Instruction Manual

LIQ_MAN_CFA3000/rev. C

September 2014

Model CFA-3000

Colorimetric Valve-Pump-based Monitor

ESSENTIAL INSTRUCTIONS

READ THIS P

AGE BEFORE PROCEEDING!

Your purchase from Rosemount Analytical, Inc. has

resulted in one of the finest instruments available for

your particular application. These instruments have

been designed, and tested to meet many national

and international standards. Experience indicates

that its performance is directly related to the quality

of the installation and knowledge of the user in operating and maintaining the instrument. To ensure their

continued operation to the design specifications, personnel should read this manual thoroughly before

proceeding with installation, commissioning, operation, and maintenance of this instrument. If this

equipment is used in a manner not specified by the

manufacturer, the protection provided by it against

hazards may be impaired.

• Failure to follow the proper instructions may cause

any one of the following situations to occur: Loss

of life; personal injury; property damage; damage

to this instrument; and warranty invalidation.

• Ensure that you have received the correct model

and options from your purchase order. Verify that

this manual covers your model and options. If not,

call 1-800-854-8257 or 949-757-8500 to request

correct manual.

• For clarification of instructions, contact your

Rosemount representative.

• Follow all warnings, cautions, and instructions

marked on and supplied with the product.

• Use only qualified personnel to install, operate,

update, program and maintain the product.

• Educate your personnel in the proper installation,

operation, and maintenance of the product.

• Install equipment as specified in the Installation

section of this manual. Follow appropriate local

and national codes. Only connect the product to

electrical and pressure sources specified in this

manual.

• Use only factory documented components for

repair. Tampering or unauthorized substitution of

parts and procedures can affect the performance

and cause unsafe operation of your process.

• All equipment doors must be closed and protective

covers must be in place unless qualified personnel

are performing maintenance.

• If this equipment is used in a manner not specified

by the manufacturer, the protection provided by it

against hazards may be impaired.

WARNINGS

RISK OF ELECTRICAL SHOCK

Equipment protected throughout by double insulation.

• Installation of cable connections and servicing of this

product require access to shock hazard voltage levels.

• Main power and relay contacts wired to separate power

source must be disconnected before servicing.

• Do not operate or energize instrument with case open!

• Signal wiring connected in this box must be rated at least

240 V.

• Non-metallic cable strain reliefs do not provide grounding

between conduit connections! Use grounding type bushings and jumper wires.

• Unused cable conduit entries must be securely sealed by

non-flammable closures to provide enclosure integrity in

compliance with personal safety and environmental protection requirements. Unused conduit openings must be

sealed with NEMA 4X or IP65 conduit plugs to maintain

the ingress protection rating (NEMA 4X).

• Electrical installation must be in accordance with the

National Electrical Code (ANSI/NFPA-70) and/or any

other applicable national or local codes.

• Operate only with front and rear panels fastened and in

place over terminal area.

• Safety and performance require that this instrument be

connected and properly grounded through a three-wire

power source.

• Proper relay use and configuration is the responsibility of

the user.

CAUTION

This product generates, uses, and can radiate radio frequency

energy and thus can cause radio communication interference.

Improper installation, or operation, may increase such interference. As temporarily permitted by regulation, this unit has not

been tested for compliance within the limits of Class A computing devices, pursuant to Subpart J of Part 15, of FCC Rules,

which are designed to provide reasonable protection against

such interference. Operation of this equipment in a residential

area may cause interference, in which case the user at his

own expense, will be required to take whatever measures may

be required to correct the interference.

WARNING

This product is not intended for use in the light

industrial, residential or commercial environments

per the instrument’s certification to EN50081-2.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihom.com

