Rosemount Guided Wave Radar Transmitters in Upstream Applications-Best Practices User Guide Manual Supplement

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Guided Wave Radar

Transmitters in Upstream Applications

Best Practices User Guide

www.rosemount.com

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Rosemount Guided Wave Radar

Transmitters in Upstream

Applications

Best Practices Users Guide

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

This product is designed to meet FCC and R&TTE requirements for a non-intentional

radiator. It does not require any licensing whatsoever and has no tank restrictions

associated with telecommunications issues.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

Rosemount 3300 Series Guided Wave Radar Level and Interface Transmitters may be protected by one or

more of the following U.S. Patent Nos. 5,955,684; 6,148,681; 6,198,424; 6,373,261 and other patents issued or

pending in the U.S. and other countries. May depend on model.

Rosemount 5300 Series High Performance Guided Wave Radar Transmitters may be protected by one or more

of the following U.S: Patent Nos. 6,148,681; 5,955,684; 6,295,018; 6,198,424; 6,972,712; 6,842,139; 6,700,530

and other patents issued or pending in the U.S. and other countries. May depend on model.

Cover Photo: cover_combined 2.jpg

www.rosemount.com

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

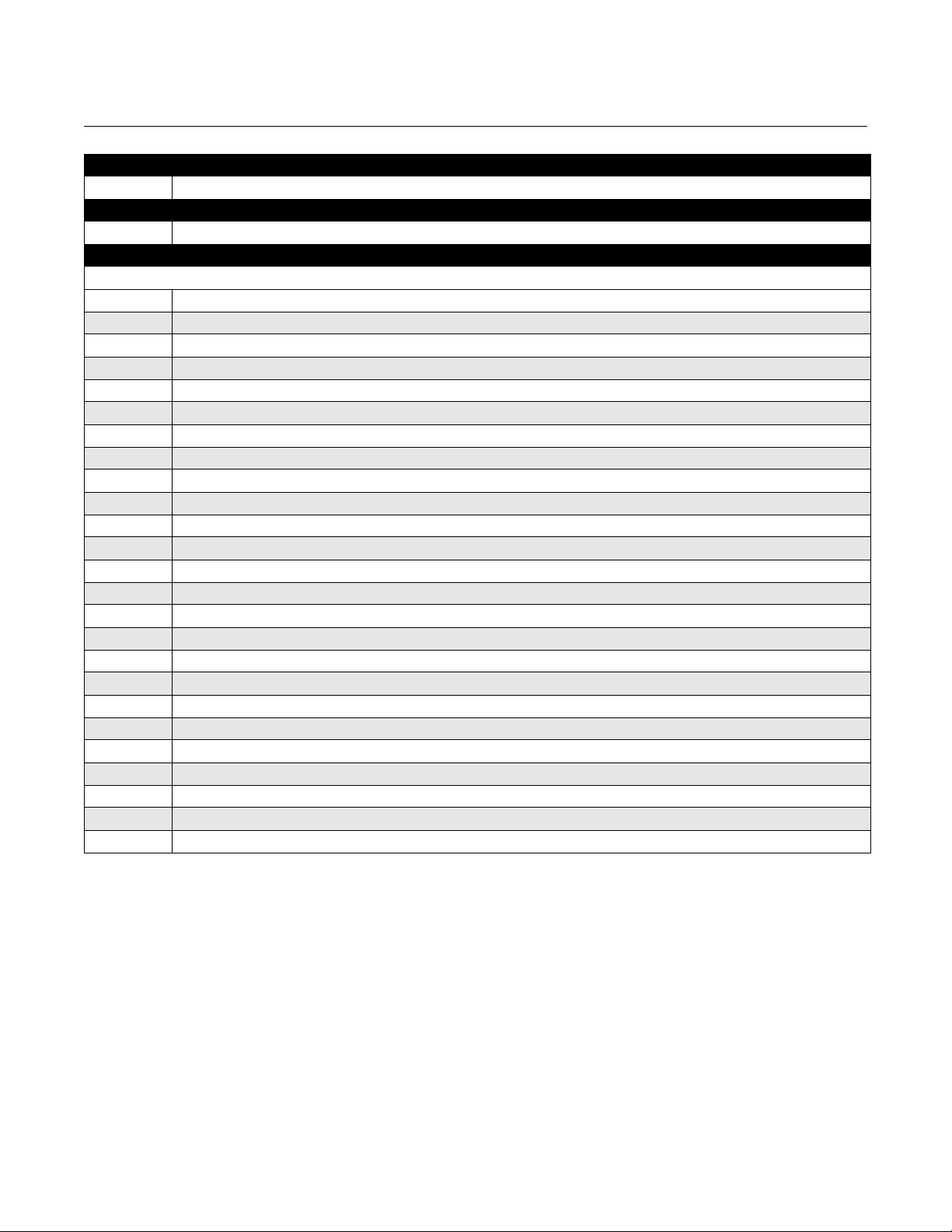

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

Considerations

SECTION 3

Upstream Applications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Integration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Recommended Mounting Position . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Transition Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Process Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Rosemount 3300 Series: HART Version . . . . . . . . . . . . . . . . . . . 2-12

Rosemount 3300 Series: Modbus Version . . . . . . . . . . . . . . . . . . 2-13

PC Communication with MA(+) MB(-) . . . . . . . . . . . . . . . . . . . . . 2-14

Cathodic Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Rosemount 5300 Series: HART Version . . . . . . . . . . . . . . . . . . . 2-16

Rosemount 5300 Series: Foundation™ fieldbus Version. . . . . . . 2-18

Specific Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Separators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Horizontal separator (bullet tank) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Vertical separator (vertical cylinder tank) . . . . . . . . . . . . . . . . . . . . 3-3

Output measurement at different interface levels. . . . . . . . . . . . . . 3-4

Production/Slop Tanks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Vertical cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Slop tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Underground or open pit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

SECTION 4

Commissioning

SECTION 5

Troubleshooting

www.rosemount.com

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Trim Near Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Store Backup and Verification Files . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Plotting the Measurement Signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Plotting the Measurement Signal for the Rosemount 3300 Series. 4-5

Plotting the Measurement Signal for the Rosemount 5300 Series. 4-6

Differences Between Plots in RRM and RCT . . . . . . . . . . . . . . . . . 4-9

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Rosemount 3300 Threshold Settings . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Case 1 - Level measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Case 2 - Level & Interface measurements . . . . . . . . . . . . . . . . . . . 5-4

Disturbances From Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Upper Null Zone adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Rosemount Radar Level Transmitters

Nozzle influence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Near Zone Threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Rosemount 5300 Threshold Settings . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Device status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Device Status: Rosemount 3300 Series. . . . . . . . . . . . . . . . . . . . 5-12

Device Status: Rosemount 5300 Series. . . . . . . . . . . . . . . . . . . . 5-13

Reference Manual

00809-0600-4811, Rev AA

February 2009

SECTION 6

Verification Procedure

APPENDIX A

Model Code Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Rosemount 3300 Plot Verification . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Rosemount 5300 Plot Verification . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Model Code 3302 and 5302, Level and Interface in Liquids . . . . . . . . A-2

Model Code Example - Rosemount 3300 Series . . . . . . . . . . . . . A-5

Model Code Example - Rosemount 5300 Series . . . . . . . . . . . . . . A-5

TOC-2

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Section 1 Introduction

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

System Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

INTRODUCTION This document describes some of the best practices learned during the

installation of thousands of Rosemount Guided Wave Radar level transmitters

in upstream oil and gas applications. However, it is not a complete set of

instructions; for more detailed information, refer to the respective product

manual:

• Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530)

• Rosemount 3300 Series Reference Manual

(Document No. 00809-0100-4811)

The Rosemount 3300 Series and 5300 Series Guided Wave Radar

transmitters are Time Domain Reflectometry Pulsed Radar level instruments.

They are utilized in the Oil and Gas industry for the measurement of

hydrocarbons and water in production and separator tanks. Both the

Rosemount 3300 and 5300 Series have the ability to measure overall level as

well as interface level in the vessels. They can be installed in several different

configurations including flanges, threaded, and side-mounted connections.

The Rosemount 3300 can transmit measurement values and diagnostics with

the 4-20 mA HART

protocols. The Rosemount 5300 is a high performance transmitter and can

transmit measurement values and diagnostics with the 4-20 mA HART and

F

OUNDATION™ fieldbus communication protocols.

This document describes which series, models, and probes to use on the

various applications within upstream Oil and Gas fields, and therefore serves

as a selection guideline specific to these applications and needs. Local

restrictions, regulations, or best practices may also apply and should be taken

into consideration.

®

and RS-485 Modicon RTU Modbus communication

www.rosemount.com

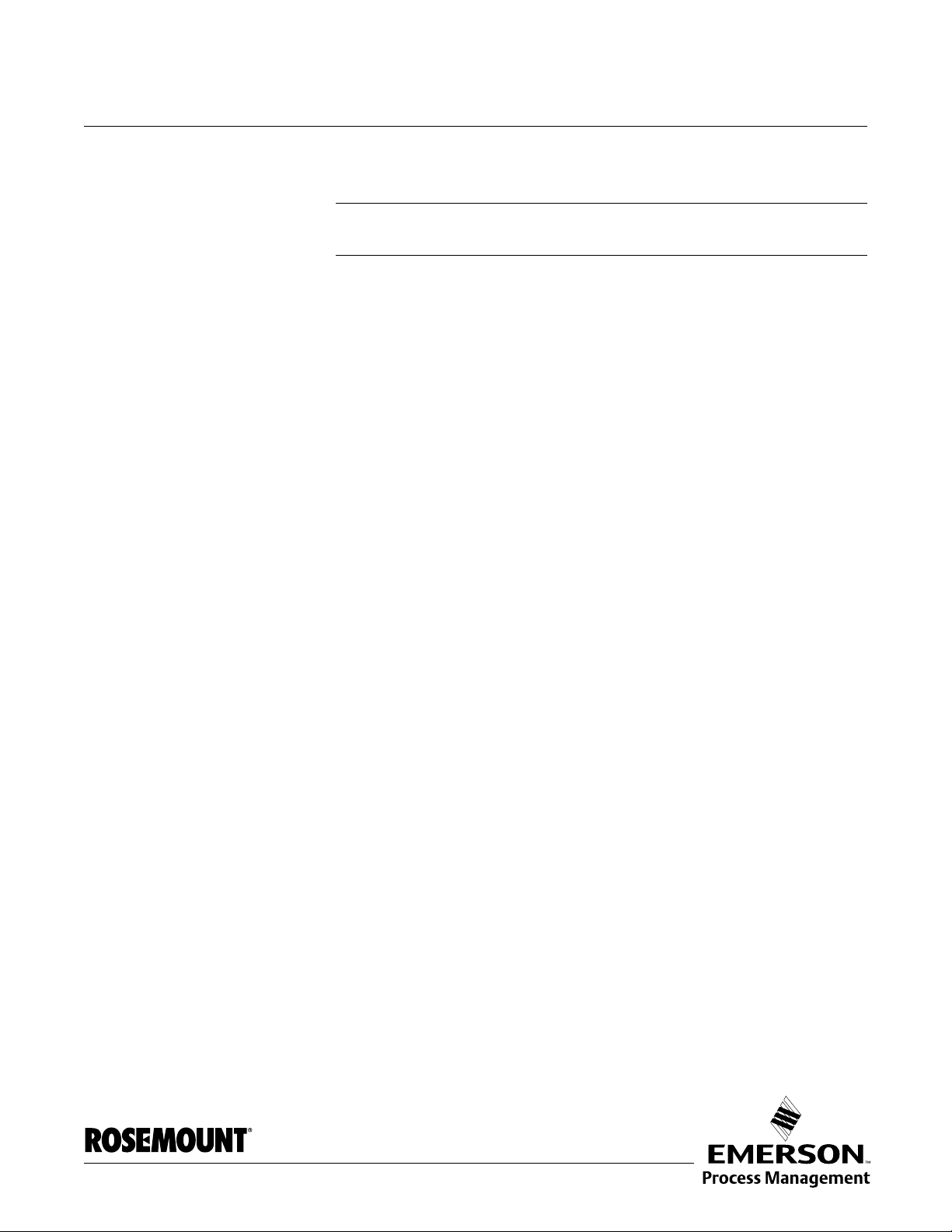

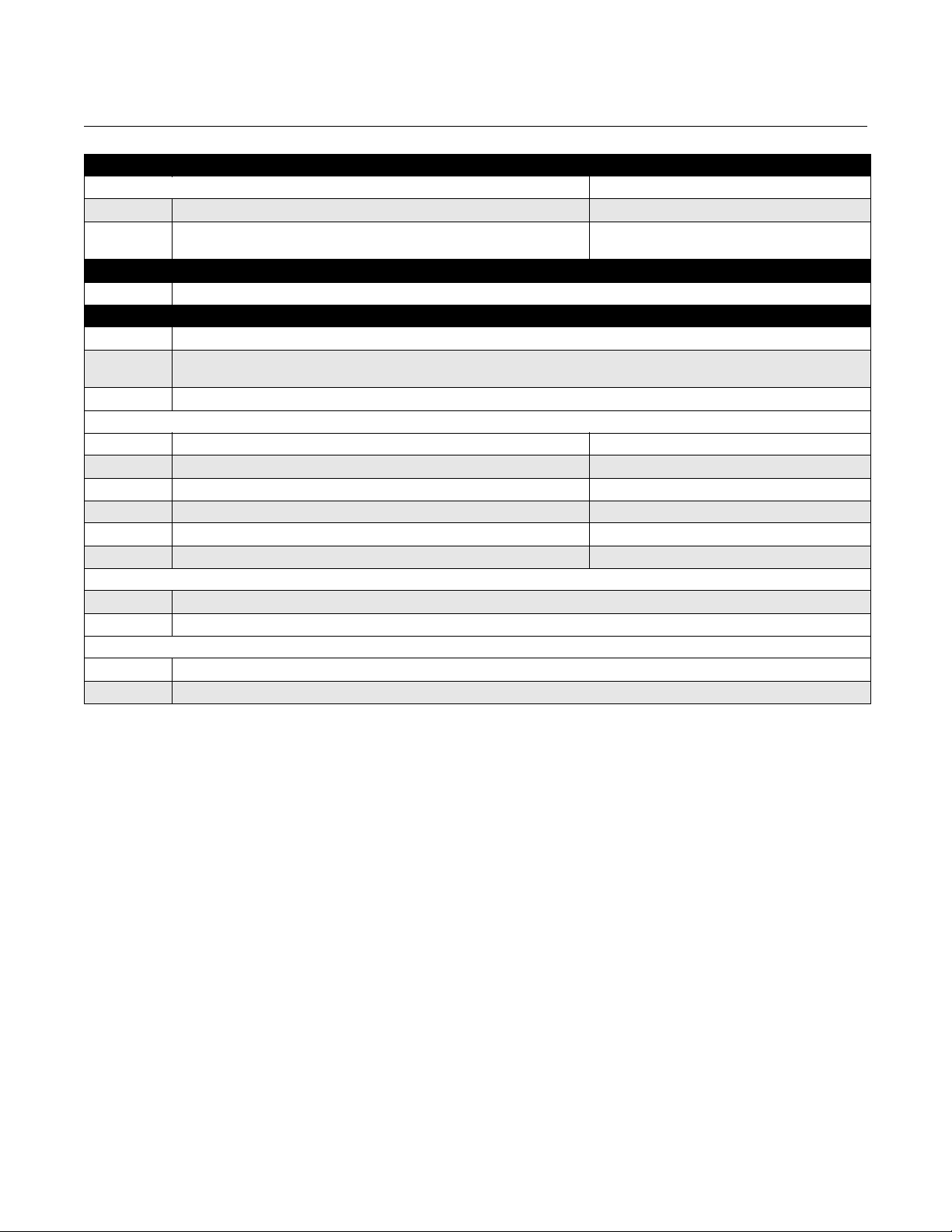

Rosemount Radar Level Transmitters

Control

System/PLC

HART

Modem

PC

Rosemount 3300 Series

transmitter

375 Field

Communicator

4-20 mA/HART

Modbus Control

System/PLC

HART

Modem

PC

Power

375 Field

Communicator

Max. cable length is

4000 ft. (1200 m)

MODBUS

Rosemount 3300 Series

transmitter

SYSTEM INTEGRATION

Figure 1-1. Rosemount 3300

Series: HART system.

Reference Manual

00809-0600-4811, Rev AA

February 2009

Figure 1-2. Rosemount 3300

Series: MODBUS system.

1-2

Reference Manual

Rosemount

5300 Series

Transmitter

Display

4-20 mA / HART

375 Field

Communicator

3 x 4-20 mA

Tri-loop

Control

System

HART

Modem

PC with Rosemount

RadarMaster

Host / DCS System (e.g. DeltaV

®)

Maintenance

H2 - High Speed Field Bus

H1 - Low Speed Field Bus

6234 ft. (1900 m) maximum

(depending upon cable

characteristics)

Fieldbus

Modem

PC with Rosemount

RadarMaster

Display

(option)

Rosemount 5601

Rosemount 5401

Rosemount 5301

375 Field

Communicator

Note:

Intrinsically safe

installations

may allow fewer

devices per I.S.

barrier due to

current

limitations.

00809-0600-4811, Rev AA

February 2009

Figure 1-3. Rosemount 5300

Series:

HART system.

Rosemount Radar Level Transmitters

Figure 1-4. Rosemount 5300

Series - F

OUNDATION™ fieldbus

system.

1-3

Rosemount Radar Level Transmitters

Reference Manual

00809-0600-4811, Rev AA

February 2009

1-4

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Section 2 Installation Considerations

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-12

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury.

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Make sure the main power to the Rosemount 3300 / 5300 Transmitter is off and the lines

to any other external power source are disconnected or not powered while wiring

the gauge.

Probes covered with plastic and/or with plastic discs may generate an ignition-capable

level of electrostatic charge under certain extreme conditions. Therefore, when the

probe is used in a potentially explosive atmosphere, appropriate measures must be

taken to prevent electrostatic discharge.

Process leaks could result in death or serious injury.

Make sure that the transmitter is handled carefully. If the Process Seal is damaged, gas

might escape from the tank if the transmitter head is removed from the probe.

www.rosemount.com

Reference Manual

00809-0600-4811, Rev AA

Rosemount Radar Level Transmitters

February 2009

INTRODUCTION In addition to selecting the appropriate radar level transmitter, mechanical

installation is one of the most critical steps of the commissioning procedure.

When done correctly, the subsequent transmitter configuration will be

considerably simplified.

The main focus of this section is to provide a framework for installations in a

variety of tanks and process connections typically found in the upstream oil

and gas industry.

