Page 1

Emerson Plantweb™ Insight

Reference Manual

00809-0100-4541, Rev GA

June 2020

Page 2

2

Page 3

Reference Manual Contents

00809-0100-4541 June 2020

Contents

Chapter 1 Introduction.............................................................................................................. 7

1.1 Using this manual........................................................................................................................ 7

1.2 Product recycling/disposal...........................................................................................................7

Chapter 2 Installation.................................................................................................................9

2.1 Safety messages.......................................................................................................................... 9

2.2 System requirements...................................................................................................................9

2.3 Installation procedure................................................................................................................10

2.4 Launching the application..........................................................................................................12

Chapter 3 Configuration...........................................................................................................15

3.1 Overview................................................................................................................................... 15

3.2 Safety messages........................................................................................................................ 15

3.3 Customize system settings........................................................................................................ 15

3.4 Application installation.............................................................................................................. 19

3.5 Application configuration.......................................................................................................... 19

Chapter 4 Version Upgrades.....................................................................................................25

4.1 Virtual machine upgrades..........................................................................................................25

4.2 Application upgrades.................................................................................................................25

4.3 Platform upgrades.....................................................................................................................25

Chapter 5 Modbus TCP Mapping.............................................................................................. 27

5.1 Setting up Modbus TCP from data system..................................................................................29

Chapter 6 Troubleshooting...................................................................................................... 33

6.1 Service support..........................................................................................................................33

6.2 Plantweb Insight: Unable to load Plantweb Insight Virtual Machine........................................... 34

6.3 Plantweb Insight: Virtual machine displaysv--IP Address Unknown--..........................................35

6.4 Plantweb Insight: OVF file error..................................................................................................36

6.5 Plantweb Insight: Web interface cannot be accesed...................................................................36

6.6 Plantweb Insight: Web interface login continues to spin after inputting email and password.....36

6.7 Plantweb Insight: Cannot connect to WirelessHART Gateway.....................................................37

6.8 Plantweb Insight: Click on application logo and nothings happens.............................................37

6.9 Steam trap application: Asset status displays "NoData/Error" after configuration....................... 38

6.10 Steam trap application: Asset status display "No Config".......................................................... 39

6.11 Steam trap application: Asset status in question......................................................................39

6.12 Pressure Relief Device Application: Numerous “No_Data/Error” events................................... 41

Appendix A Steam Trap Application configuration and information............................................ 43

A.1 Overview................................................................................................................................... 43

A.2 Global settings.......................................................................................................................... 43

Emerson.com/Plantweb 3

Page 4

Contents Reference Manual

June 2020 00809-0100-4541

A.3 Adding assets............................................................................................................................ 44

A.4 Calculated fields........................................................................................................................ 45

A.5 Modbus® TCP mapping..............................................................................................................47

Appendix B Pump Application configuration and information.....................................................49

B.1 Overview................................................................................................................................... 49

B.2 Global settings...........................................................................................................................49

B.3 Configuring assets..................................................................................................................... 49

B.4 Calculated fields........................................................................................................................ 52

B.5 Modbus TCP mapping................................................................................................................54

Appendix C Heat Exchanger Application configuration and information..................................... 55

C.1 Overview................................................................................................................................... 55

C.2 Global settings...........................................................................................................................55

C.3 Configuring assets.....................................................................................................................55

C.4 Calculated fields........................................................................................................................ 58

C.5 Modbus TCP mapping............................................................................................................... 60

Appendix D Wireless Pressure Gauge Application configuration and information........................61

D.1 Overview...................................................................................................................................61

D.2 Adding devices..........................................................................................................................61

D.3 Calculated fields........................................................................................................................61

Appendix E Air-Cooled Heat Exchanger Application configuration and information.................... 63

E.1 Overview....................................................................................................................................63

E.2 Global settings...........................................................................................................................63

E.3 Configuring assets..................................................................................................................... 63

E.4 Calculated fields.........................................................................................................................66

E.5 Modbus TCP mapping................................................................................................................68

Appendix F Pressure Relief Device (PRD) Application configuration and information.................. 69

F.1 Overview....................................................................................................................................69

F.2 Global settings...........................................................................................................................69

F.3 Adding assets.............................................................................................................................70

F.4 Baseline..................................................................................................................................... 70

F.5 Calculated fields.........................................................................................................................72

F.6 Modbus TCP mapping................................................................................................................74

Appendix G Cooling Tower Application configuration and information....................................... 75

G.1 Overview...................................................................................................................................75

G.2 Global settings.......................................................................................................................... 75

G.3 Adding assets............................................................................................................................76

G.4 Configuring assets.....................................................................................................................77

G.5 Calculated fields........................................................................................................................78

G.6 Modbus TCP mapping............................................................................................................... 79

Appendix H Network Management Application configuration and information...........................81

4 Emerson.com/Plantweb

Page 5

Reference Manual Contents

00809-0100-4541 June 2020

H.1 Overview...................................................................................................................................81

H.2 Global settings.......................................................................................................................... 81

Appendix I Power Module Application configuration and information....................................... 85

I.1 Overview.................................................................................................................................... 85

I.2 Global settings............................................................................................................................85

I.3 Adding power modules...............................................................................................................85

Appendix J Inline Corrosion application configuration and information......................................87

J.1 Overview.................................................................................................................................... 87

J.2 Global settings............................................................................................................................87

J.3 Adding devices........................................................................................................................... 90

J.4 Dashboard user interaction.........................................................................................................94

J.5 Device summary user interaction................................................................................................95

J.6 Event log user interaction........................................................................................................... 98

Emerson.com/Plantweb 5

Page 6

Contents Reference Manual

June 2020 00809-0100-4541

6 Emerson.com/Plantweb

Page 7

Reference Manual

00809-0100-4541 June 2020

Introduction

1 Introduction

1.1 Using this manual

This document is intended for system administrators and will provide details on how to set

up Plantweb Insight. For more details and configuration information on specific

applications, refer to the appropriate appendix sections.

It is recommended administrators complete all steps in the order described. An overview

of these steps is described below:

1.1.1

1.1.2

1.1.3

Install and launch

Procedure

1. Ensure system meets minimum requirements.

2. Install the Plantweb Insight virtual machine.

3. Launch Plantweb Insight web interface from a supported web browser.

Refer to Installation for more information.

Customize system settings

Procedure

1. Set up users for access.

2. Connect to Emerson Wireless Gateways and other data systems.

3. Backup and restore your system to avoid loss of settings.

Refer to Configuration for more information.

Application configuration

Procedure

1. Configure application specific global settings.

2. Add, edit, or delete assets via asset management.

Refer to Configuration for more information.

1.2 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation/regulations.

Emerson.com/Plantweb 7

Page 8

Introduction Reference Manual

June 2020 00809-0100-4541

8 Emerson.com/Plantweb

Page 9

Reference Manual Installation

00809-0100-4541 June 2020

2 Installation

2.1 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operation. Information that raises potential safety

issues is indicated by a warning symbol ( ). Refer to the following safety messages before

performing an operation preceded by this symbol.

2.2 System requirements

Plantweb Insight is delivered as a fully developed virtual machine (e.g. .ova file). Users will

receive a complete virtual machine image to install in user provided virtualization software

or hypervisors.

The Plantweb Insight virtual machine contains a web server that can be accessed by any

web client with network access. All configuration and visualization will be completed from

the web browser user interface.

2.2.1

2.2.2

Plantweb Insight can be installed on a network server or PC/laptop. Both installations have

the same requirements and installation steps. Network connection settings can be made

subject to organization policies. Any pertinent Gateways must be accessible on the

network.

Before you begin, verify your system meets the minimum requirements.

Host operating system

Virtualization software/hypervisor

• VMware Workstation Pro™ 10 or higher (requirements can be found here)

• VMware vSphere® 5.5 or higher (requirements can be found here)

OR

• Contact Rosemount™ support if utilizing a different virtualization software (Microsoft

Hyper-V®)

®

Guest operating system

• Processors = 4

• Memory = 16 GB RAM minimum

• Hard drive = 100 GB of free space

Emerson.com/Plantweb 9

Page 10

Installation Reference Manual

June 2020 00809-0100-4541

2.2.3 Application

Browsers (recent versions supported)

• Chrome™ browser

• Microsoft Internet Explorer

®

2.2.4 Other requirements

• A DVD drive is required for installations

• A DHCP server is required to assign a valid IP address (static IP address can be

configured once connected to the Plantweb Insight web interface)

2.2.5

2.2.6

Gateway compatibility

Plantweb Insight is compatible with Emerson Wireless 1410/1420 Gateways on firmware

version 4.7.68 or higher. Plantweb Insight may experience calculation response issues on

certain applications when Gateway firmware is not up to date. These may effect the Pump,

Heat Exchanger, Air Cooled Heat Exchanger, and Pressure Relief Device applications.

Device compatibility

Emerson devices must be in Emerson Optimized burst configuration. If devices are not set

to this, change using a device configuration tool.

Devices without this capability must be in either of the two configuration modes to be

compatible with Plantweb Insight:

• command 9 and command 48

• command 3 and command 48

2.3 Installation procedure

Two DVDs will be supplied for installations.

Procedure

1. Exit/close all programs, including any running in the background.

2. Insert Disk 1 into the DVD drive.

3. Open the .ova file. This file will prompt VMware Workstation/vSphere to open with

an Import Virtual Machine pop-up.

10 Emerson.com/Plantweb

Page 11

Reference Manual

Installation

00809-0100-4541 June 2020

Note

This file name may change based on version and type.

