Reference Manual

00809-0100-4022, Rev JA

January 2022

Rosemount™ 4600 Oil & Gas Panel Pressure

Transmitter

HART Revision 7

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum product performance,

ensure you thoroughly understand the contents before installing, using, or maintaining this product.

Emerson has two toll-free assistance numbers:

Customer Central

Technical support, quoting, and order-related questions.

United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

Asia Pacific- 65 777 8211

Europe/Middle East/Africa - 49 (8153) 9390

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of these areas, contact your local Emerson representative.

CAUTION

The products described in this document are NOT designed for nuclear-qualified applications. Using non-nuclear qualified

products in applications that require nuclear-qualified hardware or products may cause inaccurate readings. For information on

Rosemount nuclear-qualified products, contact your local Emerson Sales Representative.

Apply torque only to the hex flat located at the process end of the transmitter. Do not apply torque to the transmitter body or

electrical connection - severe damage could result. Do not exceed 100 ft-lb.

Static electricity can damage sensitive components.

Observe safe handling precautions for static-sensitive components.

WARNING

Explosions could result in death or serious injury.

Transmitters located in hazardous areas should be installed in accordance with local codes and requirements for that area.

Use appropriately rated Ex adapters, blanking elements, and glands during installation.

Keep process insulation at least 1-in. (25 mm) from transmitter connection.

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can cause electrical shock.

Process leaks could result in death or serious injury.

Properly tighten process connections before applying pressure.

Physical access

Unauthorized personnel can potentially cause significant damage and/or misconfiguration of end users' equipment. Protect

against all intentional or unintentional unauthorized use.

Physical security is an important part of any security program and fundamental to protecting your system. Restrict physical access

to protect users' assets. This is true for all systems used within the facility.

2

Reference Manual Contents

00809-0100-4022 January 2022

Contents

Chapter 1 Introduction.............................................................................................................. 5

1.1 Using this manual........................................................................................................................ 5

1.2 Product recycling/disposal...........................................................................................................5

Chapter 2 Configuration............................................................................................................ 7

2.1 Overview..................................................................................................................................... 7

2.2 Safety messages.......................................................................................................................... 7

2.3 Commissioning on the bench with HART Protocol....................................................................... 7

2.4 Review configuration data........................................................................................................... 9

2.5 Check output.............................................................................................................................10

2.6 Basic setup.................................................................................................................................11

2.7 Detailed setup........................................................................................................................... 14

2.8 Diagnostics and service..............................................................................................................18

2.9 Advanced functions for HART Protocol...................................................................................... 19

2.10 Multidrop communication ...................................................................................................... 22

Chapter 3 Installation...............................................................................................................25

3.1 Overview................................................................................................................................... 25

3.2 Safety messages........................................................................................................................ 25

3.3 General considerations.............................................................................................................. 26

3.4 Mechanical considerations.........................................................................................................26

3.5 Installation procedures.............................................................................................................. 27

3.6 Hazardous locations.................................................................................................................. 32

3.7 Grounding the transmitter case.................................................................................................32

Chapter 4 Operation and Maintenance.....................................................................................33

4.1 Overview................................................................................................................................... 33

4.2 Calibration for HART® Protocol.................................................................................................. 33

4.3 Sensor trim................................................................................................................................ 38

4.4 Recall factory trim......................................................................................................................40

4.5 Analog output trim.................................................................................................................... 41

Chapter 5 Troubleshooting ......................................................................................................45

5.1 Overview................................................................................................................................... 45

5.2 Safety messages........................................................................................................................ 45

Appendix A Specification and Reference Data............................................................................. 49

A.1 Product certifications................................................................................................................ 49

A.2 Ordering Information, Specifications, and Drawings..................................................................49

Emerson.com/Rosemount 3

Contents Reference Manual

January 2022 00809-0100-4022

4 Emerson.com/Rosemount

Reference Manual Introduction

00809-0100-4022 January 2022

1 Introduction

1.1 Using this manual

The sections in this manual provides information on installing, operating, and maintaining

the Rosemount™ 4600 Oil & Gas Pressure Transmitter. The sections are organized as

follows:

Configuration contains mechanical and electrical installation instructions.

Installation provides instruction on commissioning and configuring the Rosemount 4600

Transmitter. Information on software functions, configuration parameters, and online

variables is also included.

Operation and Maintenance contains operation and maintenance instructions.

Troubleshooting provides troubleshooting techniques for the most common operating

problems.

