Page 1

00809-0200-3003, Rev AA

Incus HART® Field Device Specification

Manual Supplement

December 2018

Page 2

2

Page 3

Manual Supplement Contents

00809-0200-3003 December 2018

Contents

Chapter 1 Introduction.................................................................................................................. 5

1.1 Scope............................................................................................................................................... 5

1.2 Purpose............................................................................................................................................ 5

1.3 Who should use this document?.......................................................................................................5

1.4 Abbreviations and definitions........................................................................................................... 5

1.5 References....................................................................................................................................... 5

Chapter 2 Device Identification...................................................................................................... 7

Chapter 3 Product Overview.......................................................................................................... 9

Chapter 4 Product Interfaces........................................................................................................11

4.1 Process interface............................................................................................................................ 11

4.2 Host interface.................................................................................................................................11

4.3 Local interfaces, jumpers, and switches.......................................................................................... 12

Chapter 5 Device Variables...........................................................................................................13

Chapter 6 Dynamic Variables....................................................................................................... 15

Chapter 7 Status Information....................................................................................................... 17

7.1 Device status..................................................................................................................................17

7.2 Extended device status...................................................................................................................17

7.3 Additional device status (command 48)......................................................................................... 18

Chapter 8 Universal Commands................................................................................................... 21

Chapter 9 Common Practice Grounds...........................................................................................23

9.1 Supported commands....................................................................................................................23

9.2 Burst mode.....................................................................................................................................23

9.3 Catch device variable......................................................................................................................23

Chapter 10 Device Specific Commands...........................................................................................25

10.1 Command 134: Read alarm level.................................................................................................. 25

10.2 Command 136: Set alarm level.....................................................................................................26

10.3 Command 140: Read alarm delay.................................................................................................26

10.4 Command 142: Set alarm delay....................................................................................................27

10.5 Command 143: Read alarm latch..................................................................................................28

10.6 Command 144: Set alarm latch.................................................................................................... 29

10.7 Command 145: Read operating mode..........................................................................................29

10.8 Command 147: Read heater enable..............................................................................................30

10.9 Command 161: Set test current....................................................................................................31

Chapter 11 Performance................................................................................................................ 33

11.1 Sampling rates............................................................................................................................. 33

Manual Supplement 3

Page 4

Contents Manual Supplement

December 2018 00809-0200-3003

11.2 Power-up......................................................................................................................................33

11.3 Reset............................................................................................................................................ 33

11.4 Self-test........................................................................................................................................33

11.5 Command response times (TTO)..................................................................................................33

11.6 Busy delayed response................................................................................................................. 34

11.7 Long messages.............................................................................................................................34

11.8 Non-volatile memory................................................................................................................... 34

11.9 Modes.......................................................................................................................................... 34

11.10 Write protection.........................................................................................................................34

11.11 Damping.................................................................................................................................... 34

Appendix A Capability Checklist......................................................................................................35

Appendix B Default Configuration.................................................................................................. 37

Appendix C Operation with WirelessHART® Adapters.....................................................................39

C.1 Two-wire (loop powered) WirelessHART® adapters.........................................................................39

C.2 Three-wire Ex d/Explosion Proof certified WirelessHART® adapters................................................. 39

Appendix D Customer Level and Service Level HART® Device-Specific Commands........................... 41

4 Incus

Page 5

Manual Supplement Introduction

00809-0200-3003 December 2018

1 Introduction

1.1 Scope

This document describes the function, performance, and operating procedures for the

HART® communication features provided on the Emerson™ Incus.

This document specifies all the device specific features and documents HART protocol

implementation details (e.g., engineering unit codes supported). The functionality of this

field device is described sufficiently to allow its proper application in a process monitoring

application and its complete support in HART capable host applications.

1.2 Purpose

This specification is intended to be used with other documentation and provides a

description of this Field Device from a HART® Communication perspective.

1.3 Who should use this document?

This document is intended to be a technical reference for HART® capable host application

developers, system integrators, and knowledgeable end users. It also provides functional

specifications (e.g., commands, enumerations, and performance requirements) used

during Field Device installation, maintenance, and testing. This document assumes that

the reader is familiar with HART protocol requirements and terminology and their impact

on safety systems.

