Rosemount Manual: NGA 2000 FID Hydrocarbon Analyzer Module SW 3.6 including Hardware-Rev A | Rosemount Manuals & Guides

Instruction Manual

760001-A

October 2002

Model NGA2000 FID

Flame Ionization Detector Module

http://www.processanalytic.com

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

to ensure they continue to operate within their

• Read all instructions

prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical representative

for clarification.

• Follow all warnings, cautions, and instructions

marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of

the product.

• Install your equipment as specified in the Installation Instructions of the appropriate Instruc-

tion Manual and per applicable local and national codes. Connect all products to the proper elec-

trical and pressure sources.

• To ensure proper performance, use qualified personnel

to install, operate, update, program, and

maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by

Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe

operation of your process at risk, and VOID YOUR WARRANTY

. Look-alike substitutions may result

in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons, to prevent electrical shock and personal

injury.

The information contained in this document is subject to change without notice.

Teflon and Viton are registered trademarks of E.I. duPont de Nemours and Co., Inc.

Kynar® is a registered trademark of Pennwalt, Inc.

Tygon is a registered trademark of Saint-Gobain Performance Plastics

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

Model NGA2000 FID

TABLE OF CONTENTS

Instruction Manual

760001-A

October 2002

PREFACE...........................................................................................................................................P-1

Definitions ...........................................................................................................................................P-1

Safety Summary .................................................................................................................................P-2

General Precautions For Handling And Storing High Pressure Gas Cylinders .................................P-5

Documentation....................................................................................................................................P-6

Compliances .......................................................................................................................................P-6

Glossary of Terms ............................................................................................................................P-7

1-0 DESCRIPTION AND SPECIFICATIONS..............................................................................1-1

1-1 Overview................................................................................................................................1-1

1-2 Typical Applications...............................................................................................................1-1

1-3 Theory of Technology............................................................................................................1-1

1-4 Gas Safety Features..............................................................................................................1-3

1-5 Fuel Gas Option ....................................................................................................................1-3

1-6 Specifications.........................................................................................................................1-5

a. General ...........................................................................................................................1-5

b. Gas Requirements ..........................................................................................................1-6

c. Physical...........................................................................................................................1-7

d. Gas Connections.............................................................................................................1-7

2-0 INSTALLATION ....................................................................................................................2-1

2-1 Unpacking..............................................................................................................................2-1

2-2 Assembly ...............................................................................................................................2-1

2-3 Location .................................................................................................................................2-2

2-4 Gases ....................................................................................................................................2-3

a. Overview .........................................................................................................................2-3

b. Connections ....................................................................................................................2-3

c. Specifications ..................................................................................................................2-5

d. Leak Test ........................................................................................................................2-6

2-5 Electrical Connections ...........................................................................................................2-6

3-0 OPERATION .........................................................................................................................3-1

3-1 Overview................................................................................................................................3-1

3-2 Displays .................................................................................................................................3-1

3-3 Run Mode Display .................................................................................................................3-1

3-4 Menu Displays .......................................................................................................................3-1

3-5 Help Displays.........................................................................................................................3-1

3-6 Startup Procedure .................................................................................................................3-7

3-7 Binding...................................................................................................................................3-9

3-8 Calibration..............................................................................................................................3-9

3-9 Routine Operation .................................................................................................................3-10

3-10 Safety System .......................................................................................................................3-10

4-0 MAINTENANCE AND SERVICE ..........................................................................................4-1

4-1 Burner disassembly and cleaning .........................................................................................4-1

4-2 Component Replacement......................................................................................................4-2

4-3 Burner Startup Troubleshooting ............................................................................................4-2

Rosemount Analytical Inc. A Division of Emerson Process Management Contents i

Instruction Manual

760001-A

October 2002

5-0 REPLACEMENT PARTS ......................................................................................................5-1

5-1 Replacement Parts ................................................................................................................5-1

a. Electronics.......................................................................................................................5-1

b. Burner Assembly and Components ................................................................................5-1

c. Electro-Mechanical..........................................................................................................5-1

d. O-Rings and Gaskets......................................................................................................5-1

e. Pneumatics .....................................................................................................................5-1

5-2 Matrix .....................................................................................................................................5-2

6-0 RETURN OF MATERIAL ......................................................................................................6-1

6-1 Return Of Material .................................................................................................................6-1

6-2 Customer Service ..................................................................................................................6-1

6-3 Training..................................................................................................................................6-1

7-0 APPENDIX A – MENU SCREENS .......................................................................................7-1

8-0 INDEX....................................................................................................................................8-1

Model NGA2000 FID

ii Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

LIST OF ILLUSTRATIONS

Figure 1-1. Flame Ionization Detection Technology..........................................................................1-1

Figure 1-2. FID Component Locations – Top View ...........................................................................1-2

Figure 2-1. Analyzer Module Installation into Platform......................................................................2-1

Figure 2-2. Back Panel Connections.................................................................................................2-2

Figure 2-3. FID Module Flow Diagram ..............................................................................................2-4

Figure 2-4. Front Panel Connections, Controls and Indicators .........................................................2-4

Figure 2-5. Outline and Mounting Dimensions..................................................................................2-7

Figure 2-6. FID Wiring Diagram........................................................................................................2-8

Figure 3-1. Run Mode Display...........................................................................................................3-1

Figure 3-2. Main Menu Display..........................................................................................................3-2

Figure 3-3. Basic Controls Menu Display..........................................................................................3-2

Figure 3-4. Expert Controls and Setup Menu Display.......................................................................3-2

Figure 3-5. Technical Configuration Menu Display ...........................................................................3-3

Figure 3-6. Typical Help Screen........................................................................................................3-3

Figure 3-7. Typical Curves of Module Response vs. Pressure Setting on Sample Pressure

Regulator .......................................................................................................................3-5

Figure 3-8. Typical Curves of Module Response vs. Pressure Setting on Fuel Pressure

Regulator .......................................................................................................................3-5

Figure 3-9. Typical Curves of Module Response vs. Pressure Setting on Air Pressure

Regulator .......................................................................................................................3-6

Figure 3-10. Front Panel Torque Sequence........................................................................................3-11

Figure 4-1. FID Burner Assembly – Exploded View..........................................................................4-3

Instruction Manual

760001-A

October 2002

LIST OF TABLES

Table 1-1. Analyzer Characteristics Relative to Fuel Gas ...............................................................1-4

Table 3-1. FID Analyzer Module Alarms ..........................................................................................3-4

Rosemount Analytical Inc. A Division of Emerson Process Management Contents iii

Instruction Manual

760001-A

October 2002

Model NGA2000 FID

iv Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

The purpose of this manual is to provide information concerning the components,

functions, installation and maintenance of the NGA2000 FID and the System Accessories

of the NGA2000 System.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

The following definitions apply to DANGERS, WARNINGS, CAUTIONS and NOTES found throughout

this publication.

Instruction Manual

760001-A

October 2002

PREFACE

DEFINITIONS

DANGER .

Highlights the presence of a hazard which will cause severe personal injury, death, or substantial

property damage if the warning is ignored.

WARNING .

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

CAUTION.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of effectiveness.

NOTE

Highlights an essential operating procedure,

condition or statement.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-1

Instruction Manual

760001-A

October 2002

Model NGA2000 FID

SAFETY SUMMARY

If this equipment is used in a manner not specified in these instructions, protective systems may be impaired.

AUTHORIZED PERSONNEL

To avoid explosion, loss of life, personal injury and damage to this equipment and on-site property,

all personnel authorized to install, operate and service the this equipment should be thoroughly

familiar with and strictly follow the instructions in this manual. SAVE THESE INSTRUCTIONS.

DANGER.

ELECTRICAL SHOCK HAZARD

Do not operate without doors and covers secure. Servicing requires access to live parts which can

cause death or serious injury. Refer servicing to qualified personnel. For safety and proper performance this instrument must be connected to a properly grounded three-wire source of power.

WARNING .

POSSIBLE EXPLOSION HAZARD

This equipment is used in the analysis of sample gases which may be flammable, and the burner

fuel used in the ionization process is flammable. A continuous dilution purge system is factory-installed (in accordance with Standard ANSI/NFPA 496-1993, Chapter 6, and it must be functional at all times during operation. Do not disable this purge system.

