Rosemount Manual: 1085B-C Conductivity Microprocessor Analyzer | Rosemount Manuals & Guides

Model 1054B C

Conductivity Microprocessor Analyzer

Instruction Manual

PN 51-1054BC/rev.B

April 2003

WARNING

ELECTRICAL SHOCK HAZARD

Making cable connections to and servicing this instrument require access to shock hazard level voltages

which can cause death or serious injury.

Relay contacts made to separate power sources

must be disconnected before servicing.

Electrical installation must be in accordance with

the National Electrical Code (ANSI/NFPA-70)

and/or any other applicable national or local

codes.

Unused cable conduit entries must be securely

sealed by non-flammable closures to provide

enclosure integrity in compliance with personal

safety and environmental protection requirements.

For safety and proper performance this instrument must be connected to a properly grounded

three-wire power source.

Proper relay use and configuration is the responsibility of the user.

Do not operate this instrument without front cover

secured. Refer installation, operation and servicing

to qualified personnel.

Be sure to disconnect all hazardous voltage before

opening the enclosure.

The unused conduit openings need to be sealed

with NEMA 4X or IP65 conduit plugs to maintain

the ingress protection rating (IP65).

No external connection to the instrument of more

than 43V peak allowed with the exception of power

and relay terminals. Any violation will impair the

safety protection provided.

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PRO-

CEEDING!

Rosemount Analytical designs, manufactures, and tests its

products to meet many national and international standards. Because these instruments are sophisticated technical products, you must properly install, use, and maintain

them to ensure they continue to operate within their normal

specifications. The following instructions must be adhered

to and integrated into your safety program when installing,

using, and maintaining Rosemount Analytical products.

Failure to follow the proper instructions may cause any one

of the following situations to occur: Loss of life; personal

injury; property damage; damage to this instrument; and

warranty invalidation.

• Read all instructions prior to installing, operating, and

servicing the product. If this Instruction Manual is not the

correct manual, telephone 1-949-757-8500 and the

requested manual will be provided. Save this Instruction

Manual for future reference.

• If you do not understand any of the instructions, contact

your Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions marked

on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the Installation

Instructions of the appropriate Instruction Manual and

per applicable local and national codes. Connect all

products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel

to install, operate, update, program, and maintain the

product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by

Rosemount. Unauthorized parts and procedures can

affect the product’s performance and place the safe

operation of your process at risk. Look alike substitutions may result in fire, electrical hazards, or improper

operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is

being performed by qualified persons, to prevent electrical shock and personal injury.

WARNING

This product is not intended for use in the light industrial,

residential or commercial environment, per the instrument’s

certification to EN50081-2.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.RAuniloc.com

© Rosemount Analytical Inc. 2001

MODEL 1054B C TABLE OF CONTENTS

MODEL 1054B CONDUCTIVITY MICROPROCESSOR ANALYZER

TABLE OF CONTENTS

Section Title Page

1.0 DESCRIPTION AND SPECIFICATIONS........................................................... 1

1.1 Features and Applications ................................................................................. 1

1.2 Specifications .................................................................................................... 2

1.3 Ordering Information.......................................................................................... 4

2.0 INSTALLATION.................................................................................................. 5

2.1 General.............................................................................................................. 5

2.2 Unpacking and Inspection ................................................................................. 5

2.3 Mechanical Installations .................................................................................... 5

2.4 Electrical Wiring................................................................................................. 6

3.0 DESCRIPTION OF CONTROLS ....................................................................... 14

3.1 Keyboard Functions........................................................................................... 14

3.2 Item Selection and Value Adjustment Keys....................................................... 15

4.0 CONFIGURATION............................................................................................. 19

4.1 General ............................................................................................................. 19

4.2 Alarm 1 and 2 ................................................................................................... 21

4.3 Interval Timer .................................................................................................... 22

4.4 Temperature ..................................................................................................... 23

4.5 Current Output .................................................................................................. 23

4.6 Defaults ............................................................................................................. 24

4.7 Alarm Setpoint ................................................................................................... 25

4.8 Output Scale Expansion .................................................................................... 26

4.9 Simulate Output................................................................................................. 27

5.0 START-UP AND CALIBRATION........................................................................ 28

5.1 General.............................................................................................................. 28