© Rosemount Analytical Inc. 2005

CFA-3000 Colorimetric Analyzer

Ta

ble of Contents

Instruction Manual

Table of

Contents

1.0 INTRODUCTION ....................................................................................... 1

1.1 Thoroughly Read This Manual ................................................................... 2

1.2 Analyzer Benefits ....................................................................................... 2

1.3 WARNING -- Electrical Shock Hazard ....................................................... 3

1.4 CFA-3000 Series Monitors - Approvals...................................................... 3

2.0 INSTALLING THE ANALYZER.................................................................4

2.1 Unpack Parts ............................................................................................. 4

2.2 Mount Main Cabinet................................................................................... 6

2.3 Mount Reagent Cabinet ............................................................................. 6

2.4 Install Waste Tube ..................................................................................... 9

2.5 Mount Overflow Sampling Assembly ......................................................... 9

2.6 Prepare Electrical Connections................................................................ 12

2.7 Install Colorimeter Assembly.................................................................... 13

2.8 Install Valve Pump Assembly................................................................... 14

2.9 Prepare Reagent Containers ................................................................... 16

3.0 OPERATING THE ANALYZER............................................................... 17

3.1 Operational Overview .............................................................................. 17

3.2 Check Sample Stream ............................................................................. 18

3.2.1 Check Fluidics.......................................................................................... 19

3.2.2 Check Reagents ...................................................................................... 19

3.2.3 Turn On Power......................................................................................... 19

3.2.4 Test Valve Pump Operation..................................................................... 20

3.2.5 Set Up Stream Parameters...................................................................... 23

3.3 Set Reagent Supply Time ........................................................................ 25

3.4 Set Scaling Outputs ................................................................................. 25

3.4.1 Record GAIN and mV........................................................................... 26

3.4.2 Initiate Auto Calibration............................................................................ 27

3.5 Process a Grab Sample........................................................................... 28

3.6 Manually Sample a Particular Stream...................................................... 28

3.7 Shutdown................................................................................................. 29

3.8 Quick Start ............................................................................................... 29

4.0 MAINTAINING THE ANALYZER ............................................................ 30

4.1 Analyzer Equipment................................................................................. 30

4.2 Colorimeter Assembly.............................................................................. 30

5.0 TROUBLESHOOTING PROCEDURES .................................................. 32

5.1 Troubleshooting Chart ............................................................................. 32

5.2 Test Functions ......................................................................................... 34

6.0 REPAIR PROCEDURES......................................................................... 35

6.1 Replace Valve Pump Assembly ............................................................... 35

6.2 Replace Circuit Boards ............................................................................ 37

6.3 Replace Fuses ......................................................................................... 37

6.4 Replace Colorimeter Components ........................................................... 39

2

CFA-3000 Colorimetric Analyzer

Instruction Manual

6.4.1 Replace Interference Filter................................................................ ....... 39

6.4.2 Replace Flowcell...................................................................................... 39

6.4.3 Replace 5 Vdc Source Lamp ................................................................... 40

7.0 INSTRUMENT DESCRIPTION................................................................ 41

7.1 Analyzer Front View................................................................................. 41

7.1.1 Main Cabinet............................................................................................ 41

7.1.2 Reagent Cabinet ...................................................................................... 41

7.2 Keypad Panel........................................................................................... 43

7.3 Card Cage................................................................................................ 44

7.3.1 Card Cage and Door................................................................................ 44

7.3.2 CPU Board............................................................................................... 44

7.3.3 Analog Board ................................ ........................................................... 44

7.3.4 Valve Board ............................................................................................. 44

7.3.5 Power Supply Board ................................................................................ 44

7.3.6 Analog Board DIP Switches..................................................................... 46

7.4 Colorimeter Assembly.............................................................................. 47

7.5 Rear of Main Cabinet ............................................................................... 48

7.6 Valve Pump Assembly ............................................................................. 49

7.7 Interface Ports.......................................................................................... 50

7.8 Relay Output Option ................................................................................ 50

7.9 Multi-Output Board................................................................................... 50

7.10 Overflow Sampling Assemblies................................................................ 51

8.0 ADDITIONAL FEATURES.......................................................................53

8.1 Chart Recorders and Data Loggers ......................................................... 53

8.2 Computer Interface .................................................................................. 56

8.2.1 Data Output Format ................................................................................. 56

8.2.2 Data Configuration ................................................................................... 56

8.2.3 RS232-C Function Commands ................................................................ 57

8.2.4 Initiating RS232-C Communications to Computer.................................... 58

8.2.5 Printer Interface ....................................................................................... 60

8.2.6 Set Printer Internal Clock ......................................................................... 60

Appendix A. CHEMISTRIES....................................................................................... 61

Appendix B. SPECIFICATIONS ..................................................................................62

Appendix C. POWER INTERCONNECT DESCRIPTION............................................ 64

Appendix D. BYPASS FOR CALIBRATION................................................................ 66

Appendix E. KEYPAD HELP SHEETS....................................................................... 67

ORDERING INFORMATION......................................................................................... 73

3

CFA-3000 Colorimetric Analyzer

Figures

Instruction Manual

Figure 2-1. Opened Assembled Cabinet................................................................ 10

Figure 2-2. Mounting Main and Reagent Cabinets................................................. 12

Figure 2-3. Attaching Grounding Strap .................................................................. 12

