Rosemount Manual: NGA 2000 TFID Hydrocarbon Analyzer Module SW 3.2 Software -1st Ed. | Rosemount Manuals & Guides

Rosemount Analytical

NGA 2000

Software Manual

TFID Analyzer

TFID Analyzer Module

(combined with NGA 2000 platform /

TFID analyzer / MLT analyzer

or customer-developed control unit)

Software Version 3.2.X

1. Edition 06/98

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

Catalog No.: 90 003 808

Managing The Process Better

Rosemount Analytical

This Operation Manual includes information about the operation of the instrument.

Information about the additional indications and notes regarding maintenance, troubleshooting and repair

are found in the accompanying Maintenance & Operation Manual.

T roubleshooting, component replacement and internal adjustments must be made by qualified

service personnel only.

Fisher-Rosemount GmbH & Co does not take responsibility for an y omissions or errors in this manual.

Any liability for direct or indirect damages, which might occur in connection with the deliv ery or the use of

this manual, is expressly e xcluded to the extend permitted by applicable law.

This instrument has left the works in good order according to safety regulations.

T o maintain this operating condition, the user must strictly follow the instructions and consider the warnings

in this manual or provided on the instrument.

Misprints and alterations reserved

©

1998 by FISHER-ROSEMOUNT GmbH & Co. (PAD)

1. Edition: 06/98

Read this operation manual carefully before attempting to operate the analyzer !

For expedient handling of reports of defects , please include the model and serial number which

can be read on the instrument identity plate.

Fisher - Rosemount GmbH & Co.

Industriestrasse 1

D - 63594 Hasselroth • Germany

Phone + 49 (6055) 884-0

Telefax + 49 (6055) 884-209

Internet: http://www.processanalytic.com

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

Contents

1 Introduction 1 - 1

2 Structure of Menus 2 - 1

3 Startup and Operation, General Notes and Main Menu 3 - 1

3.1 Starting and Initializing...................................................................................3 - 1

3.2 Display and Function...................................................................................... 3 - 6

3.3 "TAG" and Operating Keys ............................................................................ 3 - 6

3.4 Lines and Softkey Functionality ..................................................................... 3 - 7

3.5 Important Functions of the Softkeys...............................................................3 - 8

3.6 Entering/Changing of Variables......................................................................3 - 9

3.7 Starting a Function.........................................................................................3 -10

3.8 Main Menu .....................................................................................................3 -11

4 Basic Controls and Analyzer Module Calibration 4 - 1

4.1 Analyzer Channel Status................................................................................ 4 - 3

4.1.1 Status Details – Failures...............................................................................4 - 5

– Maintenance requests ........................................................ 4 - 9

– Function controls ................................................................ 4 -13

– Measurements/Alarms........................................................4 -15

– Events.................................................................................4 -17

– Acknowledge and clear failures..........................................4 -21

– Acknowledge and clear maintenance requests .................. 4 -25

– Acknowledge and clear function controls............................4 -29

4.1.2 Operational Settings.......................................................................................4 -33

4.2 Single Component Display - Change of Channel...........................................4 -35

4.3 Multi Component Display - Change of Channel............................................. 4 -37

4.4 Calibration Procedure Status.........................................................................4 -39

4.5 Zero Calibration..............................................................................................4 -41

4.6 Span Calibration.............................................................................................4 -45

4.7 Flow Zero Gas................................................................................................ 4 -49

4.8 Flow Span Gas...............................................................................................4 -53

4.9 Flow Sample Gas...........................................................................................4 -57

4.10 Flow Test Gas................................................................................................4 -61

4.11 Close all Valves.............................................................................................. 4 -65

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

I

5 Analyzer and I/O-Module Expert Configuration 5 - 1

5.1 Analyzer Module Setup 5 - 3

5.1.1 Calibration Parameters...................................................................................5 - 5

– Span gases.........................................................................................5 - 6

– Tolerances ..........................................................................................5 - 8

– Calibration procedure setup................................................................ 5 -10

– Time controlled calibration..................................................................5 -13

– Calibration...........................................................................................5 -15

– Advanced calibration methods............................................................ 5 -18

– Zero gases..........................................................................................5 -20

5.1.2 Alarm Parameters...........................................................................................5 -21

5.1.3 Range Parameters .........................................................................................5 -25

– Begin and end of ranges.....................................................................5 -27

– Response times (t90) ...........................................................................5 -28

– Autoranging control............................................................................. 5 -29

5.1.4 Cross Interference Compensation..................................................................5 -31

5.1.5 Linearization...................................................................................................5 -33

5.1.6 Programmable Logic Control (PLC)................................................................5 -37

5.1.7 Programmable Calculator...............................................................................5 -45

5.1.8 Measurement Display Configuration...............................................................5 -49

5.1.9 Acknowledgement of Status Reports..............................................................5 -52

5.1.10 Concentration Measurement Parameters.......................................................5 -54

5.1.11 Peak Measurement ........................................................................................5 -57

5.1.12 Differential Measurement ...............................................................................5 -59

5.1.13 Gasflow Setup................................................................................................5 -61

5.1.14 Pressure Compensation.................................................................................5 -62

5.1.15 Flow Measurement......................................................................................... 5 -64

5.1.16 Temperature Measurement............................................................................5 -65

5.1.17 Loading/Saving Configuration Parameters.....................................................5 -66

5.1.18 Inputs and Outputs.........................................................................................5 -69

– Local SIO ............................................................................................5 -70

– Local DIO............................................................................................5 -76

– Signal codes........................................................................................5 -77

5.1.19 Delay and Average.........................................................................................5 -81

5.1.20 Special Functions...........................................................................................5 -83

5.1.21 AK-Protocol Communication ..........................................................................5 -84

II

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

5.2 I/O Module Controls 5 - 85

5.2.1 SIO Module 5 - 86

5.2.2 DIO Module(s) 5 - 95

5.3 I/O Module Setup 5 -101

6 System Configuration 6 - 1

6.1 Diagnostic Menus........................................................................................... 6 - 3

6.1.1 Control Module Diagnostics.................................................................6 - 4

6.1.2 Analyzer Module Diagnostics ..............................................................6 - 5

6.2 Date and Time................................................................................................6 - 6

6.3 Security Codes...............................................................................................6 - 7

6.4 Network Module Binding ................................................................................6 - 9

6.5 System Reset.................................................................................................6 -11

6.6 System Modules.............................................................................................6 -12

7 Display Controls 7 - 1

Index

Supplement: System Calibration

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

III

IV

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

1 Introduction

This software manual describes step by step how to operate successfully with the 19"

Thermo-FID (TFID) analyzer module and analyzer of the NGA 2000 Series.

Chapter two shows the structure of the TFID software menus. Chapter three describes the

display and the keyboard of the analyzer. Chapter four describes the basic controls with

detailed illustrations. So you can easily compare the actual display of the analyzer module

with the illustrations of the manual.

Chapter five describes the expert configurations of the analyzer module and of the Input/

Output Modules (I/O modules). Chapter six describes the system configuration. The layout

of both chapters is not as detailed as in chapter four. Normally, the way to a certain menu

of the TFID software is described with the software catchwords you have to press to reach

this menu. You will find the illustration of the corresponding LCD screen at the end of the

catchword listing. After that you can read the meaning of the functions and variables of

each expert or system configuration menu.

Some contents of the expert configurations are not important for each customer. It depends

on the configuration of your NGA 2000 system, relative to the following components:

♦ Control Module CM

♦ Analyzer Module AM

♦ Input/Output Modules I/O's (SIO = Standard I/O, DIO = Digital I/O,

System Auto Calibration I/O, Analog Output with 3 Alarms I/O,

Auto Calibration I/O)

You can distinguish the following system units and SIO/DIO configurations:

System Unit SIO/DIO-Configuration

TFID analyzer module (AM):

• without front panel,

i.e. without control unit

• can be combined with a platform,

an MLT analyzer, a TFID analyzer

or a customer developed control

⇒ 1 local SIO and 1 local DIO can be

installed in the TFID analyzer

module

⇒ SIO and DIO can be configured

for the channels of the analyzer

module only

unit

Platform (CM Software):

• Control unit with front panel

• Without measurement channels

⇒ 1 SIO and up to 4 DIO's can be

installed in the platform (CM I/O)

⇒ SIO and DIO can be configured

for all channels combined with the

platform

Section

Page

∗ 5.1.18

p. 5-69

∗ 5.2

p. 5-85

TFID analyzer (CM and TFID AM

software):

• Analyzer with front panel

• CM and AM software in the same

analyzer,

i.e. all functions of the control unit

and of the AM are combined in one

controller board

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

⇒ 1 SIO and 1 DIO can be installed

in the TFID analyzer (CM I/O)

