User Manual

QCL-MAN -CT2211-Aerosol-Leak-Detection-System, Rev F

October 2015

CT2211 Aerosol Leak Detection System

Preface

All possible care has been taken in the preparation of this publication, but Cascade Technologies and its

agents and distributors accept no liability for any inaccuracies that may be found. This user manual reflects

the state of the product at the issue date below, but further enhancements while in service may mean that the

user manual does not reflect your particular system.

Cascade Technologies reserves the right to make changes without notice both to this publication and the

products which it describes.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by

any means electronic, mechanical, photocopying, recording, or otherwise without the express prior written

permission of the copyright holder.

Contact Details:

Cascade Technologies Limited.

Glendevon House

Castle Business Park

Stirling

FK9 4TZ

United Kingdom

General inquiries about this or other Cascade Technologies products should be sent to qcl.csc@emerson.com.

If you require technical assistance with this product that is not covered within this user manual, then help can

be requested from Cascade Technical Support (qcl.csc@emerson.com) or Cascade Technologies distribution

partners.

All trademarks used within this document are the property of their respective owners.

Only for EC countries:

Do not dispose of measuring tools into household waste!

According the European Guideline 2002/96/EC for Waste Electrical and Electronic Equipment and its

implementation into national right, measuring tools that are no longer usable must be collected

separately and disposed of in an environmentally correct manner.

User Manual Table of Contents

QCL-MAN- CT2211-Aerosol-Leak-Detection-System-Rev F October 2015

Table of Contents

Section 1:Introduction ................................................................................................ 1

1.1 Qualified personnel ........................................................................................ 1

1.2 Safety ......................................................................................................... 1

1.3 Certifications and approvals ........................................................................... 2

1.4 System overview ............................................................................................ 2

1.5 Leak detector overview .................................................................................. 5

1.6 Detailed system specification ......................................................................... 6

1.7 Operators’ system pre startup checklist ......................................................... 7

Section 2:System Connection ...................................................................................... 8

Section 3:System Startup .......................................................................................... 12

Section 4:Shutdown ......................................................................................... ......... 14

Section 5: Operation .................................................................................................. 15

5.1 Software screens .......................................................................................... 15

5.1.1 Home screen — aerosol leak detection system .............................. 15

5.1.2 User Login screen ........................................................................ 16

5.1.3 Program Page .............................................................................. 17

5.1.4 Error Status page ......................................................................... 18

5.1.5 CT2211 Main Screen .................................................................... 19

5.1.6 CT2211 Graphs Screen ................................................................ 20

5.1.7 Digital IO Status page .................................................................. 21

5.1.8 Optical Gates page ...................................................................... 22

5.1.9 Rejector page .............................................................................. 23

5.1.10 Line Speed page .......................................................................... 24

5.2 Errors ....................................................................................................... 24

5.2.1 Overall system healthy ................................................................. 24

5.2.2 Leak detector (CT2211) system healthy ....................................... 25

5.2.3 Leak detector (CT2211) laser healthy ........................................... 25

5.2.4 Can lost ....................................................................................... 25

5.2.5 Can found .................................................................................... 25

5.2.6 Too many consecutive rejects ...................................................... 25

5.2.7 Reject verification ........................................................................ 26

5.2.8 Encoder error ........................................... ........... ............... .......... 26

5.2.9 Air sampling healthy .................................................................... 26

5.2.10 Bin full ...................................................................................... 26

5.2.11 Mirror purge warning ................................................................... 26

5.2.12 Mirror purge error ........................................................................ 26

5.2.13 Repeatable reject error ................................................................ 27

5.2.14 Compressed air error ................................................................... 27

5.2.15 Error Flags 14/15 ......................................................................... 27

5.3 Line PLC communication .............................................................................. 27

5.3.1 Linestop (in) ................................................................... 28

5.3.2 System shutdown signal (in) ........................................... 28

5.3.3 Linestop 1 and linestop 2 (out) ........................................ 28

5.3.4 Heartbeat signal (out) .................................................. ... 28

5.3.5 Reject counter pulse (out) .............................................. 28

5.4 Control system programs ............................................................................. 29

5.4.1 Add Programs ................................................................. 30

Section 6:Maintenance ......................................................... ........................... .......... 31

