Page 1

Reference Manual

00809-0100-4002, Rev FA

Rosemount™ DP Level Transmitters and

Diaphragm Seal Systems

April 2022

Page 2

Safety Messages

NOTICE

For technical assistance. contacts are listed below:

Customer Central

Technical support, quoting, and order related questions.

United States:

Asia Pacific:

Europe/Middle East/Africa:

North American Response Center

Equipment service needs

1-800-654-7768 (24 hours - includes Canada)

Outside of these areas, contact your local Emerson representative.

1-800-999-9307 (7:00 a.m. to 7:00 p.m. CST)

65 777 8211

49 (8153) 9390

WARNING

Follow instructions

Failure to follow these installation guidelines could result in death or serious injury.

Ensure only qualified personnel perform the installation.

Explosion

Explosions could result in death or serious injury.

Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

Before connecting a handheld communicator in an explosive atmosphere, ensure that the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Verify the operating atmosphere of the transmitter is consistent with the appropriate hazardous locations certifications.

Electical hazard

Electrical shock could cause death or serious injury.

If the sensor is installed in a high-voltage environment and a fault or installation error occurs, high voltage may be present on

transmitter leads and terminals.

Use extreme caution when making contact with the leads and terminals.

Process leaks

Process leaks could result in death or serious injury.

Install and tighten all four flange bolts before applying pressure.

Do not attempt to loosen or remove flange bolts while the transmitter is in service.

Replacement equipment or spare parts not approved by Emerson for use as spare parts could reduce the pressure retaining

capabilities of the transmitter and may render the instrument dangerous.

Use only bolts supplied or sold by Emerson as spare parts.

Manifold installation

Improper assembly of manifolds to traditional flange can damage sensor module.

For safe assembly of manifold to traditional flange, bolts must break back plane of flange web (i.e., bolt hole) but must not contact

sensor module housing.

2

Page 3

WARNING

Sensor module and electronics housing

Sensor module and electronics housing must have equivalent approval labeling in order to maintain hazardous location approvals.

When upgrading, verify sensor module and electronics housing certifications are equivalent. Differences in temperature class

ratings may exist, in which case the complete assembly takes the lowest of the individual component temperature classes (for

example, a T4/T5 rated electronics housing assembled to a T4 rated sensor module is a T4 rated transmitter.)

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end users’ equipment. This could

be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your system. Restrict physical access

by unauthorized personnel to protect end users’ assets. This is true for all systems used within the facility.

CAUTION

The products described in this document are NOT designed for nuclear-qualified applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware or products may cause inaccurate

readings.

Individuals who handle products exposed to a hazardous substance can avoid injury if they are informed of and understand the

hazard. If the product being returned was exposed to a hazardous substance as defined by OSHA, a copy of the required Material

Safety Data Sheet (MSDS) for each hazardous substance identified must be included with the returned goods.

3

Page 4

4

Page 5

Reference Manual Contents

00809-0100-4002 April 2022

Contents

Chapter 1 Introduction.............................................................................................................. 7

1.1 Using this manual........................................................................................................................ 7

1.2 Product recycling/disposal...........................................................................................................7

Chapter 2 Remote Seal Systems................................................................................................. 9

2.1 DP Level and remote seal system measurement.......................................................................... 9

2.2 Terminology of system components............................................................................................9

2.3 Seal system performance...........................................................................................................10

2.4 Balanced vs. Tuned-System assemblies......................................................................................12

2.5 Specifying the right solution for vacuum applications................................................................14

2.6 Diaphragm weld types...............................................................................................................15

2.7 Differences between electronic remote sensors and capillary systems.......................................17

2.8 Instrument Toolkit: seal ordering and application process......................................................... 17

2.9 Rosemount Thermal Range Expander: proper use and applications........................................... 18

2.10 Thermal optimizer: proper use and applications...................................................................... 20

Chapter 3 Installation...............................................................................................................23

3.1 Seal handling and installation.................................................................................................... 23

3.2 Gaskets......................................................................................................................................25

3.3 Tagging..................................................................................................................................... 26

3.4 Torque sequence....................................................................................................................... 27

3.5 FFW flush flanged seal................................................................................................................28

3.6 Offline (RFW) remote flanged seal............................................................................................. 31

3.7 EFW extended flanged seal........................................................................................................ 35

3.8 PFW pancake seal...................................................................................................................... 36

3.9 FCW flush flanged seal—ring type joint (RTJ) gasket surface....................................................... 39

3.10 RCW remote flanged seal - ring type joint (RTJ) gasket surface.................................................41

3.11 FUW flush flanged groove type seals........................................................................................43

3.12 FVW flush flanged tongue type seals........................................................................................45

3.13 RTW remote threaded type seals............................................................................................. 47

3.14 HTS male threaded seal........................................................................................................... 50

3.15 SCW hygienic Tri-Clover Tri Clamp seals...................................................................................51

3.16 SSW hygienic tank spud seal.................................................................................................... 54

3.17 STW hygienic thin wall tank spud seal......................................................................................58

3.18 EES hygienic flanged tank spud extended seal..........................................................................59

3.19 VCS Tri Clamp in-line seal.........................................................................................................60

3.20 SVS VARIVENT® compatible hygienic connection seal..............................................................62

3.21 SHP hygienic Cherry-Burrell® “I” line seal................................................................................. 63

Rosemount DP Level 5

Page 6

Contents Reference Manual

April 2022 00809-0100-4002

3.22 SLS dairy process connection–female thread seal per DIN 11851.............................................64

3.23 WSP saddle seal....................................................................................................................... 65

3.24 UCP union connection pipe mount seal....................................................................................67

3.25 PMW paper mill sleeve seal......................................................................................................70

3.26 CTW chemical tee seal.............................................................................................................72

3.27 TFS wafer style In-line seal........................................................................................................73

3.28 WFW flow-thru flanged seal.....................................................................................................75

Chapter 4 Configuration...........................................................................................................77

4.1 Calculating range points............................................................................................................ 77

4.2 DP Level transmitter installation best practices..........................................................................84

Chapter 5 Fill Fluids..................................................................................................................91

5.1 Quality.......................................................................................................................................91

5.2 Fill fluid selection....................................................................................................................... 91

5.3 Fill fluid vapor pressure curves................................................................................................... 92

Chapter 6 Maintenance and Troubleshooting...........................................................................95

6.1 Cleaning.................................................................................................................................... 95

6.2 Troubleshooting........................................................................................................................95

6.3 Return of materials.................................................................................................................... 97

6.4 Service support..........................................................................................................................97

Chapter 7 Reference data......................................................................................................... 99

7.1 Product certifications.................................................................................................................99

7.2 Ordering information, specifications, and drawings...................................................................99

7.3 Spare parts................................................................................................................................ 99

6 Emerson.com/Rosemount

Page 7

Reference Manual Introduction

00809-0100-4002 April 2022

1 Introduction

1.1 Using this manual

This manual is designed to assist in installing, operating, and maintaining the Rosemount

Diaphragm Seal Systems for Pressure Transmitters and diaphragm seal systems that are

part of Rosemount DP Level Transmitters including the Rosemount 3051SAL, Rosemount

3051L and Rosemount 2051L. The manual contains information about the seal system

assemblies that are not covered in the corresponding transmitter manuals. For

information regarding transmitter configuration, operation, and maintenance, reference

the appropriate transmitter manual.

The information is organized into the following categories:

• Remote Seal Systems provides an overview of Remote Seal Systems.

• Installation contains mechanical and electrical installation instructions.

• Configuration outlines how to range a DP Level Remote Seal System.

• Fill Fluids describes the offering of fill fluids available with Remote Seal Systems.

• Maintenance and Troubleshooting provides techniques for cleaning and maintaining

the system as well as addressing the most common operating problems.

• Reference data provides resources for product certifications, ordering information,

specifications, drawings, and spare parts.

See Rosemount DP Level Transmitters and 1199 Seal Systems Product Data Sheet or 1299

Seal System Product Data Sheet for more detailed information on specific Rosemount

Remote Seals.

A remote seal system consists of a pressure transmitter, a remote diaphragm, and either a

direct mount or capillary style connection filled with a secondary fill fluid.

Rosemount uses both the 1199 and 1299 models for specifying remote seals. This manual

includes information for both.

1.2 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation/regulations.

Rosemount DP Level 7

Page 8

Introduction Reference Manual

April 2022 00809-0100-4002

8 Emerson.com/Rosemount

Page 9

A

B

C D

E

B

C

F

Reference Manual Remote Seal Systems

00809-0100-4002 April 2022

2 Remote Seal Systems

2.1 DP Level and remote seal system measurement

DP Level is a reliable measurement solution for measuring level, density, interface, or mass

of a process media inside a tank.

Remote seal system measurement is unaffected by agitation, foam, or internal obstacles.

Remote diaphragm seals extend limitations due to process conditions such as high and

low temperatures, corrosive processes, viscous mediums, and hygienic applications.

2.2 Terminology of system components

Figure 2-1 lists the basic components for seal assemblies.