MECHANICAL INSTALLATION

Recommended Mounting Position

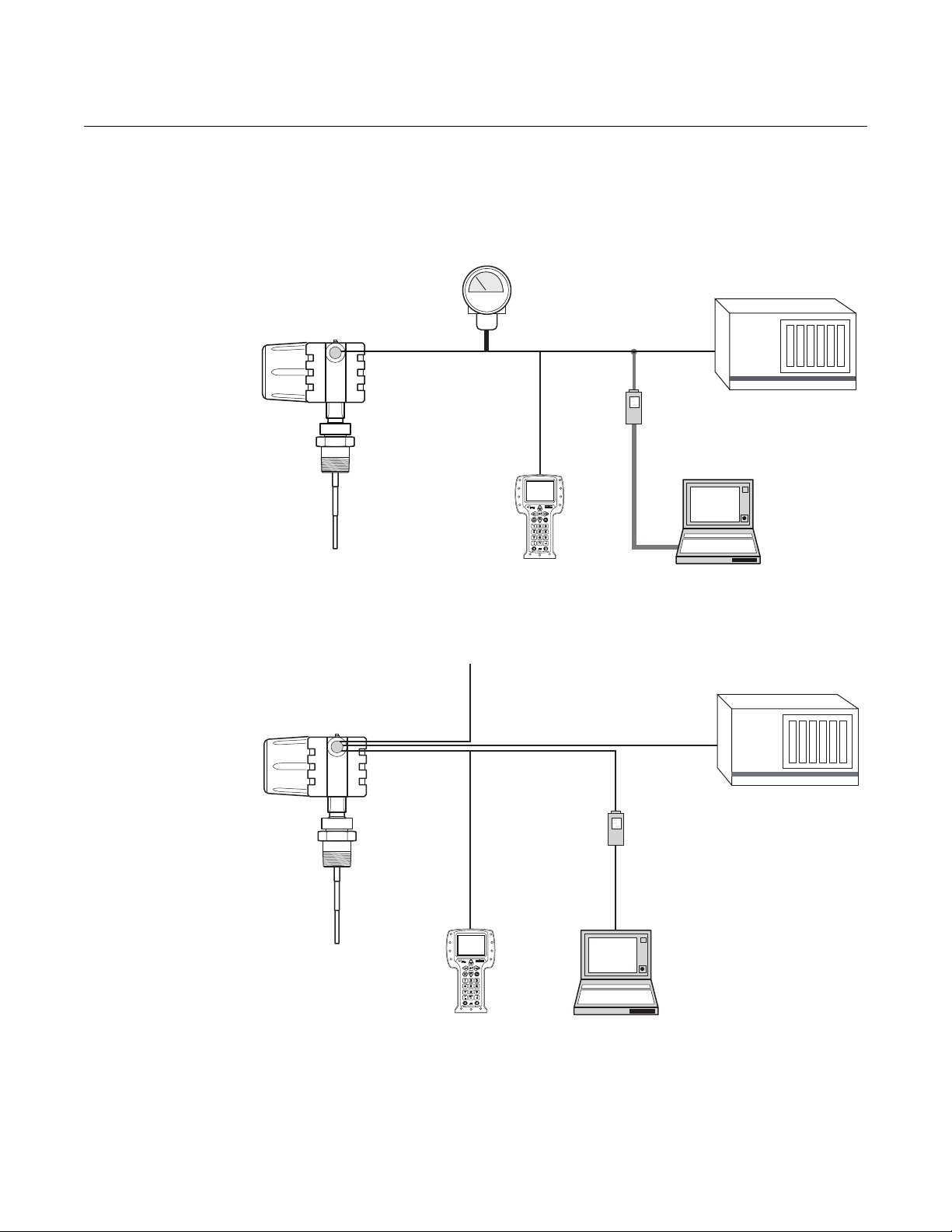

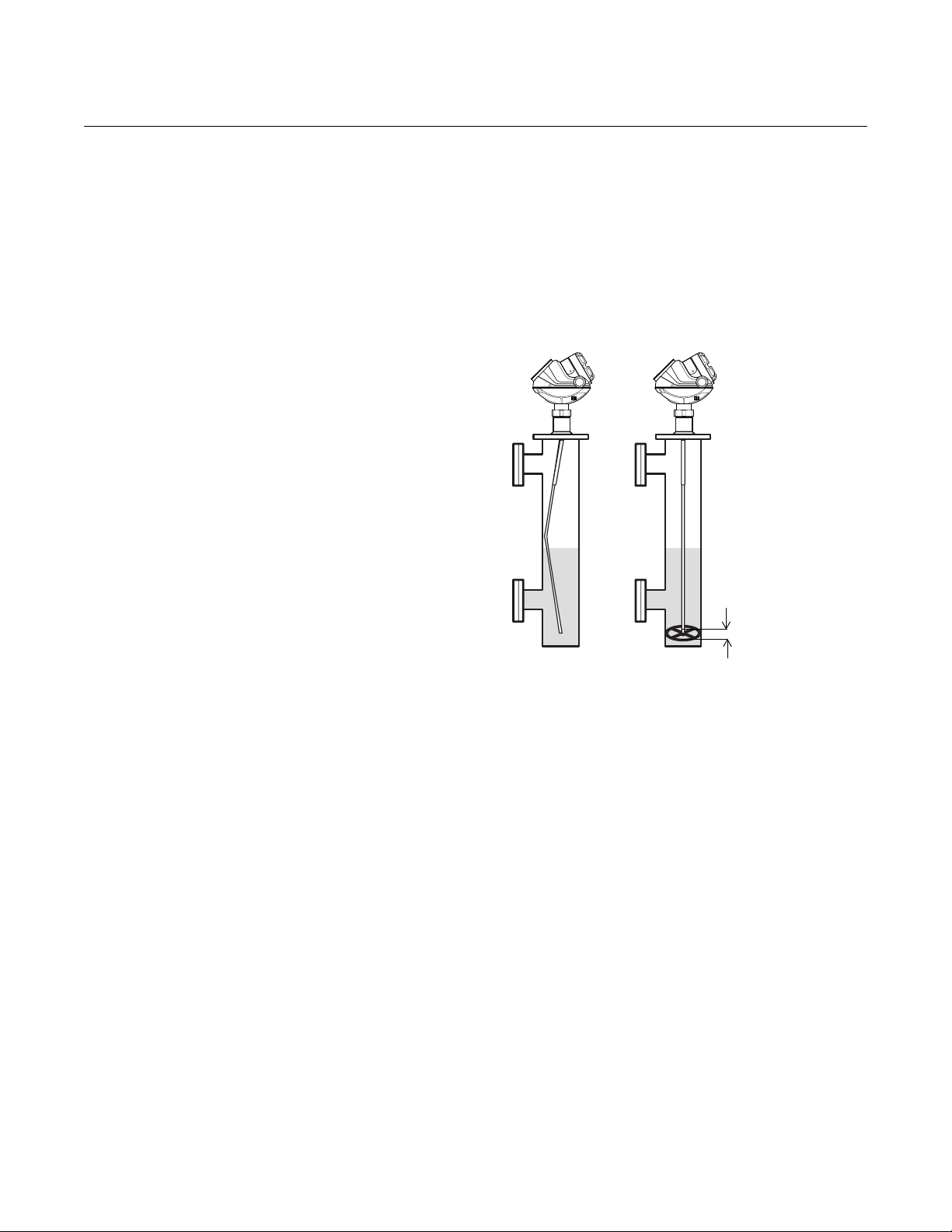

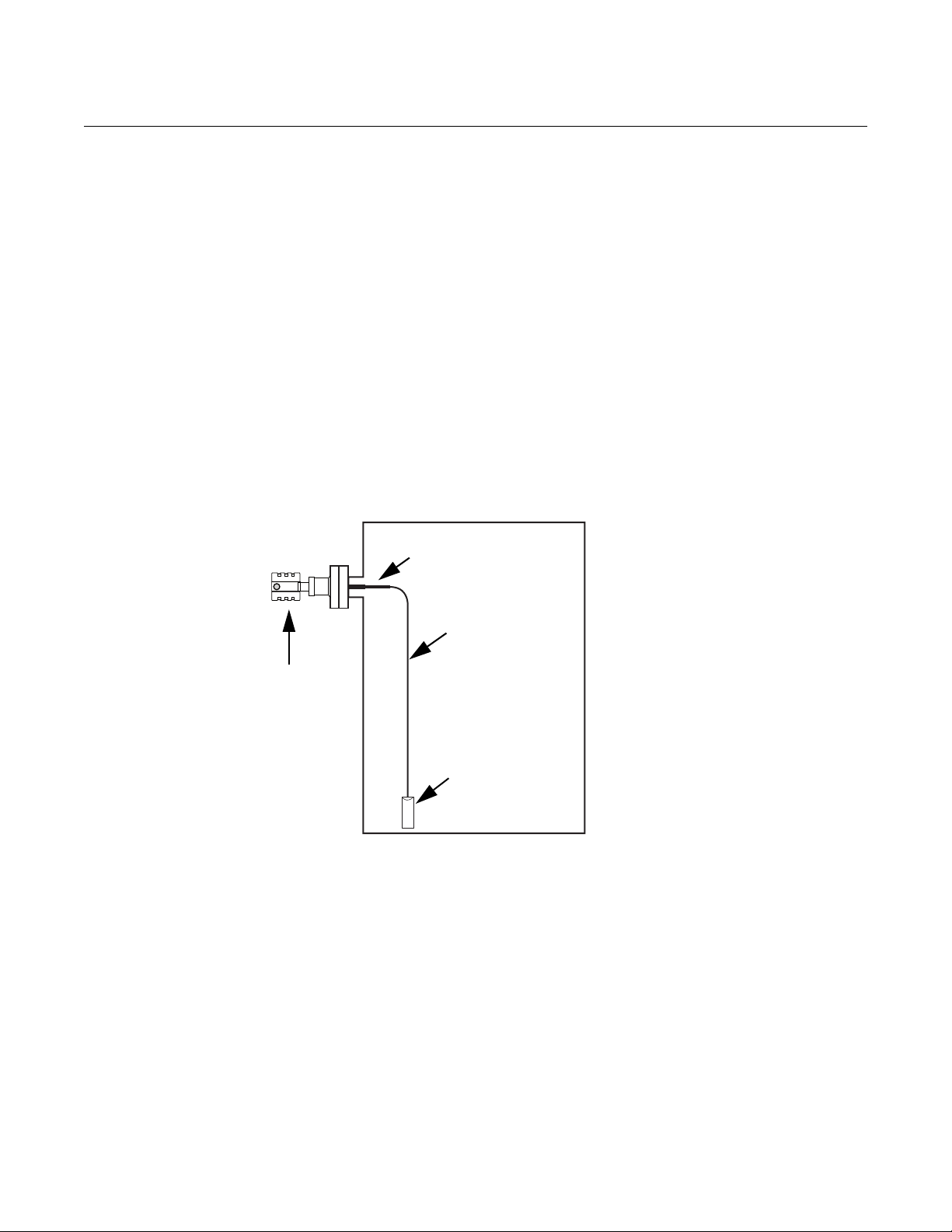

Figure 2-1. Mounting Position.

To find an appropriate mounting position for the transmitter, consider the

conditions of the tank. The transmitter should be mounted so that turbulence

from disturbing objects is reduced. If turbulence is present, the probe may

need to be anchored to the bottom.

2-2

Guidelines to be considered when mounting the transmitter:

• Do not mount close to inlet pipes

• If the probe sways because of turbulent conditions in the tank, the

probe should be anchored to the tank bottom. In these applications, the

best option is anchoring with a Magnet fastened to the weight

• Avoid mounting close to internal objects that are within 6 in. (150 mm)

from probe at any time

• The probe should not come into contact with the nozzle or other objects

in the tank

NOTE!

Violent fluid movements can cause forces that could break rigid probes.

Reference Manual

Magnet

Clamps

00809-0600-4811, Rev AA

February 2009

Figure 2-2. Anchoring the probe

with a magnet.

Rosemount Radar Level Transmitters

Anchoring a Flexible Single Lead probe

A magnet can be fastened to a threaded (M8x14) hole at the end of the

weight. Placing a metal plate beneath the magnet, as illustrated in Figure 2-2,

will help to guide the probe.

Magnets should not be used on long nozzle applications because the magnet

could attach to the side of the nozzle during installation.

Figure 2-3. Anchoring the probe

through a welded eye.

The probe rope can also be used for anchoring. The probe rope can be pulled

through a suitable anchoring point, e.g. a welded eye and fastened with two

clamps. The length from the underside of the flange to the top clamp should

be used to configure the probe length.

2-3

Rosemount Radar Level Transmitters

Make sure that the probe

does not come into

contact with the chamber

wall, e.g. by using a

centering disk.

A clearance

distance of 1 in.

(25 mm) between

the probe end and

the cage bottom is

recommended.

Installation in pipes

A centering disk is recommended when installing in pipes to prevent the

probe from contacting the chamber wall. The disk is attached to the end of the

probe to keep the probe centered in the chamber. The discs are available in

stainless steel (SST) and PTFE. The PTFE option is recommended for most

applications and the SST centering disk is used for high temperature

operations.

Figure 2-4. Improper and proper

probe positions.

Reference Manual

00809-0600-4811, Rev AA

February 2009

2-4

To avoid bending the probe (rigid probes) or twisting and coming in contact

with the chamber wall (flexible probes), a small clearance distance of 1 in.

(25 mm) between the centering disk and chamber bottom is recommended. It

should be selected with a dome shaped chamber bottom in mind, which may

prevent the centering disk from reaching the bottom.

Side-pipe locations and the effective measurement range are determined by

the mating tank connections. There are no constraints on the diameter of the

side-pipes, but build-up and clogging should be considered. Also the inlet

pipes should not protrude into the chamber since they may interfere with the

radar measurement. Always use the same construction material for the

chamber and the tank, otherwise, mechanical tensions can arise in the

side-connections.

The recommended chamber diameter is 3 in. (75 mm) or 4 in. (100 mm).

Chambers with a diameter less than 3 in. (75 mm) may have build-up

problems and it may also be difficult to center the probe. Chambers larger

than 6 in. (150 mm) can be used, but provide no advantages for the radar

measurement.

With the Rosemount 3300 / 5300 Series, single probes are recommended for

use in 3 in. (75 mm) and 4 in. (100 mm) chambers. Other probe types are

susceptible to build-up and should not be used in this application.

The probe must not touch the chamber wall and should extend the full height

of the chamber, but it does not need to touch the bottom of the chamber.

Probe type selection depends on the probe length:

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Less than 3 ft. (1 m): Use Single Rigid Probe and no centering disk is

needed. The transition zones and the height of the weight will limit the use of

single flexible probes shorter than 3 ft. (1 m).

Between 3 ft. (1 m) and 10 ft. (3 m): Use either Rigid Single or Flexible

Single Probe with the weight and centering disk. Rigid Single has smaller

transition zones, while the Flexible Single requires less head-space during

installation and is less likely to be damaged.

More than 10 ft. (3 m): Use Flexible Single Probe with a weight and centering

disk.

Light hydrocarbon applications not in chambers: Use the Rosemount

5300 Series with either a Rigid Single or Flexible Single Probe. In very light

hydrocarbons, the Rosemount 3300 signal loses too much energy on a single

probe. The Rosemount 5300 has more efficient and sensitive microwave

modules that increase signal strength. The 3300 will, however, work in light

hydrocarbon chamber applications, because chambers have similar physics

of propagation as the traditional coaxial style probe.

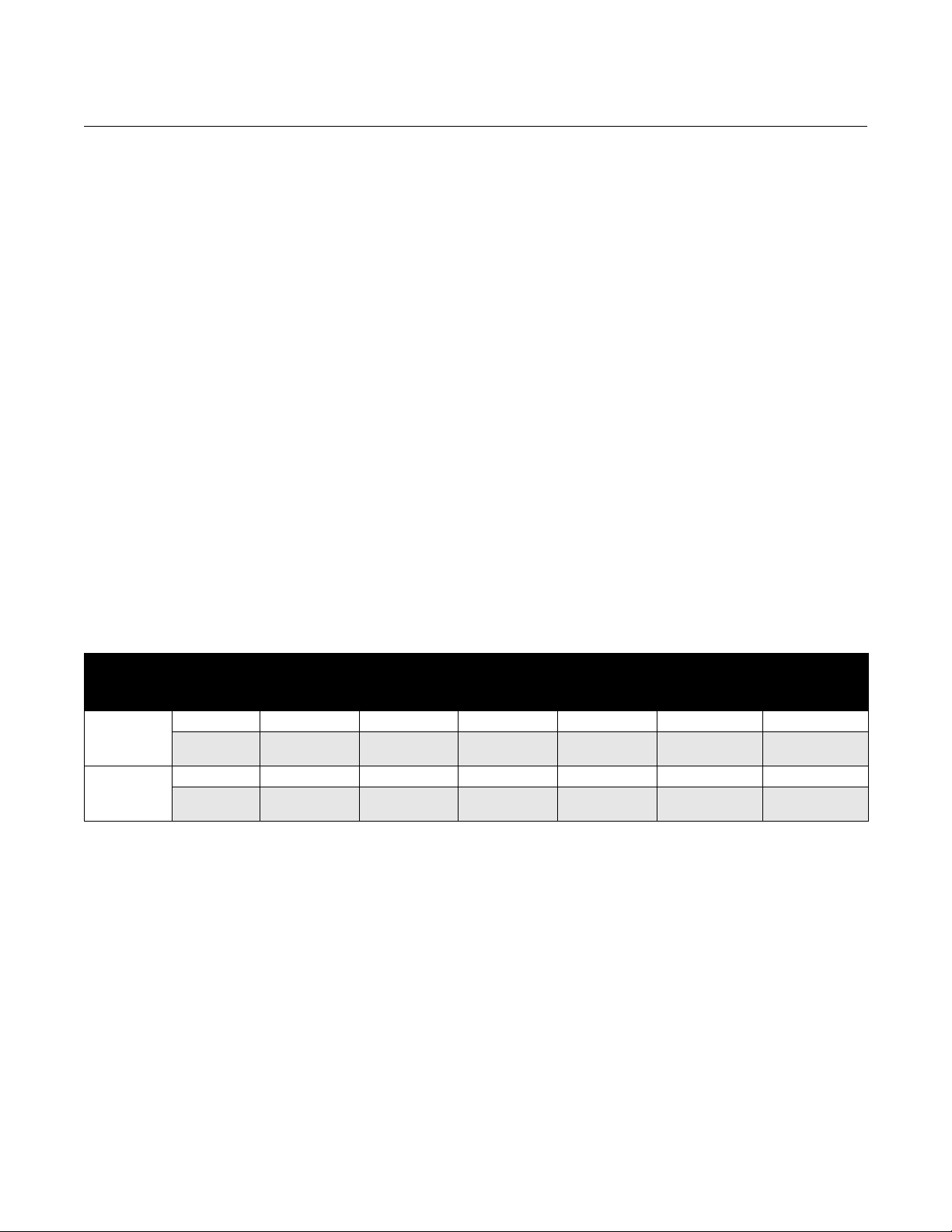

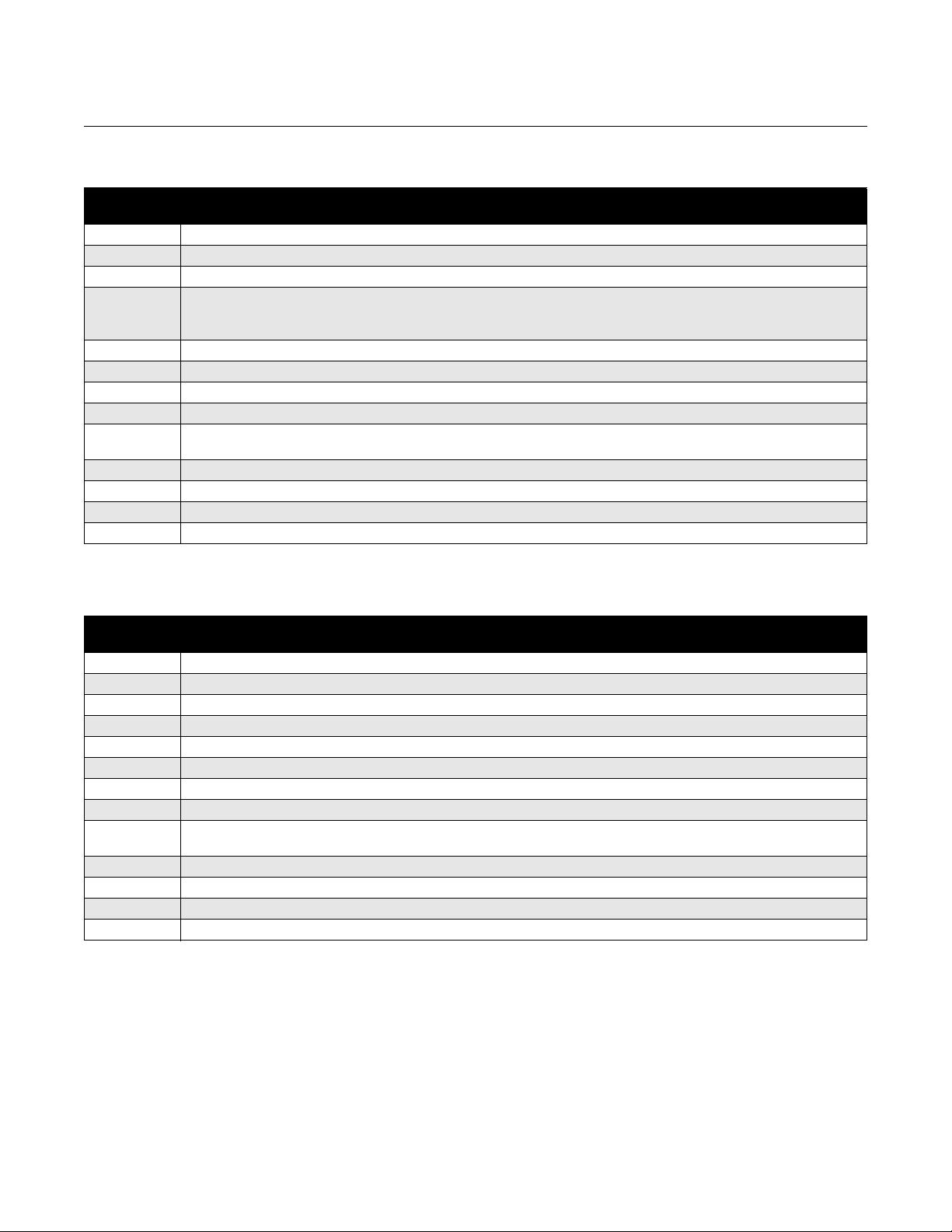

Transition Zones Transition zones, located at the very top and bottom of the probes, are

