Page 1

Quick Start Guide

00825-0100-4421, Rev CB

Emerson™ Smart Wireless Field Link

June 2017

Page 2

Quick Start Guide

June 2017

NOTICE

This guide provides basic guidelines for the Smar t Wireless Field Link. It does not provide instructions for

diagnostics, maintenance, service, or troubleshooting. This guide is also available electro nically on

www.emersonprocess.com.

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate

local, national, and international standards, codes, and practices. Review the Product Certifications

section for any restrictions associated with a safe installation.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage may be present on leads can cause electrical

shock.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following conditions:

This device may not cause harmful interference.

This devi ce must accept any interferen ce received, including interference that may cause undesired

operation.

This device must be installed to ensure a minimum antenna separation distance of 8-in. (20 cm) from all

persons.

Contents

Wireless considerations . . . . . . . . . . . . . . . . . . . 3

Physical installation . . . . . . . . . . . . . . . . . . . . . . . 5

Verif y operation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2

Reference information . . . . . . . . . . . . . . . . . . 7

Ordering information . . . . . . . . . . . . . . . . . . . . . 9

Product Certifications . . . . . . . . . . . . . . . . . . . . 10

Page 3

June 2017

A

B

C

D

E

15- to 25-ft.

(4,6 to 7,6 m)

6-ft. (2 m)

Quick Start Guide

1.0 Wireless considerations

1.1 Power up sequence

The Smart™ Wireless Field Link and wireless I/O should be installed and

functioning properly before the power modules are installed in any wireless field

devices. Wireless field devices should also be powered up in order of proximity

from the Field Link beginning with the closest. This will result in a simpler and

faster network installation.

1.2 Mounting location

The Field Link should be mounted in a location that allows convenient access to

the host system network (wireless I/O) as well as the wireless field device

network.

Find a location where the Field Link has optimal wireless performance. Ideally this

will be 15 to 25 ft. (4,6 to 7,6 m) above the ground or 6 ft. (2 m) above

obstructions or major infrastructure.

Figure 1. Mounting Location

A. Control room

B. Ground

C. Field link

D. Mast or pipe

E. Infrastructure

3

Page 4

Quick Start Guide

A

A

1.3 Antenna position

The antenna should be positioned vertically, either straight up or straight down,

and should be approximately 3 ft. (1 m) from any large structure, building, or

conductive surface to allow for clear communication to other devices.

Figure 2. Antenna Position

1.4 Conduit plug

The temporary orange plugs should be replaced with the included conduit plugs

using approved thread sealant.

June 2017

Figure 3. Conduit Plugs

A. Conduit plug

4

Page 5

June 2017

Quick Start Guide

1.5 Intended use

The Field Link must be used in conjunction with a network manager or network

Gateway. The Field Link then functions as a translator between the wired network

and a wireless field network.

Figure 4. Example System Architecture

A

E

B

D

C

F

A. Host system

B. Control network

C. Network manager

D. Field link

E. Wireless field network

F. Wireless field devices

2.0 Physical installation

2.1 Pipe mounting

1. Insert larger U-bolt around 2 in. pipe/mast, through the saddle, through the

L-shaped bracket, and through the washer plate.

1

2. Use a

3. Insert smaller U-bolt around base the Field Link and through the L-shaped

4. Use a

Figure 5. Mounting

/2-in. socket-head wrench to fasten the nuts to the U-bolt.

bracket.

1

/2-in. socket-head wrench to fasten the nuts to the U-bolt.

5

Page 6

Quick Start Guide

2.2 Power and data wiring

1. Remove housing cover labeled “Field Terminals.”

2. Connect the positive power lead to the “+” power terminal and the negative

power lead to the “–” terminal.

3. Connect the Data + lead to the “A (+)” terminal and the Data – lead to the “B

(–)” terminal.

