Rosemount Manual: IMPS 4000 Intelligent Multiprobe Test Gas Sequencer | Rosemount Manuals & Guides

IMPS 4000

Intelligent Multiprobe

Test Gas Sequencer

HIGHLIGHTS OF CHANGES

Page Summary

Effective July 2016 - Rev. 3

General Removed Rosemount Analytical logo. Changed revision number and release date.

Cover Updated revision number and release date. Removed Rosemount Analytical logo.

2-4 Revised step 3 to include information on Xi and 6888Xi.

2-5 Revised Figure 2-3 to include Xi and 6888Xi.

3-6 and 3-7 Revised Automatic Calibration instructions to include expanded autocalibration setup

details for Oxymitter and new setup details for X-STREAM.

3-7 Added new section: 6888A Oxygen Transmitter with 6888Xi.

Updated Semi-Automatic Calibration introductory paragraph to include 6888Xi.

Added new section: 6888Xi Keypad.

4-1 Edited Overview paragraph to include 6888Xi.

Back Cover Updated company addresses, URL, and disclaimer.

Added social media information and Rosemount logo.

4000 IMPS

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

Table of Contents

Essential

Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Technical Support Hotline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

SECTION 1

Description and

Specifications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Component Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

System

Overview

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Physical

Description

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Theory of

Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Z-Purge

Option

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

SECTION 2

Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Gas

Connections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Electrical

Connections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

SECTION 3

Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Calibration

Requirements

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Operator Interface Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Membrane

Keypad

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Using The Operator

Interface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Selecting a Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Changing a Typical

Parameter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Test Gas Flow

Setup

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Automatic Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Semi-Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

SECTION 4

Troubleshooting

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibration

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

PLC I/O LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Instruction Manual

IM-106-4000 IMPS, Rev 3

July 2016

TOC-2

4000 IMPS

SECTION 5

Maintenance and Service

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

PLC Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Operator Interface Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Solenoid Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Pressure Regulator Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Pressure Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Condensation Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Flowmeter

Adjustments

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Reference Gas Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Test Gas

Flowmeter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

SECTION 6

Replacement Parts

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

APPENDIX A

Safety Data

Safety

Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

APPENDIX B

Return of Material

Returning Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

Intelligent Mutiprobe Test Gas Sequencer

READ THIS PAGE BEFORE PROCEEDING!

ESSENTIAL

INSTRUCTIONS

Emerson Process Management designs, manufactures and tests its products

to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly

install, use, and maintain them to ensure they continue to operate within

their normal specifications. The following instructions MUST be adhered to

and integrated into your safety program when installing, using, and

maintaining Emerson’s Rosemount Analytical products. Failure to follow the

proper instructions may cause any one of the following situations to occur:

Loss of life; personal injury; property damage; damage to this instrument; and

warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the

product.

• If you do not understand any of the instructions, contact your

Emerson Process Management representative for clarification.

• Follow all warnings, cautions, and instructions marked on and

supplied with the product.

• Inform and educate your personnel in the proper installation,

operation, and maintenance of the product.

• Install your equipment as specified in the Installation Instructions

of the appropriate Instruction Manual and per applicable local and

national codes. Connect all products to the proper electrical and

pressure sources.

• To ensure proper performance, use qualified personnel to install,

operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Emerson Process Management.

Unauthorized parts and procedures can affect the product's

performance, place the safe operation of your process at risk, and

VOID YOUR WARRANTY. Look-alike substitutions may result in fire,

electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers

are in place, except when maintenance is being performed by

qualified persons, to prevent electrical shock and personal injury.

The information contained in this document is subject to change without

notice.

Instruction Man

ual

IM-103-400A, Rev. 3

July 2016

ii

4000 IMPS

PREFACE The purpose of this manual is to provide information concerning the

components, functions, installation and maintenance of the IMPS 4000

Intelligent Multiprobe Test Gas Sequencer.

