Instruction Manual

748183-K

April 2002

Model 755

Oxygen Analyzer

http://www.processanalytic.com

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

•

Read all instructions prior to installing, operating, and servicing the product.

If you do not understand any of the instructions, contact your Rosemount Analytical

•

representative for clarification.

•

Follow all warnings, cautions, and instructions marked on and supplied with the product.

•

Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

•

Install your equipment as specified in the Installation Instructions of the appropriate

Instruction Manual and per applicable local and national codes. Connect all products to

the proper electrical and pressure sources.

To ensure proper performance, use qualified personnel to install, operate, update, program,

•

and maintain the product.

When replacement parts are required, ensure that qualified people use replacement parts

•

specified by Rosemount. Unauthorized parts and procedures can affect the product’s

performance, place the safe operation of your process at risk, and VOID YOUR WARRANTY.

Look-alike substitutions may result in fire, electrical hazards, or improper operation.

•

Ensure that all equipment doors are closed and protective covers are in place, except

when maintenance is being performed by qualified persons, to prevent electrical shock

and personal injury.

The information contained in this document is subject to change without notice.

Teflon and Viton are registered trademarks of E.I. duPont de Nemours and Co., Inc.

Paliney No.7 is a trademark of J.M. Ney Co., Hartford, CT

SNOOP is a registered trademark of NUPRO Co.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

Model 755

PREFACE...........................................................................................................................................P-1

Definitions...........................................................................................................................................P-1

Intended Use Statement.....................................................................................................................P-2

Safety Summary .................................................................................................................................P-2

General Precautions For Handling And Storing High Pressure Gas Cylinders .................................P-4

Documentation....................................................................................................................................P-5

Compliances.......................................................................................................................................P-5

1.0 DESCRIPTION AND SPECIFICATIONS..............................................................................1-1

1-1 Overview................................................................................................................................1-1

1-2 Range Options.......................................................................................................................1-1

a. Standard Zero-Based Range Options ............................................................................1-1

b. Standard Zero-Suppressed Range Options ...................................................................1-3

c. Special Range Options ...................................................................................................1-3

1-3 Isolated Current Output Options............................................................................................1-3

1-4 Alarm Option..........................................................................................................................1-3

1-5 Case Mounting Options .........................................................................................................1-3

1-6 Electrical Options...................................................................................................................1-3

1-7 Specifications ........................................................................................................................1-5

a. General ...........................................................................................................................1-5

b. Sample ............................................................................................................................1-5

c. Electrical..........................................................................................................................1-6

d. Physical – General Purpose Enclosure ..........................................................................1-6

e. Physical – Explosion-Proof Enclosure ............................................................................1-6

Instruction Manual

748183-K

April 2002

TABLE OF CONTENTS

2.0 INSTALLATION ....................................................................................................................2-1

2-1 Unpacking..............................................................................................................................2-1

2-2 Location .................................................................................................................................2-1

a. Location and Mounting....................................................................................................2-1

2-3 voltage requirements.............................................................................................................2-1

2-4 Electrical Connections ...........................................................................................................2-2

A. Line Power Connections........................................................................................................2-2

b. Recorder Output Selection and Cable Connections.......................................................2-2

c. Output Connections, Initial Setup for Dual Alarm Option................................................2-6

2-5 Calibration Gases ..................................................................................................................2-10

a. Downscale Standard Gas ...............................................................................................2-11

b. Upscale Standard Gas....................................................................................................2-11

2-6 Sample Handling ...................................................................................................................2-11

a. Sample Temperature Requirements...............................................................................2-11

b. Sample Pressure Requirements: General ......................................................................2-11

c. Normal Operation at Positive Gauge Pressures.............................................................2-13

d. Operation at Negative Gauge Pressures........................................................................2-13

e. Sample Flow Rate...........................................................................................................2-13

f. Corrosive Gases .............................................................................................................2-14

2-7 Leak Test...............................................................................................................................2-14

2-8 Purge Kit (Optional) ...............................................................................................................2-15

Rosemount Analytical Inc. A Division of Emerson Process Management Contents i

Instruction Manual

748183-K

April 2002

3.0 OPERATION .........................................................................................................................3-1

3-1 Start-up Procedure ................................................................................................................3-1

3-2 Calibration..............................................................................................................................3-1

a. Calibration with Downscale and Upscale Standard Gases ............................................3-4

b. Alternative Calibration Procedure Using Upscale Standard Gas Only...........................3-4

3-3 Compensation for Composition of Background Gas .............................................................3-5

a. Oxygen Equivalent Values of Gases ..............................................................................3-5

b. Computing Adjusted Settings for Zero and Span Controls.............................................3-7

3-4 Routine Operation .................................................................................................................3-8

3-5 Effect of Barometric Pressure Changes on Instrument Readout ..........................................3-8

3-6 Calibration Frequency ...........................................................................................................3-8

4.0 THEORY................................................................................................................................4-1

4-1 Principles of Operation ..........................................................................................................4-1

a. Magnetic Displacement Force ........................................................................................4-1

b. Physical Configuration of Detector/Magnet Assembly....................................................4-3

4-2 Variables Influencing Paramagnetic Oxygen Measurements ...............................................4-5

a. Pressure Effects..............................................................................................................4-5

b. Temperature Effects .......................................................................................................4-5

c. Interferents ......................................................................................................................4-5

d. Vibration Effects..............................................................................................................4-6

4-3 Electronic Circuitry.................................................................................................................4-6

a. Detector/Magnet Assembly.............................................................................................4-6

b. Control Board and Associated Circuitry..........................................................................4-6

c. Case Board Assembly ....................................................................................................4-7

d. Isolated Current Output Board (Optional) .......................................................................4-8

e. Alarm Option ...................................................................................................................4-8

Model 755

5.0 CIRCUIT ANALYSIS.............................................................................................................5-1

5-1 Power Supply ±15 VDC........................................................................................................5-1

5-2 Case Heater Control Circuit...................................................................................................5-1

5-3 Detector Heater Control Circuit .............................................................................................5-6

5-4 Detector Light Source Control Circuit....................................................................................5-7

5-5 Detector With First Stage Amplifier .......................................................................................5-8

5-6 Final Output Amplifier ............................................................................................................5-10

5-7 Zero Suppression Module For Zero Adjustment ...................................................................5-12

6.0 MAINTENANCE AND SERVICE ..........................................................................................6-1

6-1 Initial Checkout with Standard Gases ...................................................................................6-1

6-2 Checkout at Test Points on Case Circuit Board ....................................................................6-2

6-3 Detector component Checkout..............................................................................................6-4

a. Detector...........................................................................................................................6-4

b. Source Lamp...................................................................................................................6-4

c. Photocell .........................................................................................................................6-4

d. Suspension .....................................................................................................................6-4

6-4 Detector Component Replacement .......................................................................................6-4

a. Detector Replacement and Calibration...........................................................................6-4

b. Source Lamp Replacement and Adjustment ..................................................................6-7

c. Photocell Replacement and Adjustment .........................................................................6-9

6-5 Heating Circuits .....................................................................................................................6-10

a. Case Heater Control Circuit ............................................................................................6-10

b. Detector/Magnet Heating Circuit.....................................................................................6-10

ii Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755

7.0 REPLACEMENT PARTS ......................................................................................................7-1

7-1 Circuit Board Replacement Policy .........................................................................................7-1

7-2 Matrix – Model 755 General Purpose Enclosure...................................................................7-2

7-3 Matrix – Model 755 Explosion Proof Enclosure.....................................................................7-3

7-4 Replacement Parts ................................................................................................................7-4

8.0 RETURN OF MATERIAL ......................................................................................................8-1

8-1 Return Of Material .................................................................................................................8-1

8-2 Customer Service ..................................................................................................................8-1

8-3 Training..................................................................................................................................8-1

9.0 INDEX....................................................................................................................................9-1

