Rosemount Manual: Rosemount 3051 Wireless Pressure Transmitters Pressure, Level, and Flow Solutions with WirelessHART™ Protocol Manuals & Guides

Reference Manual

00809-0100-4100, Rev. BA

May 2017

Rosemount™ 3051 Wireless Pressure

Transmitters

Pressure, Level, and Flow Solutions with WirelessHART® Protocol

Reference Manual

00809-0100-4100, Rev. BA

Contents

1Section 1: Introduction

2Section 2: Configuration

Contents

May 2017

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Models covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Product recycling/disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Required bench top configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.1 Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Basic setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.1 Set device tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4.2 Join device to network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.3 Configure update rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.4 Set process variable units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4.5 Remove power module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Configure for pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.1 Re-mapping device variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.2 Set range points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5.3 Set transmitter percent of range (transfer function) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Configure for level and flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.1 Configuring scaled variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.2 Re-mapping device variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6.3 Set range points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Review configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7.1 Review pressure information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7.2 Review device information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7.3 Review radio information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7.4 Review operating parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.8 Configuring the LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.9 Detailed transmitter setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.9.1 Configure process alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.9.2 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Contents

2.9.3 Write protect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.10 Diagnostics and service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.10.1 Master reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

iii

Contents

May 2017

Reference Manual

00809-0100-4100, Rev. BA

2.10.2 Join status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.10.3 Number of available neighbors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.11 Advanced functions for HART Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.11.1 Saving, recalling, and cloning configuration data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3Section 3: Installation

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Installation considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.1 Wireless considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.2 Mechanical considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3.3 Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3.4 Draft range considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4 Installation procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.1 Mounting the transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.2 Impulse piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.5.3 Process connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5.4 Inline process connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5.5 Power module installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5.6 Installing the LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.6 Rosemount 304, 305, and 306 Integral Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.6.1 Rosemount 305 Integral Manifold installation procedure . . . . . . . . . . . . . . . . . . . . . . . . 37

3.6.2 Rosemount 306 Integral Manifold installation procedure . . . . . . . . . . . . . . . . . . . . . . . . 38

3.6.3 Rosemount 304 Conventional Manifold installation procedure . . . . . . . . . . . . . . . . . . . 39

3.6.4 Manifold operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4Section 4: Commissioning

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3 Viewing network status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.4 Verifying operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.4.1 Using the Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.5 Configuring transmitter security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5Section 5: Operation and Maintenance

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.3 Calibration overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

iv

Contents

Reference Manual

00809-0100-4100, Rev. BA

Contents

May 2017

5.3.1 Determining necessary sensor trims. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3.2 Determining calibration frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.3.3 Compensating for span line pressure effects (range 4 and 5) . . . . . . . . . . . . . . . . . . . . . 57

5.4 Trim the pressure signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.4.1 Sensor trim overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.4.2 Sensor trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.4.3 Recall factory trim—sensor trim. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.4.4 Line pressure effect (range 2 and 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.4.5 Compensating for line pressure (range 4 and 5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.5 LCD display screen messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.5.1 Startup screen sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.5.2 Diagnostic button screen sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.5.3 Network diagnostic status screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.4 Device Diagnostic screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6Section 6: Troubleshooting

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.3 Removing from service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.4 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

AAppendix A: Specifications and Reference Data

A.1 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

A.1.1 Conformance to specification (±3s [Sigma]). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

A.1.2 Digital output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

A.1.3 Reference accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

A.1.4 Flow performance - flow reference accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A.1.5 Total performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A.1.6 Long term stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

A.1.7 Line pressure effect per 1000 psi (6.9 MPa). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.1.8 Ambient Temperature Effect per 50 °F (28 °C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.1.9 Mounting position effects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.1.10Vibration effect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A.1.11Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Contents

A.2 Functional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

A.2.1 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

A.2.2 Range and sensor limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

A.2.3 Zero and span adjustment requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

v

Contents

May 2017

Reference Manual

00809-0100-4100, Rev. BA

A.3 Wireless self-organizing networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3.1 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3.2 Wireless radio (internal antenna, WP option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3.3 Local display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3.4 Digital zero trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3.5 Update rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3.6 Wireless sensor module for in-line transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3.7 Power module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3.8 Overpressure limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A.3.9 Static pressure limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.3.10 Burst pressure limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.3.11 Temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.3.12 Humidity limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.3.13 Volumetric displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

A.3.14 Damping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A.4 Physical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A.4.1 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A.4.2 Process connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A.4.3 Process-wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A.4.4 Rosemount 3051L process wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A.4.5 Non-wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A.4.6 Shipping weights for Rosemount 3051 Wireless . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

A.5 Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

A.5.1 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

A.5.2 Rosemount 3051C Coplanar Pressure Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

