Rosemount Manual: OCX 8800 O2 / Combustibles Transmitter Hazardous Area with Integral Electronics and LOI Local Operator Interface-Rev 1.3 | Rosemount Manuals & Guides

Instruction Manual

IM-106-880CIL, Rev 1.3

April 2017

Rosemount

OCX8800

Oxygen and Combustibles Transmitter

TM

Hazardous Area Transmitter with Integral Electronics and Local Operator Interface

HIGHLIGHTS OF CHANGES

Effective December 2007, Rev 1.1

Page/Section Summary

Throughout Updated manual number suffixes in page headers to indicate OCX configuration.

Changed references to HART Communicator te read Field Communicator in text and

illustrations.

Page 1-9 Added new illustration Figure 1-5 .

Page 1-12 Updated Product Matrices.

Page 1-13 Revised/updated Table 1-2 .

Page 2-2 Deleted obsolete CAUTION statement.

Page 2-10 Revised paragraph 4 listing of gases for calibration.

Page 2-14 Revised Figure 2-11 to indicate minim um pr ess ur e f or actuation of the blowback valve.

Page 2-15 Revised Figure 2-12 to indicate minimum pr es sur e for actuat ion of t he blowback valve.

Page 5-4 Revised 1st paragraph.

Page 5-5 Revised HART menu items in Figure 5-3, Sh eet 1 of 4

Page 5-9 Added new step 4 to both D/A Trim Procedures.

Page 6-3 Replaced steps 6 through 10 with a repeat of step 4 instruction.

Page 6-4 Revised steps 2 and 3.

Page 8-3 Revised "Ref Current Err" fault indication heading.

Page 8-7 Revised probable cause statements of "Cal Warning/Cal Failed" fault indication.

Page 9-5 Revised parts list for Sensor Housing Components.

Appendix A Updated multi-lingual safety pages.

Effective July 2008, Rev 1.2

Page/Section Summary

Page 4-3 Added note regarding cleaning the LOI screen before each use.

Effective April 2017, Rev 1.3

Page/Section Summary

Title page Removed Rosemount Analytic a l logo.

Updated Emerson logo.

Page 1-10 Updated Blowback Air specification.

Page C-1 Updated Return of Materials information.

Back page Updated to include new addresses, social media information, and Rosemount and

Emerson logos.

Instruction Manual

April 2017

OCX 8800

IM-106-880CIL, Rev 1.3

SECTION 1

Description and

Specifications

SECTION 2

Installation

SECTION 3

Configuration and

Startup

Table of Contents

Essential Instructions ........................................................................................ i

Preface ............................................................................................................... ii

Definitions .......................................................................................................... ii

Symbols .............................................................................................................. ii

Component Checklist ................................................................................... 1-1

System Overview .......................................................................................... 1-1

Specifications ..............................................................................................1-10

Mechanical

Installation ...................................................................................................... 2-2

Electrical Installation ..................................................................................... 2-7

Pneumatic Installation ................................................................................2-10

Initial Startup ................................................................................................2-16

Verify Installation ........................................................................................... 3-1

Initial Power Up ............................................................................................. 3-3

Set Test Gas Values .................................................................................... 3-4

OCX 8800 Reset Procedure ....................................................................... 3-4

SECTION 4

Using the LOI

SECTION 5

Using HART

Communications

SECTION 6

Calibration

Overview ........................................................................................................ 4-1

Display Orientation ....................................................................................... 4-1

LOI Controls ................................................................................................... 4-2

Overview ................................................................................................... 4-2

LOI Key Functions .................................................................................. 4-2

LOI Status Codes .................................................................................... 4-3

LOI Menu Tree .............................................................................................. 4-4

D/A Trim Procedures .................................................................................... 4-8

Overview ........................................................................................................ 5-1

Field Communicator Sig na l Conn ec tio ns .................................................. 5-1

Field Communicator PC Connections ........................................................ 5-4

HART Menu Tr

D/A Trim Procedures .................................................................................... 5-9

Overview ........................................................................................................ 6-1

Fully Automatic Calibration .......................................................................... 6-1

Operator - Initiated Autocalibration ............................................................ 6-4

Manual Calibration ........................................................................................ 6-4

ee .......................................................................................... 5-5

Instruction Manual

April 2017

OCX 8800

TOC-2

IM-106-880CIL, Rev 1.3

SECTION 7

Maintenance and Service

SECTION 8

Troubleshooting

Overview ........................................................................................................ 7-1

OCX 8800 Removal

and Installation .............................................................................................. 7-1

OCX with

Integral Electronics ................................................................................. 7-2

Repair Sensor Housing ................................................................................ 7-5

Sensor Housing Disassembly ............................................................... 7-5

Sensor Housing Assembly .................................................................. 7-15

Repair Electronics Housing ...................................................................... 7-25

Electronics Housing Disassembly ..................................................... 7-25

Electronics Housing Assembly ........................................................... 7-28

Replace Tube Fittings ................................................................................7-31

Remove Tube Fittings ..........................................................................7-31

Install Tube Fittings ...............................................................................7-32

Overview ........................................................................................................ 8-1

Grounding ................................................................................................. 8-1

Electrical Noise ........................................................................................ 8-1

Electrostatic Discharge........................................................................... 8-1

Total Power Loss .................................................................................... 8-2

Diagnostic Alarms ......................................................................................... 8-2

Fault Isolation ................................................................................................ 8-3

Alarm Relay Events ....................................................................................8-11