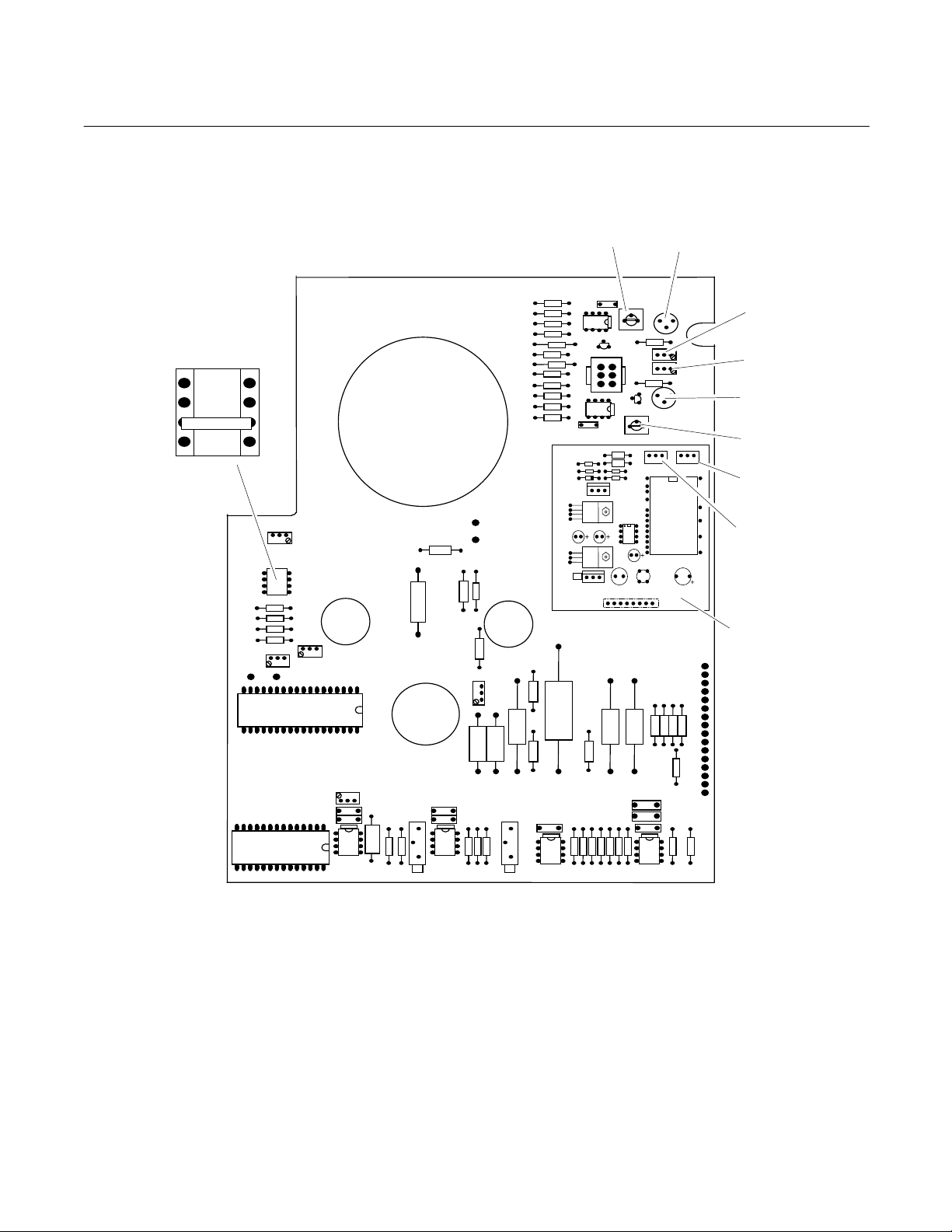

Figure 1-1. Model 755 - Front View...................................................................................................1-2

Figure 1-2. Model 755 - Location of Major Components.................................................................1-4

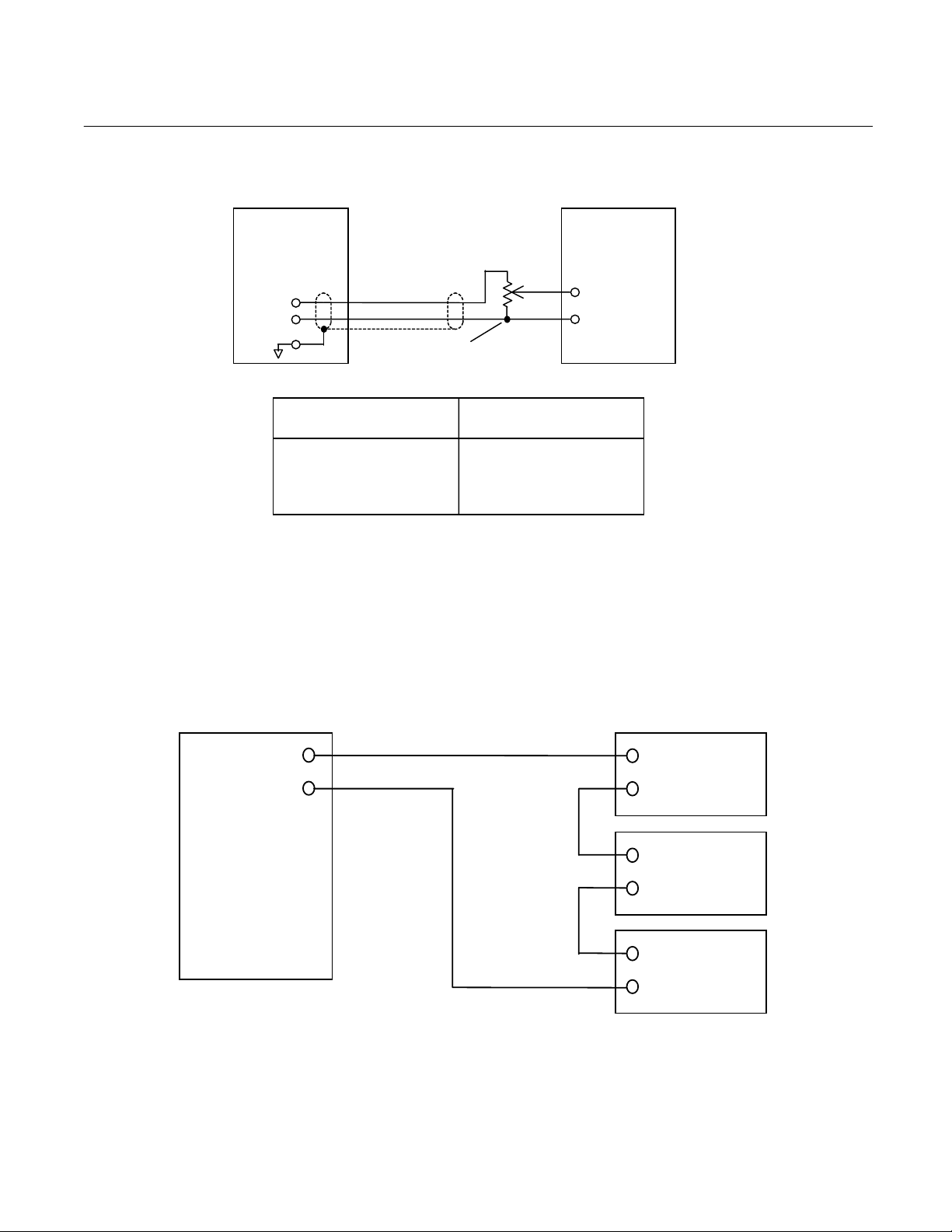

Figure 2-1. Electrical Interconnection ................................................................................................2-3

Figure 2-2. Control Board – Adjustment Locations ...........................................................................2-4

Figure 2-3. Potentiometric Recorder with Non-Standard Span.........................................................2-5

Figure 2-4. Model 755 Connected To Drive Current Output-Activated Output Devices ...................2-5

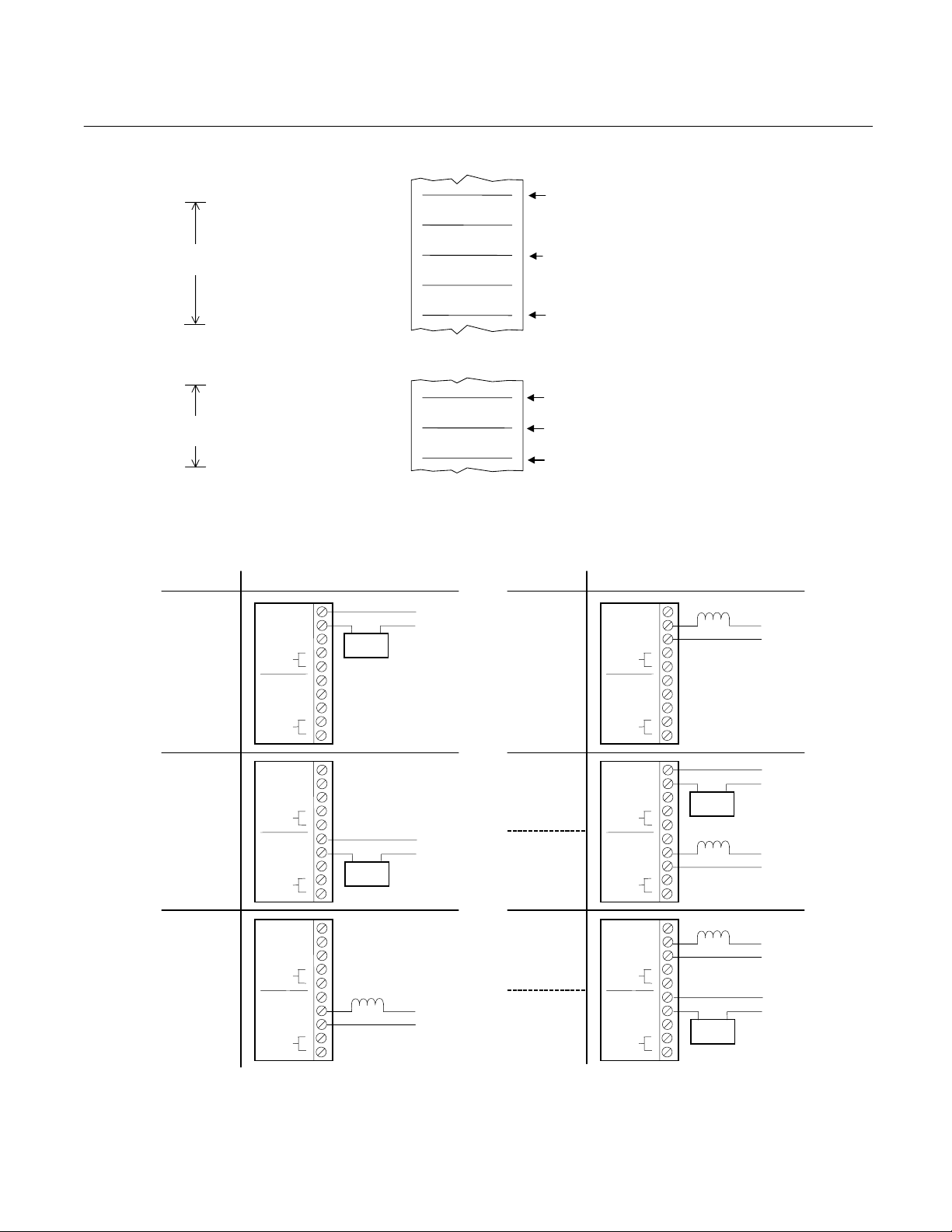

Figure 2-5. Typical Alarm Settings ....................................................................................................2-7