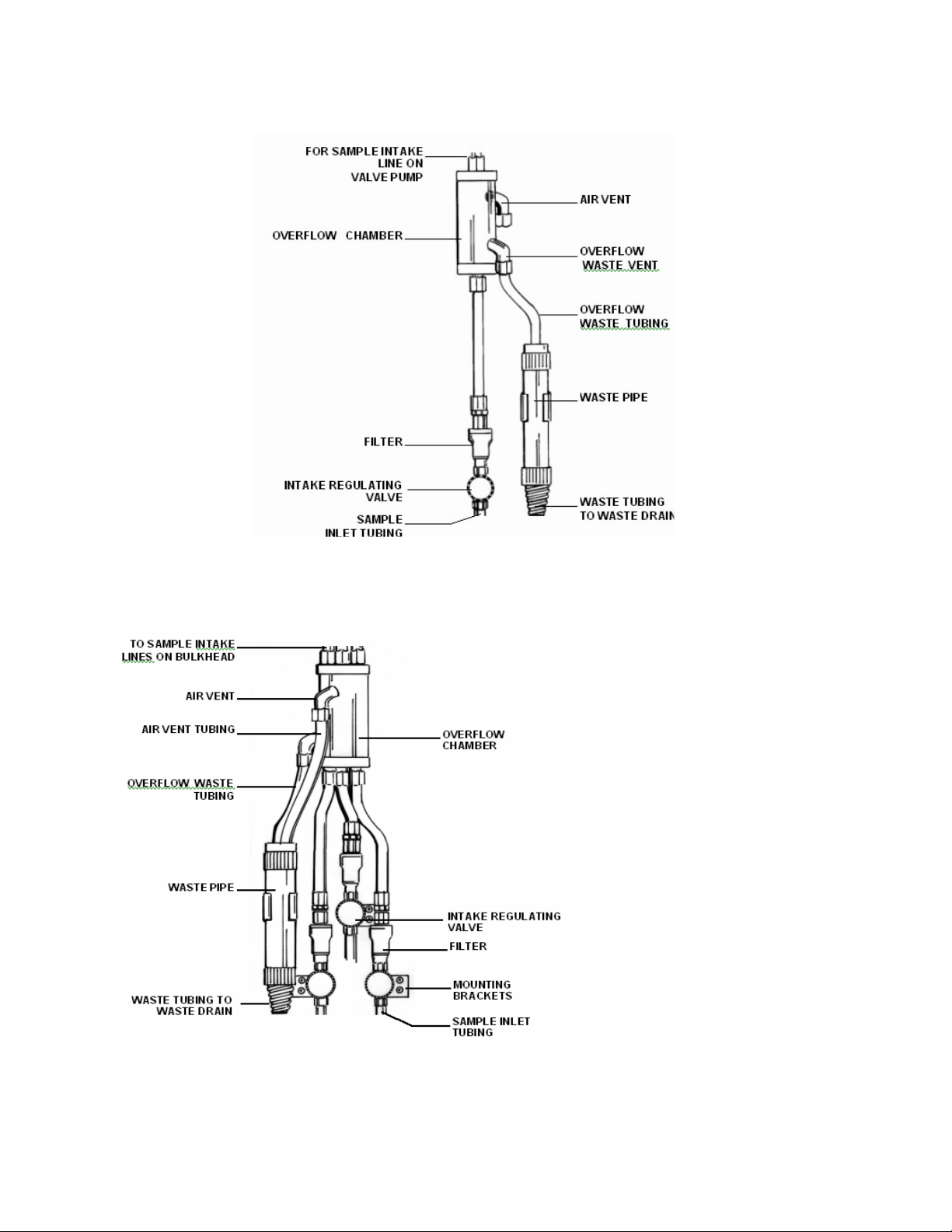

Figure 2-4a. Single-stream Overflow Sampling Assembly ....................................... 14

Figure 2-4b. Multi-stream Overflow Sampling Assembly ......................................... 14