6.1 Schedule ......................................... ............................................... .............. 31

6.1.1 Daily ................................................... ............................ 31

6.1.2 Weekly ........................................................................... 31

Table of Contents i

Table of Contents User Manual

October 2015 QCL-MAN- CT2211-Aerosol-Leak-Detection-System-Rev F

6.1.3 Monthly ................................................. ......................... 31

6.2 Analysis system ............................................................................................ 31

6.3 Venturi ....................................................................................................... 32

6.4 Replacement parts ....................................................................................... 32

Section 7:Troubleshooting and Diagnostics ............................................................... 33

7.1 Warning and error messages ........................................................................ 33

Table of Contents ii

User Manual List of Tables

QCL-MAN -CT2211-Aerosol-Leak-Detection-System-Rev F October 2015

List of Tables

Table 1-1 Leak detection system specifications .................................................... 7

Table 5-1 IO lines ................................................. .............................................. 28

Table 6-1 Aerosol leak detection system replacement parts list ......................... 32

Table 7-1 Possible problems and solutions ......................................................... 33

List of Tables iii

List of Figures User Manual

August 2015 QCL-MAN -CT2211-Aerosol-Leak-Detection-System-Rev F

List of Figures

Figure 1-1 Aerosol leak detection system - Venturi configuration .......................... 3

Figure 1-2 Aerosol leak detection system - blower configuration ........................... 4

Figure 1-3 Monitoring aerosol cans for leaks on a conveyer ................................... 5

Figure 2-1 Schematic of I/O and external connections ........................................... 8

Figure 2-2 Filter assembly and archway quick connector ....................................... 9

Figure 2-3 Air preparation plate .......................................................................... 10

Figure 2-4 Left: Sensor head, Right: Air extraction arch assembly ........................ 11

Figure 3-1 Isolation switch .................................................................................. 12

Figure 3-2 Control system display ....................................................................... 13

Figure 5-1 Control system Home screen ............................................................. 15

Figure 5-2 User login screen ................................................................................ 16

Figure 5-3 Program Page screen ......................................................................... 17

Figure 5-4 Error Status screen ............................................................................. 18

Figure 5-5 CT2211 Main Screen .......................................................................... 19

Figure 5-6 CT2211 Graphs Screen ....................................................................... 20

Figure 5-7 Digital IO Status screen ...................................................................... 21

Figure 5-8 Optical Gates page ............................................................................. 22

Figure 5-9 Rejector page ..................................................................................... 23

Figure 5-10 Line Speed page ................................................................................. 24

Figure 5-11 PLC connections ................................................................................. 27

Figure 5-12 Program Page .................................................................................... 29

Figure 5-13 Add programs screen ......................................................................... 30

Figure 7-1 Network status ................................................................................... 34

Figure 7-2 12V PSU status ................................................................................... 34

Figure 7-3 Circuit breaker ................................................................................... 35

Table of Contents iv

User Manual Introduction

QCL-MAN -CT2211-Aerosol-Leak-Detection-System-Rev F October 2015

1 Introduction

The aerosol leak detection system described in this document has been quality control

tested and left the manufacturer in pristine condition. To achieve the correct and safe

operation of the product, it must be transported, installed, operated, and maintained

as described by the manufacturer.

This manual contains all the information required to operate the leak detection

system, including basic maintenance and troubleshooting information. Please read the

manual carefully before you start work on the leak detection system, as it contains

important information that must be followed to guarantee the correct operation of

the system and the safety of personnel. The manual is divided into sections, which

allows you to rapidly find the information you need.

Cascade Technologies is committed to continuously improving its products and

documentation. Every effort will be made to include any sensor modifications by the

manufacturer in the documentation. However, it should be noted that this document

reflects the supplied sensor as of the revision number and date on the front cover.

Should you require further information or should particular problems arise that are not

covered within this user manual, then refer to the Leak Detection System Installation

and Service Manual. Additional help can also be requested from Cascade Technical

Support (qcl.csc@emerson.com) or Cascade Technologies distribution partners.

1.1 Qualified personnel

These operating instructions have been prepared for technically qualified personnel

who have been specially trained or who possess appropriate knowledge in the field of

instrumentation and control.

Knowledge of the safety information within this user manual and its technically correct

implementation are prerequisites for danger-free installation, commissioning,

operation and maintenance of the system. Only qualified persons have the required

specific knowledge to correctly interpret the general safety information and warnings

given in this user manual and thus apply them to the particular application.

1.2 Safety

During the manufacturing process of the aerosol leak detection system, a rigorous set

of safety and quality checks is performed to ensure that the equipment meets and

exceeds the safety requirements for the system. In order to maintain the operational

performance and safety of the control system, the correct installation, use, and

maintenance procedures detailed by the manufacturer must be adhered to.

