Page 1

Rosemount 751 Field Signal Indicator

Reference Manual

00809-0100-4378, Rev CE

February 2014

Page 2

Page 3

Reference Manual

NOTICE

00809-0100-4378, Rev CE

Rosemount 751 Field Signal Indicator

Title Page

February 2014

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers:

Customer Central

Technical support, quoting, and order-related questions.

1-800-999-9307 (7:00 am to 7:00 pm CST)

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of the United States, contact your local Emerson Process Management

representative.

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson

Process Management Sales Representative.

1

Page 4

Page 5

Reference Manual

00809-0100-4378, Rev CE

1Section 1: Introduction

2Section 2: Installation

Table of Contents

February 2014

1.1 LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 Analog meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.3 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4 Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.3 LCD display configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.3.1 Remove the cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.3.2 Position the decimal point and select the meter function . . . . . . . . . . . . .11

2.3.3 Store the information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3.4 Set the display equivalent to a 4 mA signal . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3.5 Set the display equivalent to a 20 mA signal . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3.6 Replace the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

AAppendix A: Reference data

A.1 Housing specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

A.1.1 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

A.2 LCD display specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

A.2.1 Functional specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

A.2.2 Performance specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

A.2.3 Physical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

A.3 Analog meter specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

A.3.1 Functional specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

A.3.2 Performance specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

A.3.3 Physical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

A.4 Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

A.5 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

BAppendix B: Product Certifications

B.1 European directive information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

B.2 Ordinary location certification for FM approvals . . . . . . . . . . . . . . . . . . . . . . . . . . .21

B.2.1 North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

B.2.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Europe22

Table of Contents

B.2.3 International . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

CAppendix C: Approval drawings

C.1 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

1

Page 6

Page 7

Reference Manual

00809-0100-4378, Rev CE

Section 1 Introduction

LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Analog meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Service support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

The Rosemount 751 Field Signal Indicators provide a means of displaying important process

variables. These devices operate with any two-wire transmitter that measures input variables

such as pressure, flow, liquid level, or temperature. Rosemount indicators are ideal for

installations where an integral meter would be difficult to view.

Rosemount 751 Indicators are designed for use in industrial environments where all-weather

performance is necessary. These units are vibration- and corrosion-resistant, and explosion-proof or intrinsically safe. An LCD display or analog meter may be ordered to meet specific

application requirements.

Section 1: Introduction

February 2014

1.1 LCD display

The LCD display requires an analog 4–20 mA dc output from a two-wire transmitter. It may be

configured from a 4 mA point of –999 to 1000 and a 20 mA point of -999 to 9999. The sum of

the 4 mA point and the span must not exceed 9999. The decimal point can be placed in any of

three positions (X.X.X.X) or not used. Calibration adjustments are made using noninteractive

zero and span buttons. The scaled meter may be labelled with the appropriate engineering

units. A twenty-segment bar graph, on the bottom of the meter faceplate, represents the 4–20

mA signal directly.

The large 2

Figure 1-1. The 4 and 20 mA points may be changed by pressing the buttons on the meter

faceplate. The meter can be rotated in 90-degree increments within the enclosure for

convenient viewing.

Figure 1-1. LCD display

1

/4-inch meter face has 1/2-inch-high characters for easy readability as shown in

LCD display

Introduction

3

Page 8

Section 1: Introduction

PERCENT

0

20

40

60

80

100

February 2014

1.2 Analog meter

The analog meter requires an analog 4–20 mA dc, 10–50 mA dc, or 40–200 mV dc transmitter

output from a two-wire transmitter. Several meter calibration options are available to suit the

requirements of a particular application. Linear 0 to 100 percent meter scaling is adequate for

the majority of applications. A logarithmic 0 to 100 percent scale is available for use with flow

transmitters. As an option, the user can specify special meter scaling for direct readout in psi,

gph, °F, °C, or other convenient engineering units.

Reference Manual

00809-0100-4378, Rev CE

The large 2

1

/4-inch diameter meter face has a two-inch long scale for easy readability as shown in

Figure 1-2. A meter-zero adjustment is located on the meter faceplate. The meter can be

rotated in 90° increments within the enclosure for convenient viewing.

Figure 1-2. Analog Meter

Analog Meter Face

4

Introduction

Page 9

Reference Manual

00809-0100-4378, Rev CE

1.3 Service support

To expedite the return process outside of the United States, contact the nearest Emerson

Process Management representative.

Within the United States, call the Emerson Process Management Instrument and Valves

Response Center using the 1-800-654-RSMT (7768) toll-free number. This center, available 24

hours a day, will assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return Material

Authorization (RMA) number. The center will also ask for the process material to which the

product was last exposed.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of and understand the hazard. If the product being returned was exposed to a

hazardous substance as defined by OSHA, a copy of the required Material Safety Data Sheet

(MSDS) for each hazardous substance identified must be included with the returned goods.

Section 1: Introduction

February 2014

Emerson Process Management Instrument and Valves Response Center representatives will

explain the additional information and procedures necessary to return goods exposed to

hazardous substances.

1.4 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in

accordance with local and national legislation/regulations.

