Page 1

Rosemount Analytical

ODEL

M

XPLOSION PROOF

E

815

ON

N

NSTRUCTION MANUAL

I

ISPERSIVE INFRARED

-D

NALYZER

A

748175-F

Page 2

Notice

Information contained in this document is subject to change without notice.

Irtran™ is a trademark of Eastman Kodak Co.

Pyrex® is a registered trademark of Corning Glass Works.

Teflon® and Viton® are registered trademarks of E.I. du Pont de Nemours & Co., Inc.

Manual Part Number 748175-F

October 1997

Rosemount Analytical

4125 East La Palma Avenue

Anaheim, California 92807-1802

Page 3

C

ONTENTS

P

REFACE

PURPOSE/SAFETY SUMMARY........................................................................P-1

SPECIFICATIONS..............................................................................................P-3

CUSTOMER SERVICE, TECHNICAL ASSISTANCE AND FIELD SERVICE ....P-4

RETURNING PARTS TO THE FACTORY..........................................................P-4

TRAINING ......................................................................................................P-4

DOCUMENTATION............................................................................................P-4

COMPLIANCES..................................................................................................P-5

S

ECTION

1.1 GENERAL DESCRIPTION.......................................................................1-1

1.2 APPLICATIONS........................................................................................1-1

1.3 AVAILABLE OPTIONS..............................................................................1-2

S

ECTION

2.1 UNPACKING..............................................................................................2-1

2.2 LOCATION.................................................................................................2-1

2.3 VOLTAGE REQUIREMENTS....................................................................2-1

2.4 ELECTRICAL CONNECTIONS ................................................................2-2

2.5 SAMPLE CONNECTIONS........................................................................2-2

2.6 CALIBRATION GAS CONNECTIONS AND REQUIREMENTS................2-2

2.7 SAMPLE HANDLING SYSTEM................................................................2-3

2.8 LEAK TEST...............................................................................................2-5

1. I

NTRODUCTION

2. U

2.4.1 Line Power Connections .............................................................2-2

2.4.2 Recorder Connections.................................................................2-2

NPACKING AND INSTALLATION

2.9 OPTIONS..................................................................................................2-6

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

i

Page 4

C

ONTENTS

S

ECTION

S

ECTION

3.1 LEAK TEST..............................................................................................3-1

3.2 POWER VERIFICATION..........................................................................3-1

3.3 OPERATING CONTROLS AND INDICATORS........................................3-2

3.4 CALIBRATION ..........................................................................................3-3

2. (

2.9.1 Air Purge Kit 652271...................................................................2-6

2.9.2 Current Output Kit 652269..........................................................2-6

2.9.3 Case Heater Temperature Control Kit 652270............................2-7

2.9.4 Linearizer Kit 652268..................................................................2-8

2.9.5 Motor/Source Assembly Purge Kit 655094.................................2-10

3. I

3.3.1 Digital Display.............................................................................3-2

3.3.2 MODE Switch.............................................................................3-2

3.3.3 ZERO Adjustment.......................................................................3-2

3.3.4 SPAN Adjustment.......................................................................3-2

3.4.1 Calibration Procedure.................................................................3-4

3.4.2 Linearizer Board Calibration.......................................................3-4

3.4.3 Calibration Curve Construction...................................................3-5

CONTINUED

NITIAL STARTUP AND CALIBRATION

)

3.5 LINEARIZATION PROCEDURE ..............................................................3-7

3.6 CURRENT OUTPUT................................................................................3-9

S

ECTION

4.1 ROUTINE OPERATION............................................................................4-1

4.2 RECOMMENDED CALIBRATION FREQUENCY.....................................4-1

4.3 SHUTDOWN.............................................................................................4-1

4.4 DETECTION SYSTEM THEORY............................................................. 4-2

4.5 ELECTRONIC CIRCUITRY ...................................................................... 4-3

4. R

4.5.1 Oscillator Circuit Board (Schematic 623995) and

4.5.2 Functioning of Modulation System in TUNE Mode ..................... 4-3

4.5.3 Functioning of Modulation System in Operating Mode...............4-3

4.5.4 Radio-Frequency Demodulator................................................... 4-4

4.5.5 Signal Board (Schematic 652431)..............................................4-4

4.5.6 Power Supply Board (Schematic 624073)..................................4-5

4.5.7 Case Heater Temperature Control Board (Schematic 624003)..4-5

4.5.8 Current Output Board (Schematic 652439) ................................4-5

4.5.9 Linearizer Board (Schematic 624674)........................................4-5

OUTINE OPERATION AND THEORY

Associated Elements of Amplitute Modulation Circuit... 4-3

ii

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 5

C

ONTENTS

S

ECTION

5.1 SYMPTOM CHART ..................................................................................5-1

5.2 TEST EQUIPMENT ..................................................................................5-2

5.3 VOLTAGE CHECKS.................................................................................5-2

5.4 OSCILLATOR TUNE ADJUSTMENT .......................................................5-2

5.5 PREAMP GAIN.........................................................................................5-2

5.6 SOURCE BALANCE SHUTTER ADJUSTMENT......................................5-4

5.7 SOURCE ALIGNMENT.............................................................................5-6

5.8 SOURCE CURRENT ADJUSTMENT.......................................................5-6

5.9 TIME CONSTANT.....................................................................................5-6

5.10 CASE HEATER TEMPERATURE CONTROL ASSEMBLY......................5-7

S

ECTION

6.1 CELL REMOVAL, CLEANING AND REPLACEMENT..............................6-2

5. T

5.5.1 Peak Adjustment.........................................................................5-4

6. R

6.1.1 Long Cell Configurations.............................................................6-2

6.1.2 Short Cell Configurations ............................................................6-2

ROUBLESHOOTING

OUTINE SERVICING

6.2 CELL DESICCANT...................................................................................6-4

6.2.1 Desiccant Replacement..............................................................6-4

6.3 SOURCE REPLACEMENT.......................................................................6-5

6.4 CHOPPER MOTOR ASSEMBLY..............................................................6-6

6.4.1 Long Cell Configurations.............................................................6-6

6.4.2 Short Cell Configurations ............................................................6-6

6.5 DETECTOR REPLACEMENT..................................................................6-7

6.5.1 Removal - Long Cell Configurations............................................6-7

6.5.2 Removal - Short Cell Configurations...........................................6-7

6.5.3 Detector Installation.....................................................................6-8

S

ECTION

7.1 CIRCUIT BOARD REPLACEMENT POLICY.............................................7-1

7.2 SELECTED REPLACEMENT PARTS .......................................................7-2

7.3 OPTION KITS...........................................................................................7-2

7. R

7.2.1 Model 815 Common Parts...........................................................7-2

7.2.2 Optical Bench..............................................................................7-2

7.3.1 Linearizer Kit PN 652268 ...........................................................7-2

7.3.2 Current Output Kit PN 652269 ....................................................7-2

EPLACEMENT PARTS

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

iii

Page 6

C

ONTENTS

S

ECTION

NFRARED CALIBRATION AND DATA SHEET (PER APPLICATION

I

ENERAL PRECAUTIONS FOR HANDLING

G

ARRANTY

W

IELD SERVICE AND REPAIR FACILITIES

F

F

IGURES

1-1 Model 815 Explosion Proof NDIR Analyzer..............................................1-1

2-1 Model 815 Component Locations.............................................................2-3

2-2 Power Supply Board.................................................................................2-4

2-3 Case Heater Temperature Control Board.................................................2-4

2-4 Current Output Board...............................................................................2-7

2-5 Installation of Current Output and Temperature Control Options.............2-8

2-6 Linearizer Board.......................................................................................2-9

2-7 Signal Board with Linearizer Board Installed............................................2-9

3-1 Model 815 Operating Controls and Indicators..........................................3-3

3-2 Signal Board Component Locations.........................................................3-5

3-3 Linearizer Board Adjustments..................................................................3-6

3-4 Typical Linearization Curve......................................................................3-7

3-5 Current Output Board...............................................................................3-9

4-1 NDIR Detection System...........................................................................4-2

4-2 Functional Block Diagram ........................................................................4-6

5-1 Modulation System ................................................................................... 5-5

6-1 Optical Bench...........................................................................................6-3

6-2 Motor/Source Assembly...........................................................................6-6

6-3 Detector Replacement..............................................................................6-9

7-1A Configurations 06, 07, 19, 21, 31, 36, 41, 45, 54, 71, 72, 81....................7-4

7-1B Configurations 35, 73................................................................................7-4

7-1C Configurations 64, 83................................................................................7-5

7-2A Configurations 08, 10, 12, 13, 18, 32, 39, 42, 43, 55, 63, 65, 67..............7-5

7-2B Configurations 22, 23, 29, 30, 33, 34, 38, 76............................................7-6

7-2C Configuration 26.......................................................................................7-6

7-2D Configurations 74, 82, 84..........................................................................7-7

7-3 Case Heater Temperature Control Assembly...........................................7-10