A.5.3 Rosemount 3051T In-Line Pressure Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

A.5.4 Rosemount 3051CF Flowmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

A.5.5 Rosemount 3051L Level Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

A.6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.6.1 Standard configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.6.2 Custom configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.6.3 Tagging (3 options available). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.6.4 Optional Rosemount 304, 305, or 306 Integral Manifolds . . . . . . . . . . . . . . . . . . . . . . . 119

A.6.5 Other seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.6.6 Output information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.6.7 Display and interface options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.6.8 Configuration buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

vi

Contents

Reference Manual

00809-0100-4100, Rev. BA

BAppendix B: Product Certifications

Contents

May 2017

A.6.9 Bolts for flanges and adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.7 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.1 European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.2 Telecommunication compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.3 FCC and IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.4 Ordinary Location Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.5 Installing in North America. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.6 USA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.7 Canada. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.8 Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.9 International . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.10 Brazil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.11 China. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.12 Japan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.13 EAC - Belarus, Kazakhstan, Russia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

B.14 Korea. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

CAppendix C: Network Design Best Practices

C.1 Effective range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

DAppendix D: Field Communicator Menu Trees and Fast Keys

D.1 Field Communicator menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

D.2 Field Communicator Fast Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Contents

vii

Contents

May 2017

Reference Manual

00809-0100-4100, Rev. BA

viii

Contents

Reference Manual

NOTICE

00809-0100-4100, Rev. BA

Rosemount™ 3051 Wireless Pressure, Flow,

and Level Solutions

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure you thoroughly understand the contents before installing, using, or

maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions.

United States - 1-800-999-9307 (7:00 am to 7:00 pm CST)

Asia Pacific- 65 777 8211

Europe/Middle East/Africa - 49 (8153) 9390

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of these areas, contact your local Emerson™ representative.

Title Page

May 2017

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate

local, national, and international standards, codes, and practices. Review the approvals section of this

manual for any restrictions associated with a safe installation.

Before connecting a Field Communicator in an explosive atmosphere, make sure the instruments are

installed in accordance with intrinsically safe or non-incendive field wiring practices.

Verify the operating atmosphere of the transmitter is consistent with the appropriate hazardous

locations certifications.

Process leaks could result in death or serious injury.

Install and tighten process connectors before applying pressure.

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can cause

electrical shock.

Title Page

ix

Title Page

May 2017

Reference Manual

00809-0100-4100, Rev. BA

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm (8-in.) from

all persons.

Replacement equipment or spare parts not approved by Emerson for use as spare parts could

reduce the pressure retaining capabilities of the transmitter and may render the instrument

dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of flange web (i.e.,

bolt hole) but must not contact sensor module housing.

The power module with the wireless unit contains a primary lithium-thionyl chloride battery. Each

power module contains approximately 5.0 grams of lithium. Under normal conditions, the power

module materials are self-contained and are not reactive as long as the batteries and the pack integrity

are maintained. Care should be taken to prevent thermal, electrical or mechanical damage. Contacts

should be protected to prevent premature discharge.

The products described in this document are NOT designed for nuclear-qualified applications. Using

non-nuclear qualified products in applications that require nuclear-qualified hardware or products may

cause inaccurate readings.

For information on Emerson nuclear-qualified products, contact your local Emerson Sales

Representative.

x

Title Page

Reference Manual

NOTICE

00809-0100-4100, Rev. BA

The Rosemount 3051 Wireless and all other wireless devices should be installed only after the Smart

Wireless Gateway has been installed and is functioning properly. Wireless devices should also be

powered up in order of proximity from the Smart Wireless Gateway, beginning with the closest. This will

result in a simpler and faster network installation.

Shipping considerations for wireless products (lithium batteries: green power module, model

number 701PGNKF).

The unit was shipped to you without the power module installed. Remove the power module from the

unit prior to shipping.

Each power module contains one “D” size primary lithium-thionyl chloride battery. Primary lithium

batteries are regulated in transportation by the U.S. Department of Transportation, and are also

covered by International Air Transport Association (IATA), International Civil Aviation Organization

(ICAO), and ARD (European Ground Transportation of Dangerous Goods). It is the responsibility of the

shipper to ensure compliance with these or any other local requirements. Consult current regulations

and requirements before shipping.

The power module with the wireless unit contains one “D” size primary lithium-thionyl chloride battery

(green power module, model number 701PGNKF). Each battery contains approximately 5.0 grams of

lithium. Under normal conditions, the battery materials are self-contained and are not reactive as long

as the battery and the pack integrity are maintained. Care should be taken to prevent thermal, electrical

or mechanical damage. Contacts should be protected to prevent premature discharge.

Battery hazards remain when cells are discharged.

Power modules should be stored in a clean and dry area. For maximum battery life, storage

temperature should not exceed 30 °C (86 °F).

