Reference Manual

303041EN, Edition 1/Rev. B

September 2007

TankMaster

Batch Handling

www.rosemount-tg.com

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

Rosemount Tank Radar REX

Rosemount Tank Radar REX

Tank Gauging System

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

For equipment service or support needs, contact your local Emerson Process

Management/Rosemount Tank Gauging representative.

The contents, descriptions and specifications within this manual is subject to change

without notice. Rosemount TankRadar AB accepts no responsibility for any errors that may

appear in this manual.

Cover Photo: TM_BatchHandling_Ed1_303041.jpg

www.rosemount-tg.com

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

TankMaster Batch Handling

Table of Contents

SECTION 1

Getting Started

SECTION 2

General

SECTION 3

System Configuration

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Definitions and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 Overview of the batch process . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2.1 Start and logon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 The WinOpi workspace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.1 Main window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Folders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.3 Batches menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.4 Tools menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3 Icons used in TankMaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3.1 Batch Server Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Batch Units and Ranges . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.3 Alert and Alarm Settings . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.4 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.5 Configure Tank Servers . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.6 Assign Tank Colors . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.7 Customize Parameters. . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.8 Parcel settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.9 Batch Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.10 User Access Levels . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 Product Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 User accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

SECTION 4

Batch Setup Phase

SECTION 5

Delivery Phase

SECTION 6

General tasks

4.1 Create new batch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Assign Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 Open/start parcel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

5.1 Monitor and log batch running data . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 Batches overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.3 Batch status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Parcel manual closing data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Close and complete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

6.1 Recalculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 System Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3 Print Unofficial Batch Summary Report . . . . . . . . . . . . . . . . . . . 6-3

6.4 Print Unofficial Delivery Ticket. . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.5 View Batch Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

www.rosemount-tg.com

TankMaster Batch Handling

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

6.6 View Batch Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.7 Batch Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.8 Release Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.9 Print Ticket and Batch Summary Report . . . . . . . . . . . . . . . . . . 6-7

6.10 Connect Batch Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.11 Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.12 Disconnect Batch Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.13 Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

APPENDIX A

Configure Batch Server

A.1 Batch Units and Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.2 Alert and Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

A.3 Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A.4 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A.5 Configure Tank Servers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

A.6 Assign Tank Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

A.7 Customize Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-10

A.8 Parcel settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-11

A.9 Batch Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

A.10 User Access Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

TOC-2

Table of Contents

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

Rosemount Tank Radar REX

Section 1 Getting Started

1.1 INTRODUCTION This document describes how to operate the TankMaster WinOpi batch

handling system developed by Emerson Process Management/Rosemount

Tank Gauging.

The batch handling system is an extension to the existing TankMaster system.

It provides you with powerful functions for setup, monitoring, alarm handling,

backup, reports, recalculation of delivery tickets and redundancy. There are

also optional functions available (require a hardware key) allowing you to

save batches in a MS Access database up to 365 days, and a transfer

calculator for planning new batches.

For instructions how to install, configure and use the TankMaster system, see

TankMaster WinSetup User’s Guide [Ref. no. 303027 E] and TankMaster

WinOpi User’s Guide [Ref. no. 303028 E].

Additional installation must be made for the batch handling system.

The TankMaster Administrator program is automatically started by the

operating system. The Administrator program has an Autostart function which

automatically starts up various TankMaster programs.

1.2 HELP A help function is available under Help in the main menu and when pressing

the F1 button or the button in different windows.

1.3 DEFINITIONS AND ABBREVIATIONS

Abbreviation Explanation

bbl Blue Barrel

FWL Free Water Level

FWV Free Water Volume

GOV Gross Observed Volume

GSV Gross Standard Volume

LAN Local Area Network

NSV Net Standard Volume

RTG Radar Tank Gauge

TOV Total Observed Volume

VCF Volume Correction Factor

WIA Weight in air

WIV Weight in Vacuum

For more information about the abbreviations, see TankMaster WinOpi User’s

Guide [Ref. no. 303028 EN].

www.rosemount-tg.com

TankMaster Batch Handling

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

1.4 OVERVIEW OF THE BATCH PROCESS

TankMaster lets you create and supervise Batch transfers between source

and target tanks. A Batch can be transferred between a plant and a ship or

truck, or between tanks within a plant.

