Model 1181 pH/ORP

Combination pH/ORP Two-Wire Transmitters

Instruction Manual

PN 51-1181pH/rev.B

March 2003

DANGER

HAZARDOUS AREA INSTALLATION

INTRINSICALLY SAFE INSTALLA

TION

Transmitter/Sensor is not Intrinsically safe.

Installations in hazardous area locations must be

carefully evaluated by qualified on site safety personnel. To secure and maintain an intrinsically safe

installation, an appropriate safety barrier must be

used and the installation must be performed in

accordance with the governing approval agency

(FM, CSA or BASEEFA/ CENELEC) installation

drawing requirements (see Section 2.0-Installation).

EXPLOSION-PROOF INSTALLATION

Sensors are not explosion-proof and must be

installed in a non-hazardous location. If the sensor

must be installed in a hazardous location an intrinsically safe system must be implemented. To maintain the explosion-proof rating of the transmitter,

the following conditions must be met:

• Discontinue power supply before removing

enclosure covers.

• Transmitter covers must be properly installed

during power on operation.

• Explosion proof "Y" fittings must be properly

installed with sealing compound prior to applying

power to the transmitter.

• Serial tag cover over the external Zero and Span

adjustments must be in place.

• See Installation Section for details.

Proper installation, operation and servicing of this

instrument in a Hazardous Area Installation is

entirely the responsibility of the user.

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its products to

meet many national and international standards. Because these instruments are sophisticated technical products, you must properly install,

use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions must be adhered to

and integrated into your safety program when installing, using, and

maintaining Rosemount Analytical products. Failure to follow the proper instructions may cause any one of the following situations to occur:

Loss of life; personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the

product. If this Instruction Manual is not the correct manual, telephone 1-800-654-7768 and the requested manual will be provided.

Save this Instruction Manual for future reference.

• If you do not understand any of the instructions, contact your

Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the Installation Instructions of

the appropriate Instruction Manual and per applicable local and

national codes. Connect all products to the proper electrical and

pressure sources.

• To ensure proper performance, use qualified personnel to install,

operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people

use replacement parts specified by Rosemount. Unauthorized parts

and procedures can affect the product’s performance and place the

safe operation of your process at risk. Look alike substitutions may

result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers

are in place, except when maintenance is being performed by qualified persons, to prevent electrical shock and personal injury.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2003

About This Document

This manual contains instructions for installation and operation of the Model 1181 pH/ORP Two-wire

transmitter. The following list provides notes concerning all revisions of this document.

Rev. Level Date Notes

A 7/01 This is the initial release of the product manual. The manual has been reformatted to

reflect the Emerson documentation style and updated to reflect any changes in the

product offering and agency certification.

B 3/03 Updated CE information.

i

MODEL 1181 pH/ORP QUICK START-UP

QUICK START-UP

I. Set up

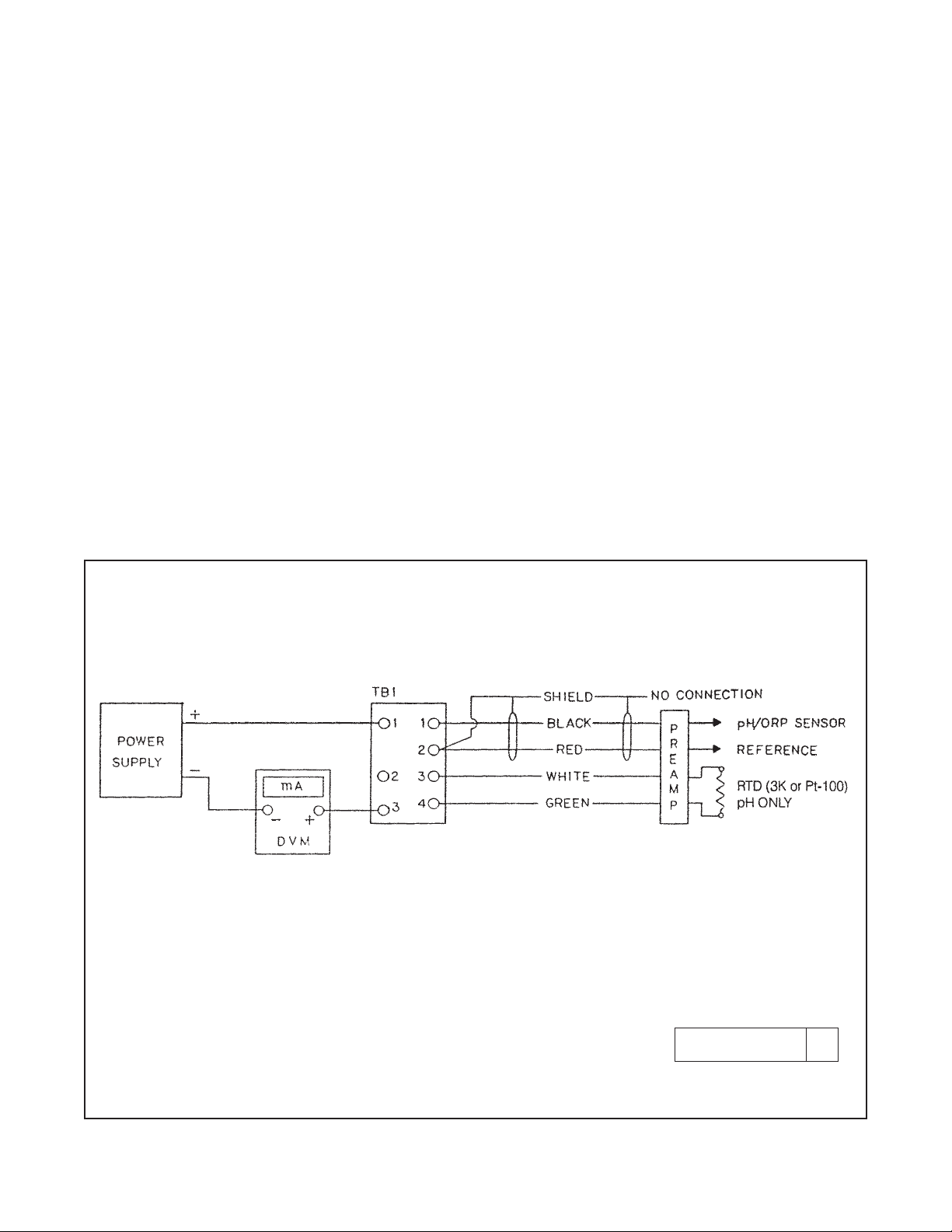

1. For non-hazardous areas or bench testing, set-up

the transmitter & sensor as illustrated in Figure A.

2. For hazardous or intrinsically safe installations,

set-up the transmitter & sensor as illustrated in the

appropriate agency drawing (Figure 2-5 through 2-

12).

The 1181pH two-wire transmitter is factory configured

to work, right out of the box, for many applications.

Factory Settings:

• 0-14pH measurement range: 0pH (low range) corresponds to 4mA output; 14pH (high range) corresponds to 20mA output.

• Automatic temperature compensation is utilized.

