Page 1

Instruction Manual

748446-D

April 2002

Model CAT200

Continuous Analyzer Transmitter

http://www.processanalytic.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures and tests its products to meet many national and

international standards. Because these instruments are sophisticated technical products, you

MUST properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions MUST be adhered to and integrated into your

safety program when installing, using, and maintaining Rosemount Analytical products. Failure to

follow the proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Rosemount Analytical representative

for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of

the product.

• Install your equipment as specified in the Installation Instructions of the appropriate Instruc-

tion Manual and per applicable local and national codes. Connect all products to the proper elec-

trical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and

maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by

Rosemount. Unauthorized parts and procedures can affect the product’s performance, place the safe

operation of your process at risk, and VOID YOUR WARRANTY. Look-alike substitutions may result

in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons, to prevent electrical shock and personal

injury.

The information contained in this document is subject to change without notice.

Teflon® and Viton® are registered trademarks of E. I. duPont de Nemours and Co., Inc.

SNOOP® is a registered trademark of NUPRO Co.

Emerson Process Management

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T (330) 682-9010

F (330) 684-4434

e-mail: gas.csc@EmersonProcess.com

http://www.processanalytic.com

Page 3

Model CAT200

PREFACE...........................................................................................................................................P-1

Definitions ...........................................................................................................................................P-1

Intended Use Statement.....................................................................................................................P-2

Safety Summary .................................................................................................................................P-2

General Precautions For Handling And Storing High Pressure Gas Cylinders .................................P-5

Documentation....................................................................................................................................P-6

Compliances .......................................................................................................................................P-6

1-0 DESCRIPTION AND SPECIFICATIONS..............................................................................1-1

1-1 Overview................................................................................................................................1-1

1-2 Typical Applications...............................................................................................................1-1

a. Standard Industry Applications .......................................................................................1-2

1-3 Detector Methodologies.........................................................................................................1-2

a. Non-Dispersive Infrared (NDIR)......................................................................................1-2

Opto-Pneum

Overall NDIR Method......................................................................................................1-5

b. Paramagnetic Oxygen Method .......................................................................................1-7

c. Electrochemical Oxygen Method ....................................................................................1-8

d. Thermal Conductivity Method .........................................................................................1-10

1-4 Specifications ........................................................................................................................1-12

a. General ...........................................................................................................................1-12

b. CAT200 Detector ............................................................................................................1-13

Instruction Manual

748446-D

April 2002

TABLE OF CONTENTS

A

tic Method .................................................................................................1-4

2-0 INSTALLATION ....................................................................................................................2-1

2-1 Process and Calibration Gas Connection .............................................................................2-1

a. Gas Conditioning.............................................................................................................2-5

b. Internal Gas Paths ..........................................................................................................2-5

2-2 Installation..............................................................................................................................2-7

a. Location...........................................................................................................................2-7

b. Limitations .......................................................................................................................2-7

c. Gas Lines ........................................................................................................................2-7

d. Services ..........................................................................................................................2-7

e. Mounting Options ............................................................................................................2-7

f. Vent Lines .......................................................................................................................2-8

g. Electrical Connections ....................................................................................................2-8

2-3 Analytical Leak Check ...........................................................................................................2-12

a. Flow Indicator Method.....................................................................................................2-12

b. Manometer Method.........................................................................................................2-13

3-0 OPERATION .........................................................................................................................3-1

3-1 Startup and initialization ........................................................................................................3-1

3-2 Display & Operating Keys......................................................................................................3-2

a. Display ............................................................................................................................3-2

b. Keys ................................................................................................................................3-2

c. Menu Lines and Softkey Functionality ............................................................................3-3

d. Common Function Keys..................................................................................................3-4

e. Entering and Changing Variables ...................................................................................3-4

f. Starting a Function..........................................................................................................3-4

g. Main Menu ......................................................................................................................3-5

Rosemount Analytical Inc. A Division of Emerson Process Management Contents i

Page 4

Instruction Manual

748446-D

April 2002

3-3 Basic Setup............................................................................................................................3-8

a. Analyzer Channel Status ................................................................................................3-8

b. Status Details ..................................................................................................................3-9

c. Acknowledge and Clear Failures ....................................................................................3-10

d. Current Operation Parameters........................................................................................3-11

e. Single Component Display..............................................................................................3-12

f. Multi Component Display ................................................................................................3-12

3-4 Calibration..............................................................................................................................3-13

a. Calibration Status............................................................................................................3-13

b. Zero Calibration...............................................................................................................3-14

c. Span Calibration..............................................................................................................3-15

d. Setup Basic Calibration Parameters ...............................................................................3-16

e. Open and Close Valves ..................................................................................................3-16

3-5 Analyzer & I/O, Expert Control & Setup ................................................................................3-17

a. Analyzer Module Setup...................................................................................................3-18

b. Load Factory Configuration.............................................................................................3-19

c. Calibration Parameters ...................................................................................................3-19

d. Span Gas Parameter ......................................................................................................3-20

e. Calibration Tolerances ....................................................................................................3-20

f. Calibration Procedure Setup...........................................................................................3-22

g. Timed Controlled Calibration ..........................................................................................3-24

3-6 Calibration Parameters – Manual Calibration........................................................................3-25

a. Advanced Calibration Methods .......................................................................................3-26

b. Zero Gas Parameters .....................................................................................................3-27

3-7 Alarm Parameters..................................................................................................................3-28

a. Alarm Setup and Control.................................................................................................3-29

3-8 Range Parameters ................................................................................................................3-30

a. Offset and Span of Range ..............................................................................................3-30

b. Response times (t90) ......................................................................................................3-31

c. Autoranging Control ........................................................................................................3-31

3-9 Cross Interference Compensation.........................................................................................3-34

3-10 Linearization ..........................................................................................................................3-36

a. Disable Linearization .....................................................................................................3-36

b. Zero and Sapn Calibration ............................................................................................3-36

c. Calculate Linearization Curve........................................................................................3-37

d. Enable Linearization .......................................................................................................3-37

e. Linearization Verification ................................................................................................3-37

3-11 Programmable Logic Control (PLC) ......................................................................................3-38

a. Disable PLC ....................................................................................................................3-38

b. Input the program............................................................................................................3-38

c. Enable PLC .....................................................................................................................3-38

d. Checking the results .......................................................................................................3-38

e. Example for PLC Programming ......................................................................................3-43

f. Placing the codes into the Program menu......................................................................3-44

g. PLC Output .....................................................................................................................3-44

3-12 Programmable Calculator......................................................................................................3-45

a. Programming the Calculator ...........................................................................................3-45

b. Example for Calculation Programming ...........................................................................3-47

3-13 Measurement Display Configuration .....................................................................................3-48

3-14 Acknowledgement of Status Reports ....................................................................................3-50

3-15 Concentration Measurement Parameters .............................................................................3-50

3-16 Concentration Peak Measurement........................................................................................3-51

3-17 Differential Measurement ......................................................................................................3-52

Model CAT200

ii Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 5

Model CAT200

3-18 Gas flow Setup ......................................................................................................................3-53

3-19 Pressure Compensation ........................................................................................................3-54

3-20 Flow Measurement ................................................................................................................3-55

3-21 Temperature Measurement ...................................................................................................3-55

3-22 Load/Save Analyzer Module Configuration ...........................................................................3-56

3-23 Inputs & Outputs (SIO/DIO)...................................................................................................3-57

a. SIO ..................................................................................................................................3-57

b. DIO..................................................................................................................................3-61

c. DIO Function Codes .......................................................................................................3-62

