Rosemount Engineering Guide: System Engineering Guidelines IEC 62591 WirelessHART Manuals & Guides

Page 1

System Engineering Guidelines

Engineering Guidelines

00809-0100-6129, Rev AB

February 2016

IEC 62591 WirelessHART

®

Page 2

February 2016

1.1 Preface

These “System Engineering Guidelines” apply to end user adoption of WirelessHART self-organizing mesh networks to automate process manufacturing. Following the guidelines will help

users take full advantage of WirelessHART systems.

The document provides complete technical guidance for using WirelessHART devices and

applications. The information presented applies to all IEC 62591 WirelessHART installations,

independent of brand. Vendor-specific ‘value added’ features are not included.

PART I of the guideline addresses use of WirelessHART technology in project execution from the

Appraise (conceptual design) stage through to the Pre-FEED (Front End Engineering and

Design), FEED, Execute and Operation stages. PART II describes the Field Network components

that comprise WirelessHART networks.

The guidelines describe WirelessHART system functions and capabilities, networks and alternate

modes of operation, and step-by-step procedures for system access and use. This document

assumes the reader is proficient with HART

unique aspects of deploying WirelessHART systems. Unless stated otherwise, the reader should

assume the project phases and steps are the same for HART and WirelessHART instrumentation.

Engineering Guidelines

00809-0100-6129, Rev AB

®

instrumentation. Therefore it focuses on the

This guideline summarizes the essential pre-requisites and general guidelines necessary for

smooth execution of the project that contains WirelessHART Technology. The guidelines are

applicable for small and large scale projects.

The technical guidelines are for use only by qualified personnel capable of observing the safety

instructions from device manuals. The document is provided on an “as is” basis only and may be

subject to future revisions without notice. The authors and contributors will not be responsible

for any loss or damage arising out of or resulting from a defect, error or omission in this

document or from personnel use or reliance on this document.

We want to hear from you

Your comments and suggestions will help us to improve the quality of system engineering

guidelines. If you have any suggestions for improvements, comments, recommendations or a

query, feel free to send feedback to a Wireless Specialist at WSEGSupport@Emerson.com.

1.1.1 Definitions and acronyms

The following definitions are used within this document.

Ancillary device

Any device that does not contain measuring sensor or output to the process for actuation.

Gateway

Enables communication between wireless field devices and host applications connected to an

Ethernet, Serial, or other existing plant communications network; management of the wireless

field network; and management of network security. Conceptually, the Gateway is the wireless

version of marshaling panels and junction boxes. The Gateway functionality may also exist in

native WirelessHART I/O cards with field radios.

ii

Page 3

Engineering Guidelines

00809-0100-6129, Rev AB

Host system

Any system accepting data produced by the WirelessHART Field Network (WFN). This could be a

DCS, PLC, RTU, Data Historian, asset management software, etc.

Join key

A 128 bit security key used to authenticate wireless field devices when joining the network,

including encryption of the join request.

A common Join Key may be used among all devices on a given network, or each device may have

a unique join key.

Note

When displayed in hexadecimal format via a browser or handheld, this results in a 32 character

hexadecimal field.

Network ID

February 2016

Each Gateway at a facility or location should be programmed with a unique Network ID. All

authenticated wireless field devices with the same Network ID will communicate on the same

network and Gateway.

Update rate

The user specified interval at which a wireless field device will detect a measurement and

transmit the measurement to the Gateway (i.e. sample rate). The update rate has the largest

impact on battery life due to the powering of the device sensor. Update rate is independent of

radio transmissions required for mesh peer-to-peer communication, “hopping” via multiple

devices to transmit a measurement back to the Gateway, and downstream communications

from the host system to the wireless field device.

Wireless adapter

Enables an existing 4-20 mA, HART-enabled field device to become wireless. Adapters allow the

existing 4-20 mA signal to operate simultaneously with the digital wireless signal.

Wireless field devices

Field device enabled with a WirelessHART radio and software or an existing installed

HART-enabled field device with an attached WirelessHART adapter.

Wireless field network

A self-organized network of wireless field devices that automatically mitigate physical and RF

obstacles in the process environment to provide necessary bandwidth for communicating

process and device information in a secure and reliable way.

Wireless repeater

Any wireless field device used to strengthen a wireless field network (by adding additional

communication paths) or expand the total area covered by a given mesh network.

iii

Page 4

February 2016

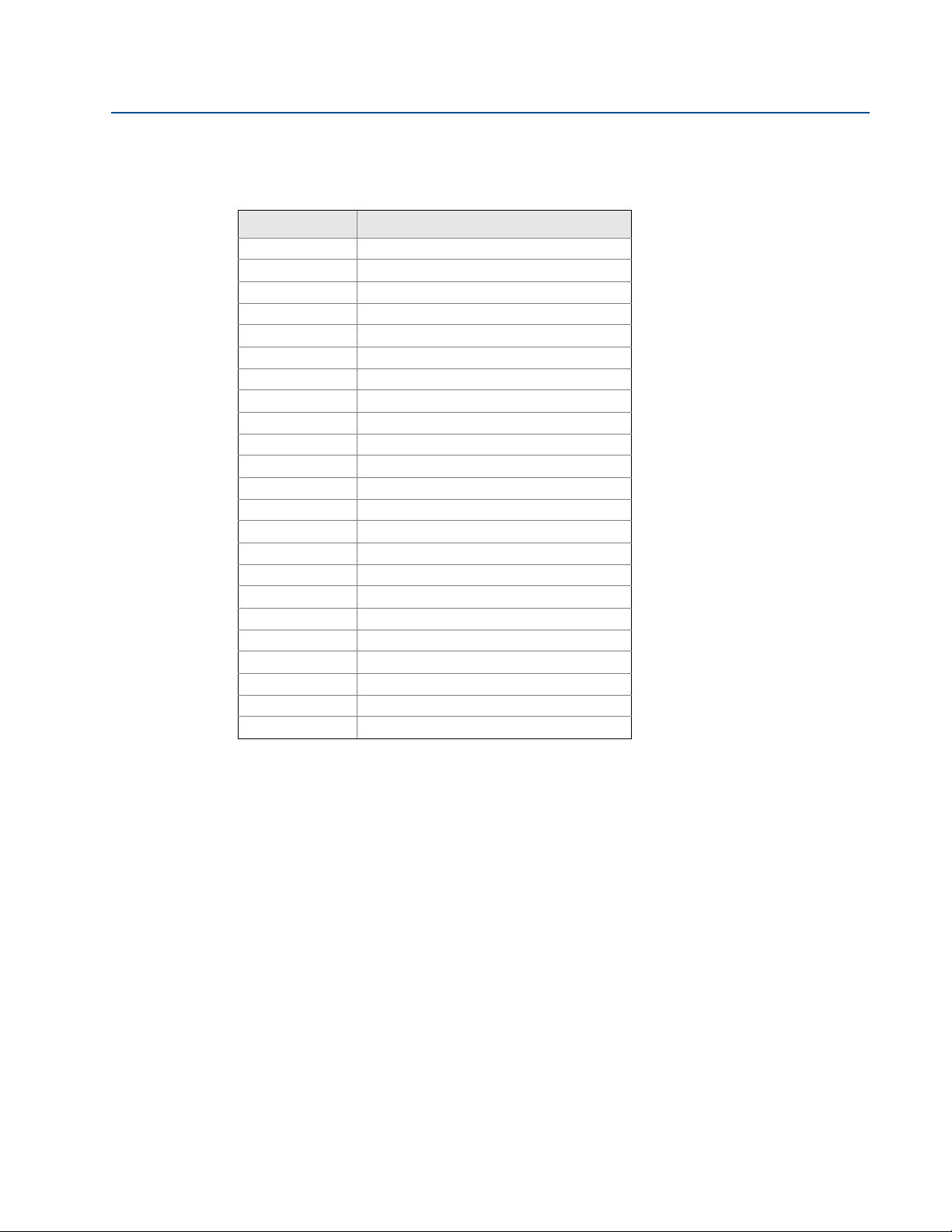

1.1.2 Acronyms

The following acronyms are used within this document.

