Rosemount Manual: NGA 2000 FID2 Hydrocarbon Analyzer Module SW 3.3-Rev C | Rosemount Manuals & Guides

OSEMOUNT ANALYTICAL

R

NGA2000

F

LAME IONIZATION

A

NALYZER

D

ETECTOR

M

ODULE

2

748412-C

NOTICE

The information contained in this document is subject to change without notice.

This manual is based on the production version of the Flame Ionization Detector 2 Analyzer Module.

Hardware and/or software changes may have occurred since this printing.

Rosemount Analytical's NGA 2000 system of Modular Gas Analyzers and Controllers are patented,

under U.S. Patent 5.787.015.

Teflon® is a registered trademark of E.I. duPont de Nemours and Co., Inc.

Kynar® is a registered trademark of Pennwalt, Inc.

Manual Part Number 748412-C

October 2000

Printed in U.S.A.

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

REFACE

P

Purpose/Safety Summary.................................................................................P1

Glossary ....................................................................................................P4

Specifications - General...................................................................................P7

Specifications - Gas Requirements..................................................................P8

Specifications - Physical...................................................................................P9

Customer Service, Technical Assistance and Field Service.............................P10

Returning Parts to the Factory..........................................................................P10

CONTENTS

Training ....................................................................................................P10

Documentation.................................................................................................P11

Compliances ....................................................................................................P11

Quick Startup Procedure..................................................................................P13

ECTION

S

1.1 Overview....................................................................................................1

1.2 Typical Applications ...................................................................................2

1.3 Theory of Technology................................................................................2

1.4 Gas Safety Features..................................................................................5

1.5 Fuel Gas Option........................................................................................5

1. I

NTRODUCTION

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

i

CONTENTS

ECTION

S

2.1 Unpacking................................................................................................. 7

2.2 Assembly.................................................................................................. 7

2.3 Location ................................................................................................... 7

2.4 Gases ................................................................................................... 8

2.5 Electrical Connections .............................................................................. 12

2.6 Installation Guidelines............................................................................... 13

ECTION

S

3.1 Overview................................................................................................... 15

NSTALLATION

2. I

2.4.1 Connections.................................................................................. 9

2.4.2 Gas Specifications......................................................................... 9

3. S

TARTUP AND OPERATION

3.2 Displays ................................................................................................... 15

3.2.1 Run Mode Display......................................................................... 15

3.2.2 Menu Displays............................................................................... 16

3.4 Optimization procedure............................................................................. 24

3.5 Binding ................................................................................................... 25

3.6 Calibration................................................................................................. 25

3.7 Calibration details ..................................................................................... 28

3.8 Routine Operation..................................................................................... 29

3.9 Shut down procedure................................................................................ 30

3.10 Safety System......................................................................................... 30

3.11 Alarm indications..................................................................................... 32

3.12 Configuration storage.............................................................................. 33

Flame Ionization Detector 2 Analyzer Module

ii

Rosemount Analytical NGA 2000

748412-C

October 2000

CONTENTS

ECTION

S

4.1 General ....................................................................................................35

4.2 Fuses ....................................................................................................37

4.3 Burner Block Removal And Installation .....................................................38

4.4 Burner Startup And Troubleshooting.........................................................39

4.5 Maintenance schedule...............................................................................42

ECTION

S

5.1 Replacement Parts....................................................................................43

4. M

5. R

AINTENANCE AND TROUBLESHOOTING

EPLACEMENT PARTS

PPENDIX

A

A.1 Gas Safety Features.................................................................................A1

PPENDIX

A

B.1 Analyzer Setup Checklist..........................................................................B1

B.2 Auxiliary module setup..............................................................................B3

B.3 Computer interface setup..........................................................................B3

A. G

B. A

B.1.1 System Setup................................................................................B1

B.1.2 Analyzer Module Setup..................................................................B1

AS SAFETY FEATURES

NALYZER SETUP CHECKLIST

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

iii

CONTENTS

PPENDIX

A

C.1 Instructions............................................................................................... C1

C.2 Menu Items............................................................................................... C1