5.2 Entering Cell Constant....................................................................................... 28

5.3 Temperature Calibration .................................................................................... 28

5.4 Initial Loop Calibration ....................................................................................... 28

5.5 Routine Standardization .................................................................................... 30

5.6 Sensor Maintenance.......................................................................................... 30

6.0 KEYBOARD SECURITY ................................................................................... 31

6.1 General.............................................................................................................. 31

6.2 Access Code ..................................................................................................... 31

7.0 THEORY OF OPERATION................................................................................ 31

8.0 DIAGNOSTICS AND TROUBLESHOOTING .................................................... 32

8.1 Diagnostics ........................................................................................................ 32

8.2 Troubleshooting................................................................................................. 33

8.3 Instrument Maintenance .................................................................................... 35

9.0 RETURN OF MATERIAL................................................................................... 37

i

MODEL 1054B C TABLE OF CONTENTS

LIST OF FIGURES

Figure No. Title Page

2-1 Panel Mounting Cutout...................................................................................... 7

2-2 Panel Mounting Tab Installation......................................................................... 8

2-3 Wall Mounting J-Box Installation........................................................................ 9

2-4 Wall Mounting J-Box Wiring............................................................................... 10

2-5 Pipe Mounting Installation ................................................................................. 11

2-6 Electrical Wiring................................................................................................. 12

2-7 Wall Mount Enclosure (Option -20).................................................................... 13

3-1 Function Select on Keypad................................................................................ 14

3-2 Accessing Editing Function ............................................................................... 14

3-3 Accessing Configuration Menus........................................................................ 14

3-4 LCD Display....................................................................................................... 15

3-5 Set Menu Items ................................................................................................. 18

4-1 Alarm 1 and 2 Configuration.............................................................................. 21

4-2 Interval Timer Configuration .............................................................................. 22

4-3 Timer Diagram for One Cycle ............................................................................ 22

4-4 Temperature Configuration................................................................................ 23

4-5 Current Output Configuration ............................................................................ 23

4-6 Default Configuration......................................................................................... 24

4-7 Alarm Setpoint................................................................................................... 25

4-8 Output Scale Expansion.................................................................................... 26

4-9 Simulate Current Output.................................................................................... 27

8-1 Simulate Conductivity Input............................................................................... 36

LIST OF TABLES

Table No. Title Page

1-1 Conductivity Range ........................................................................................... 3

1-2 Replacement Parts............................................................................................ 4

1-3 Accessories ....................................................................................................... 4

3-1 Key Description ................................................................................................. 16

3-2 Information Mnemonics ..................................................................................... 17

3-3 Set Function Mnemonics................................................................................... 17

4-1 Configuration Work Sheet ................................................................................. 20

4-2 Relay States for Various Conditions and Alarm/Default Configurations ............ 24

8-1 Fault Mnemonics ............................................................................................... 32

8-2 RTD Resistance Values..................................................................................... 32

8-3 Troubleshooting Guide ...................................................................................... 34

ii

1

MODEL 1054B C SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.1 FEATURES AND APPLICATIONS

The Model 1054B Microprocessor Analyzers, with the

appropriate sensors, are designed to continuously measure and control pH, ORP, conductivity, resistivity, ratio,

percent concentration, dissolved oxygen, ozone or total

free chlorine in industrial and municipal processes.

The Model 1054B Conductivity Analyzers are housed in

a NEMA 4X (IP65) weatherproof, corrosion-resistant,

flame retardant enclosure suitable for panel, pipe or wall

mounting. All functions are accessed through the front

panel membrane keyboard which features tactile feedback. Measurement data may be read at any time.

However, settings may be protected against accidental

or unauthorized changes by a user selectable security

code. The display indicates the measured value in engineering units as well as temperature, alarm status, hold

output and fault conditions.

The 1054B transmits a user selected isolated current

output which is continuously expandable over the measurement range for either direct or reverse action and can

be displayed in milliamps or percent. Output dampening

of 0-255 sec. is user selectable.

The output and relay default settings are user selectable

for hold or fault mode operation. The hold output function

allows manual control during routine sensor maintenance.

Continuous self diagnostics alert the operator to faults

due to analyzer electronics, integral RTD failures, open

wiring and process variable range problems. In the event

of a fault condition or hold mode diagnosed by the analyzer, the output will be set to a preset or last process

value and the relays will be set to their default settings.

Dual alarms are a standard feature on the Model 1054B

and are programmable for either high or low operation.