Introduction

5

Page 10

Page 11

Reference Manual

A

B

C

D

E

F

G

H

I

J

K

L

M

N

00809-0100-4378, Rev CE

Section 2 Installation

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

LCD display configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

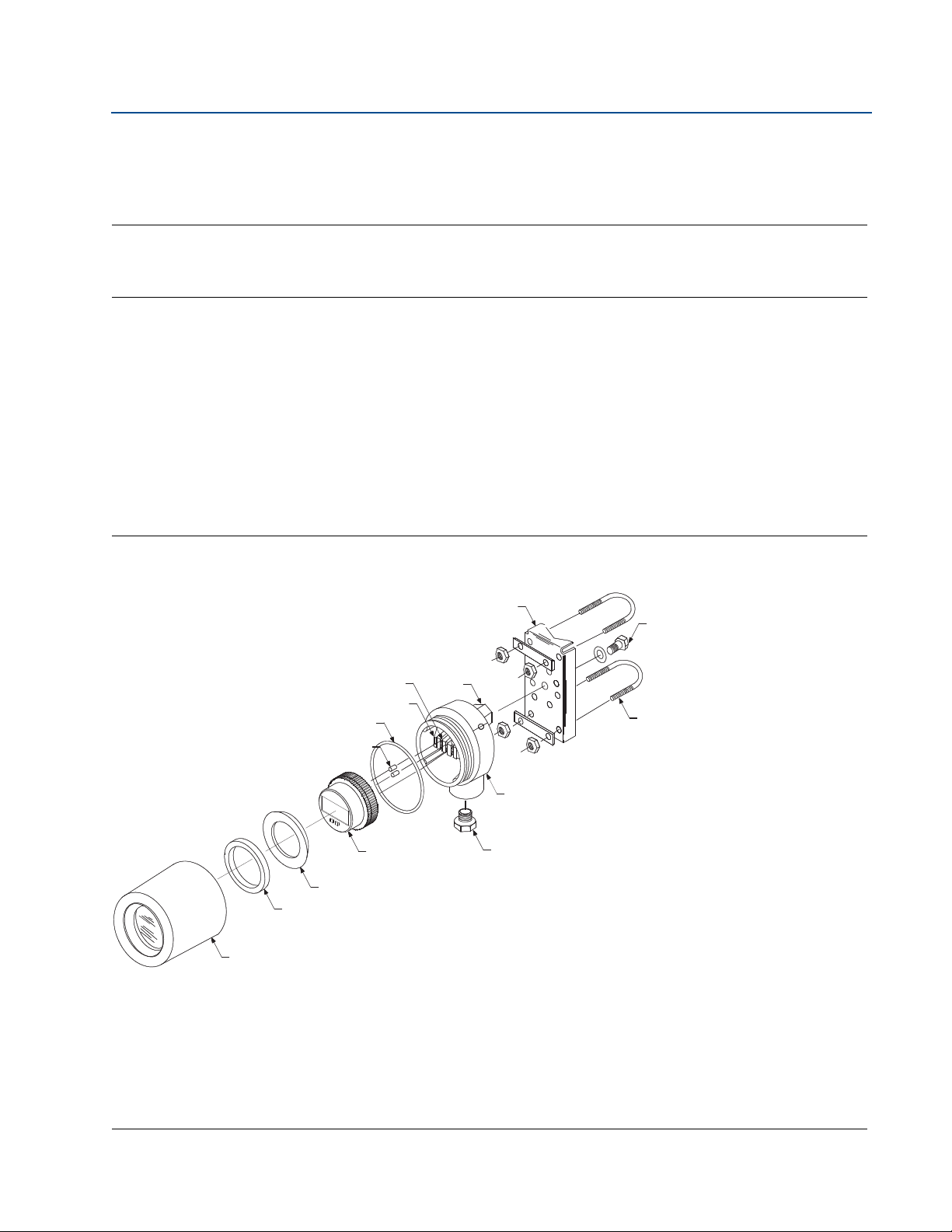

2.1 Assembly

The Rosemount 751 Field Signal Indicator is comprised of the components shown in Figure 2-1.

The housing may contain an analog or LCD display. Both meters are independent of component

parts and are completely interchangeable. Both meters plug into the terminal screws on the

housing, as shown in Figure 2-1.