PPENDIX

A

C. U

D. FID2 I

SER INTERFACE HELP

DENTIFICATION MATRIX

General Precautions For Handling and Storing High Pressure Gas Cylinders

Warranty

Field Service and Repair Facilities

Flame Ionization Detector 2 Analyzer Module

iv

Rosemount Analytical NGA 2000

748412-C

October 2000

IGURES

F

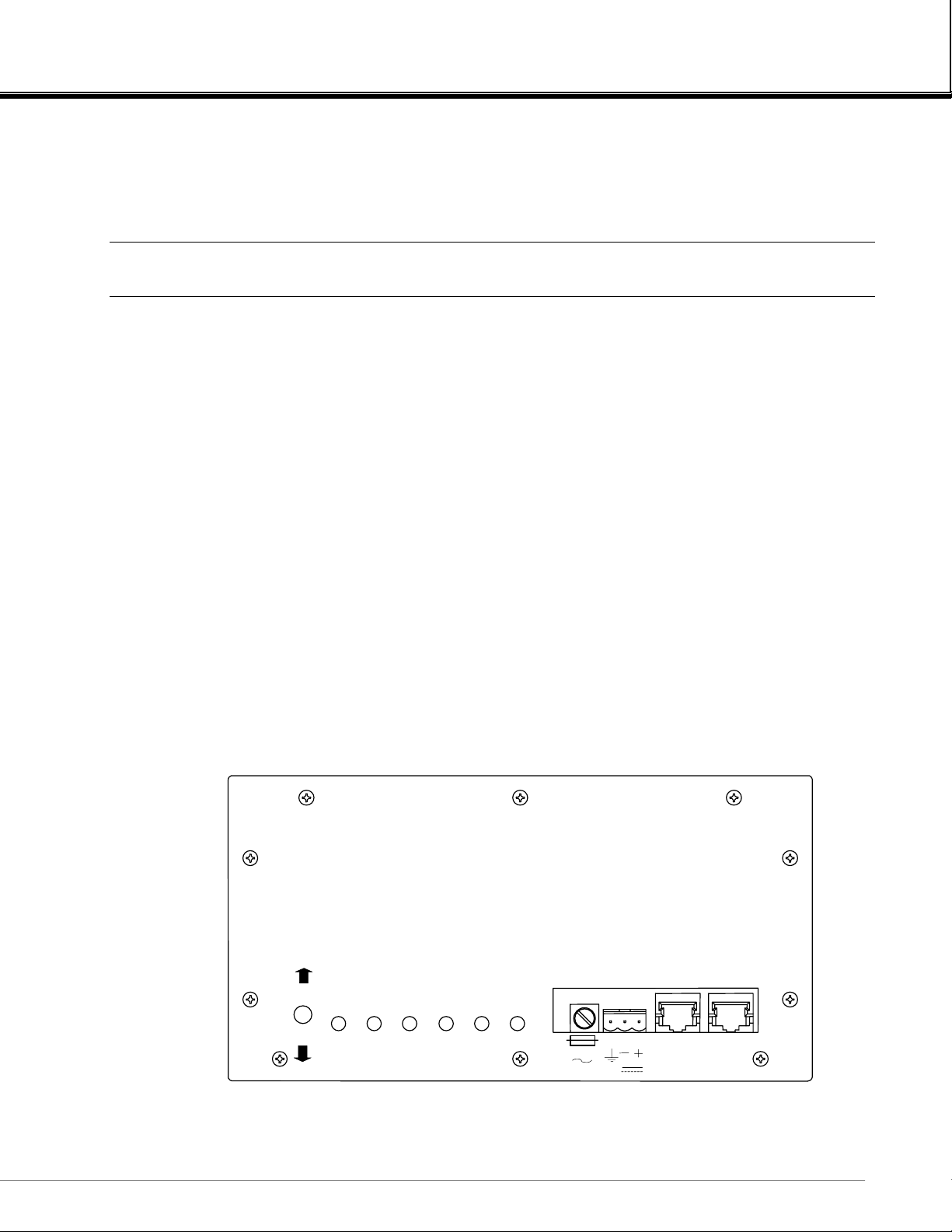

P-1. FID2 Front Panel........................................................................................P14

1-1. FID 2 Analyzer Module...............................................................................1

1-2. Flame Ionization Detection Technology......................................................2

1-3. FID 2 Analyzer Flow Diagram.....................................................................3

2-1. FID 2 Outline and Mounting Dimensions....................................................9

2-2. FID 2 Rear Panel........................................................................................10

2-3. FID 2 Front Panel......................................................................................12

3-1. Run Mode Display......................................................................................15

3-2. Main Menu..................................................................................................16

3-3. Basic Controls Menu..................................................................................17

3-4. Expert Controls Menu.................................................................................17

3-5. Analyzer Module Setup Menu ....................................................................18

3-6. Typical Help Menu......................................................................................18

3-7. Analyzer Diagnostics Menu........................................................................19

3-8. Self Test Results Menu..............................................................................20

3-9. Light Flame Menu.......................................................................................21

3-10. Typical Curves of Module Response vs. Pressure Setting on

Sample Pressure Regulator..........................................................22

3-11. Typical Curves of Module Response vs. Pressure Setting on

Fuel Pressure Regulator...............................................................23

3-12. Typical Curves of Module Response vs. Pressure Setting on

Air Pressure Regulator..................................................................23

3-13. Typical Calibration Gas List Menu............................................................25

3-14. Zero and Span Calibration Menu..............................................................26

3-15. Calibration Parameters Menu...................................................................26

3-16. Z

ERO/SPAN DIAGNOSTIC DATA

....................................................................26

3-17. Analyzer Manufacturing Data Menu .........................................................29

3-18. Store/Restore User Settings Menu...........................................................33

3-19. Store Historical Data Menu.......................................................................34

4-1. Locations Of Major Components Of The FID2 ...........................................35

4-2. Removal Of FID2 Cover.............................................................................36

4-3. Main Power Fuse........................................................................................ 36

4-4. Fuse Locations On Module Board..............................................................37

4-5. Physical Measurement Parameters Menu..................................................39

4-6. FID 2 – Exploded View...............................................................................40

4-7. Burner Block – Exploded View...................................................................41

4-8. Burner ......................................................................................................42

CONTENTS

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

v

CONTENTS

ABLES

T

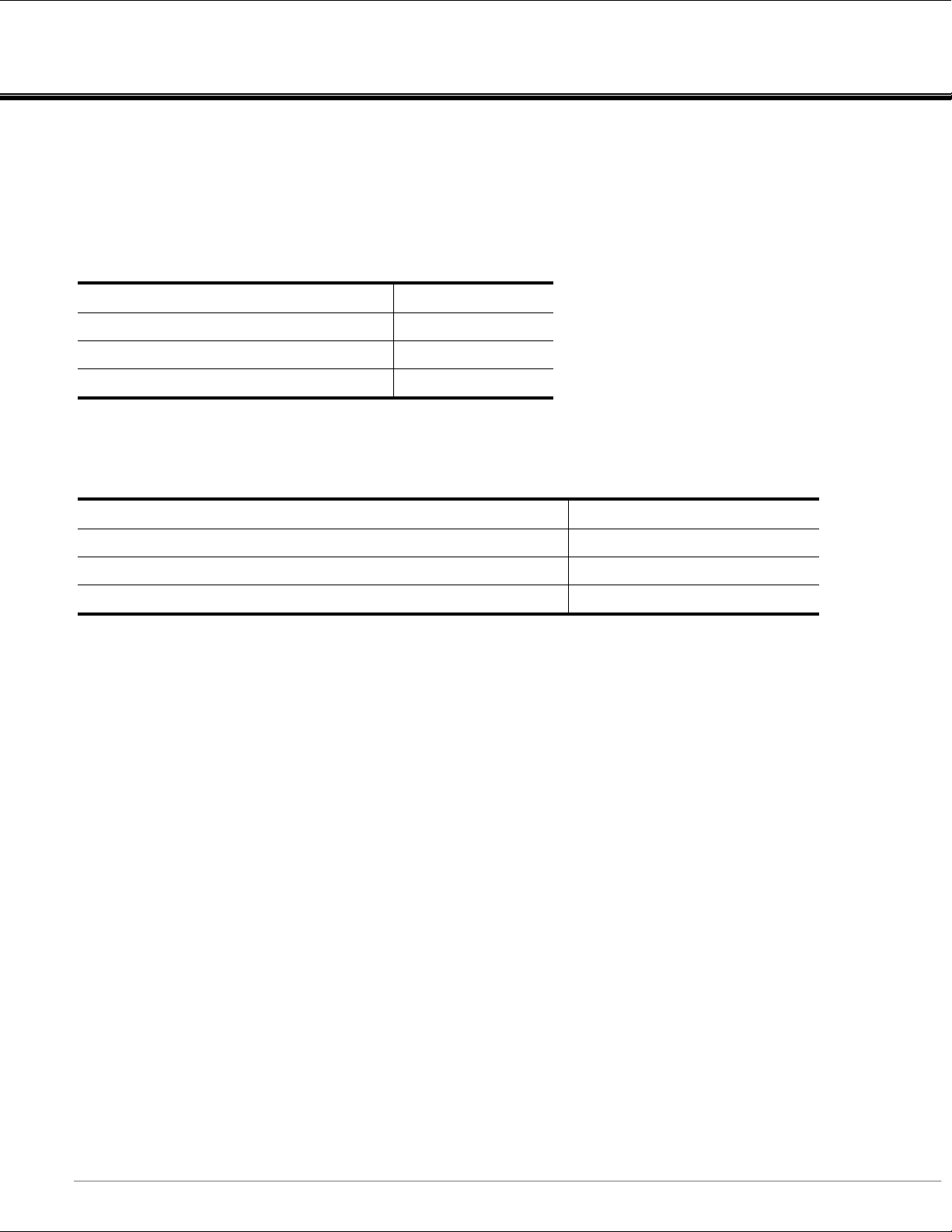

1-1. Gas Flow Rates......................................................................................... 6

1-2. Analyzer Characteristics Relative to Fuel Gas........................................... 6

2-1. Gas Supply Pressures............................................................................... 11

3-1. FID 2 Analyzer Module Alarms .................................................................. 32

A-1. Typical Flow Rates With Premixed Fuel.................................................... A1

A-2. Analyzer Characteristics For Different Fuels............................................. A1

Flame Ionization Detector 2 Analyzer Module

vi

Rosemount Analytical NGA 2000

748412-C

October 2000

CONTENTS

PURPOSE/SAFETY SUMMARY

The purpose of this manual is to provide information concerning the components, functions,

installation and maintenance of this particular NGA 2000 module.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly fa miliar with the operation of this mo dule before opera ting it. Read this

instruction manual completel y .