Figure 2-1: Components on a Two- and Single-Seal Assembly

Two-seal assembly

A. Pressure, differential pressure, or multivariable transmitter

B. Process flange

C. Remote diaphragm

D. Capillary

E. Flushing ring (optional)

F. Direct mount

Single-seal assembly

Rosemount DP Level 9

Page 10

A

B

C

D

Remote Seal Systems Reference Manual

April 2022 00809-0100-4002

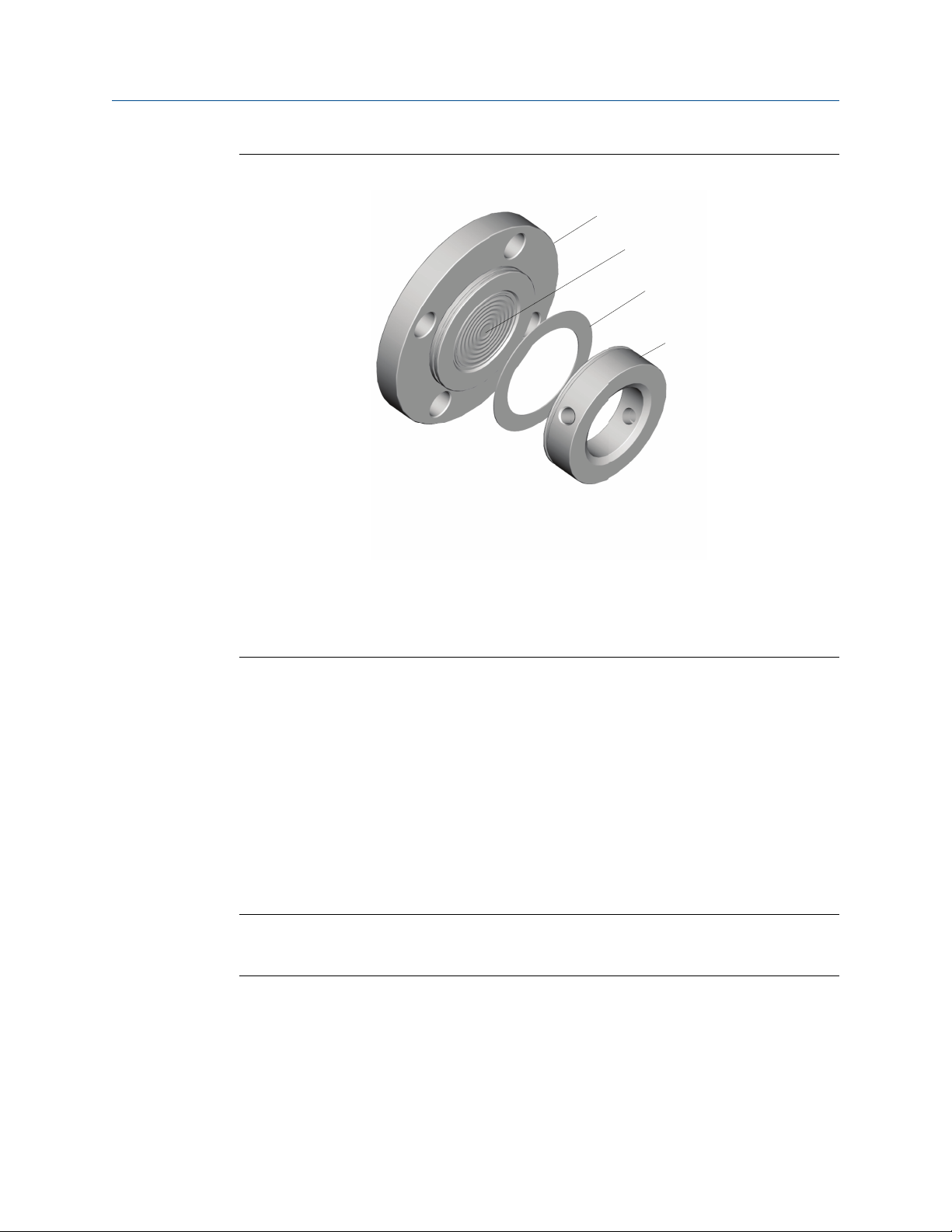

Figure 2-2: Flushed Flanged (FFW) Seal and Components

A. Process flange

B. Diaphragm

C. Gasket

D. Flushing ring (optional)

2.3 Seal system performance

2.3.1 Volume temperature effects (process temperature effects)

Fill fluids expand or contract with temperature changes, creating a volume change that is

absorbed by the diaphragm seal and is seen as back pressure at the transmitter. This back

pressure creates a shift in the transmitter reading. For symmetrical or balanced systems,

this error is usually minimal due to the back pressure being equal on both sides. However,

head temperature effect is still present.

Note

Other factors that affect seal temperature effect include diaphragm thickness, seal type

and size, capillary length, and inner diameter.

Figure 2-3 shows how diaphragm size can affect the measurement reading at the

transmitter. For smaller seal sizes, such as the 1½-in. size, the amount of back pressure on

the transmitter causes an additional 12.1 inH2O (307 mmH2O)error. Moving to the 2-in.

size gives 1.7 inH2O (43 mmH2O)and the largest 3-in. size shown only has 0.5 inH2O (13

mmH2O)error. Using a larger diaphragm can drastically improve performance and

provides a more stable reading.

10 Emerson.com/Rosemount

Page 11

Reference Manual Remote Seal Systems

00809-0100-4002 April 2022

Note

Calculations done in Instrument Toolkit™ with Silicone 200 fill fluid with Rosemount 3051

Transmitter.

Figure 2-3: Back Pressure on Diaphragm Causing Error

2.3.2

2.3.3

Note

Diaphragm temperature effects decrease as seal size increases.

Density temperature effects (head temperature effects)

Density temperature effect is due to the change in specific gravity of the fill fluid caused by

a change in ambient temperature. When installed, the weight of the fill fluid will produce

an initial pressure read by the transmitter, equaling the height between the high and low

connection taps multiplied by the fill fluid's specific gravity. As ambient temperature

changes, the fill fluid specific gravity will change causing the weight of the fill fluid to

change, thus changing the pressure read by the transmitter. Density effect will be seen in

both

Tuned-System™ Assemblies and Balanced System Assemblies and will have the same

impact on the transmitter regardless of where the transmitter is mounted.

System time response and performance

The time response of a system is based on the type of transmitter, its sensor range, the

length and inner diameter (ID) of the capillary, and the viscosity of the fill fluid (which is

directly affected by the process and ambient temperatures). These factors all play a role in

the overall performance of any seal system. The relationship between system time

response and temperature error is illustrated in Figure 2-4. It can be seen that changing

the capillary ID has an inverse affect between the time response and temperature effect of

a capillary system. As the capillary ID is increased, the time response of the system

decreases while the temperature effect increases.

Rosemount DP Level 11

Page 12

Remote Seal Systems Reference Manual

April 2022 00809-0100-4002

Figure 2-4: Response Time vs. Total Performance Example

Note

Calculations conducted using Instrument Toolkit.

Parameters: Silicone 200 fill fluid, Rosemount 3051CD2 Transmitter, 15 ft. capillary

length, 2-in. FFW Seal, and calibrated at 25 °C.

2.4 Balanced vs. Tuned-System assemblies

A balanced remote seal system is a symmetrical system that utilizes equal seals and

capillary length on the high and low pressure sides of the transmitter. Since the capillary

lengths are the same, each side ideally has the same amount of fill fluid, minimizing or

completely eliminating the seal temperature effect due to equal pressure on both sides of

the transmitter diaphragm. The balanced systems are still affected by the head pressure as

shown in Figure 2-5.

12 Emerson.com/Rosemount

Page 13

Reference Manual Remote Seal Systems

00809-0100-4002 April 2022

Figure 2-5: Balanced System

+3.6 inH2O

(9.0 mbar)

No error

(Cancels out)

+3.6 inH2O

(9.0 mbar)

Head temperature

effect

Seal temperature

effect

Total temperature

effect on system

Note

Temperature effects were calculated in Instrument Toolkit using a 2-in. (DN 50) FFW seal,

Silicone 200, 10 ft. (3 m) between the taps, over a 50 °F (28 °C) temperature change.

Tuned-Systems assemblies are asymmetrical remote seal systems with one seal directly

mounted to the high side of the differential pressure transmitter, and the other side

connected to a seal via capillary. Another possible Tuned-System assembly is any remote

seal system with unequal lengths of capillary or two different remote seals on the high and

low pressure connections. Due to the unequal lengths of capillary, there are seal

temperature effects. However, this seal temperature effect counters the head pressure

from the oil-filled capillary and reduces total temperature effects on the entire system.

Figure 2-6: Tuned-System Assembly

Head temperature

effect

Seal temperature

effect

Total temperature

effect on system

+3.6 inH2O

(9.0 mbar)

-1.7 inH2O

(4.2 mbar)

+1.9 inH2O

(4.7 mbar)

Note

Temperature effects were calculated in Instrument Toolkit using a 2-in. (DN 50) FFW seal,

Silicone 200, 10 ft. (3 m) between the taps, over a 50 °F (28 °C) temperature change.