7. (

CONTINUED

7.3.3 Case Heater Temperature Control Kit PN 652270......................7-3

7.3.4 Air Purge Kit PN 652271............................................................7-3

7.3.5 Motor/Source Purge Kit PN 655094............................................7-3

)

)

TORING HIGH PRESSURE CYLINDERS

& S

iv

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 7

T

ABLES

3-1 Typical Linearization Calibration Values...................................................3-8

3-2 Linearization Calibration Values ...............................................................3-9

5-1 Troubleshooting Chart..............................................................................5-3

6-1 Types of Desiccant...................................................................................6-5

7-1 Configuration Figure List...........................................................................7-3

7-2 Optical Bench Components by Configuration...........................................7-7

C

ONTENTS

D

RAWINGS (LOCATED IN REAR OF MANUAL

623995 Schematic Diagram, Oscillator Board

624003 Schematic Diagram, Temperature Control Board

624073 Schematic Diagram, Power Supply Board

624674 Schematic Diagram, Linearizer Board

652258 Installation Drawing, Model 815

652259 Pictorial Wiring Diagram, Model 815

652431 Schematic Diagram, Signal Board

652439 Schematic Diagram, Current Output Board

652446 Schematic Diagram, Zero/Span Control Board

)

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

v

Page 8

C

ONTENTS

N

OTES

vi

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 9

P

REFACE

P

URPOSE/SAFETY SUMMARY

To avoid explosion, loss of life, personal injury and damage to this equipment and on-site

property, all personnel authorized to install, operate and service the Model 815 Explosion

Proof Non-Dispersive Infrared Analyzer should be thoroughly familiar with and strictly

follow the instructions in this manual.

If this equipment is used in a manner not specified in these instructions, protective

systems may be impaired.

Save these instructions.

DANGER

personal injury, death, or substantial property damage if the warning is ignored.

WARNING

personal injury, death, or substantial property damage if the warning is ignored.

CAUTION

personal injury or property damage if the warning is ignored.

NOTE

important but not hazard-related.

is used to indicate the presence of a hazard which

is used to indicate the presence of a hazard which

is used to indicate the presence of a hazard which

is used to indicate installation, operation or maintenance information which is

will

cause

can

cause

will or can

cause

severe

severe

minor

WARNING: ELECTRICAL SHOCK HAZARD

Do not operate without doors and covers secure. Servicing requires access to

live parts which can cause death or serious injury. Refer servicing to qualified

personnel.

For safety and proper performance this instrument must be connected to a

properly grounded three-wire source of power.

This instrument is shipped from the factory set up to operate on 115 volt, 50/60

Hz electric power. For operation on 230 volt, 50/60 Hz power, see Section 2.3

and Figures 2-2 and 2-3 for modifications.

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

P-1

Page 10

P

REFACE

WARNING: POSSIBLE EXPLOSION HAZARD

This analyzer is of a type capable of analysis of sample gases which may be

flammable. If used for analysis of such gases the instrument explosion-proof

enclosure must be suitable for the gas.

WARNING: EXPLOSION HAZARD

If explosive gases are introduced into this analyzer, the sample containment

system must be carefully leak-checked upon installation and before initial

startup, during routine maintenance and any time the integrity of the sample

containment system is broken, to ensure the system is in leak-proof condition.

Leak-check instructions are provided in Section 2.8.

Do not operate the Model 815 Explosion-Proof Analyzer without lens cover and

door in place with all bolts secured, unless location has been determined to be

non-hazardous.

WARNING: HIGH PRESSURE GAS CYLINDERS

This analyzer requires periodic calibration with known zero and standard gases.

Refer to General Precautions for Handling and Storing High Pressure Cylinders,

in the rear of this manual.

WARNING: PARTS INTEGRITY

Tampering or unauthorized substitution of components may adversely affect

safety of this product. Use only factory documented components for repair.

P-2

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 11

S

PECIFICATIONS

P

REFACE

P

OWER REQUIREMENTS

A

MBIENT TEMPERATURE

D

IMENSIONS

W

EIGHT

E

NCLOSURE

S

IGNAL OUTPUT

R

EPEATABILITY

N

Z

S

:

OISE

ERO DRIFT

PAN DRIFT

:

:

:

:

:

1

:

1

:

120/220 VAC ±10%, 50/60 ±3 Hz, 150 W;

:

350 W with optional case heater

32°F to 113°F (0°C to 45°C)

:

Some configurations may require optional case heater for temperatures

outside 59°F to 95°F (15°C to 35°C). Refer to Appendix A.

21.5 in (55.0 cm) H

15.5 in. (39 cm) W

11.8 in. (30 cm) D

119 lbs (54 kg)

Explosion Proof, Class I, Groups B,C,D, Division 1.

Mount in weather protected area.

Standard: 0-5 VDC (0-1 VDC field selectable on board)

Optional: 4-20 mA or 0-20 mA (field selectable), 750 ohms max.

1% of fullscale

1% of fullscale

±

1% of fullscale per 24 hours

±

1% of fullscale per 24 hours

R

ESPONSE TIME

(ELECTRONIC

S

AMPLE CELL LENGTH

R

EFERENCE

M

ATERIALS IN CONTACT

S

WITH

WINDOWS

CELLS

TUBING

FITTINGS

S

1

Performance specifications based on ambient temperature shifts of less than 20°F (11°C) per hour.

AMPLE

AMPLE PRESSURE

:

)

:

:

:

:

:

:

:

Variable, 90% of fullscale in 1 sec to 10 sec, field selectable. (Application

dependent)

0.04 in. (1 mm) to 10.0 in. (254 mm)

:

Sealed

Sapphire, quartz, Irtran

Gold plated Pyrex or stainless steel

FEP Teflon

316 stainless steel

Max 10 psig (69 kPa), standard

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

P-3

Page 12

P

REFACE

C

USTOMER SERVICE

For order administration, replacement Parts, application assistance, on-site or factory

repair, service or maintenance contract information, contact:

R

ETURNING PARTS TO THE FACTORY

Before returning parts, contact the Customer Service Center and request a Returned

Materials Authorization (RMA) number. Please have the following information when

you call:

Number.

Prior authorization by the factory must be obtained before returned materials will be

accepted. Unauthorized returns will be returned to the sende r, f re ight collect.

When returnin g any pro duct o r compon ent t hat has be en expo sed to a toxic, corrosi ve

or other hazardous material or used in such a hazardous environment, the user must

attach an appropriate Material Safety Data Sheet (M.S.D.S.) or a written certification

that the material has been decontaminated, disinfected and/or detoxified.

Model Number, Serial Number, and Purchase Order Number or Sales Order

, T

ECHNICAL ASSIST ANCE AND FIELD SERVICE

Rosemount Analytical Inc.

Process Analytical Division

Customer Service Center

1-800-433-6076

Return to:

Rosemount Analytical Inc.

4125 East La Palma Avenue

Anaheim, California 92807

T

RAINING

A comprehensive Factory Training Program of operator and service classes is

available. For a copy of the

the Technical Services Depart men t at:

D

OCUMENTATION

The following Model 815 Explosion Proof Non-Dispersive Infrared Analyzer instruction

materials are available. Contact Customer Service or the local representative to

order.

748175 Instruction Manual (this document)

Current Operator and Service Training Schedule

Rosemount Analytical Inc.

Phone: 1-714-986-7600

FAX: 1-714-577-8006

contact

P-4

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 13

C

OMPLIANCES

The Model 815 Explosion Proof Non-Dispersive Infrared Analyzer is approved by

Factory Mutual for use in Class I, Groups B, C and D Division 1 hazardous locations.