Abbreviation Description

™

AMS

CSSP Control Systems Security Program

DCS Distributed Control System

DD Device Descriptor

DSSS Direct-Sequence Spread Spectrum

FAT Factory Acceptance Test

FEED Front End Engineering and Design

HART Highway Addressable Remote Transducer

HMI Human Machine Interface

LOS Line of Sight

NFPA National Fire Protection Association

PDF Process Flow Diagram

P & ID Piping and Instrument Design

PLC Programmable Logic Controller

RF Radio Frequency

RSSI Received Signal Strength Indicator

SIT Site Integration Test

SPI Serial Peripheral Interface

SPL Smart Plant Layout

TSMP Time Synchronized Mesh Protocol

TSSI Temporal Single-System Interpretation

UDF User Defined Fields

WFN WirelessHART Field Network

Engineering Guidelines

00809-0100-6129, Rev AB

Asset Management System

iv

Page 5

Reference Manual

00809-0100-3251, Rev AB

Contents

1Section 1: Introduction

2Section 2: Project Concepts

Contents

February 2016

1.1 Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

1.1.1 Definitions and acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

1.1.2 Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

1.1 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3 WirelessHART in project execution lifecycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.1 Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 Traditional approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.3 WirelessHART approach: technology assessment. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3Section 3: Appraise

3.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2 Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3 Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.5 Appraise phase documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.1 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.5.2 Deliverables from the philosophy document . . . . . . . . . . . . . . . . . . . . . . . . . 9

4Section 4: Pre-FEED

4.1 Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.1.1 WirelessHART for control and monitoring applications . . . . . . . . . . . . . . .12

4.2 Cost benefit study . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.3 Preliminary design basis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.4 Project references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.5 Pre-FEED documentation and tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.5.1 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Contents

4.5.2 Deliverables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5Section 5: Front End Engineering Design

5.1 Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.2 Scope definition of engineering execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

i

Page 6

Contents

February 2016

Reference Manual

00809-0100-3251, Rev AB

5.3 Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.4 WirelessHART functional design requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.4.1 WirelessHART functional requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.5 WirelessHART infrastructure requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.6 Operational requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.7 Design inputs documents review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.8 Development of basis for design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.8.1 Design guidelines for WirelessHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.8.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.8.3 Proof of concept test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.9 Initial design review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6Section 6: Execute

6.1 Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.2 WirelessHART Field Network – Design Engineering Overview. . . . . . . . . . . . . . . .25

6.3 Design resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.4 Wireless device selection based on process measurement . . . . . . . . . . . . . . . . . .25

6.4.1 Process monitoring and control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.4.2 Equipment measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.4.3 Health and safety systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.4.4 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.5 Design criteria development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.6 Identify candidate measurement points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.7 Database field for wireless network assignment . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.8 Network design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.8.1 WirelessHART field network – design guidelines . . . . . . . . . . . . . . . . . . . . .29

6.9 Scoping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.10Detailed design specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.10.1 Designing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.10.2 Post installation considerations for control and high speed networks . .37

6.10.3 Minimizing downstream messages for wireless output control devices.38

6.11 Spare capacity and expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.12 Fortifying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.13 WirelessHART availability and redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.14 WirelessHART security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.15 Alarm handling with WirelessHART devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.15.1 Alarm recommendations for process plant . . . . . . . . . . . . . . . . . . . . . . . . .42

ii

Content s

Page 7

Reference Manual

00809-0100-3251, Rev AB

Contents

February 2016

6.15.2 Alarm priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.16 Data sheet parameters for WirelessHART transmitter. . . . . . . . . . . . . . . . . . . . . .43

6.17 Tools and documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6.17.1 Functional design specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6.17.2 Instrument index/database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6.17.3 Instrument data sheets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6.18 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6.19 Factory Acceptance Test (FAT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.19.1 Factory staging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.19.2 Assumptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.19.3 FAT requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.19.4 FAT network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.19.5 Wireless network troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.19.6 FAT procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.19.7 FAT tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.19.8 FAT documentation and reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.20 Site installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.21 Site installation plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.21.1 Installation considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.22 Network installations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.23 Wireless connection test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.24 Network checkout procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

6.25 Lightning protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.26 Device parameter configuration verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.27 Loop checkout/site integration tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.28 Bench simulation testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.29 Provision of spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.30 Removal of redundant equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.31 Pre-commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.31.1 Pre-commissioning requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.31.2 Defining WirelessHART pre-commissioning methods and acceptance .53

6.32 Site Acceptance Test (SAT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

6.33 Commissioning and start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Contents

6.33.1 Wireless network integration with HMI and loop check . . . . . . . . . . . . . . .54

6.33.2 Integrating host and field networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

6.33.3 On-site wireless network reliability tests. . . . . . . . . . . . . . . . . . . . . . . . . . . .55

iii

Page 8

Contents

February 2016

Reference Manual

00809-0100-3251, Rev AB

7Section 7: Operate

7.1 Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

7.2 Asset monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

7.3 Alarm and alerts philosophy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

7.3.1 Configure process alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

7.4 Data management concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

7.5 Maintenance practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

8Section 8: Project Management

8.1 Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

8.2 WirelessHART project management overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

8.2.1 Customer requirements, compliance, and assumptions . . . . . . . . . . . . . .59

8.3 Work breakdown structure and cost estimation . . . . . . . . . . . . . . . . . . . . . . . . . . .59

8.4 Subcontractor scope management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

8.5 Project scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

8.6 Responsibility and skills matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

8.7 Managing project change requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

8.8 Progress reviews and reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

8.9 Customer deliverables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

8.10 Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

8.11 WirelessHART procurement and contract plan. . . . . . . . . . . . . . . . . . . . . . . . . . . .61

8.12 Material requisitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

8.13 Documentation requirements in project execution. . . . . . . . . . . . . . . . . . . . . . . .62

8.13.1 ISA documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

9Section 9: Field Device Requirements

9.1 Support for WirelessHART functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

9.1.1 Device diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

9.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

9.2.1 Device mounting considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

9.2.2 Antenna position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

9.2.3 Mounting high gain remote antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

9.3 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

9.3.1 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

9.3.2 Energy harvesting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

9.3.3 Wired power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

9.4 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

iv

Content s

Page 9

Reference Manual

00809-0100-3251, Rev AB

10Section 10: Ancillary WirelessHART Devices

11Section 11: Measurements and Choosing WirelessHART

Contents

February 2016

9.5 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.6 Accessibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.7 Manufacturer documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.1 Section overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.2 Gateways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.3 Wireless repeaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.4 WirelessHART adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.5 WirelessHART handheld communicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Devices

11.1 Use of WirelessHART® for multivariable process measurements . . . . . . . . . . . 73

11.2 Use of WirelessHART in various process applications. . . . . . . . . . . . . . . . . . . . . . 74

12Section 12: Host System Requirements

12.1 Use of standard protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.2 Wireless host system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.3 Host integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

12.4 Interoperability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.5 Host system support for WirelessHART functionality . . . . . . . . . . . . . . . . . . . . . 78

12.6 Device descriptions files (DD). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

12.7 Configuration tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

12.8 Control system graphics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

12.9 Node addressing and naming conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

12.10 Alarms and alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12.11 Maintenance station and asset monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12.12 Historian. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

13Section 13: Documenting in Intergraph SPI 2009

13.1 Section overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13.2 User defined fields (UDF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13.3 Filtered views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Contents

13.4 Creating instrument types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13.5 Loop drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.5.1 Loop drawings for WirelessHART adapters . . . . . . . . . . . . . . . . . . . . . . . . . 87

v

Page 10

Contents

February 2016

Reference Manual

00809-0100-3251, Rev AB

13.5.2 Gateway cable block drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

13.6 Drawings in smart plant layout (SPL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

13.7 Documenting security information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

AAppendix A: Example ISA Specifications

BAppendix B: Design Resources

B.1 Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

B.1.1 Network design tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

CAppendix C: Wireless Spectrum Governance

DAppendix D: References

vi

Content s

Page 11

Engineering Guidelines

00809-0100-6129, Rev AB

WirelessHART® Project Execution

Section 1: Introduction

February 2016

PART I

Introduction

1

Page 12

Section 1: Introduction

February 2016

Section 1 Introduction

WirelessHART is a global IEC-approved standard (IEC 62591) that specifies an interoperable

self-organizing mesh technology in which field devices form wireless networks that dynamically

mitigate obstacles in the process environment. The WirelessHART field networks (WFN)

communicate data back to host systems securely and reliably, and can be used for both control

and monitoring applications.

Engineering Guidelines

00809-0100-6129, Rev AB

The similarities between traditional HART

training of existing process organizations when adopting WirelessHART. As a result, change is

minimized. In addition, the reduced installed cost of WirelessHART extends the benefits of

automation to end user applications that previously were out of reach since they could not

justify the costs associated with typical wired capital projects.