Figure 2-6. Relay Terminal Connections...........................................................................................2-7

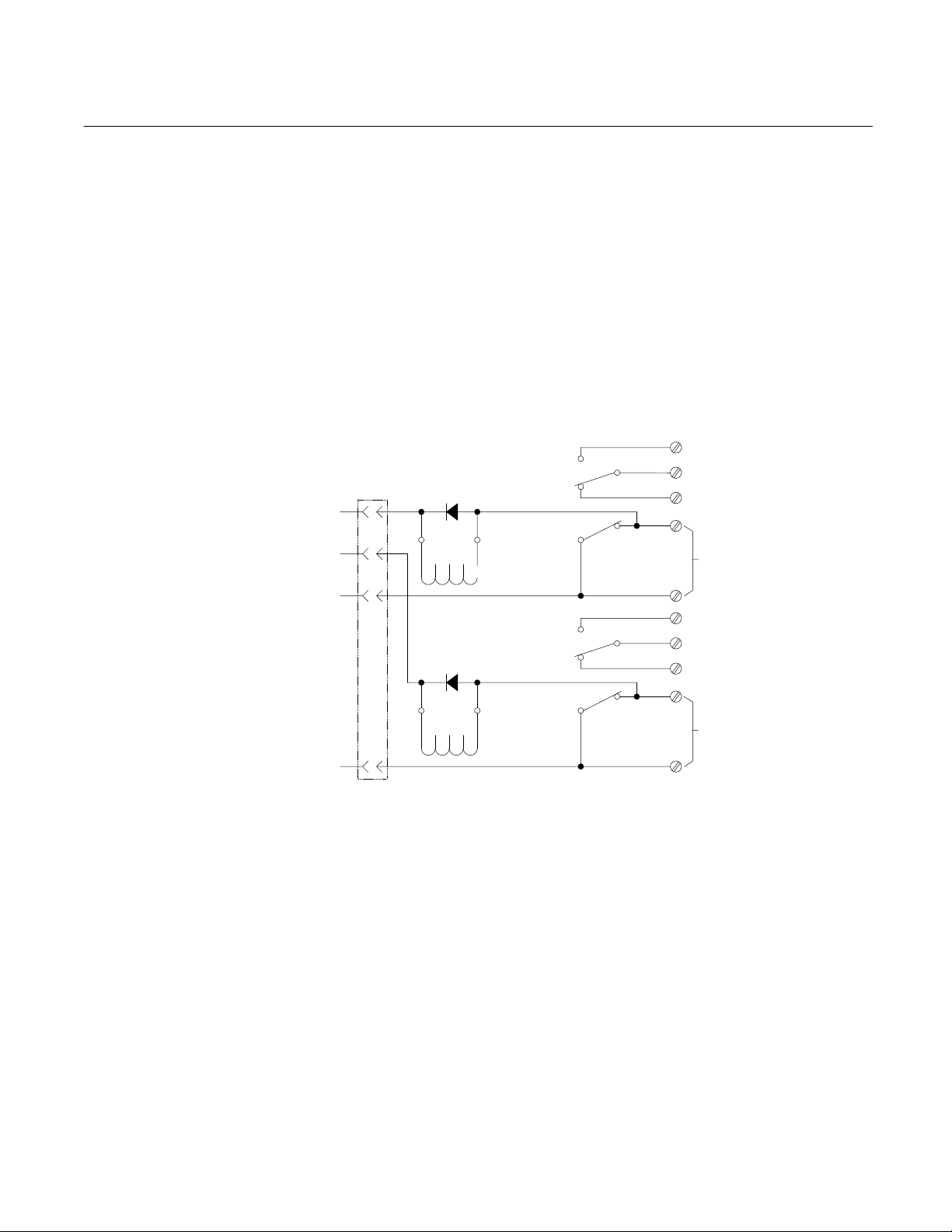

Figure 2-7. Alarm Relay Option Schematic Diagram ........................................................................2-9

Figure 2-8. Connection of Typical Gas Selector Panel to Model 755 ...............................................2-12

Figure 2-9. Installation of Purge Kit ...................................................................................................2-16

Figure 3-1. Control Board - Adjustment Locations ............................................................................3-2

Figure 4-1. Functional Diagram of Model 755 Paramagnetic Oxygen Measurement System..........4-2

Figure 4-2. Spherical Body in Non-Uniform Magnetic Field ..............................................................4-3

Figure 4-3. Detector/Magnet Assembly.............................................................................................4-4

Figure 5-1. Two-Comparator OR Circuit ...........................................................................................5-2

Figure 5-2. Case Heater Control Circuit ............................................................................................5-3

Figure 5-3. Ramp Generator .............................................................................................................5-3

Figure 5-4. Detector Heater Control Circuit.......................................................................................5-6

Figure 5-5. Detector Light Source Control Circuit .............................................................................5-7

Figure 5-6. Detector with First Stage Amplifier..................................................................................5-8

Figure 5-7. Final Output Amplifier......................................................................................................5-11

Figure 5-8. Zero-Suppression Module...............................................................................................5-12

Figure 6-1. Voltage Test Points .........................................................................................................6-2

Figure 6-2. Locations of Case Board Test Points A, B, C and D ......................................................6-3

Figure 6-3. Detector/Magnet Assembly Wiring..................................................................................6-7

Figure 6-4. Modification of 633689 Connector Board for Compatibility with Replacement Lamp.....6-8

Figure 6-5. Lamp Alignment ..............................................................................................................6-9

Figure 6-6. Photocell Adjustment Voltmeter Lead Location ..............................................................6-9

Instruction Manual

748183-K

April 2002

LIST OF ILLUSTRATIONS

Rosemount Analytical Inc. A Division of Emerson Process Management Contents iii

Instruction Manual

748183-K

April 2002

Table 1-1. Front Panel Controls ........................................................................................................1-1

Table 1-2. Range Options .................................................................................................................1-3

Table 2-1. Calibration Range for Various Operating Ranges............................................................2-10

Table 3-1. Control Board - Adjustment Functions .............................................................................3-3

Table 3-2. Oxygen Equivalent of Common Gases............................................................................3-6

Model 755

LIST OF TABLES

DRAWINGS

617186 Schematic Diagram, Case Board

620434 Schematic Diagram, Isolated Current Output Board

624549 Pictorial Wiring Diagram, Model 755

632349 Installation Drawing, Model 755 General Purpose

638277 Schematic Diagram, Alarm

643127 Installation Drawing, Model 755 Explosion Proof

652188 Schematic Diagram, Control Board

(LOCATED IN REAR OF MANUAL)

iv Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Instruction Manual

Model 755

PREFACE

The purpose of this manual is to provide information concerning the components,

functions, installation and maintenance of the 755.

Some sections may describe equipment not used in your configuration. The user should

become thoroughly familiar with the operation of this module before operating it. Read

this instruction manual completely.

DEFINITIONS

The following definitions apply to DANGERS, WARNINGS, CAUTIONS and NOTES found throughout

this publication.

DANGER .

748183-K

April 2002

Highlights the presence of a hazard which will cause severe personal injury, death, or substantial

property damage if the warning is ignored.

WARNING .

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

CAUTION.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of effectiveness.

NOTE

Highlights an essential operating procedure,

condition or statement.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-1

Instruction Manual

748183-K

April 2002

Model 755

INTENDED USE STATEMENT

The Model 755 is intended for use as an industrial process measurement device only. It is not intended for

use in medical, diagnostic, or life support applications, and no independent agency certifications or

approvals are to be implied as covering such application.

SAFETY SUMMARY

If this equipment is used in a manner not specified in these instructions, protective systems may be

impaired.

AUTHORIZED PERSONNEL

To avoid explosion, loss of life, personal injury and damage to this equipment and on-site

property, all personnel authorized to install, operate and service the this equipment should be

thoroughly familiar with and strictly follow the instructions in this manual. SAVE THESE

INSTRUCTIONS.

DANGER.

ELECTRICAL SHOCK HAZARD

Do not operate without doors and covers secure. Servicing requires access to live parts which can

cause death or serious injury. Refer servicing to qualified personnel. For safety and proper

performance this instrument must be connected to a properly grounded three-wire source of power.

WARNING.

PARTS INTEGRITY

Tampering or unauthorized substitution of components may adversely affect safety of this product.

Use only factory documented components for repair.

WARNING.

POSSIBLE EXPLOSION HAZARD

Ensure that all gas connections are made as labeled and are leak free. Improper gas connections

could result in explosion or death.

P-2 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Instruction Manual

Model 755

WARNING .

POSSIBLE EXPLOSION HAZARD

The general purpose Model 755 Oxygen Analyzer, catalog number 191102, is for operation in nonhazardous locations. It is of a type capable of analysis of sample gases which may be flammable.

If used for analysis of such gases, the instrument must be protected by a continuous dilution purge

system in accordance with Standard ANSI/NFPA-496-1086 (Chapter 8) or IEC Publication 79-2-1983

(Section Three).

The explosion-proof Model 755 Oxygen Analyzer, catalog number 632440, is for operation in

hazardous locations. The enclosure must be properly secured with all flange bolts in place and

tightened, lens cover fully engaged, all factory installed flame arrestor assemblies are properly

installed in sample inlet and outlet and any unused openings plugged with approved threaded

plugs properly secured in place. Installation must be made in accordance with applicable parts of

the NEC, especially Articles 501-4(a) and 501-5(a)(1).

If explosive gases are introduced into this analyzer, the sample containment system must be

carefully leak-checked upon installation and before initial start-up, during routine maintenance and

any time the integrity of the sample containment system is broken, to ensure the system is in leakproof condition. Leak-check instructions are provided in Section 2-7.