3-24 Delay and Average ................................................................................................................3-63

3-25 AK-Protocol Communication .................................................................................................3-64

3-26 System Configuration and Diagnostics .................................................................................3-65

a. Diagnostic Menus............................................................................................................3-65

Analyzer Module Diagnostics..........................................................................................3-66

b. Load/Save Module Configuration....................................................................................3-67

c. Date and Time.................................................................................................................3-68

d. Security Codes................................................................................................................3-69

Setting the code numbers ...............................................................................................3-69

Enable the security code.................................................................................................3-69

e. System Reset..................................................................................................................3-71

f. Memory Usage................................................................................................................3-71

3-27 Display Controls ....................................................................................................................3-72

3-28 Measurement.........................................................................................................................3-73

3-29 Shut Down .............................................................................................................................3-73

3-30 Temperature Stabilization......................................................................................................3-74

a. Controller Settings...........................................................................................................3-74

DIP switch settings:.........................................................................................................3-74

Initial menu settings: .......................................................................................................3-75

Final menu settings: ........................................................................................................3-75

Instruction Manual

748446-D

April 2002

4-0 MAINTENANCE AND SERVICE ..........................................................................................4-1

4-1 Overview................................................................................................................................4-1

4-2 Component Removal.............................................................................................................4-1

a. Analyzer Component Removal .......................................................................................4-2

b. Power Supply Assembly Removal ..................................................................................4-2

4-3 Troubleshooting Guide ..........................................................................................................4-3

a. Instrument Not Functioning (LCD Display Is Dark).........................................................4-3

b. No or Incorrect Measurement Screen.............................................................................4-3

c. Error Messages Displayed..............................................................................................4-3

d. Detector Signal Communication Failed ..........................................................................4-4

e. Light Source Failure........................................................................................................4-4

f. Detector Failure...............................................................................................................4-4

g. No Temperature Measurement.......................................................................................4-4

h. No External Input ............................................................................................................4-4

i. No or Incorrect Analog Outputs or Digital I/O .................................................................4-5

j. Calibration not Possible ..................................................................................................4-5

k. Fluctuating or Erroneous Display ....................................................................................4-5

l. Response Time Too Long (t90 time) ..............................................................................4-5

4-4 Analyzer Configuration and Adjustment ................................................................................4-7

a. Component Layout..........................................................................................................4-7

b. Circuit Board ICB ............................................................................................................4-12

c. Circuit Board PSV ...........................................................................................................4-12

d. Circuit Board PIC ............................................................................................................4-12

Rosemount Analytical Inc. A Division of Emerson Process Management Contents iii

Page 6

Instruction Manual

748446-D

April 2002

e. Circuit Board ACU...........................................................................................................4-13

f. Analyzer Rear Panel .......................................................................................................4-14

g. Thermal Conductivity Response Time ............................................................................4-17

4-5 Maintenance ..........................................................................................................................4-18

a. Checking & Cleaning of the Analyzer .............................................................................4-18

b. Photometric Components ...............................................................................................4-19

Removal of Photometer Assembly..................................................................................4-19

Light Source Replacement..............................................................................................4-20

Removal of Analysis Cells ..............................................................................................4-21

Cleaning of Analysis Cells & Windows ...........................................................................4-22

Reinstalling Analysis Cells ..............................................................................................4-22

Reinstalling Photometer Assembly .................................................................................4-22

Physical Zeroing..............................................................................................................4-22

c. Replacement of Electrochemical Oxygen Sensor ..........................................................4-23

Check of the Sensor .......................................................................................................4-23

Removal of the Sensor ...................................................................................................4-24

Replacing the Sensor......................................................................................................4-25

Reinstalling the Sensor ...................................................................................................4-25

Basic Calibration for the Oxygen Sensor........................................................................4-25

4-6 Analyzer Service....................................................................................................................4-26

a. Photometer Signal Processing (PCB PSV) ....................................................................4-26

Internal Voltage Supply...................................................................................................4-27

IR Source ........................................................................................................................4-28

Chopper ..........................................................................................................................4-28

Unamplified Signal at Detector .......................................................................................4-29

Signal on PCB “PSV” ......................................................................................................4-29

b. Physical Zero – Paramagnetic Oxygen ..........................................................................4-30

c. Removal of Operator Front Panel ...................................................................................4-30

d. Replacement of Buffer Battery........................................................................................4-31

e. Replacement of Fuses ....................................................................................................4-32

f. Test Points for OXS PC Board........................................................................................4-33

g. Power Supply ..................................................................................................................4-35

h. Wiring of DIO with External Devices ...............................................................................4-36

Model CAT200

5-0 RETURN OF MATERIAL ......................................................................................................5-1

5-1 Return Of Material .................................................................................................................5-1

5-2 Customer Service ..................................................................................................................5-1

5-3 Training..................................................................................................................................5-1

iv Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 7

Model CAT200

Figure 1-1. CAT200 Continuous Analyzer Transmitter ............................................................ 1-1

Figure 1-2. Absorption Bands of Sample Gas and Transmittance of Interference Filters ....... 1-3

Figure 1-3. Opto-Pneumatic Gas Detector............................................................................... 1-4

Figure 1-4. Overall NDIR Method............................................................................................ 1-6

Figure 1-5. Paramagnetic Oxygen Analysis............................................................................. 1-7

Figure 1-6. Electrochemical Oxygen Sensor............................................................................ 1-8

Figure 1-7. Reaction of Galvanic Cell ...................................................................................... 1-9

Figure 1-8. Thermal Conductivity Sensor............................................................................... 1-11

Figure 1-9. Response Time vs Flow Rate Dependence ........................................................ 1-11

Figure 2-1. Gas Connections ................................................................................................... 2-2

Figure 2-2. Piping Diagram (Example)..................................................................................... 2-3

Figure 2-3. Outline and Mounting Dimensions......................................................................... 2-4

Figure 2-4. Internal Gas Paths (example) ................................................................................ 2-6

Figure 2-5. Increased Safety Junction Box Terminals ........................................................... 2-11

Figure 2-6. Leak Test - Flow Indicator Method ...................................................................... 2-12

Figure 2-7. Leak Test - Manometer Method........................................................................... 2-13

Figure 3-1. Startup Display ......................................................................................................3-1

Figure 3-2. The Display and Operating Keys........................................................................... 3-2

Figure 3-3. The Display Screen ............................................................................................... 3-3

Figure 3-4. Confirmation Display.............................................................................................. 3-4

Figure 3-5. Main Menu Display ............................................................................................... 3-5

Figure 3-6. Module Manufacturing Data Displays.................................................................... 3-6

Figure 3-7. Main Menu Sub Menus.......................................................................................... 3-7