⇒ SIO and DIO can be configured

for all channels combined with the

TFID analyzer

NGA 2000

∗ 5.2

p. 5-85

1 - 1

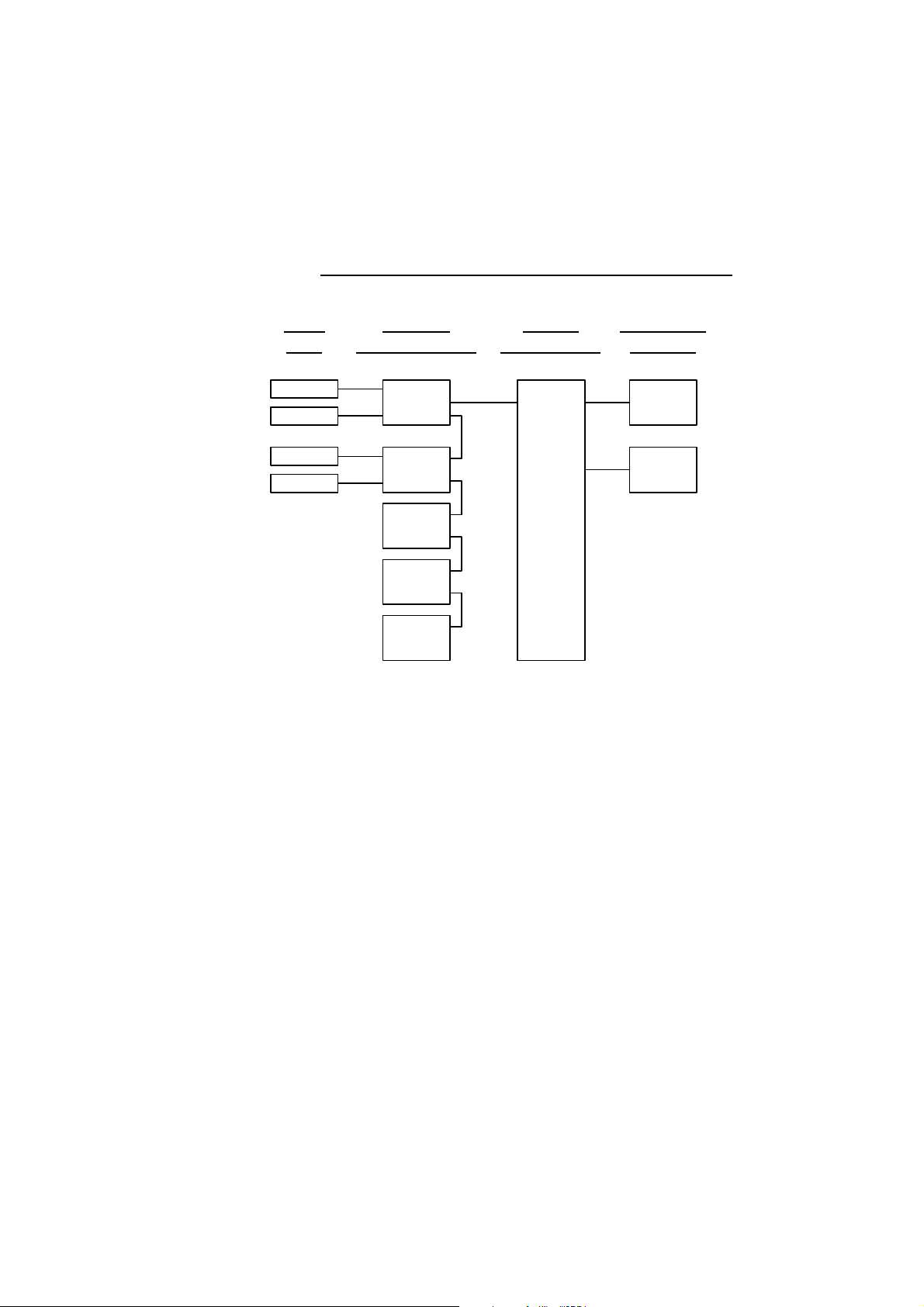

The following illustrations shall make plain the connection between the hardware configuration and the software setup of the modules:

NGA 2000 System via Platform

(see 5.1.18)

(see 5.1.18)

Local

I/O's

SIO

DIO

SIO

DIO

(additional

manuals)

(additional

manuals)

(additional

manuals)

NGA 2000 System via TFID Analyzer

Analyzer

Modules (AM's)

TFID

MLT

CLD

PMD

FID

Control

Module (CM)

Platform

I/O

Modules

1 SIO

4 DIO's

max.

Other I/O's

(see 5.2.1)

(see 5.2.2)

(see 5.1.18)

(see 5.1.18)

1 - 2

Local

I/O's

SIO

DIO

SIO

DIO

(additional

manuals)

(additional

manuals)

(additional

manuals)

Analyzer

Modules (AM's)

TFID

MLT

CLD

PMD

FID

NGA 2000

Control

Module (CM)

TFID Analyzer

System I/O

Modules

1 SIO

1 DIO

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

(see 5.2.1)

(see 5.2.2)

NGA 2000 System via MLT Analyzer

1 Introduction

(see 5.1.18)

(see 5.1.18)

Local

I/O's

SIO

DIO

SIO

DIO

(additional

manuals)

(additional

manuals)

(additional

manuals)

Analyzer

Modules (AM's)

MLT

TFID

CLD

PMD

FID

Control

Module (CM)

MLT Analyzer

System I/O

Modules

1 SIO

1 DIO

(see 5.2.1)

(see 5.2.2)

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

1 - 3

1 - 4

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

enu lines ending with three points (...) are followed by submenus with further functions and set-ups.

All set-ups in the menu "Basic controls" are valid for the

At each menu point of the "Expert configuration" and "System configuration" you can find which functionality will be set up:

nalyzer

odule), CM (

odule), I/O (

utput Module).

-

-

-

-

Section 3.8

Display controls...

front panel LCD

- Display controls of the

- Front panel control

(number of digits)

(for the

single component display)

- Auxiliary lines

2 Structure of Menus

Main Menu

Analyzer and I/O-

and diagnostics...

System configuration

module expert

configuration...

(AM, CM, I/O's: SIO, DIO

- System calibration... (CM)

- Analyzer module

and other I/O's)

- Diagnostic menus...

controls... (AM)

(I/O's: SIO, DIO)

- I/O module controls...

(Lock of each level)

(AM, CM, I/O's: SIO, DIO

- Date and time... (CM)

- Security codes...

(AM)

- Analyzer module setup...

- I/O module setup...

and other I/O's)

- Network module binding...

(Other micro processor

- System reset... (CM)

- System modules... (CM)

- System tag (CM)

controlled I/O's)

analyzer module (AM).

Input-/O

Control M

M

Analyzer module

calibration & basic

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

controls... (AM)

Section 4 Section 5 Section 6 Section 7

Calibration procedure

status...

Zero calibration of all

ranges

Span calibration of the

NGA 2000

current range

Current gas valve setting:

- Zero gas flow

- Span gas flow

- Sample gas flow

- Test gas flow

- Closing all valves

Notes:

* M

AM (A

*

*

2 - 1

2 - 2

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

3 Startup and Operation, General Notes and Main Menu

Check before starting:

♦ All pneumatic supplies and mains, especially the hydrogen mains have to be tight !

♦ All gases used must have the right input pressure !

♦ All gas supply valves have to be closed !

♦ All electrical mains have to be joint and their voltage must operate correctly !

♦ The exhaust gas output must be without pressure

(atmosphere pressure or up to 300 mbar less than atmosphere pressure) !

3.1 Starting and Initializing (Look at the operation manual, too !)

1. Switching on

♦ Join your Thermo-FID (TFID) with the supply voltage.

♦ Switch on.

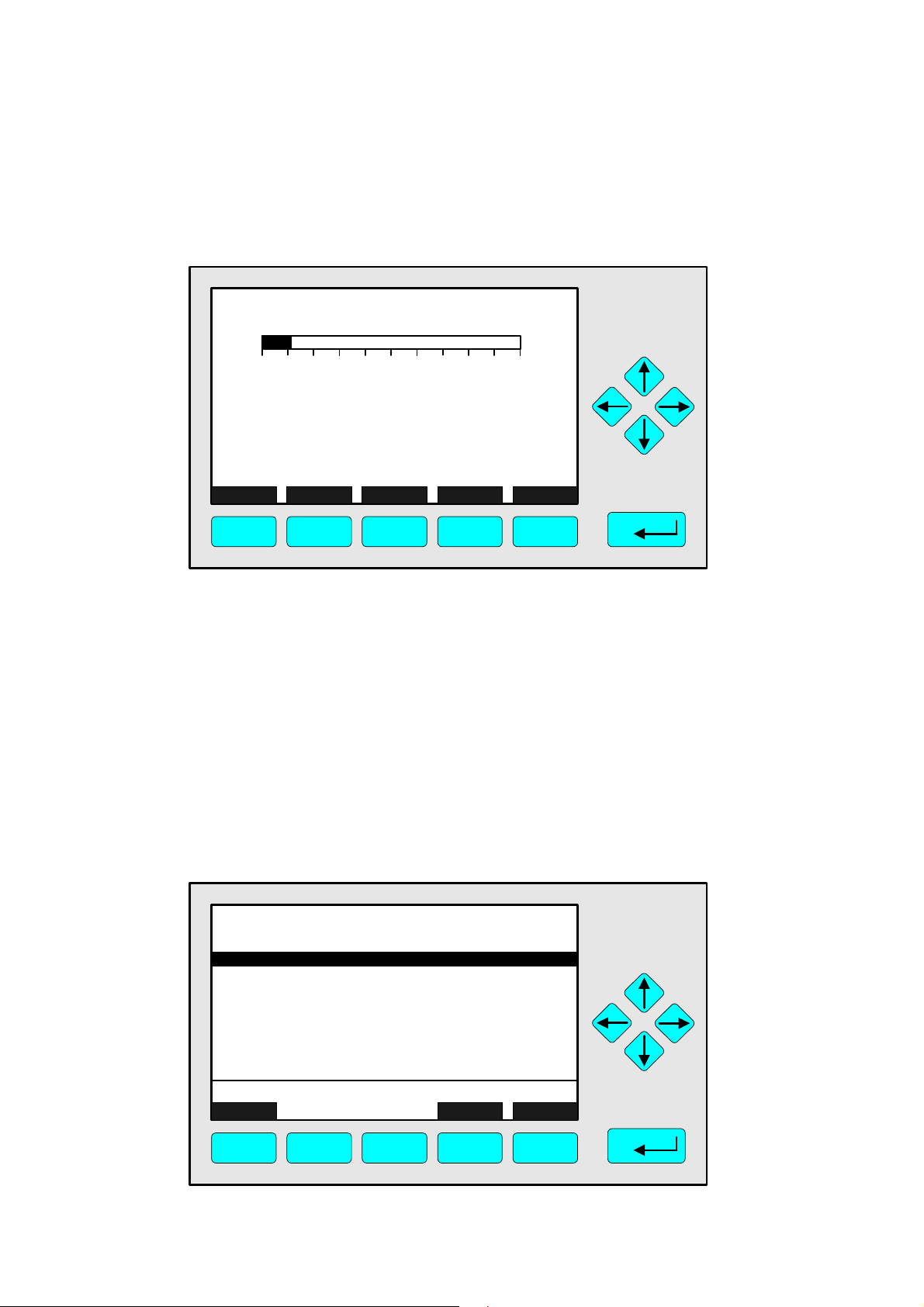

♦ The following display will appear:

(C) 1998 FISHER-ROSEMOUNT Analytical

NGA-2000 Control Module/Version 3.2.1

Initializing Network

Initializing network interface

LCDReset Abort

F1 F2 F3 F4 F5

After switching on the TFID analyzer or analyzer module (in a platform or part of a NGA

network), the initialization procedure will be performed. A self control of the analyzer

modules or the analyzer is running. You can see a sequence of several displays. They

show the status of initialization, revision notes of the TFID software and the

tag. If you press the F1 key during the initializing, you will reset the LCD brightness and

contrast to factory settings (see also section 7). Pressing the F3 key will abort the network

initializing. Then you will have no connection to any analyzer module. Only the menus of

the platform will be available.

At the end of the initializing procedure you can see the single component display of

channel one (see illustration on next page). It is the origin to all the other channels, menus

and submenus.

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

3 - 1

The instructions of the basic controls (chapter four) are all beginning with the single component display. The actual display might differ from the shown one because the customer

can configure it according to his requirements (see sections 5.1.8 p. 5-49 and section 7).

TFID-R1

5.40 ppm Propane

0.00 50.00

Failures: Yes

Maintenance-Requests: Yes

Function-Control: Yes

Operation: WarmUp

Display Status... Main... Channel Calib...

Range: 1

F1 F2 F3 F4 F5

2. Input of the correct span gas concentration

Put in the span gas concentration (Vol.-% or ppm) of the span gas certificate, the number

of carbon atoms, the name of the span gas and the response factor! The correctness of

these values is very important for the automatic calibration!

♦ Change to the menu "Span Gas Definition":

• Press the F3 key: The "Main Menu" will appear.

• Change to the line "Analyzer and I/O-module expert configuration..." with the ↓↓ -key

• Press the 88 -key: The menu "Expert Module Configuration" will appear.

• Change to the line "Analyzer module set up..."

• Press the 88 -key three times: You will reach the menu "Span Gas Definition":

3 - 2

TFID-R1

-- Span Gas Definition (1/2) --

Actual span gas concentration: 50.0 ppm

Spangas range -1: 50.00 ppm

Spangas range -2: 250.0 ppm

Spangas range -3: 2500 ppm

Spangas range -4: 10000 ppm

Span gas unit: ppm

"ppm" --> "mg/Nm3" conversion factor: 1.000

Concentration in span gas units: 37.50 ppm

Measure Back...

37.50 ppm

More...

F1 F2 F3 F4 F5

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

3 Startup and Operation, General Notes and Main Menu

You have to put in the span gas concentration of the span gas certificate in the line

"Actual span gas concentration" and in all "Spangas range" lines !

Set up parameters:

♦ Select any line of variables with the ↓↓ -key or the ↑↑ -key.

♦ Select the variable with the 88 -key or the →→ -key.

♦ Select any digit with the ←← -key or the →→ -key and adjust a new value with

the ↑↑ -key or the ↓↓ -key

resp. select the whole parameter with the ↑↑ -key or the ↓↓ -key.

♦ Confirm the new value with the 88 -key or

cancel and go back to the last value with the F2 key.

♦ Change to the second menu page with the F5 key (More...):

TFID-R1

-- Span Gas Definition (2/2) --

Span gas carbon atoms: 3

Span gas name: Propane

Response factor: 1.000

Measure Back...

F1 F2 F3 F4 F5

37.50 ppm

♦ Set up the parameters in the same way like described above !

Lines of variables "Span gas carbon atoms" and "Response factor":

The TFID originally measures the carbon atoms of a gas. So, for a correct conversion into

"ppm" and other units, it is necessary to determine the number of carbon atoms of the

span gas.

Because the raw measurement also differs with different kinds of hydrocarbons, you have

to put in the response factors of the analyzer for the type of hydrocarbons.

Note: You will find the table of response factors in the Thermo-FID operation manual (No.: 90 003

806).

Line of variables "Span gas name":

In this line you can put in the real name of the span gas you want to use, e.g. "Propane".

♦ Changing back to the single component display:

• Press the F1 key.

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

3 - 3

3. Automatic internal calibration

♦ Open the supply gas valves!

♦ Set up the supply gas pressure values (see operation manual) !

During the warm-up procedure the failures and maintenance requests will disappear:

TFID-R1

6.20 ppm Propane

0.00 50.00

Failures: No

Maintenance-Requests: No

Function-Control: Yes

Operation: WarmUp

Display Status... Main... Channel Calib...

F1 F2 F3 F4 F5

Range: 1

If all temperatures and pressures are correct, the calculator will start an automatic

calibration. The single component display will be:

TFID-R1

300.0

0.00 50.00

Failures: No

Maintenance-Requests: No

Function-Control: Yes

Operation: Calibration

Range: 1 F.S.

ppm Propane

Display Status... Main... Channel Calib...

F1 F2 F3 F4 F5

Zero and span gas concentrations will be displayed and the operation line shows

"Calibration".

After successful calibration the system will be ready for measurement. The valve will be

switched to "sample gas". In the line operation of the single component display you will

find the message "Ready" and all reports of events will be "No":

3 - 4

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

3 Startup and Operation, General Notes and Main Menu

TFID-R1

2.30 ppm Propane

0.00 50.00

Failures: No

Maintenance-Requests: No

Function-Control: No

Operation: Ready

Display Status... Main... Channel Calib...

F1 F2 F3 F4 F5

Range: 1

4. Start manual calibration

Before starting the measurement you should calibrate with zero and span gas to improve

the accuracy of measurements.

How to calibrate:

♦ The zero and span gas calibration are described detailed in the sections 4.5 p. 4-41

and 4.6 p. 4-45.

♦ Further informations about calibration you will find in the expert configuration in section

5.1.1 p. 5-5 to 20.

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

3 - 5

3.2 Display and Function

The LCD screen shows all measurement values of the analyzer and all customer instructions. You can operate with five function keys, four arrow keys (cursors) and the enter key.

The function of each key depends on:

♦ the type of analyzer/analyzer module used

♦ the optional auxiliary modules (e.g. I/O boards) used

♦ the individual menu displayed

In case of power failure all customer specific module parameters are saved by a batterypowered buffer.

3.3 "TAG" and Operating Keys

At the top left of each menu page you will find the tag of the current channel.

Typical tags:

♦ MLT/CH1/R1: MLT Analyzer or Analyzer Module / CHannel 1 / Range 1

♦ TFID-R1: Thermo FID Analyzer or Analyzer Module - Range 1

In this manual you will find normally "TAG" as general name. But in the specific TFID

menu pages you will find "TFID".

TAG

37.50 ppm Propane

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel Calib...

F1 F2 F3 F4 F5

Function Keys:

♦ keys without defined functions

♦ The current function depends on

the menu selected

♦ The softkey legend is shown on

the display above the key

Range: 1

0.0 100.0

Cursor keys:

↑↑ -key / ↓↓ -key:

♦ Line up / line down

within the same menu

♦ Alteration of numbers,

variables or digits

←← -key / →→ -key:

♦ Moving back/forwards

between the pages of

a menu

♦ Selection of digits

Enter Key:

♦ To confirm a previously entered value

(variable)

♦ To start a selected function

(Alternative: →→ -key)

♦ To go into a menu (via menu line)

3 - 6

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

3 Startup and Operation, General Notes and Main Menu

3.4 Lines and Softkey Functionality

Lines can be selected by the ↓↓ -key or the ↑↑ -key. The selected line is displayed white on

black. You have four different types of lines in the menu:

Menu line... / Menu Softkey...

♦ Line/Softkey lettering ending with three dots.

♦ You will go to a submenu/further menu by pressing the softkey resp. by pressing the

88 -key or the →→ -key in the menu line.

Function line / Function Softkey !

♦ Line/Softkey lettering ending with an exclamation-mark.

♦ You will start a function (e.g. calibration) by pressing the softkey resp. by pressing the

88 -key or the →→ -key in the function line.

Line of variables:

♦ Line ending with a colon.

♦ Display of module parameters (variables).

♦ Some parameters can be changed (e.g. begin of range), some parameters display only

a status (e.g. temperature) and cannot be changed. These variables will be displayed

below a line within the menu.

Text line

♦ Line without any punctuation marks.

♦ Only display of informations.

