Rosemount Manual: NGA 2000 CLD NO/NOx Analyzer Module SW 3.9-3rd Ed. | Rosemount Manuals & Guides

Instruction Manual

HAS60E-IM-SW39

10/2005

Software Version 3.9.x

NGA 2000 Software Manual for

CLD Analyzer Module (combined with

NGA 2000 Plat form, MLT, CAT 200 or TFID Analyzer)

www.EmersonProcess.com

CLD Software 3.9.x Instruction Manual

HAS60E-IM-SW39

10/2005

ESSENTIAL INSTRUCTIONS

READ THIS P AGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and test s

its products to meet many national and international standards. Because these instruments

are sophisticated technical products, you MUST properly install, use, and maintain

them to ensure they continue to operate within their normal specifications. The following

instructions MUST be adhered to and integrated into your safety program when installing,

using and maintaining Emerson Process Management (Rosemount Analytical) products.

Failure to follow the proper instructions may cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products

to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update, program,

and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson Process Management (Rosemount Analytical). Unauthorized parts

and procedures can affect the product’s performance, place the safe operation of your

process at risk, and VOID YOUR W ARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical

shock and personal injury.

The information contained in this document is subject to change without notice. Misprints

reserved.

st

1

Edition 05/2005 2nd Edition 07/2005

3rd Edition 10/2005

© 2005 by Emerson Process Management

Emerson Process Management

GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Contents

1 Introduction 1 - 1

2 Menu Structure 2 - 1

3 Startup and Operation, General Notes and Main Menu 3 - 1

3.1 Starting and Initializing....................................................................................3 - 1

3.2 Display and Function ......................................................................................3 - 2

3.3 "TAG" and Operating Keys .............................................................................3 - 2

3.4 Lines and Softkey Functionality ......................................................................3 - 3

3.5 Important Functions of the Soft keys...............................................................3 - 4

3.6 Entering/Changing Variables ..........................................................................3 - 5

3.7 The STATUS key ............................................................................................3 - 6

3.8 Main Menu ......................................................................................................3 - 7

4 Analyzer Basic Controls (Calibration) & Setup 4 - 1

4.1 Analyzer Channel Status: Current Measurement Parameters ........................4 - 3

4.1.1 Multi Component Display: Change of Channel ...............................................4 - 5

4.1.2 Multi Component Display: Sequence setup ....................................................4 - 7

4.1.3 Range Setting .................................................................................................4 - 9

4.1.4 Automatic Range Control................................................................................4 -13

4.1.5 Enable/Disable Ozonator Power .....................................................................4 - 17

4.1.6 Measurement Mode: NO↔NOx.......................................................................4 - 21

4.2 Calibration.......................................................................................................4 - 23

4.2.1 Zeroing (Zero Calibration)...............................................................................4 - 23

4.2.2 Spanning (Span Calibration) ...........................................................................4 - 27

5 Analyzer and I/O, Expert Controls & Setup 5 - 1

5.1 Analyzer Module Setup…………………………………………………………….5 - 3

5.1.1 Calibration/Calibration gas list.........................................................................5 - 5

5.1.2 Calibration parameters....................................................................................5 - 11

5.1.3 Concentration alarm setup..............................................................................5 - 13

5.1.4 Gas measurement parameters .......................................................................5 -15

5.1.4.1 Linearization parameters ................................................................................5 - 17

5.1.4.2 Response time/delay parameters ...................................................................5 - 19

5.1.4.3 Range setting..................................................................................................5 - 21

5.1.4.4 Automatic range control ..................................................................................5 - 23

I

HAS60E-IM-SW39(3) [CLD Software 3.9.X)] 10/05

NGA 2000

5.1.4.5 Units ............................................................................................................... 5 -25

5.1.4.6 Linearization functions.................................................................................... 5 - 27

5.1.5 Analyzer parameter list................................................................................... 5 - 33

5.1.6 Physical measurement parameters ................................................................ 5 - 33

5.1.7 Displayed parameters .................................................................................... 5 - 39

5.2 I/O Module Controls .......................................................................................5 - 41

5.2.1 System SIO Module ....................................................................................... 5 - 43

5.2.1.1 Analog output setup ....................................................................................... 5 - 45

5.2.1.2 Serial interface setup...................................................................................... 5 - 51

5.2.1.3 Relay outputs settings .................................................................................... 5 - 53

5.2.2 System DIO Module(s).................................................................................... 5 - 57

– Configuring the DIO module inputs........................................….......... 5 - 59

– Configuring the 24 DIO module outputs.....................................…...... 5 - 61

5.3 Analyzer Module Controls ..............................................................................5 - 63

6 System Configuration and Diagnostics 6 - 1

6.1 Diagnostic Menus........................................................................................... 6 - 3

6.1.1 Control Module Diagnostics............................................................................ 6 - 4

6.1.2 Analyzer Module Diagnostics ......................................................................... 6 - 5

6.2 Load/Save Configuration (CM/MCA) .............................................................. 6 - 7

6.3 Date and Time................................................................................................ 6 - 9

6.4 Security Codes ............................................................................................... 6 - 11

6.5 Measurement Display Setup ..........................................................................6 - 13

6.6 Miscellaneous................................................................................................. 6 - 15

7 Display Controls 7 - 1

Supplement:

Calculator on Control Module Level (CM Calculator) Page 1 - 14

Programmable Logic Control on Control Module Level (CM PLC) Page1 - 28

System Calibration Page1 - 34

NGA 2000

HAS60E-IM-SW39(3) [CLD Software 3.9.X)] 10/05

II

1 Introduction

This software manual describes step by step how to operate successfully the Emerson

Process Management NGA 2000 Series CLD analyzer modules and analyzers (Analyzer

Module in a platform).

Chapter 2 shows the structure of the CLD software menus. Chapter 3 describes the

display and the keyboard of the analyzer and the main menu and submenus. Chapter 4

describes the basic controls incl. measurement and calibration with detailed

illustrations. So you can easily compare the actual analyzer (module) display with the

illustrations of the manual.

Chapter 5 describes the expert configurations of the analyzer module and of the Input/

Output modules (I/O modules). Chapter 6 describes the system configuration and

diagnostics. The layout of both chapters is not as detailed. In chapter 7 you will find some

information about the display controls.