The power module may be replaced in a hazardous area. The power module has surface resistivity

greater than one gigaohm and must be properly installed in the wireless device enclosure. Care must be

taken during transportation to and from the point of installation to prevent electrostatic charge

build-up.

Using the Rosemount 3051 Wireless in a manner other than what is specified by the manufacturer may

impair the protection provided by the equipment.

Title Page

May 2017

Title Page

xi

Title Page

May 2017

Reference Manual

00809-0100-4100, Rev. BA

xii

Title Page

Reference Manual

00809-0100-4100, Rev. BA

Section 1 Introduction

1.1 Using this manual

The sections in this manual provide information on installing, operating, and maintaining the

Rosemount

organized as follows:

Section 2: Configuration provides instruction on commissioning and operating Rosemount 3051

Wireless. Information on software functions, configuration parameters, and online variables is also

included.

Section 3: Installation contains mechanical and electrical installation instructions.

Section 4: Commissioning contains techniques for properly commissioning the device.

Section 5: Operation and Maintenance contains operation and maintenance techniques.

Section 6: Troubleshooting provides troubleshooting techniques for the most common operating

problems.

Appendix A: Specifications and Reference Data supplies reference and specification data, as well as

ordering information.

™

3051 Wireless Pressure Transmitter with WirelessHART® protocol. The sections are

Introduction

May 2017

Appendix B: Product Certifications contains approval information.

Appendix C: Network Design Best Practices provides full menu trees and abbreviated Fast Key

sequences for commissioning tasks.

Appendix D: Field Communicator Menu Trees and Fast Keys provides information on how to optimize

network reliability and performance.

1.2 Models covered

The following transmitters are covered by this manual:

Rosemount 3051C Coplanar

– Measures differential and gage pressure up to 2000 psi (137.9 bar)

– Measures absolute pressure up to 4000 psi (275.8 bar)

Rosemount 3051T In-line Pressure Transmitter

– Measures gage/absolute pressure up to 10000 psi (689.5 bar)

Rosemount 3051L Level Transmitter

– Measures level and specific gravity up to 300 psi (20.7 bar)

Rosemount 3051CF Flowmeters

– Measures flow in line sizes from

™

Pressure Transmitter

1

/2-in. (15 mm) to 96-in. (2400 mm)

1.3 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in accordance

with local and national legislation/regulations.

Introduction

1

Introduction

May 2017

Reference Manual

00809-0100-4100, Rev. BA

2

Introduction

Reference Manual

00809-0100-4100, Rev BA

Section 2 Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Required bench top configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Basic setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Configure for pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Configure for level and flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Review configuration data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Configuring the LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Detailed transmitter setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Diagnostics and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Advanced functions for HART Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

2.1 Overview

Configuration

May 2017

This section contains information on commissioning and tasks that should be performed on the bench

prior to installation.

Field Communicator and AMS Device Manager instructions are given to perform configuration

functions. For convenience, Field Communicator Fast Key sequences are labeled “Fast Keys” for each

software function below the appropriate headings.

Full Field Communicator menu trees and Fast Key sequences are available in Appendix D: Field

Communicator Menu Trees and Fast Keys.

2.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the safety of the

personnel performing the operations. Information that raises potential safety issues is indicated by a

warning symbol ( ). Refer to the following safety messages before performing an operation preceded

by this symbol.

Failure to follow these installation guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate

local, national, and international standards, codes, and practices. Review the approvals section of the

manual for any restrictions associated with a safe installation.

Before connecting a Field Communicator in an explosive atmosphere, make sure the instruments are

installed in accordance with intrinsically safe or non-incendive field wiring practices.

Verify the operating atmosphere of the transmitter is consistent with the appropriate hazardous

locations certifications.

Config uration

3

Configuration

May 2017

Reference Manual

00809-0100-4100, Rev BA

Process leaks could result in death or serious injury.

Install and tighten process connectors before applying pressure.

Electrical shock could cause death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be present on leads can cause

electrical shock.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm (8-in.) from

all persons.

Replacement equipment or spare parts not approved by Emerson

reduce the pressure retaining capabilities of the transmitter and may render the instrument

dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of flange web (i.e.,

bolt hole) but must not contact sensor module housing.

The power module with the wireless unit contains a primary lithium-thionyl chloride battery. Each

power module contains approximately 5.0 grams of lithium. Under normal conditions, the power

module materials are self-contained and are not reactive as long as the batteries and the pack

integrity are maintained. Care should be taken to prevent thermal, electrical or mechanical damage.

Contacts should be protected to prevent premature discharge.

™

for use as spare parts could

2.3 Required bench top configuration

Bench top configuration requires a Field Communicator, AMS Device Manager, or any WirelessHART®

Communicator. Connect the Field Communicator leads to the terminals labeled “COMM” on the Power

Module. See Figure 2-1 on page 5.

Bench top configuration consists of testing the transmitter and verifying transmitter configuration data.