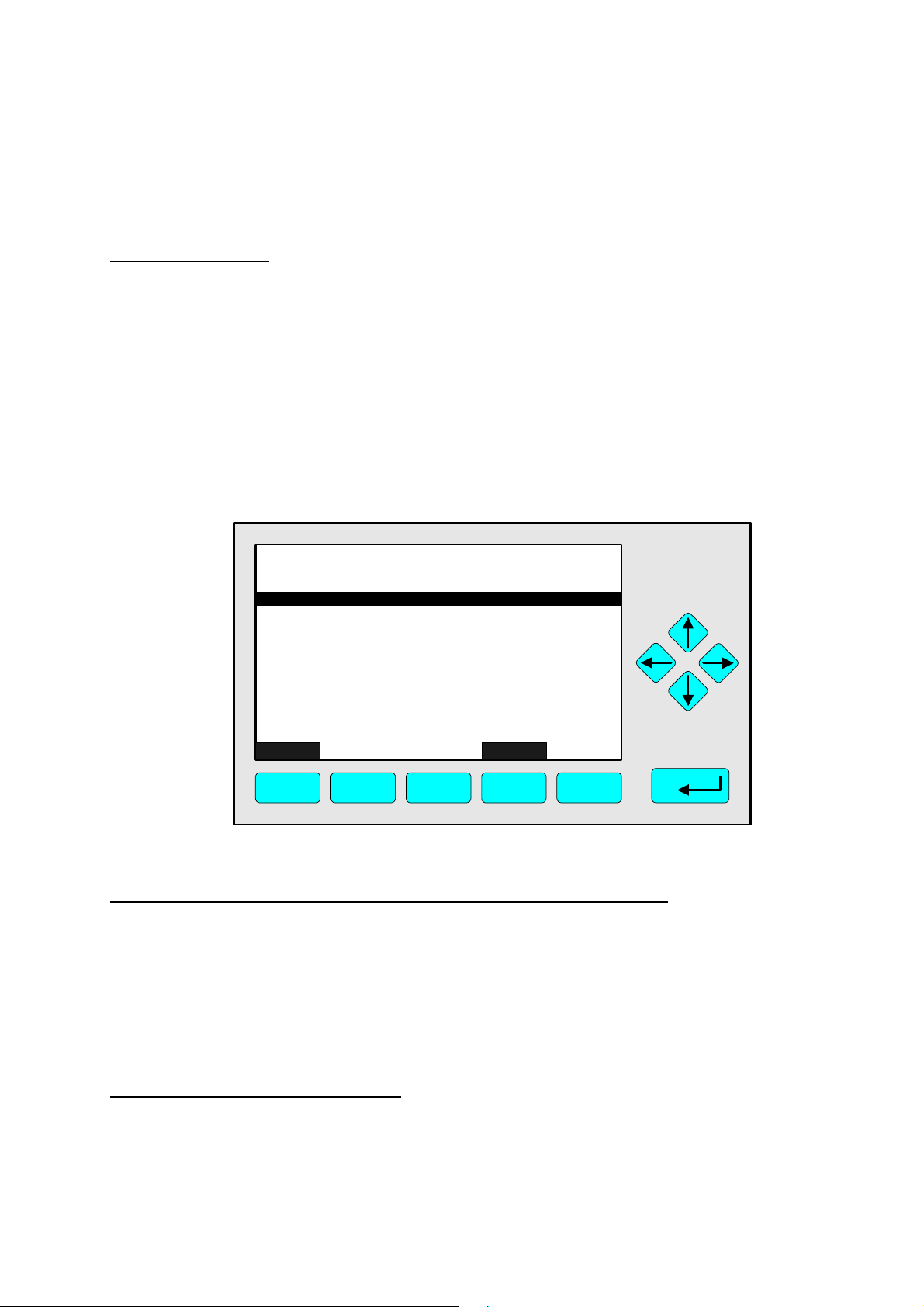

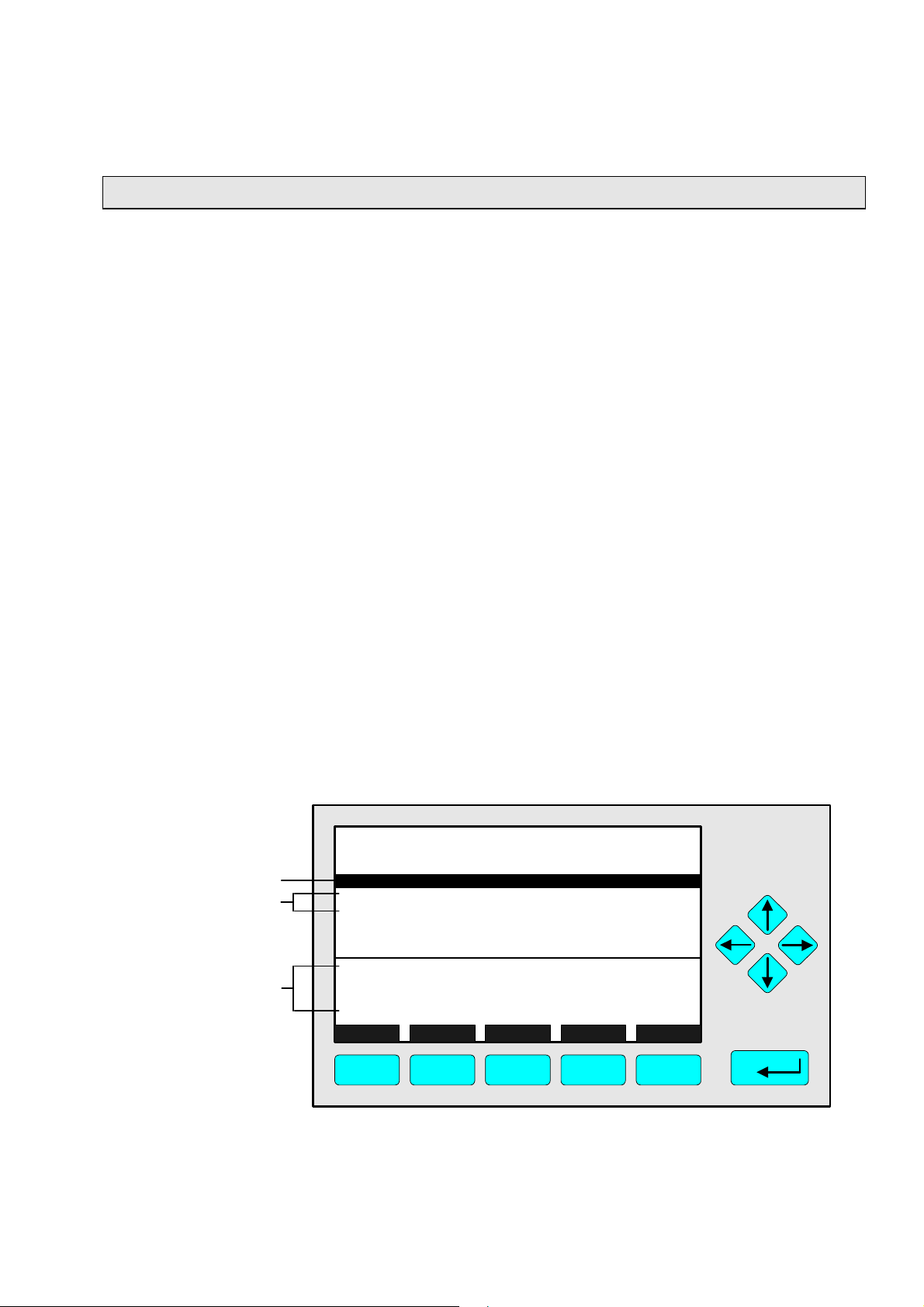

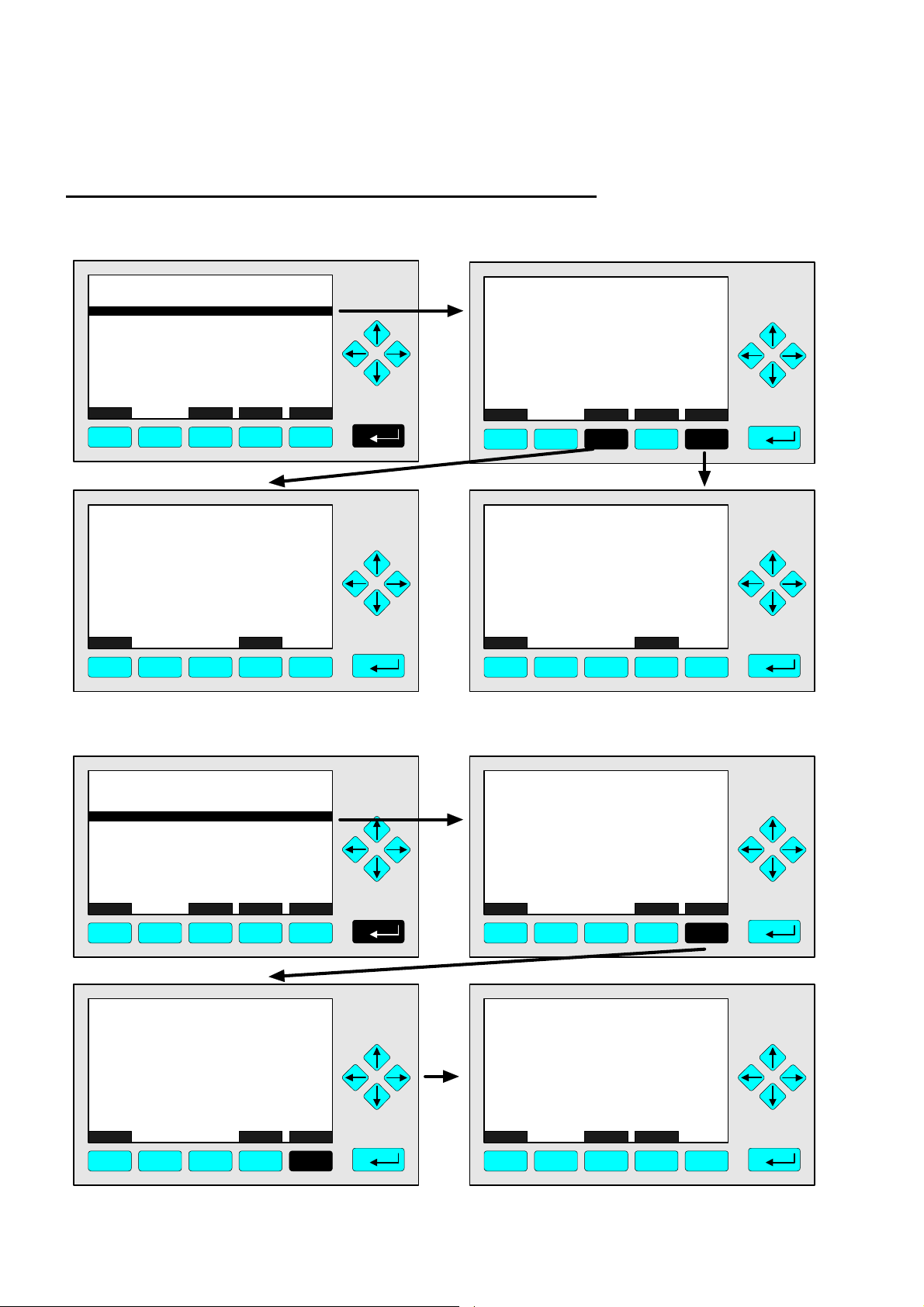

The following illustrations shall make plain the functionalities of lines and softkeys described above:

Menu Line

Function Lines

Lines of Variables

(These here cannot

be changed)

TAG

-- Analyzer Module Calibration --

Calibration procedure status...

Start zero calibration procedure !

Start span calibration procedure !

Valve position: Samplegas

Expected zero gas: 0.00 ppm

Expected span gas: 50.00 ppm

Span gas name: Propane

Measure Status... Channel Back...

F1 F2 F3 F4 F5

37.50 ppm

Valves...

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

3 - 7

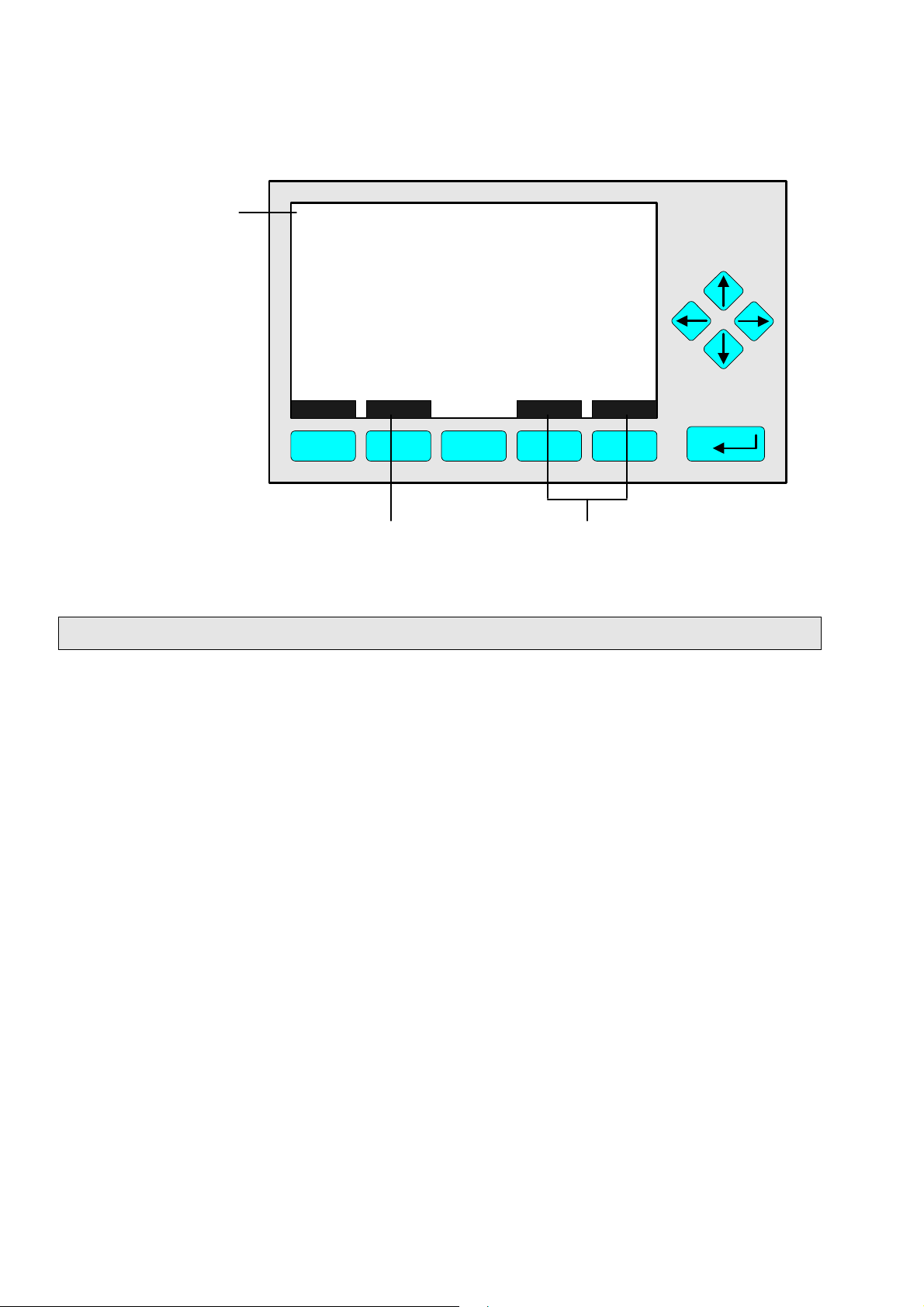

Text Line

TAG

-- Calibration Procedure Status --

Procedure status: Ready

Remaining procedure time: 0 s

Current/expected gas flow: Samplegas

Concentration in span gas units: 37.50 ppm

---------------------- Results ---------------------Last zero calibration: Success

Last span calibration: Success

Last zero calibration was: Fri 05-29-1998 13:32:06

Last span calibration was: Fri 05-29-1998 13:37:23

Successful zero+span calibrated ranges: 1+2+3+4

Measure Cancel ! Back... More...

F1 F2 F3 F4 F5

37.50 ppm

Function Softkey

Menu Softkeys

3.5 Important Functions of the Softkeys

Display

♦ Change from the single component display to the multi component display.

♦ F1 in the single component display.

Measure

♦ Change from all menus and submenus to the single component display of the channel

selected.

♦ F1.

Status (see section 4.1 p. 4-3!)

♦ Change to the menu "Analyzer Channel Status":

Display of the most important parameters and information about the status of the

current channel or module.

♦ If available: F2.

Main (see section 3.8 p. 3-11!)

♦ Change from the single component display to the main menu.

♦ F3 in the single component display.

Channel

♦ Scrolling through the channels in the same menu. In the main menu and the single

component display you can move among all channels of the connected analyzers and

analyzer modules. In the submenus you can only move among the channels of the

current analyzer or analyzer modules.

♦ If available: F3 (F4 in the single component display).

3 - 8

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

3 Startup and Operation, General Notes and Main Menu

Lock

