Rosemount Manual: Rosemount 848T High Density Temperature Transmitter with FOUNDATION Fieldbus Manuals & Guides

Reference Manual

00809-0100-4697, Rev GB

January 2022

Rosemount™ 848T High Density Temperature

Transmitter with FOUNDATION™ Fieldbus

2

Reference Manual Contents

00809-0100-4697 January 2022

Contents

Chapter 1 Introduction.............................................................................................................. 5

1.1 Hazard messages.........................................................................................................................5

1.2 Safety messages.......................................................................................................................... 5

1.3 Product recycling/disposal...........................................................................................................7

Chapter 2 Installation.................................................................................................................9

2.1 Mounting ....................................................................................................................................9

2.2 Wiring........................................................................................................................................16

2.3 Grounding................................................................................................................................. 20

2.4 Switches.................................................................................................................................... 23

2.5 Tagging..................................................................................................................................... 23

2.6 Installation ................................................................................................................................24

Chapter 3 Configuration...........................................................................................................27

3.1 Standard configuration..............................................................................................................27

3.2 Transmitter configuration..........................................................................................................27

3.3 Custom configuration................................................................................................................27

3.4 Configure methods....................................................................................................................28

3.5 Configure alarms....................................................................................................................... 28

3.6 Configure damping....................................................................................................................28

3.7 Configure the differential sensors.............................................................................................. 28

3.8 Configure measurement validation............................................................................................29

3.9 Common configurations for high density applications...............................................................29

3.10 Configure blocks......................................................................................................................33

Chapter 4 Operation and maintenance.....................................................................................61

4.1 FOUNDATION Fieldbus information...............................................................................................61

4.2 Hardware maintenance............................................................................................................. 61

4.3 Troubleshooting........................................................................................................................62

Appendix A Reference data......................................................................................................... 65

A.1 Functional specifications........................................................................................................... 65

A.2 Physical specifications............................................................................................................... 66

A.3 Function blocks......................................................................................................................... 67

A.4 Performance specifications........................................................................................................68

A.5 Dimensional drawings for Rosemount 848T FOUNDATION Fieldbus..............................................72

A.6 Ordering information................................................................................................................ 79

Appendix B Product certifications............................................................................................... 83

B.1 European Directive Information.................................................................................................83

B.2 Ordinary Location Certification.................................................................................................. 83

Emerson.com/Rosemount 3

Contents Reference Manual

January 2022 00809-0100-4697

B.3 North America........................................................................................................................... 83

B.4 USA............................................................................................................................................83

B.5 Canada...................................................................................................................................... 84

B.6 Europe.......................................................................................................................................85

B.7 International..............................................................................................................................87

B.8 Brazil..........................................................................................................................................89

B.9 China......................................................................................................................................... 90

B.10 Japan....................................................................................................................................... 92

B.11 Korea.......................................................................................................................................92

B.12 EAC - Belarus, Kazakhstan, Russia.............................................................................................93

B.13 Combinations..........................................................................................................................93

B.14 Conduit Plugs and Adapters.....................................................................................................93

B.15 Additional Certifications.......................................................................................................... 94

B.16 Intrinsically Safe and Non-Incendive installations.....................................................................95

B.17 Installation drawings................................................................................................................96

Appendix C FOUNDATION Fieldbus technology......................................................................... 105

C.1 Overview................................................................................................................................. 105

C.2 Function blocks....................................................................................................................... 105

C.3 Device descriptions................................................................................................................. 106

C.4 Block operation....................................................................................................................... 107

C.5 Network communication.........................................................................................................107

Appendix D Function blocks......................................................................................................113

D.1 Analog Input (AI) function block..............................................................................................113

D.2 Multiple analog input (MAI) function block..............................................................................122

D.3 Input selector function block...................................................................................................129

4 Emerson.com/Rosemount

Reference Manual

00809-0100-4697 January 2022

Introduction

1 Introduction

The Rosemount 848T is optimized for process temperature measurement because it can simultaneously

measure eight separate and independent temperature points with one transmitter. You can connect multiple

temperature sensor types to each transmitter. In addition, the Rosemount 848T can accept 4-20 mA inputs.

The enhanced measurement capability of the Rosemount 848T allows it to communicate these variables to

any FOUNDATION™ Fieldbus host or configuration tool.

1.1 Hazard messages

This document uses the following criteria for hazard messages based on ANSI standards Z535.6-2011

(R2017).

DANGER

Serious injury or death will occur if a hazardous situation is not avoided.

WARNING

Serious injury or death could occur if a hazardous situation is not avoided.

CAUTION

Minor or moderate injury will or could occur if a hazardous situation is not avoided.

NOTICE

Data loss, property damage, hardware damage, or software damage can occur if a situation is not avoided.

There is no credible risk of physical injury.

Physical access

NOTICE

Unauthorized personnel can potentially cause significant damage and/or misconfiguration of end users'

equipment. Protect against all intentional or unintentional unauthorized use.

Physical security is an important part of any security program and fundamental to protecting your system.

Restrict physical access to protect users' assets. This is true for all systems used within the facility.

1.2 Safety messages

Read this manual before working with the product. For personal and system safety, and for optimum product

performance, ensure you thoroughly understand the contents before installing, using, or maintaining this

product.

Emerson.com/Rosemount 5

Introduction Reference Manual

January 2022 00809-0100-4697

WARNING

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate local,

national, and international standards, codes, and practices. Review the approvals section of this manual for

any restrictions associated with a safe installation.

Before connecting a Field Communicator in an explosive atmosphere, make sure the instruments in the loop

are installed in accordance with intrinsically safe or non-incendive field wiring practices.

WARNING

Failure to follow these installation guidelines could result in death or serious injury.

Ensure the transmitter is installed by qualified personnel and in accordance with applicable code of practice.

WARNING

Process leaks could result in death or serious injury.

Do not remove the thermowell while in operation.

Install and tighten thermowells and sensors before applying pressure.

WARNING

Electrical shock could cause death or serious injury.

If the sensor is installed in a high-voltage environment and a fault or installation error occurs, high voltage

may be present on transmitter leads and terminals.

Use extreme caution when making contact with the leads and terminals.

CAUTION

This device complies with Part 15 of the FCC Rules. Operation is subject to the following conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including interference that may cause undesired

operation.

• This device must be installed to ensure a minimum antenna separation distance of 7.9 in. (20 cm) from all

persons.

6 Emerson.com/Rosemount

Reference Manual Introduction

00809-0100-4697 January 2022

NOTICE

Battery hazards remain when cells are discharged.

The power module may be replaced in a hazardous area. The power module has surface resistivity greater

than one gigaohm and must be properly installed in the wireless device enclosure. Care must be taken during

transportation to and from the point of installation to prevent electrostatic charge build-up.

Shipping considerations for wireless products.

• The unit was shipped to you without the power module installed. Remove the power module prior to any

re-shipping.

• Each power module contains two “C” size primary lithium batteries. Primary lithium batteries are

regulated in transportation by the U. S. Department of Transportation, and are also covered by IATA

(International Air Transport Association), ICAO (International Civil Aviation Organization), and ARD

(European Ground Transportation of Dangerous Goods). It is the responsibility of the shipper to ensure

compliance with these or any other local requirements. Consult current regulations and requirements

before shipping.

1.3 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in accordance with

local and national legislation/regulations.

Emerson.com/Rosemount 7

Introduction Reference Manual

January 2022 00809-0100-4697

8 Emerson.com/Rosemount

Reference Manual

00809-0100-4697 January 2022

Installation

2 Installation

2.1 Mounting

The transmitter is always mounted remote from the sensor assembly. There are three mounting

configurations as follows:

