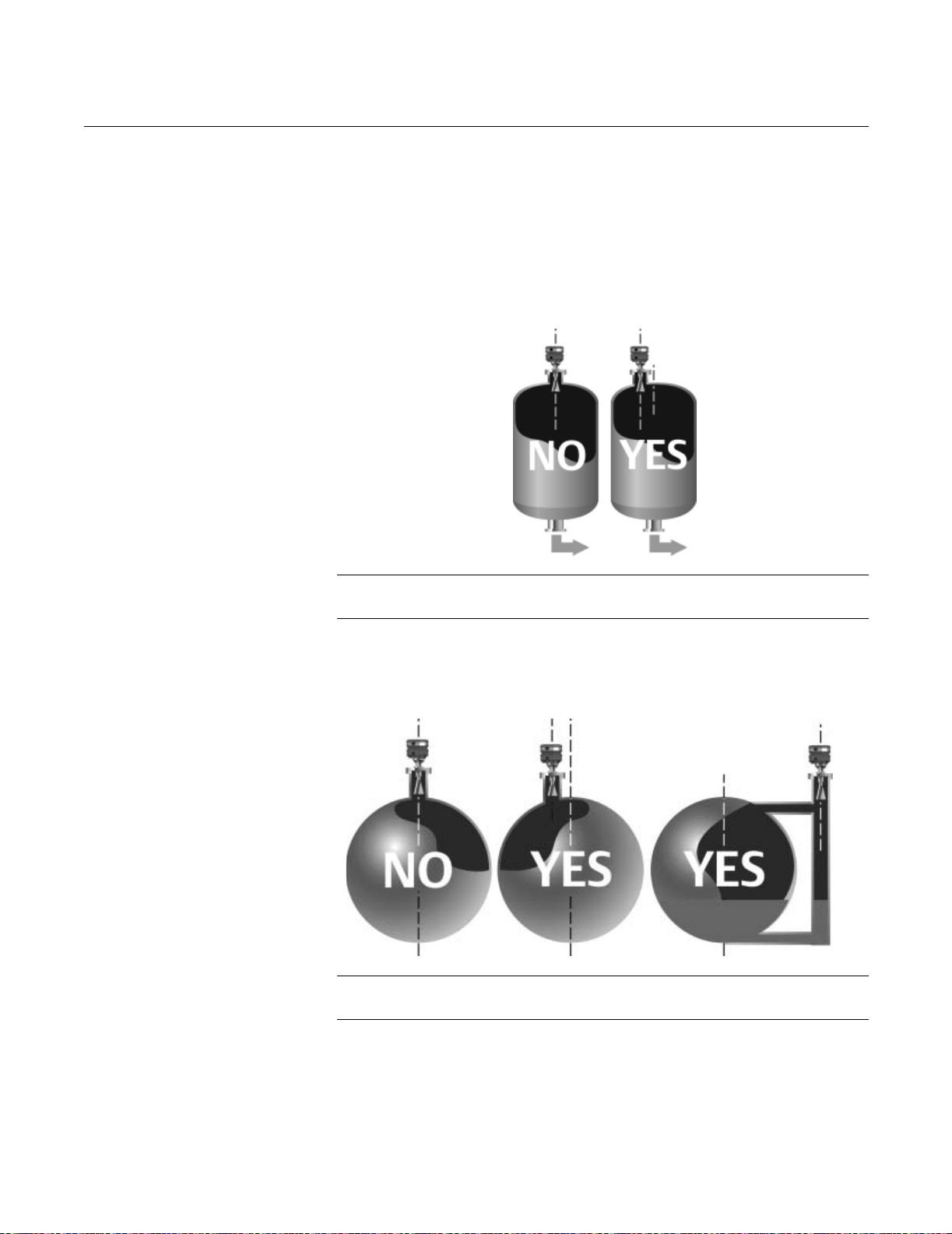

Center of tank installations should be avoided, off-center installations are

preferred (Figure 2-4).

Figure 2-4. Example of off

center tank installation.

