Rosemount Manual: Rosemount 3244MV MultiVariable™ Temperature Transmitter with FOUNDATION™ Fieldbus Manuals & Guides

00809-0100-4769

Product Discontinued

Model 3244MV MultiVariable™

Temperature Transmitter with

FOUNDATION™ Fieldbus

(Device Revision 3)

English

Rev. BA

яюэьыъщшчцхыцф

Model 3244MV MultiV a riable

Temperature Transmitter

with F

(Device Revision 3)

OUNDATION

™

fieldbus

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand t he contents before

installing,using or maintaining the this product.

In the United States, Rosemount Inc. has two toll-free assistance numbers

Customer Central:

Technical Supp ort, quoting, and or de r-related quest ions

1–800–999–9307 (7:00 a.m. to 7:00 p.m. CST)

North American Resp onse Cen ter:

Equipment service needs.

1–800–654–7768 (24 hours a day–includesCanada)

Outside of the United States, contact your local Rosemount

®

Sales Representative.

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN 55317 USA

Tel 1-800-999-9307

Fax (952) 949-7001

© 2000 Rosemount Inc.

Fisher-Rosemount Limited

Heath Place

Bognor Regis

West Sussex PO22 9SH

England

Tel 44 (1243) 863 121

Fax 44 (1243) 867 5541

Fisher-Rosemount

Singapore Pte Ltd.

1 Pandan Crescent

Singapore 128461

Tel (65) 777-8211

Fax (65) 770-8007

Email: AP.RMT-Specialist@frco.com

00809-0100-4769

© Rosemount Inc. 2000.

http://www.rosemount.com

The productsdescribedin this document are NOT designedfor nuclear-qualifiedapplicants.

Using non-nuclear qualified products in application that require nuclear-qualified hardware or

products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact you local Rosemount

Sales Representative.

NOTE:

We are very interested in your comments and suggestions on how we can

improve this product manual for the Rosemount

MuliVariable Temperature Transmitter with F

®

Model 3244MV

OUNDATION fieldbus.

Please send your comments and suggestions to the following E-Mail address

EdenPrairie.RMD-3244MVFManual@frco.com

Rosemount Model 3244MV MultiVariable Temperature Transmitter with F

protected by one or more U.S. Patents Pending. Other foreign patents pending.

Rosemount, the Rosemount logotype and Hot Backup are registered trademarks of Rosemount Inc.

Tri-Loop,MultiVariable and Complete Point Solutions is a trademark of Rosemount Inc.

PlantWeb and the PlantWeb logotype are trademarks of Fisher-Rosemount

Minigrabber is a trademark of Pomona Electronics.

Inconel is a registered trademark of International Nickel Co.

OUNDATION

F

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

COVER PHOTO: 3244-32442901

T

N

I

E

D

R

P

IN

U.

A.

S.

is a trademark of the Fieldbus Foundation

Fisher-Rosemount satisfies

all obligations coming from

legislation to harmonize

product requirements

in the European Union.

OUNDATION

fieldbus may be

Rosemount Model 3244MV MultiVariable Temperature Transmitter with FOUNDATION fieldbus

-2

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Transmitter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Foundation fieldbus Technology Overview . . . . . . . . . . . . . . . . . . . .1-3

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

General Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Power Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Surges/Transients. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Simulate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Sensor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

RTD or Ohm Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Thermocouple or Millivolt Inputs . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Installing the LCD Meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Access Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Environmental Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Temperature Effects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Moist or Corrosive Environments . . . . . . . . . . . . . . . . . . . . . . . .2-11

Hazardous Location Installations . . . . . . . . . . . . . . . . . . . . . . . .2-12

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Typical North American Configuration. . . . . . . . . . . . . . . . . . . .2-14

Typical European Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

1

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

SECTION 3

Operation

SECTION 4

Transducer Block

Device Tag and Node Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Temperature Specific Block Configuration . . . . . . . . . . . . . . . . . . . .3-2

Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Back-up LAS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Analog Input Function Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Input Selector Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Configuring Links and Scheduling Block Execution . . . . . . . . . . . . .3-4

Hot Backup Configuration (option code U1) . . . . . . . . . . . . . . . . .3-5

Two Independent Sensors Configuration

(option code U4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Differential Temperature Configuration

(option code U5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Average Temperature Configuration (Option Code U6). . . . . . . .3-7

First Good Temperature Configuration (Option Code U7). . . . . . 3-7

Minimum Temperature Configuration (Option Code U8) . . . . . .3-7

Maximum Temperature Configuration (Option Code U9) . . . . . .3-8

Single Sensor Configuration (standard) . . . . . . . . . . . . . . . . . . . .3-9

Critical Control Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Channel Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Parameters and Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Block/Transducer Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Transmitter- Sensor Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

SECTION 5

Resource Block

SECTION 6

Maintenance

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Parameters and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

LCD Meter Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Hardware Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Hardware Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Sensor Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Assembling the Electronics Housing . . . . . . . . . . . . . . . . . . . . . . .6-4

2

Table of Contents

SECTION 7

Specifications and

Reference Data

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Local Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Temperature Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Humidity Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Turn-on Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Update Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Foundation Fieldbus Specifications. . . . . . . . . . . . . . . . . . . . . . . .7-3

Hazardous Locations Certifications. . . . . . . . . . . . . . . . . . . . . . . .7-3

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Stability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

RFI Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Vibration Effect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Self Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Ambient Temperature Effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Conduit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Materials of Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Enclosure Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Reference Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Transmitter Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Spare Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13

SECTION 8

Hazardous Area Approval

Installation Drawings

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

3

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

SECTION 9

Options

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Option Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Basic Control

(option code A01). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Regulatory Control Suite

(option code B01). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

Mounting Brackets

(option codes B4 and B5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

LCD Meter (Option Code M5) . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

External Ground Lug Assembly (option code G1). . . . . . . . . . . . .9-2

Transient Protection (option code T1) . . . . . . . . . . . . . . . . . . . . . .9-2

Hot Backup (option code U1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Two Independent Sensors (option code U4) . . . . . . . . . . . . . . . . .9-3

Average Temperature (option code U6). . . . . . . . . . . . . . . . . . . . . 9-6

First Good Temperature (option code U7). . . . . . . . . . . . . . . . . . .9-6

Minimum Temperature

(option code U8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

Maximum Temperature

(option code U9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

Custom Transmitter Configuration (option code C1) . . . . . . . . . .9-7

Trim to Specific Rosemount RTD Calibration Schedule (Transmitter-

Sensor Matching) (option code C2) . . . . . . . . . . . . . . . . . . . . . . . .9-7

