Rosemount BINOS 100 Series Analyzers including OXYNOS 100, HYDROS 100 and CAT 100 Addendum to ETC00781 Regarding BKS 20 Hardware Upgrade-1st Ed. Manuals & Guides

Page 1

Instruction Sheet

HAS1xE-IS-BKS

October 2004

OXYNOS® 100, HYDROS® 100, CAT 100

Instruction Manual Addendum to Manual ETC00781

Series 100 Gas Analyzers

BINOS® 100, BINOS® 100 M

BINOS® 100 2M, BINOS® 100 F

Regarding BKS 20 Hardware Upgrade

www.EmersonProcess.com

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and tests

its products to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly install, use, and

maintain them to ensure they continue to operate within their normal specifications. The

following instructions MUST be adhered to and integrated into your safety program when

installing, using and maintaining Emerson Process Management (Rosemount Analytical)

products. Failure to follow the proper instructions may cause any one of the following

situations to occur: Loss of life; personal injury; property damage; damage to this

instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the

product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• T o ensure proper performance, use qualified personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement

parts specified by Emerson Process Management (Rosemount Analytical).

Unauthorized parts and procedures can affect the product’s performance, place the

safe operation of your process at risk, and VOID YOUR W ARRANTY. Look-alike

substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place,

except when maintenance is being performed by qualified persons, to prevent

electrical shock and personal injury.

The information contained in this document is subject to change without notice.

1st edition: 2004-10

Emerson Process Management

Manufacturing GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

Instruction Sheet

HAS1xE-IS-BKS

10/2004

BKS 20 Upgrade

INTRODUCTION

The BINOS® 100 series analyzers are subject

to a consistent improvement as well as all

EMERSON PROCESS MANAGEMENT

products. Within this improvement the main

board BKS 10 was replaced by the successor

BKS 20.

Due to the short term development of this new

printed circuit board the BINOS® 100 analyzer

series instruction manual ETC00781 could not

be adapted in time. This means that all

illustrations and references within this manual

still refer to the old board.

While during operation this is not a

disadvantage, it may cause problems when

servicing and maintaining the analyzer .

For this reasons EMERSON PROCESS

MANAGEMENT has created this instruction

sheet.

This Instruction sheet is

intended to be used in

conjunction with the

BINOS® 100 analyzer series

instruction manual ETC00781

delivered together with the

analyzer.

It deals with service aspects and

replaces respectively

completes the corresponding

chapters of the original

instruction manual ETC00781.

We recommend to replace the

corresponding chapters inside the manual

by the chapters of this sheet. For this the

pages in this sheet are numbered

corresponding to the manual.

A new section is the attachment containing

block diagrams for the different analyzer

variations.

Contents

Chapter 16............... List of Failures.......................................................... Pages 16-1 to 16-8

Chapter 17............... Measuring Points ..................................................... Pages 17-1 to 17-6

Chapter 18............... Allocation of Connectors........................................... Pages 18-1 to 18-6

Chapter 19............... BKS Jumper Configuration....................................... Pages 19-1 to 19-2

Attachment............... Block Diagrams ...........................................................Pages A-1 to A-6

EMERSON Process Management Manufacturing GmbH & Co. OHG I-1

Page 4

BKS 20 Upgrade

Instruction Sheet

HAS1xE-IS-BKS

10/2004

EMERSON Process Management Manufacturing GmbH & Co. OHGI-2

Page 5

Instruction Sheet

HAS1xE-IS-BKS

10/2004

Error Code Possible Reasons Check / Correct

16. List of Failures

BKS 20 Upgrade

Some of the failures possibly coming up during

operation are reported on the displays by the

use of error codes.

In such a case the display's show the current

concentration value alternating with

(E = error , XX = code).

The following table lists all error codes, some

related reasons and measures to repair .

Error Code Possible Reasons Check / Correct

1. Displays are “switched OFF”

If there is an "error message", an optional

digital status signal "Failure" may be set

(see chapter 10.3)!

Be sure to observe the safety

measures while working at the

analyzer!

1. Press any key.

Check parameter dOFF

(see chapter 8.7).

2. Voltage supply missing

Display dark

BINOS® 100 F

3. Connection front panel /BKS

interrupted

EMERSON Process Management Manufacturing GmbH & Co. OHG 16-1

2. Check connection mains to P/S

Check external power supply

Check electrical supply

(see Fig. 1-5 and 1-6, Item 3

Fig. 1-7 to 1-9, Item 10).