regions where measurement performance is reduced. Different factors affect

the size of the transition zones - probe type, centering disk or no centering

disk, and the material and media measured, as shown in Table 2-1.

Table 2-1. Transition Zones for

Rosemount 3300 and 5300

Series.

Dielectric

Constant

(2)

Upper

80 (water) 4 in. (10 cm) 4.3 in. (11.cm) 4 in. (10 cm) 4.3 in. (11 cm) 5.9 in. (15 cm) 4.3 in. (11 cm)

Transition

Zone

(3)

Lower

Transition

Zone

(1) Rigid Single Lead probe without SST centering disk or with PTFE centering disk.

(2) The distance from the upper reference point where measurements have reduced accuracy.

(3) The distance from the lower reference point where measurements have reduced accuracy.

(4) Note that the weight length adds to non-measurable area. For more information, see Dimensional Drawings in the Guided Wave Radar Level and Interface

Transmitter, Rosemount 3300 Series Product Data Sheet (Document No. 00813-0100-4811).

(5) The measuring range for the PTFE covered Flexible Single Lead probe includes the weight when measuring on a high dielectric media.

(6) Note that the weight length adds to non-measurable area. For more information, see Dimensional Drawings in the High Performance Guided Wave Radar,

Rosemount 5300 Product Data Sheet (Document No. 00813-0100-4530).

2 (oil) 4 in. (10 cm) 6.3 in. (16 cm) 4 in. (10 cm) 6.3 in. (16 cm) 20 in. (50 cm) 7.1 in. (18 cm)

80 (water) 2 in. (5 cm) 2 in. (5 cm) 2 in. (5 cm) 2 in. (5 cm) 2 in. (5 cm)

2 (oil) 4 in. (10 cm) 2.8 in. (7 cm) 8 in. (20 cm) 8 in. (20 cm) 4.7 in. (12 cm)

Rigid Single Lead

3300 5300 3300 5300 3300 5300

(1)

Rigid Single Lead, with

metallic centering disk

Flexible Single Lead

(4) (5)

0 in. (0 cm)

(4)

2 in. (5 cm)

(5) (6)

(6)

2-5

Rosemount Radar Level Transmitters

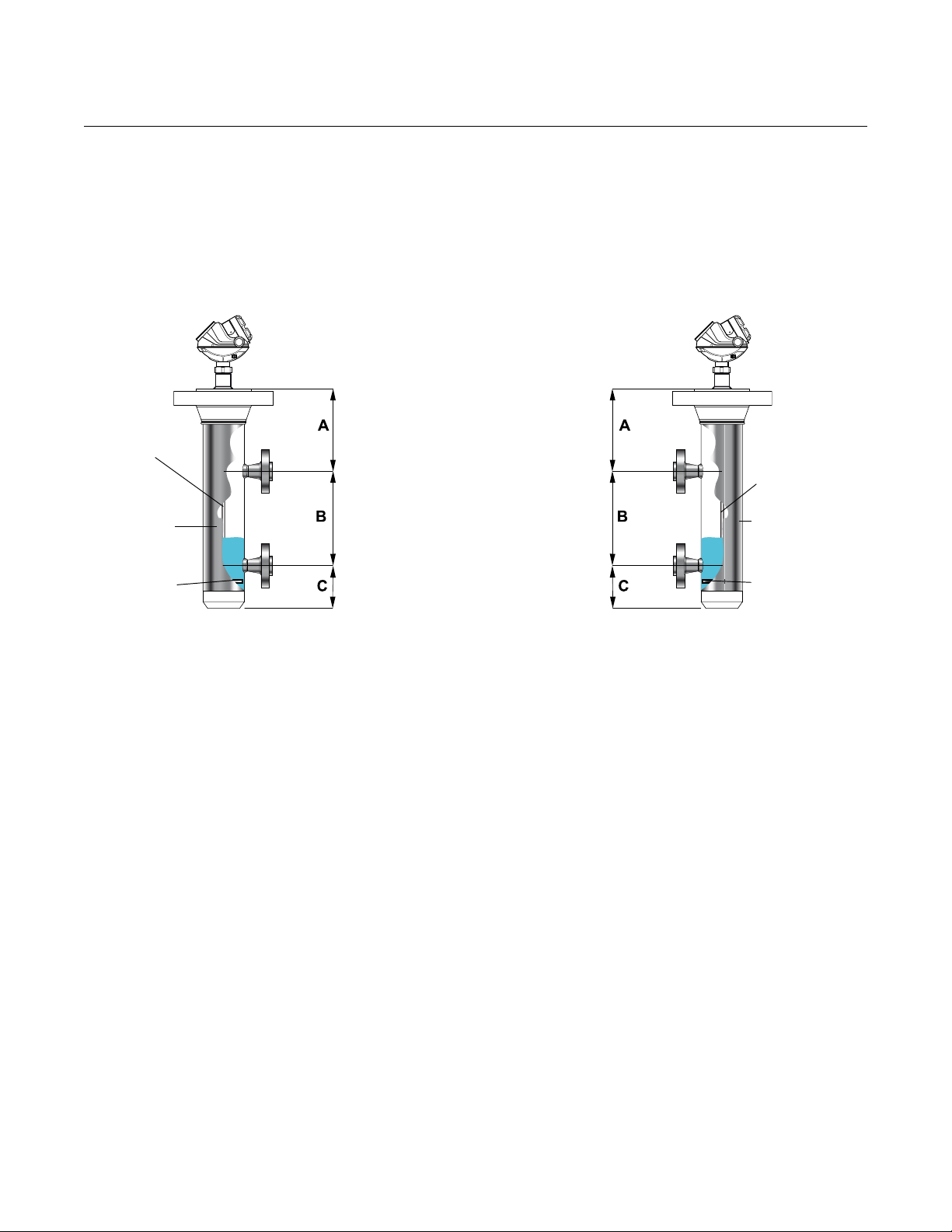

A > Upper transition zone

B = Effectice Measuring

Range, determined by

mating tank connections

C > Lower transition zone

including weight height

(for flexible probes) and

clearance distance

Single Flexible

for chambers

>= 3 ft. (1 m)

Probe/chamber

diameter must

be 3 in. or 4 in.

(7.5 cm or 10 cm)

Always use a

centering disk

Single Rigid

Probe/chamber

diameter must

be 3 in. or 4 in.

(7.5 cm or 10 cm)

Use centering

disks for probes

> 3 ft. (1 m)

The weight on the flexible probes reduces the measurement range.

Therefore, it is recommended to dimension the cage (A, C) so it does not

interfere with the effective measurement range (B). The transition zones also

limit the minimum probe length. See Figure 2-5 on page 2-6.

Figure 2-5. Measuring zones in

chambers.

Reference Manual

00809-0600-4811, Rev AA

February 2009

2-6

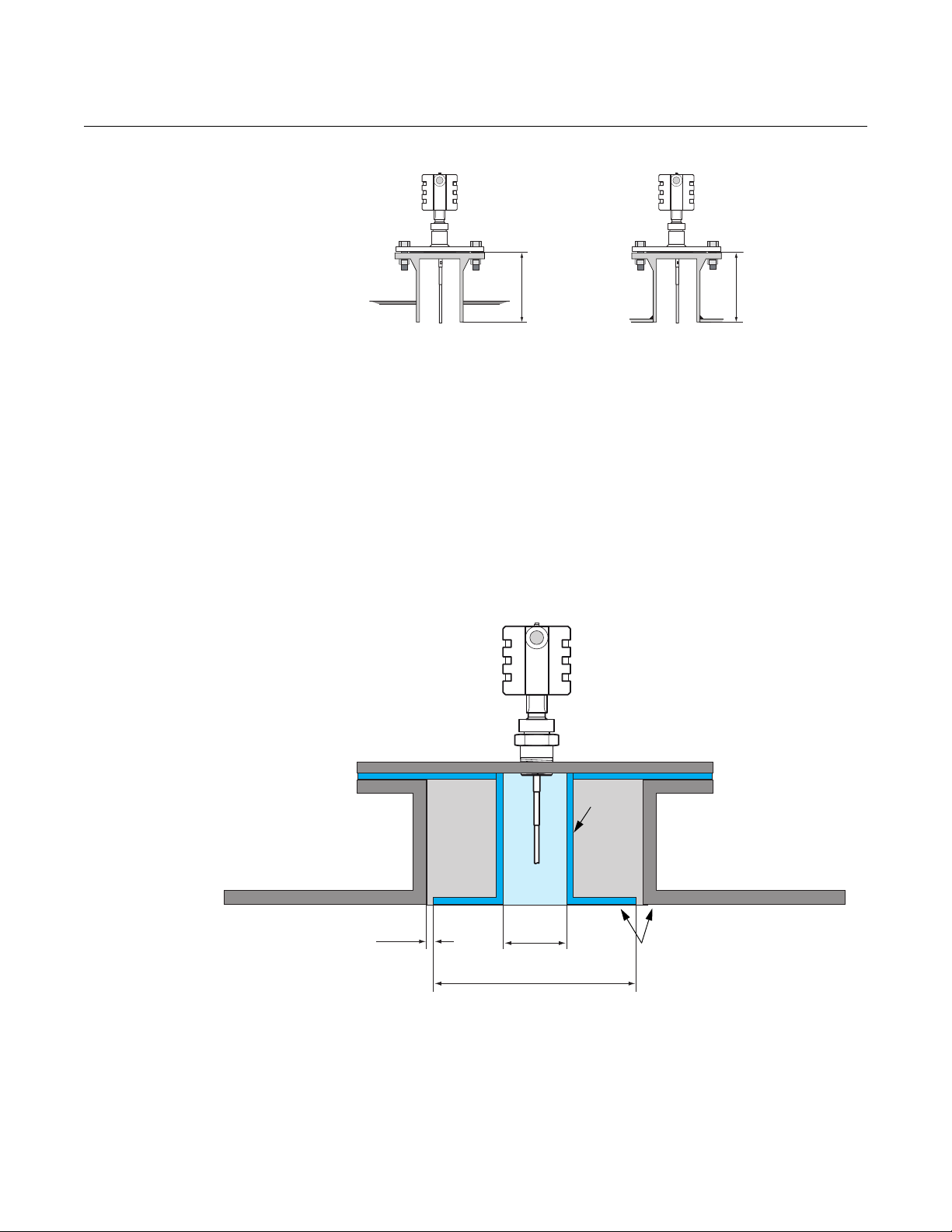

Reference Manual

UNZ H

Nozzle diameter (D)

Upper Null Zone (UNZ)

adjustments may be

needed for 2-in. (50 mm)

nozzles

Avoid nozzles with reducer

(unless using coaxial probe)

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Process Connections There are a few different types of Process Connections used in these

applications. Below are some directions and guidelines on how to install and

what to consider for the various connections.

Flanged connections

Below are recommendations for the nozzle configuration and dimensions for

flanged installations on top of the tank/vessel.

Table 2-2. Nozzle

considerations.

Recommended Nozzle Diameter (D) 4-6 in. (100-150 mm)

Minimum Nozzle Diameter (D)

Maximum Nozzle Height (H) 4 in. (100 mm) + Nozzle Diameter

(1) An Upper Null Zone setup may be required to mask the nozzle, which may reduce

the measuring range.

Nozzle height H is measured from the flange to the bottom of the nozzle,

regardless of how the nozzle is attached to the tank roof as illustrated in

Figure 2-6.

Single (Rigid / Flexible)

(1)

2 in. (50 mm)

2-7

Rosemount Radar Level Transmitters

HH

Tank roof

Tank r o o f

< ½ in. (13 mm)

6 in.

(150 mm)

Approx. flush within ± 1 in. (25 mm)

No need to be more than 15 in.

(380 mm) even for very large nozzles

for nozzles less than

15 in. ( 380 mm)

Inner

nozzle

Figure 2-6. Definition of nozzle

height H.

10-in. (250 mm) or larger flange/manway connection

If a Rosemount 3300/5300 Series Guided Wave Radar with single lead probe

is installed in a 10-in. (250 mm) (DN250) high nozzle or larger, there may be

resonance and double bounce problems. This can lead to measurement

errors for products with low dielectric constants, so 10-in. (250 mm) nozzles or

larger should be avoided.

In cases where 10-in. (250 mm) nozzles or larger are used, install an inner

steel nozzle with a smaller diameter, as illustrated in Figure 2-7.

Reference Manual

00809-0600-4811, Rev AA

February 2009

Figure 2-7. Special installation

considerations for 10 inch

nozzles.

Flat tank roof installation is not affected by this phenomenon.

2-8

Reference Manual

3 or 4 in.

(75 or 100 mm)

1 ½ in. (37.5 mm) NPT

Do not use Teflon tape

or similar

non-conductive

materials in the

threaded connections.

These connections

must be able to provide

a ground connection

between the probe and

the tank.

00809-0600-4811, Rev AA

February 2009

Figure 2-8. The Rosemount

3300 / 5300 can be installed in a

3 or 4 in. (75 or 100 mm) tank

opening by using an adaper.

Rosemount Radar Level Transmitters

Threaded tank connection

Many Oil and Gas applications have 3-in. (75 mm) or 4-in. (100 mm) threaded

connections on top of the tank roof.

For this connection, install the Rosemount 3300 / 5300 transmitters with a

1 ½-in. ( 37.5 mm) NPT threaded connection (model code option RA). The

probe can be attached to a bushing or adapter piece, reducing the tank

opening from a 3-in. (75 mm) or 4 in. (100 mm) threaded connection to the

desired 1 ½-in. (37.5 mm) standard Rosemount 3300 / 5300 process

connection.

2-9

Rosemount Radar Level Transmitters

The illustration demonstrates the Long

Stud (LS) configuration in which the rigid

portion of the single flexible probe extends

the probe further into the vessel, thus

preventing the probe from contacting the

side of the vessel.

Rosemount 3300 or

5300 transmitter

Long Stud

Flexible Probe

Counter Weight

Side mounted process connection

In some cases, tanks might not have top process connections suitable for

installation of Guided Wave Radar units, so side mounted process

connections are a viable and reliable installation practice. Certain precautions

must be taken to ensure successful level measurements in these vessels.

Both flexible and rigid single lead probes can be utilized for these

installations.

A special mechanical configuration, Long Stud (model code option LS), can

be used for the Flexible Single Lead probe to prevent contact with walls or

nozzles. The Long Stud incorporates a longer rigid rod extension piece which

connects to the flexible portion of the probe. This is useful for side mounted

probes since it allows for the probe to extend further into the vessel before it is

bent vertically down towards the tank bottom. Figure 2-9 illustrates this type of

installation:

Figure 2-9. Side mounting with

Flexible Single Lead probe.

Reference Manual

00809-0600-4811, Rev AA

February 2009

2-10

Reference Manual

The single rigid probe is bent 90° at a

distance that will ensure that the probe

protrudes into the tank and away from

the tank wall.

Rigid Probe

90

° bend

Rosemount 3300 or

5300 transmitter

00809-0600-4811, Rev AA

February 2009

Figure 2-10. Side mounting with

Rigid Single Lead probe.

Rosemount Radar Level Transmitters

For side mounting with a Rigid Single Lead probe, the probe is bent at a 90°

angle to ensure that the probe extends into the tank and away from the tank

wall. Figure 2-10 illustrates this type of installation:

Non-metallic Process Connections

See “Non-metallic process connections“ on page 3-10.

2-11

Rosemount Radar Level Transmitters

For Explosion-proof/ Flameproof

applications the resistance

between the negative terminal on

the transmitter and the power

supply must not exceed 300

.

375 Field

Communicator

PC

Power Supply

Load Resistance 250

HART

modem

Rosemount 3300

Series Transmitter

Reference Manual

00809-0600-4811, Rev AA

February 2009

ELECTRICAL INSTALLATION

This is a brief description of the Rosemont 3300 and 5300 wiring procedure.

For more information, see the respective reference manual: Rosemount 3300

Series (Document No. 00809-0100-4811) and Rosemount 5300 Series

(Document No. 00809-0100-4530).

Rosemount 3300 Series:

HART

Version

The 3300 Series is a two-wire loop powered transmitter accepting power

supplies ranging from 11 Vdc to 42 Vdc. It uses 4-20 mA power superimposed

with a HART

signal. To connect the transmitter:

1. Make sure the power supply is disconnected.

2. Remove the cover on the transmitter housing terminal side (see label).

Do not remove the cover in explosive atmospheres when the circuit is

live. All power to the transmitter is supplied over the signal wiring.