A Batch can be divided into smaller units, so called Parcels. It may consist of

several Parcels allowing you to, for example, use several source tanks to fill

up a single target tank.

In order to create, start and close a Batch you have to make certain

configurations of the system, see chapter Section 3 System Configuration for

more information about the configuration steps.

During the batch process, alarms and messages about important events in

the system are shown to the operator, see chapter 5.1 Monitor and log batch

running data and chapter 6.5 View Batch Messages for more information.

All reports in the system are pre-configured according to customized

templates. These templates can be edited with MS Notepad or a standard

HTML editor. The system will automatically generate the following reports:

• Opening ticket

• Closing ticket

• Batch summary report

The report layout is depending on the chosen Movement Type. The Opening

Ticket and Closing Ticket must be signed before opening and closing the

parcel/batch.

NOTE!

It is possible to disable signatures, see section Appendix A: Defaults for more

information.

1-2

Section 1. Getting Started

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

TankMaster Batch Handling

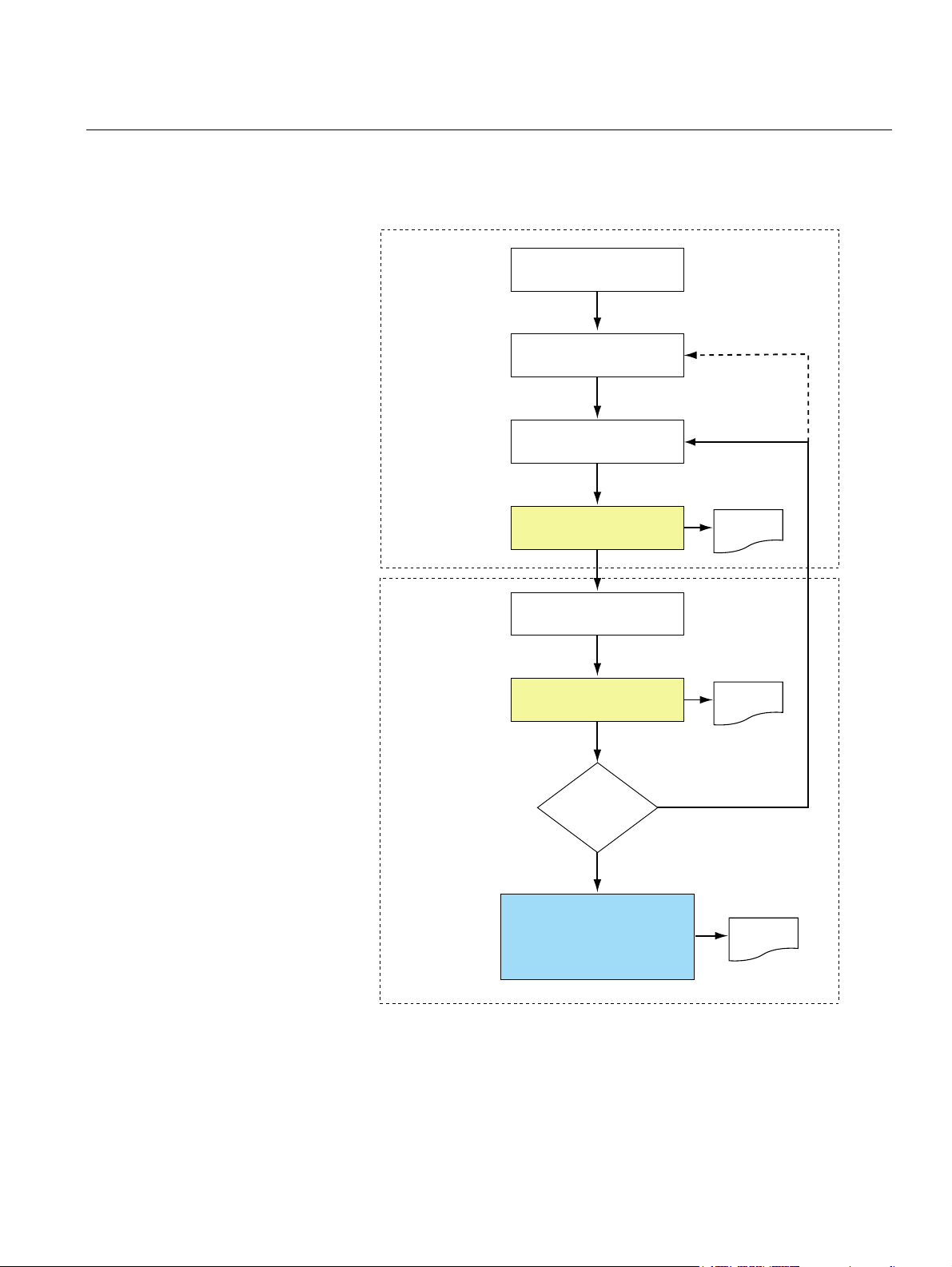

Figure 1-1. Batch handling

flowchart

Figure 1-1 below shows the different steps

Open/start phase

Create Batch

Assign Tanks

Enter parcel manual

opening data

Open and Start Parcel

Delivery phase

Enter parcel

manual closing data

(1)

in the batch transfer process:

(1)

Opening

ticket

Close and Complete

(1)

Parcel

Open parcels?

No

Enter Batch Closing Data,

Close and Complete Batch