• To a DIN rail without an enclosure

• To a panel with an enclosure

• To a 2 in (51 mm) pipe stand with an enclosure using a pipe mounting kit

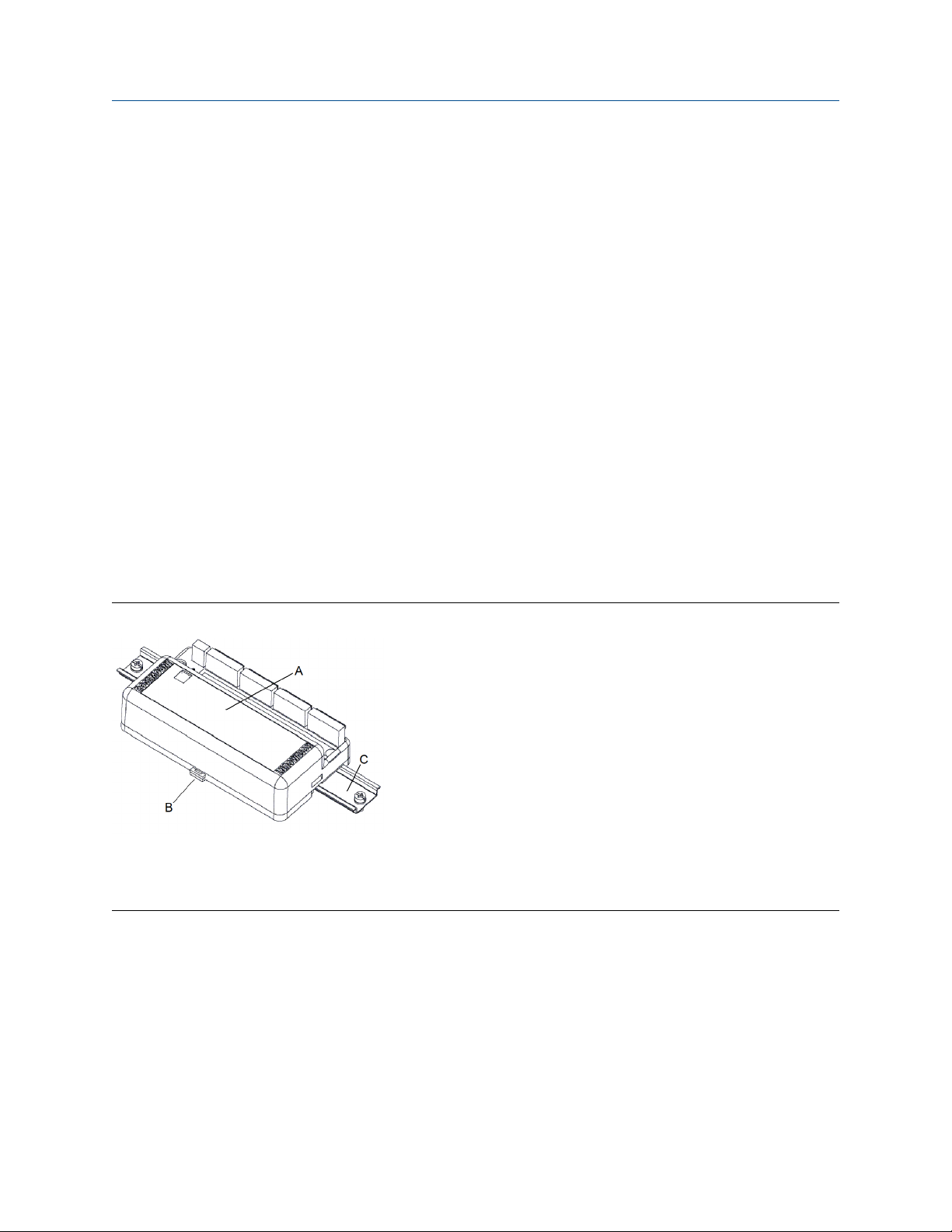

2.1.1 Mount to a DIN rail without an enclosure

To mount the transmitter to a DIN rail without an enclosure, follow these steps:

Procedure

1. Pull up the DIN rail mounting clip located on the top back side of the transmitter.

2. Hinge the DIN rail into the slots on the bottom of the transmitter.

3. Tilt the transmitter and place onto the DIN rail. Release the mounting clip. The transmitter should be

securely fastened to the DIN rail.

Figure 2-1: Mount the transmitter to a DIN rail

A. Rosemount 848T without installed enclosure

B. DIN rail mounting clip

C. DIN rail

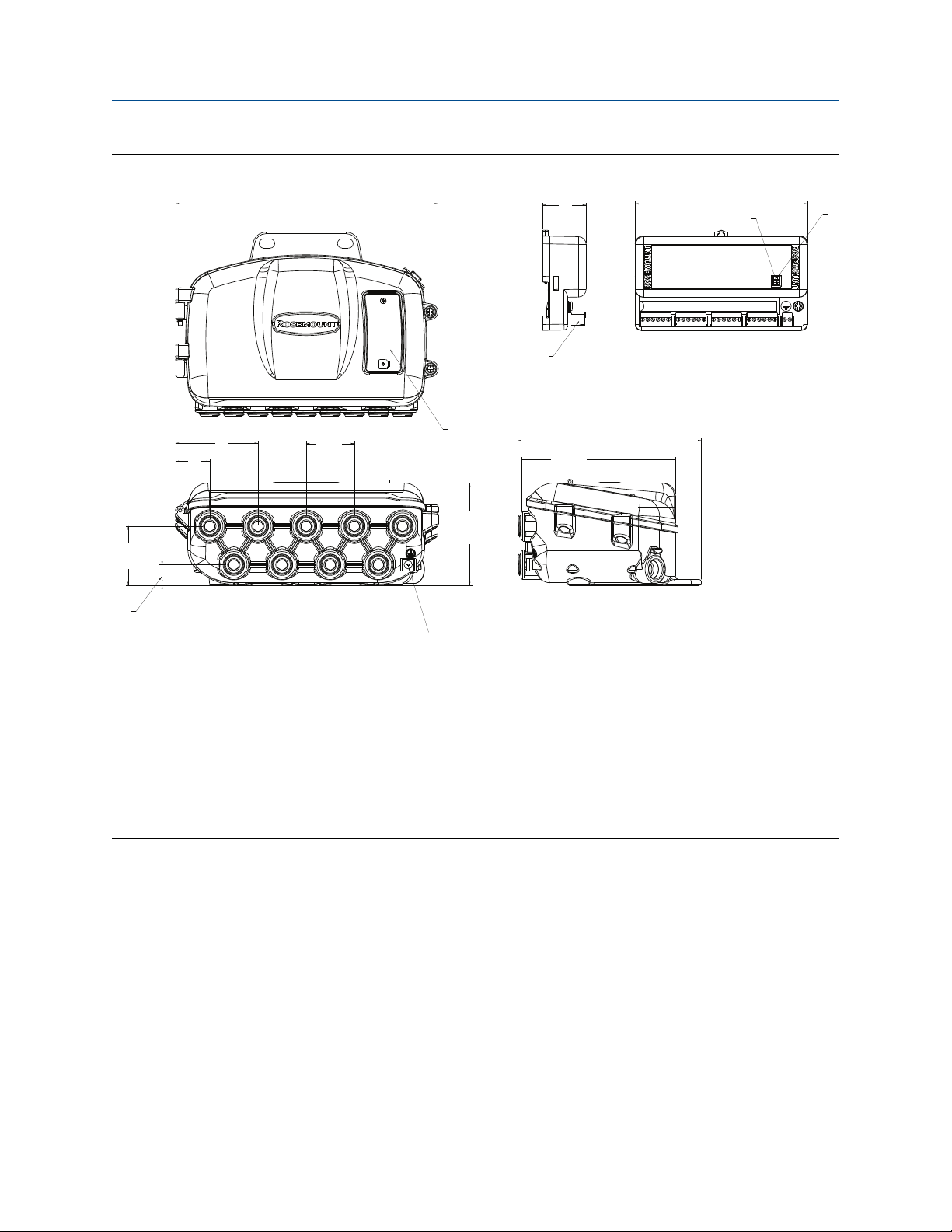

2.1.2 Mount to a panel from an aluminum junction box

Prerequisites

Use four 1/4-20 x 1.25-in. screws.

Procedure

Mount the transmitter to a panel from inside the junction box using one of the following dimension drawings.

Emerson.com/Rosemount 9

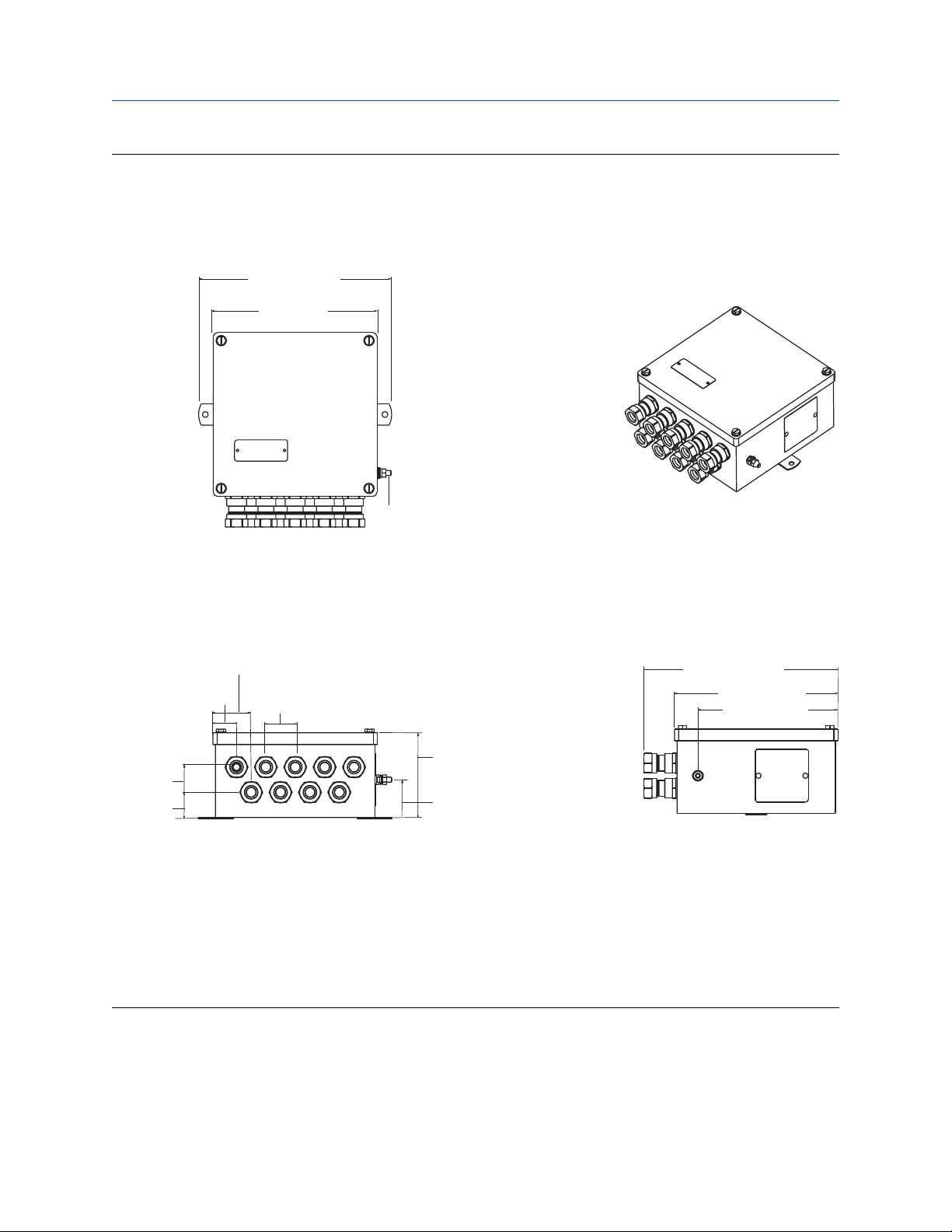

10.21

[259]

A

1.70

[43]

B

6.70

[170]

C

D

3.67

[93]

E

.80

[20]

2.30

[58]

2.27

[58]

1.33

[34]

1.88

[48]

3.98

[101]

8.42

[214]

6.00

[152]

Installation Reference Manual

January 2022 00809-0100-4697

Figure 2-2: Aluminum junction box with cable glands (option code JA4)

A. Nameplate

B. Removable wiring connector

C. Security switch

D. Simulation switch

E. External ground screw (optional)

Dimensions are in inches (millimeters).