Rosemount DP Level 13

Page 14

Remote Seal Systems Reference Manual

April 2022 00809-0100-4002

2.5 Specifying the right solution for vacuum applications

2.5.1 Vacuum application overview

When a vessel is operating in a vacuum (negative gauge pressure), it is important to

specify the correct transmitter remote seal system to measure level accurately and

reliably. Failure to do so can result in output drift or complete system failure. The

combination of high process temperature and vacuum process pressure conditions

creates additional requirements when specifying the transmitter remote seal system.

2.5.2 Vacuum applications

There are three primary transmitter-seal system components necessary to successfully

specify vacuum application solutions:

• Seal system construction

2.5.3

2.5.4

• Fill fluid selection

• Transmitter mounting position

Seal system construction for vacuum applications

Emerson offers welded-repairable or all-welded vacuum system construction styles on

diaphragm seal assembles.

The all-welded vacuum construction was designed specifically for vacuum applications. In

this construction, the sensor module gaskets are removed and a disk is welded over the

sensor isolators. This eliminates the possibility of air being drawn into the seal system in

deep vacuum conditions. This premium design is strongly suggested for vacuum pressures

below 6 psia (310 mmHga).

Transmitter mounting position

Mounting the pressure transmitter at or below the bottom vessel tap is an important

factor to ensure a stable measurement with vacuum applications. The static pressure limit

for a differential pressure transmitter is 0.5 psia (25 mmHgA), which ensures the

transmitter sensor module fill fluid remains within the liquid phase of the vapor pressure

curve.

If the vessel static limit is below 0.5 psia, mounting the transmitter below the bottom tap

provides a capillary fill fluid head pressure on the module. A general rule is to always

mount the transmitter approximately 3 ft. (1 m) below the bottom tap of the vessel.

14 Emerson.com/Rosemount

Page 15

A

B

A C

D

Reference Manual Remote Seal Systems

00809-0100-4002 April 2022

2.5.5 Fill fluid selection

When the process is under vacuum conditions, the fill fluid can vaporize at a lower

temperature than when it is under normal atmospheric or greater pressure. Each fill fluid

has a specific vapor-pressure curve. The vapor-pressure curve indicates the pressure and

temperature relationship where the fluid is in a liquid or a vapor state. Proper seal

operation requires the fill fluid to remain in a liquid state.

For vacuum applications, specify fluids that are specifically designed for use in these types

of applications such as Silicone 704 for vacuum applications, Silicone 705 for vacuum

applications, or UltraTherm™ 805 for vacuum applications. These fluids have been

specially processed to deliver the maximum vapor pressure curve performance possible.

For more information on Rosemount Diaphragm Seal fill fluids, reference the Rosemount

Fill Fluid Specifications Technical Note.

2.6 Diaphragm weld types

Weld-type is factory-determined as best for the seal typed specified. Pancake Flanged

(PFW) and FFW seals have ordering options that specify welding options.

2.6.1

Solid faceplate design

The solid faceplate design is used when diaphragm and upper housing material are the

same.

A. Material A

B. Upper housing

C. Diaphragm

D. TIG weld point

Rosemount DP Level 15

Page 16

A

B D

C

E

F

A

B

C

D

E

Remote Seal Systems Reference Manual

April 2022 00809-0100-4002

2.6.2 Seam weld design

A seam weld design is used when the upper housing material is different from the

diaphragm material. The seam welded design has a hermetic weld at the inner diameter of

the diaphragm and a TIG weld at the outer edge. The diaphragm floats on the upper

housing over the gasket surface area and could tear if a metallic gasket were used.

A. Material A

B. Material B

C. Upper housing

D. Diaphragm

E. TIG weld point

F. Seam weld point

2.6.3

Brazed design

This process uses a brazing ring where the metals are brazed to attach the diaphragm to

the upper housing. This allows the gasket surface area to solidify as it is melted to the

upper housing.

This option is used with Tantalum diaphragm when a metallic gasket is required.

A. Material A

B. Tantalum

C. Upper housing

D. Brazing ring

E. Diaphragm

16 Emerson.com/Rosemount

Page 17

A

B

Reference Manual Remote Seal Systems

00809-0100-4002 April 2022

2.7 Differences between electronic remote sensors and capillary systems

Rosemount 3051S Electronic Remote Sensors (ERS™) System technology utilizes two

Rosemount 3051S Pressure Transmitters connected via an electrical wire instead of a

single pressure transmitter with remote seals and capillary tubing. As the Rosemount

3051S ERS System calculates the differential pressure between the two transmitters,

capillary tubing is not needed, and thus eliminates all head temperature affects on the

system. Seals are not required, but may still be necessary on certain applications that

include high temperature, corrosive, or viscous processes. For more information, refer to

the Rosemount 3051S Series Product Data Sheet.

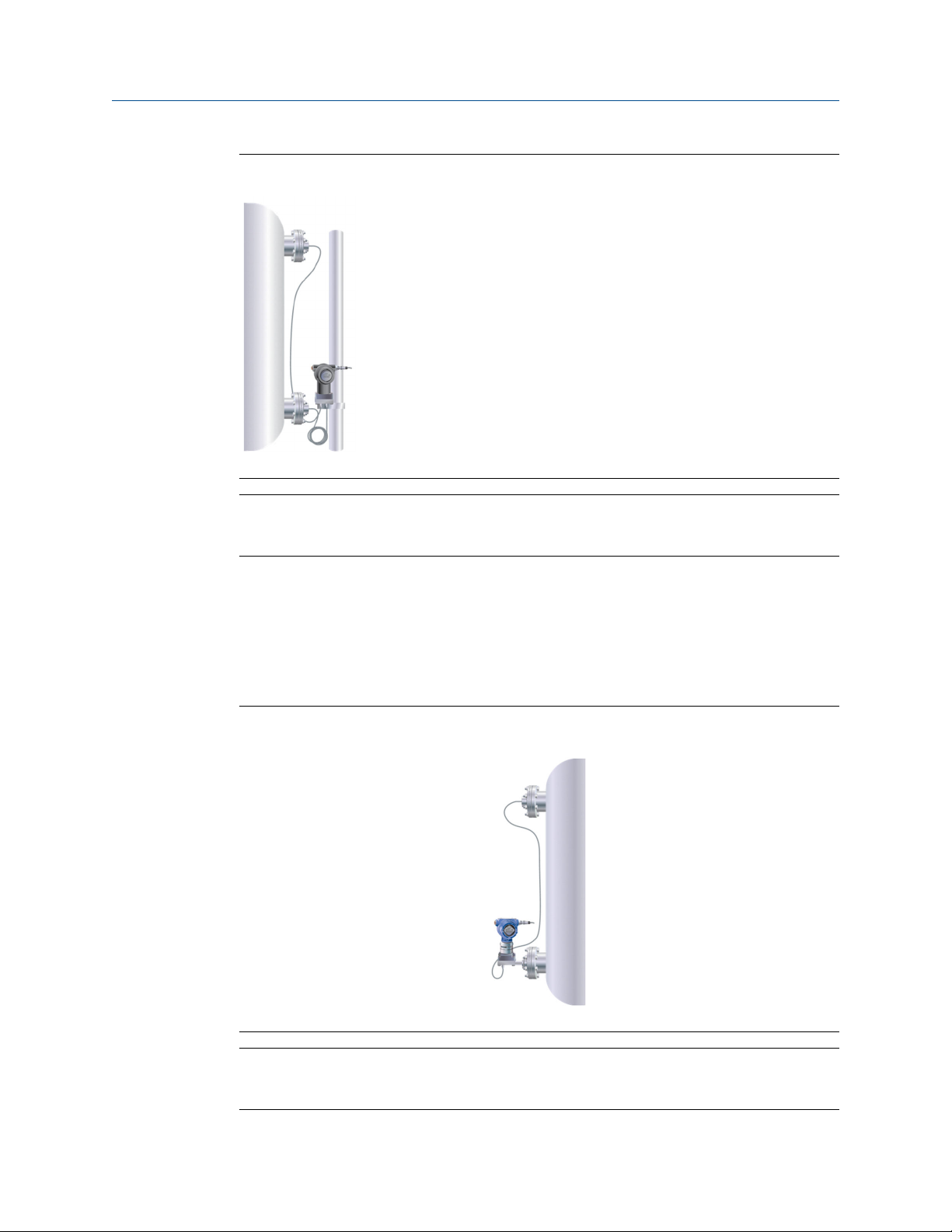

Figure 2-7: ERS vs. Capillary

Rosemount 3051S ERS

A. Non-proprietary electrical cable

B. Oil-filled capillary system

Traditional capillary system

2.8 Instrument Toolkit: seal ordering and application process

Rosemount Instrument Toolkit Software is an instrumentation specification tool that can

be used to assist in product selection. This program analyzes application and process

conditions against a configured Rosemount model number and calculates the total system

Rosemount DP Level 17

performance including expected head and seal temperature effects and system response

times.