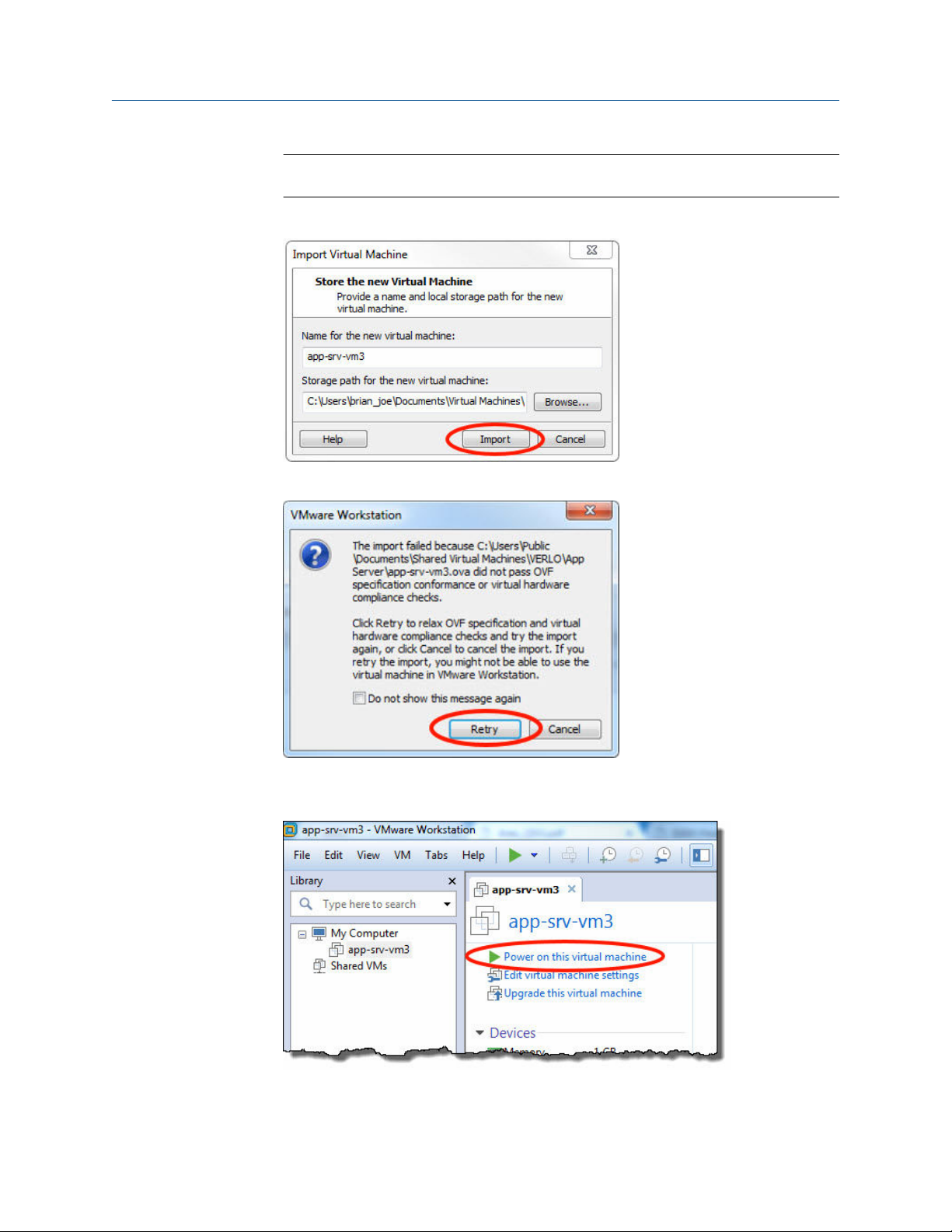

4. Name and store the new virtual machine, then select Import.

5. If the following message appears select,Retry.

6. Wait for the virtual machine to load.

7. Select Power on this virtual machine once the loading process is complete.

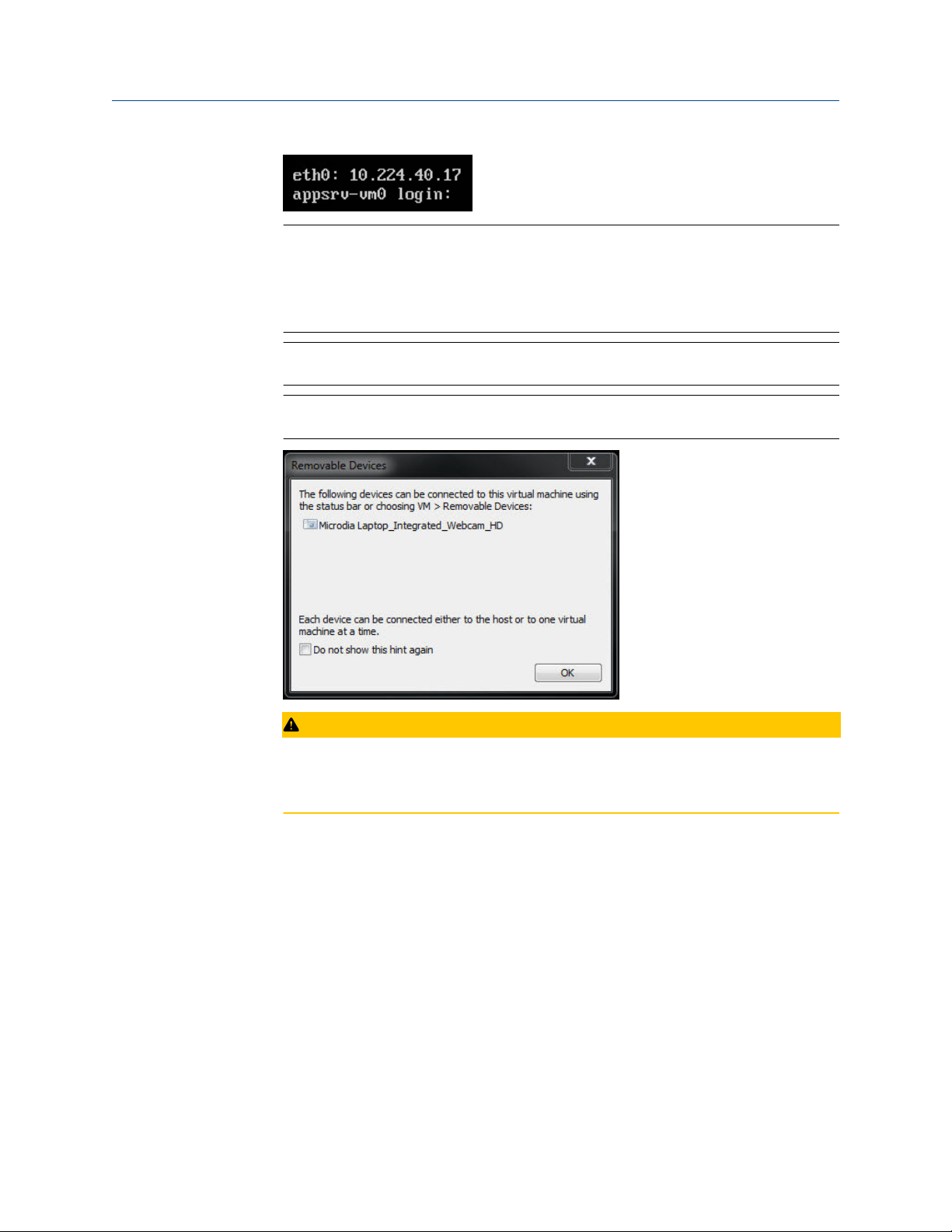

8. Find the IP address in the command window.

Emerson.com/Plantweb 11

Page 12

Installation

June 2020 00809-0100-4541

Note

This IP address will vary depending on installation. What is shown here will not be

your IP address.

A DHCP server will be required to assign an IP address. If no DHCP server is available,

contact Rosemount support (contact information on last page).

Note

The virtual machine login and password are not necessary and will not be provided.

Note

A message about features may pop up during the installation process; select OK.

Reference Manual

CAUTION

End users should not change any settings besides the ones outlined above.

Alterations could impact the performance and functionality of Plantweb Insight.

2.4 Launching the application

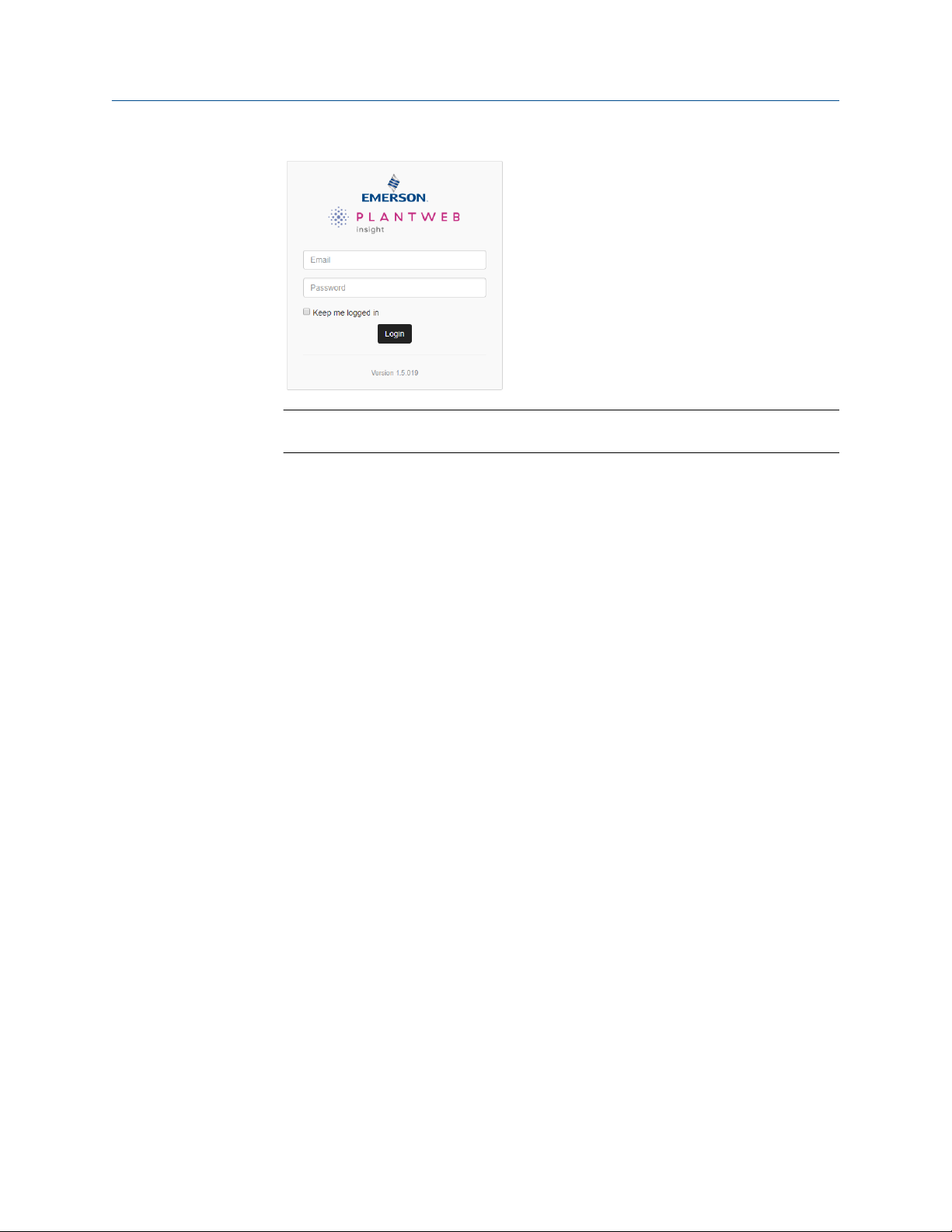

The Plantweb Insight web interface can be launched from any of the supported web

browsers shown in the system requirements.