10 Emerson.com/Rosemount

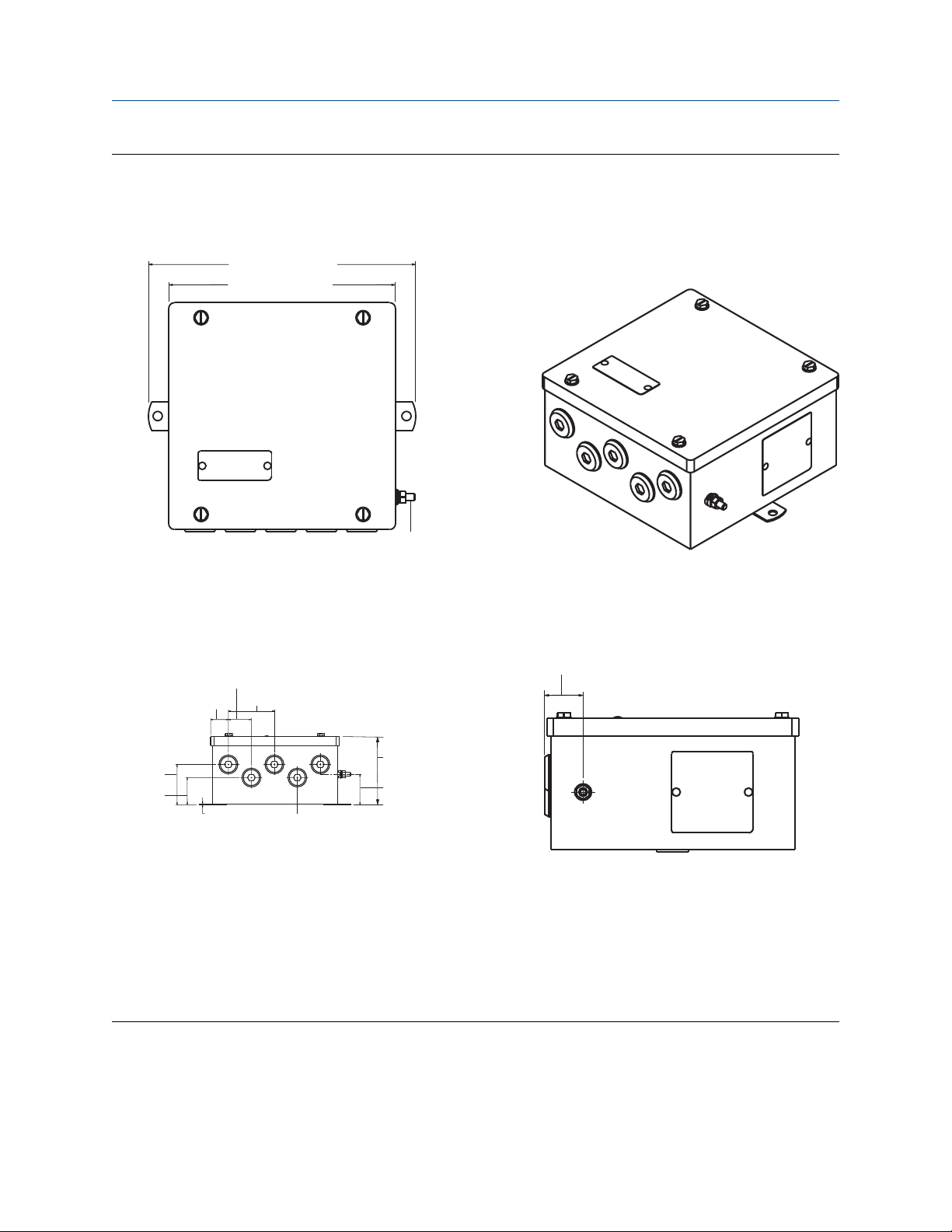

A

10.21

[259]

1.70

[43]

B

6.70

[170]

C

D

.80

[20]

2.30

[58]

3.21

[81]

1.33

[34]

1.88

[48]

3.97

[101]

E

7.14

[181]

6.00

[152]

Reference Manual Installation

00809-0100-4697 January 2022

Figure 2-3: Aluminum junction box with plugged holes (option code JA5)

A. Nameplate

B. Removable wiring connection

C. Security switch

D. Simulation switch

E. External ground screw (optional)

Dimensions are in inches (millimeters).

2.1.3 Mount to a panel from a stainless steel junction box

Prerequisites

Use two 1/4-20 x 1/2-in. screws.

Procedure

Mount the transmitter to a panel from inside the junction box using one of the following dimension drawings.

Emerson.com/Rosemount 11

9.91 (231)

7.7 (196)

C

1.8 (46)

1.1 (28)

1.73 (44)

2.4 (62)

1.2 (30)

1.8 (47)

4.0 (102)

9.14 (232.2)

7.72 (196)

6.61 (168)

A B

D E

Installation Reference Manual

January 2022 00809-0100-4697

Figure 2-4: Stainless steel junction box with cable glands (option code JS2)

A. Top view

B. 3-D view

C. Ground screw

D. Front view

E. Side view

Dimensions are in inches (millimeters).

12 Emerson.com/Rosemount

9.1 (231)

7.7 (196)

C

A

4.0 (102)

B

1.4 (35)

1.1 (27)

2.8 (70)

4.0 (102)

1.8 (4.7)

2.4 (62)

1.6 (42)

F

D

1.2 (30)

E

Reference Manual Installation

00809-0100-4697 January 2022

Figure 2-5: Stainless steel junction box with a conduit entry (option code JS3)

A. Top view

B. 3-D view

C. Ground screw

D. Front view

E. Side view

F. Five plugged 0.86 in (21.8 mm) diameter holes suitable for installing ½-in. NPT fittings

Dimensions are in inches (millimeters).

Emerson.com/Rosemount 13

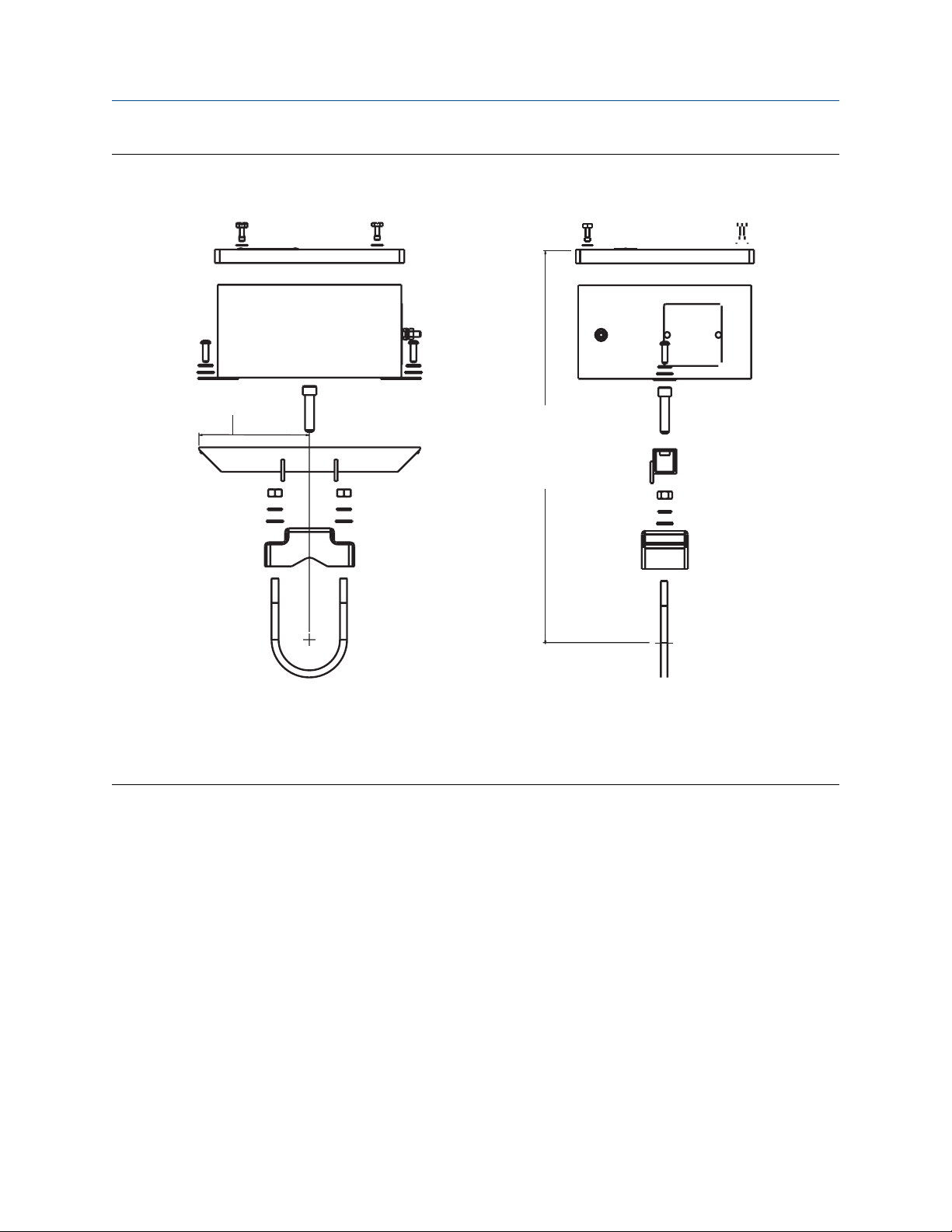

․

‥

A B

5.08

[129]

7.55

[193]

Installation Reference Manual

January 2022 00809-0100-4697

2.1.4 Mount to a 2 in (51 mm) pipe stand

Procedure

Use the optional mounting bracket (option code B6) to mount the transmitter to a 2 in (51 mm) pipe stand

when using a junction box.