DEFINITIONS The following definitions apply to WARNINGS, CAUTIONS, and

NOTES

found throughout this publication.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of

effectiveness.

NOTE

Highlights an essential operating procedure, condition, or statement.

SYMBOLS

:

EARTH

(GROUND)

TERMINAL

:

PROTECTIVE CONDUCT

OR TERMINAL

:

RISK OF ELECTRICAL SHOCK

:

WARNING: REFER TO

INSTRUCTION

MANUAL

NOTE TO USERS

The number in the lower right corner of each illustration in this publication is a

manual illustration number. It is not a part number, and is not related to the

illustration in any technical manner.

TECHNICAL SUPPORT

HOTLINE

For assistance with technical problems, please call the Customer Support

Center (CSC). The CSC is staffed 24 hours a day, 7 days a week.

Phone: 1-800-433-6076 1-440-914-1261

In addition to the CSC, you may also contact Field Watch. Field Watch

coordinates Emerson Process Management’s field service throughout the

U.S. and abroad.

Phone: 1-800-654-RSMT (1-800-654-7768)

Emerson Process Management may also be reached via the Internet through

e-mail and the World Wide Web:

e-mail: GAS.CSC@emerson.com

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

Section 1 Description and Specifications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Component Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-4

Z-Purge Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-5

INTRODUCTION The Rosemount Analytical IMPS 4000 Intelligent Multiprobe Test Gas

Sequencer is used with the Oxymitter 4000 or the X-STREAM Oxygen

Transmitter. The IMPS 4000 has the intelligence to provide test gas

sequencing of up to four oxygen transmitters to accommodate automatic and

semi-automatic calibration routines. Table 1-1 lists the available IMPS 4000

versions.

NOTE

The IMPS 4000 Intelligent Multiprobe Test Gas Sequencer operates the same

when used with the Oxymitter 4000 or the X-STREAM O2 Transmitter with

HART or FOUNDATION fieldbus Communications. References to the

Oxymitter 4000 or the X-STREAM O2 Transmitter throughout this instruction

manual also include the Oxymitter 5000 and the X-STREAM O2 Transmitter

with FOUNDATION fieldbus Communications.

Table 1-1. IMPS 4000 Versions

Part Number Description Number of O2 Transmitters

3D39695G01 IMPS 1

3D39695G02 IMPS 2

3D39695G03 IMPS 3

3D39695G04 IMPS 4

3D39695G05 IMPS w/115 V Heater 1

3D39695G06 IMPS w/115 V Heater 2

3D39695G07 IMPS w/115 V Heater 3

3D39695G08 IMPS w/115 V Heater 4

3D39695G09 IMPS w/220 V Heater 1

3D39695G10 IMPS w/220 V Heater 2

3D39695G11 IMPS w/220 V Heater 3

3D39695G12 IMPS w/220 V Heater 4

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

1-2

COMPONENT

CHECKLIST

A typical IMPS 4000 should contain the items shown in Figure 1-1. Record

the part number, serial number, and order number for the IMPS 4000 on the

back cover of this manual.

Figure 1-1. Typical System Package

1. Instruction Manual

2. IMPS 4000

SYSTEM OVERVIEW

Physical Description The main components of the IMPS 4000 are housed in a NEMA 4X (IP56)

enclosure for use in non-hazardous areas.