WARNING .

FLAMMABLE SAMPLES

Consult the factory if flammable samples will be measured.

WARNING.

PARTS INTEGRITY

Tampering or unauthorized substitution of components may adversely affect safety of this product.

Use only factory documented components for repair.

P-2 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

Do not place hands or fingers in the Platform front handles when front panel is open. Dropping the

front panel of the Platform while hand or fingers are inside either handle can cause serious injury.

Ensure that all gas connections are made as labeled and are leak free. Improper gas connections

could result in explosion or death.

This module requires periodic use of pressurized gas. See General Precautions for Handling and

Storing High Pressure Gas Cylinders, page P-5.

Instruction Manual

760001-A

October 2002

WARNING.

HAND INJURY HAZARD

WARNING.

POSSIBLE EXPLOSION HAZARD

CAUTION .

PRESSURIZED GAS

CAUTION .

PURGE AIR REQUIREMENT

This Analyzer Module must be used in conjunction with a device (Control Module or PC Interface)

that can actively monitor network variables related to pressure or flow of the continuous dilution

purge, or the front panel LEDs of the Analyzer Module, as installed, must be visible. The purpose of

this requirement is to maintain adherence to ANSI/NFPA 496 standard which assures the continued

viability of the purge system. Under no circumstances should any pressure or flow indicator be

connected to the PURGE AIR OUT outlet of the Analyzer Module because this may affect the sealing

performance of the module.

CAUTION.

OVER-VOLTAGE SPIKING

If this Analyzer Module is used with a non-Rosemount Analytical power supply, adding Rosemount

P/N 903341 Current Protector in series with the 24 V positive power line will prevent over-voltage

spiking and resultant fuse blowing when powering up the instrument.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-3

Instruction Manual

760001-A

October 2002

Model NGA2000 FID

CAUTION .

STATIC ELECTRICITY

Circuit boards in this instrument are static-sensitive. Take all static precautions when handling the

circuit boards

NOTE

This Analyzer Module is completely leak-tested at the factory for gas leakage. The user is responsible for testing for leakage at the inlet and outlet fittings on the rear panel (with a test procedure

chosen by the user). The user is also responsible for leak-testing periodically and if any internal

pneumatic components are adjusted or replaced. See leak test instructions in Section2-4d on page

2-6.

P-4 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Instruction Manual

760001-A

Model NGA2000 FID

October 2002

GENERAL PRECAUTIONS FOR HANDLING AND STORING HIGH

PRESSURE GAS CYLINDERS

Edited from selected paragraphs of the Compressed Gas Association's "Handbook of Compressed

Gases" published in 1981

Compressed Gas Association

1235 Jefferson Davis Highway

Arlington, Virginia 22202

Used by Permission

1. Never drop cylinders or permit them to strike each other violently.

2. Cylinders may be stored in the open, but in such cases, should be protected against extremes of

weather and, to prevent rusting, from the dampness of the ground. Cylinders should be stored in the

shade when located in areas where extreme temperatures are prevalent.

3. The valve protection cap should be left on each cylinder until it has been secured against a wall or

bench, or placed in a cylinder stand, and is ready to be used.

4. Avoid dragging, rolling, or sliding cylinders, even for a short distance; they should be moved by using a

suitable hand-truck.

5. Never tamper with safety devices in valves or cylinders.

6. Do not store full and empty cylinders together. Serious suckback can occur when an empty cylinder is

attached to a pressurized system.

7. No part of cylinder should be subjected to a temperature higher than 125

never be permitted to come in contact with any part of a compressed gas cylinder.

8. Do not place cylinders where they may become part of an electric circuit. When electric arc welding,

precautions must be taken to prevent striking an arc against the cylinder.

°

F (52°C). A flame should

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-5

Instruction Manual

9

6

760001-A

October 2002

Model NGA2000 FID

DOCUMENTATION

The following NGA2000 FID instruction materials are available. Contact Customer Service Center or the

local representative to order.

760001 Instruction Manual (this document)

COMPLIANCES

This product may carry approvals from several certifying agencies, including Factory Mutual and the Canadian Standards Association (which is also an OSHA accredited Nationally Recognized Testing Laboratory,

NRTL) for use in non-hazardous, indoor locations.

The certification marks appear on the product name-rating plate.

Rosemount Analytical Inc. has satisfied all obligations from the European Legislation to harmonize the

product requirements in Europe.

This product complies with the standard level of NAMUR EMC. Recommendation (May 1993).

This product satisfies all obligations of all relevant standards of the EMC framework in Australia and New

Zealand.

FM

APPROVED

®

97-C219

NAMUR

N

P-6 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

GLOSSARY OF TERMS

Analyzer Module

The module that contains all sensor/detector components for development of a Primary Variable signal; includes all signal conditioning and temperature control circuitry.

Backplane

The interconnect circuit board which the Controller Board, Power Supply, Analyzer Module power and network cables, I/O Modules and Expansion Modules plug into.

Control Module

The Operator Interface plus the Controller Board.

Controller Board

The computer board that serves as the Network Manager and operates the Display and Keypad.

Instruction Manual

760001-A

October 2002

Distribution Assembly

The Backplane and the card cages that hold I/O and Expansion Modules.

Expansion Module

A circuit board that plugs into the Backplane from the front of the Platform and performs special features

not related to I/O functions.

I/O Module

A circuit board that plugs into the Backplane from the rear of the Platform. Has a connector terminal for

communication with external data acquisition devices and provides an input/output function.

Operator Interface

The Display and Keyboard.

Platform

Any workable collection of the following: Controller Board, Power Supply, Distribution Assembly, Enclosure

and Operator Interface.

Power Supply

Any of a variety of components that provides conditioned power to other NGA2000 components, from the

Power Supply Board that plugs into the front of the Backplane in a stand-alone instrument to several larger

ones that can power larger collections of modules and components.

Primary Variable

The measured species concentration value from an Analyzer Module.

Secondary Variable

Data placed on the network by a module regarding current status, e.g., sample flow, source voltage and

other diagnostic information.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-7

Instruction Manual

760001-A

October 2002

Model NGA2000 FID

Softkeys

The five function keys located below the front panel display; they assume the function displayed directly

above each on the display, a function dictated by software.

System

Any collection of Analyzer Module(s), Platform(s), I/O Module(s) and Expansion Module(s).

P-8 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

A

DESCRIPTION AND SPECIFICATIONS

1-1 OVERVIEW

Instruction Manual

760001-A

October 2002

SECTION 1

This manual describes the Flame Ionization

Detector (FID) Analyzer Module of Rosemount Analytical's NGA2000 Series of gas

analysis components. See Figure 1-1 below

and Figure 1-2 on page 1-2.

The FID Analyzer Module is designed to continuously determine the concentration of hydrocarbons in a flowing gaseous mixture. The

concentration is expressed in parts-per-million

or percent of volume.

The entire FID Analyzer Module is designed

as a slide-in module (if configured in

stand-alone instrument fashion), removable

from the front of the Platform, with gas connections made from the rear. All electronics

relative to sample detection and conditioning

are included in this module.

1-2 TYPICAL APPLICATIONS

The monitoring of atmospheric air for low-level

hydrocarbon contaminants and determining

the hydrocarbon content of exhaust emissions

from internal combustion engines are examples of typical applications for the FID Analyzer Module.

1-3 THEORY OF TECHNOLOGY

This Analyzer Module uses the flame ionization method of detection. The sensor is a

burner in which a regulated flow of sample

gas passes through a flame sustained by

regulated flows of a fuel gas (hydrogen or a

hydrogen/diluent mixture) and air.

Within the flame, the hydrocarbon components of the sample stream undergo a complex ionization that produces electrons and

positive ions. Polarized electrodes collect

these ions, causing current to flow through an

electronic measuring circuit

The ionization current is proportional to the

rate at which carbon atoms enter the burner,

and is therefore a measure of the concentration of hydrocarbons in the sample. This

measure of concentration is placed on the

network, where it is can be shown on the Platform Display or on other data acquisition devices.