Figure 2-6: Mount an aluminum junction box

A. Front view

B. Side view

Dimensions are in inches (millimeters)

14 Emerson.com/Rosemount

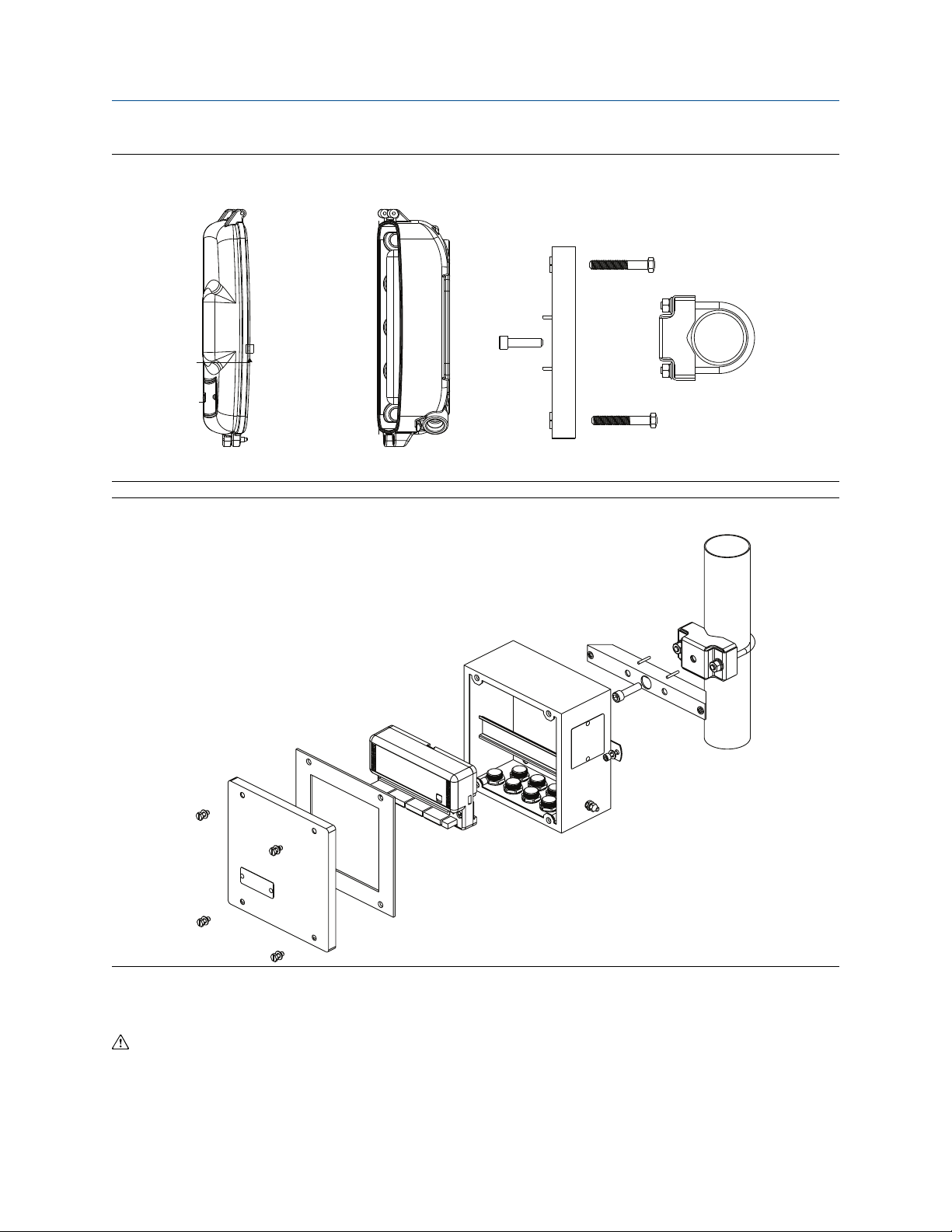

4.7 (119)

7.5 (190)

C

A B

Reference Manual Installation

00809-0100-4697 January 2022

Figure 2-7: Mount a stainless steel junction box

A. Front view

B. Side view

C. Fully assembled

Dimensions are in inches (millimeters)

Emerson.com/Rosemount 15

Installation

January 2022 00809-0100-4697

Figure 2-8: Mount aluminum on a vertical pipe

Figure 2-9: Mount stainless steel on vertical pipe

Reference Manual

2.2 Wiring

If the sensor is installed in a high-voltage environment and a fault condition or installation error occurs, the

sensor leads and transmitter terminals could carry lethal voltages. Use extreme caution when making contact

with the leads and terminals.

16 Emerson.com/Rosemount

%

$

&

)

)

*

+

'

(

Reference Manual

Installation

00809-0100-4697 January 2022

NOTICE

Do not apply high voltage (e.g. AC line voltage) to the transmitter terminals. Abnormally high voltage can

damage the unit (bus terminals are rated to 42.4 VDC).

A. Integrated power conditioner and filter

B. 6234 ft. (1900 m) max (depending upon cable characteristics)

C. Terminators (trunk)

D. Power supply

E. FOUNDATION Fieldbus host or configuration tool

F. Spurs

G. Signal wiring

H. Devices 1-16 (intrinsically safe installations may allow fewer devices per I.S. barrier)

2.2.1 Connections

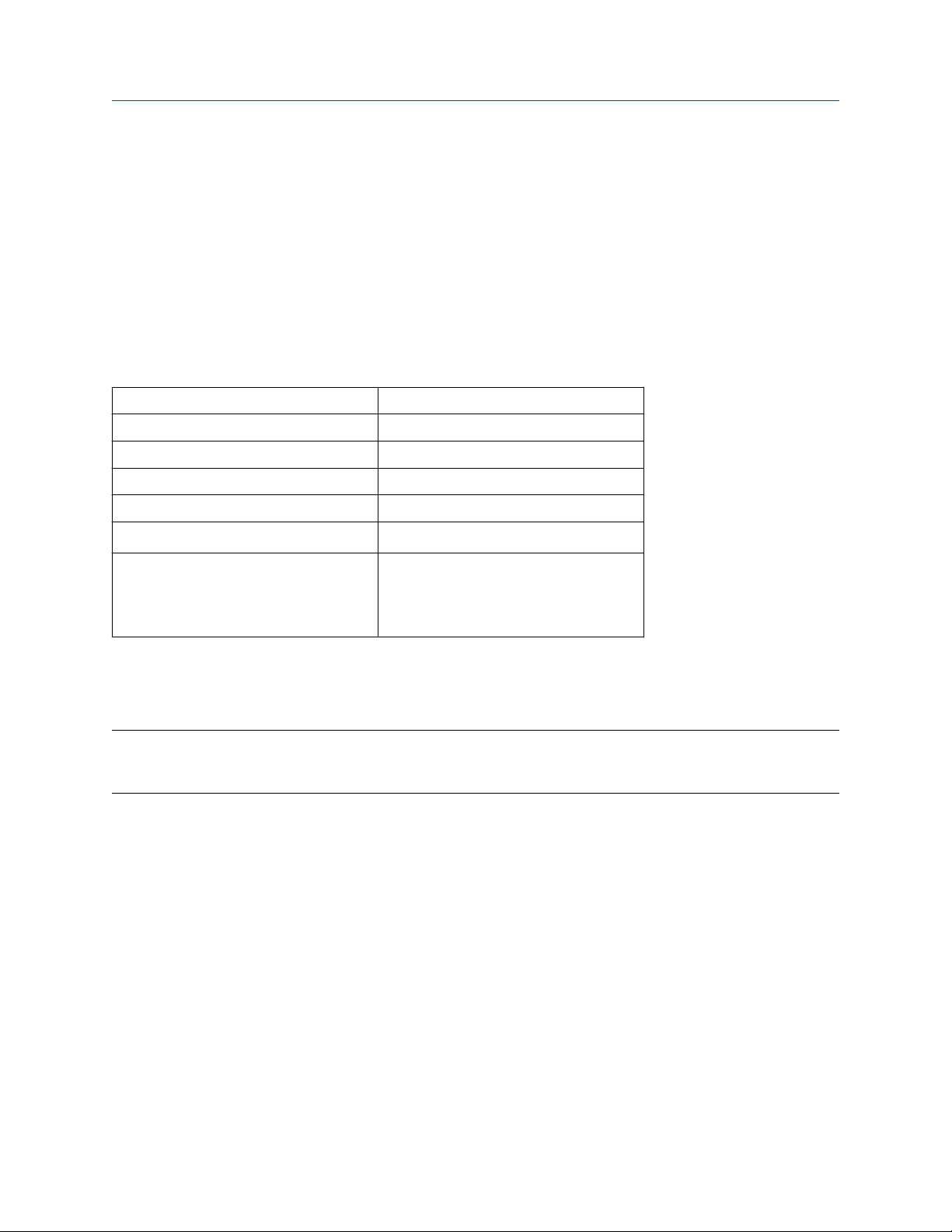

The Rosemount 848T transmitter is compatible with 2 or 3-wire RTD, thermocouple, ohm, and millivolt

sensor types. Figure 2-10 shows the correct input connections to the sensor terminals on the transmitter. The

Rosemount 848T can also accept inputs from analog devices using the optional analog input connector.