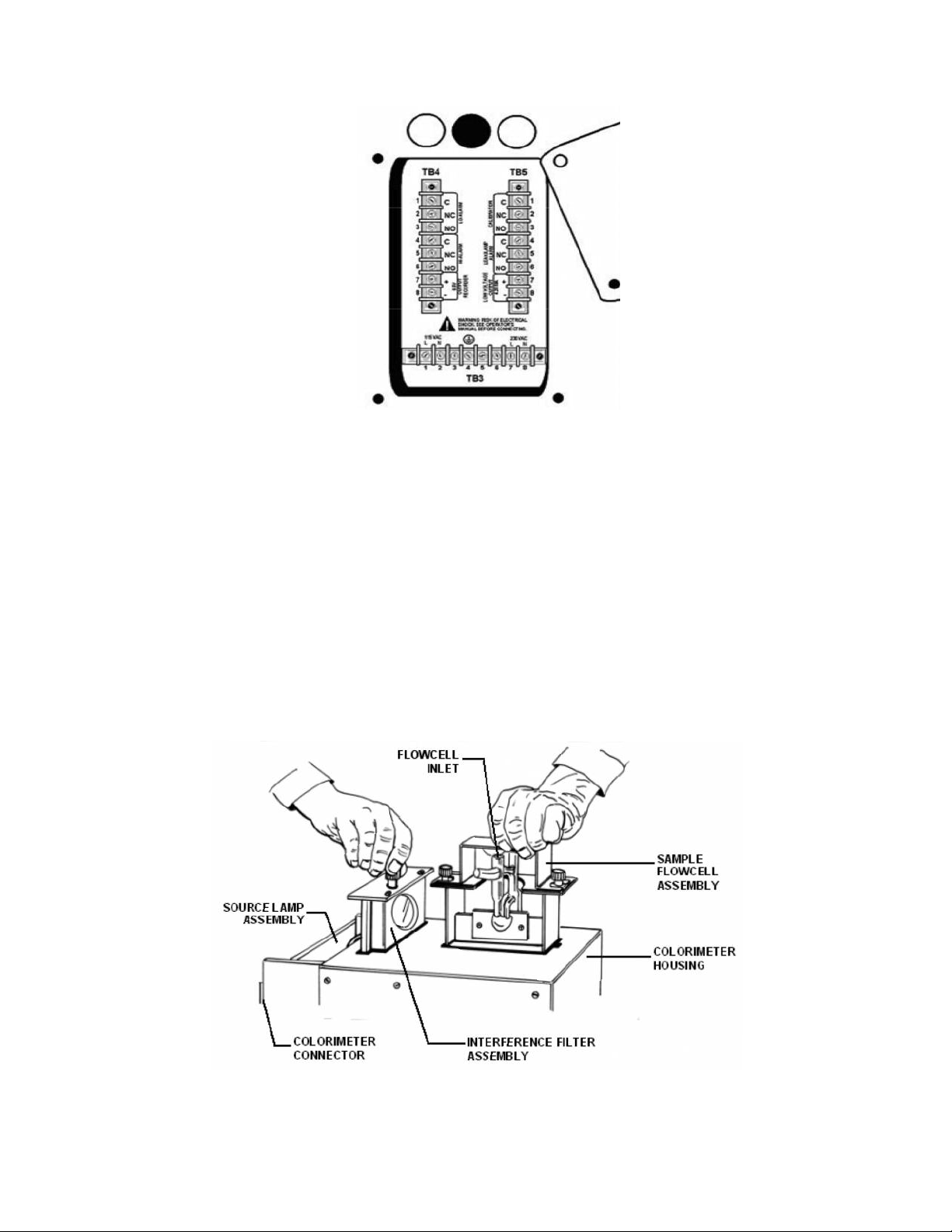

Figure 2-5. Input/Output Panel............................................................................... 16

Figure 2-6. Colorimeter Assembly.......................................................................... 16

Figure 2-7. Valve Pump Assembly......................................................................... 18

Figure 2-8. Heating Bath and Pump Connectors ................................................... 18

Figure 2-9. Sample Bottle Placement in Cabinet (for all methods; colors refer to

reagent straw colors) ........................................................................... 19

Figure 3-1. Simple Block Diagram ......................................................................... 20

Figure 3-2. Numbered Positions on a Single-Stream Keypad................................ 23

Figure 3-3. Valve Pump LED Designations............................................................ 25

Figure 3-4. Logic Flow for Single-stream Parameter Definition.............................. 26

Figure 3-5. Logic Flow for Multi-stream Parameter Definition ................................ 27

Figure 4-1. Colorimeter Assembly.......................................................................... 34

Figure 6-1. Remove Valve Pump Assembly........................................................... 36

Figure 6-2. Card Cage ........................................................................................... 38

Figure 6-3. Colorimeter Assembly.......................................................................... 39

Figure 6-4. Replace 5 V dc Source Lamp .............................................................. 40

Figure 7-1. Analyzer Front View............................................................................. 42

Figure 7-2. Card Cage and Boards ........................................................................ 45

Figure 7-3. Analog Board DIP Switches (with #3 set in OFF position for multi-stream

analyzer).............................................................................................. 46

Figure 7-4. Colorimeter Assembly.......................................................................... 47

Figure 7-5. Electrical Wiring and Components in Rear Cabinet............................. 48

Figure 7-6. Valve Pump Assembly......................................................................... 49

Figure 7-7. Interface Ports ..................................................................................... 50

Figure 7-8. "D" Connector for Relay Output ........................................................... 50

Figure 7-9. Single-Stream Overflow Sampling Assembly ...................................... 51

Figure 7-10. Multi-stream Overflow Sampling Assembly (three-stream option) ....... 52

Figure 8-1. Input/Output Panel............................................................................... 53

Figure 8-2. Typical Trace Recording with Calibration of Single Stream System .... 54

Figure 8-3. Typical Stream Trace Recording with Calibration of Multi-stream System

............................................................................................................. 55

Figure 8-4. Numbered Positions on a Single-Stream Keypad............................... 58

Figure C-1. CFA-3000 Colorimetric Analyzer Block Diagram ................................. 64

Figure D-1. Calibration Bypass Wiring.................................................................... 65

Figure E-1. Keypad Panel for Single Stream Option .............................................. 66

Figure E-2. Number Positions on a Single-Stream Keypad................................... 66

Figure E-3. Keypad Panel for Multi-stream Option................................................. 69

4

CFA-3000 Colorimetric Analyzer

Tables

Instruction Manual

Table 5-1. Troubleshooting Chart ......................................................................... 32

Table 5-2. Test Functions ..................................................................................... 34

Table 7-2. Main Cabinet Parts .............................................................................. 41

Table 7-2. Reagent Cabinet Parts ........................................................................ 41

Table 7-3. Buttons/LED Functions ........................................................................ 43

Table 7-4. Card Cage Parts.................................................................................. 44

Table 7-5. CPU Board Components ..................................................................... 44

Table 7-6. Analog Board Components.................................................................. 44

Table 7-7. Valve Board Components.................................................................... 44

Table 7-8. Power Supply Board Components....................................................... 44

Table 7-9. Analog Board DIP Switch Positions ..................................................... 46

Table 7-10. Colorimeter Assembly Parts ................................................................ 47

Table 7-11. Back Cabinet Parts .............................................................................. 48