To avoid explosion, loss of life, personal injury and damage to this equipment

and on-site property, all personnel authorized to install, operate and service this

equipment should be thoroughly familiar with and strictly follow the instructions

in this manual. Save these instructions.

If this equipment is used in a manner not specified in these instructions,

protective systems may be impaired.

DANGER is used to indicate the presence of a hazard which will cause severe personal

injury, death, or substantial property damage if the warning is ignored.

WARNING is used to indicate the presence of a hazard which can cause severe personal

injury, death, or substantial property damage if the warning is ignored.

CAUTION is used to indicate the presence of a hazard which will or can cause minor

personal injury or property damage if the warning is ignored.

NOTE is used to indicate installation, operation or maintenance information which is

important but not hazard-related.

WARNING: ELECTRICAL SHOCK HAZARD

Operate this equipment only when covers are secured. Servicing requires

access to live parts which can cause death or serious injury. Refer servicing to

qualified personnel. For safety and proper performance, this module must be

connected to a properly grounded three-wire source of electrical power.

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

vii

PREFACE

WARNING: POSSIBLE EXPLOSION HAZARD

This equipment is used in the analysis of sample gases which may be

flammable, and the burner fuel used in the ionization process IS flammable. A

system of intrinsically safe electronics and an explosion proof tower are used to

prevent any ignition of a flammable gas leak. For this to be effective, the module

MUST be placed in a well-ventilated area, with unobstructed air flow around it.

DO NOT place it within another enclosure without assuring this ventilation.

DO NOT obstruct the vent holes on the top and sides of the module.

DO NOT place the FID module within another enclosure unless the latter has a

guaranteed air circulation such as to dilute a worst case fuel or sample leak

below 25% of the LEL. Doing so will negate the safety features and may result in

an explosion, serious injury, property damage and death.

WARNING: FLAMMABLE SAMPLES

Consult the factory if flammable samples will be measured.

WARNING: PARTS INTEGRITY

Tampering with or unauthorized substitution of components may adversely

affect safety of this product. Use only factory-approved components for repair.

WARNING: POSSIBLE EXPLOSION HAZARD

Ensure that all gas connections are made as labeled and are leak free. Improper

gas connections could result in explosion and death.

WARNING: STATIC ELECTRICITY

Circuit boards in this instrument are static-sensitive. Take all static precautions

when handling the circuit boards.

Flame Ionization Detector 2 Analyzer Module

P2

Rosemount Analytical NGA 2000

748412-C

October 2000

PREFACE

WARNING: POSSIBLE EXPLOSION HAZARD

Protection against explosion depends upon a special fuel flow restrictor in the

fuel inlet fitting. DO NOT REMOVE THE FUEL INLET RESTRICTOR. Use the

correct fuel flow restrictor for the fuel being used. Do not use 100% hydrogen

fuel in a 40% H2/60% He configured FID module. Replace with factory supplied

fitting only.

CAUTION: PRESSURIZED GAS

This module requires calibration with a known standard gas. See General

Precautions for Handling and Storing High Pressure Gas Cylinders at the rear of

this manual.

CAUTION: OVERBALANCE HAZARD

This Analyzer Module may tip instrument over if it is pulled out too far and the

Platform is not properly supported.

CAUTION: CONTROLLED ENVIRONMENT

This equipment is for use in a controlled environment. Refer to the

specifications (page P7) in this manual for environmental conditions.

CAUTION: HOT OVEN COMPONENTS

The oven and sample manifold are controlled to 80

down before touching any of these components.

NOTE

This Analyzer Module is completely leak-tested at the factory for gas leakage. The

user is responsible for testing for leakage at the inlet and outlet fittings on the rear

panel (with a test procedure chosen by the user). The user is also responsible for

leak-testing periodically and if any internal pneumatic components are adjusted or

replaced. See leak test instructions on page 2-5.

°°°°

C. Allow the analyzer to cool

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

P3

PREFACE

GLOSSARY

Analyzer Module

The module that contains all sensor/detector components for development of a Primary

Variable signal; includes all signal conditioning and temperature control circuitry.

Backplane

The interconnect circuit board which the Controller Board, Power Supply, Analyzer Module

power and network cables, I/O Modules and Expansion Modules plug into.

Control Module

The Operator Interface plus the Controller Board.

Controller Board

The computer board that serves as the Network Manager and operates the Display and

Keypad.

Diluent

The material used to dilute another material. In air, nitrogen is the diluent for the oxygen we

need to breathe.

Distribution Assembly

The Backplane and the card cages that hold I/O and Expansion Modules.

Expansion Module

A circuit board that plugs into the Backplane from the front of the Platform and performs

special features not related to I/O functions.

Flame Ionization

A technique for measuring hydrocarbon gases. A flame is used to ionize the carbon atoms,

and the charge thus generated is measured.

Gas Chromatography

A technique of separating gas stream components using absorption media, allowing the

detector to measure individual species within the stream.

Flame Ionization Detector 2 Analyzer Module

P4

Rosemount Analytical NGA 2000

748412-C

October 2000

PREFACE

Hydrocarbon

A chemical containing only hydrogen and carbon atoms. Methane, propane and octane are

hydrocarbons.

Hydrocarbons

Organic molecules containing just carbon and hydrogen. Methane, propane and oils are

example of hydrocarbons.

I/O Module

A circuit board that plugs into the Backplane from the rear of the Platform. Has a connector

terminal for communication with external data acquisition devices and provides an

input/output function.

Ionization

Generation of electrically charged particles from a neutral material. In the FID, the flame

causes hydrocarbon molecules to split into such charged ions.

LED

Light Emitting Diode – a solid state indicator light.

Operator Interface

The Display and Keyboard.

Platform

Any workable collection of the following: Controller Board, Power Supply, Distribution

Assembly, Enclosure and Operator Interface.

Power Supply

Any of a variety of components that provides conditioned power to other NGA 2000

components, from the Power Supply Board that plugs into the front of the Backplane in a

stand-alone instrument to several larger ones that can power larger collections of modules

and components.

Primary Variable

The measured species concentration value from an Analyzer Module.

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

P5

PREFACE

Purge

A safety system that uses an air flow to keep any fuel gas leak under the lower explosive

limit (LEL).

Sample Conditioning

The process of altering the state of the sample gas so as to make it suitable for an analyzer.