SECTION 9

Replacement Parts

APPENDIX A

Safety Data

APPENDIX B

SPA with HART Alarm

APPENDIX C

Return of Materials

Sensor Housing ............................................................................................. 9-2

Electronics Housing ...................................................................................... 9-6

O2 Cell and Heater Strut Assembly ........................................................... 9-9

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Safety Data Sheet for Ceramic Fiber Products . . . . . . . . . . . . . . . . . A-24

High Pressure Gas Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-30

Atex Clarification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-31

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

llation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Insta

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Returning Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Instruction Manual

April 2017

OCX 8800

IM-106-880CIL, Rev 1.3

ESSENTIAL INSTRUCTIONS

Rosemount OCX 8800

Oxygen and Combustibles

Transmitter

Emerson Process Management designs, manufactures and tests its products

to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly install,

use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and

integrated into your safety program when installing, using, and maintaining

Emerson’s Rosemount Analytical products. Failure to follow the proper

instructions may cause any one of the following situations to occur: Loss of

life; personal injury; property damage; damage to this instrument; and

warranty invalidation.

•

Read all instructions prior to installing, operating, and servicing the

product.

•

If you do not understand any of the instructions, contact your

Emerson Process Management representative for clarification.

•

Follow all warnings, cautions, and instructions marked on and

supplied with the product.

•

Inform and educate your personnel in the proper installation,

operation, and maintenance of the product.

•

Install your equipment as specified in the Installation Instructions

of the appropriate Instruction Manual and per applicable local and

national codes. Connect all products to the proper electrical and

pressure sources.

•

To ensure proper performance, use qualified personnel to install,

operate, update, program, and maintain the product.

•

When replacement parts are required, ensure that qualified people use

replacement parts specified by Emerson Process Management.

Unauthorized parts and procedures can affect the product's

performance, place the safe operation of your process at risk, and

VOID YOUR WARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

•

Ensure that all equipment doors are closed and protective covers

are in place, except when maintenance is being performed by

qualified persons, to prevent electrical shock and personal injury.

READ THIS PAGE BEFORE PROCEEDING!

The information contained in this document is subject to change without

notice.

If a Model 275/375 Universal HART® Communicator is used with this unit, the software

within the Model 275/375 may require modification. If a software modification is required,

please contact your local Emerson Process Management Service Group or National

Response Center at 1-800-654-7768.

Instruction Manual

April 2017

OCX 8800

ii

IM-106-880CIL, Rev 1.3

PREFACE The purpose of this manual is to provide a comprehensive understanding of

the OCX 8800 components, functions, installation, and maintenance.

We recommend that you thoroughly familiarize yourself with the Introduction

and Installation sections before installing your transmitter.

The introduction presents the basic principles of the transmitter along with its

performance characteristics and components. The remaining sections contain

detailed procedures and information necessary to install and service the

transmitter.

Before contacting Emerson Process Management concerning any questions,

first consult this manual. It describes most situations encountered in your

equipment's operation and details necessary action.

DEFINITIONS The following definitions apply to WARNINGS, CAUTIONS, and NOTES

found throughout this publication.

Highlights an operation or maintenance procedure, practice, condition, stat ement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

SYMBOLS

Highlights an operation or maintenance procedure, practice, condition, stat ement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of

effectiveness.

NOTE

Highlights an essential operating procedure, condition, or statement.

: EARTH (GROUND) TERMINAL

: PROTECTIVE CONDUCTOR TERMINAL

: RISK OF ELECTRICAL SHOCK

: WARNING: REFER TO INSTRUCTION BULLETIN

NOTE TO USERS

The number in the lower right corner of each illustration in this publication is a

manual illustration number. It is not a part number, and is not related to the

illustration in any technical manner.

Instruction Manual

April 2017

OCX 8800

IM-106-880CIL, Rev 1.3

Section 1 Description and Specifications

Component Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-10

COMPONENT

CHECKLIST

SYSTEM OVERVIEW Scope

A typical OCX 8800 Oxygen/Combustibles Transmitter package should

contain the items shown in Figure 1-1.

Use the product matrix in Table 1-1 at the end of this section to verify your

order number. The first part of the matrix defines the model. The last part

defines the various options and features of the OCX 8800. Check the model

number against the transmitter features and options, making sure options

specified by this number are on or included with the unit. Use this complete

model number for any correspondence with Emerson Process Management.

A list of accessories for use with the OCX 8800 is provided in Table 1-2.

This Instruction Manual supplies details needed to install, startup, operate,

and maintain the OCX 8800. Signal conditioning electronics outputs separate

4-20 mA signals representing oxygen (O

This information, plus additiona l detai ls, can be ac ces s ed with the HART

Model 275/375 handheld communicator or Rosemount Analytical AMS

software. The local operator interface (LOI) also provides a communications

interface with the electronic s.

) and combustibles (COe) values.

2

System Description

The OCX 8800 is designed to measure oxygen and combustible

concentrations in flue gas temperatures up to 2600°F (1427°C). Electrical

connections, power and communications are made through two 3/4 NPT ports

in the flameproof electronics enclosure using fittings and cables provided by

the customer. Cable installation must meet NEC, IEC and/or other applicable

national or local codes for Class I, Zone 1, Group IIB +H2 T3/T6 permanently

mounted equipment. The transmitter is close coupled to the process and

requires minimal sample conditioning requirements.

