Rosemount Analytical In Situ Oxygen Probes-Instruction Bulletin Addendum-Rev. 3.0 Manuals & Guides

Page 1

Optional Isolation Valving System

Used With Rosemount Analytical

In Situ Oxygen Probes

Instruction Bulletin Addendum IB – ISO1000

Rev. 3- June, 2005

Customer Support Center-in US 800-433-6076

International 440-914-1261

Oxymitter 4000

Part no. ____________

Serial no. ____________

Order no. ____________

Visit our website at:

On-Line Ordering Available!

www.processanalytic.com

Page 2

Applicability:

Isolation Valving Option, Oxy-Iso 2000

Utilized with Rosemount Analytical’s Oxymitter 4000/5000 series of

O

analyzers or with Rosemount Analytical’s CENELEC World

2

Class O

Analyzers. May be used with pressure-balancing option,

2

p/n 3D39811Gxx

General

Rosemount Analytical’s line of in situ oxygen analyzers utilize zirconium oxide

(ZrO

) sensing technology which is sensitive to pressure variations in the

2

process.

Rosemount Analytical’s Oxymitter and World Class probes place the sensing

cell at the end of an in situ probe that inserts directly into the process gas

stream. This arrangement provides fast response and is very resistant to

pluggage from particulate material or the acids that frequently condense within

normal flue gas.

The ZrO

and an output change of approximately 1% of reading

range, or 1% O

sensing technology is sensitive to pressure changes in the process

2

(not 1 % of full scale

) for every 4 inches of H2O pressure or vacuum in the process

2

can be expected. See the instruction bulleton for the separate “pressure

balancing system” for a more complete description of the pressure effects, and

our accommodation to nullify these effects.

Process pressures of more than 1 PSI also present the challenge of removing

or inserting the probe for maintenance purposes while the process is on line.

Hot, noxious combustion gases can make the removal and installation

procedure hazardous, especially when the operation is conducted at elevation

and on less than adequate catwalks.

This isolation valving system facilitates the insertion and withdrawal of the probe

for service while the process is under pressure. This valving system is

recommended if the process cannot be shut down for probe maintenance.

Unpacking

The Isolation Valving system will be shipped separately from the O

probe and other

2

options, such as pressure balancing and automatic calibration gas sequencer. The

isolation valving system is shipped as a compact assembly, but after unpacking, it’s best

to disassemble the guide bars and packing box so that many lighter components can be

installed as opposed to one heavy assembly.

Mechanical/Pneumatic Installation- Isolation Valving System

The process must be off-line before conducting the installation and the

temperatures at the installation point must have operating temperatures of less

than 1,300

0

F (7050 C).

