Rosemount HART Communication with Flame Detectors and HART Flame Junction Box Interface Manuals & Guides

Page 1

UVS & UVIRS Flame Detectors

Junction Box with HART Interface

Part Number: MAN-0119

HART COMMUNICATION

with

& HART Flame Junction Box interface

FLAME DETECTORS

USER MANUAL

Rev 1 August 2014

Page 2

IMPORTANT INFORMATION

This manual is for informational purposes only. Although every effort has been made to ensure the

correctness of the information, technical inaccuracies may occur and periodic changes may be made

without notice. Net Safety Monitoring Inc., assumes no responsibility for any errors contained within this

manual.

If the products or procedures are used for purposes other than as described in the manual, without

receiving prior confirmation of validity or suitability, Net Safety Monitoring Inc., does not guarantee the

results and assumes no obligation or liability.

No part of this manual may be copied, disseminated or distributed without the express written consent of

Net Safety Monitoring Inc.

Net Safety Monitoring Inc., products are carefully designed and manufactured from high quality

components and can be expected to provide many years of trouble free service. Each product is

thoroughly tested, inspected and calibrated prior to shipment. Failures can occur which are beyond the

control of the manufacturer. Failures can be minimized by adhering to the operating and maintenance

instructions herein. Where the absolute greatest of reliability is required, redundancy should be designed

into the system .

Warranty

Net Safety Monitoring Inc., warrants its sensors against defective parts and workmanship for a period of

24 months from date of purchase; other electronic assemblies for 36 months from date of purchase.

No other warranties or liability, expressed or implied, will be honoured by Net Safety Monitoring Inc.

Contact Net Safety Monitoring Inc or an authorized representative for details.

.

Contact Information

Net Safety Monitoring Inc.

2721 Hopewell Place NE

Calgary, AB

Canada

T1Y 7J7

Telephone: (403) 219-0688 Fax: (403) 219-0694

www.emersonprocess.com/safety

E-mail: safety.csc@emerson.com

© Net Safety Monitoring, Inc. 2014. All rights reserved.

MAN-0119 Rev 1 HART for Flame Page 1 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 3

Table of Contents

Important Information ................................................................................................................................... 1

Warranty ....................................................................................................................................................... 1

Contact Information ...................................................................................................................................... 1

SECTION 1: INTRODUCTION .................................................................................................................. 4

1.2 Unpack ................................................................................................................................................ 5

1.3 Mounting ............................................................................................................................................. 5

1.4 Installation Considerations .............................................................................................................. 5

1.5 Wiring ................................................................................................................................................. 5

1.6 Sealing................................................................................................................................................. 6

1.7 HART for Flame Dimensional Drawing ............................................................................................. 6

Figure 1: Dimensional Drawing (Measurements are in Inches and Millimeters) ................................ 6

SECTION 2: Operation ................................................................................................................................ 6

2.1 Current Loop power configurations .................................................................................................... 7

SECTION 3: Configuring the system .......................................................................................................... 8

3.1 Terminals designations for HART and HART/Relay model Junction Box ........................................ 8

Figure 2: HART Flame Junction Box board ......................................................................................... 8

3.1.1 Configuring the relays of HART /Relay Junction Box ................................................................ 9

SECTION 4: HART Connection and Communication .............................................................................. 10

4.1 HART Communicator connection .................................................................................................... 10

Figure 4: Direct HART Communication ............................................................................................ 10

Figure 5: Remote HART Communication via HART Port separation board ..................................... 11

4.2 HART Communication Protocol ...................................................................................................... 12

4.2.1 HART Menu Tree (Structure) .................................................................................................... 13

SECTION 5: Wiring and communication diagrams .................................................................................. 14

5.1 Current Loop power block diagrams ................................................................................................ 14

Figure 6: Current sink and source wiring. ........................................................................................... 14

5.2 Typical Field wiring diagrams .......................................................................................................... 15

5.2.1 IR3S-AH/AHR Non-Isolated current output wiring .................................................................. 15

Figure 7: IR3S-AHR Non Isolated current output wiring diagram .................................................... 15

5.2.2 IR3S-AH/AHR Isolated current output wiring .......................................................................... 16

Figure 8: IR3S-AHR Isolated current output wiring diagram............................................................. 16

5.2.3 UV/IRS-AH/AHR & UVS-AH/AHR Non-Isolated current output wiring ............................... 17

Figure 9: UV/IRS -AHR & UVS-AHR Non- Isolated current output wiring diagram ...................... 17

MAN-0119 Rev 1 HART for Flame Page 2 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 4

5.2.4 UV/IRS-AH/AHR & UVS-AH/AHR Isolated current output wiring ........................................ 18

Figure 10: UV/IRS-AHR & UVS-AHR Isolated current output wiring diagram ............................... 18

SECTION 6: Maintenance ......................................................................................................................... 19

6.1 Troubleshoot ..................................................................................................................................... 19

6.2 Spare Parts / Accessories .................................................................................................................. 19

6.3 How to Return Equipment ................................................................................................................ 20

Appendix A: Electrostatic Sensitive Device (ESD) .................................................................................... 21

Appendix B: Resistance Table .................................................................................................................... 22

Appendix C: Specifications and Approvals for HART Flame Junction Box ............................................ 23

MAN-0119 Rev 1 HART for Flame Page 3 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 5

SECTION 1: INTRODUCTION

1.1 Description

With the increase in demand for effective, interactive and non-intrusive systems, Net Safety has released

its HART for Flame product providing HART communication with distinct flame detectors. This involves

HART Communication with the Phoenix Triple IR, UV/IR and UV Flame Detectors along with the

Hydrogen Flame Detection line of UV and UV/IR Flame Detectors.

The introduction of HART Communication with flam e detecto rs allows convenient access to the Flame

Detector’s features and provides easy on the spot monitoring. This is important for effective and reliable

maintenance. Access to the HART menu structure and functions of the flame detector is gained by using

the HART Communicator. This may also be done using and any other HART communication devices that

are compatible with the enhanced device descript ion language (EDDL) of Net Safety’s Flame Detectors.

Product components:

This HART for Flame product has two component products; a flame detector with Analog /AnalogDigital output alongside a HART Communication Output inter fa ce . Th is HART Outpu t ci rcuitry is

enclosed in Net Safety’s Explosion Proof Multipurpose Junction Box and allows users to choose AnalogHart or Analog-Hart with Relays outputs. The HART for Flame product is available in Aluminum and

Stainless Steel.

Choice of flame detector:

The model flame detector used with the HART Output interface will depend on users’ choice and nature

of the application. In specific cases users may want to detect hydrogen based fi re s in which case the

UV/IRS-H2-A/AR or the UVS-H2-A/AR flame detector based HART for Flame product would be

suitable. In other cases users may want to use either the IR3S-A/AD, UV/IRS-A/AR or the UVS-A/AR

flame detector based HART for Flame product to detect Hy drocarbon based fires. Refer to available

models offered below.

Available Model HART for Flame Product (this includes HART Flame Junction Box interface):

UV/IRS-AH/AHR, UVS-AH/AHR, UV/IRS-H2-AH/AHR, UVS-H2-AH/AHR

ATEX models: UV/IRS-AH-X/AHR-X, UVS-AH-X/AHR-X, UV/IRS-H2-AH-X/AHR, UVS-H2-AHX/AHR-X

Both CSA/FM and ATEX models are available in Aluminum and Stainless Steel.

Available Model HART Flame Junction Box interface:

JB-MPHF-A (HART output, Aluminum version), JB-MPHF-S (HART output, Stainless Steel version),

JB-MPHFR-A (HART & Relay output, Aluminum version), JB-MPHFR (HART & Relay output,

Stainless Steel version).

System configuration:

After choosing the type of flame detector based on the HART for Flame product, the system should be

configured. This is done via DIP Switch 2 (SW2) located on the HART Flame Junction Box PCB. See

Table 1 when configuring the system.

MAN-0119 Rev 1 HART for Flame Page 4 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 6

1.2 Unpack

Carefully remove all components from the packaging. Check components against the enclosed packing

list and inspect all components for obvious damage such as broken or loose parts. If you find any

components missing or damaged, notify the representative or Net Safety Monitoring immediately.