Figure 2-11 shows the correct input connections to the analog input connector when installed on the

transmitter. Tighten the terminal screws to ensure proper connection.

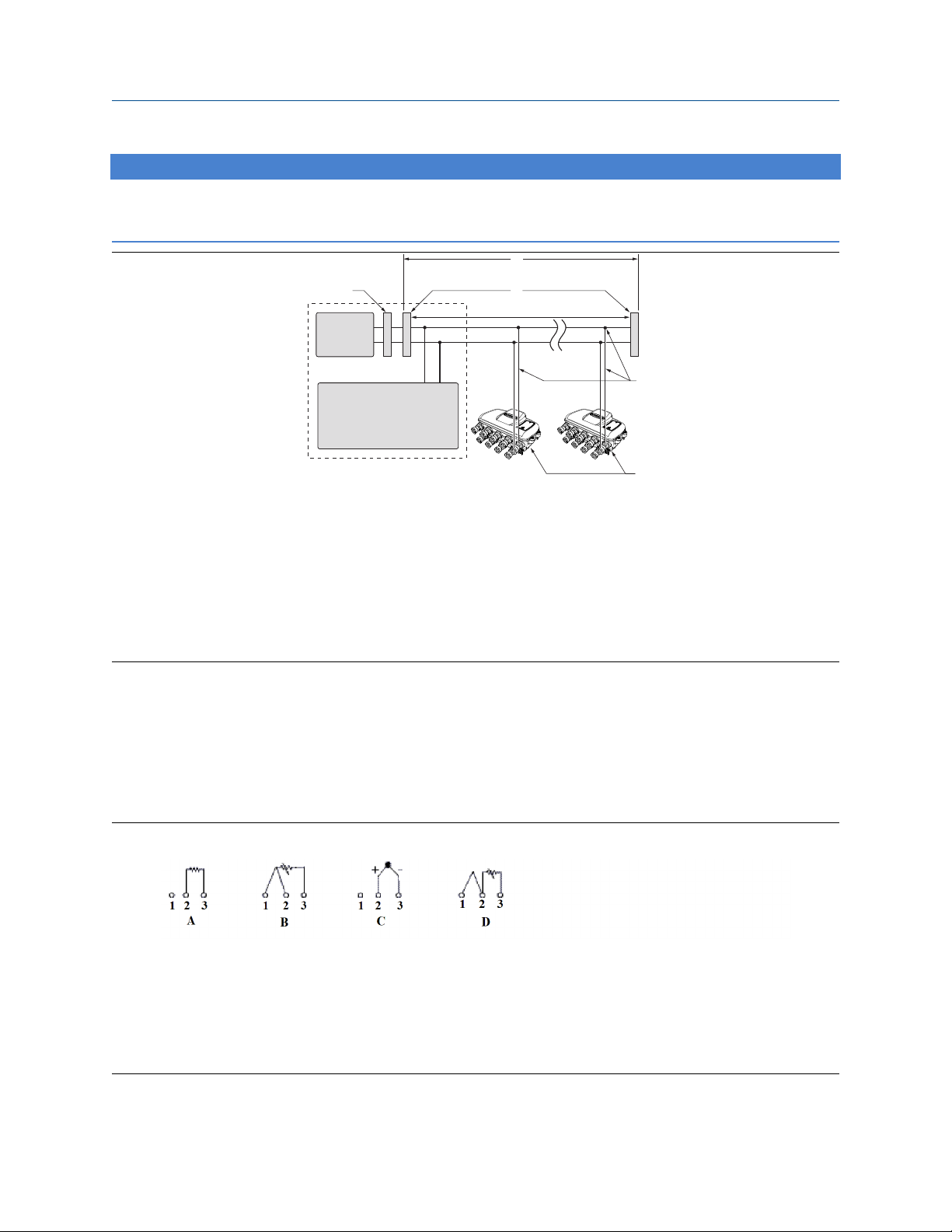

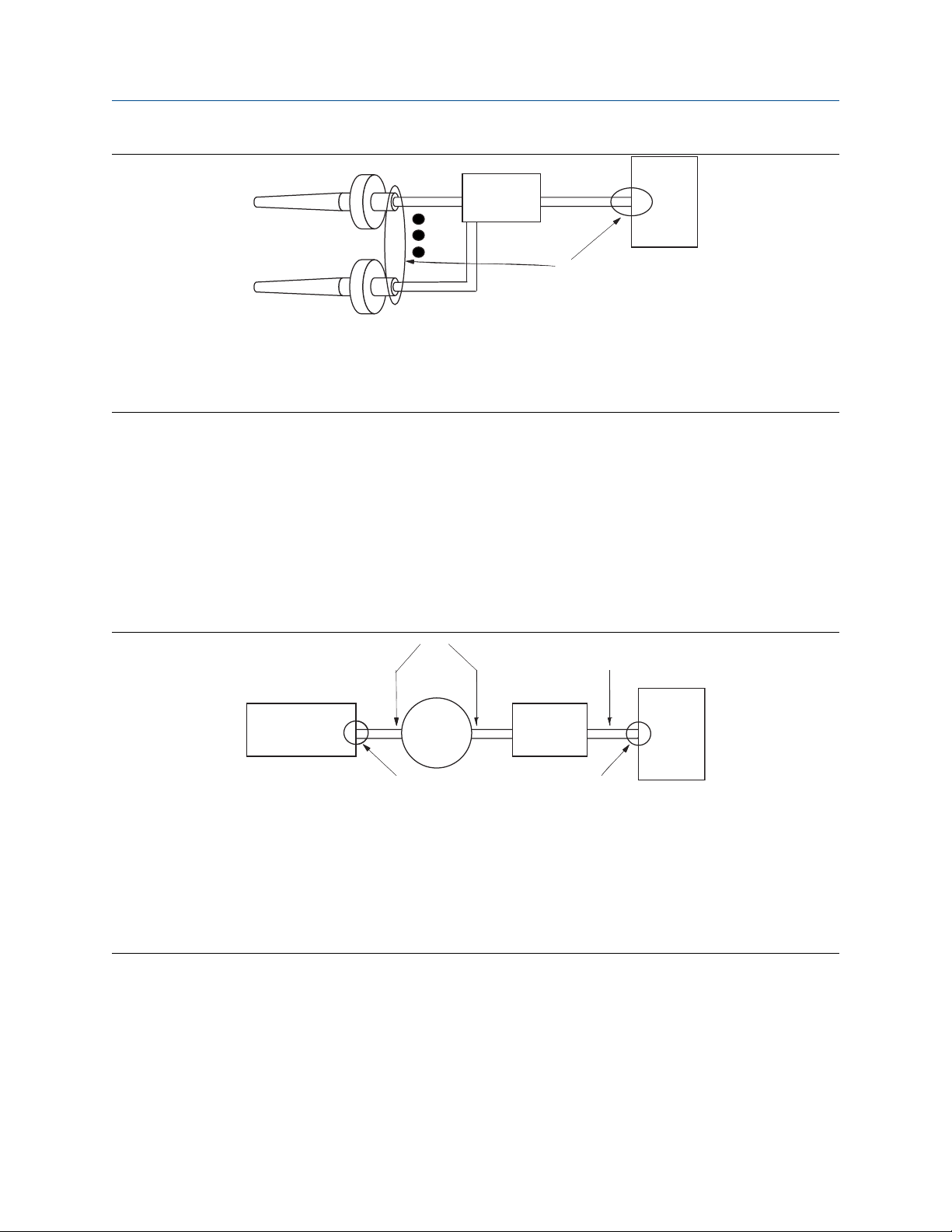

Figure 2-10: Sensor wiring diagram

A. 2-wire RTD and ohms

B. 3-wire RTD and ohms (Emerson provides 4-wire sensors for all single-element RTDs; use these RTDs in 3-wire

configurations by clipping the fourth lead or leaving it disconnected and insulated with electrical tape.)

C. Thermocouples/ohms and millivolts

D. 2-wire RTD with compensation loop (transmitter must be configured for a 3-wire RTD in order to recognize

an RTD with a compensation loop)

Emerson.com/Rosemount 17

Installation Reference Manual

January 2022 00809-0100-4697

RTD or ohm inputs

Various RTD configurations, including 2-wire and 3-wire are used in industrial applications. If the transmitter is

mounted remotely from a 3-wire RTD, it will operate within specifications, without recalibration, for lead wire

resistances of up to 60 ohms per lead (equivalent to 6,000 ft (1,829 m) of 20 AWG (0.518 mm²) wire). If using

a 2-wire RTD, both RTD leads are in series with the sensor element, so errors can occur if the lead lengths

exceed one foot of 20 AWG (0.518 mm²) wire. Compensation for this error is provided when using 3-wire

RTDs.

Thermocouple or millivolt inputs

Use appropriate thermocouple extension wire to connect the thermocouple to the transmitter. Make

connections for millivolt inputs using copper wire. Use shielding for long runs of wire.