FM

P

REFACE

APPROVED

97-C209

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

P-5

Page 14

P

REFACE

N

OTES

P-6

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 15

I

NTRODUCTION

1

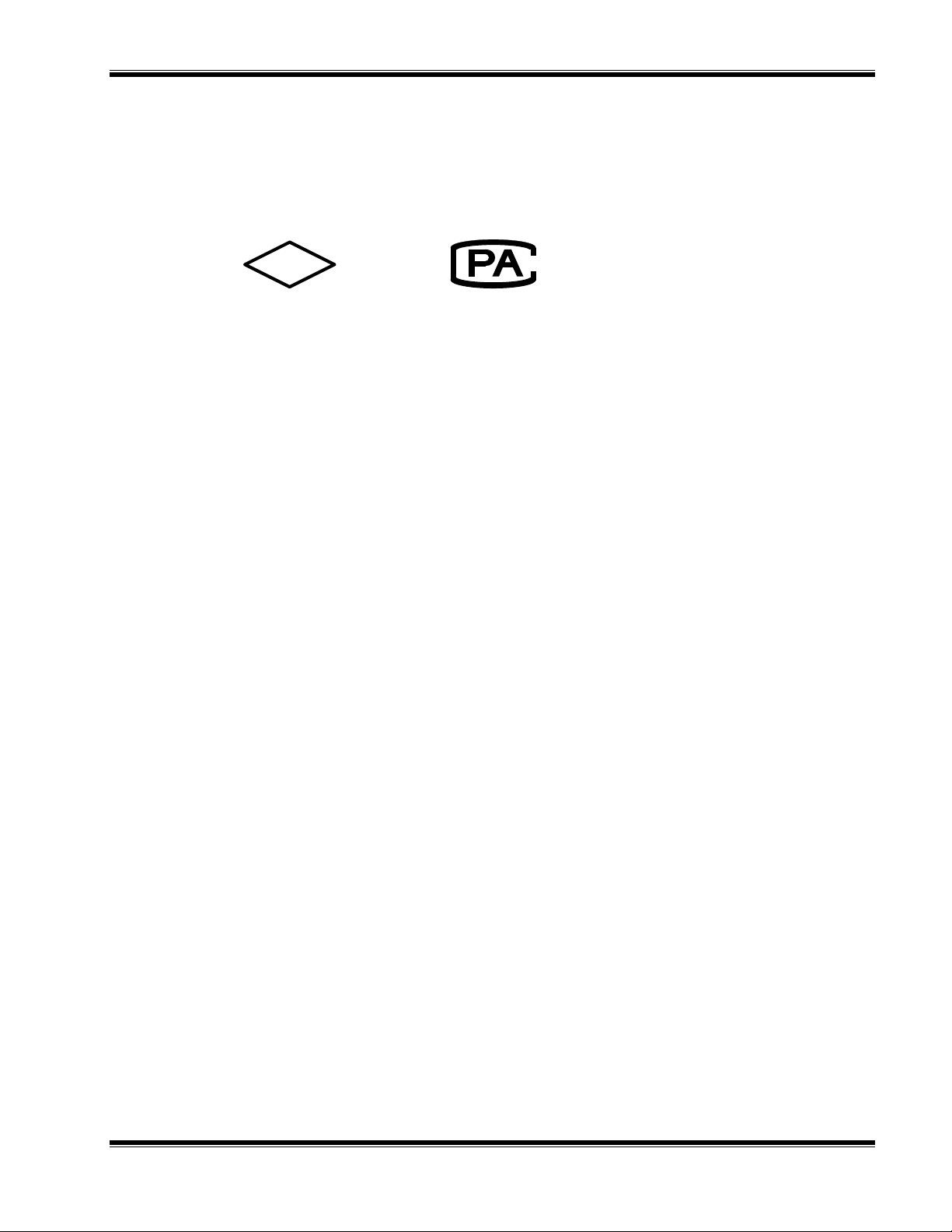

1.1 GENERAL DESCRIPTION

The Model 815 Non-Dispersive Infrared Analyzer is designed to continuously monitor

the concentration of a particular infrared absorbing component of interest in a flowing

gaseous mixture. Concentration is displayed as a percent of fullscale. Signal outputs

of 0-5 VDC or 0-1 VDC are field selectable standard.

The Analyzer enclosure is designed to meet the requirements for Class I, Division 1,

Groups B, C, and D, per the National Electrical Code (ANSI/NFPA 70), and should be

mounted in a weather-protected area.

1.2 APPLICATIONS

Monitoring applications are found in the Application Data Sheet which is available from

the local sales office (see page P-4).

IGURE

F

748175-F Rosemount Analytical October 1997

1-1. M

ODEL

815 E

XPLOSION PROOF

ZERO SPAN

DETECTOR RANGE 1

TUNE RANGE 2

Rosemount Analytical

Model 815

Oxygen Analyzer

NDIR A

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

NALYZER

1-1

Page 16

I

NTRODUCTION

Some sample streams contain various other infrared-absorbing substances, other than

the component of interest. To minimize interference in such applications, the

instrument may incorporate an optical filter and, if necessary, a sealed filter cell

containing an appropriate gas charge, as noted in the Factory Calibration and Data

Sheet located in the rear of this manual.

1.3 AVAILABLE OPTIONS

Operation of the Model 815 can be enhanced with the choice of several options, all of

which can be installed in the field after the analyzer has been ordered.

IGNAL LINEARIZER

S

A signal linearizer kit is available for each range. Linearizers enable the operator to

convert non-linear output signals into linear output signals.

SOLATED CURRENT OUTPUT

I

The current output option can be field set for either 4-20mA or 0-20mA, corresponding

to 0% to 100% of fullscale. Maximum load is 750 ohms.

ASE TEMPERATURE CONTROLLER

C

A proportional temperature controller, with heater and fan assembly, maintains proper

operating temperature inside the case.

IR PURGE

A

The air purge kit is to be installed with user-supplied components. It is designed for

use in cases where a corrosive gas is either flowing through the cell or is present in

the environment. The air purge option is provided for protection of the instrument only,

and is not intended as a safety feature for use in a hazardous area.

OTOR/SOURCE ASSEMBLY PURGE

M

This purge is recommended in some applications to provide a CO2 free, spectrally

constant atmosphere within the Motor/Source Assembly.

AMPLE HANDLING SYSTEM ACCESSORY

S

If so ordered, an associated sample-handling system may be either factory-assembled

or supplied for field installation, depending on ordering instructions. Sampling systems

are designed on the basis of information furnished by the customer, which includes a

complete stream analysis. Refer to the Factory Calibration and Data Sheet for

information on the sample handling sy stem.

1-2

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 17

U

NPACKING AND INSTALLATION

2

2.1 UNPACKING

Carefully examine the shipping carton and contents for signs of damage. Immediately

notify the shipping carrier if the carton or its contents are damaged. Retain the carton

and packing material until the instrument is operational

2.2 LOCATION

Locate the analyzer in a weather-protected location free from vibration. For best

results mount the analyzer near the sample stream to minimize sample-transport time.

Refer to Installation Drawing 652258.

If equipped with P/N 652271 air purge, refer to Section 2.9.1. The air purge is

designed to provide a corrosion-free or spectrally-constant internal atmosphere, and

not intended to provide explosion hazard protection.

is

2.3 VOLTAGE REQUIREMENTS

WARNING: ELECTRICAL SHOCK HAZARD

For safety and proper performance, this instrument must be connected to a

properly grounded three-wire source of electrical power.

Verify that power switch settings are set for the power available at the site (115 VAC or

220 VAC).

Analyzers are shipped from the factory set for 120 VAC, 50/60 Hz operation. To

convert to 220 VAC, 50/60 Hz power, position voltage select switches S1, S2 (located

on Power Supply Board, Figure 2-2), and S3 (located on the optional Case Heater

Temperature Control Board, Figure 2-3), to the 230 VAC position.

Power consumption is less than 150 watts without optional case heater; 350 watts with

optional case heater installed.

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

2-1

Page 18

U

NPACKING AND INSTALLATION

2.4 ELECTRICAL CONNECTIONS

2.4.1 L

2.4.2 R

INE POWER CONNECTIONS

Refer to Figures 2-1 and 2-5, Installation Drawing 652258 and Pictorial Wiring

Diagram 652559.

Route the power cable (customer supplied 3-wire, minimum 18 AWG) through the

power conduit opening in the bottom of the instrument.

Connect to power terminal block TB1 as follows:

HOT/L1 = TB1-1

NEUTRAL/L2 = TB1-2

GROUND = TB1-3 or TB1-4

ECORDER CONNECTIONS

Refer to Figure 2-1 and 2-5, Installation Drawing 652258 and Pictorial Wiring Diagram

652559.

Route the cable (customer supplied 2-wire shielded cable) through the signal output

conduit opening at the bottom of the enclosure.

Connect to recorder output/curr ent out put terminal block TB2 as follows:

(+)OUTPUT = TB2-1

(- ) OUTPUT = TB2-2

SHIELD (GND) = TB2-3

2.5 SAMPLE CONNECTIONS

Refer to Figure 2-1 and Installation Drawing 652258. Connect sample gas tubing to

the Model 815 through the 1/4-inch ferrule type compression fittings located on the

bottom of the enclosure.

2.6 CALIBRATION GAS CONNECTIONS AND REQUIREMENTS

Refer to Figure 2-1 and Installation Drawing 652258.

Zero and span gases are to be connected to the same inlet fitting as the sample gas.

All applications require a zero standard gas to set the baseline point on the digital

display or output signal. Refer to the Calibration and Data Sheet. Use the background

gas as the zero gas. If a background gas is not specified, use dry nitrogen for the zero

gas.

Span gas concentration is normally between 80% and 100% of the fullscale range the

analyzer will be set on. The background gas is also indicated on the Calibration and

Data Sheet. If no background gas is specified, use dry nitrogen.

2-2

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 19

U

NPACKING AND INSTALLATION

2.7 SAMPLE HANDLING SYSTEM

The Model 815 does not contain any filters in the sample flow system to prevent

contamination of the sample lines or cells.

The sample must be clean and kept above the dew point to minimize maintenance and

to prolong the life of the components in the sample flow system. Sample Handling

components and tubing must be constructed of materials compatible with the sample.