The opportunity for long-term benefit makes it compelling for end users to expand process

manufacturing project planning to evaluate the impact of WirelessHART on maintenance,

safety, environment, and reliability. Additionally, by removing the physical constraints of wiring

and power as well as reducing weight and space, wireless networks increase flexibility in project

execution, providing solutions which can mitigate risk and improve project schedules.

1.1 Purpose

This IEC 62591 WirelessHART System Engineering Guideline applies to end user adoption of

WirelessHART self-organizing mesh networks to automate process manufacturing projects of

any size. The guidelines are intended to help users take full advantage of WirelessHART systems.

1.2 Scope

The guidelines apply to use of WirelessHART technology through all stages of project execution

as well as throughout the lifecycle of facility operation.

®

and WirelessHART allow end users to leverage the

Differences between HART and WirelessHART specifications and device types are highlighted.

1.3 WirelessHART in project execution lifecycle

Figure 1-1 illustrates a typical framework for project execution. It will be used as a basis for

describing application of WirelessHART in each phase of a project. Although WirelessHART can

be introduced at any phase, a strategic benefit is realized by its introduction during the early

part of the project execution cycle.

Figure 1-1. Project Execution Lifecycle

2

Introduction

Page 13

Engineering Guidelines

00809-0100-6129, Rev AB

Section 2 Project Concepts

Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Traditional approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

WirelessHART approach: technology assessment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

2.1 Section overview

As described in this section, use of WirelessHART® over traditional technology reduces project

risk during execution and provides greater flexibility and benefits to the plant during its life

cycle.

2.2 Traditional approach

Section 2: Project Concepts

February 2016

Traditional methods of wired control networks make use of conventional communications like

4-20 mA, HART

Installation of these wired networks is complex due to inflexibility of wiring. Significant effort is

required in the pre-FEED and FEED phases for planning long run cables including room for spares

to accommodate changes during project execution. Beyond laying long run cables, wired

system complexities include cable routing, connectors, and additional materials associated with

wired technology that are greatly simplified with wireless.

Use of traditional technology also restricts measurement of parameters in locations inaccessible

to cable trays and therefore wired connection. Such wired measurements could improve

operations but are eliminated from the design process as being too costly to implement.

Since use of wired connections reduces the number of measurements and instruments during

the initial execution phase, modifications may be needed to add some of these at a later stage.

Increased spares would be needed to allow the expansion. In a typical project environment,

frequent changes in I/O database, addition/deletion or reallocation of instruments, change in

instrument types, delayed or late changes in package vendor data etc negatively impact project

time and cost.

If instruments and therefore I/O points need to be added/changed/moved during operation,

then lengthy procedures need to be followed for wired signals such as HSE, work permits,

correct isolation procedures, and requisite cabling to connect the field instrument to the

control system. These activities require coordination between multiple plant departments.

Furthermore, routine inspection to ensure that the cable and associated infrastructure continue

to operate trouble free, can be costly and time consuming and divert valuable resources away

from operating the plant.

®

, FOUNDATION™ Fieldbus, PROFIBUS® and other bussed solutions. Planning and

Project Concepts

3

Page 14

Section 2: Project Concepts

February 2016

Engineering Guidelines

00809-0100-6129, Rev AB

2.3 WirelessHART approach: technology assessment

WirelessHART technology may provide an opportunity to execute and build a more efficient

plant compared to the traditional approach.

The project technical authority can decide whether to use wireless based on the following

criteria:

Economic advantages

Application capability

Operational savings

Benefits of additional process insight from new measurements previously out of reach

economically or physically - example: monitored safety showers

Benefits of flexibility in project execution – example: ease of moving or adding I/O

points during construction to cost effectively manage onsite changes

The high cost of traditional field wiring limits the number of points that are able to be connected

in a project for process monitoring, control and safety applications. However, as the project

proceeds and over the lifecycle of the plant, additional points may need to be added to resolve

critical problems. Since WirelessHART does not require wires for communication or power, the

lower costs enable inclusion of more process points during the project. The financial

impediment in determining whether a point is automated or not is redefined,

Special consideration should be given to automation needs of new process plants. WirelessHART

may provide significant advantages in enabling automation to ensure they meet stricter safety,

environmental, reliability and performance criteria. Below are a few examples:

Many new plants are designed to operate with fewer personnel. Upgrading simple

gauges to wireless field devices can automate the manual collection of data from the

field in order to increase worker productivity and reduce field trip exposure to

hazardous environments.

Many existing facilities have been modified in order to meet emerging environmental

regulation. Real time monitoring of volatile organic compound release (VOC) from

wireless monitoring of pressure safety valves and of conductivity and temperature of

effluent waters can ensure environmental compliance.

Wireless remote monitoring of safety showers and gas detectors during construction

and operation can provide new levels of safety response.

New environmental regulation often requires redundant monitoring systems on assets

like tanks that were not required in the past. WirelessHART can provide a cost effective,

reliable secondary communication and monitoring method.

Wireless monitoring of steam traps and heat exchangers can provide real time

information for minimizing plant energy consumption.

Cost effective field information accessible via WirelessHART field devices enables non-traditional

end use of automation to be considered in the FEED and design phases. A designer should be

aware of initiatives for safety, environmental protection, energy consumption, and reliability in

addition to the traditional considerations for process automation. The WirelessHART

architecture extends the benefits of automation to multiple plant initiatives without the need

for multiple forms of I/O infrastructure.

4

Project Concepts

Page 15

Engineering Guidelines

00809-0100-6129, Rev AB

Traditional wired architecture is limited in ability to mitigate risk of project execution.

Innovative WirelessHART architecture provides greater flexibility with minimum engineering

effort and greater savings in cost and time during any project phase, as compared to the

traditional approach.

Active projects should optimize measurement and control technology by establishing design

rules to define which points are suitable for WirelessHART versus traditional technology. These

design rules will help to enable consistent and efficient engineering for subsequent project

phases.

Section 2: Project Concepts

February 2016

Project Concepts

5

Page 16

Section 2: Project Concepts

February 2016

Engineering Guidelines

00809-0100-6129, Rev AB

6

Project Concepts

Page 17

Engineering Guidelines

00809-0100-6129, Rev AB

Section 3 Appraise

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Appraise phase documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