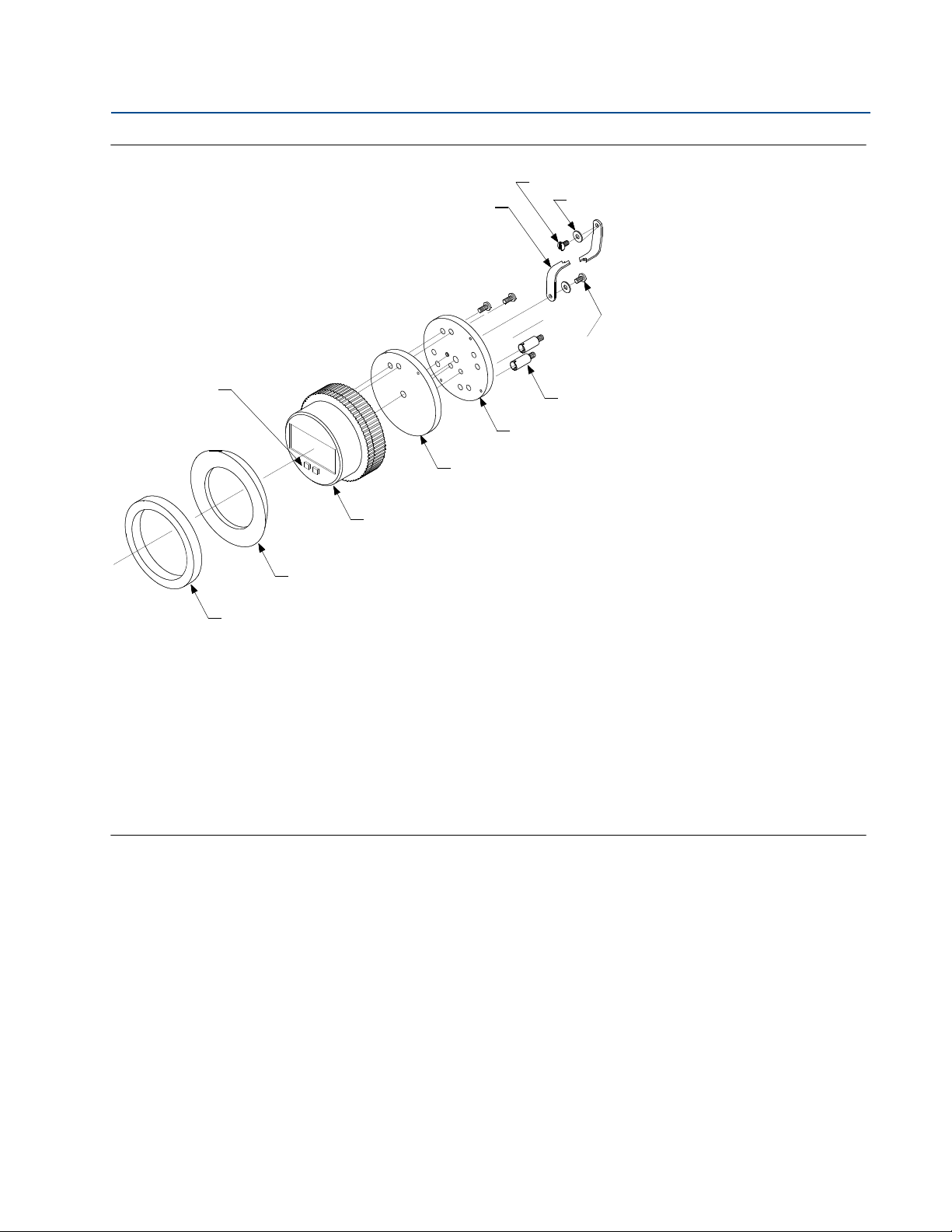

The meter subassembly contains the components shown in Figure 2-2.