3. Pull the cable through the cable gland/conduit.

4. Connect wires according to Figure 2-11 for non-intrinsically safe output.

Make sure that the transmitter housing is grounded in accordance with

national and local electrical codes. There are two grounding screw

connections provided. One is inside the Field Terminal side of the

housing identified by a ground symbol: , and the other is located on

top of the housing.

5. Attach and tighten the housing cover. Tighten the cable gland, plug and

seal any unused connections and connect the power supply.

Figure 2-11. Wiring diagram for non-intrinsically safe installations of the 3300.

2-12

For HART communication, a minimum load resistance of 250 within the

loop is required.

The power supply voltage ranges from V

Vdc to 42 Vdc where V

min

min

is the

minimum voltage given by:

11 V Non-hazardous locations certification

16 V Explosion-proof/flameproof certification

Reference Manual

RS-485 Bus

B

A

120

120

Power

Supply

HART -

HART +

In case it is the last transmitter on

the bus, connect the 120 terminator

resistor

120

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Rosemount 3300 Series: Modbus Version

To connect the Rosemount 3300:

1. Make sure the power supply is disconnected.

2. Remove the cover on the transmitter housing terminal side (see label).

Do not remove the cover in explosive atmospheres when the circuit is

live. All power to the transmitter is supplied over the signal wiring.

3. Pull the cable through the cable gland/conduit. For the RS-485 bus use

shielded twisted pair wiring, preferably with an impedance of 120

(typically 24 AWG) to comply with the EIA-485 standard and EMC

regulations. Maximum cable length is 4000 ft. (1200 m).

4. Connect wires according to Figure 2-12 and Table 2-3. Connect the lead

that originates from the “A” line from the RS-485 bus to the terminal

marked MA (+), and the lead that originates from the “B” line to the

terminal marked MB (-). Make sure that the transmitter housing is

grounded in accordance with national and local electrical codes. There

are three grounding screw connections provided. Two are inside the

Field Terminal side of the housing identified by a ground symbol:

and the other is located on top of the housing.

5. If it is the last transmitter on the bus, connect the 120 termination

resistor.

6. Connect the leads from the positive side of the power supply to the

terminal marked PWR +, and the leads from the negative side of the

power supply to the terminal marked PWR -. The power supply cables

must be suitable for the supply voltage and approved for use in

hazardous areas, where applicable.

7. Attach and tighten the housing cover. Tighten the cable gland, plug and

seal any unused connections and connect the power supply.

,

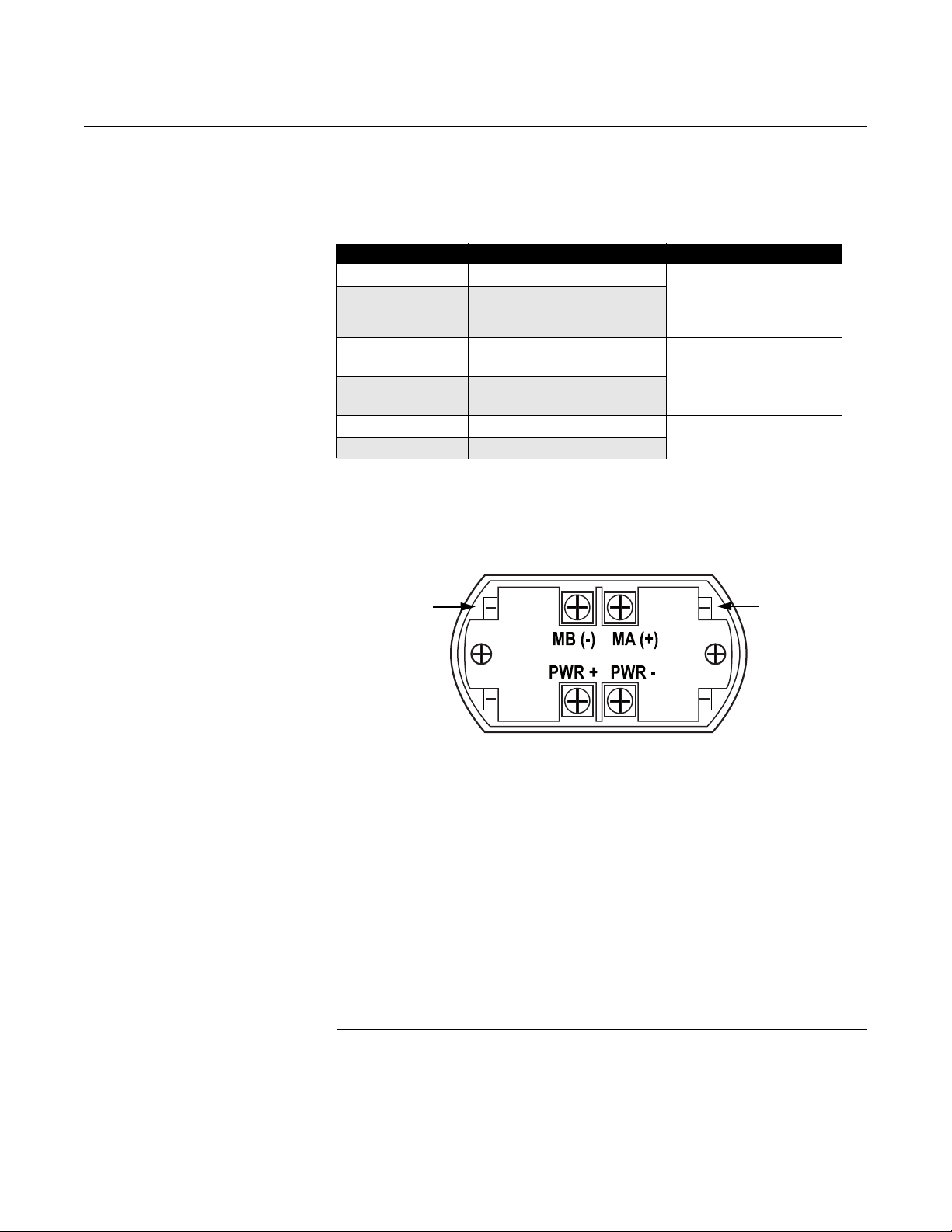

Figure 2-12. Field Wiring Connection for the 3300 with Modbus.

2-13

Rosemount Radar Level Transmitters

HART +

HART -

Connection Terminals

The connection terminals are described in Table 2-3 below:

Reference Manual

00809-0600-4811, Rev AA

February 2009

Table 2-3. Connection

Te rm i na l s

Figure 2-13. Connection Terminals

for Rosemount 3300 with Modbus

Connector label Description Comment

HART + Positive HART connector Connect to PC with RCT

software, 375 Field

HART - Negative HART connector

MA (+)

MB (-)

PWR + Positive Power input terminal

PWR - Negative Power input terminal

(1) The designation of the connectors do not follow the EIA-485 convention, which

states that RX/TX- should be referred to as 'A' and RX/TX+ as 'B'.

Modbus RS-485 A connection

(RX/TX+)

Modbus RS-485 B connection

(RX/TX-)

(1)

(1)

Communicator, or other

HART configurators

Connect to Modbus

Master

Apply +8 Vdc to +30 Vdc

PC Communication with MA(+) MB(-)

2-14

The Rosemount 3300 level transmitter can be configured with the Rosemount

Configuration Tools (RCT) software by using the MA (+), MB (-) connectors.

The PC communicates with the 3300 by transferring the HART protocol over

the RS-485. This requires using a RS-232/RS-485 Converter.

To communicate with the 3300 transmitter, the COM port used for serial

communication (RS-232) must be selected in RCT. Check the Device

Manager in Windows if unsure which COM port to use.

See Help, Contents in RCT for information on how to use a specific COM port.

NOTE

Make sure the 3300 transmitter is alone on the bus and disconnect or turn off

power from other devices.

Reference Manual

Isolator

Loop Resistor

3300 Series EEX d housing

4-20 mA

regulator

Ground current path broken by isolator

- 12 V

+ 12 V

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

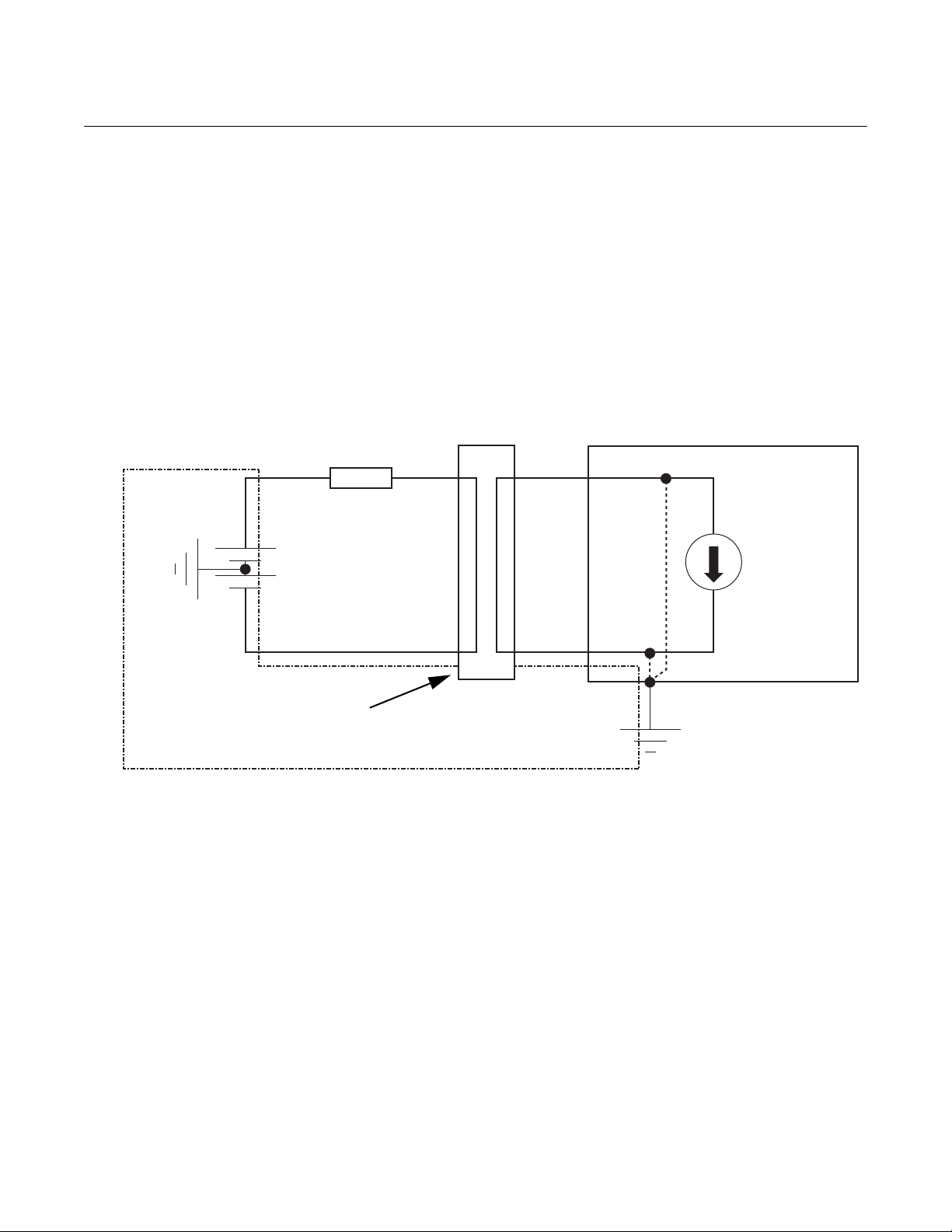

Cathodic Protection The ground plane voltage is elevated in applications where the tank is

protected by a Cathodic Protection System. For HART units, an isolator

should be used to protect the circuits from ground currents. A Modbus unit is

more robust against ground currents, and can handle a difference of ground

voltages of up to 20 V without using an Isolator.

Using an Isolator avoids undesired ground current in the 4-20 mA loop that

may interfere with the correct 4-20 mA output. Installing an isolator ensures

galvanic isolation between the control system and the transmitter and will

break the undesired loop, preventing interference with the wanted output.

Figure 2-14. 4-20 mA loop with

isolator to ensure galvanic

isolation.

Figure 2-14 above shows a 4-20 mA loop with isolator installed.

We recommend a loop powered isolator made by Dataforth;

http://www.dataforth.com/catalog/pdf/DSCL22.pdf. Rosemount part

number:DSCL22-01.

2-15

Rosemount Radar Level Transmitters

Ter min al

Block

Cover

External Ground Screw

Terminals for signal

and power supply

Cable

Entry

Cable

Entry

Internal Ground Screw

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount 5300 Series: HART Version

The Rosemount 5300 Series transmitter operates with a power supply

ranging from 16-42.4 V (16-30 V in IS applications, 20-42.4 V in

explosion-proof / flameproof applications). All configuration tools for HART

communication, such as the Rosemount 375 Field Communicator and

Rosemount Radar Master, require a minimum load resistance (RL) of 250

within the loop to function properly. See the diagrams below.

To connect the transmitter:

1. Make sure the housing is grounded (including IS ground inside Terminal

compartment) according to Hazardous Locations Certifications, national,

and local electrical codes.

2. Verify the power supply is disconnected.

3. Remove the terminal block cover (see Figure 2-15).

4. Pull the cable through the cable gland / conduit. For explosion-proof /

flameproof installations, only use cable glands or conduit entry devices

certified explosion-proof or flameproof.

5. Install wiring with a drip loop where the bottom of the loop must be lower

than the cable / conduit entry.

6. To connect the wires, see Figure 2-16.

7. Use the enclosed metal plug to seal any unused port.

8. Mount the cover and tighten the cable gland making sure the cover is

fully engaged to meet explosion-proof requirements (adapters are

required if M20 glands are used). For ATEX and IECEx installations, lock

the cover with the locking screw.

9. Connect the power supply.

Figure 2-15. Rosemount 5300

Series Terminal Block.

NOTE!

Use PTFE tape or other sealant at the NPT threads in the Cable Entries.

2-16

Reference Manual

Power

Supply

HART

Modem

PC

Load

Resistance

250

Rosemount 375

Handheld

Communicator

Rosemount 5300 Series

Radar Level Transmitter

00809-0600-4811, Rev AA

February 2009

Figure 2-16. Wiring diagram for

non-intrinsically safe

installations of the Rosemount

5300 with HART.

Rosemount Radar Level Transmitters

2-17

Rosemount Radar Level Transmitters

Rosemount 5300 Series

Radar Level Transmitter

375 Field

Communicator

Fieldbus

Modem

PC

Power

Supply

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount 5300 Series: FOUNDATION™ fieldbus Version

The 5300 Series transmitter, FOUNDATION™ fieldbus version, operates with a

power supply ranging from 9-32 V (9-30 V in IS applications and 16-32 V in

explosion-proof / flameproof applications) FISCO, IS applications: 9-17.5 V.

To connect the transmitter:

1. Make sure the housing is grounded (including IS ground inside terminal

compartment) according to Hazardous Locations Certifications, national,

and local electrical codes.

2. Verify the power supply is disconnected.

3. Remove the terminal block cover (see Figure 2-15).

4. Pull the cable through the cable gland / conduit. For explosion-proof /

flameproof installations, only use cable glands or conduit entry devices

certified explosion-proof or flameproof. Install wiring with a drip loop

where the bottom of the loop must be lower than the cable / conduit

entry.

5. To connect the wires, see Figure 2-17.

6. Use the enclosed metal plug to seal any unused port.

7. Mount the cover and tighten the cable gland making sure the cover is

fully engaged to meet explosion-proof requirements (adapters are

required if M20 glands are used). For ATEX and IECEx installations, lock

the cover with the locking screw.

8. Connect the power supply.

Figure 2-17. Wiring diagram for

non-intrinsically safe

installations of Rosemount 5300

with F

OUNDATION™ fieldbus.

2-18

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Section 3 Upstream Applications

Specific Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Separators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

Production/Slop Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-7

Slop tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-9

SPECIFIC APPLICATIONS

This document primarily describes two areas where our Guided Wave Radar

product is an excellent choice for level or level & interface measurements.

The areas are Gas Well and Oil Well applications. There are primarily three

types of applications at these production sites:

• Separator tanks (horizontal or vertical)

• Production tanks

•Slop tanks

The main difference between the tanks referenced above is the process or

product they contain. In gas wells, condensate (NGL) and water are the

primary products, whereas crude oil and water are the primary products in oil

wells.

The following description recommends which Rosemount Guided Wave

Radar transmitter to use for the different applications, along with details on the

proper model code for ordering. A complete list of recommended model code

information is found in Appendix A.

www.rosemount.com

Rosemount Radar Level Transmitters

SEPARATORS

Reference Manual

00809-0600-4811, Rev AA

February 2009

Horizontal separator (bullet tank)

Transmitter and probe selection

Horizontal separators are typically smaller in diameter and are used in both

Gas and Oil fields. The recommended installation is a Rosemount 3300 with a

Single lead probe.

Single Rigid Probes (model code option 4A) may be used if the tank height is

less than 9 ft. 10 in. (3 m 250 mm), and for anything taller, a Single Flexible

Probe (model code option 5A) must be used. If there is a high risk for a rigid

probe bending during installation, a flexible probe can be used on anything

taller than 3 ft. 4 in. (1 m 100 mm).

There are different materials of construction that can be used for the probes.

However, Stainless Steel (316/316L) is sufficient for the majority of these

applications, but material compatibility should be verified for each application.

Tank seal selection

The operating temperature is normally ambient temperature, however, the

pressure will vary in different applications/separators. The product

alternatives are either the Standard pressure and temperature tank seal

(model code option S) or the High Pressure tank seal (model code option P).

• The standard seal is rated to 580 psig (40 bar) at maximum 302 °F

(150 °C).

• The High Pressure tank seal is rated to 3500 psig (243 bar) at

maximum 392 °F (200 °C) or higher pressure for a lower temperature,

up to 5000 psig (345 bar) at a maximum of 100 °F (38 °C).

3-2

Model selection

The Rosemount 3302 is used for Level & Interface applications. If there is no

interface and only level is required, the transmitter can be configured for Level

measurement only. The separators have mounting connections either on the

top or on the side of the bullet tank in a chamber. See “Process Connections”

on page 2-7.