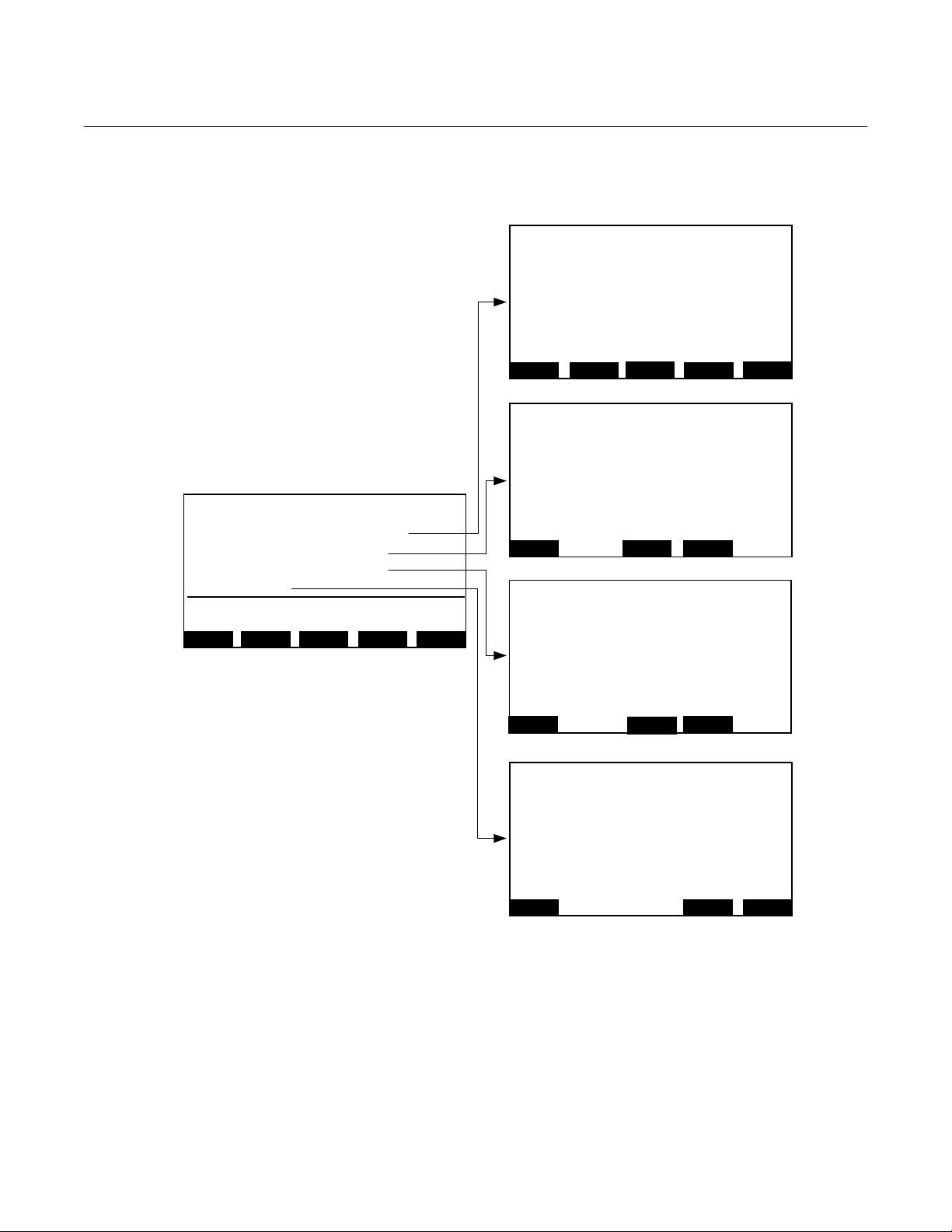

Figure 3-8. Analyzer Channel Status Menu Display ................................................................ 3-8

Figure 3-9. Status Details Displays .......................................................................................... 3-9

Figure 3-10. List of Possible Failures Menu (Screen 1 of 2)...................................................... 3-9

Figure 3-11. List of Possible Failures (Screen 2 of 2)................................................................ 3-9

Figure 3-12. Confirmation Displays.......................................................................................... 3-10

Figure 3-13. Analyzer Operation Settings Menu...................................................................... 3-11

Figure 3-14. Auto Start Procedures ......................................................................................... 3-11

Figure 3-15. Single Channel Display........................................................................................ 3-12

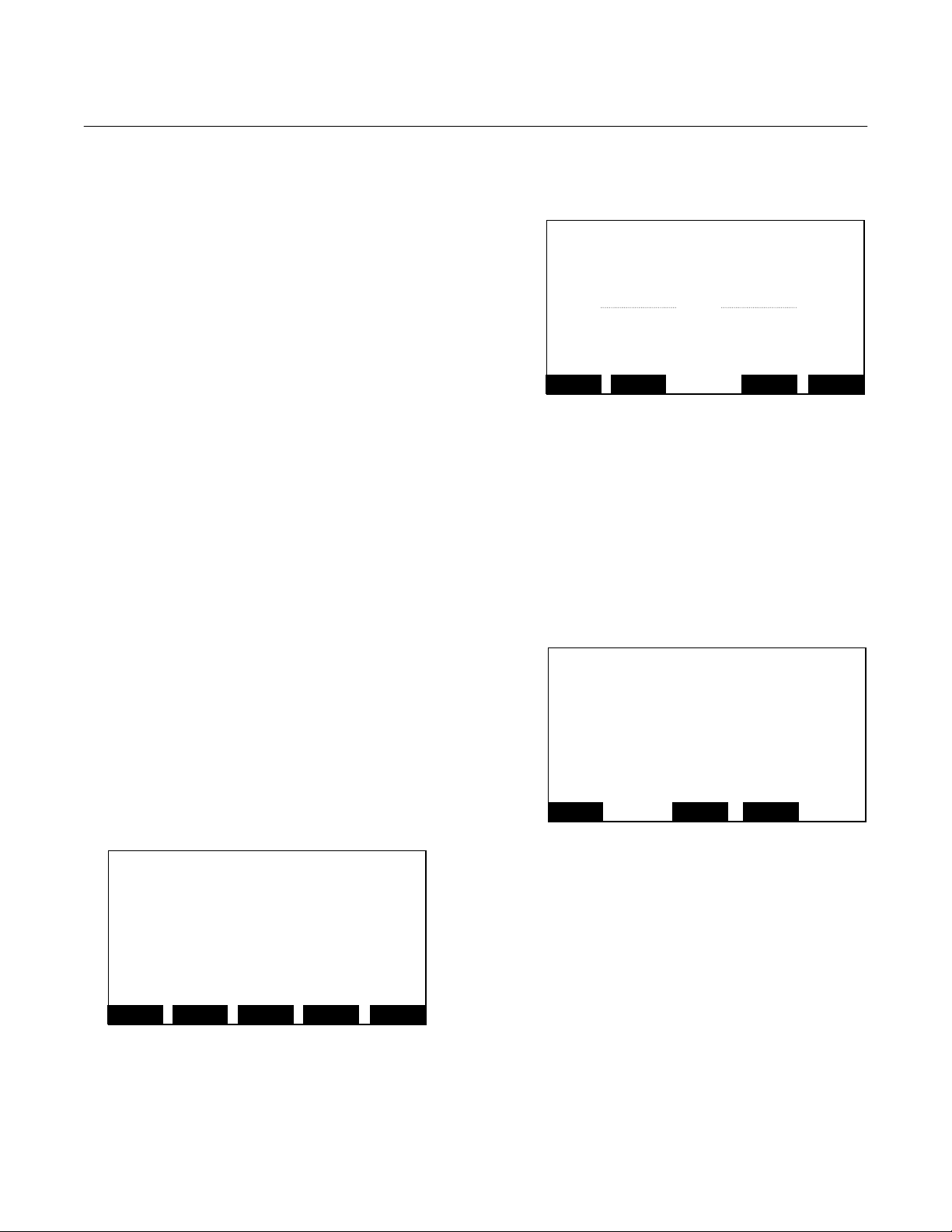

Figure 3-16. Multi Channel Display .......................................................................................... 3-12

Figure 3-17. Basic Controls and Setup Menu .......................................................................... 3-13

Figure 3-18. Calibration Procedure Status Menu..................................................................... 3-13

Figure 3-19. Calibration Deviations Menu................................................................................ 3-13

Figure 3-20. Set Gas Valves Menu .......................................................................................... 3-16