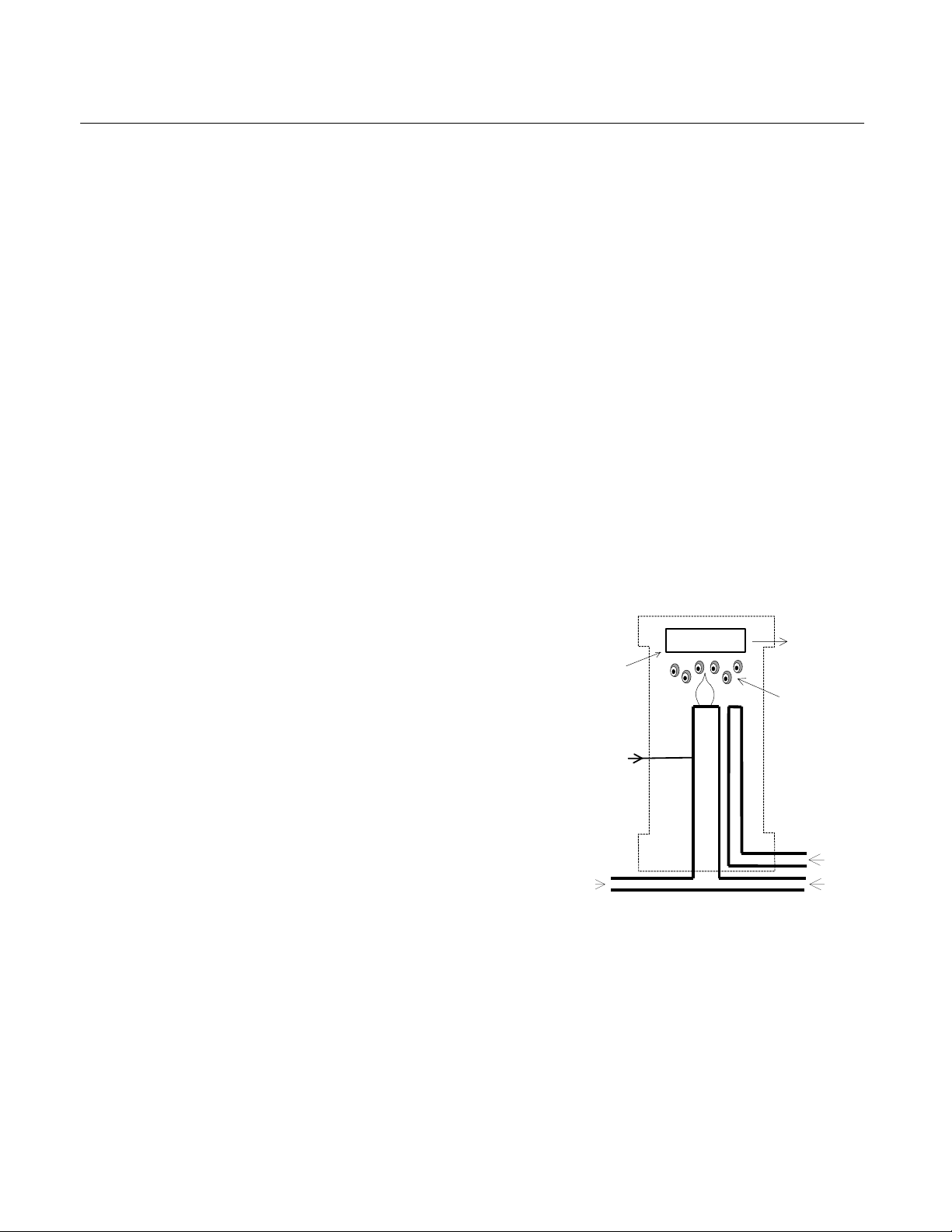

Negative Ion

Collection

Ring

+90V

Sample

Figure 1-1. Flame Ionization Detection

Technology

Signal

Conditioning

Positive

Carbon

Ions

ir

Fuel

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Instruction Manual

A

760001-A

October 2002

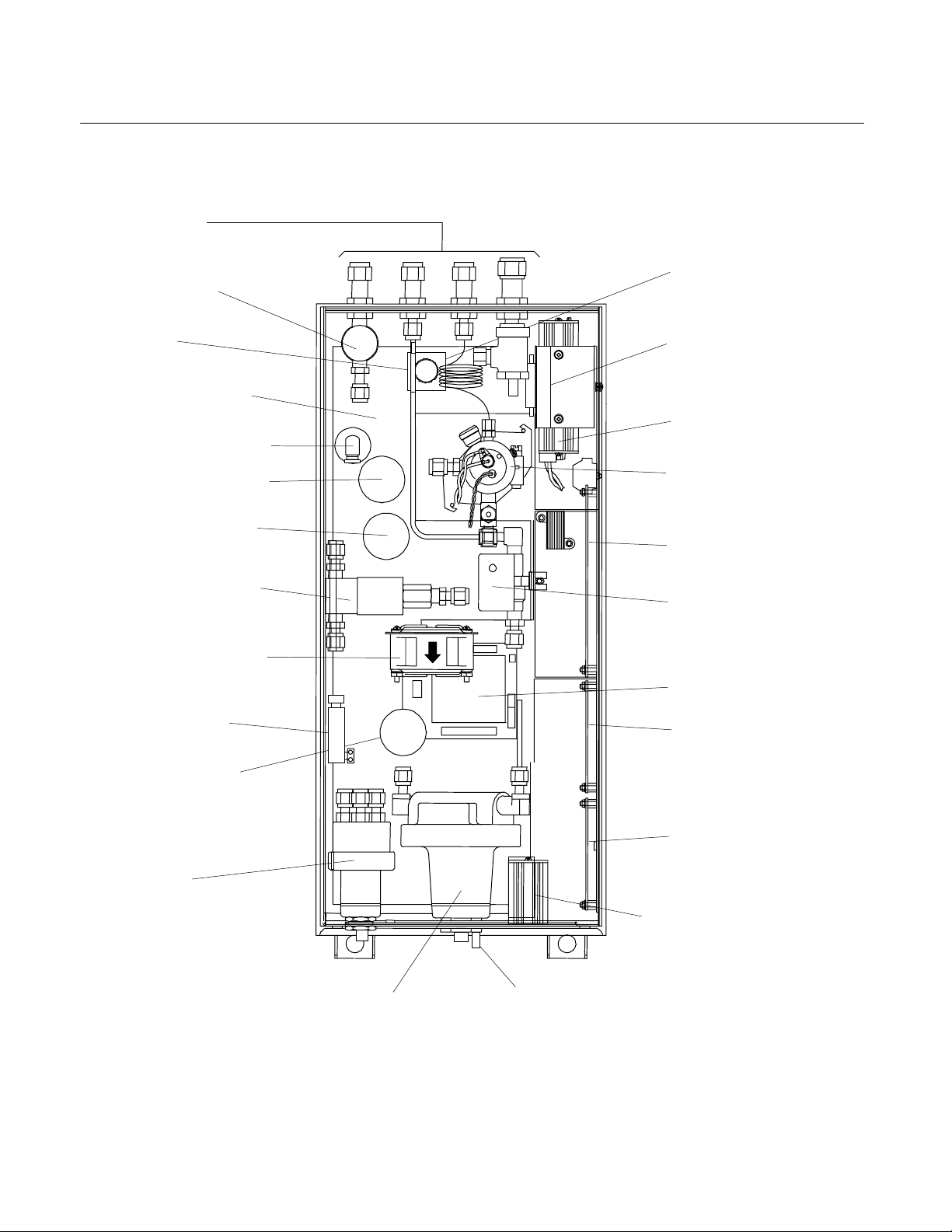

Gas Lines

(See Figure 2-2)

Fuel Shutoff

Solenoid Valve

Capillary

Case Heater Silicon

Pad (On Base)

Purge Air Flow Switch

Fuel Pressure Sensor

Air Pressure Sensor

Ignite/Operate Mode

Burner-Air Flow

Solenoid Valve

ir Circulation Fan

Purge Air

Heater Cartridge

Sample Pressure

Sensor

Burner Air

and Fuel

Regulators

(Stacked Vertically)

Sample Back Pressure Regulators

Model NGA2000 FID

Purge Air

Pressure Regulator

Purge Air Outlet

Pressure Switch

Preamp Board

(In Shield)

Detector (Burner)

Computer Board

Sample Bypass

Flow Sensor

DC-DC Converter

Safety Board

Power Supply Board

Network & Power Module

Manual Ignite Switch

Figure 1-2. FID Component Locations – Top View

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

1-4 GAS SAFETY FEATURES

The FID Analyzer Module is designed with a

factory installed continuous dilution purge system in accordance with standard ANSI/NFPA

496 - 1993, Chapter 6. Front-panel LEDs indicate that the burner flame is lit and that the

purge system is enabled. In addition, fuel gas

is automatically shut off when a flame-out

condition occurs or the safety system is disabled.