Some co nte nt s o f t he e xpe rt co nf igu ra ti ons are not important for each customer. It depends

on the configuration of your NGA 2000 system, relative to the following components:

♦ Control Module CM

♦ Analyzer Module AM

♦ Input/Output Modules I/O's (SIO = Standard I/O, DIO = Digital I/O)

♦ Network I/O Modules Analog I/O with 3 Alarms, Autocalibration I/O, System

Autocalibration I/O

You can distinguish the following system units and SIO/DIO configurations:

System Unit SIO/DIO Configuration

CLD analyzer module (AM):

• without front panel,

i.e. without control unit

• can be combined with a platform,

a MLT/ CAT 200/ TFID analyzer or

a customer developed control unit

⇒ 1 local SIO and 1 local DIO (or 2

local DIO’s) can be installed in the

MLT/TFID analyzer module only

⇒ SIO and DIO can be configured

for the MLT AM channels or the

TFID analyzer module only

⇒ => No local CLD I/O’s

Section

∗ See

MLT/TFID

Instruction

Manual

Platform (CM Software):

• Control unit with front panel

• Without measurement channels

⇒ 1 SIO and up to 4 DIO's can be

installed in the platform (CM I/O’s)

⇒ SIO and DIO can be configured

∗ 5.2

for all AM channels combined with

the platform, e.g. for the CLD

=> System I/O’s

CLD analyzer (CM plus CLD

Analyzer Module Software):

• CLD Analyzer: CLD AM in a

platform with front panel

• CLD AM combined with MLT/TFID

or CAT 200 analyzer,

i.e. all functions of the control unit

and of the CLD Analyzer Module

are shown

HAS60E-IM-SW39 (2) [CLD Software 3.9.X] 07/05

⇒ 1 SIO and 1 DIO (or 2 DIO’s) can

be installed in the MLT/ CAT 200/

TFID analyzer (CM I/O’s)

⇒ SIO and DIO can be configured

for all AM’s

combined with the MLT/

CAT 200/ TFID analyzer, e.g. CLD

=> System I/O’s

NGA 2000

∗ 5.2

1 - 1

The following illustrations shall clarify the relationship between the hardware configuration

A

A

and the software setup of the modules:

NGA 2000 System via Platform and CLD Analyzer Module

(separate

Manual)

(separate

Manual)

Local

I/O's

SIO

nalyzer

Modules (AM's)

TFID

DIO

SIO

MLT

DIO

CLD

(additional

manuals)

(additional

manuals)

HFID

FID

Control

Module (CM)

Platform

System I/O

Modules

1 SIO

4 DIO's

max.

Network

I/O’s

(see 5.2.1)

(see 5.2.2)

(see 5.2.3)

NGA 2000 System via MLT/ CAT 200 Analyzer and CLD Analyzer Module

(separate

Manual)

(separate

Manual)

Local

I/O's

SIO

nalyzer

Modules (AM's)

MLT

DIO

SIO

TFID

DIO

Control

Module (CM)

System I/O

Modules

1 SIO

1 DIO

(separate

Manual)

(separate

Manual)

CLD

(additional

manuals)

(additional

manuals)

CAT 200

FID

MLT/ CAT 200 Analyzer

1 - 2

NGA 2000

HAS60E-IM-SW39 (2) [CLD Software 3.9.X] 07/05

1 Introduction

A

NGA 2000 System via TFID Analyzer and CLD Analyzer Module

(separate

Manual)

(separate

Manual)

Local

I/O's

SIO

nalyzer

Modules (AM's)

TFID

DIO

SIO

MLT

DIO

Control

Module (CM)

System I/O

Modules

1 SIO

1 DIO

(separate

Manual)

(separate

Manual)

CLD

(additional

CAT 200

TFID Analyzer

manuals)

(additional

manuals)

FID

Chapter 5 & 6:

The layout of both chapters is not as detailed as in chapter four:

Normally, the way to a certain menu of the CLD software is described

catchwords

you have to press to reach this menu. You will find the illustration of the

with the software

corresponding LCD screen at the end of the catchword listing. After that you can read the

meaning of the functions and variables of each expert or system configuration menu.

Note:

This software manual will describe the software of all CLD analyzer modules combined

with a platform, an MLT analyzer or a TFID analyzer. This includes also CAT 200

which is

a MLT 1 in an Ex d enclosure with a magnetically operated front panel. For CAT 200 an

addendum instruction manual

is offered for CAT specific issues.

CLD Analyzer Modules being operated with a customers control unit will not be described

in this manual.

For Network I/O Modules

separate manuals are available being used for detailed

information. This CLD software manual describes the Network I/O specific functions as

short form only.

Please consult our Service Support Center for more information!

HAS60E-IM-SW39 (2) [CLD Software 3.9.X] 07/05

NGA 2000

1 - 3

1 - 4

NGA 2000

HAS60E-IM-SW39 (2) [CLD Software 3.9.X] 07/05

2 Menu structure

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.9.x)] 04/04

NGA 2000

2 - 1

2 - 2

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.9.x)] 04/04

3 Startup and Operation, General Notes and Main Menu

3.1 Starting and Initializing

After switching on the CLD analyzer or analyzer module (in a platform or part of a NGA network), the

initialization procedure will be performed. A self control of the analyzer modules or the analyzer is

running. You can see a sequence of several displays. They show the status of initialization, revision

notes of the CLD software and the Emerson tag:

(C) 2004 EMERSON Process Management

NGA 2000 Control-Module Rev. 3.7.1 /P008

LCDReset Abort

F1

Language: P014/01/00

Initializing Network

Initializing network interface

F2

F3 F4

F5

After “Initializing network interface” the next display shows “Searching for nodes” followed by “Querying

module 1: CLD, x % complete”, “Searching for nodes” and “Calculating binds”.

If you press the F1 -key during the initializing, you will reset the LCD brightness and contrast to factory

settings (see also section 7). Pressing the F3 -key will abort the network initializing. Then you will have

no connection to any analyzer module. Only the menus of the control module (platform, MLT or TFID

analyzer) will be available.

At the end of the initializing procedure you can see the single component display of the CLD

analyzer module (see illustration on next page). It is the

origin to all the other channels, menus and

submenus.

