FCL with 54eA Analyzer

Instruction Manual

PN 51-FCL-54eA rev.B

March 2012

This product generates, uses, and can radiate radio frequency

energy and thus can cause radio communication interference.

Improper installation, or operation, may increase such interfer-

ence. As temporarily permitted by regulation, this unit has not

been tested for compliance within the limits of Class A computing

devices, pursuant to Subpart J of Part 15, of FCC Rules, which

are designed to provide reasonable protection against such

interference. Operation of this equipment in a residential area

may cause interference, in which case the user at his own

expense, will be required to take whatever measures may be

required to correct the interference.

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Your purchase from Rosemount Analytical, Inc. has

resulted in one of the finest instruments available for

your particular application. These instruments have

been designed, and tested to meet many national

and international standards. Experience indicates

that its performance is directly related to the quality

of the installation and knowledge of the user in operating and maintaining the instrument. To ensure

their continued operation to the design specifications, personnel should read this manual thoroughly

before proceeding with installation, commissioning,

operation, and maintenance of this instrument. If

this equipment is used in a manner not specified by

the manufacturer, the protection provided by it

against hazards may be impaired.

• Failure to follow the proper instructions may

cause any one of the following situations to

occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Ensure that you have received the correct model

and options from your purchase order. Verify that

this manual covers your model and options. If

not, call 1-800-854-8257 or 949-757-8500 to

request correct manual.

• For clarification of instructions, contact your

Rosemount representative.

• Follow all warnings, cautions, and instructions

marked on and supplied with the product.

• Use only qualified personnel to install, operate,

update, program and maintain the product.

• Educate your personnel in the proper installation,

operation, and maintenance of the product.

• Install equipment as specified in the Installation

section of this manual. Follow appropriate local

and national codes. Only connect the product to

electrical and pressure sources specified in this

manual.

• Use only factory documented components for

repair. Tampering or unauthorized substitution of

parts and procedures can affect the performance

and cause unsafe operation of your process.

• All equipment doors must be closed and protective covers must be in place unless qualified personnel are performing maintenance.

• If this equipment is used in a manner not specified by the manufacturer, the protection provided

by it against hazards may be impaired.

Equipment protected throughout by double insulation.

• Installation of cable connections and servicing of this product

require access to shock hazard voltage levels.

• Main power and relay contacts wired to separate power

source must be disconnected before servicing.

• Do not operate or energize instrument with case open!

• Signal wiring connected in this box must be rated at least

240 V.

• Non-metallic cable strain reliefs do not provide grounding

between conduit connections! Use grounding type bushings

and jumper wires.

• Unused cable conduit entries must be securely sealed by

non-flammable closures to provide enclosure integrity in

compliance with personal safety and environmental protection

requirements. Unused conduit openings must be sealed with

NEMA 4X or IP65 conduit plugs to maintain the ingress

protection rating (NEMA 4X).

• Electrical installation must be in accordance with the National

Electrical Code (ANSI/NFPA-70) and/or any other applicable

national or local codes.

• Operate only with front and rear panels fastened and in place

over terminal area.

• Safety and performance require that this instrument be

connected and properly grounded through a three-wire

power source.

• Proper relay use and configuration is the responsibility of the

user.

This product is not intended for use in the light industrial,

residential or commercial environments per the instrument’s certification to EN50081-2.

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.rosemountanalytical.com

© Rosemount Analytical Inc. 2012

WARNING

RISK OF ELECTRICAL SHOCK

WARNING

CAUTION

About This Document

This manual contains instructions for installation and operation of the Model FCL-54eA

The following list provides notes concerning all revisions of this document.

Rev. Level

Date Notes

A 5/09 This is the initial release of the product manual. The manual has been

reformatted to reflect the Emerson documentation style and updated to

reflect any changes in the product offering.

B 3/12 Update addresses - mail and web and DNV certificate logo.

i

MODEL FCL-54eA TABLE OF CONTENTS

FCL-54eA

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS ................................................................ 1

1.1 Applications and Features ..................................................................................... 1

1.2 Specifications-General............................................................................................. 2

1.3 Ordering Information ................................................................................................ 3

2.0 INSTALLATION ....................................................................................................... 5

2.1 Unpacking and Inspection........................................................................................ 5

2.2 Installation................................................................................................................ 5

3.0 WIRING.................................................................................................................... 9

3.1 General .................................................................................................................... 9

3.2 Power, Alarm, and Output Wiring............................................................................. 9

4.0 DISPLAY AND OPERATION ................................................................................... 13

4.1 General Description ................................................................................................. 13

4.2 Display ..................................................................................................................... 13

4.3 Key Functions and Controls..................................................................................... 13

4.4 Alarm Status............................................................................................................. 13

5.0 PROGRAMMING THE ANALYZER ........................................................................ 15

5.1 Changing Alarm Setpoints ....................................................................................... 21

5.2 Ranging the Outputs ................................................................................................ 22

5.3 Test Outputs and Alarms.......................................................................................... 23

5.4 Chosing Display Options.......................................................................................... 24-25

5.5 Changing Output Parameters .................................................................................. 26-27

5.6 Changing Alarm Parameters .................................................................................... 28-31

5.7 Configuring the pH Measurement ............................................................................ 32

5.8 Temperature Compensation and Temperature Units ............................................... 33

5.9 Noise Reduction....................................................................................................... 34

5.10 Main Sensor Calibration Parameters ....................................................................... 35

5.11 Security ....................................................................................................................36

5.12 Analyzer Mode Priority............................................................................................. 37

6.0 CALIBRATION - TEMPERATURE .......................................................................... 39

6.1 Introduction .............................................................................................................. 39

6.2 Temperature Calibration........................................................................................... 40

Section Title Page

7.0 CALIBRATION CHLORINE .................................................................................... 41

7.1 Introduction .............................................................................................................. 41

7.2 Zeroing the Sensor .................................................................................................. 42

7.3 Full Scale Calibration ............................................................................................... 43

7.4 Dual Slope Calibration ............................................................................................. 44

8.0 CALIBRATION - CURRENT OUTPUTS ................................................................. 47

8.1 Introduction .............................................................................................................. 47

8.2 Trimming the Outputs............................................................................................... 47

9.0 MAINTENANCE ..................................................................................................... 49

9.1 Analyzer ................................................................................................................... 49

9.2 Chlorine Sensor ....................................................................................................... 50

9.3 Constant Head Flow Controller................................................................................ 52

10.0 TROUBLESHOOTING ........................................................................................... 55

10.1 Overview .................................................................................................................. 55

10.2 Troubleshooting When a Fault Message is Showing............................................... 55

10.3 Troubleshooting When No Fault Message is Showing - Temperature..................... 56

10.4 Troubleshooting When No Error Message is Showing - Chlorine............................ 56

10.5 Troubleshooting When No Error Message is Showing - General ............................ 59

10.6 Simulating Inputs - Chlorine..................................................................................... 59

10.7 Simulating Inputs - Temperature............................................................................... 60

LIST OF TABLES

Number Title Page

5.1 Program Settings List ............................................................................................... 15-17