Five Point Calibration (option code C4) . . . . . . . . . . . . . . . . . . . .9-7

Trim to Special non-Standard Sensor (option code C7) . . . . . . . .9-7

50 Hz Line Voltage Filter (option code F5) . . . . . . . . . . . . . . . . . . 9-7

Assembly Options (option codes X1, X2, and X3) . . . . . . . . . . . . .9-8

Calibration Certificate (option code Q4) . . . . . . . . . . . . . . . . . . . . 9-8

APPENDIX A

Foundation™Fieldbus

Technology

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Device Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Block Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Instrument- Specific Function Blocks . . . . . . . . . . . . . . . . . . . . . A-3

Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Network communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Link Active Scheduler (LAS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Device Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Scheduled Transfers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Unscheduled Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Function Block Scheduling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

LAS Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

4

Table of Contents

APPENDIX B

Analog Input

Function Block

APPENDIX C

Input Selector Function

Block

APPENDIX D

PID Function Block

Simulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Signal Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Advanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Block Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Setpoint Selection and Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Feedforward Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Output Selection and Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

Bumpless Transfer and Setpoint Tracking . . . . . . . . . . . . . . . . . D-6

PID Equation Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Reverse and Direct Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Reset Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-15

APPENDIX E

Arithmetic Function Block

APPENDIX F

Signal Characterizer

Function Block

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Block Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Advanced Topics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-8

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-3

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-3

Alarm Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-3

Block Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-4

Block Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-5

Status Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-5

Application Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-6

5

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

APPENDIX G

Operation with FisherRosemount®DeltaV

™

APPENDIX H

European ATEX Directive

Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

About DeltaV Software with AMSinside. . . . . . . . . . . . . . . . . . . G-1

Software Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

Configure the Model 3244MV . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Configure the Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Create a Device Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Define the Control Strategy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-7

Commission the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . G-8

Set Transmitter Configuration Parameters . . . . . . . . . . . . . . . G-11

Download the Control Strategy to the Device. . . . . . . . . . . . . . G-13

CENELEC/BASEEFA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

Intrinsic Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-1

CENELEC/BASEEFA Type N Approval. . . . . . . . . . . . . . . . . . . H-2

6

Section

1 Introduction

USING THIS MANUAL This manual is intended to assist in installing, operating, and

maintaining the Model 3244MV MultiVariable Temperature

Transmitters with F

Section 2: Installation

explains how to install the Model 3244MV by providing electrical,

mechanical, and environmental installation considerations.

Section 3: Operation

summarizes basic transmitter operation, software functionality, and

provides basic configuration procedures.

Section 4: Transducer Block

describes the Transducer Block and its operation.

Section 5: R esource Block

describes the Resource Block and its operation.

Section 6: Mai nten ance

OUNDATION™ fieldbus.

describes hardware diagnostics, maintenance tasks, and

hardware troubleshooting.

Section 7: Sp ecifications and Reference Data

lists functional, performance, and physical specification data for the

Model 3244MV temperature transmitter.

Section 8: Haz ardous Area Approval Installation Drawings

contains the installation drawings necessary to maintain certified

ratings for the Model 3244MV installed in hazardous locations.

Section 9: Options

presents options that can be ordered with the Model 3244MV.

Appendix A: Foundation™ Fieldbus Technology

describes the basic information about fieldbus and the function blocks

that are common to all fieldbus devices.

Appendix B: Analog Input Function Block

describes the operation and parameters of the Analog Input

function block.

Appendix C: Input Selector Function Block

describes the operation and parameters of the Input Selector

function block.

Appendix D: PID Function Block

describes the operation and parameters of the

Proportional/Integral/Derivative (PID) function block.

1-1

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

Appendix E: Arithmetic Function Block

describes the operation and parameters of the Arithmetic

function block.

Appendix F: Signal Characteriz er Function Block

describes the operation and parameters of the Signal Characterizer

function block.

Appendix G: Operation with Fisher-Rosemount® DeltaV™

provides specific instructions for performing basic configuration

operations on the Model 3244MV Temperature Transmitter using the

Fisher-Rosemount DeltaV host software.

Appendix H: European ATEX Directive Information

provides information on European ATEX compliance.

SAFETY MESSAGES Procedures and instructions in this manual may require special

precautions to ensure the safety of the personnel performing the

operations. Information that raises potential safety issues is indicated

by a warning symbol ( ). Refer to the safety messages, listed at the

beginning of each section, before performing an operation preceded by

this symbol.

TRANSMITTER OVERVIEW Thank you for selecting the Rosemount Model 3244MV MultiVariable

Temperature Transmitter with F

you will find this to be the ultimate transmitter for measuring

temperature in your control, safety, and monitoring applications. This

transmitter is designed with unsurpassed quality and reliability that

you have come to expect from Rosemount Inc. The Model 3244MV is

among the world’s first devices to be registered with the Fieldbus

Foundation.

The enhanced measurement capability of the Model 3244MV allows it

to communicate multiple variables to a F

configuration tool. This temperature transmitter has the ability to

accept simultaneous inputs from two temperature sensing elements.

These two inputs can be used for control and safety applications, which

involve control, safety interlocks, or any type of critical monitoring

points where sensor redundancy is desirable. With a dual-element

sensor, the Model 3244MV Hot Backup

sensor redundancy in case the primary sensing element fails. In

addition, the differential temperature measurement capability can be

used as a diagnostic to detect sensor drift in a dual-element sensor. The

Model 3244MV MultiVariable Temperature Transmitter with

F

OUNDATION fieldbus combines the effects of transmitter drift, sensor

interchangeability error, temperature effects, and reference accuracy to

better account for actual process conditions and to assure

maximum accuracy.

OUNDATION fieldbus. We are confident

OUNDATION fieldbus host or

®

feature provides automatic

1-2

Introduction

The Rosemount Model 3244MV is excellent for measuring temperature

in monitoring applications involving basic process monitoring because

of the transmitter’s ability to simultaneously measure two separate and

independent temperature points with one transmitter. With this dual

input configuration, instrument costs can be reduced by as much as 50

percent. In addition, the multi-drop capability of F

results in additional savings through reduced wiring costs.

OUNDATION fieldbus

FOUNDATION FIELDBUS

TECHNOLOGY OVERVIEW

FOUNDATION fieldbus is an all digital, serial, two-way communication

system that interconnects field equipment such as sensors, actuators,

and controllers. Fieldbus is a Local Area Network (LAN) for

instruments that are used in both process and manufacturing

automation, having the built-in capability to distribute the control

application across the network. The fieldbus environment is the base

level group of digital networks in the hierarchy of plant networks.

