Rosemount Manual: Rosemount 644 Head and Rail Mount Temperature Transmitters Manuals & Guides

Reference Manual

00809-0100-4728, Rev KA

July 2010

Rosemount 644 Head and Rail Mount

Temperature Transmitters

www.rosemount.com

Reference Manual

NOTICE

00809-0100-4728, Rev KA

July 2010

Rosemount 644

Rosemount 644

Temperature Transmitters

Rosemount 644 Hardware Revision

®

Device Revision

HART

Field Communicator Field Device Revision

OUNDATION

F

OUNDATION fieldbus Device Revision

F

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure to thoroughly understand the contents before

installing, using, or maintaining this product.

The United States has two toll-free assistance numbers and one international number.

Customer Central

1-800-999-9307 (7:00 a.m. to 7:00 P.M. CST)

National Response Center

1-800-654-7768 (24 hours a day)

Equipment service needs

International

1-(952) 906-8888

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact a Emerson Process

Management Sales Representative.

™

fieldbus Hardware Revision

26

5.6

Dev v6, DD v1

5

1

www.rosemount.com

Reference Manual

00809-0100-4728, Rev KA

July 2010

Table of Contents

Rosemount 644

SECTION 1

Introduction

SECTION 2

Installation

SECTION 3

HART

Configuration

SECTION 4

Foundation

fieldbus

Configuration

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

AMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Multidrop Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Block Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Foundation fieldbus function blocks . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

APPENDIX A

Specifications and

Reference Data

APPENDIX B

Product

Certifications

APPENDIX C

Foundation

fieldbus Block

Information

HART and Foundation Fieldbus Specifications . . . . . . . . . . . . . . . . . A-1

Foundation Fieldbus Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

4–20 mA / HART Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

Stainless Steel Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

European Union Directive Information . . . . . . . . . . . . . . . . . . . . . . . . B-1

Hazardous Locations Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Installation Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Basic Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Resource Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Sensor Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Analog Input (AI) Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

LCD Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

PID Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-13

TOC-1

Reference Manual

00809-0100-4728, Rev KA

July 2010

Rosemount 644

TOC-2

Reference Manual

00809-0100-4728, Rev KA

July 2010

Rosemount 644

Section 1 Introduction

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 1-2

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 1-3

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-4

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

potentially raises safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Warnings

Failure to follow these installation guidelines could result in death or

serious injury.

• Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

• Do not remove the connection head cover in explosive atmospheres when the

circuit is live.

• Before connecting HART or F

make sure the instruments in the loop are installed in accordance with intrinsically

safe or non-intrinsic field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• All connection head covers must be fully engaged to meet

explosion-proof requirements.

Process leaks could result in death or serious injury.

• Do not remove the thermowell while in operation.

• Install and tighten thermowells and sensors before applying pressure

Electrical shock could cause death or serious injury.

• Use extreme caution when making contact with the leads and terminals.

OUNDATION fieldbus in an explosive atmosphere,

www.rosemount.com

Reference Manual

00809-0100-4728, Rev KA

Rosemount 644

OVERVIEW

Manual This manual is designed to assist in the installation, operation, and

maintenance of Rosemount 644 head mount and 644 rail mount.

Section 1: Introduction

• Transmitter and Manual Overview

• Considerations

• Return of Material

Section 2: Installation

• Mounting

• Installation

• Wiring

• Power Supply

• Commissioning

Section 3: HART Configuration

• Field Communicator

• Configuration

• Multidrop Communication

July 2010

Section 4: F

• Calibration

• Hardware Maintenance

• Diagnostic Messaging

Appendix A: Specifications and Reference Data

• Specifications

• Dimensional drawings

• Ordering Information

• Biotechnology, Pharmaceutical Industries, and Sanitary Applications

Appendix B: Approvals

• Product Certifications

• Installation Drawings

Appendix C: Foundation fieldbus Block Information

• Information regarding the Function Blocks

OUNDATION fieldbus Configuration

Transmitter Features of the Rosemount 644 include:

• Accepts inputs from a wide variety of sensors

• Configuration using HART protocol or F

• Electronics that are completely encapsulated in epoxy and enclosed in

a metal housing, making the transmitter extremely durable and

ensuring long-term reliability

• A compact size and two housing options allowing mounting flexibility for

the control room or the field

OUNDATION fieldbus

1-2

Reference Manual

00809-0100-4728, Rev KA

July 2010

Refer to the following literature for a full range of compatible connection

heads, sensors, and thermowells provided by Emerson Process

Management.

• Temperature Sensors and Assemblies Product Data Sheet, Volume 1

(document number 00813-0100-2654)

• Temperature Sensors and Assemblies Product Data Sheet, Volume 2

(document number 00813-0200-2654)

Rosemount 644

CONSIDERATIONS

General Electrical temperature sensors such as RTDs and thermocouples produce

low-level signals proportional to their sensed temperature. The 644 converts

the low-level sensor signal to a standard 4–20 mA dc, digital HART, or digital

OUNDATION fieldbus signal that is relatively insensitive to lead length and

F

electrical noise. This signal is then transmitted to the control room via two

wires.

Commissioning The transmitter can be commissioned before or after installation. It may be

useful to commission it on the bench, before installation, to ensure proper

operation and to become familiar with its functionality. Make sure the

instruments in the loop are installed in accordance with intrinsically safe,

FISCO, or non-incendive field wiring practices.

Mechanical Location

When choosing an installation location and position, take into account the

need for access to the transmitter.