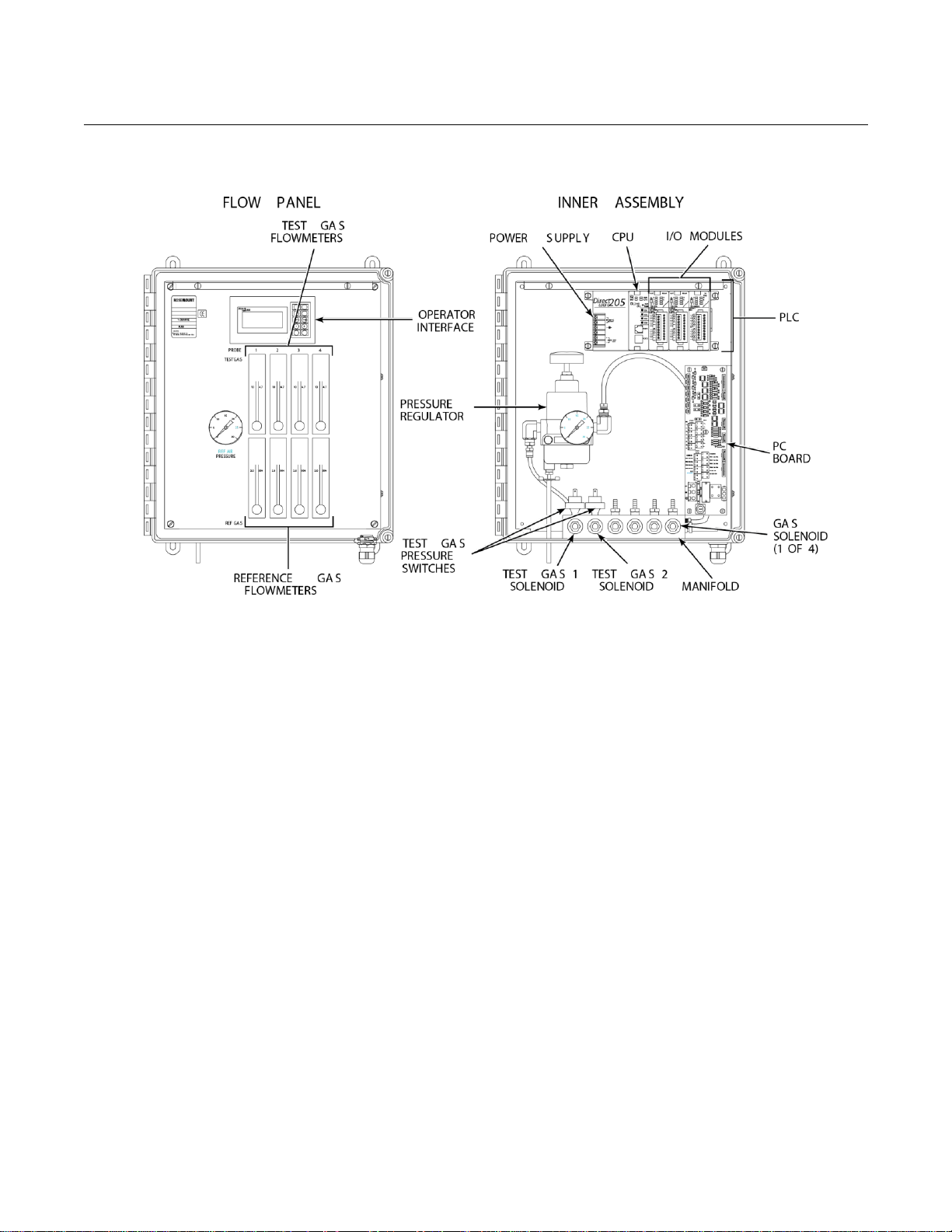

The main internal components include the flow panel and the inner assembly.

Flow Panel (Figure 1-2)

The Programmable Logic Controller (PLC) operator interface and the

reference and test gas flowmeters are mounted to the flow panel.

1. The PLC operator interface allows you to set up time-sequenced

calibration routines for up to four oxygen transmitters. It also allows you

to initiate a semi-automatic calibration.

2. Four sets of test gas and reference gas flowmeters are mounted on the

flow panel. One set of flowmeters is available for each of the four

oxygen transmitters that can be attached to the IMPS 4000. The test

gas flowmeter indicates the amount of test gas sent to the oxygen

transmitter. The reference gas flowmeter indicates the amount of

reference air flowing to the oxygen transmitter.

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

1-3

Figure 1-2. IMPS Components

Inner Assembly

The inner assembly consists of the PLC, PC board, pressure regulator, gas

solenoids, test gas pressure switches, and heater.

