Page 1

Reference Manual

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Section 2 Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Installation Flowchart and Checklist . . . . . . . . . . . . . . . .page 2-2

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 2-4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-18

Wire the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-53

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the op erations. Please refer to

the following safety messages before performin g any op eration in thi s section.

If pipe/duct wall is less than .125” (3.2mm) use extreme caution when installing sensor. Thin

walls can deform during welding, installation, or from the weight of a cantilevered flowmeter.

These installations may require a fabricated outlet, saddle, or external flowmeter support.

Please consult factory for assistance.

Explosions could result in death or serious injury:

• Do not remove the transmitter cover in explosive atmospheres when the circuit is

live.

• Before connecting a Field Communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Both transmitter covers must be fully engaged to meet explosion-proof

requirements.

Failure to follow these installation guidelines could result in death or serious injury:

• Make sure only qualified personnel perform the installation.

www.rosemount.com

Page 2

Annubar Flowmeter Series

Start.

Unpack Instrument

Review Product

Manual.

Verify proper installation location.

Hazardous

Location?

Bench

Configure?

Review Appendix B.

See Appropriate Transmitter Manual for

Bench Configuration information.

Verify model

indicated on tag.

Remote

Mounted

Transmitter

Install T ransmitter

Install flowmeter

Wire

Remote

Mounted

Electronics?

Finish.

Install hardware

Commission the transmitter. See Appropriate

Transmitter Manual for Bench Configuration

information.

Reference Manual

00809-0100-4809, Rev CB

March 2012

INSTALLATION

FLOWCHART AND

CHECKLIST

Figure 2-1. Installation Chart

Figure 2-1 is an installation flowchart that provides guidance through the

installation process. Following the figure, an installation checklist has been

provided to verify that all critical steps have been taken in the installation

process. The checklist numbers are indicated in the flowchart.

2-2

Page 3

Reference Manual

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

The following list is a summary of the steps required to complete a flowmeter

installation. If this is a new installation, begin with step 1. If the mounting is

already in place, verify that the hole size and the fittings match the

recommended specifications (see Table 2-3 on page 2-19) and begin with

step 5.

1. Determine where the flowmeter is to be placed within the piping

system.

2. Establish the proper orientation as determined by the intended

application.

3. Review Appendix B: Approvals and determine if the flowmeter is

located in a hazardous location.

4. Confirm the configuration.

5. Drill the correct sized hole into the pipe and deburr. Do not torch-cut

holes.

6. For instruments equipped with opposite-side support, drill a second

hole 180° from the first hole.

7. Weld the mounting per plant welding procedures .

8. Measure the pipe’s internal diameter (ID), preferably at 1 x ID from

the hole (upstream or downstream).

NOTE

To maintain published flowmeter accuracy, provide the pipe ID when

purchasing the flowmeter.

9. Check the fit-up of the instrument assembly to the pipe.

10. Install the flowmeter.

11. Wire the instrument.

12. Supply power to the flowmeter.

13. Perform a trim for mounting effects.

14. Check for leaks.

15. Commission the instrument.

2-3

Page 4

Annubar Flowmeter Series

MOUNTING

Tools and Supplies Tools required include the following:

• Open end or combination wrenches (spanners) to fit the pipe fittings

and bolts:

• Adjustable wrench: 15-in. (1½-in. jaw).

• Nut driver:

• Phillip’s screwdriver: #1.

• Standard screwdrivers: ¼-in., and

• Pipe wrench: 14-in.

• Wire cutters/strippers

7

•

/16-in. box wrench (required for the ferry head bolt design)

Supplies required include the following:

• ½-in. tubing or ½-in. pipe (recommended) to hook u p the el ectr onics to

the sensor probe. The length required depends upon the dist ance

between the electronics and the sensor.

• Fittings including (but not limited to)

• Two tube or pipe tees ( for steam or high temperature liquid) and

• Six tube/pipe fittings (for tube)

• Pipe compound or PTFE tape (where local piping codes allow).

9

/16-in., 5/8-in., 7/8-in.

3

/8-in. for vent/drain valves (or 3/8-in. wrench).

1

/8-in. wide.

Reference Manual

00809-0100-4809, Rev CB

March 2012

Mounting Brackets Mounting brackets are provided with any flowmeter order with a remote

mounted transmitter to facilitate mounting t o a panel, wall , or 2-in. (5 0 .8 mm)

pipe. The bracket option for use with the Coplanar flange is 316 SST with 316

SST bolts.

When installing the transmitter to one of the mounting brackets, torque the

bolts to 125 in-lb (169 n-m).

Bolt Installation

Guidelines

The following guidelines have been established to ensure a tight flange,

adapter, or manifold seal. Only use bolts supplied with the instrument or sold

by the factory.

The instrument is shipped with the coplanar flange installed with four 1.75-in.

(44.5 mm) flange bolts. The following bolts also are supplied to facilitate other

mounting configurations:

• Four 2.25-in. (57.2 mm) manifold/flange bolts for mou nting the coplanar

flange on a three-valve manifold. In this configuration, the 1.75-in. (44.5

mm) bolts may be used to mount the flange adapter s to the process

connection side of the manifold.

• (Optional) If flange adapters are ordered, four 2.88-in. (73.2 mm)

flange/adapter bolts for mounting the flange adapters to the coplanar

flange.

2-4

Page 5

Reference Manual

Carbon Steel Head

Markings (CS)

Stainless Steel Head

Markings (SST)

B7M

316

316

R

B8M

STM

316

316

SW

316

1.75 (44) ⫻ 4

2.88 (73) ⫻ 4

1.75 (44) ⫻ 4

2.25 (57) ⫻ 4

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Stain less steel bolts supplied by Rosemount Inc. are co ated with a lubricant to

ease installation. Carbon steel bolts do not require lubrication. Do not apply

additional lubricant when installing either type of bolt. Bolts supplied by

Rosemount Inc. are identified by the following head markings:

Figure 2-2. Coplanar Mounting

Bolts and Bolting Configurations

for Coplanar Flange.

Transmitter with Optional

Transmitter with

Flange Bolts

Description Size in. (mm)

Flange bolts (4) 1.75 -in. (44 mm)

Flange/adapter bolts (4) 2.88 -in. (73 mm)

Manifold/flange bolts (4) 2.25 -in. (57 mm)

Flange Adapters and

Flange/Adapter Bolts

Transmitter with 3-Valve

Manifold, Manifold/Flange

Bolts, Flange Adapters,

and Flange/Adapter bolts

Instrument Manifolds Figure 2-3 on page 2-6 identifies the valves on a 5-valve and a 3-valve

manifold. Table 2-1 on page 2-6 explains the purpose of these valves.

An instrument manifold is recommended for all installations. A manifold allows

an operator to equalize the pressures prior to the zero calibration of the

transmitter as well as to isolate the electronics from the rest of the system

without disconnecting the impulse piping. Although a 3-valve manifold can be

used, a 5-valve manifold is recommended.

5-valve manifolds provide a positive method of indicating a partially closed or

faulty equalizer valve. A closed faulty equalizer valve will block the DP signal

and create errors that may not be detectable otherwise. The labels for each

valve will be used to identify the proper valve in the procedures to follow.

NOTE

Some recently-designed instrument manifolds have a single valve actuator,

but cannot perform all of the functions available on standard 5-valve units.

Check with the manufacturer to verify the functions that a particular manifold

can perform. In place of a manifold, individual valves may be arranged to

provide the necessary isolation and equalization functions.

2-5

Page 6

Annubar Flowmeter Series

To PH To PL

MH

MV

ML

DVLDVH

MELMEH

2

1

To PH To PL

MH

ME

ML

DVLDVH

2

1

Figure 2-3. Valve Identification

for 5-valve and 3-Valve

Manifolds

Reference Manual

00809-0100-4809, Rev CB

March 2012

5-Valve Manifold 3-Valve Manifold

Table 2-1. Description of

Impulse Valves and

Components

Name Description Purpose

Manifold and Impulse Pipe Valves

PH Primary Sensor – High Pressure Isolates the flowmeter sensor from the

PL Primary Sensor – Low Pressure

DVH Drain/Vent Valve – High Pressure Drains (for gas service) or vents (for liquid or

DVL Drain/Vent Valve – Low Pressure

MH Manifold – High Pressure Isolates high side or low side pressure from

ML Manifold – Low Pressure

MEH Manifold Equalizer – High Pressure Allows high and low pressure side access to

MEL Manifold Equalizer – Low Pressure

ME Manifold Equalizer Allows high and low side pressure to equalize

MV Manifold Vent Valve Vents process fluid

Components

1 Transmitter Reads Differential Pressure

2 Manifold

3 Vent Chambers Collects gases in liquid applications.

4 Condensate Chamber Collects condensate in gas applications.

impulse piping system

steam service) the DP electronics chambers

the process.

the vent valve, or for isolating the process fluid

Isolates and equalizes transmitter

2-6

Page 7

Reference Manual

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Straight Run

Requirements

Table 2-2. Straight Run

Requirements

Use the following to aid in determining the straight run requirements

In Plane____________Out of Plane

1

Single Elbow

Single Elbow with Straightening Vanes

2

Double Elbows in plane

Plane A

Upstream Dimensions

Without

Straightening

Vanes

In

Out of

Plane A

8

10

—

—

11

16

—

—

With Straightening

Vanes

A’ C C’ B

—

—

8

4

—

—

8

4

Downstream

Dimensions

—

4

4

4

—

4

4

4

Double Elbow in plane with

Straigthening Vanes

3

Double Elbows out of plane

23—28

—

—

—

4

—

8

4

4

4

Double Elbows out of plane with

Straightening Vanes

2-7

Page 8

Annubar Flowmeter Series

Reference Manual

00809-0100-4809, Rev CB

March 2012

In Plane____________Out of Plane

4

Reducer

Reducer with Straightening Vanes

5

Expander

Upstream Dimensions

Without

Straightening

Vanes

In

Plane A

Out of

Plane A

12—12

18—18

With Straightening

Vanes

A’ C C’ B

—

—

8

—

—

8

Downstream

Dimensions

—

—

4

4

4

4

—

—

4

4

4

4

Expander with Straightening Vanes

6

Valve

30—30

—

—

—

—

8

4

4

Valve with Straightening Vanes

NOTE

• If proper lengths of straight run are not available, position th e mounting

such that 80% of the run is upstream and 20% is downstream.

