NGA 2000

N

ON

-D

ISPERSIVE INFRARED

A

NALYZER

Rosemount Analytical

M

ODULE

N

OTICE

T

HE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE

Pyrex® is a registered trademark of Corning Glass Works

®

Irtran

is a registered trademark of Eastman Kodak Co.

®

Teflon

Ty-Rap

and Viton® is a registered trademark of E.I. duPont de Nemours and Co., Inc.

®

is a registered trademark of Thomas & Betts Corp.

.

Manual Part Number 748332-D

June 1997

Printed in U.S.A.

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

C

P

REFACE

PURPOSE/SAFETY SUMMARY........................................................................P-1

GLOSSARY ......................................................................................................P-4

SPECIFICATIONS..............................................................................................P-6

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE ....P-8

RETURNING PARTS TO THE FACTORY .........................................................P-8

TRAINING ......................................................................................................P-8

DOCUMENTATION............................................................................................P-8

COMPLIANCES..................................................................................................P-9

ONTENTS

S

ECTION

1.1 OVERVIEW ...............................................................................................1-1

1.2 TYPICAL APPLICATIONS.........................................................................1-1

1.3 THEORY OF TECHNOLOGY....................................................................1-2

1.4 SAMPLE REQUIREMENTS ......................................................................1-4

1-5 PURGE KITS.............................................................................................1-5

1.6 FEATURES................................................................................................1-5

S

ECTION

2.1 UNPACKING..............................................................................................2-1

2.2 ASSEMBLY................................................................................................2-1

2.3 LOCATION ................................................................................................2-2

2.4 GASES ......................................................................................................2-2

2.5 ELECTRICAL CONNECTIONS .................................................................2-5

1. I

2. I

2.4.1 Specifications...............................................................................2-2

2.4.2 Connections.................................................................................2-3

NTRODUCTION

NSTALLATION

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

i

C

ONTENTS

S

ECTION

3.1 OVERVIEW............................................................................................... 3-1

3.2 DISPLAY SCREENS.................................................................................3-1

3.2.1 RUN MODE DISPLAY............................................................................3-1

3.3 STARTUP PROCEDURE..........................................................................3-2

3.4 BINDING ...................................................................................................3-5

3.5 CALIBRATION ..........................................................................................3-5

3.6 LINEARIZATION.......................................................................................3-8

3.7 ROUTINE OPERATION............................................................................3-9

S

ECTION

4.1 OVERVIEW............................................................................................... 4-1

4.2 PCB REPLACEMENT...............................................................................4-2

4.3 POWER FUSE REPLACEMENT ..............................................................4-2

3. S

3.2.2 Menu Displays.............................................................................3-1

3.2.3 Help Displays...............................................................................3-2

4. M

TARTUP AND OPERATION

AINTENANCE AND TROUBLESHOOTING

4.4 MODULE FAN REPLACEMENT...............................................................4-2

4.5 CHOPPER MOTOR REPLACEMENT ......................................................4-3

4.6 SOURCE REPLACEMENT.......................................................................4-3

4.7 DETECTOR REMOVAL............................................................................4-3

4.8 FLOW SENSOR REPLACEMENT............................................................4-3

4.9 CASE TEMPERATURE SENSOR REPLACEMENT ................................4-4

4.10 THERMAL FUSE REPLACEMENT...........................................................4-4

4.11 OSCILLATOR TUNE/SOURCE BALANCE SHUTTER ADJUSTMENT....4-4

4-12 CLEANING CELLS ...................................................................................4-8

4-13 CELL DESICCANT ...................................................................................4-10

4.14 MODULATION CHECK.............................................................................4-10

S

ECTION

5.1 REPLACEMENT PARTS ..........................................................................5-1

5.