1. The PLC consists of a power supply, Central Processing Unit (CPU),

and three I/O modules.

a. The power supply supplies the voltage and current needed to

operate the IMPS 4000.

b. The CPU controls most system operations. It contains the program

memory in which the information entered into the PLC operator

interface is stored, and it processes the I/O signals received from the

I/O modules.

c. The I/O modules are terminated on the PC board. They receive and

send signals between the PLC and PC board for communication

between the oxygen transmitter and the IMPS 4000.

2. The PC board contains all wiring connections for up to four oxygen

transmitters.

3. The pressure regulator ensures the instrument air (reference gas)

flowing to the oxygen transmitter is at a constant pressure. The

regulator also has a drain valve that drains excess moisture from the

internal gas circuit.

4. The manifold can have up to six solenoids: test gas 1 solenoid, test gas

2 solenoid, and a gas solenoid for each oxygen transmitter connected to

the IMPS 4000. The solenoids activate and deactivate to allow test gas

to flow between the IMPS 4000 and an oxygen transmitter.

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

1-4

5. The pressure switches detect if the pressure of a test gas is low, which

can be caused by an empty gas bottle, a disconnected gas line, etc.

Calibration is prohibited when test gas pressure is low.

6. The heater keeps the components in the ambient temperature range to

prevent electronic malfunction.

THEORY OF OPERATION Reference Figure 1-3. When a calibration is initiated, via the IMPS,

HART/AMS, oxygen transmitter, or remote location, the signal is sent to the

IMPS 4000 PLC. The PLC first energizes the oxygen transmitter solenoid and

then energizes the test gas 1 (high gas) solenoid. Test gas 1 flows through the

IMPS 4000 to the oxygen transmitter. The oxygen transmitter measures the

oxygen content of test gas 1 and sends a signal to the IMPS 4000 indicating

that it received test gas 1. When the IMPS 4000 receives the signal, the PLC

deenergizes the test gas 1 solenoid.

Figure 1-3. IMPS Calibration Setup

1-5

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

After a time delay that allows test gas 1 to clear the system, the PLC

energizes the test gas 2 (low gas) solenoid. Test gas 2 flows through the

IMPS 4000 to the oxygen transmitter. The oxygen transmitter measures the

oxygen content of test gas 2 and sends a signal to the IMPS 4000 indicating

that it received test gas 2. After measuring the two test gases, the oxygen

transmitter automatically makes the internal calibration adjustment and sends

the signal to the IMPS 4000. When the IMPS receives the signal, the PLC

deenergizes the test gas 2 solenoid and the oxygen transmitter solenoid.

Whether or not the calibration passes or fails displays on the PLC operator

interface.