Contact the local representative or the factory if an additional sample handling system

is required.

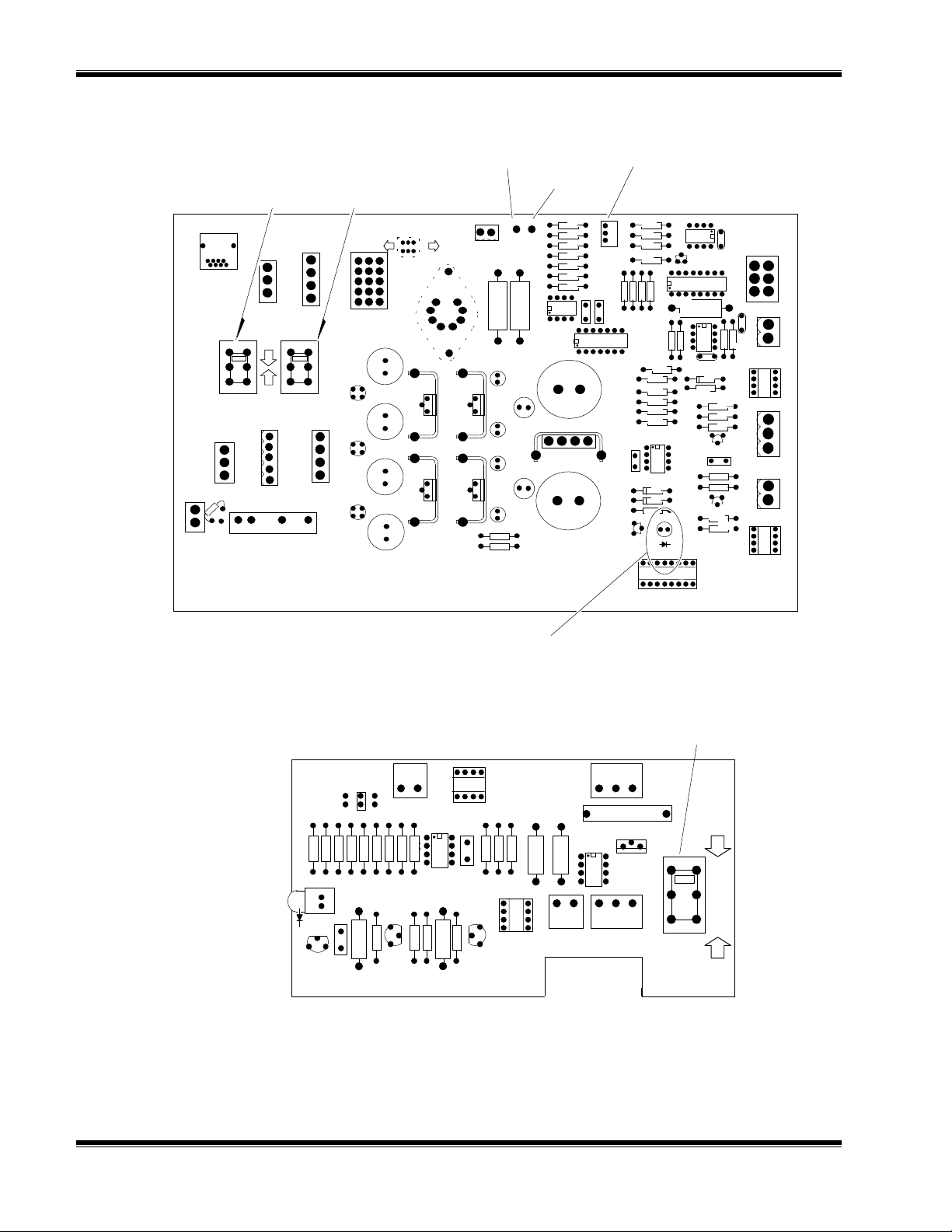

Linearizer Board

(mounted on farside of Signal Board)

(see Figures 2-6 and 2-7)

Power Supply Board

(see Figure 2-2)

Transformer

Motor/Source Assembly

(see Figure 6-2)

Signal Board

(see Figure 2-7)

Span Potentiometer

Zero/Span

Control Board

MODE Switch

Zero Potentiometer

Current Output Board

(see Figure 2-4)

Signal Output

Case Air Purge Inlet

Power

AC Power Terminal

Block TB1

Sample Cell

Sensor, Case Heater

Temperature Control

(see Figure 2-5)

Reference Cell

Detector Assembly

(see Figure 6-3)

Case Heater Temperature Control

Assembly

(see Figure 7-3)

Recorder Output /Current Output

Term inal Block TB2

Fuse

IGURE

F

2-1. M

ODEL

815 C

OMPONENT LOCATIONS

748175-F Rosemount Analytical October 1997

Sample In

Sample Out

Flame Arrestor

Fitting 1/4 inch Tube Connec tor

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

2-3

Page 20

U

NPACKING AND INSTALLATION

Set switch windows for voltage required

S2 S1

ADAPTER

1

J16

J12

115 115

TEMP

CONTROL

CASE

J5

1

R11

4 3 2 1

S2 S1

230V

115V

DETECTOR

HEATER

J4

1

K1

XFMER

FAN

J2

1

CR4

CR3

CR2

XFMER

C4

+

C2

+

C3

+

C1

S3

SS LUFT

+

+

+

+

VR4

VR3

TP1

R9

TP2

TP1

TP2

R12 R13

8

1

7

6

G

I

2

3

45

C6

+

C12

VR2

VR1

I

C8

G

O

I

G

O

+

+

C10

+

C11

C5

C7

+

C9

+

R1

R2

I

O

G

O

R3

R10

R8

R4

R5

R6

R7

AR1

- CR1 +

R9

C13

U1

+

+

R37

R34

R35

R36

R39

R18

C14

C18

C

E

Q3

1

AR4

C19

J

AR5

R17

CR8

R25

R29

R26

E

C

AK

G

R21

R22

10

C21

J14

1

R

38

1

J11

J8

1

B

Q2

C15

+

J15

R24

R23

1

Q1

1

J13

Q4

U2

R19

R20

R16

R15

C20

C16

R31

R30

R27

R28

R32

R33

B

CR6

CR7

R14

CR5

J7

IGURE

F

IGURE

F

2-2. P

OWER SUPPLY BOARD

SENSOR J18 POWER

400A 880 951E

R10 R11 R7 R8

C2

CR1

R4

C1

C

E

B

+

Q2

Set switch window for voltage required

2-3. C

ASE HEATER TEMPERATURE CONTROL BOARD

Heater LED (CR5)

R17R16 R12CR2

R3

1

AR1

R13

R2R1

Q1

K

G

A

TEMP CONTROL BD

S3

J11

J19

TEST

POWER

LINE

J5

R15

R14

1 2 1 2 3

T.I.F. HEATER

C4

3 2 1

U2

1

2

3

1

U1

S3

230

115

J17

115

SUPPLY

R6

C3

R9 R5

CR3

1

E

B

Q3

C

2-4

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 21

U

NPACKING AND INSTALLATION

2.8 LEAK TEST

Any leakage must be corrected before introduction of sample and/or application of

electrical power.

WARNING: POSSIBLE EXPLOSION HAZARD

This analyzer is of a type capable of analysis of sample gases which may be

flammable. If used for analysis of such gases the instrument explosion-proof

enclosure must be suitable for the gas.

If explosive gases are introduced into this analyzer, the sample containment

system must be carefully leak-checked upon installation and before initial

startup, during routine maintenance and any time the integrity of the sample

containment system is broken, to ensure the system is in leak-proof condition.

Leak-check instructions are provided in this section.

Internal leaks resulting from failure to observe these precautions could result in

an explosion causing death, personal injury or property damage.

The following test is designed for sample pressure up to 10 psig (69 kPa).

1. Connect air (or other inert gas such as nitrogen) at 10 psig (69 kPa) to analyzer via

a flow indicator and set flow rate to fullscale at the sample inlet (unless otherwise

specified by the Calibration and Data Sheet.

2. Seal off sample outlet with a cap while air or inert gas is flowing into the sample

inlet. If the flowmeter reading drops to zero, the system is leak free. If the

flowmeter does not drop to zero, a leak in the system is present and must be

located and sealed before operating the Model 815.

Note:

Whether or not a leak is suspected, the sample flow system should be leak

checked under pressure before the analyzer is placed in operation.

3. Refer to the note below, then liberally cover the outlet plug and all gas connections

with a suitable test liquid such as SNOOP (PN 837810) to detect leaks. Apply to all

fittings, seals, and other possible leak sources. Bubbling or foaming indicates

leakage, but the absence of bubbles does not necessarily indicate that no leaks

exist.

4. If a flow is indicated, a leak is present and may be in an area that is inaccessible to

SNOOP. Continue leak testing and tighten all connections until the flow rate drops

to zero.

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

2-5

Page 22

U

NPACKING AND INSTALLATION

Note:

Do not allow test liquid to contaminate cells, detector or source windows.