Specification and Reference Data supplies reference and specification data, as well as

ordering information and contains approval information.

1.2 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation/regulations.

Emerson.com/Rosemount 5

Introduction Reference Manual

January 2022 00809-0100-4022

6 Emerson.com/Rosemount

Reference Manual Configuration

00809-0100-4022 January 2022

2 Configuration

2.1 Overview

This section contains information on commissioning and tasks that should be performed

on the bench prior to installation. This section contains the Rosemount™ 4600 Oil & Gas

Pressure Transmitter HART® configuration information.

Field Communicator and AMS Device Manager instructions are given to perform

configuration functions. For convenience, Field Communicator Fast Key sequences are

labeled “Fast Keys” for each software function below the appropriate headings.

2.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operations. Information that raises potential safety

issues is indicated by a warning symbol ( ). Refer to the following safety messages before

performing an operation preceded by this symbol.

WARNING

Explosions could result in death or serious injury.

Transmitters located in hazardous areas should be installed in accordance with local codes

and requirements for that area.

Verify that the operating atmosphere of the transmitter is consistent with the appropriate

hazardous locations certifications.

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can

cause electrical shock.

2.3 Commissioning on the bench with HART Protocol

Commissioning consists of testing the Rosemount 4600 and verifying transmitter

configuration data. The transmitter can be commissioned either before or after

installation. Commissioning the transmitter on the bench before installation using a Field

Communicator or AMS Device Manager ensures that all transmitter components are in

working order.