This includes removing condensable water, changing the pressure, and filtering.

Secondary Variable

Data placed on the network by a module regarding current status, e.g., sample flow, source

voltage and other diagnostic information.

Softkeys

The five function keys located below the front panel display; they assume the function

displayed directly above each on the display, a function dictated by software.

Species

A particular gas within a mixture. Oxygen is a species in air.

Subnode

A subsection of the analyzer devoted to measuring one of the species for which it is set up.

Analyzers with multiple subnodes can measure multiple gases.

System

Any collection of Analyzer Module(s), Platform(s), I/O Module(s) and Expansion Module(s).

Flame Ionization Detector 2 Analyzer Module

P6

Rosemount Analytical NGA 2000

748412-C

October 2000

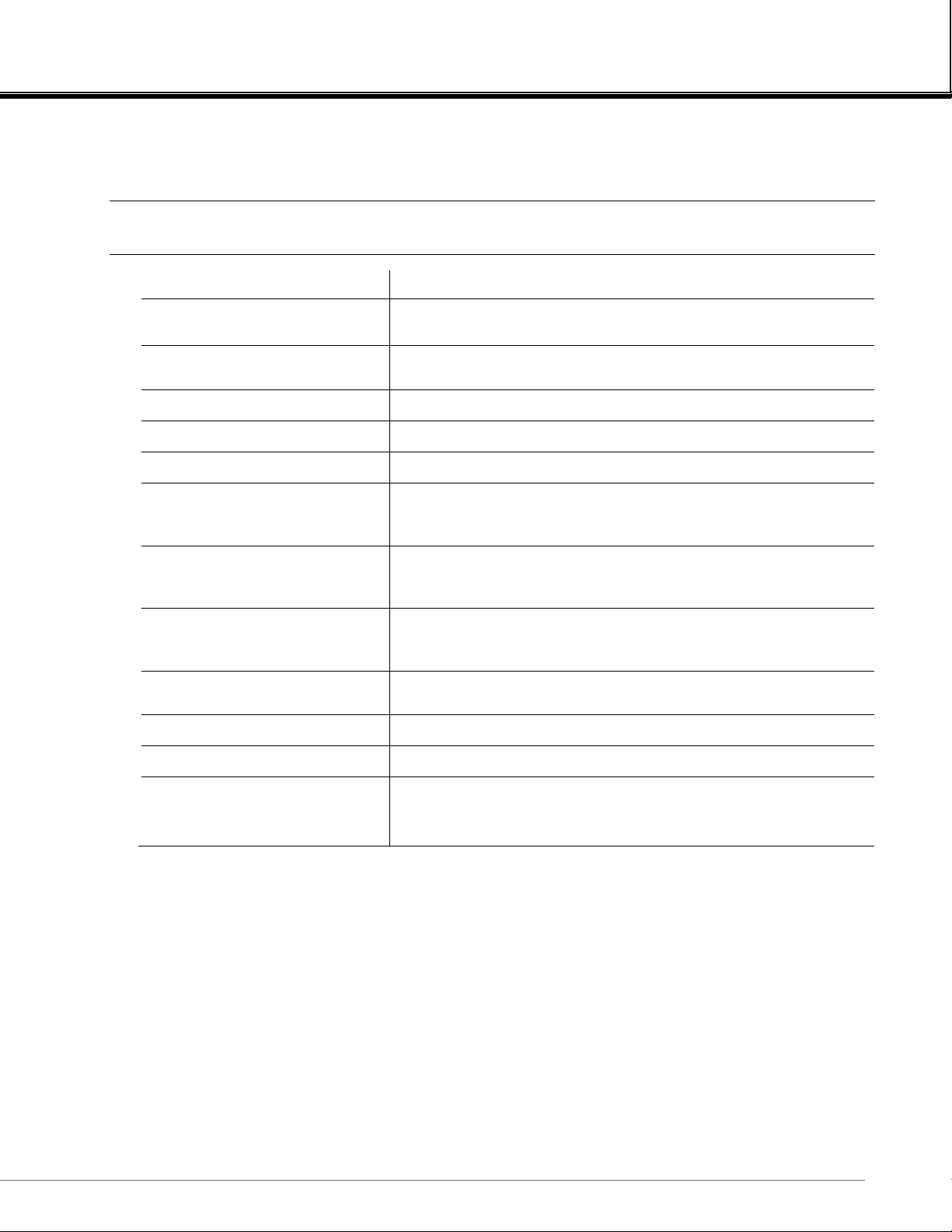

SPECIFICATIONS - GENERAL

PREFACE

M

EASUREMENT SPECIES

H2/HE FUEL

R

EPEATABILITY

MINIMUM DETECTABLE LEVEL

N

OISE

L

INEARITY

R

ESPONSE TIME

Z

ERO DRIFT

S

PAN DRIFT

E

FFECT OF TEMPERATURE

O

PERATING TEMPERATURE

Total hydrocarbons

low range: 0 to 4 ppm CH4, through 0 to 1% CH

high range:: 0 to 50 ppm CH4, through 0 to <5% CH

4

4

≤1% of fullscale at a constant temperature, sample flow

and fuel, burner air and sample pressure

0.04 ppm H2/He fuel – methane equivalent

≤1% of fullscale, peak to peak

≤ ±1% of fullscale for H2/He fuel and H2 fuel

<1 second for bypass flow rate of 500 cc/min (for a

sample change at the rear panel connector of the

instrument)

≤ ±1% of fullscale/24 hours at constant temperature,

hydrocarbon concentration of supply gases, sample flow

and fuel, burner air and sample pressure

≤ ±1% of fullscale/24 hours at constant temperature,

hydrocarbon concentration of supply gases, sample flow

and fuel, burner air and sample pressure

≤ ±2% of fullscale for any temperature chang e o f 10°C

and rate of change less than 10°C/hour

41°F to 104°F (5°C to 40°C)

O

PERATING HUMIDITY

P

OWER REQUIREMENTS

748412-C

October 2000

<95% relative humidity, non-condensing

+24 VDC ±5%, 120 W max.. direct to analyzer module;

Ripple and Noise: <100 mV peak to peak

Line and Load Regulations: <±1%

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

P7

PREFACE

SPECIFICATIONS - GAS REQUIREMENTS

B

URNER AIR

F

LOW RATE

THC

S

UPPLY PRESSURE

F

UEL GAS (STANDARD

F

LOW RATE

THC

S

UPPLY PRESSURE

Hydrocarbon free grade air

350 to 400 ml/min

≤0.1 ppm CH

4

1725 to 3450 hPa-gauge (25 to 50 psig)

Premixed 40% hydrogen and 60% helium

)

110 to 110 ml/min.

≤0.5 ppm CH

4

3101 to 3450 hPa-gauge (45 to 50 psig)

WARNING: POSSIBLE EXPLOSION HAZARD

DO NOT USE PURE HYDROGEN FUEL. An explosion res ulting in severe

personal injury or death could occur. Also, each Analyzer Module is

factory-configured for mixed, and cannot use the fuel for which it was not

configured unless field reconfiguration is done.