• “In Plane A” means the sensor is in the same plane as the elbow. “Out

of Plane A” means the sensor is perpendicular to the plane of the

elbow.

• The information contained in this manual is applicable to cir cula r pipe s

only. Consult the factory for instructions regarding use in square or

rectangular ducts.

• Straightening vanes may be used to reduce the required straight

run length.

• Row 6 in Table 2-2 applies to gate, globe, plug, and other throttling

valves that are partially opened, as well as control valves.

4

4

2-8

Page 9

Reference Manual

Transmitter

Annubar

Sensor

Mounting

Hardware

(Annubar Type)

Annubar

Sensor

Transmitter

Mounting

Hardware

(Annubar Type)

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

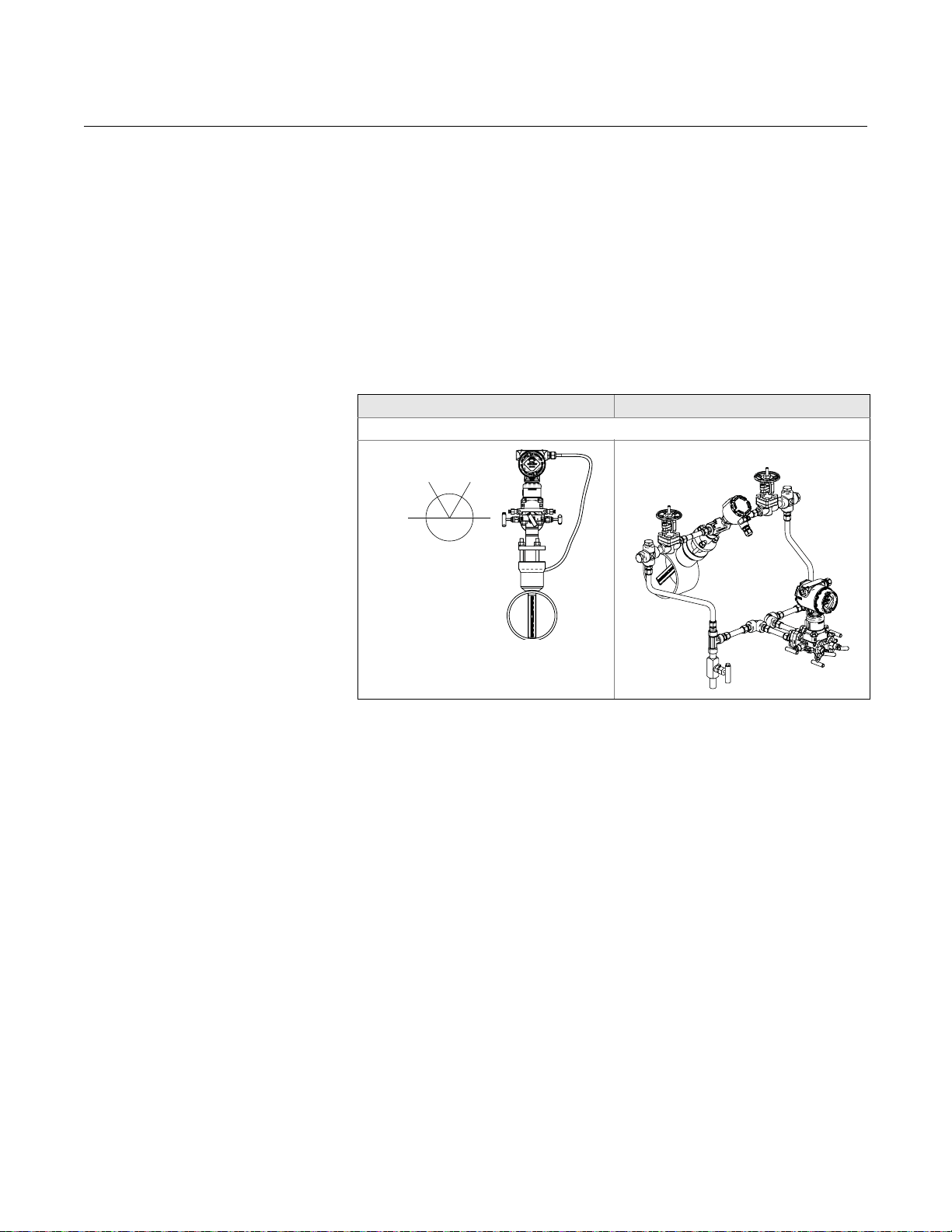

Figure 2-4. Mounting

Configuration

Integral Mount Remote Mount

NOTE

The direct-mounted flowmeter is usually shipped with the transmitter

assembled to the sensor, unless it is ordered with a Remote-mount

Transmitter Connection Platform.

2-9

Page 10

Annubar Flowmeter Series

30°

Recommended

Zone 30°

Recommended

Zone 30°

45° 45°

360°

Flow

Note: Downward flow is not recommended.

Flowmeter Orientation Liquid

Due to the possibility of air getting trapped in the Annubar sensor , it should

be located according to Figure 2-5 for liquid applications. It should be

mounted between 15° to 45° from vertical down to ensure that air is vented

from the Annubar , and that sediment or solid particle s are not collect within

the Annubar.

For liquid applications, mou nt the side drain/vent valve up ward to allow the

gases to vent. In vertical lines, the Annubar sensor can be installed in any

position around the circumference of the pipe, provided the vents are

positioned properly for bleeding or venting. Vertical pipe installations

require more frequent bleeding or venting, depe nding on the location.

For a remote mounted transmitter, mount the transmitter below the

process piping, adjust 10° to 15° above direct vertical down. Route the

impulse piping down to the transmitter and fill the system with cool water

through the two cross fittings.

Reference Manual

00809-0100-4809, Rev CB

March 2012

Figure 2-5. Liquid Applications

Direct Mount

Horizontal Liquid Vertical Liquid

Remote Mount

Horizontal Liquid Vertical Liquid

2-10

Page 11

Reference Manual

45°45°

Recommended

Zone 90°

360°

Flow

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Gas

Figure 2-6 illustrates the recommended location of the flowmeter in gas

applications. The sensor should be located on the upper half of the pipe, at

least 45° above the horizontal line.

For gas applications, mount the drain/vent valve downward to allow liquid

to drain. In vertical lines, the Annubar sensor can be installed in any

position around the circumference of the pipe, provided the vents are

positioned properly for bleeding or venting. Vertical pipe installations

require more frequent bleeding or venting, depe nding on the location.

For a remote mounted transmitter, secure the transmitter above the

Annubar sensor to prevent condensable liquids from collecting in the

impulse piping and the DP cell.

Figure 2-6. Gas Applications

Direct Mount

Horizontal Gas Vertical Gas

Remote Mount

Horizontal Gas Vertical Gas

2-11

Page 12

Annubar Flowmeter Series

30°

Recommended

Zone 30°

Recommended

Zone 30°

45° 45°

360°

Flow

Steam

In steam applications, fill the lines with water to prevent the steam from

contacting the transmitter. Condensate chambers are not required

because the volumetric displacement of the transmitter is negligible.

For a remote mounted transmitter, mount the transmitter below the

process piping, adjust to 10° to 15° above direct vertical down. Route the

impulse piping down to the transmitter and fill the system with cool water

through the two cross fittings.

Figure 2-7 illustrates the recommended location of the flowmeter in steam

applications.

Reference Manual

00809-0100-4809, Rev CB

March 2012

Figure 2-7. Steam Applica tions

Direct Mount

Horizontal Steam Vertical Steam

Note: Downward flow is not recommented.

Remote Mount

Horizontal Steam Vertical Steam

2-12

Page 13

Reference Manual

60°

Recommended Zone

60° 60°

00809-0100-4809, Rev CB

March 2012

Figure 2-8. Top Mounting for

Steam

Annubar Flowmeter Series

Top Mounting for Steam

This orientation can be used for any steam temperature. However, it is

recommended for installations above 600 °F (315 °C). For remote mount

installations, the impulse piping should slope up slightly from the instrument

connections on the Annubar to the cross fittings, allowing condensate to drain

back into the pipe. From the cross fittings, the impulse piping should be ro uted

downward to the transmitter and the drain legs. The transmitter should be

located below the instrument connections of the Annubar. Depending on the

environmental conditions, it may be necessary to insulate the mounting

hardware. The temperature limit for top mountin g a Dire ct Mou nt flowme ter is

400 °F (205 °C).