Should this occur, the cells should be cleaned (Section 6.1).

2.9 OPTIONS

The following options may be ordered as kits and installed in the field:

2.9.1 A

IR PURGE KIT

652271

WARNING: POSSIBLE EXPLOSION HAZARD

If an air purge is used, the purge inlet fitting must be equipped with a Flame

Arrestor Assembly (PN 638426) to prevent propagation of a flame or explosion

from inside the enclosure to the ambient atmosphere.

All precautions relating to the installation and operation of this instrument must

be strictly adhered to whether or not the air purge option is installed.

purge option is not intended as protection from explosion in hazardous areas.

Purging of the enclosure of the explosion-proof Model 815 may be recommended in

some applications to provide a corrosion free internal atmosphere. If the instrument is

to be equipped with an optional Air Purge Kit, refer to instruction sheet (748184)

supplied in kit for installation. This kit is designed to provide a corrosion free or

spectrally-constant internal atmosphere, and

hazard protection.

2.9.2 C

URRENT OUTPUT KIT

652269

is not intended to provide explosion

The air

2-6

Refer to Figures 2-1, 2-2, 2-4, 2-5, Pictorial Wiring Diagram 652259 and installation

Drawing 652258.

NSTALLATION

I

1. Mount the Current Output Board to the chassis next to the Power Supply Board

using the spacer and hex nut supplied in the kit.

2. Connect the two-wire cable supplied in kit (PN 749068) as follows:

Wire From To

Blue

Orange

Current Output Board

TB1-1 (-)

Current Output Board

TB1-2 (+)

Recorder Output/Current Output Terminal

Block TB2-5 (Current Output -)

Recorder Output/Current Output Terminal

Block TB2-4 (Current Output +)

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 23

U

NPACKING AND INSTALLATION

3. Connect the eight conductor flat cable supplied in kit (PN 652257) from Current

Output Board J2 to Power Supply Board J9.

4. Refer to Section 3.6 for 4-20mA or 0-20mA adjustment procedur e.

2.9.3 C

ASE HEATER TEMPERATURE CONTROL KIT

652270

Refer to Figures 2-1, 2-2, 2-3, 2-5, 7-3 and Pictorial Wiring Diagram 652259.

NSTALLATION

I

1. Mount the Temperature Control Assembly to the chassis with the 4 screws

supplied in the kit.

2. Attach the sensor (at T.I.F. 2-position terminal block) to the reference cell with a

tie wrap as shown in Figure 2-1.

3. Connect the 3-conductor cable supplied in kit (PN 622903) from Temperature

Control Board J5 to Power Supply Board J5.

4. Connect the 8-conductor flat cable supplied in kit (PN 901768) from Temperature

Control Board J11 to Power Supply Board J11.

Baseline Current

Output Adjust

(0 or 4mA)

IGURE

F

Fullscale Current

Output Adjust

(20mA)

2-4. C

URRENT OUTPUT BOARD

ZERO

SPAN

C4

+

R7

CR2

R9

CR3

U6

R1

1

1

R2

U2

U1

U3

1 2 3 4

C5

+

+

C9

+

C8

+

C5

+

C7

C1

+

C2

+

U4

C3

MA

V/I 652442 BD

I G O

+ CR1

U5

TB1

-

+

J2

J1

1

O

G

I

To Power Supply Board

J12

To Recorder Output/Current

Output Terminal Block TB2

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

2-7

Page 24

U

q

NPACKING AND INSTALLATION

Ref Power Supply Board

Ref - Fuse

SPACER

Ref - TB1

Line Power

J2

CURRENT

OUTPUT

BOARD

TB1

SCREW

NUT

6-32

4 Re

J5

SENSOR

See Figure 2-1 for

mounting location.

uired

J1

Ref - TB2

Recorder

Output/

Current Output

TEMPERATURE

CONTROL ASSEMBLY

See Figure 7-3.

IGURE

F

2.9.4 L

Refer to Figures 2-1, 2-6, 2-7 and Pictorial Wiring Diagram 656659

NSTALLATION

I

1. Mount the Linearizer Board to the Signal Board by inserting the 6-pin header on

2. Secure the Linearizer Board to the Signal Board with the screw, lock washer and

2-8

2-5. I

INEARIZER KIT

NSTALLATION OF CURRENT OUTPUT AND TEMPERATURE CONTROL

PTIONS

O

652268

the wiring side of the Linearizer Board into the 6-position single-in-line socket on

the Signal board. The through hole on the Linearizer Board (next to R19) should

be in-line with the swaged threaded spacer on the Signal Board.

flat washer supplied in the kit.

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 25

IGURE

F

2-6. L

6 Pin

Header

INEARIZER BOARD

R5

R6

R7

R8

R9

1

RP1

R10

R11

R12

LINEARIZER BD

1

R1

R2

1

CR2

1

1RP2

1

1

CR1

U5

R3

R4

R14

U1

U2

U3

U4

Through Hole

U

NPACKING AND INSTALLATION

LIN

OFF

TP1

SW1

TP2

ON

0

R15

R16

1

2

R17

3

R18

4

R19

5

R20

6

R21

7

R22

8

R23

S

SW2

TP3

R13

TP4

R24

CAL

C

R50 R4 R2 R1

C3

ZERO/SPAN

CONTROL

C2

J8

1

R46 C20 C22 R34 R29

POWER SUPPLY

J3

1

J7

1

C1

R7

C7

R60 R11 R10

DISPLAY

U9

R54 R56 R55 R57

C5

U1

R5

CR1

C4

R8 R9 R16 R14 R15 R21

U2

C9

C8

U4

R13 R18 R19

R49Y1R33 R45 R44

C21

C25 C24 R59 R58

U13

C6

R6

U3

J1

1

OSCILLATOR

METER RECORDER

1

J6

R20 R23

R31

C10

C23

U11

C12

U5

C16

U8

C14

U7

C18 R42 C18

1

TP1 TP2 TP3 TP4 TP5 TP6 TP7

SW2

R22

C11

SEC 1 2 5 10

C13 R24 R25 R26 R27 R35 R52 R36

C15

R32

R30 R40 R51

G

U6

J2

TEST

O

I

R5

R6

R7

R8

R9

RP1

J4

R10

R11

R12

LINEARIZER BD

1

GAIN PEAK BALANCE

R3

R53

U12

1

U1

1

U2

1

U3

1

U4

1

U5

R12

R47

R48

C26

U10

C17 R41 R38

R1

R2

R3

R4

CR2

1RP2

CR1

R13

R14

SIGNAL BD

6-Pin Header located on farside of Linearizer Board

CR2

E1

SW1

SW2

ZERO

R28

R37

SW1

E2

(1)LC

(2)HC

R39

LIN

OFF

ON

0

1

2

3

4

5

6

CAL

7

8

S

C

Screw, Lock Washer and

Flat Washer supplied in

Linearizer Kit

R17

TP1

TP2

R15

R16

R17

R18

R19

R20

R21

R22

R23

TP3

TP4

R24

IGURE

F

2-7. S

IGNAL BOARD WITH LINEARIZER BOARD INSTALLED

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

2-9

Page 26

U

NPACKING AND INSTALLATION

2.9.5 M

OTOR/SOURCE ASSEMBLY PURGE KIT

655094

WARNING: POSSIBLE EXPLOSION HAZARD

If a motor/source purge is used, the purge inlet fitting must be equipped with a

Flame Arrestor Assembly (PN 638426) to prevent propagation of a flame or

explosion from inside the enclosure to the ambient atmosphere.

All precautions relating to the installation and operation of this instrument must

be strictly adhered to whether or not the air purge option is installed. The air

purge option is not intended as protection from explosion in hazardous areas.

Purging of the Model 815 motor/source assembly may be installed or recommended in

some applications to provide CO

instruction sheet (748256) supplied in kit. This kit

explosion hazard protection.

NSTALLATION

I

2

free, spectrally-constant atmosphere. Refer to

is not intended to provide

Refer to instruction sheet (748256) supplied in kit

2-10

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 27

I

NITIAL STARTUP AND CALIBRATION

3

Prior to shipment, the Model 815 was subjected to extensive factory performance

testing, during which all necessary optical and electrical adjustments were made.

Normally, the analyzer requires only a verification of zero and span settings (refer to

Section 3.3) before being put into operation. If operation is unsatisfactory, refer to

Section 5, Troubleshooting. If the problem is not corrected, contact the nearest field

service facility (see Field Service and Repair Facilities in rear of this manual).

The following instructions are recommended for initial start-up, and subsequent

standardization of the analyzer.

WARNING: POSSIBLE EXPLOSION HAZARD

If explosive gas samples are introduced into the analyzer, it is recommended

that sample containment system fittings and components be thoroughly leak

tested prior to initial application of electrical power, routinely on a periodic basis

thereafter, and after any maintenance which entails breaking the integrity of the

sample containment system. Leakage of flammable samples could result in an

explosion. Refer to leak test procedure, Section 2.8.