S

AMPLE

F

LOW RATE

S

UPPLY PRESSURE

T

EMPERATURE

P

ARTICULATES

D

EWPOINT

Non-flammable (below 100% of LEL)

0.5 to 2.0 L/min.

483 to 1035 hPa-gauge (7 to 15 psig)

32°F to 248°F (0°C to 120°C), <20°C variance/24 hours,

<10°C variance/hour

Filtered to <2 microns

<45°C

Flame Ionization Detector 2 Analyzer Module

P8

Rosemount Analytical NGA 2000

748412-C

October 2000

SPECIFICATIONS - PHYSICAL

M

ATERIALS IN CONTACT WITH

SAMPLE

PREFACE

Stainless steel, Teflon, glass-filled Teflon, Viton

D

IMENSIONS

W

EIGHT

M

OUNTING

C

ASE CLASSIFICATION

MAX. S

P

EPARATION FROM

LATFORM

See Figure 2-5, Outline and Mounting Dimensions

10.43 kg (23 lbs.)

Horizontal

General Purpose for installation in weather

protected area

1600 m (1 mile)

SPECIFICATIONS - GAS CONNECTIONS

S

AMPLE IN

B

URNER AIR IN

F

UEL IN

B

YPASS OUT

B

URNER EXHAUST

O

UT

1/4 inch O.D. tube fitting

1/4 inch O.D. tube fitting

1/4 inch O.D. tube fitting

1/4 inch O.D. tube fitting

3/8 inch O.D. tube slip-fit connection, tygon or equivalent

(this connection shall slope downward 6° minimum from

horizontal)

T

HE BURNER EXHAUST AND BYPASS OUT SHALL BE VENTED TO ATMOSPHERIC PRESSURE

AND TO A NON

-

CLASSIFIED LOCATION

.

See the Preface Section of the Platform manual for specifications regarding Platform related

components.

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

P9

PREFACE

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE

For order administration, replacement Parts, application assistance, on-site or factory repair,

service or maintenance contract information, contact:

Rosemount Analytical Inc.

Process Analytical Division

Customer Service Center

1-800-433-6076

RETURNING PARTS TO THE FACTORY

Before returning parts, contact the Customer Service Center and request a Returned

Materials Authorization (RMA) number. Please have the following information when you call:

Model Number, Serial Number, and Purchase Order Number or Sales Order Number.

Prior authorization by the factory must be obtained before returned materials will be

accepted. Unauthorized returns will be returned to the send er, freight collect.

When return ing any product or compon ent that has been expo sed to a toxic, co rrosive or

other hazardous material or used in such a hazardous environment, the user must attach an

appropriate Material Safety Data Sheet (M.S.D.S.) or a written certification that the material

has been decontaminated, disinfected and/or detoxified.

Return to:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

USA

T

RAINING

A comprehensive Factory Training Program of operator and service classes is available.

For a copy of the Current Operator and Service Training Schedule contact the Technical

Services Department at:

Flame Ionization Detector 2 Analyzer Module

P10

Rosemount Analytical NGA 2000

Rosemount Analytical Inc.

Phone: 1-714-986-7600

FAX: 1-714-577-8006

748412-C

October 2000

PREFACE

DOCUMENTATION

The following Flame Ionization Detector 2 Analyzer Module instruction materials are

available. Contact Customer Service or the local representative to order.

748412 Instruction Manual (this document)

C

OMPLIANCES

This product may carry approvals from several certifying agencies, like The Canadian

Standards Association (CSA), which is also an OSHA accredited Nationally Recognized

Testing Laboratory (NRTL), and LCIE - a French Notified Body.

The certification marks appear on the product name-rating plate.

NRTL /C

®

LCIE 98 ATEX 6004 X

EEx d ib IIB (+H

0°C Ta +40°C

Date of Manufacture:

0081

) T6

2

II 2 G

Rosemount Analytical has satisfied all obligations from the European Legislation to

harmonize the product requirement in Europe.

This product complies with the standard level of NAMUR EMC

NAMUR

Recommendations (1993).

This product satisfies all obligations of all relevant standards of the EMC framework in

Australia and New Zealand.

N96

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

P11

PREFACE

NOTES

Flame Ionization Detector 2 Analyzer Module

P12

Rosemount Analytical NGA 2000

748412-C

October 2000

PREFACE

QUICK STARTUP PROCEDURE

The purpose of this reference guide is to provide a easy to follow, step by step procedure

through initial start up and ignition of the FID2 Analyzer Module. This procedure assumes

that the customer has already made all necessary electrical and gas connections and

established the proper network connections.

1. Turn on power to the instrument. The #1 LED (POWER) will illuminate. The #3 LED

(BLOCK) will begin flashin g.

2. If sample gas has been connected and the sample pressure to the analyzer is sufficient

to provide an accurate reading, the #4 LED (SAMPLE) will be illumninated.

3. Allow the analyzer module to warm up and the burner block temperature to reach the

proper minimum ignition temperature (50°C). When the burner block temperature

reaches the minimum ignition temperature, the #5 LED (IGNITE OK) will come on.

4. The instrument is now ready to be lit. Lighting the burner can be conducted in one of

two methods: a) manual ignition from the front panel of the Analyzer Module or b)

autoignite from the Platform.

FID 2

F

IGURE

748412-C

October 2000

FUEL OVERRIDE

IGNITE

P-1. FID2 F

POWER FLAME BLOCK SAMPLE IGNITE FUEL/AIR

OK

RONT PANEL

3 2 1 LON2 LON1

T 6A

24V

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

P13

PREFACE

a. To light the instrument from the Analyzer Module, hold the "FUEL

b. To light the instrument from the Platform using the autoignite mode, simply press

OVERRIDE/IGNITE" switch (located to the left of the indicator lights) in the up

(FUEL OVERRIDE) position for 30 seconds. Immediately move the switch to the

down (IGNITE) position. The "IGNITE" mode is automatically set to stay on for a

preset time period and does not require the switch to be held down. If the lighting

procedure was successful, the #2 LED (FLA ME) will begin flashing as the flame

temperature rises to the correct operating temperature. Once this LED becomes

solidly lit, the flame has reached operating temperature.

the "light" softkey shown in the "Light Flame" menu of the Platform. The Analyzer

Module will begin to go through an automated sequence of enrichment and

ignition similar to the manual mode described in step 5. If the burner fails to light

on the first try, the Analyzer Module will perform 2 more tries before terminating

the autoignite sequence. If the Analyzer Module fails to light after 3 attempts, an

error message will be displayed sho wing the cause of the fault.

5. If the burner fails to light, check all gas connections for proper gas composition and

pressure, block temperature, and outlets for obstructions. Repeat step 4.

6. If the flame is lit, the #2 LED will begin flashing. Once the flame temperature has

reached the correct operating temperature, the LED will remain on solid.

7. If the fuel and air pressures and ratios are within proper operating parameters to

support a continuous flame operation, the # 6 LED (FUEL/AIR) will illuminate. This light

will not be on before or during flame ignition.