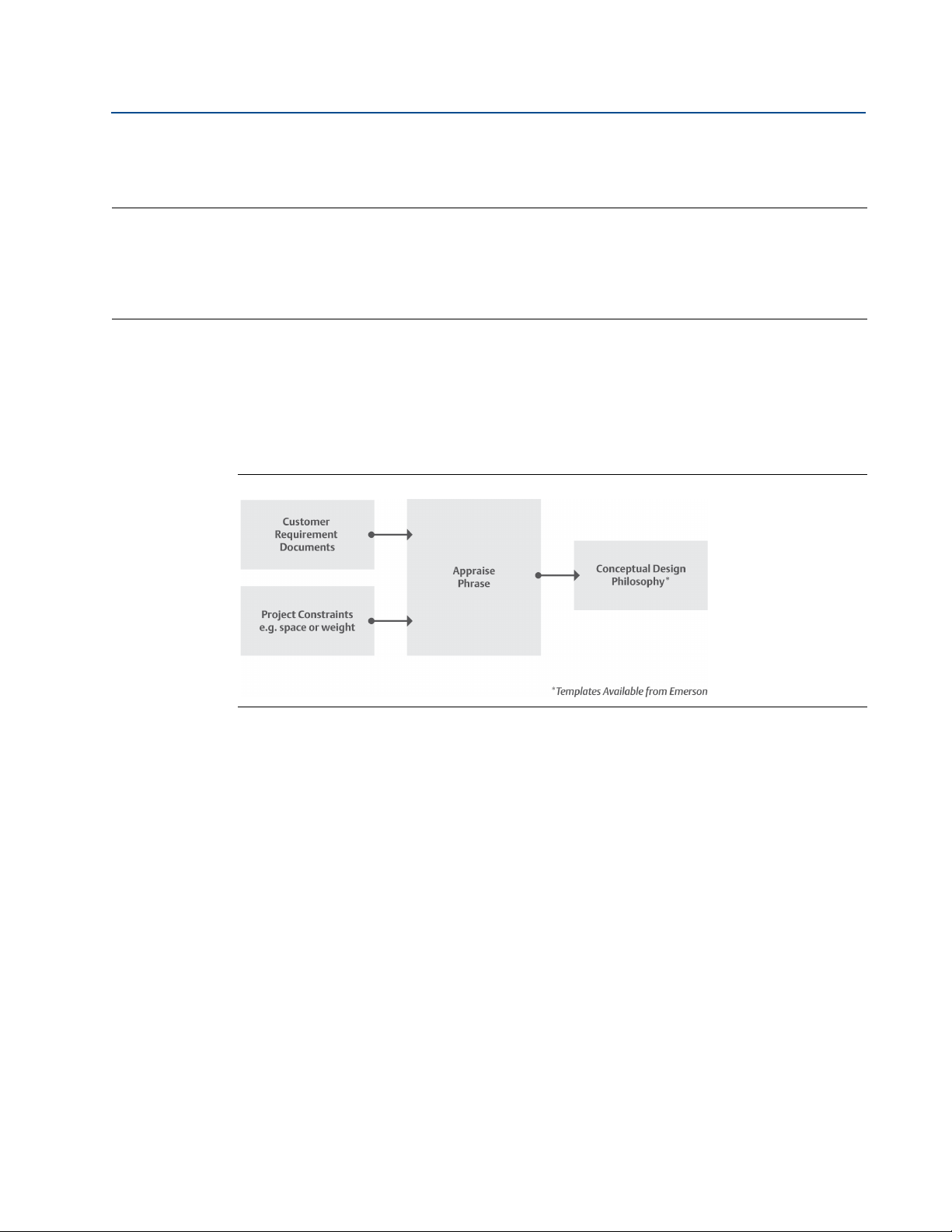

The Appraise phase (conceptual design) requires high level customer requirements or project

constraints as input. In this phase a simple statement of requirements with identified

constraints or objectives will suffice. Selection of wireless technology in this phase allows a

simple generic design philosophy statement to be made on how the architecture can be used to

meet the needs of both the business and the project. Figure 3-1 shows the inputs and outputs of

the Appraise phase.

Figure 3-1. Conceptual Design Phase

Section 3: Appraise

February 2016

During the Appraise phase it is likely that a summary of the technology and its application will

be required by the project stakeholders in order for them to formulate a practical view of

applicability to the project. Plant personnel engaged in the early phase of the project should

also be part of this appraisal.

3.1 Application

WirelessHART® can be applied to a wide variety of process applications in all process industries

spread over differing geographical terrain. Evaluate the following factors for potential

WirelessHART application:

Process monitoring and measurements which are remote and uneconomical to

consider for wired monitoring

Equipment health monitoring

Environmental monitoring, energy management, regulatory compliance

Extreme environmental conditions for wired installations (hot, wet and corrosive)

Moving rails and test skids

Rotating equipment

Appraise

7

Page 18

Section 3: Appraise

February 2016

Asset management, diagnostics and predictive maintenance

Simple closed-loop control (when appropriate)

API seal flush plans

Secondary systems

3.2 Technology

Evaluate the following factors for benefit by application of WirelessHART technology:

Minimizing the cost

Ease of installation

Reduced time for installation and commissioning

Ease of maintenance

Ease of expansion for future I/O points (scalability)

Engineering Guidelines

00809-0100-6129, Rev AB

3.3 Operations

WirelessHART field networks can help optimize contiguous or remote process operations by

collecting data in organized manner and enabling operators, shift supervisors, production/field

management, and facilities engineers to collaborate. Delivery of the right information to the

plant operations team helps them make the right decisions to improve plant throughput.

Evaluate WirelessHART operations for benefits in each of the following:

Access to monitoring points which are normally unavailable to plant operators

Increased safety by minimizing plant operator rounds in hazardous locations

Better alarm handling and reporting

Better insight by use of wireless transmitters for trending rather than gauges and

switches

3.4 Maintenance

There are no special maintenance requirements for WirelessHART devices apart from changing

the batteries. Diagnostic information provided to the Asset Management System alert

technicians of the need for maintenance.

WirelessHART devices provide advantage for maintenance in hazardous areas. The batteries are

intrinsically safe and power-limited, so they can be changed with the device locally without risk

of causing a source of ignition.

3.5 Appraise phase documentation

The Appraise phase documentation presents conceptual design that is referenced to customer

and project requirements, supported by economic analysis, and satisfies project imperatives.

8

Appraise

Page 19

Engineering Guidelines

00809-0100-6129, Rev AB

3.5.1 Reference documents

Customer requirement specification (customer statement of requirements)

Project constraints

3.5.2 Deliverables from the philosophy document

Conceptual design philosophy/architecture

Economic analysis of technology and solutions

Project imperatives

Section 3: Appraise

February 2016

Appraise

9

Page 20

Engineering Guidelines

00809-0100-6129, Rev AB

Section 3: Appraise

February 2016

Appraise

10

Page 21

Engineering Guidelines

00809-0100-6129, Rev AB

Section 4 Pre-FEED

Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Cost benefit study . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Preliminary design basis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Project references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Pre-FEED documentation and tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

4.1 Section overview

In Pre-FEED, the requirements, philosophies and imperatives established in the Appraise phase

are further elaborated. Deployment of WirelessHART

explored and verified in further detail during this phase. Figure 4-1 shows the inputs and

outputs of the Pre-FEED phase.

Section 4: Pre-FEED

®

for identified applications can be

February 2016

Figure 4-1. Pre-FEED Phase

An integrated approach should be used for incorporating wireless into a project. Wireless should

be merged with wired technology in the project procedures. It is essential to use the right field

device technology for the right application. New end user communities may be added as the

cost advantages of wireless expand applications during the FEED process.

Pre-FEED

11

Page 22

Section 4: Pre-FEED

February 2016

Engineering Guidelines

00809-0100-6129, Rev AB

4.1.1 WirelessHART for control and monitoring applications

WirelessHART is designed for both control and monitoring applications. Most current use cases

emphasize monitoring applications due to conservative adoption of new technology in the

process manufacturing industry. The use of wireless control applications is continuing to evolve

with the introduction of discrete output devices for performing simple control functions. The