♦ Lock of all three operation levels from the main menu, if a security code is activated in

the system configuration level (see section 6.3 p. 6-7).

♦ F4 in the main menu.

Calib (see section 4.4 p. 4-39 and 5.1.1 p. 5-15!)

♦ Change from the single component display to the menu "Analyzer module calibration".

♦ F5 in the single component display.

MFG Data (see section 3.8 p. 3-11/12!)

♦ Change from the main menu to the menu "Module Manufacturing Data":

Further submenus are available with informations about the control module and

analyzer module data, such as address of the manufacturer, serial number of the

modules or the software and hardware revisions.

♦ F5 in the main menu.

Back

♦ Moving back to the last menu page selected (Alternative: ←← -key) or

reset of a changed but not confirmed parameter to the former value.

♦ If available: F4 for moving back, F2 for reset.

More

♦ Changing to a further menu page.

♦ If available: F5.

3.6 Entering/Changing of Variables

88 -key

♦ If you have already selected a line of variables (displayed white on black) and press the

88 -key, only the parameter will be selected and can be changed.

If you press the 88 -key again, the new value will be confirmed.

↑↑ -key / ↓↓ -key

♦ Function depends on the variable selected: - Changing the parameter values

- Scrolling among variables selected

- Changing of digits or characters

♦ Increasing or decreasing of numbers.

←← -key / →→ -key

♦ Selection of digits within a number.

♦ For some variables you can change the quantity of digits or characters.

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

3 - 9

3.7 Starting a function

If you press the 88 -key or the →→ -key in a function line, you will be asked to confirm the

order in the following way:

TAG

-- Confirmation Required --

Do you really want to do this ??

Press "Yes" or "Back..."

Yes Back...

F1 F2 F3 F4 F5

37.50 ppm

♦ If you will press the F2 key, the function will start immediately.

♦ If you will press the F4 key, you will go back to the last menu page.

Note: If you don't want to be asked before the start of each function, you can configure it

in the menu "Measurement Display Configuration" in the expert configuration level (see

section 5.1.8 p. 5-49). Select "No" in the line "Display confirmation menus". Then, each

function will start directly after the order is done and no confirmation will be required.