8. Once the burner block temperature reaches the control temperature of 80°C, the #3

LED will stay on solid.

9. If the instrument has been successfully lit, the temperatures are up to proper operating

levels, and the fuel, air, and sample gases are properly adjusted to support the flame

and achieve reliable results, all 6 indicator lights will be lit solid.

The unit is now ready for calibration or burner optimization.

Flame Ionization Detector 2 Analyzer Module

P14

Rosemount Analytical NGA 2000

748412-C

October 2000

INTRODUCTION

1.1 OVERVIEW

This manual describes the Flame Ionization Detector (FID2) Analyzer Module of Rosemount

Analytical's NGA 2000 Series of gas analysis components. See Figure 1-1.

The FID2 Analyzer Module is designed to use a flame ionization technique to measure the

total concentration of hydrocarbon (including certain oxygenated hydrocarbons)

components within the sample stream.

The entire FID2 Analyzer Module is designed as a module with electrical connections at its

front, and gas connections made from the rear. All electronics relative to sample control and

signal conditioning are included in this module.

1

FRONT

Intrinsic Safety Board

Module Board

Computer Board

Regulator

Burner

Oven

(Cover removed)

REAR

Flow Control Manifold

F

IGURE

748412-C

October 2000

1-1. FID2 A

NALYZER MODULE

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

1

1

+++

+

+

INTRODUCTION

1.2 TYPICAL APPLICATIONS

Typical applications for the FID2 Analyzer Module include:

The monitoring of atmospheric air for low-level total hydrocarbon contaminants

Determining the total hydrocarbon content of exhaust emissions from internal combustion

engines

Carbon bed monitoring

Determining the total hydrocarbons content of process and product gases from air

separation plants

1.3 THEORY OF TECHNOLOGY

This Analyzer Module uses the flame ionization method of detection. The sensor is a burner

in which a regulated flow of gas sample passes through a flame sustained by regulated

flows of a fuel gas (a hydrogen/diluent mixture) and air.

Within the flame, the hydrocarbon components of the sample stream undergo a complex

ionization that produces electrons and positive ions. Polarized electrodes collect these ions,

causing current to flow through an electronic measuring circuit.

Igniter

Exhaust

-

Ions

Negative

Electrode

Flame

Positive

Electrode

-

-

-

-

Air

Fuel + Sample

F

IGURE

Flame Ionization Detector 2 Analyzer Module

2

Rosemount Analytical NGA 2000

1-2. F

LAME IONIZATION DETECTION TECHNOLOGY

748412-C

October 2000

INTRODUCTION

The ionization current is proportional to the rate at which carbon atoms enter the burner,

and is therefore a measure of the concentration of hydrocarbons in the sample.

The gas pressures are continuously monitored and controlled through electronic pressure

transducers.

The measurement of concentration is placed on the network, where it can be shown on the

Platform Display or on other data acquisition devices.

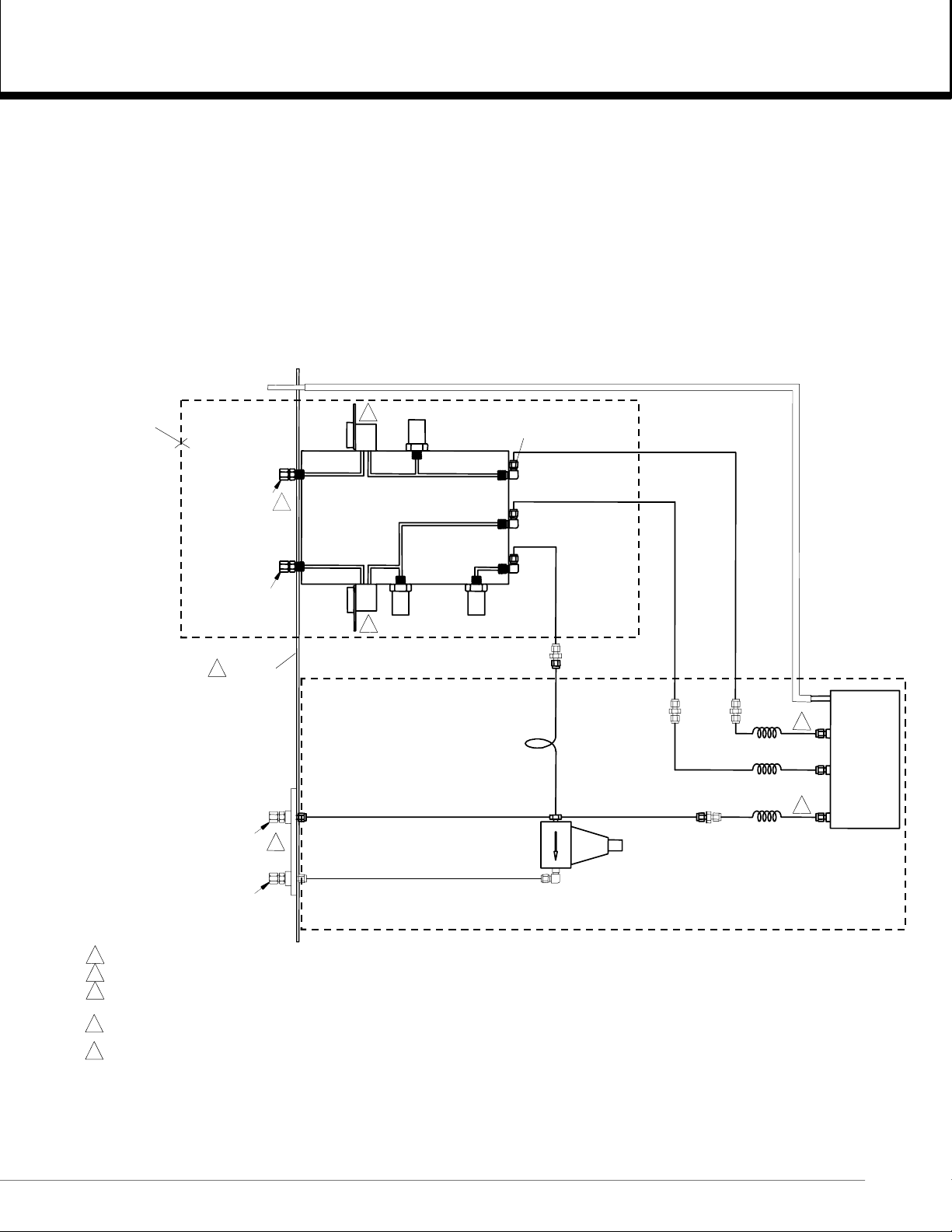

FID EXHAUST

2

FUEL FLOW

CONTROL

FLUISTER

VALVE

659541

4

MANIFOLD

SENSOR, FUEL

PRESSURE

0-30 PSIG

659498

FTG, ELBOW

1/16T-1/8MPT

904582

(3)

659072

659038

659037

FLOW CONTROL

MANIFOLD ASSEMBLY

659043

FUEL IN

FTG, BULKHEAD

W/RESTRICTOR

1/4T-1/8MPT

1

AIR IN

FTG, MALE CONN

1/4T-1/8MPT

008435

W/FILTER 017154

REAR PANEL5

SAMPLE IN

FTG, BULKHEAD

SAMPLE OUT

FTG, MALE CONN

1/4T-1/8MPT

008435

5 REAR PANEL IS INCLUDED IN F LOW CONTROL MANIFOLD ASSEMBLY 659043.

4 MANIFOLD ASSEMBLY 659043 MUST BE RETURNED TO FACTORY WHEN REPLACMENT OF AIR AND/OR FUEL FLOW FLUISTER VALVES IS REQUIRED.