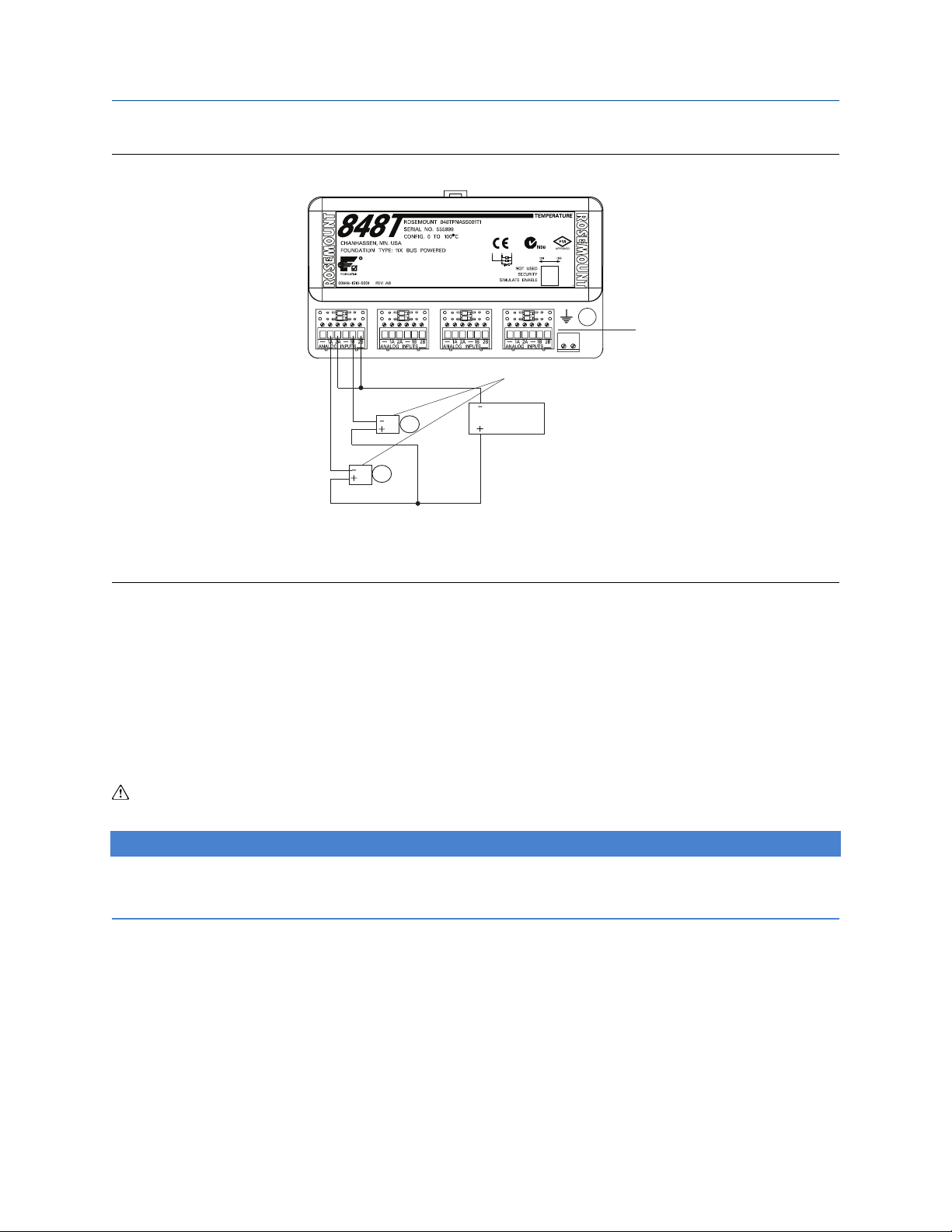

Analog inputs

The analog connector converts the 4–20 mA signal to a 20–100 mV signal that can be read by the transmitter

and transmitted using FOUNDATION Fieldbus.

Use the following steps when installing the transmitter with the analog connector:

Procedure

1. The Rosemount 848T, when ordered with option code S002, comes with four analog connectors.

Replace the standard connector with the analog connector on the desired channels.

2. Wire one or two analog transmitters to the analog connector according to Figure 2-11. There is space

available on the analog connector label for identification of the analog inputs.

Note

Power supply should be rated to support the connected transmitter(s).

3. If the analog transmitters can communicate using HART® protocol, the analog connectors are supplied

with the ability to switch in a 250 ohm resistor for HART communication (see Figure 2-11). One switch

is supplied for each input (top switch for A inputs and bottom switch for B inputs). Setting the switch in

the ON position (to the right) bypasses the 250 ohm resistor. Terminals are provided for each analog

input to connect a field communicator for local configuration.

18 Emerson.com/Rosemount

A

C

B

Reference Manual

00809-0100-4697 January 2022

Figure 2-11: Rosemount 848T Analog Input Wiring Diagram

Installation

A. Analog input connectors

B. Analog transmitters

C. Power supply

2.2.2 Power supply

Connect the power supply

The transmitter requires between 9 and 32 VDC to operate and provide complete functionality. The DC

power supply should provide power with less than 2% ripple. A fieldbus segment requires a power conditioner

to isolate the power supply filter and decouple the segment from other segments attached to the same

power supply.

All power to the transmitter is supplied over the signal wiring. Signal wiring should be shielded, twisted

pair for best results in electrically noisy environments.

NOTICE

For best performance, do not use unshielded signal wiring in open trays with power wiring or near heavy

electrical equipment.

Use ordinary copper wire of sufficient size to ensure the voltage across the transmitter power terminals does

not go below 9 VDC. The power terminals are polarity insensitive. To power the transmitter:

Procedure

1. Connect the power leads to the terminals marked Bus, as shown in Figure 2-12.

2. Tighten the terminal screws to ensure adequate contact. No additional power wiring is necessary.

Emerson.com/Rosemount 19

NOT USED

SECURITY

SIMULA

TE ENABLE

A

B

Installation

January 2022 00809-0100-4697

Figure 2-12: Transmitter label

A. Ground (required with T1 option)

B. Connect power leads here

Reference Manual

2.2.3 Surges/transients

The transmitter will withstand electrical transients encountered through static discharges or induced

switching transients. However, a transient protection option (option code T1) is available to protect the

transmitter against high-energy transients. The device must be properly grounded using the ground terminal

(see Figure 2-12).

2.3 Grounding

The Rosemount 848T transmitter provides input/output isolation up to 620 V rms.

NOTICE

Neither conductor of the fieldbus segment can be grounded. Grounding out one of the signal wires will shut

down the entire fieldbus segment.

2.3.1 Shielded wire

Each process installation has different requirements for grounding. Use the grounding options recommended

by the facility for the specific sensor type or begin with grounding option 1 (most common).

Ungrounded thermocouple, mV, and RTD/ohm inputs

There are two options for ungrounded thermocouple, mV, and RTD/ohm inputs.

Option 1

Procedure

1. Connect signal wiring shield to the sensor wiring shield(s).

2. Ensure shields are tied together and electrically isolated from transmitter enclosure.

3. Only ground shield at the power supply end.

4. Ensure sensor shield(s) is electrically isolated from the surrounding grounded fixtures.

20 Emerson.com/Rosemount

A

B

C

D

A

B

C

D

Reference Manual

00809-0100-4697 January 2022

A. Sensor wires

B. Rosemount™ 848T

C. Power supply

D. Shield ground point

Installation

Option 2

Procedure

1. If the enclosure is grounded, connect sensor wiring shield(s) to the transmitter enclosure.

2. Ensure sensor shield(s) is electrically isolated from surrounding fixtures that may be grounded.

3. Ground signal wiring shield at the power supply end.

A. Sensor wires

B. Rosemount 848T

C. Power supply

D. Shield ground points

Grounded thermocouple inputs

Procedure

1. Ground sensor wiring shield(s) at the sensor.

2. Ensure that the sensor wiring and signal wiring shields are electrically isolated from the transmitter

enclosure.

3. Do not connect the signal wiring shield to the sensor wiring shield(s).

4. Ground signal wiring shield at the power supply end.

Emerson.com/Rosemount 21

A

B

C

D

C

D

A

E F

G

G

B

Installation

January 2022 00809-0100-4697

A. Sensor wires

B. Rosemount 848T

C. Power supply

D. Shield ground points

Reference Manual

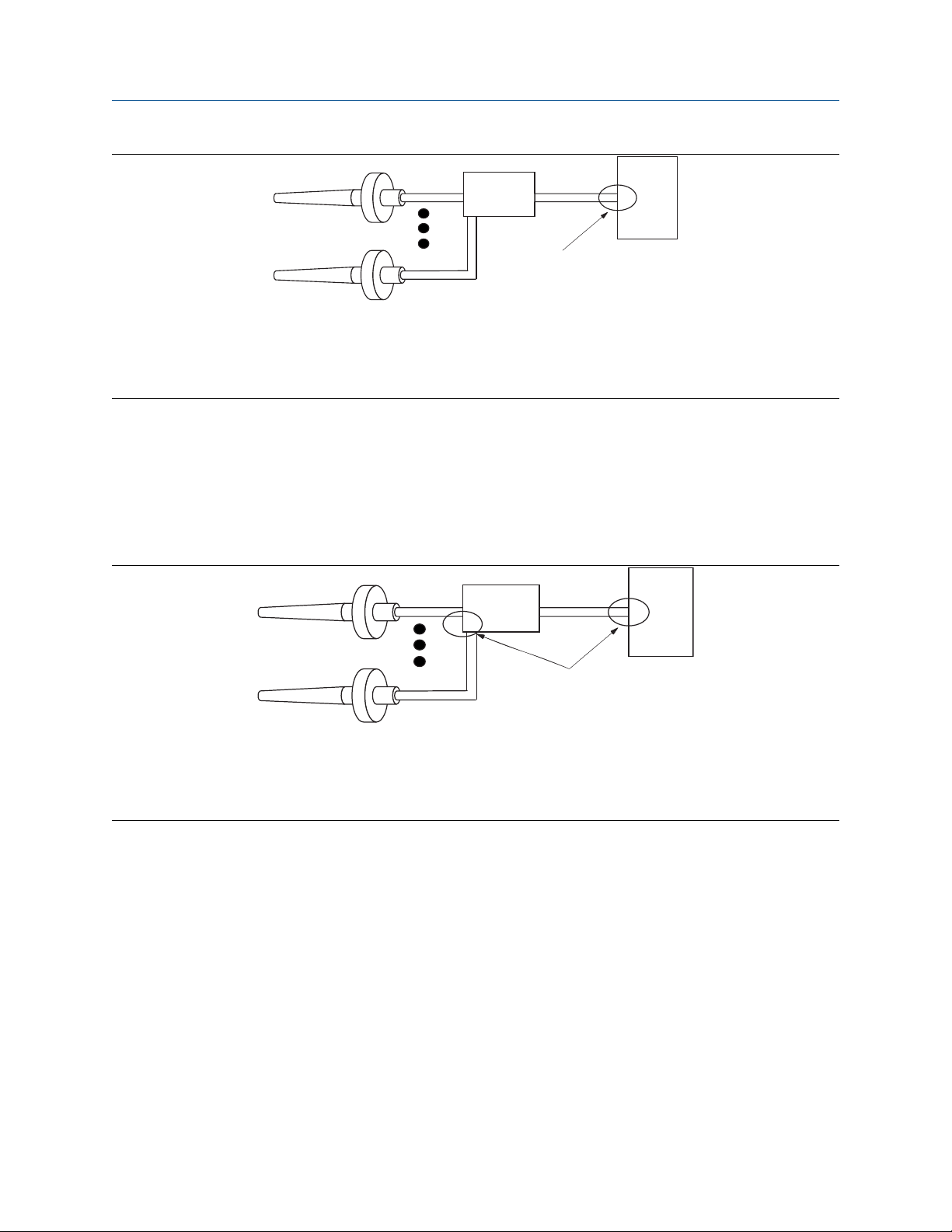

Analog device inputs

Procedure

1. Ground analog signal wire at the power supply of the analog devices.

2. Ensure the analog signal wire and the fieldbus signal wire shields are electrically isolated from the

transmitter enclosure.