Special Mounting

Special mounting hardware is available for mounting a 644 head mount

transmitter to a DIN rail, or assembling a new 644 head mount to an existing

threaded sensor connection head (former option code L1).

Electrical Proper electrical installation is necessary to prevent errors due to sensor lead

resistance and electrical noise. For best results, shielded cable should be

used in electrically noisy environments.

Make wiring connections through the cable entry in the side of the connection

head. Be sure to provide adequate clearance for cover removal.

Environmental The transmitter electronics module is permanently sealed within the housing,

resisting moisture and corrosive damage. Verify that the operating

atmosphere of the transmitter is consistent with the appropriate hazardous

locations certifications.

Temperature Effects

The transmitter will operate within specifications for ambient temperatures

between –40 and 185 °F (–40 and 85 °C). Heat from the process is

transferred from the thermowell to the transmitter housing. If the expected

process temperature is near or beyond specification limits, consider the use of

additional thermowell lagging, and extension nipple, or a remote mounting

configuration to isolate the transmitter from the process.

Figure 1-1 provides an example of the relationship between transmitter

housing temperature rise and extension length.

1-3

Rosemount 644

Housing Temperature Rise, Above

Ambient °C (°F)

3 4 5 6 7 8 9

0

60 (108)

50 (90)

40 (72)

30 (54)

20 (36)

10 (18)

3.6

22

Extension Length (in.)

815 °C (1500 °F) Oven Temperature

540 °C (1000 °F)

Oven Temperature

250 °C (482 °F) Oven Temperature

Figure 1-1. 644 head mount

Transmitter Connection Head

Temperature Rise vs. Extension

Length

Reference Manual

00809-0100-4728, Rev KA

July 2010

Example

The transmitter specification limit is 85 °C. If the ambient temperature is 55 °C

and the process temperature to be measured is 800 °C, the maximum

permissible connection head temperature rise is the transmitter specification

limit minus the ambient temperature (moves 85 to 55 °C), or 30 °C.

In this case, an extension of 100 mm meets this requirement, but 125 mm

provides a margin of 8 °C, thereby reducing any temperature effects in the

transmitter.

RETURN OF MATERIALS To expedite the return process in North America, call the Emerson Process

Management National Response Center toll-free at 800-654-7768. This

center, available 24 hours a day, will assist you with any needed information

or materials.

The center will ask for the following information:

• Product model

• Serial numbers

• The last process material to which the product was exposed

The center will provide

• A Return Material Authorization (RMA) number

• Instructions and procedures that are necessary to return goods that

were exposed to hazardous substances

For other locations, please contact a Emerson Process Management sales

representative.

NOTE

If a hazardous substance is identified, a Material Safety Data Sheet (MSDS),

required by law to be available to people exposed to specific hazardous

substances, must be included with the returned materials.

1-4

Reference Manual

00809-0100-4728, Rev KA

July 2010

Rosemount 644

Section 2 Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-9

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-13

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

potentially raises safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Warnings

Failure to follow these installation guidelines could result in death or

serious injury.

• Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

• Do not remove the connection head cover in explosive atmospheres when the

circuit is live.

• Before connecting a Field Communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with instrinsically safe or

non-incendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• All connection head covers must be fully engaged to meet

explosion-proof requirements.

Process leaks could result in death or serious injury.

• Do not remove the thermowell while in operation.

• Install and tighten thermowells and sensors before applying pressure

Electrical shock could cause death or serious injury.

• Use extreme caution when making contact with the leads and terminals.

www.rosemount.com

Rosemount 644

START

HERE

Bench

Calibration?

BASIC SETUP

Set Sensor Type

Set Number of Wires

Set Units

Set Range Values

Set Damping

VERIFY

Simulate Sensor Input

Within

Specifications?

Refer to Section 4: Foundation

fieldbus Configuration

FIELD INSTALL

Set Failure Mode

Switch

Mount Transmitter

Wire Transmitter

Power Transmitter

FINISHED

Does not apply to the 644

with F

OUNDATION fieldbus

Figure 2-1. Installation Flowchart

Reference Manual

00809-0100-4728, Rev KA

July 2010

2-2

Reference Manual

Transmitter

Mounting

Hardware

Rail Clip

Transmitter

Mounting

Hardware

Rail Clip

Kit includes

replacement bracket

and screws.

Existing Threaded Sensor Connection Head

(Former option code L1)

00809-0100-4728, Rev KA

July 2010

Rosemount 644

MOUNTING Mount the transmitter at a high point in the conduit run to prevent moisture

from draining into the transmitter housing.

The 644 head mount installs

• In a connection head or universal head mounted directly on a sensor

assembly

• Apart from a sensor assembly using a universal head

• To a DIN rail using an optional mounting clip.

The 644 rail mount attaches directly to a wall or to a DIN rail.

Mounting a 644H to a DIN Rail

To attach a head mount transmitter to a DIN rail, assemble the appropriate rail

mounting kit (part number 00644-5301-0010) to the transmitter as shown in

Figure 2-2. Follow the procedure under “Rail Mount Transmitter and Sensor

(HART only)”.

