Page 1

Rosemount™ CT5800

Continuous Gas Analyzer

Quick Start Guide

00825-0100-5800, Rev AA

October 2019

Page 2

Quick Start Guide October 2019

2 Rosemount CT5800

Page 3

October 2019 Quick Start Guide

Important information

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section must not be changed,

amended, or removed.

Important

Users must read, understand, and comply with the following information before proceeding.

All users, installers, operators, and maintainers must be familiar with operating the analyzer. To install,

start up, operate, maintain, and service the analyzer in a safe manner, it is MANDATORY to read all

additional instruction manuals shipped with the analyzer. The following instruction manual(s) are

available and/or referenced within this manual:

Rosemount CT5800 Continuous Gas Analyzer Reference Manual, 00809-0100-5800, Rev AA

User information

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section must not be changed,

amended, or removed.

Important

All users must read this page before proceeding!

Emerson (Rosemount) designs, manufactures, and tests its products to meet many national and

international standards. The Rosemount CT5800 is a sophisticated technical product, and to ensure it

continues to operate as designed and within normal specifications, it MUST be installed, used, and

maintained correctly. The following instructions MUST be adhered to and integrated into your safety

program when installing, using, and maintaining Emerson (Rosemount) products.

• Failure to follow the proper instructions may cause:

— Loss of life

— Personal injury

— Damage to property

— Damage to this instrument

— Warranty invalidation

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson (Rosemount)

representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the

product.

• Install your equipment as specified in the installation instructions of the appropriate manual and

in accordance with applicable local and national codes.

• Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and

maintain the product.

Quick Start Guide 3

Page 4

Quick Start Guide October 2019

• When replacement parts are required, ensure that qualified people use replacement parts

specified by Emerson (Rosemount).

• Unauthorized parts and procedures can affect the product’s performance, place the safe

operation of your process at risk, and VOID YOUR WARRANTY. Look-alike substitutions may result

in fire, electrical hazards, or improper operation.

• To prevent electrical shock and personal injury, all equipment doors must be closed and

protective covers in place, except when maintenance is being performed by qualified personnel.

• The information contained in this document is subject to change without notice.

4 Rosemount CT5800

Page 5

October 2019 Quick Start Guide

General safety notice/residual risk

Installation, operation, and maintenance of the analyzer must be in accordance with these

instructions.

When operated as intended and all applicable safety instructions are observed, an element of risk will

remain, including, but not limited to, the following:

• Explosion protection measures may become ineffective on the occurrence of one failure (for

Category 3 instruments).

• The emission of gases hazardous to health may be possible when all gas connections have been

correctly made.

To avoid exposure to the dangers of residual risks, take particular care when installing, operating,

maintaining, and servicing the analyzer.

Authorized personnel

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section must not be changed,

amended, or removed.

In-depth specialist knowledge is an absolute requirement for working with and on the analyzer.

Personnel installing, operating, servicing, and maintaining the analyzer must be instructed, trained,

qualified, and authorized for hazardous areas with the operating company and the manufacturer. It is

the operating company's responsibility to:

• Train staff

• Observe safety regulations

• Follow the safety instructions and procedures in the product manual

Operators must:

• Be trained

• Read and understand all relevant sections of the product manual before commencing work

• Know the safety mechanisms and regulations

WARNING

To avoid explosions, loss of life, personal injury, and damage to this equipment and on-site property,

do not install, operate, maintain, or service this instrument before reading and understanding this

instruction manual and receiving appropriate training.

Quick Start Guide 5

Page 6

Quick Start Guide October 2019

Regulations and standards

Regulations / Standards Description

2014/35/EU The Low Voltage Directive

94/9/EC (until April 19, 2016)

2014/34/EU (from April 20, 2016)

2014/30/EU The Electromagnetic Compatibility Directive

2012/19/EU Waste Electrical and Electronic Equipment (WEEE) Directive

USA 21 CFR 1040.1 Laser products

NEC 505 National Electrical Code (issued by ANSI: American National

EN 6223: 2008 EMC Safety Standard

IEC 60529:1992 + A2 2013 Ingress protection

BS EN 60825-1:2007 Safety of laser products. Equipment classification and

BS EN 61010-1 2010 IEC 61010-1 2010 Safety requirements for electrical equipment for

IEC 61241-10: 2004-06 Electrical apparatus for use in the presence of combustible

BS EN 61326-1: 2013 Electrical equipment for measurement, control, and laboratory

BS EN60079-0: 2012 Explosive atmospheres - Part 0: Equipment - General

BES EN 60079-1: 2014 Explosive atmospheres. Equipment protection by flameproof

IEC 60079-0:2011 Ed 6 Explosive atmospheres - Part 0: Equipment - General

IEC 60079-1:2014 Ed 7 Explosive atmospheres, Part 1: Equipment protection by

(1)

(2)

The ATEX Directive

Standards Institute and NFPA 70: National Fire Protection

Association)

requirements (identical to IEC 608250-1 2007).

measurements, control, and laboratory use. General

requirements.

dust. Part 10: Classification of areas where combustible dusts

are or may be present.

use. EMC requirements. General requirements.

requirements

enclosures d

requirements

flameproof enclosures d

(1) May affect equipment tested prior to April 20, 2016, but shipped at a later date.

(2) All equipment tested from April 20, 2016 will be subject to the directive.

Associated publications

Reference Manual: 00809-0100-5800

Compliance approvals

This product complies with USA 21 CFR 1040.10.

This product is designed and manufactured under an approved quality

management system to ISO 9001: 2015.

Emerson and the Rosemount CT5800 have satisfied the requirements for applying

the CE marking to the Rosemount CT5800 Gas Analyzer.

6 Rosemount CT5800

Page 7

October 2019 Quick Start Guide

This equipment meets all requirements of the EMC and Low Voltage directives.

Explosive protection This article is in accordance with IEC 60079-0: 2011 Clause 30.

Waste disposal

This article must not be changed, amended, or removed.

Emerson has satisfied the requirements of and complies with ATEX for operation of

electrical/electronic equipment in hazardous locations .

Do not dispose of measuring tools into household waste.

Only for EC countries:

In accordance with European Directive 2012/19/EU for Waste Electrical and

Electronic Equipment and its implementation into national right, measuring tools

that are no longer usable must be collected separately and disposed of in an

environmentally correct manner.

Quick Start Guide 7

Page 8

Quick Start Guide October 2019

Safety and information notices

This article is in accordance with IEC 60079-0: 2011 Clause 30. This article must not be changed

amended or removed.

DANGER

WILL CAUSE DEATH

Failure to follow this warning will result in death or serious injury to personnel.

WARNING

DANGER TO PERSONNEL

Failure to follow this warning may result in serious injury to personnel.

CAUTION

MAY CAUSE DAMAGE TO EQUIPMENT

Failure to follow this warning may result in damage to the equipment.

NOTICE

Important or tip messages will appear in this format.

8 Rosemount CT5800

Page 9

October 2019 Quick Start Guide

Safety information

All authorized users, including installation, operation, and maintenance personnel, must observe the

following safety precautions and warnings.

This article is in accordance with IEC 60079-0: 2011 Clause 30.

This article must not be changed, amended, or removed.

DANGER

FLAMMABLE SUBSTANCES

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Internal parts of the analyzer may reach temperatures of 150 °F (65 °C) and may present an ignition

source. Failure to observe this warning will cause death, personal injury, and/or damage to persons

and/or property.

Exercise care when using oil, paint, cleaning rags, and other flammable substances near the analyzer. A

fire may result if this precaution is not observed. Always assume that the interior of an analyzer is hot

unless it has been switched off and allowed to cool down.

DANGER

ELECTRIC SHOCK

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this precaution will cause death, personal injury, and/or damage to persons and/or

property.

This analyzer operates using mains voltage that is dangerous to life.

Make sure the circuit breakers are set to OFF and tagged off before opening the front cover.

DANGER

FAILURE TO LOCK-OUT GAS HANDLING SYSTEM MAY CAUSE DEATH.

