Rosemount Manual: 7D Thermal Conductivity Analyzer Explosion Proof-Rev K | Rosemount Manuals & Guides

Rosemount Analytical

M

ODEL

T

HERMAL CONDUCTIVITY

A

NALYZER

E

XPLOSION PROOF

I

NSTRUCTION MANUAL

748221-J1

7D

OTICE

N

The information contained in this document is subject to change without notice.

This manual is based on the production version of the Model 7D Thermal Conductivity Analyzer. Hardware

and/or software changes may have occurred since this printing.

Teflon® is a registered trademark of E.I. duPont de Nemours and Co., Inc.

SNOOP® is a registered trademark of NUPRO Co.

Manual Part Number 748221-K

October 2000

Printed in U.S.A.

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

C

PREFACE

PURPOSE/SAFETY SUMMARY........................................................................P5

SPECIFICATIONS..............................................................................................P3

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE....P4

RETURNING PARTS TO THE FACTORY.........................................................P4

TRAINING ......................................................................................................P4

DOCUMENTATION............................................................................................P4

COMPLIANCES .................................................................................................P5

ONTENTS

S

ECTION

1.1 ANALYZER MODULE .................................................................................1

1.2 GAS SELECTOR PANEL............................................................................4

1. I

1.1.1 Thermal Conductivity Cell..............................................................1

1.1.2 Electronic Circuitry.........................................................................3

NTRODUCTION

SECTION 2. INSTALLATION

2.1 FACILITY PREPARATION..........................................................................5

2.1.1 Installation Drawings......................................................................5

2.1.2 Customer Electrical Connections...................................................5

2.1.3 Flow Diagrams...............................................................................5

2.1.4 Location and Mounting................................................................... 5

2.2 UNPACKING...............................................................................................7

2.2.1 Gas Requirements General...........................................................7

2.2.2 Calibration Gas Requirements.......................................................7

2.2.3 Leak Check....................................................................................8

2.2.4 Gas Connections...........................................................................8

748221-K Rosemount Analytical October 2000

Model 7D Thermal Conductivity Analyzer

i

ONTENTS

C

S

ECTION

2.3 RECORDER OUTPUT SELECTION AND CABLE CONNECTIONS.......... 10

2.4 ELECTRICAL POWER CONNECT IONS.................................................... 16

2. (

CONTINUED

2.3.1 Standard (Non-linearized) Voltage Output .................................... 11

2.3.2 Linearized Voltage Output (Optional)............................................ 11

2.3.3 Isolated 4 to 20 mA Current Output (Optional).............................. 11

2.3.4 Dual Alarms (Optional).................................................................. 13

2.3.5 Linearized Voltage, Two Ranges (Optional).................................. 15

2.3.6 Linearized Voltage and Isolated 4 to 20 mA Current Output

)

(Optional)...................................................................... 16

SECTION 3. INITIAL STARTUP

3.1 ANALYZER CONTROLS AND ADJUSTMENTS........................................ 19

3.2 GAS SELECTOR PANEL CONTROLS ...................................................... 19

3.3 STARTUP PROCEDURE ........................................................................... 19

3.4 CALIBRATION............................................................................................ 21

SECTION 4. OPERATION

4.1 ROUTINE OPERATION.............................................................................. 23

4.2 RECOMMENDED CALIBRATION FREQUENCY....................................... 23

4.3 SHUTDOWN............................................................................................... 23

S

ECTION

5.1 THERMAL CONDUCTIVITY CELL AND ASSOCIATED BRIDGE

5.2 ELECTRONIC CIRCUITRY ........................................................................ 26

5. T

5.2.1 Master Board................................................................................. 26

5.2.2 Voltage Output Linearizer Board (Optional) .................................. 28

5.2.3 Isolated 4 to 20 mA Current Output Board (Optional)................... 28

5.2.4 Bridge Power Supply..................................................................... 29

5.2.5 ±15 Volt Power Supply.................................................................. 29