Figure 3-21. Analyzer and I/O, Expert Controls & Setup Sub Menus...................................... 3-17

Figure 3-22. Analyzer Module Setup and Controls (1/3) Menu (Screen 1 of 3)....................... 3-18

Figure 3-23. Analyzer Module Setup and Controls (2/3) Menu (Screen 2 of 3)....................... 3-18

Figure 3-24. Analyzer Module Setup and Controls (3/3) Menu (Screen 3 of 3)....................... 3-18

Figure 3-25. Load Factory Configuration ................................................................................. 3-19

Figure 3-26. Calibration Parameters Menu .............................................................................. 3-19

Figure 3-27. Span Gas Definition Menu................................................................................... 3-20

Figure 3-28. Tolerances Menu ................................................................................................. 3-20

Figure 3-29. Calibration Procedure Setup Menu ..................................................................... 3-22

Figure 3-30. Zero/Span Calibration Stability Diagram ............................................................. 3-22

Figure 3-31. Analog Output Chart ............................................................................................ 3-23

Figure 3-32. Time Control Menu .............................................................................................. 3-24

Figure 3-33. Auto-Start Procedures Menu ............................................................................... 3-24

Figure 3-34. Calibration Menu.................................................................................................. 3-25

Figure 3-35. Advanced Calibration Menu................................................................................. 3-26

Instruction Manual

748446-D

April 2002

LIST OF ILLUSTRATIONS

Rosemount Analytical Inc. A Division of Emerson Process Management Contents v

Page 8

Instruction Manual

748446-D

April 2002

Figure 3-36. State of Calibration Procedures Screen .............................................................. 3-26

Figure 3-37. Zero Gas Definition Menu.................................................................................... 3-27

Figure 3-38. Alarm Setup Menu ............................................................................................... 3-28

Figure 3-39. Concentration Alarm Setup Menu ....................................................................... 3-29

Figure 3-40. Range Parameters Menu..................................................................................... 3-30

Figure 3-41. Begin / End of Ranges Menu............................................................................... 3-30

Figure 3-42. Response Times Menu........................................................................................ 3-31

Figure 3-43. Auto-ranging Control Menu.................................................................................. 3-31

Figure 3-44. Hysteresis Between Ranges Graph .................................................................... 3-32

Figure 3-45. Actual Switch Levels Screen ............................................................................... 3-33

Figure 3-46. Cross Interference Compensation Menu............................................................. 3-34

Figure 3-47. Channels Display................................................................................................. 3-34

Figure 3-48. Interference Factors Menu................................................................................... 3-35

Figure 3-49. Multiple Spline Linearization Menu...................................................................... 3-36

Figure 3-50. Linearization Raw Values Menu .......................................................................... 3-36

Figure 3-51. Programmable Logic Control Menu..................................................................... 3-38

Figure 3-52. PLC Program Menu ............................................................................................ 3-44

Figure 3-53. PLC Outputs Menu .............................................................................................. 3-44

Figure 3-54. Programmable Calculator Menu.......................................................................... 3-45

Figure 3-55. Programmable Calculator – Program Menu ........................................................ 3-47

Figure 3-56. Measurement Display Configuration Menu (Screen 1 of 3) ................................ 3-48

Figure 3-57. Measurement Display Configuration Menu (Screen 2 of 3) ................................ 3-49

Figure 3-58. Measurement Display Configuration Menu (Screen 3 of 3) ................................ 3-49

Figure 3-59. Acknowledgement of Status Reports Menu ........................................................ 3-50

Figure 3-60. General Concentration Measurement Parameters Setup Menu ......................... 3-50

Figure 3-61. Concentration Peak Measurement Menu ............................................................ 3-51

Figure 3-62. Differential Measurement Menu........................................................................... 3-52

Figure 3-63. Gas Flow Setup Menu ......................................................................................... 3-53

Figure 3-64. Pressure Compensation Menu ............................................................................ 3-54

Figure 3-65. Flow Measurement Menu .................................................................................... 3-55

Figure 3-66. Pressure Compensation Menu ............................................................................ 3-55

Figure 3-67. Load/Save Analyzer Module Configuration Menu ............................................... 3-56

Figure 3-68. Analyzer Module I/O Modules Menu ................................................................... 3-57

Figure 3-69. Local SIO Configuration Parameters Menu......................................................... 3-57

Figure 3-70. Analog Outputs Menu .......................................................................................... 3-57

Figure 3-71. Analyzer Modules Menu ...................................................................................... 3-58

Figure 3-72. Output Signal If Analyzer Module Fails / Fine Adjustment Menu ........................ 3-59

Figure 3-73. Serial Interface Menu........................................................................................... 3-60

Figure 3-74. Relay Outputs Menu ............................................................................................ 3-60

Figure 3-75. Local DIO Boards Setup Menu ............................................................................ 3-61

Figure 3-76. Delay and Average Menu .................................................................................... 3-63

Figure 3-77. Example Concentration Average......................................................................... 3-63

Figure 3-78. AK-Communication Menu.................................................................................... 3-64

Figure 3-79. System Configuration Menu ................................................................................ 3-65

Figure 3-80. Diagnostic Menus ................................................................................................ 3-65

Figure 3-81. Analyzer Module Diagnostics Menu .................................................................... 3-66

Figure 3-82. Load/Save Analyzer Module Configuration Menu ............................................... 3-67

Figure 3-83. Date and Time Menu ........................................................................................... 3-68

Figure 3-84. Security Setup Menu ........................................................................................... 3-69

Figure 3-85. Define Basic Level Security PIN Menu................................................................ 3-69

Figure 3-86. System Reset Menu ............................................................................................ 3-71

Figure 3-87. Control Module RAM – Memory Usage Menu..................................................... 3-71

Figure 3-88. Display Controls Menu......................................................................................... 3-72

Model CAT200

vi Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 9

Model CAT200

Figure 3-89. Front Panel Control Menu.................................................................................... 3-72

Figure 3-90. Temperature Controller........................................................................................ 3-74

Figure 4-1. CAT200 Enclosure Assembly ................................................................................ 4-2

Figure 4-2. Photometer Analyzer Component Layout.............................................................. 4-8

Figure 4-3. Analyzer Component Layout ................................................................................. 4-9

Figure 4-4. Analyzer Component Layout ............................................................................... 4-10

Figure 4-5. Analyzer Component Layout ............................................................................... 4-11

Figure 4-6. Plug Locations PCB PIC...................................................................................... 4-12

Figure 4-7. Analyzer Rear Panel Layout ................................................................................ 4-14

Figure 4-8. SIO/DIO Pin Assignments (Option) (Front View Of Connectors) ........................ 4-15

Figure 4-9. Pin Assignments DC Power Connector............................................................... 4-16

Figure 4-10. TC Sensor Standard (Short) Response Time Setting ......................................... 4-17

Figure 4-11. TC Sensor Long Response Time Setting ............................................................ 4-17

Figure 4-12. Analyzer Photometer Assembly ( 2 Channel IR, Electrochemical Oxygen

Analyzer, Viewed From Top) ............................................................................... 4-19

Figure 4-13. Chopper Housing with IR Light Sources.............................................................. 4-20

Figure 4-14. Photometer Assembly (1 mm to 10 mm cells)..................................................... 4-21

Figure 4-15. Photometer Assembly (30 mm to 200 mm cells)................................................. 4-21

Figure 4-16. PCB OXS Test Points and Connections.............................................................. 4-24

Figure 4-17. Rear View of Front Panel with Oxygen Sensor ................................................... 4-24