• (Optional LCD is set for 0-100% read out) If these

settings are acceptable to your process you can

utilize this quick start up procedure.

FIGURE A

DWG. NO. REV.

40118153 B

TB2

ii

MODEL 1181 pH/ORP QUICK START-UP

7. Repeat Step 2 through 7 until no further adjustments are required. Rinse the sensor in clean

water prior to placing it in a different buffer solution.

8. Remove DVM and connect power supply end

directly to the transmitter.

III. Standardize to the Process

A slight adjustment of the 1181 ZERO pot may be necessary to fine tune the loop to your process.

1. Install sensor into it’s final mounting position, and

allow sensor to acclimate to the process temp.

(Wait for reading to stabilize).

2. Take a grab sample of the process, close to the

sensor, and have it analyzed. Note the pH value.

3. Adjust the 1181 ZERO control (under serial label)

until the display reads the percentages of full-scale

that corresponds to the grab sample pH value.

Grab Sample pH

14 pH

X 100 = % of full scale

6.86

14 pH

X 100 = 49.0 %

4. Start-up and calibration is now complete. Refer to

1181pH manual for further details on 1181 features.

II. Solution Calibration

1. Obtain two buffer solutions. One should represent

a low range, and the other a high range value.

Typical buffer solution values 4pH, 7 pH & 10 pH.

2. Place the sensor in the lower range buffer solution, allow the reading to stabilize.

3. a. adjust ZERO control (under the serial label)

until the DVM reads the current output value

that corresponds to the buffer value.

Buffer value-Low pH range

mA =

___________________________

x 16 mA + 4

mA

High pH range-Low pH range

Example: For 4 pH buffer solution;

Range of 0-14 pH

4 pH-0 pH

Ex.=

__________

x 16 mA + 4 mA= 8.57 mA

14 pH-0 pH

b. If a liquid crystal display is installed, adjust the

LCD ZERO pot (on LCD face) until the display

indicates the proper percentage of full scale

value.

Buffer pH value

% Reading =

______________

x 16 mA + 4 mA

High pH range

4 pH

Ex.=

______

x 100 = 28.6%

14 pH

4. Remove the sensor from the low range buffer, and

rinse it in clean water.

5. Place the sensor in high range buffer, and allow

the reading to stabilize.

6. a. adjust the SPAN control (under serial label) until

DVM reads the current output value that corresponds to the computed buffer value.

10 pH-0 pH

Ex.=

__________

x 16 mA + 4 mA= 15.43 mA

14 pH-0 pH

b. If a LCD is installed, adjust the LCD SPAN pot

(on LCD face), until the display indicates the

proper percentage of the computed full-scale

value.

10 pH

Ex.=

______

x 100 = 71.4%

14 pH

MODEL 1181 pH/ORP TABLE OF CONTENTS

MODEL 1181pH/ORP

TWO-WIRE TRANSMITTERS

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS .......................................................... 1

1.1 Features and Applications................................................................................. 1

1.2 Performance Specifications - General .............................................................. 2

1.3 Physical Specifications - General...................................................................... 3

1.4 Model 1181pH Transmitter ................................................................................ 3

1.5 Model 1181ORP Transmitter............................................................................. 3

1.6 Ordering Information ......................................................................................... 4

2.0 INSTALLATION ................................................................................................. 5

2.1 General ............................................................................................................. 5

2.2 Mechanical Installation ..................................................................................... 5

2.3 Electrical Installation ........................................................................................ 6

2.4 Hazardous Locations-Explosion Proof Installations ......................................... 7

2.5 Hazardous Locations-lntrinsically Safe Installations ........................................ 7

3.0 START-UP AND CALIBRATION ...................................................................... 18

3.1 Start-Up............................................................................................................. 18

3.2 ModeI 1181/ORP pH Start-Up .......................................................................... 18

3.3 System Calibration ........................................................................................... 21

3.4 Operation With A Fixed T.C............................................................................... 22

3.5 ModeI 1181 pH Start-Up ................................................................................. 22

3.6 Model 1181ORP System Calibration ................................................................ 24

3.7 Operating With Integral Preamp (Accessory) ................................................... 25

3.8 Start-Up ............................................................................................................ 26

3.9 Test Equipment ................................................................................................. 26

3.10 Set-Up ............................................................................................................... 26

3.11 Calibration ......................................................................................................... 28

3.12 End Test ........................................................................................................... 28

3.13 Start-Up............................................................................................................. 28

3.14 LCD: Module Only ............................................................................................ 28

4.0 THEORY OF OPERATION .............................................................................. 31

4.1 Function Description ........................................................................................ 31

5.0 MAINTENANCE AND TROUBLESHOOTING ................................................. 32

5.1 General ............................................................................................................. 32

5.2 Troubleshooting ................................................................................................ 32

5.3 Maintenance...................................................................................................... 32

6.0 PARTS LIST ..................................................................................................... 38

6.1 General ............................................................................................................. 38

7.0 RETURN OF MATERIAL................................................................................... 44

iii

MODEL 1181 pH/ORP TABLE OF CONTENTS

LIST OF FIGURES

Figure Title Page

1-1 Blind & Analog Display Load/Power Supply Requirements .............................. 2

1-2 Digital Display Load/Power Supply Requirements............................................ 2

2-1 Transmitter Mounting Details ............................................................................ 5

2-2 Transmitter Wiring Detail................................................................................... 6