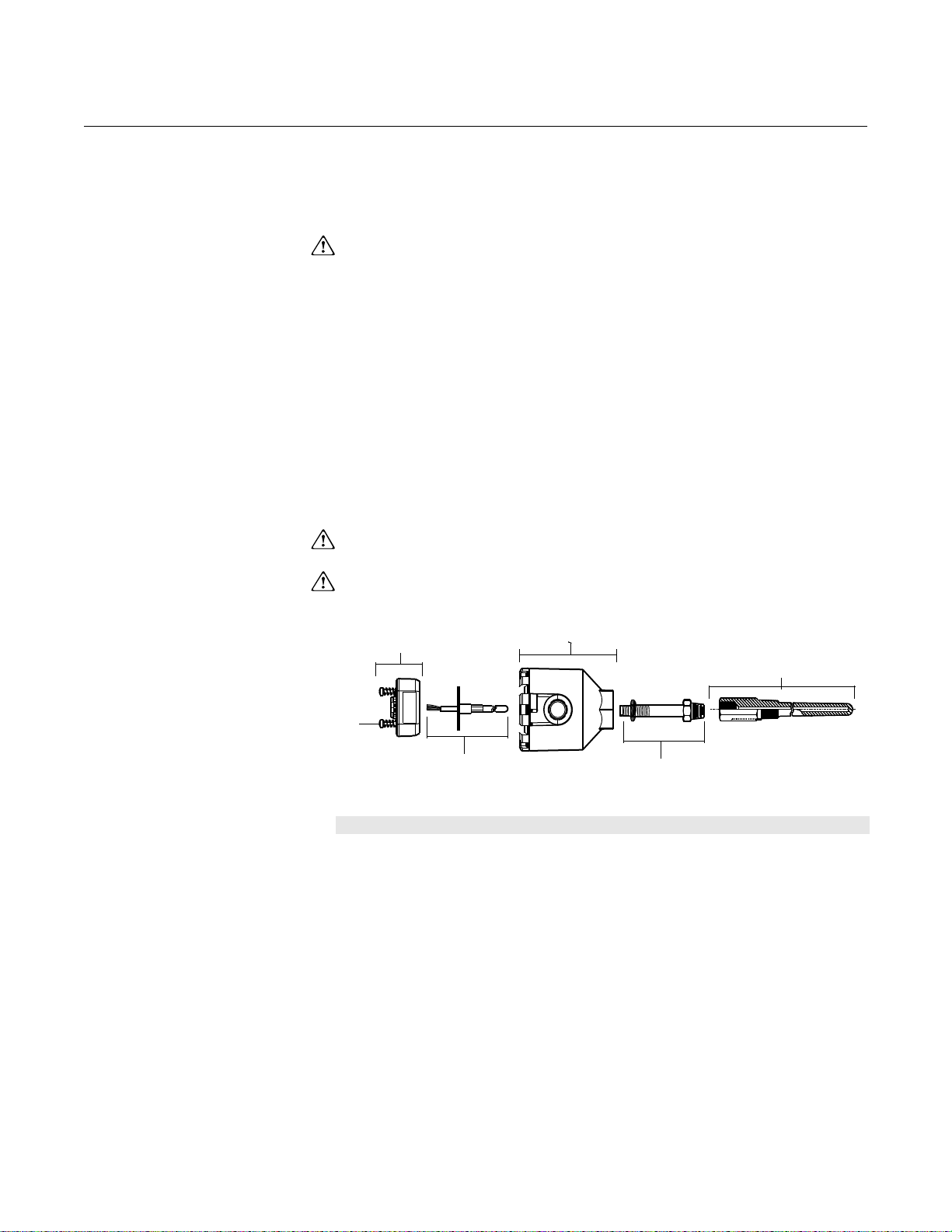

Figure 2-2. Assembling Rail Clip

Hardware to a 644H

G-Rail (asymmetric) Top Hat Rail (symmetric)

Figure 2-3. Assembling 644H for

Use in an Existing L1

Connection Head

Note: Kit includes Mounting Hardware and both types of Rail Kits.

Retrofitting a 644H for Use in an Existing Threaded Sensor Connection

Head

To mount a 644H in an existing threaded sensor connection head (former

option code L1), order the 644H retrofit kit (part number 00644-5321-0010).

The retrofit kit includes a new mounting bracket and all associated hardware

necessary to facilitate the installation of the 644H in the existing head. See

Figure 2-3.

2-3

Rosemount 644

A

D

B

C

E

F

INSTALLATION

Reference Manual

00809-0100-4728, Rev KA

July 2010

Typical European

Installation

Head Mount Transmitt er with DIN Plate Style Sensor

(HART and F

OUNDATION fieldbus)

1. Attach the thermowell to the pipe or process container wall. Install

and tighten the thermowell before applying process pressure.

2. Verify the transmitter failure mode switch (HART only).

3. Assemble the transmitter to the sensor. Push the transmitter

mounting screws through the sensor mounting plate and insert the

snap rings (optional) into the transmitter mounting screw groove.

4. Wire the sensor to the transmitter (see Figure 2-9 on page 2-11).

5. Insert the transmitter-sensor assembly into the connection head.

Thread the transmitter mounting screw into the connection head

mounting holes.Assemble the extension to the connection head.

Insert the assembly into the thermowell.

6. Attach a cable gland into the shielded cable.

7. Insert the shielded cable leads into the connection head through the

cable entry. Connect and tighten the cable gland.

8. Connect the shielded power cable leads to the transmitter power

terminals. Avoid contact with sensor leads and sensor connections.

9. Install and tighten the connection head cover. Enclosure covers must

be fully engaged to meet explosion-proof requirements.