Figure 4-18. Photometer Block Diagram.................................................................................. 4-26

Figure 4-19. PCB VVS .............................................................................................................4-27

Figure 4-20. PCB MOP ............................................................................................................ 4-28

Figure 4-21. Detector Signal .................................................................................................... 4-29

Figure 4-22. Controller Board ACU .......................................................................................... 4-31

Figure 4-23. Fuses on PCB LEM ............................................................................................. 4-32

Figure 4-24. PCB OXS Cable Connections Locations............................................................. 4-34

Figure 4-25. Power Supply Connections.................................................................................. 4-35

Figure 4-26. DIO Inductive Loads ............................................................................................ 4-36

Instruction Manual

748446-D

April 2002

LIST OF TABLES

Table 2-1. Analog Output (SIO) Terminal Assignments ......................................................... 2-9

Table 2-2. Digital Input & Output (DIO) Terminal Assignments.............................................. 2-9

Table 2-3. Relay Output Contacts (SIO) Terminal Assignments .......................................... 2-10

Table 2-4. RS232/RS485 Serial Interface (SIO) Terminal Assignments .............................. 2-10

Table 2-5. Power Connections Terminal Assignments......................................................... 2-10

Table 3-1. Available Operators ............................................................................................. 3-39

Table 3-2. Available Commands (Signal Codes 1 – 19): General Signals.......................... 3-39

Table 3-3. Available Commands (Signal Codes 20 – 39): Programmable Calculator.......... 3-39

Table 3-4. Available Commands (Signal Codes 40 – 69): Programmable Logic Controls... 3-40

Table 3-5. Available Commands (Signal Codes 70 – 89): SIO I/O Module.......................... 3-40

Table 3-6. Available Commands (Signal Codes 90 – 109): DIO I/O Module........................ 3-41

Table 3-7. Measurement Channels....................................................................................... 3-42

Table 3-8. Zero And Span Gas For Each Gas Component .................................................. 3-43

Table 3-9. Valve/Gas Sequencing ........................................................................................ 3-43

Table 3-10. Program Steps..................................................................................................... 3-43

Table 3-11. Programmable Calculator Operator Types.......................................................... 3-45

Table 3-12. Programmable Calculator Operand Types.......................................................... 3-46

Table 3-13. Programmable Calculator Program Steps........................................................... 3-47

Table 3-14. Application for Basic Controls Menu Allowable Function Variables .................... 3-49

Table 3-15. System Configuration and Diagnostic Menus Overview ..................................... 3-65

Rosemount Analytical Inc. A Division of Emerson Process Management Contents vii

Page 10

Instruction Manual

748446-D

April 2002

Model CAT200

DRAWINGS

659922 Assembly Instructions, Basic CAT200

660210 Installation Drawing, CAT200

660371 Diagram, Power Input and Ground Circuits

661581 Wiring Diagram CAT200

(LOCATED IN REAR OF MANUAL)

viii Contents Rosemount Analytical Inc. A Division of Emerson Process Management

Page 11

Instruction Manual

Model CAT200

PREFACE

The purpose of this manual is to provide information concerning the components, functions, installation and maintenance of the CAT200 .

Some sections may describe equipment not used in your configuration. The user should become

thoroughly familiar with the operation of this module before operating it. Read this instruction

manual completely.

DEFINITIONS

The following definitions apply to DANGERS, WARNINGS, CAUTIONS and NOTES found throughout

this publication.

DANGER .

Highlights the presence of a hazard which will cause severe personal injury, death, or substantial

property damage if the warning is ignored.

748446-D

April 2002

WARNING .

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in injury, death, or long-term health hazards of personnel.

CAUTION.

Highlights an operation or maintenance procedure, practice, condition, statement, etc. If not

strictly observed, could result in damage to or destruction of equipment, or loss of effectiveness.

NOTE

Highlights an essential operating procedure,

condition or statement.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-1

Page 12

Instruction Manual

748446-D

April 2002

Model CAT200

INTENDED USE STATEMENT

The CAT200 Continuous Analyzer Transmitter is intended for use as an industrial process measurement device only. It is not intended for use in medical, diagnostic, or life support applications,

and no independent agency certifications or approvals are to be implied as covering such applications.

SAFETY SUMMARY

If this equipment is used in a manner not specified in these instructions, protective systems may be

impaired.

AUTHORIZED PERSONNEL

To avoid explosion, loss of life, personal injury and damage to this equipment and on-site property,

do not operate or service this instrument before reading and understanding this instruction manual

and receiving appropriate training. Save these instructions.

DANGER.

ELECTRICAL SHOCK HAZARD

Do not open while energized. Installation requires access to live parts which can cause death or

serious injury.

For safety and proper performance this instrument must be connected to a properly grounded

three-wire source of power.

DANGER.

POSSIBLE EXPLOSION HAZARD

Do not operate without dome and covers secure. Ensure that all gas connections are made as labeled and are leak free. Improper gas connections could result in explosion and death.

P-2 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Page 13

Instruction Manual

Model CAT200

DANGER.

ELECTRICAL SHOCK HAZARD

Do not operate without dome and covers secure. Servicing requires access to live parts which can

cause death or serious injury. Refer servicing to qualified personnel. Operating personnel must

not remove instrument covers.

For safety and proper performance this instrument must be connected to a properly grounded

three-wire source of power.

WARNING.

DEVICE HAZARDOUS AREA CERTIFICATION(S)

748446-D

April 2002

Any addition, substitution, or replacement of components installed on or in this device, must be

certified to meet the hazardous area classification that the device was certified to prior to any such

component addition, substitution, or replacement. In addition, the installation of such device or

devices must meet the requirements specified and defined by the hazardous area classification of

the unmodified device. Any modifications to the device not meeting these requirements, will void

the product certification(s).

Do not open instrument when energized.

Ensure that all gas connections are made as labeled and are leak free. Improper gas connections

could result in explosion and death.

This unit’s exhaust may contain hydrocarbons and other toxic gases such as carbon monoxide.

Carbon monoxide is highly toxic and can cause headache, nausea, loss of consciousness, and

death.

WARNING: DEVICE CERTIFICATION(S)

WARNING.

POSSIBLE EXPLOSION HAZARD

WARNING

TOXIC GAS

Avoid inhalation of the exhaust gases at the exhaust fitting.

Connect exhaust outlet to a safe vent using stainless steel or Teflon line. Check vent line and connections for leakage.

Keep all tube fittings tight to avoid leaks. See Section 2-3 (page 2-12) for leak test information.

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-3

Page 14

Instruction Manual

748446-D

April 2002

DANGER

TOXIC GAS PURGE

This device may contain explosive, toxic or unhealthy gas components. Before cleaning or changing parts in the gas paths, purge the gas lines with ambient air or nitrogen.

WARNING

PARTS INTEGRITY AND UPGRADES

Tampering with or unauthorized substitution of components may adversely affect the safety of this

instrument. Use only factory approved components for repair.

Because of the danger of introducing additional hazards, do not perform any unauthorized modification to this instrument.

Contact Rosemount Analytical Inc., Customer Service Center for Return Authorization.

Model CAT200

CAUTION

PRESSURIZED GAS

This unit requires periodic calibration with a known standard gas. It also may utilizes a pressurized carrier gas, such as helium, hydrogen, or nitrogen. See General Precautions for Handling and

Storing High Pressure Gas Cylinders at the rear of this manual.

CAUTION

HEAVY WEIGHT

Use two persons or a suitable lifting device to move or carry the instrument.

