Model 371 ORP Sensor

13.5 EuroSenz

™

Instruction Sheet

PN 51A-371ORP/rev.C

January 2011

SPECIFICATIONS

ORP Range: -1500 to 1500 mV

Wetted Materials: Polypropylene, EP,

Glass, and Platinum

Process Connection: Standard PG

13.5 Thread

Electrode Connection: Single Pole

Euro Connector

Temperature Range: 0° - 85°C

(32° - 185°F)

Pressure Range: 100 - 790 kPa abs

(0 - 100 psig)

Specifications subject to change

without notice.

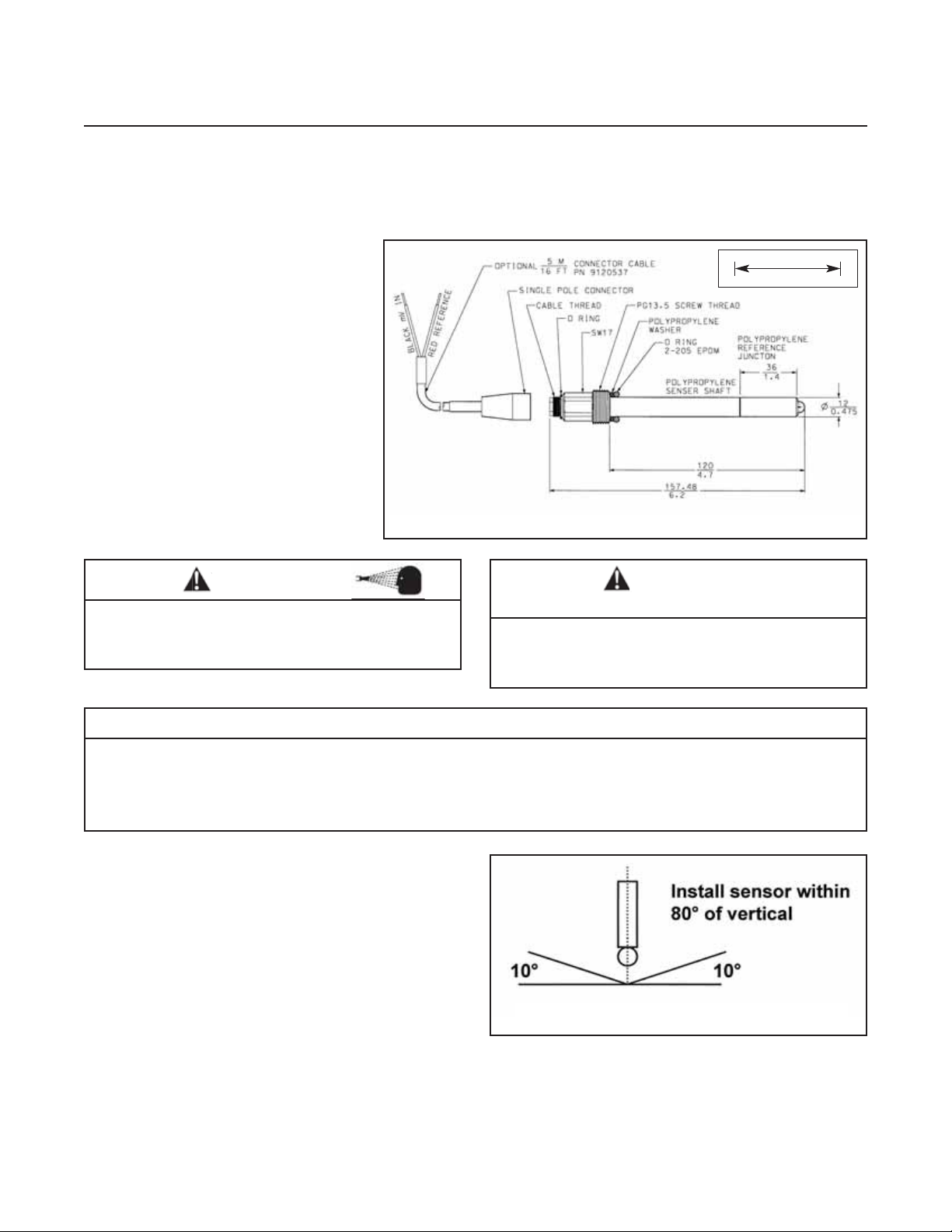

FIGURE 1. Sensor Dimensions

MILLIMETER

INCH

STORAGE

1. It is recommended that electrodes be stored in their

original shipping containers until needed.