1.4 Abbreviations and definitions

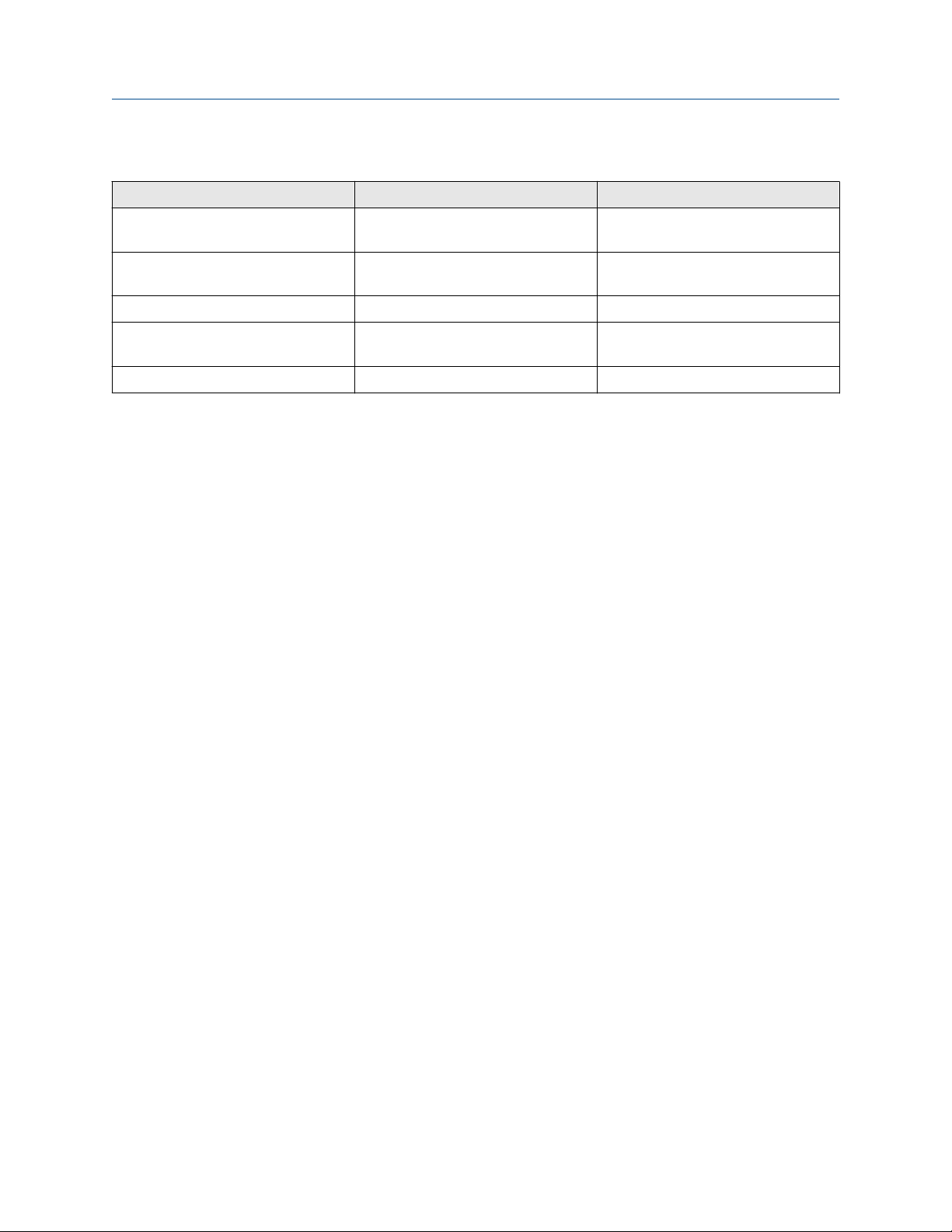

Table 1-1: Abbreviations Used within this Document

Abbreviation Meaning

EEPROM Electrically-erasable read-only memory

FSK Frequency-shift keying (a method of

modulation)

HCF HART® Communication Foundation

1.5 References

Table 1-2: Reference Document List

Document Revision Document number

HART® - FSK Physical Layer Spec 8.1 HCF_SPEC-54

HART - Data Link Layer Specification 8.2 HCF_SPEC-81

Manual Supplement 5

Page 6

Introduction Manual Supplement

December 2018 00809-0200-3003

Table 1-2: Reference Document List (continued)

Document Revision Document number

HART - Command Summary

Specification

HART- Universal Command

Specification

HART- Common Tables 21.0 HCF_SPEC-183

HART - Common Response Code

Specification

Incus Reference Manual 7.0 MAN-INCUS-rev.7

9.0 HCF_SPEC-99

7.1 HCF_SPEC-127

6.0 HCF_SPEC-307

6 Incus

Page 7

Manual Supplement Device Identification

00809-0200-3003 December 2018

2 Device Identification

Table 2-1: Device Identification

Manufacturer's name Emerson

Manufacturer ID code 6072

Model name(s) Incus

Device type code E1E6

Device revision 1 and 2 (see text)

HART® Protocol revision number 7.0

Number of device variables 1

Physical layers supported FSK

Physical device category Current output device

™

Manual Supplement 7

Page 8

Device Identification Manual Supplement

December 2018 00809-0200-3003

8 Incus

Page 9

Manual Supplement Product Overview

00809-0200-3003 December 2018

3 Product Overview

Incus is an ultrasonic gas leak detector which detects the airborne ultrasound generated

from pressurised gas leaks.

Airborne ultrasound is generated when gas moves from a high pressure area to a low

pressure area with a ratio ≥ 1.8: 1 upstream to downstream pressure. The intensity of

airborne ultrasound generated by a leak is due to a number of factors, including but not

limited to, gas pressure, leak size and gas temperature. The use of Incus as a leak detector

is only recommended for pipelines running at pressures > 2 bar.

Incus uses four individual piezo-ceramic sensing heads, mounted using Emerson’s

patent-pending floating-crystal design. The sensor design makes the sensing heads

virtually indestructible and totally immune to temperature, moisture, and other

contaminants found in hazardous industry. Incus has a wide dynamic range which

facilitates use in a variety of applications from laboratories to turbine houses. The multistage amplifier ensures a linear output across the entire detector range without drop-off

at each end of range.