Check internal fuse on board BKS

(s. page 18-1)

Check internal fuses F1 and F2

3. Check connection

BKB to BKS (X1) (see chapter 18.1).

Page 6

BKS 20 Upgrade

Error Code Possible Reasons Check / Correct

Instruction Sheet

HAS1xE-IS-BKS

10/2004

Flashing

Channel 1

Channel 2

Battery buffer failure

The EPROM default

values have been loaded

If only one code is shown:

1. A/D converter of related

channel is not driven correctly

If both codes are shown:

2. Positive or negative

reference voltage missing

Check, if Jumper J 7

is set (see chapter 19.).

Replace battery,

if battery voltage < 3,5 V

(BKS - Jumper J7 set).

The error code is cleared by pressing

any key or by serial interface

instruction $627.

1. Switch analyzer off and then on again.

2. Check reference voltage

(see chapter 17.1.2/17.1.3).

A/D Conversion Interrupt

missing

Temperature compensation

incorrect

3. Light barrier signal missing

4. IR channel:

Chopper drive inoperative

5. Supply voltage

(internal 6 V DC) missing

1. Failed to start A/Dconversion for temperature

channel

2. Supply voltage

(internal 6 V DC) absent.

3. Check connection X9 / light barrier

(see chapter 18.)

Solder bridge LB 18 not configured

properly, check measuring point (17.1.5)

4. Check connection X2 / chopper drive

(see chapter 18)

Check measuring point (17.1.4)

5. Check measuring point (17.1.1)

1. Switch analyzer off and then on again.

2. Check measuring point 17.1.1

EMERSON Process Management Manufacturing GmbH & Co. OHG16-2

Page 7

Instruction Sheet

HAS1xE-IS-BKS

10/2004

Error Code Possible Reasons Check / Correct

BKS 20 Upgrade

Channel 1

Channel 2

Tolerance error

Channel 1

Channel 2

Tolerance error

Zero gas value differs from

zero more than 10% of

measuring range .

Channel 1

Channel 2

1. Span gas in use exceeds

measuring range

1. Wrong zero gas in use.

2. IR channel:

Photometer section

contaminated.

3. Analyzer not calibrated.

1. Wrong nominal value.

2. Wrong span gas in use.

1. Check span gas in use and replace

by gas with correct nominal value

1. Check zero gas in use.

2. Check analysis cell and windows for

contamination.

Clean contaminated parts

(see chapter 24.3).

3. Switch off the tolerance check

before starting a calibration

(see chapter 8.6).

1. Enter the correct nominal value

(refer to span gas bottle certificate)

(see chapter 9.1.2).

2. Check span gas in use.

Use another or a new gas bottle.

Enter the correct nominal value

Tolerance error

Span gas value differs from

nominal value more than

10% .

Channel 1

Channel 2

Measuring value more than

10% over full scale range.

EMERSON Process Management Manufacturing GmbH & Co. OHG 16-3

3. IR channel:

Photometer section

contaminated.

4. Analyzer not calibrated.

1. Concentration of sample gas

too high.

3. Check analysis cell and windows for

contamination.

Clean contaminated parts

(see chapter 24.3).

4. Switch off the tolerance check

before starting a calibration

(see chapter 8.6).

1. Check concentration of sample gas

2. Use an analyzer suitable for

the existing concentration range

Page 8

BKS 20 Upgrade

Error Code Possible Reasons Check / Correct

Instruction Sheet

HAS1xE-IS-BKS

10/2004

Channel 1

Channel 2

Failure while entering limits

Channel 1

Channel 2

1. Absorber in NVE:

lifetime cycle ended

2. Parameter “AbS.” not set to “0”

XON (serial interface)

timed out.

wrong limit value entered due

to shift of decimal point

Wrong nominal value entered

due to shift of decimal point

1. Replace absorber. Enter menu

“SYS.-PArA” and set parameter

“AbS” to “2” (new life time cycle)

2. Enter menu “SYS.-PArA” and set

parameter “AbS.” to “0”

XON - character is missing while

driving the serial interface

(time out > 60 s).

Correct limit value in line “LI.”