5.2 Controller Mode Priority Chart.................................................................................. 37

10.2 Troubleshooting When a Fault Message is Showing ............................................... 55

10.4 Troubleshooting When No Error Message is Showing - Chlorine ............................ 56

10.5 Troubleshooting When No Error Message is Showing - General............................. 59

MODEL FCL-54eA TABLE OF CONTENTS

TABLE OF CONTENTS CONT’D

ii

LIST OF FIGURES

Number Title Page

2-1 Chlorine Sensor Parts .............................................................................................. 7

2-2 Model FCLi-01-230................................................................................................... 8

3-1 Power Input and Relay Output Wiring for Model 54eA ............................................ 10

3-2 Wiring Label .................................................................................................... 11

3-3 Wiring Sensor to Model 54eA Analyzer ...................................................................... 11

4-1 Main Display Screen ................................................................................................ 13

5-1 Menu Tree for the 54eA Controller .......................................................................... 18-20

5-2 Low Alarm ................................................................................................................ 30

5-3 High Alarm................................................................................................................ 30

5-4 Interval Timer............................................................................................................ 31

7-1 Sensor Current as a Function of Free Chlorine Concentration ................................ 41

7-2 Dual Slope Calibration.............................................................................................. 44

9-1 Chlorine Sensor Parts ............................................................................................. 51

9-2 Replacement Parts for the Flow Controller Assembly.............................................. 53

10-3 Three-Wire RTD Configuration................................................................................. 60

10-4 Simulating RTD Inputs.............................................................................................. 60

iii

Model FCL-54eA SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0.

DESCRIPTION AND SPECIFICATIONS

1

• COMPLETE SYSTEM INCLUDES sensors, connecting cables, analyzer, and flow controller.

• CONTINUOUS pH CORRECTION eliminates expensive and messy reagents and troublesome sample conditioning systems.

• MEASURES FREE CHLORINE IN SAMPLES having pH as high as 9.5.

1

• VARIOPOL QUICK-DISCONNECT FITTINGS make replacing sensors easy.

1

In some cases, the sensor can be used in samples having pH as great as 10.0. Consult the factory.

1.1 APPLICATIONS

The FCL free chlorine system is intended for the

determination of free chlorine in fresh water. Unlike

free chlorine analyzers from other manufacturers, the

FCL does not use expensive sample conditioning systems or messy reagents to control pH. Instead, the

analyzer automatically compensates for changes in

the pH of the sample. The FCL is not intended for the

determination of total chlorine or combined chlorine

(like monochloramine). Nor, can the FCL be used for

the determination of chlorine in seawater.

1.2 FEATURES

The FCL uses a membrane-covered amperometric

sensor. A polarizing voltage applied to a platinum

cathode behind the membrane destroys any chlorine

that diffuses through the membrane, keeping the concentration of chlorine in the sensor equal to zero. The

current generated by the cathode reaction is proportional to the rate of diffusion of chlorine through the

membrane. Because the concentration of chlorine in

the sensor is zero, the diffusion rate and the current

are proportional to the concentration of chlorine.

There is a difficulty, however. Amperometric free

chlorine sensors measure only hypochlorous acid.

Because free chlorine is a pH-dependent mixture of

hypochlorous acid and hypochlorite ion, a change in

pH will cause the sensor response to change even

though the free chlorine level remained constant.

Most manufacturers solve the problem by treating the

sample with acid, which lowers the pH and converts

hypochlorite ion into hypochlorous acid. The

FCL

avoids the expense and inconvenience of

sample

conditioning by measuring the pH and applying a cor-

rection to the raw chlorine sensor signal. The correction is valid between pH 6.0 and 9.5. Below pH 6.0,

no correction is needed. For samples having pH

between 9.5 and 10.0, consult the factory.

The FCL is available in two options: Model FCL-01

with manual pH correction and Model FCL-02 with

continuous pH correction. Choose the FCL-01 if

the

pH varies less than 0.2 or if pH changes are

predictable or seasonal. Choose the FCL-02 if the pH

varies more than 0.2. To provide the continuous pH

correction, the Model FCL-02 requires a separate pH

sensor.

Maintenance is fast and easy. Replacing a membrane

requires no special tools or fixtures. A screw cap holds

the pre-tensioned membrane in place. Replacing the

electrolyte solution takes only minutes.

The FCL includes the easy-to-use Model 54eA

analyz-

er. The analyzer features two fully programmable

4-20

mA analog outputs and three alarm relays.

Programming and calibration are simple and intuitive.

The large backlit display allows the user to read

chlorine at a single glance.

Valves, rotameters, and pressure regulators to control

sample flow are things of the past with the Model FCL.

A constant head overflow sampler ensures the correct

sample flow to the sensors. To eliminate wiring

hassles, quick-disconnect Variopol cable is standard.

Stable free chlorine standards do not exist. The

chlorine sensor must be calibrated using the results of

a laboratory test run on a grab sample.

2

MODEL FCL-54eA SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SPECIFICATIONS — GENERAL

Sample requirements:

Pressure: 3 to 65 psig (122 to 549 kPa abs)

A check valve in the inlet prevents the sensor

flow cells from going dry if sample flow is lost.

The check valve opens at 3 psig (122 kPa abs).

If the check valve is removed, minimum pressure is 1 psig (108 kpa abs).

Temperature: 32 to 122°F (0 to 50°)

Minimum Flow: 3 gal/hr (11 L/hr)

Maximum flow: 80 gal/hr (303 L/hr); high flow

causes the overflow tube to back up.

Sample Conductivity: >50 µS/cm at 25°C

Process connection: 1/4-in OD tubing compression

fitting (can be removed and replaced with a

barbed fitting for use with soft tubing).

Drain connection: 3/4-in barbed fitting. Sample must

drain to open atmosphere.

Wetted parts:

Overflow sampler and flow cell: acrylic, polycar-

bonate, Kynar®1, nylon, silicone

Chlorine sensor: Noryl®2, Viton®3, wood, silicone,

polyethersulfone, polyester, and platinum

pH sensor: Tefzel®4, Viton, glass, ceramic

Response time to step change in chlorine concen-

tration: <80 sec to 95% of final reading for inlet

sample flow of 3 gph (11 L/hr).

Weight/shipping weight:

Model FCL-01-230: 10 lb/13 lb (4.5 kg/6.0 kg)

Model FCL-02-230: 11 lb/14 lb (5.0 kg/6.5 kg)

[rounded to the nearest 1 lb. (0.5 kg)]

SPECIFICATIONS — SENSOR

Free chlorine range: 0 to 10 ppm as Cl2. For higher

ranges, consult the factory.

pH correction range: 6.0 to 9.5. For samples having

pH between 9.5 and 10.0, consult the factory.

For manual pH correction, choose option -01.

For continuous pH correction choose option -02.

Accuracy: Accuracy depends on the accuracy of the

chemical test used to calibrate the sensor.

Electrolyte volume: 25 mL (approx.)