Instruction Manual

April 2017

OCX 8800

1-2

3

37390006

Figure 1-1. Typical System Package

4

6

1.

Instruction Manual

2.

Field Communicator Package (optional)

3.

Adapter Plate with Mounting Hardware and Gasket

4.

Reference Air and Calibration Set

5.

Blowback Hardware (optional)

6.

OCX 8800 with Integral Electronics

MAN 4275A00

English

October 1994

HART Communicator

o

FISHER

-ROSEMOUNT

5

IM-106-880CIL, Rev 1.3

1

TM

2

1-3

Instruction Manual

April 2017

OCX 8800

IM-106-880CIL, Rev 1.3

The equipment measures oxygen percentage by reading the voltage

developed across a heated electrochemical cell, which consists of a small

yttria-stabilized, zirconia disc. Both sides of the disc are coated with porous

metal electrodes. When operated at the proper temperature, the millivolt

output of the cell is given by the following Nernst equation:

EMF = KT log10 (P

Where:

1.

P2 is the partial pressure of the oxygen in the measured gas on one side

of the cell.

2.

P1 is the partial pressure of the oxygen in the reference air on the

opposite side of the cell.

3.

T is the absolute temperature.

4.

C is the cell constant.

5.

K is an arithmetic constant.

NOTE

For best results, use clean, dry instrument air (20.95% oxygen) as the

reference air.

When the cell is at operating temperature and there are unequal oxygen

concentrations across the cell, oxygen ions will travel from the high oxygen

partial pressure side to the low oxygen partial pressure side of the cell. The

resulting logarithmic output voltage is approximately 50 mV per decade. The

output is proportional to the inverse logarithm of the oxygen concentration.

Therefore, the output signal increases as the oxygen concentration of the

sample gas decreases. This characteristic enables the OCX 8800 to provide

exceptional sensitivity at low oxygen concentrations.

1/P2

) + C

The OCX 8800 measures net oxygen concentration in the presence of all the

products of combustion, including water vapor. Therefore, it may be

considered an analysis on a "wet" basis. In comparison with older methods,

such as the portable apparatus, which provides an analysis on a "dry" gas

basis, the "wet" analysis will, in general, indicate a lower percentage of

oxygen. The difference will be proportional to the water content of the

sampled gas stream.

The OCX 8800 combustibles sensor is a catalytic sensor consisting of two

Resistance Devices (RTD). One RTD is the reference element covered with

an inert coating. The other RTD element is active, coated with a catalyst. As

the sample gases flow by the sensor, the combustible gases oxidize on the

surface of the active element. The oxidation that occurs produces heat and a

temperature rise in the active element. The temperature difference produces

a resistance relationship between the two elements that is directly

proportional to the concentration of combustibles in the sample gases.

1-4

Instruction Manual

880CIL, Rev 1.3

April 2017

OCX 8800

IM-106-

The catalyst is specifically designed to detect carbon monoxide (CO), but the

sensor responds to other combustible gases. The sensor is calibrated using

CO, thus the output should be expressed in terms of CO. However, since the

sensor detects other combustible gases, the output cannot just be labeled

CO. The response of the sensor to other combustible gases gives an output

that is equivalent to the sensor detecting CO. The term COe is used in this

manual to describe the sensor output. This term indicates that the sensor is

calibrated in terms of CO, and that the sensor output is equivalent to CO but

not specific to CO.

Dilution air is provided to the COe sensor to ensure there is adequate oxygen

to fully oxidize any combustible gases regardless of the concentration of

oxygen in the process.

System Configuration

Transmitters are available in four lengths, giving the user the flexibility to use

a penetration appropriate to the size of the stack or duct. The length options

are 18 in. (457 mm), 3 ft (0.91 m), 6 ft (1.83 m), or 9 ft (2.7 m). Probes are

available in three material options, 316L stainless steel, inconel 600, and

ceramic to accommodate higher temperatures.

The electronics are contained in a separate housing from the sensors. The

electronics and sensor housings are integrally mounted.

The electronics control both sensor temperatures and provide individual 4-20

mA isolated outputs that are proportional to the measured oxygen and

combustibles concentrations. The power supply can accept voltages of 100 to

240 VAC and 50 to 60 Hz. The electronics accepts millivolt signals generated

by the sensors and produces the outputs to be used by remotely connected

devices. The outputs are isolated 4-20 mA linearized currents. Refer to

Section 3, Configuration and Startup for specific instructions upon initial

power up.

System Features

1.

The O2 cell output voltage and sensitivity increase as the oxygen

concentration decreases.

2.

HART communication is standard. To use the HART capability, you

must have either:

a.

Model 275/375 Field Communicator.

b.

AMS software for the PC.

3.

Oxygen cell and heater/thermocouple assembly are field replaceable.

4.

Electronics are automatically configured for line voltages from 100 to

240 VAC.

1-5

Instruction Manual

April 2017

OCX 8800

IM-106-880CIL, Rev 1.3

5.

An operator can calibrate and diagnostically troubleshoot the OCX 8800

in one of two ways:

a.

LOI. The LOI is mounted to the end of the electronics module and

allows local communications with the electronics. Refer to Section 4,

Using the LOI, for more information.

b.

Optional HART Interface. Each of the OCX 8800's 4-20 mA output

lines transmit an analog signal proportional to oxygen or combustible

levels detected. The HART output is superimposed on the oxygen

4-20 mA output line only. This information can be accessed through

the following:

•

Model 275/375 Field Communicator - The handheld field

communicator requires Device Description (DD) software specific

to the OCX 8800. The DD software will be supplied with many

Model 275/375 units, but can also be programmed into existing

units at most Emerson Process Management service offices.