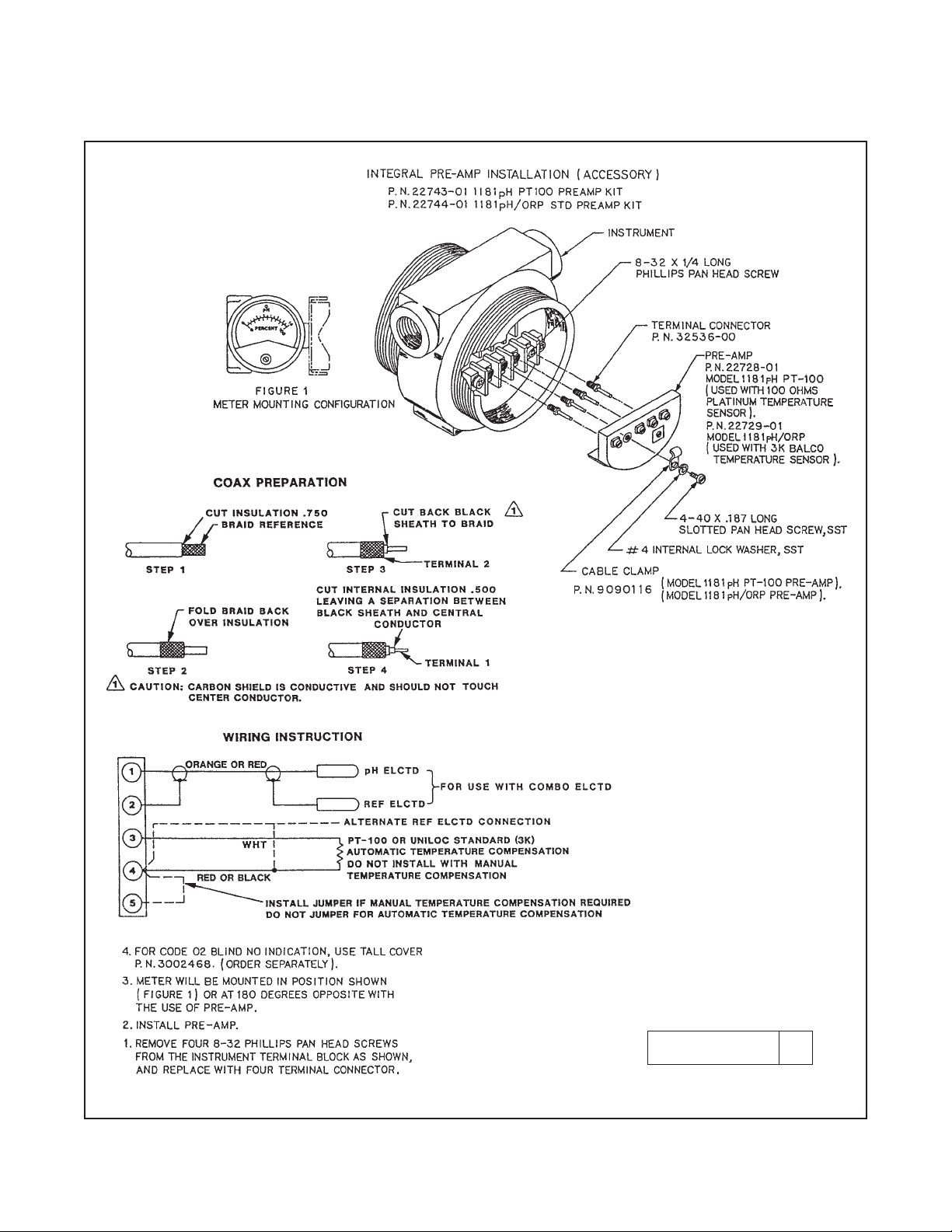

2-3 Integral Preamp Installation .............................................................................. 8

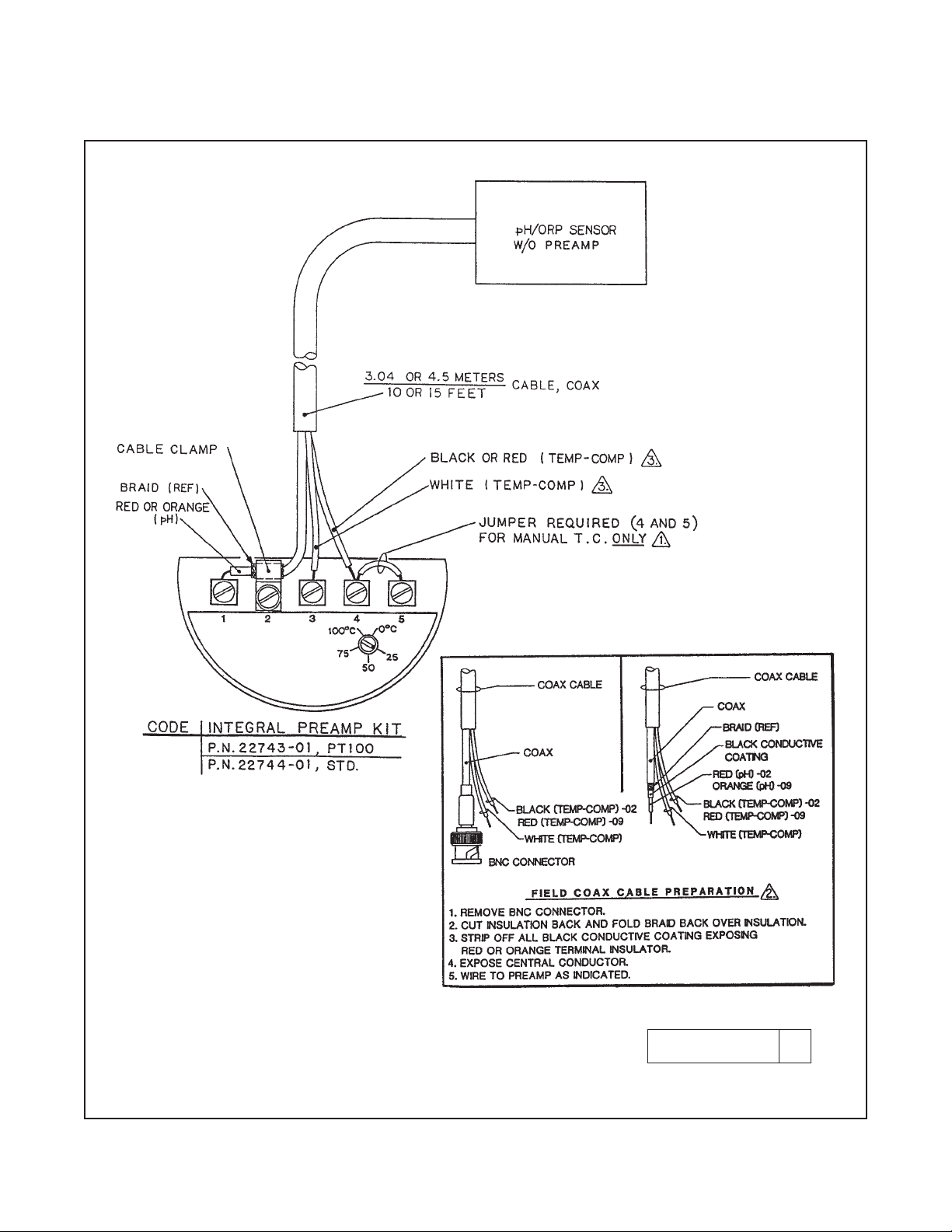

2-4 Wiring Details Integral Preamp ......................................................................... 9