™

Incus is not designed to detect specific gas types or to measure percentage LEL or ppm

concentration level, but instead responds instantaneously to a wide range of leak sizes

while being unaffected by even the most extreme weather conditions. Incus is rated to

IP66 / IP67 to withstand harsh environments and continues to work during temporary

immersion.

Incus uses a continuous electronic background monitoring test feature to ensure

complete functionality. This testing is invisible to the user and does not interrupt the

normal detection operation of the sensor. Incus also has an optional heating facility which

enables the internal electronics to be kept within normal parameters with external

temperatures as low as -67 °F (-55 °C). (Even lower temperature operation is possible,

although cold startup cannot be guaranteed). The heater uses a proportional-control

scheme, meaning the unit can be kept within an optimal operating temperature range

while minimising the additional current draw from the incoming +24 V supply.

Incus has complete customer flexibility. The current-loop output can be factory configured

as source or sink, and the scale-factor can be configured to mimic other vendor’s detector

outputs. Also provided is a multi-drop RS485 diagnostic port using an Emersonproprietary protocol. Incus also features infrared communication, using the same

proprietary protocol, which allows parameter interrogation and setting ability from up to

8M range using a proprietary USB-IR interface adapter. This allows non-contact setup of

parameters after installation.

Incus with software version 2.6 onwards has HART® communication enabled by default.

Manual Supplement 9

Page 10

Product Overview Manual Supplement

December 2018 00809-0200-3003

10 Incus

Page 11

Manual Supplement Product Interfaces

00809-0200-3003 December 2018

4 Product Interfaces

4.1 Process interface

4.1.1 Sensor input channels

The Incus uses four floating piezo ceramic heads to detect a pressurised gas leak.

Information about the sensor channels can be found in the Incus Reference Manual.

4.2 Host interface

4.2.1 Analog output channel (current loop)

The Incus is wired as a three wire sensor using the terminals marked 0 V, +24 V, and mA

inside the terminal compartment. Detailed connection details can be found in the Incus

Reference Manual. The current-loop output is factory configured as either source or sink

mode (default is source). If the Incus is configured for source mode the current loop is

connected between mA (+) and 0 V (-) terminals. If using a sink mode Incus, the current

loop is connected between +24 V (+) and mA (-).

This current-loop output is configured to be proportional to the primary variable (dB SPL);

the specific 4-20 mA signal level and scale-factor details can be found in the Incus

Reference Manual. The scale factor varies according to the operating mode selected. The

manual also describes the device malfunction indications that are available, signalled by

specific DC current levels below 4 mA viz. 2 mA, 1 mA, and 0 mA. See Operation with

WirelessHART® Adapters for implications of using external WirelessHART® adapters with

this signalling scheme.

HART communication is supported on this loop. In order for HART to operate successfully,

the loop should be terminated with a resistor in the range of 100 – 500 ohms, generally in

the control room.

Note

The Incus current-loop output operates in Active mode, meaning the power to the loop is

provided by the sensor itself.

Manual Supplement 11

Page 12

Product Interfaces Manual Supplement

December 2018 00809-0200-3003

4.2.2 Relay outputs

The Incus has configurable relay outputs used to indicate a device fault and alarm

condition. These relay configurations are not accessible through the HART® interface.

Refer to the Incus Reference Manual for more information.

4.3 Local interfaces, jumpers, and switches

4.3.1 Local controls and displays

The Incus has a seven segment display to relay information back to the user. The displayed

information cannot be controlled by the HART® interface. More information is contained

in the Incus Reference Manual.

12 Incus

Page 13

Manual Supplement Device Variables

00809-0200-3003 December 2018

5 Device Variables

There are no device variables available to the user.