1.3 Mounting

The HART Flame Junction Box has three ¾ inch-14 NPT conduit entries. The flame detector will be

connected to one of these entries. Connection of conduit and cable glands to remaining conduit entries

should be done so by use of appropriate tools. A 6mm Hex Key is required for installing or removing

conduit entry plugs. The junction box has mounting holes for installing directly on a wall or to a pole as

desired. The junction box is supplied with one ATEX stopping plug.

1.4 Installation Considerations

• Point flame detector toward where the flame is expected.

• Ensure an unobstructed view of the area to be monitored.

• Employ more than one flame detector and HART Flame Junction Box to ensure the hazard is fully

covered.

• Mount the flame detector and HART Flame Junction Box a few feet (about 1 metre) below the ceiling

so the flame detector can respond before being blocked by smoke accumulation at the ceiling.

• If dense smoke is likely to accumulate prior to flame (as in an ele ctric al fire ), supp lem ent flame

detector(s) with other protection such as Net Safety Monitoring Airborne Particle Monitor.

• The flame detector should be accessible for cleaning the window and reflector surfaces.

• Tilt the flame detector downward a minimum of 10 to 20

could obscure the detector’s viewing window.

• Securely mount the flame detector and HART Flame Junction Box so as to reduce vibration as much

as possible.

• When located outside, the flame detector’s sensitivity can be reduced by heavy fog, rain and/or ice.

• Consider shortening the time delay settings when smoke is expected to accumulate before or during a

fire. See relevant manual.

• Reduce sensitivity setting if false alarms, related to surrounding activities, occur.

• When installed near or on water (such as an off shore platform), be sure to take into account the low

horizon level when tilting detector downward.

For more on installation considerations on flame detectors refer to specific flame detector manual.

° to reduce dirt and dust accumulation wh ich

1.5 Wiring

Warning Wiring must comply with all applicable regulations relating to the installation of

electrical equipment in a hazardous area and is the responsibility of the installer. Proper shielding and

grounding procedures, for the specific area must be followed. Consult local electrical code and /or

qualified personnel before w iring .

Warning Do not open the HART Flame Junction Box or flame detector in a classified area (Do

not open when an explosive atmosphere may be present). The area should be de-classified prior to

opening.

MAN-0119 Rev 1 HART for Flame Page 5 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 7

1.6 Sealing

Warning To fully avoid any environmental exposure (water ingress), the use of seals is

recommended, especially for installations that use high-pressure or steam cleaning devices in proximity to

the HART Flame Junction Box and flame detector.

It is recommended that explosion-proof drains and conduit breathers be used. Changes in temperature and

barometric pressure can cause 'breathing' which allows moist air to enter conduit. Joints are seldom

enough to prevent 'breathing'.

Consult qualified personnel on sealing requirements relating to equipment, application and local

regulations.

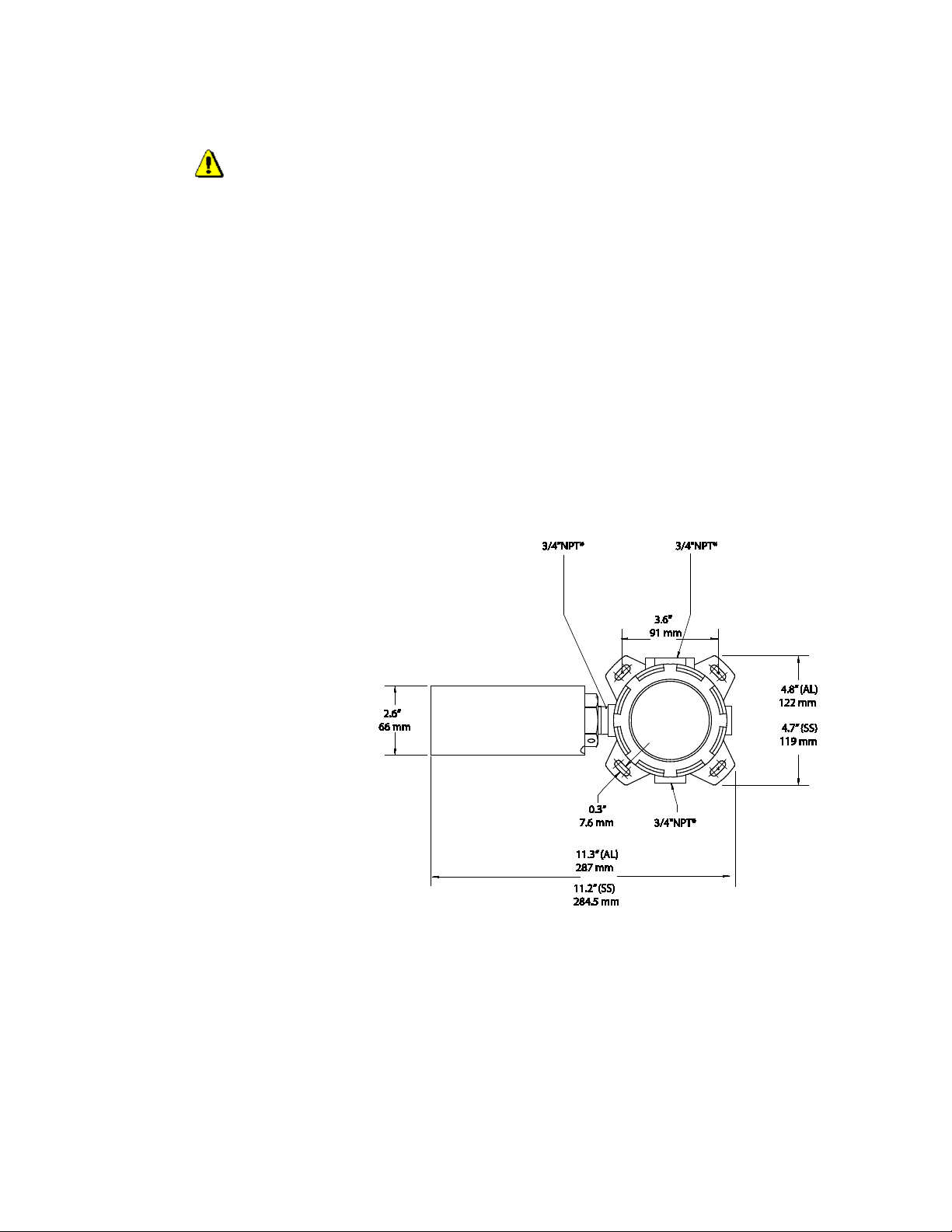

1.7 HART for Flame Dimensional Drawing

The drawing below shows the dimensions of the Aluminum (AL) and Stainless Steel (SS) models of the

flame detector with HART Flame Junction Box enclosure.

Figure 1: Dimensional Drawing (Measurements are in Inches and Millimeters)

Note: CSA/FM model shown

ATEX model has an ATEX locking collar

* M20 & ½” NPT threads also available

SECTION 2: Operation

The model flame detector will determine the model HART for flame unit being used. Specific

combinations of SW2 positions (DIP Switch 2 positions) have been assigned for each available type of

flame detector. Selecting DIP Switch 2 positions correctly will determine the operation of the unit. See

Table 1 and Figure 2 or Figure 3. Once the system has been powered up, confirm operation by referencing

the specific Flame Detector manual. Meter Test Jacks are available on the HART Flame Junction box

PCB to check and monitor the current output (4-20mA). If the HART / Relay model junction box is being

used, note that the relays are dry contacts and are Form C SPDT rated 5 Amperes at 30 VDC/250AC.

MAN-0119 Rev 1 HART for Flame Page 6 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 8

If the HART Communicator is to be placed in the current loop, ensure that the HART Jumper (J5) is in

the factory default position (pins jumpered), then place a 250 Ohm resistor in the current loop and connect

the communicator across the resistor. Refer to Figure 2 or Figure 3 along with Current Loop power block

diagrams and / or Typical Field wiring diagrams. If the HART Communicator is to be used with the

HART Port connector for direct or remote communication, see Section 4.

2.1 Current Loop power configurations

The two current loop power configurations available are the Non –Isolated power configuration and the

Isolated power configuration. When using the Non-Isolated power configuration (Non-Isolated current

loop), the Non –ISO / ISO select jumper (JP1) located on the HART Flame Junction box PCB should

remain in its default pos it io n . ‘ISO’ on the power terminal side is not used in this configuration. For the

Isolated power configuration (Isolated current loop), JP1 should be placed over pin 1 and pin 2 and a

separate power supply used to supply +24VDC to ‘ISO’ on the power terminal side. See figure 2 or figure

3 for JP1’s location. Also refer to Current Loop power block diagrams and / or Typical Field wiring

diagrams.