REPLACEMENT PARTS

A

PPENDIX

ii

A. I

DENTIFICATION MATRIX

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

NFRARED ANALYZER DATA SHEET

I

ENERAL PRECAUTIONS FOR HANDLING

G

ARRANTY

W

IELD SERVICE AND REPAIR FACILITIES

F

F

IGURES

1-1 NGA 2000 NDIR Analyzer Module (Typical - Actual configuration May

Vary)..............................................................................................1-3

1-2 NDIR Technology ......................................................................................1-4

2-1 Analyzer Module Installation Into Instrument Platform...............................2-1

2-2 Outline and Mounting Dimensions.............................................................2-4

2-3 NDIR Back Panel.......................................................................................2-5

2-4 NDIR Front Panel Electrical Connections..................................................2-5

2-5 NDIR Wiring Diagram................................................................................2-6

3-1 Run Mode Display.....................................................................................3-3

3-2 Main Menu Display....................................................................................3-3

3-3 Basic Controls Menu..................................................................................3-3

3-4 Expert Controls and Setup Menu...............................................................3-4

3-5 Technical Level Configuration Menu .........................................................3-4

3-6 Typical Help Screen...................................................................................3-4

3-7 Typical Linearization Curve, Linearizer OFF..............................................3-7

3-8 Operator-Determined Linearization Curve (Normalized)............................3-7

3-9 Display Screens (1 of 5)............................................................................3-10

3-10 Display Screens (2 of 5)............................................................................3-11

3-11 Display Screens (3 of 5)............................................................................3-12

3-12 Display Screens (4 of 5)............................................................................3-13

3-13 Display Screens (5 of 5)............................................................................3-14

4-1 Printed Circuit Board Fold-Out Panel Views..............................................4-2

4-2 Module Fan Assembly...............................................................................4-3

4-3 Motor/Source Assembly.............................................................................4-4

4-4 Cell, PCB Assembly (Exploded View)........................................................4-6

4-5 Oscillator Tune, Source Balance Shutter Adjustments..............................4-7

4-6 Detector Block (Exploded View) ................................................................4-7

4-7 Cell Disassembly.......................................................................................4-9

TORING HIGH PRESSURE CYLINDERS

& S

C

ONTENTS

T

ABLES

2-1. Cell Purging Times at Atmospheric Sample Pressure...............................2-2

3-1 NDIR Analyzer Module Alarms..................................................................3-6

4-1 Cell Desiccant............................................................................................4-10

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

iii

C

ONTENTS

N

OTES

iv

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

P

REFACE

P

URPOSE/SAFETY SUMMARY

The purpose of this manual is to provide information concerning the components,

functions, installation and maintenance of this particular NGA 2000 module.

Some sections may describe equipment not used in your configuration. The user

should become thoroughly familiar with the operation of this module before operating

it. Read this instruction manual completely.

To avoid explosion, loss of life, personal injury and damage to this equipment

and on-site property, all personnel authorized to install, operate and service this

equipment should be thoroughly familiar with and strictly follow the instructions

in this manual. SAVE THESE INSTRUCTIONS.

If this equipment is used in a manner not specified in these instructions,

protective systems may be impaired.

DANGER

personal injury, death, or substantial property damage if the warning is ignored.

WARNING

personal injury, death, or substantial property damage if the warning is ignored.

CAUTION

personal injury or property damage if the warning is ignored.

NOTE

important but not hazard-related.

is used to indicate the presence of a hazard which

is used to indicate the presence of a hazard which

is used to indicate the presence of a hazard which

is used to indicate installation, operation or maintenance information which is

will

cause

can

cause

will or can

cause

severe

severe

minor

WARNING: ELECTRICAL SHOCK HAZARD

Operate this equipment only when covers are secured. Servicing requires

access to live parts which can cause death or serious injury. Refer servicing to

qualified personnel.

For safety and proper performance, this module must be connected to a

properly grounded three-wire source of electrical power.

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-1

P

REFACE

WARNING: POSSIBLE EXPLOSION HAZARD

This equipment is not designed for and should not be used in the analysis of

flammable samples. Use of this equipment in this way could result in explosion

and death.

WARNING: POSSIBLE EXPLOSION HAZARD

Ensure that all gas connectors are made as labeled and are leak free. Improper

gas connections could result in explosion or death.