3. Do not connect the analog signal wire shield to the fieldbus signal wire shield.

4. Ground fieldbus signal wire shield at the power supply end.

A. 4-20 mA loop

B. FOUNDATION Fieldbus

C. Analog device power supply

D. Analog device

E. Rosemount 848T

F. Power supply

G. Shield ground points

2.3.2 Transmitter enclosure (optional)

Procedure

Ground the transmitter in accordance with local electrical requirements.

22 Emerson.com/Rosemount

NOT USED

SECURITY

SIMULATE ENABLE

Reference Manual Installation

00809-0100-4697 January 2022

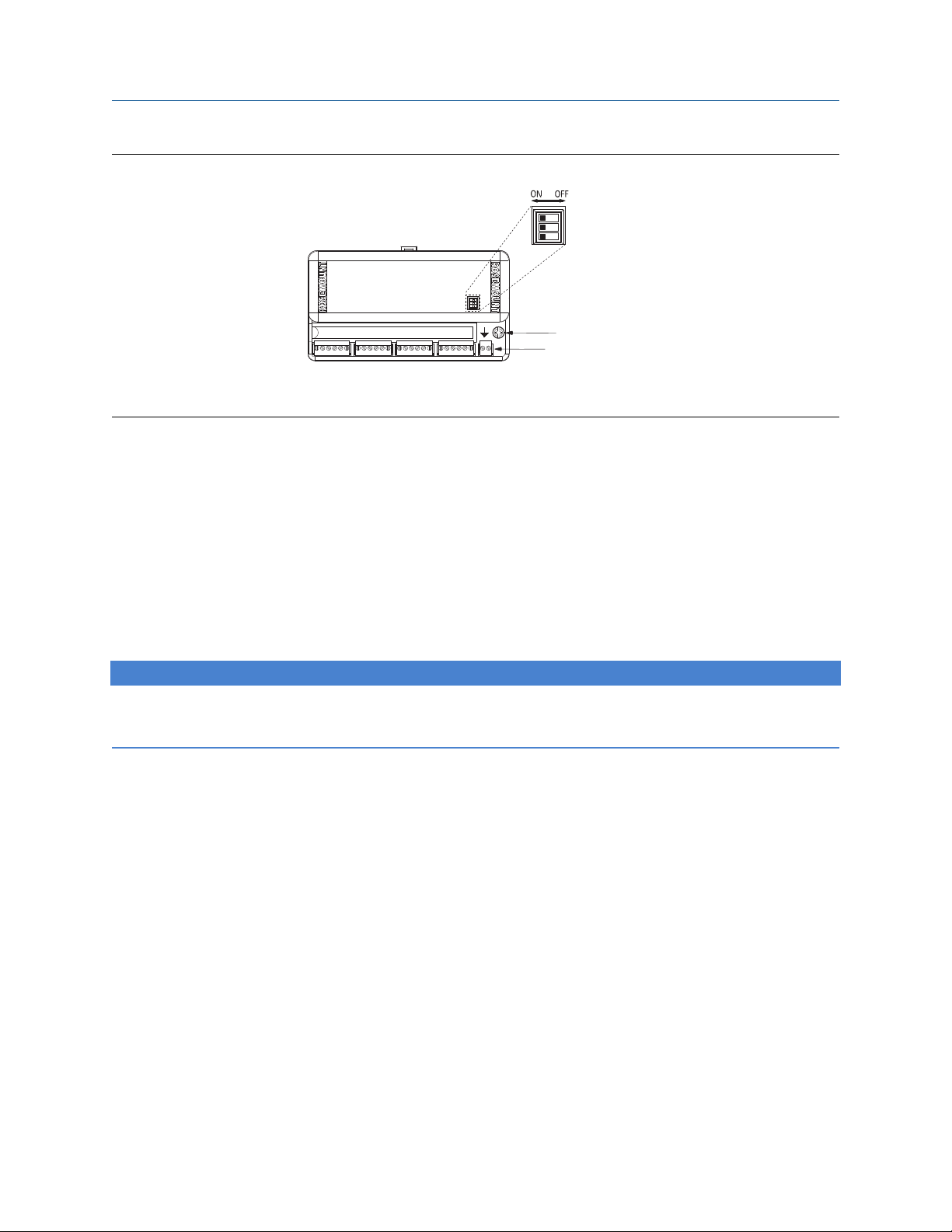

2.4 Switches

Figure 2-13: Switch location on the transmitter

Security

After configuring the transmitter, the data can be protected from unwarranted changes. Each transmitter is

equipped with a security switch that can be positioned ON to prevent the accidental or deliberate change of

configuration data. This switch is located on the front side of the electronics module and is labeled SECURITY.

For the switch location on the transmitter label, see Figure 2-13.

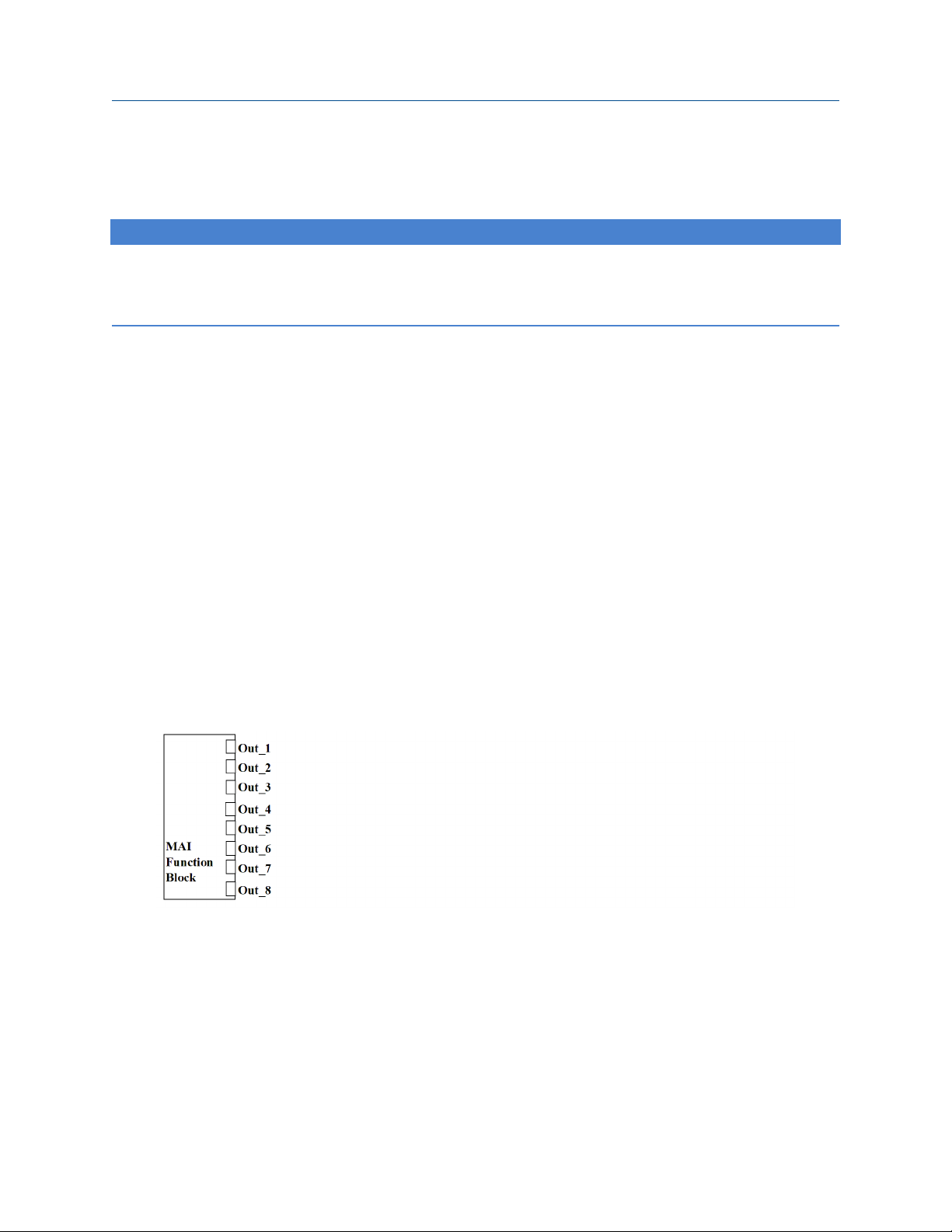

Simulate enable

The switch labeled SIMULATE ENABLE is used in conjunction with the Analog Input (AI) and Multiple Analog

Input (MAI) function blocks. This switch is used to simulate temperature measurement.