748183-K

April 2002

Internal leakage of sample resulting from failure to observe these precautions could result in an

explosion causing death, personal injury, or property damage.

CAUTION .

PRESSURIZED GAS

This module requires periodic use of pressurized gas. See General Precautions for Handling and

Storing High Pressure Gas Cylinders, page P-4

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-3

Instruction Manual

748183-K

April 2002

Model 755

GENERAL PRECAUTIONS FOR HANDLING AND STORING HIGH

PRESSURE GAS CYLINDERS

Edited from selected paragraphs of the Compressed Gas Association's "Handbook of Compressed

Gases" published in 1981

Compressed Gas Association

1235 Jefferson Davis Highway

Arlington, Virginia 22202

Used by Permission

1. Never drop cylinders or permit them to strike each other violently.

2. Cylinders may be stored in the open, but in such cases, should be protected against extremes of weather

and, to prevent rusting, from the dampness of the ground. Cylinders should be stored in the shade when

located in areas where extreme temperatures are prevalent.

3. The valve protection cap should be left on each cylinder until it has been secured against a wall or bench, or

placed in a cylinder stand, and is ready to be used.

4. Avoid dragging, rolling, or sliding cylinders, even for a short distance; they should be moved by using a

suitable hand-truck.

5. Never tamper with safety devices in valves or cylinders.

6. Do not store full and empty cylinders together. Serious suckback can occur when an empty cylinder is

attached to a pressurized system.

7. No part of cylinder should be subjected to a temperature higher than 125°F (52°C). A flame should never be

permitted to come in contact with any part of a compressed gas cylinder.

8. Do not place cylinders where they may become part of an electric circuit. When electric arc welding,

precautions must be taken to prevent striking an arc against the cylinder.

P-4 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Instruction Manual

Model 755

DOCUMENTATION

The following Model 755 instruction materials are available. Contact Customer Service Center or the local

representative to order.

748183 Instruction Manual (this document)

COMPLIANCES

Model 755 Oxygen Analyzer - General Purpose Enclosure

The Model 755 Oxygen Analyzer (general purpose enclosure), catalog number 191102, has been designed

to meet the applicable requirements of the U.S. Occupational Safety and Health Act (OSHA) of 1970 if

installed in accordance with the requirements of the National Electrical Code (NEC) of the United States in

non-hazardous areas and operated and maintained in the recommended manner.

748183-K

April 2002

®

Model 755 Oxygen Analyzer - Explosion-Proof Enclosure

The Model 755 Oxygen Analyzer (explosion-proof enclosure), catalog number 632440, is approved by

Factory Mutual (FM) for installation in Class I, Groups B, C, and D, Division 1, hazardous locations as

defined in the National Electrical Code (NEC) of the United States (ANSI/NFPA 70).

FM

APPROVED

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-5

Instruction Manual

748183-K

April 2002

Model 755

P-6 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755

Instruction Manual

748183-K

April 2002

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1-1 OVERVIEW

The Model 755 Oxygen Analyzer provides

continuous read-out of the oxygen content of

a flowing gas sample. The determination is

based on measurement of the magnetic

susceptibility of the sample gas. Oxygen is

strongly paramagnetic, other common gases

are weakly diamagnetic, with few exceptions.

The instrument provides direct read-out of

oxygen concentration on a front-panel meter.

In addition a field-selectable voltage output is

provided as standard. An isolated current

output of 4 to 20 mA or 0 to 20 mA is

obtainable through plug-in of the optional

circuit board. Current and voltage outputs

may be utilized simultaneously, if desired.

The basic electronic circuitry is incorporated

into two boards designated the Control Board

and the Case Board, see Figure 1-2, page 1-

4. The Control Board has receptacles that

accept optional plug-in circuit boards thus

permitting inclusion of such features as

current output and alarms, and facilitating

conversion from one range option to another.

The analyzer is available in a general purpose

enclosure or an explosion proof enclosure.

See Figure 1-1, page 1-2.

1-2 RANGE OPTIONS

The Model 755 is supplied, as ordered, with

four switch-selectable ranges: an overall

range and three sub-ranges, each covering a

portion of the overall range. The standard

range options are of two general types: zerobased (Section 1-2a, page 1-1) and zerosuppressed (Section 1-2b, page 1-3). In

addition, special range options incorporating

combinations of zero-based and zerosuppressed ranges are available on factory

special order, refer to Section 1-2c, page 1-3.

All range options utilize a front-panel meter

with left-hand zero. See Figure 1-1 (page 1-2)

and Table 1-1 (page 1-1).

a. Standard Zero-Based Range Options

In a zero-based range option, the lower

range-limit for all four ranges is 0% oxygen.

There are five standard zero-based range

options:

Range Option

•

Sub-Range A

•

Sub-Range B

•

Sub-Range C

•

Overall Range

•

Refer to Table 1-2, page 1-3.

CONTROL FUNCTION

Indicates oxygen content of sample, provided the analyzer has been calibrated by

Meter

%RANGE switch Select percentage oxygen range for meter and recorder

ZERO Adjust

SPAN Adjust

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

appropriate adjustment of % RANGE switch, ZERO control, and SPAN control.

Meter face is calibrated with scales covering the operating ranges provided.

Used to establish downscale calibration point on meter scale or recorder chart.

With suitable downscale standard gas flowing through the analyzer, the ZERO

Control is adjusted for appropriate reading on meter or recorder.

Used to establish downscale calibration point on meter scale or recorder chart.

With suitable downscale standard gas flowing through the analyzer, the ZERO

Control is adjusted for appropriate reading on meter or recorder.