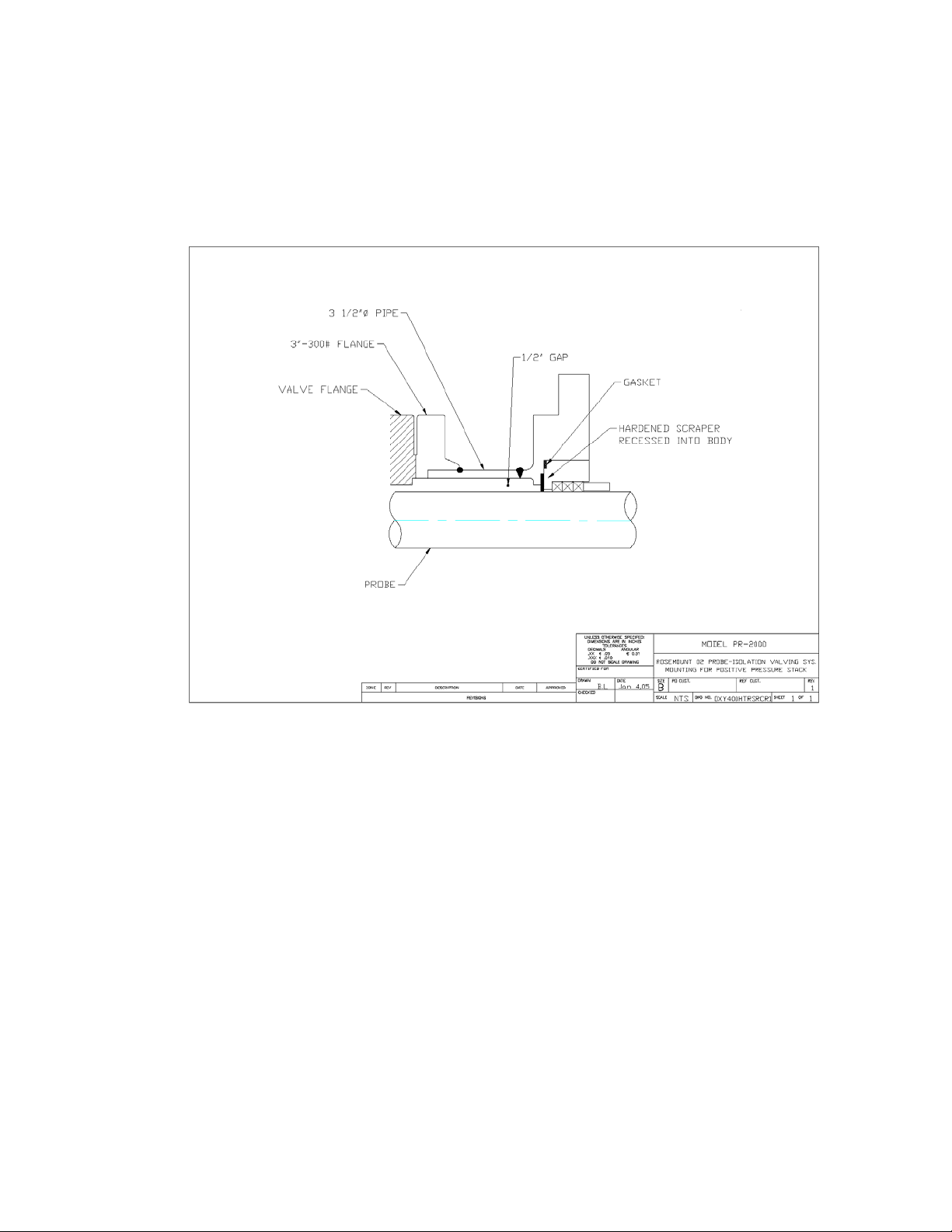

Process ductwork must be prepared by mounting a 3-inch, 300-pound nozzle

with a length no longer than 12 inches. A 3-inch, 300-pound ANSI flange is

required at the end of this nozzle. Ensure that the installation will permit the

probe to insert at least 6 inches into the process ductwork. (See

insertion/removal envelope drawing at the end of this manual). Place the

provided gasket onto the flange and bolt the isolation gate valve to the nozzle

IB Addendum ISO1000

2

Page 3

flange with the packing box assembly and O2 probe removed. O2 probe

installation may be conducted with the process on-line once the Isolation Valve

is installed and closed.