A = 644H Transmitter D = Transmitter Mounting Screws

B = Connection Head E = Integral Mount Sensor with Flying Leads

C = Thermowell F = Extension

2-4

Reference Manual

A

B

C

D

E

00809-0100-4728, Rev KA

July 2010

Rosemount 644

Typical North American

Installation

Head Mount Transmitter with Threaded Sensor

(HART and F

OUNDATION fieldbus)

1. Attach the thermowell to the pipe or process container wall. Install

and tighten thermowells before applying process pressure.

2. Attach necessary extension nipples and adapters to the thermowell.

Seal the nipple and adapter threads with silicone tape.

3. Screw the sensor into the thermowell. Install drain seals if required for

severe environments or to satisfy code requirements.

4. Verify the transmitter failure mode switch (HART only).

5. Pull the sensor wiring leads through the universal head and

transmitter. Mount the transmitter in the universal head by threading

the transmitter mounting screws into the universal head mounting

holes.

6. Mount the transmitter-sensor assembly into the thermowell. Seal

adapter threads with silicone tape.

7. Install conduit for field wiring to the conduit entry of the universal

head. Seal conduit threads with silicone tape.

8. Pull the field wiring leads through the conduit into the universal head.

Attach the sensor and power leads to the transmitter. Avoid contact

with other terminals.

9. Install and tighten the universal head cover. Enclosure covers must

be fully engaged to meet explosion-proof requirements.

A = Threaded Thermowell D = Universal Head

B = Threaded Style Sensor E = Conduit Entry

C = Standard Extension

2-5

Rosemount 644

B

C

D

E

F

A

B

Reference Manual

00809-0100-4728, Rev KA

July 2010

Rail Mount Transmitter and Sensor

(HART only)

1. Attach the transmitter to a suitable rail or panel.

2. Attach the thermowell to the pipe or process container wall. Install

and tighten the thermowell, according to plant standards, before

applying pressure.

3. Attach the sensor to the connection head and mount the entire

assembly to the thermowell.

4. Attach and connect sufficient lengths of sensor lead wire from the

connection head to the sensor terminal block.

5. Tighten the connection head cover. Enclosure covers must be fully

engaged to meet explosion-proof requirements.

6. Run sensor lead wires from the sensor assembly to the transmitter.

7. Verify the transmitter failure mode switch.

8. Attach the sensor wires to the transmitter (see Figure 2-9 on

page 2-11).

A = Rail Mount Transmitter

B = Sensor Leads with Cable Glands

C = Integral Mount Sensor with Terminal Block

D = Connection Head

E = Standard Extension

F = Threaded Thermowell

2-6

Reference Manual

A

D

E

C

B

00809-0100-4728, Rev KA

July 2010

Rosemount 644

Rail Mount Transmitter with Threaded Sensor

(HART only)

1. Attach the transmitter to a suitable rail or panel.

2. Attach the thermowell to the pipe or process container wall. Install

and tighten the thermowell before applying pressure.

3. Attach necessary extension nipples and adapters. Seal the nipple

and adapter threads with silicone tape.

4. Screw the sensor into the thermowell. Install drain seals if required for

severe environments or to satisfy code requirements.

5. Screw the connection head to the sensor.

6. Attach the sensor lead wires to the connection head terminals.

7. Attach additional sensor lead wires from the connection head to the

transmitter.

8. Attach and tighten the connection head cover. Enclosure covers must

be fully engaged to meet explosion-proof requirements.

9. Set the transmitter failure mode switch

10. Attach the sensor wires to the transmitter (see Figure 2-9 on

page 2-11).

A = Rail Mount Transmitter C = Standard Extension

B = Threaded Sensor Connection Head D = Threaded Style Sensor

E = Threaded Thermowell

2-7

Reference Manual

644H

Captive Mounting Screws and Springs

Meter Spacer

LCD Display

10 pin Connector

00809-0100-4728, Rev KA

Rosemount 644

July 2010

LCD Display Installation The LCD display provides local indication of the transmitter output and

abbreviated diagnostic messages governing transmitter operation.

Transmitters ordered with the LCD display are shipped with the meter

installed. After-market installation of the meter can be performed the

transmitter has a meter connector (transmitter revision 5.5.2 or later).

After-market installation requires the meter kit (part number

00644-4430-0001), which includes:

• LCD display assembly (includes LCD display, meter spacer,

and 2 screws)

• Meter cover with O-ring in place

Figure 2-4. Installing the LCD

Display

Use the following procedure to install the meter.

1. If the transmitter is installed in a loop, secure the loop and disconnect

the power. If the transmitter is installed in an enclosure, remove the

cover from the enclosure.

2. Decide meter orientation (the meter can be rotated in 90°

increments). To change meter orientation, remove the screws located

above and below the display screen. Lift the meter off the meter

spacer. Remove the 8-pin plug and re-insert it in the location that will

result in the desired viewing orientation.

3. Reattach the meter to the meter spacer using the screws. If the meter

was rotated 90° from its original position it will be necessary to

remove the screws from their original holes and re-insert them in the

adjacent screws holes.

4. Line up the 10-pin connector with the 10-pin socket and push the

meter into the transmitter until it snaps into place.

5. Attach the meter cover; tighten at least one-third turn after the O-ring

contacts the transmitter housing. The cover must be fully engaged to

meet explosion-proof requirements.

6. Use a Field Communicator, AMS software, or a F

OUNDATION fieldbus

Communication tool to configure the meter to the desired display.