2-5

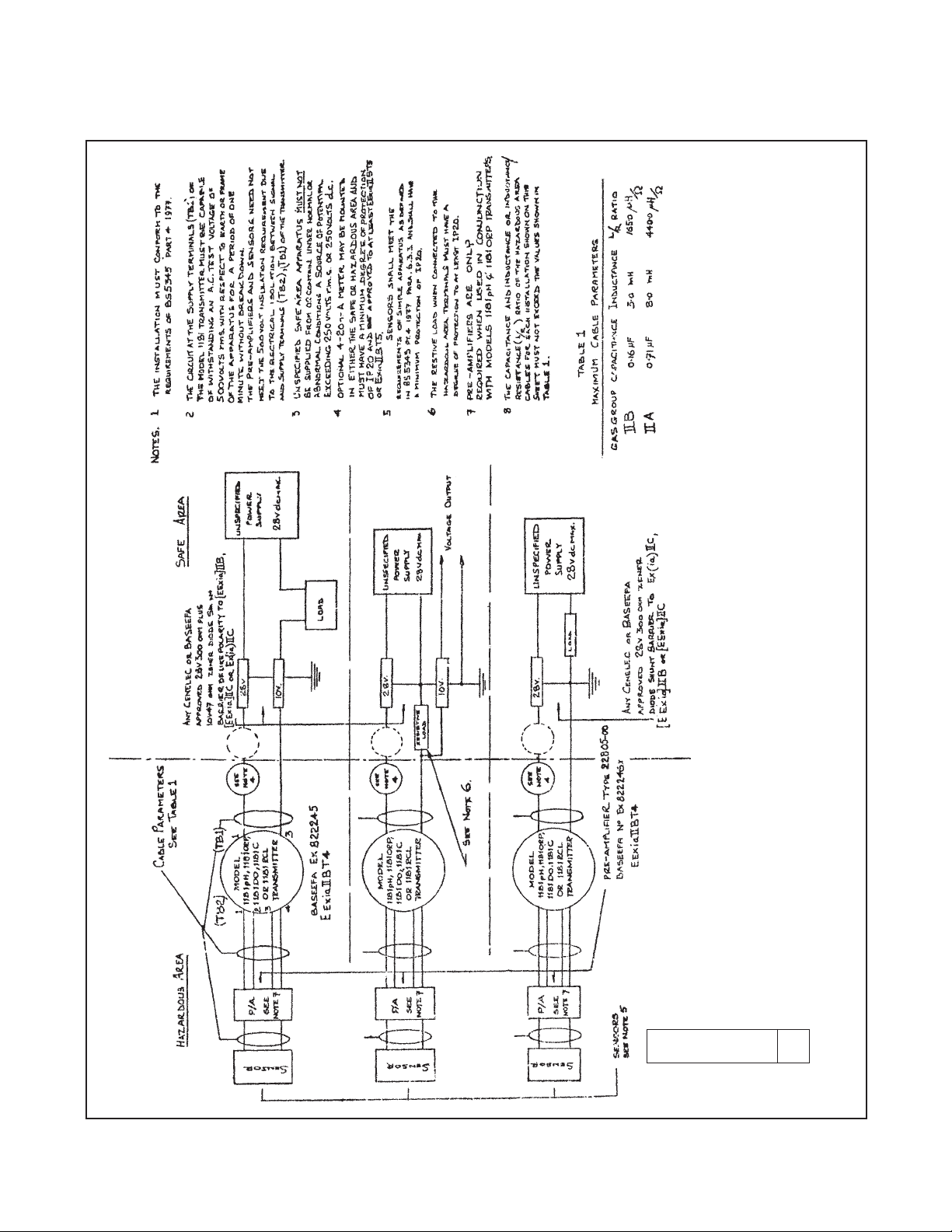

Installation of 1181 Series for Intrinsically Safe Operation (CENELEC)

................. 10

2-6

Installation of 1181 Series for Intrinsically Safe Operation (CENELEC)

................. 11

2-7

Installation of 1181 Series for Intrinsically Safe Operation (CENELEC)

................. 12

2-8 Schematic, System 1181 pH & ORP, CSA........................................................ 13

2-9 Schematic, System F.M. I.S. Approved-Entity................................................... 14

2-10 Schematic, System F.M. I.S. Approved-Entity................................................... 15

2-11 Schematic, System F.M. I.S. Approved-Entity................................................... 16

2-12 Schematic, System F.M. E.P. Approved............................................................ 17

3-1 Location of Controls .......................................................................................... 19

3-2 pH Range Selection Switches........................................................................... 20

3-3 ORP Range Selection Switches........................................................................ 23

3-4 ORP Test Setup ................................................................................................ 24

3-5 Test Wiring ........................................................................................................ 26

3-6 LCD Calibration................................................................................................. 27

3-7 LCD Test Setup Wiring ...................................................................................... 29

3-8A PCB Layout Transmitter Board P/N 22795-02 .................................................. 30

3-8B PCB Layout Transmitter Board P/N 22795-01 .................................................. 30

4-1 Simplified Block Diagram .................................................................................. 31

5-1 Model 1181 pH/ORP Schematic Diagram ......................................................... 34

5-2 Model 1181 pH/ORP Schematic Diagram — FM Intrinsically Safe ................... 35

6-1 Model 1181 pH/ORP Two-Wire Transmitters .................................................... 38

6-2 Transducer PCB (Part No. 22797-00/01 ) ........................................................ 40

6-3 Power PCB (Part No. 22796-00) ...................................................................... 41

6-4 Transmitter PCB (Part No. 22795-00) .............................................................. 42

LIST OF TABLES

Table Title Page

3-1 Typical pH Range Switch Settings .................................................................... 18

3-2 Test Unit Output Voltage in pH Mode at Four Temperatures............................. 18

3-3 pH vs. Voltage Input .......................................................................................... 21

3-4 Resistance Value for Fixed T.C......................................................................... 22

3-5 Millivolt vs. Voltage Input................................................................................... 24

3-6 ORP of Saturated Quinhydrone Solution (Millivolts) ......................................... 24

3-7 Parameters for Application ............................................................................... 28

5-1 Quick Troubleshooting ...................................................................................... 33

6-1 Parts List for Figure 6-1..................................................................................... 39

iv

1

MODEL 1181pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

•

TWO-WIRE FIELD MOUNTED TRANSMITTERS. Ideal for multiple loop installations

where central data processing and control are required. Field mounting near the sensor for

ease in routine calibration.

• NEMA 4X WEATHERPROOF, CORROSION-RESISTANT, DUAL COMPARTMENT HOUS-

ING provides maximum circuit protection for increased reliability in industrial environments.

• HAZARDOUS AREA INSTALLATION. Certified NEMA 7B explosion-proof and intrinsically

safe when used with an approved sensor and safety barrier.

• COMMONALITY OF PARTS reduces inventory required to support different field measure-

ments.

• SWITCH SELECTABLE RANGES further reduces inventory by permitting calibration of

one Model to virtually any Tag Number requiring the same measurement.

• EXTERNAL ZERO AND SPAN, 20-turn potentiometers provide for fine calibration of the

isolated 4-20 mA output signal.

1.1 FEATURES AND APPLICATIONS

The Rosemount Analytical Two-Wire field mounted

transmitters, with the appropriate sensors, are

designed to continuously measure the pH, ORP,

Conductivity, Dissolved Oxygen, or Free Residual

Chlorine in industrial processes.

The Model 1181 Transmitters include all the circuitry

necessary for the measurement and transmission of

an isolated 4-20 mA linear signal. Measurement range

selection is made through internal range switches that

are easily accessed by removing a housing cover. No

further disassembly is required. A matrix is provided

which conveniently indicates the proper switch position. Range selection can be made without the use of

the instruction manual. Fine calibration of the 4-20 mA

signal is accomplished with the 20-turn external Zero

and Span potentiometers.

The electronic printed circuits are protected from the

environment by the NEMA 4X weatherproof, corrosion

resistant enclosure. The printed circuit cards plug into a

moisture barrier which is isolated from the field wiring

and calibration terminals. Routine field calibration does

not require exposing the electronics to harsh industrial

environments. All PCBs are conformal coated for maximum protection. The PCBs are removed as a unit and

may be individually replaced. The transmitter housing

covers are sealed with large cross sectional O-rings and

need not be replaced each time the cover is removed.