Emerson.com/Rosemount 7

Configuration Reference Manual

January 2022 00809-0100-4022

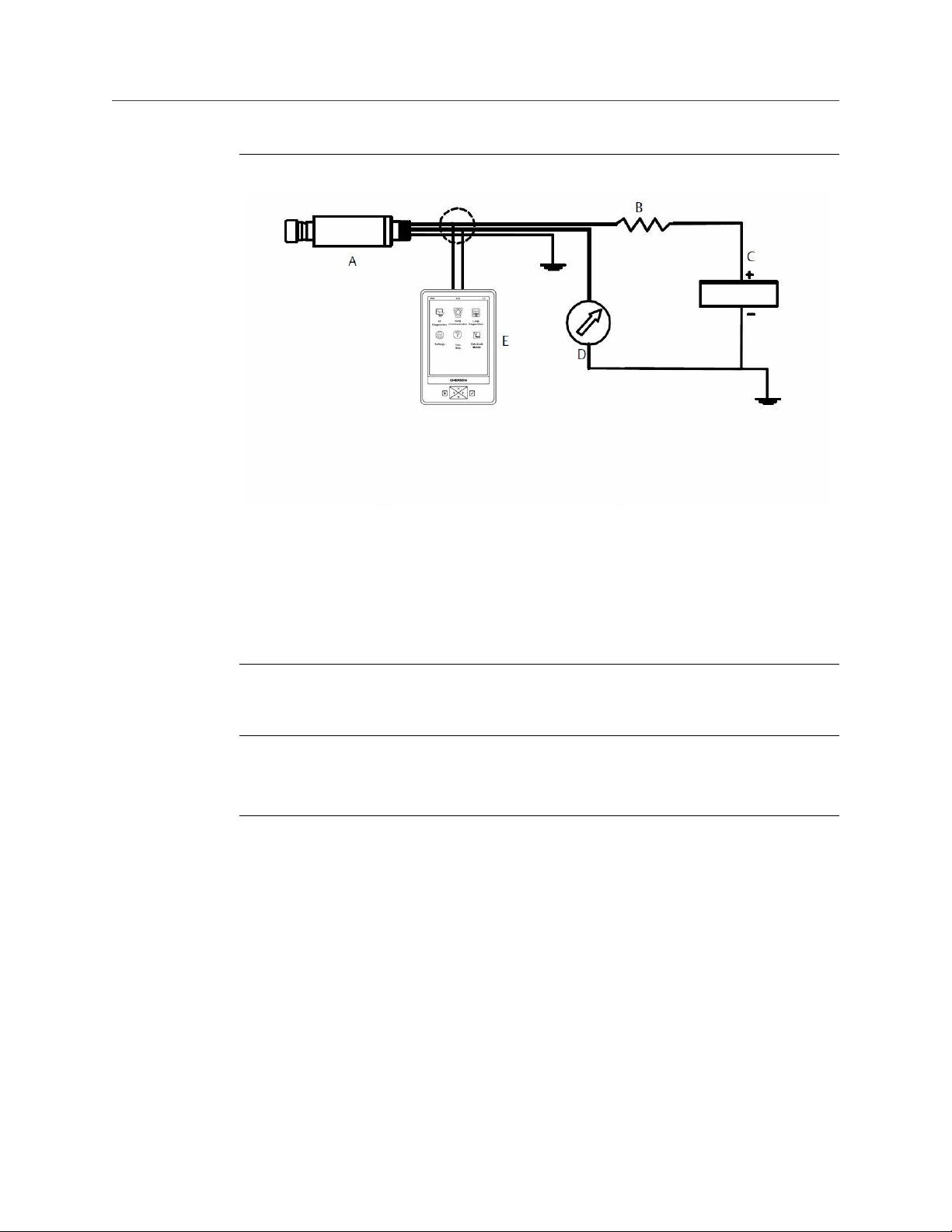

WARNING

To commission on the bench, connect the transmitter and the Field Communicator or

AMS Device Manager. Connect Field Communicator leads at any termination point in the

signal loop.

In order to commission the transmitter, the power supply must provide 10 to 42.4 Vdc at

the transmitter terminals. A current meter is also required to measure current output. To

enable communication, a resistance of at least 250 ohms must be present between the

Field Communicator loop connection and the power supply. Do not use inductive-based

transient protectors with more than 3 mH of inductance with the Rosemount 4600.

When using a Field Communicator, any configuration changes made must be sent to the

transmitter by using the “Send” key (F2). AMS Device Manger configuration changes are

implemented when the “Apply” button is selected.

For more information on the Field Communicator, see Field Communicator website for the

most up to date literature. AMS Device Manger help can be found in the AMS Device

Manager online guides within the AMS system.

2.3.1

2.3.2

Setting the loop to manual

Whenever sending or requesting data that would disrupt the loop or change the output of

the transmitter, set the process application loop to manual. The Field Communicator or

AMS Device Manager will prompt you to set the loop to manual when necessary.

Acknowledging this prompt does not set the loop to manual. The prompt is only a

reminder; set the loop to manual as a separate operation.

Wiring diagrams

Bench hook-up

Connect the bench equipment as shown in Figure 2-1 and turn on the Field Communicator

by pressing the ON/OFF key or log into AMS Device Manager. The Field Communicator or

AMS Device Manager will search for a HART-compatible device and indicate when the

connection is made. If the Field Communicator or AMS Device Manager fail to connect, it

indicates that no device was found. If this occurs, refer to Troubleshooting .

8 Emerson.com/Rosemount

Reference Manual Configuration

00809-0100-4022 January 2022

Figure 2-1: Bench Wiring (4–20 mA)

A

B

C

D

E

Rosemount 4600

RL > 250 ohm

Power supply

Current meter

Field Communicator

2.4 Review configuration data

Note

Information and procedures in this section that make use of Field Communicator Fast Key

sequences and AMS Device Manager assume the transmitter and communication

equipment are connected, powered, and operating correctly.

Field Communicator

Before placing the transmitter into operation, review the transmitter configuration data

below which was set by the factory.

PV Lower Sensor Limit (LSL)

PV Upper Sensor Limit (USL) Date

PV Lower Range Value (LRV) Descriptor

PV Upper Range Value (URV) Message

PV minimum span Write protect

Lower sensor trim point Local keys

Upper sensor trim point Universal revision

Sensor trim calibration type Field device revision

Tag

Emerson.com/Rosemount 9

Configuration Reference Manual

January 2022 00809-0100-4022

Damping Software revision

Alarm direction Hardware revision

High Alarm (Value) Physical signal code

Low Alarm (Value) Final assembly number

High saturation Device ID

Low saturation Burst mode

Alarm/Saturation type Burst option

Sensor S/N Poll address

Isolator material Number req preams

Fill fluid Distributor

Process connector

Process connector material

AMS Device Manger

Right click on the device and select Configuration Properties from the menu. Select the

tabs to review the transmitter configuration data.

2.5 Check output

Before performing other transmitter online operations, review the digital output

parameters to ensure the transmitter is operating properly and is configured to the

appropriate process variables.

2.5.1

Process variables

The process variables for the Rosemount 4600 provide transmitter output, and are

continuously updated. The pressure reading in both engineering units and percent of

range will continue to track with pressures outside of the defined range from the lower to

the upper range limit.