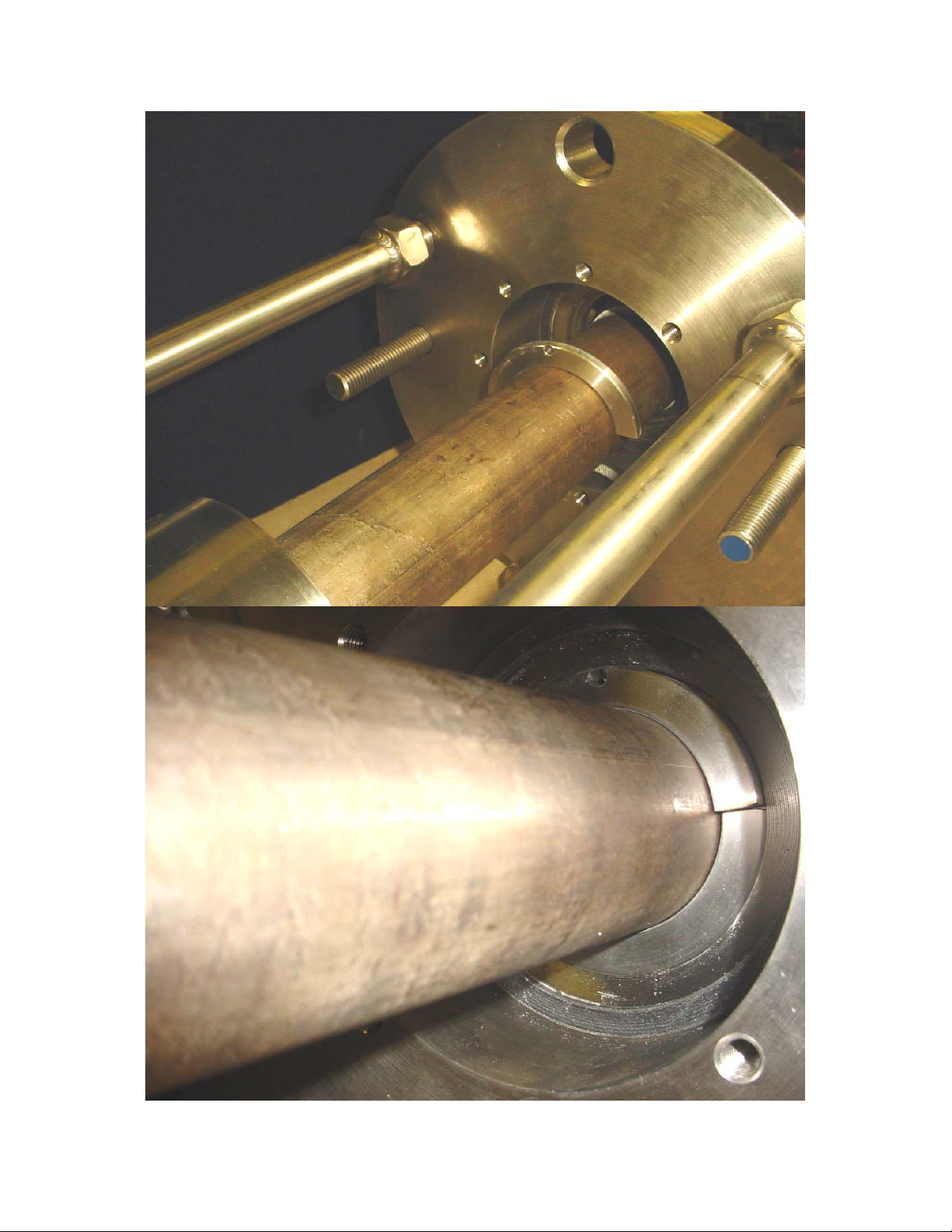

Install the packing box housing weldment onto the isolation valve.

(Isolation valve would be to the right, but is removed in this photo sequence for

clarity.)

IB Addendum ISO1000

3

Page 4

Next install the removable guide rods, and then the sliding probe carrier

assembly.

IB Addendum ISO1000

4

Page 5

Probe carrier assembly.

Remove the flame arrestor from the end of the Oxymitter O2 probe, and place

the probe into the cradle of the sliding carrier assembly with the probe flange

behind the carrier assembly, and lock the retaining bar up. Note that the Lshaped piece at the 12 o’clock position will contain the probe from sliding back

under pressure, but also permit the probe to be rotated back and forth to assist

removal.

IB Addendum ISO1000

5

Page 6

String the following components onto the probe body:

- adjustment plate for gasket compression ring

- 8-hole packing box retaining ring

- gasket compression ring

- packing box , without rope gaskets

IB Addendum ISO1000

6

Page 7

Insert the three rings of packing material into the packing box, pushing each

ring to the back of the box. Ensure that the point where the gasket ends meet

is indexed from gasket to gasket. For instance, it would be good for the ends

of gasket #1 to meet at a 12 o’clock orientation, gasket # 2 ends to meet at 4

o’clock, and gasket # 3 ends to meet at 8 o’clock.

IB Addendum ISO1000

7

Page 8

Before inserting the probe into the packing box housing, ensure that the face

gasket at the back of the housing is in place. Also shown is the split ring with

knurled teeth. This is depicted for clarity, but must be removed for probe

insertion, and reassembled around the probe body.

IB Addendum ISO1000

8

Page 9

Reinstall the flame arrestor/ diffusion element assembly onto the end of the

probe. Make sure to use Rosemount’s white mineral antisieze compound on

the threads. Do not use any petroleum based antisieze. Remember to orient

the V-deflector shield (if using a ceramic diffusion element) into the direction of

the process flow.

Slide the carrier assembly forward so that the probe inserts through the packing

box weldment, and to the closed gate of the gate valve.