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Unauthorized operation of the gas handling system when maintenance is being performed on the

analyzer or its associated pipes/hoses may result in highly flammable gas being released, causing fire

or explosion.

Always lock out the gas handling system when shutting down the analyzer.

DANGER

FAILURE TO VENT SAMPLE GAS MAY CAUSE DEATH.

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The sample gas in the system must be vented to prevent fire or explosion during maintenance and

to prevent damage to the analyzer during startup.

The sample gas in the pipes leading to the analyzer must be purged to prevent hazards to

personnel during maintenance. Purging the sample gas must be done in accordance with the safe

working procedures for the site.

Allow the analyzer and system for returning the sample gas to run for five minutes to allow any

sample gas in the system to be returned to the exhaust.

Quick Start Guide 9

Page 10

Quick Start Guide October 2019

WARNING

EXPLOSION HAZARD

The unit described in this manual may not be used in explosive atmospheres without additional safety

measures.

WARNING

ELECTRICAL SHOCK

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Installation requires access to live parts which can cause death or serious injury.

Do not operate without covers secure.

Do not open while energized.

For safety and proper performance, this instrument must be connected to a properly grounded

three-wire source of power.

WARNING

TOXIC GASES

The analyzer's exhaust may contain toxic gases, such as (but not limited to) sulfur dioxide. These gases

can cause serious injuries.

Avoid inhaling exhaust gases.

Connect the exhaust pipe to a suitable flue and inspect the pipes regularly for leaks.

Make sure all connections are airtight to avoid leaks.

WARNING

GASES HAZARDOUS TO HEALTH

Follow the safety precautions for all gases (sample and span gases) and gas cylinders.

Before opening the gas lines, purge them with air or neutral gas (N2) to avoid danger from

escaping toxic, flammable, explosive, or hazardous gases.

WARNING

FLAMMABLE OR EXPLOSIVE GASES

When supplying explosive gases or flammable gases with concentrations of more than 25% of the

lower explosion limit, Emerson recommends implementing one or more additional safety measures:

Purging the unit with inert gas

Stainless steel internal pipes

Flame arrestors on gas inlets and outlets

Infallible measuring cells

10 Rosemount CT5800

Page 11

October 2019 Quick Start Guide

WARNING

CONNECTING UNITS FOR PERMANENT INSTALLATION

Failure to complay may cause the risk of injury or death and invalidate the analyzer's warranty. Working

on units equipped with screw-type terminals for electrical components may result in the exposure of

energized components.

Only qualified personnel familiar with possible risks should install the analyzer.

Wall-mounted units have no power switch and are operational when connected to a power

supply. The operating company is therefore required to have a power switch or circuit breaker (as

per IEC 60947-1/-3) available on the premises. This switch must be installed near the unit, easily

accessible to operators, and labeled as a power cut-off for the analyzer.

WARNING

EXPLOSION HAZARD

Exhaust gases may contain hydrocarbons and other toxic gases, such as carbon monoxide. Carbon

monoxide is toxic. Faulty gas connections may lead to explosion and death.

Ensure that all gas connections are connected as labeled and airtight.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011, Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially

hazardous situation, which if not avoided, could result in death or serious injury.

Read all instruction manuals (including versions for auxiliary equipment) before installing this

instrument.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially

hazardous situation which, if not avoided, could result in death or serious injury.

When installing and wiring this equipment, comply with all relevant national legislative

requirements and regulations.

Consider all safety instructions within this manual and all associated analyzer manuals.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially

hazardous situation which, if not avoided, could result in death or serious injury.

When the analyzer is out of order, shut off all inputs and outputs connected to external equipment.

Quick Start Guide 11

Page 12

Quick Start Guide October 2019

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially

hazardous situation which, if not avoided, could result in death or serious injury.

Only properly trained personnel who understand the content of all applicable manuals and related

instructions must conduct the startup procedure.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially

hazardous situation which, if not avoided, could result in death or serious injury.

Do not open in an explosive atmosphere.

WARNING

Do not open when energized

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to comply will void certification and may cause explosions. Failure to observe this warning

and/or follow safety instructions could cause an explosion or potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Use only replacement parts and components authorized by Emerson. All replacement parts and

components must be suitable Ex-certified components for use in hazardous areas.

WARNING

EXPLOSION HAZARD BY BATTERY

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could cause an explosion or potentially

hazardous situation which, if not avoided, could result in death or serious injury.

The Rosemount CT5800 contains a low voltage battery for data backup purposes on the CPU.

Under normal operating conditions, there is no need to replace the battery during the analyzer

lifetime. However, if you do replace it, make sure to only use the same type and model.

12 Rosemount CT5800

Page 13

October 2019 Quick Start Guide

WARNING

OPTICAL RADIATION EXPOSURE HAZARD

The analyzer contains lasers. Opening the analyzer and attempting to perform adjustments or

procedures other than those specified in this manual may result in hazardous optical radiation

exposure.

Failure to follow the correct procedures may cause damage to the eye.

The Rosemount CT5800 is Class 1. The beams are fully enclosed, and there is no access to the laser

beams while the product is in operation or during maintenance. Do not look at the lasers with any kind

of magnifier or optical measuring device.

The use of control or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

In accordance with USA 21 CFR 1040, the Rosemount CT5800 has warning labels at appropriate

positions.

Classification

There are three types of lasers that may be included in the Rosemount CT5800: Quantum Cascade

Lasers (QCLs), Interband Cascade Lasers (ICLs), and Tunable Diode Lasers (TDLs). The characteristics of

the lasers contained within are given in the table below.

Parameter

Operation mode Pulsed Pulsed Pulsed

Lasers per system 1 - 6 1 - 6 1 - 6 Maximum of 6 lasers

Wavelength 4 -10 µm 2 - 5 µm 760 nm

Power < 5 mW < 5 mW < 5 mW

Pulse duration < 1 µs 1 µs < 5 µs

Pulse repetition

frequency

Duty cycle < 5% < 5% < 5%

QCL ICL TDL Comments

per system

< 100 kHz < 100 kHz < 100 kHz

Quick Start Guide 13

Page 14

Quick Start Guide October 2019

WARNING

HAZARDOUS SUBSTANCES

Gas handling components within the analyzer will contain particulate matter residue from the sample

gases. Over the life of the analyzer, the concentration of the particulate matter will become enriched

within the gas handling components.

When performing repairs or maintenance on the analyzer:

Handle used gas handling components with extreme caution.

Avoid direct skin contact with used gas handling components.

Do not smoke, drink, or eat in the work area.

Wear goggles or eye shields.

Wear a suitable face mask to protect against inhalation of particulate matter.

Do not wet fingers, eyes, or any exposed skin.

Pack used gas handling components for disposal in sealed packaging and label them

Contaminated.

Dispose of contaminated items as hazardous material according to the applicable local, national,

or international health and safety regulations and pollution regulations.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Unauthorized operation of the gas handling system when maintenance is being performed on the

analyzer or its associated pipes/hoses may release highly flammable gas, causing fire or explosion.

Always lock-out tag-out the gas handling system when shutting down the analyzer.

WARNING

HEAVY ITEM

Handle the analyzer with caution during unpacking, installing, maintaining, and transporting to

prevent crushing of hands, feet, or other body parts.

The analyzer weighs 176.4 lb. (80 kg). Always use suitable lifting/moving equipment when

moving the analyzer.

Wear suitable protective gloves and protective footwear.

When preparing the analyzer for transport by air, road, or rail, safeguard the analyzer against

movement or break-away during transport by securely strapping it in place.

WARNING

HEAVY INSTRUMENT

Failure to observe this warning and/or follow safety instructions could result in death or serious injury.

The analyzer weighs 176.4 lb. (80 kg) and must be wall or frame mounted.

Emerson recommends that a minimum of two people move and lift the analyzer using suitable

lifting and transportation equipment.

Use suitable fasteners for weight of the analyzer.

Make sure the wall or stand the analyzer is mounted on is solid, stable, and of suitable material to

hold the analyzer.