Reference Manual

• The standard seal is rated to maximum

580 psig (40 bar) at maximum 302 °F

(150 °C)

• The High Pressure tank seal is rated to

maximum 3524 psig (243 bar) at

maximum 392 °F (200 °C) or higher

pressure for a lower temperature, up to

5000 psig (345 bar) at a maximum of

100 °F (38 °C)

• One advantage of using Guided Wave

Radar technology is that it can cut through

foam because of its lower frequency

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Vertical separator (vertical cylinder tank)

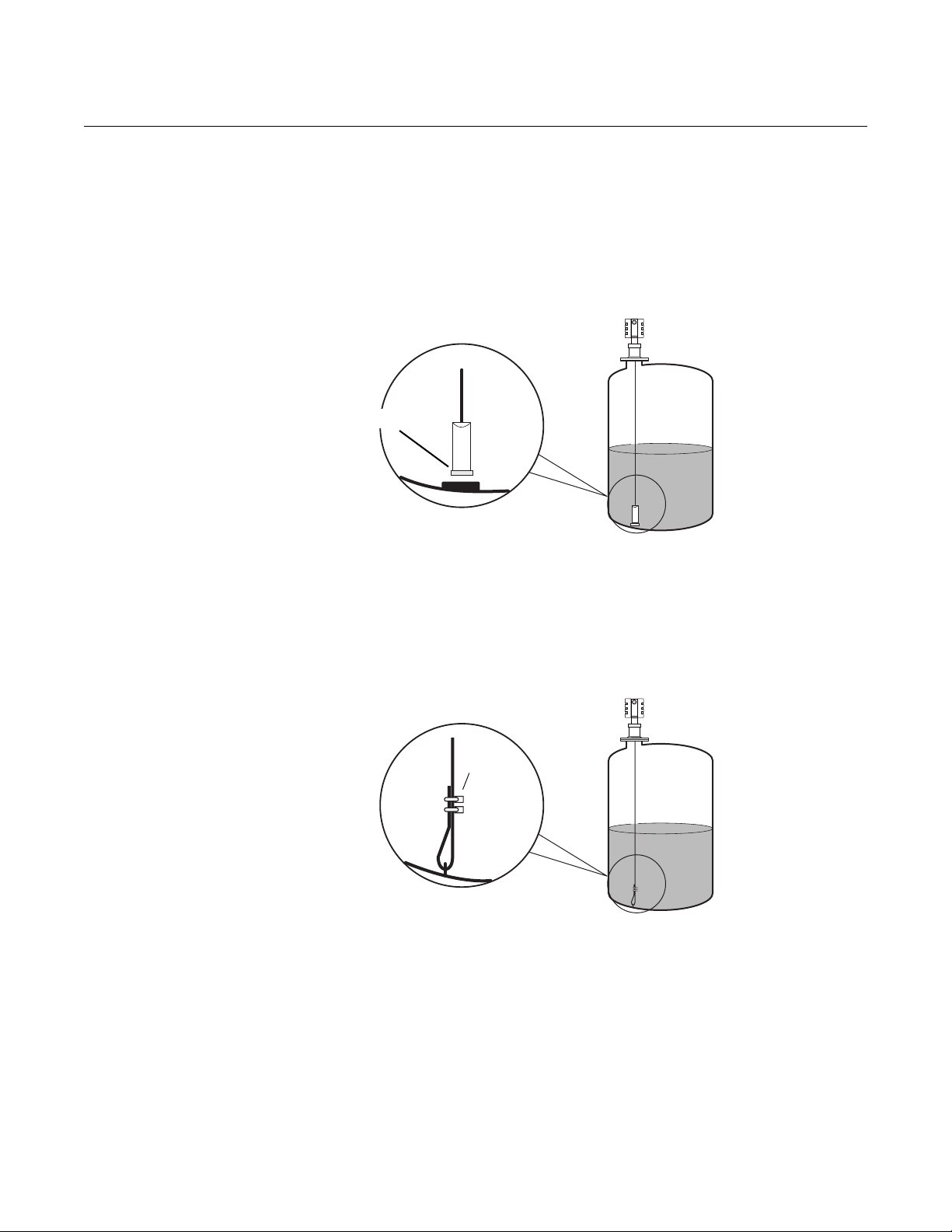

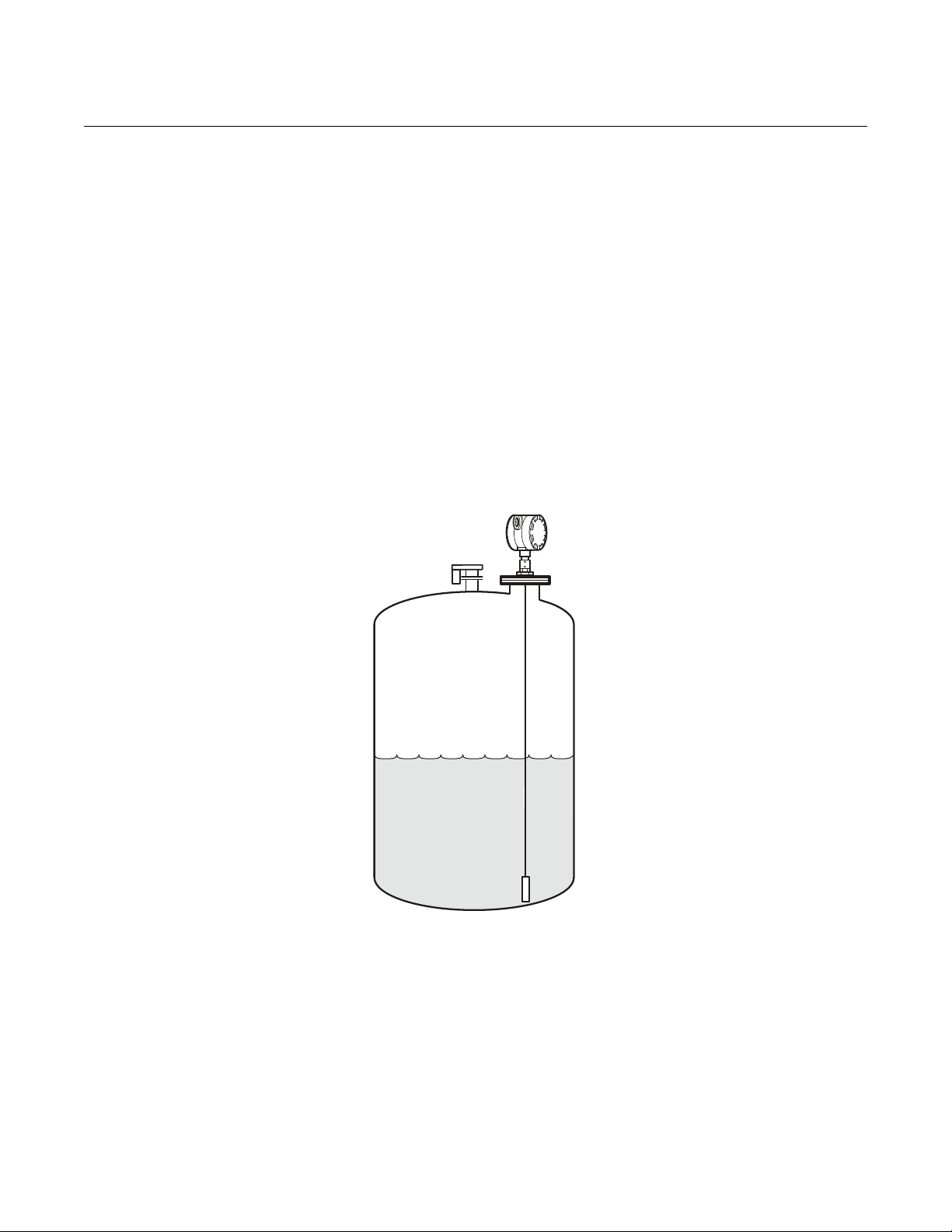

Figure 3-1. The Rosemount

3300 transmitter can be installed

on vertical separator tanks.

Transmitter and probe selection

Vertical separators vary in tank height and are used in both gas and oil fields.

The recommended product selection is a Rosemount 3300 with a Single lead

probe. It can be installed on top of the tank. On tall vertical cylinders, the 3300

may be installed on a chamber on the lower side of the separator with the

probe fully immersed.

Single Rigid Probes (model code option 4A) may be used if the tank height is

less than 9 ft. 10 in. (3 m 250 mm), and for anything taller, a Single Flexible

Probe (model code option 5A) must be used. If there is high risk for a rigid

probe bending during installation, a flexible probe can be used on anything

taller than 3 ft. 4 in. (1 m 100 mm). If the flexible probe version is used, select

the probe type that has a weight attached to the end (model code option 5A).

Tank seal selection

The operating temperature is normally ambient temperature, but the pressure

will vary in different applications/separators. One of the following product

alternatives should be selected:

• Standard pressure and temperature tank seal (model code option S)

• High Pressure tank seal (model code option P)

Model selection

Rosemount 3302 is used for Level & Interface applications in situations where

the probe is not fully immersed. The 3302 can be reconfigured for fully

immersed applications in chambers. The separators have mounting

connections either on top of the vertical tank or in a chamber on the lower side

of the tank. These process connections are used for interface measurement.

See “Process Connections” on page 2-7 for recommendations on different

process connections.

3-3

Rosemount Radar Level Transmitters

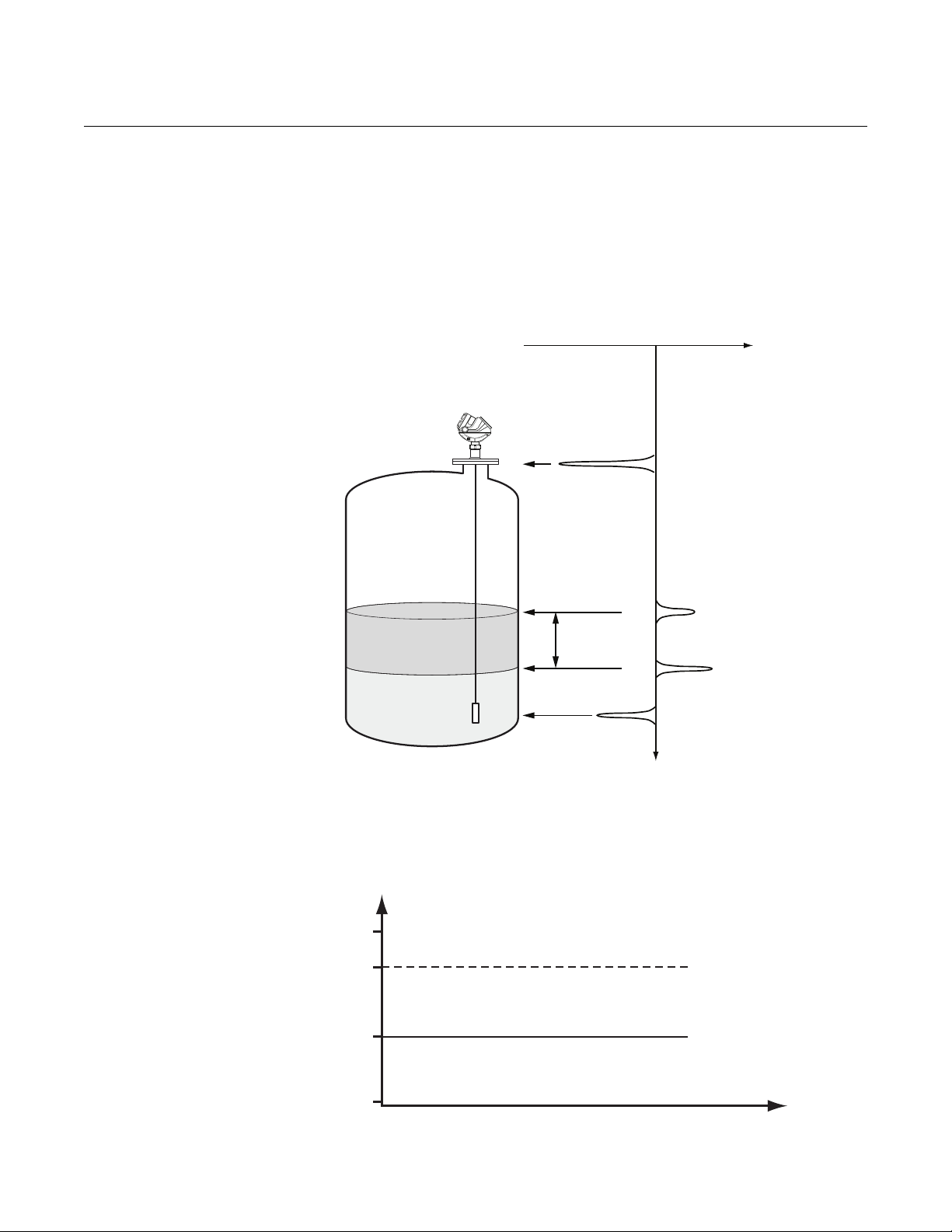

Reference Pulse

Level

Interface

Signal Amplitude

Thickness

Distance

Probe End

2

4

5

0.05

Level

Interface

Tank Height = 16.4 ft. (5 m)

Probe Length = 16.2 ft. (4.95 m)

Time

Probe End Distance

Height (m)

Reference Manual

00809-0600-4811, Rev AA

February 2009

Output measurement at different interface levels

Figure 3-2. Measurement levels.

Interface measurement depends on several factors. If the tank contains two

products, level, interface, and thickness can be measured. However, if the

upper or the lower product is pumped out, the peaks of the waveform plot

must be interpreted properly to get precise measurement data.

Figure 3-2 gives an overview of the various echoes presented on a waveform

plot when two products are found.

Figure 3-3. Level measurement

when both products are in the

tank.

3-4

Figure 3-3 shows how this state is presented on a waveform plot.

In the example below, tank height is 16.4 ft. (5 m), and probe length is 16.2 ft.

(4.95 m).

Reference Manual

Time

Level

Interface

Probe End Distance

Height (m)

00809-0600-4811, Rev AA

February 2009

Figure 3-4. The lower product is

pumped out of the tank.

Rosemount Radar Level Transmitters

Figure 3-4 illustrates the output signals presented as the lower product is

pumped out.

Level = 4 m

Interface = 2 m

Thickness = 2 m

5

Level = 2 m

4

2

0.05

Interface = 0.05 m

Thickness = 1.95 m

NOTE!

The measured thickness is different before and after emptying the lower

product. The level measurement is done until it reaches the end of the probe.

When the lower product reaches the probe end, the signal generated turns

into a constant, horizontal line, but no longer shows the actual interface. It

also effects the thickness measurement.

The plot shows that there is a large layer of the upper product left after the

lower product has been pumped out. In this case, both the upper product

surface echo and the probe end echo are easily detected. The level and

interface will not have the same value. The level will be set to the level of the

upper product, and the interface (level) will be set to the probe end level.

If both the upper and lower products are pumped out, the level and interface

(level) will have the same value until both the upper product surface echo and

the probe end echo can be detected.

Thickness is measured from the product surface (level) to the interface.

However, if the lower product is pumped out, the thickness will be measured

from the product surface to the probe end only, since further signs cannot be

detected.

When the tank refills, the level and interface output will be the same. Interface

is not detectable until the minimum thickness requirement is reached.

3-5

Rosemount Radar Level Transmitters

2

4

Level = 4 m

Interface = 2 m

Thickness = 2 m

5

Level = Interface = 2 m

Thickness = 0 m

0.05

Time

Level = Interface

Height (m)

Probe End Distance

If the upper product is pumped out of the tank, interface measurement is

presented as illustrated in Figure 3-5:

Figure 3-5. The upper product is

pumped out of the tank.

Reference Manual

00809-0600-4811, Rev AA

February 2009

3-6

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

PRODUCTION/SLOP TANKS

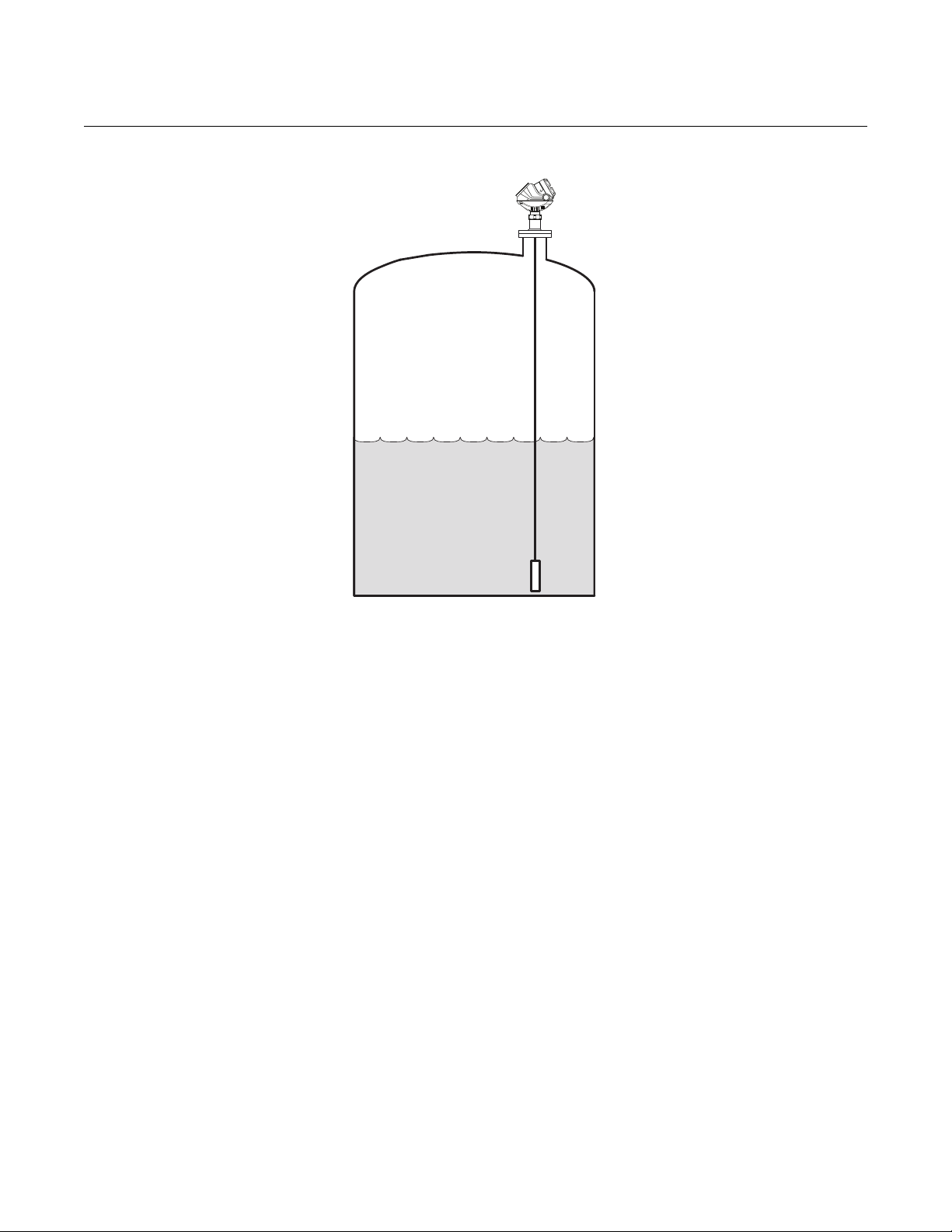

Vertical cylinder Transmitter and probe selection

Vertical cylinder tanks are holding or storage tanks where the separated

product (oil or condensate) is stored before it is moved to the next step in the

exploration process. These vertical cylinders vary in tank height.

If the tank is metallic, a Rosemount 3300 transmitter is sufficient. However, for

a non-metallic tank, a Rosemount 5300 transmitter is required for additional

EMI protection. Non-metallic tanks expose the probe to signal interference

from nearby motors or cables. The 5300 provides a more stable microwave

signal and improves EMI performance resulting in a more robust

measurement. The recommended product selection is a Rosemount 3300

with single flexible probe with a weight attached to the bottom (model code

option 5A).

Figure 3-6. The Rosemount

3300 with Single Flexible probe

is suitable for metallic Vertical

cylinder storage tanks.

3-7

Rosemount Radar Level Transmitters

Figure 3-7. The Rosemount

5300 with Single Flexible probe

is suitable for non-metallic (i.e.