IB Addendum ISO1000

9

Page 10

A split knurled ring is provided to scrape off cemented catalyst material that may

be deposited onto the probe body during subsequent removal. Insert the split

ring into the back of the packing box housing around the probe body. Ensure

that the small hole in the top half of the split ring fits over the pin in the back of

the weldment.

IB Addendum ISO1000

10

Page 11

IB Addendum ISO1000

11

Page 12

Slide the packing box assembly with 3 rope gaskets into the packing box

weldment.

IB Addendum ISO1000

12

Page 13

Bolt the 8-hole packing box retaining ring into place.

IB Addendum ISO1000

13

Page 14

Center the packing compression ring onto the packing material, and slide

the adjustment plate plate forward to the compression ring. Install two

adjustment nuts, and tighten slightly.

Adjust the packing adjustment nuts tight enough to minimize the escape

of pressurized process gas, but loose enough to let the probe slide back

and forth.

Install the two stop collars onto the two guide bars behind the carrier

assembly.

Open the gate valve fully.

Slide the probe all the way forward into the process, alternately locking

one stop collar or the other on the guide bars to prevent the probe from

sliding back under the process pressure. The probe may be rotated back

and forth as it is pushed in.

Once the probe is fully inserted, tighten the packing adjustment plate.

The packing is now the main process barrier, and no leakage should be

permitted.

IB Addendum ISO1000

14

Page 15

Entire guide bar/probe carrier assembly can now be removed if clearance is

desired around the installation.

IB Addendum ISO1000

15

Page 16

The entire valve/ packing box/ Probe assembly should be insulated to prevent

the condensation of process gases in the valve and also in the calibration gas

line inside the O

probe.

2

IB Addendum ISO1000

16

Page 17

IB Addendum ISO1000

17

Page 18

Probe removal is the reverse of the installation procedure:

1) If a pressure balancing system is being utilized, the inside (reference side) of

the probe must remain pressured up during the removal process.

2) Remove insulation from the entire assembly, exposing the packing box

assembly and probe.

Remove power from probe at an external breaker. If a World Class CENELEC

probe is used with rigid conduit, break the wire and conduit connections at the

separate close-coupled junction box. If an Oxymitter 4000/5000 is utilized,

wiring can be removed from the terminations side of the probe electronics

housing prior to retracting probe. Note:

electronics

isolated

side of the Oxymitter electronics housing until probe is

from the process and the balancing reference air is removed.

do not remove the end cap from the

IB Addendum ISO1000

18

Page 19

Re-install the probe guide rods and carrier plate. Probe flange must be

outboard of the carrier plate.

Attach retaining bar under the probe body.

IB Addendum ISO1000

19

Page 20

3) Loosen the two packing adjustment nuts enough to permit the probe to slide

out, but still maintain a minimum of process leakage.

4) Use the two safety stop collars on the guide bars, alternately locking them

into place to limit the distance the probe can slide if the process pressure

overcomes the packing friction.

IB Addendum ISO1000

20

Page 21

Rotate the probe back and forth to assist it’s withdrawal. Note that

catalyst cement may have accumulated onto the probe body (particularly

if the installation has not been well insulated), and repeated rotation back

and forth may be required to saw off this material.

IB Addendum ISO1000

21

Page 22

Installations that have been poorly insulated or heat traced well may have a

significant buildup of catalyst cement or other deposits due to condensation on the

probe body. A hydraulic cylinder can be utilized to assist in the withdrawal as

depicted below. Note that the cylinder pushes against the packing adjustment plate.

An extra nut is provided on the two threaded rods to prevent this pushing from overtightening the packing.

Cylinder kits are available from the factory – call 800-433-6076

IB Addendum ISO1000

22

Page 23

When the probe flange reaches the grooves in the guide rods, the probe is

beyond the gate, and the valve can be closed fully, isolating the process.

If the probe is not withdrawn completely, the gate of the valve will hit

the diffusion element, possibly causing breakage.

Carefully loosen the packing adjustment nuts further to ensure that the

gate valve has successfully isolated the process. Remove the nuts

completely, and slide the packing adjustment plate and the packing

adjustment ring back onto the probe body. Remove the 8 packing box

retaining bolts and the retainer plate, and string them back onto the probe

body. Continue withdrawing the probe.