4. Plug and seal any unused conduit connections.

5. Replace the housing cover.

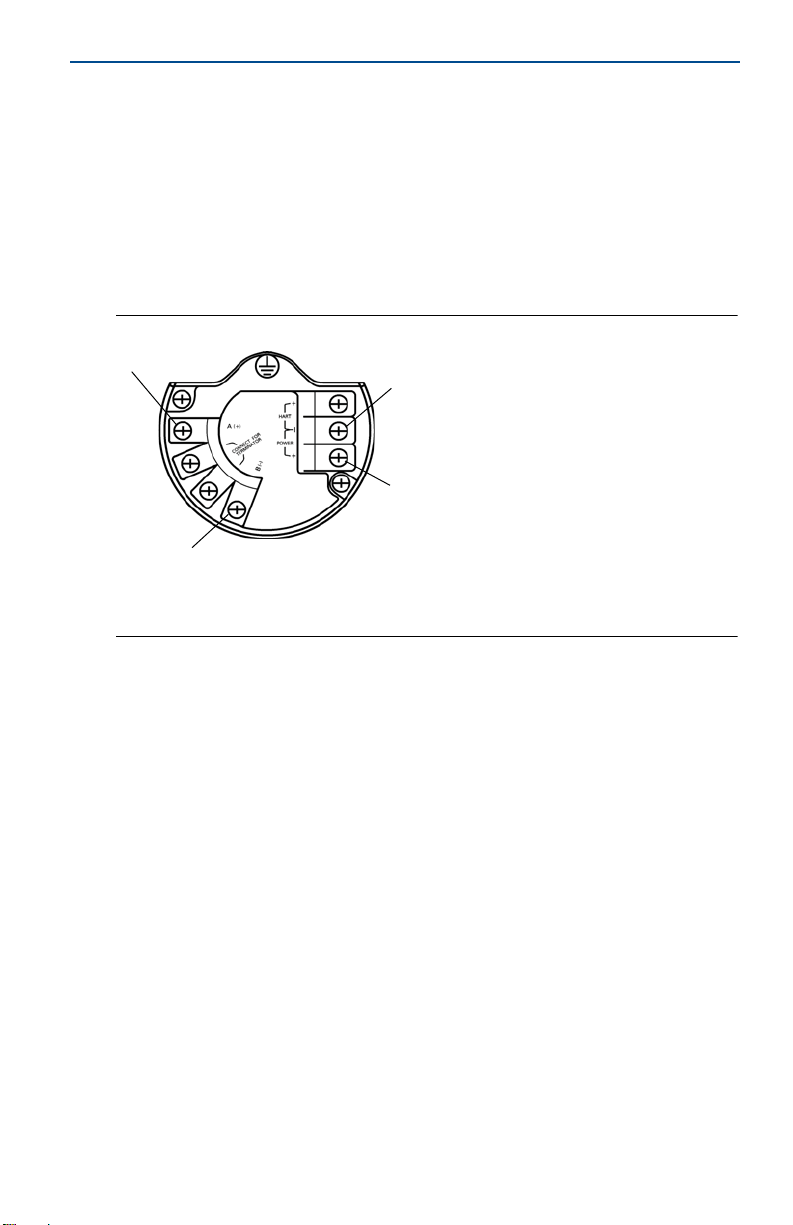

Figure 6. Smart Wireless Field Link Terminal Diagram

A

A. Data A (+)

B. Data B (

B

C. +10.5 to 30 VDC

–)

D. Return

D

C

June 2017

2.3 Grounding

The Field Link enclosure should always be grounded in accordance with national

and local electrical codes. The most effective grounding method is a direct

connection to earth ground with minimal impedance. Ground the Field Link by

connecting the external ground lug to earth ground. The connection should be

1 Ω or less.

3.0 Verify operation

3.1 Power-up sequence

Upon applying power to the Field link the LCD display meter will activate and

display a series of startup screen. The following screens are displayed during

startup.

1. Startup Screen 1 – All segments on

2. Startup Screen 2 – Device Identification

3. Startup Screen 3 – Tag

4. Startup Screen 4 – Status

6

Page 7

June 2017

A

B

C

D

Quick Start Guide

3.2 Normal operation

After the initial startup screens the Field Link will cycle through several periodic

screens.

1. Electronics Temperature Screen

2. Percent Range Screen

3. Wired Interface Usage

4. Radio Interface Usage

The Field Link will continue to rotate through each periodic screen through the

course of normal operation. If any diagnostic or fault condition occurs, a

corresponding diagnostics screen will appear.

4.0 Reference information

Figure 7. Smart Wireless Field Link Terminal Diagram

A. Data A (+)

B. Data B (

–)

C. +10.5 to 30 VDC

D. Return

Note

The Smart Wireless Field Link requires separate twisted shield pairs (four wires) for power

and data.