Alarm 2 may be programmed as a fault alarm. Both

alarms feature independent setpoints, adjustable hysteresis and time delay action. The time delay is convenient when an alarm is used for corrective action, such as

shutting down a demineralizer for regeneration. Time

delay will ignore a temporary breakthrough and prevent

shutting down a demineralizer unit prematurely. A dedicated interval timer with relay is also provided.

Automatic or manual temperature compensation is keyboard selectable. The process temperature is accurately

measured from an integral RTD in the sensor assembly

and is read on the display. For greater accuracy, the temperature indication may be standardized to the process

temperature. The temperature may be configured to read

in °C or °F.

Calibration is easily accomplished by simply immersing

the sensor in a known solution and entering the value.

With a two point calibration, the Model 1054B will automatically calculate the temperature slope of the solution.

Upon routine standardization a sensor cell factor value is

calculated, and a trend of this value can be used to track

sensor coating.

The Model 1054B Microprocessor Analyzer comes standard with an LCD display. An LED display is available as

an option.

• SELF DIAGNOSTICS with a user selectable fault alarm.

• KEYBOARD SECURITY is user selectable.

• NO BATTERY BACK-UP REQUIRED. Non-volatile EEPROM memory.

• DUAL ALARMS WITH PROGRAMMABLE LOGIC. A third relay is provided with timer functions.

• PROGRAMMABLE OUTPUT AND RELAY DEFAULTS for hold and fault modes.

• NEMA 4X (IP65) WEATHERPROOF CORROSION-RESISTANT ENCLOSURE.

2

Model 1054B C SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.2 SPECIFICATIONS -

Enclosure: Black, ABS, NEMA 4X, IP65,

CSA Enclosure 4

144 X 144 X 192 mm

(5.7 X 5.7 X 7.6 in.)

Wall Mount Enclosure: NEMA 4X, Heavy duty

fiberglass, reinforced thermoplastic.

356.4 X 450.1 X 180.2 mm* (14 X 17.7 X 7.1 in.*)

Front Panel: Membrane keyboard with tactile feed-

back and user selectable security

Digital Display: LCD, black on grey

Optional, red LED

Character Height: 18 mm (0.7 in.)

Electrical Classification:

FM Class I, Div. 2, Group A thru D

28 Vdc relays - 5.0 amps resistive only

150 mA - Groups A & B; 400 mA - Group C ;

540 mA - Group D; Ci = 0; Li = 0

CSA Class I, Div. 2, Group A thru D.

28 Vdc, 110 Vac & 230 Vac relays

5.0 Amps resistive only

Wall Mount Enclosure: General Purpose

Power: 100 - 127 VAC, 50/60 Hz ± 6%, 4.0 W

200 - 253 VAC, 50/60 Hz ± 6%, 4.0 W

Current Output: Isolated, 0-20 mA or 4-20 mA into

600 ohms maximum load at 115/230 Vac or

550 ohms maximum load at 100/200 Vac,

Direct or Reverse

Output Dampening: 0-255 seconds

Code -20 Wall Mount Enclosure does not meet CE requirements

*Includes latches and mounting feet

EMI/RFI: EN61326

LVD: EN61010-1

Ambient Temperature: -20 to 65°C (-4 to 149

°

F)

Ambient Humidity: LED max 95% RH

(LCD max 85% RH @ 50°C)

Alarms: Dual, field selectable High/Low, High/High,

Low/Low

Alarm 2 configurable as a fault alarm

Time Delay 0 to 254 seconds

Dual Setpoints, continuously adjustable

Hysteresis is adjustable up to 25% full scale

for low side/High Alarm and high side/Low Alarm

Interval Timer: Interval: 10 min. to 2999 days

On Counts: 1 to 60

On Duration: 1 to 299.9 seconds

Off Duration: 1 to 299.9 seconds

Wait Duration: 1 to 299.9 seconds

Controls dedicated relay

Relay Contacts: Epoxy Sealed Form A contacts,

SPST, Normally Open.

Resistive

Inductive

28 VDC 5.0 Amps 3.0 Amps

115 VAC 5.0 Amps 3.0 Amps

230 VAC 5.0 Amps 1.5 Amps

Weight/Shipping Weight: 1.1 kg/1.6 kg (2.5 lb/3.5 lb)

3

Model 1054B C SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

The Model 1054B Conductivity Analyzer measures over the range of 0-2 µS/cm to 0-1,000 mS/cm.