Procedure

1. Open a supported web browser.

2. Beginning with “https://”, enter the IP address found in Step 8 of Installation

procedure.

3. Login with the following credentials:

• Email: admin@emerson.com

• Password: Default.1234

12 Emerson.com/Plantweb

Page 13

Reference Manual Installation

00809-0100-4541 June 2020

Note

Both the email and password are case sensitive.

4. Change your password as prompted (default settings are listed below and can be

changed in System Settings).

• Minimum length: 12

• Minimum lowercase: 1

• Minimum uppercase: 1

• Minimum numbers: 1

5. Login with the updated credentials.

Emerson.com/Plantweb 13

Page 14

Installation Reference Manual

June 2020 00809-0100-4541

14 Emerson.com/Plantweb

Page 15

Reference Manual Configuration

00809-0100-4541 June 2020

3 Configuration

3.1 Overview

This section contains information on customizing system settings and configuring

Plantweb Insight.

3.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operation. Information that raises potential safety

issues is indicated by a warning symbol ( ). Refer to the following safety messages before

performing an operation preceded by this symbol.

3.3 Customize system settings

3.3.1

System settings should be configured during the setup of Plantweb Insight.

Users

User accounts

Add users

Procedure

1. Navigate to System Settings → Users → User Accounts then select the Add User

Account button.

2. Enter the user’s email, role, and password then select Save.

Table 3-1: Roles and Privileges

User role Privileges

Admin Read and write

User Read

Edit users

Procedure

1. Navigate to System Settings → Users.

2. Select the button next to the user to be edited.

Note

If the user is disabled, you can enable the user in the modal window.

Emerson.com/Plantweb 15

Page 16

Configuration Reference Manual

June 2020 00809-0100-4541

3. Update the information and select Save.

Note

Users can be deleted by selecting the Delete this account box.

Password options

Password requirements and settings can be made in the Password Option page. These

settings include password limitations and requirements (e.g. uppercase letters, lowercase

letters, numbers, characters), session idle timeouts, and account locking details.

Change password

Login password can be changed in the Change Password page.

3.3.2

Data source configuration

Gateway connections

Add Gateway

Procedure

1. Navigate to System Settings → Data Sources → Gateway Connections.

2. Select the Add Gateway button.

3. Enter the IP Address, Port, and Description and select Save.

Note

HART-IP™ Port 5094. Ensure both HART-IP TCP and HART-IP UDP are enabled in the

Gateway.

Edit Gateway

Procedure

1. Navigate to System Settings → Data Sources → Gateway Connections.

2. Select the button next to the user to be edited.

3. Update the information and select Save.

Delete Gateway

Procedure

1. Select the check box/boxes next to the Gateway/s to be deleted.

2. Select red Delete Selected button.

16 Emerson.com/Plantweb

Page 17

Reference Manual Configuration

00809-0100-4541 June 2020

OPC UA Server Connection

Add OPC UA Server

Procedure

1. Navigate to System Settings → Data Sources → OPC UA Server Connections.

2. Select Add OPC UA Server button.

3. Enter the IP Address, Port, Tag, and Description and select Save.

Note

The OPC UA® Port in Plantweb Insight is designated as 4880 (the OPC UA Server

must be set up for this port). Plantweb Insight uses a opc.tcp:// connection to the

OPC UA Server. Tag and Description are used for explanatory reasons only.

The IP address field will only accept IP addresses and will not accept full URLs (it

assumes the opc.tcp://).The OPC UA Server must be configured to security

configuration “none” and “allow anonymous login”.

Edit OPC UA Server

3.3.3

Procedure

1. Navigate to System Settings → Data Sources → OPC UA Server Connections.

2. Select the button next to the Server to be edited.

3. Update the information and select Save.

Delete OPC UA Server

Procedure

1. Select the check box/boxes next to the Server/s to be deleted.

2. Select red Delete Selected button.

Network configuration (optional)

CAUTION

Use caution when making changes to IP network settings. If they are lost of improperly

configured, it may be difficult to log into the application. Contact the network

administrator for information on the proper IP network setting to apply.

Plantweb Insight contains two network interfaces. Only network interface 1 allows web

client access. Network interface 1 will be associated to network adapter 1 of the virtual

machine. Network interface 2 will be associated to network adapter 2 of the virtual

machine. Network interface 2 is non-routable.

The second network adapter needs to be configured in VMware Workstation/vSphere to

activate the functionality of the second network.

To change IP Network Settings:

Emerson.com/Plantweb 17

Page 18

Configuration Reference Manual

June 2020 00809-0100-4541

Procedure

1. Navigate to System Settings → Platform Settings → Ethernet Communication.

2. To change network interface 1, select Static IP Address.

3. Enter the following:

• Hostname

• IP Address

• Netmask

• Gateway

4. To enable network interface 2, select the enable check box.

5. Select Static IP Address.

6. Enter the following:

• IP Address

• Netmask

3.3.4

7. Select Save.

Platform settings

Plantweb Insight has a system backup and restore feature that saves all user configured

data. It is best practice that a system backup be performed periodically throughout the

installation and configuration process.

Save system backup

Procedure

1. Navigate to System Settings → Platform Settings → Backup and Restore.

2. Create a Passphrase then select Save Backup button.

18 Emerson.com/Plantweb

Page 19

Reference Manual Configuration

00809-0100-4541 June 2020

Note

Passphrase is required for restoring your system to these settings.

Restore system

Procedure

1. Navigate to System Settings → Platform Settings → Backup and Restore.

2. Enter the system backup passphrase.

3. Browse for the backup file then select Install button.

3.4 Application installation

Procedure

1. Insert Disk 2 into the DVD drive.

2. In the web interface navigate to System Settings → Platform Settings → Manage

Applications.

3. Under the Install App section, select the Browse button.

4. Navigate to Disk 2.

5. Select the pertinent .app file then select Open.

6. Select Install.

7. An action prompt will appear - select Restart Server if this is the last app to install.

Otherwise, select Resume and repeat Step 3-Step 6 for subsequent apps.

8. Navigate to Home and the apps installed will appear.

3.5 Application configuration

There are a few configuration steps that are consistent across specific Plantweb Insight

applications. These are briefly discussed below. More information about configuration can

be found in the specific Appendix.

Note

All configuration mentioned below is specific to Plantweb Insight. Changes will not be

communicated to the Gateway or devices.

Emerson.com/Plantweb 19

Page 20

Configuration Reference Manual

June 2020 00809-0100-4541

3.5.1 Global settings

Each application contains specific global settings that should be set before any asset

configuration. Global settings apply to all assets. These settings could include units used

for inputs (e.g. inlet pressure units), units used for calculations (e.g. currency), or key

performance indicators to be tracked on the dashboard (e.g. overall health index).

3.5.2 Adding assets

There are two ways to add assets. The options are discussed below. Configuration of

devices occurs during addition of assets.

Add an asset

Use this method to add a single asset.

Procedure

1. Navigate to the Asset Summary tab then select the Add an Asset button.

2. Complete all information on the New Asset modal window then select Save (field

descriptions can be found in the Appendix.

Add a measurement point

Wireless device from an Emerson Wireless Gateway

Depending on the application, wireless devices can either be added using a drop-down list

or a search function.

Procedure

1. For applications (Steam Trap application) requiring specific devices, the devices can

be added by selecting the appropriate device via a drop-down list. The drop-down

list will contain all devices with the pertinent device type.

2. For applications with generic measurements (pressure, temperature, flow, etc.) the

wireless devices can be added using the following:

a. Select Source: HART-IP

b. Begin to type the device tag. After a few characters, a dropdown list of

recognized devices will appear. Select the pertinent device.

c. Select the pertinent variable (ex: PV).

20 Emerson.com/Plantweb

Page 21

Reference Manual Configuration

00809-0100-4541 June 2020

OPC-UA tags

OPC-UA® tags can be set up for certain measurement points.

Procedure

1. Select Source: OPC-UA

2. Select the pertinent OPC-UA server.

3. Type in the complete path to the pertinent measurement point (ex: Objects/

Devices/OPC_Server1/3051S/PV).

• Use forward slashes, "/", for path breaks

• The entire path is case sensitive

Manual input

Manual inputs should be used sparingly for measurement points. They should only be

considered for known consistent conditions (motor speed).

Procedure

1. Select Source: Manual

2. Type in the manual value.

3. Select the pertinent units.

Note

Depending on the application, it will likely take time for the calculations to begin

processing. Certain applications require capturing a baseline. This process is

described in the Appendix.

Emerson.com/Plantweb 21

Page 22

Configuration Reference Manual

June 2020 00809-0100-4541

Import asset config

Use this method to add/edit multiple assets at the same time.

Procedure

1. Navigate to Asset Summary tab then select Import Asset Config button.

2. Select Download asset configuration to download the csv file.

Note

If there are no assets configured, select the Empty File box.