Refer to Section 5, Using HART Communications, for additional

information.

•

Personal Computer (PC) - The use of a personal computer

requires AMS software available from Emerson Process

Management.

•

Selected Distributed Control Systems - The use of distributed

control systems requires input/output (I/O) hardware and AMS

software which permit HART communications.

6.

Optional Blowback System. The blowback system periodically blows

instrument air back throug h t he sample line filter a nd o ut the s ample

tube. This clears out particulate and keeps the sample line filter from

clogging.

System Operation

Figure 1-2 shows the relationship between the components of the OCX 8800.

The sensors and the electronics are contained in separate housings. The

sensor housing and probe mounts to a duct or process wall so that the probe

protrudes into the flue gas stream. An air powered eductor continuously pulls

samples of the process flue gas through the probe to a chamber in front of the

sensor housing wher e t he s am ple p as ses the O

the COe sensor. Dil ution ai r is pr ovided t o the C Oe se nsor and r ef erence a ir

to the O

the COe sensor, it is drawn through the eductor where it mixes with the

eductor air and exits through exhaust back into the system. The electronics

housing contains the CPU and HART boards which convert the sensor inputs

into 4-20 mA analog output signals. The CPU can also initiate and perform

calibrations. Three test gasses and instrument air can be turned on and off by

solenoids. Test gas flow to the sensors is regulated by a flow meter between

the electronics and sensor housings. Instrument air is separated into eductor

air, reference air, and dilution air. The instrument air solenoid does not allow

air flow until the heaters are up to temperature. This minimizes the amount of

sampled process flue gas being pulled into cold sensors causing

condensation.

sensor. After the gas sam ple f lows past th e O2 sensor and through

2

sensor and continues o n t o

2

1-6

Instruction Manual

880CIL, Rev 1.3

April 2017

OCX 8800

Test Gas

Figure 1-2. S ystem Operation Diagram

37390001

IM-106-

Sample

Gas

Probe

Exhaust

SENSOR

HOUSING

COe

Combustibles

Sensor

O

2

Sensor

Eductor

Dilution Air

Flow Meter

7 scfh

Reference Air

ELECTRONICS

Instrument Air

Eductor Air

Flow Meter

50 cc/min.

(0.1 scfh)

HOUSING

CPU

HART

Board

Power

Supply

Optional

Test Gas

Solenoids

Solenoid

Low O

2

High O

Test Gas

CO

Test Gas

Instrument

Air

2

Handling the OCX 8800

It is important that printed circuit boards and integrated circuits are handled only when

adequate antistatic precautions have been taken to prevent possible equipment damage.

The OCX 8800 is designed for industrial application. Treat each component of the system

with care to avoid physical damage. The probe may contain components made from

ceramics, which are susceptible to shock when mishandled.

System Considerations

Prior to installing your OCX 8800, make sure you have all the components

necessary to mak e the system installation. Ens ure al l t he c omponents are

properly integrated to make the system functional.