Note: By factory default JP1 (Non –ISO / ISO select jumper) is connected across pin 2 and pin 3 (NonIsolated power configuration). Also by factory default the HART Jumper (J5) is connected (pins are

jumpered).

MAN-0119 Rev 1 HART for Flame Page 7 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 9

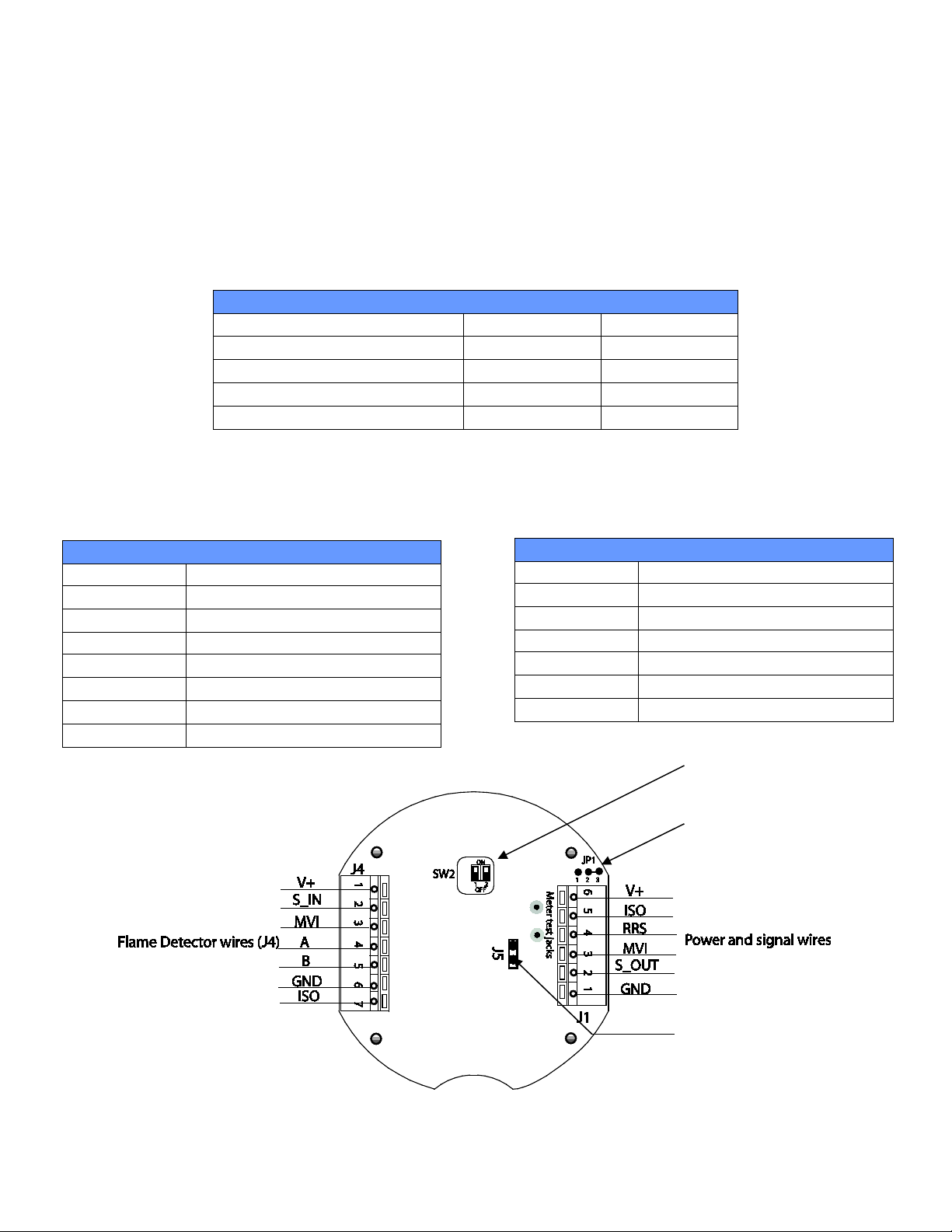

SECTION 3: Configuring the system

Flame Detector models and DIP Switch 2 (SW2) positions

Flame Detector models

(SW2)Position 1

(SW2)Position 2

IR3S-AD

ON

ON

UV/IRS-A, UVIRS-H2-A

ON

OFF

UVS-A, UVS-H2-A

OFF

ON

IR3S-A

OFF

OFF

Flame Detector Terminal (J4)wiring

Terminal J4

Designation/Function

1

V+ / VDC(+)

2

S_IN / 4-20 mA signal

3

MVI / MVI Test

4

A/communication

5

B/communication

6

GND / VDC(-)

7

ISO / Isolated V+

Power Terminal (J1) wiring

Terminal J1

Designation/Function

6

V+ / Power (+)

5

ISO/ Isolated V+

4

RRS/Alarm Reset

3

MVI / MVI Test

2

S_OUT / 4-20 mA signal

1

GND / Power (-)

SW2- detector configuration

DIP Switch

JP1- to select Non-Isolated or

configuration.)

J5- HART Jumper (default

When using the specific model flame detectors (IR3S-AD, UV/IRS-A, UV/IRS-H2-A, UVS-A, UVS-H2A, IR3S-A), corresponding SW2 (detector configuration DIP Switch located on HART Flame Jbox PCB)

positions have to be set. The correct combinations of position 1 and position 2 have to be made in order

to have proper operation of the flame detec tor and HART or HART/Relay model Junction Box. See Table

1 and Figure 2 or Figure 3.

Table 1: Configuring HART Flame Junction Box for specific Flame Detector

3.1 Terminals designations for HART and HART/Relay model Junction Box

Table 2: Flame Detector wiring Table 3: Power and output wiring

Figure 2: HART Flame Junction Box board

MAN-0119 Rev 1 HART for Flame Page 8 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Isolated power configurations

(default position - Pin 2 & 3

jumpered for Non-Isolated power

position - pins are jumpered)

Page 10

3.1.1 Configuring the relays of HART /Relay Junction Box

Coil and Latch Status

Fire Relay

Position 1

Position 2

De-Energized/Non-latching

ON

ON

Energized/Non-latching

ON

OFF

De-Energized/ Latching

OFF

ON

Energized/ Latching

OFF

OFF

Relay Terminals (J3)

Alarm Relay

Alarm Relay Contacts

Fault Relay

Fault Relay Contacts

A

NC

Normally Closed

F

NC

Normally Closed

A

C

Common

F

C

Common

A

NO

Normally Open

F

NO

Normally Open

Table 4: DIP Switch Positions (SW1)

SW1- Relay configuration

DIP Switch

Table 5: Relay Contact designations

J5- HART Jumper (default

SW2- detector configuration

DIP Switch

Note: Relays are Form C SPDT rated 5 Amperes at 30 VDC/250AC. Relays are dry contacts.

JP1- to select Non-Isolated or

configuration.)

DIP Switch 1 (SW1) is used to configure the relay coils and set the relay status. See Table 4 below.

Warning Do not open the HART Flame Junction Box or flame detector in a classified area.

Figure 3: HART /Relay Junction Box board

Isolated power configurations

(default position - Pin 2 & 3

jumpered for Non-Isolated power

MAN-0119 Rev 1 HART for Flame Page 9 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

position - pins are jumpered)

Page 11

SECTION 4: HART Connection and Communication

Flame Detector

Junction Box with HART interface

HART Communica t or

HART Communica t or

HART Port connector (HPT-001)

4.1 HART Communicator connection

The HART Communicator may be connected to the HART Flame Junction Box via the HART Port

connector. Refer to Figure 4. For remote HART communication, the HART Communicator is connected

to the Junction box interface via a HART Port connector and separation board (JB-MPH-A/S). See Figure

5. Refer to the HART Port connector manual (MAN-0083) and the Net Safety Multi-purpose Junction

Box manual (MAN-0081) during installation.

The HART Communicator may also be placed in the current loop wiring. Refer to Section 4. Place a 250

Ohm load resistor in the 4-20 mA current loop and connect the HART Communicator probes across the

resistor. Do not install a resistor within the HART interface junction box. The total current loop resistance

should be a maximum of 600 Ohms in order to have proper communication with the HART

Communicator.