Fiberglass) storage tanks.

Reference Manual

00809-0600-4811, Rev AA

February 2009

Tank seal selection

Vertical cylinder tanks are usually vented to the atmosphere, but some have a

vapor recovery system so the Rosemount 3300 standard tank seal is suitable.

For this application the Standard pressure and temperature tank seal version

(model code option S) should be used. The standard seal is rated from full

vacuum to maximum 580 psig (40 bar) at maximum 302 °F (150 °C).

Model selection

Most of these installations require both level and interface measurement,

while some only require level measurement.

For metallic tanks, a Rosemount 3302 allows for configuring the 3300 for

either Level & Interface mode or just Level.

For non-metallic tanks, a Rosemount 5302 allows for configuring the 5300 for

either Level & Interface mode or just Level.

3-8

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

SLOP TANKS

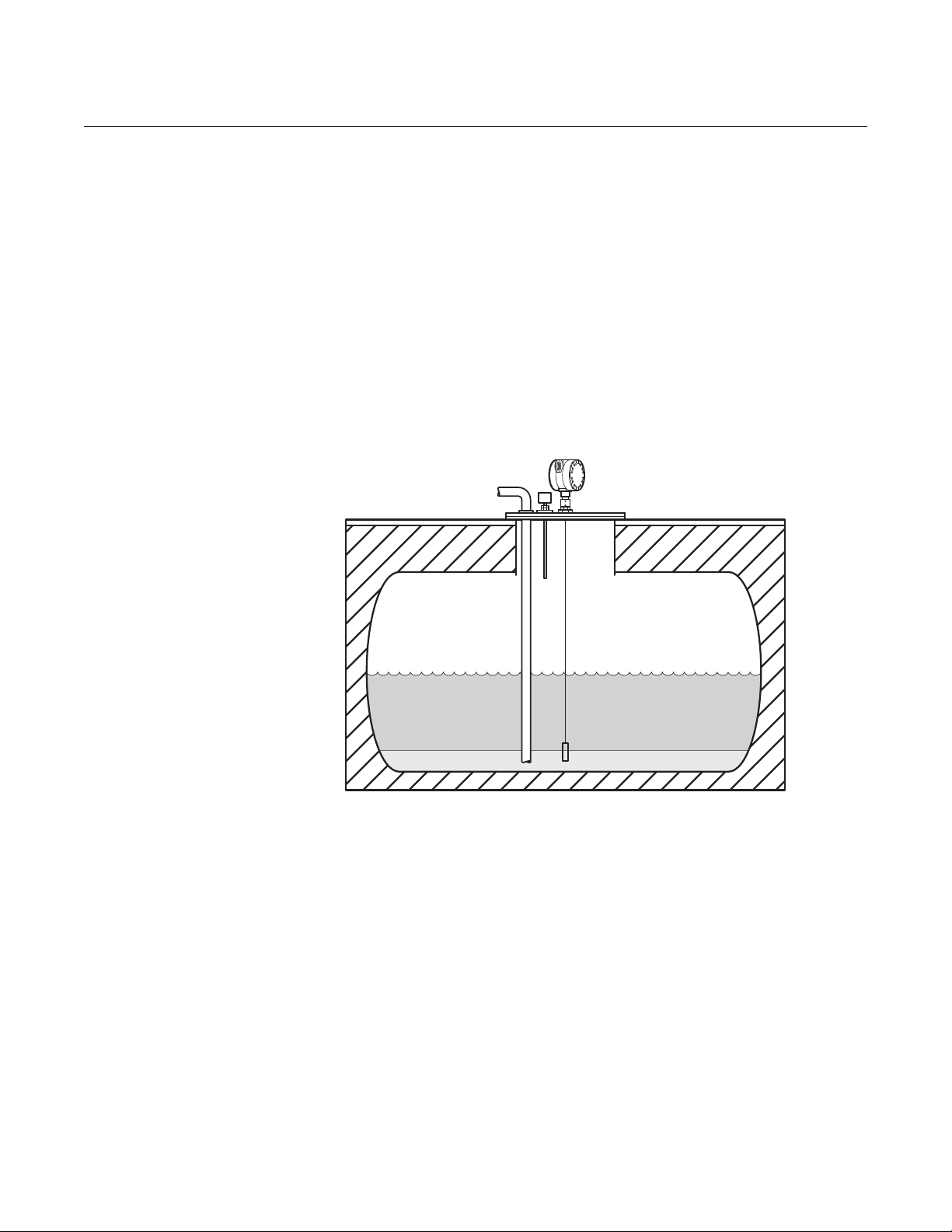

Underground or open pit Transmitter and probe selection

Oily and dirty water, as well as residue, are pumped into slop tanks for

temporary storage until further processing. Slop tanks are sometimes

underground tanks, or open pits often covered with a metal cover/plate.

A Rosemount 3300 with single lead probe is recommended. Single Rigid

Probes (model code option 4A) may be used if the tank height is less than

9 ft. 10 in. (3 m 250 mm). For anything taller, a Single Flexible Probe (model

code option 5A) must be used. If there is a high risk for a rigid probe bending

during installation, a flexible probe can be used on anything taller than

3 ft. 4 in. (1 m 100 mm).

If the flexible probe version is used, select the probe type that has a weight

attached to the end (model code option 5A).

Tank seal selection

These tanks are usually vented to the atmosphere, but some have a vapor

recovery system so the Rosemount 3300 standard tank seal is suitable.

For this application the Standard pressure and temperature tank seal version

(model code option S) should be used. The standard seal is rated from full

vacuum to maximum 580 psig (40 bar) at maximum 302 °F (150 °C).

Model selection

Most of these installations require both level and interface measurement,

while some only require level measurement.

Using a 3302 allows for configuring the 3300 for either Level & Interface mode

or just Level.

3-9

Rosemount Radar Level Transmitters

Metal flange Ø>2”/DN50

Metal sheet Ø>8”/200 mm

Non-metallic nozzle

Non-metallic nozzle

Do not use Teflon tape

or similar

non-conductive

materials in the

threaded connections.

These connections

must be able to provide

a ground connection

between the probe and

the tank.

Non-metallic process connections

For optimum measurement performance in non-metallic tanks, the

Rosemount 5300 Series is required. For tanks with non-metallic process

connections, the probe must be mounted with a metal flange, or screwed in to

a metal sheet (d>8 in./200 mm) if the threaded version is used.

Figure 3-8. Mounting in

non-metallic process

connections.

Reference Manual

00809-0600-4811, Rev AA

February 2009

3-10

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Section 4 Commissioning

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-2

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4-2

Plotting the Measurement Signal . . . . . . . . . . . . . . . . . . . page 4-5

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury.

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Make sure the main power to the Rosemount 3300 / 5300 transmitter is off and the lines

to any other external power source are disconnected or not powered while wiring

the gauge.

Probes covered with plastic and/or with plastic discs may generate an ignition-capable

level of electrostatic charge under certain extreme conditions. Therefore, when the

probe is used in a potentially explosive atmosphere, appropriate measures must be

taken to prevent electrostatic discharge.

www.rosemount.com

Reference Manual

00809-0600-4811, Rev AA

Rosemount Radar Level Transmitters

February 2009

INTRODUCTION This section is a brief outline of commissioning, and does not provide

comprehensive information on the whole procedure.

To execute the commissioning process, the product-related Quick Installation

Guides steps are to be followed.

COMMISSIONING The transmitter installation should be carried out as described in the Quick

Installation Guide, enclosed with every transmitter. Even though the

transmitter may be installed on the bench, it must be configured according to

the actual process conditions.

Do not bend the probe during any part of the installation. If it is necessary,

shorten the probe, mount a centering disk, or anchor the probe during the

mechanical installation. For more information see the respective Reference

Manuals:

• Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530)

• Rosemount 3300 Series Reference Manual

(Document No. 00809-0100-4811)

Beside these required steps, it is recommended as best practice to perform a

Trim Near Zone, save a backup of the transmitter settings, and save the initial

echo curve plot.

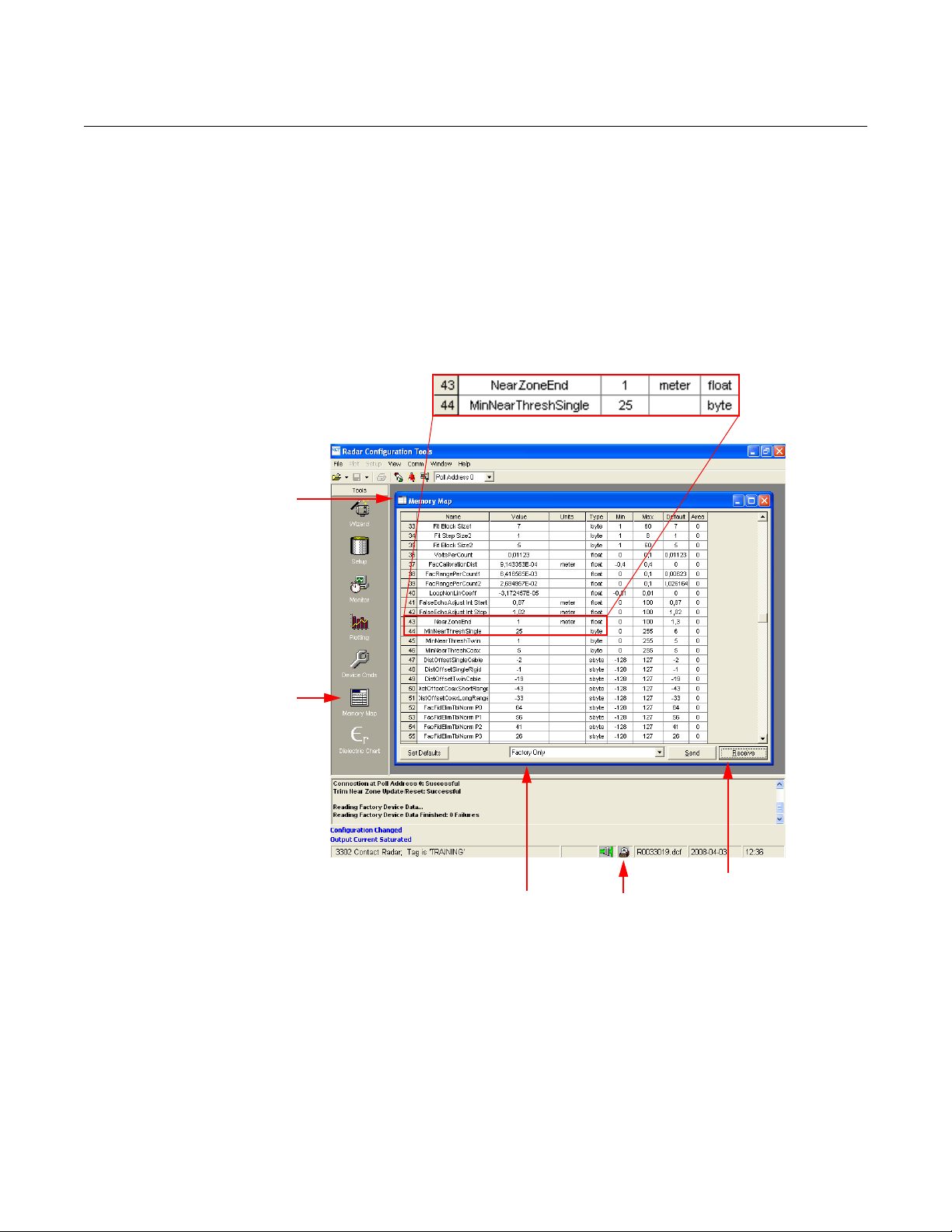

Trim Near Zone The Rosemount 3300 / 5300 Series transmitters are equipped with a firmware

functionality that minimizes the Upper Transition Zone based on the actual

mounting conditions.

To activate this functionality, ensure that the tank or chamber is empty,

alternatively, that the (upper) product is no closer than 40 in. (1 m), and then

execute the Trim Near Zone command.

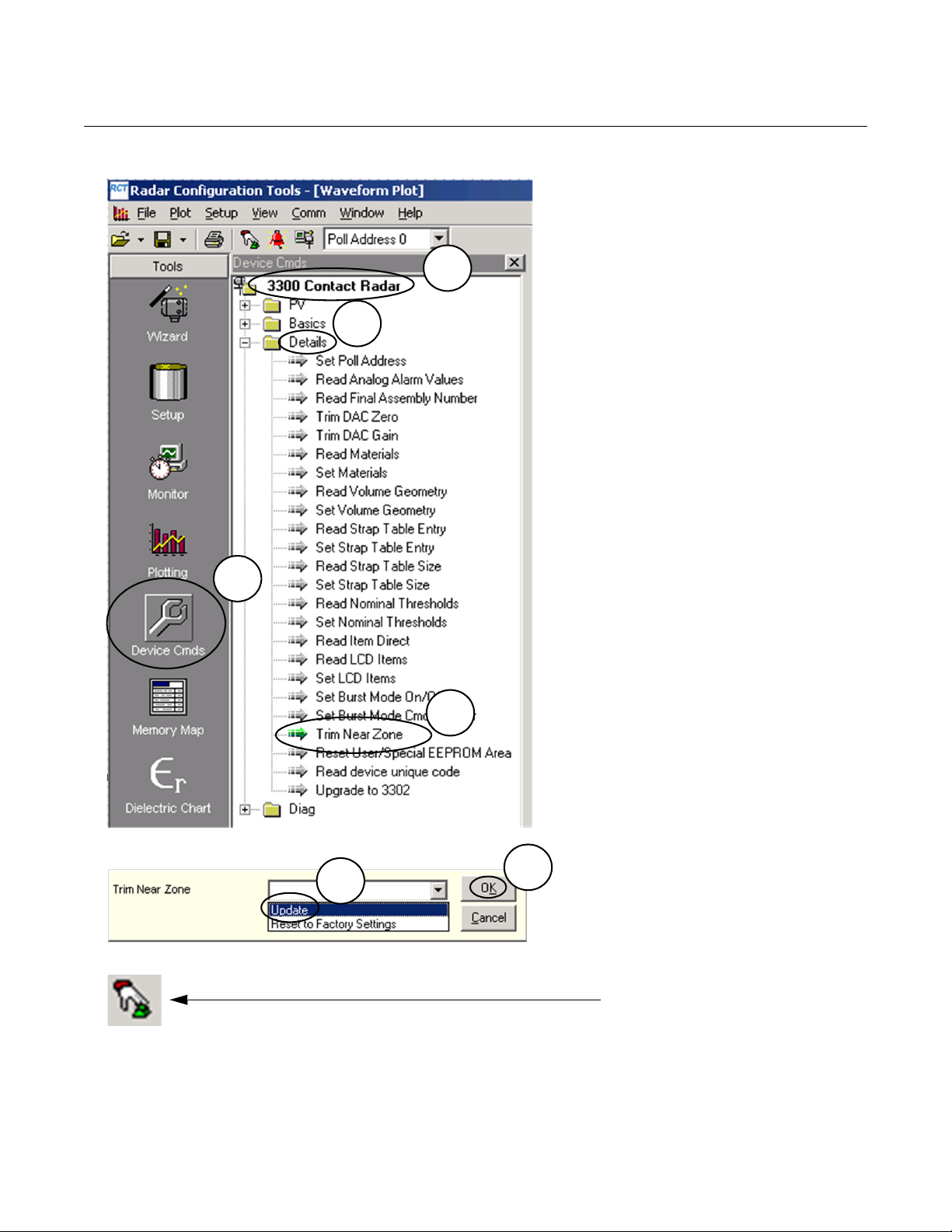

For the Rosemount 3300 Series, the Trim Near Zone command can be

completed in the Radar Configuration Tools (RCT) software. Follow these

steps to conduct a Trim Near Zone:

4-2

Reference Manual

1. Click the Device Cmds tool.

2. Double-click 330x.

3. Click Details.

4. Double-click Trim Near Zone.

5. Select Update.

6. 6. Click OK.

7. Wait 1 minute.

8. Restart the device clicking

this icon.

1

2

3

4

5

6

4

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

4-3

Rosemount Radar Level Transmitters

For the Rosemount 5300 Series, the Trim Near Zone command can be

completed with the Rosemount Radar Master (RRM) software. The function is

found in the Advanced Configuration screen.

Rosemount Radar Master > Advanced > Near Zone > Trim Near Zone

Figure 4-1. The Trim Near Zone

command is on the Advanced

Configuration screen.

Reference Manual

00809-0600-4811, Rev AA

February 2009

Store Backup and Verification Files

For detailed information on the Trim Near Zone functionality, refer to

Rosemount 3300 (Document No. 00809-0100-4811) or 5300 Series

Reference Manuals (Document No. 00809-0100-4530).

As the last step of the commissioning procedure, it is recommended that both

the transmitter settings and the echo curve be stored. These can be used for

subsequent transmitter verification or troubleshooting.

For the 3300 Series in RCT, use the following procedure:

Radar Configuration Tools > View > Setup > Basics > (right click)

Receive All > (right click) Save Setup

Radar Configuration Tools > View > Plotting > Start the plot reading

and disk logging

For the 5300 Series in RRM, use the following procedure:

Rosemount Radar Master > Device > Backup Config to file

Rosemount Radar Master > Tools > Echo Curve > Record

4-4

Reference Manual

Product surface

End of Probe

Reference pulse

Product interface

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

PLOTTING THE MEASUREMENT SIGNAL

Plotting the Measurement Signal for the Rosemount 3300 Series

Figure 4-2. Example of a 3300

Series Waveform plot.

The 3300 Series and 5300 Series are compatible with different softwares for

plotting the measurement signal. The 3300 Series transmitter utilizes the

Radar Configuration Tools (RCT) software, while the 5300 Series transmitter

utilizes the Rosemount Radar Master (RRM) software.

The two software configuration programs have similar functions. Both

programs have the ability to plot the measurement signal. This section

explains how to view plots in RCT and RMM, and highlights the differences

between the two plot views.

For the 3300 Series, the Radar Configuration Tools (RCT) program has

powerful tools for advanced troubleshooting. Using the Waveform Plot

function gives an instant view of the tank signal.

To plot the measurement signal:

1. Start the Radar Configuration Tools program by clicking the RCT desktop

icon: .

2. Choose View > Plotting menu option, or choose the Plotting icon in

the RCT workspace (Tools pane at the left-hand side of the workspace)

and click the Read button.

The plot shows peaks for the product surface (P2), reference pulse (P1) and

end of probe (EOP). The probe end may not always be visible depending on

the amount of product above.

T1 - amplitude threshold for detection of the Reference pulse P1.

T2 - amplitude threshold for detection of the product level peak P2.

T3 - amplitude threshold for detection of the interface level peak P3.

T4 - amplitude threshold that is used to detect whether the probe is fully

immersed in the upper product or not.

4-5

Rosemount Radar Level Transmitters

Reference Manual

00809-0600-4811, Rev AA

February 2009

Plotting the Measurement Signal for the Rosemount 5300 Series

For the 5300 Series, Rosemount Radar Master (RRM) and other tools using

enhanced EDDL have the functionality for advanced troubleshooting and plot

viewing. In RRM, the waveform plot is often referred to as the Echo Curve.

To open the Echo Curve:

1. Start Rosemount Radar Master program by clicking on the RRM desktop

icon:

2. Choose the Too l s > Ec h o C u rv e menu option, or choose the Echo Curve

icon in the RRM workspace (Tools or Setup pane at the left-

hand side of the workspace) and click the Read button.