Visit the Emerson website for information on how to obtain and use Instrument Toolkit.

Page 18

Remote Seal Systems Reference Manual

April 2022 00809-0100-4002

2.9 Rosemount Thermal Range Expander: proper use and applications

Figure 2-8: Rosemount Thermal Range Expander

A. Intermediate diaphragm

B. High temperature fill fluid (viscous)

C. Ambient temperature fill fluid

The Rosemount Thermal Range Expander increases the application range where DP Level

technology can be used by expanding the ambient and process temperature ranges of the

system.

Traditional remote seal systems are filled with a single fill fluid to operate in applications

with varying ambient and process conditions. Silicone 704 and 705 are commonly used

fluids for hot process applications going above 570 °F (300 °C); these fluids must be kept

above 32 °F (0 °C) and 68 °F (20 °C), respectively, in order to properly transmit the pressure

signal to the transmitter. This can prove to be difficult for outdoor installations where

extremely cold ambient conditions cause these fill fluids to gel.

The Rosemount Thermal Range Expander is a seal system that uses two different fill fluids

to extend the operating temperature range of the system. A high temperature fill fluid,

which is next to the hot process, is kept warm enough to stay responsive. A second fill

fluid, located on the other side of the intermediate diaphragm, operates over a wide

ambient temperature range. The Rosemount Thermal Range Expander can operate in

ambient temperatures as low as –103 °F (–75 °C), and process temperatures up to 770 °F

(410 °C) and 850 °F (454 °C) design temperature

percent and eliminates the need for mechanical heat tracing.

The Rosemount Thermal Range Expander can be used with any Rosemount 3051S DP

Level configuration including Balanced Systems, Tuned-System Assembles, Electronic

Remote Sensors (ERS), or direct mounted to a transmitter.

(1)

. This improves response time up to 46

UltraTherm 805 supports maximum design temperature of 850 °F (454 °C). Design temperature rating is for non-

(1)

continuous use with a cumulative exposure time less of than 12 hours. Continuous use temperature is rated to 770 °F (410

°C).

18 Emerson.com/Rosemount

Page 19

Reference Manual Remote Seal Systems

00809-0100-4002 April 2022

Figure 2-9: Rosemount Thermal Range Expander Temperature Operating Range

Rosemount DP Level 19

Page 20

212 °F (100 °C)

176 °F (80°C)

140 °F (60 °C)

104 °F (40 °C)

68 °F (20 °C)

32 °F (0 °C)

-4 °F (-20 °C)

-40 °F (-40 °C)

-76 °F (-60 °C)

-112 °F (-80 °C)

212 °F (100 °C)

176 °F (80°C)

140 °F (60 °C)

104 °F (40 °C)

68 °F (20 °C)

32 °F (0 °C)

-4 °F (-20 °C)

-40 °F (-40 °C)

-76 °F (-60 °C)

-112 °F (-80 °C)

32 °F (0 °C)

122 °F (50 °C)

302 °F (150 °C)

482 °F (250 °C)

662 °F (350 °C)

842 °F (450 °C)

401 °F (205 °C)

185 °F (85 °C)

185 °F (85 °C)

599 °F (315 °C)

-58 °F (-50 °C)

91 °F (33 °C)

Process temperature °F (°C)

Ambient temperature °F (°C)

Ambient temperature °F (°C)

Process temperature °F (°C)

122 °F (50 °C)

302 °F (150 °C)

482 °F (250 °C)

662 °F (350 °C)

842 °F (450 °C)

185 °F (85 °C)

185 °F (85 °C)

-58 °F (-50 °C)

401 °F (205 °C)

-69 °F (-56 °C)

-76 °F (-60 °C)

68 °F (20 °C)

698 °F (370 °C)

68 °F (20 °C)

68 °F (20 °C)

77 °F (25 °C)

Remote Seal Systems Reference Manual

April 2022 00809-0100-4002

2.10 Thermal optimizer: proper use and applications

The thermal optimizer keeps fill fluids from gelling in cold

ambient temperatures by using high process temperatures to

heat the transmitter and capillary.

High temperature silicone fill fluid has a low temperature limit in

ambient conditions below 32 °F (0 °C). The thermal optimizer

allows direct mounting down to –94 °F (–70 °C).

Figure 2-10: Fill Fluid Temperature Limits

Thermal optimizer with Silicone 704

Thermal optimizer with Silicone 705

20 Emerson.com/Rosemount

Page 21

Reference Manual Remote Seal Systems

00809-0100-4002 April 2022

2.10.1 Thermal optimizer limitations

Figure 2-10 shows the process and ambient temperature limits for the thermal optimizer

with Silicone 704 and Silicone 705 Fill Fluids respectively. The shaded areas represent the

temperature limitations; applications outside of the shaded area cannot be used with a

thermal optimizer.

For example, an application with an ambient temperature of 50 °F (10 °C) and a process

temperature of 300 °F (149 °C) is within the limits, a thermal optimizer can be used in this

application.

However, an application with an ambient temperature of 122 °F (50 °C) and a process

temperature of 464 °F (240 °C) is outside of the limits. These high temperatures would be

detrimental to the transmitter electronics.

Rosemount DP Level 21

Page 22

Remote Seal Systems Reference Manual

April 2022 00809-0100-4002

22 Emerson.com/Rosemount

Page 23

Reference Manual Installation

00809-0100-4002 April 2022

3 Installation

3.1 Seal handling and installation

3.1.1 Diaphragm

The remote seal diaphragm is designed to withstand pressure and wear from process, but

outside of process connection conditions, remote seals are delicate and should be handled

with care.

The protective cover should remain on the seal until the moment before installation. Try

to avoid touching the diaphragm with fingers or objects and refrain from setting the

diaphragm side of the seal down on a hard surface.

Even minor dents or scratches in the diaphragm material may impair the performance of

the seal system assembly. Care should be taken to ensure the seal diaphragm is not

dented or damaged during seal installation.

3.1.2

3.1.3

Capillary

When unpacking or handling seal system assemblies, do not lift the seal or transmitter by

gripping the capillaries. Avoid sharply bending or crimping the capillary tubing. The

minimum bending radius of the capillary tubing is 3-in. (8 cm).

Rosemount Thermal Range Expander

The Rosemount Thermal Range Expander system uses the heat from the process in order

to keep both fluids within the system functioning properly; therefore insulation is not

always required. However, it is always best practice to insulate systems to keep them

functioning with optimum performance. The Rosemount Thermal Range Expander should

never be insulated above the line marked on the seal itself.

Rosemount DP Level 23

Page 24

Rosemount 3051SAL with Thermal Range Expander

Marking:

“Do Not Insulate

Above this Line”

Ok to

Insulate

Do Not

Insulate

Installation Reference Manual

April 2022 00809-0100-4002

Figure 3-1: Rosemount 3051SAL with Rosemount Thermal Range Expander Insulation

Guidelines

3.1.4 Heat tracing

When using heat or steam tracing, exercise caution if PVC coating is added onto capillary,

as PVC coating should not be exposed to temperatures above 212 °F (100 °C) to avoid the

possibility of thermal breakdown.

Best practice for heat and steam tracing is to regulate the temperature slightly above the

maximum ambient temperature for a consistent result. To avoid accuracy effects and

thermal stress, the capillary should not be partially heated.

CAUTION

NEVER attempt to disconnect the seals or capillaries from the transmitter or loosen

bolts.

Doing so will result in loss of fill fluid and will void the product warranty.

Failing to recognize incorrect materials during installation may cause process leaks, which

can result in damage to the diaphragm seal system or death and/or serious injury to

personnel. Proper wetted material is required for specific process materials.

24 Emerson.com/Rosemount

Page 25

Reference Manual Installation

00809-0100-4002 April 2022

3.2 Gaskets

WARNING

When installing remote seal systems which employ a gasket or a gasket and flushing

connection ring, make sure the gasket is aligned properly on the gasket sealing surface.

The user is responsible to ensure the gasket used does not exceed the temperature limits

of the process. Failure to properly install the gasket may cause process leaks, which can

result in death or serious injury.

In addition, make sure the gasket does not press down upon the diaphragm face. Anything

pressing on the diaphragm will be read by the transmitter as pressure. A misaligned gasket

may cause a false reading.

The intermediate gasket between the seal and lower housing is supplied when the lower

housing or flushing connection is provided when ordered on an 1199. The default gaskets

are listed in Table 3-1 based on seal type. The process gasket must be supplied by the end

user. Tantalum diaphragms are not supplied with default gasket, so a gasket option must

be selected when applicable.

If a lower housing is supplied, then the following gaskets are the default gaskets for each

seal unless another gasket option is selected.

When ordering a 1299 seal system, the gasket option must be selected in the model

number, there will not be a default gasket shipped.