CAUTION: PRESSURIZED GAS

This module requires periodic calibration with a known standard gas. See

General Precautions for Handling and Storing High Pressure Gas Cylinders at

the rear of this manual.

CAUTION: HAND INJURY HAZARD

Dropping the front panel of the Platform while hand or fingers are inside either

case handle can cause serious injury.

P-2

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

P

REFACE

CAUTION: PARTS INTEGRITY

Tampering with or unauthorized substitution of components may adversely

affect safety of this product. Use only factory approved components for repair.

CAUTION: OVERBALANCE HAZARD

This Analyzer Module may tip instrument over if it is pulled out too far and the

Platform is not properly supported.

WARNING: OVER-VOLTAGE SPIKING

If this Analyzer Module is used with a non-Rosemount Analytical power supply,

adding Rosemount Analytical PN 903341 Current Protector in series with the

24V positive power line will prevent over-voltage spiking and resultant fuse

blowing when powering up the instrument.

Note

Apply leak test liquid to cell or detectors only as a last resort.

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-3

P

REFACE

G

LOSSARY

NALYZER MODULE

A

The module that contains all sensor/detector components for development of a

Primary Variable signal; includes all signal conditioning and temperature control

circuitry.

ACKPLANE

B

The interconnect circuit board which the Controller Board, Power Supply, Analyzer

Module power and network cables, I/O Modules and Expansion Modules plug into.

ONTROL MODULE

C

The Operator Interface plus the Controller Board.

ONTROLLER BOARD

C

The computer board that serves as the Network Manager and operates the Display

and Keypad.

ISTRIBUTION ASSEMBLY

D

The Backplane and the card cages that hold I/O and Expansion Modules.

XPANSION MODULE

E

A circuit board that plugs into the Backplane from the front of the Platform and

performs special features not related to I/O functions.

I/O M

A circuit board that plugs into the Backplane from the rear of the Platform. Has a

connector terminal for communication with external data acquisition devices and

provides an input/output function.

ODULE

P-4

PERATOR INTERFACE

O

The Display and Keyboard.

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

P

REFACE

LATFORM

P

Any workable collection of the following: Controller Board, Power Supply, Distribution

Assembly, Enclosure and Operator Interface.

OWER SUPPLY

P

Any of a variety of components that provides conditioned power to other NGA 2000

components, from the Power Supply Board that plugs into the front of the Backplane

in a stand-alone instrument to several larger ones that can power larger collections of

modules and components.

RIMARY VARIABLE

P

The measured species concentration value from an Analyzer Module.

ECONDARY VARIABLE

S

Data placed on the network by a module regarding current status, e.g., sample flow,

source voltage and other diagnostic information.

OFTKEYS

S

The five function keys located below the front panel display; they assume the function

displayed directly above each on the display, a function dictated by software.

YSTEM

S

Any collection of Analyzer M odule(s), Platform(s) , I/O Module(s) and Expansion Modul e(s).

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-5

P

REFACE

S

PECIFICATIONS

M

EASUREMENT SPECIES

R

ANGES

R

EPEATABILITY

M

INIMUM DETECTABLE

L

EVEL

N

OISE

L

INEARITY

R

ESPONSE TIME

D

RIFT (ZERO AND SPAN

E

FFECT OF

T

EMPERATURE

E

NVIRONMENT

A

MBIENT TEMPERATURE

E

FFECT OF FLOW

P

OWER REQUIREMENTS

:

:

:

:

:

:

:

:

- G

ENERAL

Heteroatomic gases such as ammonia (NH3), carbon dioxide

:

(CO2), carbon monoxide (CO), carbon monoxide + carbon

dioxide ethylene (C2H4), hexane (C6H14), methane (CH4), nitric

oxide (NO) and sulfur dioxide (SO2)

10 ppm fullscale to 100% fullscale (application-dependent); 4

fullscale selections, including suppressed zero ranges

1% of fullscale (at constant temperature)

±

0.1% CO2 (at 1 atm. sample pressure; application dependent)

<1% of fullscale, peak-to-peak

1% of fullscale with 4th order polynomial

±

.05 to 30 seconds (selectable) for 0 to 90% of fullscale

<±1% of fullscale/24 hours at constant temperature

):

(application dependent);

<±2% of fullscale/week at constant temperature (application

dependent)

<±1% of fullscale over any 10°C interval for rate of change no

greater than 10°C per hour (application dependent)

Location - Class B controlled, indoor, non-hazardous

0 to 45°C (32 to 113°F)

:

:

<1% of range when sample flow rate is changed by ≤250

ml/min. (No effect if flow rate is between 0 and 500 ml/min.)