5.2.6 Detector Blocks............................................................................. 30

5.2.7 Case Temperature Controller Assembly....................................... 30

5.2.8 Dual Alarms (Option)...................................................................... 30

HEORY

ADJUSTMENTS........................................................................... 25

ii

October 2000 Rosemount Analytical 748221-KModel 7D Thermal Conductivity Analyzer

SECTION 6. SERVICE AND MAINTENANCE

6.1 THERMAL CONDUCTIVITY CELL..............................................................32

6.2 ELECTRONIC CIRCUITRY.........................................................................32

6.2.1 Amplifier Zero Adjustments............................................................32

6.2.2 Bridge Balance and Range Sensitivity Adjustments......................32

6.2.3 Bridge Voltage Adjustment ............................................................33

6.2.4 Case Temperature Controller ........................................................33

6.2.5 Dual Alarm Module (Optional)........................................................ 34

6.3 SUPPRESSED ZERO ADJUSTMENT........................................................34

SECTION 7. REPLACEMENT PARTS

7.1 CIRCUIT BOARD REPLACEMENT POLICY ..............................................37

7.2 REPLACEMENT PARTS.............................................................................37

7.2.1 Selected Replacement Parts .........................................................37

7.2.2 Temperature Control Assembly.....................................................38

7.2.3 Alarm Option..................................................................................38

7.2.4 Range Switch Kit............................................................................38

ONTENTS

C

ATA SHEET

D

ENERAL PRECAUTIONS FOR HANDLING

G

ARRANTY

W

IELD SERVICE AND REPAIR FACILITIES

F

TORING HIGH PRESSURE CYLINDERS

& S

748221-K Rosemount Analytical October 2000

Model 7D Thermal Conductivity Analyzer

iii

ONTENTS

C

F

IGURES

1-1. Model 7D Front Panel Controls.................................................................. 2

1-2. Model 7D Major Component Locations...................................................... 3

1-3. Typical Gas Selector Panel........................................................................4

2-1. Gas Selector Panel for Thermal Conductivity Cell with

Sealed-In Reference Gas............................................................. 6

2-2. Gas Selector Panel for Thermal Conductivity Cell Using

Flowing Reference Gas................................................................ 6

2-3. Connection of Analyzer Using Sealed-In Reference Gas to

Associated Gas ............................................................................ 8

2-4. Connection of Analyzer Using Flowing Reference Gas to

Associated Gas Selector Panel.................................................... 9

2-5. Electrical Connections............................................................................... 10

2-6. Master Board............................................................................................. 12

2-7. Alarm Adjustments..................................................................................... 13

2-8. Typical Alarm Settings............................................................................... 15

2-9. Case Heater Temperature Control Board.................................................. 17

5-1. Thermal Conductivity Cell.......................................................................... 27

7-1. Analyzer Assembly - Door and Pneumatic Components........................... 39

7-2. Analyzer Assembly - Electronic Components............................................ 40

7-3. Temperature Control Assembly................................................................. 41

TABLES

1-1. Available Gas Selector Panels................................................................... 4

2-1. Alarm Output Connections......................................................................... 14

5-1. Range Switch Connections........................................................................ 26

DRAWINGS (LOCATED IN REAR OF MANUAL)

613561 Schematic Diagram, Bridge Power Supply - Regulated 5 to 15V

619710 Schematic Diagram, 15V Power Supply

624003 Schematic Diagram, Temperature Controller

652813 Schematic Diagram, Isolated Current Output

652863 Schematic Diagram, Linearizer Board

654616 Schematic Diagram, Master Board

654625 Installation Drawing, Model 7D

654642 Wiring Diagram, Model 7D

iv

October 2000 Rosemount Analytical 748221-KModel 7D Thermal Conductivity Analyzer

P

REFACE

PURPOSE/SAFETY SUMMARY

To avoid explosion, loss of life, personal injury and damage to this equipment and on-site

property, all personnel authorized to install, operate and service the Model 7D Thermal

Conductivity Analyzer should be thoroughly familiar with and strictly follow the instructions

in this manual. Save these instructions.

If this equipment is used in a manner not specified in these instructions, protective

systems may be impaired.

DANGER is used to indicate the presence of a hazard that will cause severe

personal injury, death, or substantial property damage if the warning is ignored.

WARNING is used to indicate the presence of a hazard which can cause severe

personal injury, death, or substantial property damage if the warning is ignored.

CAUTION is used to indicate the presence of a hazard which will or can cause minor

personal injury or property damage if the warning is ignored.

NOTE is used to indicate installation, operation or maintenance information which is

important but not hazard-related.

WARNING: ELECTRICAL SHOCK HAZARD

Do not operate without doors and covers secure. Servicing requires access to

live parts which can cause death or serious injury. Refer servicing to qualified

personnel.

For safety and proper performance this instrument must be connected to a

properly grounded three-wire source of power.