1-7

Instruction Manual

IM-106-880CIL, Rev 1.3

April 2017

OCX 8800

Figure 1-3. OCX 8800 HART

Connections and AMS Application

After verifying that you have all the components, select mounting locations

and determine how each component will be placed in terms of available line

voltage, ambient temperatures, environmental considerations, convenience,

and serviceability. Figure 1-3 shows a typical system wiring. Simplified

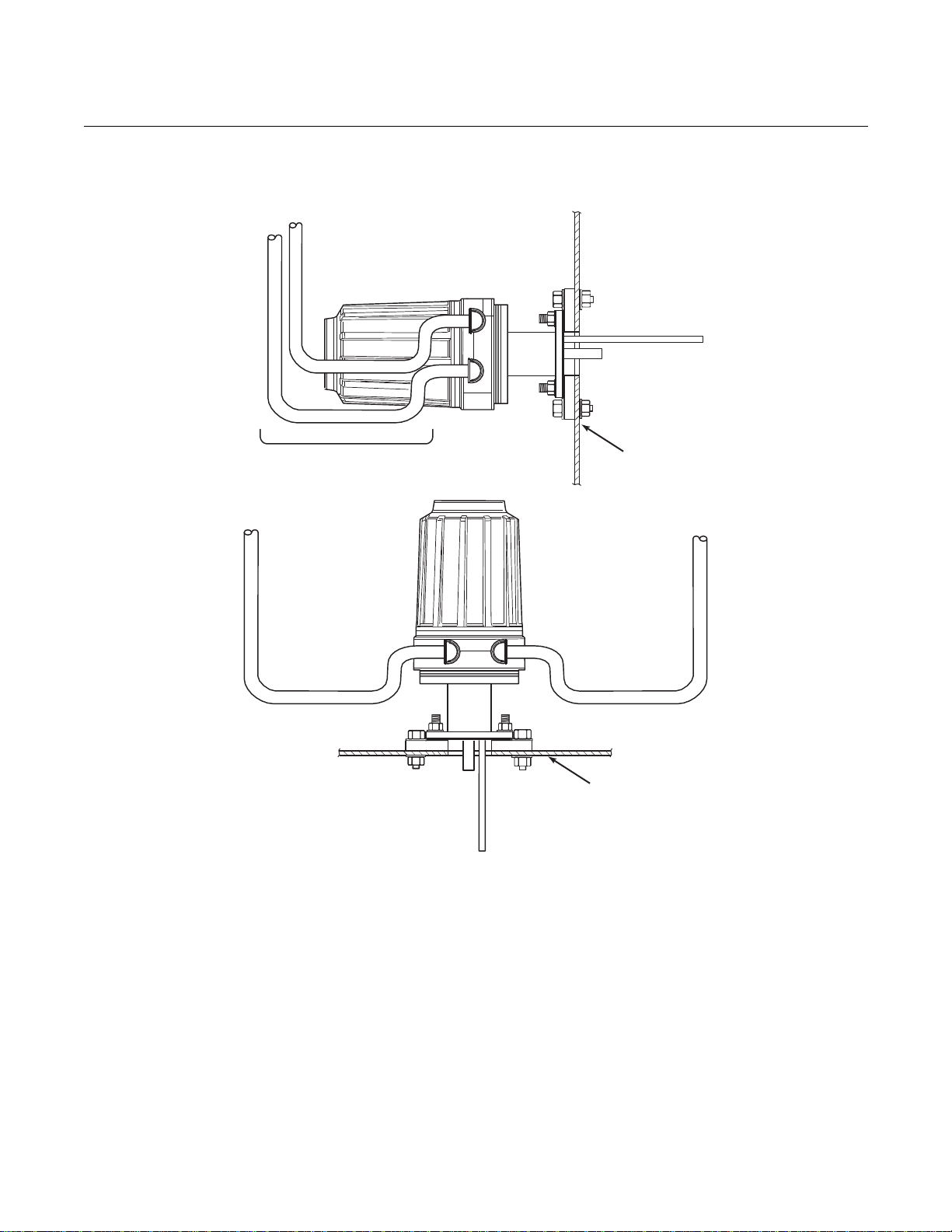

installations for the OCX 8800 are shown in Figure 1-5. Figure 1-5 shows the

dimensions for the optional sample tube support.

A source of instrument air is required at the OCX 8800 for reference air,

dilution air, and eductor air. Since the OCX 8800 is equipped with an in-place

calibration feature, provision should be made for connecting test gas tanks to

the OCX 8800 when it is to be calibrated.

NOTE

The electronics module is designed to meet NEMA 4 (IP66) and the electronic

components are rated to temperatures up to 185°F (8 5°C).

Retain packaging in which the unit arrived from the factory in case any

components are to be shipped to another site. This packaging has been

designed to protect the product.

1-8

Instruction Manual

880CIL, Rev 1.3

April 2017

OCX 8800

Figure 1-4. Typical System

37390063

Installation

IM-106-

Test Gas

Flow Meter

Gases

Stack

Dilution

Air

Flow

Meter

Adapter

Plate

Duct

Pressure

Regulator

OCX 8800 with

INTEGRAL

ELECTRONICS

4-20 mA Outputs

(2 Twisted Pairs)

Line Voltage

Instrument Air

(Reference Gas)

High O

Low O

CO Test Gas

Test Gas

2

Test Gas

2

Supply

1-9

Instruction Manual

IM-106-880CIL, Rev 1.3

April 2017

OCX 8800

Figure 1-5. Sample Tube Support

Instruction Manual

IM-106-

880CIL, Rev 1.3

April 2017

OCX 8800

1-10

SPECIFICATIONS

Hazardous Area OCX

Specifications

0-1% to 0-40% O2, fully field selectable Net O2 Range

Combustibles 0-1000 ppm to 0-5%, fully field selectable

Accuracy

± 0.75% of reading or 0.05% O2 (whichever is greater)Oxygen

Combustibles ± 2% range

System Response to

Test Gas

Oxygen 10 sec T90

25 sec T90Combustibles

Temperature Limits

32° to 2600°F (0° to 1427°C)Process

Sensors Housing -40° to 212°F (-40° to 100°C), ambie nt

Electronics Housing -40° to 149°F (-40° to 65°C), ambient

Local Operator

Interface

Nominal and Approximate

Shipping Weights

probe package

3 ft (0.91 m) probe 55 lbs (20.5 kg)

package

6 ft (1.83 m) probe

package

9 ft (2.74 m) probe

package

Materials

Probes

Enclosures

Calibration

Calibration Gas Mixtures

Recommended

(Ref. test gas bottles

kit #1A99119G04)

Calibration Gas Flow 7 scfh (3.3 l/m)

Reference Air 2 scfh (1 l/m), clean, dry instrument-quality air (20.95% O2),

Eductor Air 5 scfh (2.5 l/m), clean, dry, instrument-quality air 20.95% O2),

Dilution Air 0.1 scfh (0.5 l/m), clean, dry, instrument-quality air (20.95% O2)

Blowback Air (optional)

-40° to 185°F (-40° to 85°C), internal - operating temperature of

electronics inside instrument housing, as measured by a HART

communicator or AMS software

-40° to 158°F (-40° to 70°C), ambient

[At temperatures above 158°F (70°C) inside instrume nt housing,

the infrared keypad will cease to function, but the OCX 8800 will

continue to operate properly.]