1. Correct nominal value by performing

a span gas calibration

2. Correct nominal value via serial

interface by sending “$029”

Wrong nominal value entered

for span gas

Channel 1

Channel 2

Wrong offset value entered

Wrong offset value entered

due to shift of decimal point

EMERSON Process Management Manufacturing GmbH & Co. OHG16-4

1. Correct offset value “OFS.x”

Page 9

Instruction Sheet

HAS1xE-IS-BKS

10/2004

Error Code Possible Reasons Check / Correct

BKS 20 Upgrade

Pressure measurement

failure

EPROM checksum

failure

Test for SRAM - IC's

failed

1. Measuring range failure.

2. Connection faulty.

3. Pressure sensor faulty.

1. EPROM faulty.

2. BKS faulty.

SRAM IC's / BKS

faulty.

1. Pressure not within the sensor

measuring range

2. Check connection P1 (at BAF 01) /

pressure sensor (see chapter 18.).

3. Replace pressure sensor.

1. Replace EPROM (see chapter 28.).

2. Replace BKS.

Replace BKS.

Analog output signal

missing

Fluctuating or

erroneous display

BKS faulty.

1. Leakage in gas path

2. Ambient air contains gas

component to be measured

in a concentration influencing

measurement

Replace BKS.

1. Perform a leakage test

(see chapter 22)

2. Replace absorber material for IR

sources and chopper housing

Use sealed photometer (Option)

Purge analyzer with inert gas

EMERSON Process Management Manufacturing GmbH & Co. OHG 16-5

Page 10

BKS 20 Upgrade

Error Code Possible Reasons Check / Correct

Instruction Sheet

HAS1xE-IS-BKS

10/2004

Fluctuating or

erroneous display

(cont’d)

3. Gas pressure subject to

considerable variation

4. IR detector / Oxygen senor

not connected.

5. Electrochemical oxygen

sensor is weared

6. IR channel:

IR source not connected

or faulty.

3. Check the gas lines preceding and

beyond the sensor cell.

Eliminate any restrictions

beyond the gas outlet fitting.

Reduce pump rate or flow rate.

4. Check connections:

BKS X5 detector channel 1

(Oxygen sensor or IR detector)

BKS X6 detector channel 2

(IR detector)

(see 18.)

5. Replace sensor (see 25.)

6. Checkconnection:

BKS X3(1/2) - IR source channel 1

BKS X4(1/2) - IR source channel 2

(see 18.)

7. Faulty analog

preamplifying

8. Contamination of the gas

paths.

If IR source housing is cold:

For dual IR channel analyzer

interchange the two IR sources.

Replace the suspect IR source

(see 24.2).

7. Check measuring point 17.1.7 or

17.2.1 resp.

8. Check analysis cell and windows for

contamination.

Clean contaminated parts

(see 24.3).

Check gas paths for contamination.

EMERSON Process Management Manufacturing GmbH & Co. OHG16-6

Page 11

Instruction Sheet

HAS1xE-IS-BKS

10/2004

Error Code Possible Reasons Check / Correct

BKS 20 Upgrade

Fluctuating or

erroneous display

(cont’d)

Response time too long

(t

time)

90

9. Influence by barometric

pressure

10. Temperature in the gas

paths below dew point.

11. A/D converter failure

1. Incorrect response time

( t

time) settings.

90

2. Pump rate too low

9. Enter the correct value for barometric pressure (see chapter 8.1).

Pressure sensor failure (E.37).

10. Check the temperature of the gas

paths and remove any cold spots

Keep all temperatures at values at

least 10 °C above the dew point of

the gas.

11. Replace BKS.

1. Check the value for t

90

time

(see chapter 8.11).

2. The feeder line between the

sampling point and the analyzer is

too long.

Use a larger, external pump;

consider adding a bypass line to the

process stream for sampling

purposes (see chapter 5.1).

3. Contamination of the gas

paths.

3. Check gas paths and gas

conditioning for contamination.

Clean gas paths and replace the

filter elements.

EMERSON Process Management Manufacturing GmbH & Co. OHG 16-7

Page 12

BKS 20 Upgrade

Error Code Possible Reasons Check / Correct

Instruction Sheet

HAS1xE-IS-BKS

10/2004

No gas flow

1. Optional needle valve not

opened

2. Sample gas pump (Option)

is not switched on

3. Membrane of pump is

defective

4. Sample gas pump is

defective

5. Solenoid valves (Option)

defective

1. Open needle valve

(Option, see Fig. 1-2)

2. Press “PUMP” key

3. Replace membrane of the pump.

4. Replace sample gas pump

5. External valves:

Check connection between valves

and analyzer`s digitaloutputs

Valves controlled by optional serial

interface / digital inputs:

Any valve activated?

6. Contamination of gas paths

Check the valve seat of the solenoid

valves and replace if necessary.