Note:

Before supplying electrical power to the analyzer, remove power to the bridge

by disconnecting the red lead from the bridge to TB1-1 or TB1-2 (depending on

the bridge polarity). See drawing 654642. To safeguard against filament

damage, this lead should remain disconnected until proper gas flow has been

established.

748221-K Rosemount Analytical October 2000

Model 7D Thermal Conductivity Analyzer

P1

REFACE

P

WARNING: EXPLOSION HAZARD

Do not operate the Model 7D Explosion-Proof Analyzer without the lens cover

and door in place with all bolts secured, unless location have been determined

to be non-hazardous.

WARNING: EXPLOSION HAZARD

This analyzer is of a type capable of analysis of sample gases which may be

flammable. If used for analysis of such gases, the instruments explosion-proof

enclosure must be suitable for the gas.

If explosive gases are introduced into this analyzer, the sample containment

system must be carefully leak-checked upon installation and before initial

startup, during routine maintenance and any time the integrity of the sample

containment system is broken, to ensure the system is in leak-proof condition.

Leak-check instructions are provided in Section 2.2.3.

Internal leaks resulting from failure to observe these precautions could result in

an explosion causing death, personal injury or property damage.

WARNING: PARTS INTEGRITY

Tampering or unauthorized substitution of components may adversely affect

safety of this product. Use only factory documented components for repair.

WARNING: HIGH PRESSURE GAS CYLINDERS

This analyzer requires periodic calibration with known zero and standard gases.

Refer to General Precautions for Handling and Storing High Pressure Cylinders,

at the rear of this manual.

P2

October 2000 Rosemount Analytical 748221-KModel 7D Thermal Conductivity Analyzer

SPECIFICATIONS

EPRODUCIBILITY

R

0.5% of fullscale

±

ERO DRIFT

Z

PAN DRIFT

S

OISE

N

ELL RESPONSE TIME

C

AMPLE FLOW

S

ALIBRATION GAS FLOW

C

EFERENCE GAS FLOW (IF REQUIRED

R

UPPLY PRESSURE

S

ETER

M

PERATING RANGES

O

MBIENT TEMPERATURE RANGE

A

UTPUT VOLTAGE (STANDARD NON-LINEARIZED

O

UTPUT VOLTAGE (OPTIONAL LINEARIZED

O

SOLATED CURRENT OUTPUT (OPTIONAL

I

UAL ALARMS (OPTIONAL

D

ELL MATERIALS (STANDARD CELL

C

OWER REQUIREMENTS

P

NCLOSURE

E

1

1% of fullscale per 24 hours

±

1

1% of fullscale per 24 hours

±

Less than ±0.5% of fullscale

2

30 seconds for 95% response, with sample flow of 250 cc/min.

Nominal, 50 to 350 cc/min; recommended, 250 cc/min.

Nominal, 50 to 350 cc/min; recommended, 250 cc/min.

5 to 50 cc/min.

10 to 50 psig (69 to 345 kPa)

Indicating analog meter is standard.

Various zero-based and zero-suppressed ranges, from 0% to 100%, are

available. Single range is standard; switch-selectable dual or triple range is

optional.

32°F to 100°F (0°C to 38°C). Case Temperature controlled at 117°F (47°C).

Switch selectable: 0 to 10 mV, 0 to 100 mV, 0 to 1V or 0 to 5V DC

Switch selectable: 0 to 10 mV, 0 to 100 mV, 0 to 1V or 0 to 5V DC

4 to 20 mA, maximum load 1500 ohms

)

Relay contact rating: 1.0 A, 120V AC; 5.0 A, 120V DC, resistive loads

316 stainless steel block with tungsten or Hitempco filaments. Corrosion-

resistant filament s available on order

115/230 VAC ±10%, 50/60 Hz, 250 Watts

Class I, Groups B, C and D, Division 1 hazardous locations (ANSI/NFPA 70)

REFACE

P

)

)

)

)

)

1

Zero and Span drift specifications based on ambient temperature shifts of less than 18 Fahrenheit degrees (10 Celsius

degrees) at a maximum rate of 18 Fahrenheit degrees (11 Celsius degrees) per hour.

2

Cell response time is less than 45 seconds for 95% response, with sample flow rate of 250 cc/min, for the following gas

combinations: Argon and air, nitrogen, or oxygen; carbon dioxide and argon, nitrogen, or oxygen; helium and methane;

hydrogen and methane.

748221-K Rosemount Analytical October 2000

Model 7D Thermal Conductivity Analyzer

P3

REFACE

P

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE

For order administration, replacement Parts, application assistance, on-site or factory

repair, service or maintenance contract information, contact:

Rosemount Analytical Inc.