The aerosol leak detection system uses no ionizing radiation.

Certain parts of the Leak Detection system carry dangerous voltages. All housings

must be closed with covers in place and the sensor head mounted and connected to

the air arch before switching on. Death, personal injury, and/or damage to persons

and/or property may result if this is not observed.

Introduction 1

Introduction User Manual

October 2015 QCL-MAN-CT2211-Aerosol-Leak-Detection-System-Rev F

Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

All lasers used within the leak detection system are of class 1. The emitted laser light is

invisible (mid-infrared) and the pulse duration so short that the unprotected eye will

not be damaged. The nature of the laser beam path and beam width furthers ensures

that it should be impossible to cause any eye damage. The leak detection system has

warning labels at appropriate positions according to USA 21 CFR 1040.10.

1.3 Certifications and approvals

All in zone parts comply with the ATEX directive (94/9/EC).

This leak detector complies with USA 21 CFR 1040.10. It is

also designed and manufactured under an approved

quality management system to ISO 9001:2008.

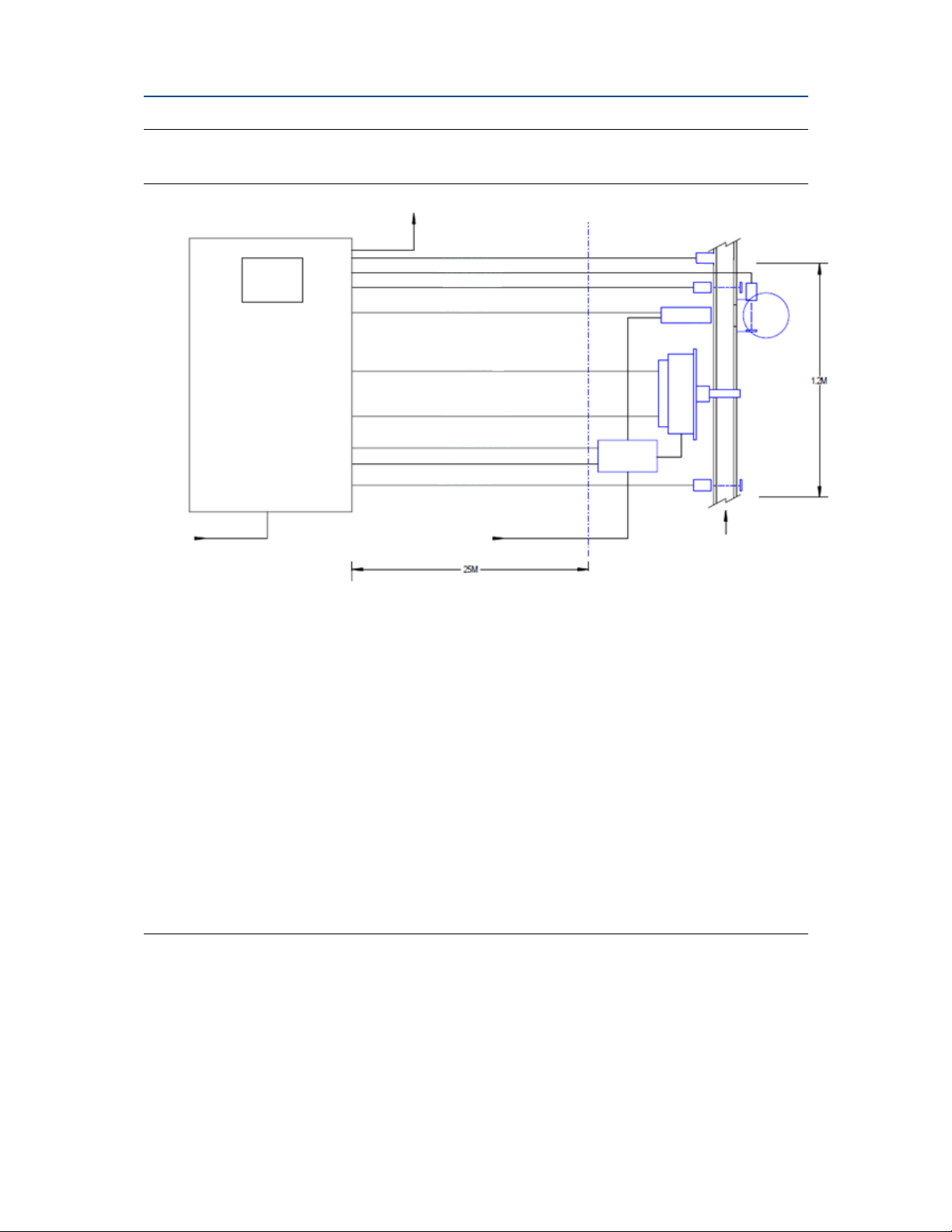

1.4 System overview

The aerosol leak detector is used on aerosol production lines in conjunction with a