Rosemount 3051 Wireless Transmitters must be configured before installation. Configuring the

transmitter on the bench before installation using a Field Communicator, AMS Device Manager, or any

WirelessHART Communicator ensures that all network settings are working correctly.

When using a Field Communicator, any configuration changes made must be sent to the transmitter by

using the Send key (F2). AMS Device Manager configuration changes are implemented when the Apply

button is selected.

AMS Device Manager

AMS Device Manager is capable of connecting to devices either directly, using a HART® modem, or

wirelessly via the Smart Wireless Gateway. When configuring the device, double click the device icon or

right click and select Configure.

4

Configuration

Reference Manual

00809-0100-4100, Rev BA

2.3.1 Connection diagrams

Bench hook-up

Connect the bench equipment as shown in Figure 2-1 on page 5, and turn on the Field Communicator by

pressing the ON/OFF key or log into AMS Device Manager. The Field Communicator or AMS Device

Manager will search for a HART-compatible device and indicate when the connection is made. If the Field

Communicator or AMS Device Manager fail to connect, it indicates that no device was found. If this

occurs, refer to Section 6: Troubleshooting.

Field hook-up

Figure 2-1 on page 5 illustrates the wiring for a field hook-up with a Field Communicator or AMS Device

Manager. The Field Communicator or AMS Device Manager may be connected at “COMM” on the

transmitter power module.

Figure 2-1. Field Communicator Connection

Configuration

May 2017

For HART Communication, a Rosemount 3051 WirelessHART DD is required.

2.4 Basic setup

2.4.1 Set device tag

Fast Keys

The tag is used to identify the device. You can use an 8–32 character tag.

1. From the Home screen, select 2: Configure

2. Select 1: Guided Setup

3. Select 1: Basic Setup

4. Select 1: Tagging

Config uration

2, 1, 1, 1

5

Configuration

May 2017

2.4.2 Join device to network

Reference Manual

00809-0100-4100, Rev BA

Fast Keys

2, 1, 3

In order to communicate with the Smart Wireless Gateway, and ultimately the host system, the

transmitter must be configured to communicate over the wireless network. This step is the wireless

equivalent of connecting wires from a transmitter to the host system.

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 3: Join Device to Network.

Using a Field Communicator or AMS Device Manager, enter the Network ID and Join Key so that they

match the Network ID and Join Key of the Smart Wireless Gateway and other devices in the network. If

the Network ID and Join Key are not identical to those set in the Gateway, the transmitter will not

communicate with the network. The Network ID and Join Key may be obtained from the Smart Wireless

Gateway on the Setup>Network>Settings page on the web server.

2.4.3 Configure update rate

Fast Keys

The update rate is the frequency at which a new measurement is taken and transmitted over the wireless

network. This by default is one minute. This may be changed at commissioning, or at any time via AMS

Device Manager. The update rate is user selectable from one second to 60 minutes.

1. From the Home screen, select 2: Configure.

2, 1, 4

2. Select 1: Guided Setup.

3. Select 4: Configure Update Rate.

2.4.4 Set process variable units

Fast Keys

The PV Unit command sets the process variable units to allow you to monitor your process using the

appropriate units of measure.

To select a unit of measure for the PV:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Pressure.

4. Select 1: Unit to select from the following engineering units:

inH

O at 4 °C mmH2O at 68 °F mmHg Mpa

2

inH

O at 60 °F cmH2O at 4 °C Psi Bar

2

inH

O at 68 °F mH2O at 4 °C Atm Mbar

2

ftH

O at 4 °C inHg at 0 °C To r r g/cm

2

ftH

O at 60 °F mmHg at 0 °C Pascals kg/cm

2

ftH

O at 68 °F cmHg at 0 °C hectoPascals kg/m

2

mmH

O at 4 °C mHg at 0 °C Kilopascals

2

2, 2, 2, 4

2

2

2

6

Configuration

Reference Manual

00809-0100-4100, Rev BA

2.4.5 Remove power module

After the sensor and network have been configured, remove the power module and replace the housing

cover. The power module should be inserted only when the device is ready to be commissioned.

Use caution when handling the power module. The Power Module may be damaged if dropped from

heights in excess of 6.10 m (20 ft).

2.5 Configure for pressure

2.5.1 Re-mapping device variables

The re-mapping function allows the transmitter primary, secondary, tertiary, and quaternary variables

(PV, SV, TV, and QV) to be configured in one of two configurations. the user may select either the option

of classic mapping or scaled variable mapping, see Tab l e 2 -1 for what is mapped to each variable. All

variables can be remapped with a Field Communicator or AMS Device Manager.

Table 2-1. Variable Mapping

Variable Classic mapping Scaled variable mapping

Configuration

May 2017

PV Pressure Scaled variable

SV Sensor temperature Pressure

TV Electronics temperature Sensor temperature

QV Supply voltage Supply voltage

Note

The variable assigned to the primary variable drives the output. this value can be selected as pressure or

scaled variable.