Do not mount the analyzer on stud or partition walls.

14 Rosemount CT5800

Page 15

October 2019 Quick Start Guide

WARNING

HAZARDOUS GAS

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The product stream that the analyzer is examining may be hazardous even at low concentrations.

Therefore, take special care to ensure that the sample gas return port either returns the sample gas to

the product stream or discharges the sample gas to a location that will not cause a hazard.

WARNING

ELECTROSTATIC CHARGING HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The keypad is non-conducting and may generate an ignition capable level of electrostatic charges

under certain extreme conditions.

Ensure that the equipment is not installed in a location where it may be subjected to external

conditions (such as high pressure steam) which might cause a build-up of electrostatic charges on nonconducting surfaces. Only clean equipment with a damp cloth.

WARNING

HIGH PRESSURE GAS AND AIR

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The calibration gas supply and compressed air supply operate at a pressure that can cause injury, e.g.,

damage to eyes and skin punctures from debris blown by the high pressure gas or compressed air.

Always lock off or tag off the calibration gas supply and compressed air supply when shutting down the

analyzer.

WARNING

BURNS

Some parts of the analyzer may be heated to 150 °F (65 °C). Failure to allow sufficient cooling may

cause serious burn injury to personnel.

Do not touch any part of the analyzer.

Assume all parts of the analyzer are hot unless it has been switched off and allowed to cool down.

Always wear proper protective equipment when handling the analyzer.

Switch off the analyzer and allow it to cool for at least two hours before fitting, removing, or

performing any maintenance.

The analysis cell is insulated against heat loss. Allow the analyzer to cool for at least 12 hours

before performing any maintenance on, or in the vicinity of, the analysis cell.

Quick Start Guide 15

Page 16

Quick Start Guide October 2019

WARNING

CRUSHING HAZARD

Take care not to crush hands when closing the frront door of analyzer field housings.

Keep out of the closing area between the enclosure cover and base.

WARNING

EXPLOSION

Danger of explosion if battery is incorrectly replaced.

Replace with only the same or equivalent type of battery.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or misconfiguration of end

users’ equipment. This could be intentional or unintentional and needs to be protected against.

Physical security is an important part of any security program and fundamental to protecting your

system. Restrict physical access by unauthorized personnel to protect end users’ assets. This is true for

all systems used within the facility.

CAUTION

EQUIPMENT DAMAGE

Failure to follow the startup procedure may result in damage to the analyzer.

Always follow the startup procedure.

CAUTION

EQUIPMENT DAMAGE

Failure to follow the shutdown procedure may result in damage to the analyzer.

Always follow the shutdown procedure.

CAUTION

EMC

This is a Class A product. In a domestic environment, this product may cause radio interference, in

which case you may be required to take adequate measures.

16 Rosemount CT5800

Page 17

October 2019 Quick Start Guide

CAUTION

EQUIPMENT DAMAGE

If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

CAUTION

EQUIPMENT DAMAGE

Ensure that the local power voltage where the unit is to be installed corresponds to the unit’s nominal

voltage as given on the name plate label.

CAUTION

EQUIPMENT DAMAGE

Do not power up or try to operate the analyzer unless it is physically secure and all electrical and

pneumatic connections to the analyzer are in place.

Before commencing the start-up process, it is important to ensure that electrical power, sample

gas handling facilities, and any calibration gases that are required are available to the analyzer.

CAUTION

EQUIPMENT DAMAGE

Additional notes for units with screw-type terminals:

Cables for external data processing must be double-insulated against mains power.

If this is not possible, cables must be laid in such a way as to guarantee a clearance of at least 0.2

in. (5 mm) from power cables. This clearance must be permanently secured (e.g., with cable ties).

Contents

Plan............................................................................................................................................19

Install......................................................................................................................................... 29

Start-up procedure.....................................................................................................................53

Operating the analyzer...............................................................................................................55

Spare parts list............................................................................................................................62

Engineering drawings.................................................................................................................64

Quick Start Guide 17

Page 18

Quick Start Guide October 2019

18 Rosemount CT5800

Page 19

October 2019 Quick Start Guide

1 Plan

1.1 Unpacking the analyzer

WARNING

HEAVY ITEM

In accordance with IEC 60079-0: 2011 Clause 30.

Failure to propery handle the analyzer may cause injury to personnel.

Make sure the wall the analyzer is mounted on is solid, stable, and of

suitable material to hold the weight of the analyzer.

Handle the analyzer with caution during unpacking, installing,

maintaining, and transporting to prevent crushing of hands, feet, or

other body parts.

The analyzer weighs 176.4 lb. (80 kg).

Emerson recommends that a minimum of two people move and lift the

analyzer.

Wear suitable protective gloves and protective footwear.

WARNING

EXPLOSION HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning and/or follow safety instructions could result

in an explosion or potentially hazardous situaiton which, if not avoided,

could result in death or serious injury.

Comply with all relevant national legislative requirements and

regulations when installing and wiring this analyzer.

Consider all safety instructions within this manual and all associated

instruction manuals.

WARNING

EXPLOSION HAZARD

Installing the instrument requires opening the enclosure and working at

the open instrument. This is permitted only when both no hazardous

atmosphere is present and the instrument and connected external

circuitry are de-energized.

Depending on the local regulations, this may require a competent hot

work supervisor to issue a hot work permit.

Quick Start Guide 19

Page 20

Quick Start Guide October 2019

CAUTION

SHOCK AND VIBRATION

Failure to follow this caution may result in damage to the analyzer.

The Rosemount CT5800 contains sensitive electronic equipment.

Do not subject it to any shock or vibration.

Procedure

1. On receipt of goods, look for any visible damage to the analyzer and

verify that all items noted to be shipped were received. Record on

the goods receipt note any damage or missing items, noting both

the item(s) and the quantity missing.

2. Visually inspect the exterior of the analyzer for signs of damage,

corrosion, gas leaks, or signs of previously overheating.

3. Use safety approved and tested lifting equipment to remove the

analyzer from the shipping container.

4. Place the analyzer on a solid, level surface and prepare to wall mount

the analyzer.

5. Make sure that the analyzer is stored in its protective plastic cover

until installation.

1.2 Installing and connecting the unit

The following notices should be followed to ensure compliance with the low

voltage directive (Europe) and other applicable regulations.

• Suitably ground all connectors provided for this purpose.

• Properly reinstate all safety covers and grounding connections after

maintenance work or troubleshooting.

• Provide a fuse at the installation site which will completely disconnect

the analyzer in case of failure. Installing an isolating switch may also be

beneficial. In either case, these components must be constructed to

conform to recognized norms.

1.3

20 Rosemount CT5800

System overview

A complete Rosemount CT5800 system consists of a gas handling system,

the analyzer, and the associated interconnecting wiring and gas piping.

The Rosemount CT5800 is supplied by Emerson. The gas handling system

may be provided by either you or Emerson, depending upon the specific

installation. The circuit breakers used to control the application of electrical

power to the analyzer, the interconnecting wires, and gas piping are

Page 21

October 2019 Quick Start Guide

provided by you. In Figure 1-1, the items supplied by Emerson are colored

blue, customer-supplied items are colored purple, and items that can be

supplied by either Emerson or you are green. Table 1-1 lists the main items

of the system.

Figure 1-1: Complete Rosemount CT5800 Gas Analysis System

A. Gas handling system

B. Sample supply line

C. Sample ENTER (exhaust) line

D. Rosemount CT5800 gas analyzer

E. Electrical power

F. Measurement data

G. Control center

Emerson has designed the analyzer for industrial process applications

requiring ATEX Zone 1 hazardous area certification; the analyzer has an Ex d

flameproof enclosure. It contains an optical system with multiple lasers and

a series of optical components that provide an optical path, a heated multipass analysis cell, and sample and outlet ports that can be connected to a

gas handling system and control and analysis electronics. The number of

lasers installed depends upon customer requirements. The complete system

operates Vac from a 110/240 Vac 50/60 Hz supply.