(1) “Open and Start Parcel”, “Close and Complete Parcel”, and “Enter Batch Closing Data,

Close and Complete Batch” can be divided into separate steps. See section Appendix A:

Defaults for more information.

Yes

(1)

Delivery

ticket

Batch

Summary

Section 1. Getting Started

1-3

TankMaster Batch Handling

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

1-4

Section 1. Getting Started

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

Rosemount Tank Radar REX

Section 2 General

2.1 START AND LOGON 1. To open the WinOpi client, double click on the WinOpi icon on the

desktop. The application will start and the Logon to TankMaster window

will be displayed.

Figure 2-1. The Logon window

2. Log on with your user name and password. The password is case

sensitive but the user name is not.

In the User name drop down menu you can see the user names of

previous users.

NOTE!

If logging on fails five times the user account is disabled. In this case the user

account has to be enabled by an administrator.

To administer user accounts, set required access levels, change protection

level of separate windows, change password or to change inactivity time-out,

see chapter User Management in the TankMaster WinOpi User´s Guide.

www.rosemount-tg.com

TankMaster Batch Handling

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

2.2 THE WINOPI WORKSPACE

For more information about the folders and menus in the Main window, see

TankMaster WinOpi User´s Guide [Ref. no. 303028 EN].

2.2.1 Main Window Configuration and operation of tanks, batches and parcels is handled in the

WinOpi main window in the TankMaster system. In order to use the Batch

Handling system, select the Batches tab in the WinOpi workspace.