3 - 10

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

3 Startup and Operation, General Notes and Main Menu

3.8 Main Menu

If you press the F3 key (Main...) or the →→ -key in any single component display, you

will change to the "Main Menu". From there you can change to all operating levels

of your TFID analyzer or analyzer module to set up and control the parameters of

measurement, calibration and data transfer !

Via the F5 key (MFG Data) you can change to several submenus, where you will find

a lot of important data about the control module (TFID analyzer or platform) and the

analyzer module, such as service address or serial number !

Ramifications from the Main Menu:

TAG

-- Main Menu --

Analyzer module calibration & basic controls...

Analyzer and I/O-module expert configuration...

System configuration and diagnostics...

Display controls...

Time & Date: 14:01:45 25 May 1998

System tag: Fisher-Rosemount

Measure Status... Channel Lock... MFG Data

F1 F2 F3 F4 F5

F1

F2

F3

Changing to the single component display of the current

channel

Changing to the menu "Analyzer Channel Status" of the

current channel

Scrolling through all channels of the connected analyzers and

analyzer modules

95.00 ppm

See chapter 4 !

See chapter 5 !

See chapter 6 !

See chapter 7 !

To setup see 6.2 p. 6-6

Factory Setting

Section 3.1 p. 3-1/2 !

+

Section 4.1 p. 4-3 !

+

See channel tag !

+

F4

F5

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

Lock of any operating level by security code

Changing to the menu "Module Manufacturing Data"

NGA 2000

+

Section 6.3 p. 6-7 !

See next pages !

+

3 - 11

Ramifications from the menu "Module Manufacturing Data":

1. Control module data:

TAG

Control module data...

Analyzer module data...

Measure <<< Back... >>>

-- Module Manufacturing Data --

F1 F2 F3 F4 F5

TAG

(C) Copyright Fisher-Rosemount Analytical Inc., 1998

Manufactured by:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, CA 92807-1802 /USA

Tel: (714) 986-7600

FAX: (714) 577-8739

Measure Back...

F1 F2 F3 F4 F5

2. Analyzer module data:

95.00 ppm

95.00 ppm

TAG

(C) Copyright Fisher-Rosemount GmbH & Co, 1998

Manufactured by:

Fisher-Rosemount GmbH & Co

Industriestrasse 1

D-63594 Hasselroth / Germany

Tel. (+49) 6055 884-0

FAX. (+49) 6055 884-209

Measure Or... Back... More...

F1 F2 F4 F5

TAG

-- Control Module Version Information --

Serial number: CM 4711

Manufacturing date: 14.05.1998

Hardware revision: ACU02 R: 3.2.2

Software revision: 3.2.1/P001

Revision date: May 29 1998

Revision time: 12:35:00

Phrase dictionary version: P001/1

Language: English

Measure Back...

F3

95.00 ppm

95.00 ppm

F1 F2 F3 F4 F5

TAG

Control module data...

Analyzer module data...

Measure <<< Back... >>>

-- Module Manufacturing Data --

95.00 ppm

F1 F2 F3 F4 F5

TAG

-- Analyzer Module Version Information --

Serial number: AM 4712

Manufacturing date: 14.05.1998

Hardware revision: ACU02 R: 3.2.2

Software revision: 3.2.1 / P001

Revision date: May 29 1998

Revision time: 12:41:18

Measure Back...

95.00 ppm

More... Measure Back...

F1 F2 F3 F4 F5

TAG

(C) Copyright Fisher-Rosemount GmbH & Co, 1998

Manufactured by:

Fisher-Rosemount GmbH & Co

Industriestrasse 1

D-63594 Hasselroth / Germany

Tel. (+49) 6055 884-0

FAX. (+49) 6055 884-209

Measure Back... More...

95.00 ppm

F1 F2 F3 F4 F5

TAG

Measurement system: PSV-System

RAM-memory: 242748 Bytes

Local SIO module installed: Enabled

Serial interface adaptor: RS-232

Heater installed: No

Local DIO module installed: 2

Sensor system revision:

-- Hardware Configuration --

Channel

95.00 ppm

F1 F2 F3 F4 F5

3 - 12

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

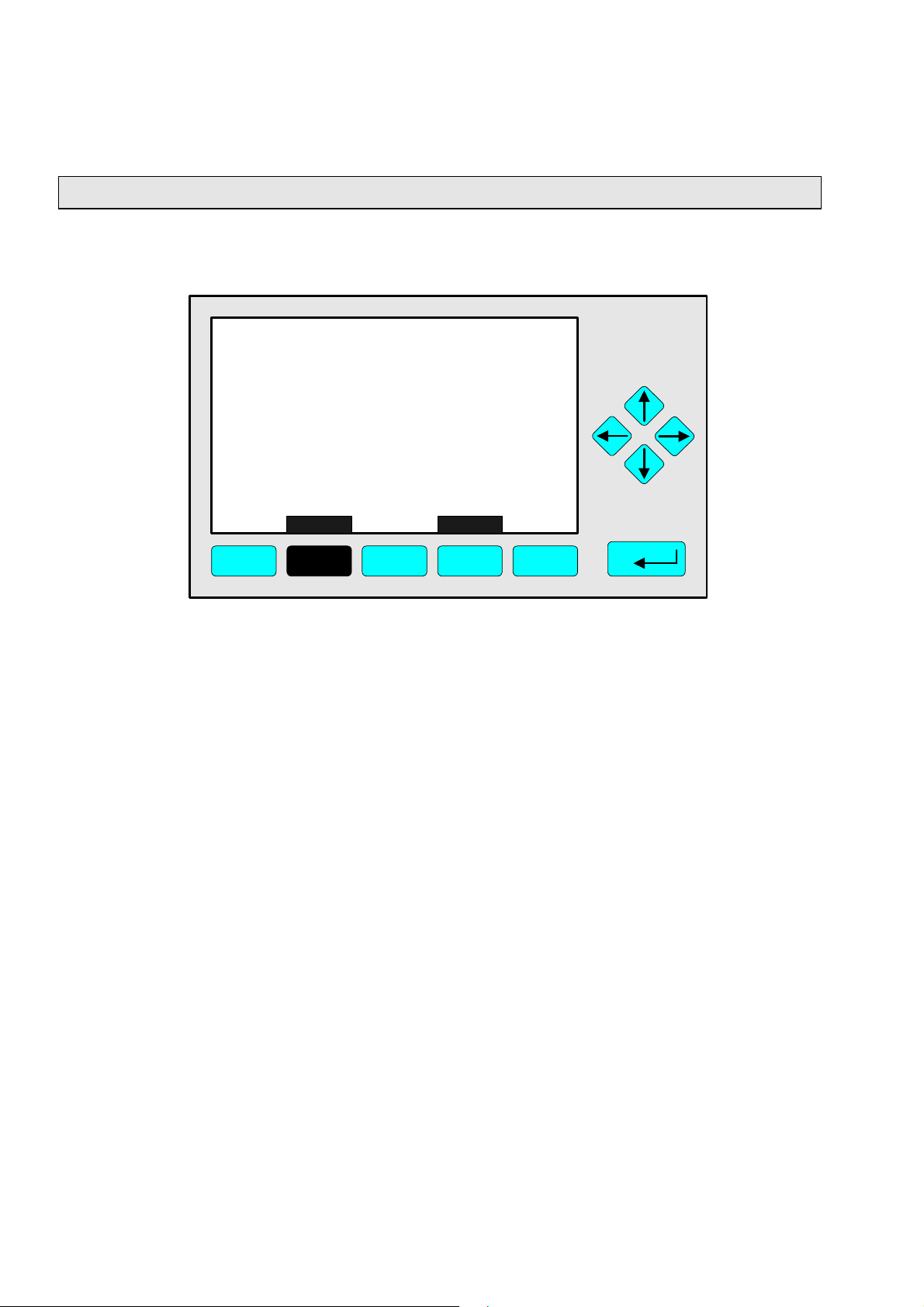

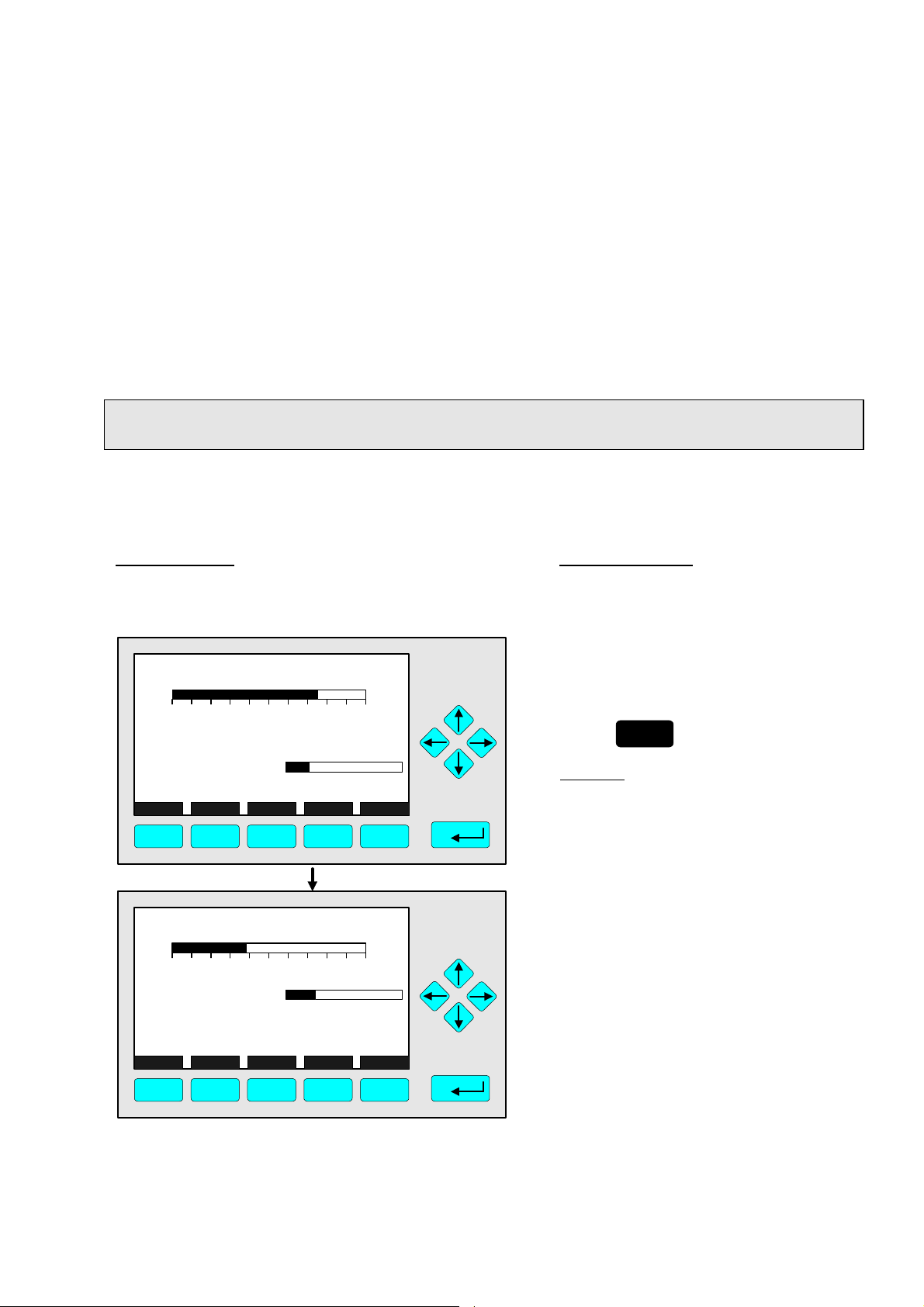

4 Basic Controls and Analyzer Module Calibration

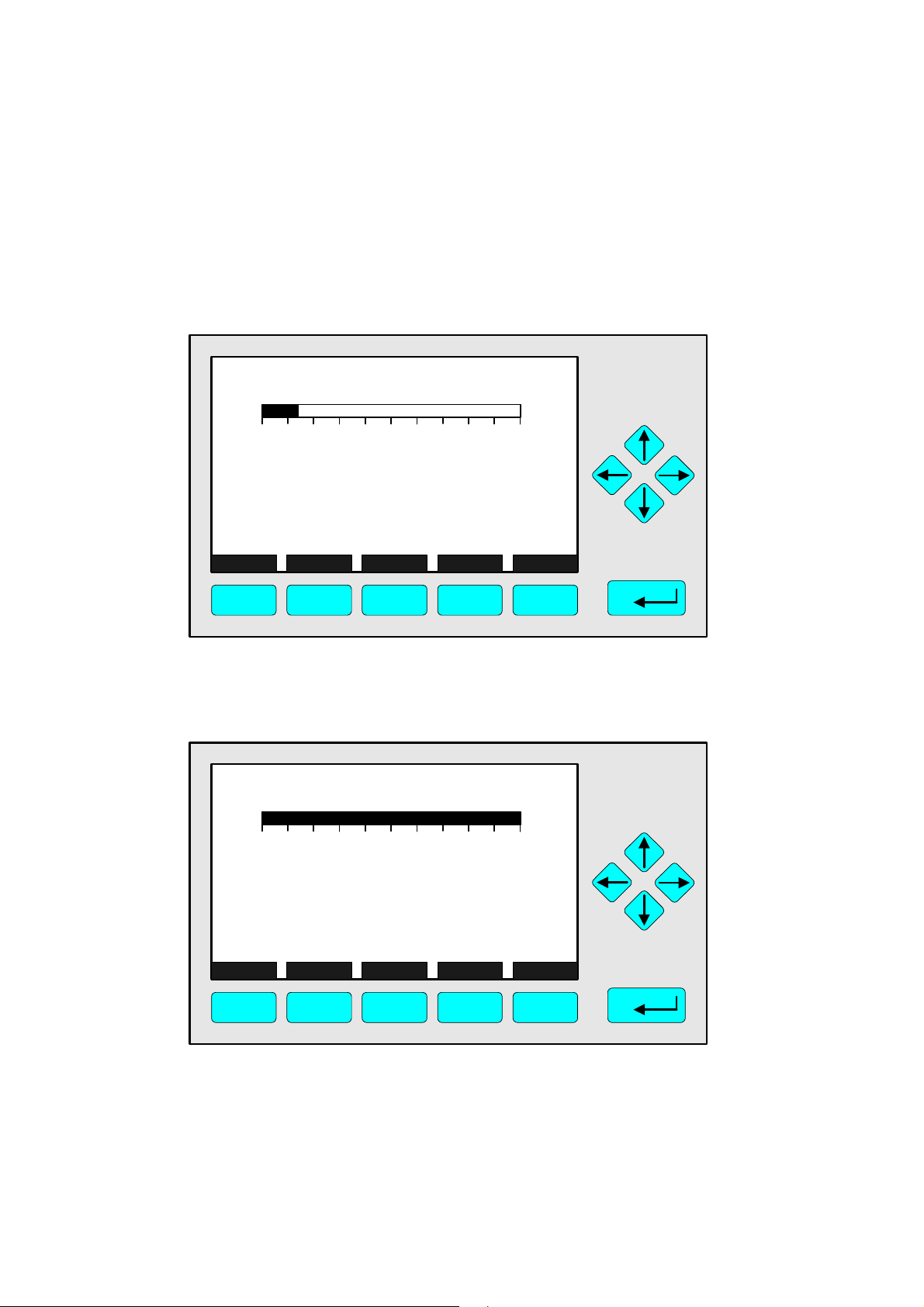

In the chapter "Basic Controls and Analyzer Module Calibration" the most important measurement and calibration functions of your TFID analyzer or analyzer module are described.

All steps are figured with detailed illustrations and operation instructions. In the left column

you can see display and keyboard of the NGA front panel. The keys you have to press are

illustrated in black. In the right column you can read the instructions and notes. All

instructions will begin with any single component display and will end with the corresponding single component display after the setups are done. So you can easily compare the

actual display of the analyzer or analyzer module with the illustrations of the manual.

Example: You want to change from the single component display of the TFID (propane)

to the single component display of the MLT-channel 2 (CO).

• Picture one shows the starting situation: single component display of propane.

• Picture two shows the result you get if you press the F4 key (Channel):

single component display of CO.

Left column: Right column:

Display and keyboard Instructions and notes

TFID-R1

37.50 ppm Propane

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel Calib...

F1 F2 F3 F4 F5

MLT25/CH2/R2

95.00 ppm CO

0 250

Temperature: 25.0 C

Maintenance-Requests: No

Any_Alarms: No

Operation: Ready

Range: 1

0.0 100.0

Range: 2

0.0 100.0

⇒ ⇒ Change to the single

component display

of another channel

F4

Press

Example:

Changing from

propane (TFID) to

CO (MLT-channel 2)

⇒ ⇒ Next instruction

or step

Display Status... Main... Channel Calib...