Field Communicator

The process variable menu displays the following process variables:

• Pressure

• Percent of range

• Analog output

• Sensor temperature

Note

Regardless of the range points, the Rosemount 4600 will measure and report all readings

within the digital limits of the sensor. For example, if the 4 and 20 mA points are set to

0 and 1,000 psi, and the transmitter detects a pressure of 2,500 psi, it digitally outputs the

10 Emerson.com/Rosemount

Reference Manual Configuration

00809-0100-4022 January 2022

2,500 psi reading and a 250 percent of span reading. However, there may be up to ±5.0

percent error associated with output outside of the range points.

AMS Device Manger

Right click on the device and select Process Variables... from the menu.The process

variable screen displays the following process variables:

• Pressure

• Percent of range

• Analog output

• Sensor temperature

2.5.2

Sensor temperature

The Rosemount 4600 contains a temperature sensor near the pressure sensor in the

transmitter. When reading this temperature, keep in mind this is not an accurate indicator

of process temperature.

Field Communicator

Enter the Fast Key sequence below Sensor Temperature to view the sensor temperature

reading.

AMS Device Manger

Right click on the device and select Process Variables... from the menu. Snsr Temp is the

sensor temperature reading.

2.6 Basic setup

2.6.1 Set process variable units

The PV Unit command sets the process variable units to allow you to monitor your process

using the appropriate units of measure.

Field Communicator

Enter the Fast Key sequence shown. Select from the following engineering units:

O bar torr

inH

2

inHg mbar atm

ftH2O g/cm

mmH2O kg/cm

mmHg Pa mmH2O at 4 °C

psi kPa

Emerson.com/Rosemount 11

2

2

MPa

inH2O at 4 °C

Configuration Reference Manual

January 2022 00809-0100-4022

AMS Device Manger

Right click on the device and select Configuration Properties from the menu. In the Basic

Setup tab, use Unit drop down menu to select units.

2.6.2 Rerange

The Range Values command sets the 4 and 20 mA points and digital lower (LRV) and upper

(URV) range values. In practice, you may reset the transmitter range values as often as

necessary to reflect changing process conditions. Changing the lower or upper range point

results in similar changes to the span.

Note

Transmitters are shipped from Emerson. fully calibrated per request or by the factory

default of full scale (span = upper range limit.)

Use one of the methods below to rerange the transmitter. Each method is unique;

examine all options closely before deciding which method works best for your process.

• Rerange with a Field Communicator only.

• Rerange with a pressure input source and a Field Communicator.

• Rerange with a pressure input source and the local zero and span targets (option D1).

• Rerange with AMS Device Manger only.

• Rerange with a pressure input source and AMS Device Manger.

Rerange with a Field Communicator only

The easiest and most popular way to rerange is to use the Field Communicator only. This

method changes the values of the analog 4 and 20 mA points independently without a

pressure input.

From the HOME screen, enter the Fast Key sequence shown.

Procedure

1. At Keypad Input select 1 and use the keypad to enter lower range value.

2. From Keypad Input select 2 and use the keypad to enter upper range value.

Rerange with a pressure input source and Field Communicator

Reranging using the Field Communicator and a pressure source or process pressure is a

way of reranging the transmitter when specific 4 and 20 mA points are unknown.

Note

The span is maintained when the 4 mA point is set. The span changes when the 20 mA

point is set. If the lower range point is set to a value that causes the upper range point to

exceed the sensor limit, the upper range point is automatically set to the sensor limit, and

the span is adjusted accordingly.

12 Emerson.com/Rosemount

Reference Manual Configuration

00809-0100-4022 January 2022

Procedure

From the HOME screen, enter the Fast Key sequence shown to configure lower and upper

range values and follow the online instructions.

Rerange with AMS Device Manger only

Right click on the device and select Configuration Properties from the menu. In the Basic

Setup tab, locate the Analog Output box and perform the following procedure:

Procedure

1. Enter the lower range value (LRV) and the upper range value (URV) in the fields

provided. Select Apply.

2. An Apply Parameter Modification screen appears, enter desired information and

select OK.

3. After carefully reading the warning provided, select OK.

Rerange with a pressure input source and AMS Device Manger

2.6.3

Right click on the device, choose Calibrate, then Apply values from the menu.

Procedure

1. Select Next after the control loop is set to manual.

2. From the Apply Values menu, follow the online instructions to configure lower and

upper range values.