24 VDC ±5%, 100 W max.; ripple and noise: <100 mV peak-to-

:

peak; line and load regulations: <±1%

S

PECIFICATIONS

T

EMPERATURE

F

LOW RATE

P

RESSURE

P

ARTICULATES

D

EWPOINT

M

ATERIALS IN CONTACT

WITH SAMPLE

:

:

:

:

:

P-6

- S

AMPLE

Non-flammable;: 0°C to 55°C (32°F to 138°F)

500 to 1400 ml/min.

Maximum 690 hPa-gauge (10 psig), higher pressure in

pressurized cell applications

:

filtered to <2 microns

<40°C (104°F), no entrained liquid

Gold plated Pyrex, sapphire, quartz, Irtran, FEP Teflon, Viton-

A, 316 stainless steel

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

P

REFACE

S

PECIFICATIONS

C

ASE CLASSIFICATION

D

IMENSIONS

W

EIGHT

M

OUNTING

M

AXIMUM LENGTH OF

LON C

:

:

ABLE

:

:

- P

HYSICAL

General purpose for installation in weather-protected areas

:

See Outline and Mounting Dimensions, Figure 2-3

Standard: 11 kg (24.2 lbs.); extended: 12.5 kg (27.5 lbs.)

Inside a Platform or custom-installed in a panel

1600 m (1 mile) between Analyzer Module and Platform

See the Preface Section of the Platform manual for specifications regarding Platform

related components.

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-7

P

REFACE

C

USTOMER SERVICE

For order administration, replacement Parts, application assistance, on-site or factory

repair, service or maintenance contract information, contact:

R

ETURNING PARTS TO THE FACTORY

Before returning parts, contact the Customer Service Center and request a Returned

Materials Authorization (RMA) number. Please have the following information when

you call:

Number.

Prior authorization by the factory must be obtained before returned materials will be

accepted. Unauthorized returns will be returned to the sender, freight collect.

When returning any product or component that has been exposed to a toxic, corrosive

or other hazardous material or used in such a hazardous environment, the user must

attach an appropriate Material Safety Data Sheet (M.S.D.S.) or a written certification

that the material has been decontaminated, disinfected and/or detoxified.

Model Number, Serial Number, and Purchase Order Number or Sales Order

, T

ECHNICAL ASSIST ANCE AND FIELD SERVICE

Rosemount Analytical Inc.

Process Analytical Division

Customer Service Center

1-800-433-6076

Return to:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

T

RAINING

A comprehensive Factory Training Program of operator and service classes is

available. For a copy of the

the Technical Services Department at:

D

OCUMENTATION

The following NGA 2000 Non-Dispersive Infrared Analyzer instruction materials are

available. Contact Customer Service or the local representative to order.

748332 Instruction Manual (this document)

Current Operator and Service Training Schedule

Rosemount Analytical Inc.

Phone: 1-714-986-7600

FAX: 1-714-577-8006

contact

P-8

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

C

9

6

OMPLIANCES

This product may carry approvals from several certifying agencies, including Factory

Mutual and the Canadian Standards Association (which is also an OSHA accredited,

Nationally Recognized Testing Laboratory), for use in non-hazardous, indoor locations

P

REFACE

FM

APPROVED

Rosemount Analytical Inc. has satisfied all obligations from the European

Legislation to harmonize the product requirements in Europe.

This product complies with the standard level of NAMUR EMC.

Recommendation (May 1993).

This product satisfies all obligations of all relevant standards of the EMC framework in

Australia and New Zealand.