P-4 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

Page 15

Instruction Manual

748446-D

Model CAT200

April 2002

GENERAL PRECAUTIONS FOR HANDLING AND STORING HIGH

PRESSURE GAS CYLINDERS

Edited from selected paragraphs of the Compressed Gas Association's "Handbook of Compressed

Gases" published in 1981

Compressed Gas Association

1235 Jefferson Davis Highway

Arlington, Virginia 22202

Used by Permission

1. Never drop cylinders or permit them to strike each other violently.

2. Cylinders may be stored in the open, but in such cases, should be protected against extremes of

weather and, to prevent rusting, from the dampness of the ground. Cylinders should be stored in the

shade when located in areas where extreme temperatures are prevalent.

3. The valve protection cap should be left on each cylinder until it has been secured against a wall or

bench, or placed in a cylinder stand, and is ready to be used.

4. Avoid dragging, rolling, or sliding cylinders, even for a short distance; they should be moved by using a

suitable hand-truck.

5. Never tamper with safety devices in valves or cylinders.

6. Do not store full and empty cylinders together. Serious suckback can occur when an empty cylinder is

attached to a pressurized system.

7. No part of cylinder should be subjected to a temperature higher than 125

never be permitted to come in contact with any part of a compressed gas cylinder.

8. Do not place cylinders where they may become part of an electric circuit. When electric arc welding,

precautions must be taken to prevent striking an arc against the cylinder.

°

F (52°C). A flame should

Rosemount Analytical Inc. A Division of Emerson Process Management Preface P-5

Page 16

Instruction Manual

748446-D

April 2002

Model CAT200

DOCUMENTATION

The following CAT200 instruction materials are available. Contact Customer Service Center or the local

representative to order (See Section 5).

748441 Instruction Manual (this document)

COMPLIANCES

This product may carry approvals from several certifying agencies. The certification marks appear on the

product name-rating plate.

Area Classifications:

USA

Class I Zone 1

AEx d e m IIB + H

T4X

2

Canada

Ex d e m IIB + H

European Union

ATEX, Category 2, Zone 1, IIB + H

USA/Canada

Certified by Canadian Standards Association, an OSHA Nationally Recognized Testing Laboratory (NRTL) for USA and Canada.

European Union

Conforms with the provisions of the EMC Directive 89/336/EEC, Low Voltage Directive 73/23/EEC, Potentially Explosive Atmospheres Directive

94/9/EC, including amendments by the CE marking Directive 93/68/EEC.

EC type Examination Certificate, LCIE 00 ATEX 6009 X.

Rosemount Analytical has satisfied all obligations from the European Legislation to harmonize the product requirements in Europe.

Australia/New Zealand

Conforms with Electromagnetic Compatibility – Generic Emission standard

and AS/NZS 4251.1 – 1994 Part 1 – Residential, commercial, and light industrial.

2

T4X

T4X

2

®

0081

EEx d e m II B (+H2) T4

LCIE 00 ATEX 6009 X

II 2 G

N96

Complies with the NAMUR RECOMMENDATION, Electromagnetic Compatibility (EMC) issue 1998.

P-6 Preface Rosemount Analytical Inc. A Division of Emerson Process Management

NAMUR

Page 17

Model CAT200

DESCRIPTION AND SPECIFICATIONS

Instruction Manual

748446-D

April 2002

SECTION 1

1-1 OVERVIEW

This manual describes the CAT200 Continuous Analyzer Transmitter.

The CAT200 is a multi-component, multimethod Continuous Gas Analyzer. Its Class I,

Zone I (IIB) + H

2

T2 X approved enclosure

makes it suitable for installation in hazardous

environments. The field mountable housing

design allows the CAT200 to be mounted

close to the process instead of in a remote

shelter. This feature greatly reduces installation and utility costs while improving process

efficiency.

The CAT200 can continuously measure 1, 2

or 3 components in a single analyzer using a

combination of Non Dispersive Infrared

(NDIR/UV/VIS), Paramagnetic Oxygen,

Thermal Conductivity, Electrochemical sensors. The CAT200 also features an optional

customized sample-handling module.

The CAT200 offers advanced menu and diagnostic functionality with the ability to network

multiple analyzers in complex process monitor

and control systems. The high speed micro-

processor architecture of the CAT200 makes

it capable of ultra low range measurements

for CO and CO

2

.

1-2 TYPICAL APPLICATIONS

The CAT200 Continuous Analyzer Transmitter

supports a variety of industry applications,

drawing on more than 40 years of development and process expertise in sensors, digital

signal processing and software technologies.

The CAT200 can satisfy the most demanding

single or multi-component analysis requirements. More than 60 gas components can be

measured including:

Carbon Monoxide (CO)

Carbon Dioxide (CO

Methane (CH

)

4

Hexane (CH equiv.) (C

Water Vapor (H

Oxygen (O

Hydrogen (H

)

2

)

2

)

2

)

6H14

O)

2

Helium (He)

Argon (Ar)

Figure 1-1. CAT200 Continuous Analyzer Transmitter

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-1

Page 18

Instruction Manual

748446-D

April 2002

Model CAT200

a. Standard Industry Applications

Petrochemical Refinery

Light Naphtha Isomerization

•

H2, CO and CO2 in make-up Hydrogen

Gas to Combined Feed

•

H2 in Scrubber Off Gas to Refinery Fuel

Gas Header

Catalytic Reforming

•

H2 in Recycle Gas from Product Sepa-

rator

•

H2 in Net Gas from Net Gas Knockout

Drum

•

H2 in CCR Nitrogen Header

•

H2 in Surge Hopper Vent

Fluidized Catalytic Cracking

•

CO and O2 Monitoring of Fluidized

Catalytic Cracking Regenerator Gas

Sulfur Recovery Units

•

Propylene in Feed to Sulfur Recovery

Plant

Petrochemical Complex

•

Ethylene in Primary and Secondary De-

Methanizer Overhead

•

CO2 in Ethane-Ethylene Splitter

•

Propylene in Splitter Bottoms

Ammonia and Urea

1-3 DETECTOR METHODOLOGIES

The CAT200 can employ up to two of four

different measuring methods depending on

the configuration chosen. The methods are:

2

NDIR, Paramagnetic O

, Electrochemical O2,

and Thermal Conductivity.

a. Non-Dispersive Infrared (NDIR)

The non-dispersive infrared method is

based on the principle of absorption of infrared radiation by the sample gas being

measured. The gas-specific wavelengths

of the absorption bands characterize the

type of gas while the strength of the absorption gives a measure of the concentration of the gas component being

measured.

An optical bench is employed comprising

an infrared light source, two analysis cells

(reference and measurement), a chopper

wheel to alternate the radiation intensity

between the reference and measurement

side, and a photometer detector. The detector signal thus alternates between concentration dependent and concentration

independent values. The difference between the two is a reliable measure of the

concentration of the absorbing gas component.

Depending on the gas being measured

and its concentration, one of two different

measuring methods may be used as follows:

•

H2, CO and CO2 in Synthesis Gas

Utilities

Interference Filter Correlation Method

With the IFC method the analysis cell is

alternately illuminated with filtered infrared

•

H2 in Cooling Gas in Turbine Generators

concentrated in one of two spectrally

separated wavelength ranges. One of

Metals

•

H2 in Endothermic Furnace

these two wavelength bands is chosen to

coincide with an absorption band of the

sample gas and the other is chosen such

All Applications

•

Continuous Emission Monitoring Sys-

that none of the gas constituents expected to be encountered in practice absorbs anywhere within the band.

tems (CEMS)

The spectral transmittance curves of the

interference filters used in the CAT200

1-2 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 19

Model CAT200

Instruction Manual

748446-D

April 2002

analyzer and the spectral absorption of

the gases CO and CO

2

are shown in

Figure 1-2 below. It can be seen that the

absorption bands of these gases each

coincide with the passbands of one of the

interference filters. The forth interference

filter, used for generating a reference signal, has its passband in a spectral region

where none of these gases absorb. Most

of the other gases of interest also do not

absorb within the passband of this reference filter.