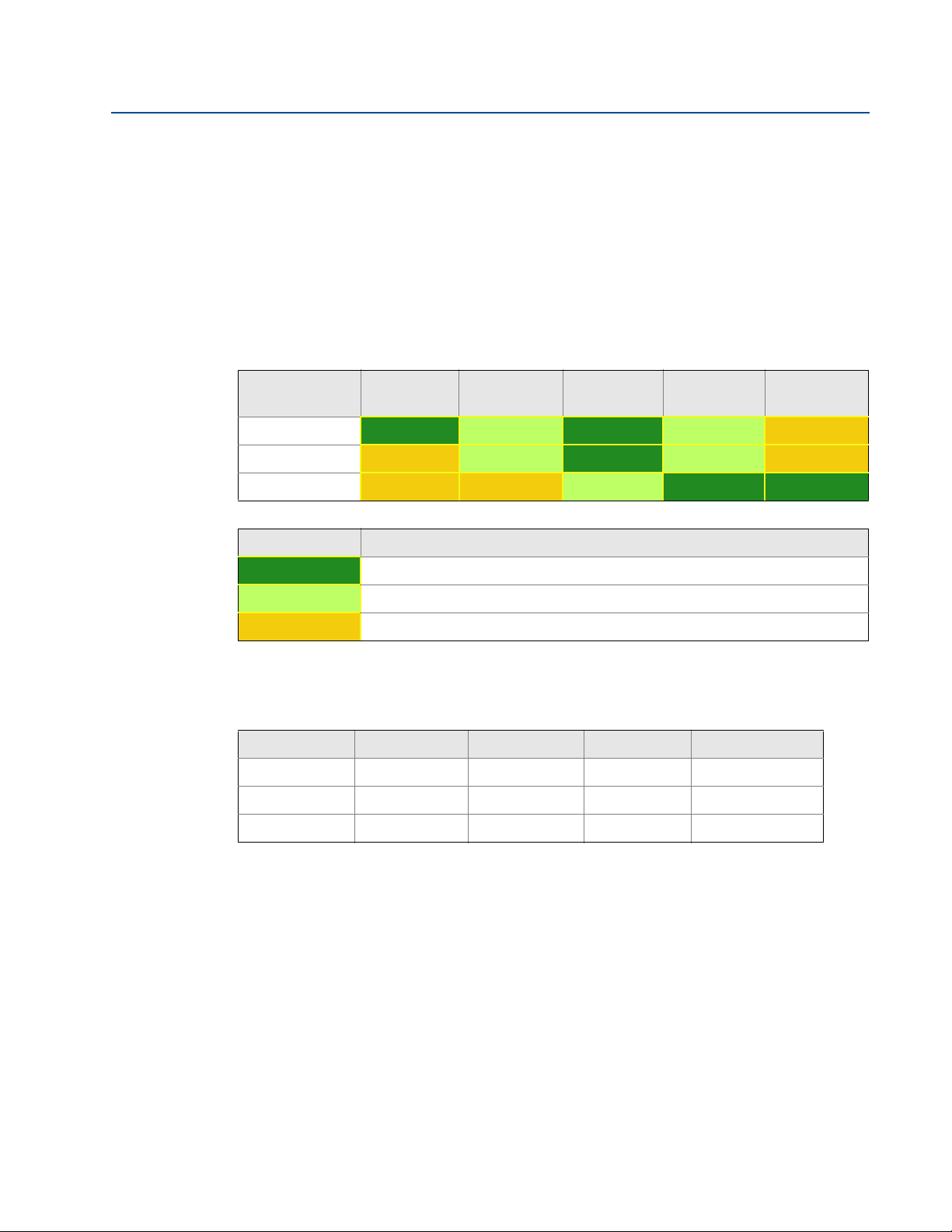

Ta bl e 4 -1 provides a high level summary for selection of the right protocol when factoring in

loop criticality; cost to engineer and implement; and location of field devices relative to main

process areas and host systems.

Table 4-1. Selecting the Right Protocol

Safety

systems

Critical

control

On-off

control

In-plant

monitoring

Conventional

Fieldbus

WirelessHART

Legend Based on technical and/or cost considerations

Most appropriate solution

Appropriate in some cases

Lease effective solution

Ta bl e 4 -2 shows the available technology solution for different signal types.

Table 4-2. Selecting Signal Types with the Right Protocol

Analog inputs Analog output Digital inputs Digital outputs

Conventional

Fieldbus

WirelessHART

N/A

Remote

monitoring

4.2 Cost benefit study

WirelessHART and wired solutions need to be evaluated during the Pre-FEED phase for

comparison from a cost and time perspective. Furthermore, assessments on the benefits to

schedule improvement (by phase) and of change management should be an input to this cost

benefit study.

The following factors can be considered for this comparison:

Main junction box requirements

Secondary junction box requirements

Main cable tray requirements

Secondary cable tray requirements

12

Pre-FEED

Page 23

Engineering Guidelines

00809-0100-6129, Rev AB

Multi-core cable requirements

Mechanical and civil work for cable routing

Power supply in system cabinets

System cabinet requirements

Marshalling cabinets

3D modeling review for cable tray routing, cable tray engineering, and location of

Cost of change request management

Time and efforts for installing cable trays and cables

Power consumption requirement

Space requirements

Material weight reduction

System design time requirements

Material consideration based on area classification and protection concept

Section 4: Pre-FEED

February 2016

junction box

In addition to the above criteria, accommodating changes is cheaper and more efficient with

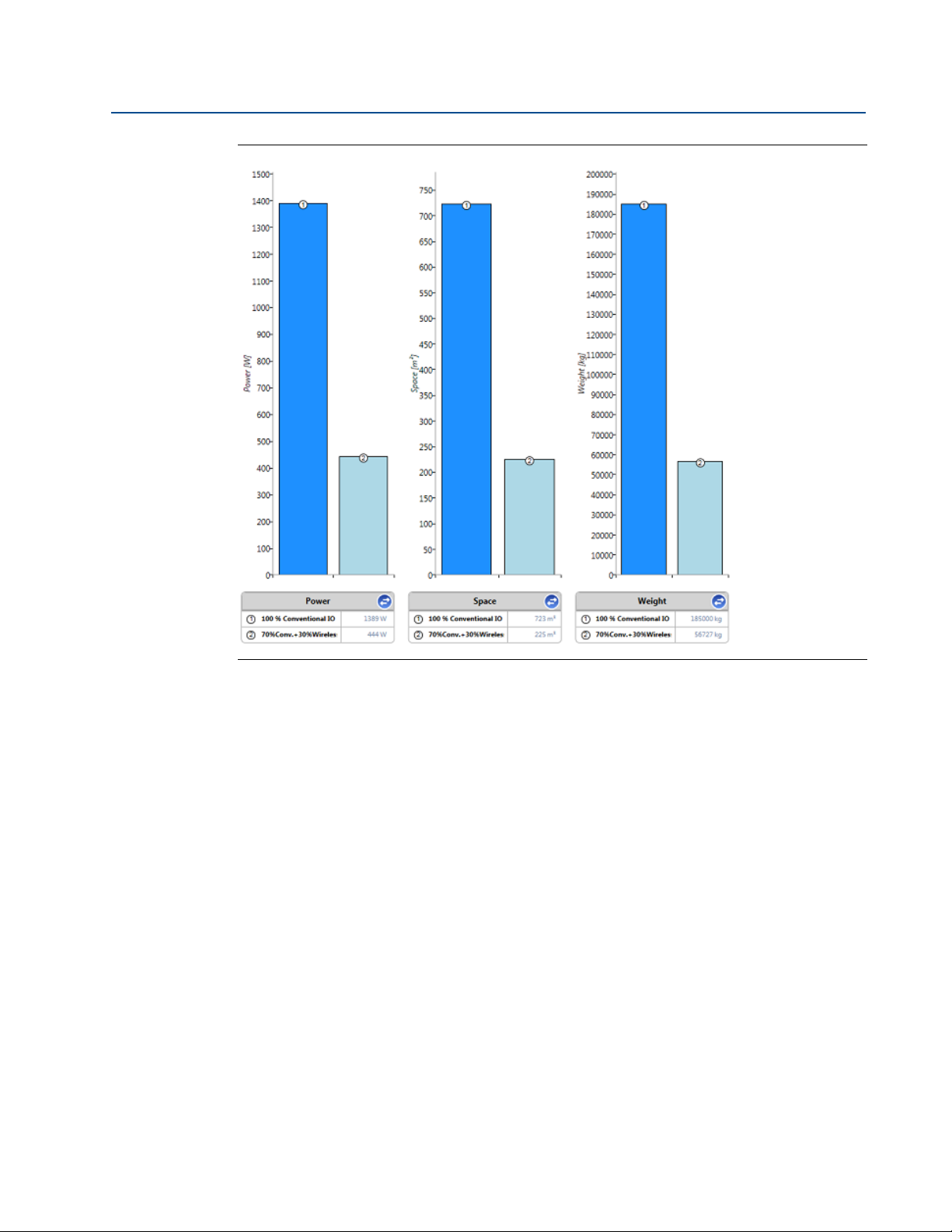

WirelessHART during any project phase. Typical case studies for cost, time, power, space and

weight savings are shown in Figure 4-2 and Figure 4-3. These case studies should consider the

criteria listed above.

Figure 4-2. Case Study for Cost and Time Savings

Pre-FEED

13

Page 24

Engineering Guidelines

00809-0100-6129, Rev AB

Figure 4-3. Case Study for Power, Space, and Weight Savings

Section 4: Pre-FEED

February 2016

4.3 Preliminary design basis

Determine a preliminary design basis using the Customer Requirement Specification updated in

the Appraise phase along with the preliminary conceptual design documents available from

Appraise like site plan/layout, P&IDs, instrument index etc. This includes the quantity of

WirelessHART instruments, Gateways and repeaters needed to create a pervasive sensing

network. Assumptions on the basis of experience for similar plants/units can be made in

absence of requisite inputs.

Considering requirements of WirelessHART for indoor, outdoor and remote locations, develop a

preliminary network topology for the Wireless Field Network.

Develop a suitable interface solution for connection of the multiple Wireless Field Networks to

the host system and asset management system.

Verify spectrum approvals for the end-user and any intermediary locations. Refer to Appendix A:

Example ISA Specifications for more details.

Pre-FEED

14

Page 25

Engineering Guidelines

00809-0100-6129, Rev AB

4.4 Project references

Previous projects operating with WirelessHART are a rich source of information and reference for

new planned WirelessHART implementation. Look towards these references as the first line of

help to overcome specific issues encountered in new installations.

4.5 Pre-FEED documentation and tools

Documentation from the Pre-FEED phase records use of conceptual design reference inputs to

develop high level functional design deliverables.