Refer to “LCD Meter Options ( 644H Only)” for information on

configuring the LCD display.

2-8

NOTE

Observe the following LCD display temperature limits:

Operating: –4 to 185 °F (–20 to 85 °C)

Storage: –50 to 185 °F (–45 to 85 °C)

Reference Manual

Transmitter

No. 1

Transmitter

No. 2

R

Lead

R

Lead

R

Lead

Readout or

Controller No. 1

Readout or

Controller No. 2

To Additional

Transmitters

dc

Power

Supply

Backup

Battery

Between 250 and 1100 if no load resistor.

00809-0100-4728, Rev KA

July 2010

Rosemount 644

Multichannel

Installations (HART)

In a HART installation, several transmitters can be connected to a single

master power supply, as shown in Figure 2-5. In this case, the system may be

grounded only at the negative power supply terminal. In multichannel

installations where several transmitters depend on one power supply and the

loss of all transmitters would cause operational problems, consider an

uninterrupted power supply or a back-up battery. The diodes shown in

Figure 2-5 prevent unwanted charging or discharging of the back-up battery.

Figure 2-5. Multichannel

Installations

WIRING All power to the transmitter is supplied over the signal wiring. Use ordinary

copper wire of sufficient size to ensure that the voltage across the transmitter

power terminals does not drop below 12.0 VDC for HART or 9 VDC for

OUNDATION fieldbus.

F

If the sensor is installed in a high-voltage environment and a fault condition or

installation error occurs, the sensor leads and transmitter terminals could

carry lethal voltages. Use extreme caution when making contact with the

leads and terminals.

NOTE

Do not apply high voltage (e.g., ac line voltage) to the transmitter terminals.

Abnormally high voltage can damage the unit. (Sensor and transmitter power

terminals are rated to 42.4 VDC. A constant 42.4 volts across the sensor

terminals may damage the unit.)

For multichannel HART installations, see above. The transmitters will accept

inputs from a variety of RTD and thermocouple types. Refer to Figure 2-6 on

page 2-10 when making sensor connections. Refer to Figure 2-8 on

page 2-10 for F

OUNDATION fieldbus installations.

Use the following steps to wire the power and sensor to the transmitter:

1. Remove the terminal block cover (if applicable).

2. Connect the positive power lead to the “+” terminal. Connect the

negative power lead to the “–” terminal (see Figure 2-7).

3. Tighten the terminal screws. When tightening the sensor and power

wires, the max torque is 6-in.-lbs (0.7 N-m).

4. Reattach and tighten the cover (if applicable).

5. Apply power (see “Power Supply”).

2-9

Rosemount 644

1 2 3 4

Sensor

Terminals

Communication

Terminals

Power Terminals

Sensor

Terminals

Power/

Configuration

Terminals

Max torque is 6

in.-lbs (0/7 N-m)

250 RL 1100

Power

Supply

Field

Communicator

250 RL 1100

Power

Supply

Field Communicator

Power

Supply

6234 ft (1900 m) max

(depending upon cable characteristics)

Integrated Power

Conditioner and Filter

Terminators

(Spur)

(Spur)

(Trunk)

(The power supply,

filter, first

terminator, and

configuration

tool are typically

located in the

control room.)

Devices 1

through 16

F

OUNDATION

fieldbus

Configuration

Tool

Power/

Signal

Wiring

Reference Manual

00809-0100-4728, Rev KA

July 2010

Figure 2-6. Transmitter Power,

Communication, and Sensor

Te rm i na l s

Figure 2-7. Connecting a HART

Communication Tool to a

Transmitter Loop

644H 644 Rail Mount

644H 644 Rail Mount

Figure 2-8. Connecting a

F

OUNDATION fieldbus Host

System to a Transmitter Loop

2-10

Note: Signal loop may be grounded at any point or left ungrounded.

Note: A Field Communicator may be connected at any termination point in the signal loop. The signal

Note: Max torque is 6 in.-lbs (0/7 N-m)

loop must have between 250 and 1100 ohms load for communications.

Reference Manual

2-wire

RTD and

3-wire RTD

and

4-wire RTD

and

T/C

and mV

*

1234

1234

1234

1234

00809-0100-4728, Rev KA

July 2010

Rosemount 644

Sensor Connections The 644 is compatible with a number of RTD and thermocouple sensor types.

Figure 2-9 shows the correct input connections to the sensor terminals on the

transmitter. To ensure a proper sensor connection, anchor the sensor lead

wires into the appropriate compression terminals and tighten the screws.

Figure 2-9. Sensor Wiring

Diagrams

* Emerson Process Management provides 4-wire sensors for all single element RTDs. Use these

RTDs in 3-wire configurations by leaving the unneeded leads disconnected and insulated withelectrical

tape.

Thermocouple or Millivolt Inputs

The thermocouple can be connected directly to the transmitter. Use

appropriate thermocouple extension wire if mounting the transmitter remotely

from the sensor. Make millivolt inputs connections with copper wire. Use

shielding for long runs of wire.

644 Sensor Connections Diagram

RTD or Ohm Inputs

The transmitters will accept a variety of RTD configurations, including 2-wire,

3-wire, 4-wire. If the transmitter is mounted remotely from a 3-wire or 4-wire

RTD, it will operate within specifications, without recalibration, for lead wire

resistances of up to 60 ohms per lead (equivalent to 6,000 feet of 20 AWG

wire). In this case, the leads between the RTD and transmitter should be

shielded. If using only two leads, both RTD leads are in series with the sensor

element, so significant errors can occur if the lead lengths exceed three feet

of 20 AWG wire (approximately 0.05 °C/ft). For longer runs, attach a third or

fourth lead as described above.