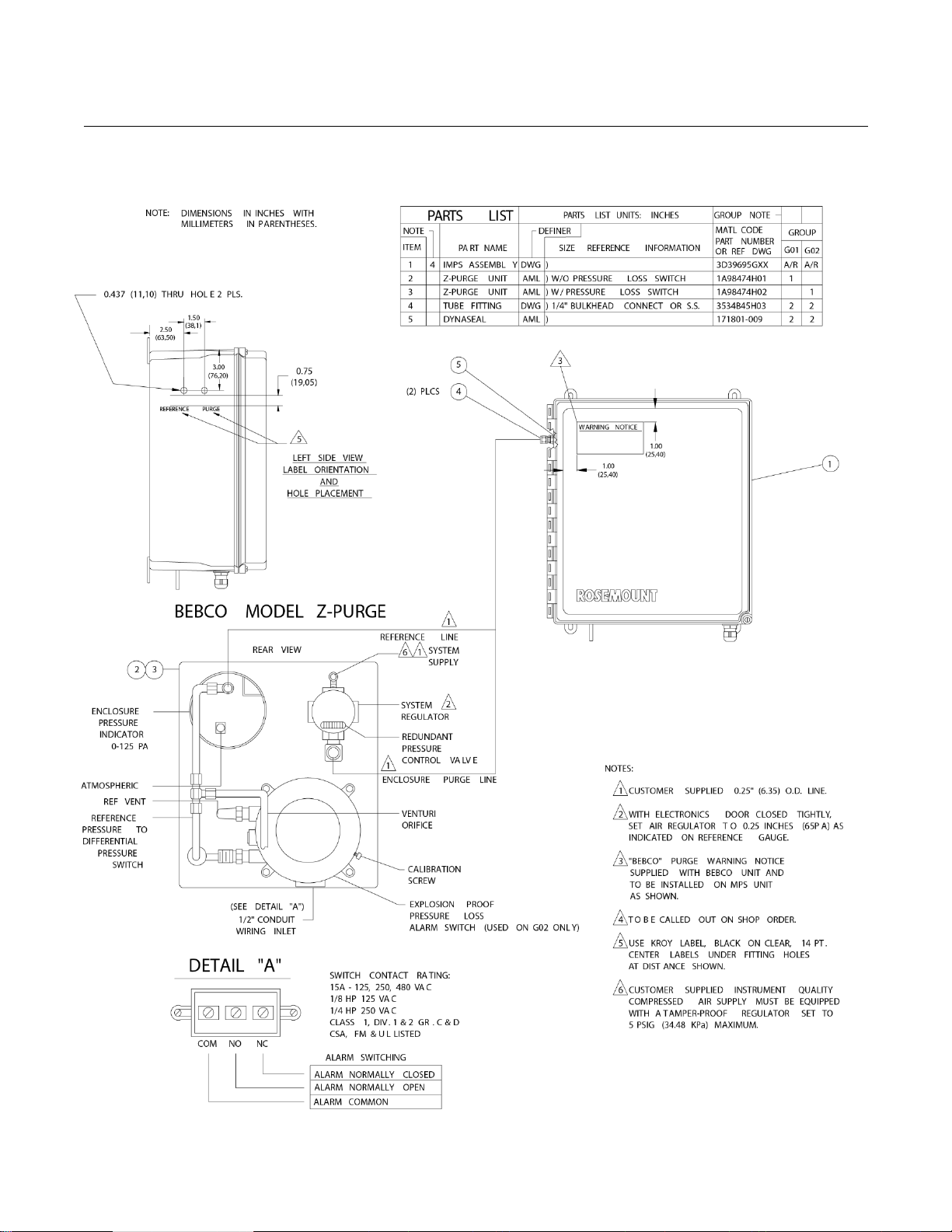

Z-PURGE OPTION Some IMPS applications have area safety requirements (Class 1, Division 2).

These requirements may be satisfied with the installation of an optional

Z-purge. The Z-Purge provides positive pressure within the IMPS 4000

enclosure to keep out dust and other foreign matter. Figure 1-4 shows the

Z-purge unit and how it connects to the IMPS 4000.

SPECIFICATIONS

Feature Specification

Electrical Classification NEMA 4X (IP56)

Humidity Range 95% Relative Humidity

Ambient Temperature Range*

Input

Power*

w/o Heater Option

w/ Heater Option

w/o Heater Option

32° to 131°F (0° to 55°C)

-35° to 131°F (-37° to 55°C)

90 to 250 V, 50/60 Hz, 50 VA

w/ 115 V Nominal Heater (Optional)

w/ 220 V Nominal Heater (Optional)

115 V Nominal, 50/60 Hz, 200 VA

230 V Nominal, 50/60 Hz, 200 VA

External Electrical Noise Minimum Interference

Handshake Signal to/from Oxygen

Transmitter (Self-Powered)

Cal Initiate Contact Input from

5 V (5 mA Maximum)

Control Room (One per Probe) 24 VDC (Self-Powered)

Relay Outputs to Control

Room (One

"In-Cal" per Probe, "Low Gas

Flowing," "High Gas Flowing,

"One "Cal Failed" per Probe,

"Gas Pressure Low"