Re-mapping using a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Fast Keys

2, 1, 1, 4

Re-mapping using AMS Device Manager

Right click on the device and select Configure.

1. Select Manual Setup and click on the HART tab.

2. Assign primary, secondary, tertiary and quaternary variables under Variable Mapping.

3. Select Send.

Config uration

4. Carefully read the warning and select Ye s if it is safe to apply the changes.

7

Configuration

May 2017

2.5.2 Set range points

From the HOME screen, enter the Fast Key sequence.

Reference Manual

00809-0100-4100, Rev BA

Fast Keys

The range values command sets the lower and upper range values used for the percent of range

measurement.

Note

Transmitters are shipped from Rosemount Inc. fully calibrated per request or by the factory default of full

scale (span = upper range limit).

1. From the Home screen, select 2: Configure

2. Select 1: Guided Setup

3. Select 1: Basic Setup

4. Select 5: Range Values

2, 1, 1, 5

2.5.3 Set transmitter percent of range (transfer function)

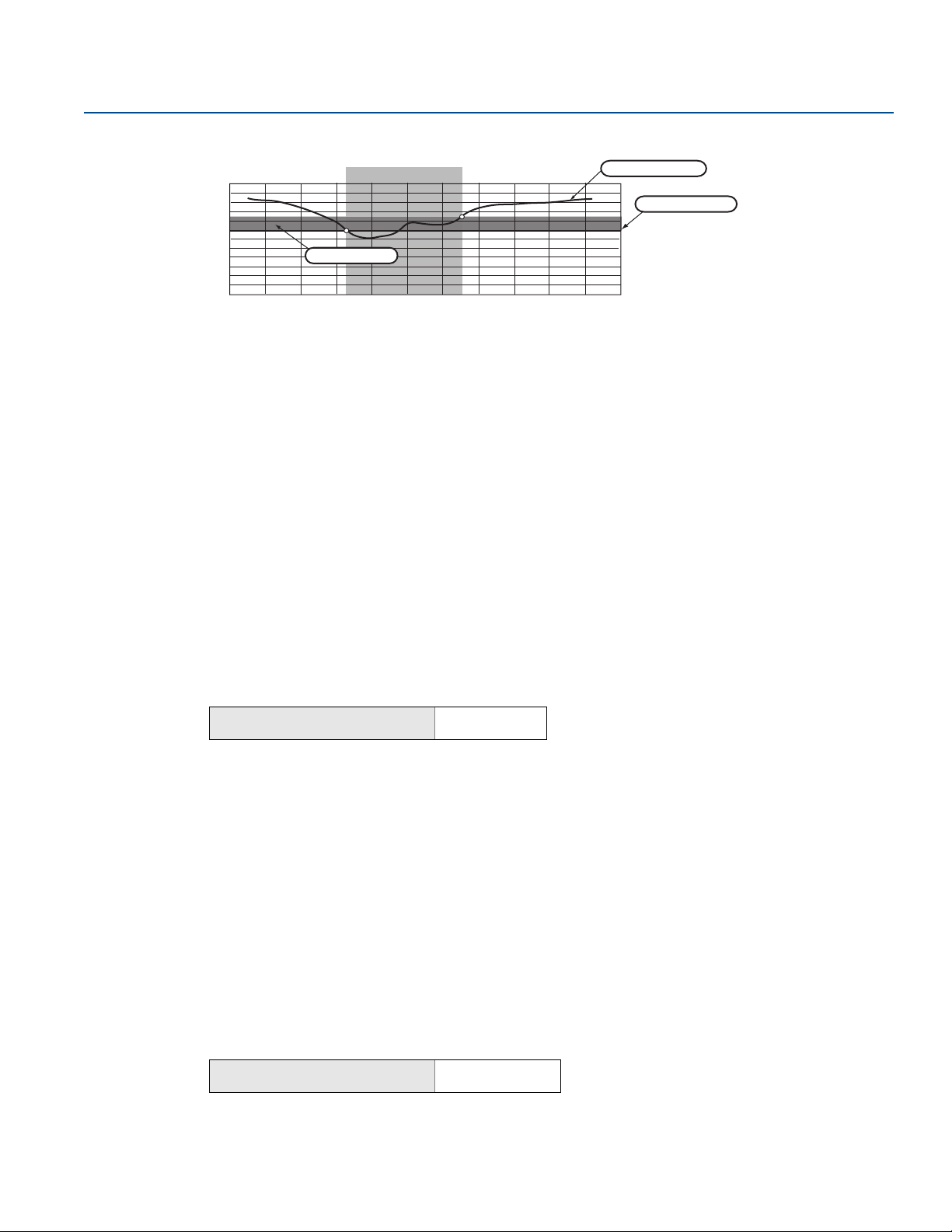

The Rosemount 3051 Wireless Transmitter has two transfer functions for pressure applications: Linear

and Square Root. As shown in Figure 2-2 on page 9, activating the square root options the transmitter

analog output proportional to flow.