54 lbs (20 kg)18 in. (457 mm)

57 lbs (21 kg)

59 lbs (22 kg)

FlangeHousings Mounting

316L stainless steel - 1300°F (704°C)

Inconel 600 - 1832°F (1000°C)

Ceramic - 2600°F (1427°C)

Low-copper aluminum

Semi-automatic or automatic

0.4% O2, Balance N2

8% O2, Balance N2

1000 ppm CO, Balance Air

regulated to 45 psi (310 kPa)

regulated to 45 psi (310 kPa)

regulated to 45 psi (310 kPa)

Clean, dry, instrument-quality air

413 kPa) or greater and ambient temperature of ≥ 0 °F (-18 °C)

Table continued on next page

(20.95% O2), regulated to ≥ 60 psi

Instruction Manual

IM-106-880CIL, Rev 1.3

April 2017

OCX 8800

1-11

Specifications

Sensors Housing

Electronics Housing

Electrical Noise

Certifications

NEMA 4, IP66 with fitting and pipe on reference exhaust port to

clean, dry atmosphere, two 3/4-14 NPT conduit ports

NEMA 4, IP66 with fitting and pipe on reference exhaust port to

clean, dry atmosphere, two 3/4-14 NPT conduit ports

EN 61326-1, Class A

Sensor Housing

0344II2G

KEMA 04ATEX2308

EExdIIB+H2T3

CUS

2005.1602514

CLASS1,ZONE1

ExdIIB+H2T3

AExDIIB+H2T3

TYPE4/IP66

APPROVED

CLASS1,ZONE1

AExDIIB+H2T3

TYPE4/IP66

Electronics Housing

0344II2G

KEMA 04ATEX2308

EExdIIB+H2T6IP66

CUS

2005.1602514

CLASS1,ZONE1

ExdIIB+H2T6

AExDIIB+H2T6

TYPE4/IP66

APPROVED

CLASS1,ZONE1

AExDIIB+H2T3

TYPE4/IP66

Line Voltage Universal 100 to 240 VAC ±10%, 50 to 60 Hz, no switches or

jumpers required, 3/4-14 NPT conduit port

Pollution Degree

Over Voltage Category

Relative Humidity

2

II

5 to 95% (non-condensing)

Isolated Output

4-20 mAdc, 950 ohm maximum, with HART capabilityOxygen

Combustibles

Alarm

4-20 mAdc, 950 ohm maximum

Alarm output relay - dry contact, form C, 30 mA, 30VDC capacity

Power Consumption 750 W maximum

NOTE

All static performance characteristics are with operating variables constant. Specifications subject to change

without notice.

Instruction Manual

880CIL, Rev 1.3

April 2017

OCX 8800

1-12

OCX88C

O2/Combustibles Transmitter - Flameproof

Code

Probe Length and Material

00

No Probe or Exhaust Tube

11

18 in. (457 mm) 316 SST

up to 1300°F (704°C)

21

18 in. (457 mm) Inconel 600

up to 1832°F (1000°C)

(4)

31

18 in. (457 mm) Ceramic

up to 2600°F (1427°C)

12

3 ft (0.91 m) 316 SST

up to 1300°F (704°C)

22

3 ft (0.91 m) Inconel 600

up to 1832°F (1000°C)

(4)

32

3 ft (0.91 m) Ceramic

up to 2600°F (1427°C)

13

6 ft (1.83 m) 316 SST

up to 1300°F (704°C)

23

6 ft (1.83 m) Inconel 600

up to 1832°F (1000°C)

(4)

14

9 ft (2.7 m) 316 SST

up to 1300°F (704°C)

24

9 ft (2.7 m) Inconel 600

up to 1832°F (1000°C)

(4)

Code

Probe Mounting Assembly

10

(ANSI 2 in. 150 lb) 6" dia. flange, 4.75" BC with 4 x 0.75" dia. holes

20

(DIN) 185 mm dia. flange, 145 mm BC with 4 x 18 mm dia. holes

Code

Mounting Hardware - Stack Side

0 No Adapter Plate (“0” must be chosen under “Mounting Adapter - Probe Side” below)

1 New Installation - Square weld plate with studs

2 Model 218/240 Mounting Plate (with Model 218/240 Shield Removed)

3 Existing Model 218/240 Support Shield

4 Special Mounting

(1)

5 Model 132 Adapter Plate

Code

Mounting Hardware - Probe Side

0 No Adapter Plate

1 Probe Only (ANSI)

2 Probe Only (DIN)

Code

Electronics Housing - Communications

H1

HART Communications

(2)

H2

HART Communications with LOI

H3

HART Communications with Calibration Solenoids

(2)

H4

HART Communications with LOI and Calibration Solenoids

Code

Electronics Mounting

02

Remote Electronics and no cable

Code

Accessories

00

None

01

Flow meters & Ref. Ai r Set

02

In-Situ Filter (Stainless Steel only)

(3)

03

In-Situ Filter (SST), Flow meters & Ref. Air Set

(3)

11

Flow meters, and Ref. Air Set with Blowback

12

In-Situ Filter (SST) with Blowback

(3)

13

In-Situ Filter (SST), Flow meters & Ref. Air Set with Blowback (3)

OCX88C

11

10 1 1

H2

02

02

Example

Plate with studs

Bolt circle diameter, number, and arrangement of studs, stud thread, stud height above mounting plate.

Plate without studs

Bolt circle diameter, number, and arrangement of holes, thread, depth of stud mounting plate with accessories.

IM-106-

Table 1-1. Product Matrix - Hazardous Area OCX 8800

NOTES:

(1)

Provide details of the existi ng mo unti ng pl at e as follows:

(2)

If the LOI is not implemented, remote access and functionality available via HART Communications (Model 275/375 Handheld Communicator)

with Oxygen/Combustibles Device Description (DD) required.