The instructions of the basic controls (chapter four) all begin with the single component display. The

actual display might differ from the shown one because the customer can configure it according to his

requirements.

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

3 - 1

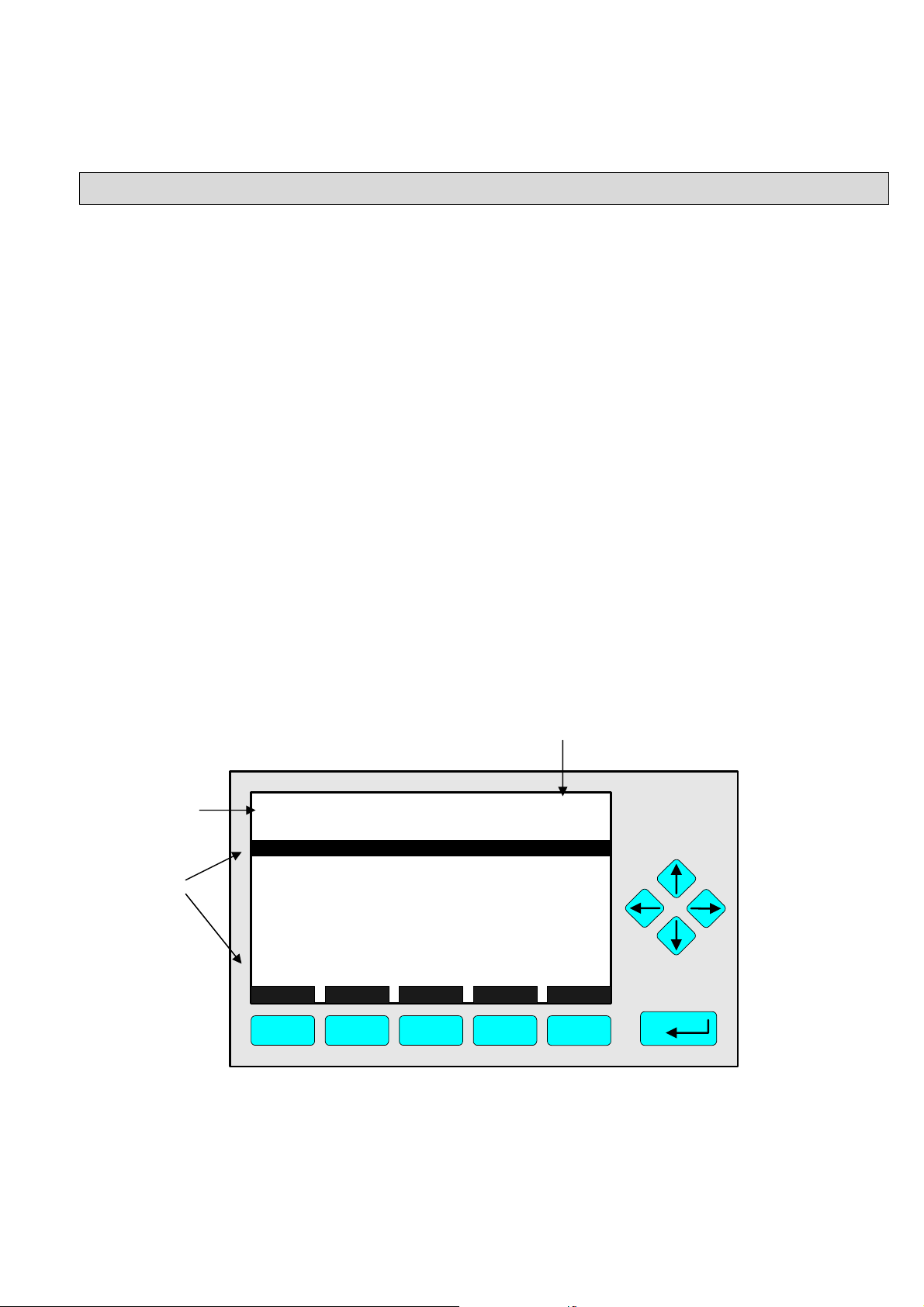

3.2 Display and Function

The LCD-screen shows all measurement values of the analyzer and all customer instruc-tions. You can

operate with five function keys, four arrow keys (cursors) and the enter key. The function of each key

depends on:

♦

the type of analyzer/analyzer module used

♦ the optional auxiliary modules (e.g. I/O boards) used

♦ the individual menu displayed

In case of power failure all customer specific module parameters are saved by a batterypowered buffer.

At the top left of each menu page you will find the tag of the current channel.

Typical tags:

♦ CLD-R1: CLD Analyzer or Analyzer Module, Range 1.

In this manual you will find normally "TAG" as general name. But in the specific CLD menu pages you

will find "CLD".

♦ CH1/NH3/R1: /

CHannel 1 / Gas: Ammonia / Range 1

System tag (factory setting: here, WO stands for "Work Order"

CLD_WO935077

95.0 ppm

95.00 ppm NOx

50

-1.5

45

150

F.S.

490

1.5

55

500

F5

0 Range: 4 250

Sample press.:

Detector temp.:

Block temp.:

Converter temp.:

Display... Status... Main... Channel BasicCal

F1

F2

340 hPa

0.5 C

51.5 C

360 C

F3 F4

Cursor keys:

↑ -key / ↓ -key:

♦ Line up / line down

within the same menu

♦ Alteration of numbers,

variables or digits

← -key/ → -key:

♦ Moving back/forwards

between the pages of

a menu

♦ Selection of digits

Function Keys:

♦ Keys without defined functions

♦ The current function depends on the

menu selected

♦ The softkey legend is shown on the

display above the key

3 - 2

NGA 2000

Enter Key:

♦ To confirm a previously entered

value (variable)

♦ To start a selected function

(

Alternative: → -key)

♦ To go into a menu (via menu line)