Table 3-1: Gasket Materials for 1199

Seal type Gaskets

Flanged seals assemblies

FFW Klingersil® C-4401

RFW Klingersil C-4401

EFW No gasket is supplied

PFW Klingersil C-4401

FCW No gasket is supplied

RCW Klingersil C-4401

FUW/FVW No gasket is supplied

Threaded seal assemblies

RTW Klingersil C-4401

HTS No gasket is supplied

Hygienic seal assemblies

(1)

SCW

No gasket is supplied

SSW Ethylene propylene O-ring

STW Ethylene propylene O-ring

EES No gasket is supplied

Rosemount DP Level 25

Page 26

Installation Reference Manual

April 2022 00809-0100-4002

Table 3-1: Gasket Materials for 1199 (continued)

Seal type Gaskets

(1)

VCS

(1)

SVS

SHP No gasket is supplied

(1)

SLS

Specialty seals

WSP Klingersil C-4401

UCP Barium-Sulfate filled PTFE O-ring

CTW No gasket is supplied

TFW No gasket is supplied

WFW Klingersil C-4401

(1) Use EHEDG approved gasket for EHEDG conformity.

No gasket is supplied

No gasket is supplied

No gasket is supplied

WARNING

The end-user is responsible for choosing a gasket and ensuring the process temperature

does not exceed the temperature limits of the gasket used. Failure to properly install the

gasket may cause process leaks, which can result in death or serious injury.

3.3 Tagging

Each remote seal system is tagged in accordance with the end-user requirements. The

remote seal model number is identified on the transmitter label, shown in Figure 3-2,

Figure 3-3, and Figure 3-4.

Figure 3-2: Rosemount 3051S Sample Label

Figure 3-3: Rosemount 3051 Sample Label

26 Emerson.com/Rosemount

Page 27

A

C

D

B

Reference Manual Installation

00809-0100-4002 April 2022

Figure 3-4: Rosemount 2051 Sample Label

3.3.1 Max working pressure

The maximum working pressure (MWP) of the seal system assembly is stamped on the

transmitter neck tag. This can be dependent upon the maximum pressure rating of the

seal system or transmitter upper range limit.

3.4 Torque sequence

When tightening the assembly bolts, use a cross-pattern to ensure even installation. Best

practice is to tighten 20 to 30 percent, check the gap, tighten 50 to 70 percent, check

flange gap and uniformity, and continue to tighten in the appropriate pattern until you

reach 100 percent torque value. Time permitting, wait a minimum of four hours and

repeat the torque pattern to restore any short-term creep/relaxation in the connection.

Figure 3-5: Cross-Pattern Sequence

A. 4-bolt flange

B. 8-bolt flange

C. 12-bolt flange

D. 16-bolt flange

Rosemount DP Level 27

Page 28

B

C

D

A

C

E

F

D

Installation Reference Manual

April 2022 00809-0100-4002

3.5 FFW flush flanged seal

Figure 3-6: FFW Two-Piece Design (Shown with Optional Flushing Ring)

A. Alignment clamp (option code SA)

B. Process flange

C. Diaphragm

D. Flushing ring (optional)

E. Connection to transmitter

F. Flushing connection

Standard expanded

Note

Two-piece design seal assembly and process flange are separate components and can be

rotated independent of each other. Alignment clamp (A) can be ordered using option

code SA on the 1199.

28 Emerson.com/Rosemount

Page 29

B

D

E

C

Reference Manual Installation

00809-0100-4002 April 2022

Figure 3-7: FFW One-Piece Design (Shown with Optional Flushing Ring)

A. Process flange

B. Diaphragm

C. Flushing ring (optional)

D. Connection to transmitter

E. Flushing connection

3.5.1

Note

Alignment clamp (option code SA) not available for FFW one-piece design.

Parts required for installation

The parts required to install the FFW flush flanged seal will be defined here. Prior to

installation, you will need the following:

• Torque wrench

• Mounting hardware (end-user-supplied)

• Gasket (end-user-supplied)

Note

Flushing rings include an Emerson-supplied gasket. If an alignment clamp is used, a Phillips

or slotted screwdriver is required for installation

Verify the gasket materials are appropriate for the application.

Inspect bolts to ensure the material is compatible with industry standards per the

application such as ASME PCC-1.

Rosemount DP Level 29

Page 30

Installation Reference Manual

April 2022 00809-0100-4002

3.5.2 Installation steps

If a flushing ring is ordered and no alignment clamp is used, it is recommended that two

people install the FFW flush flanged seal to ensure proper alignment during installation.

Follow these steps to install the FFW flush flanged seal on an existing flanged process

connection:

Procedure

1. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

2. If installing a flushing ring, ensure flushing connections are sealed before

completing installation. Flushing rings may be ordered with or without, one or two

threaded flushing connections, factory supplied plugs, or drain vent valves. If no

flushing ring was purchased, proceed to Step 3. Assemble the flushing ring,

Emerson-supplied gasket, and remote seal together. If using an alignment clamp

(option code SA on the 1199) attach the flushing ring to the remote seal. Place the

alignment clamp in the machined groove on both the remote seal and the flushing

ring. Using the applicable screwdriver, tighten the screw on the clamp to hold the

flushing ring in place.

3. Insert end-user-supplied bolts in the bottom two bolt holes of the flange on the

remote seal.

4. Place the appropriate end-user-supplied gasket on the remote seal or flushing ring

and align the gasket so that it is not inside the diaphragm weld as this will induce

errors.

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

5. Using the previously installed bolts, attach the remote seal and gasket to the

process connection. Secure with nuts and hand-tighten.

6. Insert end-user-supplied bolts in the top two bolt holes of the flange on the remote

seal. Secure with nuts and hand-tighten.

7. Using a torque wrench on the nut, tighten the assembly in a cross-pattern to ensure

even installation (see Torque sequence). The bolts should be torqued to the

applicable flange requirements. Required torque is a function of the gasket material

and surface treatment of the bolts and nuts which are end-user-supplied. Consider

leak checking the installation to ensure a robust connection.

30 Emerson.com/Rosemount

Page 31

B

D

E

Reference Manual

00809-0100-4002 April 2022

Installation

3.6 Offline (RFW) remote flanged seal

Figure 3-8: RFW Standard Design

A. Process flange

B. Diaphragm

C. Lower housing or flushing ring

D. Connection to transmitter

E. Flushing connection

Note

Lower housing always required for RFW remote flanged seal.

Figure 3-9: RFW Stud Bolt Design

A. Upper housing

B. Lower housing or flushing ring

C. Stud bolts

D. Diaphragm

E. Connection to transmitter

Rosemount DP Level 31

Page 32

Installation

Reference Manual

April 2022 00809-0100-4002

Table 3-2: RFW Upper Housing Torque Values

Bolt thread size Material (nuts

and bolts)

⅜–24 NF SST 2.4 or 4.1 150/300 23

⅜–24 NF SST 2.4 600 23

⅜–24 NF CS 2.4 or 4.1 150/300/600 53

½–20 NF SST 4.1 600 50

½–20 NF CS 2.4 900/1500 105

½–20 NF SST 2.4 900 50

¾–16 NF

¾–16 NF

M10 x 1.50 SST 2.4 or 4.1 10K/20K/40K 23

M10 x 1.50 SST 2.4 or 4.1 PN10/PN40/PN63 23

M10 x 1.50 SST 2.4 PN100 23

M12 x 1.75 SST 4.1 PN100 50

M12 x 1.75 SST 2.4 PN160 50

(1) Thread lubricant required, e.g., antiseize, thread paste.

(1)

(1)

SST 2.4 1500 120

CS 2.4 2500 180

Diaphargm Size

(in.)

Class Torque (ft.-lb)

Note

This is the specification for connecting the remote seal to the lower housing, not the

torque specification for the lower housing onto the process flanged connection. The lower

housing bolts should be torqued to the applicable flange requirements.

3.6.1

4.1-in. (104 mm) diaphragm diameter option

The standard diaphragm size for the RFW remote flanged seal is 2.4-in. A larger, 4.1-in.

(104 mm), diaphragm size is offered for small spans to reduce temperature error when

taking process measurements.

3.6.2

Parts required for installation

The parts required to install the RFW remote flanged seal will be defined here. Prior to

installation, you will need the following:

• Torque wrench

• Mounting hardware (end-user-supplied)

• Gasket (lower housing to process flange) (end-user-supplied)

• Gasket (remote seal to lower housing) (Emerson-supplied on the 1199. 1299 requires a

gasket option to be selected.)

Note

Typically, the stud bolt design includes Emerson-supplied stud bolts.

32 Emerson.com/Rosemount

Page 33

Reference Manual Installation

00809-0100-4002 April 2022

Verify the gasket material is appropriate for the application.

Inspect bolts to ensure the material is compatible with industry standards per the

application such as ASME PCC-1.

3.6.3 Standard design installation steps

It is recommended that two people install the standard design RFW remote flanged seal to

ensure proper alignment during installation.