Reference Manual

00809-0100-4731, Rev FA

April 2003

NOTE

Center of the tank installations should be avoided.

Specific Tank Shapes Spherical Vessel Considerations

Figure 2-5. Spherical vessel

installation

NOTE

Spheres should never have top-center installation options.

EXNEW/COLUMNALIGHN.TIF

SPHEREALIGN_AB.TIF

2-10

Reference Manual

00809-0100-4731, Rev FA

April 2003

Figure 2-6. Possible horizontal

vessel mounting options

APEX™and APEX Sentry™ Radar Gauge

Horizontal Vessel Mounting Surface

Horizontal cylinders often only have top-center connection options. If this is

the case, then the end of the antenna should be down into the vessel or

mounted in a widened area such as a manhole cover. Recessing the antenna

into a nozzle is not recommended (Figure 2-6).

APEXNEW_CYLINDERS.TIF

2-11

APEX™and APEX Sentry™ Radar Gauge

Stilling Well, Bypass Cage, and

Bridle Connection Considerations

Apex and Apex Sentry can be mounted on bypass cages, bridles, and stilling

wells. Non-slotted stilling wells are preferred. If holes must be present, then 1

inch diameter holes approximately 0.5 meters apart are acceptable.

Higher dielectric materials (such as water-based compounds) in a stilling well

or bypass cage will create a strong return signal to the gauge. For this reason

smaller antennas should be used. Lower dielectric materials, (such as

hydrocarbons and solvents) will attenuate the signal so the antenna size

should be as large as possible for the bypass pipe or stilling well.

Figure 2-7. 3 inch or 4 inch

bypass cages can be used.

Reference Manual

00809-0100-4731, Rev FA

April 2003

20mA

4mA

BYPASSCONNECTIONS.TIF

• Stilling wells should be non-slotted. The signal will be stronger because

it is contained within the stilling well. With higher dielectric fluids it is

possible for the signal to be too strong. If this is the case, try using a

smaller antenna.

• At the low end of the well or bridle, especially with joints or bends in

pipes the level or distance may be incorrect due to false reflections. Fill

with fluid to cover the area.