Table 1-1. Front Panel Controls

Instruction Manual

748183-K

April 2002

Model 755

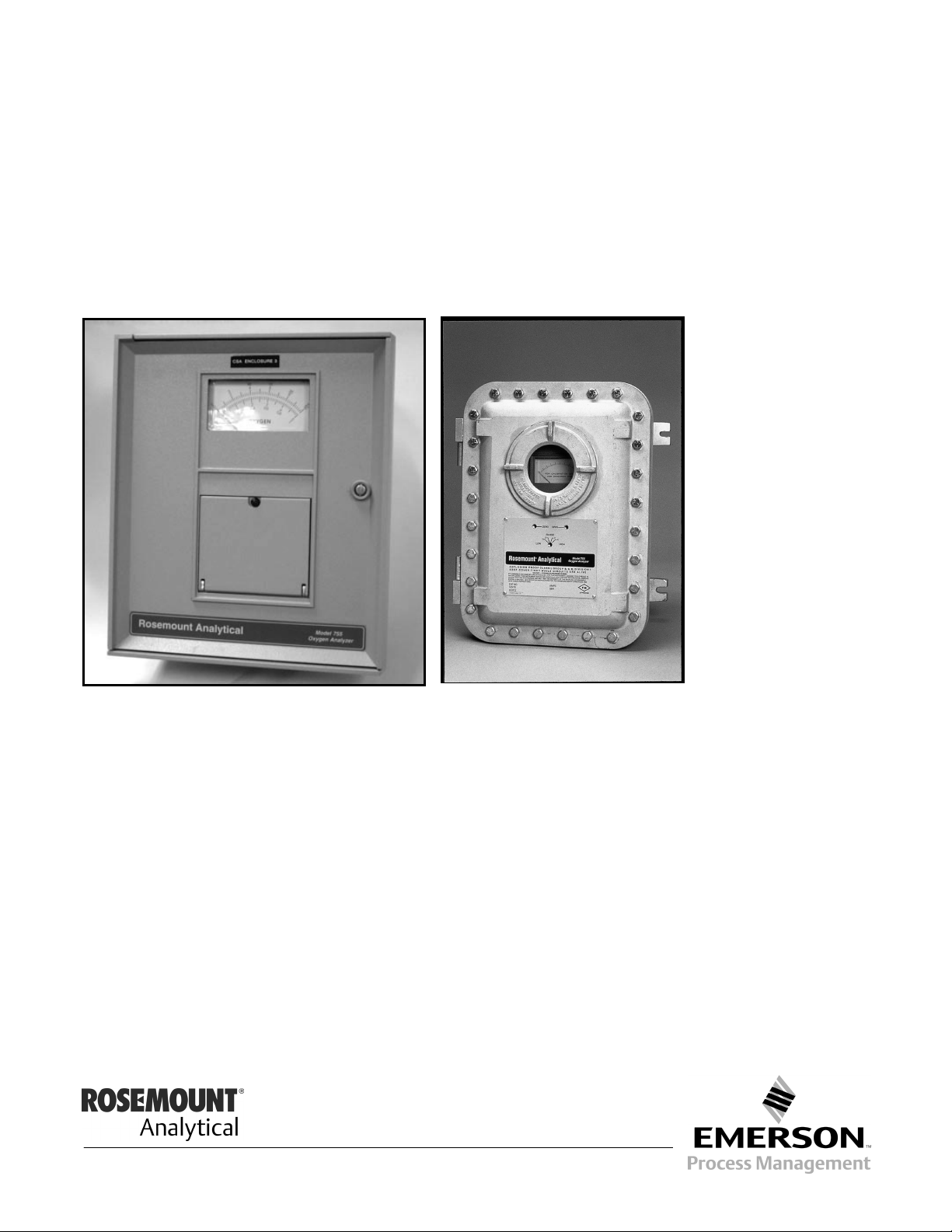

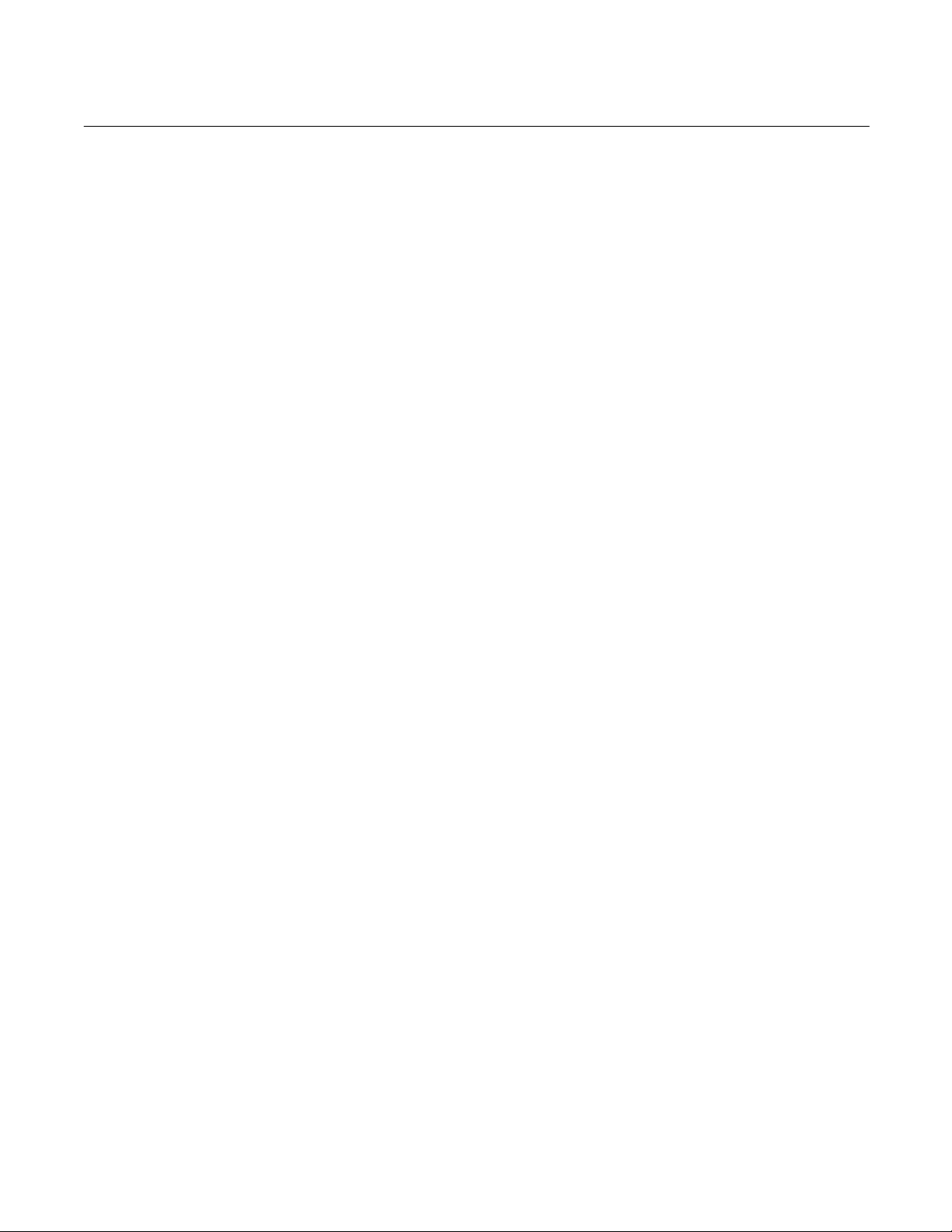

A. General Purpose Enclosure

ZERO Adjust

RANGE Switch

Rosemount Analytical

Meter

Model 755

Oxygen Analyzer

SPAN Adjust

B. Explosion-Proof Enclosure

ZERO Control

RANGE Switch

Controls have slotted shafts for

screwdriver adjustment from

outside the enclosure.

Rosemount Analytical

Model 755

Oxygen Anal yzer

Figure 1-1. Model 755 - Front View

Meter

SPAN Adjust

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755

Instruction Manual

748183-K

April 2002

RANGE

OPTION

01 0 to 1% 0 to 2.5% 0 to 5% 0 to 10%

02 0 to 5% 0 to 10% 0 to 25% 0 to 50%

03 0 to 10% 0 to 25% 0 to 50% 0 to 100%

04 0 to 1% 0 to 2.5% 0 to 5% 0 to 25%

06 90 to 100% 80 to 100% 60 to 100% 50 to 100%

b. Standard Zero-Suppressed Range

Options

With any zero-suppressed range the 0%

oxygen point lies off-scale below the lower

range-limit. In a zero-suppressed range

option the four ranges have the same upper

range-limit, but different lower range-limits.

There is a standard zero-suppressed range

option, as shown in Table 1-2 (page 1-3).

c. Special Range Options

On factory special order, the analyzer may

be provided with a special range option

incorporating any desired combination of

zero-based and zero-suppressed ranges,

arranged in ascending order according to

span.

SUB-RANGE A SUB-RANGE B SUB-RANGE C OVERALL RANGE

Table 1-2. Range Options

1-4 ALARM OPTION

If equipped with the alarm option:

1. On the Control Board there are two

comparator amplifiers, one each for the

ALARM l and ALARM 2 functions. Each

amplifier has associated set-point and

dead-band adjustments, set-point is

adjustable from l% to l00% of fullscale.

The dead-band is adjustable from l% to

20% of fullscale.

2. Alarm relay assembly, containing two

single-pole double-throw relays, one for

each of the alarm contacts. These

relays may be used to drive external,

customer-supplied alarm and/or control

devices.

1-3 ISOLATED CURRENT OUTPUT OPTIONS

An isolated current output is obtainable by

installation of the optional Current Output Board,

either during factory assembly or subsequently

in the field. The maximum load resistance for

this board is 850 ohms.

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

1-5 CASE MOUNTING OPTIONS

General Purpose Enclosure, see drawing

632349.

Explosion Proof Enclosure, see drawing

643127.

1-6 ELECTRICAL OPTIONS

The analyzer is supplied, as ordered, for

operation on either 120 VAC, 50/60 Hz, or

240 VAC, 50/60 Hz.

Instruction Manual

G

748183-K

April 2002

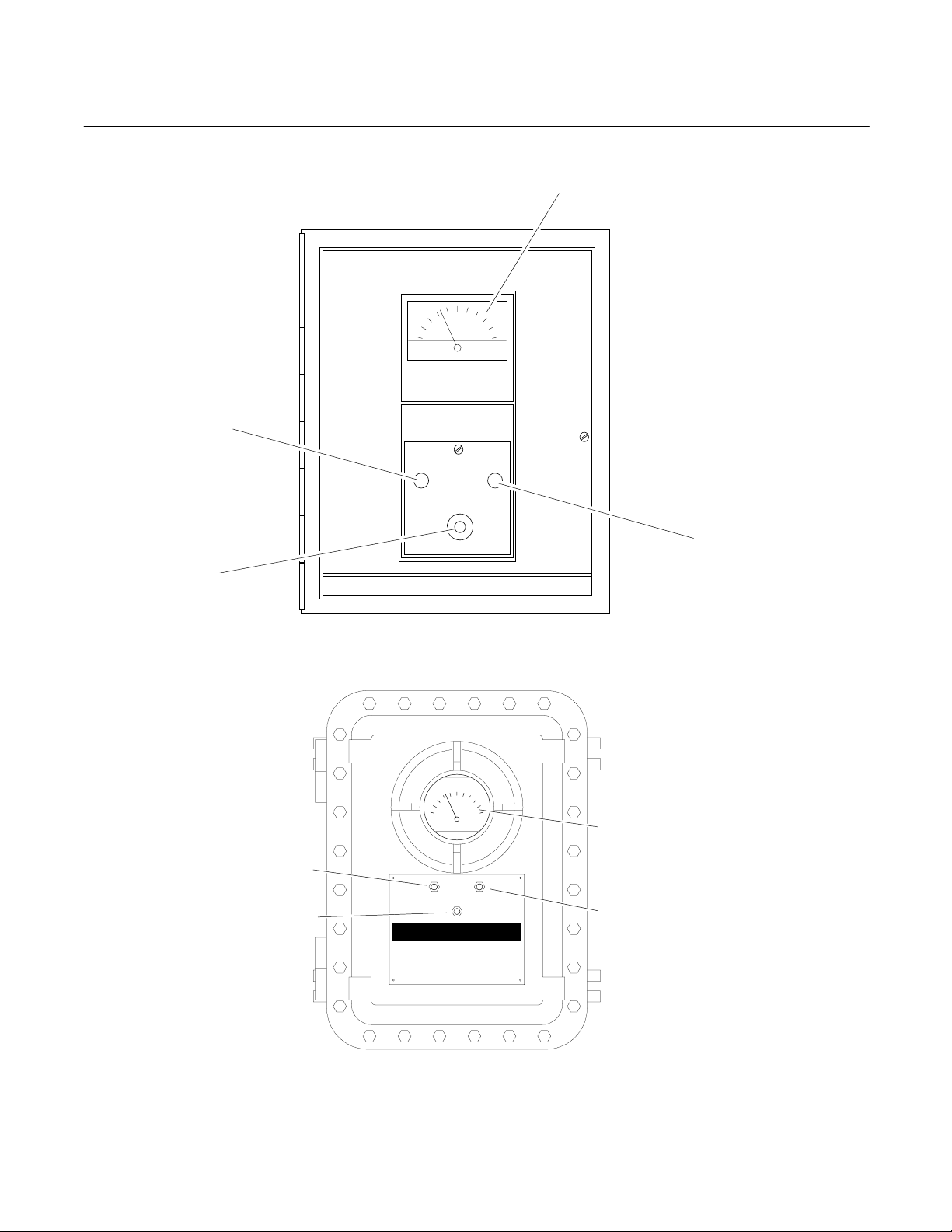

Control Board

Door

Model 755

Current Output

Board (Option)

R

R

R

1

U

I

Alarm Relay

Assembly

(Alarm Option)

Fuse

AC Power

AC Power

TB1

Transformer, Power

T1

(Behind TB1)

NO. 1

RESET

NO. 2

RESET

NO

COM

NC

NO

COM

NC

GND

Case Board

N

H

E

O

U

T

Recorder Output

TB2

Case Heater

Assembly

HOT

MA MV

+

-

+

COM

TB2

Fuse

Case

Heater

TB1

Detector/Magnet

Assembly Shock

Mount

Detector/Magnet

Assembly

General Purpose enclosure shown. Components mounted in same locations in Explosion-Proof enclosure.