Process Analytical Division

Customer Service Center

1-800-433-6076

RETURNING PARTS TO THE FACTORY

Before returning parts, contact the Customer Service Center and request a Returned

Materials Authorization (RMA) number. Please have the following information when

you call: Model Number, Serial Number, and Purchase Order Number or Sales Order

Number.

Prior authorization by the factory must be obtained before returned materials will be

accepted. Unauthorized returns will be returned to the sender, freight collect.

When returning any product or component that has been exposed to a toxic, corrosive

or other hazardous material or used in such a hazardous environment, the user must

attach an appropriate Material Safety Data Sheet (M.S.D.S.) or a written certification

that the material has been decontaminated, disinfected and/or detoxified.

Return to:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807-1802

USA

TRAINING

A comprehensive Factory Training Program of operator and service classes is

available. For a copy of the Current Operator and Service Training Schedule contact

the Technical Services Department at:

Rosemount Analytical Inc.

Phone: 1-714-986-7600

FAX: 1-714-577-8006

DOCUMENTATION

The following Model 7D Thermal Conductivity Analyzer instruction materials are

available. Contact Customer Service or the local representative to order.

748221 Instruction Manual (this document)

P4

October 2000 Rosemount Analytical 748221-KModel 7D Thermal Conductivity Analyzer

COMPLIANCES

The explosion-proof Model 7D Thermal Conductivity Analyzer is approved by Factory

Mutual Research Corp. (FMRC) for installation in Class I, Groups B, C, and D, Division

1 hazardous locations as defined in the National Electrical Code (NEC), ANSI/NFPA-

70.

FM

APPROVED

REFACE

P

748221-K Rosemount Analytical October 2000

Model 7D Thermal Conductivity Analyzer

P5

REFACE

P

NOTES

P6

October 2000 Rosemount Analytical 748221-KModel 7D Thermal Conductivity Analyzer

I

NTRODUCTION

1

The Model 7D Thermal Conductivity Analyzer is designed to continuously measure the

concentration of a single component of interest in a flowing gas mixture. The

measurement is based on the different thermal conductivity's of the individual

components of the sample stream. The method is especially well suited to analysis

of two-component sample streams. However, analysis of multi-component streams is

possible if the various components of the background gas occur in relatively constant

ratio, or have similar thermal conductivity's.

Each Model 7D Analyzer is factory-assembled, as ordered, for determination of a

specified component, with specified range of concentration, contained in a

background component or background mixture of known composition. Typical

examples include: 0 to 100 % hydrogen in nitrogen; 20 to 50 % helium in methane;

and 0% to 3% carbon dioxide in air. If so ordered, the instrument is provided with two

or three ranges; selectable via a front-panel switch. Information specific to the

individual instrument is provided in the data sheet inserted in the back of this

instruction manual.

A Model 7D Analyzer consists of an analyzer module, Section 1.1, and, if ordered, an

accessory gas selector panel, Section 1.2.

1.1 ANALYZER MODULE

The analyzer module is supplied in an explosion-proof enclosure suitable for

installation in hazardous locations classified as Class I, Division 1, Groups B, C, and D

per the National Electrical Code (ANSI/NFPA 70) (See DWG 654625).

1.1.1 T

HERMAL CONDUCTIVITY CELL

The thermal conductivity cell is a metal block with separate passages for the sample

and reference gases. In all applications, the sample passage receives a continuous

flow of sample gas. Depending on the application, the reference passage may receive

a continuous flow of reference gas, or may have the reference gas sealed within.

The sample passage contains a pair of temperature-sensitive resistive filaments. The

reference passage contains a similar pair. Electrically, the filaments are connected as

legs of a Wheatstone bridge. An internal voltage-regulated power supply is

connected via a 20-ohm dropping resistor, to the bridge.

With the power supply output adjusted to provide an appropriate voltage across the

748221-K Rosemount Analytical October 2000

Model 7D Thermal Conductivity Analyzer

1

NTRODUCTION

I

bridge, an electric current flows through the filaments, heating them and thus

increasing their electrical resistance. The heat-dissipation rate for each filament

depends on the thermal conductivity of the surrounding gas.

Initially, with suitable downscale calibration gas flowing through the sample passage

(and also through the reference passage if of the flow-through configuration), the

bridge is balanced. Thereafter, any change in the relative proportions of the

components passing through the sample passage changes the thermal conductivity of

the gas mixture, causing a temperature differential between sample and reference

filaments. The resultant change in filament resistance unbalances the bridge,

applying a signal to the electronic circuitry (Section 1.1.2).