F1 F2 F3 F4 F5

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

4 - 1

4 - 2

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

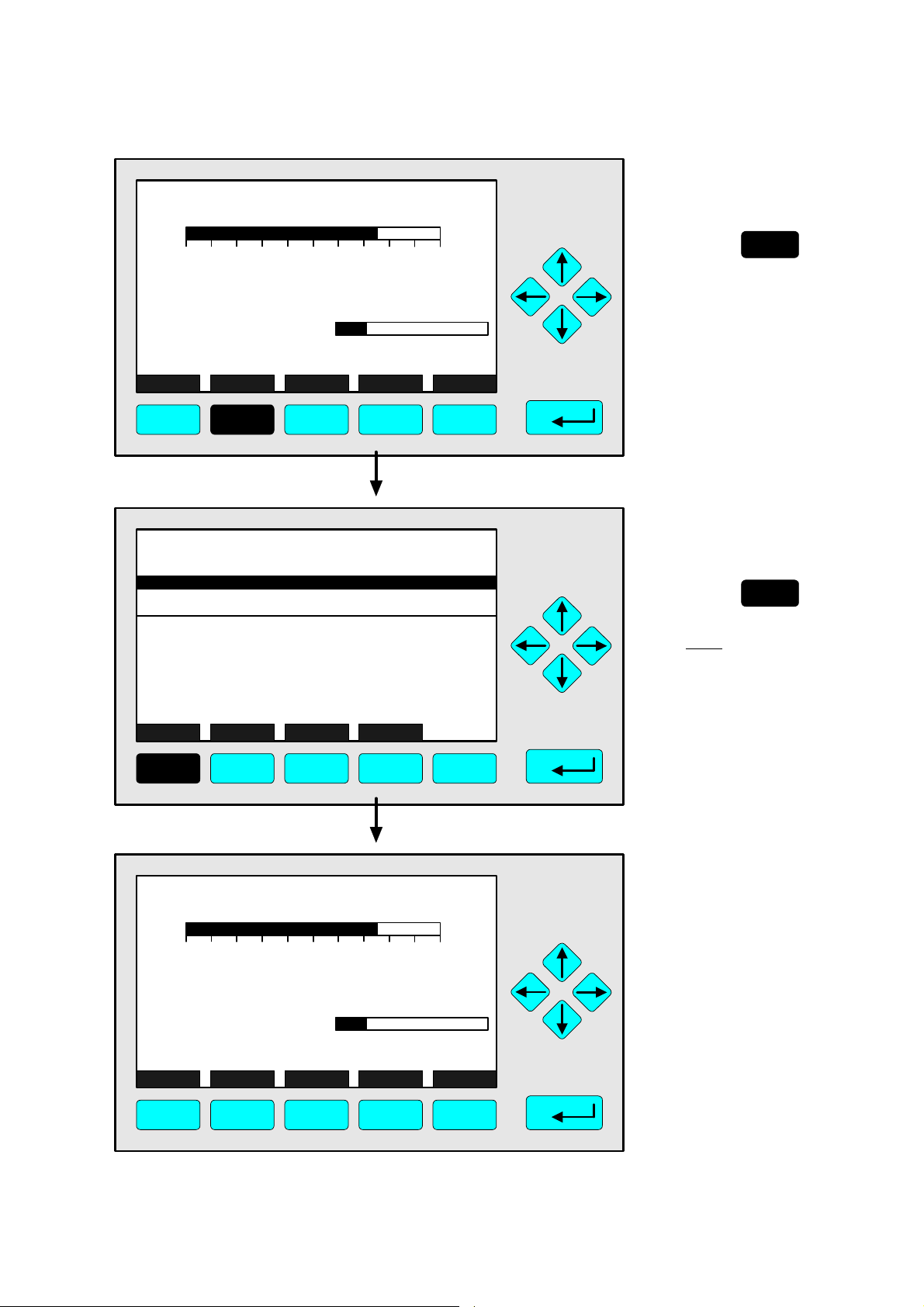

TAG

37.50 ppm Propane

0.00 50.00

Range: 1

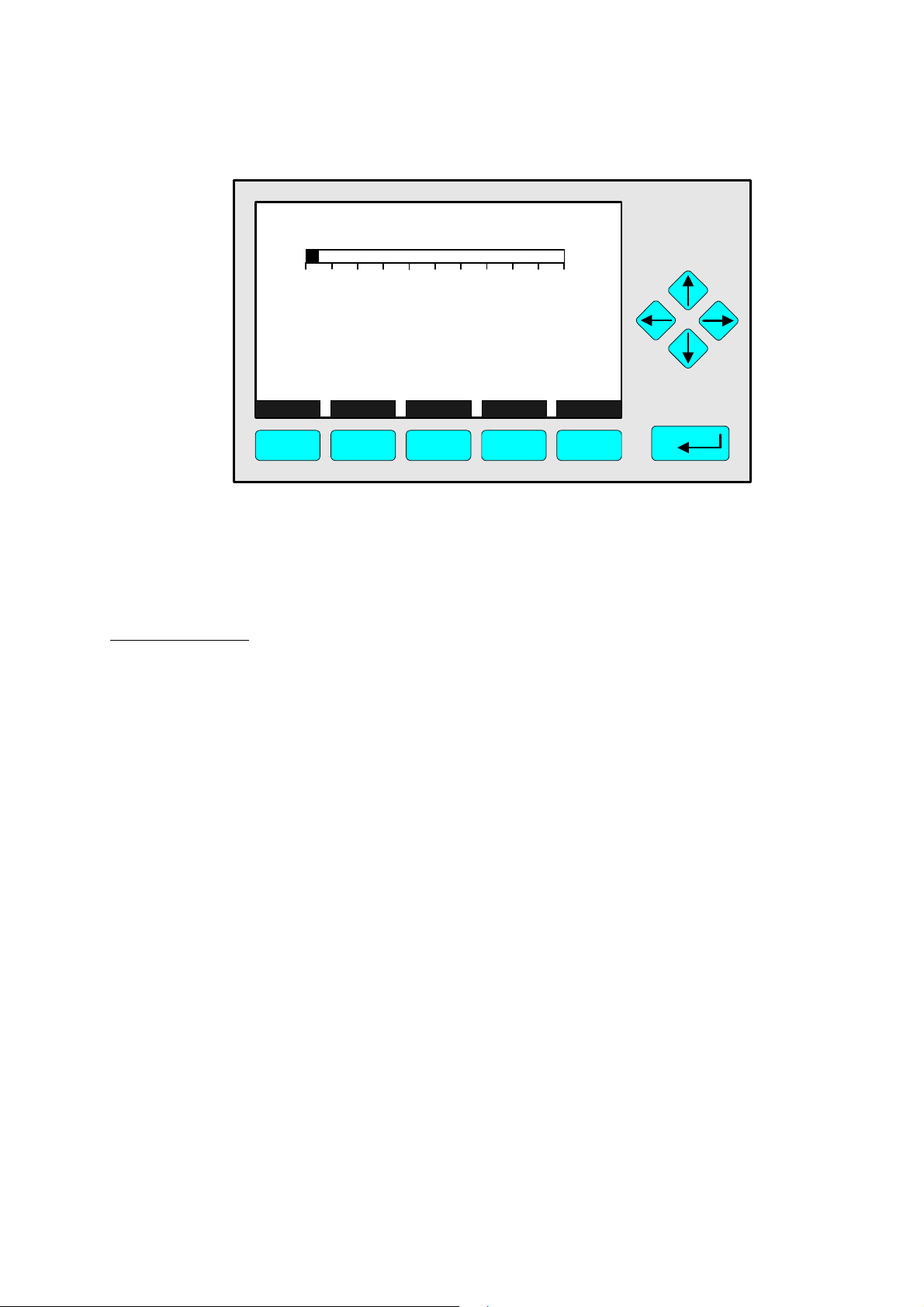

4.1 Analyzer Channel Status

⇒ ⇒ Change to the

menu "Analyzer

Channel Status"

F2

Press

Failures: No

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel Calib...

0.0 100.0

F1 F2 F3 F4 F5

TAG

-- Analyzer Channel Status --

Status details...

Operational settings...

Hours of operations: 164

Operation status: Ready

Events: No

Alarms: No

Failures: No

Maintenance requests: No

Function control/Service: No

Measure Channel Back...

RawMeas

37.50 ppm

In the menu "Analyzer

Channel Status" you can

find status informations

of the current channel.

Via the menu lines "Status

details..." and "Operational

settings..." you can change

to further submenus.

(see 4.1.1 p. 4-5...32 and

4.1.2 p. 4-33/34)

⇒ ⇒ Change to the

single component

display

F1

Press

Note:

Via the F2 key you can

change to submenus

containing the primary

and secondary raw

measurements.

F1 F2 F3 F4 F5

TAG

37.50 ppm Propane

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel Calib...

F1 F2 F3 F4 F5

Range: 1

0.0 100.0

⇒ ⇒ Back in the single

component display

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

4 - 3

4 - 4

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

4.1.1 Analyzer Channel Status - Status Details

TAG

37.50 ppm Propane

Failures

⇒ ⇒ Change to the

menu "Analyzer

Channel Status"

0.00 50.00

Failures: No

Maintenance-Requests: No

Temperature: 20.0 C

Operation: Ready

Display Status... Main... Channel Calib...

Range: 1

0.0 100.0

F1 F2 F3 F4 F5

TAG

-- Analyzer Channel Status --

Status details...

Operational settings...

Hours of operations: 164

Operation status: Ready

Events: No

Alarms: No

Failures: No

Maintenance requests: No

Function control/Service: No

Measure Channel Back...

RawMeas

37.50 ppm

F2

Press

⇒ ⇒ Change to the

submenu "Status

Details"

Press

or

F1 F2 F3 F4 F5

TAG

-- Status Details --

Failures...

Maintenance requests...

Function controls...

Measurements/Alarms...

Events...

Acknowledge and clear failures !

Acknowledge and clear maintenance requests !

Acknowledge and clear function controls !

Measure Back...

37.50 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the "List

of Possible Failures

(page 1 of 4)"

Press

or

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

NGA 2000

4 - 5

TAG

-- List of Possible Failures (1/4) --

One or more failures: No

Configuration replaced by factory setting: No

Hydrogen pressure too low: No

No source voltage: No

Sample gas pump #1 fail: No

Sample gas pump #2 fail: No

Detector temperature too low: No

Flame is off: No

Ignition canceled: No

Measure Back... More...

37.50 ppm

F1 F2 F3 F4 F5

TAG

-- List of Possible Failures (2/4) --

External Input: No

Probe temperature too low: No

Probe temperature too high: No

Flame temperature sensor fail: No

Sample under pressure too high: No

Capillary #1: No

Control of sample gas pump #1 fail: No

Sample gas pressure too high: No

37.50 ppm

⇒ ⇒ Change to the

second menu page

F5

Press

⇒ ⇒ Change to the

third menu page

F5

Press

Control of sample gas pump #2 fail: No

Measure Back... More...

F1 F2 F3 F4 F5

TAG

-- List of Possible Failures (3/4) --

Sample gas (Filter/supply/under pressure): No

Capillary #3 or H2 supply: No

Detector signal communication failed: No

Power supply less than 23V: No

Air pressure less than 2.9 bar: No

Igniter broken: No

Igniter short-circuit: No

Detector temperature sensor fail: No

Sensor temperature sensor fail: No

Ambient temperature too high: No

Measure Back... More...

37.50 ppm

F1 F2 F3 F4 F5

⇒ ⇒ Change to the

last menu page

F5

Press

4 - 6

NGA 2000

90003808(1) [NGA-e (TFID-Software 3.2.X)] 06/98

Loading...

Loading...