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

3 Startup and Operation, General Notes and Main Menu

y

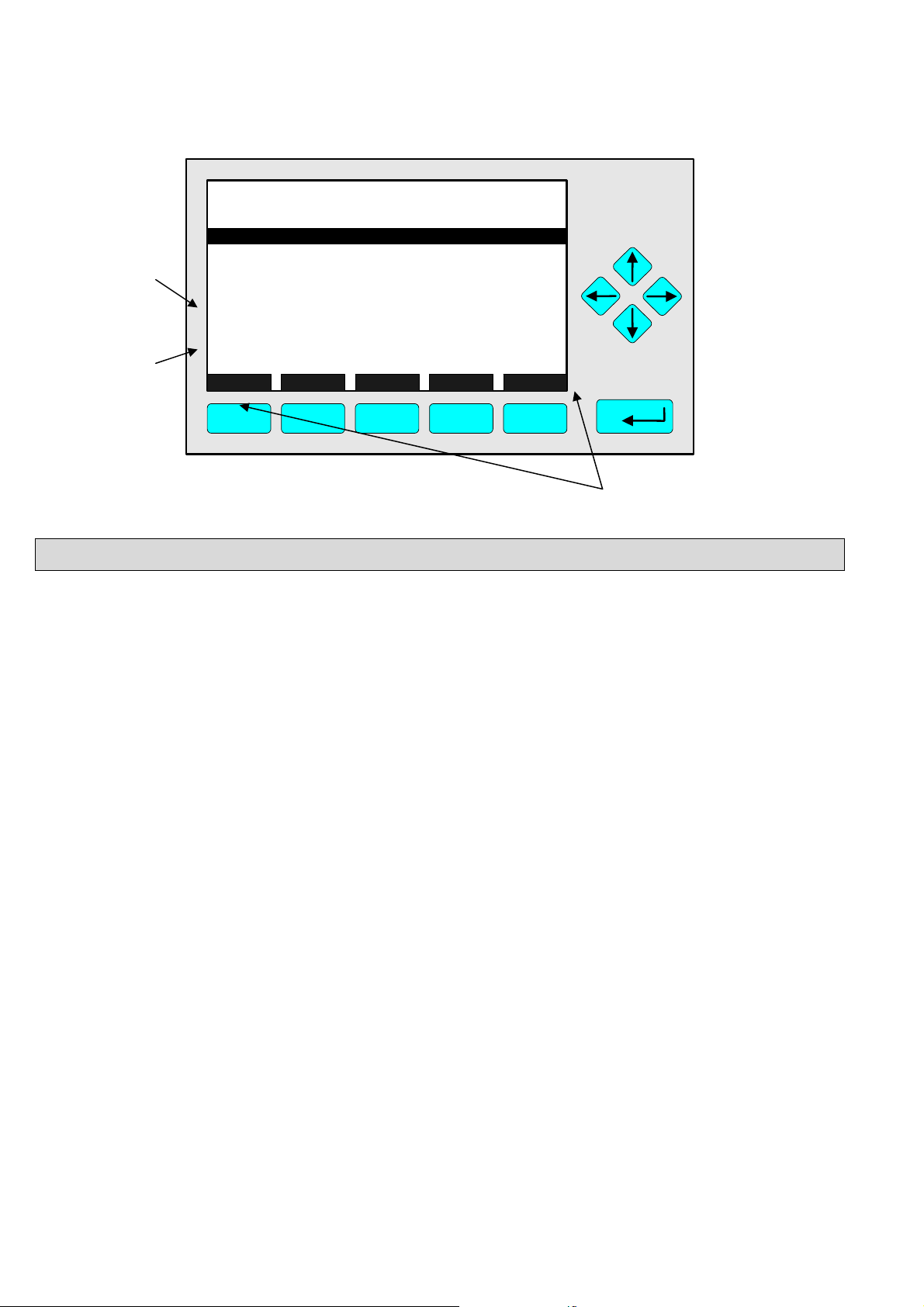

3.4 Lines and Softkey Functionality

Lines can be selected by the ↓ -key or the ↑ -key. The selected line is displayed white on black. You

have four different types of lines in the menu:

Menu line...

♦ Line ending with three dots.

♦ You will go to a submenu by pressing the ENTER key or the → -key in such a line.

Function line !

♦ Line ending with an exclamation-mark.

♦ You will start a function (e.g. NO/NO

the → -key in such a line.

Line of variables:

♦ Line ending with a colon.

♦ Display of module parameters (variables).

♦ Some parameters can be changed (e.g. range number), some parameters display only a

status (e.g. calibration status) and cannot be changed.

Text line

♦ Line without any punctuation marks.

♦ Only display of informations (e.g. analyzer module tag).

Signal of the current channel (see TAG).

Is always displayed on the single component

-toggle) by pressing the ENTER key or

x

displa

.

Text line

Lines of

variables

TAG

Basic Controls

Measurement range number:

Range upper limit:

Automatic range change control:

Ranges with valid calibration:

Calibration status:

Span gas concentration:

Status:

Measurement mode:

Ozonator status:

Ozonator power:

HOME NO/NOx ZERO SPAN INFO

F1

F2

F3 F4

95.0 ppm

250.0 ppm

Disabled

1&2&3&4

READY

0.0 ppm

STANDBY

NOx mode

Enabled

F5

4

ON

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

3 - 3

Function

line

Menu

line

TAG

Zero/span calibration

Measurement range number:

Zero gas concentration:

Span gas concentration:

Sample flo

Raw

Measur

NO/NOx toggle!

Status:

Result...

Calibrati

HOME FACTORS ZERO SPAN INFO

F1

w:

measurement signal:

ement gas:

on adjustment limits:

F2

F3 F4

95.0 ppm

1

0.0 ppm

100.0 ppm

1100 ml/min

528218.1

NO mode

READY

Disabled

F5

Function key legend

3.5 Important Functions of the Softkeys

DISPLAY

♦ Change from the single component display to the multi component display.

MEASURE

♦ Change from the main menu to the single component display.

STATUS (see 3.7)

♦ Change to the “Analyzer Channel Status" : Display of the most important parameters and

status informations of the CLD module or of the current channel.

♦ If available, this command is always assigned to the F2 -key.

MAIN

♦ Change from the single component display to the main menu.

CHANNEL

♦ Change of the channel in the same menu. This will only be possible, if several channels of an

analyzer or of combined analyzers are existing. Then, all available channels can be selected

one after another.

♦ In the main menu you can move among all channels of the connected analyzers and

analyzer modules. In the submenus you can only move among the channels of the current

analyzer or analyzer module.

ESCAPE or <<<

♦ Changing back to the last menu page selected.