3. Complete the csv file and save files.

Note

Data fields have strict requirements for entries; these can be found in Import Specs

File.

Configuring device

For configuring the device, use the following guides.

For HART-IP™ from a WirelessHART® Gateway:

Entry tag Description Data type Values Example

XXXX_source Data source String HART-IP HART-IP

XXXX_tag Device tag String String 3051S

XXXX_value Device parameter String • PV

• SV

• TV

• QV

PV

For OPC UA data points:

Entry tag

XXXX_source Data source String OPC UA OPC UA

XXXX_tag Device tag String String 3051S.PV

Description Data type Values Example

For Manual data entry:

Entry tag

Description Data type Values Example

XXXX_source Data source String Manual Manual

XXXX_tag Parameter value Float Any value 100.00

Procedure

1. Browse and upload the csv file via the Import Asset Config modal window then select

Save.

22 Emerson.com/Plantweb

Page 23

Reference Manual Configuration

00809-0100-4541 June 2020

2. Check all assets were successfully downloaded.

3. If assets fail download, check all fields are filled out correctly and download again.

3.5.3 Editing assets

There are two ways to edit assets. The options are discussed below.

Edit singular asset

Procedure

1. Navigate to Asset Summary tab.

2. Select Asset to edit. The Details modal window will pop up with all fields to edit.

3. Select Save when complete.

Note

Assets can be deleted by selecting the Delete Asset button.

Import asset config

Procedure

1. Navigate to Asset Summary tab and select the Import Asset Config button.

2. Select Download asset configuration and download the csv file.

3. Edit the csv file and save files.

Note

Data fields have strict requirements for entries; these can be found in the

appropriate manual supplement.

4. Browse and upload the csv file via the Import Asset Config modal window and select

Save.

5. Check all assets were successfully downloaded.

6. If assets fail download, check all fields are filled out correctly and download again.

Emerson.com/Plantweb 23

Page 24

Configuration Reference Manual

June 2020 00809-0100-4541

24 Emerson.com/Plantweb

Page 25

Reference Manual Version Upgrades

00809-0100-4541 June 2020

4 Version Upgrades

Backup all files before installing a new version.

4.1 Virtual machine upgrades

Procedure

1. Ensure an up to date backup has been saved following the steps in the Save System

Backup procedure.

2. Install the new Plantweb Insight virtual machine following the steps in Installation

procedure.

3. Restore the backup file following the steps in the Restore System procedure.

4.2 Application upgrades

Procedure

1. Navigate to System Settings → Platform Settings → Manage Applications.

2. Install the new version following the steps in Application installation. You will

receive a prompt to replace the old version of the application.

3. If applicable, restore the system backup to retrieve configuration.

4.3 Platform upgrades

Procedure

1. Navigate to System Settings → Platform Settings → Manage Base Platform.

2. Browse and upload the pertinent upgrade file.

3. Select Update.

4. Select Restart Server.

5. If applicable, restore the system backup to retrieve configuration.

Emerson.com/Plantweb 25

Page 26

Version Upgrades Reference Manual

June 2020 00809-0100-4541

26 Emerson.com/Plantweb

Page 27

Reference Manual Modbus TCP Mapping

00809-0100-4541 June 2020

5 Modbus TCP Mapping

The following default Modbus® TCP ports are defined in Plantweb™ Insight:

Table 5-1: Modbus TCP Ports

Application Modbus TCP port

Steam trap 502

Pump 503

Heat exchanger 505

Air cooled heat exchanger 506

Pressure relief valve 507

Cooling tower 508

Registers and tags are prepopulated in specific Plantweb Insight applications and can be

accessed using the Download Modbus Mapping csv file in each application’s Settings

page. These registers and tags cannot be changed.

An example csv file will appear like the table shown below.

Function

1 0 ST-001.OOS

4 0 ST-001.STATE

4 1 ST-001.EMISSIONS

4 3 ST-001.COST

The function in the first column refers to the generic Modbus TCP function codes.

Emerson.com/Plantweb 27

Register Tag

Page 28

Modbus TCP Mapping Reference Manual

June 2020 00809-0100-4541

Function code Function Description

01 Read Coil Obtain status of one or more discrete

outputs

02 Read Discrete Input Obtain status of one or more discrete

inputs

03 Read Holding Registers Obtain value of one or more output

data registers

04 Read Input Registers Obtain value of one or more input

data registers

05 Write Single Coil Force a single discrete output

06 Write Single Holding Register Force a single data register to a

specified value

15 Write Multiple Coils Force multiple discrete outputs

16 Write Multiple Holding Registers Force multiple data registers to a

specified value

The second column refers to the register number (ex: ST-001.STATE uses function code 4

– read input registers, starting at 30000):

Function Register #s (Data

addresses)

Coil 00000-09999 FC01 FC05 FC15

Discrete Input 10000-19999 FC02 N/A N/A

Input Register 30000-39999 FC04 N/A N/A

Holding Register 40000-49999 FC03 FC06 FC16

Read Write single Write multiple

28 Emerson.com/Plantweb

Page 29

Reference Manual Modbus TCP Mapping

00809-0100-4541 June 2020

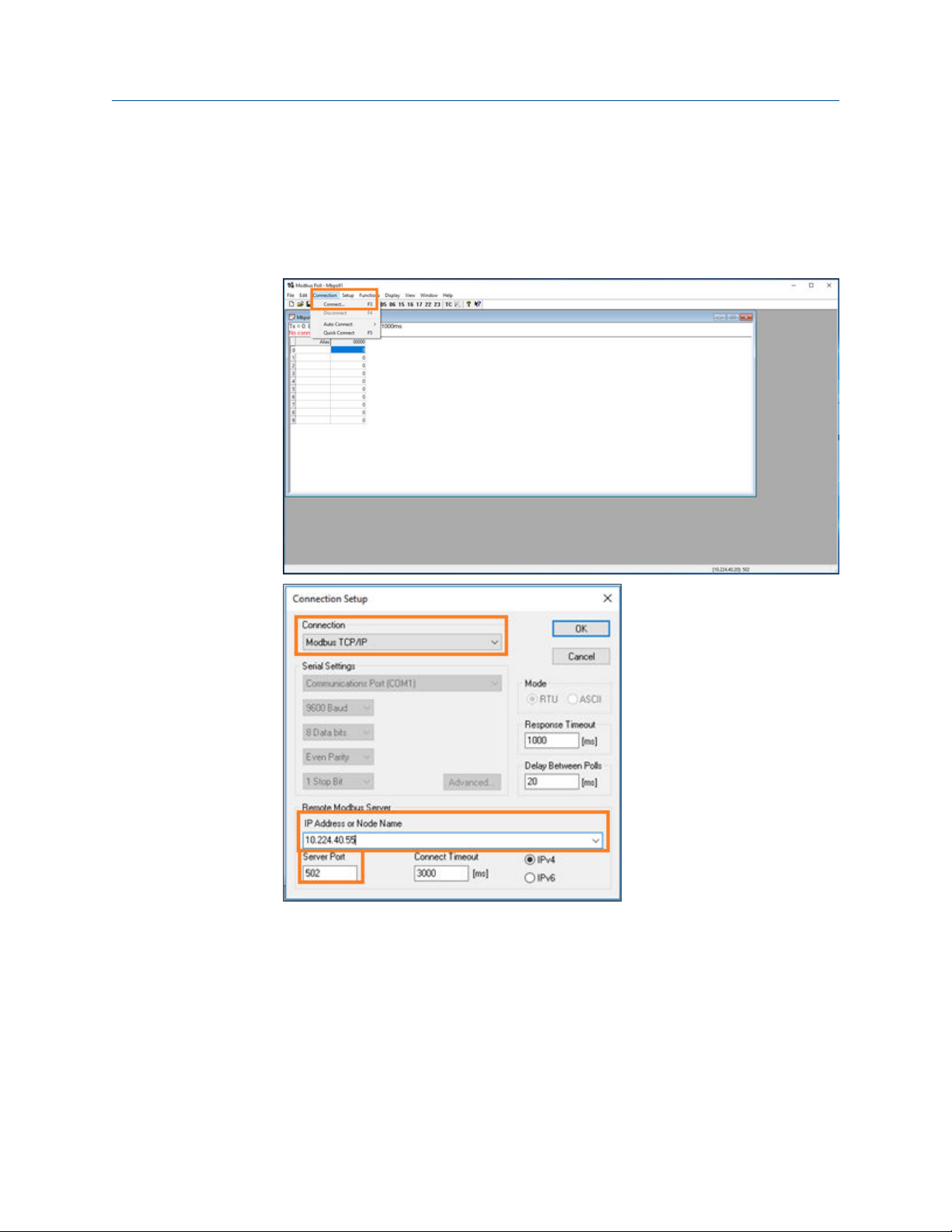

5.1 Setting up Modbus TCP from data system

Procedure

1. In the Modbus TCP enabled device, establish connection to Plantweb Insight. Select

Connection > Connect (F3)

Connection: Modbus TCP/IP

IP Address: IP address of Plantweb Insight

Server Port: TCP Port of the application being connected (ex: Steam Trap

application = 502)