The analyzer uses mid-infrared optical absorption spectroscopy to measure

gas concentrations. The light sources are lasers, which are operated to

produce wavelength sweeps that cover the absorption lines of the gases.

The light from each laser is routed through an optical path to the analysis

cell, which provides measurement of low concentrations of the subject

gases. An external sample handling system conditions the sample gas and

draws it through the analysis cell. The light exits the multi-pass analysis cell

and is directed to a receiver in the analyzer. The variation in the intensity of

light in the vicinity of the absorption lines is measured, and the

concentration is determined using a comprehensive spectral fitting routine.

Quick Start Guide 21

Page 22

Quick Start Guide October 2019

Table 1-1: Main Items of the Rosemount CT5800 System

Item Name or

description

1 Rosemount

CT5800

2 Rosemount

CT5800

software

package,

version 5.x.x

3 Gas handling

system

4 Heated gas

sample line

hose

5 Exhaust line

hose (for

sample gas)

6 Reference gas

cylinders

(instrument

gas) for

calibration

purposes

7 Pressure

regulator

8 Pneumatic T-

piece

9 Excess flow line Customer Customer

10 240 Vac power

cable

11 Cable from

analyzer to

control center

12 Main circuit

breaker

Supplied by Part number Quantity Notes

Emerson 1 N/A

Emerson N/A 1 Software is

Customer

(optionally by

Emerson)

Customer/

Emerson

Customer Customer

Customer Customer

Customer Customer

Customer Customer

Customer Customer 1 Connect

Customer Customer

Customer Customer

Customer

choice

choice

choice

choice

choice

choice

choice

choice

embedded in

PC board.

Version

described in

manual

1 Optional

1 Optional

1 Optional

Dependent

upon number

of gases being

measured

1 per gas

cylinder

1 N/A

1 Required for

1 N/A

1 N/A

supply by

Emerson

supply by

Emerson

supply by

Emerson

N/A

N/A

calibration

Rosemount

CT5800 to

mains power

supply

22 Rosemount CT5800

Page 23

October 2019 Quick Start Guide

1.4 Equipment purpose and role

The analyzer is a gas sensor system that can be configured to measure the

concentrations of multiple small molecules in a gas sample that is provided

to the analyzer via a sample line.

The types of molecules that are measured depend on the system

configuration.

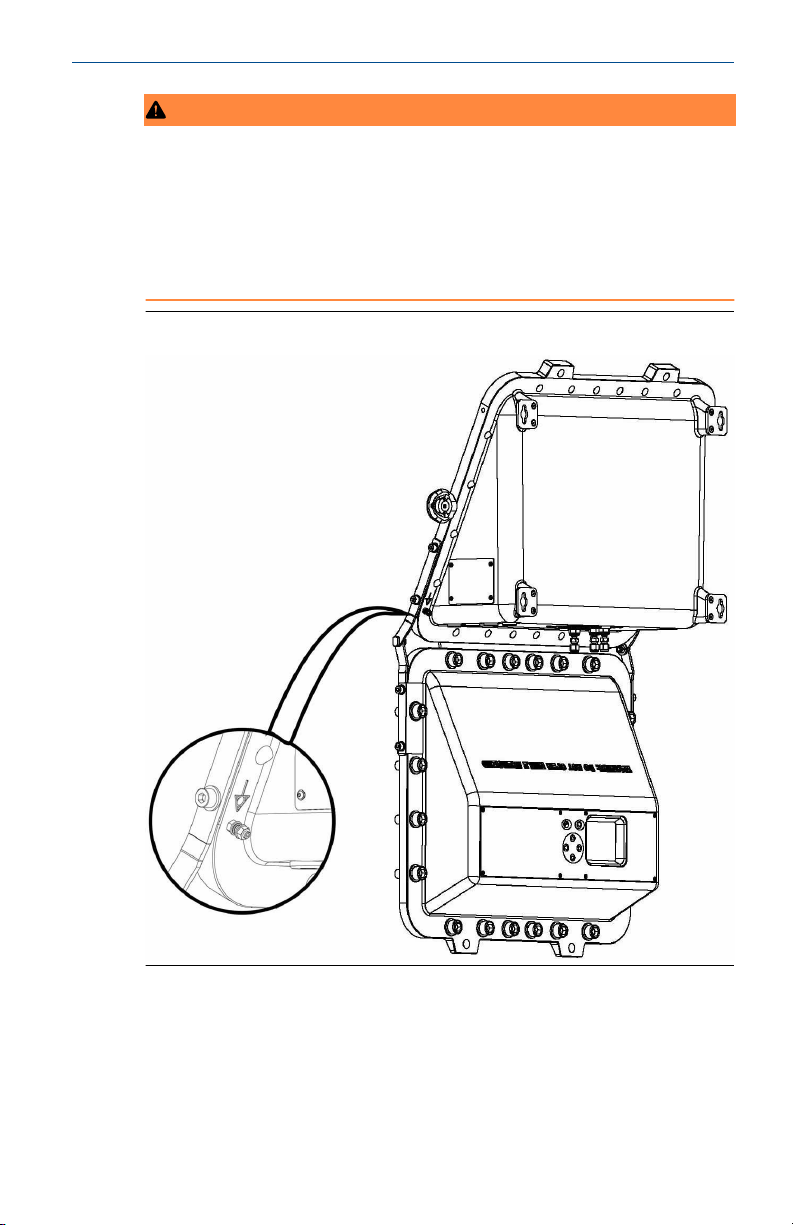

Figure 1-2: Rosemount CT5800

The analyzer can be configured to detect and measure up to twelve different

gases, depending on the combination of laser modules fitted.

1.5

Detailed system specifications

Table 1-2: General Characteristics

Rosemount CT5800 Value Comment

Voltage 220/240 ± 10% Vac

110/120 ± 10% Vac

Peak power consumption 1100 W Max consumption per gas analyzer

Continuous steady-state

power consumption

Quick Start Guide 23

800 W N/A

50 Hz ± 5% (factory set)

60 Hz ± 5% (factory set)

Page 24

Quick Start Guide October 2019

Table 1-2: General Characteristics (continued)

Rosemount CT5800 Value Comment

Electrical compartment

enclosure

Optical compartment

enclosure

Measurement technique N/A Mid IR absorption spectroscopy

Mid IR source N/A Quantum Cascade™ Laser

Near IR source N/A Interband Cascade Laser Tunable diode laser

Laser classification Class 1 BS EN 60825-1: 2007 safety of laser products.

Inlet gas port connector ¼ in.

Outlet (exhaust) gas port

connector

Measurement result

signals

Warm-up time 90 minutes N/A

N/A Aluminum

N/A Aluminum

Equipment classification and requirements

(identical to IEC 60825-1 2007)

6 mm

¼ in.

6 mm

4 to 20 mA 4 or 8 channel outputs, specify on order

Swagelok® type, factory-configured, specify

on order

Swagelok type, factory-configured, specify on

order

24 Rosemount CT5800

Page 25

October 2019 Quick Start Guide

Figure 1-3: Rosemount CT5800 Dimensions: Front View

A. User interface

B. 2 off lifting eyelets

Quick Start Guide 25

Page 26

Quick Start Guide October 2019

Figure 1-4: Rosemount CT5800 Dimensions: Side View

A. Rating plate

B. External earth point

26 Rosemount CT5800

Page 27

October 2019 Quick Start Guide

Figure 1-5: Rosemount CT5800 Radius for Opening

A. Opening arc

Table 1-3: Environmental Characteristics

Environmental

characteristic

Operating temperature range -4 to 131 °F (-20 to 55 °C) Ambient temperature

Sample gas temperature

range (condition for safe use

Europe)

Sample gas temperature

range (condition for safe use

North America)

Sample gas moisture content 8% Maximum

Sample gas particulate

density

Quick Start Guide 27

Value Comment

39 to 140 °F (4 to 60 °C) Factory set, specify on order

122 to 176 °F (50 to 80 °C) Factory set, specify on order

3

5 mg/m

Maximum

Page 28

Quick Start Guide October 2019

Table 1-3: Environmental Characteristics (continued)

Environmental

characteristic

Sample gas particulate size 10 µm Maximum

IP code 66 IP to IEC 60529

Sensor humidity range 10 to 95% Relative humidity (non-

Value Comment

condensing) at 113 °F (45 °C)

1.5.1 Optical description

The laser modules are located in the core of the analyzer. Each laser module

produces a separate light beam, and these beams are combined linearly as

the modules are aligned in the system. The combined beams are closely

coupled, parallel, and coaxial about a virtual line. The laser light beams pass

through an optical steering assembly, which directs the laser beam through

the sample cell.