Manual Supplement 13

Page 14

Device Variables Manual Supplement

December 2018 00809-0200-3003

14 Incus

Page 15

Manual Supplement Dynamic Variables

00809-0200-3003 December 2018

6 Dynamic Variables

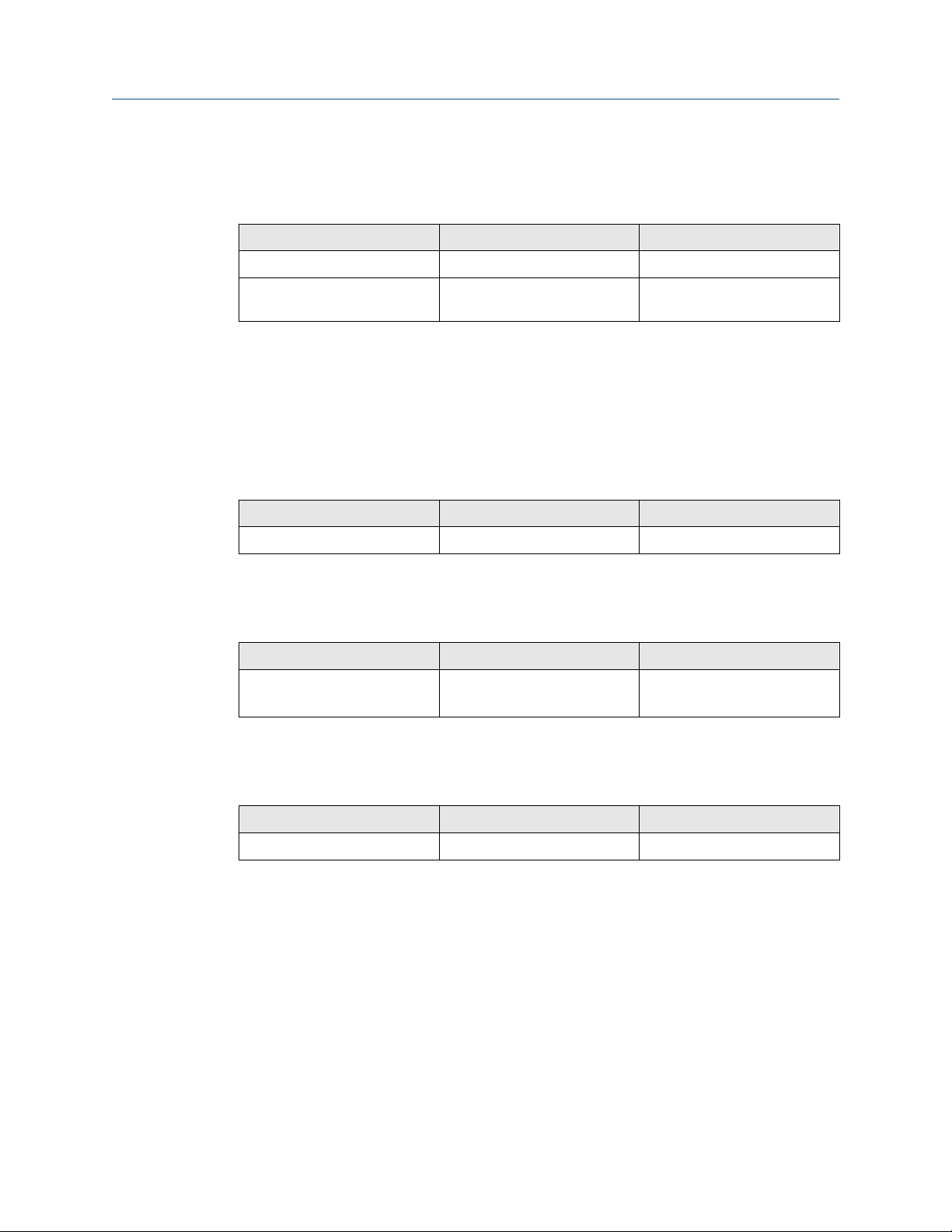

Table 6-1: HART® Variables Supported by the Incus

HART variable Description Units

Primary variable (PV) The dB reading seen on the main

sensor display and reported via the

4-20 mA current-loop, being the

sound pressure level in decibels (dB).

(2)

(2)

The temperature, in degrees Celsius,

or the internal sensor electronics.

The temperature, in degrees Celsius,

of the internal heater electronics.

Reports NaN if heater not fitted

(optional).

Secondary variable (SV)

Tertiary variable (TV)

(1) The current Incus Device Description (available from Emerson™) interprets the "manufacturer-specific unit code '240'" to

represent the symbol "dB".

(2) SV and TV are only supported for the Device Revision 2 onwards.

dB (240 unit code

°C

°C

(1)

)

Manual Supplement 15

Page 16

Dynamic Variables Manual Supplement

December 2018 00809-0200-3003

16 Incus

Page 17

Manual Supplement Status Information

00809-0200-3003 December 2018

7 Status Information

7.1 Device status

The device status byte, which is contained in the second data byte of the Incus reply to any

HART® command, is defined below.

Table 7-1: Device Status Bits to be Included into Each Incus HART Response

Bit mask Definition Incus conditions to be set

0x80 (bit 7) Device malfunction Set on detection of a device

malfunction.

0x40 (bit 6) Configuration changed Set whenever the unit configuration is

changed.

0x20 (bit 5) Cold start Set, for one transaction only, for each

master when device is powered up.

0x10 (bit 4) More status bits available Set whenever a bit detailed in the

additional device status is set

(1)

(alarm

, malfunctions).

0x08 (bit 3) Loop current fixed Set when loop current is parked

(3.5 mA)

0x04 (bit 2) Loop current saturated Not used by Incus.

0x02 (bit 1) Primary variable out of limits Not used by Incus.

0x01 (bit 0) Non-primary variable out of limits Not used by Incus.

(1) Device Revision 2 onwards

(1)

.

7.2 Extended device status

The extended device status byte, contained in byte 6 of command 48 response data byte,

contains the following bitwise status information.

Table 7-2: Extended Device Status Bits in Byte 6 of the Response Data Bytes for Command 48

Bit mask Definition Incus conditions to be set

0x80 (bit 7) Undefined N/A

0x40 (bit 6) Undefined N/A

0x20 (bit 5) Undefined N/A

0x10 (bit 4) Undefined N/A

0x08 (bit 3) Undefined N/A

0x04 (bit 2) Critical power failure Not used by the Incus.

0x02 (bit 1) Device variable alert Set if the device is in alarm condition.

0x01 (bit 0) Maintenance required Not used by the Incus.

Manual Supplement 17

Page 18

Status Information Manual Supplement

December 2018 00809-0200-3003

7.3 Additional device status (command 48)

This is the response returned by command 48. (Command 48 will normally be executed by

a host if bit 4 of the field device status byte is set in any command response, but can only

be executed independently).