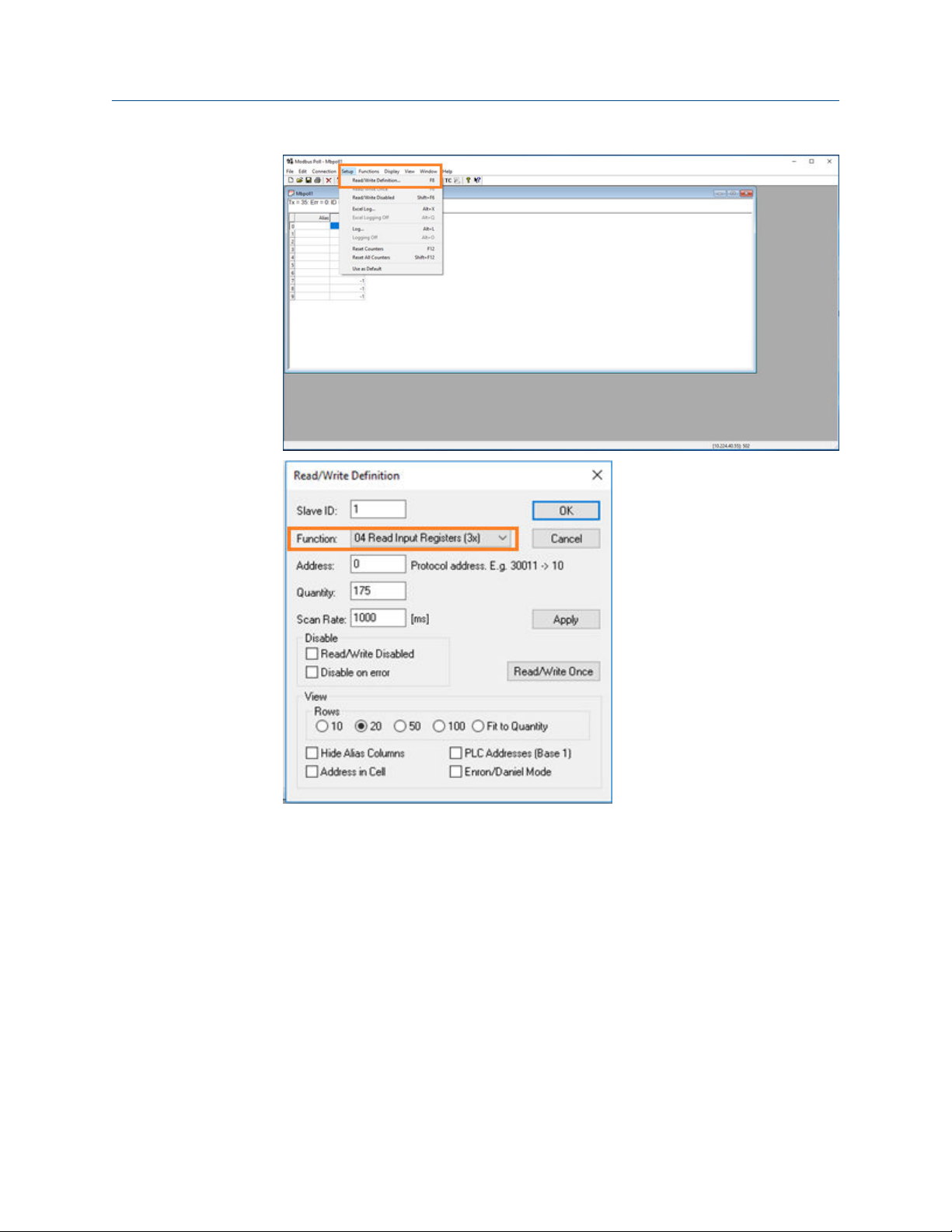

2. Configure the read/write definitions properly. Select Setup > Read/Write

Definition...

Emerson.com/Plantweb 29

Page 30

Modbus TCP Mapping Reference Manual

June 2020 00809-0100-4541

Function: 04 Read Input Registers (3x)

30 Emerson.com/Plantweb

Page 31

Reference Manual Modbus TCP Mapping

00809-0100-4541 June 2020

Result formats may need to be changed to match the following requirements:

See below example:

• State:

• Emissions:

Output Format

State 16-bit signed

Emissions 32-bit signed float big-endian

Cost 32-bit signed float big-endian

Health 32-bit signed float big-endian

Alert 16-bit signed

Emerson.com/Plantweb 31

Page 32

Modbus TCP Mapping Reference Manual

June 2020 00809-0100-4541

32 Emerson.com/Plantweb

Page 33

Reference Manual Troubleshooting

00809-0100-4541 June 2020

6 Troubleshooting

6.1 Service support

To expedite the return process outside of the United States, contact the nearest Emerson

representative.

Within the United States, call the Emerson Instrument and Valve Response Center using

the 1-800-654-RSMT (7768) toll-free number. This center, available 24 hours a day, will

assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return

Material Authorization (RMA) number. The center will also ask for the process material to

which the product was last exposed.

CAUTION

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of and understand the hazard. Returned products must include a copy of the

required Safety Data Sheet (SDS) for each substance.

Emerson Instrument and Valve Response Center representatives will explain the additional

information and procedures necessary to return goods exposed to hazardous substances.

NOTICE

Shipping considerations for wireless products.

• The unit was shipped to you without the Power Module installed. Please remove the

Power Module prior to shipping the unit.

• Each Power Module contains two "C" size primary lithium/thionyl chloride batteries.

Primary lithium batteries (charged or discharged) are regulated during transportation

by the U.S. Department of Transportation. They are also covered by IATA (International

Air Transport Association), ICAO (International Civil Aviation Organization), and ARD

(European Ground Transportation of Dangerous Goods). It is the responsibility of the

shipper to ensure compliance with these or any other local requirements. Consult

current regulations and requirements before shipping.

Emerson.com/Plantweb 33

Page 34

Troubleshooting Reference Manual

June 2020 00809-0100-4541

6.2 Plantweb Insight: Unable to load Plantweb Insight Virtual Machine

Possible cause: Intel VT-x is diabled

Recommended actions

1. Verify that the BIOS/firmware settings enable Intel VT-x and disable 'trusted

execution.'

2. Power-cycle the host if either of these BIOS/firmware settings have been

changed.

3. Power-cycle the host if you have not done so since installing VMware Player.

4. Update the host's BIOS/firmware to the latest version.

5. For more detailed information, see http://vmware.com/info?id=152.

Possible cause: System settings configuration

Recommended action

Follow the steps in the

have similar procedures.

video to resolve. Different operating systems and hardware will

34 Emerson.com/Plantweb

Page 35

Reference Manual Troubleshooting

00809-0100-4541 June 2020

6.3 Plantweb Insight: Virtual machine displaysv--IP Address Unknown--

Possible cause: No available DHCP server to assign a valid IP address

Recommended actions

1. Ensure the Plantweb Insight machine has access to a DHCP server.

2. Check both VMware Workstation Pro™/EXSi virtual network editor settings and

the Ethernet adapter settings.

3. Contact Rosemount Customer Central if a static IP address is necessary from

the start (static IP can be configured once into the web user interface).

VMware Workstation Pro does contain a native DHCP server. When utilizing this

program, the following procedure can be followed.

If there is no DHCP server available, VMware Workstation Pro contains a native

DHCP server through its NAT connections.

a. To utilize this, load the virtual machine and set the Network Adapter to

NAT.

b. Power on the virtual machine. It will return an IP address like the

following.

Emerson.com/Plantweb 35

Page 36

Troubleshooting Reference Manual

June 2020 00809-0100-4541

c. Type the IP address into a supported browser and begin the initial

configuration.

d. Configure a Static IP address using instructions found in Network

configuration (optional).

6.4 Plantweb Insight: OVF file error

Possible cause: Plantweb Insight virtual machine is installed in VMware vSphere

client

Recommended actions

Install the Plantweb Insight virtual machine in the VMware vSphere® Web Client or

ESXi Embedded Host Client.

6.5 Plantweb Insight: Web interface cannot be accesed

Recommended actions

1. Ping Plantweb Insight IP address to check for connection (ping is open).

2. Ensure client and Plantweb Insight are connected to the same subnet.

3. Ensure connection is through https://.

4. This could relate to a DHCP server related issue - Consult Rosemount Customer

Central.

6.6 Plantweb Insight: Web interface login continues to spin after inputting email and password

36 Emerson.com/Plantweb

Page 37

Reference Manual Troubleshooting

00809-0100-4541 June 2020

Recommended actions

External connections that are port forwarded to the Plantweb Insight platform will

likely cause issues - if this is necessary, consult Rosemount Customer Central.

6.7 Plantweb Insight: Cannot connect to WirelessHART Gateway

Recommended actions

After navigating to System Settings > Data Source Config > Gateway Connections,

theGateway IP Address, Port (5094), and description were inputted. The Inactive box is

stillchecked.

nsure WirelessHART® Gateway is upgraded to the most recent firmware

1. E

version.

2. Ensure HART-IP UDP and HART-IP TCP are both enabled in the Gateway.

a. In the Gateway, navigate to System Setting → Protocols → Protocols

and Ports

3. Ensure Plantweb Insight has access to the WirelessHART Gateway.

a.

The Plantweb Insight machine needs to be able to see and communicate

with the Gateway.

b. Both must be on the same subnet.

c. HART-IP traffic must be allowed through the communication channel.

6.8 Plantweb Insight: Click on application logo and nothings happens

After installing applications and navigating to the homepage the user selects an

application. Nothing occurs when the user clicks on the application.

Emerson.com/Plantweb 37

Page 38

Troubleshooting Reference Manual

June 2020 00809-0100-4541

Possible cause: Application installed is not compatible with the Plantweb Insight

version

Recommended actions

Check the compatibility matrix below. If a different application and/or platform is

required, contact Rosemount Customer Central.

6.9 Steam trap application: Asset status displays "NoData/Error" after configuration

Possible cause: The steam trap algorithm takes around 90 minutes to calculate a

status once it is configured

Recommended actions

1. Wait for 90 minutes until status populates.

2. To ensure this is the error, you may check the Device Health field and make sure

it has a “Good” status.

38 Emerson.com/Plantweb

Page 39

Reference Manual Troubleshooting

00809-0100-4541 June 2020

6.10 Steam trap application: Asset status display "No Config"

Possible cause: Failure configuration of the required inputs

Recommended actions

More information on a “No Config” error can be viewed on the “Device Health” field of the

Asset Details.

1. Configure these required inputs for the Steam Strap Application:

• Pressure inlet

• Pressure outlet

• Line size

• Orifice size

• Trap type

2. Ensure the Rosemount Wireless Acoustic 708 Transmitter update rate is

between one minute and five minutes.

6.11 Steam trap application: Asset status in question

Use the following table to troubleshoot asset status questions. If these do not resolve the

issue, contact Rosemount Customer Central.

Emerson.com/Plantweb 39

Page 40

Troubleshooting Reference Manual

June 2020 00809-0100-4541

Plantweb insight

asset status

Blowthrough Good • Check the outlet pressure user input. Keep in

Confirmed steam trap

status

Comments

mind this value is pertaining to the

condensate return line. If the trap is venting

to atmosphere, the pressure outlet should

be 0. Only if there is backpressure in the

condensate line should this value be greater

than 0.