Electrolyte life: 3 months (approx.); for best results

replace electrolyte monthly.

SPECIFICATIONS — MODEL 54eA

ANALYZER

Case: Epoxy-painted cast aluminum, NEMA4X (IP65).

Front Panel: Membrane keypad with tactile feedback.

Three green LEDs indicate alarm status. Red

LED indicates fault condition.

Conduit Openings: Accepts PG 13.5 or 1/2 inch con-

duit fittings

Display: Three-line, back-lit, dot matrix LCD, 70 x 35 mm.

First line is measurement reading. Second line is

temperature and current output. Third line is userselectable. Character heights: 1st line - 16 mm

(0.6 in.), 2nd and 3rd lines - 7 mm (0.3 in.).

Ambient Temperature and Humidity: 0 to 50°C (32

to 122°F). 95% (maximum) non-condensing.

Analyzer can be operated between -20 and 60°C

(-4 to 140°F) with some degradation in display

quality.

Power: 100-127 Vac ± 10%, 50/60 Hz ± 6%, 8 W

200-253 Vac ± 10%, 50/60 Hz ± 6%, 8 W

RFI/EMI: EN-61326

LVD: EN-61010-1

Outputs: Two 4-20 mA or 0-20 mA isolated outputs.

Continuously adjustable. Outputs can be

assigned to chlorine or temperature. Output

dampening is user-selectable. Maximum load

at 115/230 Vac is 600Ω. Maximum load at

100/200 Vac is 550Ω.

Alarms: Three alarm relays for process measurement,

temperature or interval timer. The fourth alarm

relay is a sensor/analyzer fault alarm.

Relay Contacts: Relays 1-3: Form A, SPST, NO,

epoxy sealed. Relay 4: Form C, SPDT, epoxy

sealed

1

Kynar is a registered trademark of Elf Atochem North America.

2

Noryl is a registered trademark of General Electric.

3

Viton is a registered trademark of E.I. duPont de Nemours & Co.

4

Tefzel is a registered trademark of E.I. duPont de Nemours & Co

Resistive Inductive

28 Vdc 5.0 3.0

115 Vac 5.0 3.0

230 Vac 5.0 1.5

SECTION 2.0.

INSTALLATION

MODEL FCL-54eA SECTION 2.0

INSTALLATION

3

2.1 UNPACKING AND INSPECTION

Inspect the shipping container. If it is damaged, contact the shipper immediately for instructions. Save the box. If

there is no apparent damage, unpack the container. Be sure all items shown on the packing list are present. If

items are missing, notify Rosemount Analytical immediately.

2.1.1 FCL-01-230 (free chlorine without continuous pH correction)

Model FCL-01-230 consists of the following items mounted on a back plate.

1. Model 54eA-01 analyzer with sensor cable attached.

2. Constant head overflow sampler with flow cell for chlorine sensor.

The free chlorine sensor (Model 499ACL-01-54-VP), shipped with three membrane assemblies and a bottle of

electrolyte solution, are in a separate package.

2.1.2 FCL-02-230 (free chlorine with continuous pH correction)

Model FCL-02-230 consists of the following items mounted on a back plate.

1. Model 54eA-01 analyzer with sensor cables attached.

2. Constant head overflow sampler with flow cells for pH and chlorine sensors.

3. Stand to hold pH buffer solution during calibration.

The free chlorine sensor (Model 499ACL-01-54-VP), shipped with three membrane assemblies and a bottle of

electrolyte solution, and the Model 399VP-09 pH sensor are in separate packages.

4

MODEL FCL-54eA SECTION 2.0

INSTALLATION

2.2 INSTALLATION

2.2.1 General Information

1. Although the system is suitable for outdoor use, do not install it in direct sunlight or in areas of extreme temperature.

2. To keep the analyzer enclosure watertight, install plugs (provided) in the unused cable openings.

3. Install the system in an area where vibrations and electromagnetic and radio frequency interference are minimized or absent.

4. Be sure there is easy access to the analyzer and sensors.

2.2.2 Sample Requirements

Be sure the sample meets the following requirements:

1. Temperature: 32 to 122ºF (0 to 50ºC)

2. Pressure: 3 to 65 psig (122 to 549 kPa abs)

3. Minimum flow: 3 gal/hr (11 L/hr)

2.2.3 Mounting, Inlet, and Drain Connections

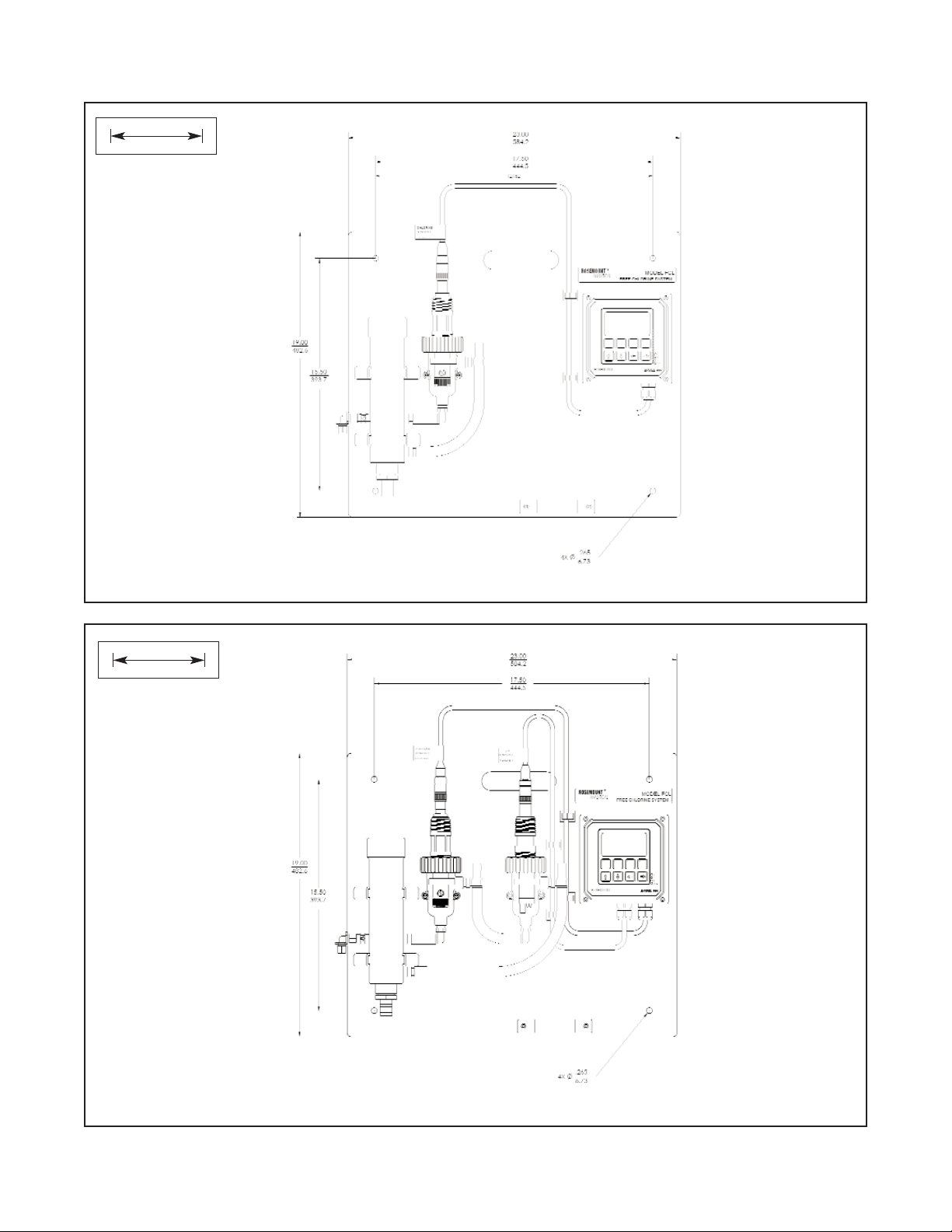

The Model FCL is intended for wall mounting only. Refer to Figure 2-1 or 2-2 for details. The sensor(s) screw into

the flow cell adapters as shown in the figures. For Model FCL-02 (free chlorine with continuous pH adjustment),

the pH sensor must be installed as shown in Figure 2-2.

A 1/4-inch OD tubing compression fitting is provided for the sample inlet. If desired, the compression fitting can

be removed and replaced with a barbed fitting. The fitting screws into a 1/4-inch FNPT check valve. The check

valve prevents the sensor flow cells from going dry if sample flow is lost.

The sample drains through a 3/4-inch barbed fitting. Attach a piece of soft tubing to the fitting and allow the waste

to drain open atmosphere. Do not restrict the drain line.

Remove the foam packing insert between the outer tube and the inner overflow tube. Adjust the sample flow

until the water level is even with the central overflow tube and excess water is flowing down the tube.

2.2.4 Electrical Connections

Refer to Section 3.1 for details.

2.2.5 Installing the Sensor(s)

The Model FCL is provided with sensor cables pre-wired to the analyzer. Connect the chlorine sensor (Model

499ACL-01-54-VP) to the cable labeled CHLORINE. Connect the pH sensor (Model 399VP-09) to the cable

labeled pH. The terminal end of the sensor is keyed to ensure proper mating with the cable receptacle. Once the

key has slid into the mating slot, tighten the connection by turning the knurled ring clockwise.

The sensor(s) screw into the plastic fitting(s), which are held in the flow cell(s) by the union nut. Do not remove the

protective cap on the sensor(s) until ready to put the sensor(s) in service.

Model FCL-54eA SECTION 2.0

INSTALLATION

FIGURE 2-1. Model FCL-01

FIGURE 2-2. Model FCL-02

INCH

MILLIMETER

INCH

MILLIMETER

5

This page left blank intentionally

6

MODEL FCL-54eA SECTION 2.0

INSTALLATION

SECTION 3.0.

WIRING

MODEL FCL-54eA SECTION 3.0

WIRING

7

3.1 GENERAL

WARNING

Electrical installation must conform to the National Electrical Code, all state and local codes, and all plant

codes and standards for electrical equipment. Electrical installation and wiring must be done by qualified

personnel.

The five holes in the bottom of the instrument case accept 1/2-in. strain relief connectors or conduit fittings. The

rear openings are for power and alarm relay wiring. The left front opening is for sensor wiring (already installed)

and the right front opening is for analog output wiring. Seal unused openings with conduit plugs.

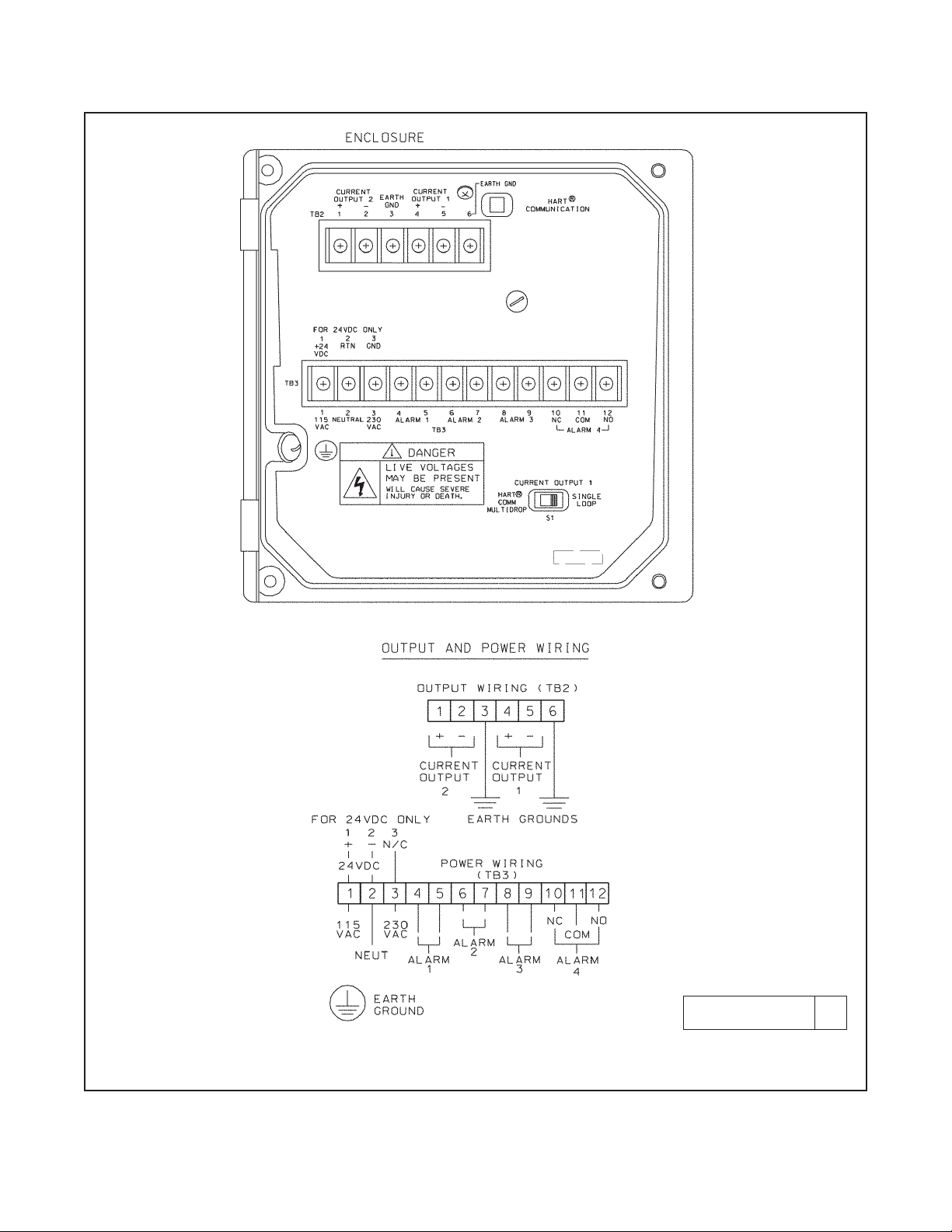

3.2 POWER, ALARM, AND OUTPUT WIRING

Refer to Figure 3-1. Make power and alarm connections on TB3. Make analog output wiring connections on TB2. For

access to power and alarm terminals, loosen the screw holding the protective cover in place and remove the cover.