Direct Mount Remote Mount

Horizontal Top Mounting for Steam

Remote Mounted

Transmitter

NOTE

For wet steam, do not mount the flowmeter at the

direct vertical position. Mounting at an angle will

avoid measurement inaccuracy due to water

running along the bottom of the pipe.

Instrument head connections differ between horizo nt al and vertical pipes. For

horizontal lines, the instrument connections are parallel to the pipe and for

vertical lines, the instrument connection ar e pe rp e ndi cu lar.

Valves and Fittings

Throughout the remote mounting process:

• Use only valves, fittings, and pipe thread sealant compounds that are

rated for the service pipeline design pressure and temperature as

specified in Appendix A: Specifications and Reference Data.

• Verify that all connections are tight and that all instrument valves are

fully closed.

• Verify that th e Annubar sensor is properly oriented for the intended type

of service: liquid, gas, or steam (see “Flowmeter Orientation” on

page 2-10).

2-13

Page 14

Annubar Flowmeter Series

Impulse Piping

Impulse piping connects a remote mounted tra nsmitter to the Annubar se nsor .

Temperatures in excess of 250 °F (121 °C) at the transmitter will damage

electronic components; impulse piping allows service flow temperatures to

decrease to a point where the transmitter is no longer vulnerable.

The following restrictions and recommendations apply to impulse piping

location.

• Piping used to connect the Annubar sensor and transmitter must be

rated for continuous operation at the pipeline-designed pressure and

temperature.

• Impulse piping that runs horizontally must slope at least 1–in. per foot

(83 mm/m).

• With the Annubar mounted below the pipe, impulse piping must slope

downwards (toward the transmitter) for liquid and steam applications.

• With the Annubar mounted above the pipe, impulse piping must slope

up (toward from the transmitter) for gas and top mount steam

applications.

• For applications where the pipeline temperature is below 250 °F

(121 °C), the impulse piping should be as short as possible to minimize

flow temperature changes. Insulation may be required.

• For applications where pipeline temperature is above 250 °F (121 °C),

the impulse piping should have a minimum length of 1-ft. (0.30 m) for

every 100 °F (38 °C) over 250 °F (121 °C), which is the maximum

operating transmitter temperature. Impulse piping must be uninsulated

to reduce fluid temperature. All threaded connections should be

checked after the system comes up to temperature, beca u se

connections may be loosened by the expansion and contraction

caused by temperature changes.

• A minimum of

with a wall thickness of at least 0.035-in. is recommended.

• Outdoor installations for liquid, saturated gas, or steam service may

require insulation and heat tracing to preven t fre e zing .

• For installations where the transmitter is more than 6-ft. (1.8m) from the

Annubar sensor, the high and low impulse piping must be run together

to maintain equal temperature. They must be supported to prevent

sagging and vibration.

• Threaded pipe fittings are not recomme nded because they create voids

where air can become entrapped and have more possibilities for

leakage.

• Run impulse piping in protected areas or against walls or ceilings. If the

impulse piping is run across the floor, ensure that it is protected with

coverings or kick plates. Do not locate the impulse piping near high

temperature piping or equipment.

• Use an appropriate pipe sealing compound rated for the service

temperature on all threaded connections. When making threaded

connections between stainless steel fittings, Loctite

recommended.

Reference Manual

00809-0100-4809, Rev CB

March 2012

1

/2-in. (12mm) outer diameter (OD) stainless steel tubing

®

PST® Sealant is

2-14

Page 15

Reference Manual

Recommended Zone

30°

360°

Flow

00809-0100-4809, Rev CB

March 2012

Flo-Tap Models

Figure 2-9. Gas Service Gas

Annubar Flowmeter Series

Direct Mount

Horizontal Gas Vertical Gas

Remote Mount

Horizontal Gas Vertical Gas

2-15

Page 16

Annubar Flowmeter Series

30°

Recommended Zone

360°

Flow

Note: Downward flow is not recommented.

Liquid

Reference Manual

00809-0100-4809, Rev CB

March 2012

Figure 2-10. Liquid Service

Direct Mount

Horizontal Liquid Vertical Liquid

Remote Mount

Horizontal Liquid Vertical Liquid

2-16

Page 17

Reference Manual

30°

Recommended Zone

Flow

360°

Note: Downward flow is not recommented.

60°

Recommended Zone

60° 60°

00809-0100-4809, Rev CB

March 2012

Figure 2-11. Steam Steam

Annubar Flowmeter Series

Direct Mount

Horizontal Steam Vertical Steam

Remote Mount

Horizontal Steam Vertical Steam

Figure 2-12. Top Mounting for

Steam

Direct Mount Remote Mount

Horizontal Top Mounting for Steam

Note

For wet steam, do not mount the flowmeter at the

direct vertical position. Mounting at an angle will

avoid measurementinaccuracy due to water

running along the bottom of the pipe.

2-17

Page 18

Reference Manual

Transmitter

Compression Plate

Coplanar

Flange

with Drain

Vents

O-Rings (2)

485 Annubar Sensor

Retaining Ring

Direct Mount Transmitter

Connection with Valves

Studs

Pak-Lok Body

Packing Rings (3)

Follower

Nuts

Transmitter and

housing are shown for

clarity purposes – only

supplied if ordered.

00809-0100-4809, Rev CB

Annubar Flowmeter Series

March 2012

INSTALLATION This manual contains the horizonta l and vertical installation procedures for the

Pak-Lok, Flanged, Flange-Lok, Threaded Flo-Tap, Flanged Flo-tap, and Main

Steam Annubar models.

Pak-Lok Annubar Type

(for 485 Annubar

Flowmeters)

Figure 2-13. Components

Figure 2-13 identifies the components of the Pak-Lok assembly.

2-18

Step 1: Determine the Proper Orientation

Please refer to “Mounting” on page 2-4 for straight run requirements and

orientation information.

Page 19

Reference Manual

P/N: 28-109001-922 Rev. AC

Drill to Hole Size

Drill the appropriate

diameter hole through

the pipe wall.

Note: Drill the hole 180°

from the first hole for

opposite- side support

models.

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Step 2: Drill a Hole into the Pipe

1. Determine the drill hole size based on the Sensor Size of Sensor

Width.

2. Determine the sensor size based on the width of the Annubar. See

Table 2-3.

3. From the previous steps, select the location to drill the hole.

4. Determine the diameter of the hole to be drilled according to the

specifications in Table 2-3 and drill the hole with a hole saw or drill.

Do not torch cut the hole.

Table 2-3. 485 Sensor Size /

Hole Diameter Chart

Sensor

Size

Sensor Width Hole Diameter

1 0.590-in.

(14.99 mm)

2 1.060-in.

(26.92 mm)

3 1.935-in.

(49.15 mm)

3

/4-in.

(19 mm)

15/16-in.

(34 mm)

21/2-in.

(64 mm)

+ 1/32-in (0.8 mm)

– 0.00

+ 1/16-in. (1.6 mm)

– 0.00

+ 1/16-in. (1.6 mm)

– 0.00

5. If opposite-side support coupling is supplied, a second identically

sized hole must be drilled opposite the first hole so that the sensor

can pass completely through the pipe. (To determine an opposite-side

support model, measure the distance from the tip of the first slot or

hole. If the distance is greater than 1-in. (25.4 mm), it is the

opposite-side model.) To drill the second hole, follow these steps:

a. Measure the pipe circumference with a pipe tap e, sof t wire, or string

(for the most accurate measurement the pipe tape needs to be

perpendicular to the axis of flow).

b. Divide the measured circumference by two to determin e the location

of the second hole.

c. Rewrap the pipe tape, soft wire, or string from the center of the first

hole. Then, using the number calculated in the preceding step, mark

the center of what will become the second hole.

d. Using the diameter determined from Table 2-3, drill the hole into the

pipe with a hole saw or drill. Do not torch cut the hole.

6. Deburr the drilled hole(s) on the inside of the pipe.

2-19

Page 20

Annubar Flowmeter Series

LMH

(1)

Tack

Welds

Serial No. Date

Model

Customer T ag

Pipe I.D. Wall

Max. Allow FlowRate

Max. Insert/Retract Flow

Max. Press. @ Temp

Span (20mA)

00-370000-2X1 Rev. AC

Step 3: Weld the Mounting Hardware

1. Center the Pak-Lok body over the mounting hole, gap

and place four

2. Check alignment of the Pak-Lok body both p arallel a nd perpendicu lar

to the axis of flow. If alignment of mounting is within tolerances (see

Figure 2-14), finish weld per local codes. If alignment is outside of

specified tolerance, make adjustments prior to finish weld.

Figure 2-14. Alignment

Reference Manual

00809-0100-4809, Rev CB

1

1

/4-in. (6-mm) tack welds at 90° increments.

/16-in. (1.5 mm)

March 2012

3. If opposite side support is being used, center the fitting for the

1

opposite side support over the opposite side hole, gap

1

mm) and place four

/4-in. (6 mm) tack welds at 90° increments. Insert

/16-in. (1.5

the sensor into the mounting hardware. Verify that the tip of the bar is

centered in the opposite side fitting and verify that the plug will fit

around bar . If the ba r is cen tered in the fitting and plug fits around the

bar, finish weld per local cod es. If the alignment of the bar does not

allow enough clearance to insert the opposite side plug, make the

necessary adjustments prior to making the finish weld.