Replace solenoid valves

6. Check gas paths including filters for

contamination.

Clean gas lines and replace

the filter elements.

EMERSON Process Management Manufacturing GmbH & Co. OHG16-8

Page 13

Instruction Sheet

HAS1xE-IS-BKS

10/2004

17 . Measuring Points of BKS and OXS

Be sure to observe the safety measures !

17.1 Measuring points of BKS

(Connector’s pins 1 on the board are identified

by a mark or a square solder pad)

All measuring points are measured against

ground (X 1 1 or X 28) !

17.1.1 Supply Voltage +6 V

BKS 20 Upgrade

Measuring point: X14

Measuring device: DVM

Signal: + 6 V DC (+10 mV / -200 mV)

(adjust with potentiometer R90, if necessary)

Failure: No signal

Possible reasons: a) Supply voltage is missing

b) Supply voltage < 9 V

or of reverse polarity

c) BKS faulty (replace)

d) Fuse F2 opened

17.1.2 Positive Reference Voltage

Measuring point: X5, pin 6

Measuring device: DVM

Signal: + 5,535 V DC (± 60 mV)

Possible reasons: a) Supply voltage (+6V) is faulty

b) Reference voltage +3 V not

correct (measure at C179,

pin 1(left pin in fig. 17-1a))

EMERSON Process Management Manufacturing GmbH & Co. OHG

Front panel side

Fig. 17-1a: PCB “BKS”, measuring points

17-1

Page 14

BKS 20 Upgrade

17.1.3 Negative Reference Voltage

Measuring point: X5, pin 4

Measuring device: DVM

Signal: inverted positive

reference voltage

The difference between negative reference

voltage and positive reference voltage must not

Instruction Sheet

HAS1xE-IS-BKS

10/2004

be more than 10 mV (U

ref. pos.

+ U

ref. neg.

!

If the difference is higher , replace BKS.

17.1.4 Temperature Sensor

Measuring point: X8

Measuring device: DVM

Signal: approx. 0 ± 500 mV DC

(at ambient temperature)

Possible reasons

- IR measurement or paramagnetic oxygen

measurement

a) Temperature sensor not connected

(see chapter 18.1).

b) Temperature sensor faulty (replace sensor).

c) Broken temperature sensor cable

≤ ± 10 mV)

(replace sensor).

d) BKS faulty (replace BKS).

- Electrochemical oxygen measurement:

a) Temperature sensor not connected

(see chapter 18.2).

b) PCB OXS faulty (replace OXS).

c) PCB BKS faulty (replace BKS).

17-2

Front panel side

Fig. 17-1b: PCB “BKS”, measuring points

EMERSON Process Management Manufacturing GmbH & Co. OHG

Page 15

Instruction Sheet

HAS1xE-IS-BKS

10/2004

17.1.5 Light Barrier Signal

Measuring point: X9, pin 2

Measuring device: Oscilloscope

Signal: square impulse, level see below

Frequency = 24 Hz (± 0,1 Hz)

Failure: No signal or incorrect measuring values

Possible reasons (IR measurement):

Expected signal level: U = 6 VSS (± 0,3 V)

BKS 20 Upgrade

a) Chopper not connected (see chapter 18.1).

b) Chopper inoperative (switch analyzer off and then on again).

c) Light barrier not connected (see chapter 18.1).

d) Light barrier defect (replace chopper)

e) Broken cable of light barrier or faulty light barrier (replace

chopper).

f) BKS faulty (replace BKS).

Possible reasons (oxygen measurement without IR channel):

Expected signal level: LOW < 0.45 V; HIGH > 2.4 V (TTL logic signal)

a) Solder bridge LB 18 not configured properly (pins 1-2 connected)

b) µP not operating (switch analyzer off and on)

c) BKS faulty (replace BKS).

EMERSON Process Management Manufacturing GmbH & Co. OHG

17-3

Page 16

BKS 20 Upgrade

17.1.6 Analog Preamplifiers

a) Paramagnetic Oxygen measurement

Measuring point: X 25 channel 1

Measuring device: DVM

Signal: At zero gas purge: 0 V dc (± 50 mV)

At ambient air (approx. 21 Vol. - % O2):

100 % O2 measuring cell: approx. 840 mV

25 % O2 measuring cell: approx. 3.36 V

Instruction Sheet

HAS1xE-IS-BKS

10/2004

Failure: No signal or incorrect measuring values.