2. Do not store at temperatures below -5°C (23°F).

3. Electrodes should be stored with a protective cap

containing KCl solution (PN 9210342).

4. For overnight storage, immerse the sensor in tap

water or 4 pH buffer solution.

ELECTRODE PREPARATION

1. Remove electrode from shipping container.

2. Remove the protective boot covering the electrode

bulb.

NOTE

Do not allow lubricant to coat the platinum band

or reference junction. If it does, wipe it clean

before installation.

INSTALLATION

For sensor orientation, see Figure 2.

For wiring, see Figure 3.

FIGURE 2. Sensor Orientation

For additional information, please visit our website at www.emersonprocess.com/raihome/liquid/.

WARNING

Before removing the sensor, be absolutely certain

that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level!

WARNING

The wetted sensor materials may not be compatible

with process com position and operating conditions.

Application compat ibility is entirely the

responsi-

bility of the user.

CAUTION

SENSOR/PROCESS APPLICATION COMPATIBILITY

ATEX DIRECTIVE

Special Conditions for safe use

1. All pH/ORP sensors have a plastic enclosure which must only be cleaned with a damp cloth to avoid the

danger due to a build up of an electrostatic charge.

2. All pH/ORP sensor Models are intended to be in contact with the process fluid and may not meet the 500V

r.m.s. a.c. test to earth. This must be taken into consideration at installation.