4. To avoid serious burns, allow the mounting hardware to cool before

continuing.

Step 4: Insert Annubar

After the mounting hardware has cooled, use the following steps for

installation.

1. Thread studs into the Pak-Lok body.

2. To ensure that the flowmeter contacts the opposite side wall, mark the

tip of the sensor with a marker. (Do not mark if the sensor was

ordered with special-cleaned option code P2 or PA.)

3. Insert the flowmeter into the Pak-lok body until the sensor tip contact s

the pipe wall (or support plug). Rotate the flowmeter back and forth.

4. Remove the flowmeter.

2-20

Page 21

Reference Manual

Packing Rings (3)

Retaining Ring

Compression Plate

Follower

1. Install the first Packing Ring underneath

the Follower.

2. Use the Follower and the Compression

Plate to compress the first Packing

Ring against the Retaining Ring.

3. Install the second Packing Ring

underneath the Follower. Alternate

packing ring splits by 120 degrees to

each other.

4. Use the Follower and the Compression

Plate to compress the second Packing

Ring against the first Packing Ring.

5. Install the third Packing Ring

underneath the Follower.

6. Use the Follower and the Compression

Plate to compress the third Packing

00809-0100-4809, Rev CB

March 2012

Figure 2-15. Packing Ring Detail

Annubar Flowmeter Series

5. Verify that the sensor tip made co nt act with the pipe wall by removing

the pipe and ensuring that some of the marker has been rubbed off.

For special-cleaned Annubar sensors, look for wear marks on the tip.

If the tip did not touch the wall, verify pipe dimensions and the height

of mounting body from the outer diameter of the pipe and re-insert.

6. Align the flow arrow with the direction of flow. Re-insert the flowmeter

into the Pak-Lok body and install the first packing ring on the sensor

between the lock ring and the packing follower. Take care not to

damage the split packing rings.

7. Push the packing ring into the Pak-Lok body and against the weld

lock ring. Repeat this process for the two remaining rings, alternating

the location of the packing ring split by 180°.

8. Tighten the nuts onto the studs:

• Place the included split-ring lock washer between each of the nuts

and the compression plate. Give each nut one half (

succession until the split-ring lock washer is flat between the nut

NOTE

On sensor size (1), failure to use the split-ring lock washers, improper wash er

orientation, or over-tightening the nuts may result in damage to the flowmeter.

and the compression plate.

Sensor Size Torque

• Inspect the unit for leakage; if any exists, tighten the nuts in

one-quarter (

1 40-in. / lb (4.52 Nm)

2 100-in. / lb (11.30 Nm)

3 250-in. / lb (28.25 Nm)

1

/4) turn increments until there is no leakage.

1

/2) turn in

2-21

Page 22

Annubar Flowmeter Series

Before Tightening After Tightening

Split ring

lock washer

Nut

Stud

Compression

Plate

Split ring

lock washer

Nut

Stud

Compression

Plate

GAP

WELD RING

FOLLOWER

(3) P ACKING

RINGS

Figure 2-16. Split-Ring Lock

Washer Orientation

NOTE

Pak-Lok sealing mechanisms generate significant force at the poin t where the

sensor contacts the opposite pipe wall. Caution needs to be exercised on

thin-walled piping (ANSI Schedule 10 and below) to avoid damage to the

pipe.

Reference Manual

00809-0100-4809, Rev CB

March 2012

Figure 2-17. Complete

installation of Pak-lok

Figure 2-17 shows a view of the Pak-lok Annubar when installation is

completed. Please note that there should be a gap between the Pak-lok Body

and the Weld Ring.

Step 5: Mount the Transmitter

Direct Mount Head

With Valves

• Place PTFE O-rings into grooves on the face of head.

• Align the high side of the transmitter to the high side of the pr ob e

(“Hi” is stamped on the side of the head) and install.

• Tighten the nuts in a cross pattern to 400 in-lb (45 N-m).

2-22

Page 23

Reference Manual

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Without Valves

• Place PTFE O-rings into grooves on the face of head.

• To install a manifold, orient the equalizer valve or valves so they are

easily accessible. Install manifold with the smooth face mating to the

face of the head. Tighten in cross pattern to a torque of 400 in-lb (45

N-m).

• Place PTFE O-rings into grooves on the face of the manifold.

• Align the high side of the transmitter to the high side of the pr ob e

(“Hi” is stamped on the side of the head) and install.

• Tighten the nuts in a cross pattern to 400 in-lb (45 N-m).

2-23

Page 24

Annubar Flowmeter Series

Transmitter

Sensor Flange

Coplanar Flange with

Drain Vents

O-Rings (2)

485 Annubar Sensor

Mounting Flange Assembly

Direct Mount Transmitter

Connection with Valves

Studs

Gasket

Nuts

Opposites Side Support

Transmitter and housing

are shown for clarity

purposes – only supplied

if ordered.

Reference Manual

00809-0100-4809, Rev CB

March 2012

Flanged with Opposite

Side Support Annubar

Type (for 485 and 585

Annubar Flowmeters)

Figure 2-18. Components

Figure 2-18 identifies the components of the Flanged assembly.

Step 1: Determine the Proper Orientation

Please refer to “Mounting” on page 2-4 for straight run requirements and

orientation information.

2-24

Page 25

Reference Manual

Drill the appropriate

diameter hole through

the pipe wall.

Note: Drill the hole 180°

from the first hole for

opposite- side support

models.

Drill the appropriate

diameter hole through

the pipe wall.

Note: Drill the hole 180°

from the first hole for

opposite- side support

models.

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Step 2: Drill a Hole into the Pipe

1. Determine the drill hole size based on the Sensor Size of Sensor

Width.

2. Depressurize and drain the pipe.

3. From the previous steps, select the location to drill the hole.

4. Determine the diameter of the hole to be drilled according to the

specifications in Table 2-1 and drill the hole with a hole saw or a drill.

Do not torch cut the hole.

Table 2-1. 485 Sensor Size/

Hole Diameter Chart

Table 2-2. 585 Sensor Size/

Hole Diameter Chart

SensorSize Sensor Wid th Hole Diameter

3

1 0.590-in.

(14.99 mm)

2 1.060-in.

(26.92 mm)

3 1.935-in.

(49.15 mm)

Sensor Size Sensor Width Hole Diameter

11 0.80-in.

(20.32 mm)

22 1.20-in.

(30.48 mm)

44 2.30-in. 2

(58.42 mm)

/4-in.

(19 mm)

15/16-in.

(34 mm)

1

/2-in.

2

(64 mm)

7

/8-in.

(23 mm)

15/16-in.

(34 mm)

1

/2-in. +

(64 mm)

+ 1/32-in (0.8 mm)

– 0.00

+ 1/16-in. (1.6 mm)

– 0.00

+ 1/16-in. (1.6 mm)

– 0.00

1

+

/32-in (0,8 mm)

– 0.00

+ 1/16-in. (1,6 mm)

– 0.00

1

/16-in. (1,6 mm)

– 0.00

5. If opposite-side support coupling is supplied, a second identically

sized hole must be drilled opposite the first hole so that the sensor

can pass completely through the pipe. To drill the second hole, follow

these steps:

a. Measure the pipe circumference with a pipe tap e, sof t wire, or string

(for the most accurate measurement the pipe tape needs to be

perpendicular to the axis of flow).

b. Divide the measured circumference by two to determin e the location

of the second hole.

c. Rewrap the pipe tape, soft wire, or string from the center of the first

hole. Then, using the number calculated in the preceding step, mark

the center of what will become the second hole.

d. Using the diameter determined from Table 2-1, drill the hole into the

pipe with a hole saw or drill. Do not torch cut the hole.

6. Deburr the drilled holes on the inside of the pipe.

2-25

Page 26

Annubar Flowmeter Series

The

same

within

1

/8-in.

(3 mm)

Pipe Outside

Diameter

Port A

Port B

ODF

Step 3: Assemble and check Fit-Up

For accurate measurement, use the following step s to ensure that Port s A and

B are equal distances from the inside walls of the pipe.

1. Assemble the Annubar sensor to the mounting hardware with the

gaskets and bolts.

2. Hand tighten the bolts just enough to hold the position of the sensor

centered in the mounting hardware.

3. Measure the distance from the high point of the weldolet to the first

sensing hole, port B, then subtract

4. Measure the distance from the end of the transferred length in step 3

to the last sensing hole, port A.

5. Compare the numbers obtained in steps 3 and 4.

Small discrepancies can be compensated for with the fit-up of the mounting

hardware. Large discrepancies may cause installation problems or error.

Figure 2-19. Fit-up Check for

Annubar with Opposite Side

Support

Reference Manual

00809-0100-4809, Rev CB

1

/16-in. (1.6 mm).

March 2012

2-26

Step 4: Weld the Mounting Hardware

1. Center the Flanged body over the mounting hole, gap

and measure the distance from the out side diameter of the pipe to the

face of the flange. Compare this to the table below and adjust the gap

as necessary.