Possible reasons: a) oxygen sensor not connected (see chapter 18.).

a) IR measurement

Measuring point: X 25 channel 1 (not for analyzer with oxygen measurement)

Measuring device: DVM

Signal: At zero gas purge: 0 V dc (± 100 mV)

Failure: No signal or incorrect measuring values.

(for identification of cell see nameplate label on cell)

b) oxygen sensor faulty (replace sensor).

c) BKS faulty (replace BKS).

X 27 channel 2

There should be a minimum difference of 600 mV

(measuring ranges < 1000 ppm difference 500 mV) between

zeropoint voltage and sensitivity voltage.

17-4

Possible reasons: a) Detector not connected (see chapter 18.).

b) Detector faulty (replace detector).

c) BKS faulty (replace BKS).

EMERSON Process Management Manufacturing GmbH & Co. OHG

Page 17

Instruction Sheet

HAS1xE-IS-BKS

10/2004

BKS 20 Upgrade

17.2 Measuring points of OXS (electrochemical oxygen measurement)

17.2.1 Sensor Signal

Measuring point: Tp 1 (Signal)

Tp 2 (

⊥⊥

⊥)

⊥⊥

Measuring device: DVM

Signal: At ambient air (approx. 21 Vol. - % O2): approx. 3.36 V (new cell)

Failure: No signal or faulty voltage

Possible reasons: a) Oxygen sensor not connected to PCB "OXS"

b) PCB “OXS” not connected / faulty

c) Oxygen sensor faulty or weared (replace)

d) BKS faulty (replace)

Note !

If the measured value is less than 2.8 V at gas flow with ambient air , the sensor is weared.

Replace the sensor.

Tp 2

Tp 1

Fig. 17-2: PCB “OXS”, assembled, horizontal projection

EMERSON Process Management Manufacturing GmbH & Co. OHG

17-5

Page 18

BKS 20 Upgrade

Instruction Sheet

HAS1xE-IS-BKS

10/2004

17-6

EMERSON Process Management Manufacturing GmbH & Co. OHG

Page 19

Instruction Sheet

HAS1xE-IS-BKS

10/2004

BKS 20 Upgrade

18. Allocation of Connectors on Printed Circuit Boards

Be sure to observe the safety measures !

18.1 BKS

X19 (+)

X20 (GND) 24 V DC power supply input

F2 Fuse for 24 V DC input

type: Wickmann 372

rating: T 4 A / 250 V

P 1 or P2 24 V DC distribution for

optional internal load

(e.g. heater for paramagn. O2 sensor)

X 1 Front panel BXF (P8)

X 16 Digital Outputs, parallel

X 18 Analog Outputs

J 9 Option BSI 10:

Status signals and

serial interface

Front panel

Fig. 18-1: PCB “BKS”, location of connectors

EMERSON Process Management Manufacturing GmbH & Co. OHG 18-1

Page 20

BKS 20 Upgrade

18.1.1 IR measurement without Oxygen Channel

X 2 Chopper

X 3 (pins 1 & 2) IR source channel 1

X 4 (pins 1 & 2) IR source channel 2

X 5 IR detector (channel 1)

X 6 IR detector (channel 2)

Instruction Sheet

HAS1xE-IS-BKS

10/2004

X 7 Temperature sensor (chopper)

X 9 Light barrier (chopper)

18.1.2 Oxygen Measurement without IR channel

X 5 Oxygen sensor (channel 1)

[ electrochemical measurement:

PCB OXS (cable P1, 5 pin connector)]

X 6 Oxygen sensor (channel 2)

[electrochemical measurement:

PCB OXS (cable P1, 5 pin connector)]

X 7 Temperature sensor

[electrochemical measurement:

PCB OXS (cable P1, 2 pin connector)]

EMERSON Process Management Manufacturing GmbH & Co. OHG18-2

Page 21

Instruction Sheet

HAS1xE-IS-BKS

10/2004

18.1.3 IR / Oxygen Measurement Combination

X 2 Chopper

X 4 (pins 1 & 2) IR source channel 2

X 5 Oxygen sensor

X 6 IR detector (channel 2)

X 7 Temperature sensor (chopper)

BKS 20 Upgrade

X 9 Light barrier (chopper)

18.1.4 TC Measurement without IR channel

In preparation !

EMERSON Process Management Manufacturing GmbH & Co. OHG 18-3

Page 22

BKS 20 Upgrade

18.1.5 IR / TC Measurement combined

X 2 Chopper

X 4 (pins 1 & 2) IR source channel 2

X 5 TC sensor (from PCB WAP 100, cable P15, 5 pin connector))

X 6 IR detector (channel 2)

Instruction Sheet

HAS1xE-IS-BKS

10/2004

X 7 Temperature sensor (chopper)

X 9 Light barrier (chopper)

18.1.6 Oxygen / TC Measurement combined

In preparation !