4.5.1 Reference documents

Initial plot plan

Initial 3D layout drawings

Initial P&ID

Instrument index

Customer specification documents

Section 4: Pre-FEED

February 2016

Proposal documents for cost estimates

4.5.2 Deliverables

Initial wireless field network system architecture

Measurement signal types

Bill of quantity

Pre-FEED

15

Page 26

Section 4: Pre-FEED

February 2016

Engineering Guidelines

00809-0100-6129, Rev AB

16

Pre-FEED

Page 27

Engineering Guidelines

00809-0100-6129, Rev AB

Section 5: Front End Engineering Design

February 2016

Section 5 Front End Engineering Design

Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Scope definition of engineering execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

WirelessHART functional design requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

WirelessHART infrastructure requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

Operational requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Design inputs documents review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Development of basis for design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Initial design review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

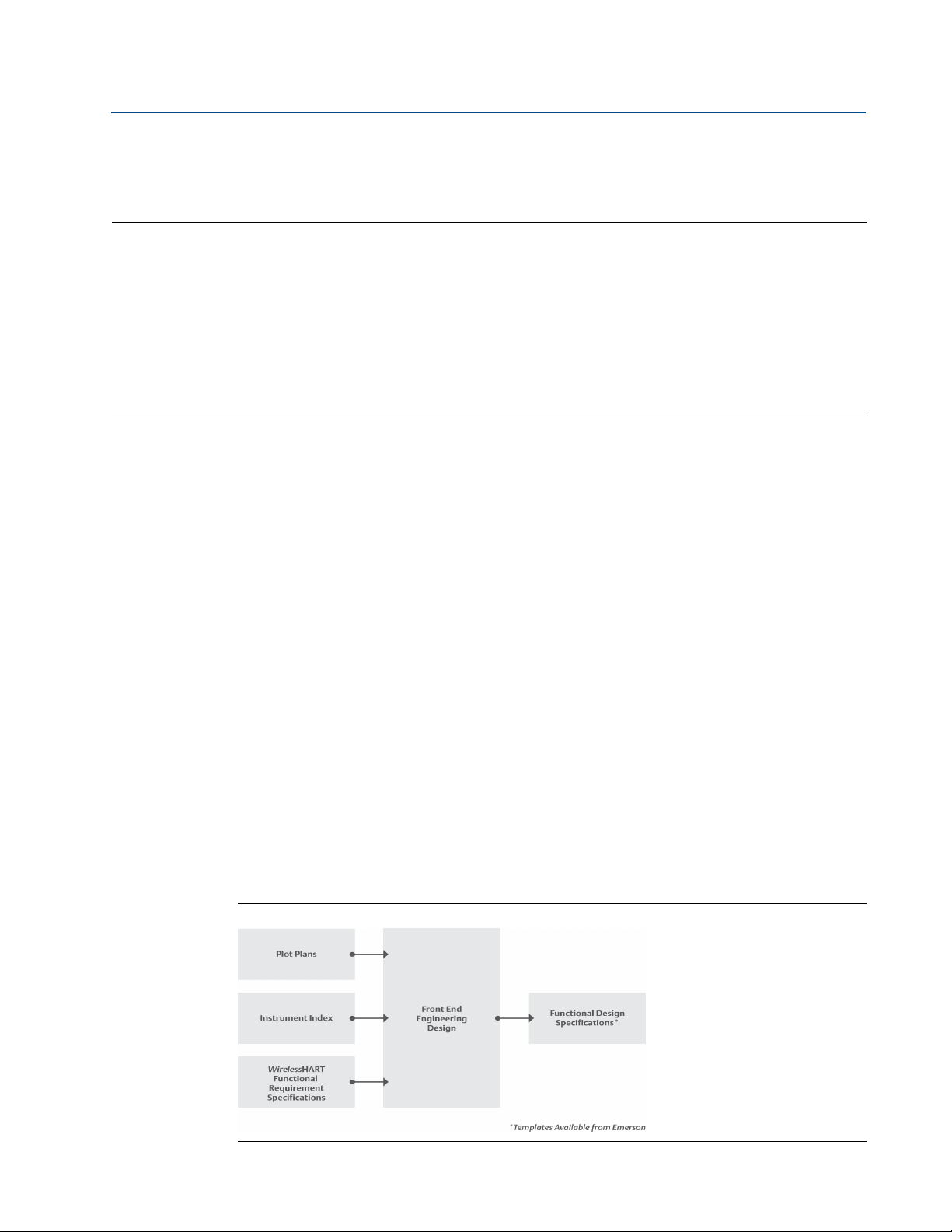

5.1 Section overview

Front End Engineering Design (FEED) is an important stage where key deliverables exist for

wireless including cost estimation, design guidelines, and specifications. Collaborative efforts

put in by all stakeholders during FEED, will help in capturing all project specific requirements and

avoiding significant changes during the Execution phase.

The following factors can be evaluated during the FEED phase for WirelessHART

®

deployment in

the project.

Environmental considerations

WirelessHART functional design requirements

Scope definition of engineering execution

WirelessHART infrastructure requirements

Operational requirements

Design inputs documents review

Development of basis for design

Risk assessment and initial design philosophy review

Figure 5-1 shows the inputs and outputs of the FEED phase.

Figure 5-1. FEED Phase

Front End Engineering Design

17

Page 28

Section 5: Front End Engineering Design

February 2016

Engineering Guidelines

00809-0100-6129, Rev AB

5.2 Scope definition of engineering execution

Stakeholder meetings are important to ensure all disciplines understand the scope of wireless

applications. Agenda items should include the following:

Review potential benefits in key areas of the work structure

Put in place appropriate training and strategy to achieve potential benefits.

Clearly distribute project work to optimize dependencies within the project team so

that schedule efficiencies can be achieved.

Identify In-house wireless network requirements to define the scope of Integration of

WFN and WPN network.

Clearly define wireless communication network availability, redundancy, WirelessHART

equipment supply, installation, configuration and commissioning site work activities,

and spare requirements scope

Define and include in the scope: overall wireless network architecture design, wireless device

location, minimum distance and coverage between access points, network coverage and

performance requirements.

Identify and include in the scope: supplementary wireless network devices such as WirelessHART

handheld communicator, mobile worker supply.

Determine the field device types and WirelessHART signal types for project implementation,

including consideration of the following signal and device types (refer to Emerson

™

Process

Management literature for the most up to date measurement types and innovations).

Pressure

Tem p er at ur e

Flow

Level

Tuning fork level

Conductivity

pH

Corrosion

Tank gauging

Guided wave radar

Discrete position monitoring

Discrete inputs

Discrete outputs

18

Acoustic (steam trap and PRV monitoring)

Vibration

Flame detection

Front End Engineering Design

Page 29

Engineering Guidelines

00809-0100-6129, Rev AB

Section 5: Front End Engineering Design

February 2016

5.3 Environmental considerations

Check for compliance with hazardous area classification requirements, temperature class, and

ambient temperature of plant.

Ensure compliance with regional and country specific RF frequency usage norms.

5.4 WirelessHART functional design requirements

During the initial stage of FEED, translate owner-operator’s functional requirements into a

network infrastructure, device characteristics, host interfaces, and applications. Document

these in the design specification; also include boundary conditions (e.g. all monitoring points on

this project will be wireless) associated with WirelessHART applications.

5.4.1 WirelessHART functional requirements

Develop the WirelessHART design, including the following:

Network environment and area classification

WirelessHART system architecture

Operational requirements

Data requirements

Interfaces

Te st in g

Spares consideration

Documentation requirements

Training

WirelessHART network Security, reliability and interoperability requirements

5.5 WirelessHART infrastructure requirements

Conduct plot plan reviews and determine the infrastructure requirements for the following:

System architecture

Wireless

Field network design including IEC62591 WirelessHART Field Instruments

Automation

Host system interface

Process control network interface

Asset management system diagnostics including those for field device and the field

Front End Engineering Design

network configuration

19

Page 30

Section 5: Front End Engineering Design

February 2016

5.6 Operational requirements

Determine operational requirements for the following:

Process monitoring and signal types

Device diagnostics

Loop response time

DCS HMI

Redundancy

WirelessHART network components

Reduction in field inspections of physical wired infrastructure (IECC60079)

Elimination/reduction of operator rounds

5.7 Design inputs documents review

Collect initial design documents that describe project requirements including plot plans,

equipment layout plans, preliminary instrument index, and three-dimensional layout drawings.

Engineering Guidelines

00809-0100-6129, Rev AB

Project team shall make sure inputs are sufficient to define the project initial design philosophy.

If documentation is inadequate then project team needs to seek technical clarification from the

facility owner-operator.