1

/16-in. (1.5 mm)

Page 27

Reference Manual

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Table 2-3. 485 and 585 Flange Sizes and ODF Per Sensor Size

485 Sensor

Size

(1) Tolerances for the ODF dimension above a 10-in. (254 mm) line size is ±0.060-in. (1,6 mm). Below

585 Sensor

Size

1 11

2 22

3 44

10-in. (254 mm) line size is ±0.030-in. (0,8 mm).

Flange Type Pressure Class

A 1 11/2-in. 150# RF 3.88 (98.6)

R 1 11/2-in. 150# RTJ 4.06 (103.1)

D 1 DN40 PN16 RF 3.21 (81.5)

A 1 2.0-in. 150# RF 4.13 (104.9)

R 1 2.0-in. 150# RTJ 4.31 (119.5)

D 1 DN50 PN16 RF 3.40 (86.4)

A 1 3.0-in. 150# RF 4.63 (117.6)

R 1 3.0-in. 150# RTJ 4.81 (122.2)

D 1 DN80 PN16 RF 3.85 (97.8)

Flange Size / Rating

/ Type

3 11/2-in. 300# RF 4.13 (104.9)

6 11/2-in. 600# RF 4.44 (112.8)

N / 9 11/2-in. 900# RF 4.94 (125.5)

F 11/2-in. 1500# RF 4.94 (125.5)

T 11/2-in. 2500# RF 6.76 (171.7)

3 11/2-in. 300# RTJ 4.31 (109.5)

6 11/2-in. 600# RTJ 4.44 (112.8)

N / 9 11/2-in. 900# RTJ 4.94 (125.5)

F 11/2-in. 1500# RTJ 4.94 (125.5)

T 11/2-in. 2500# RTJ 6.81 (173.0)

3 DN40 PN40 RF 3.21 (81.5)

6 DN40 PN100 RF 3.88 (98.6)

3 2.0-in. 300# RF 4.38 (111.3)

6 2.0-in. 600# RF 4.75 (120.7)

N / 9 2.0-in. 900# RF 5.88 (149.4)

F 2.0-in. 1500# RF 5.88 (149.4)

T 3.0-in. 2500# RF 9.88 (251.0)

3 2.0-in. 300# RTJ 4.63 (117.6)

6 2.0-in. 600# RTJ 4.81 (122.2)

N 2.0-in. 900# RTJ 5.94 (150.9)

F 2.0-in. 1500# RTJ 5.94 (150.9)

T 3.0-in. 2500# RTJ 10.00 (254.0)

3 DN50 PN40 RF 3.52 (89.4)

6 DN50 PN100 RF 4.30 (109.5)

3 3.0-in. 300# RF 5.00 (127.0)

6 3.0-in. 600# RF 5.38 (136.7)

N / 9 4.0-in. 900# RF 8.19 (208.0)

F 4.0-in. 1500# RF 8.56 (217.4)

T 4.0-in. 2500# RF 11.19 (284.2)

3 3.0-in. 300# RTJ 5.25 (133.4)

6 3.0-in. 600# RTJ 5.44 (138.2)

N / 9 4.0-in. 900# RTJ 8.25 (209.6)

F 4.0-in. 1500# RTJ 8.63 (219.2)

T 4.0-in. 2500# RTJ 11.38 (289.1)

3 DN80 PN40 RF 4.16 (105.7)

6 DN80 PN100 RF 4.95 (125.7)

ODF in. (mm)

(1)

2. Place four 1/4-in. (6-mm) tack welds at 90° increments. Check

alignment of the mounting both parallel and perpendicular to the axis

of flow (see Figure 2-20). If alignment of the mounting is within

tolerances, finish weld per local codes. If alignment is outside of

specified tolerance, make adjustments prior to making the finish weld.

2-27

Page 28

Annubar Flowmeter Series

ODF

Tack Welds

Figure 2-20. Alignment

Reference Manual

00809-0100-4809, Rev CB

March 2012

3. Center the fitting for the opposite side support over the opposite side

1

hole, gap

/16-in. (1.5 mm) and place four 1/4-in. (0.5 mm) tack welds at

90° increments. Insert the sensor into the mounting hardware. Verify

that the tip of the bar is centered in the opposite side fitting and that

the plug will fit around bar. If the sensor is centered in the fitting and

plug fits around the sensor, finish weld per local codes. If alignment of

the sensor does not allow enough clearance to insert the opposite

side plug, make the necessary adjustments prior to making the finish

weld.

4. To avoid serious burns, allow the mounting hardware to cool

before continuing.

Step 5: Insert the Annubar Sensor

1. If opposite side support is threaded, apply an appropriate thread

sealing compound to the support plug threads and tighten until no

leakage occurs.

2. Align the flow arrow on the head with the direction of flow. Assemble

the Annubar to the mounting flange using a gasket, bolts, and nuts.

3. If opposite side support is a socket weld fitting, insert the plug into the

1

sockolet fitting until the parts contact. Retract the plug

/16-in. (1.5

mm), remove the Annubar sensor and apply fillet weld per local

codes.

4. Tighten the nuts in a cross pattern to allow even compression of the

gasket.

2-28

Step 6: Mount the Transmitter

Direct Mount Head

With Valves

1. Place PTFE O-rings into grooves on the face of head.

2. Align the high side of the transmitter to the high side of the probe

(“Hi” is stamped on the side of the head) and install.

3. Tighten the nuts in a cross pattern to 400 in-lb (45 N-m).

Page 29

Reference Manual

Transmitter

Compression Plate

Coplanar Flange with

Drain Vents

O-Rings (2)

485 Annubar Sensor

Flange-Lok Assembly

Direct Mount Transmitter

Connection with Valves

Studs

Gasket

Nuts

Mounting Flange Assembly

Packing Rings (3)

Follower

Transmitter and housing

are shown for clarity

purposes – only supplied if

ordered.

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Without Valves

1. Place PTFE O-rings into grooves on the face of head.

2. To install a manifold, orient the equalizer valve or valves so they are

easily accessible. Install manifold with the smooth face mating to the

face of the head. Tighten in cross patte rn to a torque of 400 in-lb (45

N-m).

3. Place PTFE O-rings into grooves on the face of the manifold.

4. Align the high side of the transmitter to the high side of the probe

(“Hi” is stamped on the side of the head) and install.

5. Tighten the nuts in a cross pattern to 400 in-lb (45 N-m).

Flange-Lok Model (for

485 Annubar

Flowmeters)

Figure 2-21. Components

Figure 2-21 identifies the components of the Flange-L ok assembly.

2-29

Page 30

Annubar Flowmeter Series

Drill the appropriate

diameter hole through

the pipe wall.

Note: Drill the hole 180°

from the first hole for

opposite- side support

models.

Step 1: Determine the Proper Orientation

Please refer to “Mounting” on page 2-4 for straight run requirements and

orientation information.

Step 2: Drill a Hole into the Pipe

1. Determine the drill hole size based on the Sensor Size of Sensor

Width.

2. Depressurize and drain the pipe.

3. Select the location to drill the hole.

4. Determine the diameter of the hole to be drilled according to the

specifications in Table 2-4 and drill the hole with a hole saw or a drill.

Do not torch cut the hole.

Reference Manual

00809-0100-4809, Rev CB

March 2012

Table 2-4. Drill Hole into Pipe

SensorSize Sensor Width Hole Diameter

3

1 0.590-in.

(14.99 mm)

2 1.060-in.

(26.92 mm)

3 1.935-in.

(49.15 mm)

/4-in.

(19 mm)

15/16-in.

(34 mm)

1

/2-in.

2

(64 mm)

+ 1/32-in (0.8 mm)

– 0.00

+ 1/16-in. (1.6 mm)

– 0.00

+ 1/16-in. (1.6 mm)

– 0.00

5. If opposite-side support coupling is supplied, a second identically

sized hole must be drilled opposite the first hole so that the sensor

can pass completely through the pipe. (To determine an opposite-side

support model, measure the distance from the tip of the first slot or

hole. If the distance is greater than 1-in. (25.4 mm), it is the

opposite-side model.) To drill the second hole, follow these steps:

a. Measure the pipe circumference with a pipe tap e, sof t wire, or string

(for the most accurate measurement the pipe tape needs to be

perpendicular to the axis of flow).

b. Divide the measured circumference by two to determin e the location

of the second hole.

c. Rewrap the pipe tape, soft wire, or string from the center of the first

hole. Then, using the number calculated in the preceding step, mark

the center of what will become the second hole.

d. Using the diameter determined from Table 2-4, drill the hole into the

pipe with a hole saw or drill. Do not torch cut the hole.

6. Deburr the drilled hole or holes on the inside of the pipe.

2-30

Page 31

Reference Manual

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Step 3: Weld the Mounting Hardware

1. Center the Flange-Lok body over the mounting hole, gap

mm) and measure the distance from the OD of the pipe to the face of

the flange. Compare this to the table below and adjust the gap as

necessary.