Figure 1-2. Model 755 - Location of Major Components

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755

1-7 SPECIFICATIONS

Instruction Manual

748183-K

April 2002

a. General

1

Catalog Number ............................ 191102 General Purpose for operation in non-hazardous locations

632440 Explosion-Proof for operation in hazardous locations

Standard Range Options

(% oxygen fullscale) 2.................... 0 to 1, 2.5, 5, and 10% fullscale

0 to 5, 10, 25, and 50% fullscale

0 to 10, 25, 50, and 100% fullscale

0 to 1, 2.5, 5 and 25% fullscale

0 to 1, 5, 10, and 25% fullscale

50 to 100, 60 to 100, 80 to 100, and 90 to 100% fullscale

Response Time (90% of fullscale) Factory set for 20 seconds; adjustable from 5 to 25 seconds.

Reproducibility............................... ±0.01% Oxygen or ±1% of fullscale, whichever is greater

Ambient Temperature Limits ......... Maximum: 49°C (120°F)

Minimum: -7°C (20°F)

Zero and Span Drift 3..................... ±1% of fullscale per 24 hours, provided that ambient temperature

does not change by more than 11.1°C (20°F).

±2.5% of fullscale per 24 hours with ambient temperature change

over entire range.

b. Sample

Dryness ......................................... Sample dewpoint below 43°C (110°F), sample free of entrained

liquids.

Temperature Limits ....................... Maximum: 66°C (150°F)

Minimum: 10°C (50°F)

Operating Pressure ....................... Maximum: 69 kPa (10 psig).

Minimum: 88.1 kPa absolute (660 mm Hg absolute pressure)

Flow Rate 4.................................... Maximum: 500 cc/min

Minimum: 50 cc/min

Recommended: 250 ±20 cc/min

Materials in Contact with

Sample Gas................................... 316 stainless steel, glass, titanium, Paliney No. 7, epoxy resin,

Viton-A, platinum, nickel.

1

Performance specifications based on recorder output.

2

For applications requiring suppressed ranges other than those provided, we recommend the Model 755A Oxygen Analyzer,

Catalog Number 617720. This instrument includes automatic correction for barometric pressure variations and provides

maximum accuracy for suppressed ranges. This particularly important at high level suppressed ranges such as 99 to 100%

where a barometric pressure change from standard 29.90 inches Hg (101 kPa) to 31.5 inches Hg (106 kPa) would result in

an actual oxygen change in the order of 5%. The Model 755A provides automatic barometric pressure correction and optimum accuracy for such suppressed ranges. The Model 755A also provides direct readout from 0.00% to 100.00% oxygen

on a digital display. Optimum resolution of the oxygen reading is provided.

3

Zero and span drift specifications based on following conditions: Operating pressure constant; ambient temperature change

from initial calibration temperature, less than 11.1 Celsius degrees (20 Fahrenheit degrees); deviation from set flow held to

within ±10% or ±20 cc/min, whichever is smaller.

4

Deviation from set flow would be held to within ±10% or ±20 cc/min, whichever is smaller. If so, zero and span drift will be

within specifications, provided that operating temperature remains constant.

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Instruction Manual

748183-K

April 2002

c. Electrical

Supply Voltage and Frequency

(selectable when ordered)............ Standard: 115 VAC ±10 VAC, 50/60 Hz

Power Consumption ...................... Maximum: 300 watts

Outputs.......................................... Standard: Field selectable voltage output of 0 to 10mV, 0 to

Alarm Option.................................. High-Low Alarm

Contact Ratings ..................... 5 amperes, 240V AC, resistive 3 amperes, 120 VAC inductive

Setpoint ......................................... Adjustable from 1% to 100% of fullscale

Deadband...................................... Adjustable from 1% to 20% of fullscale (Factory set at 10% of

d. Physical – General Purpose Enclosure

Mounting........................................ Standard: Panel mount

Enclosure Classification ................ Meets requirements for NEMA 3R

Refer to Installation Drawing 632349 in the rear of this manual.

Model 755

Optional: 230 VAC ±10 VAC, 50/60 Hz

100mV, 0 to 1V, or 0 to 5VDC

Optional: Isolated current output of 0 to 20mA or 4 to 20mA (with

Current Output Board)

1 amperes, 24V DC, resistive 5 amperes, 30 VDC resistive

5 amperes, 120V AC, resistive 3 amperes, 30 VDC inductive

fullscale)

Optional: Surface or stanchion mount accessory available

Air Purge Option1: NFPA 496 (1989) Type Z purge

e. Physical – Explosion-Proof Enclosure

Mounting........................................ Surface or wall

Enclosure Classification ................ Class I, Groups B, C, and D, Division 1 hazardous locations

(ANSI/NFPA 70)

Refer to Installation Drawing 643127 in the rear of this manual.

1

When installed with user supplied components, meets requirements for Class I, Division 2 locations per National Electrical

Code (ANSI/NFPA 70) for analyzers sampling nonflammable gases. Analyzers sampling flammable gases must be protected by a continuous dilution purge system in accordance with Standard ANSI/NFPA 496-1986, Chapter 8. Consult factory

for recommendations.

1-6 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755

Instruction Manual

748183-K

April 2002

SECTION 2

INSTALLATION

2-1 UNPACKING

Carefully examine the shipping carton and

contents for signs of damage. Immediately

notify the shipping carrier if the carton or its

contents are damaged. Retain the carton and

packing materials until the instrument is

operational.

2-2 LOCATION

a. Location and Mounting

Shock and mechanical motion can reduce

instrument accuracy; therefore, mount the

instrument in an area that is as vibration

free as possible

General Purpose Enclosure

The analyzer is designed to meet NEMA

3R enclosure requirements and may be

mounted outdoors. Permissible ambient

temperature range is 20°F to 120°F (-7°C

to 49°C).

The analyzer is designed for either

surface or stanchion (optional kit)

mounting. Avoid mounting outside in

direct sunlight, or inside in a closed

building, where ambient temperature may

exceed the allowable maximum.

Explosion-Proof Enclosure

The analyzer can be either surface or wall

mounted and meets (ANSI/NFPA 70)

Class 1, Groups B, C, and D, Division 1

Hazardous Locations.

2-3 VOLTAGE REQUIREMENTS

DANGER

ELECTRICAL SHOCK HAZARD

For safety and proper performance this

instrument must be connected to a

properly grounded three-wire source of

power.

DANGER

ELECTRICAL SHOCK HAZARD

Do not operate without doors and covers

secure. Servicing requires access to live

parts which can cause death or serious

injury. Refer servicing to qualified

personnel.

CAUTION

ENCLOSURE INTEGRITY

With reference to Installation Drawing

632349 or 643127, any unused cable

conduit openings must be securely sealed

by permanent closures in order to provide

enclosure integrity in compliance with

personnel safety and environmental

protection requirements. The plastic

closures provided are for shipping

protection only.

NOTE

Refer to Installation Drawing 632349 or

643127 at the rear of this manual for

recommended cable conduit openings.

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-1

Instruction Manual

748183-K

April 2002

Model 755

NOTE

For NEMA 3R service, all conduit must be

connected through approved fittings.

The analyzer is supplied, as ordered, for

operation on 120 VAC or 240 VAC, 50/60 Hz.

Make sure that the power source conforms to

the requirements of the individual instrument,

as noted on the name-rating plate.

2-4 ELECTRICAL CONNECTIONS

a. Line Power Connections

Electrical power is supplied to the

analyzer via a customer-supplied threeconductor cable, type SJT, minimum wire

size 18 AWG. Route power cable through

conduit and into appropriate opening in

the instrument case. Refer to Installation

Drawing (632349 or 643127). Connect

power leads to HOT, NEUT, and GND

terminals on TB1, Figure 2-1. Connect

analyzer to power source via an external

fuse or breaker, in accordance with local

codes.

NOTE

Cable connections and output selection

for potentiometric and current-actuated

devices are explained below.

NOTE

Do not allow internal cable service

loop to touch the shock-mounted

detector assembly or associated

sample inlet and outlet tubing. This

precaution ensures against possible

transmission of mechanical vibration

through the cable to the detector,

which could cause noisy readout.

Potentiometric Output

1. Insert RECORDER OUTPUT Selector

Plug (Figure 2-2, page 2-4) in position

appropriate to the desired output: 10

mV, 100 mV, 1 V, or 5 V.

2. On TB2 (Figure 2-1, page 2-3)

connect leads of shielded recorder

cable to MV+ and COM terminals.

3. Connect free end of output cable to

appropriate terminals of recorder or

other potentiometric device:

Do not draw power for associated

equipment from the analyzer power

cable.

b. Recorder Output Selection and Cable

Connections

If a recorder, controller, or other output

device is used, connect it to the analyzer

via a 22 or 24 AWG two-conductor

shielded cable. Route the cable through

conduit to the analyzer, and into the case

through the appropriate opening shown in

Installation Drawing (632349 or 643127).

Connect the shield only at the recorder

end.