The sample cell contains a set of mirrors to create a path through the sample

gas that is between 0.7 ft. (0.2 m) and 49.2 ft. (15 m) through multiple

reflections along the length of the cell. The laser beams exit the cell at the

opposite end from where they entered and are directed using a second

optical block to a receiver.

By measuring and analyzing the light detected by the receiver unit, it is

possible to accurately determine the concentrations of the target molecules

within the gas sample cell.

28 Rosemount CT5800

Page 29

October 2019 Quick Start Guide

2 Install

This section describes the correct installation procedure for the analyzer.

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section

must not be changed, amended, or removed.

2.1 Site requirements

Select an appropriate site for installing the analyzer.

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section

must not be changed, amended, or removed.

WARNING

INSTALLATION REQUIREMENTS

The place of installation must be clean, dry, and protected against strong

vibrations and frost.

Observe the advisable operating temperatures given in Detailed system

specifications.

Do not subject analyzer to direct sunlight or heat sources.

For outdoor installation, Emerson recommends installing the analyzer in

a cabinet. At a minimum, protect it against rainfall.

WARNING

FIRE AND EXPLOSION

In accordance with IEC 60079-0: 2011 Clause 30.

Failure to ensure the area is safe or leaving the device powered on can cause

an explosion or fire and seriously injure personnel.

Do not open the Ex d enclosure unless the area is known to be free of

flammable materials or unless all devices are switched off.

Quick Start Guide 29

Page 30

Quick Start Guide October 2019

DANGER

ELECTRIC SHOCK

This article is in accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this precaution may cause death, injury, and/or damage

to persons and/or property.

The analyzer operates using mains voltage that is dangerous to life.

Make sure that the circuit breakers are set to OFF and tagged off before

opening the front cover.

In accordance with IEC 60079-0:2011 Clause 30, install the analyzer in a

suitable position with shading to protect it from the elements. The displays

and control panel on the front of the housing must not be exposed to direct

UV light sources or direct sunlight.

WARNING

POTENTIAL ELECTROSTATIC CHARGING HAZARD

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The keypad is non-conducting and may generate an ignition capable of

electrostatic charges under certain extreme conditions.

Ensure that the equipment is not installed in a location where it may be

subjected to external conditions (such as high pressure steam), which

might cause a build-up of electrostatic charges on non-conducting

surfaces.

Only clean the analyzer with a damp cloth.

The analyzer has a T4 temperature classification which specifies the

maximum surface temperature of the instrument, under a fault condition, is

275 °F (135 °C). You must ensure that no combustible gas concentrations

are present, whether on a continual or occasional basis, which have an

ignition temperature below the T classification of the unit.

WARNING

FIRE AND EXPLOSION

Failure to observe this precaution may cause death, personal injury, and/or

damage to equipment.

Do not open the Ex d enclosure of the analyzer unless the atmosphere of the

area is known to be below the ignitable concentration of combustible gases

or materials.

30 Rosemount CT5800

Page 31

October 2019 Quick Start Guide

In accordance with IEC 60079-0: 2011 Clause 30, install the analyzer in a

suitable position with shading to protect it from the elements. Do not

expose the displays and control panel on the front of the housing to direct

UV light sources or direct sunlight.

Provide a fuse at the installation site which will completely disconnect the

analyzer in case of failure. Installing an isolating switch may also be

beneficial. In either case, these components must be constructed to

conform to recognized norms.

In accordance with IEC 60664-1, install the analyzer in an area of not more

than Pollution Degree 2.

Provide sufficient space around the analyzer to allow maintenance and

servicing of this unit.

2.2 Mounting

This procedure requires a minimum of two people to safely move and mount

the analyzer.

Detailed system specifications shows outline dimensional drawings of the

analyzer.

NOTICE

In accordance with IEC 60079-0: 2011 Clause 30. Figure 2-4 shows the

positions of the glands for the three electrical conduits. Do not redesign or

reposition these glands without consulting Emerson.

WARNING

HEAVY ITEM

In accordance with IEC 60079-0: 2011 Clause 30.

Failure to properly handle the analyzer may cause injury to personnel.

Make sure the wall the analyzer is mounted on is solid, stable, and of a

suitable material to hold the weight of the analyzer.

Handle the analyzer with caution during unpacking, installing,

maintaining, and transporting to prevent crushing of hands, feet, or

other body parts.

The analyzer weighs 176.4 lb. (80 kg).

Emerson recommends that a minimum of two people move and lift the

analyzer.

Wear suitable protective gloves and protective footwear.

Make sure that the wall fixing points are capable of supporting a load of

176.4 lb. (80 kg) each; this includes a x2 safety factor. All mounting points

are 0.6 in. (15 mm) diameter holes.

Quick Start Guide 31

Page 32

Quick Start Guide October 2019

Procedure

1. Use safety approved equipment to lift the analyzer from the stable

platform. One person guides the unit into position as the other

person carefully operates the lifting equipment.

2. Mount the analyzer using the factory fitted and pre-drilled wall

mounting brackets (Figure 2-1) using four M8 x 1.25 (5/16 - 18 UNC)

A2/A4 grade 70 bolts.

Figure 2-1: Mounting Details

A. Wall mounting bracket

Mounting brackets are 1/16-in. (4 mm) thick stainless steel. Position

the bolts in such a way to allow maximum use of all thread length.

Make sure that the fasteners used are suitable for the load and

surface the analyzer is mounted on.

32 Rosemount CT5800

Page 33

October 2019 Quick Start Guide

Emerson recommends installing the analyzer in an upright (vertical)

position; other orientations may affect the measuring results.

3. If you want to increase security on the installation of the analyzer by

thread-locking the fittings, only do this with compounds compatible

with the hazardous area zone classification of the installation

location.

4. Make sure the bolts are secure. Apply maximum torque permissible

for the material combination of the supporting structure.

5. Remove the lifting eyes and retain them for future use. Protect the

threads with plastic grommets and a suitable grease.

Postrequisites

Do not place any additional load on the analyzer.

2.3 Connecting the system

2.3.1 Opening the enclosure

Use these procedures to make the electrical, power, and gas line

connections.

Procedure

1. Make sure that the hinges are securely connected to the enclosure.

WARNING

HEAVY FRONT HOUSING

Failure to properly support the lid may cause injury to personnel.

The analyzer's front housing is heavy, 68.1 lb. (30 kg).

After removing the captive bolts, provide support when opening

the lid.

CAUTION

EQUIPMENT HAZARD

Inspect the hinges for damage before removing the M16 x 45

captive bolts to open the housing.

Make sure no obstructions are in the opening radius when the

front housing is opened.

Make sure no obstructions are in the opening radius when the

front housing is opened.

2. Unscrew the 20 off M16 x 1.5 inch captive bolts holding the front and

rear housings of the enclosure together.

Quick Start Guide 33

Page 34

Quick Start Guide October 2019

Figure 2-2: Rosemount CT5800 Housing

A. 20 off M16 captive bolts

3. Carefully lower the front enclosure to the fully open position.

34 Rosemount CT5800

Page 35

October 2019 Quick Start Guide

Figure 2-3: Enclosure Open

A. Flamepath (green highlight)

B. Seal

C. Flanges

4. Apply masking tape to the flanges, seal, and flamepath to protect

them from scratches, chipping, and other forms of damage of

deformation.