7

Page 8

Quick Start Guide

Figure 8. Smart Wireless Field Link Dimensional Drawing

June 2017

C

90°

D

12.43

(316)

10.91

(277)

4.20

(107)

A

3.55

(90.17)

5.51

(140)

A. 23 Conduit plug

B. Possible antenna rotation shown

B

C. Extended range antenna

D. WirelessHART

3.55

(90.17)

5.51

(140)

®

antenna

Tabl e 1. Smart Wireless Field Link Specifications

Item Specifications

Input Power 10.5 – 30 VDC

Operating Temperature –40 to 185 °F (–40 to 85 °C)

Wiring (Power) 24 AW G - 14 AWG t wisted sh ielded pair

Wiring (RS-485 Communications)

Wiring Distance 656 ft. (200 m)

Wireless Protocol WirelessHART, 2.4 – 2.5 GHz DSSS

Wireless Output Power, EIRP 10 dBm with WK antenna and 12.5 dBm with WM antenna

Mounting All SST, 2-in. pipe and panel mount bracket

Humidity 0 – 90% relative humidity

24 AW G - 14 AWG t wisted sh ielded pair

Less than 15 pF/ft capacitance.

(1)

1

5.21

(132)

1. Ambient temperatures above 60 °C require wiring rated to at least 5 °C above max ambient temperature.

8

Page 9

June 2017

Quick Start Guide

5.0 Ordering information

Table 2. Smart Wireless Field Link

H The Standard offering represents the most common options. The starred options (H) should be selected for best delivery.

The Expanded offering is subject to additional delivery lead time.

Model Product description

781 Smart Wireless Field Link

Physical connection

A1 RS485

Housing

D Dual compartment housing - Aluminum

E Dual compartment housing - Stainless Steel

Conduit threads

1

2 M20

Product certifications

I5 FM Intrinsically Safe, Non-incendive

I6 CSA Intrinsically Safe

I1 ATEX Intrinsically Safe

I7 IECEx Intrinsic Safety

KL FM & CSA Class 1 Division 1, ATEX Zone 0 Intrinsically Safe

NA No Approvals

Wireless update rate, operating frequency and protocol

WA3 User configurable update rate, 2.4 GHz DSSS, WirelessHART

Omnidirectional wireless antenna and SmartPower™

WK3 External antenna, line pow er 10 – 30 VDC

WM3 Extended range, external antenna, line power 10 – 30 VDC

1

/2 – 14 NPT

H

H

H

H

H

H

H

H

H

H

H

H

H

H

Options (Include with selected model number)

Meter

M5 LCD disp lay

Gland and connector options

G2 Cable gland (7,5 mm – 11,9 mm)

G4 Thin wire cable gland (3 mm – 8 mm)

Typical model number: 781 A1 D 1 KL WA3 WK3 M5

H

9

Page 10

Quick Start Guide

6.0 Product Certifications

Rev 1.1

6.1 European Directive Information

A copy of the EC Declaration of Conformity can be found at the end of the Quick

Start Guide. The most recent revision of the EC Declaration of Conformity can be

found at www.rosemount.com.

6.2 Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine the

design meets the basic electrical, mechanical, and fire protection requirements

by a nationally recognized test laboratory (NRTL) as accredited by the Federal

Occupational Safety and Health Administration (OSHA).

6.3 Installing in North America

The US National Electrical Code (NEC) and the Canadian Electrical Code (CEC)

permit the use of Division marked equipment in Zones and Zone marked

equipment in Divisions. The markings must be suitable for the area classification,

gas, and temperature class. This information is clearly defined in the respective

codes.

USA

I5 USA Intrinsically Safe (IS), Nonincendive (NI) and Dust-ignitionproof

Certificate: FM 3040398

Standards: FM Class 3600 – 1998, FM Class 3610 – 2010, FM Class 3611 – 2004,

FM Class 3810 – 2005, ANSI/NEMA 250 – 2003, ANSI/IEC 60529 – 2004;

Markings: IS CL I, DIV 1, GP A, B, C, D; CL II, DIV 1, GP E, F, G; Class III T4;

Class 1, Zone 0 AEx ia IIC T4;

NI CL I, DIV 2, GP A, B, C, D T4;

DIP CL II, DIV 1, GP E, F, G; CL III T4;

when installed per drawing 00781-1010

T4(-40 °C ≤ T

Input parameters

(power terminals)