3.1 LEAK TEST

Per Section 2.8, perform the Leak Test.

3.2 POWER VERIFICATION

1. Verify power select switches S1, S2 (on Power Supply Board) and S3 (on

Temperature Control Board)are set for available power (115 VAC/220 VAC). Refer

to Section 2.3.

2. Verify electrical connections are correct. Refer to Section 2.

3. Apply power. Verify that heater LED (CR5 on the Power Supply Board) is ON.

Refer to Figure 2-2 and Drawing 624073.

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

3-1

Page 28

I

NITIAL STARTUP AND CALIBRATION

3.3 OPERATING CONTROLS AND INDICATORS

External controls (located on the analyzer door) are described in the following section.

Refer to Figure 3-1.

3.3.1 D

IGITAL DISPLAY

3 1/2 digit LCD displays sample data or oscillator tuning check, depending on position

of the 4-position MODE switch (see Section 3.3.2).

During linearization, a calibration curve is used to convert display readings into

concentration values. (Alternatively, linear readout of concentration values for a given

operating range is obtainable through use of an optional signal output linearizer

board.)

3.3.2 MODE S

WITCH

A 4-position rotary switch for selection of the following:

TUNE -

Test position used periodically to verify and adjust proper oscillator tuning. In

TUNE mode, digital display should indicate the previously determined “Normal Tuning

Value.” If not, adjust the OSC TUNE (refe r to Section 5.4 Oscillator Tune Adjustment).

DETECTOR RANGE 1

To adjust preamp gain (see Section 5.5 Preamp Gain Adjustment).

-

Low concentration range.

Percent of fullscale of the lower concentration

range is displayed on the digital display and a proportional signal is output at Recorder

Output/Current Output Terminal Block TB2.

RANGE 2

range is displayed on the digital display and a proportional signal is output at Recorder

Output/Current Output Terminal Block TB2.

3.3.3 ZERO A

To adjust zero point on digital display or signal output.

3.3.4 SPAN A

To adjust calibration span point on display or signal output.

3-2

-

High concentration range.

DJUSTMENT

DJUSTMENT

Percent of fullscale of the lower concentration

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 29

Digital Display

(see Section 3.3.1)

I

NITIAL STARTUP AND CALIBRATION

SPAN Adjustment

(see Section 3.3.4)

IGURE

F

ZERO Adjustment

(see Section 3.3.3)

MODE Switch

(see Section 3.3.2)

3-1. M

ODEL

815 O

ZERO SPAN

DETECTOR RANGE 1

TUNE RANGE 2

Rosemount Analytical

Model 815

Oxygen Ana l yzer

PERATING CONTROLS AND INDICATORS

3.4 CALIBRATION

CAUTION: HIGH PRESSURE GAS CYLINDERS

This analyzer requires periodic calibration with known zero and standard gases.

Refer to General Precautions for Handling and Storing High Pressure Cylinders,

in the rear of this manual.

Note:

Refer to the Factory Calibration and Data Sheet at the end of this manual for

specifications of the calibration gases and procedures.

Note:

Component electronic offsets will shift slightly as the interior temperature of the

instrument changes. For this reason, it is recommended that immediately prior

to adjustment of the electronics, the instrument be allowed to run with the

enclosure door securely closed for at least two hours (or long enough for the

instrument to reach its regulated operating temperature).

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

3-3

Page 30

I

NITIAL STARTUP AND CALIBRATION

Clean, dry nitrogen is recommended for use as the zero gas, unless otherwise

specified on the data sheet. Span gas is typically 80-100% of the fullscale

concentration of the range being used. Background composition of the span gas is

typically as similar to the composition of the sample being monitored as practical.

3.4.1 C

ALIBRATION PROCEDURE

Refer to Figures 2-1 and 3-1.

1. Connect zero or span gases to the sample

connection port on the bottom of

inlet

the enclosure.

2. Set the calibration gas flow rate to the same flow rate as the sample being

analyzed, typically 1-2 SCFH (500-1000 /min.), and at the same pressure as the

sample gas. Note that the analyzer is not flow rate dependent; however,

calibration and sampling conditions should always be as similar as possible.

3. Monitor the signal at the recorder output or the analyzer digital display.

4. Introduce zero gas through the sample inlet, and set the ZERO adjustment for a

reading of zero output.

5. Set the MODE switch to RANGE 2 (high range). Introduce a span gas of 80-100%

fullscale. Set the SPAN adjustment for the corresponding voltage.

For example, if fullscale is 10% and the span gas is 8.5%, adjust the span screw

for 85% of fullscale, if linearizer is installed. If linearizer is not used, refer to the

Calibration and Data Sheet.

6. Set the MODE switch to RANGE 1 (Low Range), introduce a low range span gas,

and check the output for the correct value. If the lower range span gas value

agrees with the calculated value, the analyzer has been calibrated correctly.

If the output value does not agree, verify the concentration of the span gas.

3.4.2 L

Linearizers ordered with the instrument are calibrated at the factory for the particular

operating range specified by the order and should need no further adjustment.

To verify proper operation, connect different concentrations of span gas to the sample

inlet and record the output signal or digital display (on analyzer door) reading. Plot th e se

values versus concentration (typical curve shown in Figure 3-4). If the curve is linear,

the linearizer for that range is properly calibrated.

If the calibration curve is not linear, perform one of the following calibration

procedures.

The first method requires use of a DVM; the second uses recorder output.

3-4

INEARIZER BOARD CALIBRATION

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 31

I

NITIAL STARTUP AND CALIBRATION

3.4.3 C

ALIBRATION CURVE CONSTRUCTION

A typical calibration curve showing the relationship between the non-linearized and

linearized output is shown in Figure 3-4. The curve is a plot of signal output versus

concentration. Examples of curves normalized for concentration and for recorder

output are shown in Figure 3-4.

Zero Potentiometer R28

Not active on Model 815

Span Potentiometer

R37 For low

concentration

Range Switch SW1

Not active on Model

815

Span Potentiometer

R39

DIP Switch SW2

Time Constant Select

SW2

SEC 1 2 5 10

Jumper E2 - High Concentration

Note: Must be installed if

Linearizer Board not installed.

Jumper E1 - Low Concentration

Note: Must be installed if

Linearizer Board not installed.

Peak Potentiometer R12

Gain Potentiometer R3

Jumper E3

0 to 5 VDC

E3

GAIN PEAK

R12

R3

ZERO

R28

R37

SW1

E2

E1

R39

(1)LC

(2)HC

R50 R4 R2 R1

C3

ZERO/SPAN

CONTROL

C2

J8

1

R46 C20 C22 R34 R29

POWER SUPPLY

J3

1

J7

1

C1

R7

C7

R60 R11 R10

DISPLAY

U9

R54 R56 R5 5 R57

C5

U1

R5

CR1

C4

R8 R9 R16 R14 R15 R21

U2

C9

C8

U4

R13 R18 R1 9

R49Y1R33 R45 R4 4

C21

C25 C24 R59 R58

U13

C6

R6

U3

J1

1

OSCILLATOR

METER REC ORDER

1

J6

R20 R23

R31

C10

C23

U11

TP2

TP1 TP2 TP3 TP4 TP5 TP6 TP7

C11

C12

U5

C16

U8

R32

C14

U7

R30 R40 R5 1

G

U6

C18 R42 C18

1

J2

TEST

TP6

SW2

R22

SEC 1 2 5 10

C13 R24 R25 R26 R27 R35 R52 R36

C15

R5

R6

R7

R8

R9

1

I

RP1

J4

R10

R11

R12

LINEARIZER BD

O

TP7

GAIN PEAK BALANCE

R3

R53

U12

1

U1

1

U2

1

U3

1

U4

1

SIGNAL BD

R12

R47

R48

C26

U10

C17 R41 R38

CR2

1RP2

CR1

U5

R14

CR2

E1

R15

R16

R17

R18

R19

R20

R21

R22

R24

R23

E2

SW1

SW2

SW1

ZERO

R28

R37

(1)LC

(2)HC

R39

LIN

OFF

ON

0

1

CAL

2

3

4

5

6

7

8

S

C

Linearizer Board

See Figure 3-3.

R17

TP1

R1

R2

TP2

R3

R4

TP3

R13

TP4

IGURE

F

3-2. S

IGNAL BOARD COMPONENT LOCATIONS

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

3-5

Page 32

I

NITIAL STARTUP AND CALIBRATION

R5

R6

R7

R8

R9

1

RP1

R10

R11

R12

LINEARIZER BD

U1

U2

U3

U4

1

1

CR2

1

1RP2

1

1

CR1

U5

R14

R1

R2

R3

R4

R13

TP4

TP1

TP1

TP2

R15

R16

R18

R19

R20

R21

R22

TP3

TP4

R24

R17

R23

SW1

SW2

LIN

CAL

OFF

ON

S

C

Slide Switch SW1

Linearize ON/OFF

0

1

2

3

4

5

6

7

8

Linearizer Potentiometers

Slide Switch SW2 Signal Selection:

S = Signal

C = Calibration

IGURE

F

3-3. L

INEARIZER BOARD ADJUSTMENTS

To construct a new calibration curve, use the following procedure:

1. Determine the fullscale range to be calibrated. On the Linearizer Board (Figure 3-

3) set SW1 to OFF.