The Model 1181 is available with or without an analog

or digital display. The digital display may be calibrated in engineering units and the analog display features multiple scales in engineering units.

The transmitters are certified explosion-proof, NEMA

7B, and intrinsically safe when installed with an

approved barrier and sensor. Hazardous area certificates are provided by BASEEFA to CENELEC regulations, FM, CSA, SAA, SEV, and TUV. CSA has

determined that the moisture barrier qualifies as

Factory Sealed which means Explosion Proof Y fittings

and sealing compound are not required for installation

when this approval is selected.

Accessory items are available for the two-wire transmitters. The Model 515 Isolated Power Supply provides

power for up to 20 transmitters. Two transmitters may

be wired directly to the power supply. For more than

two transmitters, junction boxes are available, each

accommodating wiring for a maximum of ten transmitters. Remote alarms are available with independently

adjustable set points and hysteresis. Contacts of the

Model 230A may be specified for high/low, high/high, or

low/low operation. The impedance of the Model 230A

Alarm Module is less than 100 ohms. For further information on the Models 515 and 230A, please refer to to

their respective product data sheet.

2

1.2 PERFORMANCE SPECIFICATIONS – GENERAL

Power Supply Requirements: (See Load/Supply Chart)

Lift Off Voltage: Blind & Analog: 10 VDC

Digital: 12.5 VDC

Maximum Operating Power: 40 milliwatts

Output: Blind & Analog: Isolated 4-20 mA into 700 ohms at 24 VDC

Digital: Isolated 4-20 mA into 575 ohms at 24 VDC

Input/Output Isolation: 600 Volts

Ambient Temperature: –30° to 55°C

Ambient Humidity: 0-99% RH

Digital Display Accuracy: 0.1% reading ±1.0 count

Analog Display Accuracy: ±2.0%

External Zero: ±7.5% full scale (25% for 1181T)

External Span: ±7.5% full scale (50% for 1181T)

Shock: 10G maximum for 10 milliseconds

Vibration: 0.025 inches double amplitude

5 to 50 Hz for 2 hours

EMI/RFI: EN61326

MODEL 1181pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

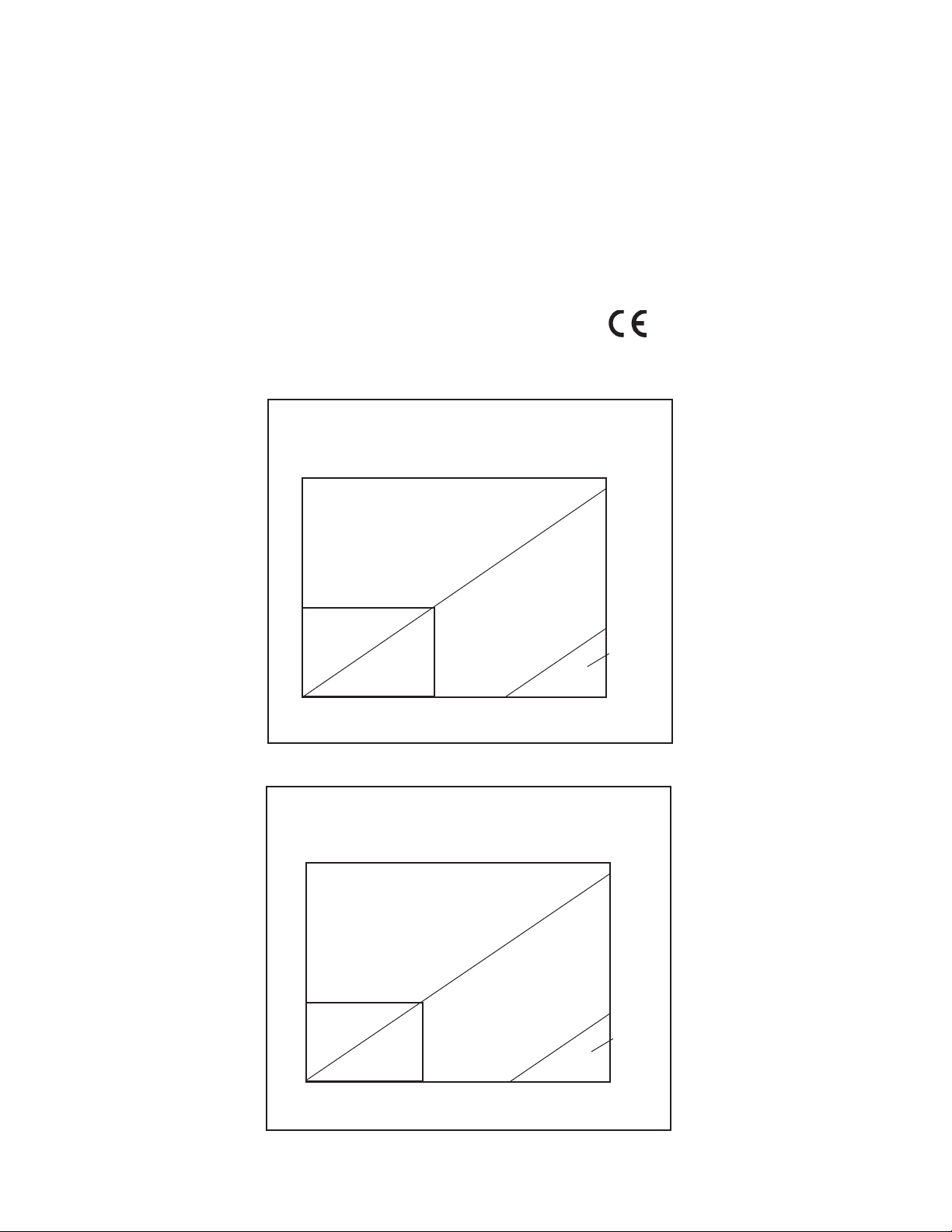

FIGURE 1-1

BLIND & ANALOG DISPLAY

LOAD/POWER SUPPLY REQUIREMENTS

+45 VDC @ 800 OHMS MIN. 1750 OHMS MAX.

10 VDC 24 VDC 33 VDC @ ZERO LOAD 45 VDC

LIFT OFF NOMINAL MAXIMUM

POWER SUPPLY VOLTAGE

1750 OHMS

@ 45 VDC

600 OHMS

@ 45 VDC

LOAD

RESISTANCE

REQUIRED

1.8 –

1.7 –

1.6 –

1.5 –

1.4 –

1.3 –

1.2 –

1.1 –

1.0 –

0.9 –

0.8 –

0.7 –

0.6 –

0.5 –

0.4 –

0.3 –

0.2 –

0.1 –

0.0 –

OPERATING

REGION

FIGURE 1-2

DIGITAL DISPLAY

LOAD/POWER SUPPLY REQUIREMENTS

+45 VDC @ 800 OHMS MIN. 1750 OHMS MAX.