CO

The signal generation is accomplished

with a pyroelectrical (solid-state) detector.

The detector records the incoming infrared radiation. This radiation is reduced by

the absorption of the gas at the corresponding wavelengths. By comparing the

measurement and reference wavelength,

an alternating voltage signal is produced.

This signal results from the cooling and

heating of the pyroelectric detector material

2

CO

Absorption Band

Transmittance (%)

0 15 30 54 60 75 90

Transmittance (%)

0 18 36 54 72 90

3000 3200 3400 3600 3800 4000 4200 4400 4600 4800 5000 5200 5400 5600

HC CO2 CO

Reference

Wave Length (nm)

Figure 1-2. Absorption Bands of Sample Gas and Transmittance of Interference Filters

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-3

Page 20

Instruction Manual

748446-D

April 2002

Model CAT200

b. Opto-PneumAtic Method

In the opto-pneumatic method, a thermal

radiator generates the infrared radiation

which passes through the chopper wheel.

This radiation alternately passes through

the filter cell and reaches the measuring

and reference side of the analysis cell

with equal intensity. After passing another

filter cell, the radiation reaches the pneumatic detector.

The pneumatic detector compares and

evaluates the radiation from the measuring and reference sides of the analysis

cell and converts them into voltage signals proportional to their respective intensity.

The pneumatic detector consists of a gasfilled absorption chamber and a compen-

sation chamber which are connected by a

flow channel in which a Microflow filament

sensor is mounted. This is shown in

Figure 1-3 below. In principle the detector

is filled with the infrared active gas to be

measured and is only sensitive to this distinct gas with its characteristic absorption

spectrum. The absorption chamber is

sealed with a window which is transparent

for infrared radiation. The window is usually Calcium Fluoride (CaF

2

).

When the infrared radiation passes

through the reference side of the analysis

cell into the detector, no pre-absorption

occurs. Thus, the gas inside the absorption chamber is heated, expands and

some of it passes through the flow channel into the compensation chamber.

Absorption chamber

Flow channel with

Microflow sensor

CaF2 Window

Figure 1-3. Opto-Pneumatic Gas Detector

Compensation chamber

1-4 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 21

Model CAT200

Instruction Manual

748446-D

April 2002

When the infrared radiation passes

through the open measurement side of

the analysis cell into the detector, a part

of it is absorbed depending on the gas

concentration. The gas in the absorption

chamber is, therefore, heated less than in

the case of radiation coming from the reference side. Absorption chamber gas becomes cooler, gas pressure in the

absorption chamber is reduced and some

gas from the compensation chamber

passes through the flow channel into the

absorption chamber.

The flow channel geometry is designed in

such a way that it hardly impedes the gas

flow by restriction. Due to the radiation of

the chopper wheel, the different radiation

intensities lead to periodically repeated

flow pulses within the detector.

The Microflow sensor evaluates these

flow pulses and converts them into electrical pulses which are processed into the

corresponding analyzer output.

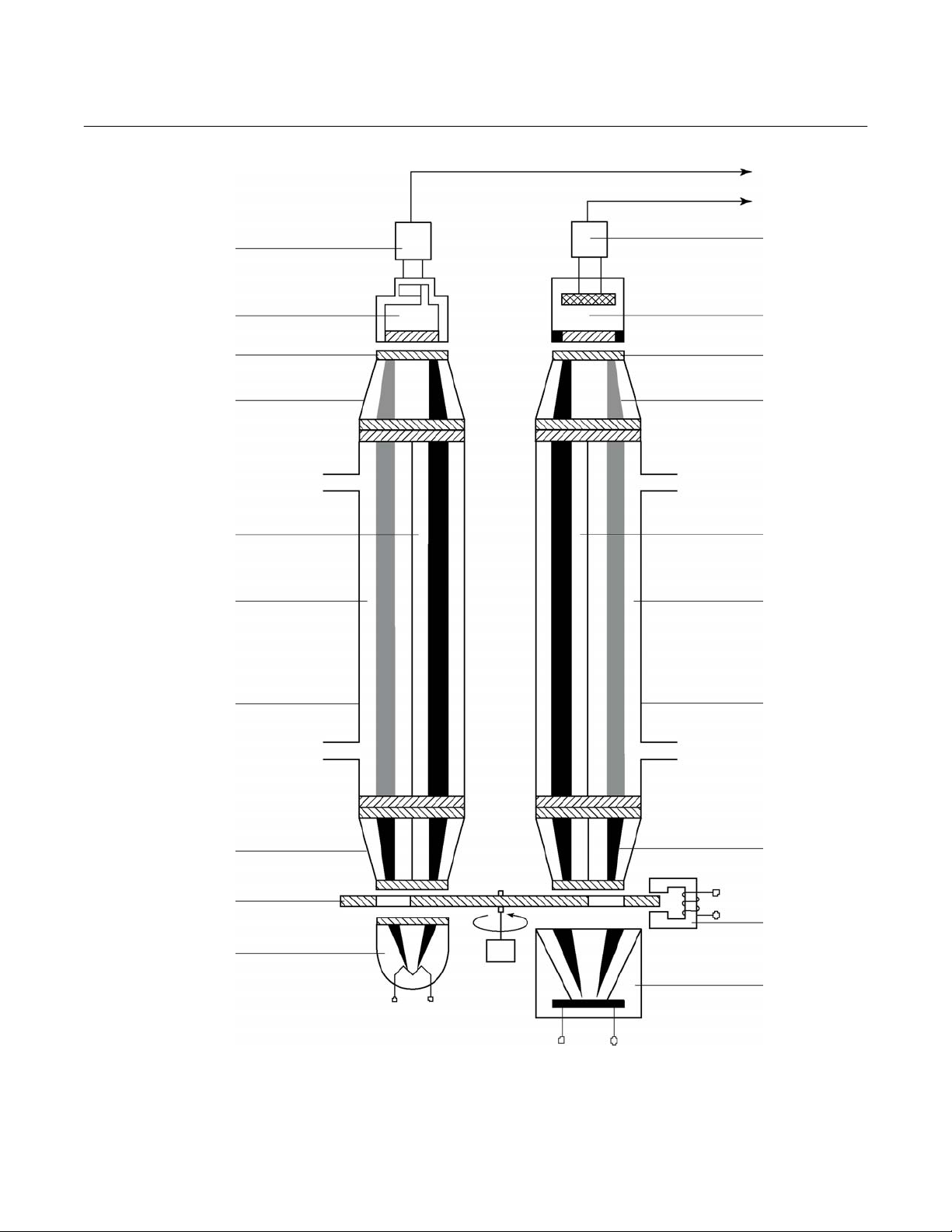

c. Overall NDIR Method

In the case of dual-channel analyzers, the

broadband emission from two infrared

sources pass through the chopper wheel.

In the case of the Interference Filter Correlation (IFC) method, the infrared radiation then passes through combinations of

interference filters. In the case of the

opto-pneumatic method, the infrared radiation passes through an optical filter

depending on the application and need for

reduction of influences. Then the infrared

radiation enters the analysis cells from

which it is focused by filter cells onto the

corresponding detector. The preamplifier

detector output signal is then converted

into the analytical results expressed directly in the appropriate physical concentration units such as percent volume,

ppm, mg/Nm

Figure 1-4 (page 1-6).