Section 2: Installation

February 2014

Figure 2-1. Rosemount 751 Exploded View

A. Terminal Screws

B. Housing O-Ring

C. Field Wiring Terminals

D. Loop Protection Diode

E. Tapped Mounting Boss

F. Optional Mounting Bracket

G. Mounting Bolt with Washer

H. U-Bolt for 2-inch Pipe

I. Housing

J. Optional ¾ to ½-inch Conduit Reducing Bushing (if required)

K. Meter

L. Bushing

M. Foam Spacer

N. Housing Cover

7Installation

Page 12

Section 2: Installation

A

B

C

D

K

J

I

H

G

F

E

February 2014

Figure 2-2. LCD display exploded view

Reference Manual

00809-0100-4378, Rev CE

A. Retaining Straps

B. Mounting Screw into Housing

C. Washer for Retaining Strap

D. Mounting Screws into Mounting Plate

E. Terminal Screws (2)

F. Mounting Plate

G. Spacer Plate

H. LCD Display

I. Bushing

J. Foam Spacer

K. Configuration Buttons

8

Installation

Page 13

Reference Manual

Power Supply

Power Supply

751

4–20 dc Input Signal for

Rosemount 2051

4–20 mA dc Input Signal for

Rosemount 3144P

+

+

–

–

Optional Ground

Load Resistor

T

2051

+

–

+

–

3144P

Optional Ground

Load Resistor

–

+

T

751

+

–

Power Supply

Power Supply

4–20 dc Input Signal for

Rosemount 3051S

4–20 mA dc Input Signal for

Rosemount 3051C

+

+

–

–

Optional Ground

Load Resistor

T

3051C

751

+

–

+

+

–

–

Optional Ground

Load Resistor

T

3051S

751

+

–

00809-0100-4378, Rev CE

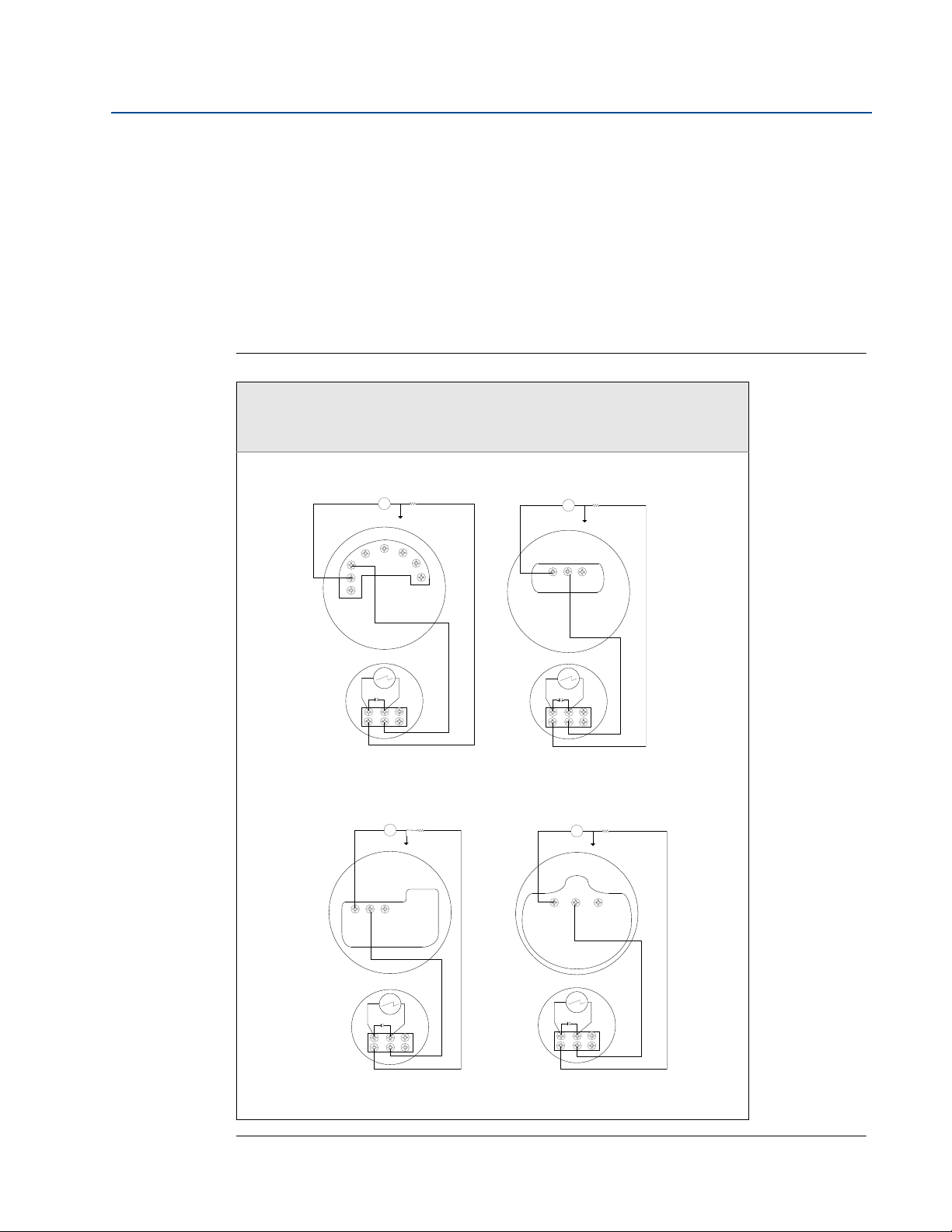

2.2 Wiring diagrams

Use the following wiring diagrams to wire the Rosemount 751 Field Signal Indicator, in series or

in parallel, with Rosemount transmitters. Use shielded cable for best results in electrically noisy

environments.

It is recommended that the 751 indicator be wired in a series configuration when the 4-20 mA

transmitter does not contain a test terminal. The 751 is designed so the analog or LCD display

can be removed from the housing without impacting the integrity of the 4-20 mA loop.

Removal of the entire 751 device from the series configuration will disrupt the loop.

Figure 2-3. Rosemount 751 Series Wiring Diagrams

Series Wiring Diagrams for Rosemount 3144P Temperature

transmitters and Rosemount 2051, 3051C, or 3051S Pressure

Section 2: Installation

February 2014

Tra ns mitt er s

Installation

9

Page 14

Section 2: Installation

Power Supply

Power Supply

751

4–20 dc Input Signal for

Rosemount 2051

4–20 mA dc Input Signal for

Rosemount 3144P

+

+

–

–

Optional Ground

Load

Resistor

T

2051

+

–

+

–

3144P

Optional Ground

Load

Resistor

–

+

T

751

+

–

Power Supply

Power Supply

4–20 dc Input Signal for

Rosemount 3051S

4–20 mA dc Input Signal for

Rosemount 3051C

+

+

–

–

Optional Ground

Load

Resistor

T

3051C

751

+

–

+

+

–

–

Optional Ground

Load

Resistor

T

3051S

751

+

–

3051C

4–20 mA dc Input Signal for

Rosemount 3051C

February 2014

It is recommended that the 751 indicator be wired in a parallel configuration when the 4-20 mA

transmitter includes a test terminal. Utilization of the test terminal is required in a parallel

configuration. Connecting the 751 indicator across the positive and negative terminals of the

4-20 mA transmitter could impact the loop.

A parallel configuration will allow the removal of the 751 indicator without affecting the

integrity of the 4-20 mA loop. Additionally, spare 751 indicators can be added without

disrupting the loop.

Figure 2-4. Rosemount 751 Parallel Wiring Diagrams

Reference Manual

00809-0100-4378, Rev CE

Parallel Wiring Diagrams for Rosemount 3144P Temperature

Tra ns mitt er

and Rosemount 2051, 3051C or 3051S Pressure Transmitters

10

Installation

Page 15

Reference Manual

00809-0100-4378, Rev CE

2.3 LCD display configuration

The 20-segment bar graph is factory calibrated and represents 4–20 mA directly, but the end

points of the LCD display are user-definable. The meter requires a current between 4 and 20 mA

in order to be scaled, but the actual value of the current is not significant.

2.3.1 Remove the cover

Explosions can result in death or serious injury. Do not remove the instrument cover in

explosive environments when the circuit is alive.

1. Unscrew and remove the transparent housing cover from the

LCD display body.

Note

The LCD display time-out is approximately 16 seconds. If you do not press the configuration

buttons within 16 seconds, the indicator will revert to reading the current signal.

Section 2: Installation

February 2014

2.3.2 Position the decimal point and select the meter function

1. Press the left and right configuration buttons simultaneously and release them

immediately.

2. To move the decimal point to the desired location, press the left configuration button.

Note that the decimal point wraps around.

3. To scroll through the mode options, press the right configuration button repeatedly

until the meter displays the desired mode (See Ta bl e 2 -1 ).

Table 2-1. LCD display mode options

Options Relationship between input signal and digital display

L in Linear

LinF Linear with five-second filter

Srt Square root

SrtF Square root with five-second filter

Square root function only relates to the digital display. The bar graph output remains linear

with the current signal.

Square root response

The digital display will be proportional to the square root of the input current where 4 mA = 0

and 20 mA = 1.0, scaled per the calibration procedure. The transition point from linear to

square root is at 25 percent of full scale flow.

Installation

Filter response operates upon “present input” and “input received in the previous five second

interval” in the following manner:

Display = (0.75 ⫻ previous input) + (0.25 ⫻ present input)

This relationship is maintained provided that the previous reading minus the present reading

is less than 25 percent of full scale.