12.5 VDC 24 VDC 35.5 VDC @ ZERO LOAD 45 VDC

LIFT OFF NOMINAL MAXIMUM

POWER SUPPLY VOLTAGE

1750 OHMS

@ 45 VDC

600 OHMS

@ 45 VDC

LOAD

RESISTANCE

REQUIRED

1.8 –

1.7 –

1.6 –

1.5 –

1.4 –

1.3 –

1.2 –

1.1 –

1.0 –

0.9 –

0.8 –

0.7 –

0.6 –

0.5 –

0.4 –

0.3 –

0.2 –

0.1 –

0.0 –

OPERATING

REGION

3

MODEL 1181pH/ORP SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.3 PHYSICAL SPECIFICATIONS - GENERAL

Enclosure: NEMA 4X, weatherproof and corrosion-resistant

NEMA 7B, explosion proof

Hazardous Area Classification:

Explosion Proof:

FM: Class I, Groups B, C, & D, Div. 1

Class II, Groups E, F, & G, Div. 1

Class III

60°C Maximum

CSA: Class I, Groups C, & D,

Class II, Groups E, F, & G

Class III, Encl 4

Class I, Groups A, B, C, & D, Div. 2

Encl 4, Factory Sealed

Intrinsic Safety:

FM: Class I, II, & III, Div. 1

Temperature Code T4

CSA: Class I, Groups A, B, C, & D, Encl 4

Temperature Code T4

CENELEC: Ex ia IIB T4 (Tamb = 55°C)

Display:

Analog: plug in, 90 degree, 2.5 inch diameter

1181pH: dual scale, 0-100% & 0-14pH

1181ORP: dual scale, 0 center, ±1.0 & 0-100%

1181C: single scale, 0-100%

1181T: single scale, 0-100%

1181DO: triple scale, 0-5, 0-10, 0-20 ppm

1181PB: triple scale, 0-5, 0-10, 0-20 ppb X10

1181SO: triple scale, 0-100, 0-200, 0-800 mm Hg

1181RC: triple scale, 0-5, 0-10, 0-20 ppm

Digital: 3.5 digit, LCD, adjustable range in engineering units

Recommended Cable: Transmitter to Power Supply

Two Wire, 18 AWG, shielded, Belden 8760

or equal (Rosemount Analytical P/N 9200001)

Weight/Shipping Weight:

1181pH, ORP, DO, PB, SO, RC, CL:

Blind: 1.44 kg/1.89 kg (3.18 lbs/4.18 lbs)

Analog/Digital: 2.15 kg/2.6 kg (4.74 lbs/5.75 lbs)

1181C, T:

Blind: 1.8 kg/2.25 kg (4.0 lbs/5.0 lbs)

Analog/Digital: 2.48 kg/2.93 kg (5.5 lbs/6.5 lbs)

1.4 MODEL 1181pH TRANSMITTER The Model 1181 pH Trans-

mitter measures over the full range of 0-14 pH. The 4-20 mA isolated output may be field calibrated to represent any 2 to 14 pH span. Two

digital displays are offered with the 1181pH. The Code 04 LCD display

receives its input from the pH preamplifier. The advantage of the Code

04 display is that it will continue to display the measured pH regardless

of the calibrated output. The Code 06 LCD display and the analog display receive their input from the 4-20 mA loop current and will display

pH to the calibrated output only.

The 1181pH Transmitter is available with an integral preamp. The

Code 43 integral preamp is for use with sensors having a PT100 temperature compensator and the Code 44 internal preamp is for use with

the Rosemount Analytical standard 3K temperature compensator. An

integral preamp is not compatible with the Code 04 LCD display and

Code 02 Blind. These options require a Tall Housing Cover (P/N

3002468). The maximum recommended distance between the sensor

and integral preamp is 15 feet (4.5 meters).

PERFORMANCE SPECIFICATIONS @ 25°C

(Electronics only)

Measurement Range: 0-14 pH

Internal Range Select: Any 2 to 14 pH span in one pH steps

Accuracy: ±0.1% F.S.

Stability: ±0.1%/month

Repeatability: ±0.1 pH

Temperature Coefficient: +0.0028 pH/ÞC F.S.

Automatic Temperature Compensations: 0-100ÞC

RECOMMENDED SENSORS:

Model 300 Retractable pH Sensor

Model 320B Flow Through pH Sensor

Model 320HP High Purity pH Sensor

Model 328A Steam Sterilizable pH Sensor

Model 381 Insertion/Submersion/Flow pH Sensor

Model 385 Retractable pH Sensor

Model 389 Disposable ORP Sensor

Model 396 TUpH Disposable Sensor

Model 399 Disposable pH Sensor

1.5 MODEL 1181ORP TRANSMITTER The Model 1181

ORP Transmitter measures over the range of ±1200 mV. The 4-20

mA isolated output may be calibrated to represent any 200 to 2400

mV range.

PERFORMANCE SPECIFICATIONS @ 25°C

Measurement Ranges Span: 200 mV to 2400 mV in 200 mV steps

Zero: 0 to ± 1200 mV in 200 mV steps

Accuracy: ±0.1% full scale

±2.0 mV full scale

Stability: ±0.1% F.S./month

±2.0 mV/month non-cumulative

Repeatability: ±2.0 mV/month

±0.1% full scale

Temperature Coefficient: ±0.4 mV/°C F.S.

±200 ppm/°C full scale

Automatic Temperature Compensations: N/A

RECOMMENDED SENSORS:

Model 300 Retractable ORP Sensor

Model 330B Flow Through ORP Sensor

Model 381 Insertion/Submersion/Flow ORP Sensor

Model 385 Retractable ORP Sensor

Model 389 Disposable ORP Sensor

Model 399 Disposable ORP Sensor

4

MODEL 1181 pH/ORP SECTION 1.0

INTRODUCTION

MODEL

1181 TWO-WIRE TRANSMITTER

CODE INPUT (Required Selection)

pH pH measurement in an aqueous solution

ORP Oxidation Reduction Potential

CODE DISPLAY (Required Selection)

01 Analog display

02 Blind, without indication

03 Analog display

06 Digital display

CODE OPTIONS

07 Two-inch pipe/wall mounting bracket

11 Stainless steel nameplate (specify marking)

CODE AGENCY APPROVALS

67 FM Explosion proof and Intrinsically Safe

69 CSA Explosion proof and Intrinsically Safe

73 CENELEC Intrinsically Safe/CE (not available with Code 01)

1181 pH 01 07-11 67 EXAMPLE

1.6 ORDERING INFORMATION

Model 1181 Two Wire Transmitter is housed in a NEMA 7B explosion-proof, 4X weatherproof, corrosion-resistant enclosure and includes all

the circuitry necessary for measurement and transmission of an isolated 4-20 mA signal. The transmitter may be selected with or without an

analog or digital display.

5

MODEL 1181 pH/ORP SECTION 2.0

INSTALLATION

SECTION 2.0

INSTALLATION

2.1 GENERAL. The transmitter may be installed in

harsh environmental locations. The transmitter should,

however, be located to minimize the effects of temperature gradients and temperature fluctuations, and to

avoid vibration and shock.