The echo curve represents the tank, as seen by the radar transmitter. Each

peak corresponds to a reflection of the radar signal (e.g. the surface of the

level or interface, an obstacle, or something else). By viewing single instances

or movies of the echo curve, the transmitter configuration can be adjusted to

achieve a reliable level measurement. Additionally, the echo curve gives

insight into transmitter functionality. Usually, an echo curve analysis is not

needed, because the transmitter automatically sets the appropriate

parameters based on the startup information, such as tank height and tank

media. However, the echo curve functionality is valuable for troubleshooting

difficult applications.

4-6

Reference Manual

Reference

peak

Surface peak

Interface peak

Amplitude

UNZ

Interface

peak

Interface

threshold

Surface

peak

Surface

threshold

Reference

peak

Distance

As presented in

Rosemount Radar Master

Amplitude

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Echo Curve Constituents

In a typical measurement situation, the following peaks appear in the echo

curve:

Reference peak. This reference pulse is caused by the transition between

transmitter head and probe.

Surface peak. This pulse is caused by a reflection from the product surface.

The measurement output from the device is presented with an arrow at the

top of the plot. Normally, the output arrow points directly at the surface or

interface echo peak, but sometimes the output and echo peak distance do not

coincide. When this happens, a line is drawn from the echo peak to the

position of the measurement output arrow.

4-7

Rosemount Radar Level Transmitters

The output arrow can be displaced when there are rapidly changing surface

echo peaks because the transmitters filter the echo peaks to stabilize the

measurement output. The displacement also occurs during interface

measurement.

In the plot shown on page 4-7, the interface peak does not align with the

interface output because the transmitter compensates for the decreased

speed of microwaves through the upper product by using the dielectric

constant of the upper product. The transmitters put the arrow at the actual

physical distance to the interface, which is less than the distance to the

interface peak.

Interface peak (5302 only). This pulse is from the reflection from the

interface between the upper and lower product. This peak will only be

identified by the transmitter when it is configured for Measurement Mode

Level & Interface.

Table 4-1. Typical peak

amplitudes for Rosemount 5300

Series with single lead probe in

4 in. (100 mm) chambers

Reference peak

Surface peak, 5301 with oil (DC=2) ~2,000 mV

Surface peak, 5301 with water (DC=80) at 3 ft

(1 m) distance

Interface peak, 5302 with oil and water ~8,000 mV

(1) This value does not apply and may be considerably lower when the probe is completely submerged

in product.

Peak

Reference Manual

00809-0600-4811, Rev AA

February 2009

Approximate signal strength, ideal

conditions for single lead probe in 4 in.

(100 mm) chambers

~10,000 mV

~10,000 mV

(1)

Various amplitude thresholds filter out unwanted signals and pick up the

different peaks. The transmitter uses certain criteria to select which peaks

correspond to the actual level and interface surfaces.

Counting from the top of the tank, the first echo above the Surface Threshold

is considered the product surface. Pulses further from the top, although above

the Surface Threshold, are ignored. When the surface echo is identified, the

next pulse that is below the product surface with a signal strength above the

Interface Threshold is considered the Interface.

Surface Threshold - amplitude threshold for detection of the Product level

peak. The surface threshold is a number of individually adjustable amplitude

threshold points, called the Amplitude Threshold Curve (ATC).

Interface Threshold - known as amplitude threshold for detection of the

Interface level peak.

Upper Null Zone / Hold Off Distance - measurements are not performed

within the Upper Null Zone (UNZ) / Hold Off Distance, and can be used to

avoid measurements above a certain level, e.g. disturbances in the nozzle.

4-8

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Differences Between Plots in RRM and RCT

Figure 4-3. Surface Threshold

Curve.

There are a few differences between functionality of the Waveform Plot in

RCT and the Echo Curve in RRM. In RRM, the x-axis plots the physical

distance to the product or disturbance. The x-axis in RCT represents the

electrical distance.

Additionally, there are a few differences in the threshold settings. RRM has

automated recognition of a fully submersed probe, so there is no need for a

T4 threshold. In RCT, the T2, surface threshold, setting is linear. But in RRM,

the surface threshold setting is a curve that can be manipulated by moving

points along the threshold curve. The T3, interface threshold, is linear for both

RCT and RRM. Figure 4-3 demonstrates a multi-point threshold curve.

4-9

Rosemount Radar Level Transmitters

Reference Manual

00809-0600-4811, Rev AA

February 2009

4-10

Reference Manual

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Section 5 Troubleshooting

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5-2

Rosemount 3300 Threshold Settings . . . . . . . . . . . . . . . . page 5-3

Disturbances From Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . page 5-5

Device status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5-12

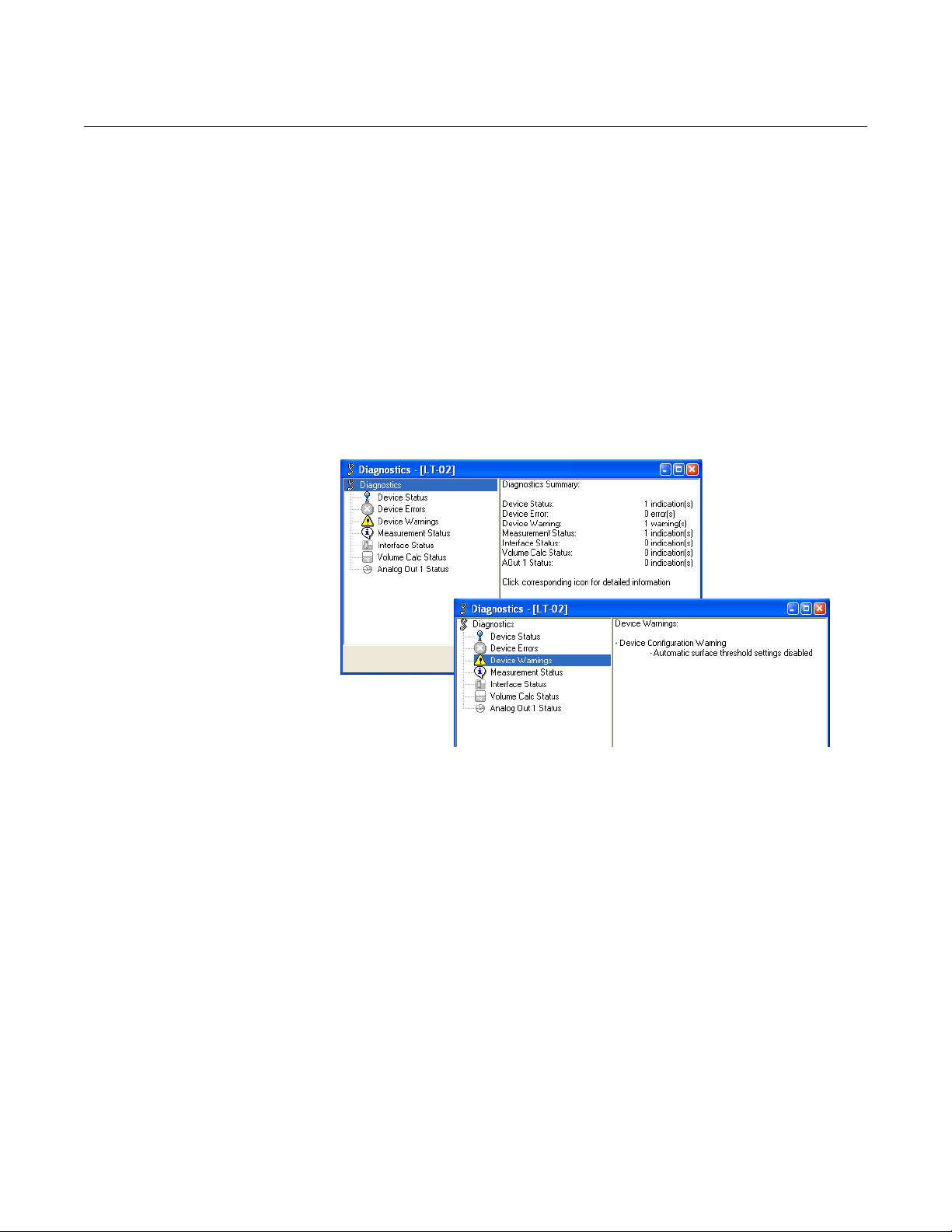

This section describes examples of measurement problems that might occur.

The examples show how these problems are identified using the Waveform

Plot function, and the result after adjustments.

The Waveform Plot function can be found in the Radar Configuration Tools

(RCT) program for the Rosemount 3300 Series.

The Rosemount 5300 Series transmitter utilizes the Rosemount Radar Master

software for plotting and configuring functionality. The two software systems

are not interchangeable between the different transmitter series.

Warning, Error, and Device Status messages are listed in the Reference

Manuals:

• Rosemount 5300 Series Reference Manual

(Document No. 00809-0100-4530)

• Rosemount 3300 Series Reference Manual

(Document No. 00809-0100-4811)

www.rosemount.com

Reference Manual

00809-0600-4811, Rev AA

Rosemount Radar Level Transmitters

February 2009

SAFETY MESSAGES Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury.

Verify that the operating environment of the gauge is consistent with the appropriate

hazardous locations certifications.

Before connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Make sure the main power to the Rosemount 3300 / 5300 Transmitter is off and the lines

to any other external power source are disconnected or not powered while wiring

the gauge.

Probes covered with plastic and/or with plastic discs may generate an ignition-capable

level of electrostatic charge under certain extreme conditions. Therefore, when the

probe is used in a potentially explosive atmosphere, appropriate measures must be

taken to prevent electrostatic discharge.

Process leaks could result in death or serious injury.

Make sure that the transmitter is handled carefully. If the Process Seal is damaged, gas

might escape from the tank if the transmitter head is removed from the probe.

5-2

Reference Manual

The product surface

is undetected

The product surface

is detected

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

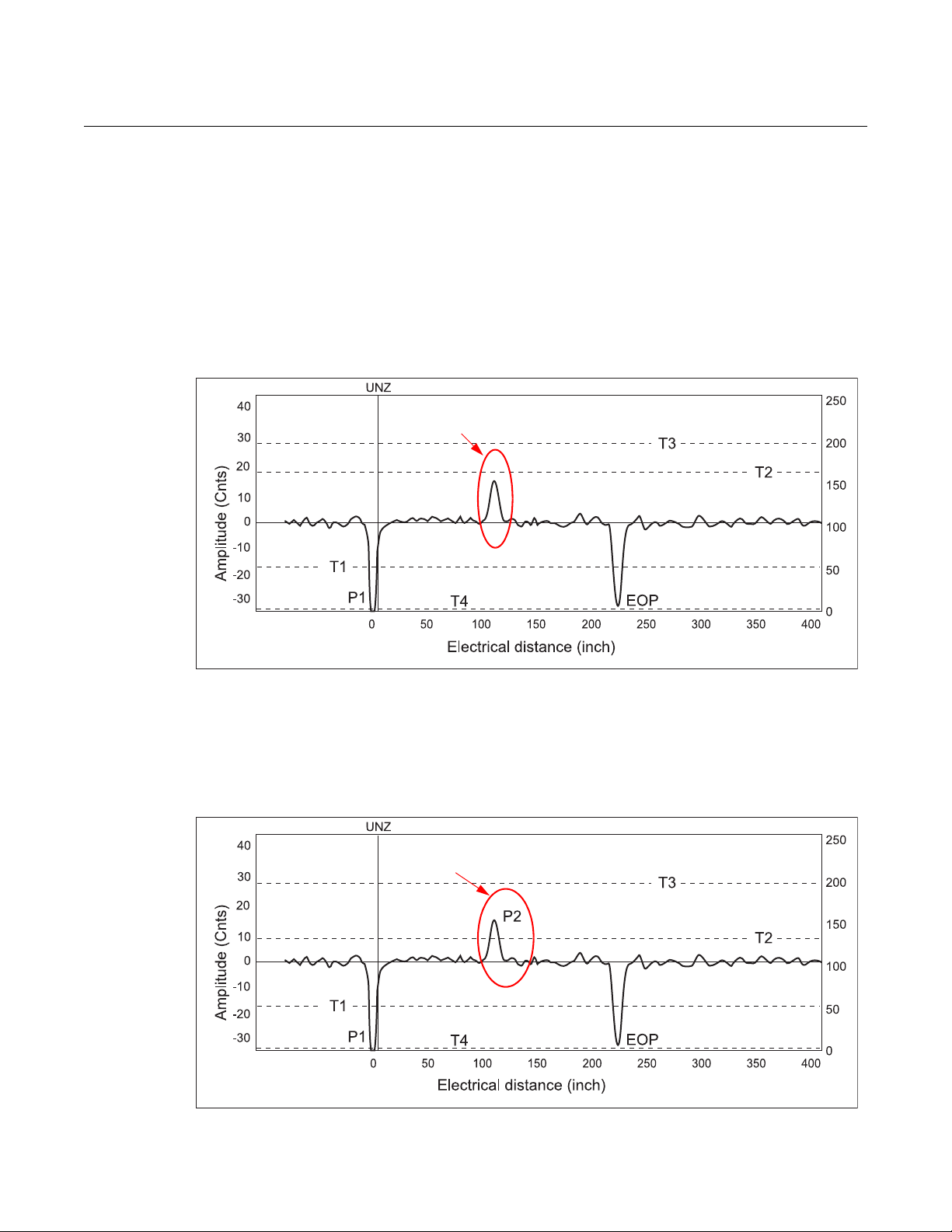

ROSEMOUNT 3300 THRESHOLD SETTINGS

Case 1 - Level measurements

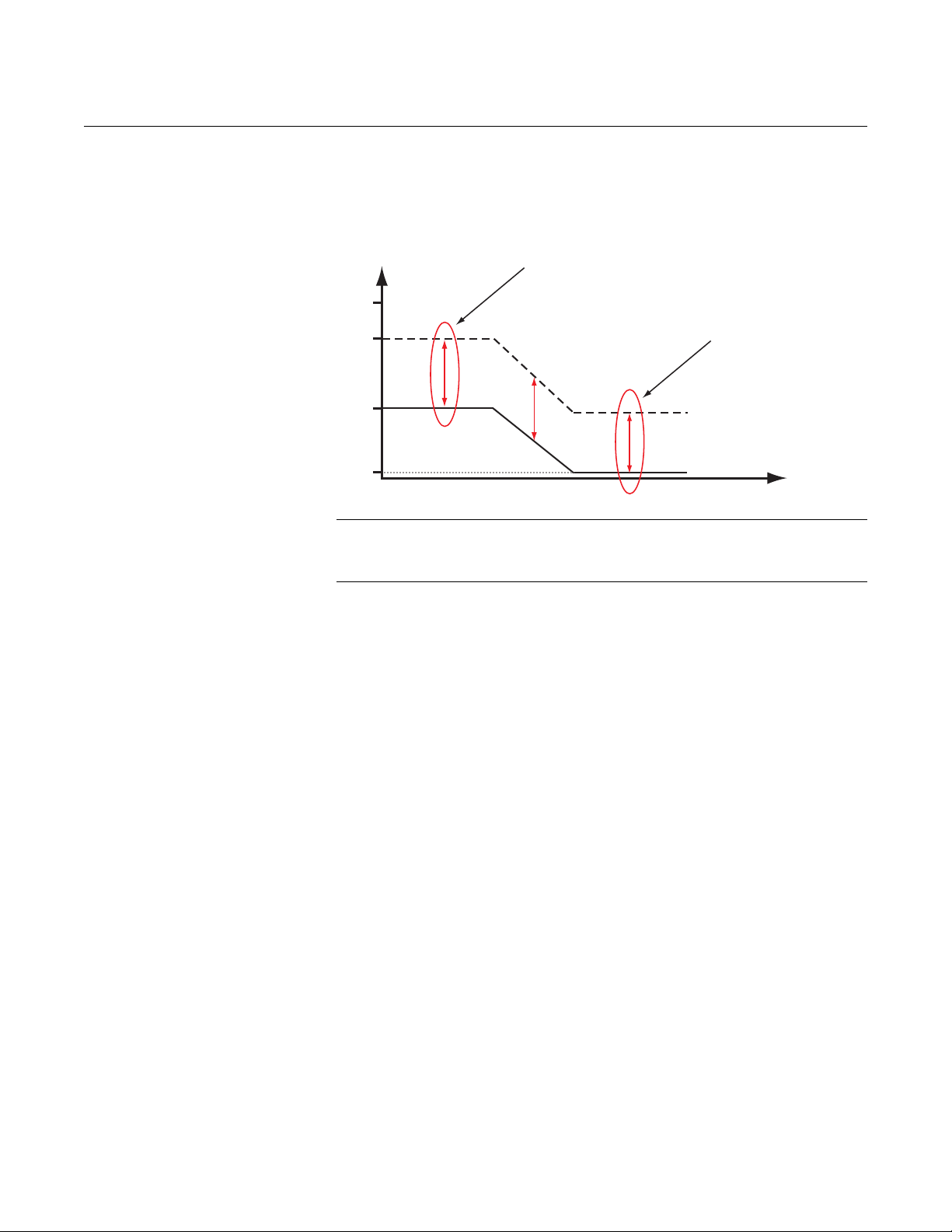

Figure 5-1. Threshold T2 too

high. Level peak not detected.

The following Threshold Setting scenarios are shown using the Waveform

Plot tool in RCT (connected to a Rosemount 3300 Series transmitter).

Threshold settings for RRM (connected to a Rosemount 5300 Series

transmitter) can be similarly configured. General guidelines for 5300 threshold

settings can be found on page 5-10.

The Product Dielectric Constant is wrong, resulting in an amplitude threshold

T2 above the actual product surface peak.

Figure 5-2. Threshold T2

lowered. Product surface P2

detected.

The Product Dielectric Constant is corrected, resulting in an amplitude

threshold T2 properly set to pick up the product surface level.