ZERO SPAN

ALARM 1 ALARM 2

50%

25%

75%

0% 100%

Rosemount Analytical

RANGE

1 3

2

25%

0% 100%

Model 7D

Thermal Conductivity

Analyzer

50%

75%

ZERO SPAN

ALARM 1 ALARM 2

50%

25%

0% 100%

75%

RANGE

1 3

Rosemount Analytical

2

50%

25%

0% 100%

Model 7D

Thermal Conductivity

Analyzer

75%

F

IGURE

2

1-1. M

ODEL

7D F

RONT PANEL CONTROLS

October 2000 Rosemount Analytical 748221-KModel 7D Thermal Conductivity Analyzer

NTRODUCTION

I

1.1.2 E

LECTRONIC CIRCUITRY

The analyzer module contains solid-state circuitry that conditions the bridge-imbalance

signal as required to provide readout on the front-panel meter. In addition, a

field-selectable output for a voltage-type recorder is provided as standard. A

field-selectable output of 4 to 20 mA for a current-actuated recorder or other device is

obtainable through use of an optional plug-in circuit board. A calibration curve can be

used to convert meter or recorder readings into concentration values. Typical

calibration curves are supplied for standard ranges. Calibration curves for special

ranges are available as options.

To avoid use of a calibration curve in an application where it would otherwise be

required, the analyzer may be equipped with an optional linearizer board. If so, the

linearizer is factory set for a given range only, and is not usable on another range.

Note that a linearizer is usable only if nonlinearity at midscale does not exceed

approximately 20% of fullscale.