control and reject mechanism, to form the aerosol leak detection system, which is

used to manage the interaction with the line and the safe removal of faulty cans at

high speed. The system consists of a detector, control console (non-ATEX), encoder,

optical gates, rejecter (air based reject as standard), reject chute, air preparation

equipment, and mounting mechanics. Figure 1-1and Figure 1-2 below show the

schematic of the leak detection system:

Introduction 2

User Manual Introduction

U.

N

QCL-MAN -CT2211-Aerosol-Leak-Detection-System-Rev F October 2015

Figure 1-1 Aerosol leak detection system - Venturi configuration

A. HMI

Micro leak control console

B. System DC power supplies (+12V & +24V). System controlling PC Windows OS. Micro leak

D

and control system software. National instruments digital I/O and digital

timing card. Line driver and opto barrier circuitry. Customer Line PLC interface.

Circuit protection. AC power control. Console thermal management and

A

control.

Out of zone

components

E

F

G

H

C. AC supply voltage 110V/220V AC, 50-60HZ 13A (customer supplied)

Rated components

O

P

Q

— zone 2

D. Line status signals to customer comms (running, waiting, error)

E. Encoder signal

F. Rejected can signal

G. Output gate signal

B

H. Reject signal

I. CT2211 comms (cat5)

J. CT2211 I/O and power

I

J

R

K

L

M

S

T

K. Mirror cleaning signal

L. Air status signal

C

M. Input gate signal

Line direction

N. Compressed air supply min 5 BAR, max 10 BAR (customer supplied)

O. Encoder

Max cable run

P. Output gate

Q. Reject

Input gate signal

A. HMI

B. Leak Detection System

1

N. Compressed air supply min 5 BAR, max 10 BAR

M.

(customer supplied)

U

V

C. AC supply voltage 110V/220V AC, 50-60 Hz

13A (customer supplied)

D. Line status signals to customer

communications

(running, waiting, error)

E. Encoder signal Q. Reject

F. Rejected can signal R. Micro leak detector

G. Output gate signal S.

H. Reject signal T. Input gate

I. CT2211

J. CT2211 I/O and power V. Reject bin (customer supplied)

K. Mirror cleaning signal

L. Air status signal

communications (cat5)

Encoder

O.

P.

Output gate

Air status air control

Rejected can gate

1

The leak detection system components are: DC power supplies (+12V & 24V); system controlling PC with

Microsoft® Windows operating system; micro leak and control system software; national instruments digital I/O and

digital timing card; line driver and opto barrier circuitry; customer line PLC interface; vircuit protection; AC power

control; and console thermal management and control.

Introduction 3

Introduction User Manual

J

X

E

H I J

—

October 2015 QCL-MAN-CT2211-Aerosol-Leak-Detection-System-Rev F

Figure 1-2 Aerosol leak detection system - blower configuration

D

leak control console

Micro

Out of zone

Rated components

components

P

A

F

G

Q

zone 2

X

B

K

L

M

N

C

O

V

Max cable run

A. HMI

B. Leak detection system

C. AC supply voltage 110V/220V AC, 50-60 Hz

13A (customer supplied)

D. Line status signals to customer

communications (running, waiting, error)

E. Encoder signal

F. Rejected can signal R. Reject.

G. Output gate

H. Reject signal T. Air status air control

I. CT2211 communications (cat5) U. Input gate

. CT2211

K. Mirror cleaning signal W. ATEX zone 2 rated blower

L. Air status signal

Y. Reject bin (customer supplied)

signal S. Micro Leak detector

I/O and power V. ATEX zone 2 disconnect switch

2

N. Compressed air supply min 5 BAR, max 10 BAR

M. Input gate signal

(customer supplied)

O. Phase controlled power

P. Encoder

Q. Output gate

. Rejected can gate

R

Y

S

T

U

W

Line direction

2

The leak detection system components are: DC power supplies (+12V & 24V); system controlling PC with

Microsoft® Windows operating system; micro leak and control system software; national instruments digital I/O and

digital timing card; line driver and opto barrier circuitry; customer line PLC interface; circuit protection; AC power

control; and console thermal management and control.