• There is a possibility the steam trap is being

overused and registering a blowthrough

status due to excessive operation. This could

indicate the trap is undersize for its

application. Ensure this is not the case

before adjusting settings.

• The Rosemount 708 transmitter is indicating

a high acoustic count situation. If this is due

to background noise and not the steam trap,

there are two steps to alleviate:

— Change the steam trap configuration to

“medium” or “high” noise filter level to

account for background noise.

— Enable the “noise suppression” function

in the Rosemount 708.

Inactive

Good Blowthrough • Ensure all configuration inputs are current

Plugged/flooded Good • Ensure all configuration inputs are correct

• The Rosemount 708 transmitter is reading a

very low skin temperature of the steam pipe.

If this is incorrect, ensure the Rosemount

708 foot has flush contact to the steam pipe.

(inlet pressure, outlet pressure, etc.).

• The Rosemount 708 transmitter is reading

low acoustic counts. If this is incorrect,

ensure the Rosemount 708 foot has flush

contact to the steam pipe and ensure the

Rosemount 708 is installed according to

best practices (six inches from the inlet of

the steam trap).

(inlet pressure, outlet pressure, etc.).

• The Rosemount 708 transmitter is reading

relatively low skin temperature of the steam

pipe. If this is incorrect, ensure the

Rosemount 708 foot has flush contact to the

steam pipe.

40 Emerson.com/Plantweb

Page 41

Reference Manual Troubleshooting

00809-0100-4541 June 2020

6.12 Pressure Relief Device Application: Numerous “No_Data/Error” events

No_Data/Error events occur when data from the Rosemount 708 is not received in

Plantweb Insight in a reasonable time interval. It is designed to indicate when there is a

loss of visibility into the operation of a pressure relief device.

The Plantweb Insight platform does provide leeway for missed updates, however, if the

Rosemount 708 update rate is close to the minimum event duration of the PRD (ex: four

second update rate for the Rosemount 708 and four second minimum event duration)

there is an increased possibility of No_Data/Error events. To reduce the frequency of these

events, lengthen the minimum event duration or shorten the Rosemount 708 update rate

(keep network best practices in mind).

Note

Rule of thumb

Minimum event duration should be four times the Rosemount 708 update rate.

Emerson.com/Plantweb 41

Page 42

Troubleshooting Reference Manual

June 2020 00809-0100-4541

42 Emerson.com/Plantweb

Page 43

Reference Manual Steam Trap Application configuration and information

00809-0100-4541 June 2020

A Steam Trap Application configuration

and information

A.1 Overview

This document provides information on set up and configuration of the Steam Trap

Application within Plantweb™ Insight.

Prior to configuring your Steam Trap Application, be sure to complete all steps in the

Plantweb Insight Quick Start Guide. Some steps in the guide will be reiterated in this

document in more detail.

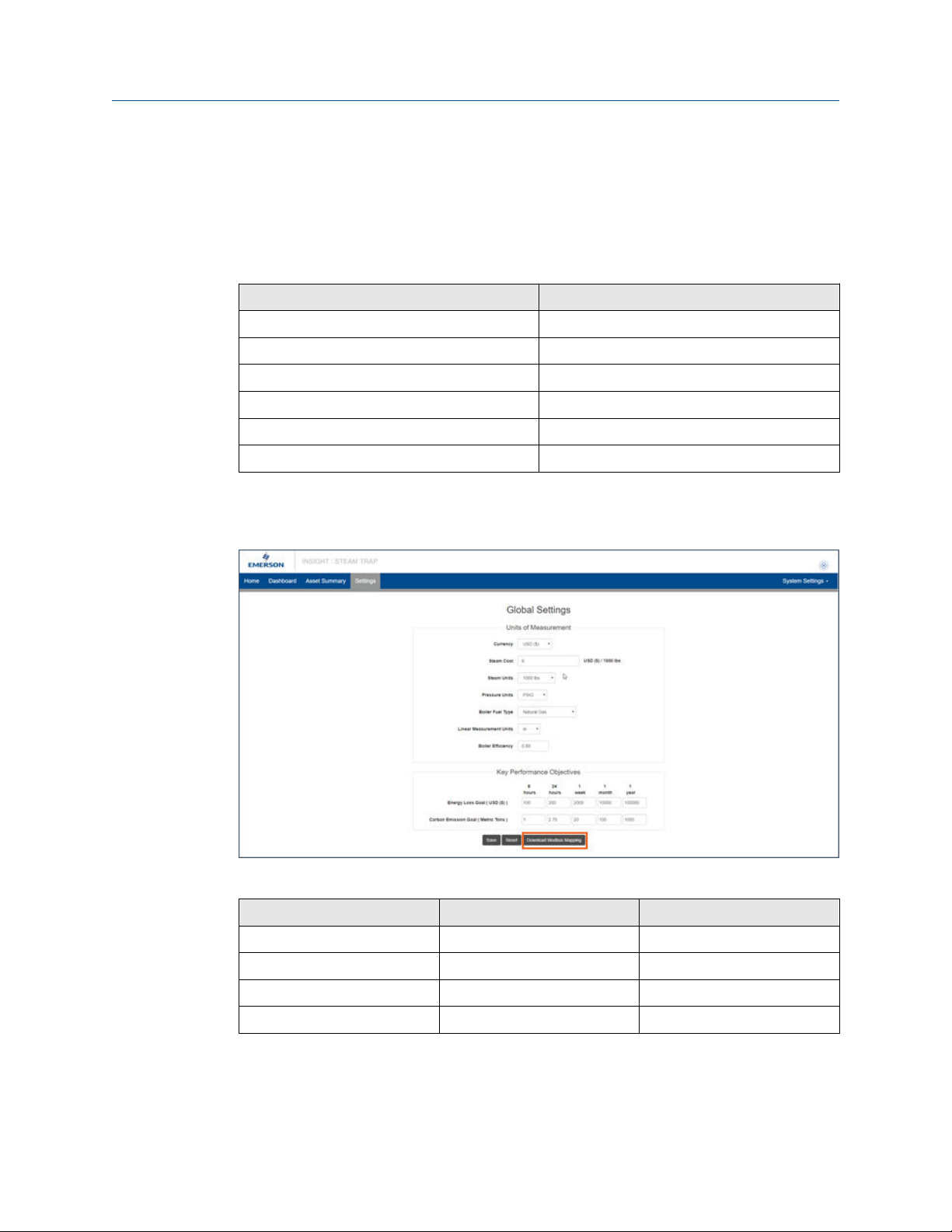

A.2 Global settings

Global settings should be set before any asset configuration is completed. These settings

apply to all assets within a specific application but do not change any settings within the

Gateway or devices. Changing any of these settings can be done in the Settings tab.

Table A-1: Units of Measurement

Field Input type Description/use

Currency Drop-down selection Used for determining the currency unit of your

energy costs

Steam cost Number entry Used for calculations

Steam units Drop-down selection Used for steam cost units

Pressure units Drop-down selection Used for inlet and outlet pressure entries

Boiler fuel type Drop-down selection Used for calculations

Linear measurement units Drop-down selection Used for orifice size and pipe size entries

Boiler efficiency Number entry (0–1) Used for calculations

Table A-2: Key Performance Objectives

Field Input type Description/use

Energy loss goal Number entry Used on dashboard for energy costs gauge goal

Carbon emissions goal Number entry Used on dashboard for carbon emissions gauge

goal

Emerson.com/Plantweb 43

Page 44

Steam Trap Application configuration and information Reference Manual

June 2020 00809-0100-4541

A.3 Adding assets

A.3.1 Fields of note

Pressure inlet

The inlet pressure can be tracked using a manual input, HART-IP™ variable, or OPC-UA

variable. To configure HART-IP and OPC-UA variables, follow the instructions from Adding

assets.

Orifice size

If orifice size information is not available, the table below can be used as a guide.

Table A-3: Orifice Specifications

Pressure (PSIG)

®

Line

size

(in.)

Pressure (BARG)

Line

size

(mm)

0 5 10 20 25 50 75 100 125 150 200 250

0

0.000 0.000

¼

3/8

½

¾

1

1½

1¾

2

0 0.3 0.7 1 2 3.5 5 7 8.5 11 15 20

0

0 0

5

10

15

20

0.125 0.125 0.125 0.094 0.094 0.094 0.094 0.094 0.094

0.188 0.188 0.125 0.125 0.125

0.250 0.250 0.188 0.156 0.156 0.125 0.125

0.375 0.313 0.250 0.219 0.188 0.156 0.125 0.125 0.125

0.500 0.438 0.344 0.313 0.281 0.250 0.219 0.188 0.188

0.500 0.469 0.438 0.375 0.375 0.344 0.313 0.281

0.500 0.469 0.438 0.438 0.375 0.344 0.344

0.500 0.500 0.500 0.469 0.438 0.375

3 3 3 2.5 2.5 2.5 2 2 2

5 5 4 3 3 2.5 2.5 2 2

7 7 5 4 3.5 3 3 3 2.5

10 9 7 6 5.5 5 4.5 4 3

25

40

45

50

44 Emerson.com/Plantweb

13 11 9 8 7.5 7 6 5.5 5

12.5 12 11 10.5 10 9 7.5 7

13 13 12 11.5 11 10 9.5 9

13 13 13 13 13 11 10 9.5

Page 45

Reference Manual Steam Trap Application configuration and information

00809-0100-4541 June 2020

Noise filter level

In noisy environments it may become necessary to filter out the surrounding noise so

sensitivity to leaking steam noise is restored. This can be accomplished by using the Noise

Filter Level advanced setting.

Temp deadband

Use Temperature Deadband settings to slow or contain state change “flipping”. Flipping

may occur when a trap is operating under “swinging” temperature conditions, including

heavy loads and rapidly modulating steam supply.

Temp rate alarm

Some critical steam systems require rapid indication of condensate accumulation. The

thermal mass of the trap and piping system introduce a significant thermal lag that can be

compensated through calculation. When Temp Rate Alarm is enabled, transition occurs

quickly.