The purge system is enabled only if there is

proper purge gas flow in, purge gas pressure,

and internal case pressure, and after five

times the case volume has been exchanged.

All tubing ahead of the burner is rigid metallic

tubing assembled with ferrule/nut type compression fittings. However, should an internal

fuel leak occur, a worst-case leak would be

dissipated below 25% of the LEL of hydrogen

through the combination of an inlet fuel flow

restrictor and purge gas flow.

This module is designed to use 100% hydrogen fuel or 40% H

mum inlet pressure of 3446 hPa-gauge (50

psig). A different flow restrictor is used for

each fuel type.

A standard FID Analyzer Module is only

equipped to analyze a non-flammable sample,

below 100% of the LEL.

POSSIBLE EXPLOSION HAZARD

Protection against explosion depends

upon a special fuel flow restrictor in the

fuel inlet fitting. Do not remove fuel inlet

restrictor. Use the correct fuel flow restrictor for the fuel being used. Do not use

100% hydrogen fuel in a 40% H2/60% He

configured Analyzer Module. Replace only

with factory supplied fitting.

2/60% He fuel at a maxi-

WARNING

Instruction Manual

760001-A

October 2002

equipped to use 100% hydrogen fuel. The

particular application and characteristics of

the sample gas to be measured will dictate

the preferred type of fuel. The following guidelines can be used for determining fuel gas

type:

1. For measuring low-level hydrocarbons in

ambient air or in other sample gas with

relatively constant oxygen content, 100%

hydrogen is preferable. It provides the

highest obtainable sensitivity and maximum stability. Zero drift caused by ambient temperature variations of the fuel

cylinder is somewhat lower for 100%

hydrogen than for mixed fuel. (With either

fuel, it is desirable to maintain a constant

cylinder temperature.)

2. For monitoring internal combustion exhaust emissions or other sample gas with

varying oxygen content, mixed fuel is

preferable. In fact, a hydrogen/helium

mixture is more desirable than a hydrogen/nitrogen mixture. With this type of

sample, the use of mixed fuel gas minimizes the error introduced by oxygen

synergism.

An effective way to reduce the effect of internal oxygen is to dilute it with an inert gas. This

can be accomplished with a constant dilution

of sample and calibration gases upstream

from the burner. But it is simpler and more accurate to provide that diluent in the form of

premixed fuel. Both nitrogen and helium have

been used as a diluent, but helium has proven

to be most effective in improving the quality of

response to the various species of hydrocarbons.

As indicated earlier the flame output signal is

optimum when the ratio of hydrogen flow to

inert flow is about 40/60. Therefore, this is the

chosen composition for hydrogen/helium premixed fuel.

The sample flow is kept low to maximize the

1-5 FUEL GAS OPTION

The standard FID Analyzer Module requires

40% hydrogen/60% helium burner fuel gas.

As an option, the analyzer module can be

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

dilution effect while still providing adequate

sensitivity. The burner air flow is normally

about four times the fuel flow, and changes

have little effect on signal strength. For a

Instruction Manual

760001-A

October 2002

given flow, the signal can be optimized by adjusting the fuel flow rate.

Typical flow rates with premixed fuel:

Model NGA2000 FID

with the latter. However, in any application

where the sample contains more than one

species of hydrogen and/or a varying concentration of oxygen, mixed fuel is preferred.

Fuel 100 cc/min

Sample 7 cc/min

Air 400 cc/min

Note that with a 40/60 premixed fuel, the

above flow rates amount to 40 cc (8%) hydrogen, 67 cc (13%) inert plus sample and 400

cc (79%) air, which compare closely to the 30

cc (8%) hydrogen, 45 cc (12%) inert/sample

and 300 cc (80%) air noted earlier for straight

hydrogen fuel.

Since sample flow in the case of mixed fuel

operation is only about 1/6 of that with straight

hydrogen fuel, higher sensitivity is obtained

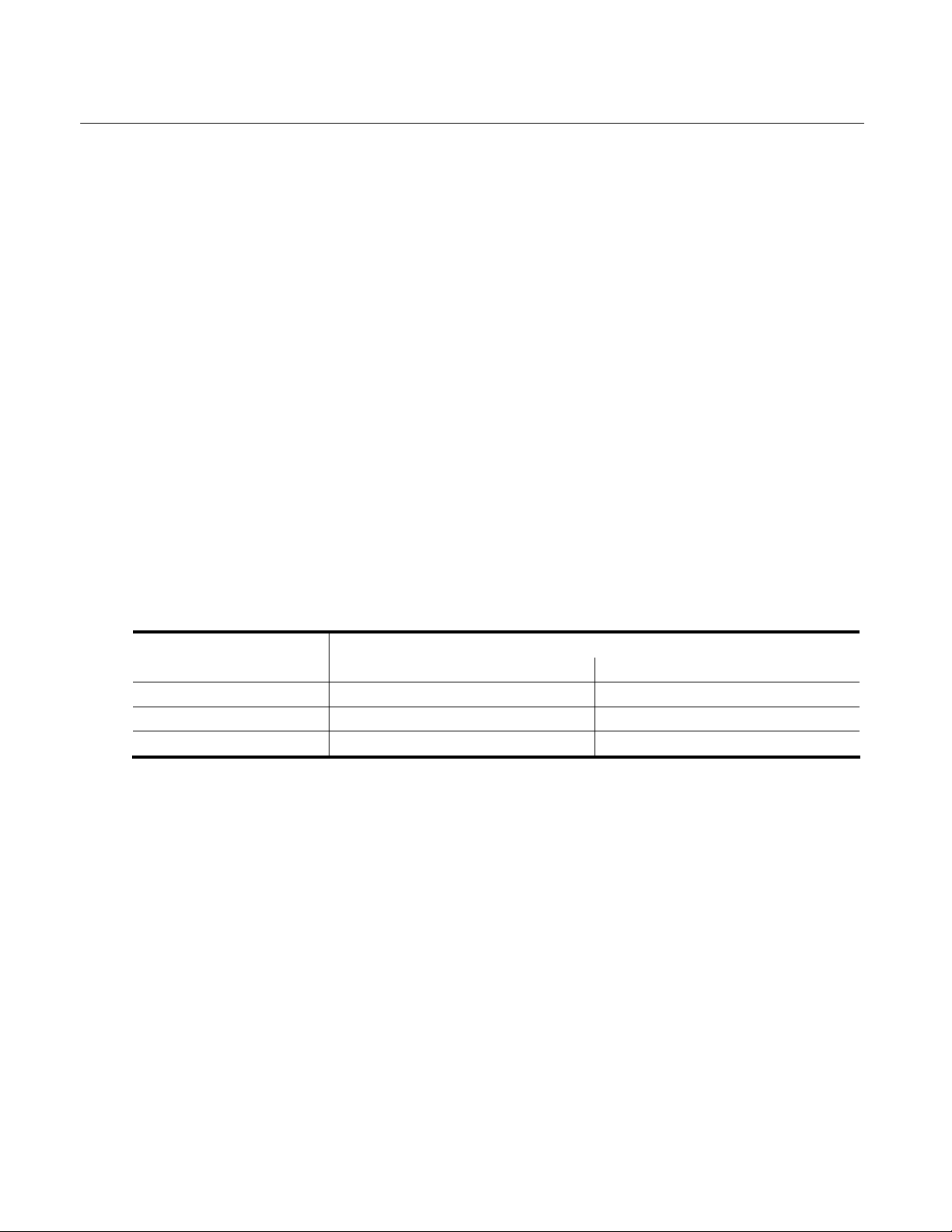

ANALYZER FUEL GAS

CHARACTERISTICS 100% H2 40% H2/60% He

Fullscale Sensitivity 1 ppm, CH4 to 2%, CH4 4 ppm, CH4 to <5%, CH4

Fuel Consumption 35 to 40 cc/min 75 to 80 cc/min

Operating Range 276 to 345 hPa-gauge (4 to 5 psig) 207 to 345 hPa-gauge (3 to 5 psig)

Table 1-1. Analyzer Characteristics Relative to Fuel Gas

The mixed fuel is recommended, not only for

sample containing variable concentrations of

oxygen, but also for a specific pure gas application. If straight oxygen samples are used

with straight hydrogen fuel, the mixture entering the burner is essentially 40% H

which tends to produce an unstable signal.