3. Select Exit to leave the Apply Values screen.

4. Select Next to acknowledge the loop can be returned to automatic control.

5. Select Finish to acknowledge the method is complete.

Damping

The Damp command introduces a delay in processing which increases the response time

of the transmitter; smoothing variations in output readings caused by rapid input changes.

Determine the appropriate damp setting based on the necessary response time, signal

stability, and other requirements of the of loop dynamics of your system. The default

damping value is 0.4 seconds and is user-selectable from 0 to 60 seconds.

AMS Device Manger

Right click on the device and select Configuration Properties from the menu.

Procedure

1. In the Basic Setup tab, enter the damping value in the Damp field, select Apply.

2. An Apply Parameter Modification screen appears, enter desired information and

select OK.

3. After carefully reading the warning provided, select OK.

Emerson.com/Rosemount 13

Configuration Reference Manual

January 2022 00809-0100-4022

2.7 Detailed setup

2.7.1 Failure mode alarm and saturation

The Rosemount 4600 Transmitter automatically and continuously perform self-diagnostic

routines. If the self-diagnostic routines detect a failure, the transmitter drives the output

to configured alarm values. The transmitter will also drive the output to configured

saturation values if the applied pressure goes outside the 4–20 mA range values.

Note

The failure mode alarm direction can also be configured using the Field Communicator or

AMS Device Manager.

Note

Under some failure conditions, the transmitter will ignore user configured alarm

conditions and drive the transmitter to low alarm.

The Rosemount 4600 Transmitter have three configurable options for failure mode alarm

and saturation levels:

• Rosemount (standard), see Table 2-1

• Custom, see Table 2-2

Table 2-1: Rosemount (Standard) Alarm and Saturation Values

Level 4–20 mA saturation 4–20 mA alarm

Low 3.9 mA ≤ 3.75 mA

High 20.8 mA ≥ 21.75 mA

Table 2-2: Custom Alarm and Saturation Values

Level 4–20 mA saturation 4–20 mA alarm

Low 3.7 mA — 3.9 mA 3.6 mA — 3.8 mA

High 20.1 mA — 21.5 mA 20.2 mA — 23.0 mA

Failure mode alarm and saturation levels can be configured using a Field Communicator or

AMS Device Manager, see Alarm and saturation level configuration. Per Table 2-2, custom

alarm and saturation levels can be configured between 3.6 mA and 3.9 mA for low values

and between 20.1 mA and 23 mA for high values. The following limitations exist for

custom levels:

• Low alarm level must be less than the low saturation level

• High alarm level must be higher than the high saturation level

• High saturation level must not exceed 21.5 mA

• Alarm and saturation levels must be separated by at least 0.1 mA

The Field Communicator or AMS Device Manager will provide an error message if a

configuration rule is violated.

14 Emerson.com/Rosemount

Reference Manual Configuration

00809-0100-4022 January 2022

2.7.2 Alarm and saturation level configuration

To configure alarm and saturation levels with a Field Communicator or AMS Device

Manager perform the following procedure:

Field Communicator

Procedure

1. From the HOME screen, follow the Fast Key sequence under Alarm and Saturation

Levels.

2. Select 7, Config. Alarm Level to configure alarm levels.

3. Select OK after setting the control loop to manual.

4. Select OK to acknowledge current settings.

5. Select desired setting, if OTHER is selected, enter HI and LO custom values.

6. Select OK to acknowledge the loop can be returned to automatic control.

7. Select 8, Config. Sat. Levels to configure saturation levels.

8. Repeat Step 3-Step 6 to configure saturation levels.

2.7.3

AMS Device Manger

Procedure

1. Right click on the device, select Device Configuration,

2. Select Alarm/Saturation Levels,

3. Select Alarm Levels from the menu.

4. Select Next after setting the control loop to manual.

5. Select Next after acknowledging the current alarm levels.

6. Select the desired alarm settings: NAMUR, Rosemount, Other.

7. If Other is selected, enter desired HI Value and LO Value custom values.

8. Select Next to acknowledge new alarm levels.

9. Select Next to acknowledge the loop can be returned to automatic control.

10. Select Finish to acknowledge the method is complete.

11. Right click on the device, select Device Configuration, then select Alarm/

Saturation Levels, then Alarm Levels from the menu.

12. Select Saturation Levels.

13. Repeat Step 5-Step 11 to configure saturation levels.

Alarm and saturation levels for burst mode

Transmitters set to burst mode handle saturation and alarm conditions differently.

Alarm conditions

• Analog output switches to alarm value

Emerson.com/Rosemount 15

Loading...

Loading...