Follow these steps to install the standard design RFW remote flanged seal on an existing

process flange:

Procedure

1. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

2. Ensure flushing connections are sealed before completing installation. Flushing

rings may be ordered with or without, one or two threaded flushing connections,

factory supplied plugs, or drain vent valves.

3. Assemble the flushing ring, Emerson-supplied gasket, and remote seal together.

Place the Emerson-supplied gasket inside the recessed cavity within the flushing

ring which is designed to hold the gasket in place.

4. Assemble to remote seal assembly to the process flange. Place the appropriate end-

user-supplied gasket between the flushing ring and process flange. Ensure that the

end-user-supplied gasket is centered on both the flushing ring and process flange.

Ensure the flange bolt holes between the remote seal and the process flange are

aligned.

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

5. Put the first end-user-supplied bolt through one of the holes on the bottom of the

seal and process flange. Secure with a nut and hand-tighten.

6. Install the remaining end-user-supplied bolts in a cross pattern, hand-tightening

each nut as the bolts are installed.

7. Using a torque wrench on the nut, tighten the assembly in a cross-pattern to ensure

even installation (see Torque sequence). The bolts should be torqued to the

applicable flange requirements. Required torque is a function of the gasket material

and surface treatment of the bolts and nuts which are end-user-supplied. Consider

leak checking the installation to ensure a robust connection.

Rosemount DP Level 33

Page 34

Installation Reference Manual

April 2022 00809-0100-4002

3.6.4 Stud bolt installation steps

Follow these steps to install the stud bolt design RFW remote flanged seal on an existing

process flange:

Procedure

1. Ensure flushing connections are sealed before completing installation. Lower

housing may be ordered with or without, one or two threaded flushing

connections, factory supplied plugs, or drain vent valves.

2. Install the stud bolts onto the lower housing.

3. Assemble the lower housing to the process flange. Place the appropriate end-user-

supplied gasket between the lower housing and process flange. Ensure that the

end-user-supplied gasket is centered on both the lower housing and process flange.

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

4. Hand-tighten nuts onto the studs.

5. Using a torque wrench on the nut, tighten the assembly in a cross-pattern to ensure

even installation (see Torque sequence). The nuts should be torqued to the

applicable flange requirements.

6. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

7. Assemble the remote seal, Emerson-supplied gasket, and lower housing. Place the

Emerson-supplied gasket inside the recessed cavity within the lower housing which

is designed to hold the gasket in place.

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

8. Install the bolts in a cross pattern and hand-tighten.

9. Using a torque wrench on the bolt, tighten the assembly in a cross-pattern to

ensure even installation (see Torque sequence). The bolts should be torqued per

Offline (RFW) remote flanged seal based on size and bolt material. Consider leak

checking the installation to ensure a robust connection.

34 Emerson.com/Rosemount

Page 35

A

B

C

C

D

Reference Manual

00809-0100-4002 April 2022

Installation

3.7 EFW extended flanged seal

Figure 3-10: EFW Extended Flanged Seal Assembly

3.7.1

3.7.2

A. Process flange

B. Extension

C. Diaphragm

D. Connection to transmitter

Note

Flushing ring/lower housing not available for EFW extended flanged seal.

Parts required for installation

The parts required to install the EFW extended flanged seal will be defined here. Prior to

installation, you will need the following:

• Torque wrench

• Mounting hardware (end-user-supplied)

• Gasket (end-user-supplied)

Verify the gasket material is appropriate for the application.

Inspect bolts to ensure the material is compatible with industry standards per the

application such as ASME PCC-1.

Installation steps

Rosemount DP Level 35

Follow these steps to install the EFW extended flanged seal on an existing process flange:

Procedure

1. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

Page 36

B

C

D

A

E

C

D

F

E

Installation

April 2022 00809-0100-4002

2. Insert end-user-supplied bolts in the bottom two bolt holes of the flange on the

remote seal.

3. Place the appropriate end-user-supplied gasket on the remote seal.

Reference Manual

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

4. Using the previously installed bolts, attach the remote seal and gasket to the

process flange. Secure with nuts and hand-tighten.

5. Insert end-user-supplied bolts in the top two bolt holes of the flange on the remote

seal. Secure with nuts and hand-tighten.

6. Using a torque wrench on the nut, tighten the assembly in a cross-pattern to ensure

even installation (Torque sequence). The bolts should be torqued to the applicable

flange requirements. Required torque is a function of the gasket material and

surface treatment of the bolts and nuts which are end-user-supplied. Consider leak

checking the installation to ensure a robust connection.

3.8 PFW pancake seal

Figure 3-11: PFW Pancake Seal

A. Alignment clamp (option code SA)

B. Process flange

C. Flushing connection

D. Flushing ring (optional)

E. Diaphragm

F. Connection to transmitter

Note

Alignment clamp (A) can be ordered using option code SA on the 1199.

36 Emerson.com/Rosemount

Page 37

Reference Manual Installation

00809-0100-4002 April 2022

3.8.1 Capillary support tube

A common option for the pancake type seal is the 4-in. capillary support tube. Due to the

side capillary-to-seal connection, the support tube provides a handle for aligning the

pancake seal during installation. The support tube should not be used for supporting any

weight.

3.8.2 Process flange

Emerson offers the option of supplying the process flange, otherwise the process flange is

furnished by the end-user. There is a 5/16–24 threaded connection on the back of the PFW

pancake seal. For certain pancake seal assemblies, the Emerson-supplied process flange

has a machined hole through the center of the flange that corresponds to the threaded

connection in the back of the pancake seal. This allows the flange to be connected to the

seal before installation to make handling easier. If the process flange is furnished by the

end-user, a 2 1/64-in. to ⅜-in. through hole could be drilled into the flange to support ease

of installation.

Rosemount DP Level 37

Page 38

Installation

April 2022 00809-0100-4002

Reference Manual

3.8.3 Parts required for installation

The parts required to install the PFW pancake seal will be defined here. Prior to installation,

you will need the following:

• Torque wrench

• Mounting hardware (end-user-supplied)

• Gasket (end-user-supplied)

Note

Flushing rings include an Emerson-supplied gasket. If an alignment clamp is used, a Phillips

or slotted screwdriver is required for installation.

Verify the gasket materials are appropriate for the application.

Inspect bolts to ensure the material is compatible with industry standards per the

application such as ASME PCC-1.

3.8.4

Installation steps

If no alignment clamp is used on the flushing ring, it is recommended that two people

install the PFW pancake seal to ensure proper alignment during installation.

Follow these steps to install the PFW pancake seal on an existing process flange:

Procedure

1. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

2. If installing a flushing ring, ensure flushing connections are sealed before

completing installation. Flushing rings may be ordered with or without, one or two

threaded flushing connections, factory supplied plugs, or drain vent valves. If no

flushing ring was purchased, proceed to Step 3. Assemble the flushing ring,

Emerson-supplied gasket, and remote seal together. If using an alignment clamp

(option code SA) attach the flushing ring to the remote seal. Place the alignment

clamp in the machined groove on both the remote seal and the flushing ring. Using

the applicable screwdriver, tighten the screw on the clamp to hold the flushing ring

in place.

3. Insert end-user-supplied bolts in the bottom two bolt holes of the flange on the

remote seal.

4. Place the appropriate end-user-supplied gasket on the remote seal or optional

flushing ring and align the gasket so that it is not inside the diaphragm weld as this

will induce errors.

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

5. Using the previously installed bolts, attach the remote seal and gasket to the

process flange. Secure with nuts and hand-tighten.

38 Emerson.com/Rosemount

Page 39

A

C

D

B

C

Reference Manual

00809-0100-4002 April 2022

6. Insert end-user-supplied bolts in the top two bolt holes of the flange on the remote

seal. Secure with nuts and hand-tighten.

7. Using a torque wrench on the nut, tighten the assembly in a cross-pattern to ensure

even installation (Torque sequence). The bolts should be torqued to the applicable

flange requirements. Required torque is a function of the gasket material and

surface treatment of the bolts and nuts which are end-user-supplied. Consider leak

checking the installation to ensure a robust connection.

Installation

3.9 FCW flush flanged seal—ring type joint (RTJ) gasket surface

Figure 3-12: FCW Two-Piece Design (Shown with Flushing Ring)

A. Process flange

B. Diaphragm

C. Flushing ring (optional)

D. Connection to transmitter

3.9.1

Parts required for installation

The parts required to install the FCW flush flanged seal with RTJ gasket surface will be

defined here. Prior to installation, you will need the following:

• Torque wrench

• Mounting hardware (end-user-supplied)

• Gasket (end-user-supplied)

Verify the gasket materials are appropriate for the application.

Rosemount DP Level 39

Page 40

Installation Reference Manual

April 2022 00809-0100-4002

Inspect bolts to ensure the material is compatible with industry standards per the

application such as ASME PCC-1.