The mixed fuel works better. Note that the

choice of fuel determines certain analyzer

characteristics, as shown in Table 1-1 below.

2/60% O2,

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

1-6 SPECIFICATIONS

a. General

Measurement Species................... Total hydrocarbons

Ranges .......................................... 0 to 100 ppm (output scalable down to 0-2 ppm

H2/He fuel.............................. low range: 0 to 4 ppm CH

H2 fuel

Repeatability.................................. ≤1% of fullscale at a constant temperature, sample

Minimum Detectable Level

H2/He fuel.............................. 0.04 ppm

H2 fuel

Noise ............................................. ≤1% of fullscale, peak to peak

Linearity ......................................... ≤ ±1% of fullscale for H

Response Time

CEMS .................................... ≤30 sec. For 10% to 90% of fullscale, with sample

ICEE ...................................... ≤1 sec. For 10% to 90% of fullscale, with sample

Zero Drift........................................ ≤ ±1% of fullscale/24 hours at constant

Span Drift....................................... ≤ ±1% of fullscale/24 hours at constant

Effect of Temperature.................... ≤ ±2% of fullscale for any temperature change of

Operating Temperature ................. 32°F to 113°F (0°C to 45°C)

Power Requirements..................... +24 VDC ±5%, 120 W max.. direct to analyzer

1

.................................. low range: 0 to 1 ppm CH4, through 0 to 2500 ppm

1

................................. 0.01 ppm H2 fuel

Instruction Manual

fullscale)

4, through 0 to 1% CH4

high range: 0 to 50 ppm CH4, through 0 to <5%

CH

4

CH4

high range: 0 to 10 ppm CH

CH4

flow and fuel, burner air and sample pressure

bypass flow at 0.5 L/min. (non-flammable sample)

bypass flow at 0.5 L/min. (non-flammable sample)

temperature, hydrocarbon concentration of supply

gases, sample flow and fuel, burner air and sample

pressure

temperature, hydrocarbon concentration of supply

gases, sample flow and fuel, burner air and sample

pressure

10°C and rate of change less than 10°C/hour

module;

Ripple and Noise: <100 mV peak to peak

Line and Load Regulations: <±1%

4, through 0 to 2%

2/He fuel and He fuel

760001-A

October 2002

1

Option

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Instruction Manual

760001-A

October 2002

b. Gas Requirements

Sample .......................................... Non-flammable, below 100% of LEL

Flow rate ................................ 0.5 to 40 ml/min.

THC ....................................... ≤0.5 ppm, CH

Supply pressure..................... 483 to 1035 hPa-gauge (7 to 15 psig)

Temperature .......................... 32°F to 132°F (0°C to 55°C), <20°C variance/24

Particulates............................ Filtered to <2 microns

Dewpoint................................ <45°C

Purge Air........................................ Instrument air, nitrogen or other non-flammable

Flow rate: .............................. 16 to 18 L/min.

Supply pressure:.................... 689 to 1378 hPa-gauge (10 to 20 psig)

Fuel Gas (Standard)...................... Premixed 40% hydrogen and 60% helium

Flow rate ................................ 75 to 80 ml/min.

THC ....................................... ≤0.5 ppm, CH

Supply pressure..................... 2415 to 3450 hPa-gauge (35 to 50 psig)

Model NGA2000 FID

4

hours, <10°C variance/hour

gas (refer to ANSI/NFPA 496 for the requirements

for the Protective Gas System)

4

WARNING

POSSIBLE EXPLOSION HAZARD

Unless this Analyzer Module is factory- or field-configured specifically for using

100% hydrogen fuel, DO NOT USE PURE HYDROGEN FUEL. An explosion resulting

in severe personal injury or death could occur. Also, each Analyzer Module is factory-configured for either mixed or pure hydrogen fuel, and cannot use the fuel for

which it was not configured unless field reconfiguration is done.

Fuel Gas (H2 option) ..................... Zero-grade hydrogen

Flow rate ................................ 35 to 40 ml/min.

THC ....................................... ≤0.5 ppm, CH

Supply pressure..................... 2415 to 3450 hPa-gauge (35 to 50 psig)

Burner Air ...................................... Zero-grade air

Flow rate ................................ 350 to 400 ml/min

THC ....................................... ≤ ppm, CH

Supply pressure............................. 1725 to 3450 hPa-gauge (25 to 50 psig)

4

4

1-6 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

c. Physical

Case Classification:....................... General purpose for installation in

Maximum Separation .................... 1600m (1 mile) from Analyzer Module to Platform

Materials in Contact With Sample . Stainless steel, Teflon, glass-filled Teflon, brass,

Dimensions.................................... See Outline and Mounting Dimensions, Figure 2-5

Weight ........................................... 10.43 kg (23 lbs.)

Mounting........................................ Horizontal, inside a Platform or custom installed in

d. Gas Connections

Sample In: ..................................... 1/4" O.D. tube fitting, stainless steel

Regulated Air In: ..............................1/4" O.D. tube fitting, brass

Burner Air In: ....................................1/4" O.D. tube fitting, brass

Fuel In:..............................................1/4" O.D. tube fitting, stainless steel

Purge Air In: .....................................3/8" O.D. tube fitting, brass

Purge Air Out: ..................................3/8" O.D. tube fitting, brass

Bypass Out:......................................1/4" O.D. tube fitting, stainless steel

Burner Exhaust Out: ........................1/2 inch O.D. tube connection, Tygon or equivalent

Pressure Relief Valve

Instruction Manual

760001-A

October 2002

weather-protected area

neoprene, Kynar

on page 2-7

a panel

(this connection shall slope downward 6° minimum

from horizontal)

CAUTION

PRESSURE RELIEF VALVE RESTRICTION

No connection shall be made to this fitting. If this caution is ignored, damage to the

case seals may occur, and the instrument will not operate properly.

See the Preface section of the Platform Components manual for specifications regarding Platform-related components and the Preface of the I/O Module manual for

specifications regarding I/O (e.g., relay outputs).

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-7

Instruction Manual

760001-A

October 2002

Model NGA2000 FID

1-8 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

A

2-1 UNPACKING

If the FID Analyzer Module is received as a

separate unit, carefully examine the shipping

carton and contents for signs of damage.

Immediately notify the shipping carrier if the

carton or contents is damaged. Retain the

carton and packing material until all

components associated with the Analyzer

Module are operational.