CAUTION

AVOID GROUND LOOPS:(Sensor's shield

wire must not contact a grounded surface).

1. Use well insulated wire. Clean up all

metal burrs on conduit before pulling

cable.

2. Follow wiring instructions for the sensor. Shields aren't grounded on our

analyzers.

3. Seal the sensor conduit from liquids,

which can cause a short.

NOTE

Intrinsically safe units must be installed in

accordance with their designated drawing

numbers. See Section 2.5 for details.

Further non-certified components CANNOT be substituted with certified units.

This would void all certifications.

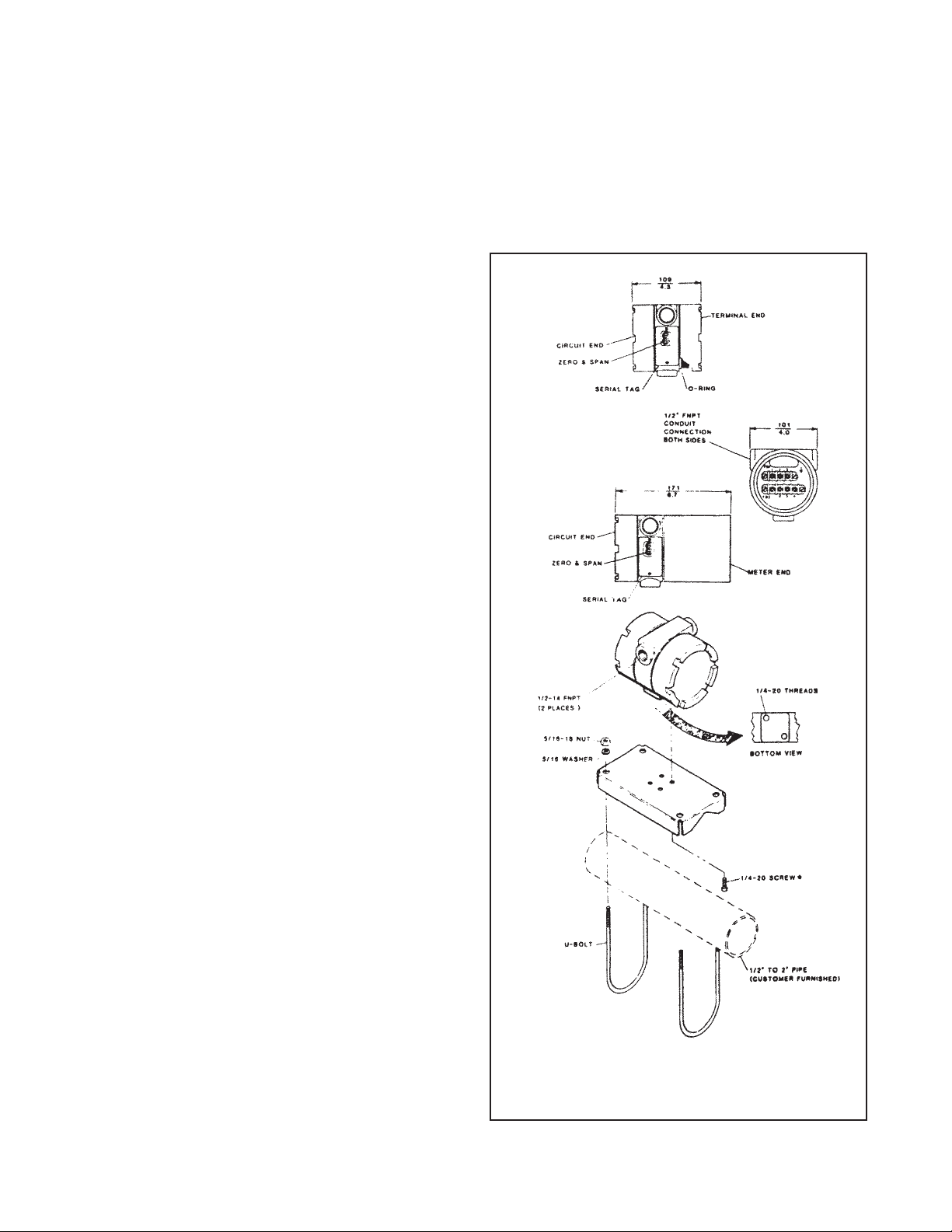

2.2 MECHANICAL INSTALLATION. Two threaded

mounting holes are located in the bottom of the transmitter housing (see Figure 2-1). These holes are provided for mounting to a flat surface or for attaching the

transmitter to the pipe mounting bracket (see Figure 21 ).

NOTE

If the transmitter is mounted in a vertical

position, the sensor leads should come into

the top of the housing and the power leads

should come into the bottom of the housing.