Introduction 4

User Manual Introduction

QCL-MAN -CT2211-Aerosol-Leak-Detection-System-Rev F October 2015

1.5 Leak detector overview

The leak detector identifies aerosol cans that are leaking propellant as they are carried

along a conveyor belt at high speed. The leak detector consists of an air extraction

arch, air filter/regulator, sample cell, sensor head and either a Venturi or 3-phase

blower.

Figure 1-3 Monitoring aerosol cans for leaks on a conveyer

D

B

A

C

E

A. Air extraction arch — draws the air from around the aerosol can into the

sample handling system

B. Air filter — for the removal of air particles and leaked contents of the

aerosol cans

C. Sample cell — laser light is directed through the air extracted from around

the cans and back into the sensor head.

D. Sensor head — contains the lasers and laser light detector. It is ATEX

Category 3 rated for a Zone 2 explosive environment.

E. Conveyor belt — transporting the aerosol cans

Aerosol cans (not shown) are moving along the conveyor belt.

The control console (not shown) is located outside the explosive environment and is

not ATEX rated.

Introduction 5

Introduction User Manual

October 2015 QCL-MAN-CT2211-Aerosol-Leak-Detection-System-Rev F

The power supply (not shown) for the sensor is also mounted outside the explosive

environment.

The Venturi (not shown) is powered by compressed air and mounted in the exhaust

line below the sample cell. It is used to draw air from around the aerosol cans via the air

extraction arch.

The 3-phase blower (not shown) is powered from the control cabinet and mounted in

the exhaust line below the sample cell. It is used to draw air from around the aerosol

cans via the air extraction arch.

The Venturi air status pressure switch (not shown) signals a third party controller if the

air pressure drops below that required by the Venturi.

Gas concentrations are measured using mid-infrared optical absorption spectroscopy.

The light sources are quantum cascade lasers, which are operated to produce

wavelength sweeps that cover the absorption lines of the gases.

The lasers are mounted in the leak detector, and light is directed into the sample cell,

where it is partially absorbed by the gas from the stack. The reflected light from the

cell is detected by a receiver in the leak detector. The variation in the intensity of the

light in the vicinity of the absorption lines is measured, and the concentration is

determined using a comprehensive spectral fitting routine.