Table 7-3: Additional Device Status (x = Undefined)

Byte Bit mask Incus condition to be set

0 0000 0001 Alarm active

0 0000 0010 Cleaning active - obsolete

0 0000 0100 Production test 10 minute counteractive

0 0000 1000 Low 24 V supply

0 0001 0000 High 24 V supply

0 0010 0000 Low 12 V supply

0 0100 0000 High 12 V supply

0 1000 0000 Blown warranty fuse

1 0000 0001 Low gain ping error head 0

1 0000 0010 Low gain ping error head 1

1 0000 0100 Low gain ping error head 2

1 0000 1000 Low gain ping error head 3

1 0001 0000 High gain ping error head 0

1 0010 0000 Ping order error

1 0100 0000 High/low gain comparison on Head 0

1 1000 0000 Over temperature/case temp sensor fault

2 0000 0001 Obsolete

2 0000 0010 Obsolete

2 0000 0100 Obsolete

2 0000 1000 Obsolete

2 0001 0000 Obsolete

2 0010 0000 Obsolete

2 0100 0000 Undefined

2 1000 0000 Undefined

3 xxxx xxxx Undefined

4 xxxx xxxx Undefined

5 xxxx xxxx Undefined

6 xxxx xx1x Alarm 1: Monitored sound level is in excess of the present

alarm threshold.

7 xxxx xxxx Undefined

18 Incus

Page 19

Manual Supplement Status Information

00809-0200-3003 December 2018

Table 7-3: Additional Device Status (x = Undefined) (continued)

Byte Bit mask Incus condition to be set

8 0000 0001 Undefined

8 0000 0010 Undefined

8 0000 0100 Undefined

8 0000 1000 Undefined

8 0001 0000 Voltage error

8 0010 0000 Temperature error

8 0100 0000 Cleaning error - obsolete

8 1000 0000 Undefined

9-24 0000 0000 Unused: Message truncated after bye 13 for HART® 5, 6,

and 7 cross-compatibility.

Manual Supplement 19

Page 20

Status Information Manual Supplement

December 2018 00809-0200-3003

20 Incus

Page 21

Manual Supplement Universal Commands

00809-0200-3003 December 2018

8 Universal Commands

All universal commands are supported, although command 6 (Write polling address) is not

fully supported for Device Revision 1.

Table 8-1: HART® Universal Commands Supported by Incus

Number Command name Supported by

Incus

0 Read unique identifier ✓ Device ID number

1 Read primary variable ✓ dB sound pressure level

2 Read current loop and percent of

range

3 Read dynamic variable and loop

current

6 Write polling address ✓

7 Read loop configuration ✓ Incus does not support multi-drop

8 Read dynamic variable classifications ✓ N/A

9 Read device variables with status ✓ Maximum of 4 variable slots available.

11 Read unique identifier associated with

a tag

12 Read message ✓ Returns data written by command 17.

13 Read tag, descriptor, date ✓ Returns data written by command 18.

14 Read primary variable transducer

information

✓ 4-20 mA output level

(1)

✓

(2)

✓ Device ID number (as command 0)

✓ N/A

Comment

4-20 mA output level and dB SPL level

(returns only the PV giving a total of 9

bytes response data).

Device Revision 2 onwards

operation for Device Revision < 2.

15 Read device information ✓ N/A

16 Read final assembly number ✓ Returns data written by command 19.

17 Write message ✓ N/A

18 Write tag, descriptor, date ✓ N/A

19 Write final assembly number ✓ N/A

20 Read long tag ✓ Returns data written by command 22.

21 Read unique identifier associated with

long tag

22 Write long tag ✓ N/A

(3)

38

Manual Supplement 21

Read configuration changed tag ✓ This command will reset the bit

✓ N/A

associated with the device issuing the

command.

Page 22

Universal Commands Manual Supplement

December 2018 00809-0200-3003

Table 8-1: HART® Universal Commands Supported by Incus (continued)

Number Command name Supported by

Comment

Incus

(3)

48

Read additional device status ✓ This returns the additional device

status bytes as detailed in Table 7-3.

(1) SV (case temperature) and TV (optional heater temperature) supported for Device Revision 2 and greater.

(2) This mode is restricted for Device Revision 1.

(3) Commands 38 and 48 were only introduced into the Universal Commands at HART 7 (HCF_SPEC-127 rev 7.0).

22 Incus

Page 23

Manual Supplement Common Practice Grounds

00809-0200-3003 December 2018

9 Common Practice Grounds

9.1 Supported commands

The Incus does not support any common practice commands.

9.2 Burst mode

The Incus does not support burst mode.

9.3 Catch device variable

The Incus does not support the catch device variable feature.

Manual Supplement 23

Page 24

Common Practice Grounds Manual Supplement

December 2018 00809-0200-3003

24 Incus

Page 25

Manual Supplement Device Specific Commands

00809-0200-3003 December 2018

10 Device Specific Commands

Table 10-1: HART® Device Specific Commands supported by Incus

Number Command name Supported by

Incus

134 Read alarm level ✓ Returns the alarm level set point.

136 Set alarm level

140 Read alarm delay ✓ Returns the alarm delay value.

142 Set alarm delay

143 Read alarm latch ✓ Reads the alarm latch value.

144 Set alarm latch

145 Read op-mode

147 Read heater enable ✓ Reads the heater enable setting.

161 Test current ✓ Sets a constant loop current for 10

(1) Device Revision 2 onwards.