®

97-C219

NAMUR

N

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infrared Analyzer

P-9

P

REFACE

N

OTES

P-10

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infrared Analyzer

I

NTRODUCTION

1

1.1 OVERVIEW

This manual describes the Non-Dispersive Infrared (NDIR) Analyzer Module of

Rosemount Analytical's NGA 200 Series of gas analysis components. See Figure 1-1.

The NDIR Analyzer Module is designed to continuously determine the concentration

of oxygen in a flowing gaseous mixture. The concentration is expressed in one of

three fashions:

parts-per-million

•

percent of composition

•

percent of fullscale

•

The user can obtain an output that is linear with concentration by initiating a linearizer,

which is based on a fourth-order polynomial. The linearizer is incorporated in the

Analyzer Module's electronic circuitry and is adjustable through interconnection with

the network.

The entire Analyzer Module is designed as a slide-in module (if configured in standalone instrument fashion), removable from the front of the Platform, with gas

connections made from the rear. All electronics relative to sample detection and

conditioning are included in this module.

1.2 TYPICAL APPLICATIONS

The NDIR Analyzer Module is designed to cover a wide range of process, stack and

automotive applications. Typical measurements include:

HEMICAL AND PETROLEUM

C

Carbon dioxide: Manufacture of ethylene oxide, phthalic anhydride and

•

ammonia; nitrogen generation; and producer gas monitoring

Carbon Monoxide: Stack monitoring

•

Methane: Ammonia manufacture

•

Acetylene: Manufacture of acetylene, acrylonitrile, and vinyl chloride

•

Sulfur Dioxide: Sulf uric acid stack gas

•

748332-D Rosemount Analytical June 1997

NGA Non-Dispersive Infraraed Analyzer

1-1

I

NTRODUCTION

OOD AND AGRICULT URE

F

EROSPACE AND OCEANOGRAPHY

A

ETALS AND CERAMICS

M

Carbon Dioxide and Water Vapor: Blanketing of perishables, fermentation

•

processes, photosynthesis studies, personnel protection

Carbon Dioxide, Carbon Monoxide, and Water Vapor: Diving and space

•

chambers

Carbon Dioxide: Monitoring of producer gas, steel converting, manufacture of

•

cement, soaking pit, heat treating

Carbon Monoxide: Inert gas generation, producer gas monitoring, rotary kiln

•

roasting, tin plate annealing, steel converting, aluminum power processing,

porcelain kilns, tunnels

Water Vapor: Heat treating, hydrogen brazing, nickel and chrome plating

•

Sulfur Dioxide: Flash smelting

•

Ammonia: Ammonia dissociation

•

1.3 THEORY OF TECHNOLOGY

Inside of the Analyzer Module, two equal-energy infrared beams are directed through

two parallel optical cells, a flow-through sample cell and a reference cell. The

reference cell may be sealed or may contain a continuously flowing reference gas.

(See Figure 1-2.)

The infrared radiation is interrupted by a chopper at a frequency of 5 Hz.

During analysis, a portion of the infrared radiation is absorbed by the component of

interest in the sample. The quantity of infrared radiation that is absorbed is

proportional to the component concentration.