♦ Reset of a changed but not confirmed parameter to the former value resp. to zero.

BACK

♦ Moving back to the last menu page selected (Alternative: ← -key) or

reset of a changed but not confirmed parameter to the former value.

3 - 4

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

3 Startup and Operation, General Notes and Main Menu

BasicCal

♦ Change from the single component display to the menu "Analyzer module calibration".

♦ F5 in the single component display.

LOCK

♦ Lock of any operation level, if activated. Each of the three operation levels has to be

activated separately.

♦ F4 in the main menu.

MFG Data (see section 8 pp. 8-1ff)

♦ Change from the main menu to the menu "Module Manufacturing Data":

Further submenus are available with information about the control module and analyzer

module data, such as address of the manufacturer, serial number of the modules or the

software and hardware revisions.

♦ F5 in the main menu.

Info

♦ Change from the single component display to the menu "Analyzer module calibration".

♦ F5 in the single component display.

More

♦ Changing to a further menu page.

3.6 Entering/Changing of Variables

ENTER Key

♦ If you will press this key in a line of variables, the parameter will be displayed white on black

and can be changed. After you will have set up a new value, you can confirm it by pressing

the ENTER key again.

↑ -key / ↓ -key

♦ Function will depend on the variable selected: - Changing of the parameter values

- Scrolling among variables selected

- Changing of digits or characters

♦ Increasing or decreasing of numbers.

← -key / → -key

♦ Selection of digits within a parameter.

♦ For some variables you can change the quantity of digits or characters.

3.7 The STATUS Key

From the single component display or from the main menu you can change with the

F2 -key (STATUS) to the menu "Current measurement parameters" (illustration on next page):

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

3 - 5

TAG

Current measurement parameters

Analyzer gas measured:

Measurement range number:

Range change control:

Linearization mode:

Analyzer operational state:

Analyzer alarm state:

Alarms reported:

Current total variable updates per second:

HOME ESCAPE MORE INFO

F1

F2

F3 F4

↓

TAG

Current measurement parameters

Response time:

Bypass flow:

Capilliary pressure:

Detector temperature:

95.0 ppm

NOx

3

Local

Disabled

STANDBY

NORMAL

FAILURE

24

F5

95.0 ppm

3.0 s

1100 ml/min

340 hPa

0.5 C

HOME ESCAPE MORE INFO

F1

F2

F3 F4

F5

In the menu "Current measurement parameters" you can control the status of the CLD analyzer

module. With the F3 -key (MORE) you can change to a further menu page of this menu. With

the F2 -key (ESCAPE) you can always go back to the main menu. From the second menu page

you can return to the first with the F4 -key (MORE) or the ← -key.

In the menu "Current measurement parameters" you will only find status information. You

cannot change the setups there. If you want to modify some parameters, you have to change to

the menu "Basic Controls" (see chapter 4) or to the menu "Analyzer module set up" (see

chapter 5.1) or "Analyzer module controls" (see chapter 5.3).

3.8 Main Menu

If you press the F3 -key (Main...) or the → -key in any single component display, you will change

to the "Main Menu". From there you can change to all operating levels of your CLD analyzer or

analyzer module to set up and control the parameters of measurement, calibration and data

transfer!

3 - 6

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

3 Startup and Operation, General Notes and Main Menu

p

Via the F5 -key (MFG Data) you can change to several submenus, where you will find a lot of

important data about the control module (CLD analyzer or platform) and the analyzer module,

such as service address or serial number!

Options from the Main Menu:

TAG

-- Main Menu --

Analyzer basic controls (calibration) & setup...

Analyzer and I/O, expert controls & setup...

System configuration and diagnostics...

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure Status... Channel Lock... MFG Data

F1

F2

F3 F4

14:03:25 May 02, 2005

F1

F2

F3

F4

Changing to the single component display of the

current channel

Changing to the menu "Current measurement

parameter" of the current channel

Scrolling through all channels of the connected

analyzers and analyzer modules

Lock of any operating level by security code

95.0 ppm

Emerson

F5

See chapter 4!

See chapter 5!

See chapter 6!

See chapter 7!

To setu

Factory Setting

Section 3.1 pp. 3-1/2!

Section 4.1 p. 4-3!

See channel tag!

Section 6.4 p. 6-31!

see 6.3 p. 6-29

F5

Changing to the menu "Module Manufacturing Data"

Section 8 pp. 8-1ff

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

3 - 7

3 - 8

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

4 Analyzer Basic Controls (Calibration) & Setup

Basic Controls

In chapter 4 "Analyzer basic controls (calibration) & setup " you will find the most important

functions to set up your CLD analyzer module via an NGA front panel:

1) Measurement pp. 4 - 3ff (Chapters 4.1.1 and 4.1.2, pp. 4-5 to 4-8, are only important

for systems with several channels.)

2) Calibration pp. 4 - 23ff

All the necessary steps are explained with detailed illustrations and operation instructions. The

left column shows the display and keyboard of the NGA front panel. The keys you have to

press are illustrated in black. Instructions and notes are in the right-hand column. All the

instructions begin and end with a single component display, so you can compare the actual

display of the analyzer or analyzer module with the illustrations in this manual. Instructions are

completed, where needed, with notes and further information.

Example: You want to change from the single component display of NOx to the main menu

• Picture one shows the starting situation: single component display of NO

• If you press the F3 -key you will change to menu page shown in picture 2: Main Menu.

.

x

Left column: Right column:

LCD and keyboard Instructions and notes

CLD_WO935077

95.00 ppm NOx

0 Range: 4 250

Sample press.:

Detector temp.:

Block temp.:

Converter temp.:

Display... Status... Main... Channel BasicCal

F1

TAG

A naly zer basic cont r ols (calibration) & setup...

Analyzer and I/O, expert controls & setup...

Sy stem configuration and diagnostics.. .

Display controls.. .

Time & Date: 14:01: 4 5 29 July 19 99

System tag:

Measure Status... Channel Lock... MFG Data

F1 F2 F3 F4 F5

0.5 C

51.5 C

360 C

50

-1.5

F.S.