Table 7-12. Valve Pump Parts................................................................................ 49

Table 7-13. Interface Ports ..................................................................................... 50

Table 7-14. Relay Output Option Pin Assignments................................................ 50

Table 7-15. Multi-output Pin Assignments on “D” Connector................................. 50

Table 7-16. Overflow Sampling Assembly Parts ..................................................... 51

Table 8-1. Stream Identification Blips (SIBs) ........................................................ 53

Table 8-2. Normal Data Output Format ................................................................ 56

Table 8-3. Data Configuration............................................................................... 56

Table 8-4. RS232-C Pin Configuration ................................................................. 57

Table 8-5. RS232-C Commands........................................................................... 59

Table 8-6. Printer Port Pin Configuration .............................................................. 60

Table E-1. Single-stream Keypad Help Sheet....................................................... 68

Table E-2. Multi-stream Keypad Help Sheet ......................................................... 71

5

CFA-3000 Colorimetric Analyzer

Instruction Manual

1.0 Introduction

The Rosemount Analytical CFA-3000 Series analyzers are designed for minimum

maintenance and maximum reliability. The touch of a button starts the microprocessorcontrolled program, calibrates the analyzer, keeps it calibrated, and reports results directly

- unattended - for months at a time. Maintenance is simplified by a modular design with

quick disconnect fittings, labeled tubing, and color-coded components.

The CFA-3000 Series includes analyzers for many common chemical parameters,

including: silica, phosphate, hexavalent chromium (Cr+6), iron, copper, and ammonia.

Sample concentration is clearly indicated on the digital display panel, and output signals

are provided to drive recorders, alarms, or other external devices such as printers or

computers. The specific chemistry of your individual analyzer is discussed in Appendix A,

Chemistries.

Your purchase from Rosemount Analytical provides you with one of the finest instruments

available for your particular application. These instruments have been designed and

tested to meet many national and international standards. Experience indicates that its

performance is directly related to the quality of the installation and knowledge of the user

in operating and maintaining the instrument.

6

CFA-3000 Colorimetric Analyzer

Instruction Manual

1.1 Thoroughly Read This Manual

This instruction manual describes installation, operation, and maintenance of the CFA3000 Colorimetric Analyzer. To ensure continued operation to the design specifications,

personnel should read this manual thoroughly before proceeding with installation,

operation, or maintenance of the analyzer.

Ensure that you have received the correct model and options from your purchase

order. Verify that this manual covers your model and options. If not, call: 1-800-8548257 or 949-757-8500 to request the correct manual.

For any inquiries about your analyzer, contact your Rosemount Analytical

representative.

Failure to follow the documented instructions may cause any one of the following

situations to occur: damage to this instrument and warranty invalidation.

Follow all warnings, cautions, and instructions supplied with the product.

Only qualified personnel should install, operate, update, program, and maintain the

product.

All personnel must learn proper installation, operation, and maintenance of the

product.

Install, operate, and maintain equipment exactly as specified in this manual.

Follow appropriate local and national codes.

Only connect the analyzer to electrical sources specified in this manual.

Use only components supplied by Rosemount Analytical or recommended by them

for replacement. Tampering or unauthorized substitution of parts and procedures

may affect the performance of the analyzer as well as void the warranty.

All protective covers must be in place and cabinet panels must be closed at all

times after installation or maintenance.

1.2 Analyzer Benefits

The CFA-3000 Colorimetric Analyzer offers the following benefits:

Maintenance-free pump

Patented blank baseline for silica

7

CFA-3000 Colorimetric Analyzer

Instruction Manual

1.3 WARNING --Electrical Shock Hazard

Installation of cable connections and servicing of this product require access to shock

hazard voltage levels.

Main power and relay contacts wired to separate power sources must be disconnected

before servicing.

Non-metallic cable strain relief does not provide grounding between conduit connections!

Use grounding type bushings and jumper wires.

Electrical installation must be in accordance with the National Electrical Code (ANSI/NFPA-

70) and/or any other applicable national or local codes.

Operate only with:

1. Main console rear cover fastened.

2. Left side power terminal cover closed.

3. Keypad assembly latched closed.

Safety and performance require that this instrument be connected and properly grounded

through a three-wire power source.

Proper configuration and use is the responsibility of the user.

1.4 CFA-3000 Series Monitors Approvals

Mark ID Description

9700516

EN 61010-1

Safety of electrical

equipment

EN 55011 Limits of RF equipment

EN 50082-1:92 Generic immunity from

electrostatic discharge,

RF & Fast Transient/

Burst Immunity

ETL LISTED CONFORMS

TO UL STD. 3101-1

ETL LISTED CERTIFIED

TOCAN/CSA C22.2

No. 1010.1-92

8

CFA-3000 Colorimetric Analyzer

Instruction Manual

2.0 Installing The Analyzer

2.1 Unpack Parts

When you receive your new CFA-3000 analyzer, carefully unpack the items in the

following list.