Sensor Lead Wire Resistance Effect– RTD Input

When using a 4-wire RTD, the effect of lead resistance is eliminated and

has no impact on accuracy. However, a 3-wire sensor will not fully cancel

lead resistance error because it cannot compensate for imbalances in

resistance between the lead wires. Using the same type of wire on all

three lead wires will make a 3-wire RTD installation as accurate as

possible. A 2-wire sensor will produce the largest error because it directly

adds the lead wire resistance to the sensor resistance. For 2- and 3-wire

RTDs, an additional lead wire resistance error is induced with ambient

temperature variations. The table and the examples shown below help

quantify these errors.

2-11

Rosemount 644

Basic Error

Imbalance of Lead Wires

PtRo

------------------------------------------------------------------=

Error due to amb. temp. variation

Cu

T

amb

Imbalance of Lead Wires

Pt

Ro

-------------------------------------------------------------------------------------------------------------------------=

Basic error

0.5

0.00385 / C100

--------------------------------------------------------------------------------- - 1.3 C==

Error due to amb. temp. var. of 25 °C

0.0039 / C25 C 0.5

0.00385 / C100

-------------------------------------------------------------------------------------------------------

0.1266 C==

Basic Error

Lead Wire Resistance

PtRo

----------------------------------------------------------=

Error due to amb. temp. variation

Cu

T

amb

Lead Wire Resistance

Pt

Ro

-----------------------------------------------------------------------------------------------------------------=

Basic error

7.5

0.00385 / C100

--------------------------------------------------------------------------------- - 19.5 C==

Error due to amb. temp. var. of 25 °C

0.0039 / C25 C 7.5

0.00385 / C100

-------------------------------------------------------------------------------------------------------

1.9 C==

Table 2-1. Examples of

Approximate Basic Error

Reference Manual

00809-0100-4728, Rev KA

July 2010

Sensor Input Approximate Basic Error

4-wire RTD None (independent of lead wire resistance)

3-wire RTD ± 1.0 in reading per ohm of unbalanced lead wire resistance

(Unbalanced lead wire resistance = maximum imbalance between

any two leads.)

2-wire RTD 1.0 in reading per ohm of lead wire resistance

Examples of Approximate Lead Wire Resistance Effect Calculations

Given:

Total cable length: 150 m

Imbalance of the lead wires at 20 °C: 1.5

Resistance/length (18 AWG Cu): 0.025 /m °C

Temperature coefficient of Cu (Cu): 0.039 / °C

Temperature coefficient of Pt(Pt): 0.00385 / °C

Change in Ambient Temperature (T

RTD Resistance at 0 °C (Ro): 100 (for Pt 100 RTD)

• Pt100 4-wire RTD: No lead wire resistance effect.

• Pt100 3-wire RTD:

): 25 °C

amb

Lead wire imbalance seen by the transmitter = 0.5

• Pt100 2-wire RTD:

Lead wire resistance seen by the transmitter = 150 m × 2 wires ×

0.025

/m = 7.5

2-12

Reference Manual

4–20 mA dc

1322

1100

1000

750

500

250

0

1012.0 20 30 40 42.4

Load (Ohms)

Supply Voltage (VDC)

Operating

Region

00809-0100-4728, Rev KA

July 2010

POWER SUPPLY HART Installation

To communicate with a transmitter, a 18.1 VDC minimum power supply is

required. The power supplied to the transmitter should not drop below the

transmitter lift-off voltage (see Figure 2-10). If the power drops below the

lift-off voltage while the transmitter is being configured, the transmitter may

interpret the configuration information incorrectly.

The dc power supply should provide power with less than 2 percent ripple.

The total resistance load is the sum of the resistance of the signal leads and

the load resistance of any controller, indicator, or related pieces of equipment

in the loop. Note that the resistance of intrinsic safety barriers, if used, must

be included.

Figure 2-10. Load Limits

Rosemount 644

Maximum Load = 40.8 x (Supply Voltage – 12.0)

OUNDATION fieldbus Installation

F

Powered over F

OUNDATION fieldbus with standard fieldbus power supplies.

The transmitter operates between 9.0 and 32.0 VDC, 11 mA maximum.

Transmitter power terminals are rated to 42.4 VDC.

The power terminals on the 644 with F

OUNDATION fieldbus are polarity

insensitive.

2-13

Reference Manual

Sensor Wires

F

OUNDATION fieldbus segment

or 4–20 mA loop

Shield ground point

Connect shields together, electrically isolated from the transmitter.

Transmitter

00809-0100-4728, Rev KA

Rosemount 644

July 2010

Ground the Transmitter The transmitter will operate with the current signal loop either floating or

grounded. However, the extra noise in floating systems affects many types of

readout devices. If the signal appears noisy or erratic, grounding the current

signal loop at a single point may solve the problem. The best place to ground

the loop is at the negative terminal of the power supply. Do not ground the

current signal loop at more than one point.

The transmitter is electrically isolated to 500 V DC/AC rms (707 VDC), so the

input circuit may also be grounded at any single point. When using a

grounded thermocouple, the grounded junction serves as this point.

Neither side of the loop should be grounded on F

OUNDATION fieldbus devices.

Only the shield wire should be grounded.