2. Obtain calibration gases (or use a dilution system) of concentrations from 0-100%

fullscale in 10% increments.

3. Introduce the zero gas and note the recorder output voltage (or digital display

reading).

4. Repeat step 3 using the other calibration gases.

5. Normalize the readings, so that 100% fullscale is 1 and 0% is 0. Plot the

concentration versus linearizer output on a graph similar to Figure 3-4.

6. Draw a straight line from the 0% data point to the 100% point. This will be the

linear output after the linearizer is properly adjusted.

7. Segment the line into eight equal points for an 8-point linearization. Draw the

vertical lines from each of the data points to the straight line. From where the

vertical lines intersect the straight line, draw horizontal line to the right axis. The

value on the right axis will be the value to which each data point will be adjusted.

3-6

8. Enter the values in Table 3-2, using Table 3-1 as a guide. These values will be

used to perform Section 3.5.3 Line ari zation Procedure.

9. The linearizer can now be adjusted using potentiometers R15 through R23 on the

Linearizer Board (Figure 3-3).

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 33

I

NITIAL STARTUP AND CALIBRATION

SIGNAL IN

(NORMALIZED)

Refer to Calibration and

Data Sheet for the curve

corresponding to the

application specified for this

Model 815.

IGURE

F

3-4. T

YPICAL LINEARIZA TION CURVE

1

0.875

0.750

0.625

0.500

0.375

0.250

0.125

0

0 1

CONCENTRATION NORMALIZED

1

0.8274

0.6696

0.5266

0.3974

0.2812

0.1770

0.0838

0

SIGNAL OUT

(NORMALIZED)

3.5 LINEARIZATION PROCEDURE

WARNING: EXPLOSION HAZARD

Do not operate the Model 815 Explosion-Proof Analyzer without lens cover and

door in place with all bolts secured, unless location has been determined to be

non-hazardous.

1. Locate analyzer in a non-hazardous area before opening the enclosure door.

2. Allow the analyzer to warm-up for a minimum of two hours prior to calibration.

3. Remove the bolts fastening the enclosure door to access the Linearizer Board

which is mounted to the Signal Board inside the enclosure door (see Figure 2-1).

4. On the Linearizer Board (Figure 3-3):

a. Set SW2 to C (Calibration)

b. Connect a DVM to TP4

c. Set SW1 to ON

d. Connect another DVM to TP1

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

3-7

Page 34

I

NITIAL STARTUP AND CALIBRATION

5. Adjust R16 through R23 full counterclockwise.

6. Refer to Table 3-2 or the Calibration and Data Sheet and make the following

adjustments: (Note: Adjusting R24 simulates an input signal to the Linearizer

Board. R15 through R23 are adjusted to bring the output signal at the level onto

the linear curve.)

a. Adjust R24 so TP4 reads 0 volts.

b. Adjust R15 so TP1 reads 0 volts.

c. Adjust R24 so TP4 reads 0.625 volts.

d. Adjust R16 so TP1 reads 0.419 volts (or the value indicated in the Calibration

and Data Sheet or Table 3-2).

e. Adjust R24 so TP4 reads 1.25 volts.

f. Adjust R17 so TP1 reads 0.885 volts (or the value indicated in the Calibration

and Data Sheet or Table 3-2).

g. Continue with the remaining potentiometers (R18 through R23), adjusting R24

to each value in column 3 of Table 3-2, and then adjusting R18 through R23 to

each value in column 5.

7. Set SW2 to S (Signal).

8. The Linearizer Board is now calibrated.

INPUT VOLTAGE TO LINEARIZER AT TP4

Reading to be obtained by setting SW2 to C (CAL) and

adjusting potentiometers R15 through R23

% FULLSCALE

0.0 0.000 0.000 R15 0.000 0.000

12.5 0.125 0.625 R16 0.084 0.419

25.0 0.250 1.250 R17 0.177 0.885

37.5 0.375 1.875 R18 0.281 1.405

50.0 0.500 2.500 R19 0.397 1.987

62.5 0.625 3.125 R20 0.527 2.633

75.0 0.750 3.750 R21 0.670 3.348

87.5 0.875 4.375 R22 0.827 4.137

100.0 1.000 5.000 R23 1.000 5.000

TEST METER RE AD I N G

on Linearizer Board

NORMALIZED

VALUE/GRAPH

VOLTAGE AT TP4 POTENTIOMETER

Reading at TP1 obtained with the specified linearizer

LINEARIZED OUTPUT

potentiometer

NORMALIZED

VALUE/GRAPH

VOLTAGE AT TP1

ABLE

T

3-8

3-1. T

YPICAL LINEARIZA TION CALIBRATION VALUES

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 35

I

NITIAL STARTUP AND CALIBRATION

INPUT VOLTAGE TO LINEARIZER AT TP4

TEST METER RE AD I N G

Reading to be obtained by setting SW2 to C (CAL) and

adjusting potentiometers R15 through R23

Reading at TP1 obtained with the specified linearizer

on Linearizer Board

% FULLSCALE

NORMALIZED

VALUE/GRAPH

VOLTAGE AT TP4 POTENTIOMETER

R15

R16

R17

R18

R19

R20

R21

R22

R23

ABLE

T

3-2. L

INEARIZA TION CALIBRATION VALUES

3.6 CURRENT OUTPUT

The current output board can be adjusted for 4-20mA or 0-20mA.

LINEARIZED OUTPUT

potentiometer

NORMALIZED

VALUE/GRAPH

VOLTAGE AT TP1

Refer to Figure 3-5. Adjust potentiometer R1 for the baseline output current (0 or

4mA), and R2 for the fullscale output (20mA).

Fullscale Current Output

Adjust (20mA)

Baseline Current Output

Adjust (0 or 4mA)

IGURE

F

3-5. C

U6

R1

1

ZERO

1

R2

SPAN

C4

U2

+

U3

R7

CR2

R9

CR3

1 2 3 4

URRENT OUTPUT BOARD

U1

C5

+

+

C9

+

C8

+

C5

+

C7

C1

+

C2

+

U4

C3

MA

V/I 652442 BD

I G O

+ CR1

U5

TB1

-

+

J2

J1

1

O

G

I

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

3-9

Page 36

I

NITIAL STARTUP AND CALIBRATION

N

OTES

3-10

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 37

R

OUTINE OPERATION AND THEORY

4

4.1 ROUTINE OPERATION

As a check of instrument performance, a log book should be kept with the analyzer for

recording notes on operation, calibration, performance and maintenance.

4.2 RECOMMENDED CALIBRATION FREQUENCY

The calibration interval should be determined by the user based on the accuracy

required. Initially, the instrument should be calibrated every 24 hours until experience

indicates that some other interval is more appropriate.

If barometric pressure changes significantly, recheck the calibration against an

upscale standard gas. A change in cell pressure of 1 inch of mercury (3 kPa) will

result in a readout error of approximately 3% of reading.

4.3 SHUTDOWN

Instrument power is normally left on at all times except during a prolonged shutdown

or maintenance.

1. To shutdown the instrument:

2. Disconnect electrical power.

3. If hazardous samples have been flowing through the analyzer, adequate venting of

the gases and adequate ventilation must be provided for before disconnecting

sample lines from the analyzer.

4. Inspect the sample lines and “wetted” parts of the analyzer, clean if necessary.

5. Flush sample lines and analyzer cell with dry nitrogen or dry air, verify that they are

dry.

6. Plug sample lines.

Following prolonged shutdown, repeat Section 2.8 Leak Test, Section 3.1 Initial

Startup and Calibration to restore analyzer to service.

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

4-1

Page 38

R

OUTINE OPERATION AND THEORY

4.4 DETECTION SYSTEM THEORY

As shown in Figure 4-1, infrared radiation is produced from two separate energy

sources. This radiation is interrupted by a chopper at 5 Hz. Depending on the

application, the radiation may then be optically filtered to reduce background

interference from other infrared-absorbing components. The two equal beams are

then directed through two parallel optical cell, a flow-through sample cell and a sealed

reference cell.

During analysis, a portion of the infrared radiation is absorbed by the component of

interest in the sample, with the quantity of infrared radiation absorbed being

proportional to the component concentration.

The detector is a “gas microphone” based on the Luft principle. It continuously

monitors the infrared energy passing through the sample and reference cells. During

the portion of the chopping cycle when the chopper is not blocking the sample and

reference beams, the diaphragm distends away from the metal button, thus

decreasing detector capacitance. This capacitance is directly proportional to the

difference between the reference and sample cells signals, and is used to modulate

the amplitude of a radio frequency voltage, which is demodulated into a resulting DC

voltage signal. The output signal is proportional to the component concentration; it is

amplified and sent to the digital display and to the recorder connections.