The fieldbus retains the desirable features of the 4–20 mA analog

system, including standardized physical interface to the wire,

bus-powered devices on a single pair of wires, and intrinsic safety

options. It also enables the following capabilities:

• Increased capabilities due to full digital communication.

• Reduced wiring and wire terminations due to multiple devices on

one pair of wires.

• Increased supplier selection due to interoperability.

• Reduced loading on control room equipment due to the

distribution of some control and input/output functions to

field devices.

1-3

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

1-4

Section

2 Installation

OVERVIEW This section contains specific information pertaining to the installation

of the Model 3244MV MultiVariable Temperature Transmitter with

F

OUNDATION fieldbus.

SAFETY MESSAGES Instructions and procedures in this section may require special

precautions to ensure the safety of the personnel performing the

operations. Information that raises potential safety issues is indicated

by a warning symbol ( ). Please refer to the following safety messages

before performing an operation preceded by this symbol.

WARNINGS

Explosions could result in death or serious injury:

• Do not remove the transmitter cover in explosive atmospheres

when the circuit is live.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Both transmitter covers must be fully engaged to meet

explosion-proofrequirements.

Electrical shock could cause death or seriousinjury. If the sensor is installedin a

high-voltage environment and a fault condition or installation error occurs, high voltage

may be present on transmitter leads and terminals.

• Use extremecautionwhen making contact with the leads and terminals.

Processleaks could result in death or serious injury:

• Installand tightenthermowellsor sensorsbeforeapplyingpressure, or process

leakage may result.

• Do not remove the thermowell whilein operation.Removing while in operation

maycause process fluid leaks.

Failure to follow these installation guidelines could result in death or serious injury:

• Make sure only qualified personnel perform the installation.

2-1

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

GENERAL CONSIDERATIONS

ELECTRICAL CONSIDERATIONS

Electrical temperature sensors, such as RTDs and thermocouples,

produce low-level signals proportional to temperature. The Model

3244MV MultiVariable Temperature Transmitter converts the analog

sensor signal to a digital signal that is relatively insensitive to lead

length and electrical noise. This signal is then transmitted over the

F

OUNDATION fieldbus to the control room using two wires.

Proper electrical installation is necessary to prevent errors due to

sensor lead resistance and electrical noise. Shielded, twisted cable

produce the best results in electrically noisy environments. Figure 2-1

on page -3 shows a typical F

OUNDATION fieldbus installation.

Power Supply The transmitter requires between 9 and 32 V dc to operate and provide

complete functionality. The dc power supply should provide power with

less than 2% ripple.

Power Filter A fieldbus segment requires a power conditioner to isolate the power

supply filter and decouple the segment from other segments attached to

the same power supply.

Field Wiring All power to the transmitter is supplied over the signal wiring. Signal

wiring should be a shielded, twisted pair for best results. Do not run

unshielded signal wiring in conduit or open trays with power wiring or

near heavy electrical equipment.

If the sensor is installed in a high-voltage environment and a fault

condition or installation error occurs, the sensor leads and transmitter

terminals could carry lethal voltages. Use extreme caution when

making contact with the leads and terminals.

NOTE

Do not apply high voltage (e.g. ac line voltage) to the transmitter

terminals. Abnormally high voltage can damage the unit. Sensor and

transmitter power terminals are rated to 42.4 V dc.

2-2

Installation

Power Connections

Use copper wire of sufficient size to ensure that the voltage across the

transmitter power terminals is not below 9 V dc.

To connect power to the transmitter, follow the steps below:

1. Remove the transmitter cover to expose the transmitter terminal

block. Do not remove transmitter covers in explosive

atmospheres when the circuit is live.

2. Connect the power leads to the terminals marked “+” and “T” as

shown in Figure 2-2 on page -4. The power terminals are not

polar sensitive, meaning that the electrical polarity of the power

leads is not significant when connecting to the power terminals.

The use of crimped lugs is recommended when wiring to screw

terminals.

3. Tighten the terminal screws to ensure adequate contact. No

additional power wiring is needed.

4. Replace the transmitter cover, tightening the cover threads at

least one-third turn after the o-ring contacts the housing.

Both transmitter covers must be fully engaged to meet

explosion-proof requirements.

Figure 2-1. FOUNDATION

FieldbusInstallation

NOTE

After installation, it may take several seconds for the LCD meter to

function once power is applied to the transmitter.

Integrated

Power

Conditioner

and Filter

Power

Supply

(Thepower

supply,filter,first

terminator, and

configuration

toolare typically

located in the

control room.)

FOUNDATION

fieldbus

Configuration

Tool

6234 ft (1900 m) max

(depending upon cable characteristics)

Terminators

(Trunk)

(Spur)

(Spur)

Power/Signal

Wiring

* Intrinsic safe installations may allow fewer devices per I.S. barrier.

Devices 1

through 16

*

3144-3144_01C

2-3

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

Figure 2- 2. Transmitter Ter minal Block

Sensor

Terminals

Power Terminals

(not polarity–sensitive)

Transmitter

Terminals

“T” and “+”

Ground

Terminal

Grounding Transmitters are electrically isolated to 500 V ac rms. If desired, you

can ground the signal wiring at any single point. When using a

grounded thermocouple, the grounded junction serves as this point.

NOTE

Do not ground the signal wire at both ends.

Shielded Wire

To avoid grounding the loop, the recommended grounding techniques

for shielded wire usually requires a single grounding point for each

shielded wire. The following examples illustrate the single grounding

point technique:

Example 1

Connect the shield for the signal wiring to the shield for the sensor

wiring. Verify that the two shields are tied together and electrically

isolated from the transmitter housing. Ground the shield at the

power supply end.

3144-0200E01C

2-4

Example 2

Connect the shield for the sensor wiring to the ground terminal,

which is located inside the terminal compartment of the transmitter

housing. The shield for the signal wiring should be cut and isolated

from the transmitter housing and should be grounded only at the

power supply end. Never connect the shield for the signal wiring to

the ground terminal inside the transmitter housing.

Transmitter Housing

Ground the transmitter housing in accordance with local electrical

requirements. An internal ground terminal is standard. If necessary, an

optional external ground lug assembly (option code G1) can be ordered.

An external ground lug is installed when ordering certain hazardous

locations approvals (see Figure 7-5 on page 7-10). External grounding

is recommended when using the optional transient protector

(option code T1).