11

Page 16

Section 2: Installation

February 2014

2.3.3 Store the information

1. Press both configuration buttons simultaneously for two seconds.

Note

The meter displays “- -” for approximately 7.5 seconds while the information is being stored.

2.3.4 Set the display equivalent to a 4 mA signal

1. Press the left configuration button for two seconds.

2. To decrease the display numbers, press the left configuration button. To increase the

numbers, press the right configuration button. Set the numbers between –999 and

1000.

3. To store the information, simultaneously press both configuration buttons for two

seconds.

2.3.5 Set the display equivalent to a 20 mA signal

Reference Manual

00809-0100-4378, Rev CE

1. Press the right configuration button for two seconds.

2. To decrease the display numbers, press the left configuration button. To increase the

numbers, press the right configuration button. Set the numbers between –999 and

9999.

Note

The sum of the 4 mA point and the span must not exceed 9999.

3. To store the information, simultaneously press both configuration buttons for two

seconds. The LCD display is now configured.

2.3.6 Replace the cover

1. Make sure the rubber gasket is seated properly, and thread the transparent housing

cover onto the LCD display body.

12

Installation

Page 17

Reference Manual

00809-0100-4378, Rev CE

Appendix A Reference data

Housing specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

LCD display specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Analog meter specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

A.1 Housing specifications

A.1.1 Physical specifications

Appendix A: Reference Data

February 2014

Materials of construction

Enclosure

Low-copper aluminum

Paint

Polyurethane

O-rings

Buna N

Meter mounting materials

Noryl® plastic

Electrical connections

3-pole terminal block with 8–32 nickel-plated brass screw terminals, with 3/4–14 NPT conduit.

(Stainless steel

3

1

/4- to

/2-inch reducer available as an option.)

Enclosure rating

NEM A Type 4x . CSA Type 4x . IP66.

Weight

Indicator only: 1.8 kg (4 lb)

Indicator with optional mounting bracket: 2.27 kg (5 lb)

13Reference Data

Page 18

Appendix A: Reference Data

February 2014

A.2 LCD display specifications

A.2.1 Functional specifications

Input signal

4–20 mA dc

Display

4 mA point limits

–999 to 1000

20 mA point limits

-999 to 9999

The sum of the 4 mA point and span must not exceed 9999. Adjustments are made using

non-interactive zero and span buttons.

Reference Manual

00809-0100-4378, Rev CE

Display options

Standard display response is linear with mA input. Optional square root or filtered response may

be selected.

Overload limitations

666 mA, maximum

Temperature limits

Storage

–40 to 85 °C (–40 to 185 °F)

Operating

–40 to 70 °C (–40 to 158 °F)

(1)

Humidity limitation

0 to 95% non-condensing relative humidity

Update period

750 ms

(1) For temperatures below -20 °C or above 60 °C the LCD may not be readable, but the loop will remain intact and the LCD will not

be damaged.

14

Reference Data

Page 19

Reference Manual

00809-0100-4378, Rev CE

Response time

Responds to changes in input within a maximum of two update periods. If the filter is activated,

then the display responds to the change within nine update periods.

Voltage drop

0.7 Vdc typical, 1.0 Vdc maximum

A.2.2 Performance specifications

Digital display resolution

0.05% of calibrated range ± 1 digit

Analog bar graph resolution

0.5% of calibrated range

Appendix A: Reference Data

February 2014

Indication accuracy

0.25% of calibrated range ± 1 digit

Stability

0.1% calibrated range ± 1 digit per six months

Temperature effect

0.01% of calibrated range per °C on zero

0.02% of calibrated range per °C on span over the operating temperature range

Power interrupt

All calibration constants are stored in EEPROM memory and are not affected by power loss.

Failure mode

LCD display failure will not affect transmitter operation.

Under/over range indication

Input current < 3.5 mA: Display blank

Input current > 22.0 mA: Display flashes 112.5% of full scale value or 9999, whichever is less

A.2.3 Physical specification

Meter size

21/4-inch diameter face with four

Reference Data

1

/2-inch high characters

15

Page 20

Appendix A: Reference Data

February 2014

A.3 Analog meter specifications

A.3.1 Functional specifications

Input signal

4–20 mA dc

10–50 mA dc

40–200 mV

Note

Maximum series resistance is ten ohms for ammeters.

Meter indication

0 to 100% linear scale

0 to 100% flow scale

Special optional ranges

Reference Manual

00809-0100-4378, Rev CE

Overload limitation

150% of rated end scale value for two minutes

Temperature limits

-40 to 65 °C (–40 to 150 °F)

Humidity limits

0 to 100% relative humidity

Zero adjustment

Adjustment screw on face of meter

A.3.2 Performance specifications

Indication accuracy

±2% of calibrated span

Temperature effect

Less than 2% of full scale at any point within the temperature limits

A.3.3 Physical specification

Meter size

21/4-inch diameter face with 2-inch long scale

16

Reference Data

Page 21

(95)

2.8

(71)

5.0

(127)

6.0

(152)

4.1

(104)

.37 (9.4) Diameter Holes

(typically four places)

Optional

Mounting

Bracket

7.0

(178)

4.2

(107)

1.0

(25)

3.0

(76)

4.0

(102)

1.1

(28)

Optional

Mounting

Bracket

Permanent

Tag

FM or CSA Tag

(if required)

3/4-14 NPT

Conduit

Connection

Reference Manual

00809-0100-4378, Rev CE

A.4 Dimensional drawings

Figure A-1. Dimensional Drawing

3.75

Appendix A: Reference Data

February 2014

Dimensions are in inches (millimeters).