5-3

Rosemount Radar Level Transmitters

Reference Manual

00809-0600-4811, Rev AA

February 2009

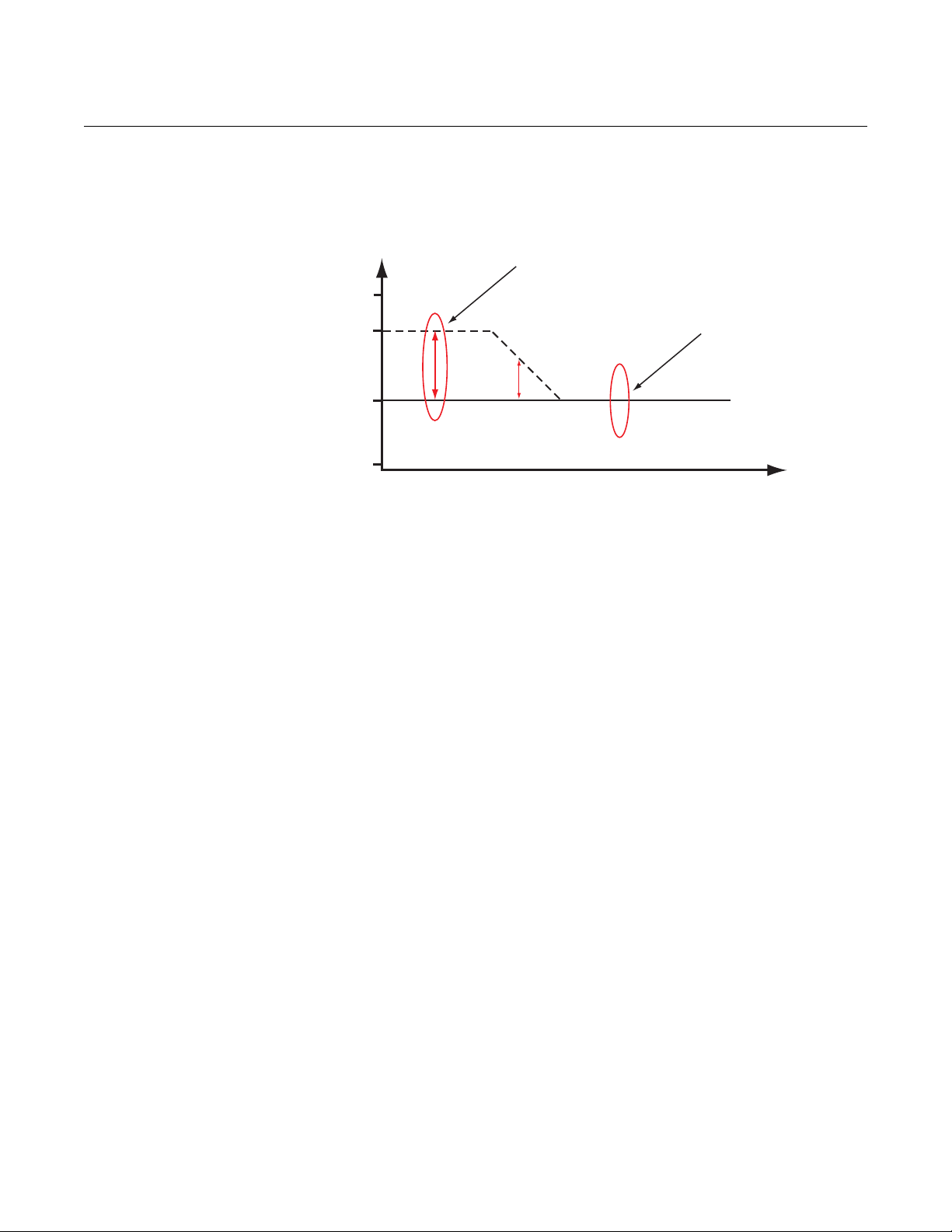

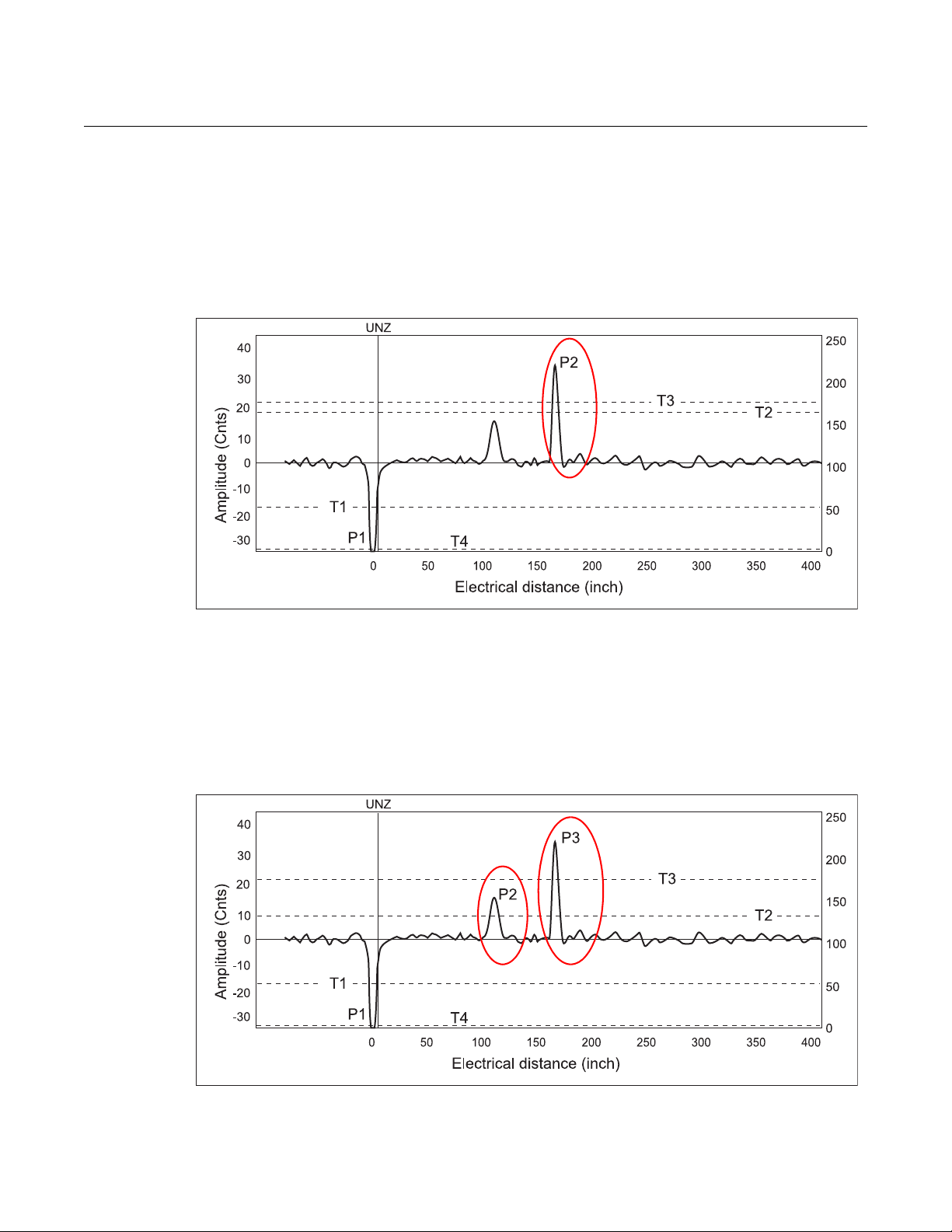

Case 2 - Level & Interface measurements

Figure 5-3. Using the wrong

Upper Product DC may result in

a threshold T2 above the

surface peak.

The wrong Upper Product Dielectric Constant is set, resulting in an amplitude

threshold T2 above the actual product surface peak. The interface peak is

incorrectly interpreted as the product surface.

Figure 5-4. Correct Upper

Product DC allows the

transmitter to detect both the

product level and the interface.

When the correct Upper Product Dielectric Constant is set, the amplitude

threshold T2 is located below the product surface level peak. Both the product

surface level and the interface level are detected.

5-4

Reference Manual

Actual product surface

UPPER NULL ZONE

Incorrect

interpretation as

product surface

Product surface

UPPER NULL ZONE

Disturbance

00809-0600-4811, Rev AA

February 2009

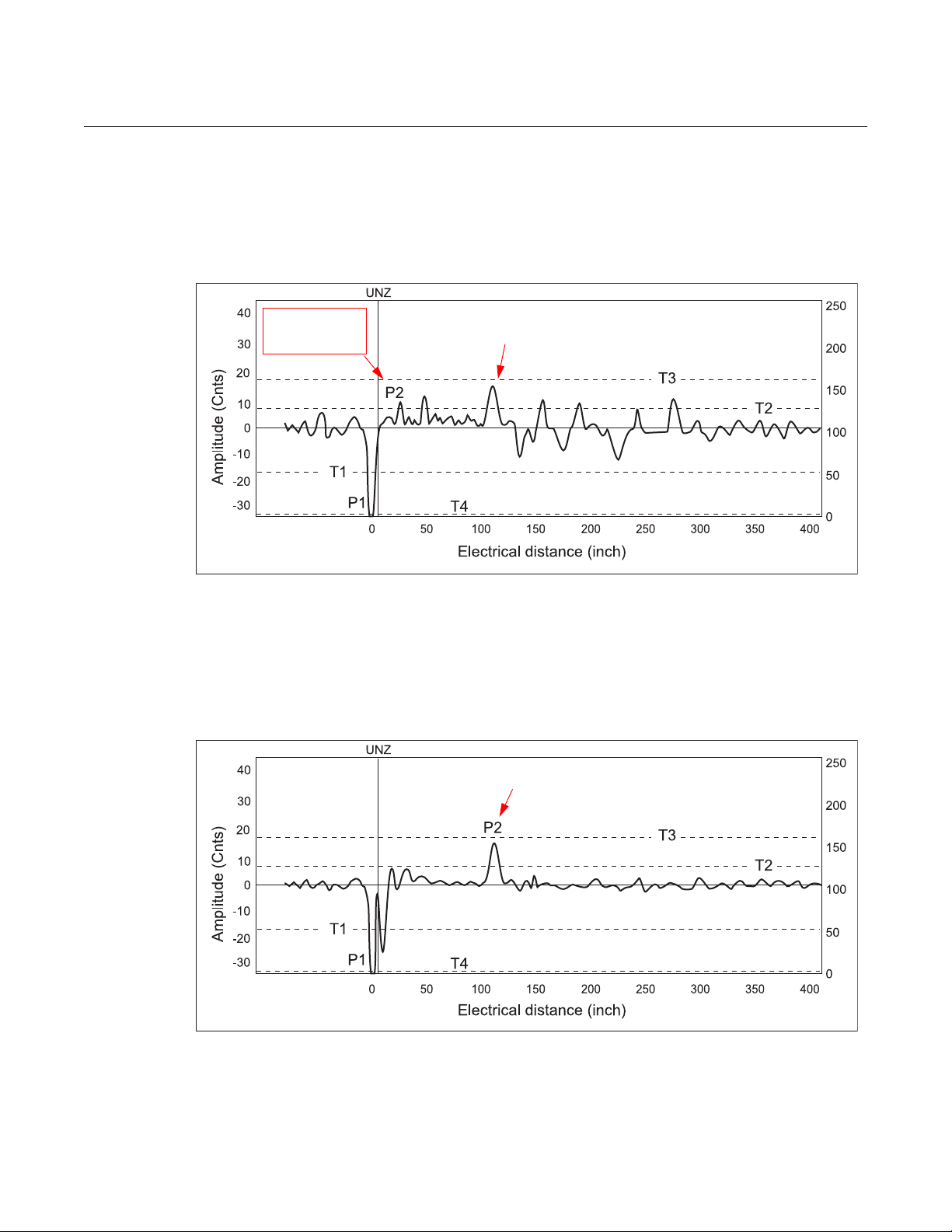

DISTURBANCES FROM NOZZLE

Rosemount Radar Level Transmitters

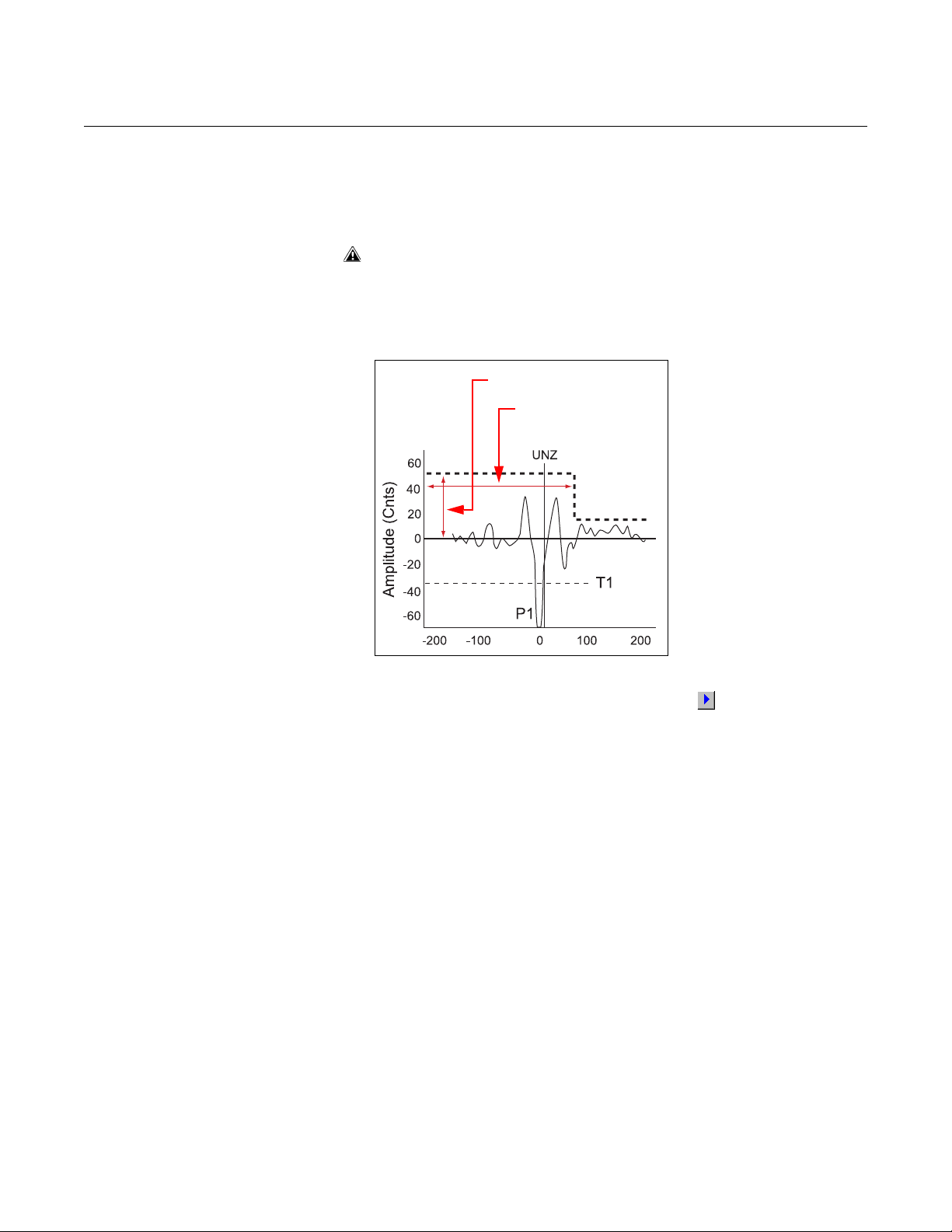

Upper Null Zone adjustment

Figure 5-5. Waveform plot

indicates that the transmitter

misinterprets a disturbing echo

as the product surface.

The transmitter identifies a disturbance from the nozzle as the product surface

(P2), as shown in Figure 5-5.

Figure 5-6. Waveform plot after

UNZ was adjusted.

To change the Upper Null Zone in RCT:

View>Device Commands>Basics>Set Null Zones.

After the Upper Null Zone (UNZ) is adjusted, the transmitter ignores the

disturbing echo and correctly shows the product surface.

5-5

Reference Manual

Incorrect

interpretation as

product surface

Actual product

surface

Product surface

00809-0600-4811, Rev AA

Rosemount Radar Level Transmitters

February 2009

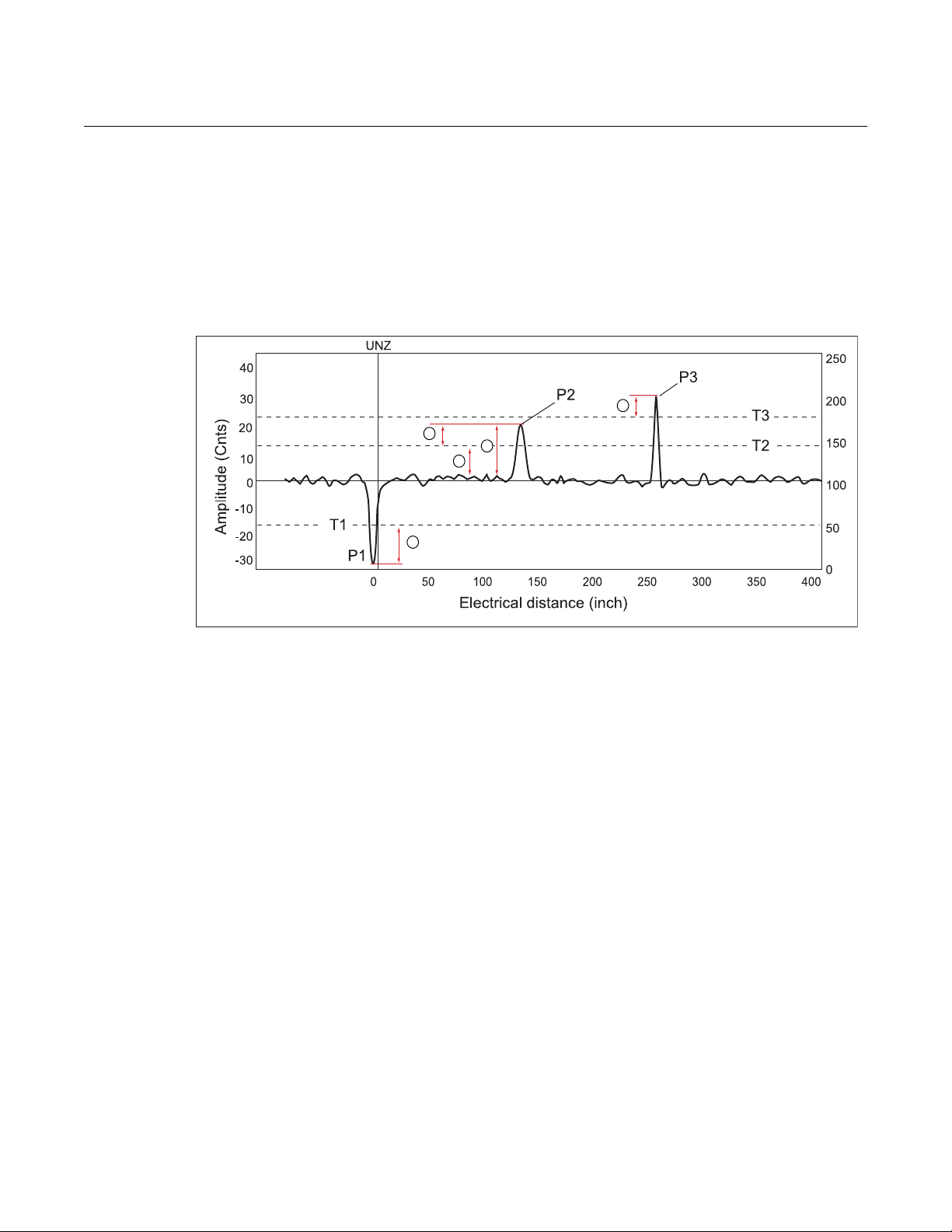

Nozzle influence Installation in a rough nozzle may result in several disturbing echoes, as

illustrated in Figure 5-7.

Figure 5-7. Example of a

waveform plot for an installation

in a rough nozzle.

Figure 5-8. Typical plot for an

installation in a 4 in. (100 mm)

nozzle with a smooth interior.

With a 4-in. (100 mm) smooth nozzle that is clean on the inside, the Level and

Interface peaks are easily distinguished from noise and other disturbing

peaks.

5-6

Reference Manual

Near Zone threshold

00809-0600-4811, Rev AA

February 2009

Rosemount Radar Level Transmitters

Near Zone Threshold Disturbing echoes may result from rough edges in the nozzle. Figure 5-9