(1)

(1)

(1)

(1)

✓ Sets level (db) at which alarm relay

✓ Sets time above alarm threshold

✓ Enables latching of generated alarm

✓ Reads the operating mode (mA out

Comment

trips.

before alarm generated.

(one shot). Also used to reset latched

alarm.

scale factor and fault signaling

options).

minutes.

10.1 Command 134: Read alarm level

Command 134 will return the dB SPL value at which an alarm condition will occur.

10.1.1

10.1.2 Response data bytes

Manual Supplement 25

Request data bytes

Table 10-2: Request Data Byes for HART® Command 134

Byte Format Description

None N/A N/A

Table 10-3: Response Data Bytes for HART® Command 134

Byte Format Description

0 Unsigned: 8 Alarm level in dB

Page 26

Device Specific Commands Manual Supplement

December 2018 00809-0200-3003

10.1.3 Command specific response codes

Table 10-4: Command Specific Response Codes for HART® Command 134

Byte Class Description

0 Success (0) No command specific errors

10.2 Command 136: Set alarm level

Command 136 will set the alarm trip point in dB SPL.

10.2.1 Request data bytes

Table 10-5: Request Data Bytes for HART® Command 136

Byte Format Description

0 Unsigned: 8 Level of alarm setpoint in dB.

Valid range: 40 - 200 dB

10.2.2 Response data bytes

Table 10-6: Response Data Bytes for HART® Command 136

Byte Format Description

0 Unsigned: 8 Alarm level in dB

10.2.3 Command specific response codes

Table 10-7: Command Specific Response Codes for HART® Command 136

Byte Class Description

0 Success (0) No command specific errors

0 Parameter too large (3) Requested alarm level > 200 dB

0 Parameter too small (2) Requested alarm level < 40 dB

10.3 Command 140: Read alarm delay

Command 140 will return the amount of time an alarm can be delayed before an alarm

condition is signalled.

10.3.1

Request data bytes

Table 10-8: Request Data Bytes for HART® Command 140

Byte Format Description

0 N/A N/A

26 Incus

Page 27

Manual Supplement Device Specific Commands

00809-0200-3003 December 2018

10.3.2 Response data bytes

Table 10-9: Response Data Bytes for HART® Command 140

Byte Format Description

0 ENUM 0 to 99 = 0 to 990 sec (in 10 sec

steps)

100 to 127: 0 to 27 sec (in 1 sec

steps)

10.3.3 Command specific response codes

Table 10-10: Command Specific Response Codes for HART® Command 140

Byte Class Description

0 Success (0) No command specific errors

10.4 Command 142: Set alarm delay

Command 142 will set the time the signal has to be continuously in excess of the alarm

threshold before an alarm is generated.

10.4.1

10.4.2 Response data bytes

Request data bytes

Table 10-11: Request Data Bytes for HART® Command 142

Byte Format Description

0 ENUM Enumerate list of alarm delays

Table 10-12: Response Data Bytes for HART® Command 142

Byte Format Description

0 ENUM 0 TO 99 = 0 to 990 sec (in 10

0 to 99 = 0 to 990 sec (in 10 sec

steps)

100 to 127 = 0 to 27 sec (in 1

sec steps)

sec steps)

100 to 127 = 0 to 27 sec (in 1

sec steps)

Manual Supplement 27

Page 28

Device Specific Commands Manual Supplement

December 2018 00809-0200-3003

10.4.3 Command specific response codes

Table 10-13: Command Specific Response Codes for HART® Command 142

Byte Class Description

0 Success (0) No command specific errors

0 Parameter too large (3) Requested alarm delay ENUM >

127

10.5 Command 143: Read alarm latch

Command 143 will return the alarm latch parameter.

10.5.1

Request data bytes

Table 10-14: Request Data Bytes for HART® Command 143

Byte Format Description

None N/A N/A

10.5.2 Response data bytes

Table 10-15: Response Data Bytes for HART® Command 143

Byte Format Description

0 ENUM 0 = Off

10.5.3 Command specific response codes

Table 10-16: Command Specific Response Codes for HART® Command 143

Byte Class Description

0 Success (0) No command specific errors

1 = On

28 Incus

Page 29

Manual Supplement Device Specific Commands

00809-0200-3003 December 2018

10.6 Command 144: Set alarm latch

Command 144 sets Incus in a 1-shot mode where an alarm event triggers and sets the

alarm relays; relays remain set until after power is cycled. This command can also be used

to reset the alarm latch after it has been triggered by an alarm event.

10.6.1 Request data bytes

Table 10-17: Request Data Bytes for HART® Command 144

Byte Format Description

None ENUM 0x00 = Off

0x01 = On

10.6.2 Response data bytes

Table 10-18: Response Data Bytes for HART® Command 144

Byte Format Description

0 ENUM 0 = Off/Reset

1 = On/Arm

10.6.3 Command specific response codes

Table 10-19: Command Specific Response codes for HART® Command 144

Byte Class Description

0 Success (0) No command specific errors

Parameter too large ENUM out of range

10.7 Command 145: Read operating mode

Command 145 will return the operating mode of the Incus sensor.