(3)

For use with stainless steel sample tube only.

(4)

For high temperature applications that require a filter, please order 1A99762H03 separately.

Instruction Manual

IM-106-880CIL, Rev 1.3

April 2017

OCX 8800

1-13

Table 1-2. Accessories

PART NUMBER DESCRIPTION

1A99119H01

1A99119H02

1A 99119H07

1A99120H02

1A99120H03

1A99119G06

1A99119G05

1A99119G04

1A99292H01

1A99339H03

4851B40G01

1A99762H03

6A00171G01

6A00288G01

6A00288G02

6A00288G02

6A00288G04

6P00162H02

Oxygen test gas bottle; 0.4% O2, balance N

Oxygen test gas bottle; 8.0% O2, balance N

CO test gas bottle; 1000 ppm CO, balance air

Regulator for Oxygen (may need 2)

Regulator for CO test gas

Wall mount bracket for test gas bottles

Test gas regulators kit

Test gas bottles kit

Moore Industries SPA for Low O2 Alarm, High COe Alarm,

Calibration Status, and Unit Fail

Blowback valve, air operated

Wall or Pipe Mounting Kit

Hasteloy In Situ Filter, High Temperature

Power line filter kit

Sample Tube Support, 18 in. (457 mm)

Sample Tube Support, 3 Ft. (0.91 m)

Sample Tube Support, 6 Ft. (1.83 m)

Sample Tube Support, 9 Ft. (2.7 m)

Flange Insulator

2

2

Instruction Manual

880CIL, Rev 1.3

April 2017

OCX 8800

1-14

IM-106-

Instruction Manual

April 2017

OCX 8800

IM-106-880CIL, Rev 1.3

Section 2 Installation

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-7

Pneumatic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-10

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-16

Before installing this equipment, read the "Safety instructions for the wiring and installation

of this apparatus" in Appendix A: Safety Data. Failure to follow the safety instructions could

result in serious injury or death.

To maintain explosion-proof protection of the OCX 8800 in hazardous areas, all cable entry

devices and blanking elements for unused apertures must be certified flameproof, suitable

for the conditions of use and properly installed.

To maintain explosion-proof protection of the OCX88C in hazardous areas, the sensor

housing must not be mounted to any surface or flange that exceeds 200ºC (392ºF).

To maintain explosion-proof protection of the OCX88C in hazardous areas, the sample

entering the sensor housing must not exceed 200ºC (392ºF).

Instruction Manual

880CIL, Rev 1.3

April 2017

OCX 8800

2-2

IM-106-

MECHANICAL INSTALLATION

Selecting Location

1.

The location of the OCX 8800 in the stack or flue is most important for

maximum accuracy in the oxygen analyzing process. The probe must

be positioned so the gas it measures is representative of the process.

Best results are normally obtained if the transmitter is positioned near

the center of the duct (40-60% insertion). Longer ducts may require

several transmitters since the oxygen and combustibles can vary due to

stratification. A point too near the wall of the duct or the inside radius of

a bend, may not provide a representative sample because of the very

low flow conditions. The sensing point should be selected so the

process gas temperature falls within the range of probe material used.

Figure 2-1 through Figure 2-3 provide mechanical installation

references. The ambient temperature inside the electronics housing

must not exceed 185°F (85°C).

2.

Check the flue or stack for holes and air leakage. The presence of this

condition will substantially affect the accuracy of the oxygen and

combustibles readings. Therefore, either make the necessary repairs or

install the transmitter up stream of any leakage.

3.

Ensure the area is clear of internal and external obstructions that will

interfere with installation and maintenance access to the unit. Allow

adequate clearance for the removal of the OCX 8800.

Do not allow the temperature of the electronics housing to exceed 185°F (85°C) or damage

to the electronics may result.

Whenever a positive stack pressure exists at the installation site, be sure to connect all

pneumatic lines prior to installing the OCX 8800 in the stack or ductwork. Failure to connect

the pneumatic lines can allow the flow of contaminants into the OCX 8800 ports.

Installation

1.

Ensure all components are available to install the OCX 8800.

2.

The OCX 8800 may be installed intact as it is received.

3.

Weld or bolt adapter plate (Figure 2-2) onto the duct.

4.

Ensure the conduits drop vertically from the OCX 8800 and the conduit

is routed below the level of the conduit ports on the housing to form a

drip loop. Drip loops minimize the possibility that moisture will damage

the electronics (Figure 2-3).

5.

Where a positive stack pressure exists at the installation site, connect all

pneumatic lines prior to installing the OCX 8800 in the stack or

ductwork.

Instruction Manual

April 2017

OCX 8800

2-3

IM-106-880CIL, Rev 1.3

NOTE

If process temperatures will exceed 392°F (200°C), use anti-seize compound

on stud threads to ease future removal of the OCX 8800.

6.

Insert sample and exhaust tubes through the opening in the mounting

flange and bolt the unit to the flange.

Uninsulated stacks or ducts may cause ambient temperatures in the electronics housing to

exceed 185°F (85°C) and damage the electronics.

7.

If insulation is removed to access the duct for OCX 8800 mounting,

make sure to replace insulation afterward.

Enclosures

The OCX 8800 enclosures are designed to meet ingress conditions of IP66.

Each enclosure cover is threaded to its base and sealed with an o-ring that

isolates the threads from external contaminants.