Figure 2-2. WinOpi main window

2-2

Section 2. General

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

TankMaster Batch Handling

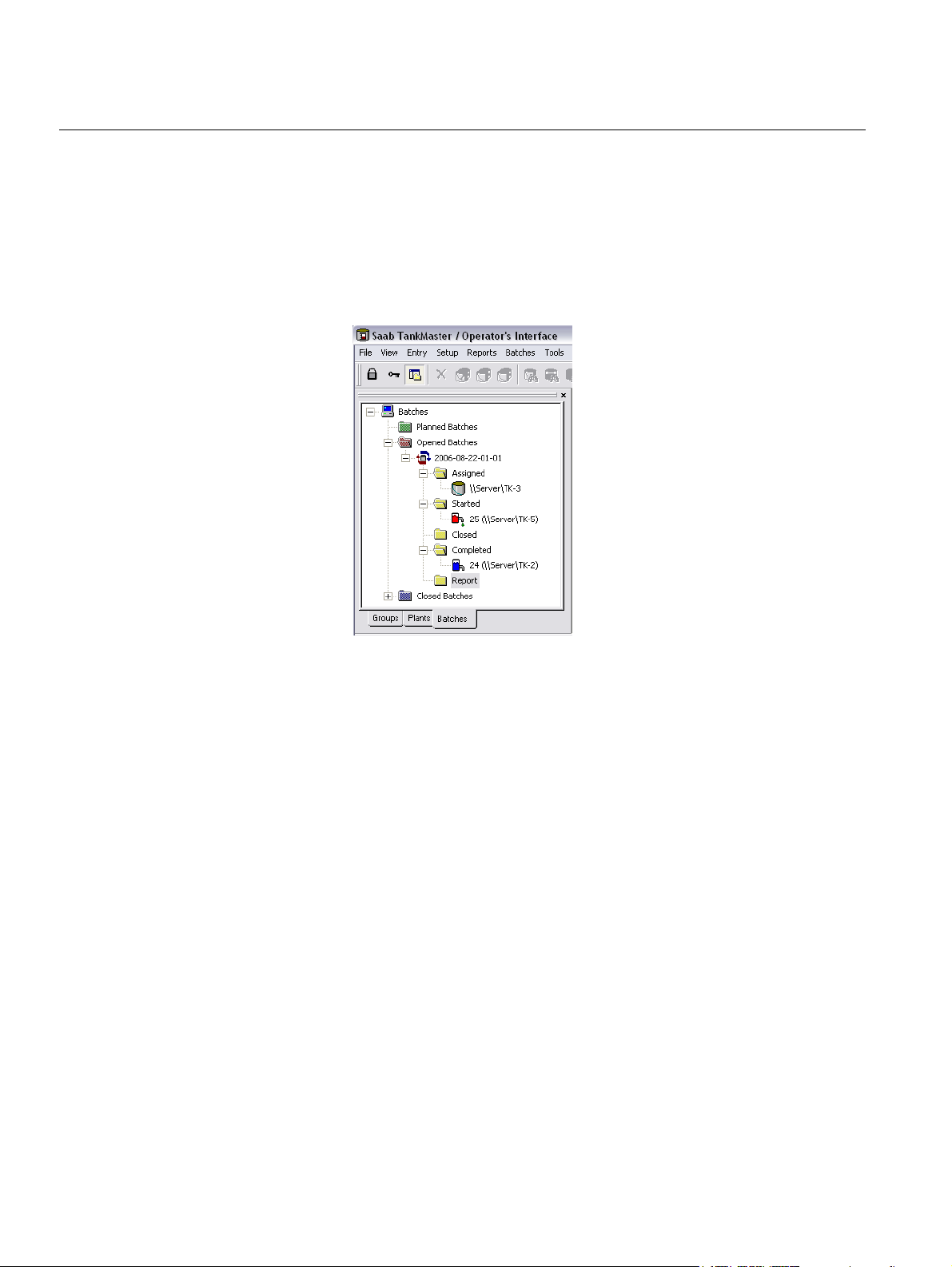

2.2.2 Folders Batches are organized in different folders corresponding the current state. For

each batch there are folders with all included parcels.

Figure 2-3. Batches and Parcels

are organized in a folder

structure

Batches Folders

Planned Batches This folder keeps all planned batches. These Batches are not yet

assigned to one or several tanks.

Opened Batches This folder keeps all opened batches.

Closed Batches This folder keeps all completed batches for 24 hours (if you haven’t

changed the default value for closed batches, see section Appendix A:

Miscellaneous for more information).

Batch Subfolders

Assigned This folder keeps all assigned tanks in a batch.

Started This folder keeps all started parcels.

Closed This folder keeps all closed parcels. This option is only used when

Close Parcel and Complete Parcel are handled as separate

operations.

Completed This folder keeps all completed parcels.

Report Each batch has a Report folder which stores Opening Ticket and

Delivery Ticket for each parcel as well as the Batch Summary. A report

is stored 100 days by default. The report lifetime can be changed to

any number of days, see section Appendix A: Miscellaneous for more

information.