V

= 30 V V

MAX/Ui

I

= 200 mA I

MAX/Ii

P

= 1 W P

MAX/Pi

Ci = 10 nF Ci = 5 nF Ca/Co = 10 nF

Li = 3.3 μH Li = 2.2 μH La/Lo= 3.3 μH

≤ +70 °C)

a

Input parameters

(sensor terminals)

MAX/Ui

MAX/Ii

MAX/Pi

Output parameters

(sensor terminals)

= 11 V Voc/Uo = 7.14 V

= 300 mA Isc/Io = 112 mA

= 1 W P

MAX/Po

= 640 mW

June 2017

Special Conditions for Safe Use (X):

1. The Model 781 transmitter housing contains aluminum and is considered a potential

risk of ignition by impact or fric tion. Care must be taken into account during installation

and use to prevent impact and friction.

2. The surface resistivity of the unit is greater than 1 gigaohm. To avoid electrostatic

charge buildup, it must not be rubbed or cleaned with solvents or a dry cloth.

3. The Model 781 transmitter will not pass the 500 Vrms electric strength test and this

must be taken into account during installation.

10

Page 11

June 2017

Quick Start Guide

Canada

I6 Canada Intrinsically Safe

Certificate: CSA 2330424

Standards: CSA C22.2 No. 0-10, CSA C22.2 No.94-M91, CSA Std. C22.2 No. 142-1987,

CSA-C22.2 No. 157-92, CSA Std. C22.2 No. 60529 – 2005

Markings: Intrinsically Safe Class I, Division 1, Groups A, B, C, and D T3C (T

Type 4X; IP 66/67; when installed per 00781-1011

Europe

I1 ATE X In tri nsi c Sa fet y

Certificate: Baseefa11ATEX0059X

Standards: EN 60079-0: 2009, EN 60079-11: 2007

Markings: II 1 G Ex ia IIC T4 Ga, T4(–40 °C ≤ T

Input parameters

(power terminals)

Ui = 30 V Ui = 11 V Uo = 7.14 V

Ii = 200 mA Ii = 300 mA Io = 112 mA

Pi = 1 W Pi = 1 W Po = 1 W

Ci = 0 μF Ci = 5.1 nF Co = 13.9 μF

Li = 0 mH Li = 0 mH Lo=1000 μH

Input parameter s

(RS485)

Special Conditions for Safe Use (X):

1. The plastic antenna may present a potential electrostatic ignition hazard and must not

be rubbed or cleaned with a dry cloth.

2. The Model 781 enclosure is made of aluminum alloy and given a protective paint finish;

howev er, car e should be t aken to pr otect i t from im pact or abrasio n if loca ted in a zo ne 0

environment.

3. The apparatus is not capable of withstanding the 500 V isolation test required by EN

60079-11:2007 Clause 6.3.12. This must be taken into account when installing the

apparatus.

≤ +70 °C)

a

Output parameters

(RS485)

≤ +60 °C)

a

International

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 11.0026X

Standards: IEC 60079-0: 2004, IEC 60079-0: 2007-10, IEC 60079-11: 2006

Markings: Ex ia IIC T4 Ga, T4(–40 °C ≤ T

Input parameters

(power terminals)

Ui = 30 V Ui = 11 V Uo = 7.14 V

Ii = 200 mA Ii = 300 mA Io = 112 mA

Pi = 1 W Pi = 1 W Po = 1 W

Ci = 0 μF Ci = 5.1 nF Co = 13.9 μF

Li = 0 mH Li = 0 mH Lo=1000 μH

Input parameter s

(RS485)

≤ +70 °C)

a

Output parameters

(RS485)

11

Page 12

Quick Start Guide

Special Conditions for Safe Use (X):

1. The plastic antenna may present a potential electrostatic ignition hazard and must not

be rubbed or cleaned with a dry cloth.

2. The Model 781 enclosure is made of aluminum alloy and given a protective paint finish;

however, care should be taken to protect it from impact or abrasion if located in a zone

0 environment

3. The apparatus is not capable of withstanding the 500 V isolation test required by EN

60079-11:2007 Clause 6.3.12. This must be taken into account when installing the

apparatus.