A.4 Calculated fields

The Rosemount 708 Acoustic Transmitters update period must be between one and five

minutes due to polling and filtering considerations. The steam trap application will take at

least 90 minutes to complete its filtering and calculation cycle. During this time period,

the steam trap status will indicate “NO DATA/ERROR”.

A.4.1

Trap status

Trap state calculations are derived from ultrasonic amplitude (acoustic) and temperature

readings from the Rosemount 708 Acoustic Transmitters as well as static configuration

information. The following states are calculated.

Table A-4: State Descriptions

Value Name Description Action

0 GOOD Trap operating normally None

1 INACTIVE Trap is near room temperature None

2 UNUSED N/A N/A

3 BLOW-

THROUGH

4 NO DATA/

ERROR

Trap is within operational temperature limits and

is continuously allowing steam to escape into the

condensate return

The Rosemount 708 is not publishing data or is

publishing a fault condition

Investigate trap

Investigate Rosemount

708

5 NO CONFIG Critical user configuration information is missing Configure asset

6 OUT OF

SERVICE

(1)

7

Emerson.com/Plantweb 45

PLUGGED The trap is stuck in the closed position or there is

The trap is out of service (user writable) None

Investigate trap

a blockage in the trap inlet or outlet

Page 46

Steam Trap Application configuration and information Reference Manual

June 2020 00809-0100-4541

Table A-4: State Descriptions (continued)

Value Name Description Action

(1)

8

(1) To ensure safety, check trap temperature before performing maintenance on a cold trap.

FLOODED The trap temperature is below expected

operation limits but acoustic energy is present

(trap is operating)

Investigate trap sizing

and/or load conditions

A.4.2 Lost energy cost

When a steam trap is in a blow through state, unnecessary energy is used to produce

excess steam. There are different ways the lost energy costs can be viewed. One is a

accumulation of cost over the selected time period (8 hours, 24 hours, 1 week, 1 month, 1

year). Costs can also be viewed as an annual projection of the current state of the trap.

A.4.3

A.4.4

Emissions lost

When a steam trap is in a blow-through state, unnecessary emissions are expended to

produce excess steam. There are different ways the emissions loss can be viewed. One is a

accumulation of loss over the selected time period (8 hours, 24 hours, 1 week, 1 month, 1

year). Losses can also be viewed as an annual projection of the current state of the trap.

Device status

Table A-5: Device Status

Device health Description Action

GOOD Device operating normally None

POWER_MODULE_LOW Power module has low battery Prepare to replace

power module

POWER_MODULE_CRITICAL Power module has a critically low

battery

DEVICE_MALFUNCTION Device has a malfunction Investigate device

NO_DATA No polling data was found Investigate device

ASSET_OUT_OF_SERVICE The asset is set to out of service (user

writable)

DEVICE_NOT_FOUND The asset's device can not be found Investigate device

Replace power module

None

DEVICE_OUT_OF_SERVICE The asset's device is set to out of

service

GATEWAY_NOT_FOUND The Gateway associated with the

asset's device can not be found

GATEWAY_OUT_OF_SERVICE The Gateway associated with the

asset's device is set to out of service

NO_APP_TYPE The steam trap type is not configured Configure the steam

46 Emerson.com/Plantweb

None

Investigate Gateway

None

trap type

Page 47

Reference Manual Steam Trap Application configuration and information

00809-0100-4541 June 2020

Table A-5: Device Status (continued)

Device health Description Action

NO_O_SIZE The steam trap orifice size is not

configured

NO_L_SIZE The steam trap line size is not

configured

NO_P_IN The steam trap inlet pressure is not

configured

NO_P_OUT The steam trap outlet pressure is not

configured

UPDATE_RATE<60s The Rosemount 708 update rate is

less than 60 seconds

DATA_TOO_OLD Polling data period is longer than

anticipated

A.5 Modbus® TCP mapping

Procedure

1. There are three Modbus TCP outputs and one Modbus TCP input that are predefined in the steam trap app for every asset.

Configure the steam

trap orifice size

Configure the steam

trap line size

Configure the steam

trap inlet pressure

Configure the steam

trap outlet pressure

Configure the

Rosemount 708 update

rate to the

recommended 5

minutes

Investigate device

Input

Output Steam trap status (value described in Table A-4)

Output Lost energy cost

Output Emissions lost

Out of service

2. Modbus TCP registers and tags are pre-populated in Plantweb Insight and cannot be

changed.

3. Registers and codes can be found in each app by going to the app Settings (Global

Settings) and then selecting Download Modbus Mapping.

4. A csv file will open with the listed registers and tags.

Emerson.com/Plantweb 47

Page 48

Steam Trap Application configuration and information Reference Manual

June 2020 00809-0100-4541

48 Emerson.com/Plantweb

Page 49

Reference Manual Pump Application configuration and information

00809-0100-4541 June 2020

B Pump Application configuration and

information

B.1 Overview

This document provides information on set up and configuration of the pump application

within Plantweb™ Insight.

Prior to configuring your pump application, be sure to complete all steps in the Plantweb

Insight Quick Start Guide. Some steps in this guide will be reiterated in this document in

more detail.

B.2 Global settings

Global settings should be set before any configuration is completed. These settings apply

to all assets within a specific application but do not change any setting within the Gateway

or devices. Changing any of these settings can be done in the Settings tab.

B.2.1

B.2.2

Overall health index goal

Overall Health Index Goal is a number entry from 0–100 percent (100 percent =

completely healthy). It is used on the dashboard for the overall health index goal indicator.

Alert weights

Select the Alert Weights button on the Settings page.

Alert weights correspond to the severity of an alert (0 least severe, 100 most severe).

Defaults values are preconfigured for the application and can be changed at any time. The

most severe alert weight will be used for the health index indication for a given pump.

Alert Weight

0–15 Good

16–50 Warning

50+ Critical

Severity

B.3 Configuring assets

To finish configuring assets, navigate to the specific asset Details page by selecting the

asset from the Asset Summary page.

Emerson.com/Plantweb 49

Page 50

Pump Application configuration and information Reference Manual

June 2020 00809-0100-4541

B.3.1 Capture baseline

The pump application compares the current state of a pump against a baseline. The

baseline should be captured after all pertinent measurement points are configured and

the pump is in an ideal/typical operating state.

Once these criteria are met, the admin should capture a baseline using the following steps:

Procedure

1. Select the Capture Baseline button on the Details page. See Figure B-1.

Figure B-1: Capture Baseline

2. Ensure this is the indented baseline pump condition and select Yes.

50 Emerson.com/Plantweb

Page 51

Reference Manual Pump Application configuration and information

00809-0100-4541 June 2020

B.3.2 Editing alerts

After the baseline is captured, the pump application will automatically set alert thresholds

and limits for measurement points and calculations. Alerts will only be enabled when the

applicable measurement points are available. Use the below fault matrix to identify which

measurement points are required for which alerts. Alerts can be disabled and thresholds

can be manually configured.

Figure B-2: Pump Fault Matrix

Procedure

1. Select the Edit Alerts button on the Details page, as shown in the figure below.

Figure B-3: Edit Alerts

2. Use the Enable check boxes to enable/disable alerts.

3. Configure alert limits by manually filling in boxes. See figure below.

Emerson.com/Plantweb 51

Page 52

Pump Application configuration and information Reference Manual

June 2020 00809-0100-4541

Figure B-4: Asset Alert Details

Note

Some alerts may have complex calculations that do not allow configuration.

Note

Alerts can be reset to defaults at any time using the Reset to Default button.

B.4 Calculated fields

B.4.1 Measurement point thresholds

Based on the baseline capture, the pump application will automatically configure

thresholds for measurement points (Example: low pump flow, high DP across the strainer,

etc.). These thresholds are meant to alert the user to abnormal conditions pertaining to

the pump that could affect the overall health and performance.

B.4.2

Vibration and PeakVue increase

The “increase detected” and “SPC” (statistical performance calculation) alerts for both

vibration and PeakVue are used to identify statistically relevant changes in the vibration

measurements. These calculations use statistical analysis to detect an increase in vibration

readings over a period of time.

B.4.3

52 Emerson.com/Plantweb

Cavitation detection

Pump cavitation is detected from a significant increase in the discharge pressure (standard

deviation) and an increase in the PeakVue parameter of the pump. If the pump vibration is

not available, the standard deviation of the discharge pressure can be used to indicate

“precavitation” with less certainty.

Page 53

Reference Manual Pump Application configuration and information

00809-0100-4541 June 2020

B.4.4 Pump health index

The Pump Health Index is a 0–00 percent variable determined by the severity of pump

alerts. The pump health is 100 percent if there are not active alerts. Otherwise, the pump

health is calculated based on the following equation (100 percent – highest alert weight).

Therefore, pump status and health index are correlated to the alert weights. See Table B-1

and Table B-2.

Table B-1: Pump Health Index

Health index Pump status

86–100% Good

51–85% Warning

≤50% Critical

B.4.5 Pump status

Table B-2: Pump Status

Value Pump state Description

0 GOOD Pump health > 85%

4 NO DATA/ERROR There is not enough data for the pump state to

calculate

5 NO CONFIG Baseline has not been captured for the pump

6 OUT OF SERVICE Pump is out of service (user writable)

7 WARNING Pump health is between 50% and 85%

8 CRITICAL Pump health is < 50%

Emerson.com/Plantweb 53

Page 54

Pump Application configuration and information Reference Manual

June 2020 00809-0100-4541

B.5 Modbus TCP mapping

There are three Modbus® Transmission Control Protocol (TCP) outputs and one Modbus

TCP input that are predefined in the pump app for every asset. See table below.

Table B-3: Modbus TCP Definitions

Modbus TCP Definition

Input Out of service

Output Pump state (value described in Table B-2)

Output Pump alert

Output Pump health

Note

Modbus TCP registers and tags are automatically populated in Plantweb Insight and

cannot be changed.

Procedure

1. Registers and codes can be found in each app by going to the app Settings (Global

Settings) then select Download Modbus Mapping.