Reference Data

2-in. Pipe

17

Page 22

Appendix A: Reference Data

February 2014

A.5 Ordering information

Model Product description

751 Remote Signal Indicator

Input signal

A 4–20 mA dc

B 10–50 mA dc (Not Available with LCD display)

C 40–200 mV dc (Not Available with LCD display)

Meter scale

M1 Linear Analog Meter, 0–100% Scale

M2 Square Root Analog Meter, 0–100% Flow

M6 Square Root Analog Meter, 0–10

(1)

M4

(1)

M7

(1)

M8

(1)

M9

Product certificates

NA No Approval Required

E2 INMETRO Flameproof

I2 INMETRO Intrinsic Safety

K2 INMETRO Flameproof, Intrinsic Safety

E3 NEPSI Flameproof

E5 FM Explosion-Proof

E6 CSA Explosion-Proof

E7 IECEx Flameproof

E8 ATE X Fl ameproof

I5 FM Intrinsic Safety and Non-incendive

I6 CSA Intrinsic Safety

I7 IECEx Intrinsic Safety

I8 ATEX Intrinsic Safety

N1 ATEX Type N Non-incendive

C6 CSA Intrinsic Safety, Non-incendive, and Explosion-proof approval combination

K5 FM Intrinsic Safety, Non-incendive, and Explosion-proof approval combination

Options

Mounting bracket

B Mounting Bracket for Flat Surface or 2-inch Pipe

Reducer

C Stainless Steel Reducer ¾- to ½-in. for Conduit Connection (See Figure 1 for reference.)

Bar code tag

BT Customer Specified Barcode Tag

Typical model number: 751 A M1 NA BC

(1) May be reconfigured in the field.

Linear LCD display, 0–100% Scale

Special Scale LCD display (specify range, mode, and engineering units)

Square Root LCD display, 0–100% Flow

Square Root LCD display, 0–10

Reference Manual

00809-0100-4378, Rev CE

18

Reference Data

Page 23

Reference Manual

00809-0100-4378, Rev CE

Tagg in g

Appendix A: Reference Data

February 2014

The indicator will be tagged, at no charge, in accordance with customer requirements. All tags are

stainless steel. The standard tag is permanently attached to the indicator. Tag character height is

1

in. (1.6 mm). A wired-on tag is available upon request.

/16

Reference Data

19

Page 24

Appendix A: Reference Data

February 2014

Reference Manual

00809-0100-4378, Rev CE

20

Reference Data

Page 25

Reference Manual

00809-0100-4378, Rev CE

Appendix B: Product Certifications

February 2014

Appendix B Product Certifications

European directive information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Ordinary location certification for FM approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

B.1 European directive information

A copy of the EC Declaration of Conformity can be found at the end of the Quick Start Guide.

The most recent revision of the EC Declaration of Conformity can be found at

www.rosemount.com.

B.2 Ordinary location certification for FM approvals

As standard, the transmitter has been examined and tested to determine that the design meets

the basic electrical, mechanical, and fire protection requirements by FM Approvals, a nationally

recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety and Health

Administration (OSHA).

B.2.1 North America

E5 FM Explosionproof

Certificate: 0T2H8.AE

Standards Used: FM Class 3600: 1989, FM Class 3615: 1989

Markings: XP CL I, DIV 1, GP B, C, D; DIP CL II/III, DIV 1, GP E, F, G; Type 4X

I5 FM Intrinsic Safety and Nonincendive

Certificate: 0T9H2AX

Standards Used: FM Class 3600: 2011, FM Class 3610: 2010, FM Class 3611: 2004, FM Class

3810: 1989, NEMA-250: 1991, ANSI/ISA 60079-0: 2009, ANSI/ISA 60079-11: 2009

Markings: IS CL I / II / III, DIV 1, GP A, B, C, D, E, F, G; T5(-60 °C T

AEx ia IIC T5(-60 °C T

installed per Rosemount drawing 00751-0074; Type 4X

E6 CSA Explosionproof

Certificate: 1718395

Standards Used: CSA Std C22.2 No. 25-1966; CSA Std C22.2 No. 30-M1986;

CAN/CSA-C22.2 No. 94-M91; CSA Std C22.2 No. 142-M1987

Markings: Explosionproof for CL I, GP C, D; CL I, GP E, F, G; CL III; Suitable for CL I DIV 2, GP

A, B, C, D; Type 4X

I6 CSA Intrinsic Safety

Certificate: 1718395

Standards Used: CSA Std C22.2 No. 25-1966; CSA Std C22.2 No. 30-M1986;

CAN/CSA-C22.2 No. 94-M91; CSA Std C22.2 No. 142-M1987; CAN/CSA-C22.2 No. 157-92;

CSA Std C22.2 No. 213-M1987

Markings: Intrinsically Safe for CL I Groups A, B, C, D; when installed per Rosemount

drawing 00751-0068; Type 4X

+60 °C); IS CL I, Zone 0,

+60 °C); NI CL I, DIV 2, GP A, B, C, D; T5(-60 °C Ta+60 °C); when

a

a

Product Certifications

21

Page 26

Appendix B: Product Certifications

February 2014

B.2.2 Europe

E8 ATEX Flameproof

Certificate: DEKRA11ATEX0240X

Standards Used: EN 60079-0:2009, EN 60079-1:2007

Markings: II 2 G Ex d IIC T5/T6 Gb, T6(-20 °C T

Special Condition for Safe Use (X):

The original manufacturer shall be contacted for information on the dimensions of the

flameproof joints.

I8 ATEX Intrins ic Safety

Certificate: Baseefa03ATEX0448X

Standards Used: EN 60079-0:2009, EN 60079-11:2007

Markings: II 1 G Ex ia IIC T5/T6 Ga; T6(-60 °C T

Special Condition for Safe Use (X):

The apparatus enclosure may contain light metals. The apparatus must be installed in such

a manner as to minimize the risk of impact or friction with other metal surfaces.