Main cabinet

Reagent cabinet

Mounting brackets

Overflow sampler assembly

Flowcell assembly

Colorimeter assembly with interference filter assembly

Waste tube assembly

Accessories pack

Startup reagents

Valve pump assembly (integrated housing includes pump, labeled tubes with

straws)

If any of the items are missing or damaged, contact Rosemount Analytical at:

Toll-free number: (800) 854-8257

Direct number: (949) 757-8500

Fax: (949) 863-9159

Inspect each piece to confirm that there is no damage or loose parts. If anything is missing

or appears broken or damaged, contact Rosemount Analytical at the toll-free phone

number above.

Fill out the warranty card located on the back of this manual and mail it

immediately.

9

CFA-3000 Colorimetric Analyzer

Instruction Manual

After analyzer has been unpacked and all parts accounted for, install as described in

following sections. Refer to Figure 2-1 to view a completely installed analyzer.

Figure 2-1. Opened Assembled Cabinet

10

CFA-3000 Colorimetric Analyzer

Instruction Manual

2.2 Mount Main Cabinet

General Recommendations:

This cabinet is not for outdoor installation.

Environmental conditions of enclosed facility:

Temperature:

min. 50°F to max. 113°F

(min 10°C – max. 45°C)

±10° within regulated range.

Humidity: non-condensing

Mount cabinet on a wall or other suitable vertical surface, at least 42” (107 cm)

wide and 43-1/2” (111 cm) off the floor.

Mounting surface must be able to support 250 pounds (113.6 kg).

Allow 1-1/2 feet (.5 m) of clearance at left side of analyzer for access to

input/output panel, and allow for swing out for rear access.

Allow 12” (.3 m) at right side for access to overflow tube assembly (if single

stream).

Mount cabinet level, or with a slight backward tilt for proper leak detector

operation.

To mount main cabinet, proceed as follows ( see Figure 2-2):

1. Securely attach supplied "L" brackets to wall using suitable hardware. Brackets

must be anchored properly to support 250 pounds (113.6 kg).

2. Attach main cabinet to "L" brackets using supplied four bolts, split ring washers,

and hex nuts.

2.3 Mount Reagent Cabinet

To mount reagent cabinet, proceed as follows:

1. Loosen the four bolts in bottom of main cabinet.

2. Lift reagent cabinet and attach to main cabinet by placing heads of bolts into

keyhole slots in top of reagent cabinet.

3. Slide reagent cabinet back.

4. Feed grounding strap on bottom of main cabinet through notched hole in left rear

corner and attach it to stud on back of reagent cabinet (see Figure 2-3).

5. Tighten screws to attach reagent cabinet to main cabinet.

6. For multi-stream units, plug valve bank cable into positive fit receptacle at left side

of cabinet (refer to Figure 7-1, “Multi-stream Valve Panel Connector”).

11

CFA-3000 Colorimetric Analyzer

Figure 2

-

2. Mounting Main

Figure 2

-

3. Attaching

Instruction Manual

and Reagent Cabinets

Grounding Strap

12

CFA-3000 Colorimetric Analyzer

Instruction Manual

2.4 Install Waste Tube

To install waste tube, proceed as follows (refer to Figure 2-1):

1. Guide waste tube through main cabinet into reagent cabinet and out through

bottom of reagent cabinet.

2. Secure plastic waste tube in clamp in lower right side of main cabinet.

3. Insert Colorimeter drain tube into waste tube.

2.5 Mount Overflow Sampling Assembly

The Sample intake tube should extend into

The overflow tube approximately ½” – 1”

To mount overflow sampling assembly proceed as follows (for sample configurations, see

Figures 2-4a and 2-4b):

1. Mount overflow sampler assembly on outer, right side of reagent cabinet using the

provided four machine screws. For multi-stream units, mount overflow assembly on

left side of cabinet. (If using IF-100 In-Line Filter, refer to instruction sheet

accompanying filter for complete installation instructions.)

2. Place ends of air vent tubing and overflow waste tubing into waste pipe.

3. Connect waste pipe to drain.

4. Supply sample stream to regulating or intake valve with 1/4? tubing (plastic or

steel) as follows: Insert tubing into tube fitting. Make sure tubing rests firmly on

shoulder of fitting and nut is finger-tight. Mark nut at 6 o’clock position. While

holding fitting body steady with a wrench, tighten nut 1-1/4 turns (go to 9 o’clock

position).

5. For multi-stream assembly, connect sample intake line to bulkhead fitting.

6. For single-stream assembly, attach sample intake line to valve pump.

7. Make sure that sample liquid overflows into overflow chamber.

(1.25 – 2.54 cm).

13

CFA-3000 Colorimetric Analyzer

Instruction Manual

Figure 2-4a. Single-stream Overflow Sampling Assembly

Figure 2-4b. Multi-stream

Overflow Sampling

Assembly

three-stream option)

14

CFA-3000 Colorimetric Analyzer

Instruction Manual

2.6 Prepare Electrical Connections

WARNING:

Connect output signals, if any, before connecting the power supply.

CAUTION:

For proper operation and for safety, electrical connections to this equipment

must be made in accordance with local or national electrical code as applicable.

This equipment must be grounded. A qualified electrician should wire this

equipment to an electrical circuit.