NOTE

Do not ground the signal wire at both ends.

Ungrounded Thermocouple, mV, and RTD/Ohm Inputs

Each process installation has different requirements for grounding. Use the

grounding options recommended by the facility for the specific sensor type, or

begin with grounding Option 1 (the most common).

Option 1:

1. Connect signal wiring shield to the sensor wiring shield.

2. Ensure the two shields are tied together and electrically isolated from

the transmitter housing.

3. Ground shield at the power supply end only.

4. Ensure that the sensor shield is electrically isolated from the

surrounding grounded fixtures.

2-14

Option 2:

1. Connect sensor wiring shield to the transmitter housing (only if the

housing is grounded).

2. Ensure the sensor shield is electrically isolated from surrounding

fixtures that may be grounded.

3. Ground signal wiring shield at the power supply end.

Rosemount 644

Sensor Wires

Shield ground point

Transmitter

F

OUNDATION fieldbus segment

or 4–20 mA loop

Sensor Wires

Shield ground point

Transmitter

F

OUNDATION fieldbus segment

or 4–20 mA loop

Sensor Wires

Shield ground point

Transmitter

F

OUNDATION fieldbus segment

or 4–20 mA loop

Reference Manual

00809-0100-4728, Rev KA

July 2010

Option 3:

1. Ground sensor wiring shield at the sensor, if possible.

2. Ensure that the sensor wiring and signal wiring shields are electrically

isolated from the transmitter housing.

3. Do not connect the signal wiring shield to the sensor wiring shield.

4. Ground signal wiring shield at the power supply end.

Grounded Thermocouple Inputs

1. Ground sensor wiring shield at the sensor.

2. Ensure that the sensor wiring and signal wiring shields are electrically

isolated from the transmitter housing.

3. Do not connect the signal wiring shield to the sensor wiring shield.

4. Ground signal wiring shield at the power supply end.

2-15

Rosemount 644

Reference Manual

00809-0100-4728, Rev KA

July 2010

2-16

Reference Manual

00809-0100-4728, Rev KA

July 2010

Section 3 HART Configuration

Rosemount 644

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-3

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-3

Multidrop Communication . . . . . . . . . . . . . . . . . . . . . . . . . page 3-18

Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . page 3-19

OVERVIEW This section provides information on configuring, troubleshooting, operating,

and maintaining the Rosemount 644 with HART protocol.

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

potentially raises safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Warnings

Failure to follow these installation guidelines could result in death or

serious injury.

• Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

• Do not remove the connection head cover in explosive atmospheres when the

circuit is live.

• Before connecting a Field Communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with instrinsically safe or

non-incendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• All connection head covers must be fully engaged to meet

explosion-proof requirements.

Process leaks could result in death or serious injury.

• Do not remove the thermowell while in operation.

• Install and tighten thermowells and sensors before applying pressure

Electrical shock could cause death or serious injury.

• Use extreme caution when making contact with the leads and terminals.

HART

www.rosemount.com

HART

Reference Manual

00809-0100-4728, Rev KA

Rosemount 644

July 2010

Surges/Transients The transmitter will withstand electrical transients of the energy level

encountered in static discharges or induced switching transients. However,

high-energy transients, such as those induced in wiring from nearby lightning

strikes, welding, heavy electrical equipment, or switching gears, can damage

both the transmitter and the sensor. To protect against high-energy transients,

install the transmitter into a suitable connection head with the Rosemount 470

Transient Protector. Refer to the 470 Transient Protector Product Data Sheet

(document number 00813-0100-4191) for more information.

COMMISSIONING The 644 must be configured for certain basic variables to operate. In many

cases, all of these variables are pre-configured at the factory. Configuration

may be required if the transmitter is not configured or if the configuration

variables need revision.

Commissioning consists of testing the transmitter and verifying transmitter

configuration data. 644 transmitters can be commissioned either before or

after installation. Commissioning the transmitter on the bench before

installation using a Field Communicator or AMS ensures that all transmitter

components are in working order.

To commission on the bench, connect the transmitter and the Field

Communicator or AMS as shown in Figure 2-7 on page 2-10. Make sure the

instruments in the loop are installed according to intrinsically-safe or

non-incendive field wiring practices before connecting a communication in an

explosive atmosphere. Connect HART Communication leads at any

termination point in the signal loop. For convenience, connect them to the

terminals labeled “COMM” on the terminal block. Connecting across the

“TEST” terminals will prevent successful communication. Avoid exposing the

transmitter electronics to the plant environment after installation by setting all

transmitter jumpers during the commissioning stage on the bench.

When using a Field Communicator, any configuration changes made must be

sent to the transmitter by using the “Send” key (F2). AMS configuration

changes are implemented when the “Apply” button is clicked.

For more information on using the Field Communicator with the 644

transmitter, see Section 3: HART Configuration.

Setting the Loop to

Manual

When sending or requesting data that would disrupt the loop or change the

output of the transmitter, set the process application loop to manual. The Field

Communicator or AMS will prompt you to set the loop to manual when

necessary. Acknowledging this prompt does not set the loop to manual. The

prompt is only a reminder; set the loop to manual as a separate operation.

Failure Mode As part of normal operation, each transmitter continuously monitors its own

performance. This automatic diagnostics routine is a timed series of checks

repeated continuously. If diagnostics detect an input sensor failure or a failure

in the transmitter electronics, the transmitter drives its output to low or high

depending on the position of the failure mode switch. Saturation levels are

3.90 mA for standard configuration (3.8 mA if configured for NAMURcompliant operation) on the low end and 20.5 mA for standard or NAMURcompliant configuration on the high end, if the sensor temperature is outside

of range limits. These values are also custom configurable by the factory or

using the Field Communicator.