2-12

Reference Manual

00809-0100-4731, Rev FA

April 2003

APEX™and APEX Sentry™ Radar Gauge

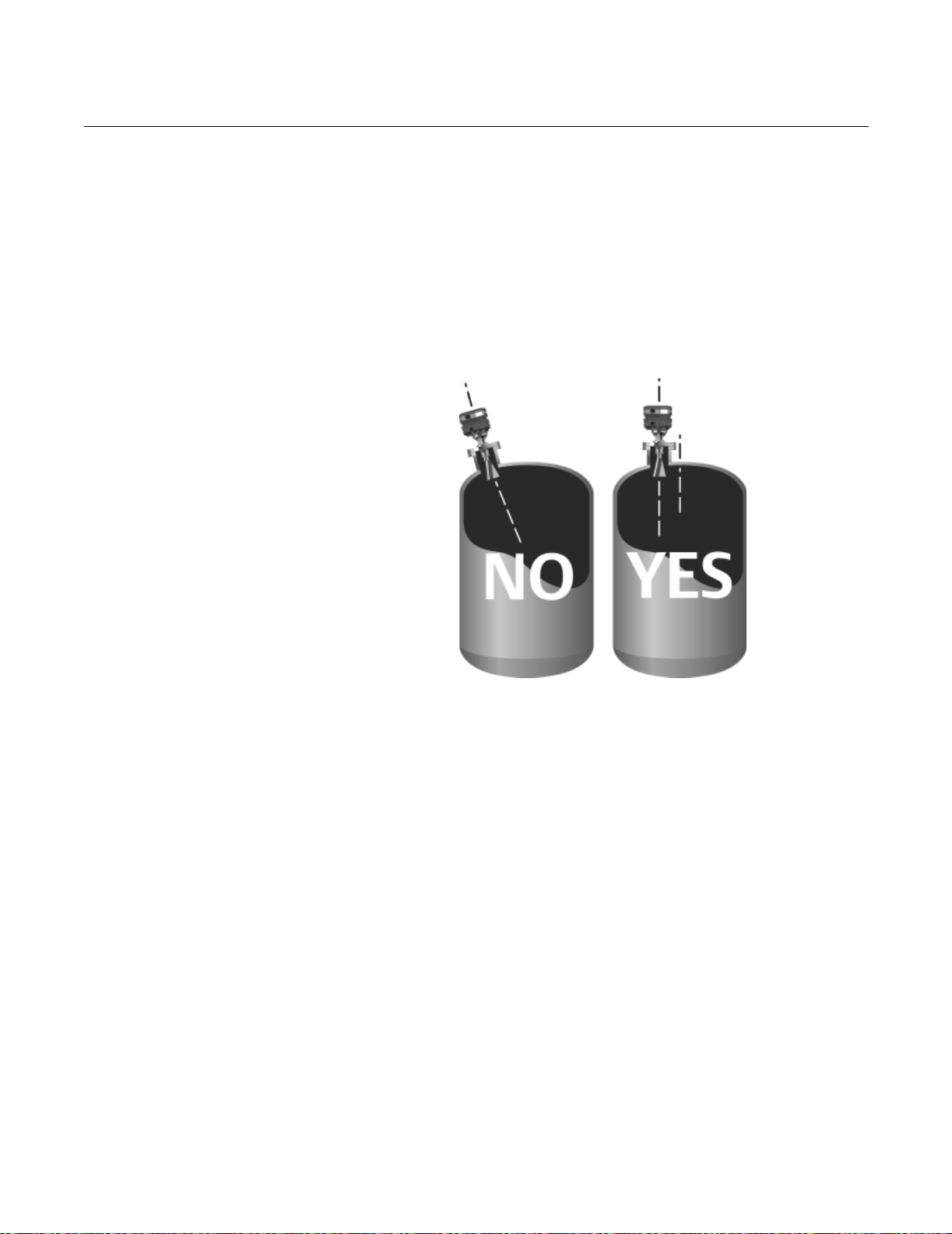

Nozzle Considerations Non-horizontal Mounting Surface

In most applications, the gauge should be mounted perpendicular to the level

surface. It is acceptable to have the mounting flange up to 2° off from

perpendicular. In applications with low dielectric constants or long measuring

ranges, mounting the radar gauge with the flange horizontal to the product

level becomes more important in order to receive an adequate return signal

(Vessel Characteristics on page 2-7). For more information regarding

mounting considerations, contact Rosemount Customer Central at

1-800-999-9307.

Figure 2-8. Example of

Non-horizontal mounting

APEXNEW/HORIZONTALMOUNTING.TIF

2-13

APEX™and APEX Sentry™ Radar Gauge

Tank Nozzle Considerations

Nozzles should be wide open and smooth without any intersecting lines. The

nozzles should not be too long because it will cause a reflection and attenuate

signal. Valves can be used as long as they are open and smooth (no

reducers, lips, or rough edges).

• Nozzles should be open and smooth; no weld lines or ledges should

protrude inside the nozzle, and there should be no restrictions.

• Maximum length of nozzle: 1m for 3 and 4 inch antennas, and 0.3m for

2 inch antennas.

• Full port valves may be used.

• The antenna can be recessed in the nozzle or can extend into the

vessel. However, the end of the antenna should never be even with the

roof of the tank (Figure 2-9).