Figure 4: Direct HART Communication

This drawing is a general representation in connecting the system.

The HART Port connecto r ground

wire should be connected to

intrinsically safe ground.

Probes/wires

Warning

grounded type barrier. The port requires this safe ground to divert the excess energy. The grounding of

the HART Port must meet local safety guidelines

Built within the HART Port connector are intrinsically safe barrier circuits, which are a

.

MAN-0119 Rev 1 HART for Flame Page 10 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 12

Figure 5: Remote HART Communication via HART Port separation board

HART Communica t or

HART Communica t or

HART Port connector

Conduit to PLC/DCS/RTU

Junction Box with HART interface

Flame Detector

JB-MPH-A/S

Conduit

To intrinsically safe ground inside

This drawing is a general representation in connecting the system.

the JB-MPH-A/S

Probes/wires

Warning Built within the HART Port connector are intrinsically safe barrier circuits which are a

grounded type barrier. The port requires this safe ground to divert the excess energy. The grounding of

the HART Port must meet local safety guidelines

Important note and Instructions

Note: Refer to The Net Safety Multipurpose Junction Box manual (MAN-0081) and HART Port

connector manual (MAN-0083) when wiring for remote communication.

Instructions: For remote HART communication, connect the HART Jumper (J5) located on the HART

Flame Junction Box terminal board, across the pins (jumper pins). See Figure 2 or Figure 3 for location of

the Jumper.

.

MAN-0119 Rev 1 HART for Flame Page 11 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 13

4.2 HART Communication Protocol

The HART protocol incorporates an “Enhanced Device Description Language”, (EDDL) that enables

HART instrument manufacturers to define and document their product in a consistent format. This format

is readable by handheld communicators, PC’s and other process interface devices that support EDDL.

For the Flame Detector- Junction Box Hart interface, handheld HART communicators, PC’s and other

process interface devices must support the latest 16 bits manufacture ID and 16 bits device type. For the

375 model HART Communicator the software version must be at least version 2.0.

Establishing HART Communication with the flame detector and HART Flame Junction Box.

1. Ensure system is wired properly, then power up the unit and ensure no faults are indicated.

2. If the HART Port connector connected to the junction box as an interface, unscrew the HART

Port connector’s protective cap.

3. Connect the HART Communicator non-polarized probes to the 2 non polarized HART Port

connector terminals.

4. If the HART Port connector is not used, ensuring the HART current loop jumper inside the

junction box is in place. Then put the HART communicator probes across a resistor (min. 250

Ohms) within the 4-20 mA loop wiring. The maximum loop resistance of the wiring should be

600 Ohms.

5. Turn on the HART Communicator and proceed to initiate communication. If not familiar with the

communicator, consult the specific HART Communicator manual for operating instructions.

Important Notes:

• Proper analog signal output termination and minimum loop resistance must be completed in

all cases to enable HART communication. Failure to provide proper analog signal output loop

resistance will preclude all HART communication.

• If the HART Communication is not programmed with specific DD or does not support 16 bits

IDs, the JB-MPFH can still connect to the communicator but in the Generic HART

communication mode. In this mode, HART communication with the system will be

established, but the Communicator will not recognize the system (unit). Generic HART

communication will not provide access to the JB-MPHF EDDL menu and important set-up,

diagnostics or operation functions.

If you cannot find Net-Safety or JB-MPHF under Net-Safety on your Communicator, the specific EDDL

is not programmed into communicator. Your HART Communicator will require an EDD L upgrade in

order to access all the JB-MPHF functions.

The HART Communication Foundation, (www.hartcomm.org

Library and programming sites for HCF Approved field communicators. A complete listing of the DD

Library is available for download and provides manufacturer and device type file identification.

See HART Menu Tree (Structure) on next page.

), manages the HCF Approved EDDL

MAN-0119 Rev 1 HART for Flame Page 12 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 14

4.2.1 HART Menu Tree (Structure)

Manufacturer Net Safety monitoring inc

MPHF series

Process

Device

PV Value xx mA

Test device

Signal condt

Manufacturer..... Net Safety Monitoring Inc

MPHF series

Long Tag....xx

Tag......xxxxxxxxxxxxxxx

Descriptor....xxxxxxxxxxxxxxx

Message....xxxxxxxxxxxxxxxx

Final asmbly num...xxxxxxxxxxxxxx

Fld dev rev....xxxxxxxxxxxxx

Software rev....xxxxxxxxxxxxx

Root menu

PV LRV..........0.0

PV URV ........20.0

PV rnge..........0.00%

Analog output

Loop current mode

Num reg preams …xx

Num resp preams…xx

PV…….4.00 mA

Loop Test

Date....xx/xx/xx

Time (HHMM)

*MVI*

Reset

Event date......xx/xx/xx

nt time.... HHMM

Most recent......xxxxxx

Status…xxxxxxxx

Start MVI

Flame unit type....xxxxxxxxxxxx (serial number

part number, manufacture date, unit version)

PV .........XX mA

Status.........Normal/xxx

variables

Diag/Service

Detail setup

Date and time

Review

Note: *The MVI function indicated in the above menu tree is not available for the IR3S-A models*. Also

Menus may exist when using communicator but should be ignored if they are not available in this menu

tree.

MAN-0119 Rev 1 HART for Flame Page 13 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

PV % rnge 0.00%

PV xx mA

Events log

Flame unit type....IR3S, UVS, UV/IRS

Status.....Normal/xxxxxxx

CLP Modbus output.....good/xxxxxxx

DIP switch settings.....good/xxxxxxx

Output condt

Device information

Model ..... JB-

Dev ID xxxxxx

Tag xxxxxxxxxxx

Long Tag xxxxxxxxxxxxxx

Descriptor xxxxxxxxxxxxxx

Message xxxxxxxxxxxxxx

Date xx/xx/xx

Final asmbly num xxxxxxx

Universal rev 7

Fld dev rev xx

Software rev xx

Poll addr xx

Loop current mode Disabled/Enabled

Num reg preams xx

Num resp preams xx

Loop Test

HART output

Model......JB-

Device ID.....xx

Date.....xx/xx/xx

Universal rev....xxxxxxxxxxxxxx

Flame Unit Information

Stop MVI

Eve

Event type....xxxxxxxx

Next log......xxxxxxxxx

Previous log..... xxxxxx

Poll addr……xx

Page 15

SECTION 5: Wiring and communication diagrams

5.1 Current Loop power block diagrams

Warning DIP Switch 1 position 4 on the IR3S-AD Flame Detector electronics, should remain in

the factory default position (OFF); do not change this position. Also do not change the position of the

current output jumper on the IR3S-A/AD electronics; the jumper should remain in the factory default

position (INT position). See IR3S Flame Detector manual.

Note the position of the Non-ISO / ISO select jumper (JP1) on the HART Flame Junction Box

interface for each configuration.

Figure 6: Current sink and source wiring.

MAN-0119 Rev 1 HART for Flame Page 14 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 16

5.2 Typical Field wiring diagrams

The following drawings are typical ways in wiring each flame detector and the HART/Relay Junction

Box using general wiring requirements. Consult qualified personnel on specific wiring requirements. Note

that alarms are wired in parallel in the examples shown.

Warning DIP Switch 1 position 4 on the IR3S-AD Flame Detector electronics, should remain in

the factory default position (OFF); do not change this position. Also do not change the position of the

current output jumper on the IR3S-A/AD electronics; the jumper should remain in the factory default

position (INT position). See IR3S Flame Detector manual.