2. A csv file will open with the listed registers and tags.

54 Emerson.com/Plantweb

Page 55

Reference Manual Heat Exchanger Application configuration and information

00809-0100-4541 June 2020

C Heat Exchanger Application

configuration and information

C.1 Overview

This document provides information on set up and configuration of the Heat Exchanger

Application within Plantweb™ Insight.

Prior to configuring your Heat Exchanger Application, be sure to complete all steps in the

Emerson Plantweb Insight Quick Start Guide. Some steps in this guide will be reiterated in

this document in more detail.

C.2 Global settings

Global settings should be set before any configuration is completed. These settings apply

to all assets within a specific application but do not change any setting within the Gateway

or devices. Changing any of these settings can be done in the Settings tab.

C.2.1

C.2.2

Energy loss goal

Used in the dashboard for energy costs gauge goal.

Alert weights

Select the Alert Weights button on the Settings page.

Alert weights correspond to the severity of an alert (0 least severe, 100 most severe).

Defaults values are preconfigured for the application and can be changed at any time. The

most severe alert weight will be used for the health index indication for a given heat

exchanger.

Alert weight

0–15 Good

16–50 Warning

50+ Critical

Severity

C.3 Configuring assets

To finish configuring assets, navigate to the specific asset Details page by selecting the

asset from the Asset Summary page.

Emerson.com/Plantweb 55

Page 56

Heat Exchanger Application configuration and information Reference Manual

June 2020 00809-0100-4541

C.3.1 Capture baseline

The Heat Exchanger Application compares the current state of a heat exchanger against a

baseline. The baseline should be captured after all pertinent measurement points are

configured and the heat- exchanger is in an ideal/typical operating state (usually after

cleaning).

Once these criteria are met, the admin should capture a baseline using the following steps:

Procedure

1. Select the Capture Baseline button on the Details page. See Figure C-1.

2. Ensure this is the intended baseline heat exchanger condition and select Yes.

Figure C-1: Capture Baseline

56 Emerson.com/Plantweb

Page 57

Reference Manual Heat Exchanger Application configuration and information

00809-0100-4541 June 2020

C.3.2 Editing alerts

After the baseline is captured, the Heat Exchanger Application will automatically set alert

thresholds and limits for measurement points and calculations. Alerts will only be enabled

when the applicable measurement points are available. Use the below fault matrix to

identify which measurement points are required for which alerts. Alerts can be disabled

and thresholds can be manually configured.

Figure C-2: Heat Exchanger Fault Matrix

Procedure

1. Select the Edit Alerts button on the Details page, as shown in figure below.

Figure C-3: Edit Alerts

2. Use the Enable check boxes to enable/disable alerts

3. Configure alert limits by manually filling in boxes. See Figure C-4.

Note

Some alerts may have complex calculations that do not allow configuration.

Emerson.com/Plantweb 57

Page 58

Heat Exchanger Application configuration and information Reference Manual

June 2020 00809-0100-4541

Figure C-4: Asset Alert Details

Note

Alerts can be reset to defaults at any time using the Reset to Default button.

C.4 Calculated fields

C.4.1 Measurement point thresholds

Based on the baseline capture, the heat exchanger application will automatically configure

thresholds for measurement points (Example: low hot side flow, high cold side DP, etc.).

These thresholds are meant to alert the user to abnormal conditions pertaining to the heat

exchanger that could affect the overall health and performance.

C.4.2

Heat duty

Heat duty is calculated using flow, temperature, heat capacity, vapor fractions, and heat of

vaporization. It can be used as an indication of the amount of heat transferred from one

fluid to another. Heat duty is calculated for both the hot and cold sides as well as a delta to

check degradation.

58 Emerson.com/Plantweb

Page 59

Reference Manual Heat Exchanger Application configuration and information

00809-0100-4541 June 2020

C.4.3 Heat exchanger coefficient

The heat exchanger coefficient is an indication of current heat transfer coefficient.

C.4.4 Fouling factor

The current heat exchanger coefficient is compared to the baseline value to determine the

fouling factor. When the fouling rate is higher than anticipated, an alert will be triggered.

C.4.5 Lost energy cost/cost of degradation

The cost of degradation is an indication of the lost energy costs resulting from a fouled

heat exchanger.

C.4.6

C.4.7

Cleaning required indication

When multiple alarms are triggered (lost energy cost, fouling factor, dP) the “exchanger

cleaning required” alert will be shown.

Heat exchanger health index

The heat exchanger health index is a 0–100 percent variable determined by the severity of

heat exchanger alerts. The heat exchanger health is 100 percent if there are not active

alerts. Otherwise, the heat exchanger health is calculated based on the following equation

(100 percent– highest alert weight). Therefore, pump status and health index are

correlated to the alert weights. See Table C-1 and Table C-2.

Table C-1: Heat Exchanger Health Index

Health index Heat exchanger status

86–100% Good

51–85% Warning

≤ 50% Critical

Emerson.com/Plantweb 59

Page 60

Heat Exchanger Application configuration and information Reference Manual

June 2020 00809-0100-4541

C.4.8 Heat exchanger status

Table C-2: Heat Exchanger Status

Value State Description

0 GOOD Heat exchanger health > 85%

4 NO DATA/ERROR There is not enough data for the heat exchanger state

to calculate

5 NO CONFIG Baseline has not been captured for the heat exchanger

or required inputs are not entered

6 OUT OF SERVICE Heat exchanger is out of service (user writable)

7 WARNING Heat exchanger health is between 50% and 85%

8 CRITICAL Heat exchanger health is < 50%

C.5 Modbus TCP mapping

Procedure

1. There are four Modbus® Transmission Control Protocol (TCP) outputs and one

Modbus TCP input that are predefined in the heat exchanger app for every asset.

See table below.

Table C-3: Modbus TCP Definitions

Modbus TCP Definition

Input Out of service

Output Heat exchanger state (value described on the table in section 5.8)

Output Heat exchanger alert

Output Heat exchanger health

Output Heat exchanger lost energy costs

2. Modbus TCP registers and tags are automatically populated in Plantweb Insight and

cannot be changed. The Modbus TCP port for the Heat Exchanger Application is

505.

3. Registers and codes can be found in each app by going to the app Settings (Global

Settings) and then selecting Download Modbus Mapping.

4. A csv file will open with the listed registers and tags.

60 Emerson.com/Plantweb

Page 61

Reference Manual Wireless Pressure Gauge Application configuration and information

00809-0100-4541 June 2020

D Wireless Pressure Gauge Application

configuration and information

D.1 Overview

This document provides information on set up and configuration of the Emerson Wireless

Pressure Gauge Application within Plantweb™ Insight.

Prior to configuring your Wireless Pressure Gauge Application, be sure to complete all

steps in the Emerson Plantweb Insight Quick Start Guide. Some steps in this guide will be

reiterated in this document in more detail.

D.2 Adding devices

Pressure threshold alerts

When pressure drops below or rises above the configured limit, a pressure threshold alert

is triggered.

Low pressure warning limit

User configurable low pressure threshold. When the pressure drops below this value, a

Low Pressure Warning alert will be triggered.

High pressure warning limit

User configurable high pressure threshold. When the pressure rises above this value, a

High Pressure Warning alert will be triggered.

D.3 Calculated fields

D.3.1 Pressure status

The wireless pressure gauge application within Plantweb Insight calculates the following

pressure value (PV) states, shown below.

Table D-1: Calculated Pressure Status

Status Description

NORMAL Pressure is within the anticipated range

LOW PRESSURE WARNING Pressure is below the anticipated range

HIGH PRESSURE WARNING Pressure is above the anticipated range

OVERPRESSURE NOTIFICATION Pressure exceeded 105% of the maximum working pressure of

the device. Physical device must be reset.

Emerson.com/Plantweb 61

Page 62

Wireless Pressure Gauge Application configuration and information Reference Manual

June 2020 00809-0100-4541

62 Emerson.com/Plantweb

Page 63

Reference Manual Air-Cooled Heat Exchanger Application configuration and information

00809-0100-4541 June 2020

E Air-Cooled Heat Exchanger

Application configuration and

information

E.1 Overview

This document provides information on set up and configuration of the Air-Cooled Heat

Exchanger Application within Plantweb™ Insight.

Prior to configuring your Air-Cooled Heat Exchanger Application, be sure to complete all

steps in the Emerson Plantweb Insight Quick Start Guide. Some steps in this guide will be

reiterated in this document in more detail.

E.2 Global settings

E.2.1

E.2.2

Global settings should be set before any configuration is completed. These settings apply

to all assets within a specific application but do not change any setting within the Gateway

or devices. Changing any of these settings can be done in the Settings tab.

Overall health index goal

Overall Health Index Goal is a number entry from 0–100 percent (100 percent =

completely healthy). It is used on the dashboard for the overall health index goal indicator.

Alert weights

Select the Alert Weights button on the Settings page.

Alert weights correspond to the severity of an alert (0 least severe, 100 most severe).

Defaults values are preconfigured for the application and can be changed at any time. The

most severe alert weight will be used for the health index indication for a given air-cooled

heat exchanger.

Alert weight

0–15 Good

16–50 Warning

50+ Critical

Severity

E.3 Configuring assets

To finish configuring assets, navigate to the specific asset Details page by selecting the

asset from the Asset Summary page.

Emerson.com/Plantweb 63

Page 64

Air-Cooled Heat Exchanger Application configuration and information Reference Manual

June 2020 00809-0100-4541

E.3.1 Capture baseline

The Air-Cooled Heat Exchanger Application compares the current state of a heat

exchanger against a baseline. The baseline should be captured after all pertinent

measurement points are configured and the air-cooled heat exchanger is in an ideal/

typical operating state (usually after cleaning).

Once these criteria are met, the admin should capture a baseline using the following steps:

Procedure

1. Select the Capture Baseline button on the Details page. See Figure E-1.

2. Ensure this is the indented baseline air-cooled heat exchanger and select Yes.

Figure E-1: Capture Baseline

E.3.2

64 Emerson.com/Plantweb

Editing alerts

After the baseline is captured, the Air-Cooled Heat Exchanger Application will

automatically set alert thresholds and limits for measurement points and calculations.