3.9.2 Installation steps

Follow these steps to install the FCW flush flanged seal with RTJ gasket surface on an

existing process flange:

Procedure

1. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

2. If installing a flushing ring, ensure flushing connections are sealed before

completing installation. Flushing rings may be ordered with or without, one or two

threaded flushing connections, factory supplied plugs, or drain vent valves. If no

flushing ring was purchased, proceed to Step 3. Assemble the flushing ring,

appropriate end-user-supplied gasket, and remote seal together.

WARNING

Failure to properly install the gasket may cause process leaks, and measurement

errors which can result in death or serious injury.

3. Insert end-user-supplied bolts in the bottom two bolt holes of the flange on the

remote seal.

4. Place the appropriate end-user-supplied gasket on the remote seal or optional

flushing ring.

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

5. Using the previously installed bolts, attach the remote seal and gasket to the

process flange. Secure with nuts and hand-tighten.

6. Insert end-user-supplied bolts in the top two bolt holes of the flange on the remote

seal. Secure with nuts and hand-tighten.

7. Using a torque wrench on the nut, tighten the assembly in a cross-pattern to ensure

even installation (Torque sequence). The bolts should be torqued to the applicable

flange requirements. Required torque is a function of the gasket material and

surface treatment of the bolts and nuts which are end-user-supplied. Consider leak

checking the installation to ensure a robust connection.

40 Emerson.com/Rosemount

Page 41

D

Reference Manual Installation

00809-0100-4002 April 2022

3.10 RCW remote flanged seal - ring type joint (RTJ) gasket surface

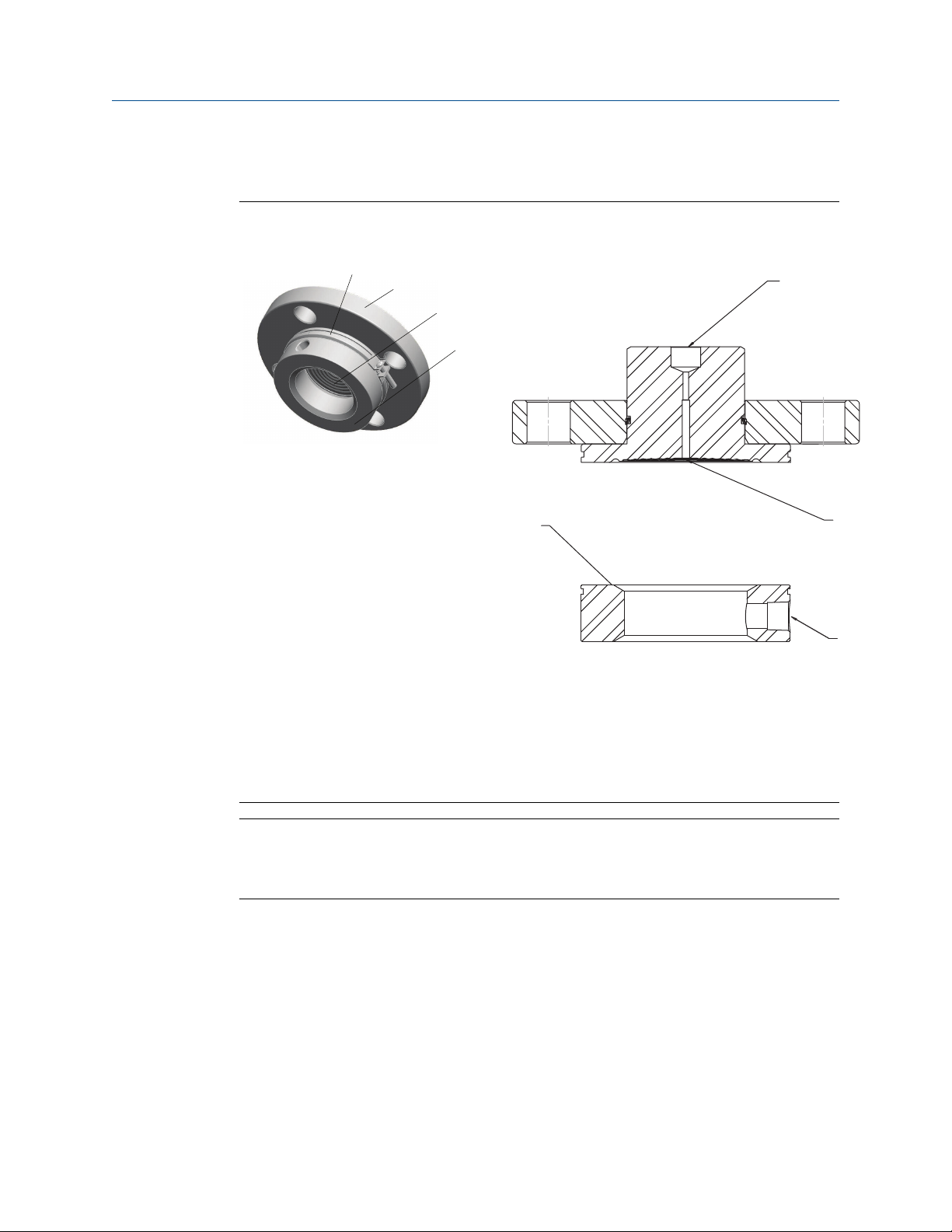

Figure 3-13: RCW Flanged Remote Seal RTJ and Flushing Connection Ring

A. Upper housing

B. Diaphragm

C. Lower housing or flushing ring

D. Stud bolts

Note

A lower housing is always required for the RCW type seal.

Table 3-3: RCW Upper Housing Torque Values

Bolt thread size Material (nuts

and bolts)

⅜–24 NF SST 2.4 or 4.1 150 23

⅜–24 NF SST 2.4 300/600 23

⅜–24 NF CS 2.4 or 4.1 150/300/600 53

½–20 NF SST 4.1 300/600 50

½–20 NF CS 2.4 900/1500 105

½–20 NF SST 2.4 900 50

¾–16 NF

¾–16 NF

(1) Thread lubricant required, e.g. antiseize, thread paste.

(1)

(1)

SST 2.4 1500 120

CS 2.4 2500 180

Diaphargm Size

(in.)

Class Torque (ft-lb)

Rosemount DP Level 41

Page 42

Installation

April 2022 00809-0100-4002

Note

This is the specification for connecting the remote seal to the lower housing, not the

torque specification for the lower housing onto the process flanged connection. The lower

housing bolts should be torqued to the applicable flange requirements.

Reference Manual

3.10.1 4.1-in. (104 mm) diaphragm diameter option

The standard diaphragm size for the RCW remote flanged seal with RTJ gasket surface is

2.4-in. A larger, 4.1-in. (104 mm), diaphragm size is offered for small spans to reduce

temperature error when taking process measurements.

3.10.2 Parts required for installation

The parts required to install the RCW remote flanged seal with RTJ gasket surface will be

defined here. Prior to installation, you will need the following:

• Torque wrench

• Mounting hardware (end-user-supplied)

3.10.3

• Gasket (lower housing to process connection) (end-user-supplied)

• Gasket (remote seal to lower housing) (Emerson-supplied on the 1199. 1299 requires a

gasket option to be selected.)

Note

Typically, Emerson-supplied stud bolts are included.

Verify the gasket material is appropriate for the application.

Inspect bolts to ensure the material is compatible with industry standards per the

application such as ASME PCC-1.

Installation steps

Follow these steps to install the RCW remote flanged seal with RTJ gasket surface on an

existing process flange:

Procedure

1. Ensure flushing connections are sealed before completing installation. Lower

housing may be ordered with or without, one or two threaded flushing

connections, factory supplied plugs, or drain vent valves.

2. Install the stud bolts onto the lower housing.

3. Assemble the lower housing to the process flange. Place the appropriate end-user-

supplied gasket between the lower housing and process flange.

WARNING

Failure to properly install the gasket may cause process leaks, and measurement

errors which can result in death or serious injury.

4. Hand-tighten nuts onto the studs.

42 Emerson.com/Rosemount

Page 43

C

B

Reference Manual

00809-0100-4002 April 2022

5. Using a torque wrench on the nut, tighten the assembly in a cross-pattern to ensure

even installation (Torque sequence). The nuts should be torqued to the applicable

flange requirements.

6. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

7. Assemble the remote seal, Emerson-supplied gasket, and lower housing. Place the

Emerson-supplied gasket inside the recessed cavity within the lower housing which

is designed to hold the gasket in place.

Installation

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

8. Install the bolts in a cross pattern and hand-tighten.

9. Using a torque wrench on the bolt, tighten the assembly in a cross-pattern to

ensure even installation (Torque sequence). The bolts should be torqued per Table

3-3 based on size and bolt material. Consider leak checking the installation to

ensure a robust connection.

3.11 FUW flush flanged groove type seals

Figure 3-14: FUW Flush Flanged Type Seal—EN1092-1 Type D

A. Process flange

B. Diaphragm

C. Connection to transmitter

3.11.1

Parts required for installation

The parts required to install the FUW flush flanged groove type seal will be defined here.

Prior to installation, you will need the following:

• Torque wrench

• Mounting hardware (end-user-supplied)

Rosemount DP Level 43

• Gasket (end-user-supplied)

Page 44

Installation Reference Manual

April 2022 00809-0100-4002

Verify the gasket material is appropriate for the application.