NOTE!

Open/Start Parcel and Close/Complete Parcel can be handled as separate

operations. For more information see section Appendix A: Defaults.

Section 2. General

2-3

Reference Manual

TankMaster Batch Handling

303041EN, Edition 1/Rev. B

September 2007

2.2.3 Batches Menu All functions are available under Batches in the main menu and also by

clicking the right mouse button on the appropriate icon.

The following commands are not related to a specific batch. They are

available when the Batches icon is selected:

Table 2-1. Batch menu items

related to the Batches icon

Menu item Description

Configure Batch Server Settings for the Batch server. For more information see

chapter 3.1 Batch Server Configuration and Appendix A

Configure Batch Server.

Connect Batch Server Enabled if there is no connection to the Batch Server.

Otherwise disabled. See chapter 6.10 Connect Batch

Server for more information.

Redundancy Select the Backup Batch Server, see chapter 6.11

Redundancy for more information.

Disconnect Batch Server Disconnects the Batch server, see chapter 6.12 Disconnect

Batch Server for more information.

Status Opens the OPC Server Information window. In this window

information about the OPC server and also all events are

presented, see chapter 6.13 Status for more information.

New Batch Opens the Batch Manual Data window.

Batches overview Opens the Batches Overview window. In this window

information about all opened and closed batches are

shown. See chapter 6.7 Batch Overview for more

information.

Batch Messages Opens the Active Messages window. In this window you

can see all active messages in the system. See chapter 6.5

View Batch Messages for more information.

2-4

Section 2. General

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

Table 2-2. Batch menu items

related to a specific batch

TankMaster Batch Handling

The following commands are related to a specific batch and are available

when a batch icon is selected:

Menu item Description

Batch Status Opens the Batch Status window. In this window you can find

data and messages regarding the selected batch. See

chapter 6.6 View Batch Status for more information.

Batch Manual Data Opens the Batch Manual Data window allowing you to enter

the desired descriptions and specifications for the batch.

See chapter 4.1 Create new batch for more information.

Assign Tanks Opens the Assign Tanks window. This window is used to

choose tanks to be included in a batch transfer, and to

specify the amount to be transferred.

See chapter 4.2 Assign Tanks for more information.

Enter Closing Data Opens the Batch Manual Closing Data window. In this

window you can choose Operator and Supervisor

signatures. Available when Close Batch and Complete

Batch are handled as separate operations. See section

Appendix A: Defaults.

Close Batch Opens the Batch Closing Data window. In this window

signature data must be entered to close the batch, see

chapter 5.3 Close and complete for more information.

Complete Batch Change status from closed batch to completed. This menu

item is only available when Close Batch and Complete

Batch are handled as separate operations, see section

Appendix A: Defaults for more information.

Delete Batch This menu item is only available when the batch does not

have associated tanks or parcels. It removes the batch from

the workspace and the database.

Remove Batch from Workspace Removes a completed batch from the workspace. It is

possible to put the batch back by using the Add Batch to

Workspace menu item.

Unofficial Summary Report Before a parcel is completed it is possible to print an

Unofficial Summary Report to check and identify missing

data. The report is marked with “Unofficial”. This menu item

is only available when Close Batch and Complete Batch are

configured as separate commands, see section

Appendix A: Defaults for more information.

Summary Report If you mark a closed batch and choose this menu item, you

can select Print Official or Save Official. If Close Batch and

Complete Batch are configured as separate commands,

you can select the Print Unofficial option for a closed batch.

Section 2. General

2-5

TankMaster Batch Handling

Table 2-3. Batch menu items

related to a parcel

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

The following commands are available when a parcel icon is selected:

Menu item Description

Parcel Manual Opening Data Opens the Parcel Manual Opening Data window which lets

you specify Operator and Supervisor signatures as well as

edit some inventory parameters, see chapter 4.3 Open/start

parcel for more information.

Open Parcel Changes status from assigned to opened parcel.

Start Parcel Changes status from opened to started parcel. This menu

item is only available when Open Parcel and Start Parcel

are configured as separate commands, see Appendix A:

Defaults for more information about the configuration.