EMERSON Process Management Manufacturing GmbH & Co. OHG18-4

Page 23

Instruction Sheet

HAS1xE-IS-BKS

10/2004

18.2 OXS (electrochemical oxygen measurement)

Strip P2 Oxygen sensor

Cable P1, 5 pin connector PCB BKS, X 5 (sensor signal)

Cable P1, 2 pin connector PCB BKS, X 7 (temperature sensor)

(not used in combination with IR measurement)

View A: PCB OXS assembled, horizontal projection

BKS 20 Upgrade

PCB

“OXS”

Connection

View A

↓↓

↓

↓↓

Oxygen sensor

(Pin-base“P 2”)

Fig. 18-2: PCB “OXS”

Cable

“P 1”

Sensor cell

EMERSON Process Management Manufacturing GmbH & Co. OHG 18-5

Page 24

Instruction Sheet

BKS 20 Upgrade

18.3 WAP 100 (TC measurement)

P2 24 V DC supply from PCB BKS (P1 or P2)

T erminals P 18 to sensor

Cable P15, 5 - pin connector PCB BKS, X 5 (sensor signal)

P 10 PCB BSE 01 (analog input for cross compensation)

HAS1xE-IS-BKS

10/2004

P 16 sensor heater

P 10

orange

P 18

1

P 16

P 15

blue

green

1

yellow

Fig. 18-3: PCB “WAP 100”,

(principle drawing)

1

P 2

EMERSON Process Management Manufacturing GmbH & Co. OHG18-6

Page 25

Instruction Sheet

HAS1xE-IS-BKS

10/2004

19. BKS Jumper Configuration

There is only one jumper on board BKS 20:

J7, which activates battery buffering for the

SRAM data.

Opening J7 deletes all data changed by the

operator when power supply is disconnected.

The analyzer configuration in this case is reset

to default values (stored into EPROM at factory

startup).

BKS 20 Upgrade

J7 Buffer Battery

(normally closed)

Front panel

Fig. 19-1: PCB “BKS”

EMERSON Process Management Manufacturing GmbH & Co. OHG 19-1

Page 26

BKS 20 Upgrade

Instruction Sheet

HAS1xE-IS-BKS

10/2004

EMERSON Process Management Manufacturing GmbH & Co. OHG19-2

Page 27

Instruction Sheet

HAS1xE-IS-BKS

10/2004

BKS 20 Upgrade

A. ATTACHMENT

A.1 BINOS® 100 (M) / HYDROS® 100 / OXYNOS® 100 Block Diagram

X19 (+)

X20 (GND)