NOTE

Route recorder cable through a

separate conduit, not with power cable

or alarm output cable.

a. For device with a span of 0 to

10mV, 0 to 100mV, 0 to 1V, or 0 to

5V, connect cable directly to input

terminals of the device, making

sure polarity is correct.

b. For device with intermediate span,

i.e., between the specified values,

connect cable to device via a

suitable external voltage divider, as

shown in Figure 2-3, page 2-5.

Isolated Current Output (Option)

The isolated current output board (Figure

2-2, page 2-4) is optional, and can be

adjusted for either 0 to 20 mA or 4 to 20

mA. The adjustments made on this board

are for zero and span. To set output:

1. With analyzer meter at zero, adjust

R1 for desired zero level (typically 0

for 0 to 20 mA, 4 for 4 to 20 mA).

2-2 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755

Instruction Manual

748183-K

April 2002

2. With analyzer at fullscale, adjust R2

for desired fullscale current (typically

20 mA).

3. To connect current activated output

devices:

4. On TB2 (Figure 2-1, page 2-3)

connect leads of shielded recorder

cable to MA+ and " - " terminals.

5. Connect free end of output cable to

input terminals of recorder or other

current-actuated device, making sure

that polarity is correct. If two or more

current-actuated devices are to be

used, they must be connected in

series, see Figure 2-4, page 2-5. Do

not exceed the maximum load

resistance (see Section 1-3, page 1-

3).

Explosion-Proof

Enclosure

6. For the set up of optional boards, the

isolated current output board

(optional) can be adjusted for either

0 to 20 mA or 4 to 20 mA. The

adjustments made on this board are

for zero and span.

a. With analyzer meter at zero, adjust

R1 for desired zero level, typically

0 for 0 to 20 mA, and 4 for 4 to 20

mA..

b. With analyzer meter at fullscale,

adjust R2 for desired fullscale

current (typically 20 mA).

7. Current and voltage outputs may be

utilized simultaneously, if desired.

Optional Alarm Kit

Power Connections

(see detail)

NO

NC

RESET

NO. 2

RESET

COM

NC

TB1

N

H

E

O

U

T

T

COM

-

TB2

Figure 2-1. Electrical Interconnection

General Purpose

Enclosure

+

mV Recorder

-

+

mA Recorder

-

120 VAC CONFIGURATION

Jumpers

N

GND

240 VAC CONFIGURATION

Jumper

GND

H

E

O

U

T

T

N

H

E

O

U

T

T

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-3

Instruction Manual

748183-K

April 2002

Model 755

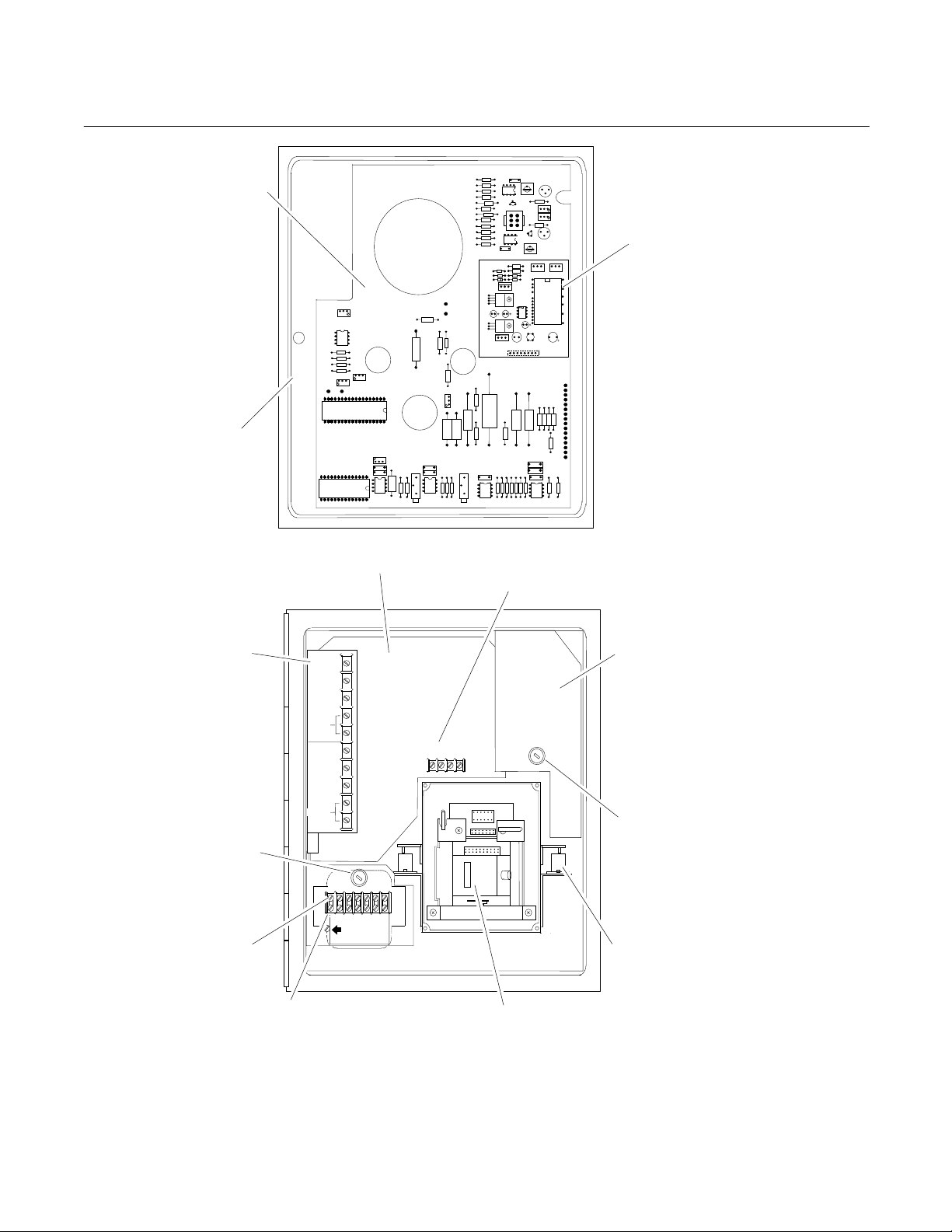

RECORDER OUTPUT

Selector Plug

5V

1V

100mV

10mV

R63

R64

R73

R78

R68

R3

I G O

U6

C4

R4

R2 R1

R5

R6

U3

U2

C2

U4

C3 CR1 C1

U1

J1

R8

R9

CR2

1

2

3

4

C5

I

G

O

I G O

R67

R1

R2

Current Output Board

Figure 2-2. Control Board – Adjustment Locations

2-4 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755

Instruction Manual

748183-K

April 2002

755

Analyzer

Position of Recorder Output

Selector Plug

10 mV 1K Ohm

100 mV 10K Ohm

1 V 100K Ohm

5 V 2K Ohm

Voltage Divider

(Customer Supplied)

Minimum Permissible

Resistance for R1 + R2

Potentiometric

Recorder

Input

Terminals

(Make sure polarity

is correct)

Figure 2-3. Potentiometric Recorder with Non-Standard Span

+

Recorder

-

mA

+

-

755

Analyzer

+

Controller

-

+

Remote

Indicator

Figure 2-4. Model 755 Connected To Drive Current Output-Activated Output Devices

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-5

Instruction Manual

748183-K

April 2002

Model 755

c. Output Connections, Initial Setup for

Dual Alarm Option

If so ordered the analyzer is factoryequipped with alarm output. Alternatively

the alarm feature is obtainable by

subsequent installation of the Alarm Kit.

Alarm Output Connections

The alarm output provides two sets of

relay contacts for actuation of alarm or

process-control functions. Leads from the

customer-supplied external alarm system

connect to terminals on the Alarm

Assembly, see Figure 2-1 page 2-3.

Note the following recommendations:

1. A fuse should be inserted into the line

between the customer-supplied power

supply and the alarm relay terminals

on the Alarm Relay Assembly.

2. If the alarm contacts are connected to

any device that produces radio

frequency interference (RFI), it should

be arc-suppressed. The 858728 Arc

Suppressor is recommended.

3. If at all possible, the analyzer should

operate on a different AC power

source, to avoid RFI.

Alarm Relay Characteristics

The Alarm 1 and Alarm 2 outputs of the

638245 Alarm Relay Assembly are

provided by two identical single-pole

double-throw relays. Relay contacts are

rated at:

5 amperes, 240 VAC resistive

1 ampere, 240 VAC inductive

5 amperes, 120 VAC resistive

3 amperes, 120 VAC inductive

5 amperes, 30 VDC resistive

3 amperes, 30 VDC inductive

Removal of AC power from the analyzer,

as in power failure, de-energizes both

relays, placing them in alarm condition.

Switching characteristics of the Alarm 1

and Alarm 2 relays are as follows:

Alarm 1 Relay

The Alarm I relay coil is de-energized

when the meter needle moves downscale

through the value that corresponds to

setpoint minus dead-band. This relay coil

is energized when the needle moves

upscale through the value that

corresponds to setpoint plus dead-band.

See Figure 2-5A, page 2-7.

Alarm 2 Relay

Relay The Alarm 2 relay coil is deenergized when the meter needle moves

upscale through the value that

corresponds to the setpoint plus deadband. This relay coil is energized when

needle moves downscale through the

value that corresponds to setpoint minus

dead-band, see Figure 2-5B, page 2-7.

Alarm Reset

Normally both the ALARM 1 and ALARM

2 functions incorporate automatic rest.

When the meter reading goes beyond the

selected limits, the corresponding relay is

de-energized; when the meter reading

returns within the acceptable range, the

relay is turned on.