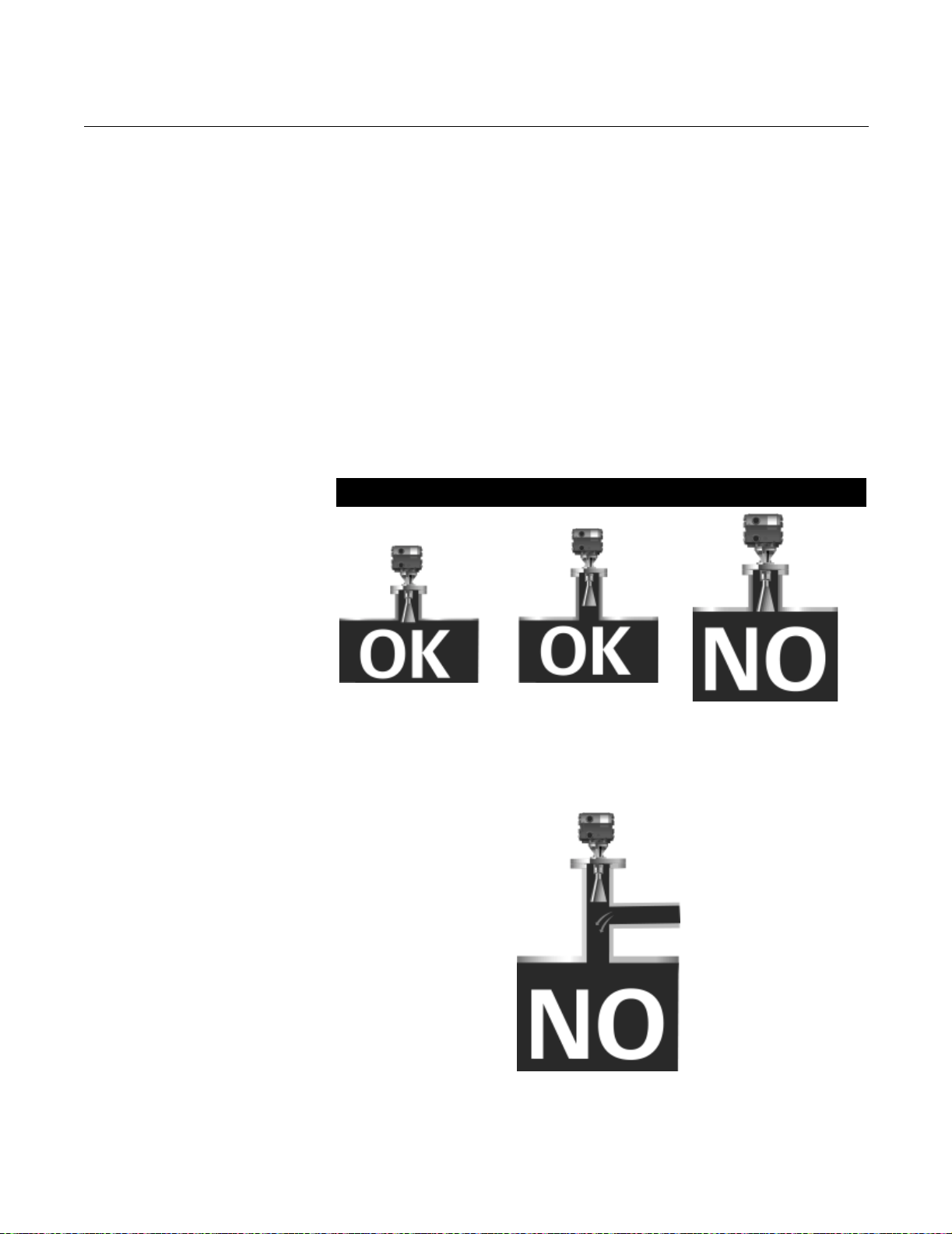

Figure 2-9. Tank Nozzle

Recommendation

Recommended Not Recommended

Reference Manual

00809-0100-4731, Rev FA

April 2003

Figure 2-10. Example of multiple

nozzle function

Note: Do not install an APEX

Radar Gauge where

there is a T-intersection in the

mounting nozzle.

Note: Antenna must not be even with the roof tank.

APEX_CONEALIGNBA.TIF

The gauge should be mounted so antenna extends 1 inch or more into the

tank, or is recessed into the nozzle by 1 inch or more.

APEX_CONEALIGN.TIF

GASPURGE_AB.TIF

2-14

Loading...

Loading...