Reference Manual

00809-0100-4378, Rev CE

+40 °C), T5(-20 °C Ta +70 °C)

a

+40 °C), T5(-60 °C Ta +80 °C)

a

N1 ATEX Type n

Certificate: Baseefa03ATEX0454

Standards Used: EN 60079-0:2009; EN 60079-15:2010

Markings: II 3 G Ex nA IIC T6 Gc; (-40 °C T

B.2.3 International

E7 IECEx Flameproof

Certificate: IECEx DEK 11.0082X

Standards Used: IEC 60079-0:2007-10; IEC 60079-1:2007-04

Markings: Ex d IIC T5/T6 Gb, T6(-20 °C T

Special Condition for Safe Use (X):

The original manufacturer shall be contacted for information on the dimensions of the

flameproof joints.

I7 IECEx Intrinsic Safety

Certificate: IECEx BAS 11.0064X

Standards Used: IEC 60079-0: 2011; IEC 60079-11: 2011

Markings: Ex ia IIC T5/T6 Ga; T6(-60 °C T

Special Condition for Safe Use (X):

The enclosure may be made of aluminum alloy and given a protective polyurethane or

epoxy polyester paint finish; however, care should be taken to protect it from impact or

abrasion if located in a Zone 0 environment.

+70 °C)

a

+40 °C), T5(-20 °C Ta +70 °C)

a

+40 °C), T5(-60 °C Ta +80 °C)

a

22

Product Certifications

Page 27

Reference Manual

00809-0100-4378, Rev CE

E2 INMETRO Flameproof

I2 INMETRO Intrinsic Safety

E3 China Flameproof

Appendix B: Product Certifications

February 2014

Brazil

Certificate: NCC 12.1204X

Standards Used: ABNT NBR IEC 60079-0:2011, ABNT NBR IEC 60079-2011

Markings: Ex d IIC T5/T6 Gb; T6(-20 °C T

+40 °C), T5(-20 °C Ta +70 °C)

a

Special Condition for Safe Use (X):

The manufacturer should be contacted for information on the dimensions of the

flameproof joints.

Certificate: NCC 12.1163X

Standards Used: ABNT NBR IEC 60079-0:2011, ABNT NBR IEC 60079-11:2009, ABNT NBR

IEC 60079-26:2009

Markings: Ex ia IIC T5/T6 Ga; T6(-60 °CT

+40 °C), T5(-60 °C Ta+80 °C)

a

Special Condition for Safe Use (X):

The enclosure may be made of aluminum alloy; however, care should be taken to protect it

from impact or abrasion if located in a Zone 0 environment.

China

Certificate: GYJ12.1034X

Standards Used: GB 3836.1-2010, GB 3836.2-2010

Markings: Ex d IIC T6 Gb

Special Conditions for Safe Use (X):

1. Symbol “X” is used to denote specific conditions of use: Contact the original

manufacturer when repair work relates to the flamepath.

2. Ambient temperature range is: -20 °C T

+60 °C.

a

3. The earth connection facility in the enclosure should be connected reliably.

4. During installation, there should be no mixture harmful to flameproof housing.

5. During installation in hazardous location. Cable glands, conduits and blanking plugs,

certified by state-appointed inspection bodies with Ex d IIC Gb degree, should be used.

6. During installation, use and maintenance in explosive gas atmospheres, observe the

warning “Do not open when energized.”

7. End users is not permitted to change any components insides, but to settle the problem

in conjunction with manufacturer to avoid damage to the product.

8. When installation, use and maintenance of this product, observe following standards:

GB3836.13-1997 “Electrical apparatus for explosive gas atmospheres Part 13: Repair

and overhaul for apparatus used in explosive gas atmospheres.”

GB3836.15-2000 “Electrical apparatus for explosive gas atmospheres Part 15: Electrical

installations in hazardous area (other than mines).”

GB3836.16-2006 “Electrical apparatus for explosive gas atmospheres Part 16:

Inspection and maintenance of electrical installation (other than mines).”

GB50257-1996 “Code for construction and acceptance of electric device for explosion

atmospheres and fire hazard electrical equipment installation engineering.”

K2 Combination of E2 and I2

K5 Combination of E5 and I5

C6 Combination of E6 and I6

Product Certifications

Combinations

23

Page 28

Page 29

Reference Manual

00809-0100-4378, Rev CE

Appendix C: Approval Drawings

Appendix C Approval drawings

This section contains the following drawings:

Rosemount Drawing 00751-0068, Rev. A, 2 sheets: Rosemount 751 CSA Intrinsic Safety

Approval Configuration Installation.

Rosemount Drawing 01151-0214, Rev. V, 6 sheets: Index of Intrinsically Safe Barrier

Systems and Entity Parameters for 444, 1135, 1144, 1151, and 3051 Transmitters and

751 Field Signal Indicators.

You must follow the installation guidelines presented by these drawings in order to maintain

certified ratings for installed instruments.