EMERSON Process Management Manufacturing GmbH & Co. OHG A-1

Page 28

BKS 20 Upgrade

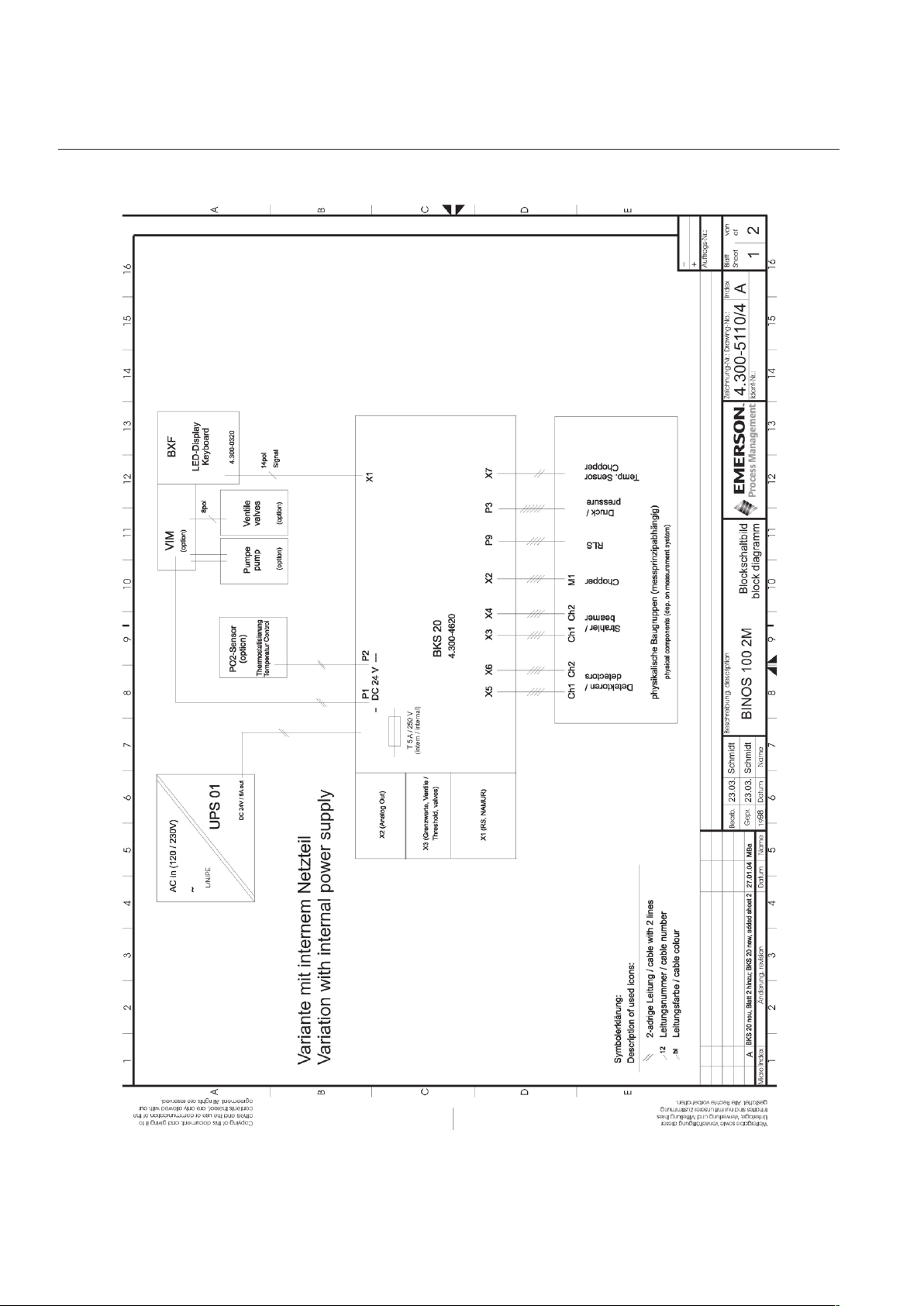

A.2 BINOS® 100 2M Block Diagram

Instruction Sheet

HAS1xE-IS-BKS

10/2004

X19 (+)

X20 (GND)

EMERSON Process Management Manufacturing GmbH & Co. OHGA-2

Page 29

Instruction Sheet

HAS1xE-IS-BKS

10/2004

BKS 20 Upgrade

X19 (+)

X20 (GND)

EMERSON Process Management Manufacturing GmbH & Co. OHG A-3

Page 30

BKS 20 Upgrade

A.3 BINOS® 100 2M for CAT Block Diagram

Instruction Sheet

HAS1xE-IS-BKS

10/2004

X19 (+)

X20 (GND)