Alarm contacts are dry (i.e., not powered) and are normally open. Refer to Section 1.0 for relay specifications.

For best EMI/RFI protection, shield the output cable and enclose it in an earth-grounded, rigid, metal conduit.

Connect the outer shield of the output cable to the earth ground connection on TB2 (see Figure 3-1).

Keep sensor and output signal wiring separate from power wiring. Do not run sensor and power cables in the same

conduit or close together in a cable tray.

AC wiring must be 14 gauge or greater. Be sure to connect earth ground from the power cable to the nearby

ground lug. A good earth ground is necessary for proper operation of the controller. Provide a switch or breaker to

disconnect the analyzer from the main power supply. Install the switch or breaker near the analyzer and label it as

the disconnecting device.

NOTE

The Model 54eA analyzer leaves the factory configured to measure dissolved oxygen, not free

chlorine. Before connecting the sensor to the cable, configure the analyzer to measure free chlorine. See section 5.4

Live voltages may be present. Will

cause severe injury or death

DANGER

WARNING

RISK OF ELECTRICAL SHOCK

AC connections and grounding must comply with UL

508 or local electrical code. DO NOT apply power to

the analyzer until all electrical connections are verified and secure.

WARNING

MODEL FCL-54eA SECTION 3.0

WIRING

8

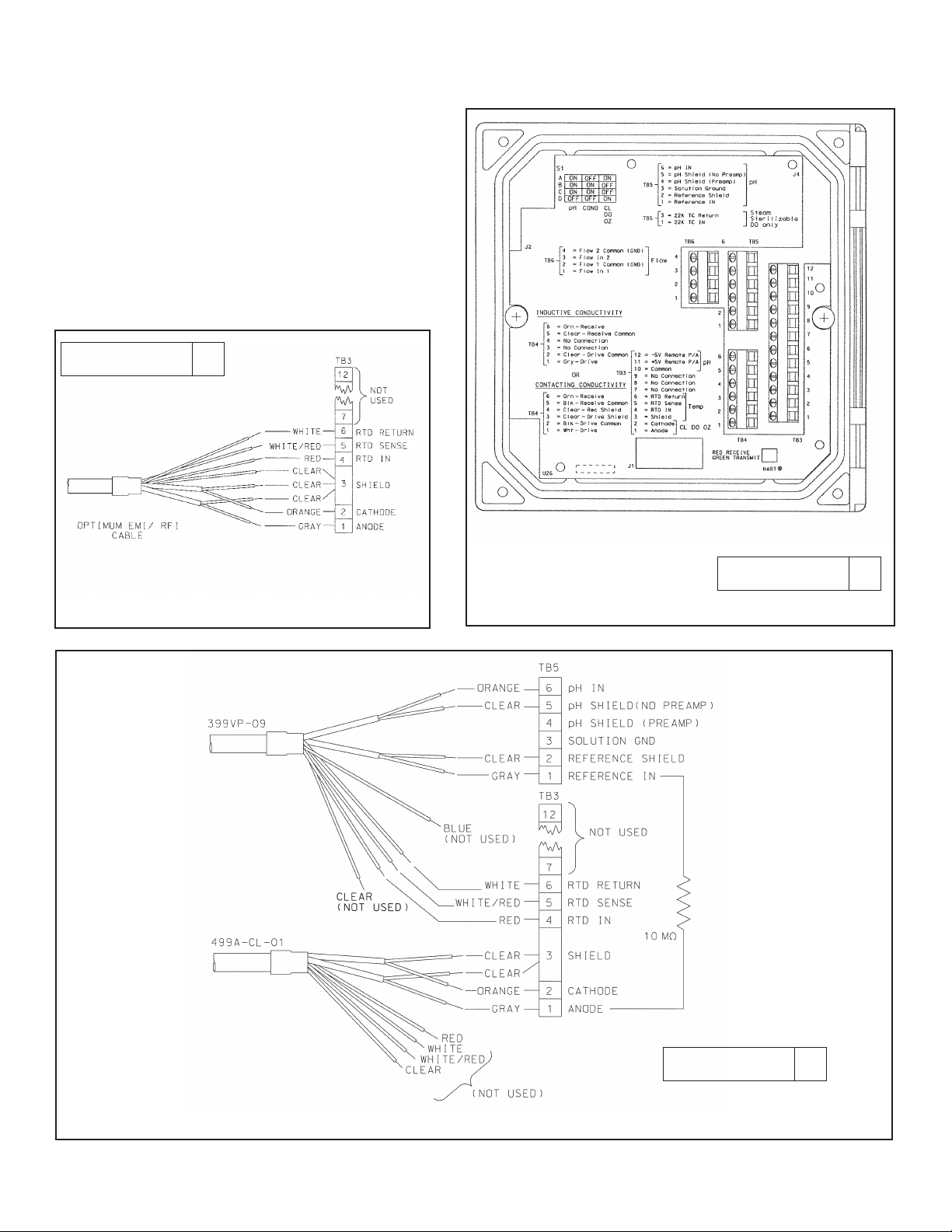

FIGURE 3-1. Power Input and Relay Output Wiring for Model 54eA

DWG. NO. REV.

454EPH02 D

9

MODEL FCL-54eA SECTION 3.0

WIRING

FIGURE 3-2. Wiring Label

3.3 SENSOR WIRING

3.3.1 General

The wiring label is a general purpose label. It

has wiring information concerning other

sensors, for example, contacting and inductive

conductivity sensors, that can be used with the

54e instrument platform. The Model FCLi is

provided with sensor cable pre-wired to the

analyzer. If it is necessary to replace the

cable, refer to Figures 3-2 (wiring label) and

3-3 and 3-4 (wiring diagrams).

DWG. NO. REV.

40054e03 A

FIGURE 3-3. Wiring Chlorine Sensor to

Model 54eA Analyzer

FIGURE 3-4. Wiring Chlorine and pH Sensor to 54eA Analyzer.

DWG. NO. REV.

4054eA02 B

DWG. NO. REV.

40499A24 A

This page left blank intentionally

10

MODEL FCL-54eA SECTION 3.0

WIRING

11

MODEL FCL-54eA SECTION 4.0

DISPLAY AND OPERATION

SECTION 4.0

DISPLAY AND OPERATION

4.1 GENERAL DESCRIPTION

The 54eA analyzer is a single input, dual output instrument. It does, however, accept a second input for pH

when the main measurement is free chlorine.