Installation

Surges/Transients The transmitter will withstand the electrical transients of energy level

that usually occurs through static discharges or induced switching.

However, high-energy transients, such as those induced by lightning

strikes, can damage both the transmitter and the sensor.

To protect against high-energy transients, install the integral transient

protection board (option code T1). The integral transient protection board

is available as an ordered option or as an accessory. Refer to “Transient

Protection (option code T1)” on page 9-2 for more information.

SWITCHES

Security After configuring the transmitter, you may want to protect the

configuration data from unwarranted changes. Each transmitter is

equipped with a security switch that can be positioned “ON” to prevent

the accidental or deliberate change of configuration data. This switch is

located on the front side of the electronics module and is labeled

SECURITY (see Figure 2-3 on page -5).

Simulate The simulate switch is used in conjunction with the Analog Input (AI)

function block. This switch is used to simulate temperature

measurement and as a lock-out feature for the AI function block. To

enable the simulate feature, the switch must transition from “OFF” to

“ON” after power is applied to the transmitter. When the LCD meter is

installed, the simulate feature is enabled with a jumper (see Figure 2-3

on page 2-5). This feature prevents the transmitter from being left in

simulator mode.

Figure 2-3. Transmitter

Switch Locations.

.

Transmitter Electronics Modu le LCD Met er

Switches

ON OFF

Jumper

SENSOR CONNECTIONS The Model 3244MV is compatible with a number of RTD and

thermocouple sensor types. Figure 2-4 on page 2-6 shows the correct

input connections to the sensor terminals on the transmitter. To

ensure an adequate sensor connection, anchor the sensor lead wires

beneath the flat washer on the terminal screw. Do not remove the

transmitter cover in explosive atmospheres when the circuit is live.

Both transmitter covers must be fully engaged to meet

explosion-proof requirements.

ÿ

2-5

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

If the sensor is installed in a high voltage environment and a fault

condition or installation error occurs, the sensor leads and transmitter

terminals could carry lethal voltages. Use extreme caution when

making contact with the leads and terminals.

RTD or Ohm Inputs Various RTD configurations, including 2-wire, 3-wire, 4-wire, and

compensation loop designs, are used in industrial applications. When

the transmitter is mounted remotely from a 3- or 4-wire RTD, it will

operate within specifications, without recalibration, for lead wire

resistances of up to 10 ohms per lead (equivalent to 1,000 feet of 20

AWG wire). In this case, the leads between the RTD and transmitter

should be shielded. When using only two leads (or a compensation loop

lead wire configuration), both RTD leads are in series with the sensor

element. Significant errors can occur if the lead lengths exceed one foot

of 20 AWG wire.

Thermocouple or

Millivolt Inputs

Figure 2-4. Transmitter Sensor

Wiring Diagram.

2-wire RTD

and Ohms

***

**

W

R

W&G

G

3-wire RTD

and Ohms**

For direct-mount applications, connect the thermocouple directly to the

transmitter. When mounting the transmitter remotely from the sensor,

use appropriate thermocouple extension wire. Make connections for

millivolt inputs with copper wire. Use shielding for long runs of wire.

NOTE

The use of two grounded thermocouples with the Model 3244MV is not

recommended. For applications in which the use of two thermocouples

is desired, connect either two ungrounded thermocouples, one grounded

and one ungrounded thermocouple, or one dual element thermocouple.

*

4-wire RTD

and Ohms

Thermocouples

and Millivolts

** ****

RTD with

Compensation Loop

Backup/Dual Sensor

* Transmitter must be configured for a 3-wire RTD in order to recognize an RTD with a compensation loop.

** Rosemount provides 4-wire sensors for all single-element RTDs. You can use these RTDs in 3-wire configurations by

*** Typicalwiring configurationof a Rosemount dual-element RTD is shown (R=Red, W=White, G=Green,B=Black

2-6

B

Average.

Temp./DT/Hot

with 2 RTDs

leaving the unneededleads disconnected and insulatedwith electricaltape.

Average.

Temp./DT/Hot

Backup/Dual Sensor

with 2 Thermocouples

Average. Temp./DT/

Hot Backup/Dual

Sensor with

RTDs/Thermocouples

Average. Temp./DT/

Hot Backup/Dual

Sensor with

RTDs/Thermocouples

Average. Temp./DT/

Hot Backup/Dual

Sensor with 2 RTDs

with Compensation

Loop

3144-0000F05A

Installation

MECHANICAL CONSIDERATIONS

Using an optional mounting bracket (see Figure 2-7 on page 2-10), you

can attach the Model 3244MV to:

• directly to a sensor

• apart from the sensor

• to a flat surface

• to a 2-inch diameter pipe

Installing the LCD Meter Transmitters ordered with the LCD meter option (option code M5) are

shipped with the meter installed. If later installation of the LCD meter

is desired, a small instrument screwdriver and a LCD meter with the

Meter Cover Kit are required (see “Spare Parts List” on page 7-13). The

Meter Cover Kit includes:

• LCD meter display

• Meter cover with o-ring in place

• Captive mounting screws (quantity 2)

• 10-pin interconnection header

To install the LCD Meter with Meter Cover Kit refer to Figure 2-5 and

Figure 2-7 while following the steps below.

1. Remove the transmitter cover to expose the transmitter

electronics. Do not remove the transmitter covers in explosive

atmospheres when the circuit is live.

2. Ensure that the transmitter SECURITY switch is set to the

“OFF” position.

3. Insert the long pins on the interconnection header into the

ten-pin socket located on the face of the electronics

module assembly.

4. Orient the LCD meter. The LCD meter can be rotated in

90-degree increments for easy viewing. Position one of the four

ten-pin sockets into the back of the meter to accept the

interconnection header. Insert the captive mounting screws into

the two holes on the meter that coincide with the appropriate

holes on the electronics module assembly.

5. Attach the meter to the electronics with the captive

mounting screws.

6. Insert the SIMULATE jumper into the three pin socket located

on the face of the meter.

7. Thread the meter cover onto the housing. Be sure to tighten the

cover threads at least one-third turn after the o-ring contacts the

housing. Both transmitter covers must be fully engaged to meet

explosion-proof requirements.

8. When power is applied to the transmitter, the LCD meter will

need to be configured by setting the DISPLAY_MODE parameter

(see Section 5: Resource Block for more details on configuring

the LCD meter).