EMERSON Process Management Manufacturing GmbH & Co. OHGA-4

Page 31

Instruction Sheet

HAS1xE-IS-BKS

10/2004

A.4 CAT 100 Block Diagram

BKS 20 Upgrade

EMERSON Process Management Manufacturing GmbH & Co. OHG A-5

Page 32

BKS 20 Upgrade

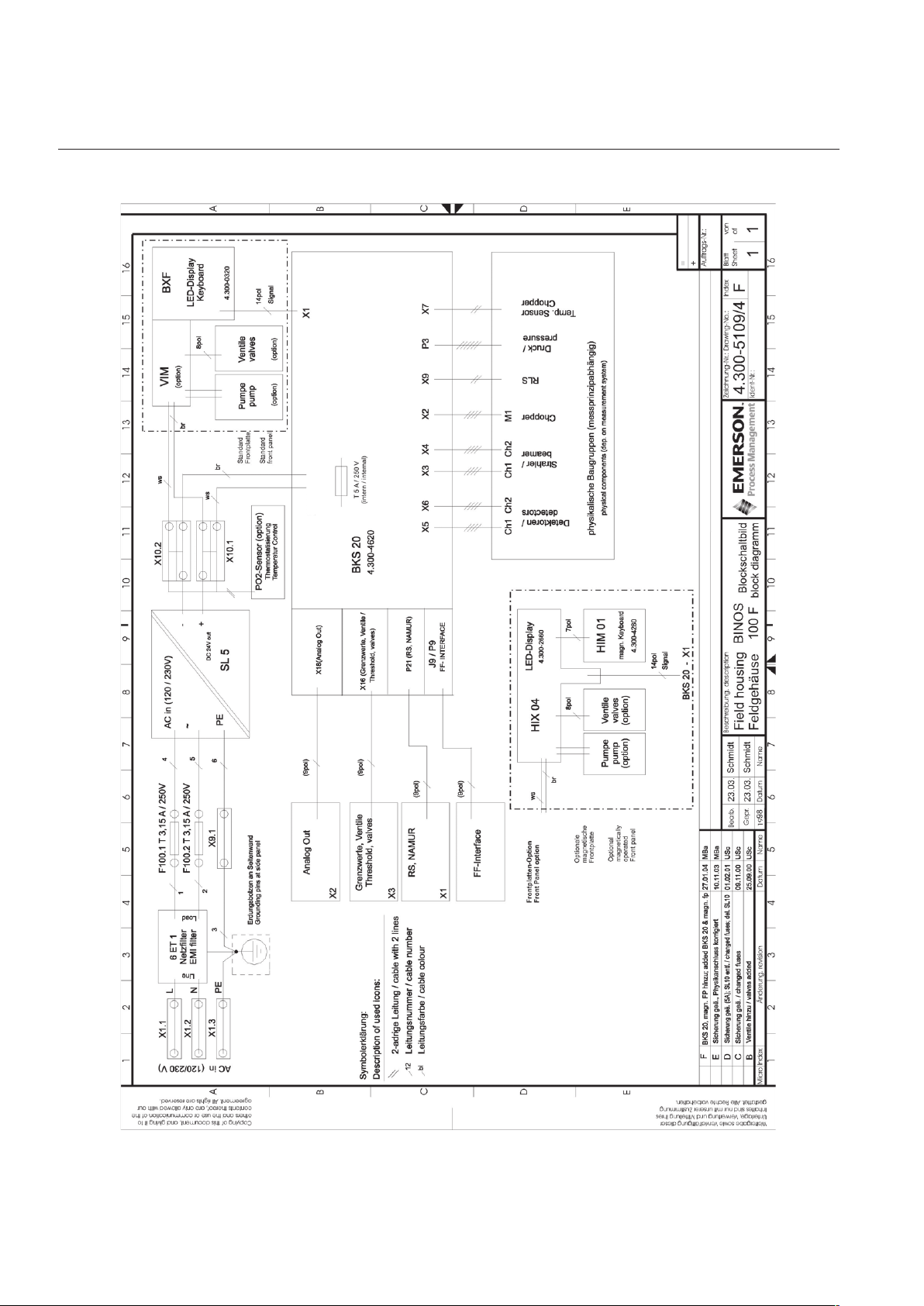

A.5 BINOS® 100 F Block Diagram

X19 (+)

X20 (GND)

Instruction Sheet

HAS1xE-IS-BKS

10/2004

EMERSON Process Management Manufacturing GmbH & Co. OHGA-6

Page 33

BKS 20 Upgrade

EUROPE

Emerson Process Management

Manufacturing GmbH & Co. OHG

Industriestrasse 1

63594 Hasselroth

Germany

T +49 (6055) 884-0

F +49 (6055) 884-209

Internet: www.emersonprocess.de

EUROPE, MIDDLE EAST , AFRICA

Emerson Process Management

Shared Services Limited

Heath Place

Bognor Regis

West Sussex PO22 9SH

England

T +44-1243-863121

F +44-1243-845354

Internet: www.emersonprocess.co.uk

Instruction Sheet

HAS1xE-IS-BKS

10/2004

NORTH AMERICA

Rosemount Analytical Inc.

Process Analytic Division

1201 N. Main St.

Orrville, OH 44667-0901

T +1 (330) 682-9010

F +1 (330) 684-4434

Internet: www.emersonprocess.com

LATIN AMERICA

Emerson Process Management Ltda

Avenida Hollingsworth, 325

Iporanga-SorocabeSP 18087-000

Brazil

T:+55 (152) 38-3788

F:+55 (152) 38-3300

Internet: www.emersonprocess.com.br

ASIA - PACIFIC

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

Tel +65 6777 8211

Fax +65 6777 0947

Internet: www.ap.emersonprocess.com

© Emerson Process Management Manufacturing GmbH & Co. OHG 2004

Loading...

Loading...