5.8 Development of basis for design

5.8.1 Design guidelines for WirelessHART

During the FEED process, all project stakeholders should be made aware of the capability and

benefits of WirelessHART so that design engineers can identify potential application candidates.

The project team should develop a wireless design and circulate to all project stakeholders.

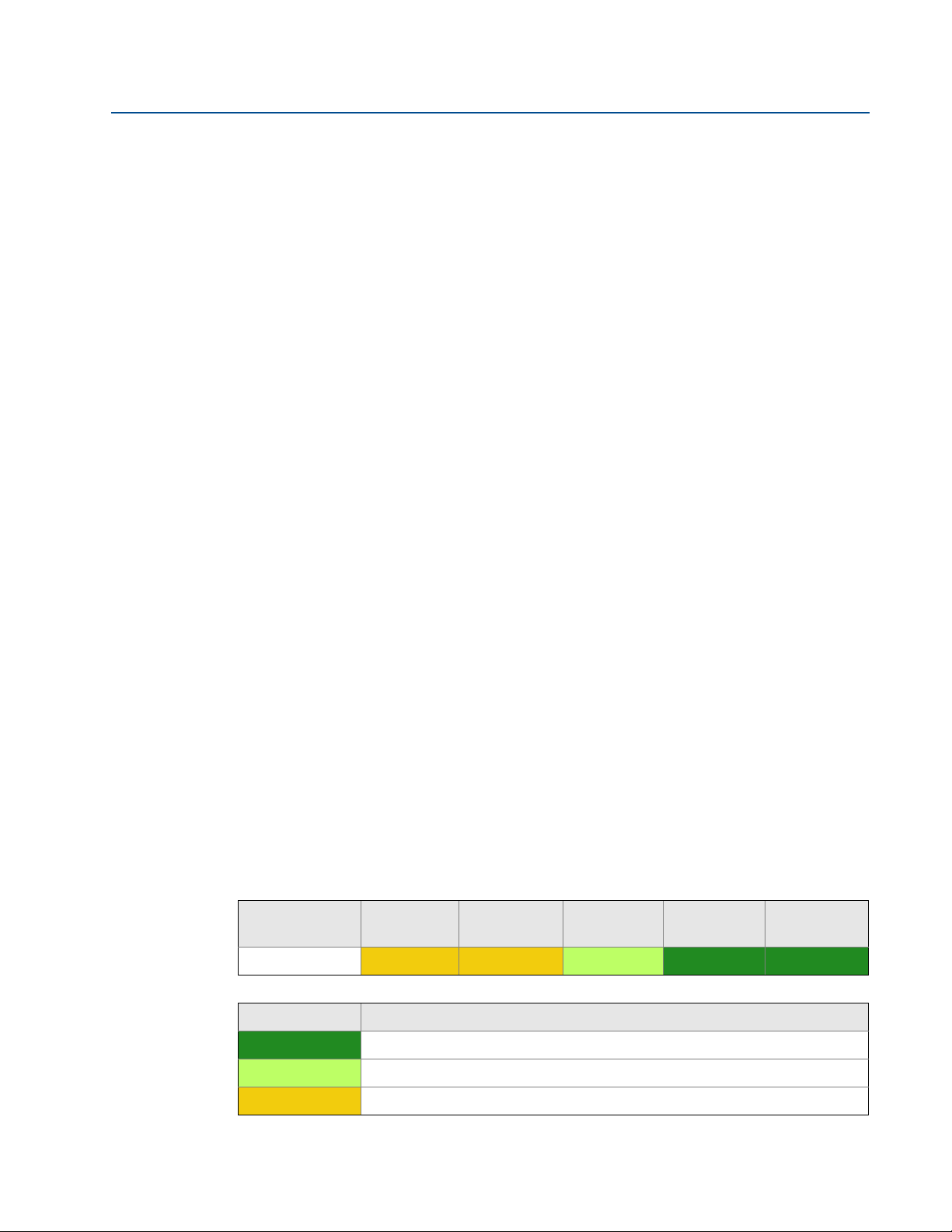

For example, the process design engineer can use a set of criteria as shown in Ta b le 5 - 1 to

identify wireless application candidates.

Table 5-1. Example Criteria of Wireless Application Candidates

Safety

systems

WirelessHART

Critical

control

On-off

control

In-plant

Monitoring

Remote

Monitoring

20

Legend Based on technical and/or cost considerations

Most appropriate solution

Appropriate in some cases

Lease effective solution

Front End Engineering Design

Page 31

Engineering Guidelines

00809-0100-6129, Rev AB

Ideally, WirelessHART application candidates are identified early in the FEED process design

phase. This could be during development of the Process Flow Diagram (PFD) or Piping and

Instrument Design (P&ID) Diagram. However, if an early decision is not taken, this should not

preclude the use of the technology later in the project.

The basis for WirelessHART design should be shared among all stakeholders so that other

technical design authorities can identify potential wireless applications and benefit from the

installed wireless infrastructure. Furthermore, this process ensures consistent implementation

across all design authorities and allows for an efficient decision process for use of wireless

technology.

Include the following steps when developing the WirelessHART design guidelines:

Determine which categories of points are eligible to be wireless: safety, control,

Determine if new users are eligible for automation: process efficiency, maintenance,

Determine percent spares required and necessary spare capacity.

Factor in distance considerations between Gateways and wireless field devices.

Section 5: Front End Engineering Design

February 2016

monitoring, and local indication.

reliability, asset protection, health/safety/environmental, and energy management.

Distance considerations are elaborated on in Section 0, Designing.

Determine whether WirelessHART field network backhaul is required.

5.8.2 Specifications

Specifications for WirelessHART field devices are nearly the same as for wired HART® devices.

See Appendix B: Design Resources for key differences.

Table 5-2. Differences Between Wired and WirelessHART

Specification field Typical HART specification Ty pi ca l WirelessHART specification

Output signal 4-20 mA HART IEC 62591 WirelessHART

Power supply 24V DC Loop Powered Intrinsically Safe Battery

Update rate 1 second 1 second to 60 minutes

Protection/enclosure Explosion Proof Intrinsically Safe

IEC 62591 WirelessHART is an international standard for wireless process automation devices.

Devices that comply with the standard include advanced provisions for security, protocol, and

other features essential to wireless networks and therefore specification of such attributes

covered in the standard are not necessary.

Appendix A: Example ISA Specifications provides example specifications for a WirelessHART

Gateway and wireless adapter that can be generically specified as transceivers/receivers.

5.8.3 Proof of concept test

WirelessHART is well established in a comprehensive range of process plants and environments.

On occasion it may be necessary to conduct a proof of concept test to familiarize stakeholders

with the capability and applications of the technology; this can be done in a workshop setting.

Front End Engineering Design

21

Page 32

Section 5: Front End Engineering Design

February 2016

5.9 Initial design review

Upon completion of site plot plan review, gather the report results from various WirelessHART

tools, proof of concepts and compliance to customer requirements, and discuss these with all

stakeholders. Also discuss any requirement changes, deviations or assumptions with the

stakeholders. Since WirelessHART is extremely flexible it is easy to incorporate necessary

architecture changes.

Engineering Guidelines

00809-0100-6129, Rev AB

22

Front End Engineering Design

Page 33

Engineering Guidelines

00809-0100-6129, Rev AB

Section 6 Execute

Section overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

WirelessHART Field Network – Design Engineering Overview . . . . . . . . . . . . . . . . . . . . . page 25

Design resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Wireless device selection based on process measurement . . . . . . . . . . . . . . . . . . . . . . . . page 25

Design criteria development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Identify candidate measurement points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Database field for wireless network assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Network design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

Scoping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Detailed design specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 33

Spare capacity and expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 38

Fortifying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 38

WirelessHART availability and redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 39

WirelessHART security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 40

Alarm handling with WirelessHART devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 40

Data sheet parameters for WirelessHART transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 43

Tools and documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 44

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 44

Factory Acceptance Test (FAT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 45

Site installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 47

Site installation plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 48

Network installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 48

Wireless connection test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 49

Network checkout procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 50

Lightning protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 51

Device parameter configuration verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 51

Loop checkout/site integration tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 51

Bench simulation testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 52

Provision of spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 52

Removal of redundant equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 52

Pre-commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 52

Site Acceptance Test (SAT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 53

Commissioning and start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 54

Section 6: Execute

February 2016

6.1 Section overview

During the Execute phase (Detailed Design and Testing) of a project, the engineer must account

for WirelessHART

to the project database, and follow wireless field network design procedures to ensure best

practices are implemented.