Table 2-5. 485 and 585 Flange Sizes and ODF Per Sensor Size

Flange Size / Rating

485 Sensor Size Flange Type Pressure Class

1 A 1 11/2-in. 150# RF 3.88 (98.6)

3 11/2-in. 300# RF 4.13 (104.9)

6 11/2-in. 600# RF 4.44 (112.8)

N 11/2-in. 900# RF 4.94 (125.5)

F 11/2-in. 1500# RF 4.94 (125.5)

T 11/2-in. 2500# RF 6.76 (171.7)

R 1 11/2-in. 150# RTJ 4.06 (103.1)

3 11/2-in. 300# RTJ 4.31 (109.5)

6 11/2-in. 600# RTJ 4.44 (112.8)

N 11/2-in. 900# RTJ 4.94 (125.5)

F 11/2-in. 1500# RTJ 4.94 (125.5)

T 11/2-in. 2500# RTJ 6.81 (173.0)

D 1 DN40 PN16 RF 3.21 (81.5)

3 DN40 PN40 RF 3.21 (81.5)

6 DN40 PN100 RF 3.88 (98.6)

2 A 1 2.0-in. 150# RF 4.13 (104.9)

3 2.0-in. 300# RF 4.38 (111.3)

6 2.0-in. 600# RF 4.75 (120.7)

N 2.0-in. 900# RF 5.88 (149.4)

F 2.0-in. 1500# RF 5.88 (149.4)

T 3.0-in. 2500# RF 9.88 (251.0)

R 1 2.0-in. 150# RTJ 4.31 (119.5)

3 2.0-in. 300# RTJ 4.63 (117.6)

6 2.0-in. 600# RTJ 4.81 (122.2)

N 2.0-in. 900# RTJ 5.94 (150.9)

F 2.0-in. 1500# RTJ 5.94 (150.9)

T 3.0-in. 2500# RTJ 10.00 (254.0)

D 1 DN50 PN16 RF 4.63 (117.6)

3 DN50 PN40 RF 5.00 (127.0)

6 DN50 PN100 RF 5.38 (136.7)

3 A 1 3.0-in. 150# RF 4.63 (117.5)

3 3.0-in. 300# RF 5.00 (126.9)

6 3.0-in. 600# RF 5.38 (136.6)

R 1 3.0-in. 150# RTJ 4.81 (122.2)

3 3.0-in. 300# RTJ 5.25 (133.4)

6 3.0-in. 600# RTJ 5.44 (138.2)

D 1 DN80 PN16 RF 3.85 (97.8)

3 DN80 PN40 RF 4.16 (105.7)

6 DN80 PN100 RF 4.95 (125.7)

(1) Tolerances for the ODF dimension above a 10-in. (254 mm) line size is ±0.060-in. (1,6 mm).

Below 10-in. (254 mm) line size is ±0.030-in. (0,8 mm).

/ Type

1

/16-in. (2

ODF in. (mm)

(1)

2-31

Page 32

Annubar Flowmeter Series

ODF

Tack Welds

2. Place four 1/4-in. (6-mm) tack welds at 90° increments. Check

alignment of the mounting both parallel and perpendicular to the axis

of flow (see Figure 2-22). If alignment of the mounting is within

tolerances, finish weld per local codes. If outside of specified

tolerance, make adjustments prior to making the finish weld.

Figure 2-22. Alignment

Reference Manual

00809-0100-4809, Rev CB

March 2012

3. If opposite side support is being used, center the fitting for the

1

opposite side support over the opposite side hole, gap

1

mm) and place four

/4-in. (6-mm) tack welds at 90° increments. Insert

/16-in. (1.5

the sensor into the mounting hardware. Verify that the tip of the bar is

centered in the opposite side fitting and that the plug will fit around the

bar. If the sensor is centered in the fitting and plug fits around the

sensor, finish weld per local codes. If alignment of the sensor does

not allow enough clearance to insert the opposite side plug, make the

necessary adjustments prior to making the finish weld. The Annubar

sensor must be removed before welding or installing the opposite

side support plug.

4. To avoid serious burns, allow the mounting hardware to cool

before continuing.

Step 4: Insert into Pipe

1. After the mounting hardware has cooled, use the following steps for

installation.

2. Assemble the sensor flange to the mounting flange using gasket,

studs, and nuts.

3. Tighten the nuts in a cross pattern to allow even compression of

the gasket.

4. Thread studs into Flange-Lok body.

5. To ensure that the flowmeter contacts the opposite side wall, mark the

tip of the sensor with a marker. (Do not mark if the sensor was

ordered with special-cleaned option code P2 or PA.)

6. Insert the flowmeter into the Flange-lok body until the sensor tip

contacts the pipe wall (or support plug), rotating back and forth.

7. Remove the flowmeter.

2-32

Page 33

Reference Manual

Packing Rings (3)

Retaining Ring

Compression Plate

Follower

00809-0100-4809, Rev CB

March 2012

Figure 2-23. Packing Ring Detail

Annubar Flowmeter Series

8. Verify that the sensor tip made contact with the pipe wall by ensuring

that some of the marker has been rubbed off. For special-cleaned

bars, look for wear marks on the tip. If the tip did not touch the wall,

verify pipe dimensions and the height of the mounting body from the

OD of the pipe and re-insert.

9. Re-insert the flowmeter into the Flange-Lok body and install the first

packing ring on the sensor between the lock ring and the packing

follower. Take care not to damage the split packing rings.

10. Push the packing ring into the Flange-Lok body and against the weld

retaining ring. Repeat this process for the two remaining rin gs,

alternating the location of the packing ring split b y 180°.

11. Tighten the nuts onto the studs:

a. Place the included split-ring lock washer between each of the nuts

1

and the compression plate. Give each nut one half (

/2) turn in

succession until the split-ring lock washer is flat between the nut

and the compression plate. Torque is as follows:

Sensor Size Torque

1 40-in. / lb (4.52 Nm)

2 100-in. / lb (11.30 Nm)

3 250-in. / lb (28.25 Nm)

b. Inspect the unit for leakage; if any exists, tighten the nuts in

1

one-quarter (

/4) turn increments until there is no leakage.

NOTE

On sensor size (1), failure to use the split-ring Lock washers, improper

washer orientation, or over-tightening the nuts may result in damage to the

flowmeter.

2-33

Page 34

Annubar Flowmeter Series

Before Tightening After Tightening

Split ring

lock washer

Nut

Stud

Compression

Plate

Split ring

lock washer

Nut

Stud

Compression

Plate

GAP

WELD RING

FOLLOWER

(3) P ACK ING

RINGS

Figure 2-24. Split-Ring Lock

Washer Orientation

NOTE

Flange-Lok sealing mechanisms generate significant force at the po int wh ere

the sensor contacts the opposite pipe wall. Caution needs to be exercised on

thin-walled piping (ANSI Schedule 10 and below) to avoid damage to the

pipe.

Figure 2-25. Complete

installation of Flange-lok

Reference Manual

00809-0100-4809, Rev CB

March 2012

2-34

Figure 2-25 shows a view of the Flange-lok Annubar when installation is

completed. Please note that there should be a gap between the Flange-lok

Body and the Weld Ring.

Page 35

Reference Manual

Transmitter

Temperature Sensor

Connection Housing

Direct Mount Transmitter

Connection with Valves

Cage Nipple

O-Rings (2)

Head Plate

Drive Rods

Threaded

Pipe Fitting

Guide Nipple

Isolation Valve

Support Plate

Packing Gland

Packing

Follower

Compression

Plate

Coplanar Flange

with Drain Vents

Transmitter and

housing are shown

for clarity purposes

– only supplied if

ordered.

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Step 5: Mount the Transmitter

Direct Mount Head

With Valves

1. Place PTFE O-rings into grooves on the face of head.

2. Align the high side of the transmitter to the high side of the Annubar

(“Hi” is stamped on the side of the head) and install.

3. Tighten the nuts in a cross pattern to 400 in-lb (45 N-m).

Without Valves

1. Place PTFE O-rings into grooves on the face of head.

2. To install a manifold, orient the equalizer valve or valves so they are

easily accessible. Install manifold with the smooth face mating to the

face of the head. Tighten in cross patte rn to a torque of 400 in-lb (45

N-m).

3. Place PTFE O-rings into grooves on the face of the manifold.

4. Align the high side of the transmitter to the high side of the Annubar

(“Hi” is stamped on the side of the head) and install.

5. Tighten the nuts in a cross pattern to 400 in-lb (45 N-m).

Threaded Flo-Tap (for

485 Annubar Flowmeter)

Figure 2-26. Components

Figure 2-26 identifies the components of the Threaded Flo- Tap assembly.

2-35

Page 36

Annubar Flowmeter Series

LMH

Tack

Weld

Step 1: Determine the Proper Orientation

Please refer to “Mounting” on page 2-4 for straight run requirements and

orientation information.

Step 2: Weld the Mounting Hardware

NOTE

Rosemount-supplied mounting includes critical alignment hardware that

assists in the correct drilling of the mounting hole. This significantly reduces

problems encountered during insertion.

1. At the pre-determined position, pl ace the threadolet on the pipe, gap

1

/16 in. (16 mm) and place four 1/4-in. (6-mm) tack welds at 90°

increments.

2. Check alignment of the mounting both parallel and perpendicular to

the axis of flow. If the mounting alignment is within tolerances, finish

weld per local codes. If outside of tolerances, make adjustments prior

to making the finish weld.

3. To avoid serious burns, allow mounting hardware to cool before

continuing.