1-2

June 1997 Rosemount Analytical 748332-DNGA Non-Dispersive Infraraed Analyzer

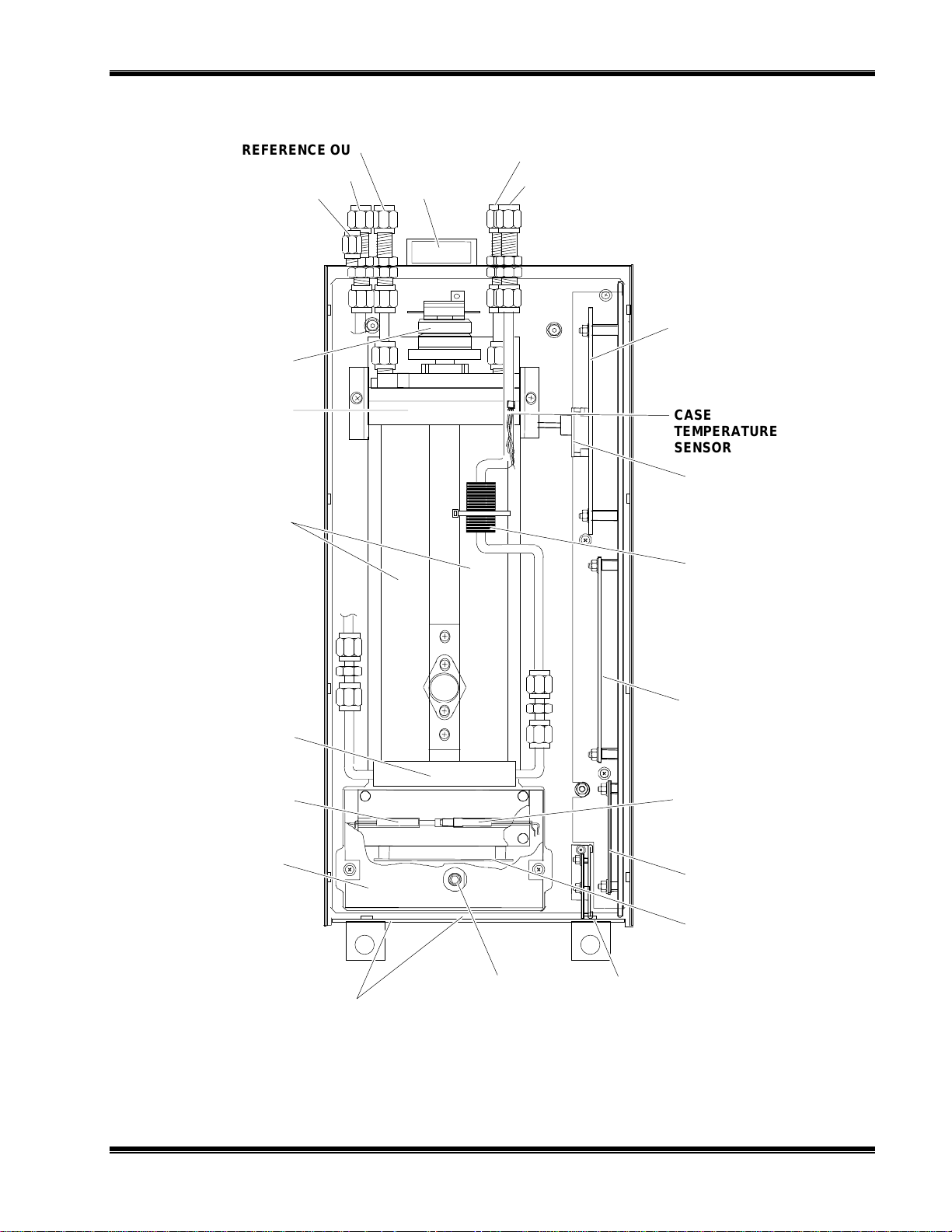

REFERENCE OUT

(

)

REFERENCE IN

PURGE GAS IN

CHOPPER MOTOR

FAN

SAMPLE OUT

(BOTTOM)

SAMPLE IN

POWER SUPPLY

BOARD

I

NTRODUCTION

SOURCE

CELLS

DETECTOR

THERMAL FUSE

DETECTOR COVER

CASE

TEMPERATURE

SENSOR

PRESSURE

COMPENSATION

BOARD

FLOW SENSOR

MICRO BOARD

DETECTOR

TEMPERATURE

CONTROL RTD

SIGNAL BOARD

OPTION

IGURE

F

748332-D Rosemount Analytical June 1997

1-1. NGA 2000 NDIR A

SHUTTER ADJUST

ACCESS HOLES

NALYZER MODULE (TYPICAL

ONFIGURATION MAY VARY

C

OSCILLATOR

TUNE ADJUST

)

OSCILLATOR

BOARD

NETWORK INPUT

MODULE

CTUAL

- A

NGA Non-Dispersive Infraraed Analyzer

1-3

Loading...

Loading...