Isolated Current Output Board

Linearizer Board

±15V Power Supply

Bridge Power Supply

Master Board

Temperature Control Assembly

Alarm Kit

F

IGURE

1-2. M

ODEL

7D M

REF Hinge Side

AC Power Input

Terminal Block TB6

Fuse

Cell Enclosure

AJOR COMPONENT LOCATIONS

748221-K Rosemount Analytical October 2000

Model 7D Thermal Conductivity Analyzer

3

NTRODUCTION

1

1

I

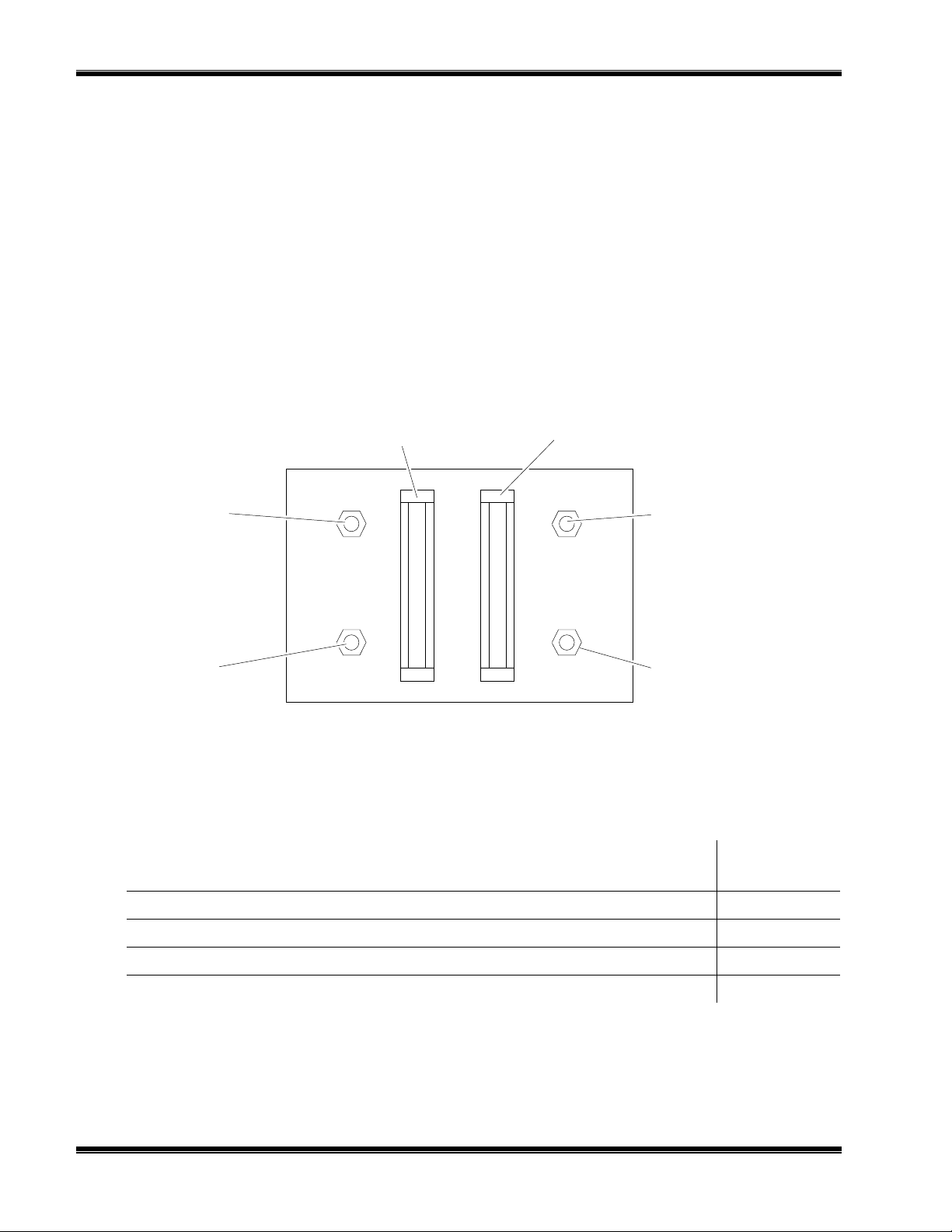

1.2 GAS SELECTOR PANEL

If so ordered, the analyzer module is provided with an appropriate gas selector panel,

Figure 1-3. The gas selector panel permits selection, flow adjustment, and flow

measurement for the various gases: sample; flowing reference gas, if used; and

downscale and upscale calibration gases. Proper choice of a gas selector panel

depends on:

1. Configuration of the thermal conductivity cell, i.e., flowing or sealed-in reference

gas.

2. Composition of the sample stream. For non-corrosive streams, the gas selector

panel is assembled with brass components. For corrosive streams, stainless steel

is used.

F

IGURE

1 Reference Gas

Flow Meter

Downscale

Calibration Gas

Needle Valve

Upscale

Calibration Gas

Needle Valve

Provided only if thermal conductivity cell uses flowing reference gas.

1-3. T

YPICAL GAS SELECTOR PANEL

DOWNSCALE

CAL GAS

UPSCALE

CAL GAS

REF

SAMPLE

DESCRIPTION

Sample/Calibration

Gas Flow Meter

SAMPLE

REFERENCE

Sample Gas

Needle Valve

Reference Gas

Needle Valve

NUMBER

PART

Brass and Copper construction for use with sealed reference

Stainless steel construction for use with sealed reference

Brass and Copper construction for use with flowing reference

Stainless steel construction for use with flowing reference

T

ABLE

4

1-1. A

VAILABLE GAS SELECTOR PANELS

October 2000 Rosemount Analytical 748221-KModel 7D Thermal Conductivity Analyzer

113357

113920

117195

118210

I

NSTALLATION

2

2.1 FACILITY PREPARATION

Sections 2.1.1 through 2.1.4 provide information that may be required prior to

installation.

2.1.1 I

2.1.2 C

2.1.3 F

2.1.4 L

NSTALLATION DRAWINGS

For outline and mounting dimensions of the analyzer and gas selector panel modules,

refer to drawing 654625 and Figure 2-1or 2-2.

USTOMER ELECTRICAL CONNECTIONS

Customer electrical connections are shown in Figure 2-5.

LOW DIAGRAMS

For gas connections, refer to appropriate flow diagram:

• Analyzer using sealed reference gas, Figure 2-3

• Analyzer using flowing reference gas, Figure 2-4.

OCATION AND MOUNTING

OCATION

L

Proper location for the analyzer depends on two basic considerations:

• Accessibility to the samp ling point

• Protection of the instrument

Ideally, the analyzer should be located as close to the sampling point as possible. Short

sample lines reduce time lag in readings. In practice, however, protection of the

instrument sometimes calls for more remote placement.

The analyzer should be mounted in a clean, dry atmosphere. Ambient temperature

should be within the range of 32oF to 100 F (0oC to 38oC).

OUNTING

M

The analyzer is designed for surface mounting, utilizing the hardware provided. Refer

to drawing 654625.

748221-K Rosemount Analytical October 2000

Model 7D Thermal Conductivity Analyzer

5

Loading...

Loading...