IB Addendum ISO1000

23

Page 24

The large flame arrestor on the end of the probe will be close to the back

of the packing box. As the probe withdrawal continues, the flame

arrestor should push the entire packing box assembly back out of the

packing box weldment.

IB Addendum ISO1000

24

Page 25

String the packing box back onto the probe body. Recover the knurled

split ring, which should fall out behind the packing box. Inspect the

face gasket , and leave it in place if it appears to be in good condition.

5) Withdraw the probe until the end of the diffuser just rests inside the packing

box weldment.

6) Drop the retaining bar that holds the probe into the carrier assembly, and

completely remove the probe.

IB Addendum ISO1000

25

Page 26

Unscrew the large flame arrestor/diffuser from the end of the probe, and

slide the packing box off. The gasket material should be pushed out, and

should be inspected. Slide the packing adjusting ring, the 8-hole

packing box retaining ring, and the packing adjustment plate off of the

probe body.

Catalyst fines may have accumulated inside the packing box weldment.

Remove this by vacuuming, or blowing with an air hose.

IB Addendum ISO1000

26

Page 27

Pneumatic

Follow instructions in the instruction bulletin for the probe system. Applications

where process pressures are greater than a few PSI will require a pressure

balancing system, p/n 3D39811Gxx. This system operates by pressurizing the

inside of the O

probe with instrument reference air at the same pressure as the

2

process. The instrument air lines will have to remain connected as the probe is

inserted into and withdrawn from the process. This will require an extra length

of flexible reference air tubing. See IB 3D39811 for pressure balancing system.

Electrical Installation

Follow instructions in the instruction bulletin for the probe system. If a

CENELEC

World Class probe is being installed, utilize procedures to ensure

that an air-tight seal is made at the cable entry point. This will consist of a good

cable seal on the outside diameter of the cable, as well as potting or sealing

where the individual wires exit the overall cable sheath. This will prevent the

migration of high pressure balancing instrument air down the electrical cables.

The probe will be required to slide approximately 3 feet into and out of the

process. An extra length of power and signal cable may be provided to

accommodate this installation/removal procedure.

If rigid conduit is required, place an air-tight junction box close to the probe with

terminations inside. Prior to retraction, the terminations and conduit can be

removed at the junction box and the remaining length of cable/conduit and

junction box can ride with the probe as it retracts.

If an Oxymitter

probe is being installed, the electrical connections are isolated

from the pressure balancing instrument air by a cast bulkhead. The cover from

the terminations side (only) can be removed and electrical connections can be

removed at the probe prior to retraction while the inside of probe is still

IB Addendum ISO1000

27

Page 28

balanced. Do not attempt to remove the cover from the electronics side of the

probe until the pressure inside is at ambient as noted by the gauges provided.

Insulate the junction box (World Class) or electronics (Oxymitter) at the rear of

the probe to prevent condensation of process gases in the calibration gas line,

which runs the length of the probe. If an Oxymitter is used, monitor the

electronics temperature with a Model 275 HART communicator to ensure that

the temperature is not above 85°C (185°F)

IB Addendum ISO1000

28

Page 29

IB Addendum ISO1000

29

Page 30

Isolation Valving System Designations

OxyIso PR 2000 Material

1 316 Stainless Steel

2 Other

Valve

1 3” 300 # Gate Valve- 316 SS

2 Other

Probe

Probe Flange

Nozzle for Welding to Process

1 Rosemount General Purpose, 36”

2 Rosemount Hazardous Area, 36”

1 ANSI Gen Purpose 6.00” OD, 4.75 “ BC

2 DIN Gen Purpose 7.50” OD, 5.71” BC

3 JIS Gen.Purpose 6.50” OD, 5.12” BC

4 ANSI Haz. Area 7.75” OD, 6.00” BC

5 DIN Haz. Area 8.50” OD, 6.70” BC

6 Other

7 ANSI Haz. Area 3” 300 #

1 None- customer provided

2 3” 300# x 12” long 316 SS

3 Other

IB Addendum ISO1000

30

Page 31

Spare Parts

Item #6 Packing 1A99624H01

Item #4- Gasket 1A99624H02

Item #12 Gasket 1A99624H03

IB Addendum ISO1000

31

Loading...

Loading...