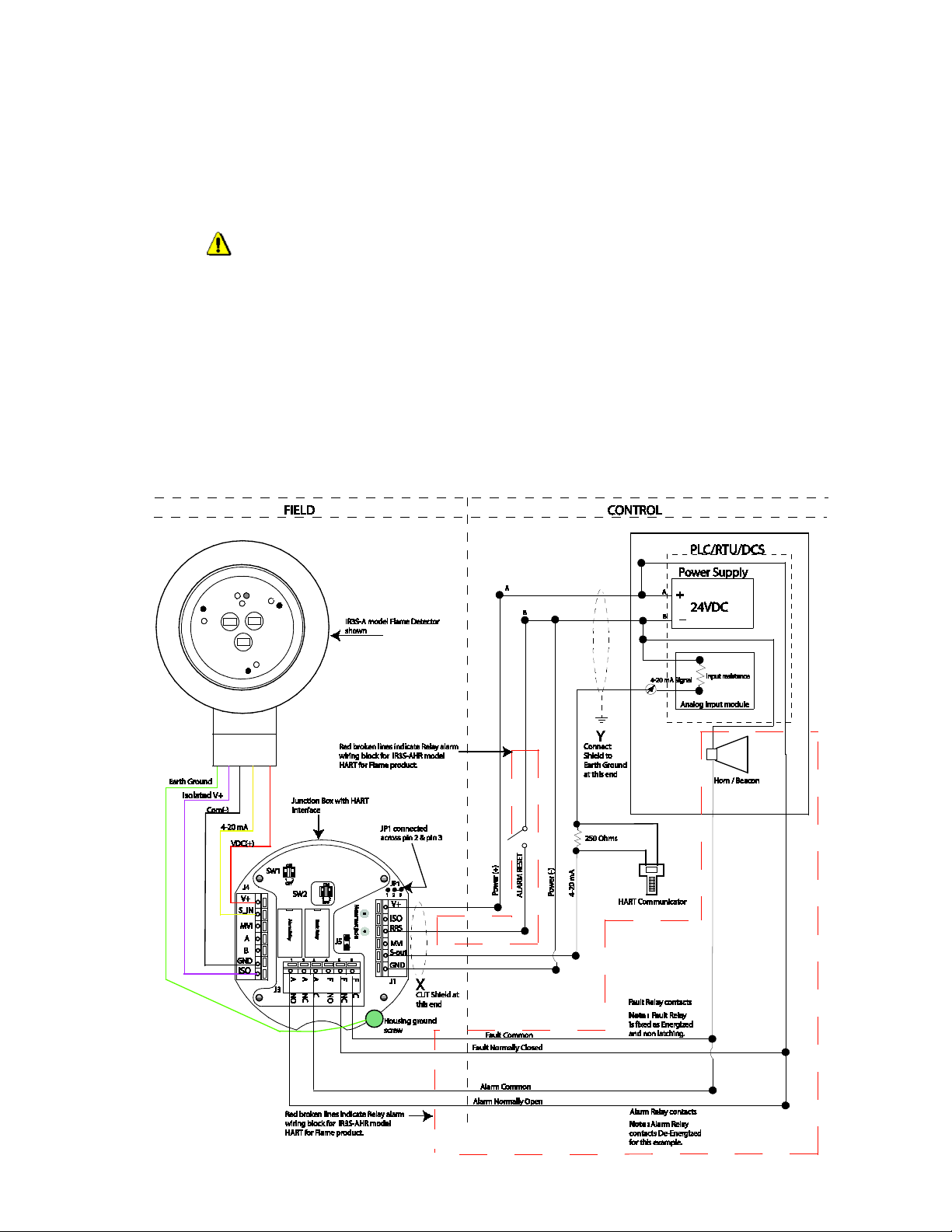

5.2.1 IR3S-AH/AHR Non-Isolated current output wiring

Wiring of the IR3S-AH and IR3S-AHR model HART for flame products is similar , except for the re lay

alarm wiring shown in broken red lines. Ignore this block if the IR3S-AH is being wired.

Note the position of the Non-ISO / ISO select jumper (JP1) on the HART Flame Junction Box

interface.

Figure 7: IR3S-AHR Non Isolated current output wiring diagram

MAN-0119 Rev 1 HART for Flame Page 15 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 17

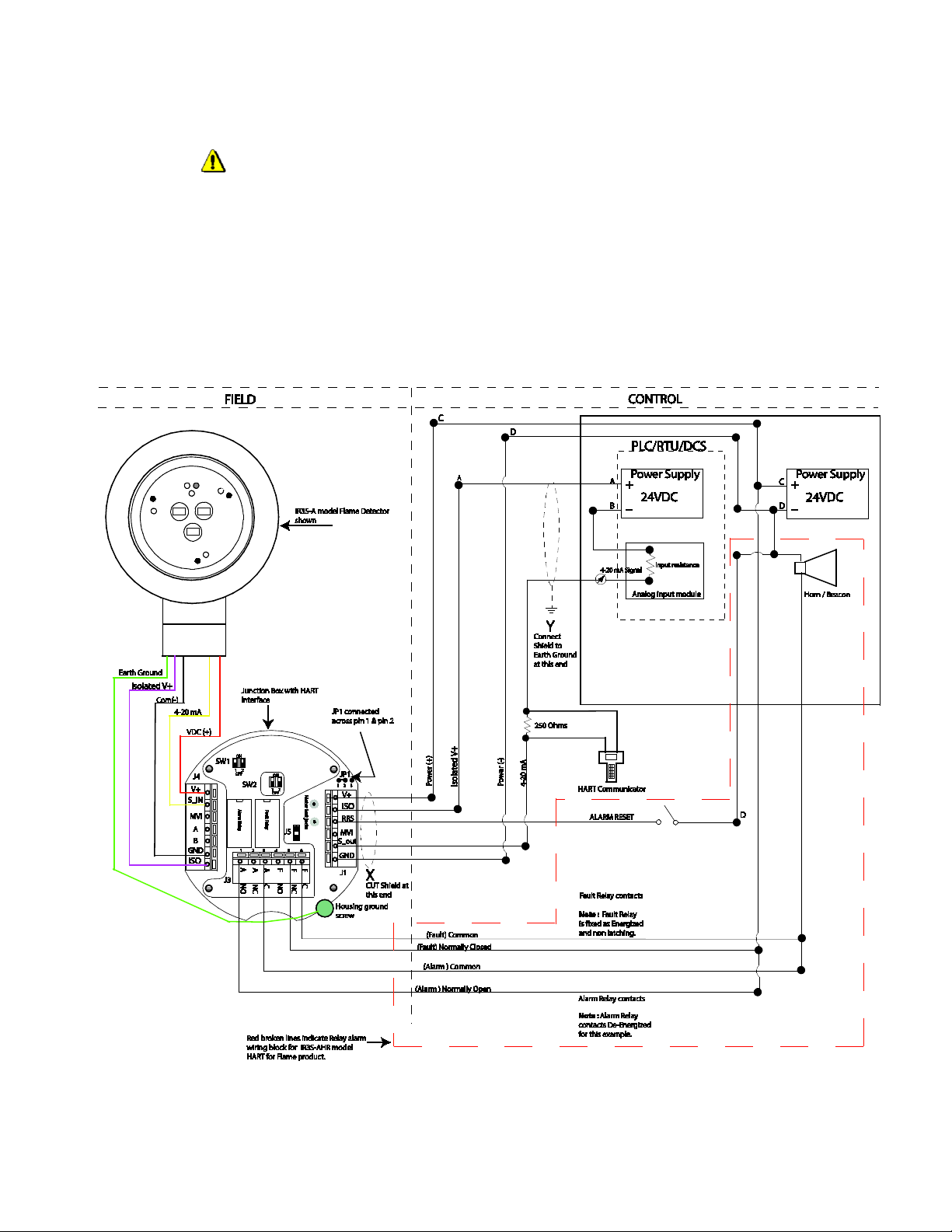

5.2.2 IR3S-AH/AHR Isolated current output wiring

Warning DIP Switch 1 position 4 on the IR3S-AD Flame Detector electronics, should remain in

the factory default position (OFF); do not change this position. Also do not change the position of the

current output jumper on the IR3S-A/AD electronics; the jumper should remain in the factory default

position (INT position). See IR3S Flame Detector manual.

Wiring of the IR3S-AH and IR3S-AHR model Hart for flame products is similar, except for the relay

alarm wiring shown in broken red lines. Ignore this block if the IR3S-AH model is being wired.

Note the position of the Non-ISO / ISO select jumper (JP1) on the HART Flame Junction Box

interface.