2-7

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

NOTE

Observe the following LCD meter temperature limits:

Operating: –4 to 185 °F (–20 to 85 °C)

Storage: –50 to 185 °F (–45 to 85 °C)

NOTE

Option code M5 can be added to the Model 3244MV Rev. 2 without

upgrading the device software.

Figure 2-5. Transmitter and Meter

Exploded View

Housing

10-pin Interconnection Header

Electronics

Module Assembly

LCD Meter Display

Meter Cover

Captive Mounting Screws

FIELDBUS-3244MV-0000A03A

Mounting The transmitter may require supplementary support under

high-vibration conditions, particularly if used with extensive

thermowell lagging or long extension fittings. Pipe stand mounting,

using one of the optional mounting brackets, is recommended for use in

high-vibration applications.

Access Requirements Take into account the need to access the transmitter when choosing an

installation location and position.

Housing Rotation

You may rotate the electronics housing up to 90 degrees in either

direction to improve field access to the two compartments.

Terminal Block Side of the Housing

Mount the transmitter so the terminal block side is accessible. Allow

adequate clearance for cover removal. Make wire connections through

the conduit openings on the bottom of the housing.

Electronics Side of the Housing

Mount the transmitter so the electronics-side is accessible. Provide

adequate clearance for cover removal and leave additional room if an

LCD meter is installed.

NOTE

If you consider adding a LCD Meter at a later date, the electronics-side

of the transmitter should be mounted in a visible position

2-8

Tagging Commissioning Tag

The transmitter has been supplied with a removable commissioning tag

that contains both the Device ID and a space to record the device tag.

The Device ID is a unique code that identifies a particular device in the

absence of a device tag. The device tag is used as an operational

identification for the device and is usually defined by the Piping and

Instrumentation Diagram (P & ID).

When commissioning more than one device on a fieldbus segment, it

can be difficult to identify which device is at a particular location. The

removable tag provided with the transmitter can aid in this process by

linking the Device ID and a physical location for each transmitter on

the segment. The installer should note the transmitter’s physical

location on both the removable commissioning tag and the bottom

portion of the tag, which can be torn off. The bottom portion of the tags

can be used for commissioning the segment in the control system.

Figure 2-6. Commissioning Tag

Installation

Device ID

DeviceTag to denote

physical location

FIELDBUS-3244MV-COMMTAG

2-9

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

)

Figure 2-7.

Option Code B4 and B5

Mounting Bracket

Panel Mount PipeMount

3.65 ±0.06

(92.7)

Option C ode B4 Brack et

1.04 (26)

1.55

(39.4)

яюэьыъщющш

üþ

яющыъы щющш

ùþý

Note: Dimensionsare in inches (millimeters)

2 (51) D iameter

Washer (Provided)

6.6 (162.6

чюьцхыфутцщсующсыъяцыущыущэрцсыптушшутцьцясо

1.0

(25.4)

ùþüûüùþ

ùþøûþ

2-inch (50.8)Pipestand

3044-2101A01A, 3144-0427C, 0427B, 3144A 14A

Option C ode B5 Brack et

1.0 (25)

7.15 (181.6.5)

ÿ

ENVIRONMENTAL CONSIDERATIONS

Tem perature Effects See Table 2-1.

Aside from ambient temperature variations, process-induced

temperature in a direct mounting configuration is transferred from the

thermowell to the transmitter housing. If the expected process

temperature is near or beyond specification limits, consider using an

additional thermowell lagging, an extension nipple, or a remote

mounting configuration to isolate the transmitter from these excessive

temperatures. Figure 2-8 provides an example of the relationship

between transmitter housing temperature rise and extension length.

Use Figure 2-8 and the accompanying example to determine adequate

thermowell extension length.

2-10

TABLE 2-1. Temperature Ranges for

Transmitter Operation

Figure 2-8. Model 3244MV Transmitter

Housing Temperature Rise versus

Extension Length fora TestInstallation

Installation

With LCD Meter Without LCD Meter

–4 to 185 °F –40 to 185 °F

(–20 to 85 °C) (–40 to 85 °C)

60 (108)

50 (90)

40 (72)

HOUSING TEMPERATURE

RISE ABOVE AMBIENT °C (°F)

30 (54)

20 (36)

10 (18)

0

ÿ

ÿ

EXTENSION LENGTH (IN.)

EXAMPLE:

The maximum permissible housing temperature rise (T) can be

calculated by subtracting the maximum ambient temperature (A)

from the transmitter’s ambient temperature specification limit (S).

For instance, suppose A = 40 °C

T = S – A

T = 85 °C – 40 °C

T = 45 °C

For a process temperature of 540 °C, an extension length of 3.6

inches yields a housing temperature rise (R) of 22 °C, which provides

a safety margin of 23 °C. A six-inch extension length (R = 10 °C)

would offer a higher safety margin (35 °C) and would reduce

temperature-effect errors but would probably require extra support

for the transmitter. Gauge the requirements for individual

applications along this scale. If a thermowell with lagging is used,

the extension length may be reduced by the length of the lagging.

3044-0123A

Moist or Corros ive Environments

The Model 3244MV has a highly reliable, dual-compartment housing

designed to resist moisture and corrosives. The electronics module

assembly is mounted in a compartment that is isolated from the

terminal side conduit entries. When covers are installed correctly,

o-ring seals protect the interior of each compartment from the

environment. However, in humid environments it is possible for

moisture to accumulate in conduit lines and drain into the housing.