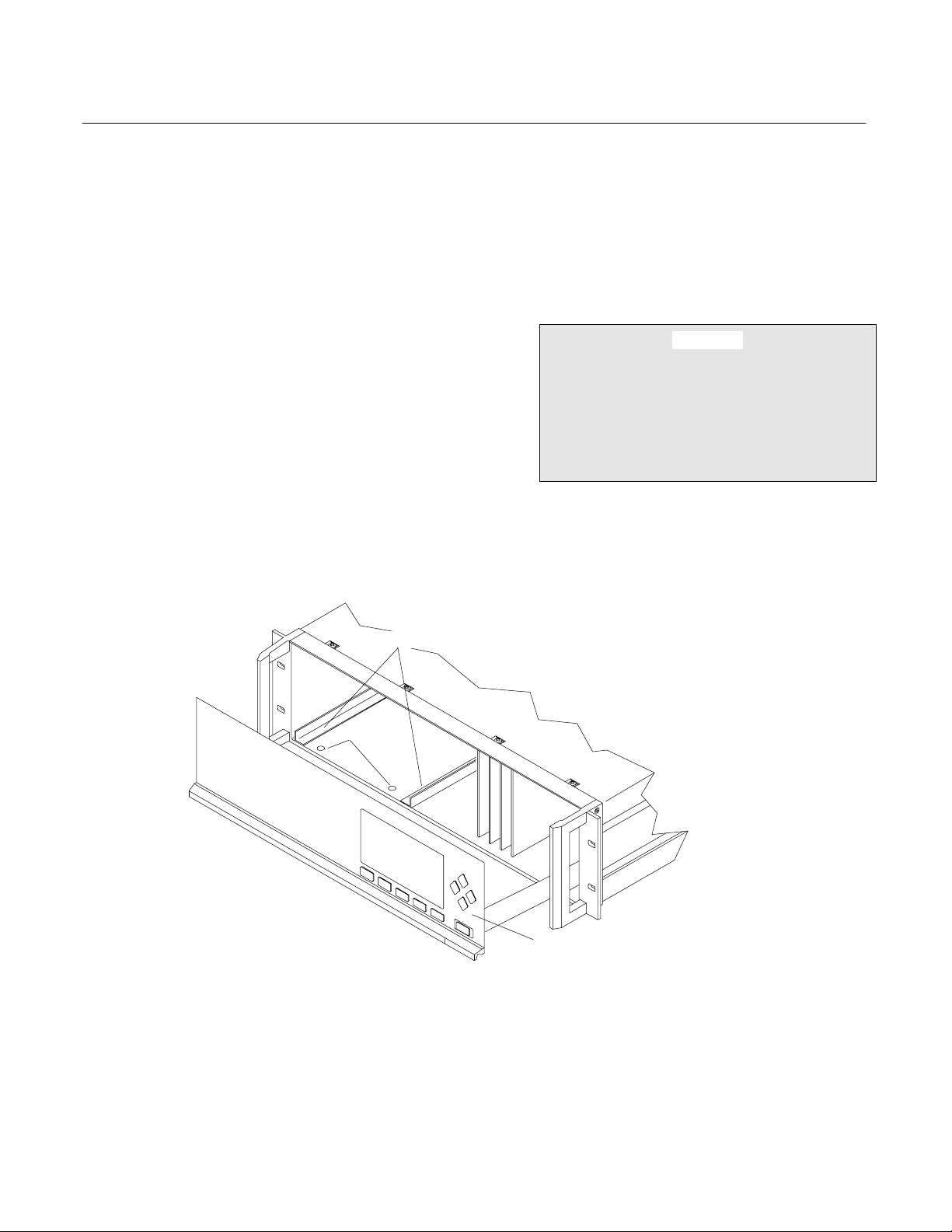

2-2 ASSEMBLY

If the Analyzer Module requires assembly with

other components (e.g., the Platform and

associated I/O Modules), do so at this time.

PIN SEATS

Instruction Manual

760001-A

October 2002

SECTION 2

INSTALLATION

Following the guides on the bottom left and

bottom center of the Platform, carefully slide

the Analyzer Module halfway into place.

CAUTION

HAND INJURY HAZARD

Do not place hands or fingers in Platform

front handles when the front panel is open.

Dropping front panel while hand or fingers

are inside either handle can cause serious

injury.

NALYZER MODULE GUIDES

DISENGAGED FRONT PANEL

Figure 2-1. Analyzer Module Installation Into Platform

Rosemount Analytical Inc. A Division of Emerson Process Management Installation

2-1

Instruction Manual

760001-A

October 2002INSTALLATION

Lift the spring loaded pins on the front of the

module, and carefully slide it the rest of the

distance. Secure the module in position by

releasing the pins, which seat in the available

holes in the bottom of the case (see Figure

2-1 on page 2-1). If the module and Platform

are difficult to assemble, remove the module,

ensure the top cover of the module is firmly

seated on the hold down screws, and repeat

the assembly procedure.

Connect the network cable to either the

NETWORK 1 or NETWORK 2 connection on

the Analyzer Module (see Figure 2-4 on page

2-4), and the NETWORK connection on the

Backplane (see Platform manual). Connect

the power cable to both the Analyzer Module

front panel and to the Backplane.

Install I/O Module(s) according to guidelines in

the I/O manual. After startup and calibration

have been performed, secure the Front Panel

with the six screws provided.

Model NGA2000 FID

WARNING

INSTALLATION RESTRICTIONS

For safety, the Analyzer Module should be

installed in a non-confined, ventilated

space. Do not block any of the rear panel

outlets as they are part of the safety

system.

Operating ambient temperature is 0°C to

45°C, limited to temperature changes of less

than 10°C/hr. Acceptable dewpoint range is

less than 95% relative humidity, but not in

excess of 45°C wet bulb temperature.

The cylinders of fuel, air, and calibration

gas(es) and the source of purge air should be

located in an area of relatively constant

ambient temperature.

2-3 LOCATION

Install the Analyzer Module in a clean,

weather-proofed, non-hazardous, vibration

free location free from extreme temperature

variations. For best results, install the

Analyzer Module near the sample stream to

minimize sample transport time.