Figure 8: IR3S-AHR Isolated current output wiring diagram

MAN-0119 Rev 1 HART for Flame Page 16 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 18

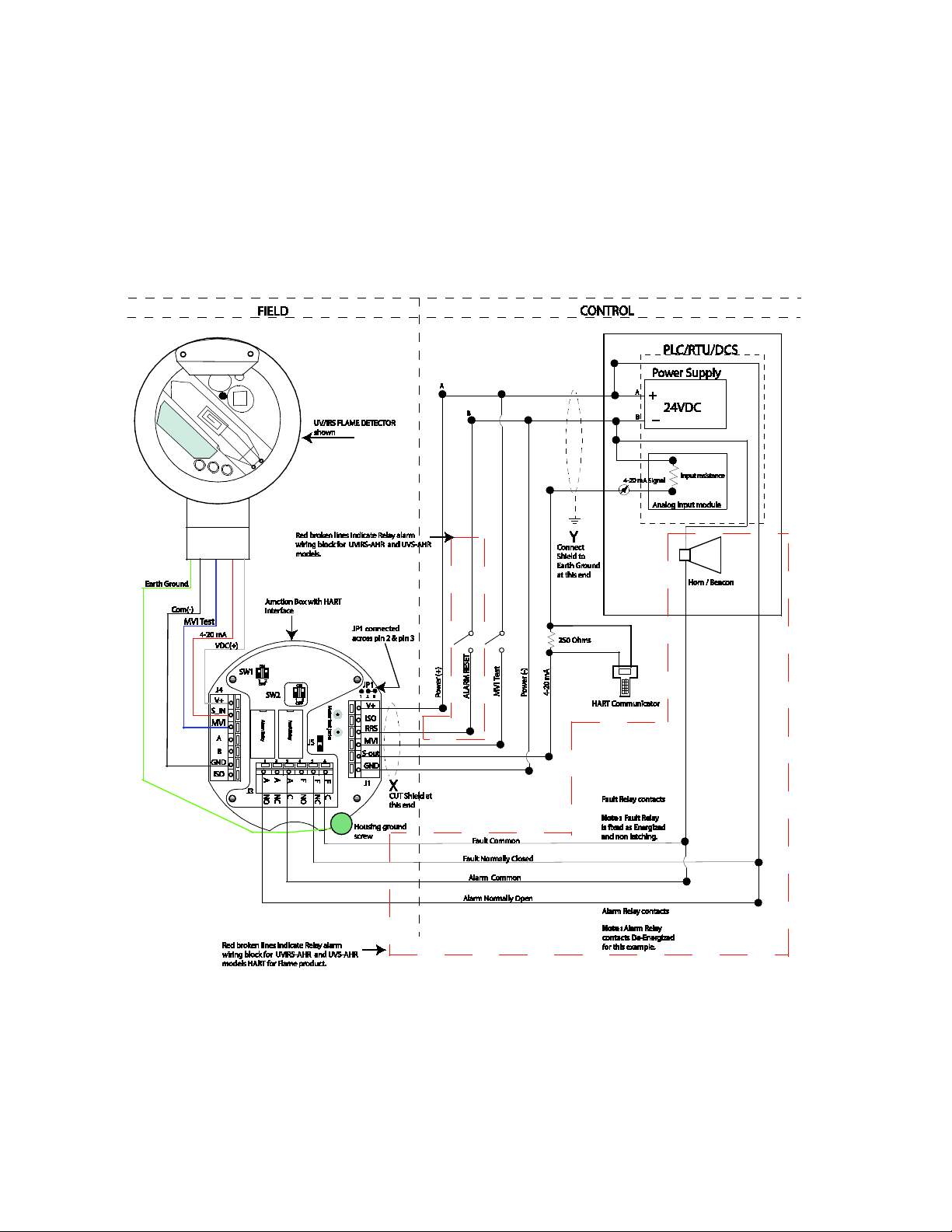

5.2.3 UV/IRS-AH/AHR & UVS-AH/AHR Non-Isolated current output wiring

Wiring of the UV/IRS-AH/AHR & UVS-AH/AHR HART for flame products is similar, except for the

relay alarm wiring shown in broken red lines. Ignore this block if the UV/IRS-AH or UVS-AH model is

being wired.

Note the position of the Non-ISO / ISO select jumper (JP1) on the HART Flame Junction Box

interface.

Figure 9: UV/IRS -AHR & UVS-AHR Non- Isolated current output wiring diagram

MAN-0119 Rev 1 HART for Flame Page 17 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 19

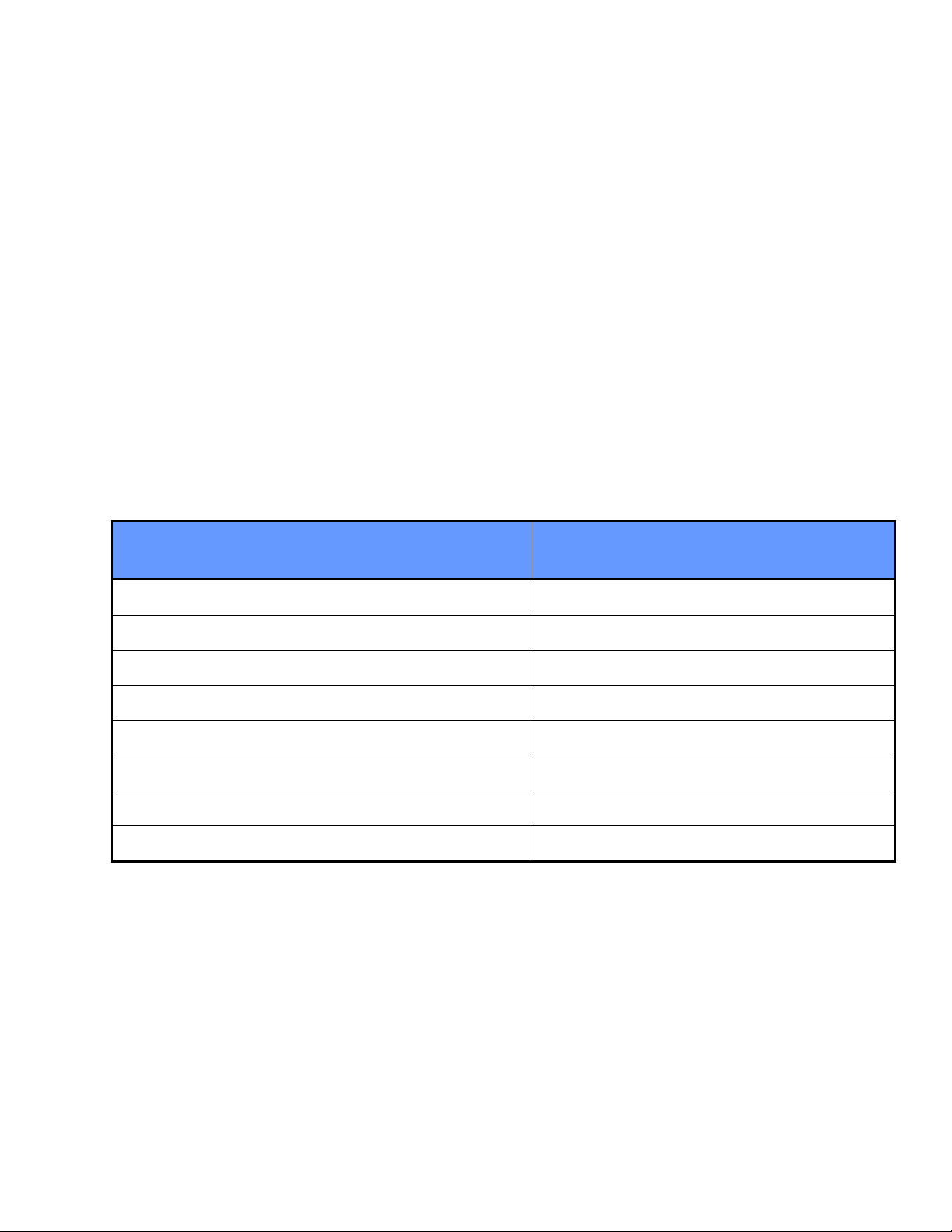

5.2.4 UV/IRS-AH/AHR & UVS-AH/AHR Isolated current output wiring

Wiring of the UV/IRS-AH/AHR & UVS-AH/AHR HART for flame products is similar, except for the

relay alarm wiring shown in broken red lines. Ignore this block if the UV/IRS-AH or UVS-AH model is

being wired.

Note the position of the Non-ISO / ISO select jumper (JP1) on the HART Flame Junction Box

interface.

Figure 10: UV/IRS-AHR & UVS-AHR Isolated current output wiring diagram

MAN-0119 Rev 1 HART for Flame Page 18 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 20

SECTION 6: Maintenance

Each type of flame detector performs an automatic visual integrity test on the optics to ensure there is no

obstruction on or near the detectors lens. Though this test is done, it is important to perform routine

maintenance checks and cleaning of the window/lens. It is recommended that cleaning be done with Net

Safety cleaning products. In addition to established maintenance rou tines, perform response tests on the

detector by using the appropriate Net Safety Test Lamp to simulate fire con d it ions. Refer to specific

flame detector and test lamp manuals when performing the above checks.