2-11

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

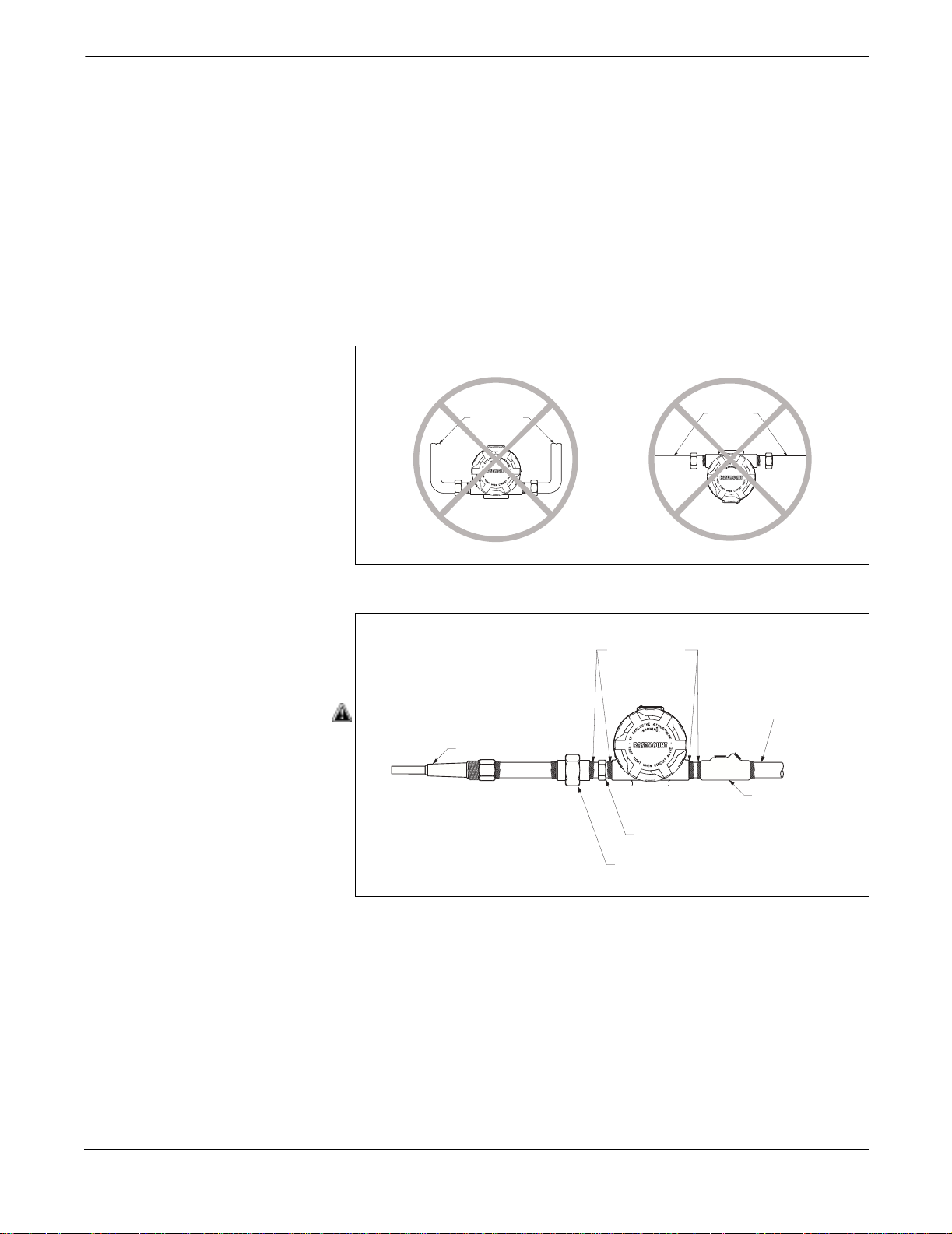

Proper installation of the transmitter ensures maximum operation and

service life. It can also have a significant impact on preventing moisture

from accumulating in the housing. Refer to Figure 2-9 before mounting

the transmitter.

If possible, mount the transmitter at a high point in the conduit run so

moisture from the conduits will not drain into the housing. If the

transmitter is mounted at a low point, the terminal compartment could

fill with water. In some instances the installation of a poured conduit

seal, such as the one pictured in Figure 2-10, is advisable. Periodically

remove the terminal compartment cover and inspect the transmitter for

moisture and corrosion.

Figure 2-9. IncorrectConduit

Installation

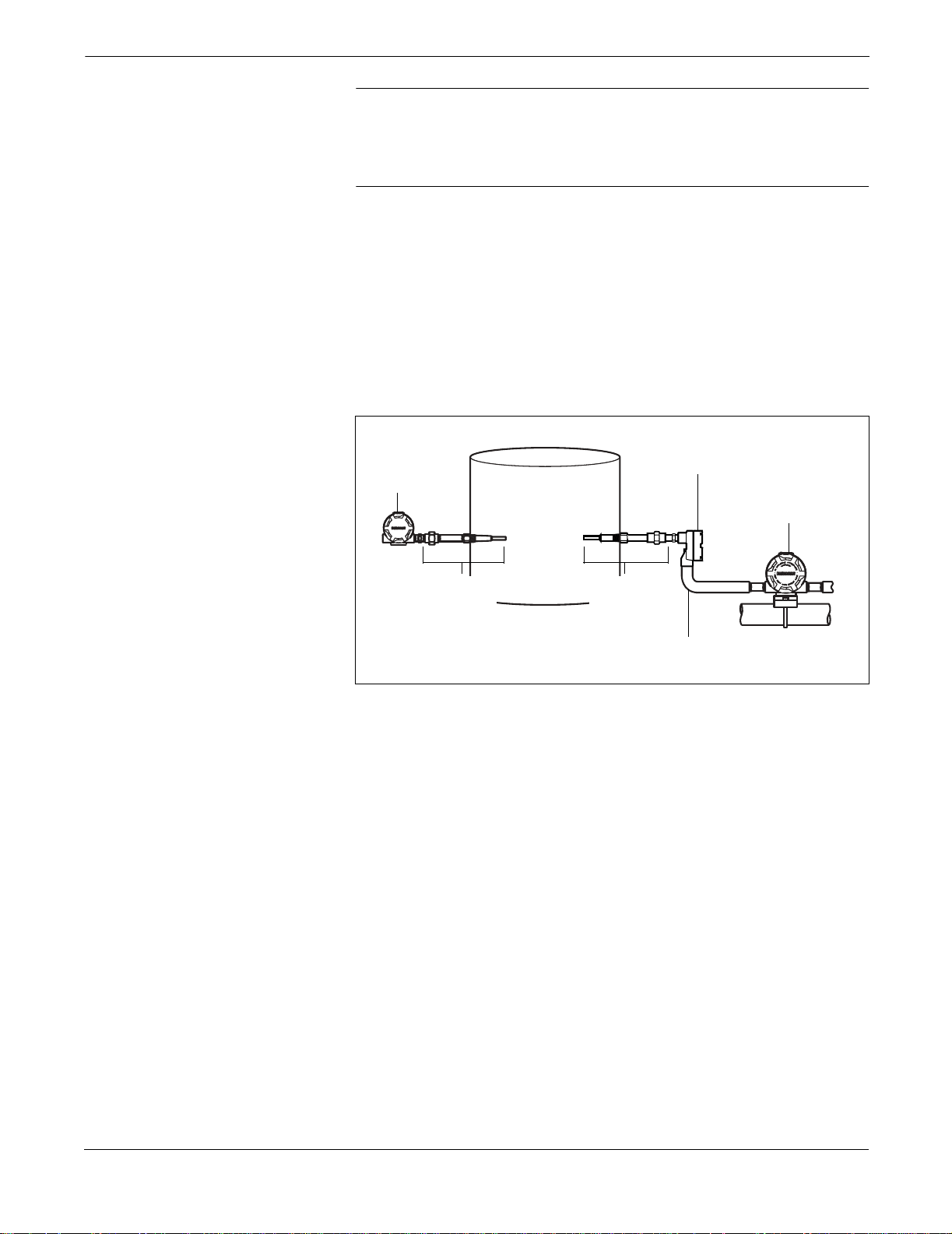

Figure 2- 10. Process Mounting with

Drain Seal

Hazardous Location Installations

Sealing

Compound

Conduit for

Field Wiring

Thermowell

Poured

Conduit Seal

Sensor Hex

Union Coupling

with Extension

(Where Required)