45

150

340 hPa

F2

Emerson

F3 F4

-- Main M enu --

95.0 ppm

490

1.5

500

F5

95.00 ppm

55

⇒ Change to the

“Main Menu”

Press

or

⇒ Next instruction

Press

or

F3

or step,

here e.g.:

Change to the

“Basic controls”:

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

4 - 1

4 - 2

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

4.1 Analyzer Channel Status

Current Measurement parameters

CLD_WO935077

95.00 ppm NOx

0.5 C

51.5 C

360 C

50

-1.5

45

150

F.S.

0 Range: 4 250

Sample press.:

Detector temp.:

Block temp.:

Converter temp.:

Display... Status... Main... Channel BasicCal

F1

F2

340 hPa

F3 F4

95.0 ppm

490

1.5

55

500

F5

⇒ Change to the

menu "Current

measurement

parameters"

Press

In the menu "Current

measurement parameters"

you will find the main

measurement parameters

These can be controlled in

the various set up menus.

F2

TAG

Current measurement parameters

Analyzer gas measured:

Measurement range number:

Range change control:

Linearization mode:

Analyzer operational state:

Analyzer alarm state:

Alarms reported:

Current total variable updates per second:

HOME

F1

ESCAPE

F2

MORE

F3

95.0 ppm

NOx

3

Local

Disabled

STANDBY

NORMAL

FAILURE

24

INFO

F4 F5

⇒ Change to the

“Main Menu”

F1

Press

Notes:

• Press the F3 key

(“MORE”) for further

information about the

current measurement

parameters.

• Pressing the F2 -key

(“ESCAPE”) will also

take you to the “Main

Menu”.

TAG

-- Main Menu --

Analyzer basic controls (calibration) & setup...

Analyzer and I/O, expert controls & setup...

System configuration and diagnostics...

Display controls...

_____________________________________________

Time & Date:

System tag:

Measure

Status...

04:03:25 May 02, 2005

Channel Lock MFG Data

F1 F2 F3 F4 F5

95.0 ppm

Emerson

⇒ Change to the

single component

display

Press

F1

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

4 - 3

4 - 4

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

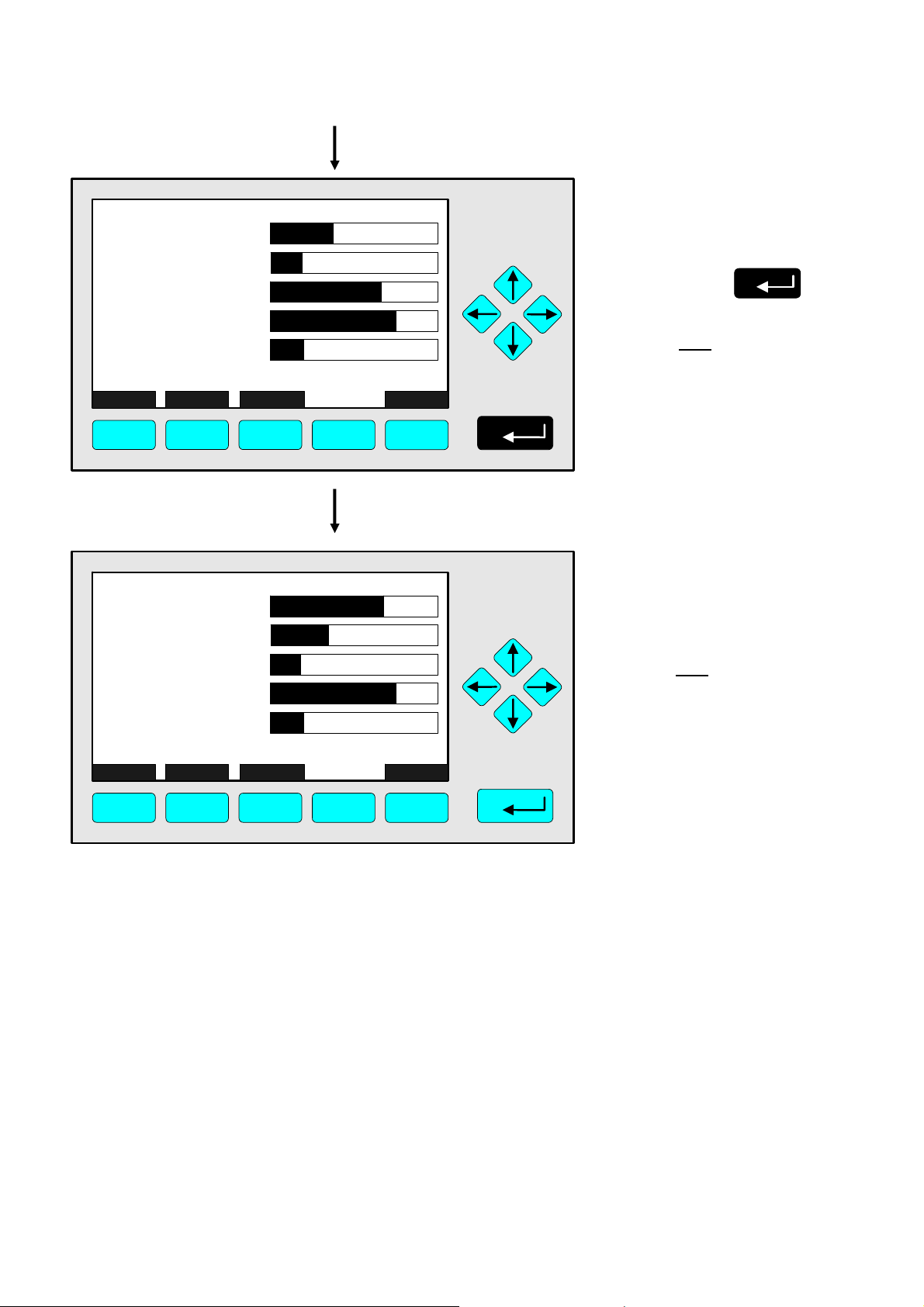

4.1.1 Measurement - Multi Component Display:

Change of channel

F2

0.5 C

360 C

50

-1.5

45

150

F.S.