Electrical connections are made to and from the cabinet at the input/output panel, located on

the left side of the analyzer. See Figure 2-5.

Terminals are provided for ground, power supply, high/low alarms, output signals,

calibration and status relays

.Output signals - a voltage output of 0-5 Vdc and a floating, ungrounded current

output of 4-20 mA are available for remote readout or control of a process.

Also available are contact closures for the following:

High alarm Leak Alarm

Low Alarm Lamp Alarm

Calibration

To make electrical connections, proceed as follows:

Use cable glands to hold cables securely in holes above input/output panel.

1. Remove solid caps from the holes above the input/output panel by puncturing with an

awl and prying them out. (Note: remove caps only from those holes that will be used.)

2. Replace with permanent connectors.

3. Connect alarms and external computer interfaces (if any).

4. Feed 3-wire power cable into analyzer through hole above the input/output panel.

5. Connect wires to appropriate contacts on Terminal Strip TB3.(See next page)

15

CFA-3000 Colorimetric Analyzer

Instruction Manual

Figure 2-5. Input/Output Panel

2.7 Colorimeter Assembly Installation

(assembly comes factory-installed)

To install colorimeter assembly, proceed as follows:

1. Insert flowcell assembly into slot on top of colorimeter (interference filter and lamp

pre-installed as part of the colorimeter assembly (see Figure 2-6).

2. Hand-tighten thumbscrews on top of flowcell assembly. Then, tighten screws onehalf turn with screwdriver.

3. Slide colorimeter into connector in inside back of cabinet (refer to Figure 2-1).

Housing will latch in place, automatically.

Figure 2-6. Colorimeter Assembly

Pls Note: lamp may be halogen or LED; filter or aperture may be used

16

CFA-3000 Colorimetric Analyzer

Instruction Manual

2.8 Install Valve Pump Assembly

The pump assembly has a vacuum pressure system that:

o Eliminates internal pump tubing

o Uses significantly less reagent

o Accurately moves fluids through the analyzer.

Perform the following procedure to install valve pump assembly:

1. Tilt pump assembly towards you.

2. .Align the hinge pins and sockets, and slide assembly tray as far as possible to

right (see Figure 2-7). Carefully lay tray down into cabinet

3. Plug in the two connectors to the back of the cabinet (6-position connector for

heating bath; 9-position connector for pump) (see Figure 2-8).

4. Connect 16-pin connector from pump assembly to small connector on CPU board

(yellow ejector) above connector for keypad panel.

5. Attach colorimeter inlet tubing on left side of pump to flowcell inlet (see Figure 2-

1).

6. Continue with procedure depending on whether system is single-stream or multistream

For single-stream, continue:

6. Thread tube labeled Sample" through hole 0n bottom of shelf to the right of pump

assembly, and out through hole on left side of cabinet.

7. Connect Sample tube to top of overflow sample on left side of cabinet.

8. Guide all other tubes that are attached to valve pump assembly through reagent

cabinet access hole.

For multi-stream, continue:

6. Thread Sample tube from pump assembly through reagent access hole on the

right side of the valve pump assembly, and connect to Common (C) on #1 multistream solenoid valve on left side of reagent cabinet.

Guide all other tubes that are attached to valve pump assembly through reagent cabinet

access hole.

17

CFA-3000 Colorimetric Analyzer

Instruction Manual

Figure 2-7. Valve Pump Assembly (comes factory-installed)

Figure 2-8. Pump Connector

(Pls Note: Heating Bath is not usually used on colorimetric Valve-Pump systems,

but may be required for ammonia systems.

18

CFA-3000 Colorimetric Analyzer

Instruction Manual

2.9 Prepare Reagent Containers

Prepare reagent containers as follows:

1. Remove screw caps from reagent bottles.

2. Using an awl, make one hole in foil for the reagent straw. DO NOT let awl touch

reagent.

3. Place Standard and Reagent bottles into reagent cabinet, as shown in Figure 2-9.

4. Insert color-coded reagent straws and labeled Standard straw leading from valve

pump assembly into holes punched in corresponding bottles.

Figure 2-9. Five Liter Sample Bottle Placement in Cabinet (for all methods; colors

refer to reagent straw colors)

19

CFA-3000 Colorimetric Analyzer

3.0

Operating the Analyzer

Instruction Manual

2.0 Analyzer

2.0 Analyzer

3.1 Operational Overview

The analyzer uses a batch flow method for automatically analyzing a sample against a fixed

standard (refer to block diagram in Figure 3-1). That is, the touch of a button starts the

microprocessor-controlled program, calibrates the analyzer, takes measurements of

samples, and reports results directly --- unattended---for months at a time.