CAUTION

PROTECT FLAMEPATH

Any damage to the flamepath will invalidate certification.

Protect the flamepath with masking tape.

5. Continue the installation with the power and signal cables.

Quick Start Guide 35

Page 36

Quick Start Guide October 2019

See AC power safety information.

2.3.2 AC power safety information

NOTICE

This section is in accordance with IEC 60079-0:2011 Clause 30.

This section must not be changed, amended, or removed.

WARNING

ELECTRIC SHOCK

Failure to follow instructions may cause personal injury or death.

Only qualified personnel, taking into account all applicable standards

and legislative requirements, should install the analyzer and connect the

power and signal cables.

Instruments providing screw terminals for electrical connections may

require working near live parts.

The analyzer does not have power switches and is operable when

connected to power.

A customer-supplied power switch or circuit breaker (complying with IEC

60947-1/ -3) must be in the building installation. The switch has to be

installed near the analyzer, must be easily accessible, and has to be

assigned as a disconnector for the analyzer.

Disconnect instruments with screw terminals from power when working

at power terminals (pull power plug or operate power switch / circuit

breaker in building installation).

The analyzer provides a protective earth terminal. To prevent electrical

shock hazards, connect the instruments to a protective earth. The

instruments must be connected to power with a three wire power cable

with earth conductor. Any interruption of the earth connector inside or

outside the instrument or disconnecting the earth terminal may cause

potential electrical shock hazard.

36 Rosemount CT5800

Page 37

October 2019 Quick Start Guide

WARNING

EXPLOSION HAZARD

In accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning could cause an explosion or potentially

hazardous situation which, if not avoided, may cause death or personal

injury.

Only enable the purge controller bypass function during setup or

maintenance and only when the area is known to be non-hazardous.

The customer supplied circuit breaker must be in accordance with ATEX /

IECEx / North American protection concepts. The main power isolator

controls the application of electrical power to the analyzer.

Electrical protection for the instrumentation circuitry of the analyzer is

provided by fuses F1 and F2 located inside the analyzer.

Table 2-1: Electrical power requirements

Electrical supply Power consumption Voltage Fuse

Instrumentation

supply voltage

Purge supply voltage 10 W 110 to 240 Vac, 50/60

500 W (peak)

300 W (usual)

110 to 240 Vac, 50/60

Hz ± 10%

Hz ± 10%

3.15 A internal fuses

F1 and F2. See

Connecting the signal

cables.

1 A (located in

secondary circuit

breaker)

For the electrical power wiring, use 16 AWG stranded, 3 conductor copper or

tin plated copper power wire, rated for at least 250 Vac, of the required

length.

Cables must be rated for operation in ambient temperatures greater than

176 °F (80 °C).

Cables must be terminated in accordance with local electrical codes.

A switching system is not supplied with this equipment. You must supply a

suitably rated switch or circuit breaker to be included with this installation.

Check the installation of the switch for conformity in accordance with

national/local regulations and standards by inspection.

The switch or circuit breaker must be suitably located, easily reached, and

identified as the disconnection device for the analyzer.

Quick Start Guide 37

Page 38

Quick Start Guide October 2019

Figure 2-4: Rosemount CT5800 Bottom View: Gas Connectors and Cable

Glands

A. Gas connections (flame arrestor) (M18 x 1.5)

B. Conduit / cable entry apertures (M20 x 1.5)

C. Wall fixing line

D. Earth (ground) bond

The customer supplied circuit breaker must be in accordance with suitably

certified hazardous area Ex protection concepts. The main power isolator

controls the application of electrical power to the analyzer.

WARNING

EXPLOSION

Do not open the instrument when it is energized.

Ensure that external circuitry is disconnected or de-energized before

opening the instrument.

All cables (power and signal) must end (be connected) in either a safe

(nonhazardous) area or in a protecting enclosure (e.g., explosion-proof

junction box).

38 Rosemount CT5800

Page 39

October 2019 Quick Start Guide

WARNING

INSTALLATION USING CONDUITS

The analyzer has metric threads for installing cable entries.

Installing conduits requires metric to national pipe thread (NPT)

adapters.

To be compliant with North American ordinarly location (Ordloc) and

hazardous area (Hazloc) certification, use stainless steel with captive Oring seals.

Select a type of conduit and seals in accordance with local codes and

suitable for the site of installation.

For North American sites, do not fit seals more that 2 in. (50 mm) from

the Ex d entry point.

Unused entries are provided with plugs, secured in place with thread

locking compound.

WARNING

INSTALLATION USING CABLE GLANDS

All cable glands must be suitable certified for use in area of application

(Zone/Class/Division).

When installing the analyzer in a hydrogen environment and/or applying

hydrogen to the analyzer, do not use the standard compression type

cable glands. Use suitable compound barrier cable glands to stay

compliant to EN 60079-14.

When selecting cable glands, make sure the correct diameter is selected

to ensure correct cable fit.

CAUTION

SELECT THE CORRECT TYPE OF CABLE ENTRY.

Before starting to install the analyzer, verify what type of cable entry is

required at your site of installation.

Rosemount CT5800 gas analyzers may be equipped with cable glands

(e.g., regulated for installations covered by ATEX/IEX/Ex) or may be

installed with conduits (e.g., in North America).

Electrical protection for the instrumentation circuitry of the analyzer is

provided by fuses F1 and F2 located inside the analyzer.

Quick Start Guide 39

Page 40

Quick Start Guide October 2019

Figure 2-5: Fuses

Connect power to the system through the power gland on the base of the

analyzer (Figure 2-4).

2.3.3 Earthing/grounding the analyzer

The system must be suitably earthed / grounded using the M5 stud bonded

to the rear of the system and the connector inside with cable between 1.5

and 4 mm square.

NOTICE

This section is in accordance with IEC 60079: 2011 Clause 30. This article

must not be changed, amended, or removed.

40 Rosemount CT5800

Page 41

October 2019 Quick Start Guide

WARNING

ELECTRIC SHOCK

In accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning may cause death or personal injury.

The analyzer must be earthed/grounded in accordance with national/local

regulations.

Figure 2-6: Earth Bond

Quick Start Guide 41

Page 42

Quick Start Guide October 2019

2.3.4 Connecting the signal cables

Connect the signal cables through conduit outlets 2 and 3 as shown in the

figures below.

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section

must not be changed, amended, or removed.

The signal cables are connected to the system through conduit outlets 2 and

3 as shown in Figure 2-7 and Figure 2-9. All signal cables are to be minimum

20 AWG tri-rated switchgear cables. Customer supplied conduit and cables

must be terminated in the conduit outlets in accordance with local electrical

codes.

Figure 2-7: Cable Glands, Conduits, and Gas Line Connections

A. Breather

B. Gas connection out (flame arrestor) (M18 x 1.5)

C. Gas connection in (flame arrestor) (M18 x 1.5)

D. Conduit / cable entry apertures (M20 x 1.5)

42 Rosemount CT5800

Page 43

October 2019 Quick Start Guide

Figure 2-8: Signal Connections

Figure 2-9: Signal Cable Connections

Table 2-2: Power, Digital, and Analog Connections

Terminal Function

1 System supply (L)

2 System supply (N)

3 Digital output 1

4 Digital output 2

Quick Start Guide 43

Page 44

Quick Start Guide October 2019

Table 2-2: Power, Digital, and Analog Connections (continued)

Terminal Function

5 Digital output 3

6 Digital output 4

7 Digital output 5

8 Digital output 6

9 Digital output 7

10 Digital output 8

11 Digital output 9

12 Digital output 10

13 Digital output 11

14 Digital output 12

15 Analog output 1

16 Analog output 2

17 Analog output 3

18 Analog output 4

19 Analog output 5

20 Analog output 6

21 Analog output 7

22 Analog output 8

23 Status output 1 (check function)

24 Status output 2 (maintenance required)

25 Status output 3 (out of specification)

26 Status output 4 (failed)

Table 2-3: Ethernet Interface Module wiring to MOXA Ethernet Socket

Terminal Designation Color coding

1 Tx+ Orange / White

2 Tx Orange

3 Rx+ Green / White

4 Not used Blue

5 Not used Blue / White

44 Rosemount CT5800

Page 45

October 2019 Quick Start Guide

Table 2-3: Ethernet Interface Module wiring to MOXA Ethernet Socket

(continued)

Terminal Designation Color coding

6 Rx- Green

7 Not used Brown / White

8 Not used Brown

2.3.5 Connecting the sample supply and return lines

Sample gas supply and sample return connections are from ¼-in. (6 mm)

Swagelok® type fittings.