Temperature slope may be adjusted anywhere between 0 and 5% to provide greater accuracy in chemical concentration control. The temperature slope is factory set at 2% as a representative value, but each conductive

solution has its own set of temperature vs. concentration curves. The Model 1054B C will automatically calculate the temperature slope for any given solution, or permit manual adjustment of the temperature slope if

already known. On calibration the analyzer will also automatically correct for cell constant variations for better

measurement accuracy.

ANALYZER SPECIFICATIONS @ 25°C

Measurement Range: (See Table 1)

Output Scale: Zero suppression: up to 90% full scale.

Span: from 10% to 100% full scale

Accuracy: ±0.5% of reading

Repeatability: ±0.25% of reading

Stability: ±0.25% month, non-cumulative

Temperature Effect: 0.02% of reading/°C

Temperature Compensation: -20 to 200°C

(-4 to 392°F) (automatic or manual)

Temperature Slope Adjustment: 0-5%/

°

C

RECOMMENDED SENSORS:

Model 140 Retractable Conductivity

Model 150 Insertion/Submersion Conductivity

Model 400 Screw-in Conductivity

Model 401-14 Screw-in Conductivity

Model 402 Retractable Conductivity

Model 403 Sanitary Flange Conductivity

Model 404 Low Flow Conductivity

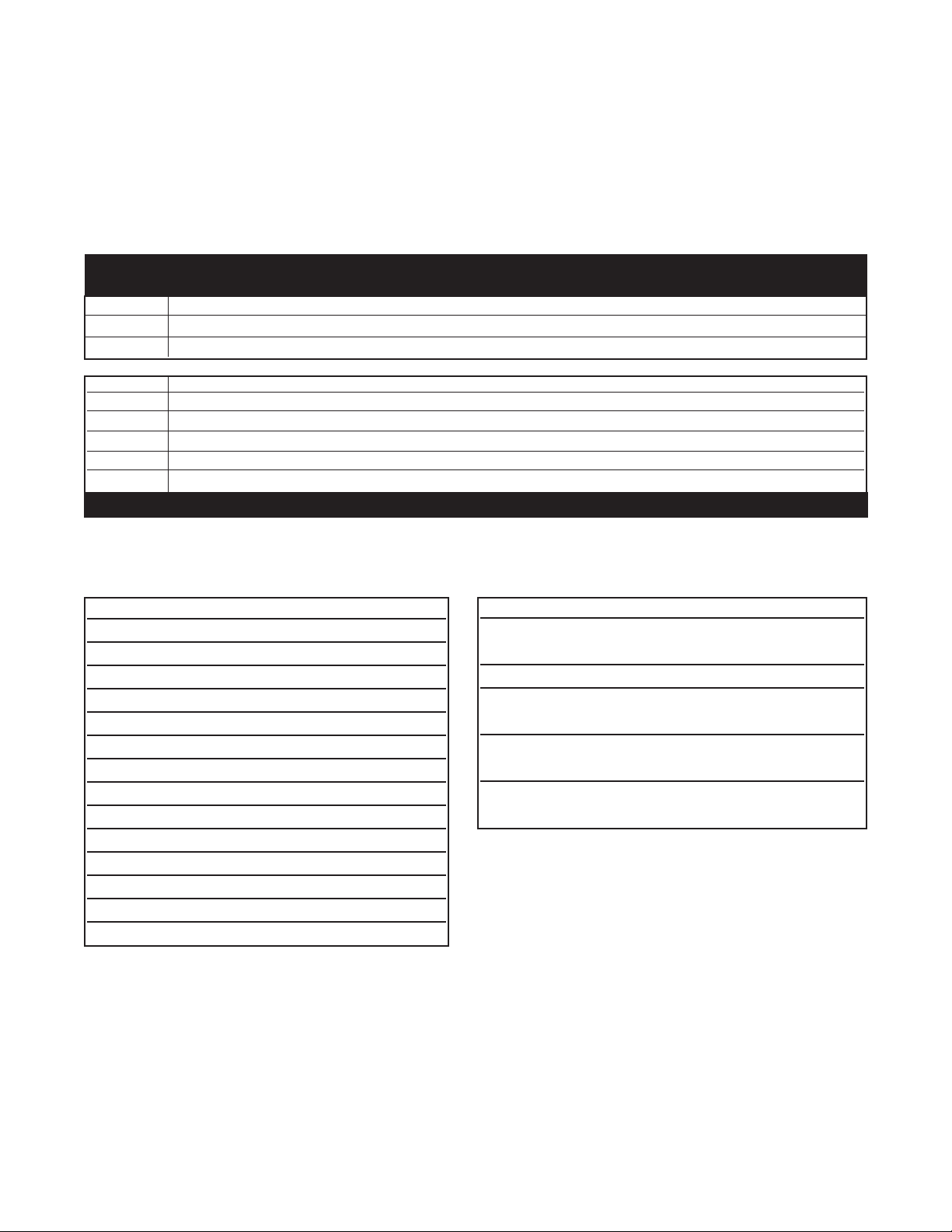

FULL SCALE MICROSIEMENS/cm

TABLE 1-1. CONDUCTIVITY RANGE

Conductivity Sensor 150 140

Model Number 400 140 150 150

402/403 400/402/403

404

Cell Constant 0.1 0.2 0.5 1.0

Min. Range 2 4 100 200

Max. Range* 2,000 4,000 10,000 20,000

* Values shown are absolute conductivi-

ty. Maximum range will be reduced for

compensated conductivity at elevated

process temperatures.

4

MODEL 1054B C SECTION 1.0

DESCRIPTION AND SPECIFICATIONS

1.3 ORDERING INFORMATION

The Model 1054B Microprocessor Analyzer: Housed in a corrosion resistant, weatherproof enclosure and oper-

ates on either 115 or 230 VAC, 50/60 Hz power. Standard features include digital display, isolated current output,

dual alarms, and automatic and manual temperature compensation.

MODEL

1054B MICROPROCESSOR ANALYZER (3.5 lbs/1.5 kg)

Code Measurement

C Contacting Conductivity