340 hPa

51.5 C

F3 F4

CLD_WO935077

95.00 ppm NOx

0 Range: 4 250

Sample press.:

Detector temp.:

Block temp.:

Converter temp.:

Display... Status... Main... Channel BasicCal

F1

95.00

45.00

333.0

150.0

20.00

Select Status... Tags Off

F1 F2 F3 F4 F5

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

95.00

>

45.00

333.0

150.0

20.00

Select Status... Tags Off

F1

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

F2 F3 F4 F5

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

95.0 ppm

490

1.5

55

500

F5

10

10

10

10

10

LCDReset

10

10

10

10

10

LCDReset

⇒ Change to the single

component display

of the channel

selected

Press

F1

⇒ Enable the selecting:

">"

Press

F1

or

Note:

If no channels of other

analyzer modules are

combined to the CLD,

only the bargraph of the

CLD module will be displayed.

A change of channel will then

not be possible.

⇒ Select any channel

Press

or

as often as necessary to

put the > -mark into the

selected line.

Example:

Change from

NO

(CLD) to

X

CO (MLT channel 1)

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

4 - 5

95.00

>

45.00

333.0

150.0

20.00

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

10

10

10

10

10

⇒ Single component

display of the

channel selected

will appear

F1

Press

Select Status... Tags Off

F1 F2 F3 F4 F5

CLD_WO935077

45.00 ppm CO

0.5 C

51.5 C

360 C

50

-1.5

45

150

F.S.

0 Range: 4 250

Sample press.:

Detector temp.:

Block temp.:

Converter temp.:

Display... Status... Main... Channel BasicCal

F1

F2

340 hPa

F3 F4

LCDReset

95.0 ppm

490

1.5

55

500

F5

⇒ Single component

display of the

channel selected

will appear

4 - 6

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

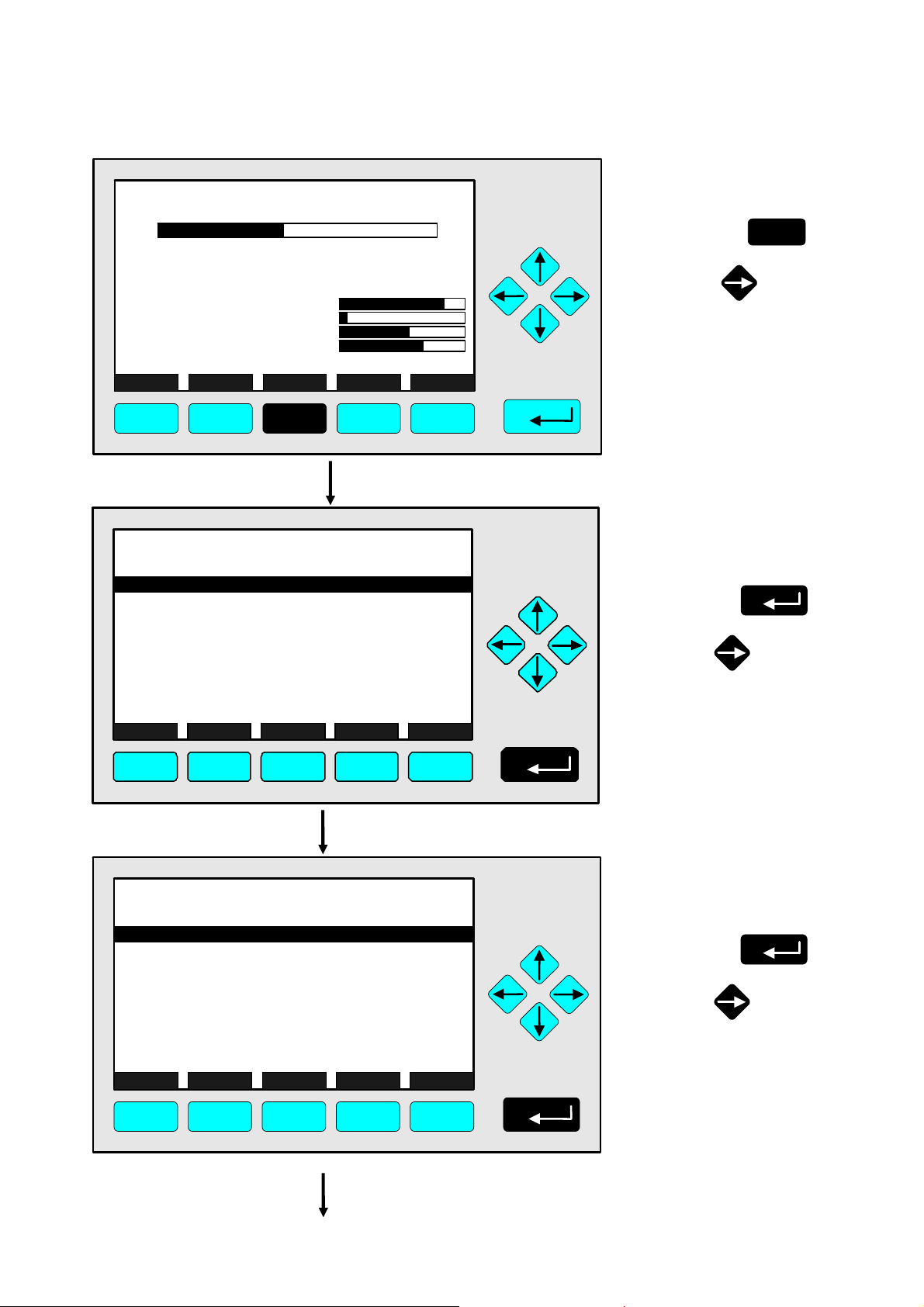

4.1.2 Measurement - Multi Component Display:

Sequence setup

F2

0.5 C

50

-1.5

45

150

F.S.

340 hPa

51.5 C

360 C

F3 F4

CLD_WO935077

95.00 ppm NOx

0 Range: 4 250

Sample press.:

Detector temp.:

Block temp.:

Converter temp.:

Display... Status... Main... Channel BasicCal

F1

95.00

45.00

333.0

150.0

20.00

Select Status... Tags Off

F1 F2 F3 F4 F5

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

95.00

>

45.00

333.0

150.0

20.00

Select Status... Tags Off

F1

MLT25/CH1/R2

MLT25/CH2/R2

MLT25/CH3/R2

MLT25/CH4/R2

F2 F3 F4 F5

CLD

ppm NOx

ppm CO

ppm SO2

ppm NO

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

95.0 ppm

490

1.5

55

500

F5

10

10

10

10

10

LCDReset

10

10

10

10

10

LCDReset

⇒ Change to the multi

component display

F1

Press

⇒ Enable the selecting:

">"

Press

F1

or

Note:

If no channels of other

analyzer modules are

combined to the CLD,

only the bargraph of the

CLD module will be displayed.