The analyzer has one gas input and one gas output, which are located on the

base of the analyzer (Figure 2-7).

The gas sample that is to be measured for impurities enters the instrument

through the sample gas input port.

Once the sample gas has been examined for impurities, it is expelled from

the instrument through the sample gas return port.

NOTICE

Remove the breather blanking cap and never connect anything to this port.

To avoid the risk of gas leaks, make sure that these connections are made

correctly and tightly. Both the sample gas supply pipe and the sample return

pipe should be thermal insulated.

NOTICE

The Swagelok recommendation for pipe fittings of this size is to tighten the

nut finger tight and then tighten an additional one and a quarter (1 and ¼)

turns with a spanner.

The maximum gas supply pressure is 1 BarG.

The sample supply line must be heated all the way to the sample gas input

port on the analyzer to prevent condensation forming at any point in the

sample supply line.

Quick Start Guide 45

Page 46

Quick Start Guide October 2019

WARNING

HAZARDOUS GAS

This article is in accordance with IEC 60079-0: 2011 Clause 30.

The product stream that the analyzer is examining may be hazardous even

at low concentrations.

Take special care to ensure that the sample gas return port either returns the

sample gas to the product stream or discharges the sample gas to a location

that will not cause a hazard.

WARNING

MAINS SUPPLY CABLE

Failure to follow this warning may result in personal injury.

Make sure that the mains supply cable used is of a suitable rating for the

analyzer's power requirements.

The Ethernet connector provides an Ethernet output from the analyzer that

may be used for downloading data for failure diagnostic purposes.

The analyzer outputs the results of the gas analysis through the 4-20 mA

analog outputs and sends them to your process control center.

The status outputs provide fault indications to your process control center.

Each digital output is connected to a normally closed relay, located inside

the analyzer, which will open in response to the detection of a specific fault.

The possible causes of a fault indication are:

• The sample gas concentration is outside of specification (i.e., the sample

gas concentration has exceeded the measurement range of the

instrument).

• The analyzer is out of specification or has developed a fault.

WARNING

HIGH VOLTAGE

Failure to obey the wiring regulations may result in serious injury to

personnel.

Voltages up to 250 Vac, 50 Hz may be present on the digital output

terminals.

Install external circuits in accordance with national wiring regulations.

46 Rosemount CT5800

Page 47

October 2019 Quick Start Guide

WARNING

ELECTRIC SHOCK

Attaching cables and wiring harnesses longer than 9.8 ft. (3 m) may cause

injury to personnel.

The analyzer passed electromagnetic compatibility (EMC) tests based on all

electrical cables and harnesses attached to it being 9.8 ft. (3 m) long.

2.3.6 Closing the housing

After all internal connections have been made and proved/tested, close the

enclosure and secure the 20 off M16 x 45 captive screws and form A washers

in accordance with the torque sequence.

See Figure 2-11.

Procedure

1. Remove all protective covering from the flamepath and enclosure

sealing gasket.

2. Inspect the seal.

If any damage is detected, stop the process immediately and report

to maintenance.

3. Clean the seal to remove any adhesive from the protective cover.

4. Inspect the flanges/flamepath for damage (i.e., scratches, chipping,

and/or other form of damage/deformation).

If any damage is detected, stop the process immediately and report

to maintenance.

5. Carefully lift the housing up and align with the rear housing.

6. Make sure that all holes are aligned. If necessary, use the two holes

(Figure 2-10) to assist alignment.

Quick Start Guide 47

Page 48

Quick Start Guide October 2019

Figure 2-10: Alignment holes

A. Alignment holes

7. Insert the captive M16 bolt and engage the threads on the rear

housing.

8. Refer to the torque sequence (Figure 2-11) and tighten all bolts.

WARNING

HAZARDOUS AREA PROTECTION

Failure to follow the warning will invalidate hazardous area Ex d

protection.

Always use captive M16 x 45 screws and form A washers to secure

the enclosure shut.

48 Rosemount CT5800

Page 49

October 2019 Quick Start Guide

Figure 2-11: Torque sequence

Tighten all bolts in sequence to a torque value of 18.44 ft.-lb. (25

Nm).

2.4 Test connections

Before sealing the cable glands, it is vital to test the new connections in

order that any faults can be remedied before the cables are permanently

sealed.

WARNING

EXPLOSION HAZARD

In accordance with IEC 60079-0: 2011 Clause 30.

Failure to observe this warning could cause an explosion or potentially

hazardous situation which, if not avoided, may cause death or personal

injury.

The cable glands used in this analyzer are only suitable for use in areas with a

low risk of mechanical damage. Protect the cable glands suitably.

Temporarily seal the cable glands with a suitable sealant to allow testing.

The tests described below are a basic check to prove function, rather than a

test of sensor capability.

Quick Start Guide 49

Page 50

Quick Start Guide October 2019

To start the analyzer, follow the steps in Start-up procedure.

WARNING

INSTALLER RESPONSIBILITY

In accordance with IEC 60079-0: 2011 Clause 30

Failure to observe this warning could cause a potentially hazardous situation

which, if not avoided, may cause death or personal injury.

It is the installer's responsibility to connect the analyzer to a suitable alarm or

shutdown facility.

2.4.1 Testing power input cables and circuit breakers

The power input cables and circuit breakers can be tested as follows.

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section

must not be changed, amended, or removed.

Procedure

1. Set the main circuit breaker to ON.

2. Check that the display controller lights up.

The instrument begins to power up.

2.4.2 Testing temperature sensor and cell heater

The sample cell is controlled to operate at a pre-set temperature. This

involves a heater and a temperature sensor.

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section

must not be changed, amended, or removed.

Procedure

1. Check that a temperature reading is displayed against

Temperature on the display controller as described in Operating

the analyzer.

2. Leave the analyzer operating and confirm that the temperature rises

until the analysis cell reaches the pre-set operating temperature

around 122 °F (50 °C).

This takes approximately 90 minutes.

50 Rosemount CT5800

Page 51

October 2019 Quick Start Guide

2.4.3 Pressure sensor

The pressure sensor monitors the pressure in the analysis cell.

NOTICE

This section is in accordance with IEC 60079-0: 2011 Clause 30. This section

must not be changed, amended, or removed.

Procedure

1. Check that a pressure reading is displayed under Pressure on the

display controller.

The reading is approximately 760 Torr at atmospheric pressure.

NOTICE

A Torr is a non SI unit of pressure, defined as 1/760 of standard

atmospheric pressure, and is equal to the fluid pressure of 1 mm of

mercury.

2. If desired, cap off the gas inlet and use an external pump to evacuate

the cell.

Make sure the pressure drops as expected.

Quick Start Guide 51

Page 52

Quick Start Guide October 2019

2.4.4 Testing analog output cables

Prerequisites

In order to generate a 4-20 mA output, let the analyzer warm up for 90

minutes and make sure the analysis cell is at the correct pressure.

The 4-20 mA outputs operate when the analysis cell is between 104 and 140

°F (40 and 60 °C) and the pressure is between 180 and 220 Torr. It is not

essential to flow sample gas through the system; nitrogen or atmospheric air

is adequate for this test.

Procedure

With the analyzer at operating temperature and pressure, ensure that a

current between 4 mA and 20 mA is generated on each 4-20 mA output, as

listed in Connecting the signal cables.

Use a multimeter to measure the current.

2.4.5 Testing the measurement valid flag

The measurement flag is normally open contact. It is simplest to test this

with a multimeter.