4.2 DISPLAY

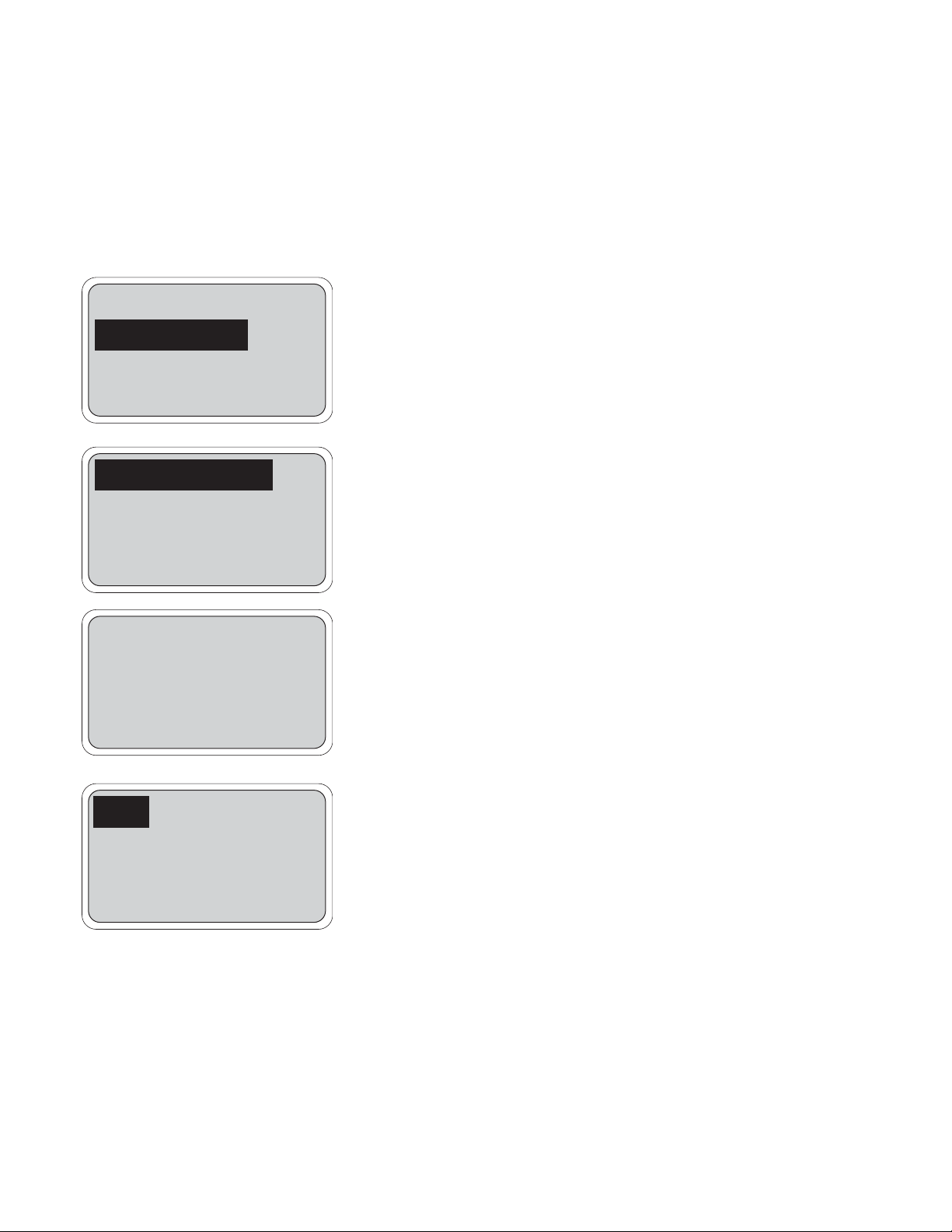

Figure 4-2 shows the main display.

4.3 KEY FUNCTIONS AND CONTROLS

The keys labeled F1, F2, F3, and F4 are multi-function.

The function appears in the main display just above the

key. For example, F1 is usually labeled Exit and F4

may be labeled Edit, Save, or Enter.

1. To enter the main menu, press any key.

2. Use the é and ê keys to move the cursor to the

desired sub-menu. The position of the cursor is

shown in reverse video.

NOTE

When the last item of a menu has been

reached, the cursor will be on the third line

of the display. If the cursor is on the second

line of the display more items remain.

Continue pressing the ê key.

3. Press Enter (F4) to access a sub-menu or an item

in a sub-menu.

4. To change a number or a setting press Edit (F4).

The display will change to show the cursor on the

first digit or on a + or - sign. Use the é and ê keys

to increase or decrease a digit or to toggle the +

and - signs. Use the ç and è keys to move the

cursor left and right.

5. If an entire number or a word is highlighted, use the

é and ê keys to scroll through the list of choices.

6. To store a number or setting in memory, press

Save (F4).

7. To leave without storing changes, press Esc (F3).

8. To leave and return to the previous screen, press

Exit (F1).

9. To end a calibration step and leave the previous

calibration in place, press Abort (F1).

10. Occasionally, information screens will appear. To

leave the information screen and move to the next

screen press Cont (F3).

4.4 ALARM STATUS

Green LEDs (labeled 1, 2, and 3) indicate when alarm

relays 1, 2, and 3 are energized. The fourth relay indicates a fault condition. When a fault occurs, the red

LED (labeled FAIL) lights up, a descriptive error message appears, and the outputs and alarm relays act as

programed in Sections 5.5 and 5.6.

The red LED also indicates when the interval timer

routine is activated and when the time limit has been

reached on a feed limit timer. For more information on

these subjects, see Section 5.6.

FIGURE 4-1. Main Display Screen

Chlorine is always displayed continuously in large

numerals. The temperature and output current are

always displayed on the second line of the main display.

The third line can be configured by the user. In the example, the third line shows the pH readings and the raw

sensor current in nA.

1.00 ppm

26.2°C. 12.00 mA

pH: 8.00 I: 340 nA

This page left blank intentionally

12

MODEL FCL-54eA SECTION 4.0

DISPLAY AND OPERATION

13

SECTION 5.0

PROGRAMMING THE ANALYZER

MODEL FCL-54eA SECTION 5.0

PROGRAMMING THE ANALYZER

The Model 54eA analyzer can be used to measure dissolved oxygen, ozone, total chlorine, and monochloramine

in addition to free chlorine. It is configured at the factory to measure dissolved oxygen. Before connecting the

sensor to the cable, the analyzer must be configured to measure free chlorine. See section 5.4.