The sequence setup will then

not be possible.

⇒ Select the channel

for position one

Press or

as often as necessary to

put the > -mark into the

selected line.

Example:

MLT channel 2 (SO

appear at position one of the

multi component display.

) will

2

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

4 - 7

95.00

45.00

333.0

>

150.0

20.00

Select Status... Tags Off

F1

ppm NOx

MLT25/CH1/R2

MLT25/CH2/R2

ppm SO2

MLT25/CH3/R2

MLT25/CH4/R2

F2 F3 F4 F5

CLD

ppm CO

ppm NO

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

10

10

10

10

10

LCDReset

⇒ Assignment of the

selected channel to

position one

Press

Note:

The channel selected will

appear at position one.

All the other channels will

automatically appear one

line below their previous

position.

333.0

95.00

45.00

150.0

20.00

Select Status... Tags Off

F1

MLT25/CH2/R2

ppm SO2

ppm NOx

MLT25/CH1/R2

MLT25/CH3/R2

MLT25/CH4/R2

F2 F3 F4 F5

CLD

ppm CO

ppm NO

%O2

0

0

0

0

0

[1]

[2]

[3]

[4]

[5]

10

10

10

10

10

LCDReset

⇒ Multi component

display will appear

with the changed

sequence

Note:

Now you can change

to any available single

component display.

The method is described in

the previous chapter

(4.1.1).

4 - 8

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

4.1.3 Measurement - Range Setting

F2

0.5 C

360 C

50

-1.5

45

150

F.S.

340 hPa

51.5 C

F3 F4

CLD_WO935077

95.00 ppm NOx

0 Range: 4 250

Sample press.:

Detector temp.:

Block temp.:

Converter temp.:

Display... Status... Main... Channel BasicCal

F1

TAG

-- M ain Menu --

Analyz er basic cont r ols (calibration) & setup.. .

Analyz er and I/O, exper t c ontrols & setup...

Syst em conf iguration and diagnostics...

Di spl ay cont r ols...

_____________________________________________

Time & Date:

Sy stem tag:

Measure

F1

Status...

F2

F3

04:03: 25 May 02, 2005

Channel

Lock

F4

TAG

Basic Controls

Measurement range number:

Range upper limit:

Automatic range control:

Ranges with valid calibration:

Calibration status:

Span gas concentration:

Status:

Measurement mode:

Ozonator status:

Ozonator power:

HOME NO/NOx ZERO SPAN INFO

F1 F2 F3 F4 F5

95.0 ppm

490

1.5

55

500

F5

95.0 ppm

Emerson

MFG Data

F5

95.0 ppm

250.0 ppm

Disabled

1&2&3&4

READY

0.0 ppm

STANDBY

NOx mode

On

Enabled

⇒ Change to the

“Main Menu”

Press

F3

or

⇒ Change to

“Analyzer Basic

Controls”

Press

or

4

⇒ Choose

“Measurement

range number”

Press

or

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

4 - 9

TAG

Basic Controls

Measurement range number:

Range upper limit:

Automatic range control:

Ranges with valid calibration:

Calibration status:

Span gas concentration:

Status:

Measurement mode:

Ozonator status:

Ozonator power:

Back...

95.0 ppm

4

250.0 ppm

Disabled

1&2&3&4

READY

0.0 ppm

STANDBY

NOx mode

On

Enabled

F1 F2 F3 F4 F5

⇒ Select the

range number

Press

or

as often as necessary

to select another range

number.

Example:

Change from

range 4 (250 ppm) to

range 3 (100 ppm)

TAG

Basic Controls

Measurement range number:

Range upper limit:

Automatic range control:

Ranges with valid calibration:

Calibration status:

Span gas concentration:

Status:

Measurement mode:

Ozonator status:

Ozonator power:

Back...

95.0 ppm

3

250.0 ppm

Disabled

1&2&3&4

READY

0.0 ppm

STANDBY

NOx mode

On

Enabled

F1 F2 F3 F4 F5

⇒ Confirm the

range selected

Press

Note:

If you don't want to set the

new range number, you

can reactivate the former

selection:

Press

F2

TAG

Basic Controls

Measurement range number:

Range upper limit:

Automatic range control:

Ranges with valid calibration:

Calibration status:

Span gas concentration:

Status:

Measurement mode:

Ozonator status:

Ozonator power:

HOME NO/NOx ZERO SPAN INFO

95.0 ppm

250.0 ppm

Disabled

1&2&3&4

READY

0.0 ppm

STANDBY

NOx mode

Enabled

3

On

F1 F2 F3 F4 F5

⇒ Change to the

“Main Menu”

Press

2 times

Note:

The range upper limit (line 2)

of the range selected will be

set up automatically after the

range setting is confirmed.

F1

or

4 - 10

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

4.1.3 Measurement - Range Setting

TAG

-- M ain Menu --

Analyz er basic cont r ols (calibration) & set up...

A nalyzer and I/O, expert controls & setup...

Syst em conf iguration and diagnostics...

Di spla y cont r ols...

_____________________________________________

Time & Date:

Sy stem tag:

Measure

F1

Status...

F2

F3

04:03: 25 May 02, 2005

Channel

Lock

F4

F2

0.5 C

360 C

50

-1.5

45

150

F.S.

340 hPa

51.5 C

F3 F4

CLD_WO935077

95.00 ppm NOx

0 Range: 3 100

Sample press.:

Detector temp.:

Block temp.:

Converter temp.:

Display... Status... Main... Channel BasicCal

F1

95.0 ppm

Emerson

MFG Data

F5

95.0 ppm

490

1.5

500

F5

55

⇒ Change to the single

component display

F1

Press

⇒ Singe component

display will appear

with the new range.

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

NGA 2000

4 - 11

4 - 12

NGA 2000

HAS6OE-IM-SW39(1) [NGA-e (CLD-Software 3.7.x)] 04/04

Loading...

Loading...