The desired ALARM 1 or ALARM 2 alarm

function may be converted to manual

reset. The conversion consists of

substituting an external push-button or

other momentary-contact switch for the

jumper that normally connects the RESET

terminals on the Alarm Relay Assembly,

see Figure 2-1 page 2-3. If the

corresponding relay is now de-energized,

i.e., in alarm condition, the relay remains

de-energized until the operator

momentarily closes the switch.

2-6 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Model 755

Instruction Manual

748183-K

April 2002

A. Typical ALARM 1 Setting

DEADBAND SET FOR

20% OF FULLSCALE

B. Typical ALARM 2 Setting

DEADBAND SET FOR

10% OF FULLSCALE

Low Alarm,

Fail-Safe

Percent of Fullscale

No. 1

COM

RESET

COM

RESET

No. 2

INPUT SIGNAL

Percent of Fullscale

INPUT SIGNAL

Figure 2-5. Typical Alarm Settings

NO

NC

NO

NC

Alarm Bell

or Lamp

40

30

20

55

50

45

115 VAC

When input signal moves upscale through this point, the coil of

ALARM 1 relay (K1) is energized, providing continuity between the

common and normally-closed contacts of the relay.

ALARM 1 Setpoint

When input signal moves downscale through this point, the coil of

ALARM 1 relay (K1) is de-energized, providing continuity between the

common and normally-open contacts of the relay.

When input signal moves upscale through this point, the coil of

ALARM 2 relay (K2) is de-energized, providing continuity between the

common and normally-open contacts of the relay.

ALARM 2 Setpoint

When input signal moves upscale through this point, the coil of ALARM

2 relay (K2) is energized, providing continuity between the common

and normally-closed contacts of the relay.

REQUIREMENT TYPICAL CONNECTIONSREQUIREMENT TYPICAL CONNECTIONS

Solenoid

No. 1

RESET

RESET

No. 2

NO

COM

NC

NO

COM

NC

N

H

Low Control

Limit,

Fail-Safe

Valve

115 VAC

H

N

High Alarm,

Fail-Safe

Low Control

Limit,

Fail-Safe

No. 1

RESET

RESET

No. 2

No. 1

RESET

RESET

No. 2

COM

COM

COM

COM

NO

NC

NO

NC

NO

NC

NO

NC

Alarm Bell

or Lamp

Solenoid

Valve

115 VAC

115 VAC

N

H

H

N

Lower

Low Alarm

Indicator,

Fail-Safe

Low Control,

Fail-Safe

High Control,

Fail-Safe

Higher

High Alarm

Indicator,

Fail-Safe

No. 1

RESET

RESET

No. 2

No. 1

RESET

RESET

No. 2

COM

COM

COM

COM

NO

NC

NO

NC

NO

NC

NO

NC

Alarm Bell

or Lamp

Solenoid

Valve

Solenoid

Valve

Alarm Bell

or Lamp

115 VAC

115 VAC

115 VAC

115 VAC

N

H

H

N

H

N

N

H

Figure 2-6. Relay Terminal Connections

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-7

Instruction Manual

748183-K

April 2002

Model 755

Fail-Safe Applications

By appropriate connection to the doublethrow relay contacts, it is possible to

obtain either a contact closure or a

contact opening for an energized relay.

Also either a contact closure or a contact

opening may be obtained for a deenergized relay. It is important that for failsafe applications, the user understand

what circuit conditions are desired in

event of power failure and the resultant

relay de-energization. Relay contacts

should then be connected accordingly,

see Figure 2-6 page 2-7.

Alarm Setpoint Adjustment

The ALARM 1 and ALARM 2 circuits have

independent setpoint and dead-band

adjustments. Before the ALARM 1 and

ALARM 2 setpoints can be set, the alarm

dead-band must be calibrated according

to the following procedure.

1. Set the front panel TEST switch to

position 1.

2. Introduce upscale span gas through

analyzer at a flow rate of 50 to 500

cc/min.

3. Verify that ALARM 1 and ALARM 2

dead-band adjustments, R73 and R78

(Figure 2-2, page 2-4) are turned fully

counter-clockwise to set the deadband at minimum. Normally these

potentiometers are factory-set for

minimum dead-band. Both

potentiometers must remain at this

setting throughout calibration of the

alarm setpoint adjustments.

b. Adjust SPAN control to give a

display or recorder reading exactly

fullscale. If the fullscale setting

cannot be reached, set to a reading

higher than the desired alarm

setpoint.

c. Set ALARM 1 calibration

adjustment, R63, to its clockwise

limit (Figure 2-2, page 2-4). Rotate

R63 counter-clockwise the

minimum amount required to

energize ALARM 1, relay K1. Verify

that the alarm has been energized

with the ohmmeter on the relay

contacts (Figure 2-7, page 2-9).

6. Calibration of ALARM 2, LOW.

a. Rotate setpoint adjustment, R68,

fully counter-clockwise.

b. Adjust SPAN control for display or

recorder reading exactly fullscale. If

the fullscale setting cannot be

reached, then set to a reading

higher than the desired alarm

setpoint.

c. Set ALARM 2 calibration

adjustment, R67, to its clockwise

limit. Rotate R67 counterclockwise, the minimum amount

required to energize ALARM 2,

relay K2. Verify that the alarm has

been energized with the ohmmeter

on the relay contacts (Figure 2-7,

page 2-9).

7. Setpoint adjustment of ALARM 1,

HIGH.

4. Connect an ohmmeter to relay

terminals on 638254 Alarm Relay

Assembly to verify when alarms have

been energized.

5. Calibration of ALARM 1, HIGH.

a. Rotate setpoint adjustment, R64,

fully counter-clockwise.

2-8 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

a. With span gas flowing, adjust SPAN

control to read desired alarm

setpoint on display or recorder.

b. Rotate setpoint adjustment, R64,

clockwise to energize relay.

c. Check this setting by adjusting the

SPAN control to lower the output

below the setpoint. This will deenergize the relay. Rotating R64

Model 755

Instruction Manual

748183-K

April 2002

above the setpoint will energize the

relay.

8. Setpoint adjustment of ALARM 2,

LOW.

a. With span gas flowing, adjust the

SPAN control to read desired alarm

setpoint on display or recorder.

+15V

-15V

ALARM 1

ALARM 2

J5

1

14

2

4

-

14

6

-

CR1

CR2

K1

K2

13

13

b. Rotate setpoint adjustment, R68,

c. Check setting by adjusting the

1

5

12 8

1

5

12 8

clockwise to energize relay.

SPAN control to lower the output

below the setpoint. This will

energize the relay. Rotating R68

above the setpoint will de-energize

the relay.

NO

9

COM

NC

ALARM 1

RESET

NO

9

COM

NC

ALARM 2

RESET

2. RELAYS SHOWN IN ENERGIZED POSITION.

1. CR1 AND CR2 ARE ANY 600 V, 1 AMP DIODE.

NOTES:

Figure 2-7. Alarm Relay Option Schematic Diagram

Rosemount Analytical Inc. A Division of Emerson Process Management Installation 2-9

Instruction Manual

748183-K

April 2002

Model 755

2-5 CALIBRATION GASES

WARNING

HIGH PRESSURE GAS CYLINDERS

Calibration gas cylinders are under

pressure. Mishandling of gas cylinders

could result in death, injury, or property

damage. Handle and store cylinders with

extreme caution and in accordance with

manufacturer instructions. Refer to

General Precautions for Handling and

Storing High Pressure Gas Cylinders, page

P-4.

Analyzer calibration consists of establishing a

downscale calibration point and an upscale

calibration point.

Downscale calibration may be performed on a

range that will be used during sample

analysis. For maximum precision, however, it

should be performed on the range of highest

sensitivity, i.e., most narrow span.

Preferably upscale calibration should be

performed on a range to be used in sample

analysis. In some applications, however, it

may be desirable to perform upscale

calibration on a range of higher sensitivity,

i.e., more narrow span, and then move the %

RANGE switch to the desired operating range.

For example, if the operating range is to be 0

to 50% oxygen, upscale calibration may be

performed on the 0 to 25% range to permit

use of air as the upscale standard gas.

Recommendations on calibration gases for

various operating ranges are tabulated in

Table 2-1, page 2-10, and are explained in

Sections 2-5a (page 2-11) and 2-5b (page 2-

11).

Each standard gas should be supplied from a

cylinder equipped with dual-stage metaldiaphragm type pressure regulator, with

output pressure adjustable from 0 to 50 psig

(0 to 34.5 kPa).

A. ZERO BASED RANGES

RANGE % O

0 to 1 Nitrogen 0.9% O2, balance N2

0 to 2.5 Nitrogen 2.3% O2, balance N2

0 to 5 Nitrogen 4.5% O2, balance N2

0 to 10 Nitrogen 9% O2, balance N2

0 to 25 Nitrogen Air (20.93% O2)

0 to 50 Nitrogen 0.45% O2, balance N2

0 to 100 Nitrogen 100% O2

RANGE % O

90 to 100 91% 0.5% O2, balance N2 High-purity O2

80 to 100 82% 1% O2, balance N2 100% O2

60 to 100 62% 1% O2, balance N2 100% O2

50 to 100 52% 1% O2, balance N2 100% O2

Each standard gas used should have a composition within the specified limits, and should have a

certified analysis provided by the supplier.

2

2

RECOMMENDED DOWNSCALE

STANDARD GAS

B. ZERO SUPPRESSED RANGES

RECOMMENDED DOWNSCALE

STANDARD GAS

NOTE

Table 2-1. Calibration Range for Various Operating Ranges

RECOMMENDED UPSCALE

STANDARD GAS

RECOMMENDED UPSCALE

STANDARD GAS

2-10 Installation Rosemount Analytical Inc. A Division of Emerson Process Management

Loading...

Loading...