Introduction 6

User Manual Introduction

x

QCL-MAN -CT2211-Aerosol-Leak-Detection-System-Rev F October 2015

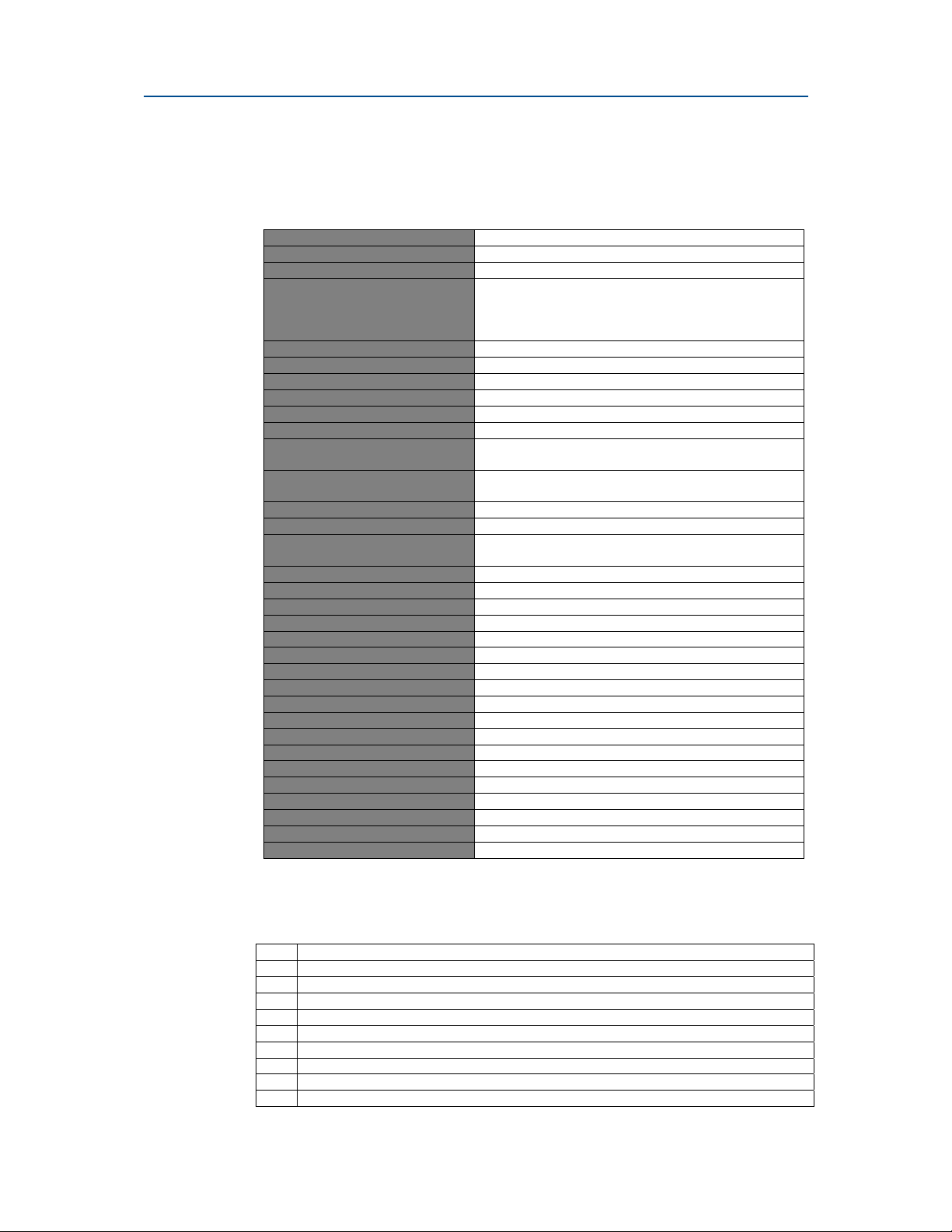

1.6 Detailed system specification

The following table shows the general characteristics of the leak detection system.

Table 1-1 Leak detection system specifications

Application Leak detection system

Measurement technique

IR source Quantum cascade laser

Laser classification Class1

Sensitivity 2 X 10

Line speed Up to 500 cpm

Can dimensions Up to 350 mm (H) by 80 mm (D)

Response time 20 ms

Temperature range 10 — 30 °C (50 — 86 °F)

Sample gas temperature range Room temperature

Leak detector humidity range 10 to 95 % relative humidity (non-condensing) at 35 °C

ATEX Approvals (in zone sensor) Zone 2 Ex II 2G Ex nR II T6 (10 °C≤T

Leak detection system CE approved

Protection class IP65

Hazardous area classification Ex II 3G Ex nR II T6 (10 ° C ≤ T

Analog signal out n/a

Analog signal in n/a

Digital signal out 3 X normally closed contact

Digital signal in 10/100 Base T ethernet

Inlet gas port connector ¾ in. BSPT

Exhaust gas port connector ¾ in. BSPT

Power supply 120 VAC 60 Hz/240 VAC 50 Hz 200 W/A

Control console size 1,200 x 600 x 560 mm (H x W x D)

Control console weight 70 kg

Sensor head size 590

Sensor head weight

Installation On production line

System operating voltage

System power consumption

Max factory air consumption

Factory compressed air pressure 8-10 bar, clean, dry, and oil free

Line space requirement 1.2 m straight free line (maximum)

Air filter particulate filter 2 um, inline filter/regulator required

IR absorption spectroscopy

BS EN 60825-1:2007 Safety of laser products

Equipment classification and requirements (identical to

IEC 60825-1 2007)

-3

(95 °F)

(50 °F≤T

(50 °F≤T

330 x 330 mm (H x W x D) sensor only

20 kg (sensor only)

110 — 240 V AC 50 -60 Hz, specify on order

600 W maximum power requirement

25 L/min approximately on regular usage

mbar.L

≤ 86 °F)

amb

≤ 86 °F)

amb

-1

≤30 °C)

amb

≤ 30° C)

amb

1.7 Operators’ system pre startup checklist

Remove hose from air line.

Check and bleed air line.

Check filter condition and color before switching on system.

Change filter if more than 60% discolored.

Ensure that there are no cans between the input and output gates.

Power on system.

Power on conveyor; do not let cans though.

Clear any error messages, e.g., encoder.

Purge air in chamber

Let cans through to commence normal working activity.

Introduction 7

Loading...

Loading...