Inspect bolts to ensure the material is compatible with industry standards per the

application such as ASME PCC-1.

3.11.2 Installation steps

Follow these steps to install the FUW flush flanged groove type seal on an existing process

flange:

Procedure

1. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

2. Insert end-user-supplied bolts in the bottom two bolt holes of the flange on the

remote seal.

3. Place the appropriate end-user-supplied gasket on the remote seal.

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

4. Using the previously installed bolts, attach the remote seal and gasket to the

process flange. Secure with nuts and hand-tighten.

5. Insert end-user-supplied bolts in the top two bolt holes of the flange on the remote

seal. Secure with nuts and hand-tighten.

6. Using a torque wrench on the nut, tighten the assembly in a cross-pattern to ensure

even installation (Torque sequence). The bolts should be torqued to the applicable

flange requirements. Required torque is a function of the gasket material and

surface treatment of the bolts and nuts which are end-user-supplied. Consider leak

checking the installation to ensure a robust connection.

44 Emerson.com/Rosemount

Page 45

C

B

Reference Manual

00809-0100-4002 April 2022

Installation

3.12 FVW flush flanged tongue type seals

Figure 3-15: FVW Flush Flanged Type Seal—EN1092-1 Type C

A. Process flange

B. Diaphragm

C. Connection to transmitter

3.12.1

3.12.2

Parts required for installation

The parts required to install the FVW flush flanged tongue type seal will be defined here.

Prior to installation, you will need the following:

• Torque wrench

• Mounting hardware (end-user-supplied)

• Gasket (end-user-supplied)

Verify the gasket material is appropriate for the application.

Inspect bolts to ensure the material is compatible with industry standards per the

application such as ASME PCC-1.

Installation steps

Follow these steps to install the FVW flush flanged tongue type seal on an existing process

flange:

Procedure

1. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

2. Insert end-user-supplied bolts in the bottom two bolt holes of the flange on the

remote seal.

3. Place the appropriate end-user-supplied gasket on the remote seal.

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

Rosemount DP Level 45

Page 46

Installation Reference Manual

April 2022 00809-0100-4002

4. Using the previously installed bolts, attach the remote seal and gasket to the

process flange. Secure with nuts and hand-tighten.

5. Insert end-user-supplied bolts in the top two bolt holes of the flange on the remote

seal. Secure with nuts and hand-tighten.

6. Using a torque wrench on the nut, tighten the assembly in a cross-pattern to ensure

even installation (Torque sequence). The bolts should be torqued to the applicable

flange requirements. Required torque is a function of the gasket material and

surface treatment of the bolts and nuts which are end-user-supplied. Consider leak

checking the installation to ensure a robust connection.

46 Emerson.com/Rosemount

Page 47

Reference Manual Installation

00809-0100-4002 April 2022

3.13 RTW remote threaded type seals

Figure 3-16: RTW Threaded Seal

A. Upper housing

B. Lower housing or flushing ring

C. Diaphragm

D. Connection to transmitter

Note

A lower housing is always required for the RTW type seal.

Table 3-4: RTW Upper Housing Torque Values

Bolt thread size Material (nuts and

bolts)

⅜–24 NF SST 1,500

⅜–24 NF CS 2,500 53

½–20 NF SST 1,500

½–20 NF SST 2,500 50

½–20 NF CS 5,000 105

¾–16 NF

¾–16 NF

M12 x 1.75 SST 1,500

M12 x 1.75 SST 2,500 50

(2)

(2)

SST 5,000 120

CS 10,000 180

MWP (psi) Torque (ft-lb)

(1)

(1)

(1)

23

50

50

M20 x 2.50 SST 5,000 120

(1) 1500 psi MWP RTW's are only available on 4.1-in diaphragm sizes.

(2) Thread lubricant required, e.g. antiseize, thread paste.

Rosemount DP Level 47

Page 48

Installation Reference Manual

April 2022 00809-0100-4002

Note

This is the specification for connecting the remote seal to the lower housing, not the

torque specification for the lower housing onto the process threaded connection.

Standard NPT torque values for the size threads in the lower housing should be applied

here.

48 Emerson.com/Rosemount

Page 49

Reference Manual

00809-0100-4002 April 2022

Installation

3.13.1 Parts required for installation

The parts required to install the RTW remote threaded type seal will be defined here. Prior

to installation, you will need the following:

• Torque wrench

• Spanner wrench

• Mounting hardware (Emerson-supplied)

• Gasket (Emerson-supplied on the 1199. 1299 requires a gasket option to be selected.)

• Thread sealant

Thread sealant must meet the requirements of the application. An example thread sealant

is PTFE tape.

Verify the gasket material is appropriate for the application.

Inspect bolts to ensure the material is compatible with industry standards per the

application such as ASME PCC-1.

3.13.2

Installation steps

Follow these steps to install the RTW remote threaded type seal on an existing threaded

process connection:

Procedure

1. Apply thread sealant to the male threaded end of the connection. This will be the

process connection if using a female threaded lower housing, or the remote seal

itself if using a male threaded lower housing.

2. Thread the lower housing to the process connection. The lower housing includes a

small hole designed for a spanner wrench to facilitate installation and applying the

required torque. The applied torque should comply with ANSI B1.20.1 for NPT

connections or applicable torque requirements for pipe connections.

3. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

4. Place the Emerson-supplied gasket into the groove of the lower housing.

5. Place the remote seal on top of the gasket ensuring alignment with the lower

housing groove.

WARNING

Failure to properly install the gasket may cause process leaks, which can result in

death or serious injury.

6. Install the bolts and hand-tighten.

7. Using a torque wrench on the bolt, tighten the assembly in a cross-pattern to

ensure even installation (see Torque sequence). The bolts should be torqued per

Table 3-4 based on size and bolt material. Consider leak checking the installation to

ensure a robust connection.

Rosemount DP Level 49

Page 50

A

B

Installation Reference Manual

April 2022 00809-0100-4002

Note

RTW remote threaded type seals with a 10,000 PSI pressure rating are supplied with

carbon steel bolts only.

3.14 HTS male threaded seal

Figure 3-17: HTS Male Threaded Seal

3.14.1

A. Connection to transmitter

B. Diaphragm

Parts required for installation

The parts required to install the HTS male threaded seal will be defined here. Prior to

installation, you will need the following:

• Thread sealant

Thread sealant must meet the requirements of the application. An example thread sealant

is PTFE tape.

50 Emerson.com/Rosemount

Page 51

A

B

A

B

A

B

Reference Manual Installation

00809-0100-4002 April 2022

3.14.2 Installation steps

Follow these steps to install the HTS remote threaded seal on an existing process flange:

Procedure

1. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

2. Apply the thread sealant to the male thread.

3. Thread the remote seal onto the process connection. The remote seal is designed

with a small hole to facilitate installation and applying torque. The applied torque

should comply with ANSI B1.20.1 for NPT connections or applicable torque

requirements for pipe connections.

3.15 SCW hygienic Tri-Clover Tri Clamp seals

Figure 3-18: SCW Tri Clamp Seal

2½-, 3-, and 4-in. size

2-in. size 1½-in. size

A. Connection to transmitter

B. Diaphragm

Rosemount DP Level 51

Page 52

Installation Reference Manual

April 2022 00809-0100-4002

3.15.1 Clamp and gasket

The clamp is furnished by the end-user with the exception of an optional Emersonsupplied high pressure Ladish™ clamp. Maximum pressure rating of the system is

dependent upon the clamp pressure rating.

The gasket is furnished by the end-user with the exception of an optional Emersonsupplied Nitrile Butadiene (NBR) gasket.

Table 3-5: High Pressure Ladish Clamp Maximum Working Pressure

Process connection size 70 °F (21 °C) 250 °F (121 °C)

1½-in. 1,500 psi (103 bar) 1,200 psi (83 bar)

2-in. 1,000 psi (69 bar) 800 psi (55 bar)

2½-in. 1,000 psi (69 bar) 800 psi (55 bar)

3-in. 1,000 psi (69 bar) 800 psi (55 bar)

4-in. 600 psi (41 bar) 480 psi (34 bar)

3.15.2 Parts required for installation

The parts required to install the SCW hygienic Tri Clamp seal will be defined here. Prior to

installation, you will need the following:

• Clamp

• Gasket

• Wrench (optional, depending on clamp)

Verify the gasket material is appropriate for the application. Ensure to use an EHEDG

approved gasket if EHEDG conformance is needed.

52 Emerson.com/Rosemount

Page 53

D

L

Reference Manual Installation

00809-0100-4002 April 2022

3.15.3 Installation steps

Follow these steps to install the SCW hygienic Tri Clamp seal:

Procedure

1. Remove the protective cover from the diaphragm of the remote seal. Use extreme

caution during installation to ensure the diaphragm is not damaged.

2. Place the appropriate gasket for the application on the remote seal and align the