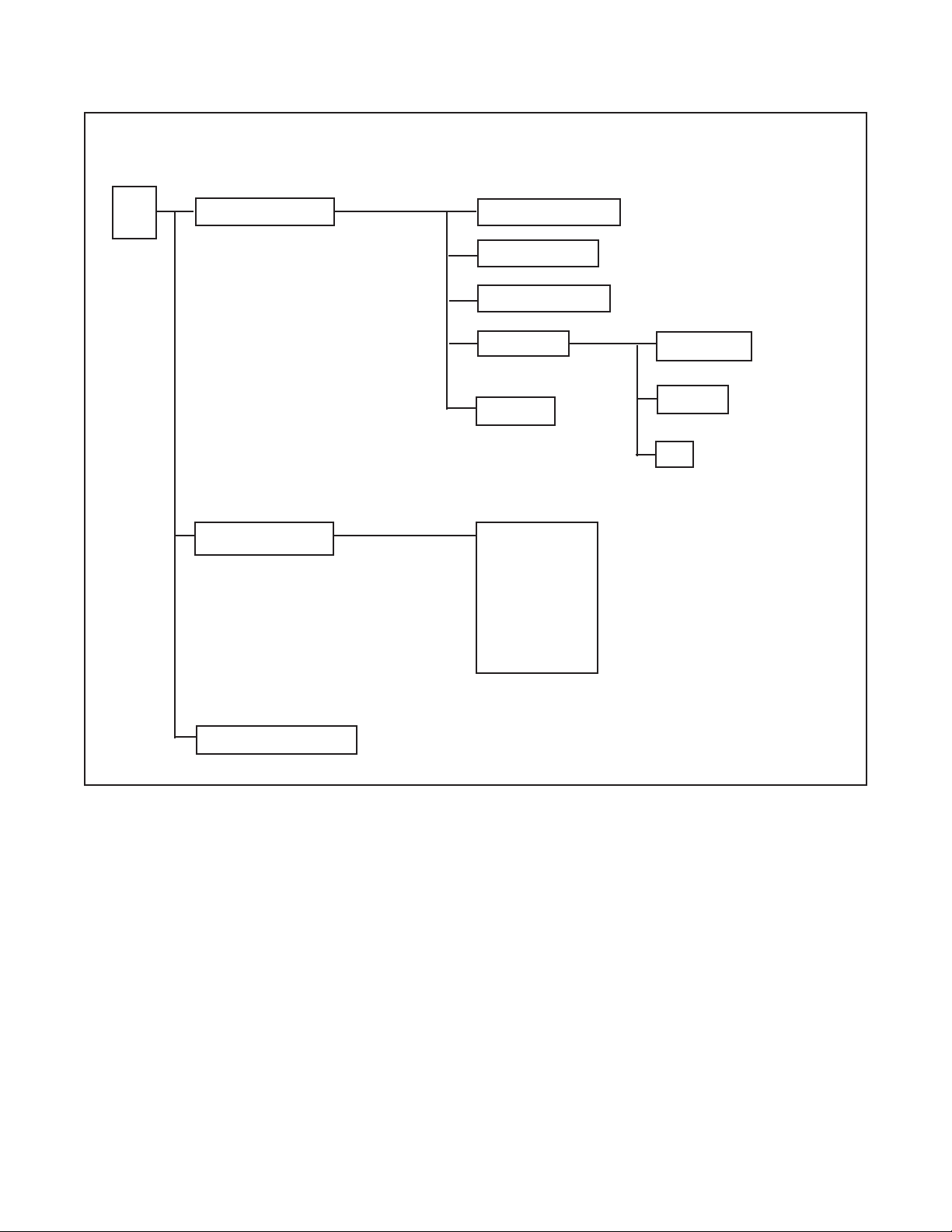

Figure 5-1 is an outline of the analyzer menu structure. Settings that do not apply to the measurement of free chlorine

are grayed out. Settings that apply to PID and TPC control and HART digital communications, features not

available in the analyzer option provided with the FCL, are also grayed out.

Table 5-1 list the default settings and the choices available for each setting. Only the choices available for free

chlorine are shown.

TABLE 5-1. Program Settings List

Continued on the following page

ITEMS CHOICES FACTORY SETTINGS

A. Alarms setpoints (Section 5.1)

1. Alarm 1 (low action)

a. if chlorine -9999 to 9999 ppm 0 ppm

b. if temperature -5 to 130°C 0.1°C

2. Alarm 2 (high action)

a. if chlorine -9999 to 9999 ppm 20 ppm

b. if temperature -5 to 130°C 130°C

3. Alarm 3 See alarm 2 See alarm 2

B. Output ranging (Section 5.2)

1. Output 1 or 2: 4 mA setting

a. if chlorine -9999 to 9999 ppm 0 ppm

b. if temperature -5 to 130°C 0.1°C

2. Output 1 or 2: 20 mA setting

a. if chlorine -9999 to 9999 ppm 20 ppm

b. if temperature -5 to 130°C 130°C

C. Display options (Section 5.4)

1. Measurement Oxygen, ozone, free chlorine, total chlorine, monochloramine Oxygen

2. Temperature units °C or °F °C

3. Output 1 mA or % of full scale mA

4. Output 2 mA or % of full scale mA

5. Language English, Français, Español, Deutsch, Italiano English

6. Main display left See section 5.4 Sensor current

7. Main display right See section 5.4 Output 1 current

8. Display contrast 00-99 (darkest) 50

9. Test timeout On or off On

10. Timeout value 1 to 60 min 10 min

D Output parameters (Section 5.5)

1. Output 1 Control

a. Measurement Oxygen, chlorine, ozone, pH, or temperature Oxygen

b. Control Normal Normal

14

MODEL FCL-54eA SECTION 5.0

PROGRAMMING THE ANALYZER

ITEMS CHOICES FACTORY SETTINGS

D. Outputs (Section 5.5) (continued)

2. Output 1 Setup (normal)

a. Current 4-20 mA or 0-20 mA* 4-20 mA

b. Dampening 0-299 sec 0 sec

c. Hold mode Hold last value or go to fixed value Hold last value

d. Fixed hold value 0-22 mA 21 mA

e. Fault value 0-22 mA 22 mA

3. Output 2 See output 1 See output 1

4. Hold feature Enable, disable, or 20 min timeout Disable

E. Alarms parameters (Section 5.6)

1. Alarm 1 Control

a. Activation method Oxygen, chlorine, ozone, temperature, pH Oxygen

b. Control mode Normal Normal

2. Alarm 1 setup (normal)

a. Configuration Low, high, or off High

b. Hysteresis

if chlorine -9999 to 9999 ppm 0 ppm

if temperature 0 to 10°C 0.1°C

c. Delay time 0-99 sec 0 sec

d. Relay fault none, open, closed None

3. Alarm 2 Control

a. Activation method Oxygen, chlorine, monochloramine, ozone, temperature, pH Oxygen

b. Control mode Normal Normal

4. Alarm 2 setup (normal)

a. Configuration Low, high, or off Low

Rest of alarm 2 setup is the same as alarm 1

5. Alarm 3 control and setup is the same as alarm 1

6. Alarm 4 control

Alarm Fault or off Fault

7. Feed limit timer

a. Feed limit Disable, alarm 1, alarm 2, or alarm 3 Disable

b. Timeout value 0 to 10,800 sec 600 sec

8. Interval timer

a. Select alarm Disable, alarm 1, alarm 2, or alarm 3 Disable

b. Interval time 0 to 999.9 hr 24.0 hr

c. Repeats 1 to 60 1

d. On time 0 to 2999 sec 120 sec

e. Off time 0 to 2999 sec 1 sec

f. Recovery time 0 to 999 sec 600 sec

F. Temperature compensation (Section 5.8)

1. Temperature compensation Auto or manual Auto

2. Manual temperature -15 to 130°C 25°C

TABLE 5-1. Program Settings List (continued)