3 15 PSI 2 L/MIN.: 659178

2 PSI 1 L/MIN.: 659073

NO RESTRICTOR: 0084 35

2 STD MIXED FUEL: 659514

1 STD MIXED FUEL: 658146 FUEL CAPILLARY, 659031 SAMPLE CAPILLARY

AIR FLOW

CONTROL

FLUISTER

VALVE

659541

4

SENSOR, AIR

PRESSURE

0-30 PSIG

659498

3

SENSOR, SAMPLE

PRESSURE

0-15 PSIG

659497

BACK PRESSURE

REGULATOR

659063

FTG, UNION

1/16T

818270

FTG ASSEMBLY

659173

FTG, FLBOW

1/4T-1/4MPT

902147

FTG, UNION

1/16T

818270

FTG, UNION

1/16T

818270

FTG, UNION

1/16T

818270

FUEL

CAPILLARY

AIR

CAPILLARY

SAMPLE

CAPILLARY11

FLAME

IONIZA TION

DETECTOR

(FID)

F

IGURE

748412-C

October 2000

1-3. FID2 A

NALYZER FLOW DIAGRAM

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

3

1

INTRODUCTION

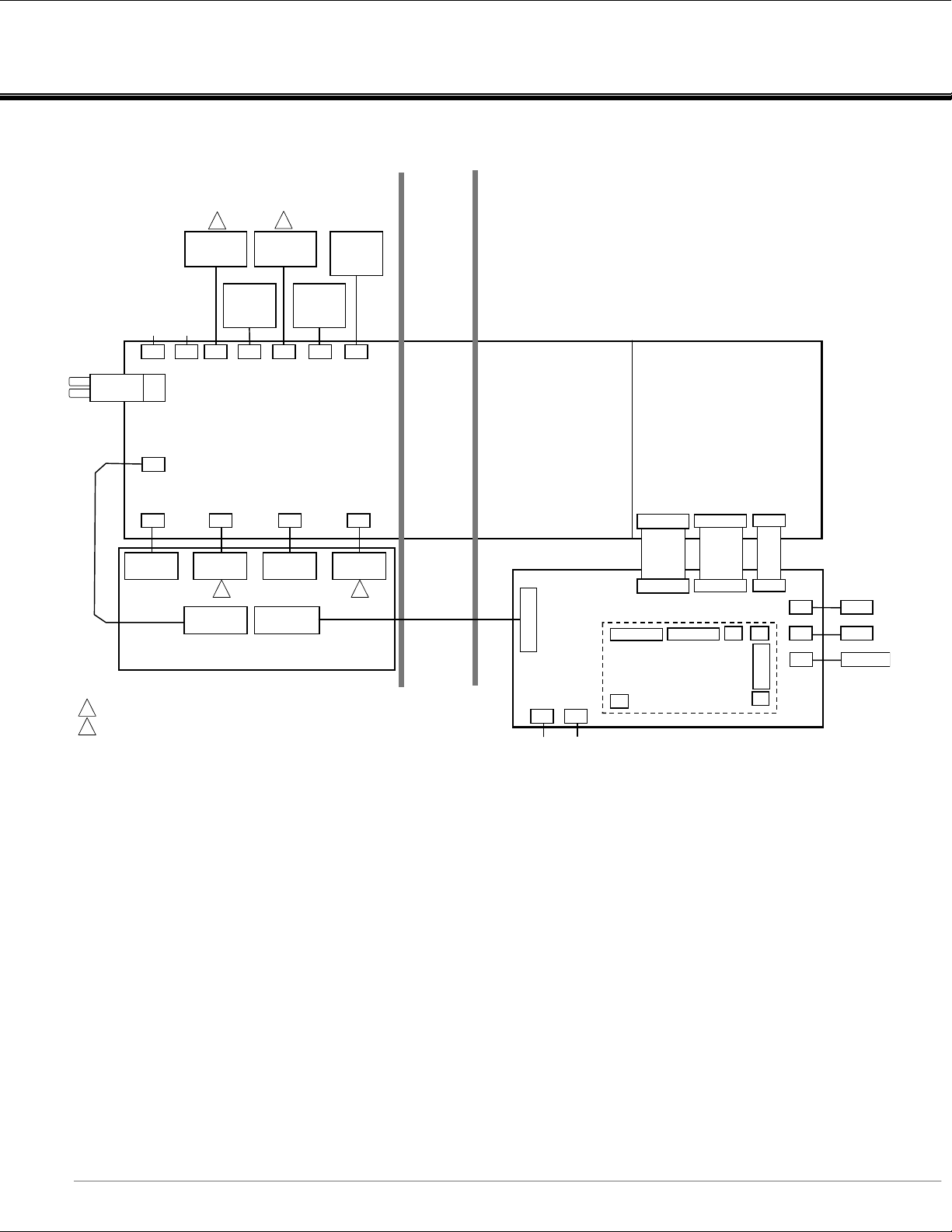

REAR SECTION OF ANALYZER FRONT SECTION OF ANALYZER

FLOW CONTROL

FLUISTOR

AIR

659070

THERMISTOR

BURNER

BLOCK HEATER

2

FUEL

J1

FLAME

FUEL

PRESSURE

SENSOR

0-30 PSIG

J12 J13J3 J11 J4

SAMPLE

RESSURE

SENSOR

0-15 PSIG

J6

POLARIZED

COLLECTOR

1

CABLE

CONTINUITY

FLOW CONTROL

NCNC

J7J2

J9

J16

J8 J5

IGNITER

BURNER BLOCK

2

AIR

FLUISTOR

PRESSURE

SENSOR

0-30 PSIG

INTRINSICALLY SAFE BOARD

POLARIZED

COLLECTOR

1

RTD

BURNER BLOCK ASSEMBLY

1

CONNECTORS J5 AND J6 ON INTRINSICALLY SAFE BOARD ARE INTERCHANGEABLE.

FACTORY REPLACEMENT.

2

MIDDLE

SECTION OF

ANALYZER

THIS SECTION OF INTRINSICALLY

SAFE BOARD CONTAINS CURRENT-

LIMITING RESISTORS

J15

J8J11

NCNC

THIS SECTION OF

INTRI N S I CALLY SAF E BO ARD

CONTAINS ±15 SUPPLIES,

+90V SUPPLY AND LOW-

LEVEL ANALOG CIRCUITS

J15

J15 J14 J25

MODULE BOARD 659060

J6 J5

COMPUTER BOARD

658350

J7

J14 J17

J1J4

J2

J3

J22

J24

J22

LON1

LON2

24V POWER

F

IGURE

Flame Ionization Detector 2 Analyzer Module

4

Rosemount Analytical NGA 2000

1-4. FID2 W

IRING DIAGRAM

748412-C

October 2000

INTRODUCTION

1.4 GAS SAFETY FEATURES

The FID2 module is divided into two parts - a pneumatic section and an electronic section.