With the analyzer closed and compressed air applied as described in the

startup procedure (Startup procedure) when the system is operating

correctly, an open contact is created between the two contact wires (white).

Procedure

To test the Error state, shut off the sample gas and allow the pump to reduce

the cell pressure below 180 Torr.

At this point, the contact should close and there should be no resistance

between the two white wires.

WARNING

FIRE AND EXPLOSION

In accordance with IEC 60079-0: 2011 Clause 30.

Failure to ensure the area is safe or leaving the device powered on can cause

an explosion or fire and serious injury to personnel.

Do not open the Ex d enclosure unless the area is known to be free of

flammable materials or unless all devices are switched off.

2.5 Commissioning

Once the sensor is fully installed as described above, commission it

according to the commissioning plan agreed on between you and Emerson.

52 Rosemount CT5800

Page 53

October 2019 Quick Start Guide

3 Start-up procedure

3.1 Introduction

CAUTION

EQUIPMENT DAMAGE

Damage to the analyzer may result from a failure to follow this procedure.

Always follow the start-up procedure.

The analyzer normally operates continuously. It should only be necessary to

start up the analyzer under the following circumstances:

• When the analyzer is first switched on following installation.

• Following repair or maintenance.

• When the analyzer has been switched off as part of a plant shutdown or

maintenance.

3.2 Preparation for use

The analyzer must be installed and fully commissioned prior to startup.

WARNING

BURNS

Failure to allow sufficient cooling may cause serious burn injury to personnel.

Do not touch any part of the analyzer.

Assume all parts of the analyzer are hot unless it has been switched off

and allowed to cool down.

Some parts of the analyzer may be heated to 150 °F (65 °C).

Always wear proper protective equipment when handling the analyzer.

Switch off the analyzer and allow it to cool for at least two hours before

fitting, removing, or performing any maintenance.

The analysis cell is insulated against heat loss. Allow the analyzer to cool

for at least twelve hours before performing any maintenance on, or in

the vicinity of, the analysis cell.

Quick Start Guide 53

Page 54

Quick Start Guide October 2019

3.3 Startup procedure

NOTICE

The gases shown in the screenshots and the measurements thereof may be

different from those shown in your particular analyzer. They indicate the

functionality of the software, which is the same regardless of the gases being

measured.

NOTICE

To stop the startup procedure at any time, set the main circuit breaker to

OFF.

To start up the analyzer, perform the following steps:

Procedure

1. Visually inspect the exterior of the analyzer for signs of damage,

corrosion, gas leaks, or overheating. Report anything found to the

hazardous area Ex maintenance organization.

2. Make sure that the analyzer has been correctly installed.

See Install.

3. Make sure that the enclosure is closed and all bolts are correctly

torqued.

If the enclosure cannot be closed and locked, report it to the

maintenance organization and do not proceed further until the door

has been repaired.

4. Make sure that the gas handling system is turned OFF.

5. Make sure that the external circuit breaker is set to OFF.

6. Visually examine the gas ports to make sure that the sample supply

line and the sample return line are correctly attached to the analyzer.

7. Visually check that the electrical connections have been made to the

instrument.

8. Set the main circuit breaker to ON, which applies main power to the

instrument.

The analyzer begins its automatic startup. The control PC that forms

part of the instrument is configured to automatically load the

necessary gas sensor software and configuration files. The startup

sequence commences automatically under software control.

At the end of the startup procedure, the gas measurements initially appear

as 0.00 ppm until the first readings are taken. After a few seconds, the

initial gas concentrations will be displayed.

54 Rosemount CT5800

Page 55

October 2019 Quick Start Guide

4 Operating the analyzer

4.1 Introduction

This chapter describes the controls, displays, and indicators on the

Rosemount CT5800 and how to use the display controller located on the

front panel of the instrument.

NOTICE

The gases shown in the screenshots and the measurements may be different

from those shown in your particular analyzer. They indicate the functionality

of the software, which is the same regardless of the gases or gas

concentrations being measured.

4.2 Normal operation

The analyzer is designed for long term continuous operation, and therefore

its normal state is to be switched on and performing gas measurements. The

analyzer is usually only switched off for maintenance.

Figure 4-1: Gas Sensor Main Screen

Quick Start Guide 55

Page 56

Quick Start Guide October 2019

Figure 4-2: Pressure and Temperature Screen

4.3 Front panel controls and indicators

The analyzer is configured from the display controller located on the front

panel.

56 Rosemount CT5800

Page 57

October 2019 Quick Start Guide

Figure 4-3: Front Panel Display Controller

Quick Start Guide 57

Page 58

Quick Start Guide October 2019

4.4 Display controller

Figure 4-4: Front Panel Display Controller

A. LCD display

B. Navigation buttons

You can control the analyzer through six navigation buttons (Figure 4-4, B)

on the display controller.

The LCD display (A) can be used to display:

• Gas concentration measurements obtained

• Operating temperature and pressure

• Help screens

• Step-by-step calibration

• Diagnostics

The navigation buttons (B) are configured to perform different functions

according to which software screen is shown on the LCD display.

4.5

Gas Sensor Main screen

When the analyzer is switched on, at the end of the start-up procedure, the

Gas Sensor Main screen (Figure 4-5) appears.

The Gas Sensor Main screen is the screen that is normally displayed.

NOTICE

The gas concentrations shown in the following screenshots may be different

from those shown in your particular analyzer. The screenshots indicate the

functionality of the software, which is the same regardless of the gases or

gas concentrations being measured.

58 Rosemount CT5800

Page 59

October 2019 Quick Start Guide

Figure 4-5: Gas Sensor Main Screen

At the end of the start-up procedure, the gas measurements initially appear

as 0.00 ppm until the first readings are taken. After a few seconds, the

initial gas concentrations are displayed.

The Gas Sensor Main screen also shows the status of the analyzer. In the

example shown in the analyzer is Running and OK (i.e., no faults have been

identified).

If a fault is identified, ? is displayed; if maintenance is required, is

displayed.

To access other screens through the Main menu, press . (Refer to ).

is a link between the Gas Sensor Main screen () and the Pressure and

Temperature screen (Figure 4-6). Press to toggle between the two

screens.

is a link to the Help system. Press to go to a Help screen (described

in Help system).

On the Gas Sensor Main screen, has no function when the analyzer is

operating correctly. If, however, the software detects a fault, an error

message is displayed. Press to get further information on the error.

4.6

Quick Start Guide 59

Pressure and Temperature screen

The Pressure and Temperature screen (Figure 4-6) shows pressure and

temperature measurements taken inside the analyzer.

Page 60

Quick Start Guide October 2019

Figure 4-6: Pressure and Temperature Screen

NOTICE

A Torr is a non-SI unit of pressure defined as 1/760 of standard atmospheric

pressure and is equal to the fluid pressure of 1 mm of mercury.

4.7 Help system

The analyzer software includes a context-sensitive help system. Press ,

which is available on most of the software screens, to open the help system.

The help system contains a number of different Help screens, each

conveying a different message. As the help system is context-sensitive, the

Help screen that appears is the one that is most appropriate to the software

function engaged when was pressed. Figure 4-7 shows an example of a

Help screen.

60 Rosemount CT5800

Page 61

October 2019 Quick Start Guide

Figure 4-7: Example of a Help Screen

4.8 Main menu

To access the Main menu , press on either the Gas Sensor Main screen

(Figure 4-5) or the Pressure and Temperature screen (Figure 4-6). The Main

menu ( ) options are:

• DIAGNOSTICS: Displays various parameters used in the internal

calculations and compares desired and actual parameters, for example,

the analysis cell pressure and temperature. The diagnostics routines and

screens are used to perform fault diagnosis.

• FAULTS: Takes you to a screen that lists any faults affecting the analyzer.

This option is used as part of the failure diagnosis procedures.

• GAS SERVICE: Allows you to check the sensor readings against a known

gas source (verification) or, if necessary, to calibrate the analyzer against