Reference Manual

00809-0100-4809, Rev CB

March 2012

Figure 2-27. Alignment

Step 3: Install the Isolation Valve

1. Thread the guide nipple into the mounting.

2. Thread the isolation valve into the guide nipple, ensuring that the

valve stem is positioned so that when the Flo-Tap is installed, the

insertion rods will straddle the pipe and the valve handle will be

centered between the rods (see Figure 2-28).

NOTE:

Interference will occur if the valve is located inline with the insertion rods.

2-36

Page 37

Reference Manual

Isolation Valve

Pressure

Drilling

Machine

Isolation Valve is

fully open when

inserting drill

Isolation Valve is

fully closed after

withdrawing drill

00809-0100-4809, Rev CB

March 2012

Figure 2-28. Install the Isolation

Valve

Annubar Flowmeter Series

Step 4: Mount the Drilling Machine and Drill Hole

Drilling Machine is not provided with the assembly.

1. Determine the drill hole size based on the sensor size or sensor

width.

2. Mount the drilling machine to the isolation valve.

3. Open the valve fully.

4. Drill the hole into the pipe wall in accordance with the instructions

provided by the drilling machine manufacturer.

5. Fully retract the drill beyond the valve.

Table 2-6. Sensor Size / Hole

Diameter Chart

Sensor

Size

1 0.590-in.

2 1.060-in.

3 1.935-in.

Sensor

Width

(14.99 mm)

(26.92 mm)

(49.15 mm)

Hole Diameter

3

/4-in.

(19 mm)

15/16-in.

(34 mm)

1

/2-in.

2

(64 mm)

+ 1/32-in

(0.8 mm)

– 0.00

+ 1/16-in.

(1.6 mm)

– 0.00

+ 1/16-in.

(1.6 mm)

– 0.00

Step 5: Remove the Drilling Machine

Follow these steps to remove the drilling machine:

1. Verify that the drill has been fully retracted past the valve.

2. Close the isolation valve to isolate the process.

3. Bleed drilling machine pressure and remove.

4. Check isolation valve and mounting for leakage.

2-37

Page 38

Annubar Flowmeter Series

Isolation Valve

Support Plate

Step 6: Mount the Annubar

1. Install the complete Flo-Tap assembly (fully retracted) onto the

isolation valve by threading the close nipple into the valve using the

proper thread sealant compound.

2. Rotate the Flo-Tap assembly until the flow arrow on the head aligns

with the direction of flow in the pipe.

3. Ensure that the vent valves are closed before proceeding to the

next step.

4. Quickly open and close the isolation valve to pressurize the Annub ar.

Use extreme caution if the flowing medium is steam or caustic.

5. Check the entire installation for leakage. Tighten as required to stop

any connection from leaking. Repeat steps 4 and 5 until there is no

leakage.

a. If the Flo-tap comes equipped with the gear drive option, place the

NOTE

Flo-Tap Annubars have the potential to carry a large amount of weight at a

great distance from the piping, necessitating external support. The support

plate has threaded holes to assist in supporting the Annubar. Threaded holes

(3/8"-16 UNC) are provided on the support plate for external support.

Reference Manual

00809-0100-4809, Rev CB

March 2012

PVC protector rod assembly over the drive rods and attach to the

gear drive with the supplied hardware.

Figure 2-29. Flo-Tap Installation

2-38

Page 39

Reference Manual

Drive

Nuts

Lock

Nuts

Drive

Lock

Pin

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Step 7: Insert the Annubar

Insert the sensor with one of the two drive options available – manual drive

(M) or gear drive (G).

Manual (Not recommended for line sizes above 12 inches (300 mm))

1. Open the isolation valve fully.

2. Rotate drive nuts clockwise (as viewed from the top) as shown in

Figure 2-29. The nuts must be tightened alternately, about two turns

at a time to prevent binding caused by unequal loading.

3. Continue this procedure until the tip of the probe firmly contacts the

opposite side of the pipe.

a. The orange stripes are a visual indication of when the sensor is

approaching the opposite side wall.

b. As the orange stripe approaches the support plate, place a finger

above the packing gland while cranking.

1

c. Turn the drive nuts an additional

Gear Drive (G)

/4 to 1/2 turn to secure the sensor.

Figure 2-30. Insert Annubar

1. Fully open the isolation valve.

2. Rotate the crank clockwise. If a power drill with an adapter is used, do

not exceed 200 rpm.

a. Continue rotating the crank until the sensor firmly contacts the

opposite side of the pipe. The orange stripes are a visual in dication

of when the sensor is approaching the opposite side wall.

b. As the orange stripes approach the support plate, remove the

power drill and continue cranking manually. Place a finger above

the packing gland while cranking. When the movement stops, the

sensor is in contact with the opposite side wall.

1

c. Turn the handle an additional

/4 to 1/2 turn to secure the sensor.

3. Secure the drive by inserting the drive lock pin as shown in

Figure 2-30.

NOTE:

Do not place a finger above the packing gland for high temperature

applications.

Manual Drive (M) Gear Drive (G)

2-39

Page 40

Annubar Flowmeter Series

Step 8: Mount the Transmitter

Direct Mount Head

With Valves

1. Place PTFE O-rings into grooves on the Annubar head.

2. Align the high side of the transmitter to the high side of the se ns or

(“Hi” is stamped on the side of the head) and install.

3. Tighten the nuts in a cross pattern to 400 in•lb (45 N•m).

Without Valves

1. Place PTFE O-rings into grooves on the Annubar head.

2. To install a manifold, orient the equalizer valve or valves so they are

easily accessible. Install manifold with the smooth face mating to the

face of the head. Tighten in cross pattern to a torque of 400 in•lb (45

N•m).

3. Place PTFE O-rings into grooves on the face of the manifold.

4. Align the high side of the transmitter to the high side of the probe

(“Hi” is stamped on the side of the head) and install.

Reference Manual

00809-0100-4809, Rev CB

March 2012

Tighten the nuts in a cross pattern to 400 in-lb (45 N-m).

Step 9: Retract the Annubar

Manual Drive (M)

1. Retract by rotating the drive nuts counter-clockwise. The nuts must

be turned alternately, about two turns at a time, to prevent binding

caused by unequal loading.

2. Continue this procedure until the rod end nut s are against the p acking

body mechanism.

Gear Drive (G)

1. Remove the drive lock pin.

2. Retract the sensor by rotating the crank counter-clockwise. If a power

drill with an adapter is used, do not exceed 200 rpm.

3. Retract until the rod end nuts are against the p acking body

mechanism.

2-40

Page 41

Reference Manual

Transmitter

Temperature

Sensor

Connection

Housing

Direct Mount

Transmitter

Connection with

Valves

Cage Nipple

O-Rings (2)

Head Plate

Drive Rods

Mounting Flange Assembly

Gasket

Isolation Valve

Support

Plate

Packing

Gland

Packing

Follower

Compression

Plate

Coplanar Flange

with Drain Vents

Transmitter and

housing are shown

for clarity purposes

– only supplied if

ordered.

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Flanged Flo-Tap (for 485

and 585 Annubar

Flowmeters)

Figure 2-31. Components

Figure 2-31 identifies the components of the Flanged Flo-Tap assembly.

Step 1: Determine the Proper Orientation

Please refer to “Mounting” on page 2-4 for straight run requirements and

orientation information.

Step 2: Weld the Mounting Hardware

NOTE

Rosemount-supplied mounting includes critical alignment hardware that

assists in the correct drilling of the mounting hole. This significantly reduces

problems encountered during insertion.

1. At the pre-determined position, place the flanged assembly on the

pipe, gap

1

/16 in. (1,6 mm) and measure the distance from the outside

diameter of the pipe to the face of the flange. Compare this to the

chart below and adjust the gap as necessary.

2-41

Page 42

Annubar Flowmeter Series

Table 2-7. 485 and 585 Flange Sizes and ODF Per Sensor Size

485 Sensor

Size

1 11

2 22

3 44

(1) Tolerances for the ODF dimension above a 10-in. (254 mm) line size is ±0.060-in. (1,6 mm). Below

10-in. (254 mm) line size is ±0.030-in. (0,8 mm).