T Toroidal Conductivity

P/N DESCRIPTION

22966-00 PCB, LCD Digital Display

23025-01 Panel Mounting Kit

23739-00 PCB, Power Supply

23664-01 PCB, CPU, Conductivity

23245-01 PCB, LED Digital Display

23740-00 PCB, Motherboard

23695-04 Keyboard Overlay, LCD Version

23695-05 Keyboard Overlay, LED Version

33469-00 Enclosure, Body

33470-00 Enclosure, Rear Cover

32938-00 Gasket, Rear Cover

9100157 Fuse, 0.1A, 3AB, 250V, Slo-Blow

9100160 Fuse, .250A, 125V

9100189 Fuse, .750A, 125V

TABLE 1-2. Replacement Parts

CODE STANDARD ENCLOSURE OPTIONS

01 LCD Display

02 LED Display

CODE OPTIONS

20 Wall Mount Enclosure

1054BC 01 20 EXAMPLE

TABLE 1-3. Accessories

P/N DESCRIPTION

2001492 Tag, Stainless Steel, Specify

Marking

23053-00 Mounting Bracket, 2-inch Pipe

23054-01 Mounting Bracket, Wall, with

Junction Box

23268-01 Heater, 115 VAC, 50/60 Hz,

1054B (Code 20 Only)

23268-02 Heater, 230 VAC, 50/60 Hz,

1054B (Code 20 Only)

5

MODEL 1054B C SECTION 2.0

INSTALLATION

SECTION 2.0

INSTALLATION

2.1 GENERAL. Installation must be performed by a

trained technician. This analyzer's enclosure is suitable for outdoor use. However, it should be located in

an area where temperature extremes and vibrations

are minimized or absent. Installation must be performed by a trained technician.

2.2 UNPACKING AND INSPECTION. Inspect the

analyzer for shipping damage. If damaged, notify the

carrier immediately. Confirm that all items shown on

the packing list are present. Notify Rosemount

Analytical if items are missing.

2.3 MECHANICAL INSTALLATION. Select an instal-

lation site that is at least one foot from any high voltage conduit, has easy access for operating personnel,

and is not in direct sunlight. Mount the analyzer as follows:

1. Remove the four screws that secure the rear

cover of the enclosure.

2. Remove the four screws holding the front panel

assembly of the enclosure and carefully pull the

front panel and connected printed circuit boards

straight out.

3. Follow the procedure for the appropriate mounting

configuration: Section 2.3.1 for panel mounting,

Section 2.3.2 for wall mounting, Section 2.3.3 for

pipe mounting.