However, for DP Flow and DP Level applications it is recommended to use scaled variable. Refer to

“Diagnostics and service” on page 17 for setup instructions.

From 0 to 0.6 percent of the ranged pressure input, the slope of the curve is unity (y = x). This allows

accurate calibration near zero. Greater slopes would cause large changes in output (for small changes at

input). From 0.6 percent to 0.8 percent, curve slope equals 42 (y = 42x) to achieve continuous transition

from linear to square root at the transition point.

Setting transmitter output with a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Fast Keys

8

2, 2, 2, 6

Configuration

Reference Manual

Sq. root curve

Tra nsit ion p oint

Linear section

Slope=1

Slope= 42

Tra nsit ion poi nt

Sq. root curve

Full scale

flow (%)

00809-0100-4100, Rev BA

Setting transmitter output with AMS Device Manager

Right click on the device and select Configure.

1. Select Manual Setup and select output type from Transfer Function and select Send.

2. Carefully read the warning and select Ye s if it is safe to apply the changes.

Figure 2-2. Square Root Output Transition Point

Configuration

May 2017

2.6 Configure for level and flow

2.6.1 Configuring scaled variable

The scaled variable configuration allows the user to create a relationship/conversion between the

pressure units and user-defined/custom units. There are two use cases for scaled variable. The first use

case is to allow custom units to be displayed on the transmitter's LCD display. The second use case is to

allow custom units to drive the transmitter's PV output.

If the user desires custom units to drive the PV output, Scaled Variable must be re-mapped as the

primary variable. Refer to “Re-mapping device variables” on page 11.

The Scaled Variable configuration defines the following items:

Scaled variable units - custom units to be displayed.

Scaled data options - defines the transfer function for the application.

– Linear

– Square root

Pressure value position 1 - lower known value point with consideration of linear offset.

Scaled variable value position 1 - custom unit equivalent to the lower known value point.

Pressure value position 2 - upper known value point.

Scaled variable value position 2 - custom unit equivalent to the upper known value point.

Linear offset - the value required to zero out pressures affecting the desired pressure reading.

Config uration

9

Configuration

H

L

230-in.

200-in.

12-in.

0.94 sg

May 2017

Reference Manual

00809-0100-4100, Rev BA

Low flow cutoff - point at which output is driven to zero to prevent problems caused by process

noise. It is highly recommended to use the low flow cutoff function in order to have a stable output

and avoid problems due to process noise at a low flow or no flow condition. A low flow cutoff value

that is practical for the flow element in the application should be entered.

Configuring Scaled Variable using a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

2, 1, 7, 1

1. Follow the screen prompts to configure Scaled Variable.

a. When configuring for level, select Linear under Select Scaled data options.

b. When configuring for flow, select Square Root under Select Scaled data options.

Configuring Scaled Variable using AMS Device Manager

1. Right click on the device and, select Configure.

2. Select the Scaled Variable tab and select the Scaled Variable button.

3. Follow screen prompts to configure Scaled Variable

a. When configuring for level applications, select Linear under Select Scaled data options.

b. When configuring for flow applications, select Square Root under Select Scaled data options.

DP Level Example

Figure 2-3. Example Tank

10

Configuration

Reference Manual

00809-0100-4100, Rev BA

A differential transmitter is used in a level application. Once installed on an empty tank and taps vented,

the process variable reading is –209.4 inH

by fill fluid in the capillary. Based on Table 2-2 on page 11, the scaled variable configuration would be as

follows:

Table 2-2. Scaled Variable Configuration for Tank Application

Scaled Variable units inch

Scaled data options linear

Pressure value position 1 0 inH2O

Scaled Variable position 1 12-in.

Pressure value position 2 188 inH2O

Scaled Variable position 2 212-in.

Linear offset –209.4 inH2O

DP Flow example

A differential pressure transmitter is used in conjunction with an orifice plate in a flow application where

the differential pressure at full scale flow is 125 inH

scale flow is 20,000 gallons of water per hour. It is highly recommended to use the low flow cutoff

function in order to have a stable output and avoid problems due to process noise at a low flow or no flow

condition. A low flow cutoff value that is practical for the flow element in the application should be

entered. In this particular example, the low flow cutoff value is 1000 gallons of water per hour. Based on

this information, the scaled variable configuration would be as follows:

Configuration

May 2017

O. The process variable reading is the head pressure created

2

O. In this particular application, the flow rate at full

2

Table 2-3. Scaled Variable Configuration for Flow Application

Scaled variable units: gal/h

Scaled data options: square root

Pressure value position 2: 125 inH

Scaled variable position 2: 20,000 gal/h

Low flow cutoff: 1000 gal/h

O

2

Note

Pressure value position 1 and Scaled Variable position 1 are always set to zero for a flow application. No

configuration of these values is required.