Cabling Distance Between IMPS 4000

and Oxygen Transmitter

Cabling Distance Between IMPS 4000

and Customer-Supplied Status

Relay I/O in Control Room

Piping Distance Between IMPS 4000

and Oxygen Transmitter

5 to 30 VDC Form A (SPST),

1.5 A per point, 3 A total per common

1000 ft (303 m) Maximum

1000 ft (303 m) Maximum

300 ft (91 m) Maximum

Approximate Shipping Weight 40 lbs (18 kg)

*If using the heater option, the low temperature value of the ambient temperature range may vary depending on

the input voltage supply.

1-6

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

Figure 1-4. IMPS 4000 with

Z-Purge

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

Section 2 Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-3

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-6

OVERVIEW This section describes the installation requirements for the IMPS 4000

Intelligent Multiprobe Test Gas Sequencer.

Before starting to install this equipment, read the “Safety Instructions for the Wiring and

Installation of this Apparatus” in Appendix A of this Instruction Manual. Failure to follow the

safety instructions could result in injury or death.

Install all protective equipment covers and safety ground leads after installation. Failure to

install covers and ground leads could result in serious injury or death.

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

2-2

MECHANICAL

INSTALLATION

The outline drawing in Figure 2-1 shows mounting centers and clearances for

the IMPS 4000. The unit is designed to mount on a wall or bulkhead. Ensure

the unit is installed according to the following instructions.

1. Install the module no further than 300 ft (91 m) from the probe and no

further than 1000 ft (303 m) from a remote connection or from the status

relay indicators.

2. Locate units without the optional heater where the ambient temperature

is between 32° and 131°F (0° and 55°C). For units with the optional

heater, install where the ambient temperature is between -35° and

131°F (-37° and 55°C).

Figure 2-1. Mounting Dimensions

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

2-3

GAS CONNECTIONS Gas connections are located on the bottom of the IMPS 4000 and are 1/8-27

NPT fittings (Figure 2-2). Use the following procedure to connect the test

gases:

1. Connect the reference air supply to INSTR AIR. The pressure regulator

valve is set at the factory to 20 psi (138 kPa). If necessary, readjust by

turning the knob on the top of the valve until the desired pressure is

obtained.

2. Connect the O2 test gas 1 to HIGH CAL GAS IN. The test gas pressure

should be set at 20 psi (138 kPa).

3. Connect the O2 test gas 1 to LOW CAL GAS IN. The test gas pressure

should be set at 20 psi (138 kPa).

4. Connect the oxygen transmitter REF GAS to REF AIR OUT.

5. Connect the oxygen transmitter CAL GAS to TEST GAS OUT.

Figure 2-2. Gas Connections

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

2-4

ELECTRICAL

CONNECTIONS

All wiring must conform to local and national codes. Refer to Figure 2-3 and

use the following procedure to connect the first oxygen transmitter. Repeat

the procedure for each remaining oxygen transmitter.

1. Run the line voltage through the bulkhead fitting on the bottom of the

IMPS 4000 marked LINE IN. Connect the line voltage to the J24

terminal. The power supply automatically adjusts to the input voltage.

Tighten the cord grips to provide strain relief.

2. When connecting an Oxymitter O2 Transmitter, run the handshake logic

I/O wires for each oxygen transmitter through a bulkhead fitting on the

bottom of the IMPS 4000 marked SIGNAL IN. Dedicate one fitting for

each oxygen transmitter. Connect the oxygen transmitter logic I/O wires

as shown in Figure 2-3.

3. When connecting an XI or 6888XI electronics, run the handshake

signal wires from connector J3 of the Xi or 6888Xi I/O board through

a bulkhead fitting on the bottom of the IMPS 4000 marked SIGNAL

IN. Dedicate one fitting for each oxygen transmitter. Connect the

oxygen transmitter handshake signal wires as shown in Figure 2-3.