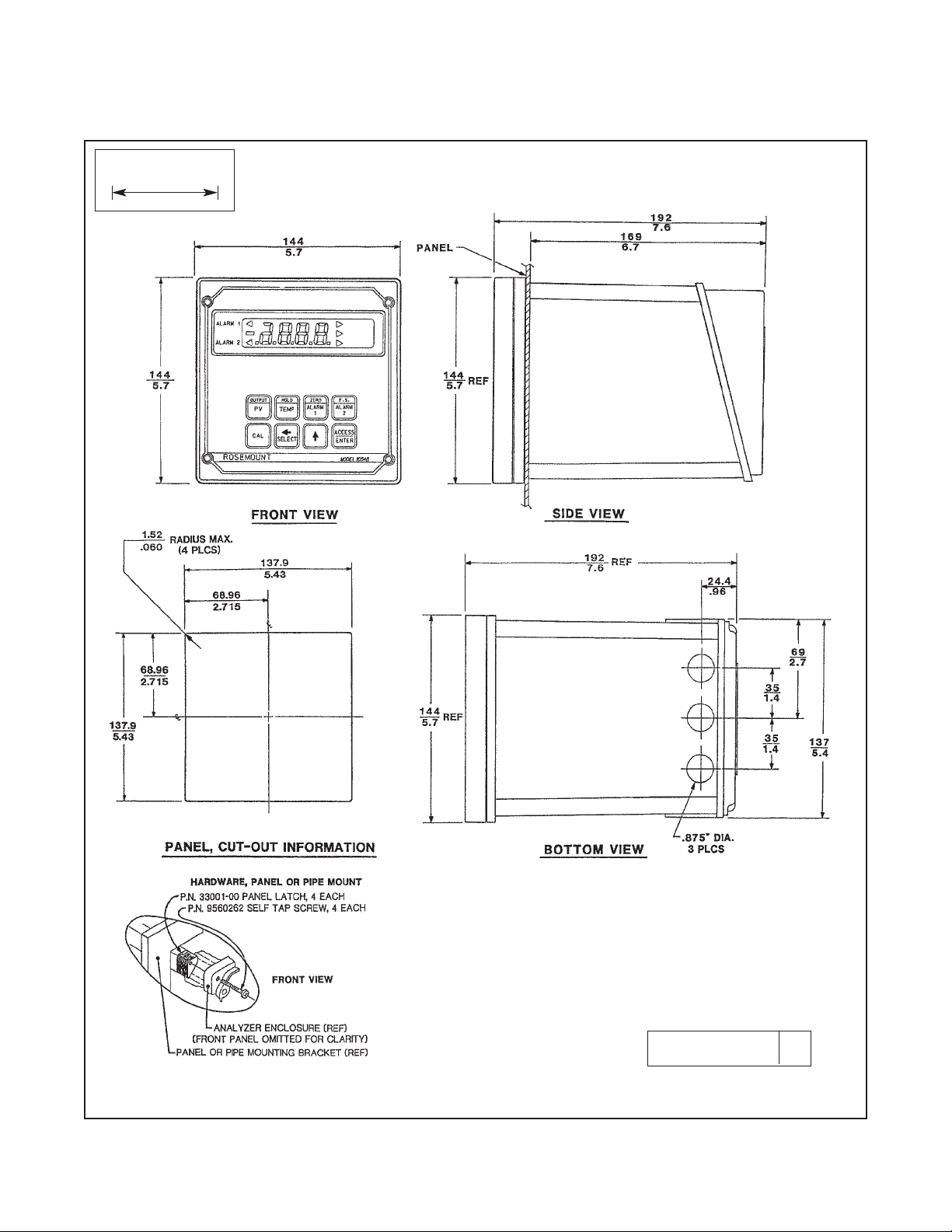

2.3.1 Panel Mounting (Standard). The Model 1054B

is designed to fit into a DIN standard 137.9 mm x

137.9 mm (5.43 in. x 5.43 in.) panel cutout (Refer to

Figure 2-1 and Figure 2-2).

1. Prepare the analyzer as described in Section 2.3.

2. Install the mounting latches as described in Figure

2-2 (latches are shown oversize for clarity). If the

latches are not installed exactly as shown, they

will not work correctly. The screws provided are

self-tapping. Tap the screw the full depth of the

mounting latch (refer to side view) leaving a gap

greater than the thickness of the cutout panel.