Not used

The switch is not functional.

2.5 Tagging

Commissioning tag

The Rosemount 848T has been supplied with a removable commissioning tag that contains both the Device

ID (the unique code that identifies a particular device in the absence of a device tag) and a space to record the

device tag (the operational identification for the device as defined by the Piping and Instrumentation Diagram

[P&ID]).

When commissioning more than one device on a fieldbus segment, it can be difficult to identify which device

is at a particular location. The removable tag, provided with the transmitter, can aid in this process by linking

the Device ID to its physical location. The installer should note the physical location of the transmitter on both

the upper and lower location of the commissioning tag. The bottom portion should be torn off for each

device on the segment and used for commissioning the segment in the control system.

Emerson.com/Rosemount 23

A

B

Installation

Reference Manual

January 2022 00809-0100-4697

Figure 2-14: Commissioning tag

A. Device ID

B. Device tag to denote physical location

Transmitter tag

Hardware

Software • The transmitter can store up to 32 characters.

• Tagged in accordance with customer requirements

• Permanently attached to the transmitter

• If no characters are specified, the first 30 characters of

the hardware tag will be used.

Sensor tag

Hardware

Software • If sensor tagging is requested, the Transducer Block

• A plastic tag is provided to record identification of eight

sensors.

• This information can be printed at the factory upon

request.

• In the field, the tag can be removed, printed onto, and

reattached to the transmitter.

SERIAL_NUMBER parameters will be set at the factory.

• The SERIAL_NUMBER parameters can be updated in the

field.

2.6 Installation

2.6.1 Using cable glands

Procedure

1. Remove the junction box cover by unscrewing the cover screws.

24 Emerson.com/Rosemount

%

+,-.

&'()*$

Reference Manual Installation

00809-0100-4697 January 2022

2. Run the sensor and power/signal wires through the appropriate cable glands (see Figure 2-15).

3. Install the sensor wires into the correct screw terminals (follow the label on the electronics module).

4. Install the power/signal wires onto the correct screw terminals. Power is polarity insensitive, allowing

the user to connect positive (+) or negative (–) to either fieldbus wiring terminal labeled “Bus”.

5. Replace the enclosure cover and securely tighten all cover screws.

Figure 2-15: Installing the transmitter with cable glands

A. Enclosure cover screws (2)

B. Cable glands (9)

C. Sensor 1

D. Sensor 3

E. Sensor 5

F. Sensor 7

G. Power/signal

H. Sensor 2

I. Sensor 4

J. Sensor 6

K. Sensor 8

Emerson.com/Rosemount 25

Installation Reference Manual

January 2022 00809-0100-4697

26 Emerson.com/Rosemount

Reference Manual Configuration

00809-0100-4697 January 2022

3 Configuration

3.1 Standard configuration

Each FOUNDATION Fieldbus configuration tool or host system has a different way of displaying and performing

configurations. Some will use Device Descriptions (DDs) and DD Methods to make configuration and

displaying of data consistent across host platforms.

Unless otherwise specified, the transmitter will be shipped with the following configuration (default):

Table 3-1: Standard configuration settings

(1)

(1)

(1)

(1)

(1)

Type J Thermocouple

5 seconds

°C

Linear with Temperature

60 Hz

Sensor Type

Damping

Measurement Units

Output

Line Voltage Filter

Temperature Specific Blocks • Transducer Block (1)

FOUNDATION Fieldbus Function Blocks • Analog Input (8)

• Multiple Analog Input (2)

• Input Selector (4)

(1) For all eight sensors

Refer to the systems documentation to perform configuration changes using a FOUNDATION Fieldbus host or

configuration tool.

Note

To make configuration changes, ensure that the block is Out of Service (OOS) by setting the

MODE_BLK.TARGET to OOS, or set the SENSOR_MODE to Configuration.

3.2 Transmitter configuration

The transmitter is available with the standard configuration setting. The configuration settings and block

configuration may be changed in the field with the Emerson Process Management Systems DeltaV™, with

AMS™ inside, or other FOUNDATION Fieldbus host or configuration tool.

3.3 Custom configuration

Custom configurations are specified when ordering.

Emerson.com/Rosemount 27

Configuration Reference Manual

January 2022 00809-0100-4697

3.4 Configure methods

For FOUNDATION Fieldbus hosts or configuration tools that support device description (DD) methods, there are

two configuration methods available in the transducer block. These methods are included with the DD

software.

• Sensor Configuration

• Sensor Input Trim (user input trim)

See the host system documentation for information on running DD methods from the host system. If the

FOUNDATION Fieldbus host or configuration tool does not support DD methods, for information on how to

modify sensor configuration parameters, refer to Configure blocks.

3.5 Configure alarms

Use the following steps to configure the alarms, which are located in the Resource Function Block:

Procedure

1. Set the resource block to OOS.

2. Set WRITE_PRI to the appropriate alarm level (WRITE_PRI has a selectable range of priorities from 0 to

15, see Table 3-4. Set the other block alarm parameters at this time.

3. Set CONFIRM_TIME to the time, in 1/32 of a millisecond, that the device will wait for confirmation of

receiving a report before trying again (the device does not retry if CONFIRM_TIME is 0).

4. Set LIM_NOTIFY to a value between zero and MAX_NOTIFY. LIM_NOTIFY is the maximum number of

alert reports allowed before the operator needs to acknowledge an alarm condition.

5. Enable the reports bit in FEATURES_SEL. (When multi-bit alerts is enabled, every active alarm is visible

for any of the eight sensors, generated by a Plantweb™ and field diagnostics alert. This is different than

only viewing the highest priority alarm.)

6. Set the resource block to AUTO.

For modifying alarms on individual function blocks (AI or ISEL blocks), refer to Function blocks.

3.6 Configure damping

Use the following steps to configure the damping, which is located in the transducer function block:

Procedure

1. Set Sensor Mode to Out of Service.

2. Change DAMPING to the desired filter rate (0.0 to 32.0 seconds).

3. Set Sensor Mode to In Service.

3.7 Configure the differential sensors

Use the following steps to configure the differential sensors:

28 Emerson.com/Rosemount

Reference Manual Configuration

00809-0100-4697 January 2022

Procedure

1. Set Dual Sensor Mode to Out of Service.

2. Set Input A and Input B to the sensor values that are to be used in the differential equation diff = A–B.

Note

Unit types must be the same.

3. Set the DUAL_SENSOR_CALC to either Not Used, Absolute, or INPUT A minus INPUT B.

4. Set Dual Sensor Mode to In Service.

3.8 Configure measurement validation

Use the following steps to configure measurement validation:

Procedure

1. Set mode to Disabled for specific sensor.

2. Select sample rate. 1-10 sec/sample is available. 1 second/sample is preferred for sensor degradation.

The higher the number of seconds between samples, the more emphasis put on process variation.

3. Select Deviation Limit from 0 to 10 units. If deviation limit is exceeded, a status event will be triggered.

4. Select Increasing Limit. Sets the limit for increasing rate of change. If limit is exceeded, a status event

will be triggered.

5. Select Decreasing Limit. Sets the limit for decreasing rate of change. If limit is exceeded, a status event

will be triggered.

Note

The decreasing limit selected is required to be a negative value.

6. Set the Deadband from 0 to 90%. This threshold is used to clear the PV status.

7. Set Status Priority. This determines what happens when the specific limit has been exceeded.

No Alert Ignores limit settings

Advisory Sets a Advisory Plant Web Alert, but does not do

anything with PV status

Warning Sets a Maintenance Plant Web Alert and sets PV status

to uncertain

Failure Sets a Failure Plant Web Alert and sets PV status to Bad

8. Set mode to Enabled for specific sensor.

3.9 Common configurations for high density applications

For the application to work properly, configure the links between the function blocks and schedule the order

of their execution. The Graphical User Interface (GUI) provided by the FOUNDATION Fieldbus host or

configuration tool will allow easy configuration.

Emerson.com/Rosemount 29

Configuration Reference Manual

January 2022 00809-0100-4697

The measurement strategies shown in this section represent some of the common types of configurations

available in the Rosemount 848T. Although the appearance of the GUI screens will vary from host to host, the

configuration logic is the same.

NOTICE

Ensure the host system or configuration tool is properly configured before downloading the transmitter

configuration. If configured improperly, the FOUNDATION Fieldbus host or configuration tool could overwrite

the default transmitter configuration.

3.9.1 Configure a typical profiling application

Procedure

1. Place the Multiple Analog Input (MAI) function block in OOS mode (set MODE_BLK.TARGET to OOS).

2. Set CHANNEL = channels 1 to 8. Although the CHANNEL_X parameters remain writable, CHANNEL_X

can only be set = X when CHANNEL = 1.

3. Set L_TYPE to direct or indirect.

4. Set XD_SCALE (transducer measurement scaling) to the appropriate upper and lower range values, the

appropriate sensor units, and display decimal point.

5. Set OUT_SCALE (MAI output scaling) to the appropriate upper and lower range values, the appropriate

sensor units, and display decimal point.

6. Place the MAI Function Block in auto mode.

7. Verify that the function blocks are scheduled.

Example

The following illustration describes a distillation column temperature profile where all channels have the

same sensor units (°C, °F, etc.).

3.9.2 Monitor an application with a single selection

Procedure

1. Link the MAI outputs to the ISEL inputs.

2. Place the Multiple Analog Input (MAI) function block in OOS mode (set MODE_BLK.TARGET to OOS).

3. Set CHANNEL = channels 1 to 8. Although the CHANNEL_X parameters remain writable, CHANNEL_X

can only be set = X when CHANNEL = 1.

4. Set L_TYPE to direct or indirect.

30 Emerson.com/Rosemount

Loading...

Loading...