The two sections are separated by a pair of solid partitions to prevent any leak of gas in the

pneumatic section from reaching the electronics. The electrical connections into the

pneumatic section are made intrinsically safe by a series of over-voltage protection devices

and current limiting resistors. The burner itself is an explosion-proof assembly. The

combination of these two techniques allows the analyzer to meet international safety

standards without the use of an expensive continuous-dilution purge - but ONLY when it is

installed in a general purpose area with good air circulation.

WARNING: POSSIBLE EXPLOSION HAZARD

Hydrocarbon concentration(s) in the sample gas must be below the Lower

Explosion Limit (LEL).

1

All tubing ahead of the burner is rigid metallic tubing assembled with ferrule/nut type

compression fittings. However, should an internal fuel leak occur, a worst-case leak would

be dissipated below 25% of the LEL of hydrogen by natural dilution outside of the pneumatic

section before it could be ignited by any external ignition source, and there is nothing within

the pneumatic section to ignite it.

The FID2 is designed to use 40% H2/60% He fuel at a maximum inlet pressure of 3446 hPagauge (50 psig).

1

WARNING: POSSIBLE EXPLOSION HAZARD

Protection against explosion depends upon a special fuel flow restrictor at the

fuel inlet. DO NOT REMOVE THE FUEL INLET RESTRICTOR.

1.5 FUEL GAS OPTION

The standard FID2 Analyzer Module requires 40% hydrogen/60% helium burner fuel gas.

For monitoring internal combustion exhaust emissions or other sample gas with varying

oxygen content, mixed fuel is preferable. In fact, a hydrogen/helium mixture is more

desirable than a hydrogen/nitrogen mixture. With this type of sample, the use of mixed fuel

gas minimizes the error introduced by oxygen synergism.

1

The fuel restrictor is part of the Flow Control Manifold Assembly, which is specific to an application.

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

5

1

INTRODUCTION

Changes in the burner air flow rate have little effect on signal strength. For a given flow, the

signal can be optimized by adjusting the fuel flow rate.

Typical flow rates to the burner:

GAS FLOW MIXED FUEL

F

UEL

S

AMPLE

A

IR

T

ABLE

1-1. G

AS FLOW RATES

100 cc/min

10 cc/min

400 cc/min

ANALYZER CHARACTERISTICS 40% H2/60% He

F

ULL SCALE SENSITIVITY

F

UEL CONSUMPTION

O

PERATING SETTING FOR SAMPLE PRESSURE REGULATOR

T

ABLE

1-2. A

NALYZER CHARACTERISTICS RELATIVE TO FUEL GAS

4 ppm, CH4 to <1%, CH

100 to 110 cc/min

345 hPa-gauge (5 psig)

4

Flame Ionization Detector 2 Analyzer Module

6

Rosemount Analytical NGA 2000

748412-C

October 2000

INSTALLATION

2.1 UNPACKING

When the FID2 Analyzer Module is received, carefully examine the shipping carton and

contents for signs of damage. Immediately notify the shipping carrier if the carton or

contents is damaged. Retain the carton and packing material until all components

associated with the Analyzer Module are operational.

2.2 ASSEMBLY

The FID2 analyzer module MUST NOT be placed within a conventional NGA platform,

single module enclosure or dual module enclosure since the latter would not allow free flow

of air around the module, thus violating its safety certification. The enclosure is designed so

that this would be very hard to do anyway.

2

There is a special platform specifically designed to accept this module; consult the factory

for details.

Install the Platform and I/O Module(s) according to guidelines in the Platform manual.

2.3 LOCATION

WARNING: POSSIBLE EXPLOSION HAZARD

Do not place the FID2 module within another enclosure unless the latter has a

guaranteed air circulation such as to dilute a worst case fuel or sample leak

below 25% of the LEL. Failure to will negate the safety features and may result

in explosion, serious injury, material damage and death. Also, do not cover the

vent holes on the top and sides of the module.

Install the Analyzer Module in a clean, weather-proofed, non-hazardous, vibration-free

location free from extreme temperature variations. For best results, install the Analyzer

Module near the sample stream to minimize sample transport time.

Operating ambient temperature is 5 °C to 40 °C, limited to temperature changes of less than

10 °C/hr. Acceptable dew point range is less than 95% relative humidity, but not in excess

of 40°C wet bulb temperature.

748412-C

October 2000

Flame Ionization Detector 2 Analyzer Module

Rosemount Analytical NGA 2000

7

2

INSTALLATION

The cylinders of fuel, air, and calibration gases should be located in an area of relatively

constant ambient temperature .

2.4 G

During normal operation, the Analyzer Module requires fuel and air to maintain the burner

flame as well as suitable standard gases for. Refer to the criteria for selection of these

gases in Section 2.4.2.

After initial startup or after startup following a prolonged shutdown, the analyzer may display

baseline drift for a considerable period of time, particularly on the most sensitive range.

Commonly, the drift is caused by small amounts of organics (such as hydrocarbons) in the

inner walls of the tubing in both the internal flow system and the external gas supply system.

Drift results from any factor influencing the equilibrium of these adsorbed hydrocarbons,

such as temperature or pressure. Hydrocarbons adsorbed within the analyzer in the gas

passageways (or in the fuel or air lin es) will elevate the overall baseline.

Note that this type of drift occurs only when the flame is burning. If drift occurs when the

flame is extinguished, the electronic circuitry is at fault or the burner or cabling is

contaminated with a conductive film. To minimize drift, use clean fuel and air, keep the

analyzer clean, and locate the gas cylinders in an area of relatively constant ambient

temperature.

The cylinders supplying all gases each should be equipped with a clean, hydrocarbon-free,

two-stage regulator and a shutoff valve.

ASES

All new external gas tubing (except for SAMPLE BYPASS) is strongly recommended,

preferably pre-cleaned, stainless steel, gas chromatograph-grade tubing. Thoroughly clean

before use (if a hydrocarbon-based cleaning solvent such as acetone is used, purge tubing

with dry nitrogen or helium for several minutes before using.)

Gas line connections are compression fittings. Do not use pipe thread tape on such fittings.

Since the oxidation of hydrogen is accompanied by the formation of water vapor, the

exhaust tubing always should be slanted downward at least 6 degrees from horizontal.

Otherwise, water may accumulate in the line, causing back pressure and noisy readings, or

may back up in the line and flood the burner.

If the sample is toxic or noxious, or is to be reclaimed, connect the Bypass outlet to a

suitable disposal system. Do not use any device that may cause back pressure in the line.

Flame Ionization Detector 2 Analyzer Module

8

Rosemount Analytical NGA 2000

748412-C

October 2000

Loading...

Loading...