The Model 3244MV is designed with an explosion-proof housing and

circuitry suitable for intrinsically safe and non-incendive operation.

When specified, each transmitter is marked with an approval label. To

maintain certified ratings, install in accordance with all applicable

installation codes and approval drawings (Section 8: Hazardous Area

Approval Installation Drawings). Verify that the atmosphere in which

the transmitter operates is consistent with the appropriate hazardous

location certifications. Both transmitter covers must be fully engaged to

meet explosion-proof requirements.

3144-0429A, 0429B

3144-0430B

2-12

Installation

NOTE

Once a transmitter labeled with multiple approval types is installed, it

should not be reinstalled using any other labeled approval types. To

ensure this, the approval label should be permanently marked to

distinguish the used from the unused approval types.

INSTALLATION PROCEDURES

Figure 2- 11. Direct Mount and Remote

Mount Examples

Installation of the transmitter consists of mounting the transmitter, the

sensor, and making the electrical connections. You can mount the

transmitter directly to the sensor assembly or you can mount it

remotely (Figure 2-11). For a remote mount, use conduit or suitable

shielded cable with cable glands. The remainder of this section provides

the installation procedures for typical configuration in North America

and Europe.

Connection

Direct

Mount

Sensor

Assembly

Process Vessel

Sensor

Assembly

Head

Remote

Mount

Conduit or

Shielded Cable

3144-3144_04B

2-13

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

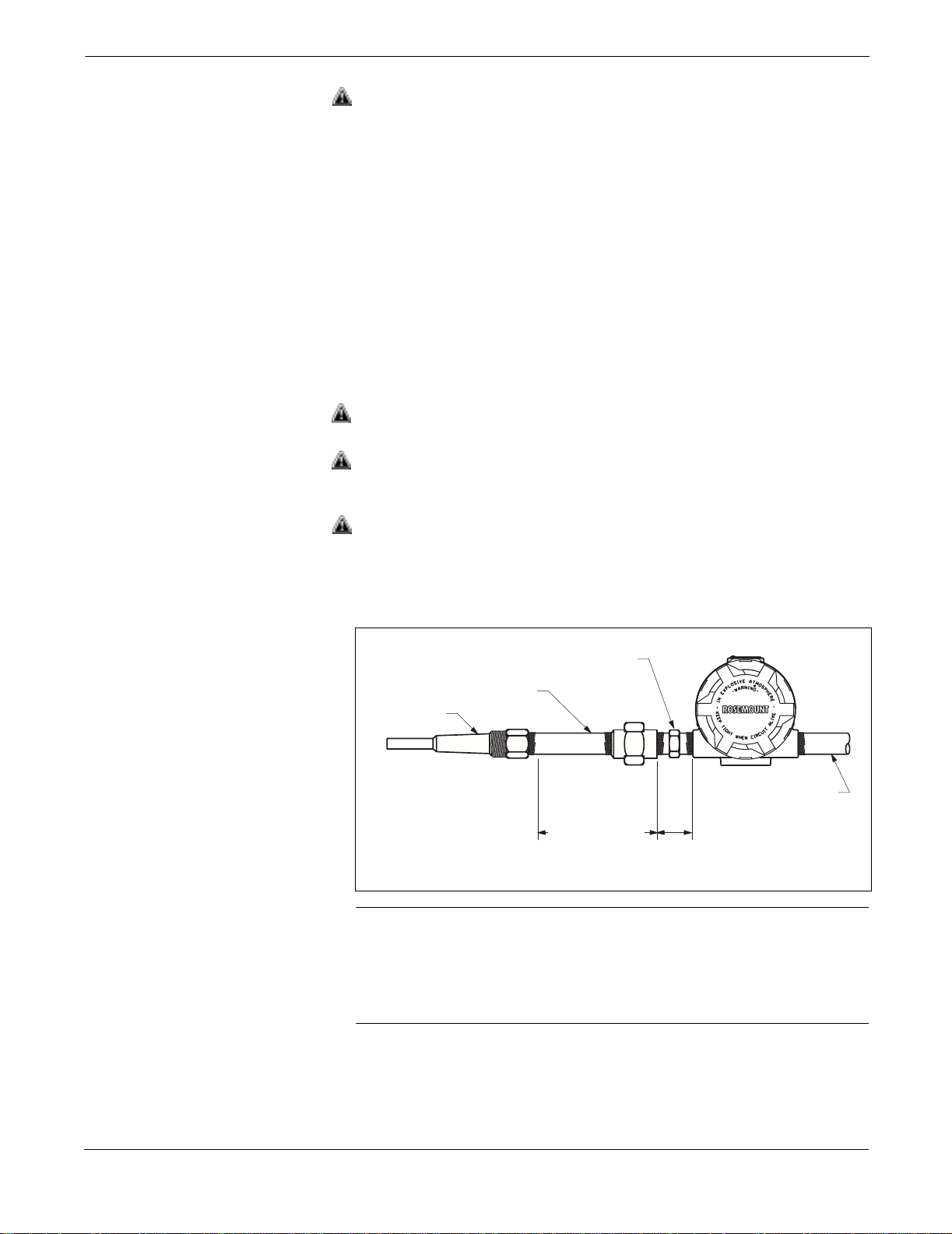

Typical North American Configuration

1. Mount the thermowell to the pipe or process container wall. Be

sure to install and tighten thermowells and sensors. Perform a

leak check before applying pressure.

2. Attach any necessary unions (or couplings) and extension

fittings. Seal the fitting threads with silicone or tape (if required).

3. Screw the sensor into the thermowell.

4. Verify all sealing requirements for severe environments or to

satisfy code requirements.