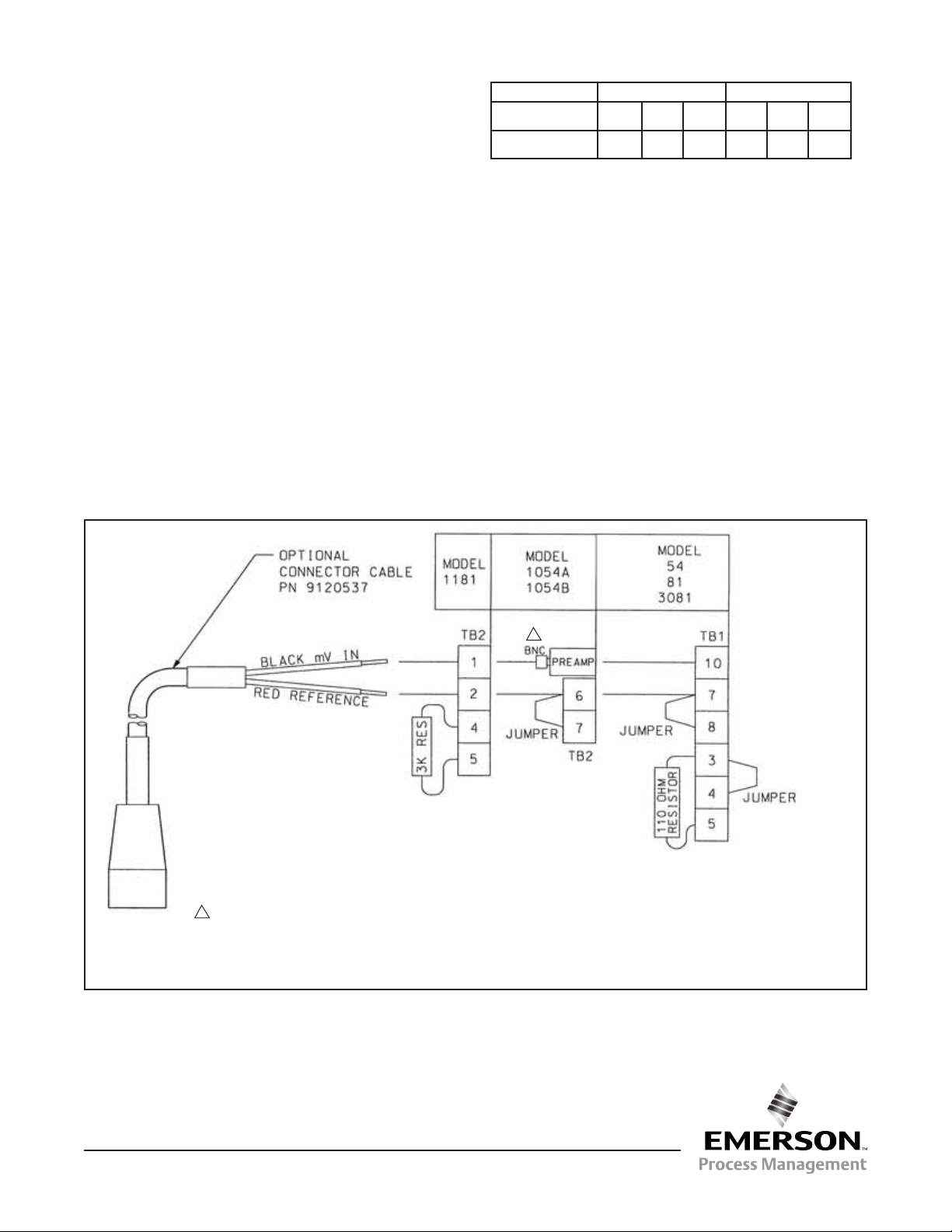

FIGURE 3. Electrical Connection

1. INSTRUMENTS MUST BE USED IN MANUAL TEMPERATURE COMPENSATION

MODE.

2. A SEPARATE THERMOCOUPLE MAY BE USED IF TEMPERATURE COMPENSATION IS DESIRED. PLEASE CONSULT APPROPRIATE ANALYZER/TRANSMITTER

MANUAL FOR MORE WIRING DETAILS.

FOR USE WITH 1054 SERIES WITH INTEGRAL PREAMP IN ANALYZER,

REQUIRES THE USE OF BNC ADAPTER (PN 9120516) TO BE PLACED ON THE

BLACK WIRE.

3

3

ORP CALIBRATION

1. After making an electrical connection between the

sensor and the instrument, obtain a standard solution of saturated quinhydrone. This can also be

made quite simply by adding a few crystals of quinhydrone to either pH 4 or pH 7 buffer. Quinhydrone

is only slightly soluble, therefore only a few crystals

will be required.

2. Immerse the sensor in the standard solution. Allow

1-2 minutes for the ORP sensor to stabilize.

3. Adjust the standardize control of the instrument to

the solution value shown in the table below. The

resulting potentials, measured with a clean platinum electrode and saturated KCl/AgCl reference

electrode, should be within +/- 20 millivolts of the

value shown in the table below. Solution temperature must be noted to ensure accurate interpretation of results. The ORP value of saturated quinhydrone solution is not stable over long periods of

time. Therefore, these standards should be made

up fresh each time they are used.

4. Remove the sensor from the buffer, rinse, and

install in the process.

MAINTENANCE

Electrodes should respond rapidly. Sluggishness, offsets, and erratic readings are indicators that the electrodes may need cleaning or replacement.

1. To remove oil deposit, clean the electrode with a

mild non-abrasive detergent.

2. To remove scale deposits, soak electrodes for 30 to

60 minutes in a 5% hydrochloric acid solution.

3. ORP (metallic) electrodes should be polished with

moistened baking soda.

pH 4 Solution pH 7 Solution

Temp °C 20 25 30 20 25 30

mV Potential 268 264 260 94 87 80

ORP of Saturated Quinhydrone Solution (millivolts)

NOTE: NEWER CABLES MAY HAVE

DIFFERENT WIRE COLORS. IN THIS

CASE, THE BLACK WIRE IS REFERENCE, AND THE CLEAR/COPPER

WIRE IS mV IN.

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2011

Loading...

Loading...