3

, etc. This is shown in

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-5

Page 22

Instruction Manual

748446-D

April 2002

Model CAT200

To electronics

Preamplifier

Pneumatic or pyroelectric detector

(solid-state detector)

window

Filter cell without dividing

wall (IFC) with optical

filters

reference side

measuring side

Preamplifier

Duplex filter disc

VIS / UV

semiconductor detector

window

Filter cell without

dividing wall (IFC)

with optical filters

reference side

measuring side

Analysis cell

Filter cell with dividing wall (IR)

Chopper blade

IR source with

reflector

Motor

Figure 1-4. Overall NDIR Method

Analysis cell

Filter cell with dividing wall (UV)

Eddy current drive

VIS / UV source

with reflector

1-6 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 23

Model CAT200

Instruction Manual

748446-D

April 2002

d. Paramagnetic Oxygen Method

The paramagnetic principle refers to the

induction of a weak magnetic field, parallel and proportional to the intensity of a

stronger magnetizing field.

The paramagnetic method of determination of oxygen concentration utilizes nitrogen filled quartz spheres arranged at

opposite ends of a bar, the center of

which is suspended by and free to rotate

on a thin platinum wire ribbon in a cell.

Nitrogen (N

2

) is used because it is dia-

magnetic or repelled by a magnet.

A small mirror that reflects a light beam

coming from a light source to a photodetector, is mounted on the platinum ribbon.

A strong permanent magnet specifically

shaped to produce a strong, highly inhomogeneous magnetic field inside the

analysis cell, is mounted outside the wall

of the cell.

When oxygen molecules enter the cell,

their paramagnetism will cause them to

be drawn towards the region of greatest

magnetic field strength. The oxygen

molecules thus exert different forces on

the two suspended nitrogen filled quartz

spheres, producing a torque which

causes the mirror to rotate away from its

equilibrium position.

The rotated mirror deflects the incident

light onto the photodetector creating an

electrical signal which is amplified and fed

back to a coil attached to the bar holding

the quartz spheres, forcing the suspended

spheres back to the equilibrium position.

The current required to generate the restoring torque to return the quartz bar to

its equilibrium position is a direct measure

of the O

2

concentration in the sample gas.

The complete paramagnetic analysis cell

consists of an analysis chamber, permanent magnet, processing electronics, and

a temperature sensor. The temperature

sensor is used to control a heat exchanger to warm the measuring gas to

about 55 °C. Refer to Figure 1-5 below.

Permanent Magnet

Platinum Wire

Mirror

Light

Source

Photodetector

Amplifier

Display

Quartz Sphere(s)

Wire Loop

Figure 1-5. Paramagnetic Oxygen Analysis

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-7

Page 24

Instruction Manual

748446-D

April 2002

Model CAT200

e. Electrochemical Oxygen Method

The electrochemical method of determining oxygen concentration is based on the

galvanic cell principle shown in Figure 1-6

below.

incorporates a lead and gold galvanic

process with a lead anode and a gold

cathode, using an acid electrolyte.

Oxygen molecules diffuse through a nonporous Teflon membrane into the electrochemical cell and are reduced at the gold

cathode. Water is the byproduct of this

reaction.

On the anode, lead oxide is formed which

is transferred into the electrolyte. The lead

anode is continuously regenerated and,

therefore, the electrode potential remains

unchanged for a long time. The rate of

diffusion and corresponding response

time (t

90

) of the sensor is dependent on

the thickness of the Teflon membrane.

The electric current between the electrodes is proportional to the O

2

concen-

tration in the sample gas being measured.

The resultant signal is measured as a

voltage across the resistor and thermistor,

the latter of which is used for temperature

compensation. A change in the output

voltage (mV) represents oxygen concentration.

NOTE

The electrochemical O

cell requires a

2

minimum internal consumption of

oxygen. Sample gases with an oxygen

concentration of less than 2% could

result in a reversible detuning of sensitivity and the output will become unstable. The recommended practice is

to purge the cell with conditioned ambient air between periods of measurement. If the oxygen concentration is

below 2% for several hours or days,

the cell must be regenerated for about

one day with ambient air. Temporary

flushing with nitrogen (N

) for less

2

than one hour (analyzer zeroing) will

have no effect on the sensitivity or

stability.

Lead Wire (Anode)

Lead Wire (Cathode)

Anode (Lead)

O-Ring

Plastic Disc

Plastic Disk

Black

Red

Resistor

Thermistor

Acid Electrolyte

Sponge Disc

Cathode (Gold Film)

Teflon Membrane

Figure 1-6. Electrochemical Oxygen Sensor

1-8 Description and Specifications Rosemount Analytical Inc. A Division of Emerson Process Management

Page 25

Model CAT200

(

)

(

)

)

)

Instruction Manual

748446-D

April 2002

Red

Thermistor (5

(-) (+)

Gold Lead

Cathode (2) Anode (1)

O2 + 4 H + 4 e → 2 H2O2 Pb + 2 H

Summary reaction O2 + 2 Pb → 2 PbO

V out

Electrolyte (3)

(ph 6)

Black

Resistor (6

O → 2PbO + 4 H + 4 e

2

Figure 1-7. Reaction of Galvanic Cell

Rosemount Analytical Inc. A Division of Emerson Process Management Description and Specifications 1-9

Page 26

Instruction Manual

748446-D

April 2002

Model CAT200

f. Thermal Conductivity Method

Thermal conductivity is an efficient

method to measure two-component gas

2

mixtures such as H

Thermal conductivity measuring cells incorporate electrically heated wires with

cooling rates that are influenced by the

sample gas in the cell. The cell combines

short response time with minimum interference, which can be effected by variations in the sample gas flow rate.

The measuring cells consist of an outer

ring enclosing a inner cylindrical chamber.

This chamber contains two lateral passages, each equipped with two thermal

sensor devices. One passage is supplied

with sample gas and the other is supplied

with an optional reference gas or a closed

loop. A variable bypass arrangement

permits adjustments of response time

versus flow rate dependence. The cell

can be set between extremes of fast response with relative high dependence on

flow rate, or low response time with least

dependence on sample flow rate by rotating the outer section with respect to the

inner section.

Both the cell volume and the mass of its

measurement resistor have been minimized on order to obtain short response

time. A nickel resistor is placed between

two superimposed square ceramic plates

which form the walls of the measurement

cell. The cell volume is approximately 1

µl. A total of four such cells are integrated

to form the sensor, two of these function

as the measurement cells, and the other

two function as the reference cells. The

latter may be either sealed off, or connected to a flow of a reference gas.

, HE, CO2 and Ar.

rounding gas to colder chamber walls. For

otherwise stable conditions, this heat absorption will be proportional to the thermal

conductivity of the gas present between

the sensor and the chamber wall. Interconnecting the four sensors into a Wheatstone bridge circuit provides an electronic

signal proportional to gas density.

The annular inner chamber is provided

with two transverse passages, each of

which is equipped with two temperature

sensors. One of these transverse passages is subjected to a flow of the sample

gas, while to other is subjected to a flow

of the reference gas (optional), or is

sealed off as a closed loop (standard version). The gas flow will distribute itself

between the transverse passages, or

between the annular grooves on the periphery of the annular chamber.

This results in a variable bypass configuration. If the transverse passages are

aligned directly opposite the gas inlet and

outlet fittings, there will result the shortest

response times and an enhanced dependence of the analytical signal upon the

sample-gas flow rate.