2.6.2 Re-mapping device variables

The re-mapping function allows the transmitter primary, secondary, tertiary, and quaternary variables

(PV, SV, TV, and QV) to be configured in one of two configurations. The user may select either the option

of classic mapping or scaled variable mapping, see Tab l e 2 -4 for what is mapped to each variable. All

variables can be remapped with a Field Communicator or AMS Device Manager.

Config uration

11

Configuration

May 2017

Reference Manual

00809-0100-4100, Rev BA

Table 2-4. Variable Mapping

Variable Classic mapping Scaled variable mapping

PV Pressure Scaled variable

SV Sensor temperature Pressure

TV Electronics temperature Sensor temperature

QV Supply voltage Supply voltage

Note

The variable assigned to the primary variable drives the output. This value can be selected as pressure or

scaled variable.

Re-mapping using a Field Communicator

From the HOME screen, enter the Fast Key sequence

Devise Dashboard Fast Keys

Re-mapping using AMS Device Manager

1. Right click on the device and select Configure.

2. Select Manual Setup and select on the HART tab.

3. Assign primary, secondary, tertiary and quaternary variables under Variable Mapping.

4. Select Send.

5. Carefully read the warning and select Ye s if it is safe to apply the changes.

2.6.3 Set range points

From the HOME screen, enter the Fast Key sequence

Devise Dashboard Fast Keys

The Range Values command sets the lower and upper range values used for the percent of range

measurement.

Note

Transmitters are shipped from Emerson fully calibrated per request or by the factory default of full scale

(span = upper range limit).

2, 1, 1, 4

2, 1, 1, 5

12

1. From the Home screen, select 2: Configure

2. Select 1: Guided Setup

3. Select 1: Basic Setup

4. Select 5: Range Values

Configuration

Reference Manual

00809-0100-4100, Rev BA

2.7 Review configuration data

The following is a list of factory default configurations that can be viewed by using the Field

Communicator or AMS Device Manager. Follow the steps below to review the transmitter configuration

information.

Note

Information and procedures in this section that make use of Field Communicator Fast Key sequences and

AMS Device Manager assume that the transmitter and communication equipment are connected,

powered, and operating correctly.

2.7.1 Review pressure information

Configuration

May 2017

Devise Dashboard Fast Keys

To view pressure information:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Pressure.

4. Select from the corresponding number to view each field:

1 Set range points

2 Set range points manually

3 Sensor limits

4 Units

5 Damping

6 Transfer function

2.7.2 Review device information

Devise Dashboard Fast Keys

To view device information:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

2, 2, 2

2, 2, 8

Config uration

3. Select 8: Device Information.

4. Select from the corresponding number to view each field:

1 Identification

2 Model Numbers

3 Flange Information

4 Remote seal Information

5 Serial number

13

Configuration

May 2017

2.7.3 Review radio information

Reference Manual

00809-0100-4100, Rev BA

Devise Dashboard Fast Keys

1, 9, 3

To view radio information:

1. From the Home screen, select 1: Overview.

2. Select 9: Device Information.

3. Select 3: Radio.

4. Select from the corresponding number to view each field

1 Manufacturer

2 Device type

3 Device revision

4 Software revision

5 Hardware revision

6 Transmit power level

7 Minimum update rate

2.7.4 Review operating parameters

Devise Dashboard Fast Keys

The pressure output value in both engineering units and percent of range will reflect the applied

pressure even when the applied pressure is outside of the configured range as long as the applied

pressure is between the upper and lower range limit of the transmitter. For example, if a Range 2 3051T

(LRL = 0 psi, URL = 150 psi) is ranged from 0 to 100 psi, an applied pressure of 150 psi will return a percent

of range output of 150% and an engineering output of 150 psi.

3, 2

To view the Operating Parameters menu:

1. From the Home screen, select 3: Service Tools.

2. Select 2: Variables.

The Operating Parameters menu displays the following information pertaining to the device:

1. Process

Pressure

Percent of range

Last update time

Last update time

Enter Fast Update Mode

2. Device

Sensor temperature

Supply voltage

14

Configuration

Reference Manual

00809-0100-4100, Rev BA

2.8 Configuring the LCD display

The LCD display configuration command allows customization of the LCD display to suit application

requirements. The LCD display will alternate between the selected items.

Pressure units Sensor temperature

% of range Supply voltage

Scaled variable

In the following instructions, the LCD display can also be configured to display configuration information

during the device startup. Select Review Parameters at Startup to enable or disable this functionality.

Configuring LCD display with a Field Communicator

From the HOME screen, enter the Fast Key sequence

Configuration

May 2017

Device Dashboard Fast Keys

2, 2, 4

Configuring LCD display with AMS Device Manager

Right click on the device and select Configure.