585 Sensor

Size

Reference Manual

00809-0100-4809, Rev CB

March 2012

Flange Size / Rating

Flange Type Pressure Class

A 1 11/2-in. 150# RF 3.88 (98.6)

3 11/2-in. 300# RF 4.13 (104.9)

6 11/2-in. 600# RF 4.44 (112.8)

N 11/2-in. 900# RF 4.94 (125.5)

F 11/2-in. 1500# RF 4.94 (125.5)

T 11/2-in. 2500# RF 6.76 (171.7)

R 1 11/2-in. 150# RTJ 4.06 (103.1)

3 11/2-in. 300# RTJ 4.31 (109.5)

6 11/2-in. 600# RTJ 4.44 (112.8)

N 11/2-in. 900# RTJ 4.94 (125.5)

F 11/2-in. 1500# RTJ 4.94 (125.5)

T 11/2-in. 2500# RTJ 6.81 (173.0)

D 1 DN40 PN16 RF 3.21 (81.5)

3 DN40 PN40 RF 3.21 (81.5)

6 DN40 PN100 RF 3.88 (98.6)

A 1 2.0-in. 150# RF 4.13 (104.9)

3 2.0-in. 300# RF 4.38 (111.3)

6 2.0-in. 600# RF 4.75 (120.7)

N 2.0-in. 900# RF 5.88 (149.4)

F 2.0-in. 1500# RF 5.88 (149.4)

T 3.0-in. 2500# RF 9.88 (251.0)

R 1 2.0-in. 150# RTJ 4.31 (119.5)

3 2.0-in. 300# RTJ 4.63 (117.6)

6 2.0-in. 600# RTJ 4.81 (122.2)

N 2.0-in. 900# RTJ 5.94 (150.9)

F 2.0-in. 1500# RTJ 5.94 (150.9)

T 3.0-in. 2500# RTJ 10.00 (254.0)

D 1 DN50 PN16 RF 3.40 (86.4)

3 DN50 PN40 RF 3.52 (89.4)

6 DN50 PN100 RF 4.30 (109.5)

A 1 3.0-in. 150# RF 4.63 (117.6)

3 3.0-in. 300# RF 5.00 (127.0)

6 3.0-in. 600# RF 5.38 (136.7)

N 4.0-in. 900# RF 8.19 (208.0)

F 4.0-in. 1500# RF 8.56 (217.4)

T 4.0-in. 2500# RF 11.19 (284.2)

R 1 3.0-in. 150# RTJ 4.81 (122.2)

3 3.0-in. 300# RTJ 5.25 (133.4)

6 3.0-in. 600# RTJ 5.44 (138.2)

N 4.0-in. 900# RTJ 8.25 (209.6)

F 4.0-in. 1500# RTJ 8.63 (219.2)

T 4.0-in. 2500# RTJ 11.38 (289.1)

D 1 DN80 PN16 RF 3.85 (97.8)

3 DN80 PN40 RF 4.16 (105.7)

6 DN80 PN100 RF 4.95 (125.7)

/ Type

ODF in. (mm)

(1)

2-42

Page 43

Reference Manual

ODF

Tack Weld

Isolation Valve

00809-0100-4809, Rev CB

March 2012

Figure 2-32. Alignment

Annubar Flowmeter Series

2. Place four 1/4-in. (6-mm) tack welds at 90° increments. Check

alignment of the mounting both parallel and perpendicular to the axis

of flow.

3. If the mounting alignment is within tolerances, finish weld per local

codes. If outside of tolerances, make adjustments prior to making th e

finish weld.

4. To avoid serious burns, allow the mounting hardware to cool

before continuing.

Figure 2-33. Install

Isolation Valve

Step 3: Install the Isolation Valve

1. Position the isolation valve onto the mounting flange. Ensur e that the

valve stem is positioned so that when the Flo-Tap is installed, the

insertion rods will straddle the pipe and the valve handle will be

centered between the rods (see Figure 2-33).

NOTE:

Interference will occur if the valve is located inline with the insertion rods.

2. Fasten the isolation valve to the mounting using gasket, bolts, and

nuts.

2-43

Page 44

Annubar Flowmeter Series

Pressure

Drilling

Machine

Isolation Valve is

fully open when

inserting drill

Isolation Valve is

fully closed after

withdrawing drill

Step 4: Mount the Drilling Machine and Drill Hole

Drilling Machine is not provided with the assembly

1. Determine the drill hole size based on the sensor size or sensor

width.

2. Mount the drilling machine to the isolation valve.

3. Open the valve fully.

4. Drill the hole into the pipe wall in accordance with the instructions

provided by the drilling machine manufacturer.

5. Retract the drill fully beyond the valve.

Table 2-8. 485 Drill Hole Sizes

Sensor

Sensor

Size

Width

1 0.590-in.

(14.99 mm)

2 1.060-in.

(26.92 mm)

3 1.935-in.

(49.15 mm)

Hole Diameter

3

/4-in.

(19 mm)

15/16-in.

(34 mm)

1

/2-in.

2

(64 mm)

+ 1/32-in

(0.8 mm)

– 0.00

+ 1/16-in.

(1.6 mm)

– 0.00

+ 1/16-in.

(1.6 mm)

– 0.00

Reference Manual

00809-0100-4809, Rev CB

March 2012

Table 2-9. 585 Drill Hole Sizes

Sensor

Sensor

Size

Width

11 0.8-in.

(20.32 mm)

22 1.20-in.

(30.48 mm)

44 2.30-in.

(58.42 mm)

Hole Diameter

7

/8-in.

(23 mm)

15/16-in.

(34 mm)

1

/2-in.

2

(64 mm)

+ 1/32-in

(0,8 mm)

– 0.00

+ 1/16-in.

(1,6 mm)

– 0.00

1

+

/16-in.

(1,6 mm)

– 0.00

2-44

Page 45

Reference Manual

Isolation Valve

Support Plate

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Step 5: Remove the Drilling Machine

1. Verify that the drill has been fully retracted past the valve.

2. Close the isolation valve to isolate the process.

3. Bleed drilling machine pressure and remove.

4. Check isolation valve and mounting for leakage.

Step 6: Mount the Annubar

1. Align the flow arrow on the head with the direction of flow.

2. Use the supplied gaskets and flange bolts to fasten the Flo-Tap

assembly to the isolation valve.

3. Tighten the nuts in a cross pattern to compress the gasket evenly.

4. Ensure that the vent valves are closed before proceeding.

5. Quickly open and close the isolation valve to pressurize the Annub ar.

Use extreme caution if the flowing medium is steam or caustic.

6. Check the entire installation for leakage. Tighten as required to stop

any connection from leaking. Repeat steps 4 and 5 until there is no

leakage.

Figure 2-34. Flo-Tap Installation

a. If the Flo-tap comes equipped with the gear drive option, place the

PVC protector rod assembly over the drive rods and attach to the

gear drive with the supplied hardware.

NOTE

Flo-Tap Annubars have the potential to carry a large amount of weight at a

great distance from the piping, necessitating external support. The support

plate has threaded holes to assist in supporting the Annubar. Threaded holes

(3/8"-16 UNC) are provided on the support plate for external support.

2-45

Page 46

Annubar Flowmeter Series

Drive

Nuts

Lock

Nuts

Drive

Lock

Pin

Step 7: Insert the Annubar

Insert the sensor with one of the two drive options available – manual (M) or

gear drive (G).

Manual (M) (Not recommended for line size above 12 in. (300 mm))

1. Open the isolation valve fully.

2. Rotate drive nuts clockwise (as viewed from the top) as shown in

Figure 2-34. The nuts must be tightened alternately, about two turns

at a time to prevent binding caused by unequal loading.

3. Continue this procedure until the tip of the probe firmly contacts the

opposite side of the pipe.

a. The orange stripes are a visual indication of when the sensor is

b. As the orange stripe approaches the support plate, place a finger

c. Turn the drive nuts an additional

Gear Drive (G)

approaching the opposite side wall.

above the packing gland while cranking.

1

/4 to 1/2 turn to secure the sensor.

Reference Manual

00809-0100-4809, Rev CB

March 2012

Figure 2-35. Insert Annubar

1. Open the isolation valve fully.

2. Rotate the crank clockwise. If a power drill with an adapter is used, do

not exceed 200 rpm.

a. Continue rotating the crank until the sensor firmly contacts the

opposite side of the pipe. The orange stripes are a visual in dication

of when the sensor is approaching the opposite side wall.

b. As the orange stripes approach the support plate, remove the

power drill and continue cranking manually. Place a finger above

the packing gland while cranking. When movement stops, the

sensor is in contact with the opposite side wall.

1

c. Turn the handle an additional

/4 to 1/2 turn to secure the sensor.

3. Secure the drive by inserting the drive lock pin as shown in

Figure 2-35.

Manual Drive (M) Gear Drive (G)

2-46

Page 47

Reference Manual

00809-0100-4809, Rev CB

March 2012

Annubar Flowmeter Series

Step 8: Retract the Annubar

Manual Drive (M)

1. Retract by rotating the drive nuts counter-clockwise. The nuts must

be turned alternately, about two turns at a time, to prevent binding

caused by unequal loading.

2. Continue this procedure until the rod end nut s are against the p acking

body mechanism.

Gear Drive (G)

1. Remove the drive lock pin.

2. Retract the sensor by rotating the crank counter-clockwise. If a power

drill with an adapter is used, do not exceed 200 rpm.

3. Retract until the rod end nuts are against the p acking body

mechanism.

Step 9: Mount the Transmitter

Direct Mount Head

With Valves

1. Place PTFE O-rings into grooves on the face of head.

2. Align the high side of the transmitter to the high side of the se ns or

(“Hi” is stamped on the side of the head) and install.

3. Tighten the nuts in a cross pattern to 400 in-lb (45 N-m).

Without Valves

1. Place PTFE O-rings into grooves on the face of head.

2. To install a manifold, orient the equalizer valve or valves so they are

easily accessible. Install manifold with the smooth face mating to the

face of the head. Tighten in cross patte rn to a torque of 400 in-lb (45

N-m).

3. Place PTFE O-rings into grooves on the face of the manifold.

4. Align the high side of the transmitter to the high side of the probe

(“Hi” is stamped on the side of the head) and install.

5. Tighten the nuts in a cross pattern to 400 in-lb (45 N-m).

2-47

Page 48

Annubar Flowmeter Series

Packing Gland Nuts

Packing Gland Washers

Roll Pins

Packing Gland Cover

Packing Gland

Locking Nuts

Locking Washers

Remote Mount

Instrument