5. Attach the transmitter to the thermowell assembly. Seal all

threads with silicone or tape (if required).

6. Pull sensor leads through the extensions and unions (or

couplings) into the terminal side of the transmitter housing.

7. Install conduit for field wiring to the remaining conduit entry of

the transmitter.

8. Pull the field wiring leads into the terminal side of the

transmitter housing. Avoid contact with leads and terminals.

9. Attach the sensor leads to the transmitter sensor terminals.

Attach the power leads to the transmitter power terminals. Avoid

contact with the leads and the terminals.

10. Attach and tighten both transmitter covers. Both transmitter

covers must be fully engaged to meet explosion-proof

requirements

Figure 2-12. Typical North American

Process M ounting Configuration

Sensor Hex

Union or Coupling

and Extension

Thermowell

Conduit for

3.2

Extension

Fitting

Length (E)

Note: Dimensionsare in inches (millimeters)

(81)

Field Wiring

(dc power)

NOTE

To prevent process fluid from entering the electrical conduit and

continuing to the control room, the National Electrical Code requires

that a barrier or seal be used in addition to the primary (sensor) seal.

Professional safety assistance is recommended for installations in

potentially hazardous processes.

Fieldbus-3244MV-0433B

2-14

Installation

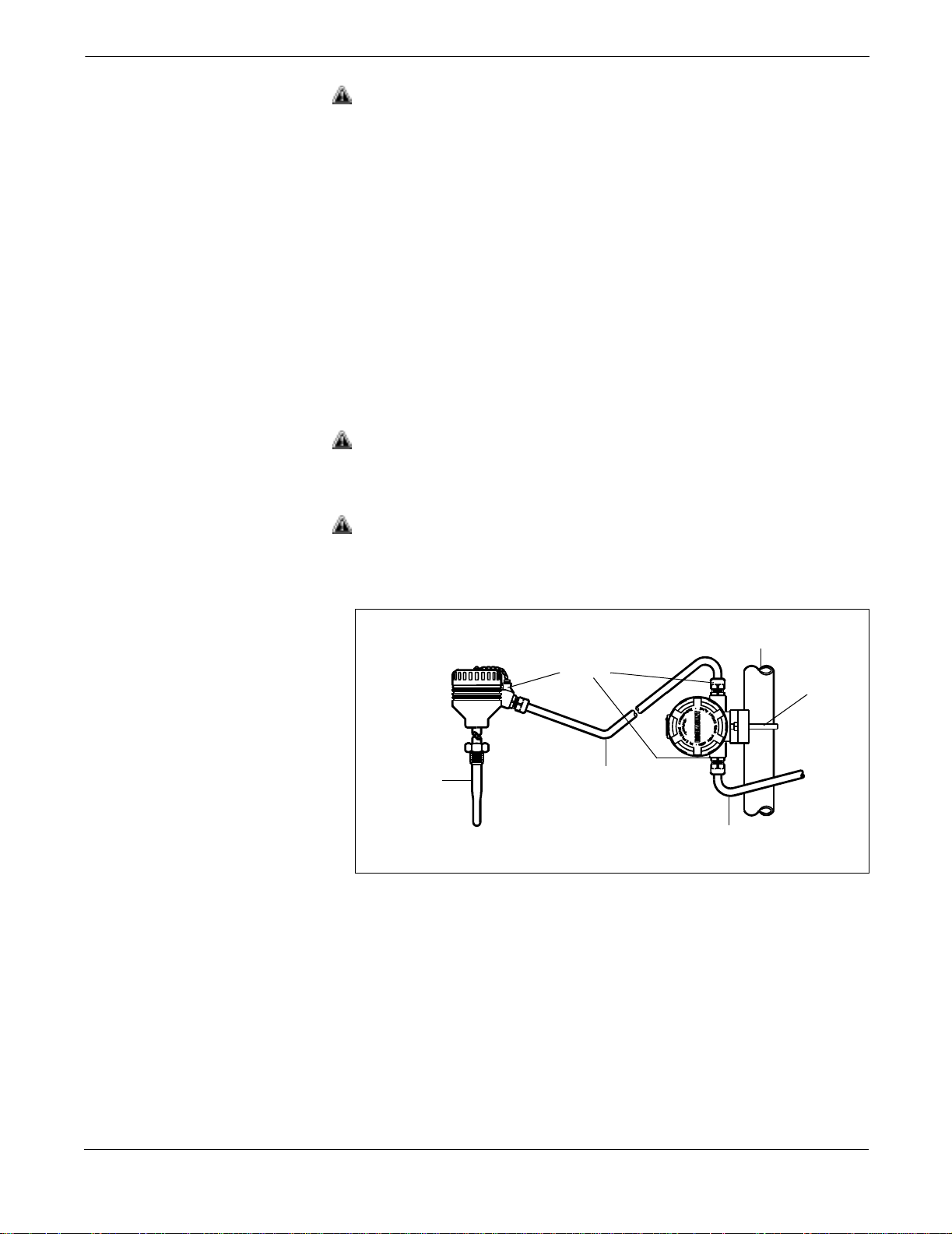

Typical European Configuration

1. Mount the thermowell to the pipe or the process container wall.

Install and tighten thermowells and sensors. Perform a leak

check before applying

process pressure.

2. Attach the connection head to the thermowell.

3. Insert the sensor into the thermowell and attach it to the

connection head.

4. Mount the transmitter to a 2-inch pipe or a suitable panel using

one of the optional mounting brackets (see Figure 2-7 on page

-10). The B4 mounting bracket is shown in Figure 2-13.

5. Attach cable glands to the shielded cable running from the

connection head to the transmitter and from the transmitter to

the control room.

6. Insert the shielded cable leads into the connection head and the

transmitter through the cable entries. Connect and tighten the

cable glands.

7. Connect the shielded cable leads to the sensor wiring leads inside

of the connection head, and the sensor wiring terminals inside

of the transmitter housing. Avoid contact with the leads and

the terminals.

8. Connect the shielded cable leads to the transmitter power

terminals. Avoid contact with the leads and the terminals.

Figure2-13. Typical European Process

Mounting Configuration

Sensor/

Thermowell

Cable

Glands

Shielded

Cable

fromSensor

2-Inch Pipe

Shielded Cable

from Transmitter

to Control Room

B4

Mounting

Bracket

644-0000B05b

2-15

Rosemount Model 3244MV MultiVariable Temperature Transmitter with Foundation Fieldbus

2-16

Loading...

Loading...