4. To set up the IMPS 4000 to initiate a calibration from a remote location,

run the remote contact input wires through the SIGNAL IN bulkhead

fitting. Connect the remote contact input wires as shown in Figure 2-3.

5. Status relay connections are available on the IMPS 4000 PC board to

signal when the oxygen transmitter is in or out of calibration and to

indicate calibration gas status. Status relays can be connected to either

indicator lights or a computer interface. Relay contacts are capable of

handling up to 5 to 30 V, 1.5 A per point, 3.0 A total per common

maximum power source. Cabling requirement is 1000 ft (303 m)

maximum. Make the status relay switch connections as shown in

Figure 2-3.

2-5

Instruction

Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

Figure 2-3. Electrical

Connections

2-6

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

SWITCH

SETTINGS

Figure 2-4. RUN/TERM

Switch

Settings

The PLC RUN!TERM switch must be in the TERM position for

proper

operation. When the RUN!TERM switch is in the RUN position, the PLC

will

display an "E525 Keyswitch" error message. Refer to Figure 2-4 and

verify

that the RUN!TERM switch is in the RUN position.

RUN/TERM

SWITCH

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

Section 3 Operation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Calibration Requirements . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Operator Interface Description . . . . . . . . . . . . . . . . . . . . . page 3-2

Message Display Mode Parameters . . . . . . . . . . . . . . . . . page 3-5

Test Gas Flow Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-6

Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-6

Semi-Automatic Calibration . . . . . . . . . . . . . . . . . . . . . . . . page 3-7

OVERVIEW This section specifies the requirements to set up an oxygen transmitter

calibration. It describes the PLC operator interface and explains how to set up

time-sequenced calibration routines for up to four oxygen transmitters using

the IMPS 4000. This section also explains the differences between automatic

and semi-automatic calibrations and how to initiate them.

CALIBRATION

REQUIREMENTS

The following components are required for an oxygen transmitter calibration

using the IMPS 4000:

1. Two tanks of precision calibration gas mixtures are required.

Recommended calibration gases are nominally 0.4% and 8.0% oxygen

in nitrogen. Two sources of calibrated gas mixtures are:

LIQUID CARBONIC GAS CORP.

SPECIALTY GAS LABORATORIES

700 South Alameda Street

Los Angeles, California 90058

213/585-2154

767 Industrial Road

San Carlos, California 94070

415/592-7303

9950 Chemical Road

Pasadena, Texas 77507

713/474-4141

12054 S.W. Doty Avenue

Chicago, Illinois 60628

312/568-8840

603 Bergen Street

Harrison, New Jersey 07029

201/485-1995

255 Brimley Road

Scarborough, Ontario, Canada

416/266-3161

Instruction Manual

IM-106-400 IMPS, Rev. 3

July 2016

4000 IMPS

3-2

SCOTT ENVIRONMENTAL

TECHNOLOGY, INC.

SCOTT SPECIALTY GASES

2600 Cajon

Blvd.

San Bernardino, California 92411

714/887-2571

TWX:

910-390-1159

1290 Combermere Street

Troy, Michigan

48084

314/589-2950

Route

611

Plumsteadville, Pennsylvania 18949

215/766

8861

TWX:

510-665-9344

2616 South Loop

West

Suite

100

Houston, Texas 77054

713/669-0469

2. A check valve is required at the oxygen transmitter (between the

calibration fitting and the gas line) to prevent the migration of process

gases down the calibration gas line. A typical calibration setup is shown

in Section 1, Figure 1-3 of this manual.

OPERATOR INTERFACE

DESCRIPTION

See Figure 3-1. The operator interface consists of a membrane keypad and a

4-line, 16-character, backlit LCD display. The LCD display is divided into two

areas. The left side is a descriptive field that identifies the calibration

parameter. The right side shows the current value or status of the calibration

parameter.

Figure 3-1. Operator Interface

Loading...

Loading...