China

I3 China Intrinsic Safety

Certificate: GYJ13.1444X

Standards: GB3836.1-2010, GB3836.4-2010, GB3836.20-2010

Markings: Ex ia IIC T4 Ga, –40 ~ + 70 °C

Special Condition for Safe Use (X):

1. See certificate for special conditions.

EAC – Belarus, Kazakhstan, Russia

IM Technical Regulation Customs Union (EAC) Intrinsic Safety

Certificate: RU C-US.Gb05.B.00643

Markings: 0Ex ia IIC T4 Ga X

Input parameters

(power terminals)

Ui = 30 B Ui = 11 B Uo = 7.14 B

Ii = 200 MA Ii = 300 MA Io = 112 MA

Pi = 1 BT Pi = 1 BT Po = 1 BT

Ci = 0 мкΦ Ci = 5.1 HΦ Co = 13.9 мкΦ

Li = 0 MГH Li = 0 MГH Lo=0 MГH

Input parameters

(RS485)

Output parameters

(RS485)

June 2017

Special Condition for Safe Use (X):

1. See certificate for special conditions.

Combinations

KD Combination of I1, I5, and I6

KL Combination of I1, I5, I6, and I7

12

Page 13

June 2017

EU Declaration of Conformity

No: RMD 1083 Rev. F

Page 1 of 3

We,

Rosemount, Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

declare under our sole responsibility that the product,

Rosemount 781 Wireless Field Link

manufactured by,

Rosemount, Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

to which this declaration relates, is in conformity with the provisions of the European Union

Directives, including the latest amendments, as shown in the attached schedule.

Assumption of conformity is based on the application of the harmonized standards and, when

applicable or required, a European Union notified body certification, as shown in the attached

schedule.

Vice President of Global Quality

Chris LaPoint

6-June-2017

Figure 9. Rosemount 781 Declaration of Conformity

Quick Start Guide

(signature)

(name)

(function)

(date of issue)

13

Page 14

Quick Start Guide

EU Declaration of Conformity

No: RMD 1083 Rev. F

Page 2 of 3

EMC Directive (2014/30/EU)

Harmonized Standards:

EN 61326-1:2013

Radio Equipment Directive (RED) (2014/53/EU)

Harmonized Standards:

EN 300 328: V2.1.1

EN 301 489-17: V3.2.0

EN 60950-1: 2006+A11+A12+A1+A2

EN 50371:2002

ATEX Directive (2014/34/EU)

Baseefa11ATEX0059X – Intrinsic Safety Certificate

Equipment Group II, Category 1 G

Ex ia IIC T4 Ga

Standards Used:

EN 60079-0: 2009 (A review against EN60079-0:2012, which is

harmonized, shows no significant changes relevant to this equipment

so EN60079-0:2009 continues to represent “State of the Art”)

EN 60079-11: 2007 (A review against EN60079-11:2012, which is

harmonized, shows no significant changes relevant to this equipment

so EN60079-11:2007 continues to represent “State of the Art”)

June 2017

14

Page 15

June 2017

EU Declaration of Conformity

No: RMD 1083 Rev. F

Page 3 of 3

ATEX Notified Body

SGS Baseefa Limited [Notified Body Number: 1180]

Rockhead Business Park

Staden Lane

Buxton, Derbyshire

SK17 9RZ United Kingdom

ATEX Notified Body for Quality Assurance

SGS Baseefa Limited [Notified Body Number: 1180]

Rockhead Business Park

Staden Lane

Buxton, Derbyshire

SK17 9RZ United Kingdom

Quick Start Guide

15

Page 16

Quick Start Guide

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

List of

Rosemount 781

Rosemount 781 Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘䍘/ Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

X O O O O

O

༣փ㓴Ԧ

Housing

Assembly

X O O X O

O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

June 2017

16

Page 17

June 2017

Quick Start Guide

17

Page 18

*00825-0100-4421*

Quick Start Guide

00825-0100-4421, Rev CB

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com Linkedin.com/company/Emerson-Process-Management

Europe Regional Office

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emi rates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/us er/RosemountMeasur ement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at

www.Emerson.com/en-us/pages/Terms-of-Use.aspx

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

SmartPower, Rosemount, and Rosemount logotype are

trademarks of Emerson.

WirelessHART is a registered trademark of the FieldComm Group.

All other marks are the property of their respective owners.

© 2017 Emerson Process Management. All rights reserved.

June 2017

Loading...

Loading...