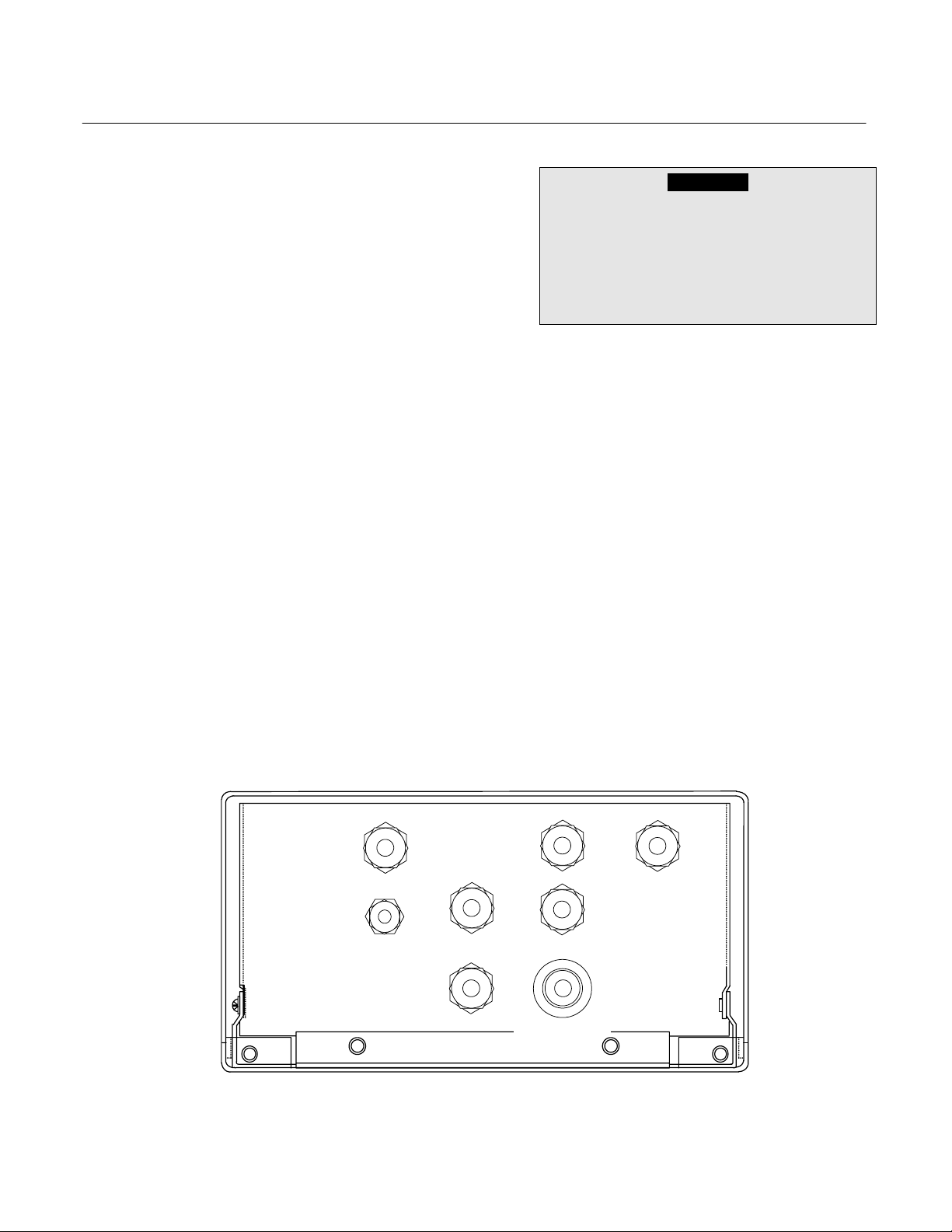

PURGE

AIR OUT

PRESSURE

RELIEF

VALVE

MIXED

FUEL

IN

BURNER

SAMPLE

IN

PURGE

AIR IN

AIR IN

BYPASS

OUT

VENT TO SAFE AREA

SLOPE DOWNWARD

6 MINIMUM

MAXIMUM INPUT PRESSURE

BURNER AIR: 50 PSIG (3450 hPa)

PURGE AIR: 20 PSIG (1378 hPa)

BURNER

EXHAUST

OUT

FUEL: 50 PSIG (3450 hPa)

SAMPLE: 15 PSIG (1035 hPa)

Figure 2-2. Back Panel Connections

Installation Rosemount Analytical Inc. A Division of Emerson Process Management

2-2

Model NGA2000 FID

2-4 GASES

a. Overview

During normal operation, the Analyzer

Module requires fuel and air to maintain

the burner flame as well as suitable standard gases for calibration and instrument

air for purge requirements. Criteria for selection of these gases follow in 2-4c on

page 2-5.

After initial startup or after startup following a prolonged shutdown, the analyzer

may display baseline drift for a considerable period of time, particularly on the

most sensitive range. Commonly, the drift

is caused by small amounts of hydrocarbons in the inner walls of the tubing in

both the internal flow system and the external gas supply system. Drift results

from any factor influencing the equilibrium

of these absorbed hydrocarbons, such as

temperature or pressure.

Note that this type of drift occurs only

when the flame is burning. If drift occurs

when the flame is extinguished, the electronic circuitry is at fault. To minimize drift,

use clean fuel and air, keep the analyzer

clean, and locate the gas cylinders in an

area of relatively constant ambient temperature.

The cylinders supplying all gases each

should be equipped with a clean, hydrocarbon free, two stage regulator and a

shutoff valve.

All new external gas tubing (except for

PURGE IN/OUT and SAMPLE BYPASS) is

strongly recommended, preferably precleaned, stain-less steel, gas chromatograph

grade tubing. Thoroughly clean before use. if

a hydrocarbon based cleaning solvent

such as acetone is used, purge tubing

with dry nitrogen or helium for several

minutes before using.

Instruction Manual

760001-A

October 2002

Since the oxidation of hydrogen is accompanied by the formation of water vapor, the Exhaust tubing always should be

slanted downward at least 6 degrees from

horizontal. Otherwise, water may accumulate in the line, causing back pressure and

noisy readings, or may back up in the line

and flood the burner.

If the sample is toxic or noxious, or is to

be reclaimed, connect the Bypass outlet

to a suitable disposal system. Do not use

any device that may cause back pressure

in the line.

Purge air and burner air should be supplied from separate sources.

b. Connections

Reference Figure 2-2 on page 2-2. Connect inlet and outlet lines for sample,

burner fuel and air, exhaust, bypass, and

purge to appropriately labeled fittings on

the rear panel. All connections are 1/4

inch ferrule type compression fittings except the PURGE AIR IN and OUT connections, which are 3/8 inch compression

fittings. The BURNER EXHAUST OUT is

a 1/2 inch connection. Burner exhaust,

bypass and purge air out must be vented

at atmospheric pressure to a nonclassified location in accordance with

ANSI/NFPA-496.

It is recommended that no connection be

made to the PURGE AIR OUT port. If,

however, the analyzer's location requires

interconnection with a venting system, the

3/8" O.D. line should be kept as short as

possible, and no longer than four feet.

CAUTION

POSSIBLE INSTRUMENT DAMAGE

No connection should be made to the

PRESSURE RELIEF VALVE fitting. Doing

so may cause damage to the instrument.

Gas line connections are compression fittings. Do not use pipe thread tape.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-3

Instruction Manual

V

760001-A

October 2002

BURNER

EXHAUST

OUT

REGULATOR

Restrictor

PURGE AIR

Plug

1/4MPT

Brass

Run Tee

1/4T - 1/8MPT

Brass

Tubing, Teflon

1/4” OD

PURGE

FLOW

SWITCH

Bulkhead

3/8T

Brass

Tubing, SS

3/8” OD

PURGE AIR

SENSOR

PURGE

AIR

HEATER

Model NGA2000 FID

SAMPLE

IN

IN

CAPILLARY

Tubing, Viton

1/4” OD

PURGE

PRESS

SAMPLE

PRESS

SENSOR

Branch Tee

1/8T - 1/8FPT

SS

SAMPLE

BACK PRESS

REGULATOR

Figure 2-3. FID Module Flow Diagram

BURNER

AIR

!

!

FUEL

Figure 2-4. Front Panel Connections, Controls and Indicators

BYPASS

SAMPLE

Elbow

1/8T - 1/8MPT

Kynar

Connector

1/8T - 1/8MPT

Kynar

WARNING

ATTENTION

OUT

Bulkhead Reducer

1/4T - 1/8T

Brass

Tubing,

Teflon

1/8” OD

FLOW

SENSOR

Tubing,

Teflon

1/8” OD

Elbow

1/8T - 1/4MPT

SS

BURNER

AIR PRESSURE

REGULATOR

SAMPLE

FUEL OVERRIDE

BURNER

AIR IN

Bulkhead Reducer

1/4T - 1/8T

SS

GA

IN OUT

BURNER

AIR

PRESS

SENSOR

POWER

HEAT

FLAME

ON

PURGE

Filter

LON

LON

1 +

AIR

2 -

3 GND

T 6A

260V

COM

3-WAY

VALVE

1

2

IGNITE

Run Tee

1/4T - 1/4FPT

Brass

PURGE AIR

OUT

NC

Run Tee

1/8T - 1/8MPT

SS

FID

WARNING

!

ATTE NTION

!

Bulkhead Connector

1/4T - 1/8NPT

SS

Fuel Restrictor

Purge Exit

Restrictor

PRESS

SW

Connector

1/16T - 1/8MPT

SS

BURNER

MIXED FUEL

IN

SOLENOID

ALVE

Tubing,

Viton

1/4” OD

FUEL

PRESS

SENSOR

Fuel Restrictor

NETWORK 1

NETWORK 2

POWER

FUSE

Connector

1/8T - 1/8MPT

SS

FUEL

PRESSURE

REGULATOR

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

c. Specifications

Fuel Gas

Standard analysis usually requires mixed

fuel, i.e., 40% (±2%) hydrogen and 60%

helium. H2/He mixed fuel is recommended over H2/N2 fuel because of better linearity in concentration output. Such

blends are supplied by many gas vendors

specifically for this use, with a guaranteed

maximum total hydrocarbon content of 0.5

ppm, measured as methane. This specification should be used when obtaining

these mixtures.

NOTE

The fuel restrictor is marked with a red

dot, and the sample capillary is marked

with a red or green dot for mixed fuel

applications.

Some applications require the use of

100% hydrogen fuel. When using this

option, always ensure that sample

pressure (4 to 5 psig) is present when

fuel flow is present. Otherwise, the detector tip may be damaged.

The fuel restrictor and sample capillary

are marked with a white dot for 100%

hydrogen fuel applications.

Burner Air

In order to ensure a low background signal, burner air should contain less than 1

ppm maximum total hydrocarbon content.

An alternate source for burner air and

zero gas (see CALIBRATION GASES below) is a combination diaphragm pump

and heated palladium catalyst. This process continuously removes moderate

amounts of hydrocarbons and carbon

monoxide from ambient air.