The automated monitoring program determines the sequence for activating each of the valve

pumps in the valve pump assembly to inject air and fluids into the reaction chamber. Each

valve pump is associated with a specific input via the quick disconnect connector on the side

of the assembly (the number of reagents is determined by your particular chemistry and

procedure).For example, the inputs for silica chemistry would be:

Sulfuric acid, reagent #1

Ammonium molybdate, reagent #2

Oxalic acid, reagent #3

Reducing reagent #4

Sample

Grab sample

Baseline

Standard

Air

Flow cell wash

Evacuation of chamber

Re-circulate

For a multi-stream system, solenoid valves in the analyzer reagent cabinet open and close

streams for sampling. When sampling, the keypad panel LEDs identify which sample stream

(valve number) is associated with the displayed value, and which valve is now open for

sampling. Although the system runs samples on its own, you may also perform a manual

grab sampling or a manual calibration at any time.

20

Figure 3-1. Simple Block Diagram

CFA-3000 Colorimetric Analyzer

Instruction Manual

3.2 Check Sample Stream

Check that the sample intake tube is ½ to 1 inch (1.25 to 2.54 cm) into the liquid.

Sample should just overflow the overflow tube. There should be no particulate or

bubbles in the tube.

Using a Multi-Stream Overflow Sampler

Multi-stream analysis requires an overflow sampler assembly that will accommodate the

extra sample streams. One multi-stream chamber allows for up to three sample streams; for

4 - 6 streams, use two chambers.

The sample tubes connect to solenoid valves in the reagent cabinet. The analyzer uses the

valves to cycle through all sample lines, in sequence. First, stream 1 valve is opened, and

Valve 1 LED on the keypad panel is lit. When the measurement is complete, Valve 1 will be

closed, and Valve 2 is opened to begin sampling stream 2. The keypad panel will show

Valve 1 LED lit as the Displayed Stream, and Valve 2 LED is lit for the Selected Stream.

LEDs on the valve pump assembly light up when a particular fluid is taken up by the valve

pump assembly. Figure 3?2 identifies the valve pump LED designations.

3.2.1 Check Fluidics

Check the following:

Colorimeter inlet tubing is in place and secure in sample flowcell inlet.

Liquid should overflow in overflow chamber.

Waste tubing is in waste pipe.

Sample tube is connected to Overflow Sampler Assembly for single stream; and, for

multi-stream, it is connected to Common (C) port of sample solenoid valve #1, on left

side of reagent cabinet.

System has no leaks.

3.2.2 Check Reagents

Check the following:

One hole has been punched in all reagent cap liners.

Reagent straws are placed in appropriate reagent containers.

High and low standard tubing are in appropriate containers.

3.2.3 Turn On Power

1. Open the keypad panel door to expose the circuit boards.

2. Press each board in to ensure proper seating.

3. Simultaneously press Power button on the back wall of upper cabinet and Reset

button on the CPU board (yellow ejector), then release.

21

CFA-3000 Colorimetric Analyzer

Instruction Manual

4. First release the Power button, then the Reset button. The Keypad should display

”H E L O", then four dashes "-- -- -- --".

5. Pull pump forward and check leak detector by dipping finger in tap water and

touching detector behind pump. Leak detector LED on keypad panel will light up.

6. Turn main power switch to OFF

7. Dry leak detector.

8. Wait 20 seconds, then switch main power switch back to ON. Leak detector LED

should be off.

3.2.4 Test Valve Pump Operation

Reaction cell takes approx. 30 minutes to heat up.

If leak detector LED does not light up:

Adjust potentiometer on analog board counter-clockwise for more sensitivity.

Turn off power to reset system.

Wait 20 seconds, and simultaneously press Power and Reset buttons.

Dip finger in tap water and touch leak detector contacts on bottom of cabinet behind

the valve pump. LED should light up.

If problem persists, contact Rosemount Analytical.

The test procedure allows you to confirm that all physical connections are installed properly,

and to ensure that the pump is taking up the proper fluids at the correct time.

Enter Test Mode:

1. Put all straws and Sampling tube into a beaker of DI water.

2. Turn power on by simultaneously pressing Power button on the back of upper

cabinet and Reset button on CPU board (yellow ejector).

3. First release Power button, then Reset button. Keypad should display "H E L O",

then four dashes "-- -- -- --".

To enter test mode, continue with the step appropriate for your analyzer setup:

For single-stream,

continue:

For multistream,

continue:

Referring to Figure

3-2, on keypad

panel, press

position 15 and

then 2.

On keypad panel,

press:

then

.

22

CFA-3000 Colorimetric Analyzer

Instruction Manual

The keypad buttons may now be used to test pump operation. Do not rush through the

test steps – when a specific step is initiated, it takes approx. 2 seconds to pump air

through the system. Actual pumping of a liquid takes approximately 4 seconds. After this

operation is finished, another 4 seconds elapses before the pump is primed for the next

test step.

To exit the test at any time, press the ENTER button on the keypad panel.

If a test step does not work properly, try the following:

Take a syringe and shoot air through straw to make sure it is not clogged.

Check that corresponding LED on valve pumps lights up (refer to Figure 4-1).

Check that fluid is picked up in correct tube.

If the problem still persists, contact Rosemount Analytical.

Single-Stream

Keypad

Multi-stream

Option

Figure 3-2. Numbered Positions

Begin Test:

Confirm that the corresponding Pump LED lights up for each step (refer to Figure 3-3 for

LED designations during test):

23

Loading...

Loading...