6.1 Troubleshoot

If a problem should develop, Check DIP Switch 2 (SW2) positions to confirm correct configuration, ref er

to specific flame detector manual and ensure all wiring is correctly done. If the problem remains refer to

“How to Return Equipment”.Net Safety Flame Detectors and HART Flame Junction boxes are not

designed to be repaired in the field.

Repairs to faulty or damaged equipment should only be performed at

the factory; otherwise warranty on the product will be voided.

6.2 Spare Parts / Accessories

Table 6: Available Spare Parts

Description Net Safety Part Number

Analog model IR3S Electronics IR3S-EMOD-A

Analog/Digital model IR3S Electronics IR3S-EMOD-AD

Analog model UV./IRS Electronics UV/IRS-EMOD-A

Analog model UVS-A Electronics UVS-EMOD-A

Analog model UV/IRS-H2-A Electronics UV/IRS-H2-EMOD-A

Analog model UVS-H2-A Electronics UVS-H2-EMOD-A

HART PCB for HART Flame Junction Box KIT-0505

Relay PCB for HART Flame Junction Box KIT-0506

MAN-0119 Rev 1 HART for Flame Page 19 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 21

6.3 How to Return Equipment

A Material Return Authorization number is required in order to return equipment. Please contact Net

Safety Monitoring at (403) 219-0688, before ret urning equip ment or consul t our Service Department t o

possibly avoid returning equipment.

If you are required to return equipment, include the following information:

1. A Material Return Authorization number (provided over the phone to you by Net Safety).

2. A detailed description of the problem. The more specific you are regarding the problem, the

quicker our Service Department can determine and correct the problem.

3. A company name, contact name and telephone number.

4. A purchase order, from your company, authorizing repairs or request for quote.

5. Ship all equipment, prepaid to: Net Safety Monitoring Inc.,

2721 Hopewell Place NE,

Calgary, Alberta, Canada, T1Y 7J7

6. Mark all packages: RETURN for REPAIR.

7. Waybills, for shipment outside Canada, must state: Equipment being returned for repair

All charges to be billed to the sender

Ensure a duplicate copy of the packing slip is enclosed inside the box indicating item 1 – 4 along with the

courier and account number for returning the goods.

Pack items to protect them from damage and use anti-static bags or aluminum-backed cardboard as

protection from electro-static discharge.

ALL equipment must be shipped prepaid. Collect shipments will not be accepted.

MAN-0119 Rev 1 HART for Flame Page 20 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 22

Appendix A: Electrostatic Sensitive Device (ESD)

Definition: Electrostatic discharge (ESD) is the transfer, between bodies, of an electrostatic charge

caused by direct contact or induced by an electrostatic field.

The most common cause of ESD is physical contact. Touching an object can cause a discharge of

electrostatic energy—ESD! If the charge is sufficient and occurs near electronic components, it can

damage or destroy those components. In some cases, damage is instantaneous and an immediate

malfunction occurs. However , symptoms are not always immediate—performance may be marginal or

seemingly normal for an indefinite period of time, followed by a sudden failure.

To eliminate potential ESD damage, review the following guidelines:

• Handle boards by metal shields—taking care not to touch electronic components.

• Wear grounded wrist or foot straps, ESD shoes or heel grounders to dissipate unwanted static

energy.

• Prior to handling boards, dispel any charge in your body or equipment.

• Ensure all components are transported and stored in static safe packaging

• When returning boards, carefully package in the original carton and static protective wrapping

• Ensure ALL personnel are educated and trained in ESD Control Procedures

In general, exercise accepted and proven precautions normally observed when handling electrostatic

sensitive devices. A warning label is placed on the packaging, identifying product using electrostatic

sensitive semiconductor devices.

MAN-0119 Rev 1 HART for Flame Page 21 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 23

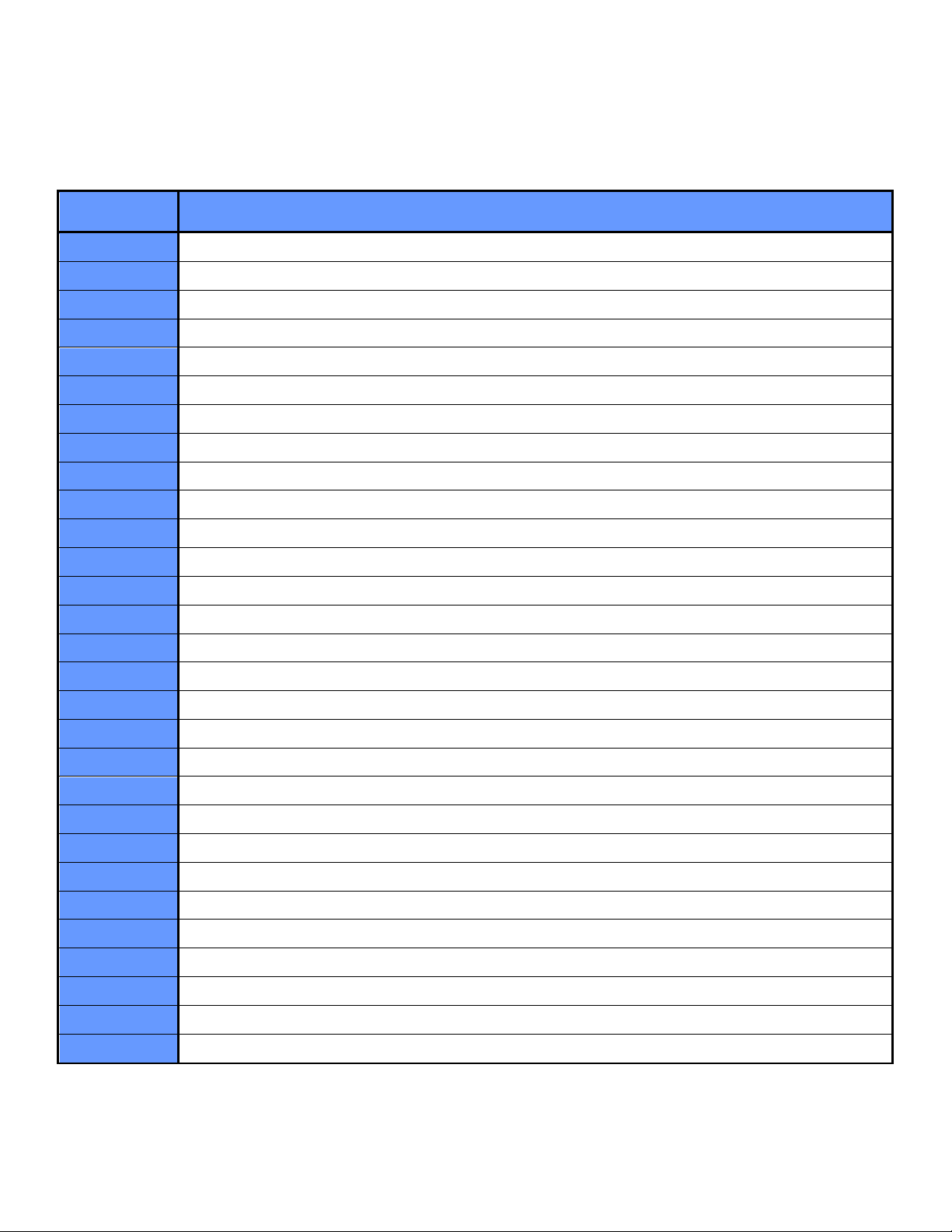

Appendix B: Resistance Table

Distance

(Feet)

Table 7: Wire resistance with distance and gauge

AWG #20 AWG #18 AWG #16 AWG #14 AWG #12 AWG #10 AWG #8

100

200

300

400

500

600

700

800

900

1000

1250

1500

1750

2000

2250

2500

1.02 0.64 0.40 0.25 0.16 0.10 0.06

2.03 1.28 0.80 0.51 0.32 0.20 0.13

3.05 1.92 1.20 0.76 0.48 0.30 0.19

4.06 2.55 1.61 1.01 0.64 0.40 0.25

5.08 3.20 2.01 1.26 0.79 0.50 0.31

6.09 3.83 2.41 1.52 0.95 0.60 0.38

7.11 4.47 2.81 1.77 1.11 0.70 0.44

8.12 5.11 3.21 2.02 1.27 0.80 0.50

9.14 5.75 3.61 2.27 1.43 0.90 0.57

10.20 6.39 4.02 2.53 1.59 1.09 0.63

12.70 7.99 5.03 3.16 1.99 1.25 0.79

15.20 9.58 6.02 3.79 2.38 1.50 0.94

17.80 11.20 7.03 4.42 2.78 1.75 1.10

20.30 12.80 8.03 5.05 3.18 2.00 1.26

22.80 14.40 9.03 5.68 3.57 2.25 1.41

25.40 16.00 10.00 6.31 3.97 2.50 1.57

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

9000

10000

Resistance shown is one way. Thi s fi gure sho uld be doubled when determining closed loop resistance.