Change Nominated This menu item is enabled when the parcel is started. It

opens the Parcel Nominated Value Data window which

allows you to change the nominated value. Note that it can

only be changed to a value higher than the transferred

amount.

Pause/Resume Parcel Pauses a parcel or resumes a paused parcel.

Enter Closing Data Opens the Parcel Manual Closing Data window. In this

window you can change parameters and choose

signatures, see chapter 5.2 Parcel manual closing data for

more information.

Close Parcel Opens the Parcel Gauge Closing Data window. In this

window you can check if the values are correct and press

the Close and Print button to close the parcel.

Complete Parcel Change status from closed to completed parcel. This menu

item is only available when Close Parcel and Complete

Parcel are configured as separate commands, see

Appendix A: Defaults for more information about the

configuration.

Release Tank You can release a tank when the parcel is closed. This

makes it possible to assign a tank to another parcel before

it is completed. This menu item is only available when

Close Parcel and Complete Parcel are configured as

separate commands, see Appendix A: Defaults for more

information.

Print & Save Tickets This menu item lets you print Official Opening Ticket, save

Official Opening Ticket, print Official Delivery Ticket and

save Official Delivery Ticket.

View Tickets This menu item makes it possible to view the Official

Delivery Ticket or a Recalculated Ticket.

Recalculate This menu item makes it possible to recalculate a parcel in

a completed batch. You can enter new opening and/or

closing data for the parcel and confirm the new values, see

chapter 6.1 Recalculation for more information.

Print Report Prints a selected report.

Add Batch to Workspace This menu option makes it possible to put batches which

have been removed from workspace back (see Remove

Batch from Workspace). Choose the desired batch by

clicking the Select check box in the Add Batch to the

Workspace window.

Expand all Expands all items under a folder. This menu item is only

available when clicking the right mouse button.

Collapse all Collapses all items under a folder. This menu item is only

available when clicking the right mouse button.

2-6

Section 2. General

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

TankMaster Batch Handling

2.2.4 Tools Menu The Tools menu includes the Tank Transfer Calculation option which may be

used as a tool for planning new batches.

For information about the other Tools menu items, see TankMaster WinOpi

User’s Guide [Ref. no. 303028 EN].

Figure 2-4. The Tank Transfer

Calculator window offers the

option to calculate transferred

volumes based on specifiec

Opening and Closing values

Section 2. General

2-7

TankMaster Batch Handling

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

2.3 ICONS USED IN TANKMASTER

In the Batches tab the server, batches and parcels are represented by the

following icons:

One server is running (on non-redundant system).

No connection with the server.

Tank ic o n

Batch icon

Tank - assigned.

Yellow - assigned and opened.

Yellow - planned parcel, i.e. manually open data entered.

The pipe direction shows whether shipping or receiving.

Green- opened parcel, i.e. opened data saved and

opening ticket printed

Red - started parcel. The pipe of the icon shows if it is

shipping or receiving.

Red /Green - paused parcel.

Red - pre-closed parcel, i.e. manually closed data saved.

Green/Brown - closed parcel, i.e. closed data saved.

Completed parcel.

2-8

Section 2. General

Reference Manual

303041EN, Edition 1/Rev. B

September 2007

TankMaster Batch Handling

Section 3 System Configuration

Before using the Batch Handling function you should make the following

preparations:

• Configure the Batch Server

• Set up the Product Table

• Specify User accounts

3.1 BATCH SERVER CONFIGURATION

Figure 3-1. Configure Batch

Server window

The Configure Batch Server window allows you to make customized settings

of the batch handling process. These settings will affect the Batch server. A

few settings in the Customize Parameters and Defaults tabs will affect the

local client.

3.1.1 Batch Units and

Ranges

Section 3. System Configuration

Select the measurement units for the batch. Only tanks using the same units

can be assigned to a batch. Density and Temperature differences can be

specified for verification of entered values and for checking measured open

and close values.

For more information, see Appendix A: Batch Units and Ranges.

3-1

Loading...

Loading...