1. Click Manual Setup, select the Display tab.

2. Select desired display options and select Send.

2.9 Detailed transmitter setup

2.9.1 Configure process alerts

Devise Dashboard Fast Keys

Process alerts allow the transmitter to indicate when the configured data point is exceeded. Process

alerts can be set for pressure, temperature, or both. An alert will be displayed on a Field Communicator,

AMS Device Manager status screen or in the error section of the LCD display. The alert will reset once the

value returns within range.

Note

HI alert value must be higher than the LO alert value. Both alert values must be within the pressure or

temperature sensor limits.

2, 1, 6

Config uration

Example 1: Rising Alert

Alert “OFF” Alert “ON” Alert “OFF”

Deadband

Units of Measurement

Time

Alert Set Point

Assigned Value

15

Configuration

Deadband

Assigned Value

Alert Set Point

Alert “OFF” Alert “ON” Alert “OFF”

Units of Measurement

Time

May 2017

Example 2: Falling Alert

To configure the process alerts, perform the following procedure:

1. From the Home screen, select 2: Configure.

2. Select 1: Guided Setup.

3. Select 6: Configure Process Alerts and follow the on-screen instructions to complete configure of

process alarms.

2.9.2 Damping

The damping command introduces a delay in processing which increases the response time of the

transmitter; smoothing variations in output readings caused by rapid input changes. In the Rosemount

3051 Wireless, damping only takes effect when the device is placed in high power refresh mode and

during calibration. In normal power mode, the effective damping is zero. Note that when the device is in

high power refresh mode, battery power will be depleted rapidly. Determine the appropriate damp

setting based on the necessary response time, signal stability, and other requirements of the loop

dynamics of your system. The damping value of your device is user selectable from zero to 60 seconds.

Reference Manual

00809-0100-4100, Rev BA

Damping with a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

Enter desired damping value and select Apply.

Damping with AMS Device Manager

1. Right click on the device and select Configure.

2. Select Manual Setup.

3. Within the Pressure Setup box, enter desired damping value and click Send.

4. Carefully read the warning and select Ye s if it is safe to apply the changes.

2.9.3 Write protect

The Rosemount 3051 Wireless has a software write protect security feature.

Enabling write protect with a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

Select Write Protect to enable.

2, 2, 2, 5

2, 2, 6, 3

16

Configuration

Reference Manual

00809-0100-4100, Rev BA

Enabling write protect with AMS Device Manager

1. Right click on device and select Configure.

2. Select Manual Setup.

3. Select the tab labeled Device Information.

4. Select Write Protect to enable this feature.

2.10 Diagnostics and service

Diagnostics and service functions listed below are primarily for use after field installation. The

Transmitter Test feature is designed to verify the transmitter is operating properly, and can be

performed either on the bench or in the field.

2.10.1 Master reset

The master reset function will reset the device electronics. To perform a master reset:

Performing master reset using a Field Communicator

Configuration

May 2017

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

Performing master reset using AMS Device Manager

1. From the Home screen, select 3: Service Tools.

2. Select 5: Maintenance

3. Select 1: Calibration

4. Select 2: Factory Calibration

5. Select 1: Restore to restore to factory presets.

2.10.2 Join status

Viewing join status using a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Device Dashboard Fast Keys

3, 5, 1, 2, 1

3, 4, 1

Config uration

17

Configuration

May 2017

Viewing join status using AMS Device Manager

To view the join status of the device, perform the following procedure:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Communications.

3. Select 1: Join Status.

Wireless devices join the secure network through a four step process:

Step 1. Network Found

Step 2. Network Security Clearance Granted

Step 3. Network Bandwidth Allocated

Step 4. Network Join Complete

2.10.3 Number of available neighbors

Viewing number of available neighbors using a Field Communicator

From the HOME screen, enter the Fast Key sequence.

Reference Manual

00809-0100-4100, Rev BA

Device Dashboard Fast Keys

3, 4, 3

Viewing number of available neighbors using AMS Device Manager

In a self-organizing network, the more neighbors a device has, the more robust the network will be. To

view the number of available neighbors for the wireless device, perform the following procedure:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Routine Maintenance.

3. Select 3: Number of Available Neighbors.

2.11 Advanced functions for HART Protocol

2.11.1 Saving, recalling, and cloning configuration data

Device Dashboard Fast Keys

Use the cloning feature of the Field Communicator or the AMS “User Configuration” feature to configure

several Rosemount 3051 Wireless similarly. Cloning involves configuring a transmitter, saving the

configuration data, then sending a copy of the data to a separate transmitter. Several possible

procedures exist when saving, recalling, and cloning configuration data. For complete instructions refer

to the Field Communicator Reference Manual

left arrow, 1, 2

or AMS Books Online. One common method is as follows:

18

Configuration

Loading...

Loading...