February 2014

Approval Drawings

25

Page 30

Appendix C: Approval Drawings

February 2014

Reference Manual

00809-0100-4378, Rev CE

26

Approval Drawings

Page 31

Reference Manual

00809-0100-4378, Rev CE

Appendix C: Approval Drawings

February 2014

Approval Drawings

27

Page 32

Appendix C: Approval Drawings

February 2014

Reference Manual

00809-0100-4378, Rev CE

28

Approval Drawings

Page 33

Reference Manual

00809-0100-4378, Rev CE

Appendix C: Approval Drawings

February 2014

Approval Drawings

29

Page 34

Appendix C: Approval Drawings

February 2014

Reference Manual

00809-0100-4378, Rev CE

30

Approval Drawings

Page 35

Reference Manual

00809-0100-4378, Rev CE

Appendix C: Approval Drawings

February 2014

Approval Drawings

31

Page 36

Appendix C: Approval Drawings

February 2014

Reference Manual

00809-0100-4378, Rev CE

32

Approval Drawings

Page 37

Reference Manual

00809-0100-4378, Rev CE

Appendix C: Approval Drawings

February 2014

Approval Drawings

33

Page 38

Appendix C: Approval Drawings

EC Declaration of Conformity

No: RMD 1012 Rev. E

Vice President, Quality

(signature) (function- printed)

Timothy J. Layer

March 1, 2012

(name-printed) (date of issue)

We,

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN 55317-9685

USA

declare under our sole responsibility that the product,

Model 751 Field Signal Indicator

manufactured by,

Rosemount Inc.

12001 Technology Drive and 8200 Market Boulevard

Eden Prairie, MN 55344-3695 Chanhassen, MN 55317-9687

USA USA

to which this declaration relates, is in conformity with the provisions of the European

Community Directives, including the latest amendments, as shown in the attached schedule.

Assumption of conformity is based on the application of the harmonized standards and, when

applicable or required, a European Community notified body certification, as shown in the

attached schedule.

February 2014

C.1 Declaration of conformity

Reference Manual

00809-0100-4378, Rev CE

34

Approval Drawings

Page 39

Reference Manual

Schedule

EC Declaration of Conformity RMD 1012 Rev. E

File ID: Page 2 of 3 C:\Documents and Settings\sharrem\Local Settings\Temporary Internet

Files\Content.Outlook\RJ7U20GO\751_RMD1012_E (2).doc

EMC Directive (2004/108/EC)

Harmonized Standards: EN 61326-1:2006

ATEX Directive (94/9/EC)

Baseefa03ATEX0448X Intrinsic Safety

Equipment Group II Category 1 G; Ex ia IIC T5 or T6 Ga,

T5(-60°C Ta +80°C), T6 (-60°C Ta +40°C);

Harmonized Standards Used:

EN60079-0:2009; EN60079-11:2007

Baseefa03ATEX0454X Type n

Equipment Group II Category 3 G; Ex nA IIC Gc T6 (-40°C Ta +70°C);

Harmonized Standards Used:

EN60079-0:2009; EN60079-15:2010

DEKRA11ATEX0240X Flameproof

Equipment Group II Category 2 G; Ex d IIC T5 or T6 Gb,

T5(-20°C Ta +70°C), T6(-20°C Ta +40°C)

Harmonized Standards Used:

EN60079-0:2009; EN60079-1:2007

00809-0100-4378, Rev CE

Appendix C: Approval Drawings

February 2014

Approval Drawings

35

Page 40

Appendix C: Approval Drawings

Schedule

EC Declaration of Conformity RMD 1012 Rev. E

File ID: Page 3 of 3 C:\Documents and Settings\sharrem\Local Settings\Temporary Internet

Files\Content.Outlook\RJ7U20GO\751_RMD1012_E (2).doc

ATEX Notified Bodies for EC Type Examination Certificate

DEKRA Certification B.V.

[Notified Body Number: 0344]

Utrechtseweg 310, 6812 AR

Arnhem, The Netherlands

Baseefa. [Notified Body Number: 1180]

Rockhead Business Park

Staden Lane

Buxton, Derbyshire

SK17 9RZ United Kingdom

ATEX Notified Body for Quality Assurance

Baseefa. [Notified Body Number: 1180]

Rockhead Business Park

Staden Lane

Buxton, Derbyshire

SK17 9RZ United Kingdom

February 2014

Reference Manual

00809-0100-4378, Rev CE

36

Approval Drawings

Page 41

Page 42

Reference Manual

00809-0100-4378, Rev CE

February 2014

Standard Terms and Conditions of Sale can be found at www.rosemount.com/terms_of_sale

The Emerson logo is a trademark and service mark of Emerson Electric Co.

Rosemount. the Rosemount logotype, and SMART FAMILY are registered trademarks of Rosemount Inc.

Coplanar is a trademark of Rosemount Inc.

Halocarbon is a trademark of the Halocarbon Products Corporation.o.

Fluorinert is a registered trademark of Minnesota Mining and Manufacturing Company Corporation

Syltherm 800 and D.C. 200 are registered trademarks of Dow Corning Corporation.

Neobee M-20 is a registered trademark of PVO International, Inc.

HART is a registered trademark of the HART Communication Foundation.

Foundation fieldbus is a registered trademark of the Fieldbus Foundation.

All other marks are the property of their respective owners.

© February 2014 Rosemount, Inc. All rights reserved.

Emerson Process Management

Rosemount Measurement

8200 Market Boulevard

Chanhassen MN 55317 USA

Tel (USA) 1 800 999 9307

Tel (International) +1 952 906 8888

Fax +1 952 906 8889

Emerson Process Management

Latin America

1300 Concord Terrace, Suite 400

Sunrise Florida 33323 USA

Tel + 1 954 846 5030

Emerson Process Management

GmbH & Co.

Argelsrieder Feld 3

82234 Wessling

Germany

Tel 49 (8153) 9390

Fax 49 (8153) 939172

Emerson Process Management Asia

Pacific Private Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211

F (65) 6777 0947

Enquiries@AP.EmersonProcess.com

Beijing Rosemount Far East

Instrument Co., Limited

No. 6 North Street,

Hepingli, Dong Cheng District

Beijing 100013, China

T (86) (10) 6428 2233

F (86) (10) 6422 8586

Loading...

Loading...