10.7.1

Request data bytes

Table 10-20: Request Data Bytes for HART® Command 145

Byte Format Description

None N/A N/A

Manual Supplement 29

Page 30

Device Specific Commands Manual Supplement

December 2018 00809-0200-3003

10.7.2 Response data bytes

Table 10-21: Response Data Bytes for HART® Command 145

Byte Format Description Scale factor

0 ENUM 0, 2 4 mA normal, 20 mA in-alarm

1 4 mA normal, 12 mA in-alarm

50 4 - 20 mA :: 56 dB to 104 dB

64, 65 4 - 20 mA :: 40 dB to 200 dB

70, 71 4 - 20 mA :: 40 dB to 120 dB

96, 97 4 - 20 mA :: 40 dB to 104 dB

10.7.3 Command specific response codes

Table 10-22: Command Specific Response Codes for HART® Command 145

Byte Class Description

0 Success (0) No command specific errors

10.8 Command 147: Read heater enable

Command 147 will return the heater enable parameter.

10.8.1

10.8.2 Response data bytes

Request data bytes

Table 10-23: Request Data Bytes for HART® Command 147

Byte Format Description

0 N/A N/A

Table 10-24: Response Data Bytes for HART® Command 147

Byte Format Description

0 ENUM 0 = Off

1 = Auto

2 = On

10.8.3 Command specific response codes

Table 10-25: Command Specific Response Codes for HART® Command 147

Byte Class Description

0 Success (0) No command specific errors

30 Incus

Page 31

Manual Supplement Device Specific Commands

00809-0200-3003 December 2018

10.9 Command 161: Set test current

Command 161 will enable and program a constant test current to be transmitted via the

4-20 mA loop for 10 minutes maximum. Test current can also be terminated via this

command.

10.9.1 Request data bytes

Table 10-26: Request Data Bytes for HART® Command 161

Byte Format Description

0 ENUM 0x00 = Off

0x01 = On

1 Unsigned: 8 0 - 200 :: 0 - 20 mA in 100 µA

increments. > 200 invalid.

10.9.2 Response data bytes

Table 10-27: Response Data Bytes for HART® Command 161

Byte Format Description

0 ENUM 0 = Off

1 Unsigned: 8 Programmed current in units of

10.9.3 Command specific response codes

Table 10-28: Command Specific Response Codes for HART® Command 161

Byte Class Description

0 Success (0) No command specific errors

Invalid selection (2) Invalid ENUM for On/Off

Parameter too large (3) Selected test current out of

1 = On

100 µA.

control

range

Manual Supplement 31

Page 32

Device Specific Commands Manual Supplement

December 2018 00809-0200-3003

32 Incus

Page 33

Manual Supplement Performance

00809-0200-3003 December 2018

11 Performance

11.1 Sampling rates

Please refer to the Incus Reference Manual for details of the measurement process.

11.2 Power-up

Upon power-up, a brief diagnostic check will run to ensure detector functionality. This

check will last for no more than 10 seconds. Once the check is completed, Incus will go

into normal operation using the factory/customer defaults specified at time of order or

signal any faults that may be present. No response to any HART® command is guaranteed

during the power-up phase.

More information on the power-up sequence is available in the Incus Reference Manual.

11.3 Reset

Command 42 (Device reset) is not supported.

11.4 Self-test

The Incus does not support command 41 (Self-test). A self-test is continuously performed

during the normal measurement cycle. Any errors or faults can be determined using

command 48 (Read additional device status). More information about the self-test can be

found in the Incus Reference Manual.

11.5 Command response times (TTO)

Table 11-1: Command Response Times

Minimum 0 ms

Typical 12 ms

Maximum 100 ms

Manual Supplement 33

Page 34

Performance Manual Supplement

December 2018 00809-0200-3003

11.6 Busy delayed response

The delayed response mechanism is not used.

11.7 Long messages

The longest message supported is the response to a command 9 (Read device variables

with status); this message can return a maximum of 37 bytes, dependent on the request

from the Master.

11.8 Non-volatile memory

EEPROM is used to hold sensor configuration data. The data is stored immediately

following a write command (e.g., command 17: Write messages).

11.9 Modes

Operating modes can only be changed by factory personnel.

11.10 Write protection

Write protection is not implemented on the Incus.

11.11 Damping

Damping is not implemented on the Incus.

34 Incus

Page 35

Manual Supplement Capability Checklist

00809-0200-3003 December 2018

A Capability Checklist

Table A-1: HART® Capability Checklist for Incus

Manufacturer, model, and revision Emerson™ Incus

Device type Ultrasonic detector

HART Revision 7.3

Device description (DD) available? Yes, not HCF registered at present.

Device type manager (DTM) available? Can be accessed using generic HART DTM.