Purge Air

Instrument quality air, nitrogen, or other

nonflammable gas is required for the

safety purge system.

Instruction Manual

760001-A

October 2002

Calibration Gases

Calibration method and gases depends

on the type of fuel gas used, the operating

range, and the desired measurement accuracy. In all methods, zero and span

gases are used, and are introduced

through the sample inlet at the rear of the

module.

Z

ERO GAS - Analysis is affected by the

background gas of the sample. Therefore,

it is recommended to use zero gas with as

close to the background composition of

the sample as possible. Normally less

than 0.5 THC as CH

If the burner fuel is 100% hydrogen, the

zero gas, background gas of the sample

or background gas of the span gas cannot

be hydrogen or oxygen. These gases

combined with pure hydrogen fuel would

generate excessive heat in the burner,

causing deterioration of the internal components of the burner.

S

PAN GAS - Span gas consists of a speci-

fied concentration of methane or other

hydrocarbon in a background gas such as

nitrogen. Analysis is affected by the

background gas of the sample. Therefore, span gas containing the same

background gas as the sample is recommended. Then, the background effect is canceled out.

S

AMPLE GAS - Sample gas should be non-

flammable (below 100% of the sample's

LEL). For high sensitivity applications requiring background gas compensation,

contact the factory.

F

LOW RATE - The sample flow rate must

be between 0.5 L/min. and 2 L/min. Flow

rate for purge air should be 16 to 18

L/min.

P

RESSURIZATION/FILTRATION - Sample

pressure at the SAMPLE inlet should be

within the range of 483 to 1035

hPa-gauge (7 to 15 psig), and internally,

should be 345 hPa-gauge (5 psig) nominally. Burner fuel pressures should be:

4 is sufficient.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-5

Instruction Manual

760001-A

October 2002

1725 to 3450 hPa-gauge (25 to 50 psig)

for cylinder regulator, 1518 to

1723 hPa-gauge (22 to 25 psig) internal.

Burner air pressures should be: 1725 to

3450 hPa-gauge (25 to 50 psig) for cylinder regulator, 965 to 1103 hPa-gauge (14

to 16 psig) internal. Purge air (external

supply) pressure should be between 689

and 1378 hPa-gauge (10 and 20 psig),

689 to 827 hPa-gauge (10 to 12 psig)

nominal. The internal purge air regulator

pressure is factory preset at a nominal

setting of 551 hPa-gauge (8 psig) with a

supply pressure of 689 hPa-gauge (10

psig). Noncompliance with these specifications, particularly those concerning

purge air, could cause over-pressure

damage to the module. The nominal internal case pressure is about 0.5 to 1.0

inch of water, and the pressure relief

valve is set at 1/3 psig (nominal).

At the very least, the module's safety system, which requires a certain volume of

purge air flowing through the case before

allowing burner ignition, will not allow the

instrument to operate.

Model NGA2000 FID

for accuracy. Sample should be filtered

for particulates down to two microns.

d. LEAK TEST

The Analyzer Module is completely tested

at the factory for gas leakage. The user is

responsible for testing for leakage at the

inlet and outlet fittings on the rear panel.

The user is also responsible for internal

leak testing periodically and if any internal

pneumatic components are adjusted or

replaced (with a test procedure chosen by

the user).

2-5 ELECTRICAL CONNECTIONS

Two electrical connections are required on the

Analyzer Module: POWER and NETWORK.

See Figure 2-4 on page 2-4. On the Analyzer

Module, two NETWORK connectors are

available, either of which is appropriate for: 1)

interconnection with the Backplane of the

Platform or 2) "daisy-chaining" with other

NGA2000 components. Connect Analyzer

Module POWER to Backplane POWER or external 24 VDC power source.

All internal pressure settings are preset at

the factory, but the operator should check

2-6 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Model NGA2000 FID

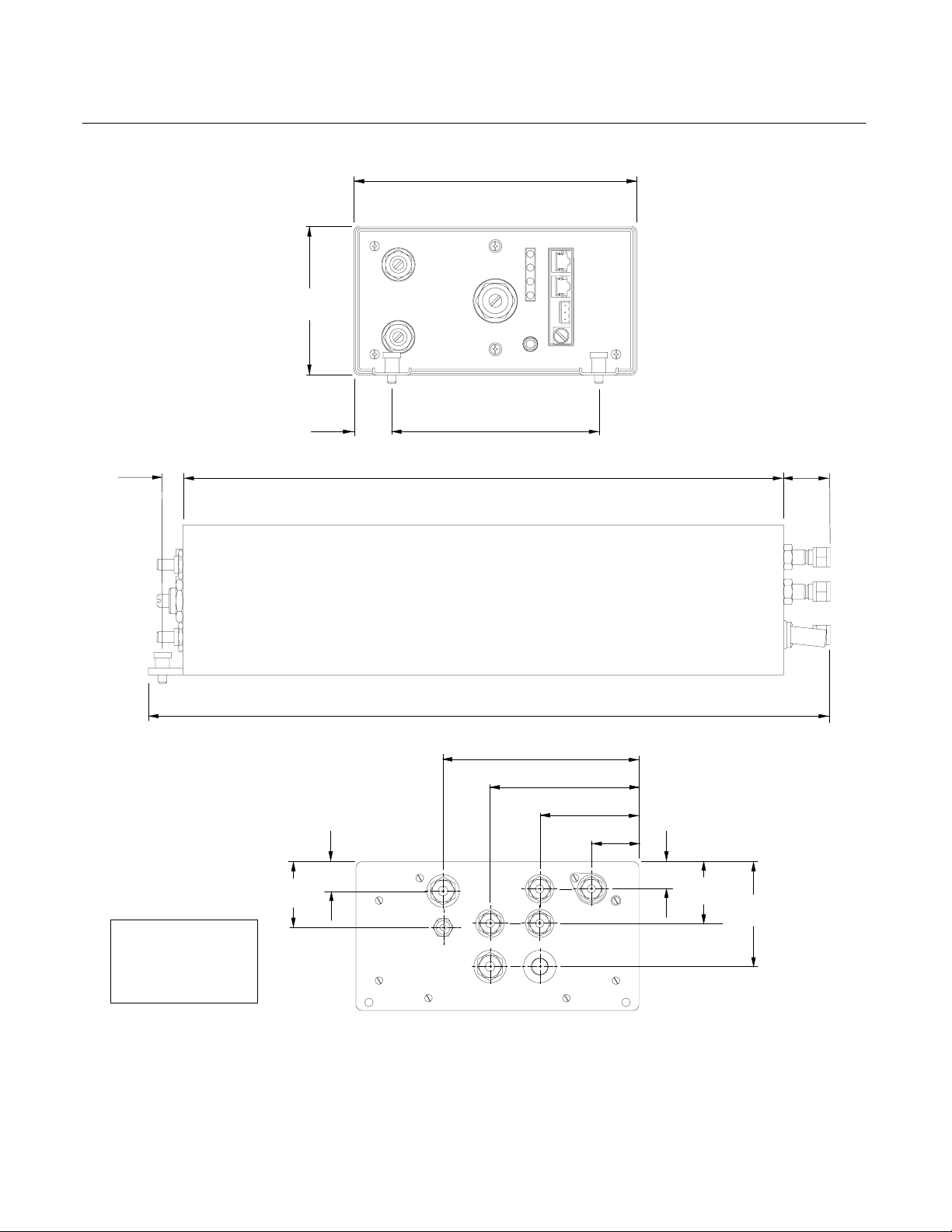

.25

[6.3]

Dimensions:

INCHES

[MM]

4.3

[109.7]

1.1

[27.9]

.9

[22.5]

1.9

[49.4]

Figure 2-5. Outline and Mounting Dimensions

[208.2]

[152.4]

17.75

[450.9]

20.0

[510.0]

8.2

6.0

[143.6]

5.7

4.3

[109.1]

FID

2.9

[73.6]

1.4

[35.6]

.8

[20.9]

D

Instruction Manual

760001-A

October 2002

1.7

[43.4]

1.8

[46.3]

3.1

[78.0]

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-7

Loading...

Loading...