Continued on the following page

15

MODEL FCL-54eA SECTION 5.0

PROGRAMMING THE ANALYZER

TABLE 5-1. Program Settings List (continued)

ITEMS CHOICES FACTORY SETTINGS

G. Noise Reduction (section 5.9)

Noise rejection 50 or 60 Hz 60 Hz

H. Main sensor calibration (Section 5.10)

1. Stabilize reading (Chlorine) 0 to 999 ppm 0.05 ppm

2. Stabilize time 0 - 30 sec 10 sec

3. Sensor zero stabilization value

4. Dual range calibration Enable or disable disable

I. Security (Section 5.11)

1. Lock all 000-999 (000 disables) 000

2. Lock program 000-999 (000 disables) 000

3. Lock configuration 000-999 (000 disables) 000

16

MODEL FCL-54eA SECTION 5.0

PROGRAMMING THE ANALYZER

FIGURE 5-1. Menu Tree for the 54eA Controller

Calibrate

Program (see page 17)

Diagnostic Variables

Main

Menu

Calibrate main sensor

Zero main sensor

Adjust temperature

Calibrate pH

Slope

Buffer calibration

Standardize

Main measurement

Main sensor current

Sensitivity (µA/ppm)

Zero current

pH reading

pH mV reading

pH slope (mV/pH)

pH offset

Glass impedance

Noise rejection

Software version

Output trim

17

MODEL FCL-54eA SECTION 5.0

PROGRAMMING THE ANALYZER

Program

Calibrate (see page 16)

Diagnostic Variable (see page 16)

Main

Menu

Alarms 1, 2, and 3 setpoints

4 mA or 0 mA

20 mA

Present output current

Alarm Setpoints

Output setpoints

Test output 1 or 2

Test alarm 1, 2, 3, or 4

Simulated tests

Configure

Display

Main

Sensor

Oxygen

Free Chlorine

Total Chlorine

Monochloramine

Ozone

Outputs

Output 1 and 2

control

Measurement: main snr, pH, temp.

Control mode: normal, PID

Output 1 and 2

setup

Range (0-20 or 4-20 mA)

Dampen*

Hold - keep last value

Hold - go to specified value

Fault

Setpoint, proportional, integral

Derivative**

Hold feature setup

*Normal only

**PID only

Alarms

Alarm 1, 2, & 3

control

Measurement: main snr, pH, temp.

Control mode: normal, TPC

Alarm 1, 2, & 3

setup

Alarm: High, low, or off*

Setpoint

Hysteresis*

Delay*

Time period, URV, LRV**

Relay default

Interval timer

Timer: Alarm 1, 2, or 3 or disable

Interval

Repeats

On time

Off time

Recovery time

Alarm 4 setup

Feed limit timer

Feed limit: Alarm 1, 2, or 3 or disable

Timeout

*Normal only **TPC only

Continued on page 20

FIGURE 5-1. Menu Tree for the 54eA Controller

(continued)

Sensor type and manufac.

Units: ppm, ppb, % sat

°C or °F

Output 1 (mA or %FS)

Output 2 (mA or %FS)

Language

Line 3 display

Display contrast

Timeout (on or off)

Timeout - limit

Polling address

18

MODEL FCL-54eA SECTION 5.0

PROGRAMMING THE ANALYZER

FIGURE 5-1. Menu Tree for the 54eA Controller (continued)

Display (see page 17)

Outputs (see page 17)

Alarms (see page 17)

Program

Calibrate (see page 16)

Diagnostic Variable (see page 16)

Main

Menu

Alarm Setpoints (see page 17)

Output setpoints

(see page 17)

Simulated tests

(see page 17)

Configure

pH

(available with free

chlorine only)

Disable

Enable

pH

diagnostics

Diagnostics: on or off

Glass impedance high

Glass impedance low

Zero offset

Impedance temp comp: on or off

Temperature

Temperature comp: auto or manual

Units: °C or °F

Noise

Rejection

Noise rejection: 50 or 60 Hz

Barometric

Pressure

Measurement: Auto or manual

Units: mm Hg, kPa, atm, barg, in Hg

Main sensor cal

Stabilize conc’n

Stabilize time

Salinity (oxygen only)

Security

pH

calibration

Autocal: standard, manual, Merck,

Ingold, DIN 19267

Stabilize pH

Stabilize time

Temperature

coefficient

Temperature coeff

Operating isopotential

Sensor isopotential

Lock all

Lock program

Lock configure

(oxygen only)

19

MODEL FCL-54eA SECTION 5.0

PROGRAMMING THE ANALYZER

5.1 CHANGING ALARM SETPOINTS

2. Press any key to enter the main menu. Move the cursor to "Program"

and press Enter (F4).

3. Press Enter (F4).

4. Move the cursor to the desired alarm and press Enter (F4).

5. A screen like the one shown will appear. The alarm is a low alarm

and the setpoint is 0.00 ppm. Press Edit (F4). Use the arrow keys to

change the setpoint. Press Save (F4) to store the new value. Press

Exit (F1) to return to the screen in step 4. Choose a new alarm.

Alarm setpoints

Output setpoints

Simulate tests

Exit Enter

Alarm 1 setpoint

Alarm 2 setpoint

Alarm 3 setpoint

Exit Enter

Alarm Low : 0.000 ppm

Exit Edit

1. Before changing alarm setpoints, be sure that alarms are properly configured. See Section 5.6.

20

MODEL FCL-54eA SECTION 5.0

PROGRAMMING THE ANALYZER

5.2 RANGING THE OUTPUTS

2. Press any key to enter the main menu. Move the cursor to "Program"

and press Enter (F4).

3. Move the cursor to "Output setpoints" and press Enter (F4).

4. Move the cursor to the desired output and press Enter (F4).

5. This screen confirms that changes to output 1 are going to be made.

Use caution. Changes may degrade process control. Press Cont

(F3) to continue. Otherwise, press Abort (F1).

6. This screen shows the present settings for Output 1. If the output

was configured to be 0-20 mA, the first line will show "0mA" instead

of "4mA". The live current output is shown on the third line.

Move the cursor to the desired line and press Edit (F4). Use the

arrow keys to change the setpoint. Press Save (F4) to store the new

value.

Press Exit (F1) to return to the screen in step 4. Choose the other

output and continue.

Output 1 setpoints

Output 2 setpoints

Exit Enter

Alarm setpoints

Output setpoints

Simulated test

Exit Enter

CAUTION: Current

Output 1 will be

affected.

Abort Cont

1. Ranging the outputs means assigning values to the low (0 or 4 mA) and high (20 mA) outputs. Before rang-

ing the outputs, be sure the outputs are properly configured. See Section 5.5.

4 mA : 0.00 ppm

20 mA: 20.00 ppm

Output 1: 12.00 mA

Exit Edit

Loading...

Loading...