3. Align the latches as shown and insert the analyzer enclosure through the front of the panel cutout.

Tighten the screws for a firm fit. To avoid damaging the mounting latches, do not use excessive

force.

4. Replace the front panel assembly. Circuit boards

must align with the slots on the inside of the

enclosure. Assure that the continuity wire is connected to the rear cover and the interface board’s

closest mounting screw. Replace the door and

four front panel screws.

2.3.2 Wall Mounting Plate with Junction Box

(P/N 23054-01). Refer to Figure 2-3 and Figure 2-4.

1. Prepare the analyzer as described in Section 2.3.

2. Mount the junction box and bracket to the analyzer with the hardware provided. All wiring can be

brought to the terminal strip prior to mounting the

analyzer.

3. Place the metal stiffener on the inside of the analyzer and mount the two 1/2-inch conduit fittings

using two each weather seals as shown. Mount

NEMA 4X conduit plug (included) into center conduit hole.

4. Mount the analyzer to the junction box using the

1/2-inch conduit fittings.

5. Complete wiring from the analyzer to the junction

box (Refer to Figure 2-4).

NOTE

Run sensor wiring out of the left opening

(From front view) to J-Box. All others out

right opening to J-Box.

2.3.3 Pipe Mounting (P/N 23053-00). The 2-inch pipe

mounting bracket includes a metal plate with a cutout

for the analyzer (Refer to Section 2.3 for mounting the

analyzer into the plate). Mounting details are shown in

Figure 2-5.

2.3.4 Wall Mount Enclosure (option -20). See

Figure 2-7 for installation details.

6

MODEL 1054B C SECTION 2.0

INSTALLATION

2.4 ELECTRICAL WIRING. The Model 1054B has

three conduit openings in the bottom rear of the analyzer housing which will accommodate 1/2-inch conduit fittings. From the front view, the conduit opening

on the left is for sensor wiring; the center is for signal

output and the opening on the right is for timer, alarm,

and AC connections. Sensor wiring should always be

run in a separate conduit from power wiring. AC

power wiring should be 14 gauge or greater.

NOTE

For maximum EMI/RFI protection the

output cable should be shielded and

enclosed in an earth grounded, rigid

metal conduit. When wiring directly to

the instrument connect the output

cable’s outer shield to the transmitter’s

earth ground via terminal 8 on TB3.

When wiring to the wall mounting junction box connect the output cable’s outer

shield to the earth ground terminal on

TB-A.

The sensor cable should also be shielded. When wiring directly to the instrument connect the sensor cable’s outer

shield to the transmitter’s earth ground

via terminal 8 of TB-2. If the sensor

cable’s outer shield is braided an appropriate metal cable gland fitting may be

used to connect to braid to earth ground

via the instrument case. When wiring to

the wall mounting junction box connect

the sensor cable’s outer shield to the

earth ground terminal on TB-A.

The user must provide a means to disconnect the main power supply in the

form of circuit breaker or switch. The circuit breaker or the switch must be located in close proximity to the instrument

and identified as the disconnecting

device for the instrument.

2.4.1 Power Input Wiring. The Model 1054B can be

configured for either 115 VAC or 230 VAC power.

Connect AC power to TB1-8 and -9 (115 VAC) or TB17 and -8 (230 VAC) ground to the ground terminal at

TB3-8 (refer to Figure 2-6).

CAUTION

The sensitivity and stability of the analyzer

will be impaired if the input wiring is not

grounded. DO NOT apply power to the

analyzer until all electrical connections are

verified and secure. The following precautions are a guide using UL 508 as a safeguard for personnel and property.

1. AC connections and grounding must be in compliance with UL 508 and/or local electrical codes.

2. The metal stiffener is required to provide support

and proper electrical continuity between conduit

fittings.

3. This type 4/4X enclosure requires a conduit hub

or equivalent that provides watertight connect,

REF UL 508-26.10.

4. Watertight fittings/hubs that comply with the

requirements of UL 514B are to be used.

5. Conduit hubs are to be connected to the conduit

before the hub is connected to the enclosure, REF

UL 508-26.10.

6. If the metal support plate is not used, plastic fittings must be used to prevent structural damage

to the enclosure. Also, appropriate grounding lug

and awg conductor must be used with the plastic

fittings.