Number and type of sensors 4 x piezo transducers

Number and type of actuators 0

Number and type of host side signals 1: 4-20 mA analog

Number of device variables 1 (3 for Device Revision 2 onwards)

Number of dynamic variables 0

Multiple dynamic variables? No

Number of common-practice commands 0

Number of device specific commands 9

Bits of additional device status 8

Alternative operating modes 0 field settable; 5 factory options

Burst mode? No

Write-protection? No

Manual Supplement 35

Page 36

Capability Checklist Manual Supplement

December 2018 00809-0200-3003

36 Incus

Page 37

Manual Supplement Default Configuration

00809-0200-3003 December 2018

B Default Configuration

Table B-1: HART® Default Configuration for Incus

Parameter Default value

Polling address 0

Unique identifier The unit serial number

Tag Incus

Descriptor Incus

PV units Decibels (dB) sent with unit code 240,

manufacturer specific

Number of response preambles 5

Manual Supplement 37

Page 38

Default Configuration Manual Supplement

December 2018 00809-0200-3003

38 Incus

Page 39

Manual Supplement Operation with WirelessHART® Adapters

00809-0200-3003 December 2018

®

C Operation with WirelessHART

Adapters

C.1 Two-wire (loop powered) WirelessHART

®

adapters

Owing to the use of sub 4 mA signalling levels for indication of fault conditions, the

standard operating modes of the Incus are not suitable for use with loop-powered

WirelessHART adapters, e.g., the Emerson™ THUM.

These wireless adapters generally have a minimum operating current level of 3.5 mA;

below this level, they are not guaranteed to have sufficient power to remain connected to

the wireless network. Within the Incus, special operating modes are provided in which the

low loop current signalling modes are inhibited. This may facilitate operation with this

type of wireless adapter. Alternatively, for Device Revision 2 and greater, loop current may

be parked at 3.5 mA, (via HART command 6) for wireless only operation. Contact Emerson

for further information.

C.2 Three-wire Ex d/Explosion Proof certified

WirelessHART® adapters

The Incus has been verified for operation with suitably certified WirelessHART adapters;

these adapters can be powered from a local DC source, e.g., the Mactek Bullet

wiring diagram is shown in Figure C-1 below. The loop termination resistor shown can be

mounted inside the Incus terminal enclosure, using a two-way splice block. Alternatively,

the resistor could be part of the Input card in the control room. The Bullet also has the

facility to switch its own termination resistor into the circuit, under control from a local

Emerson™ 475 handheld field terminal, AMS configuration software, or a device running

the Pactware FDT software and Bullet DTM.

(1)

. A typical

(1) May require a Bullet firmware update.

Manual Supplement 39

Page 40

DC POWER SOURCE

3 WIRE HART ENABLED FIELD DEVICE

(+)

(-)

TERMINAL

+24VDC

4-20mA OUTPUT

24v RETURN (0V)

MACTek Corporation

BULLET WirelessHART Adapter

DIRECT POWER

LOOP POWER

RETURN

HART

INTERNAL CHASSIS [EGND]

EXTERNAL CHASSIS [EGND]

BLACK

RED

WHITE

YELLOW

GRN/YEL

R1

340

®

Operation with WirelessHART® Adapters Manual Supplement

December 2018 00809-0200-3003

Figure C-1: Three-Wire HART Enabled Field Device Wiring Diagram

Connecting the Incus (Field Device) to a three-wire Ex d WirelessHART adapter. Option

shown uses a local termination resistor.

40 Incus

Page 41

Manual Supplement Customer Level and Service Level HART® Device-Specific Commands

00809-0200-3003 December 2018

D Customer Level and Service Level

HART® Device-Specific Commands

Table D-1: Published Device-Specific HART Commands (Customer Level)

Command Read/Write Software

version

134 Read > 2.1 Read alarm level N/A

136 Write > 2.1 Set alarm level Device Revision 02 onwards.

140 Read > 2.1 Read alarm delay N/A

142 Write > 2.1 Set alarm delay Device Revision 02 onwards.

143 Read > 2.1 Read alarm latch N/A

144 Write > 2.1 Set alarm latch Device Revision 02 onwards.

145 Read > 2.6 Read op-mode Device Revision 02 onwards.

147 Read > 2.1 Read heater enable N/A

161 Write > 3.3 Send test current Programmable fixed loop

Command name Notes

current, 10 minutes timeout.

0-20 mA in 100 µA increments.

Device Revision 02 onwards.

Table D-2: Service Level HART Commands (Not Supported in DD/DTM)

Command Read/Write Software

version

150 Write > 2.1 Request unlock key Used to request timed access

Command name Notes

token for service level write

commands.

146 Write > 2.6 Set op-mode Device Revision 02 onwards.

148 Write > 2.1 Set heater enable N/A

151 Read > 3.0 Read ping 0 level Device Revision 02 onwards.

152 Write > 3.0 Trim ping up/down Device Revision 02 onwards.

160 Write > 2.1 Write unlock key Used to unlock timed service

access. Send modified access

token to unlock.

Manual Supplement 41

Page 42

00809-0200-3003

Rev. AA

2018

GLOBAL HEADQUARTERS

6021 Innovation Blvd.

Shakopee, MN 55379

+1 866 347 3427

+1 952 949 7001

safety.csc@emerson.com

EUROPE

Emerson Automation Solutions

Neuhofstrasse 19a PO Box 1046

CH-6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

safety.csc@emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

google.com/+RosemountMeasurement

MIDDLE EAST AND AFRICA

Emerson Automation Solutions

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

+971 4 811 8100

+971 4 886 5465

safety.csc@emerson.com

©

2018 Emerson. All rights reserved.

ASIA-PACIFIC

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

Republic of Singapore

+65 6 777 8211

+65 6 777 0947

safety.csc@emerson.com

Loading...

Loading...