This section addresses the following aspects of Execute Detail design phase.

Design resources

Execute

®

devices per the guidelines established in the FEED, add wireless specific fields

23

Page 34

Section 6: Execute

February 2016

Engineering Guidelines

00809-0100-6129, Rev AB

Design guidelines

Wireless field networks design description

- Key components of the wireless field network solution

- Wireless devices and Gateway

- Wireless device selection criteria and data sheets

Field network deployment

- Project environmental considerations, intrinsic safety requirements

- Equipment environmental specification

- Radio regulatory compliance

- Plant areas and candidate areas for further wireless deployments

Host system interface

- Host/DCS components and architecture

- Network identification

- Asset management software interface

Third party interface

Wireless field network infrastructure

- Typical architecture,

- Equipment location

- Power specification and power distribution philosophy

- Cable specifications and types

- Field data backhaul philosophy and backhaul specification

Design philosophy deployment

- Topology, wireless field network control philosophy

- Monitoring, closed loop control

- Module design and scan rates

- Alarm and status Information

Figure 6-1 shows the inputs and outputs of the Execute-Detailed Design phase.

Figure 6-1. Execute-Detailed Design Phase

24

Execute

Page 35

Engineering Guidelines

00809-0100-6129, Rev AB

6.2 WirelessHART Field Network – Design Engineering Overview

Follow these three key steps for designing a network:

1. Scope – Decide if you need to reference wireless field networks by process unit or

subsection of a process unit. Factors include:

Number of devices in the process unit

Update rates need for wireless devices

Capacity of the Gateway

2. Design – Apply design rules to ensure optimum connectivity.

3. Fortify – Identify and correct any potential weaknesses in the network design.

The three basic steps apply for all process environments in all industries, although the context

may vary slightly depending on the physical structure of the process environment. The basic

steps also apply regardless of the vendor of the WirelessHART devices. Since WirelessHART

networks become stronger as more devices are added, the Scope step is the most critical for

high density applications.

Section 6: Execute

February 2016

WirelessHART is designed for both control and monitoring applications. Refer to Section 2:

Project Concepts for detailed recommendations on using wireless control systems and devices.

In general, control with WirelessHART is appropriate for most cases of open loop control that

require manual interaction with the process and some cases of supervisory control for set point

manipulation and process optimization. Applications for closed loop regulatory control of a

critical loop may be evaluated case by case.

6.3 Design resources

See the Design Resources Appendix for more information. Contact your respective

WirelessHART vendor for automated design tools to aid:

Wireless network planning

Network design

Gateway capacity planning

Device type availability and battery life estimation

6.4 Wireless device selection based on process measurement

Execute

WirelessHART devices are available for various process measurement applications including

those described below.

25

Page 36

Section 6: Execute

February 2016

6.4.1 Process monitoring and control

Hard to reach locations

Process efficiency calculations

Better insight into the process

Ad-hoc measurements

Additional measurements from multivariable devices

Calculated variables in devices

6.4.2 Equipment measurement

Vibration

Corrosion

Oil pressure

Air flow

6.4.3 Health and safety systems

Gas detectors

Analyzers

Engineering Guidelines

00809-0100-6129, Rev AB

6.4.4 Environmental

Steam traps (energy usage)

Water/discharge treatment

Flow

pH

Stack emissions

Relief valves

WirelessHART devices can be deployed in harsh environments and hazardous areas. Table 6-1

lists examples of WirelessHART application deployment. For a comprehensive list of

applications, refer to the Wireless Application Guide available through your local Emerson

Project Specialist.

Table 6-1. WirelessHART Applications

Steam Cracker Diesel and Kerosene Production Monitoring

Trea ted Water Usage Rotating Calciner

Filter Condition Pipeline Leak Detection

Pipeline System Compressor Emissions Compliance

Remote Storage Tanks Rotating Roaster

Cold Box Boiler and Heater Gas Flow

Steam Distribution Lines Bitumen Tank Farm

Rotating Alumina Kiln Gas & Diesel Tank Inventory Management

Power Industry Applications NOx Emissions

Storage Tank Monitoring System Critical Oil Movement Tank Gauging

Pipelines Sugar Bin Motor Monitoring

Fuel Supply Systems Gas Storage

Remote Tanks Steam Trap and PRV Monitoring

™

26

Execute

Page 37

Engineering Guidelines

00809-0100-6129, Rev AB

6.5 Design criteria development

Each wireless field network should be scoped to a single process unit.

Minimize the number of hops to the Gateway in order to reduce latency. A minimum of five

wireless instruments should be within effective range of the Smart Wireless Gateway.

A mesh network gets its reliability from multiple communication pathways. Ensuring each

device has multiple neighbors within range will result in the most reliable network. Each device

in the network should have a minimum of three devices within range to provide a potential

communication path.

Include 25 percent of each network’s wireless instruments within effective range of the Smart

Wireless Gateway. Other enhancing modifications include creating a higher percentage of

devices, up to 35 percent or more, within effective range of the Gateway. This clusters more

devices around the Gateway and ensures fewer hops and more bandwidth available to

WirelessHART devices with fast scan rates.

6.6 Identify candidate measurement points

Section 6: Execute

February 2016

Using the wireless guidelines established in the FEED, the design engineer should segregate all

points in the project database to identify the eligible wireless I/O points. For example, if

monitoring is deemed to be an eligible category, these points should be sor ted from the control

and other points. Afterwards, further requirements of the field devices can be applied. For

example, some control and monitoring points may be excluded from wireless eligibility because

the required update rate exceeds either the desired life of the battery or the capability of the

field device.

Typical control applications may require 1 second or faster update rates. There is a trade-off for

wireless devices between update rate and battery life; the faster the update rate, the lower the

battery life will be. It is recommended that the update rate of the measurements shall be three

times faster than the process time constant. As an example, a typical update rate for measuring

temperature changes with a sensor inside a thermowell can be 16 seconds or longer given how

much time is required for heat to penetrate the thermowell.

6.7 Database field for wireless network assignment

Each wireless field device must be assigned to a Gateway that manages a specific wireless field

network.

Each Gateway will manage its own wireless field network and can have an assigned HART Tag

like any HART device. Each wireless field network in a plant must have a unique Network ID to

prevent devices from attempting to join the wrong network. In order to ensure the desired

security level is achieved, a decision must be made whether to use a common join key for all

devices in a given field network, or unique join keys for each field device. The combination of

these two parameters provides identification and authentication down to the field device.

Execute

Ta bl e 6 -2 presents definitions of network Parameters when using a common Join Key, including

examples of a Gateway HART Tag, Network ID and Common Device Join Key.

27

Page 38

Section 6: Execute

February 2016

Engineering Guidelines

00809-0100-6129, Rev AB

Table 6-2. Definitions of Network Parameters When Using a Common Join Key

Parameter Parameter options Example Technical details

Gateway HART

Ta g

Network ID Integer 10145 Integer between 0 and 65535

Field UNIT_A_UA_100 32 characters – any in ISO Latin-1

(ISO 8859-1) character set

The Join Key is the most important parameter for implementing security. Users can know the

Gateway HART tag and the Network ID for the network that the Gateway manages, but a

wireless field device cannot join the network without a Join Key. The design engineer should be

sensitive to the security policies of the design firm and the security policies of the future

owner-operator and, as a minimum, treat the Join Key with the same sensitivities as a password

for a server to a DCS or database. For this reason, storing the join key as a field in a design

database is not prudent.

Fields should be added to the project database to indicate that a field device is wireless and to

describe its association with a Gateway by using the Gateway HART tag or other labeling

convention. Parameters required to be managed confidentially should be controlled in a secure

means in alignment with established security policies. Staff members with IT security or process

security responsibilities are well suited to provide consultation into the handling of sensitive

information.

Finally, the design engineer should be aware of available WirelessHART devices. Many come with

multiple inputs, enabling fewer devices to satisfy the total number of points in a project. For

example, several vendors have a multiplexed WirelessHART temperature device that reduces

costs.

6.8 Network design

Once wireless candidate devices have been identified in the instrument database, the field

network design can begin.

Ideally wireless points should be organized by process unit and by subsection of process unit as

typically depicted in the master drawing. This information can be used to determine the

number of Gateways required. Additional Gateways can be added to ensure spare I/O capacity

per guidelines or other project requirements. From here, the Gateways should be logically

distributed throughout the process unit like junction boxes. Wireless field devices should be