2.4.2 Output Wiring. The signal output and alarm

connections are made to terminals 1 through 6 of TB1

and TB3-1 and 2. (Refer to Figure 2-6).

7

MODEL 1054B C SECTION 2.0

INSTALLATION

FIGURE 2-1. Panel Mounting Cutout

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

DWG. NO. REV.

41054B01 B

8

MODEL 1054B C SECTION 2.0

INSTALLATION

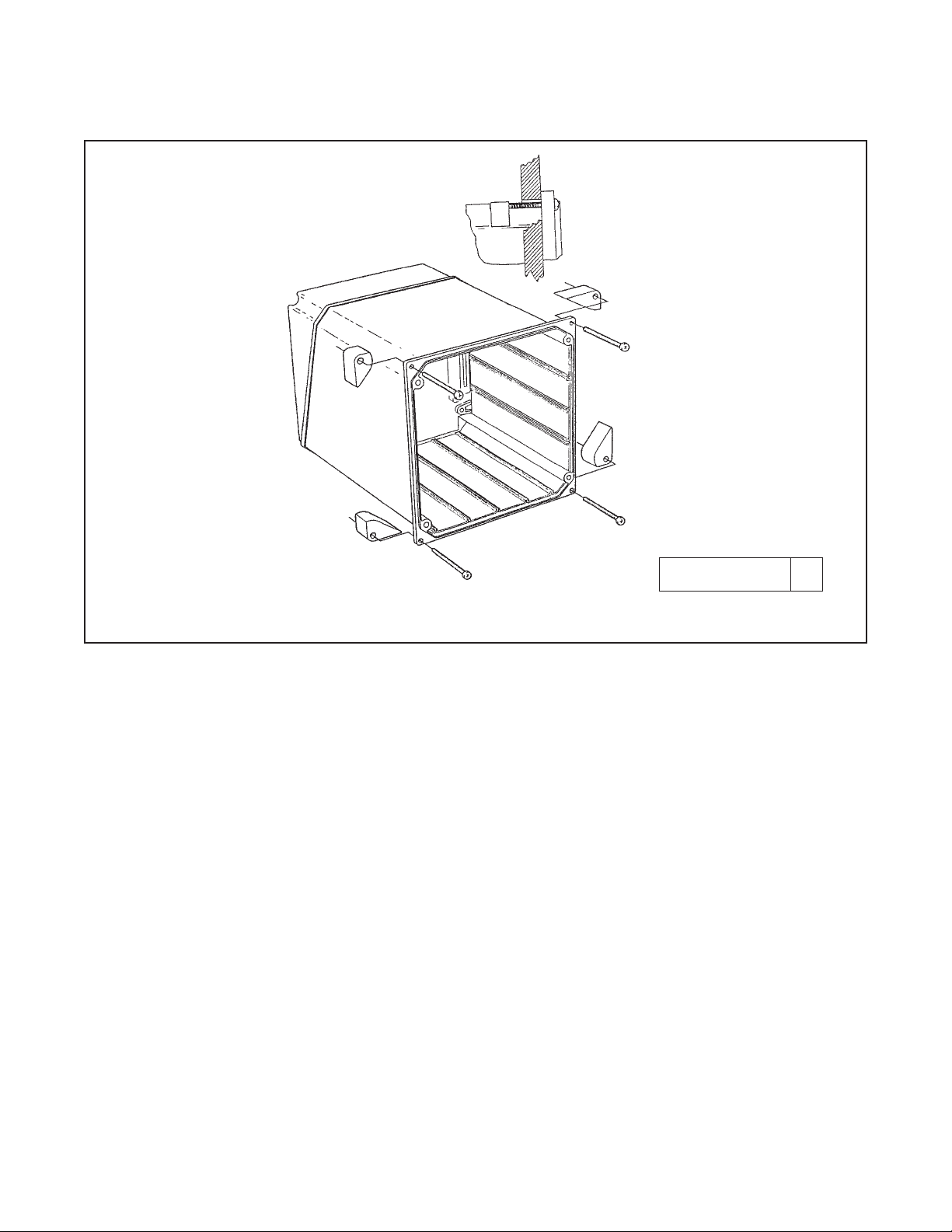

FIGURE 2-2. Panel Mounting Tab Installation

DWG. NO. REV.

41054A26 A

Loading...

Loading...