30.50 19.20 12.00 7.58 4.76 3.00 1.88

35.50 22.40 14.10 8.84 5.56 3.50 2.21

40.60 25.50 16.10 10.00 6.35 4.00 2.51

45.70 28.70 18.10 11.40 7.15 4.50 2.82

50.10 32.00 20.10 12.60 7.94 5.00 3.14

55.80 35.10 22.10 13.91 8.73 5.50 3.46

61.00 38.30 24.10 15.20 9.53 6.00 3.77

66.00 41.50 26.10 16.40 10.30 6.50 4.08

71.10 44.70 28.10 17.70 11.10 7.00 4.40

76.10 47.90 30.10 19.00 12.00 7.49 4.71

81.20 51.10 23.10 20.20 12.70 7.99 5.03

91.40 57.50 36.10 22.70 14.30 8.99 5.65

102.00 63.90 40.20 25.30 15.90 9.99 6.28

MAN-0119 Rev 1 HART for Flame Page 22 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 24

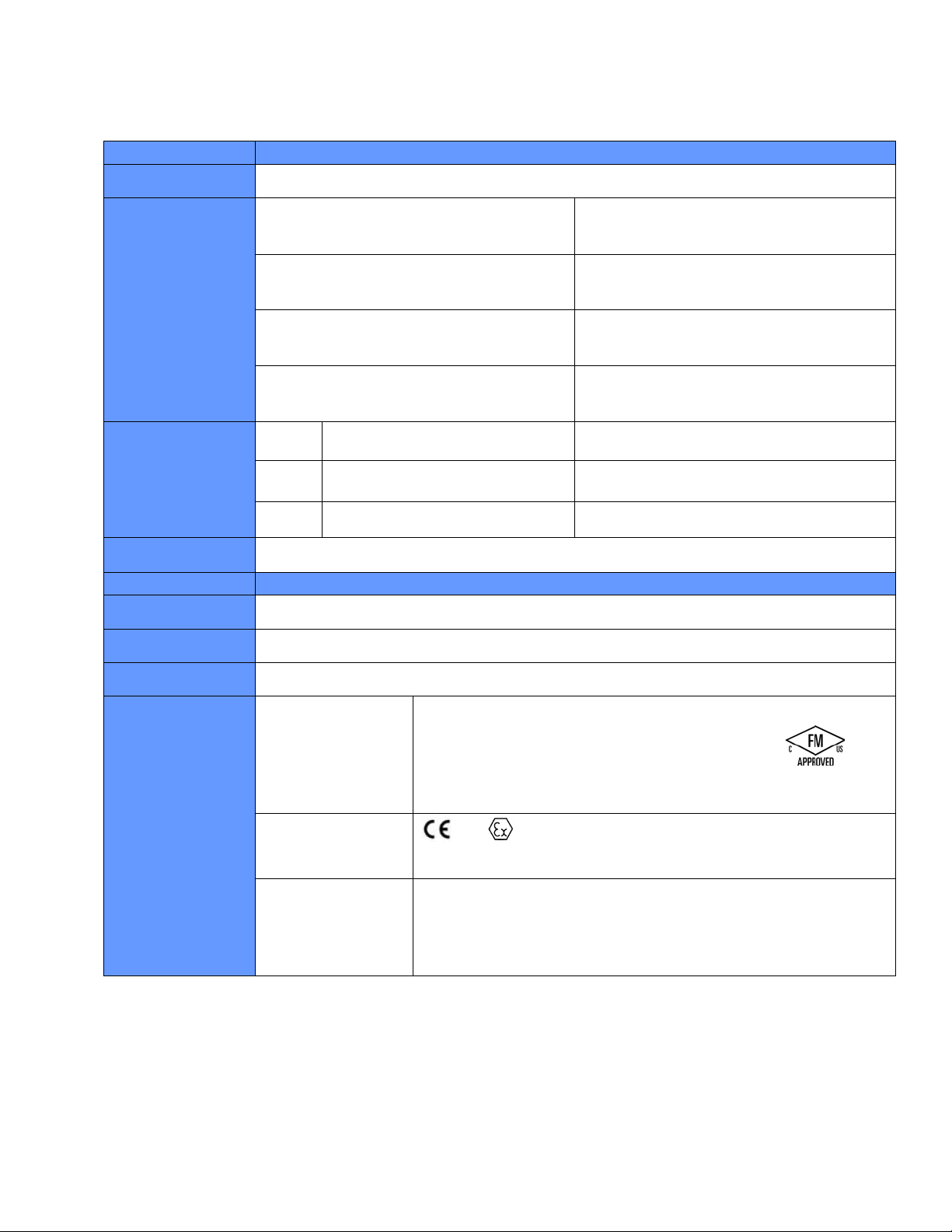

Appendix C: Specifications and Approvals for HART Flame Junction Box

Specification

HART for Flame Junction Box Electronics

Specification

Junction Box

FM07ATEX0044

Electrical Rating

Power Consumption

Power Consumption

with Flame Detector

Temperature

Metallurgy

IR3S

UV/IRS

UVS

Operation Voltage: 18 to 32 VDC

HART MODEL

At 18VDC: Nominal 33mA/0.6W

Max 67mA/1.2W

At 24 VDC: Nominal 26mA/0.6W

Max 58mA/1.4W

At 32 VDC: Nominal 22mA/0.6W

Max 53mA/1.7W

2.84W @ 24Vdc 3.44W @ 24Vdc

4.16W @ 24Vdc 4.76W @ 24Vdc

4.16W @ 24Vdc 4.76W @ 24Vdc

-40°C to +75°C (electronics)

HART/RELAY MODEL

(Relays are rated 5A at 30VDC/250AC. Relays are

Form C SPDT, dry contacts)

At 18VDC: Nominal 53mA/0.95W

Max 105mA/1.9W

At 24VDC: Nominal 41mA/0.98W

Max 83mA/2.0W

At 32VDC: Nominal 33mA/1.1W

Max 68.8mA/2.2W

Aluminum or 316 SS

Weight

NEMA / IP Rating

North American

Approvals

ATEX

IECEx

Aluminum: 0.8 Kg / 2.0 lbs (316 SS 1.6 Kg / 3.5lbs)

NEMA 4X, IP67

Class 1 Division 1 Groups BCD, T5

Class 1 Zone 1 Ex d IIB +H2 T5 (Canada)

Class 1 Zone 1 AEx d IIB +H2 T5 (USA)

-55°C ≤ Ta + 85°C

NEMA Type 4X/IP67

0575 II 2G Ex d IIB+H2 T5 Gb

-55°C to +85°C, IP67

EX d IIB+H2 T5

-55°C ≤ Ta + 85°C IP 67

IEC 60079-0:2011/IEC 60079-1:2007

IECEx FMG 14.0009X

MAN-0119 Rev 1 HART for Flame Page 23 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 25

Notes:

MAN-0119 Rev 1 HART for Flame Page 24 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 26

Notes:

MAN-0119 Rev 1 HART for Flame Page 25 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 27

Notes:

MAN-0119 Rev 1 HART for Flame Page 26 of 28

© Copyright Net Safety Monitoring, Inc. 2014 All Rights Reserved

Page 28

Net Safety Monitoring Inc.

2721 Hopewell Place NE, Calgary, AB Canada T1Y 7J7

1-866-FIREGAS (347-3427) | ph. (403) 219-0688 | fx. (403) 219-0694

www.emersonprocess.com/safety | Email: safety.csc@emerson.com

Loading...

Loading...