The analyzer can incorporate cells of short or long optical path lengths, depending on

the particular component of interest and its concentration range. If cell length is 4 to

32mm, the pair of sample and reference cells consists of a single stainless steel cell

block with two parallel holes bored through (see Figure 7.2). If cell length is over

32mm, sample and reference cells are separate cylindrical Pyrex tubes, with gold

plated inner diameter (see Figure 7.1).

INFRARED

SOURCE

REFERENCE

CELL

DETECTOR

STATIONARY

BUTTON

SIGNAL

SIGNAL

CONDITIONING

CIRCUITRY

CHOPPER

SAMPLE IN

SAMPLE

CELL

SAMPLE OUT

DIAPHRAGM

DISTENDED

COMPONENT OF INTEREST

OTHER MOLECULES

IGURE

F

4-2

4-1. NDIR D

ETECTION SYSTEM

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 39

R

OUTINE OPERATION AND THEORY

4.5 ELECTRONIC CIRCUITRY

The block diagram in Figure 4-2 traces the signal through the electronic circuitry and

depicts the various waveforms involved.

4.5.1 O

SCILLATOR CIRCUIT BOARD (SCHEMATIC

LEMENTS OF AMPLITUDE MODULATION CIRCUIT

E

623995)

AND ASSOCIATED

A 10 MHz carrier wave is generated by a crystal-controlled radio frequency oscillator

using crystal Y1 and transistors Q1 and Q2.

The modulation circuit is driven by the detector, the sensing element of the analyzer.

Considered electronically, the detector is a two-plate variable capacitor. The tuned

tank circuit is coupled inductively, through one winding of inductance in L1, to the

oscillator. Amplitude of the 10 MHz carrier thus varies with the 5 Hz modulation signal,

which corresponds to the capacitance change of the detector. See Section 4.3

Detection System Theory.

4.5.2 F

UNCTIONING OF MODULATION SYSTEM IN

TUNE M

ODE

In this mode the display indicates the rms value of the halfwave-rectified carrier. The

tank circuit is now adjusted in the following two-step sequence:

Tuning:

Initially, the OSC TUNE adjustment is set somewhat counterclockwise from

its correct setting. Then, it is rotated clockwise to move the slug into the core, thus

increasing inductance and decreasing resonant frequency. The adjustment is set for

maximum obtainable reading. At this setting, tank-circuit resonant frequency is the

same as oscillator frequency (i.e., nominal 10 MHz). See Resonance Curve Number 1 ,

Figure 5-1B.

Detuning:

By counterclockwise rotation of the OSC TUNE adjustment, the slug is

partially withdrawn from the core, thus decreasing inductance and increasing resonant

frequency. The adjustment is set so reading decreases to between 75 % and 80 % of

the maximum obtainable value noted in Tuning, above. See Resonance Curve

Number 2, Figure 5-1B. This curve has the same shape as that obtained in Tuning, but

is displaced to the right.

4.5.3 F

UNCTIONING OF MODULATION SYSTEM IN OPERATING MODE

Overall sensitivity of the analyzer system may now be checked by placing SPAN gas

in the sample beam to simulate absorption of sample-beam energy and thus provide

the maximum obtainable 5 Hz detector-output signal.

During that portion of the chopping cycle, while the chopper is not blocking the sample

and reference beams, the diaphragm distends away from the metal button, thus

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

4-3

Page 40

R

OUTINE OPERATION AND THEORY

decreasing detector capacitance and shifting the tank-circuit resonance curve to the

right. At the moment the diaphragm reaches maximum distention, the curve reaches

the position of Curve 3, Figure 5-1B.

The diaphragm now pulses cyclically, causing the resonance curve to move

continuously back and forth within the limits defined by Curves 2 and 3 of Figure 5-1B.

Carrier amplitude decreases as the curve moves to the right and increases as it moves

to the left. Thus, the response characteristics of the system depend on the location of

Curve 2. Position of this curve depends on the degree of tank-circuit detuning used.

By detuning to 75% to 80% of the maximum obtainable carrier amplitude and

operating on the portion of the curve thus obtained, maximum slope yields highest

sensitivity and minimum curvature provides best linearity.

4.5.4 R

ADIO-FREQUENCY DEMODULATOR

The amplitude-modulated 10 MHz carrier from the detector/oscillator circuit is applied

to the radio-frequency demodulator. This circuit is a voltage-doubler type rectifier

utilizing diodes CR1, CR2, CR3, CR4 and capacitor C7. The circuit gives

approximately double the output voltage of a conventional halfwave rectifier. This

result is obtained by charging a capacitor during the normally wasted half-cycle, and

then discharging it in series with the output voltage during the next half-cycle.

4.5.5 S

IGNAL BOARD (SCHEMATIC

652431)

The 5 Hz sinewave detector signal goes through an AC amplifier U1A and associated

resistor. The output signal goes through bandpass filter network U2 and U4 to remove

harmonics and distortion.

The signal next goes through a precision signal rectifier U3 and Q1 and then through

low pass filter U5. This output goes to a time constant network and then to inverting

buffer amplifier U8 with zero control R28.

The signal goes to either range amplifier high concentration SW2, U10A and R39 or

range amplifier low concentration SW2, U10A and R37. For the low concentration

range, the gain of U10A is adjustable with R37.

4-4

The recorder/digital display output consists of a non-inverting buffer amplifier U12A/B.

The signal board is designed to accept two operational linearizer boards. J4 is the

connector for the linearizer range low concentration and J5 is the connector for the

linearizer range high concentration. If a linearizer board is installed, the appropriate

jumper (E1 for low concentration, E2 for high concentration) must be removed.

October 1997 Rosemount Analytical 748175-FModel 815 Explosion Proof Non-Dispersive Infrared Analyzer

Page 41

R

OUTINE OPERATION AND THEORY

4.5.6 P

OWER SUPPLY BOARD (SCHEMATIC

624073)

The Power Supply Board supplies the different voltages to the various boards.

Additionally, the Power Supply Board includes an adjustable source driver circuit, a

chopper motor driver circuit and proportional temperature controller circuit.

4.5.7 C

ASE HEATER TEMPERATURE CONTROL BOARD (SCHEMATIC

624003)

This is a proportional temperature controller, which works on a variable time method.

Resistors R7, R8, R9, R10, R11 and the sensor form a bridge which feeds a

comparator, AR1. AR1 operates in an ON/OFF mode to drive transistor Q3. The

sensor is a resistor with a positive temperature coefficient (1.925 ohms/°C).

The resistance is 500 ohms at 0°C. Resistors R1 through R6, Q1, Q2 and C1 provide

the circuit for the time proportioning action; C1 charges until the voltage on C1 reaches

9.0 V. Q1 then discharges C1, and the charging process repeats itself. The emitter of

Q2 follows the voltage on C1, which is essentially a sawtooth. This is injected into the

bridge, which causes the setpoint to bump on a variable time basis. Q3 (through LED

CR1) triggers optical coupler U1 which gates TRIAC (U2). U2 allo ws fullwave VAC to

flow through the case heater element.

4.5.8 C

URRENT OUTPUT BOARD (SCHEMATIC

652439)

The Current Output Board converts the standard DC voltage output to 0-20mA or 420mA for use with external recorders or data gathering systems.

The output voltage signal is connected to J2-6 and is converted to a current signal

using rectified 24 VDC input power from pins 1 and 2. The isolated current signal is

output at pins 8 (+) a nd 7 (-) of J1 and also on connections 2 (+) and 1 (-) of te rminal

block TB1.

4.5.9 L

INEARIZER BOARD (SCHEMATIC

624674)

The Linearizer Board converts a non-linear

signal input into a linearized signal which is output to the display or recorder. Switch

SW2 selects the input for the buffer amplifier AR5B. In calibration mode (SW2 on C),

the input signal can be simulated with R24.

A linear or non-linear output may be selected by switching SW1 ON (linear) or OFF

(non-linear).

748175-F Rosemount Analytical October 1997

Model 815 Explosion Proof Non-Dispersive Infrared Analyzer

4-5

Page 42

R

OUTINE OPERATION AND THEORY

SOURCE

Information Signal

(5 Hz capacitance change)

Detector

(Modulator)

OSCILLAT O R BOARD

UNFILTERED

5 HZ SIGNAL

BUFFER

AMPLIFIER

SIGNAL BO ARD

FULLWAVE

RECTIFIER

FULLWAVE

RECTIFIED

5 HZ SIGNAL

OSCILLATOR

5 MHz CARRIER

AMPLIFIED

LOWPASS

GAIN CONTROL

(on analyzer door)

FILTER

AMPLITUDE-MODULATED

5 MHz CARRIER

5 Hz

BANDPASS

FILTER

FEEDBACK (RANGE)

RESISTORS

TP2

YEL

VOLTAGE

DOUBLER

SIGNAL