FIGURE 2-1. Transmitter Mounting Details

6

MODEL 1181 pH/ORP SECTION 2.0

INSTALLATION

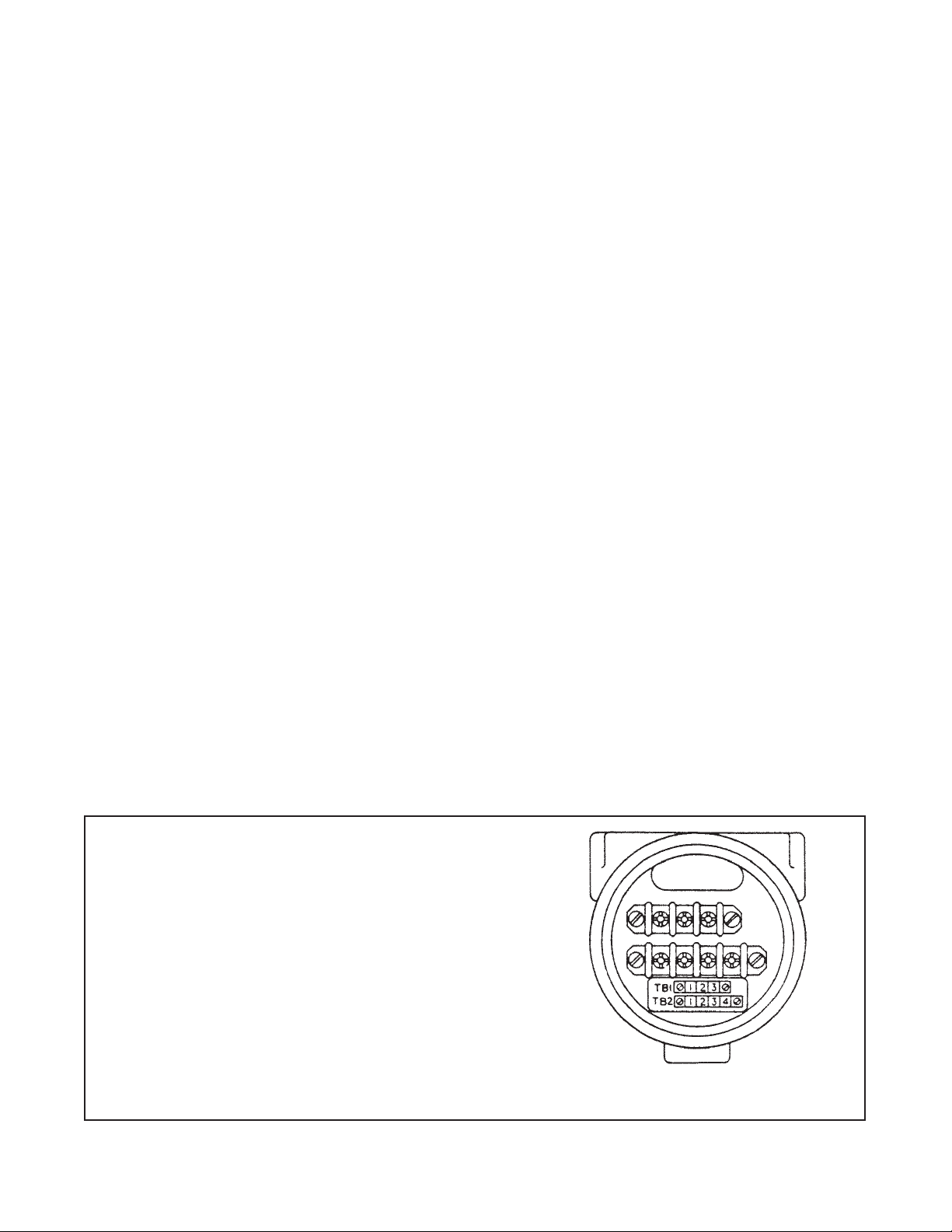

2.3 ELECTRICAL INSTALLATION. The transmitter

has two ¼-inch conduit openings, one on each side of

the housing. One opening is for the power or signal

wiring, and the other is for the input wiring from the

sensor.

NOTE

On models with the meter, make sure the

meter wiring is securely connected after

the signal and input wiring have been

attached.

2.3.1 Sensor input wiring terminals are located on the

side of the housing designated TERM SIDE on the

serial label, and are the lower set of terminals (TB2).

Remove the end cap from the TERM SIDE of the housing to gain access to the terminals (see Figure 2-2).

If the Model1181pH/ORP transmitter has been supplied with an integral preamplifier (Code Preamp

Options 43 or 44), please refer to Figure 2-3 Integral

Preamp Installation, and Figure 2-4 Wiring Details

Integral Preamp for sensor input wiring instructions.

2.3.2 Power and signal wiring terminals are located

directly above the sensor input wiring terminals and

are designated TBl. For models with a meter, the terminals leads are also attached to TBl.

2.3.3. Conduit connection on the transmitter housing

should be sealed or plugged (using a sealing compound) to avoid accumulation of moisture in housing. If

the connections are not sealed, the transmitter should

be mounted with the electrical housing downward for

draining.

2.3.4. The transmitter case shall be grounded. Power

supply regulation is not critical. Even with the power

supply ripple, of one volt peak to peak, the ripple in the

output signal would be negligible.

NOTE

For best EMI/RFI protection, the power supply/signal cable must be shielded and placed

in an earth grounded, rigid metal conduit.

Connect the outer shield to the earth ground

terminal provided next to TB1.

The sensor cable should also be shielded.

Connect the sensor cable’s outer shield to the

transmitter’s earth ground via the ground terminal next to TB1. If the sensor cable’s outer

shield is braided an appropriate metal cable

gland fitting may be used to connect the braid

to earth ground via the instrument case.

A new addition to the suite of tests done to

ensure CE compliance is IEC 1000-4-5. This is

a surge immunity test that simulates overvoltages due to switching and lightning transients.

In order to meet the requirements of this test,

additional protection must be added to the

instrument in the form of a Transient Protector

such as the Rosemount Model 470D. This is a

3½-inch tube with ½-inch MNPT threads on

both ends. Inside the tube are gas discharge

and zener diode devices to limit surges to the

transmitter from the current loop. No additional

protection is needed on the sensor connections.

FIGURE 2-2. Transmitter Wiring Detail

TB1-1 Loop Signal (Power Supply + Vdc)

TB1-2 Meter (+) Red

TB1-3 Meter (–) Black & Loop Signal (4-20 mA Output)

TB2-1 pH/ORP Signal (Black)

TB2-2 Reference (Shield) & TC (Red)

TB2-3 Preamp (+5V, White)

TB2-4 Preamp (–5V, Green)

7

MODEL 1181 pH/ORP SECTION 2.0

INSTALLATION

2.4 HAZARDOUS LOCATIONS-EXPLOSION PROOF

INSTALLATIONS. In order to maintain the explosion

proof rating for installed transmitter, the following conditions must be met.

1. The transmitter enclosure covers must be on hand

tight and the threads must not be damaged.

NOTE

These covers seat on rings which serve to

provide a dust proof enclosure for Class II

and Class III installations.

2. Explosion proof "Y" fittings must be properly

installed and plugged with a sealing compound to

prevent explosive gases from entering the transmitter. CSA has determined that the transmitter

housing is "Factory Sealed". Installation of "Y" fittings and the use of sealing compound is not

required for CSA approved Explosion Proof installations.

NOTE

Do not install sealing compound until all

field wiring is completed.

CAUTION

Sealing compound must be installed prior

to applying power to the transmitter.

3. If one of the conduit connections on the housing is

not used, it must be closed with a threaded metal

plug with at least five threads engaged.

4. The serial tag cover on the external ZERO and

SPAN adjustments must be in place.

6. Explosion proof installation must be in accordance

with Drawing Number 1400155 (see Figure 2-12).

5. For sensors in hazardous area locations, explosion proof junction boxes can be provided to

house the preamplifier. This does not warrant the

pH or ORP sensor explosion-proof. Maximum

safety can be achieved by installing an intrinsically

safe system where Hazardous Area requirements

must be met.

2.5 HAZARD LOCATIONS - INTRINSICALLY SAFE

INSTALLATIONS. To secure and maintain intrinsically

safe installations for the appropriate approval agency,

the following conditions must be met:

1. Code 73 must be specified when ordering CENELEC/BASEEFA units. Installation must be performed in accordance with Drawing Number

1400143 (see Figures 2-5, 6 & 7).

2. Code 69 must be specified when ordering C.S.A.

(Canadian Standards Association) units.

Installation must be in accordance with Drawing

Number 1400123 (see Figure 2-8).

3. Code 67 must be specified when ordering F.M.

(Factory Mutual) units. Approved “Entity” installation must be in accordance with Drawing Number

1400153 (see Figures 2-9, 2-10, and 2-11).

8

MODEL 1181 pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-3. Integral Preamp Installation

DWG. NO. REV.

40118154 C

9

MODEL 1181 pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-4. Wiring Details Integral Preamp

DWG. NO. REV.

40118119 C

10

MODEL 1181 pH/ORP SECTION 2.0

INSTALLATION

FIGURE 2-5. Installation of 1181 Series for Intrinsically Safe Operation (CENELEC) Page 1 of 3

DWG. NO. REV.

1400143 C

Loading...

Loading...