Each cover is secured by a clip attached to the base that engages the cover

between the ribs of the cover sidewall. The clip is held in place by an Allen

head cap screw and lockwasher mounted in a recess. Cover removal and

installation requires an Allen wrench to loosen and tighten the screw.

Instruction Manual

880CIL, Rev 1.3

April 2017

OCX 8800

4-2

Optional

In Situ Filter

8.3

(211)

Table 2. Installation/Removal

18

(457)

34

(864)

36

(914)

52

(1321)

72

(1829)

88

(2235)

108

(2743)

124

(3150)

37390008

0.06 In. Thick Gasket

ANSI

3535B18H02

DIN

3535B45H01

Table 1. Mounting

Flange

ANSI

5R10244H01

DIN

5R10244H02

Flange

6.00

7.28

Dia.

(152)

(185)

Hole

Dia.

0.75

0.71

(4) Holes

spaced on

(121)

(145)

B.C. dia

Figure 2-1. Installation, OCX 8800

NOTE

All dimensions are in inches with millimeters in parentheses.

Insulate if exposed to adverse weather or extreme temperature changes,

install a protective housing and/or insulation around the unit.

IM-106-

equally

Flange Dia.

B.C. Dia.

Hole Dia.

(19)

4.75

(18)

5.71

Allow 9 in.

(229 mm) for

Cover Removal

Dim “B”

Removal Envelope

Dim “A”

Insertion Depth

Probe Dim “A” Dim “B”

18 in.

3 ft

6 ft

9 ft

BOTTOM VIEW

Instruction Manual

IM-106-880CIL, Rev 1.3

April 2017

OCX 8800

2-5

Figure 2-2. Adapter Plate Installat ion

Instruction Manual

880CIL, Rev 1.3

April 2017

OCX 8800

6-2

Figure 2-3. Installation

Conduit Drip Loops

Duct Wall

Conduit Drip Loop

Conduit Drip Loop

Duct Wall

37020004

with Drip Loops

IM-106-

Instruction Manual

IM-106-880CIL, Rev 1.3

April 2017

OCX 8800

2-7

ELECTRICAL INSTALLATION

All wiring must conform to local and national codes. For reference, factory

wired solenoid power connections are shown in Figure 2-4.

Disconnect and lock out power before connecting the unit to the power supply. Failure to

lock out power could result in serious injury or death.

Install all protective equipment covers and safety ground leads after installation. Failure to

install covers and ground leads could result in serious injury or death.

To meet the Safety Requirements of IEC 1010 (EC requirement), and ensure safe operation

of this equipment, connection to the main electrical power supply must be made through a

circuit breaker (min 10 A) in close proximity and marked for this equipment which will

disconnect all current-carrying conductors during a fault situation. This circuit breaker

should also include a mechanically operated isolating switch. If not, then another external

means of disconnecting the supply from the equipment should be located close by. Circuit

breakers or switches must comply with a recognized standard such as IEC 947.

To maintain explosion-proof protection of the OCX 8800 in hazardous areas, all cable entry

devices and blanking elements for unused apertures must be certified flameproof, suitable

for the conditions of use and properly installed.

To maintain explosion-proof protection of the OCX88C in hazardous areas, the sensor

housing must not be mounted to any surface or flange that exceeds 200ºC (392ºF).

To maintain explosion-proof protection of the OCX88C in hazardous areas, the sample

entering the sensor housing must not exceed 200ºC (392ºF).

Instruction Manual

880CIL, Rev 1.3

April 2017

OCX 8800

8-2

IM-106-

NOTE

To maintain proper earth grounding, ensure a positive connection exists

between the sensor housing, the electronics housing, and earth. The

connecting ground wire must be 14 AWG minimum. Refer to Figure 2-4.

NOTE

Line voltage, signal, and relay wiring must be rated for at least 105ºC (221ºF).

Electrical Connections

Electrical connections, power and communications are made to the electronic

enclosure. The connections are made through two 3/4 NPT ports in the

enclosure using fittings and cables provided by the customer. Cable

installation must meet NEC, IEC and/or other applicable national or local

codes for Class I, Zone 1, IIB +H2 T3/T6 permanently mounted equipment.

Connect Line Voltage

The OCX 8800 operates on 100 to 240 VAC line voltage at 50 to 60 Hz. The

power supply requires no setup. Connect the line (L wire) to the L terminal,

and the neutral (N wire) to the N terminal on the AC power input terminal

block in the electronics housing. Connect the ground (G wire) to the ground

stud in the electronics housing as shown in Figure 2-4.

Connect 4-20 mA Signals

Connect the 4-20 mA current loop to the 4-20 mA signal output terminals in

the electronics housing as shown in Figure 2-4. Use individual shielded

twisted wire pairs. Terminate the shield at the electronics housing.

4-20 mA Signal

O

2

One 4-20 mA signal represents the O

value. Superimposed on the O

2

2

signal is the HART information accessible through a Model 275/375

Handheld Communicator or AMS software. The O

signal is at the AOUT 1

2

terminals.

COe 4-20 mA Signal

Another 4-20 mA signal at the AOUT 2 terminals represents the COe

value. HART information is not available on the COe signal.

Alarm Output Relay

Connect any customer-supplied relay input to the alarm output relay terminal.

Use shielded wire and terminate the shield at the electronics housing. The

alarm output relay terminal is a set of dry, no. 2, form C, contacts with 30 mA,

30 VDC capacity.

Loading...

Loading...