3-2

Reference Manual

00809-0100-4728, Rev KA

July 2010

Rosemount 644

The values to which the transmitter drives its output in failure mode depend

on whether it is configured to standard, NAMUR-compliant, or custom

operation. See “Hardware and Software Failure Mode” on page A-7 for

standard and NAMUR-compliant operation parameters.

Changing Switch

Positions

To change the failure mode on the 644 transmitter, follow the steps below.

1. If applicable, remove the enclosure cover.

2. Locate the orange failure mode switch. On the 644H the switch is

located near the power terminals and located in the center of the front

panel on the 644 rail mount (see Figure 2-6).

3. Move the switch to the desired alarm setting. To set the failure mode

to high alarm, position the switch toward the “HI” mark on the terminal

block. To set the failure mode to low alarm, position the switch in the

opposite direction.

4. Replace the enclosure cover (if applicable). Enclosure covers must

be fully engaged to meet explosion-proof requirements.

FIELD COMMUNICATOR The Field Communicator exchanges information with the transmitter from the

control room, the instrument site, or any wiring termination point in the loop.

To facilitate communication, connect the Field Communicator in parallel with

the transmitter (see Figure 2-11). Use the loop connection ports on the rear

panel of the Field Communicator. The connections are non-polarized. Do not

make connections to the serial port or the NiCad recharger jack in explosive

atmospheres. Before connecting the Field Communicator in an explosive

atmosphere, make sure the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

For more information regarding the Field Communicator, please see the Field

Communicator Reference Manual.

HART

CONFIGURATION The 644 transmitter can be configured either on-line or off-line using a Field

Communicator or AMS. During on-line configuration, the transmitter is

connected to a Field communicator. Data is entered in the working register of

the communicator and sent directly to the transmitter. Off-line configuration

consists of storing configuration data in a Field Communicator while it is not

connected to a transmitter. Data is stored in nonvolatile memory and can be

downloaded to the transmitter at a later time.

3-3

HART

The review menu lists all of the

information stored in the 644. This

includes device information, measuring

element, output configuration, and

software revision

1. TEST DEVICE

2. CALIBRATION

3. Write Protect

On-line Menu

1. Snsr 1 Digital Reading

2. Terminal Digital Reading

1. Snsr 1 Input Trim

2. Snsr 1 Trim-Fact

3. Active Calibrator

1. Loop Test

2. Self test

3. Master Reset

4. Status

1. SNSR 1 TRIM

2. D/A trim

3. Scaled D/A trim

1. Revision #s

2. Sensor Review

3. Dev Outputs Review

4. Device Information

5. Measurement

Filtering

1. PROCESS

VARIABLES

2. DIAGNOSTICS

AND SERVICE

3. CONFIGURA TION

4. REVIEW

1. VARIABLE

MAPPING

2. SENSOR

CONFIGURATION

3. DEVICE OUTPUT

CONFIGURATION

4. DEVICE

INFORMATION

5. MEASUREMENT

FILTERING

1. TRANSMITTER VARS

2. PV is

3. PV Digital Reading

4. PV AO

5. PV% rnge

6. PV LRV

7. PV URV

8. PV Lower Sensor Limits

9. PV Upper Sensor Limits

10.PV Damping

1. DEVICE SETUP

2. PV is

3. PV

4. PV AO

5. % RNGE

6. PV LRV

7. PV URV

1. PV is

2. SV is

3. TV is

4. QV is

5. Variable re-map

1. SENSOR 1

2. TERMINAL TEMP

1. Connections

2. SNSR 1 SETUP

3. CAL VANDUSEN

4. Sensor S/N

1. Terminal Units

2. Terminal Damp

3. Terminal LSL

4. Terminal USL

1. PV RANGE

VALUES

2. ALARM

SATURATION

3. HART OUTPUT

4. LCD METER

OPTIONS

1. AO Alarm Type

2. Low Alarm

3. High Alarm

4. Low Sat.

5. High Sat.

1. Poll Addr

2. Num Req Preams

3. Burst Mode

4. Burst Option

1. Meter Configuration

2. Meter Decimal Pt

1. Tag

2. Date

3. Descriptor

4. Message

5. Final Assembly number

1. 50/60 Hz Filter

2. Active Calibrator

3. Open Sensor Holdoff

4. Intermit Detect

5. Intermit Thresh

1. 2-wire Offset

2. Snsr 1 Units

3. Snsr 1 Damp

4. Snsr LSL

5. Snsr USL

1. R0

2. Alpha

3. Delta

4. Beta

1. PV LRV

2. PV URV

3. PV Damping

4. PV Units

5. Apply Values

6. PV LSL

7. PV USL

8. PV Min. Span

These numbers are to

be entered by the user.

When the hardware alarm

switches are changed, the

communicator should be

power cycled to see new

readings.

Reference Manual

00809-0100-4728, Rev KA

Rosemount 644

July 2010

HART Menu Tree Options listed in bold type indicate that a selection provides other options. For

ease of operation, changing calibration and setup, such as sensor type,

number of wires, and range values, can be completed in several locations.

Figure 3-1. Field Communicator Menu Tree

3-4

Loading...

Loading...